Page 1

P

P

rroodduucctt&

&

T

T

eecchhnnoollooggy

Efi Fiery

Calibration Manuals

y

Fiery XJ

Fiery X2

Fiery X2e

Fiery ZX

Fiery Z4

Page 2

Page 3

1-1 Managing color on the Fiery

1

Chapter 1:

Fiery Color

Management

The first part of this chapter describes the options available from the ColorWise color

management system and explains how you can customize the color settings for your

particular needs. It provides descriptions of the preset default settings of ColorWise

and covers additional options for users who need to customize ColorWise.

Beginning on page 1-13 is a detailed explanation of what a PostScript Level 2 or

PostScript 3 printer driver does, as well as information on the capabilities of various

printer drivers and instructions for setting color options with the PostScript drivers for

Windows NT 4.0, Windows 95/98, and Mac OS.

Managing color on the Fiery

There are three ways to modify the Fiery’s printing behavior:

• You can select ColorWise options for an individual print job using menus that

appear from the printer driver.

• You can select most ColorWise options as server defaults from Fiery Setup or from

the Control Panel, as described in the

to all subsequent print jobs unless you override them.

• You can select some ColorWise options, particularly default

and calibration options, from ColorWise Pro Tools. These options include default

Simulation Profile (see page 1-10), Simulation Method (see page 1-11), Appear in

Driver as (see page 4-7), default Source Profile (see page 1-8), RGB Separation (see

page 1-9), and associated calibration set (see page 3-3).

Configuration Guide

. These defaults will apply

ICC profile

settings

Applications can generate color data for the Fiery in many different

most common type of color data produced from office applications is RGB, while

prepress applications generally produce CMYK data. Desktop applications can also

generate spot colors such as PANTONE colors. To complicate matters, a single page

may contain a mix of RGB, CMYK, and spot colors. The Fiery lets users control the

printing of these mixed-color documents with features that apply specifically to RGB,

CMYK, or spot color data.

color spaces

. The

Page 4

1-2 Fiery Color Management

1

Fiery color management generates CMYK data to be sent to the copier; additional

processing may then be performed before printing begins.

The diagram below illustrates the print options in the Fiery color management process

that affect color data conversions. You access these print options when you send a print

job to the Fiery. Most of these options and settings are described in subsequent

sections of this chapter.

RGB data

CMYK data

Spot color data

RGB Source Profile

Gamma

Phosphors

White Point

Rendering Style (CRD)

Brightness

Pure Black Text/Graphics

Black Overprint

RGB Separation

Output profile

CMYK Simulation Profile

CMYK Simulation Method

Brightness

Pure Black Text/Graphics

Black Overprint

Combine Separations

Output profile

Spot Color Matching

Fiery

color

processor

Color data

sent to

copier

RGB Source Profile is the only color option that applies strictly to RGB color data.

The other options that affect RGB color also affect the more rarely used Lab, XYZ, and

other calibrated color spaces.

N

:

OTE

For users who are familiar with PostScript 3.0 color, all CIE-based ABC spaces

are affected. Also, if you send CMYK data to the Fiery in DEFG format, for example,

by choosing PostScript Color Management in Adobe Photoshop, options affecting

RGB data also affect this CMYK data.

Page 5

1-3 Managing color on the Fiery

1

Settings for the following options can be specified via print options when you send a

job to the Fiery. Some can also be set as defaults by the administrator during Fiery

Setup. Settings specified via print options override the defaults.

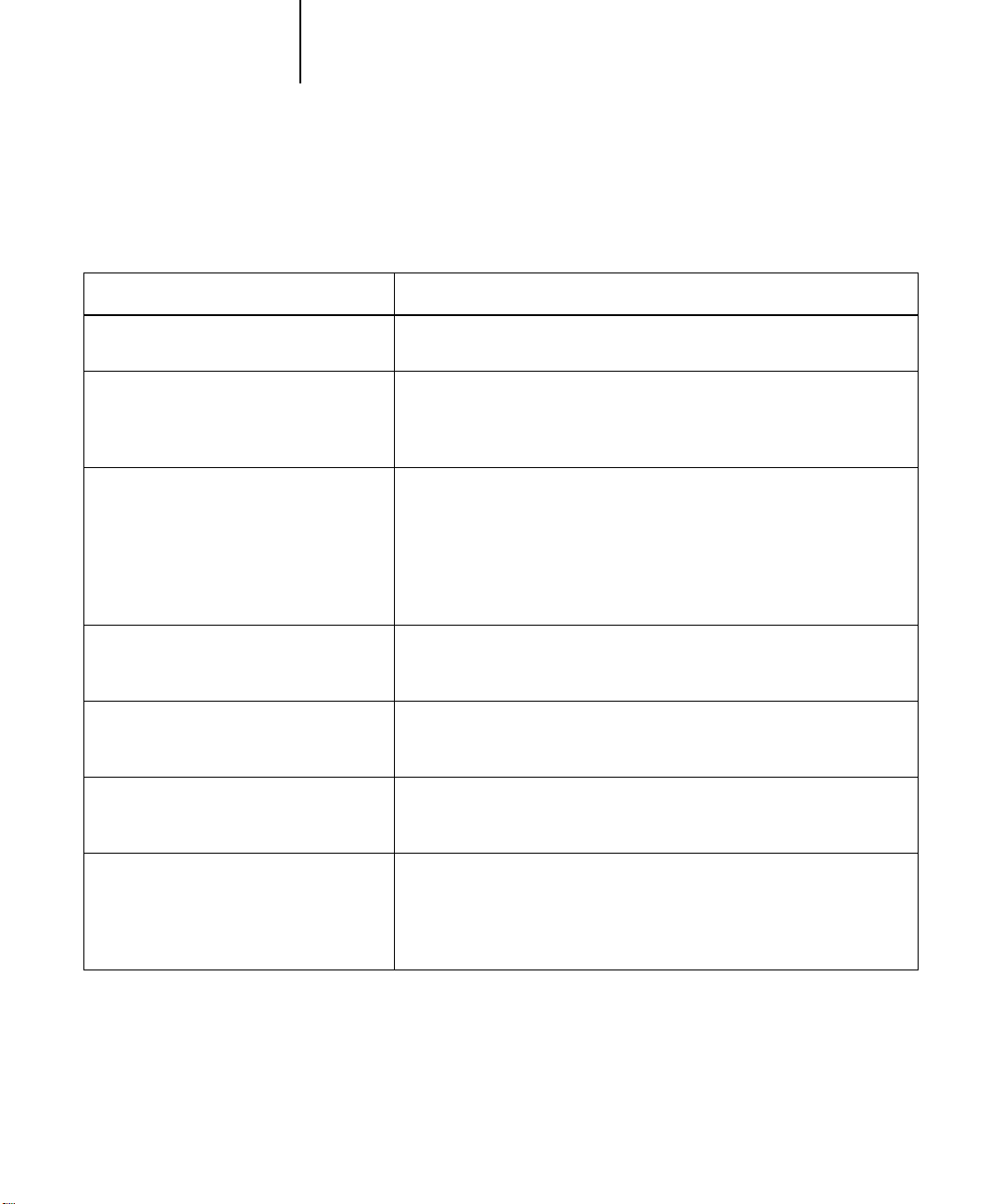

Fiery color print option: What it does:

Brightness

85% Lightest to 115% Darkest

Rendering Style

Photographic/Presentation/Relative

Colorimetric/Absolute Colorimetric

(Default set at Setup)

RGB Source Profile

EFIRGB/sRGB (PC)/Apple Standard/Other/

Source 1–10/None

(Default set at Setup or with

ColorWise Pro Tools)

(Other) Gamma

1.0/1.2/1.4/1.6/1.8/2.0/2.2/2.4/2.6/2.8/3.0

(Other) Phosphors

Hitachi EBU/Hitachi-Ikegami/NTSC/

Radius Pivot/SMPTE/Trinitron

(Other) White Point

5000 K (D50)/5500 K/6500 K (D65)/

7500 K/9300 K

Performs a color adjustment on all

lighter or darker.

Applies a Fiery color rendering style (CRD) to RGB data (see page 1-5), or to

any incoming data with a PostScript

CMYK.

Applies an RGB source space definition to RGB data (see page 1-8). If you

choose the Other setting, you can specify particular settings for gamma,

phosphors, and white point. See the corresponding options in this table. This

option, along with Gamma, Phosphors, and White Point, are the only

ColorWise options that effect

RGB data also affect other, less commonly used color spaces, such as CIELAB

or CIE XYZ.

Applies the specified

page 1-8). To use this print option, you must choose Other as the RGB Source

setting.

Applies the specified phosphor (monitor type) information to the RGB source

space definition (see page 1-8). To use this print option, you must choose

Other as the RGB Source setting.

Applies the specified white point value to the RGB source color space

definition (see page 1-8). To use this print option, you must choose Other as

the RGB Source setting.

gamma value to the RGB source space definition (see

color channels

source color space

strictly

RGB data. All other options that affect

to make the printed output

definition, including

RGB Separation

Output/Simulation

Determines which CMYK color space your original RGB data will be

separated into—CMYK for the copier (Output) or CMYK for a specified

simulation (Simulation) (see page 1-9). It is important to note that when RGB

Separation is set to Simulation, RGB colors are affected by CMYK Simulation

Profile and CMYK Simulation Method.

Page 6

1-4 Fiery Color Management

1

Fiery color print option: What it does:

CMYK Simulation Profile

SWOP-Coated/DIC/Euroscale/Simulation

1–10/Match Copy/None

(Default set at Setup or in

ColorWise Pro Tools)

CMYK Simulation Method

Quick/Full

(Default set at Setup or in

ColorWise Pro Tools)

Output Profile

default output profile/Output 1–10

(Default set at Setup or in

ColorWise Pro Tools)

Pure Black Text/Graphics

On/Off

(Default set at Setup)

Black Overprint

On/Off (Default set at Setup)

Spot Color Matching

On/Off

(Default set at Setup or with

ColorWise Pro Tools)

Adjusts CMYK color data to simulate an offset press standard or a custom

color gamut defined at your site. The Match Copy setting bypasses Fiery

calibration to match a copy made from the copier glass. Choosing None

bypasses simulation (see page 1-10).

N

OTE: Some of the Simulation settings have slightly different names depending

on the model of copier.

Quick simulation applies one-dimensional transfer curves that adjust output

density only. Full simulation applies colorimetric transformations that adjust

hue as well as output density (see page 1-11).

The Output Profile is applied to all data in the print job (see page 1-11). Userdefined output profiles can be downloaded to the Fiery with

ColorWise Pro Tools (see Chapter 4).

The On setting optimizes the quality of black text and line art output (see

page 1-6).

The On setting overprints black text placed on colored backgrounds; it

automatically activates the Pure Black Text/Graphics option (see page 1-7).

The On setting enables Fiery matching of PANTONE colors; Off instructs the

Fiery to match color output to a Pantone-specified CMYK combination (see

page 1-12).

More-detailed explanations of how these and other settings affect your print jobs are

provided in subsequent sections of this chapter.

Page 7

1-5 Managing color on the Fiery

1

Rendering styles

The Rendering Style option specifies a CRD for color conversions. You can modify the

Rendering Style option to control the appearance of images, such as prints from office

applications or RGB photographs from Photoshop. The Fiery lets you select from the

four rendering styles currently found in industry standard ICC profiles.

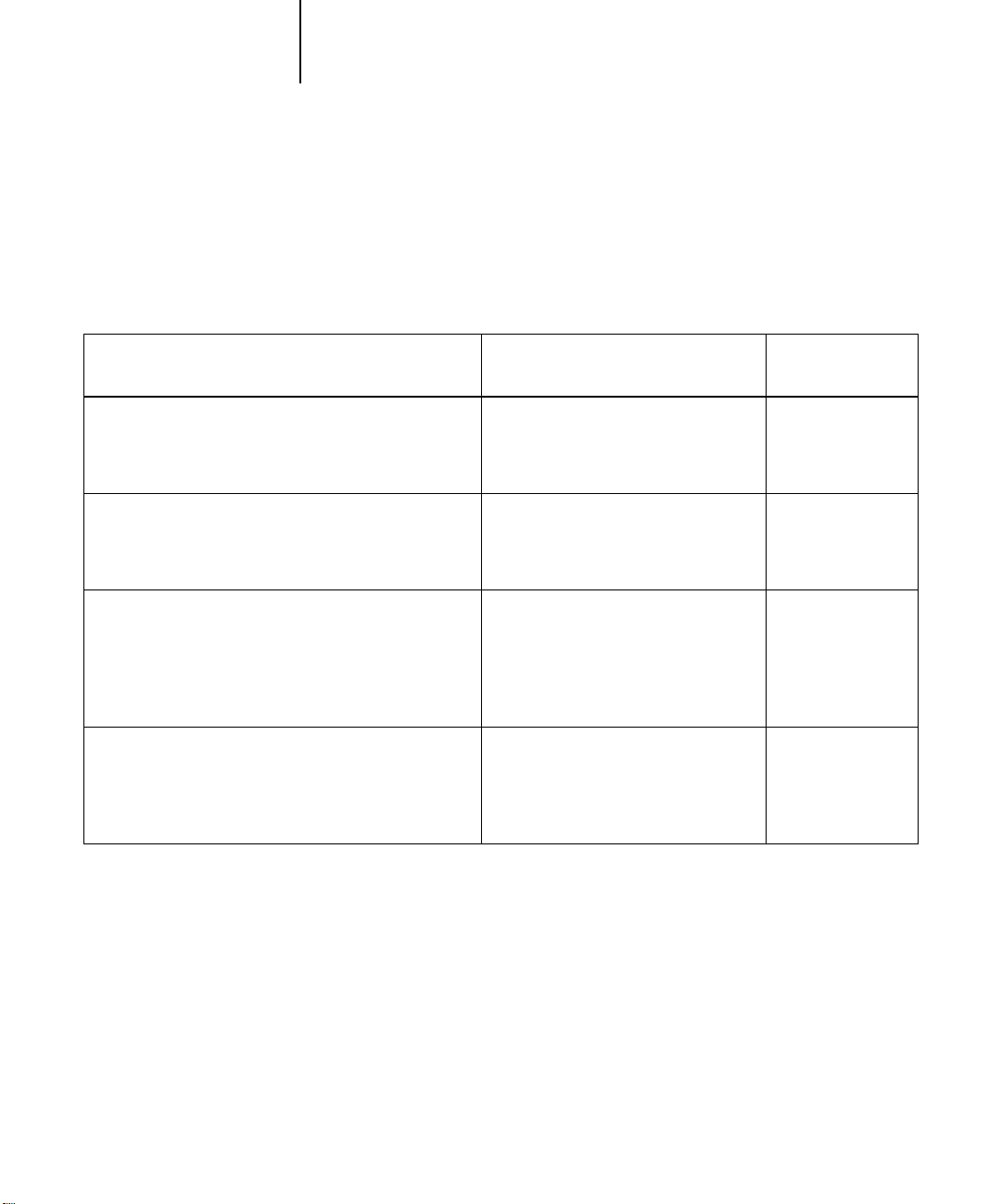

Fiery rendering style: Best used for:

Photographic rendering typically results in less saturated

output than presentation rendering when printing outof-gamut colors. It preserves tonal relationships in

images.

Presentation—Creates saturated colors but does not

match printed colors precisely to displayed colors. Ingamut colors such as flesh tones are rendered well,

similar to the Photographic rendering style.

Relative Colorimetric—

transformation between the source and destination white

points. For example, the bluish gray of a monitor will

map to neutral gray. You may prefer this style to avoid

visible borders when not printing full-bleed.

Absolute Colorimetric—

transformation between the source and destination white

points. For example, the bluish gray of a monitor will

map to a bluish gray.

Provides white-point

Provides no white point

Photographs, including scans and

images from stock photography CDs.

Artwork and graphs in presentations.

In many cases it can be used for mixed

pages that contain both presentation

graphics and photographs.

Advanced use when color matching is

important but you prefer white colors

in the document to print as paper

white. It may also be used with

PostScript color management to affect

CMYK data for simulation purposes.

Situations when exact colors are

needed and visible borders are not

distracting. It may also be used with

PostScript color management to affect

CMYK data for simulation purposes.

Equivalent ICC

rendering style:

Image, Contrast,

and

Perceptual

Saturation,

Graphics

Same

Same

Page 8

1-6 Fiery Color Management

1

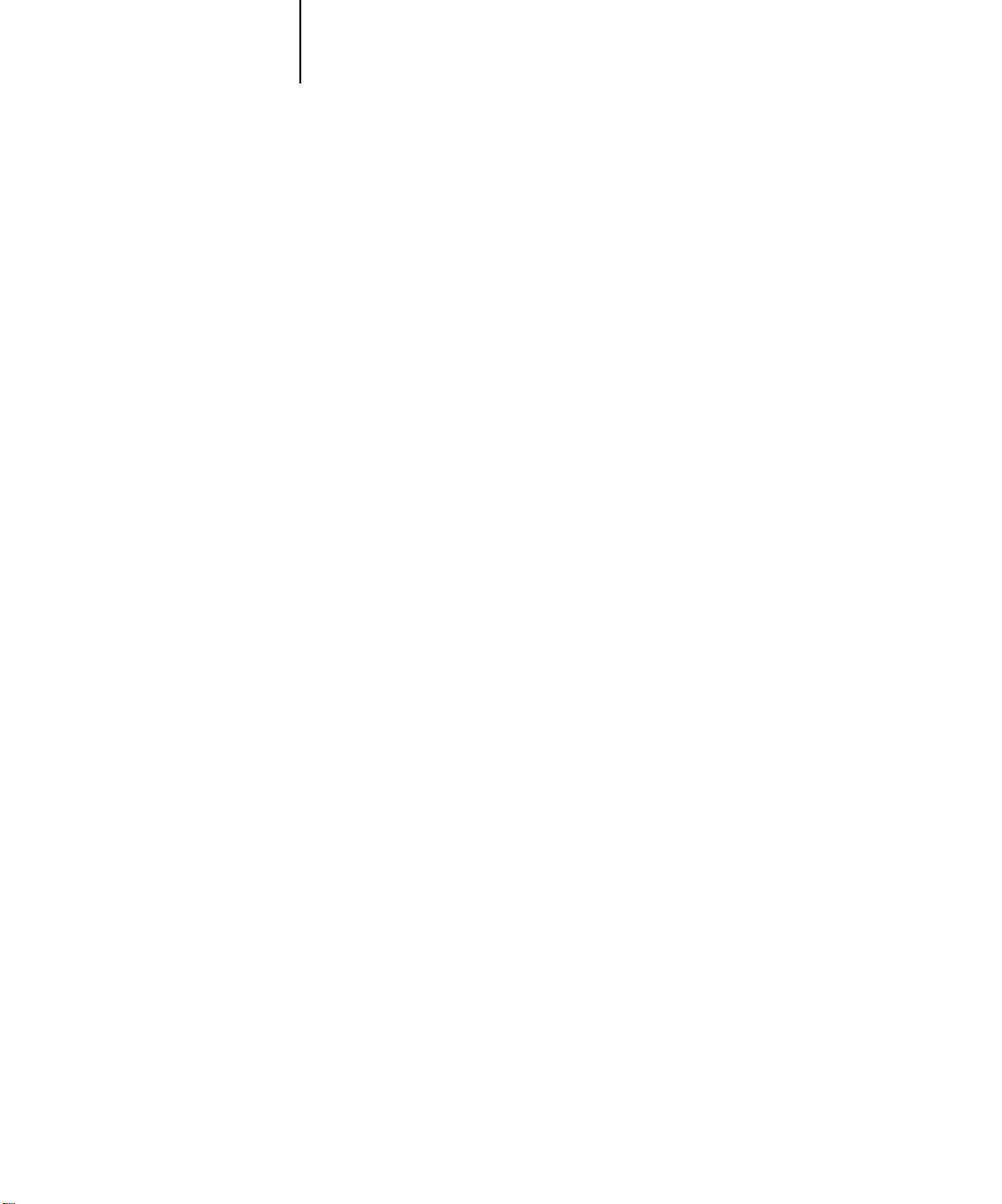

Pure Black Text/Graphics

The Pure Black Text/Graphics option affects the printout for black text and vector

graphics on a page. Under most circumstances it is preferable to leave this option set to

the On position. When Pure Black Text/Graphics is on, black colors generated by

applications are printed using 100 percent black-only toner (for example,

RGB = 0%, 0%, 0%; CMYK = 0%, 0%, 0%, 100%; or K = 100%). This means the

black text and line art will not exhibit halftone artifacts and will not be misregistered,

since there is only one toner used. In addition, this setting eliminates blasting. This

option is automatically set to On when the Black Overprint option is set to On.

For some jobs it is preferable to turn this option Off, for example, if the page includes

gradient fills that use black. The table below describes the behavior of the Pure Black

Text/Graphics option with black data defined in different color spaces.

NOTE: The Pure Black Text/Graphics option can be used only when printing

composites, not when printing separations.

Input

black color

RGB

CMYK

Prints 100% black

Spot

NOTE: PostScript applications, such as QuarkXPress, may convert elements defined as

RGB = 0%, 0%, 0% to four-color CMYK black before sending the job to the Fiery.

These elements are not affected by the Pure Black Text/Graphics option. See the

application notes for details. Also, black text and line art defined as RGB = 0%, 0%,

On Off

Pure Black Text/Graphics

With the default profile, prints a rich black

using all toners.

Prints only with black toner, because CMYK

simulations preserve the black channel. The

actual amount of toner used depends on the

current simulation and the calibration state of

the copier.

Prints only with black toner, because spot

color simulations preserve the black channel.

The actual amount of toner used depends on

the current simulation and the calibration state

of the copier.

Page 9

1-7 Managing color on the Fiery

1

0% in office applications (such as Microsoft Word) are converted to single-color black

(CMYK = 0%, 0%, 0%, 100%) by the Microsoft PostScript Level 2 driver for

Windows NT 4.0. To print this single-color black at the maximum toner density of the

copier, set the Pure Black Text/Graphics option to On.

Black Overprint

The Black Overprint option lets you specify whether or not black text, defined as

RGB = 0%, 0%, 0%, or as CMYK = 0%, 0%, 0%, 100%, overprints colored

backgrounds.

• On—Black text overprints colored backgrounds, eliminating white gaps and

reducing halo affects or misregistration of colors. Setting Black Overprint to On

automatically activates the Pure Black Text/Graphics option.

• Off—Black text knocks out colored backgrounds.

The Compression option must be set to On to use this option.

NOTE: PostScript applications may perform their own black overprint conversions

before sending the print job to the Fiery. See the application notes for details.

One example of how you might use this setting is with a page that contains some black

text on a light blue background. The background blue color is CMYK = 40%, 30%,

0%, 0% and the black text is CMYK = 0%, 0%, 0%, 100%.

• With Black Overprint On, the final text portions of the page are overprinted, or

combined with the underlying colors. This results in CMYK = 40%, 30%, 0%,

100% for the color used for the text. There is no transition in the cyan and magenta

toners, and the quality of the output is improved since it will not show artifacts near

the edges of the text. The option also works with text defined in the RGB color

space, that is RGB = 0%, 0%, 0%.

• With Black Overprint Off, the border of the text is on an edge that has cyan and

magenta toners on one side (outside the text) and black toner on the other side

(inside the text). On many copiers, this transition causes visible artifacts because of

the practical limitations of the copier.

Page 10

1-8 Fiery Color Management

1

RGB Source Profile

The RGB Source Profile setting allows you to define the characteristics of the RGB

data in your document so that the appropriate color conversion can occur on the Fiery.

Commonly used monitor color spaces are available from the driver and from the

ColorWise Pro Tools Profile Manager. In addition, for special needs you can use

ColorWise Pro Tools to download custom monitor or scanner profiles.

When you specify a setting other than None for the RGB Source Profile, the Fiery

overrides source color space definitions or profiles that other color management

systems may have specified. For example, if you specified a ColorSync System Profile

on your Mac OS computer, the RGB Source Profile setting overrides it. In cases where

you do not want this setting to override another specified source color space, choose the

None setting.

When you specify a setting other than None for the RGB Source Profile—since the

color space definitions are overridden—the prints from the Fiery will be consistent

across platforms. Below are the Fiery’s RGB Source Profile options.

• EFIRGB specifies an EFI-defined color space recommended for users who have no

detailed information about their RGB data.

• sRGB (PC) specifies the industry standard definition for a generic Windows PC

monitor.

• Apple Standard specifies the definition of all standard Mac OS computer monitors.

• Other allows you to specify custom RGB source settings. If you choose Other as the

RGB Source setting, you can choose settings for the Gamma, Phosphors, and White

Point options.

• Sources 1-10 specify the definitions you download as RGB source profiles. (For

more information about downloading RGB source profiles, see Chapter 4.)

If you are printing with the PostScript driver for Windows 95/98, the name of each

downloaded or custom profile is represented in the RGB Source Profile setting popup menu. If you are printing with the AdobePS driver from a Mac OS or

Windows NT computer, downloaded or custom profiles appear as Source 1 through

Source 10.

Page 11

1-9 Managing color on the Fiery

1

• None instructs the Fiery to allow the RGB sources you defined elsewhere, such as in

the application, to be used. When you set RGB Source to None, the appearance of

colors will not be independent of the file type. For example, RGB EPS files will look

different from RGB TIFF files.

With RGB Source set to None, PostScript RGB data that contains a source color

space definition is converted using the CRD specified by the Rendering Style option

(see page 1-5). NonPostScript RGB data and PostScript RGB data that does not

contain a source color space definition is converted using a general undercolor

removal conversion method.

RGB Separation

The RGB Separation option determines how RGB colors (as well as Lab and XYZ

colors) are converted to CMYK. The name of this option is meant to be descriptive,

since the option defines the color spaces that will be used by the Fiery to “separate” the

RGB data into CMYK values.

The two choices available for this option determine whether RGB data is converted

into the full gamut of the copier (Output) or whether it is first converted into the

gamut of another digital printer or a press standard (Simulation). This feature is

helpful for making one device behave like another for RGB data. For example, if a

high-quality ICC profile is available for another print device, the copier can simulate

the behavior of that device.

RGB Separation is also useful for prepress applications. For example, it lets you

experiment with the appearance of an RGB scan under different press printing

conditions without having to convert the RGB data to CMYK data for each printing

condition. When the desired printing condition is found, you can then convert the file

to CMYK, if desired, using the same CMYK simulation profile that was used during

the experimentation.

NOTE: The RGB Separation print option should be used in conjunction with the

Output Profile or CMYK Simulation Profile print options.

Page 12

1-10 Fiery Color Management

1

• Output converts all RGB colors into the CMYK color space of your copier (when the

Output Profile option is set to Printer’s default), or a customized CMYK color space

for your copier (when the Output Profile option is set to Output 1–10).

• Simulation converts all RGB colors into the CMYK color space for a specified

simulation (make sure to select the desired simulation with the CMYK Simulation

Profile print option).

CMYK Simulation Profile

The CMYK Simulation Profile print option allows you to print press proofs or

simulations. This setting specifies the offset press standard or other color printing

device that you want to simulate. This option affects CMYK data only.

On Windows 95/98, you can also view an unlimited number of custom Quick and

Full simulations created using ColorWise Pro Tools. On Windows NT and Mac OS

computers, you can view up to 10 Quick and 10 Full custom simulations. The number

of custom simulations is limited by the disk space on the Fiery.

NOTE: If you are printing with the PostScript printer driver on a Windows 95/98

computer, the name of each profile is visible in the pop-up menu for the CMYK

Simulation Profile setting. If you are printing with the AdobePS driver on Windows

NT or a Mac OS computer, custom simulations appear as Simulation 1 through

Simulation 10.

The CMYK Simulation Profile setting you should specify depends on the press

standard for which the CMYK data was separated.

• For images that were separated using a custom separation (such as a separation

produced with an ICC profile), choose the corresponding profile on the Fiery with

the CMYK Simulation Profile setting.

• For images that were separated for SWOP, choose SWOP as the CMYK Simulation

Profile setting.

Page 13

1-11 Managing color on the Fiery

1

NOTE: To properly simulate a printed image that was separated through the use of an

ICC profile, the same profile must be present on the Fiery. For more information

about downloading ICC profiles to the Fiery, see “Downloading profiles” on page 4-4.

• The Match Copy setting bypasses Fiery calibration to simulate the color of a copy

produced by the copier. Use this setting when you print images scanned with the

Fiery Scan plug-in set to Match Copy.

CMYK Simulation Method

The CMYK Simulation Method setting specifies the quality of simulation to perform.

• Quick applies one-dimensional transfer curves that adjust output density only.

• Full provides a more complete and accurate simulation by applying colorimetric

transformations that adjust hue as well as output density. The Full Simulation

option also maintains the integrity of the black channel by adjusting it

independently. This is especially important for images separated using an optimized

black generation (UCR/GCR) setting either from a scan or from within an

application such as Photoshop.

Output Profile

The output profile is applied to all data in the print job, so make sure the selected

profile is right for your job. The default output profile consists of both a profile for

your copier, describing the copier’s color characteristics, and a calibration target that

describes the expected behavior of the copier. In certain cases you may wish to

customize the default output profile to achieve particular color effects (see page 4-6). If

so, the new customized output profile is applied to all data in the print job.

NOTE: Changing only the output profile does not affect its associated calibration target

(since the target is based on a copier model). If you wish, you can edit D-Max values of

the calibration target separately (see page 4-6).

You can also use ColorWise Pro Tools to download your own output profile to the

Fiery (see page 4-4). Downloaded output profiles are at first associated with the default

calibration target. As mentioned above, you can edit calibration target D-Max values

separately.

Page 14

1-12 Fiery Color Management

1

Spot Color Matching

The Spot Color Matching option provides automatic matching of PANTONE colors

with their best CMYK equivalents.

• On—The Fiery uses its built-in table to generate the closest CMYK matches of

PANTONE colors your copier can produce. (New tables are generated when you

add new output profiles.)

• Off—The Fiery uses the CMYK equivalents defined by your application to print

PANTONE colors.

For jobs that include PANTONE spot colors, set Spot Color Matching to On unless

you are printing press simulations. In that case, set Spot Color Matching to Off and

choose the appropriate CMYK Simulation setting (see page 1-10).

NOTE: You can use the Spot Color Matching option only when printing composites,

not when printing separations.

Spot Color Matching and the PANTONE Coated Color Reference

The PANTONE Coated Color Reference (described on page 5-8) prints differently

depending on the Spot Color Matching setting.

• On—The Fiery uses its built-in table to generate the best matches of the PANTONE

colors that your copier can produce. The PANTONE number is printed below each

swatch.

• Off—The Fiery prints swatches using the CMYK values recommended by Pantone

(and used by applications that provide PANTONE color libraries). The CMYK

values used to generate the color, as well as the PANTONE number of the color, are

printed below each swatch. These CMYK values are printed through the selected

CMYK Simulation and Output Profile settings.

Page 15

2-1 Workflow concepts

2

Chapter 2:

Simple and

Advanced

Workflows

This chapter discusses color management workflows used in short-run color printing

as well as color proofing on the Fiery. It also gives examples of color management in

specific desktop applications and the interaction between those applications and

ColorWise color management.

Workflow concepts

The term “workflow” is used to describe the path a job follows from its creation in a

desktop application to final printed output. It is helpful to think of the following

categories when describing workflows:

• Short-run printing versus color proofing for eventual output on an offset press

• RGB, CMYK, and PANTONE color systems

• Desktop color management within an application versus color management on the

Fiery, along with the notion that different versions of desktop applications handle

color management differently. So it is important to pay close attention to the version

of a particular application when considering the workflows in this chapter.

Short-run printing versus color proofing

Short-run color printing refers to those jobs for which the Fiery is the final print

device. Printing jobs to the Fiery in preparation for printing on an offset press is

referred to as color proofing. Both types of Fiery print jobs use RGB, CMYK, and

PANTONE colors.

• For short-run jobs, bright, saturated colors are often desirable. These are achieved by

using the full range of colors available, referred to as the full gamut of copier, or

more simply copier CMYK. See “Advanced Workflows” on page 2-10 for short-run

printing examples.

• Offset jobs proofed on the Fiery require the printed colors to match those from

another set of CMYK printing conditions. Colors that are specified for an offset

press require CMYK simulation optimized for proofing on the copier. See Advanced

Workflows on page 2-10 for color proofing examples that simulate the gamut of

another digital printer or press standard.

Page 16

2-2 Simple and Advanced Workflows

2

RGB, CMYK, and PANTONE colors

Colors can be defined in several different color models, the most common being RGB,

CMYK, and the PANTONE color matching system. Each model requires a different

color conversion at the Fiery. These different color conversion workflows are explained

below.

• RGB source profiles and color rendering dictionaries are used to map RGB colors

through a device-independent color space to a destination space, either the full

copier gamut in a short-run printing workflow or CMYK simulation in a color

proofing workflow.

• CMYK colors are device-dependent. In a proofing scenario, colors specified in

prepress applications are adjusted so the Fiery copier’s gamut can simulate that of the

press. In a short-run printing workflow, specifying CMYK colors according to the

calibrated copier output eliminates the need for simulation during printing.

• PANTONE spot colors are special inks manufactured to run on an offset printing

press. Spot colors can be simulated using CMYK copier toners or process color inks.

Two basic workflows exist for printing PANTONE colors to the Fiery:

Spot Color Matching On instructs the Fiery to match the PANTONE spot color to

the output of the copier.

Spot Color Matching Off instructs the Fiery to match the copier output to a

PANTONE-specified process simulation. This CMYK combination is then printed

with the CMYK Simulation setting you choose, such as SWOP or Custom, and

CMYK Simulation Method set to Full.

Page 17

2-3 Workflow concepts

2

Desktop versus Fiery color management

A desktop color management system uses ICC profiles to convert colors from one

device gamut to the next (see Appendix B). Desktop color management systems

convert color data when it is passed from one application to another or when the job is

sent to the copier.

ColorWise uses standard ICC profiles to convert colors to the copier gamut or to

simulate other devices such as an offset printing press. ColorWise manages color

conversions for all users printing to the Fiery from Windows and Mac OS computers.

It lets users follow a simple workflow with minimal intervention using robust default

settings, while giving advanced users the control and precision they need.

The Fiery can intelligently manage the printed appearance of RGB, CMYK, and

PANTONE colors. You can let the Fiery manage color for most short-run color

printing jobs without adjusting any settings.

Managing most or all of your color on the Fiery can eliminate the potential for

undesirable color management-related conflicts, such as iterative color conversions and

inconsistent color. The Fiery applies global corrections to specific groups of RGB,

CMYK, and PANTONE colors to avoid such conflicts, and color conversions on the

Fiery are in most cases much faster than similar conversions on a host computer.

Finally, by sending RGB files instead of larger CMYK files from applications to the

Fiery, network traffic is minimized and jobs are generally printed more quickly.

Page 18

2-4 Simple and Advanced Workflows

r

2

Simple workflows

Every time you print a document containing colors that were not chosen for your

specific copier, those colors need to be converted, which requires color management.

There are many places where color management can take place. Since ColorWise is

compatible with most other color management systems, you can use the workflow

most familiar to you.

This section provides examples of color workflows that should meet the needs of most

Fiery users. For information on specific desktop applications, see Chapters 6 through

9.

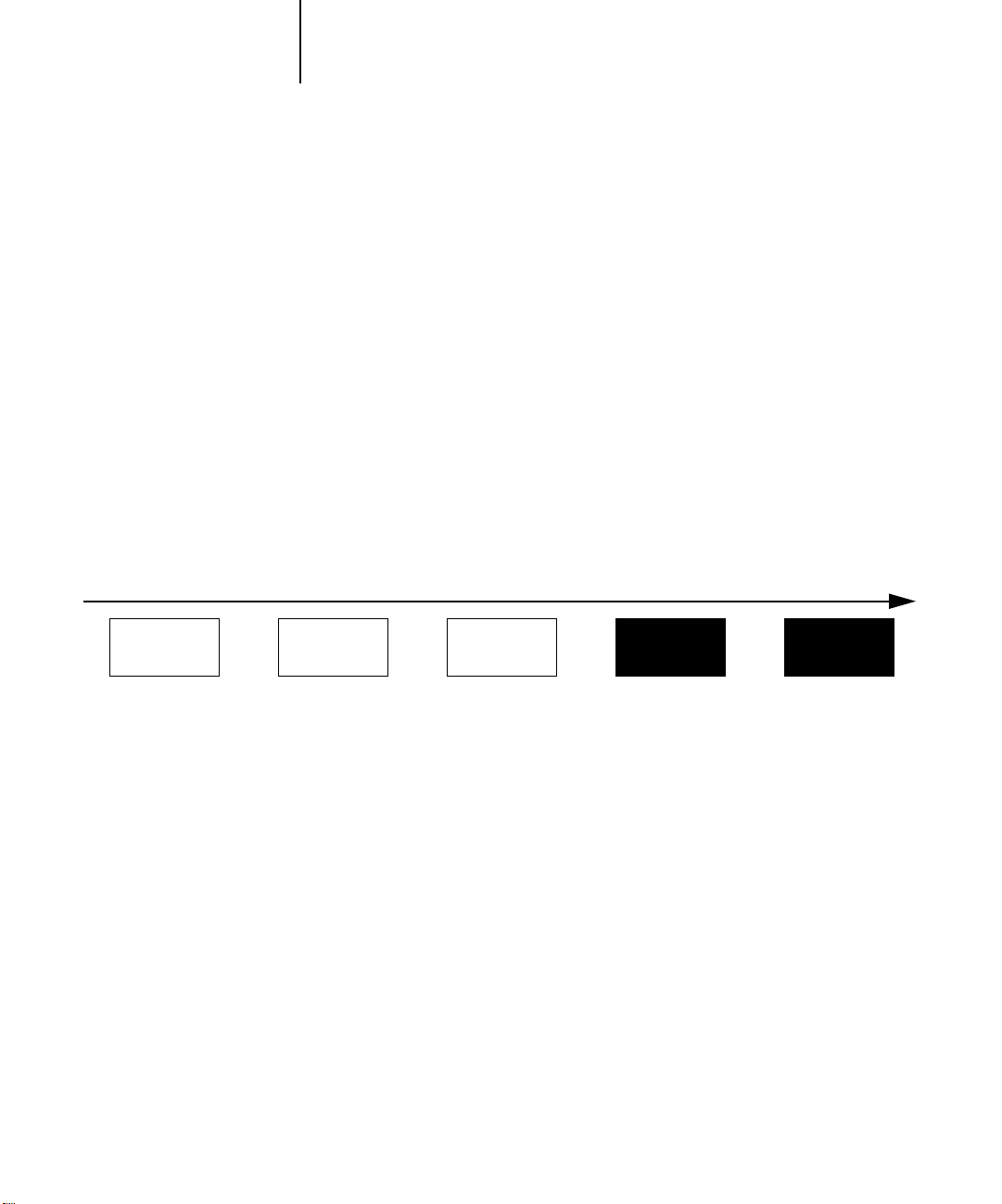

Consider that colors can be defined or modified at any stage in the workflow, as illustrated

in the following diagram.

Colors you define in an application Colors in output from the copie

Application

CMS

File format Printer driver

ColorWise

CMS

ColorWise

calibration

Page 19

2-5 Simple workflows

2

Select your colors wisely

For the colors you see on your monitor to match those on your printed output, they

must go through color management, including precise calibration of your monitor and

copier. If you are not equipped or inclined to maintain accurate monitor color

management, you may opt for an easier approach. First, determine which is more

important for you—printed colors or monitor displayed colors.

If displayed colors are more important, trust your eyes and your monitor. Visually

select colors on your monitor, but be aware that colors will be optimized only for your

monitor. When the document is opened on other monitors, the colors may look

different. And even though printed colors may not match those displayed on your

monitor, they will still print on the Fiery with good results.

If printed colors are your priority, choose colors from printed samples. Printed colors

will be consistent, even on different monitors. Print the palette of available colors from

business applications and then select colors from the printed samples. The Fiery comes

with color reference files on the user software CD (see page 5-2). You can also print the

color charts from the Control Panel and select colors by numbers or by name from the

printed samples. Advanced applications let you define colors in the easier-to-control

PANTONE and CMYK color spaces. See Chapter 5 for more advice on color

selection.

No matter which workflow most closely matches your own, you should calibrate your

copier regularly (see Chapter 3).

Page 20

2-6 Simple and Advanced Workflows

r

2

Select a short workflow

Every time colors are converted, performance and color accuracy are affected.

Therefore, a workflow with fewer steps minimizes the risk of error.

Workflow 1 using ColorWise calibration—minimal workflow

A minimal color workflow requires that you calibrate the copier. Set the CMYK

Simulation option to None, since simulation is not needed when colors are already

defined using CMYK values optimized for your calibrated copier.

CMYK Simulation set to None is useful when you want to prepare an output profile of

your calibrated copier or when you use less efficient color management from the

desktop (such as ColorSync or ICM).

In this workflow, colors are modified only at the calibration stage. This is indicated by

the black box in the diagram below.

Workflow 1

Colors you define in an application Colors in output from the copie

Application

CMS

File format Printer driver

While this workflow lends some control over the color quality produced by the copier,

you should consider additional ColorWise color management, as described in the next

section.

ColorWise

CMS

ColorWise

calibration

Page 21

2-7 Simple workflows

r

2

Workflow 2 using ColorWise color management—standard workflow

Fiery servers are highly optimized for the specific copier they drive, and ColorWise

addresses many issues unique to your copier, including screens, individual toner

response, interactions among toners, natural smoothness of blends, and the capability

to render PANTONE and custom colors. The Fiery distinguishes text and graphic

from image elements, so the black channel information is preserved while parameters

used for CMYK color separations are maintained.

Conventional color management systems typically address only color conversions, and

they occupy your computer’s processor. When you use ColorWise, jobs leave your

computer faster to be processed more quickly on the Fiery.

The recommended standard color workflow (indicated by the black boxes in the

diagram below) uses ColorWise calibration and color management.

Workflow 2

Colors you define in an application Colors in output from the copie

Application

CMS

File format Printer driver

The Fiery comes into play near the end of the color workflow. To ensure that the colors

you have selected reach the Fiery and ColorWise in a usable form, you should bypass

any color management from applications and printer drivers. (Keep in mind, however,

that color management from applications and printer drivers is fully supported by

ColorWise (see “Advanced workflows” on page 2-10).

ColorWise

CMS

ColorWise

calibration

Page 22

2-8 Simple and Advanced Workflows

r

2

You must print with the CMYK Simulation print option set to match the CMYK

color space in your application when you selected the colors. Any CMYK Simulation

setting (except Match Copy) applies calibration, so the copier’s response will appear to

be stable.

The recommended values for CMYK Simulation are SWOP in America, Euroscale in

Europe, and DIC in Japan—choices that respect the color standard for each region. If

colors have been selected specifically for your calibrated copier, set CMYK Simulation

to None.

See the table on page 1-3 for the list and descriptions of ColorWise print options

affecting CMYK, RGB, PANTONE, and other colors.

Workflow 3 bypassing ColorWise—not recommended

Bypassing ColorWise color management, while an option, is not a recommended

workflow. When you bypass ColorWise, you must choose colors using only CMYK

formulas designed specifically for your copier, and you must print with the CMYK

Simulation option set to Match Copy. The Fiery still prints pages using your PostScript

files, and drives the copier and its accessories, but it does not perform CMYK color

transformation, nor does it consider the copier’s calibration. Calibration is needed in

order to get consistent output, since the color response from your copier’s engine varies

significantly depending on wear, heat, humidity, and service.

The diagram below indicates that no modifications are made to colors in this

workflow.

Workflow 3

Colors you define in an application Colors in output from the copie

Application

CMS

File format Printer driver

ColorWise

CMS

ColorWise

calibration

Page 23

2-9 Simple workflows

2

Turn off color management in your application

Generally, when printing to the Fiery, it is best to disable color management in the

application to ensure that the Fiery receives color data properly and prints it accurately.

Examples later in this chapter illustrate the advantage of disabling color management

in the application, and you can find more specific information in Chapters 6

through 9.

Save your files using color-safe settings

There are several additional steps you can take to ensure color accuracy.

• When saving EPS files, do not include PostScript Color Management information.

This minimizes the risk conflicting data and multiple color conversions. PostScript

Color Management causes your CMYK and RGB colors to be interpreted by the

Fiery as though they were supplied in the Lab color space and, as a result, to be

processed by CRDs rather than your simulation settings.

• Include ICC color information in files. ColorWise will not conflict with this

information, and such data can be useful to identify the specific color space used by

your files.

• Do not include halftone and transfer functions.

• Turn off color management in the printer driver.

On Windows machines, if the printer driver offers Image Color Matching options,

select Printer Image Color Matching.

On Mac OS computers, you should set the printer driver to include no color

management commands at print time (see page 1-18).

Page 24

2-10 Simple and Advanced Workflows

2

Advanced workflows

The following sections present advanced color management workflow examples for

three short-run printing and three color proofing situations. Each workflow example

consists of a brief description, steps for creating and manipulating the files, a list of the

ColorWise settings used in the example, and a table that summarizes the workflow.

NOTE: These examples use specific software packages to represent image-editing,

illustration, page-layout, and business/office applications; they are Adobe Photoshop,

Adobe Illustrator, QuarkXPress, and Microsoft PowerPoint, respectively.

Short-run printing examples

The following examples illustrate short-run printing on the Fiery.

Photoshop RGB workflow

This short-run workflow of printing an RGB image from Photoshop is one of the

simplest Fiery color workflows. In it, RGB data is sent from the application, through

the printer driver, to the Fiery, and the RGB-to-CMYK conversion takes place on the

Fiery using a CRD rather than in the application. Use the settings illustrated in this

workflow for printing photographs and artwork.

This document could be created as follows:

• Create an RGB image in Photoshop.

• Print the file directly to the Fiery.

See Chapter 7 for recommended print settings from Photoshop.

• Use ColorWise to convert the RGB image to copier CMYK for short-run printing.

The ColorWise settings used in this example are:

• RGB Source Profile set to EFIRGB or another RGB source definition

• Rendering Style set to Photographic

• RGB Separation set to Output

Page 25

2-11 Advanced workflows

2

The diagram below indicates the steps for this particular workflow in black.

Photoshop RGB workflow

Photoshop Printer driver

Read Embedded Profiles

Define RGB Source

Embed Source Profiles

Convert RGB to CMYK

Convert CMYK to CMYK

Select RGB Mode

Select CMYK Mode

Select Destination Profile

Save as TIFF

Save as EPS

Save as JPEG

Print

ColorSync Color Matching

PostScript Color Matching

(Mac OS-only)

Black and White

Color/Grayscale

Select Rendering Style (CRD)

Select RGB Separation: Output

Select RGB Separation: Simulation

Convert Press CMYK to Press Sim.

Convert Press CMYK to Custom Sim.

Select Copier CMYK Simulation: None

Turn Spot Color Matching On

Turn Spot Color Matching Off

Select Custom Output Profile

ColorWise

print options

Define RGB Source

Select RGB Source: None

Select Output Profile

Photoshop RGB with Illustrator and QuarkXPress CMYK and PANTONE colors

This workflow involves short-run printing of a complex page layout with images saved

in Photoshop, illustrations created in Illustrator, and PANTONE spot colors. A

Photoshop image is saved in an RGB color space using the EPS file format. Illustrator

artwork contains objects defined as CMYK and as PANTONE spot colors, and they

are saved using the Illustrator EPS file format. After all of these individual objects are

imported into QuarkXPress, additional design elements in QuarkXPress are colored

using CMYK process colors or PANTONE spot colors. Use the settings illustrated in

this workflow for printing brochures, newsletters, and other layouts.

This document could be created as follows:

• Create an RGB image in Photoshop and save it as an EPS.

• Create a graphic in Illustrator using CMYK and PANTONE colors and save as

Illustrator EPS.

• Use CMYK colors and a PANTONE color in a QuarkXPress document.

• Import the Illustrator EPS into QuarkXPress and place the Photoshop EPS image.

• Print the QuarkXPress document to the Fiery.

Page 26

2-12 Simple and Advanced Workflows

P

2

• Use ColorWise to convert the RGB image to copier CMYK, to adjust the process

colors for short-run printing, and to match the PANTONE spot colors using the

full copier gamut.

The ColorWise settings used in this example are:

• RGB Source Profile set to EFIRGB or another RGB source definition

• Rendering Style set to Photographic

• RGB Separation set to Output

• Spot Color Matching set to On

The diagram below indicates the steps for this particular workflow in black.

hotoshop RGB workflow with Illustrator, QuarkXPress CMYK, and PANTONE colors

Photoshop Illustrator QuarkXPress Printer driver

Read Embedded Profiles

Define RGB Source

Embed Source Profiles

Convert RGB to CMYK

Convert CMYK to CMYK

Select RGB Mode

Select CMYK Mode

Select Destination Profile

Save as TIFF

Save as EPS

Save as JPEG

Print

Read Embedded Profile

Define RGB Colors

Define CMYK Colors

Define PANTONE Colors

Convert RGB to CMYK

Convert PANTONE to CMYK

Embed Source Profile

Select Destination Profile

Export as TIFF

Save as EPS

Print

Read Embedded Profile

Define RGB Colors

Define CMYK Colors

Define PANTONE Colors

Convert RGB to CMYK

Convert CMYK to CMYK

Convert PANTONE to CMYK

Embed Source Profile

Select Destination Profile

Export as TIFF

Save as EPS

Print

(Mac OS-only)

Black and White

Color/Grayscale

ColorSync Color

Matching

PostScript Color

Matching

Select Rendering Style (CRD)

Select RGB Separation: Output

Select RGB Separation: Simulation

Convert Press CMYK to Press Sim.

Convert Press CMYK to Custom Sim.

Select Copier CMYK Simulation: None

Turn Spot Color Matching On

Turn Spot Color Matching Off

Select Custom Output Profile

ColorWise

print options

Define RGB Source

Select RGB Source: None

Select Output Profile

Page 27

2-13 Advanced workflows

2

Photoshop RGB with Illustrator CMYK and PANTONE and PowerPoint RGB

This workflow involves short-run printing of a complex presentation document with

images saved in Photoshop, illustrations created in Illustrator, and PANTONE spot

colors. All elements are imported into PowerPoint for output.

This document could be created as follows:

• Create an RGB image in Photoshop and save it as Photoshop EPS.

• Create a graphic in Illustrator using CMYK colors and a PANTONE spot color and

save as Illustrator EPS.

• Create a presentation in PowerPoint using RGB colors.

• Import the Illustrator EPS graphic into the PowerPoint presentation and place the

Photoshop EPS image.

• Print the PowerPoint document to the Fiery.

• Use ColorWise to convert the PowerPoint RGB colors and Photoshop RGB image

to copier CMYK, to adjust the process colors for more saturated short-run printing,

and to match the PANTONE spot colors using the full copier gamut.

The ColorWise settings used in this example are:

• RGB Source Profile set to EFIRGB or another RGB source definition

• Rendering Style set to Presentation

• RGB Separation set to Output

• Spot Color Matching set to On

Page 28

2-14 Simple and Advanced Workflows

P

2

The diagram below indicates the steps for this particular workflow in black.

hotoshop RGB and Illustrator CMYK and PANTONE in PowerPoint RGB workflow

Photoshop Illustrator PowerPoint Printer driver

Read Embedded Profiles

Define RGB Source

Embed Source Profiles

Convert RGB to CMYK

Convert CMYK to CMYK

Select RGB Mode

Select CMYK Mode

Select Destination Profile

Save as TIFF

Save as EPS

Save as JPEG

Print

Read Embedded Profile

Define RGB Colors

Define CMYK Colors

Define PANTONE colors

Convert RGB to CMYK

Convert PANTONE to CMYK

Embed Source Profile

Select Destination Profile

Export as TIFF

Save as EPS

Print

Define RGB Colors

Convert CMYK to RGB

Print

(Mac OS-only)

Black and White

Color/Grayscale

ColorSync Color

Matching

PostScript Color

Matching

Select Rendering Style (CRD)

Select RGB Separation: Output

Select RGB Separation: Simulation

Convert Press CMYK to Press Sim.

Convert Press CMYK to Custom Sim.

Select Copier CMYK Simulation: None

Turn Spot Color Matching On

Turn Spot Color Matching Off

Select Custom Output Profile

ColorWise

print options

Define RGB Source

Select RGB Source: None

Select Output Profile

Color proofing examples

The following examples illustrate methods for simulating the output from another

printing system, such as an offset press. Each of the proofing examples uses an ICC

profile to describe the destination color space. While some examples use built-in

simulation profiles, others use ColorWise Pro Tools (see Chapter 4) to download

custom ICC output profiles to the Fiery for use as simulation profiles.

Photoshop 5.x RGB-to-CMYK conversion using a custom ICC profile

This workflow is useful for prepress environments that have integrated ICC color

management and have profiles for the presses they use. In this example, an image in

Photoshop 5.x is converted from RGB to CMYK using Photoshop’s ICC color

conversion features in the CMYK Setup option. (For more information on CMYK

Setup, see your Photoshop 5.x documentation.) Using the Simulation settings available

in ColorWise, the CMYK image is printed to the Fiery, and the output is made to

appear as if it were printed on an offset press.

Page 29

2-15 Advanced workflows

2

This document could be created as follows:

• In Photoshop 5.x, set CMYK Model in CMYK Setup to ICC.

• In the Profile menu, select an ICC profile for the desired offset press. Click OK.

• Open an RGB image. From the Image pull-down menu select Mode>CMYK Color.

• Save the image as Photoshop EPS.

• Print directly to the Fiery.

• Use ColorWise Pro Tools to select a simulation profile or download a custom ICC

profile to the Fiery for use as a CMYK Simulation Profile.

The ColorWise settings used in this example are:

• CMYK Simulation Profile set to the desired press standard or to the corresponding

custom simulation (Simulation 1-10) if you downloaded your profile with

ColorWise Pro Tools

• CMYK Simulation Method set to Full

The diagram below indicates the steps for this particular workflow in black.

Photoshop RGB-to-CMYK workflow using ICC profile

Photoshop 5.x Printer driver

Read Embedded Profiles

Define RGB Source

Embed Source Profiles

Convert RGB to CMYK

Convert CMYK to CMYK

Select RGB Mode

Select CMYK Mode

Select Destination Profile

Save as TIFF

Save as EPS

Save as JPEG

Print

(Mac OS-only)

Black and White

Color/Grayscale

ColorSync Color Matching

PostScript Color Matching

Select Rendering Style (CRD)

Select RGB Separation: Output

Select RGB Separation: Simulation

Convert Press CMYK to Press Sim.

Convert Press CMYK to Custom Sim.

Select Copier CMYK Simulation: None

Turn Spot Color Matching On

Turn Spot Color Matching Off

Select Custom Output Profile

ColorWise

print options

Define RGB Source

Select RGB Source: None

Select Output Profile

Page 30

2-16 Simple and Advanced Workflows

2

Photoshop 5.x Built-in RGB-to-CMYK workflow

This workflow is useful for prepress environments that have not integrated ICC color

management and do not have profiles for the presses they use. In this example, an

image is converted from RGB to CMYK using Photoshop 5.x’s Built-in color

conversion features in the CMYK Setup option. (For more information on CMYK

Setup, see your Photoshop 5.x documentation). Using the Simulation settings available

in ColorWise, the CMYK image is printed to the Fiery, and the output is made to

appear as if it were printed on an offset press.

This document could be created as follows:

• Select the Built-in radio button from CMYK Setup in Photoshop 5.x’s

Color Settings.

• Adjust the Ink Options and Separation Options to match your offset press.

• Select the Tables radio button in CMYK Setup and click Save.

This saves your settings as a CMYK ICC profile that you will later download to the

Fiery as a custom simulation profile.

• Click on the Built-in radio button in CMYK Setup again and click OK.

• Launch ColorWise Pro Tools and download your new CMYK ICC profile to the

Fiery as a custom Simulation profile.

For the Appear in Driver as option in Profile Settings, select Simulation-1. (For more

information on downloading profiles, see page 4-4.)

• Open an RGB image in Photoshop 5.x. From the Image menu, select

Mode >CMYK Color. Save the image as Photoshop EPS.

• Print the image directly to the Fiery and choose Simulation-1 as the CMYK

Simulation Profile setting.

The ColorWise settings used in this example are:

• CMYK Simulation Profile set to Simulation-1

• CMYK Simulation Method set to Full

Page 31

2-17 Advanced workflows

2

The diagram below indicates the steps for this particular workflow in black.

Photoshop5.x RGB-to-CMYK workflow

Photoshop 5.x Printer driver

Read Embedded Profiles

Define RGB Source

Embed Source Profiles

Convert RGB to CMYK

Convert CMYK to CMYK

Select RGB Mode

Select CMYK Mode

Select Destination Profile

Save as TIFF

Save as EPS

Save as JPEG

Print

(Mac OS-only)

Black and White

Color/Grayscale

ColorSync Color Matching

PostScript Color Matching

Select Rendering Style (CRD)

Select RGB Separation: Output

Select RGB Separation: Simulation

Convert Press CMYK to Press Sim.

Convert Press CMYK to Custom Sim.

Select Copier CMYK Simulation: None

Turn Spot Color Matching On

Turn Spot Color Matching Off

Select Custom Output Profile

ColorWise

print options

Define RGB Source

Select RGB Source: None

Select Output Profile

Photoshop RGB and QuarkXPress CMYK

This workflow exemplifies the use of the RGB Separation feature of ColorWise. An

RGB image, originally saved in Photoshop, is printed to the Fiery from QuarkXPress.

To simulate how the RGB image would print on an offset press, the RGB Separation

feature of ColorWise is set to Simulation. This workflow—useful for proofing

brochures, newsletters, and other layouts—lets you maintain consistency by using the

source RGB file for multiple purposes.

This document could be created as follows:

• Create an RGB image in Photoshop and save it as Photoshop EPS.

• Place the EPS image in a QuarkXPress document.

• Create several process-colored page elements alongside the image and print.

• Use ColorWise to convert the RGB image to simulated press CMYK and to adjust

the process colors for proofing to the copier.

Page 32

2-18 Simple and Advanced Workflows

2

The ColorWise settings used in this example are:

• RGB Source Profile set to EFIRGB or another RGB source definition

• Rendering Style set to Photographic

• RGB Separation set to Simulation

• CMYK Simulation Profile set to SWOP

• CMYK Simulation Method set to Full

The diagram below indicates the steps for this particular workflow in black.

Photoshop RGB and QuarkXPress CMYK workflow

Photoshop QuarkXPress Printer driver

Read Embedded Profiles

Define RGB Source

Embed Source Profiles

Convert RGB to CMYK

Convert CMYK to CMYK

Select RGB Mode

Select CMYK Mode

Select Destination Profile

Save as TIFF

Save as EPS

Save as JPEG

Print

Read Embedded Profile

Define RGB Colors

Define CMYK Colors

Define PANTONE Colors

Convert RGB to CMYK

Convert CMYK to CMYK

Convert PANTONE to CMYK

Embed Source Profile

Select Destination Profile

Export as TIFF

Save as EPS

Print

ColorSync Color Matching

PostScript Color Matching

(Mac OS-only)

Black and White

Color/Grayscale

ColorWise

print options

Define RGB Source

Select RGB Source: None

Select Rendering Style (CRD)

Select RGB Separation: Output

Select RGB Separation: Simulation

Convert Press CMYK to Press Sim.

Convert Press CMYK to Custom Sim.

Select Copier CMYK Simulation: None

Turn Spot Color Matching On

Turn Spot Color Matching Off

Select Output Profile

Select Custom Output Profile

Page 33

P

P

rroodduucctt&

&

Fiery XJ

T

T

eecchhnnoollooggy

y

Page 34

Page 35

6

6-1 Understanding calibration

Chapter 6:

Color

Calibration

Calibrating your Fiery XJ M ensures consistent, reliable color output. You can calibrate

the Fiery XJ M in several ways:

™

• Scan a page from the copier glass and use automatic calibration (AutoCal

• Connect a densitometer to your Fiery XJ M and calibrate it from the Control Panel.

• Connect a densitometer to your Macintosh or IBM PC-compatible and download

calibration to your Fiery XJ M with the Fiery XJ Print Calibrator utility.

This chapter describes the function of calibration and describes how to calibrate your

Fiery XJ M.

NOTE: Changing calibration affects all jobs for all users, so you may want to limit the

number of people authorized to calibrate the Fiery XJ M and use Fiery XJ Print

Calibrator.

).

Understanding calibration

Calibration allows you to:

• Maximize the color reproduction capabilities of the Fiery XJ

• Ensure consistent color quality across time

• Produce consistent output across Fiery XJ servers of the same kind

• Optimize your Fiery XJ for use with EFICOLOR color management software

• Use your Fiery XJ as a proofing system

• Achieve better color matches when you’re reproducing spot colors, such as

PANTONE colors or other named color systems

• Linearize your Fiery XJ while maintaining the currently available density range

• Create custom calibration targets and custom calibration curves

Page 36

6

6-2 Color Calibration

How calibration works

Success in obtaining satisfactory print quality from a digital color printer depends on

many factors. Among the most important are establishing and maintaining optimal

toner densities. Density is a measure of the light absorbed by a surface. The saturation

of toner colors, which affects output densities from your copier, is affected by such

variables as room humidity and service settings, and also tends to drift over time.

Regular calibration corrects for day-to-day variations in densities.

Calibration works by creating calibration curves on your Fiery XJ server that

compensate for deviations from desired density values. These calibration curves are

generated by creating a measurements file—a file containing numerical values

corresponding to the amount of toner being printed for the full range of colors—and

comparing it to a target.

Measurements

Measurements files provide numerical values that correspond to your copier’s toner

density for each color. To create a measurements file, you can scan a page from your

copier and use AutoCal, connect an X-Rite DTP32 densitometer to the Fiery XJ M

and record values, or connect an X-Rite DTP32 densitometer to your Macintosh

computer’s modem port or your IBM-PC compatible’s serial port and measure values

with the Fiery XJ Print Calibrator utility. You may also be able to connect any Status T

densitometer to your Macintosh or IBM-PC if you have utility software provided by

the densitometer manufacturer to create a measurements file.

Targets

Target files define desired calibration results. Several target files are provided with the

Fiery XJ M, and you can create additional ones as needed by modifying existing

targets. When you calibrate the Fiery XJ M, you can select the target file that

corresponds to the type of printing you are doing.

The targets provided with the Fiery XJ M are:

• Copier-M—Optimized for best results for specific copier performance. You should

use the copier target if you are going to use the copier’s EFICOLOR profile to print

CMYK data or the Color Rendering Dictionaries (CRD). The CRDs are used if you

Page 37

6

6-3 Understanding calibration

print an RGB file from Photoshop, or if you use a PostScript Level 2 Printer Driver

(Adobe PostScript Printer Driver for Macintosh, Adobe PostScript Printer Driver for

Windows, or Apple LaserWriter Printer Driver version 8.0 or later).

• DIC—Japanese press standard.

• Euroscale—European press standard.

• Linear—Results in output that divides the maximum measured density for each

color into equal density steps to provide an even distribution of tones over the

copier’s density range. When you linearize the Fiery XJ M, the entire measured

density range in each color channel is divided into equal steps. Equal steps in ink

percentage, such as 0%, 10%, and 20%, are printed in equal steps in density, and l

appear as roughly equal visual steps. This gives a linear response using the range of

densities available.

• SWOP-Coated—US press standard.

Scheduling calibration

In general, you should calibrate the Fiery XJ M at least once a week. If it is very

important to maintain consistent colors, or if your Fiery XJ M is subject to wide

fluctuations in temperature or humidity, you should calibrate every few hours. In

general, to get the best performance from your copier, calibrate whenever there is a

noticeable change in print quality.

If you need to split a print job into two or more batches, it is especially important to

calibrate before printing each batch.

You should also calibrate your Fiery XJ M system after copier maintenance. However,

because your copier may be unstable immediately after maintenance, you should wait

until you have printed approximately 50 pages before you calibrate.

NOTE: Copier output is very sensitive to changes in temperature and humidity. To

minimize these effects, your copier should not be installed near a window or in direct

sunlight, or near a heater or air conditioner.

Your copier may have a self-calibration feature that optimizes toner densities after

scanning a test page on the copier glass or some other method. You can use this feature

in conjunction with Fiery XJ M calibration. Always run the copier’s self-calibration

Page 38

6

6-4 Color Calibration

routine before calibrating. Using the copier’s calibration feature alone will not

necessarily bring output densities from your copier to the optimal values for

Fiery XJ M printing.

NOTE: All color copiers allow you to adjust printed color from their control panels. You

can typically increase or decrease toner density for one or all toner colors. These

control panel settings affect copies made from the copier glass, and may affect

Fiery XJ M output as well. If they do, make sure these settings remain the same

(preferably at a neutral position) prior to calibration, and from one print job to the

next. If you change these settings, calibrate the Fiery XJ M when you are finished

changing settings.

Set up a standard printing environment in Control Panel Setup by selecting printing

options that correspond to the way you usually print. Then print one or more standard

color pages. You can print the Color Charts from the Control Panel and the Color

Reference pages that are included with your user software. See “Using the Color

Reference pages” on page 2-4 or page 3-13. All of these pages include fully saturated

color patches and pale tints of cyan, magenta, yellow, and black. Images with skin

tones offer a very good basis for comparison. You can save and compare pages you

printed at different times. If there is a noticeable change in appearance, you should

calibrate or linearize your Fiery XJ M system.

If your solid density patches (100% cyan, magenta, yellow or black) look less saturated

with time, show the pages to the copier or printer technician to find out if an

adjustment can be made to improve the output.

Checking calibration status

Before printing a job, you should check to see whether the Fiery XJ M is calibrated,

what target was used, and when the printer was last calibrated. You can view

information about the last calibration:

• At the Fiery XJ M, by printing a Configuration Page or Test Page from the Control

Panel Functions menu.

• With the Fiery XJ Print Calibrator utility by choosing Calibration Status from the

Server menu. This method gives you additional information. See “To view

information with the Fiery XJ Print Calibrator:” on page 6-14.

Page 39

6

6-5 Understanding calibration

Using a densitometer

If you calibrate your Fiery XJ M from either the Control Panel or the Fiery XJ Print

TO CONNECT THE X-RITE DTP32:

Calibrator utility, you can use a densitometer to input color information. The

procedure is the same in both cases.

For additional information about setting up and using your densitometer, see the

documentation that came with it.

Setting up the densitometer

Before you calibrate the Fiery XJ M, configure and zero your reflection densitometer to

prepare for measuring the printed patches.

1. Plug the square end of the interface cable (like a modular phone plug) into the I/O

port on the side of the X-Rite DTP32.

Square connector

Page 40

6

6-6 Color Calibration

2. Attach the round 8-pin mini-connector to the modem port on the back of your

Macintosh. Or attach the 9-pin connector to the COM1 or COM2 port on your PC. Or

attach the 9-pin connector to the serial port on the back of the Fiery XJ M

Macintosh PCServer

3. If you are using a Macintosh, attach the round 4-pin mini-connector to one of the

Apple Desktop Bus (ADB) ports.

The Macintosh ADB port provides power to the DTP32.

Page 41

6

Small connector

AC adapter

6-7 Understanding calibration

4. If you are using a PC, a Macintosh without an ADB port available (or a PowerBook), or

the Fiery XJ M, use the optional AC adapter (available from X-Rite) to provide power.

If you use the optional AC adapter, plug the small connector on the adapter cable into

the side of the X-Rite DTP32 and plug the adapter into a wall outlet.

TO CONNECT THE X-RITE DTP32 TO A POWERBOOK:

1. Turn the PowerBook off.

2. Connect the network cable to the PowerBook’s EtherTalk port.

3. Plug the square end of the densitometer interface cable into the I/O port on the side

of the X-Rite DTP32.

4. Attach the round 8-pin mini-connector to the serial port on the PowerBook.

5. If the densitometer display indicates that densitometer battery power is low, use the

external AC adapter for the densitometer.

N

OTE: Don’t connect the densitometer to the PowerBook ADB port.

6. Configure the densitometer to factory defaults and save the settings. (See the

densitometer manual for details.)

Factory default settings for the X-Rite DTP32 are:

Page 1 LANG (ENG) TONE (loud) TYPE (ser)

Page 2 BAUD (9600) HAND (xon) AXMT (on)

Page 3 DPT (on) SEP (spc) DLIM (crlf)

Page 4 DEF (off) X10 (off ) DAP (off )

Page 42

6

6-8 Color Calibration

Page 5 M/M (max) LOCK (off)

TO CALIBRATE THE X-RITE DTP32:

7. Turn on the PowerBook.

8. In the PowerBook Setup Control Panel, select Normal for Modem Controls.

9. Calibrate the densitometer, as described below.

1. On the X-Rite DTP32, simultaneously press the two buttons marked MENU.

The words MAIN MENU appear in the display.

2. Press the p1 key until p2 appears.

3. Press the cal key.

CALIBRATION appears in the display.

4. Press the den key.

CALIBRATING TRANSMISSION is displayed, followed by the words INSERT CAL STRIP.

5. Position the strip guide at 5.

Strip guide

6. Insert the arrow end of the Auto-Cal strip into the entrance of the X-Rite DTP32 until

the roller starts pulling the strip.

READING appears momentarily, followed by the density values and CALIBRATION OK.

UNRECOGNIZABLE STRIP appears, try cleaning the strip (see your X-Rite DTP32

If

Operating Manual).

7. Recalibrate the densitometer at least once month.

Page 43

6

6-9 Understanding calibration

Measuring values with a DTP32 densitometer

You can connect a DTP32 densitometer to the Fiery XJ M or to your Macintosh or

TO MEASURE CALIBRATION PATCHES WITH AN X-RITE DTP32:

PC if you are using Fiery XJ Print Calibrator. The densitometer scans the density of

the first patch, automatically advances to the next patch, and automatically transmits

the measured values to the Fiery XJ M or Fiery XJ Print Calibrator. The DTP

densitometer has an adjustable strip guide to the right of the strip entrance.

After each column is scanned, the density measurements are used to create a

Measurements file. In general, valid measurements for all patches fall within the range

of -0.05 to 3.05.

1. When prompted on the Control Panel or Fiery XJ Print Calibrator, position the pointer

on the strip guide to 15 and click OK on the Control Panel or Fiery XJ Print Calibrator

to begin measuring.

First, you’ll measure the cyan column. Slide the paper guide left or right until the

arrow points to 15.

2. With the arrow below the cyan column pointing towards the densitometer, align the

right side of the patches page with the strip guide.

Page 44

6

6-10 Color Calibration

3. Insert the patches page into the densitometer until it rests against the drive rollers

and the motor is activated.

4. Hold the page against the guide to prevent any skewing while the strip is being

5. When prompted, move the strip guide to 30 and measure the magenta column.

6. Turn the patches page around so that the arrow above the yellow column is pointing

7. When prompted, align the right side of the patches page with the strip guide and

8. When prompted, move the page guide to 15 and measure the black column.

There may be a slight hesitation before the rollers start.

measured.

After the strip is measured, Pass #1 of 4 OK! appears in the densitometer display.

Transmitting Data appears briefly after each pass.

After the magenta strip is measured, Pass #2 of 4 OK! appears in the densitometer

display.

toward the densitometer.

Leave the strip guide set to 30.

measure the yellow column.

After the yellow strip is measured, Pass #3 of 4 OK! appears in the densitometer

display.

After the black strip is measured, Pass #4 of 4 OK! appears in the densitometer display.

NOTE: If there is a problem measuring a color, follow the instructions on the

densitometer to remeasure it.

Page 45

6

6-11 Understanding calibration

Calibrating the Fiery XJ M from the Control Panel

USING AUTOMATIC CALIBRATION:

You can calibrate the Fiery XJ M from the Control Panel by connecting a densitometer

to the serial port on the back of the Fiery XJ M, or by using AutoCal.

Automatic calibration

You can calibrate the Fiery XJ M without a densitometer with AutoCal.

1. When the Fiery XJ M restarts, press the Menu key when prompted to enter Setup.

2. Press Run Setup.

3. Scroll down to choose Calibration.

4. Choose Calibrate.

The Calibration Method screen appears.

5. Select Copier Glass for the Calibration Method.

6. When prompted to Select Target, use the up/down arrow keys to scroll through the list

of target names, then choose OK.

You can choose from the list of all targets on the Fiery XJ M hard drive. This includes

several targets included with the Fiery XJ M as well as any custom targets you have

loaded.

7. When prompted, select Yes to print the Measurements page.

This page is comprised of bands of color that will be measured by the copier and then

compared to the target calibration.

After the page is printed, the Measure Page screen displays.

8. Select Yes and then choose OK.

Page 46

6

6-12 Color Calibration

9. When prompted “Position page on copier, then press OK,” place the Measurements

page on the copier glass and click OK.

TO CALIBRATE WITH A DENSITOMETER:

Position the page as you would a standard portrait copy with the top of the page at the

far edge of the copier glass. The copier scans the page on the glass, creates a

measurements table, and automatically compares it to the target you selected. It then

adjusts measurements to match the target.

10. When prompted to Print Comparison Page, select Yes.

Verify that the colors on the page are correct.

11. When Prompted to Overwrite Calibration, select Yes.

12. Select Yes to confirm.

13. When calibration is complete, choose Exit Calibration. This automatically restarts your

Fiery XJ M.

Calibrating with a densitometer

To calibrate with a densitometer, the Fiery XJ M must have a serial port to connect the

densitometer to. Contact your authorized service/support center for information about

Fiery XJ M hardware.

1. Connect the DTP32 densitometer to your Fiery XJ M

For instructions, see “Setting up the densitometer” on page 6-5.

2. Restart the Fiery XJ M and press the Menu key when prompted to enter Setup.

3. Press Run Setup.

4. Scroll down to choose Calibration.

5. Choose Calibrate.

The Calibration Method screen appears.

6. Select Densitometer for the Calibration Method.

7. When prompted to Select Target, use the up/down arrow keys to scroll through the list

of target names, then choose OK.

Page 47

6

6-13 Understanding calibration

8. When prompted, select Yes to print the Measurements page.

9. Select Yes and then choose OK.

10. When prompted on the Control Panel, position the cyan strip in the densitometer.

You can choose from the list of all targets on the Fiery XJ M. This includes several

targets included with the Fiery XJ M as well as any custom targets you have created

from your workstation with Fiery XJ Print Calibrator.

This page is comprised of swatches of color that will be measured by the densitometer

and then compared to the target calibration.

After the page is printed, the Measure Page screen displays.

See “Measuring values with a DTP32 densitometer” on page 6-9 for instructions.

Status messages display the progress of scanning and collecting measurements. If there

is a problem, you may need to calibrate your densitometer. See “To calibrate the X-Rite

DTP32:” on page 6-8.

11. When prompted, repeat step 10 to scan magenta, yellow, and black.

12. When prompted to Print Comparison Page, select Yes.

This page provides you with a preview of the selected calibration.

13. When Prompted to Overwrite Calibration, select Yes.

14. Select Yes to confirm.

Status messages display progress information.

15. When calibration is complete, choose Exit Calibration. This automatically restarts your

Fiery XJ M.

Removing calibration

If desired, you can remove calibration from the Fiery XJ M. In general, it is not

necessary because any new calibration replaces the existing one.

TO REMOVE CALIBRATION USING THE CONTROL PANEL:

1. When the Fiery XJ M restarts, press the Menu key when prompted to enter Setup.

2. Press Run Setup.

Page 48

6

6-14 Color Calibration

3. Scroll down to choose Calibration.

4. Choose Remove Calibration.

5. When prompted, verify that you want to proceed with removing calibration.

The current calibration curves are removed and the printer is uncalibrated. After

calibration is removed, you can download a new calibration.

Using the Fiery XJ Print Calibrator utility

The Fiery XJ Print Calibrator utility allows you to perform extended calibration

procedures from your networked workstation. You can calibrate to targets provided

with your Fiery XJ M, or you can customize targets and calibration curves to suit the

specific needs of your printing environment.

NOTE: The utilities for Macintosh and Windows users are fundamentally the same;

differences are noted in this chapter. Screens for both the Macintosh and Windows

utilities appear in this document.

TO VIEW INFORMATION WITH THE FIERY XJ PRINT CALIBRATOR:

1. Double-click the Fiery XJ Print Calibrator icon.

The Chooser window appears.

2. Select the Fiery XJ M in the Chooser window that appears and click Connect or OK.

If there is no Measurements file on the Fiery XJ M or no Target selected, you will be

notified during startup.