Page 1

Spectrophotometer

CM-700d/600d

Instruction Manual

E

E

Manual de instrucciones

Es

Page 2

Notes on this Manual

• Copying or reproduction of all or part of the contents of this manual without KONICA MINOLTA

SENSING’s permission is strictly prohibited.

• The contents of this manual are subject to change without prior notice.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its contents.

However, should you have any questions or find any errors, please contact a KONICA MINOLTA

SENSING-authorized service facility.

• KONICA MINOLTA SENSING will not accept any responsibility for consequences arising from the

use of the instrument.

Page 3

• This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

- Consult the dealer or an experienced radio/TV technician for help.

• This device complies with FCC RF radiation exposure limits set forth for an uncontrolled

environment. The antenna used for this transmitter must be installed to provide a separation distance

of at least 20 cm from all persons and must not be co-located or operating in conjunction with any

other antenna or transmitter.

• You are cautioned that changes or modifications not expressly approved by the party responsible for

compliance could void your authority to operate the equipment.

• This Class B digital apparatus complies with Canadian ICES-003.

• Cet appareil numerique de la classe B est conforme a la norme NMB-003 du Canada.

Page 4

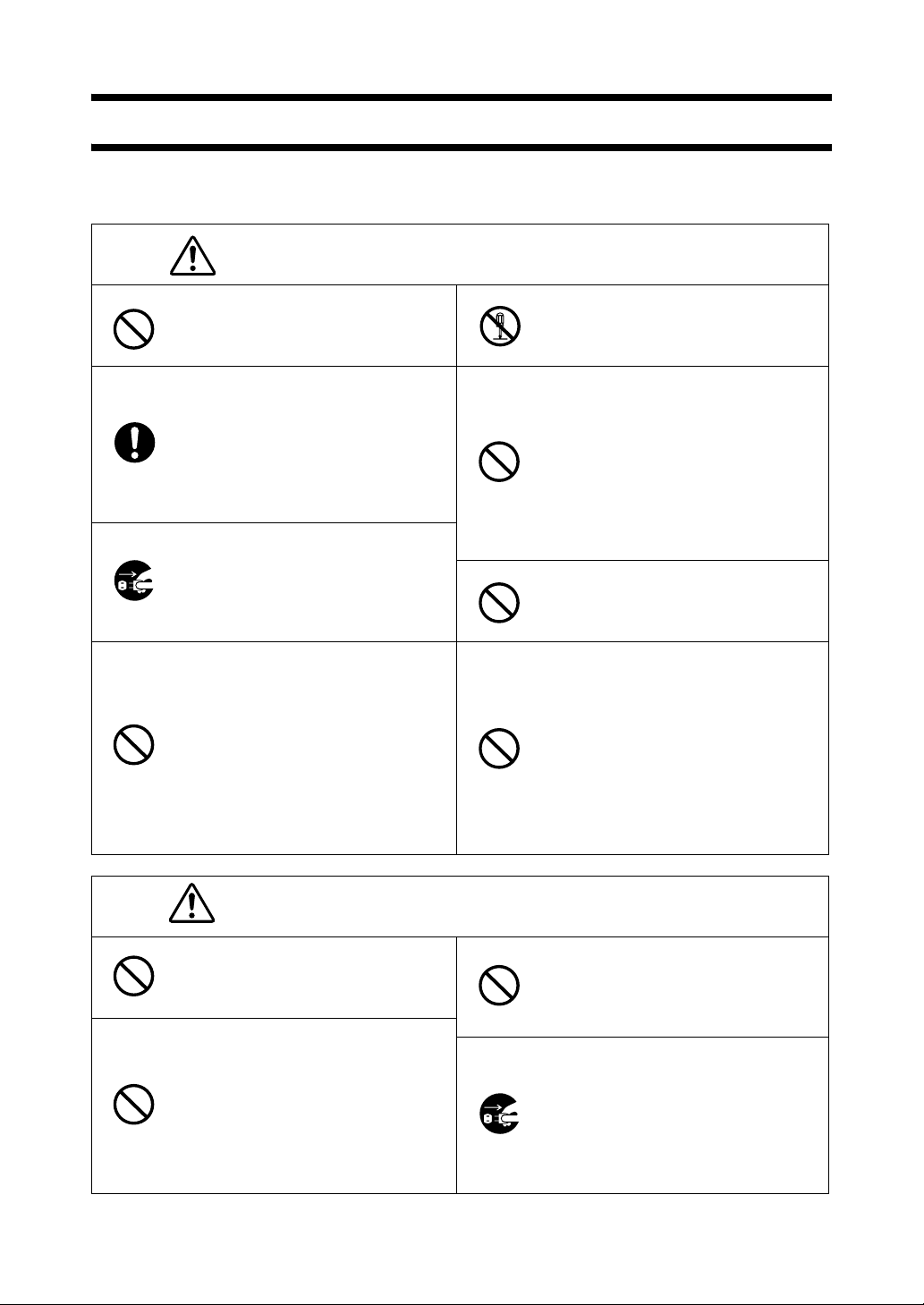

Safety Symbols

The following symbols are used in this manual to prevent accidents which may occur as result of

incorrect use of the instrument.

Denotes a sentence regarding a safety warning or note.

Read the sentence carefully to ensure safe and correct use.

Denotes a prohibited operation.

The operation must never been performed.

Denotes an instruction.

The instruction must be strictly adhered to.

Denotes a prohibited operation.

Never disassemble the instrument.

Denotes an instruction.

Disconnect the AC power cord from the AC outlet.

Trademarks

• Windows

• Bluetooth

®

is a registered trademark of Microsoft Corporation in the United States and other countries.

®

is a registered trademark of Bluetooth SIG, Inc.

Page 5

Safety Precautions

To ensure correct use of this instrument, read the following points carefully and adhere to them. After

you have read this manual, keep it in a safe place where it can be referred to anytime a question arises.

WARNING

Do not use the instrument in places

where flammable or combustible gases

(gasoline etc.) are present. Doing so

may cause a fire.

Always use the AC adapter supplied as

a standard accessory or the optional AC

adapter, and connect it to an AC outlet

of the rated voltage and frequency. If an

AC adapter other than those specified by

KONICA MINOLTA SENSING is

used, it may result in damage to the unit,

fire or electric shock.

If the instrument will not be used for a

long time, disconnect the AC adapter

from the AC outlet. Accumulated dirt or

water on the prongs of the AC adapter’s

plug may cause a fire and should be

removed.

Take special care not to allow liquid or

metal objects to enter the instrument.

Doing so may cause a fire or electric

shock. Should liquid or metal objects

enter the instrument, turn the power

OFF immediately, disconnect the AC

adapter from the AC outlet (or remove

the batteries if they are being used), and

contact the nearest KONICA

MINOLTA SENSING-authorized

service facility.

(Failure to adhere to the following points may result

in death or serious injury.)

Do not disassemble or modify the

instrument or the AC adapter. Doing so

may cause a fire or electric shock.

The instrument should not be operated if

it is damaged or the AC adapter is

damaged, or if smoke or odd smells

occur. Doing so may result in a fire. In

such situations, turn the power OFF

immediately, disconnect the AC adapter

from the AC outlet (or remove the

batteries if they are being used) and

contact the nearest KONICA MINOLTA

SENSING-authorized service facility.

Do not insert or disconnect the AC

adapter with wet hands. Doing so may

cause electric shock.

Do not dispose of batteries in fire, short

their terminals, apply heat to them, or

disassemble them. Also, do not recharge

them (if they are not chargeable). Doing

so may cause explosion or heat

generation, resulting in fire or injury.

CAUTION

Do not perform measurement with the

specimen measuring port directed

towards your face. Doing so may

damage your eyes.

Do not use batteries other than those

specified by KONICA MINOLTA

SENSING. When installing batteries in

the instrument, make sure that they are

correctly oriented according to the (+)

and (-) marks. Failure to adhere to these

instructions may cause batteries to

explode or leak electrolyte, resulting in

fire, injury or air pollution.

(Falling to adhere to the following points may result in

injury or damage to the instrument or other property.)

Do not place the instrument on an

unstable or sloping surface. Doing so

may result in its dropping or overturning,

causing injury. Be careful not to drop the

instrument when carrying it.

When using the AC adapter, make sure

that the AC outlet is located near the

instrument and that the AC adapter can

be connected to and disconnected from

the AC outlet easily.

E-1

Page 6

Introduction

Thank you for purchasing the CM-700d/600d.

This is a precise, lightweight and compact spectrophotometer developed for color and color difference

measurement of reflective objective colors in various industries.

Packing materials of the product

Be sure to keep all packing materials used for shipping the product (cardboard box, cushioning

material, plastic bags, etc.).

The CM-700d/600d is a precision measuring instrument. When transporting the instrument to a

service facility for maintenance or for other reasons, be sure to use the packing materials to minimize

shock or vibration.

If the packing materials are lost or damaged, contact a KONICA MINOLTA SENSING-authorized

service facility.

Notes on Use

Operating Environment

• Use the CM-700d/600d at ambient temperature between 5°C and 40°C and relative humidity 80% or less (at

35°C) with no condensation.

Be sure to use the instrument within this range. Do not use it in areas of rapid temperature changes.

• Do not leave the CM-700d/600d in direct sunlight or near sources of heat, such as stoves etc. The internal

temperature of the instrument may become much higher than the ambient temperature in such cases.

• Do not use the CM-700d/600d in areas where dust, cigarette smoke or chemical gases are present. Doing so

may cause deterioration in performance or a breakdown.

• Do not use the CM-700d/600d near equipment which produces a strong magnetic field (such as speakers etc.).

• The CM-700d/600d belongs to installation category II products (equipment which is powered by an AC

adapter connected to commercially available power).

• The CM-700d/600d belongs to pollution level 2 products (equipment which may cause temporary electrical

hazards due to contamination or condensation or products which are used in such an environment).

• Do not use the CM-700d/600d at altitudes higher than 2000 m.

• The CM-700d/600d and the AC adapter supplied as a standard accessory have been designed exclusively for

indoor use. They should never be used outdoors because rain or other factors may damage the instrument.

Measurement

• When using the instrument upside-down, make sure no dirt or dust get into the specimen measuring port.

• When using the instrument for long periods of time, the displayed value may change depending on changes in

the environment. Therefore, in order to achieve accurate measurements, we recommend that white calibration

be done regularly using the White Calibration Cap.

White Calibration Cap

• The White Calibration Cap must be used in combination with the instrument that bears the same pairing number.

•

The calibration data for the White Calibration Plate attached to the White Calibration Cap was measured at 23°C.

To achieve the highest accuracy when measuring absolute values (colorimetric values), calibration and

measurement should be performed at 23°C.

• Do not allow the White Calibration Plate to get scratched or stained.

• When not using the White Calibration Cap, invert it so that the White Calibration Plate is not exposed to

ambient light.

• When the White Calibration Cap is attached to the instrument, do not hold on to the White Calibration Cap to

move the instrument. The cap may become detached from the instrument, causing the instrument to fall and

become damaged.

Target Mask

• Do not touch the Target Mask’s inner surface by hand, scratch it or make it dirty.

• When not in use, Target Masks should be stored in the cardboard box used for shipment or in the optional hard

case so that they will not be exposed to ambient light.

E-2

Page 7

Power Source

• Make sure that the power switch is set to OFF (“ ”) when the CM-700d/600d is not in use.

• The CM-700d/600d can be powered from either the AC adapter (AC-A305) or AA-size alkaline or nickelmetal-hydride rechargeable batteries. Note, however, that you cannot use this AC adapter to charge the nickelmetal-hydride rechargeable batteries installed in the instrument.

• Always use the AC adapter supplied as a standard accessory (AC-A305) and connect it to an AC outlet of the

rated voltage and frequency. Use an AC power supply of the rated supply voltage (within ±10%).

System

• Do not subject the CM-700d/600d to strong impact or vibration. Doing so may cause deterioration in

performance or a breakdown.

• Since the specimen measuring port and integrating sphere are extremely precise optical components, great

care should be taken to prevent them getting dirty or exposing them to impact.

• When not in use, the instrument must be stored with the White Calibration Cap being attached.

• The CM-700d/600d may cause interference if used near a television, radio, etc.

• When the instrument is exposed to strong external static electricity, the LCD may go blank or the measurement

result may not be displayed properly. If the instrument is communicating with an external device, the

communication may be interrupted. In these cases, turn the power OFF and then turn it ON again. If black

smudges appear on the LCD, wait until they disappear naturally.

• When turning the power OFF and then ON again, wait several seconds after turning the power OFF.

Backup Battery

• Measured data and various settings are stored in the memory backed up by batteries. The backup batteries are

automatically charged during operation of this instrument, and can retain the contents of the memory for 5

months if they have been fully charged. At the time of purchase, the backup battery may not be fully charged.

To charge the backup battery, set the power switch to ON. Charging of the backup battery is performed

continuously while the instrument is switched on, even while the instrument is being used. Full charging is

completed in 24 hours, and there is no danger of overcharging.

• It is recommended to keep a backup for your important data on another recording medium using the optional

Color Data Software SpectraMagic™ NX (CM-S100w).

Note

• The backup batteries' model number is ML2020 (3 V).

• Do not try to replace the backup batteries by yourself. Contact a KONICA MINOLTA SENSING-authorized

service facility.

Notes on Storage

• The CM-700d/600d should be stored at temperatures between 0°C and 45°C, and at a relative humidity of 80%

or less (35°C) without condensation. Do not store the instrument in areas subject to high temperatures, high

humidity, sudden changes in temperature, or where freezing or condensation may occur, because these

circumstances may cause a breakdown. It is recommended to store the CM-700d/600d with a drying agent

(such as silica gel) at a temperature around 20°C.

• Do not leave the CM-700d/600d inside a car such as in the cabinet or trunk. Otherwise, the temperature and/

or humidity may exceed the allowable range for storage during midsummer or midwinter, resulting in a

breakdown.

• Keep the packing materials used for shipment and use them to transport the CM-700d/600d. This protects the

instrument from sudden changes in temperature, vibration, and shock.

• Do not store the CM-700d/600d in areas where dust, cigarette smoke or chemical gases are present. Doing so

may cause deterioration in performance or a breakdown.

• Entry of dust into the specimen measuring port will hinder accurate measurement. When the instrument is not

in use, you must attach the White Calibration Cap to the instrument to prevent the entry of dust into the

integrating sphere through the specimen measuring port.

E-3

Page 8

• The White Calibration Plate attached to the White Calibration Cap may become discolored if left exposed to

light. Therefore, make sure that the cap is inverted when it is not in use so that the White Calibration Plate is

not exposed to ambient light.

• The Target Masks may discolor if they are left exposed to light. When they are not in use, keep them in a safe

place to prevent exposure to light and to protect them from scratches and dust.

• Be sure to keep all packing materials (cardboard box, cushioning material, plastic bags, etc.). They can be used

to protect the instrument during transportation to the service facility for maintenance (re-calibration etc.).

• If you are not going to use the CM-700d/600d for more than two weeks, the batteries must be removed. If the

batteries are left in the instrument, battery electrolyte may leak and damage the instrument.

Notes on Cleaning

• If the CM-700d/600d becomes dirty, wipe it with a soft, clean dry cloth. Never use solvents such as thinner or

benzene.

• If the White Calibration Plate attached to the White Calibration Cap becomes dirty, wipe it gently with a soft,

clean and dry cloth. If dirt is difficult to remove, wipe it off with a cloth dampened with commerciallyavailable lens cleaning solution. Then remove the solution with a cloth dampened with water, and leave the

plate to dry.

• If the inner surface of the Target Masks or the inside of the integrating sphere get dirty, contact a KONICA

MINOLTA SENSING-authorized service facility.

• Should the CM-700d/600d break down, do not try to disassemble and repair it by yourself. Contact a KONICA

MINOLTA SENSING-authorized service facility.

Disposal Method

• When disposing of used batteries, insulate the terminals with insulating tape etc. If the terminals of the battery

come into contact with metal objects, heat generation, explosion or fire may result.

• Make sure that the CM-700d/600d, its accessories and used batteries are either disposed of or recycled

correctly in accordance with local laws and regulations.

E-4

Page 9

E-5

Page 10

Contents

Safety Precautions ......................................................................................................................... E-1

Introduction ................................................................................................................................ E-2

Notes on Use .............................................................................................................................. E-2

Notes on Storage ........................................................................................................................ E-3

Notes on Cleaning ...................................................................................................................... E-4

Disposal Method ........................................................................................................................ E-4

Conventions ............................................................................................................................... E-8

Chapter 1 Before Using the Instrument

Accessories ...................................................................................................................................... E-10

Standard Accessories ................................................................................................................. E-10

Optional Accessories ................................................................................................................. E-11

Names and Functions of Parts ...................................................................................................... E-12

Preparation .................................................................................................................................... E-14

White Calibration Cap CM-A177 .............................................................................................. E-14

Attaching/Removing a Target Mask .......................................................................................... E-15

Cleaning Parts ............................................................................................................................ E-16

Attaching Wrist Strap to the Instrument .................................................................................... E-17

Inserting the Batteries ................................................................................................................ E-18

Connecting the AC Adapter ....................................................................................................... E-19

Turning Power ON/OFF ............................................................................................................ E-20

System Diagram ............................................................................................................................. E-21

Items You Must Know .................................................................................................................. E-22

Initial Settings of the CM-700d/600d ........................................................................................ E-22

Control Panel ............................................................................................................................. E-22

Battery Alarm ............................................................................................................................ E-24

Data Saving ................................................................................................................................ E-24

Pairing Number .......................................................................................................................... E-24

Chapter 2 Preparation for Measurement

Flow of Measurement .................................................................................................................... E-26

Calibration ..................................................................................................................................... E-27

Zero Calibration ......................................................................................................................... E-27

White Calibration ....................................................................................................................... E-29

User Calibration.......................................................................................................................... E-31

Condition Setting ........................................................................................................................... E-32

Setting the Display Conditions ................................................................................................... E-32

Setting the Measurement Conditions ......................................................................................... E-42

Color Difference Target Color Data Operation ......................................................................... E-47

Setting a Target Color................................................................................................................. E-47

Target Color Menu ..................................................................................................................... E-48

Registering Conditions (Cond) ..................................................................................................... E-56

Naming a Condition ................................................................................................................... E-58

Setting the Default Color Difference Tolerance (Tolerance (Def.)) .......................................... E-59

Selecting Color Difference Tolerances ...................................................................................... E-62

Deleting the Default Color Difference Tolerance Setting ......................................................... E-63

Naming the Color Difference Tolerance Setting ....................................................................... E-64

E-6

Page 11

Other Settings ................................................................................................................................ E-66

Setting the Display Language .................................................................................................... E-66

Setting the Date and Time ......................................................................................................... E-67

Setting the Power Save Mode .................................................................................................... E-70

Initialization ............................................................................................................................... E-72

Chapter 3 Measurement

Measurement .................................................................................................................................. E-74

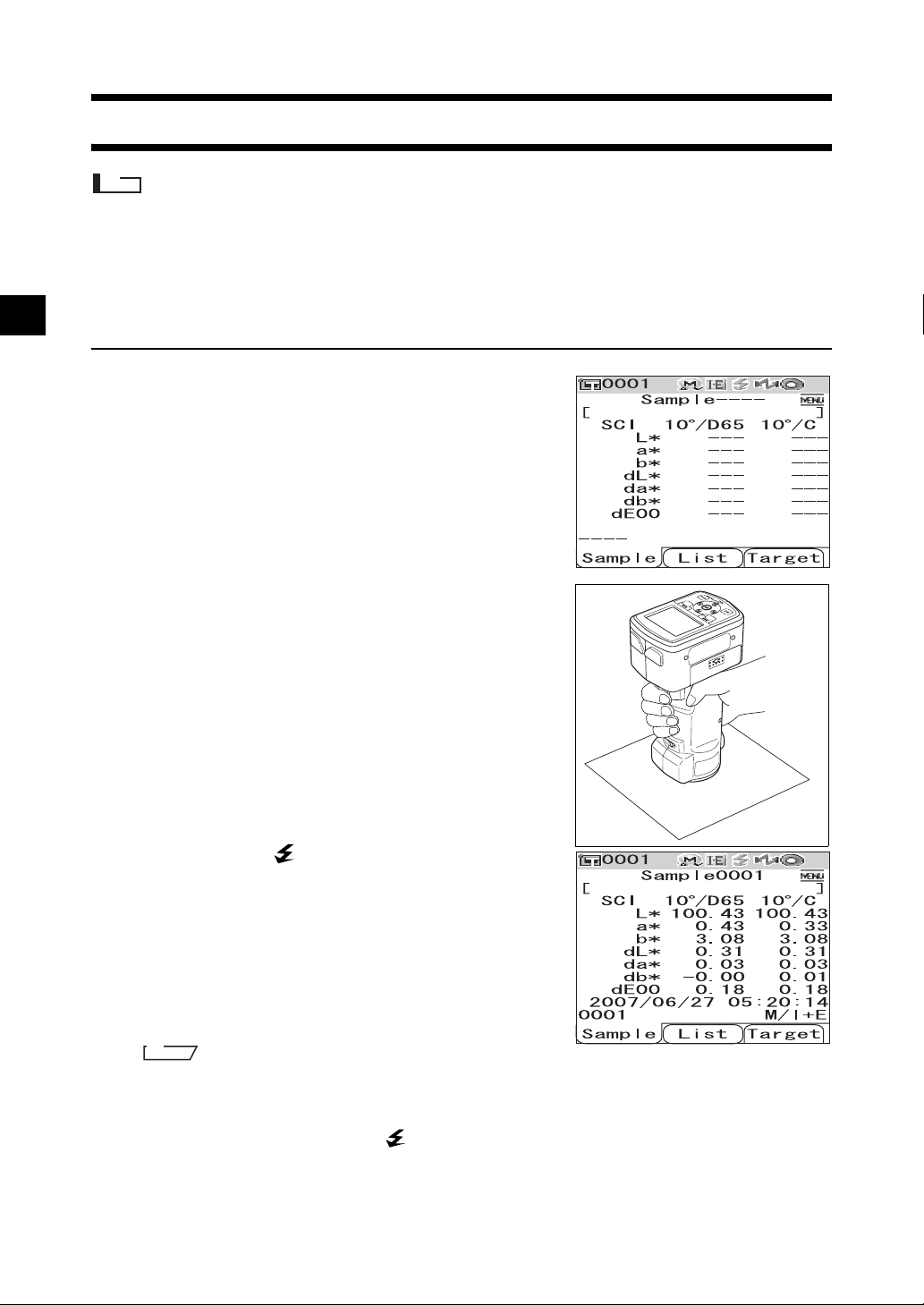

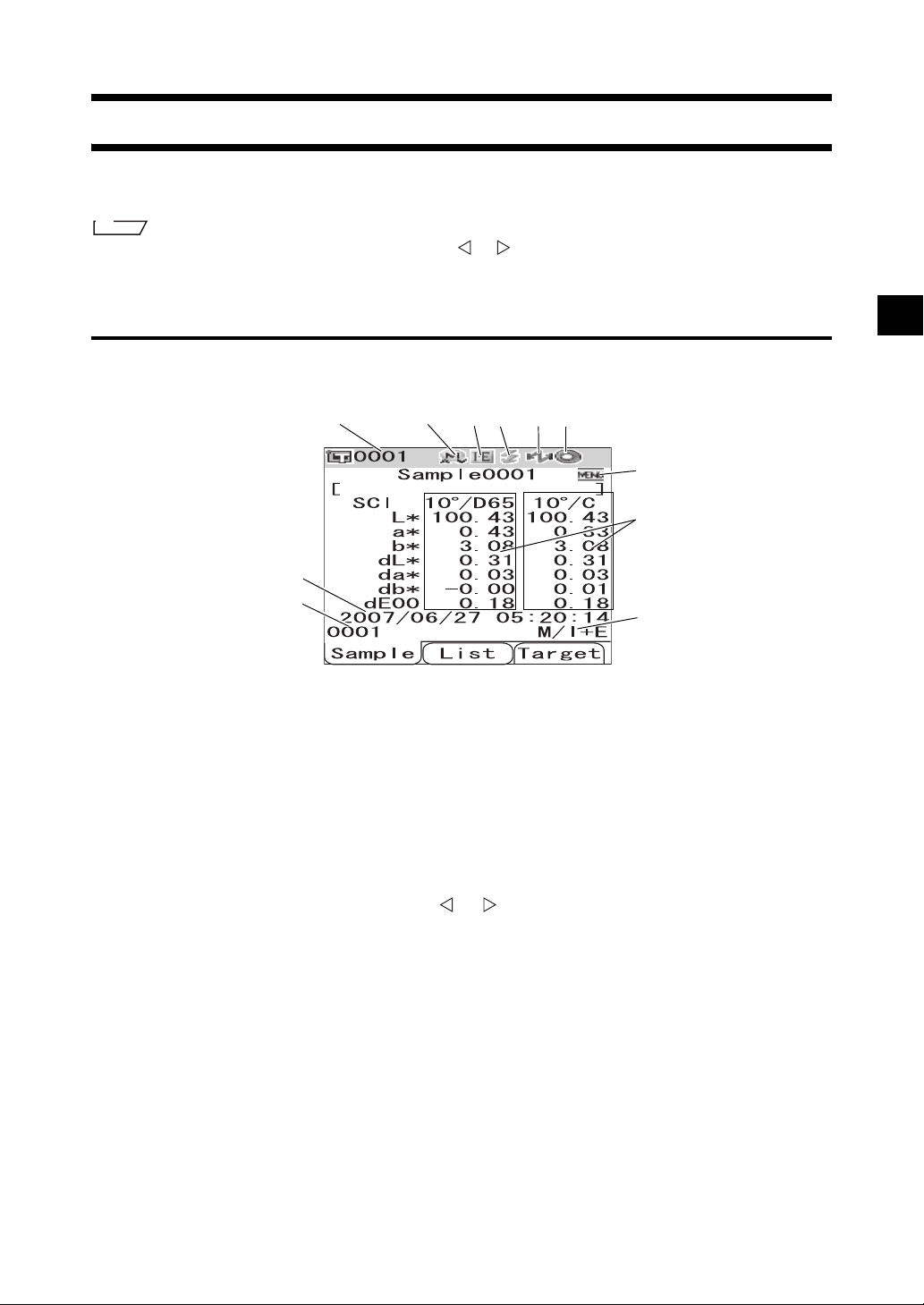

Displaying the Measurement Results ........................................................................................... E-75

Measured Data ........................................................................................................................... E-75

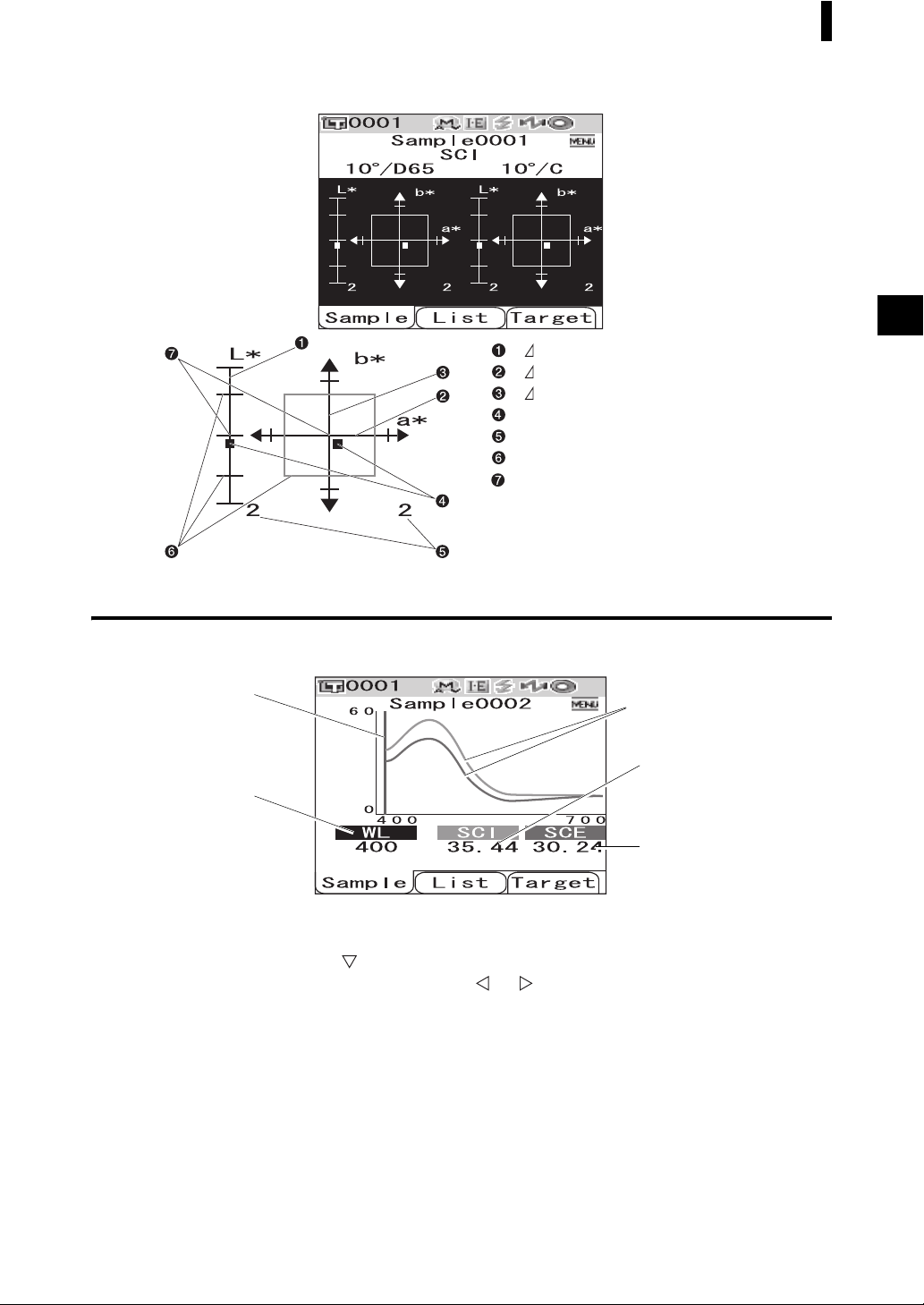

Pass/Fail Judgment .................................................................................................................... E-76

Color Difference Graph ............................................................................................................. E-76

Spectral Reflectance Graph ....................................................................................................... E-77

Switching the Display Contents of the Measurement Results ................................................... E-78

Measured Data Operation ............................................................................................................ E-81

Print ............................................................................................................................................ E-82

Delete ......................................................................................................................................... E-82

Edit Name .................................................................................................................................. E-83

Setting the List (List) ................................................................................................................. E-84

Auto Target ................................................................................................................................ E-84

Delete All ................................................................................................................................... E-85

Chapter 4 Other Functions

Average Measurement .................................................................................................................. E-88

Manual Averaging ..................................................................................................................... E-88

Auto Averaging .......................................................................................................................... E-90

Pass/Fail Judgment for Color Difference .................................................................................... E-91

Pass/Fail Judgment Based on Tolerances .................................................................................. E-91

Connecting to an External Device ................................................................................................ E-94

Connecting a Personal Computer .............................................................................................. E-94

Connecting a Printer .................................................................................................................. E-98

Displaying the Instrument Information ...................................................................................... E-1

Chapter 5 Troubleshooting

Error Messages .............................................................................................................................. E-108

Troubleshooting ............................................................................................................................. E-111

Chapter 6 Appendix

Principles of Measurement ........................................................................................................... E-114

Illuminating/Viewing System .................................................................................................... E-114

Illumination Area and Measurement Area ................................................................................. E-115

Simultaneous SCI/SCE Measurement ....................................................................................... E-115

Communication Mode ............................................................................................................... E-115

Initial Settings ............................................................................................................................ E-116

Specifications .................................................................................................................................. E-117

Dimensions ..................................................................................................................................... E-119

06

E-7

Page 12

Conventions

This manual describes how to safely operate the CM-700d/600d using a specific procedure to perform

measurement.

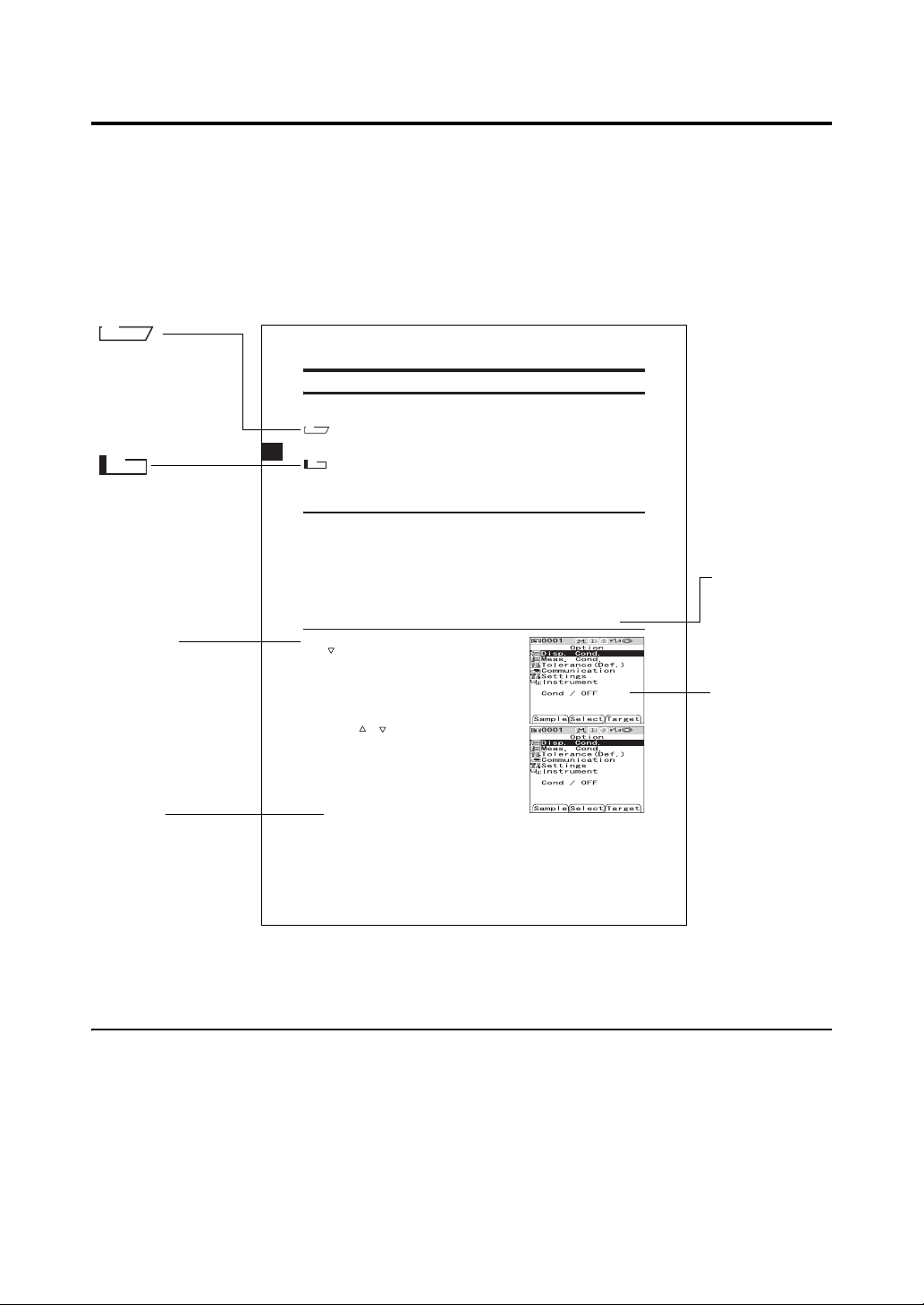

• Page layout

Symbols used in this manual are explained below.

*Note that the page shown in the illustration is for explanatory purposes only, and is not an actual page

from this manual.

M

emo

Gives useful

Information and

additional

explanations.

Note

Gives the points that

you should know to

perform operations

correctly. Make sure

that you read the notes.

Procedure

Shows the operating

procedure.

Settings

Gives the range and

explanation of the

values to be set in this

screen.

Condition Setting

The CM-700d/600d requires condition settings (display and measurement conditions) before

measurement can be started.

M

emo

To configure condition settings, select “Disp. Cond.” (display conditions) or “Meas. Cond.” (measurement

conditions) from the <Option> screen to open an appropriate screen.

N

ote

The results for “Difference”, “Abs. & Diff.”

specified.

Setting the Display Conditions

To set the display conditions, select “Disp. Cond.” on the <Option> screen.

You can select or specify the following seven items as the display conditions:

• Disp. Type: Specify items to be displayed as measurement results.

• Color Space: Select a color space to be used.

• Equation: Select a color difference formula to be used.

• Color Index: Select an index (WI, YI, etc.) to be used.

• Observer: Select a measuring angle from 2° or 10°

• Illuminant 1: Select an illuminant used to measure colorimetric data.

• Illuminant 2: Select a secondary illuminant used for MI (metamerism index) calculation, etc.

[Setting Procedure]

Hold down the [MENU] button and press the

1

button of the cross key.

The <Option> screen is displayed.

Use the or button of the cross key to

2

move the cursor to "Disp. Cond." and then

press the [SAVE/SEL] button.

The <Disp. Cond.> screen is displayed.

Settings

Absolute: Display the absolute value of the colorimetric data.

Difference:

Display the color difference from the target color. The measured data which failed the pass/fail judgment

based on the specified tolerances will be highlighted in red.

Abs. & Diff.:

Display the absolute value and the color difference from the target color. The measured data which

failed the pass/fail judgment based on the specified tolerances will be highlighted in red.

E-32

and “Graph Diff.” will be displayed only when the target color has been

Start the procedure from the <Disp. Cond.> screen.

Start screen

Shows the screen

from which

operation must

be started.

Screen

Shows the

contents of the

current screen

when the given

operation is

carried out.

For the version of the instrument firmware

The version of the instrument firmware can be confirmed on the <Instrument> screen. For details, refer

to page E-106 “Displaying the Instrument Information” in this manual.

E-8

Page 13

Chapter 1

Before Using the Instrument

E-9

Page 14

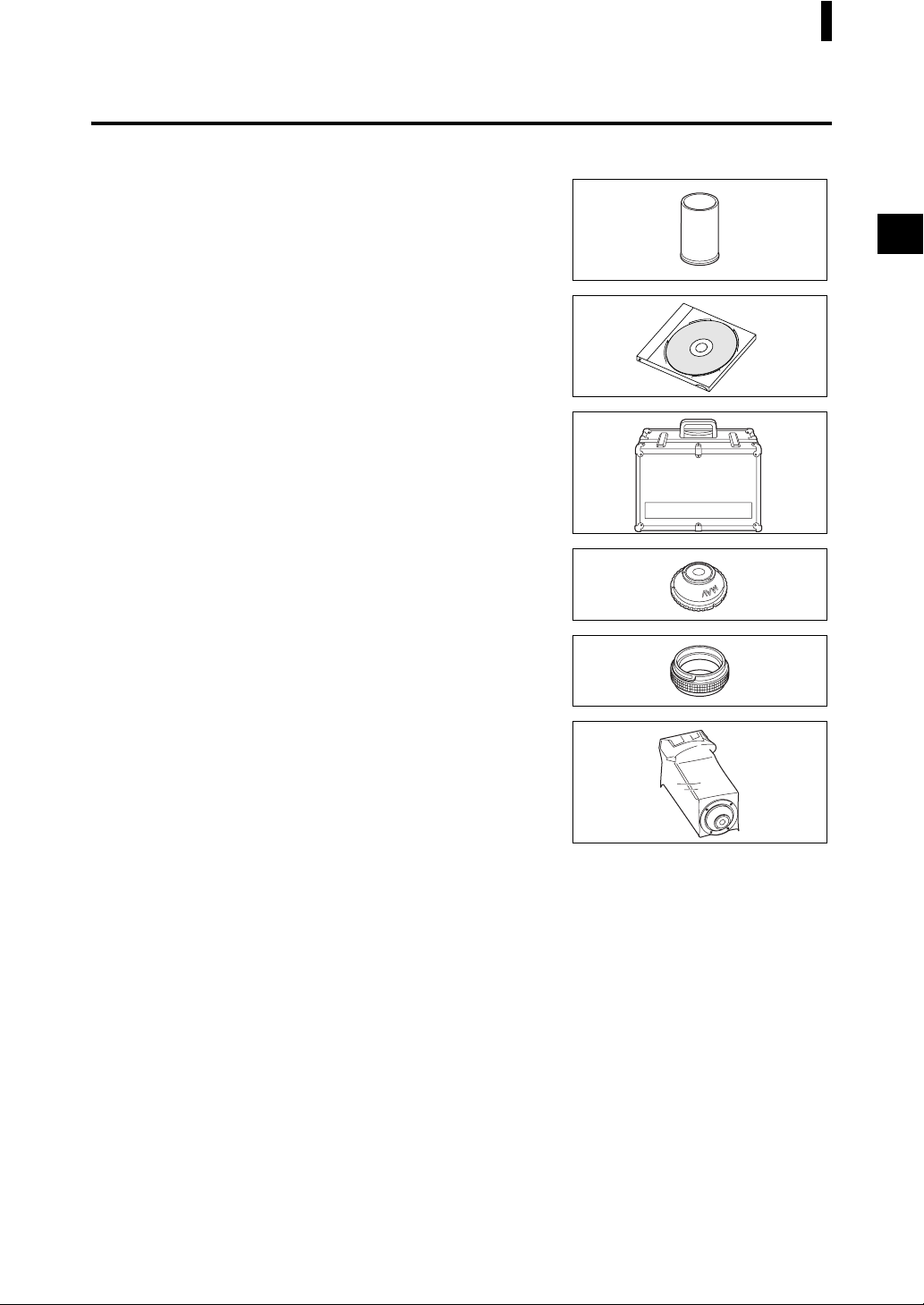

Accessories

Standard and optional accessories are available with the instrument.

Standard Accessories

Make sure that all the following items are present.

White Calibration Cap CM-A177

(w/ white calibration data CD-R)

Target Mask

Used to switch the illumination area (specimen measuring port

size) according to the specimen.

Target Mask

Target Mask

Target Mask

Target Mask

M

emo

• The instrument is shipped with the CM-A178 Target Mask φ 8 mm

with plate (for MAV) being attached.

• The CM-A179 and CM-A181 Target Masks

not included in the package of the CM-600d.

AC Adapter AC-A305

Used to supply power from an AC outlet to the instrument.

Input: 100-240 V 50/60 Hz 24-38 VA

Output: 5 V 2 A

USB Cable IF-A17

Used to connect the instrument to a personal computer (PC).

4 AA-size alkaline dry batteries

φ

8 mm (w/ plate) CM-A178 <For MAV>

φ

3 mm (w/ plate) CM-A179 <For SAV>

φ

8 mm (w/o plate) CM-A180 <For MAV>

φ

3 mm (w/o plate) CM-A181 <For SAV>

φ

3 mm (for SAV) are

Wrist Strap CR-A73

E-10

Page 15

Optional Accessories

You may purchase the following accessories if necessary.

Zero Calibration Box CM-A182

Used to perform zero calibration.

Accessories

Color Data Software S

Used to operate the instrument from a PC for data processing and

file management.

Hard Case CM-A176

Used to store the instrument together with accessories.

*Do not use the hard case for transportation purposes.

Target Mask

Used to measure viscous or damp specimens.

Granular-Materials Attachment CM-A184

Used to contain paste or powder specimens to ensure

measurements under stable conditions.

Dust Cover Set CM-A185

Prevents foreign matters from entering the instrument in dusty

environments.

φ

pectraMagic™ NX CM-S100w

8 mm (with glass) CM-A183

Replacement Dust Cover (Polyolefin) CM-A186

E-11

Page 16

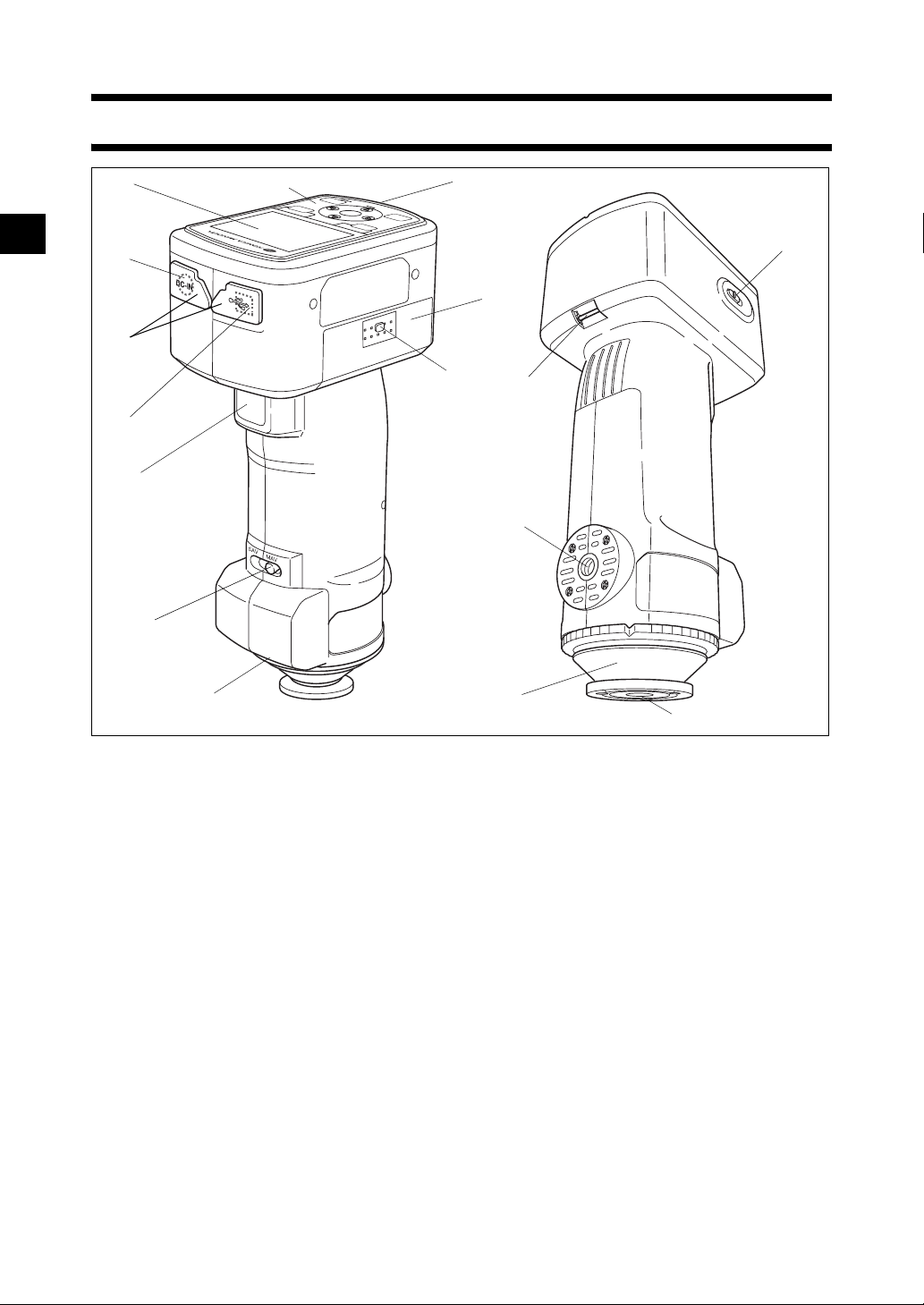

Names and Functions of Parts

10

11

12

9

16

13

1

3

5

4

6

8

2

7

1 LCD screen

Displays setting items, measurement results and messages.

2 Control panel

Used to switch screens or select/determine/save setting items.

For details, refer to page E-23 “Control Buttons”.

3 AC adapter terminal

When using the supplied AC adapter (CM-A305), connect the adapter’s plug to this terminal.

4 USB connection terminal

Used to connect the instrument to a PC with the supplied USB cable (IF-A17).

5 Connector protection covers

Protects the AC adapter terminal and USB connection terminal.

6 Measuring button

Push this button to perform calibration or measurement.

7 Pairing No. label

Shows the identification No. of the White Calibration Cap that can be used with the instrument.

14

15

E-12

Page 17

Names and Functions of Parts

8 Measurement area selector

Used to change the lens position according to the

measurement area.

M

emo

The CM-600d does not have this switch.

9 Battery chamber cover

The cover of the battery chamber. Four AA-size batteries must be set in the battery chamber with the

correct polarity alignment.

10 Battery chamber cover button

Press this button to open or close the battery chamber cover.

11 READY Lamp

Ready to measure (and fully charged) when green.

12 Power switch

Used to turn ON/OFF power. Setting this switch to “ ” turns the power OFF, and setting it to “|”

turns the power ON.

13 Tripod mount

14 Target Mask

Used to change the measurement area according to the measurement area selector setting. Selectable

from several types depending on the application.

15 Specimen measuring port

The port for measuring the specimen.The port size can be changed by changing the Target Masks.

Note

The measurement area cannot be changed with the CM-600d.

16 Strap holder

Used to attach the supplied Wrist Strap.

M

emo

For details of attaching Wrist Strap, refer to “Attaching Wrist Strap to the Instrument” (page E-17).

E-13

Page 18

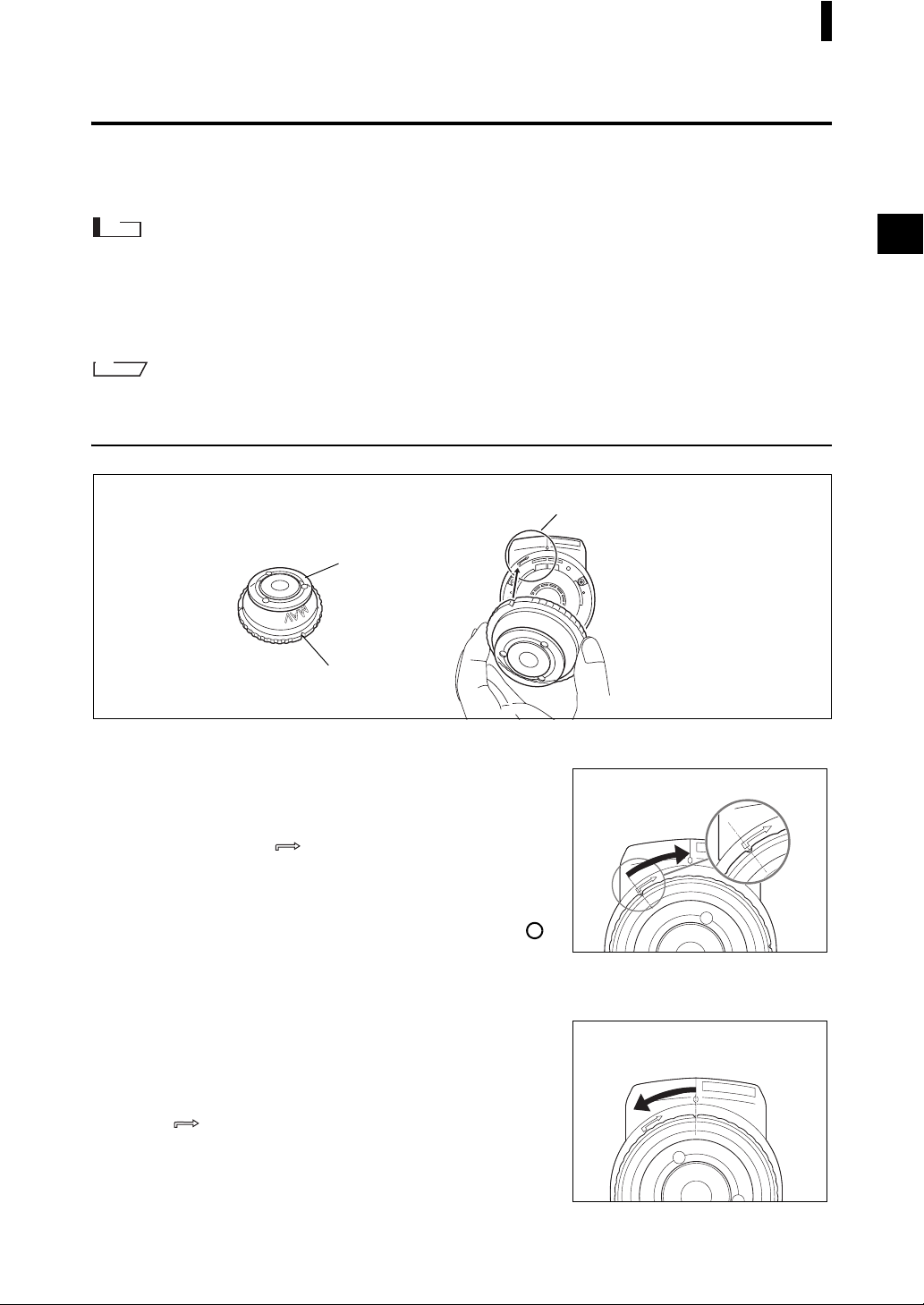

Preparation

White Calibration Cap CM-A177

The instrument is shipped with a White Calibration Cap and white calibration data CD-R.

The White Calibration Cap has the structure shown below. It should be attached to the instrument before

white calibration.

Note

• The White Calibration Cap must be used in combination with the instrument that bears the same pairing number.

• When the White Calibration Cap is not in use, invert it so that the White Calibration Plate is not exposed to

ambient light or dust.

• When the CM-700d/600d is not in use, you must attach the White Calibration Cap to the instrument to prevent

the entry of dust into the integrating sphere through the specimen measuring port.

White Calibration Cap lock buttons

Latch

White

Calibration Plate

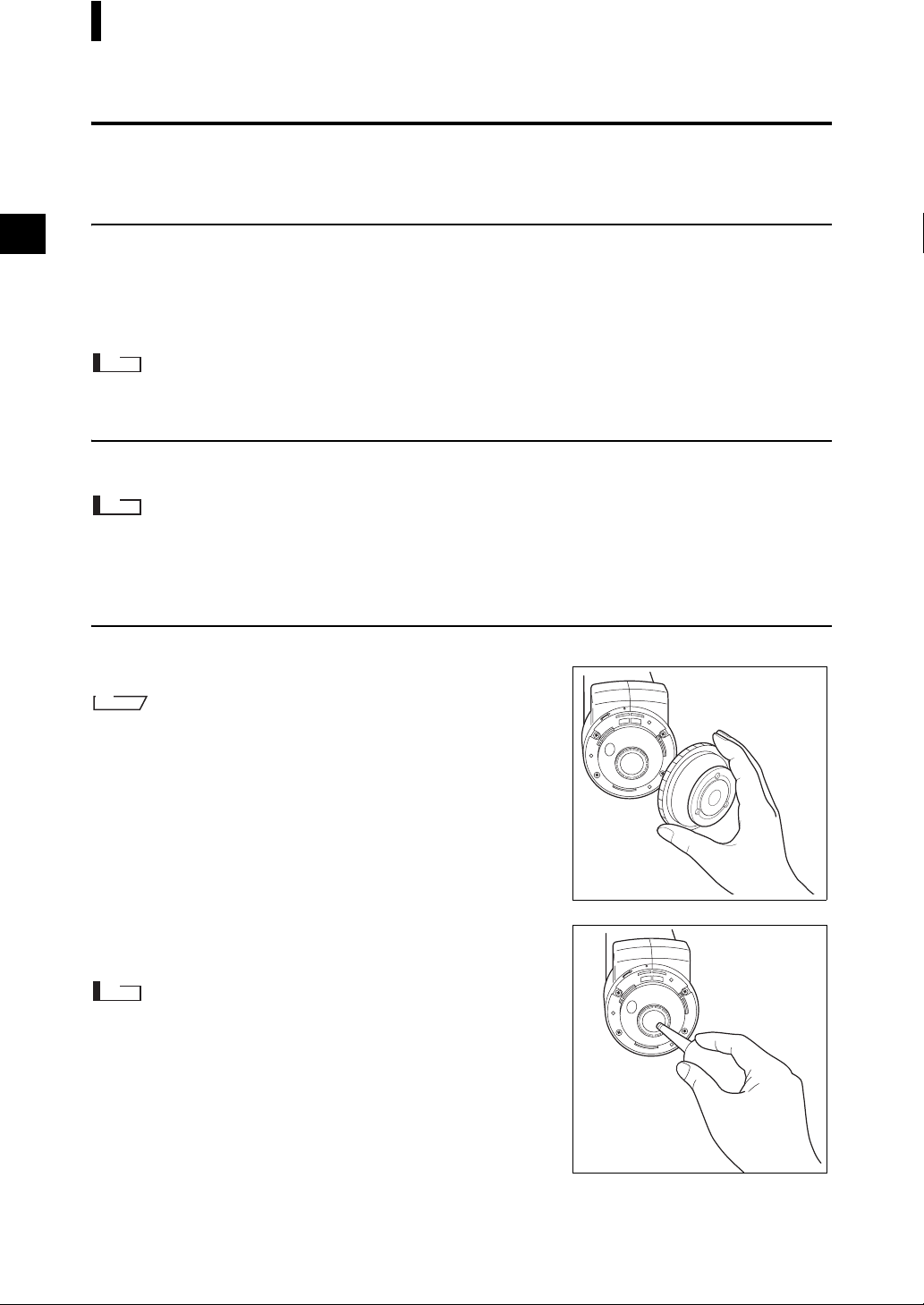

Attachment/Removal to/from the Instrument

• Attachment

1. Hold the instrument securely.

2. Squeeze the White Calibration Cap lock buttons,

place the White Calibration Cap on the Target Mask

of the instrument, and release the lock buttons to

secure the cap.

Note

Do not move the instrument by holding the White Calibration Cap. The

instrument may detach from the cap, possibly resulting in the

instrument falling and being damaged.

• Removal

1. While squeezing the White Calibration Cap lock

buttons, pull the cap out straight from the

instrument.

Pairing No.

Serial number of the

White Calibration Cap

E-14

Page 19

Preparation

Attaching/Removing a Target Mask

The CM-700d/600d must be used with a Target Mask conforming to the selected lens position and

measurement condition.

To attach/remove a Target Mask, follow the procedure given below.

Note

• When attaching/removing a Target Mask, be careful not to allow dirt or dust to enter the integrating sphere

though the specimen measuring port.

• Do not touch the white-coated inner surface of the integrating sphere, wipe it with a cloth or put an object inside it.

• Do not exert excessive force on the latch of the Target Mask. Doing so may damage the latch, disabling use of

the Target Mask.

M

emo

If a Target Mask is damaged, contact a KONICA MINOLTA SENSING-authorized service facility.

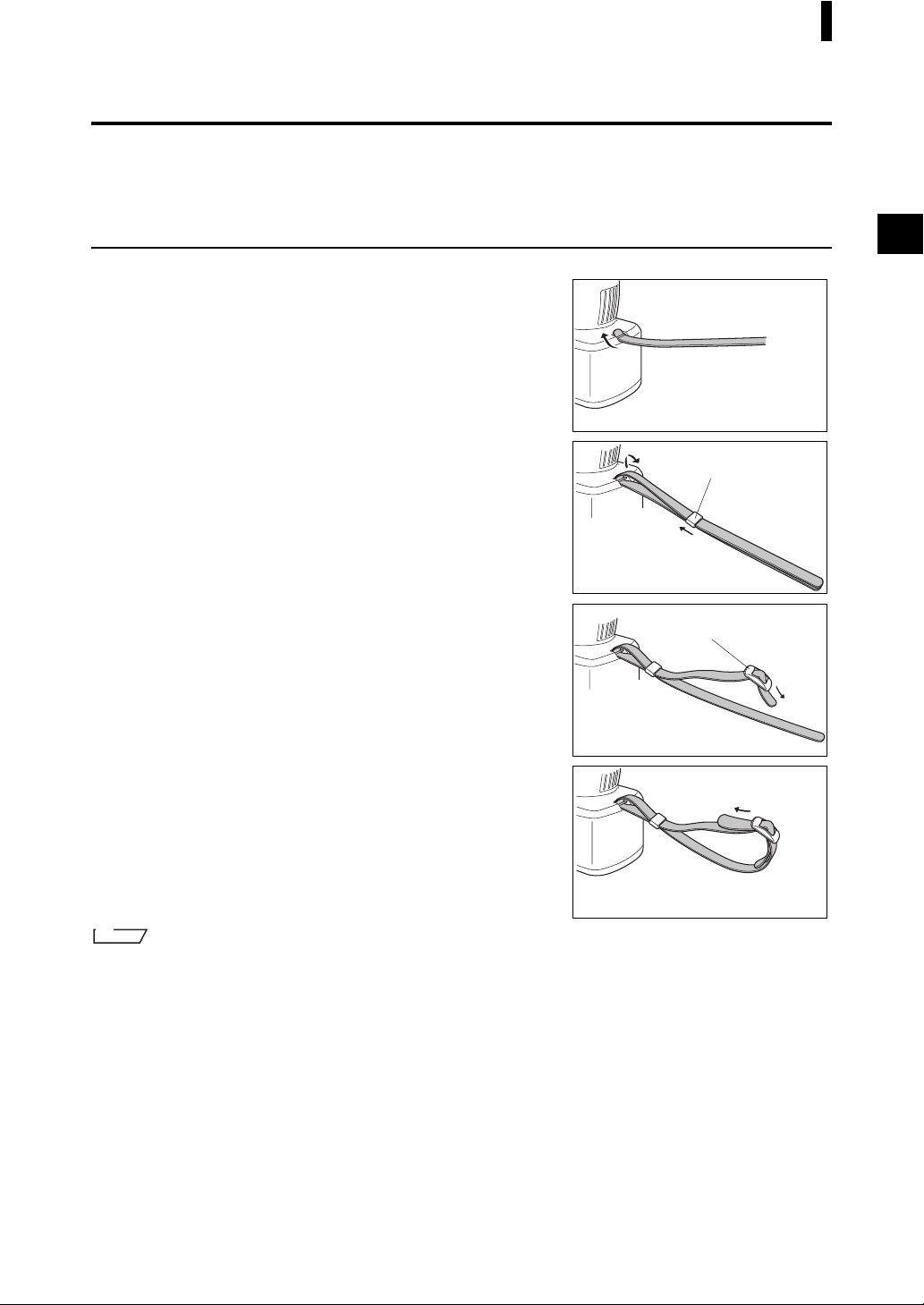

Attachment/Removal to/from the Instrument

Target Mask

The figure shows the φ 8 mm type (w/ plate) <For MAV>.

Plate

Cut in the outer edge

• Attachment

1. Place the Target Mask over the specimen measuring

port so that the cut in the outer edge of the Target

Mask is aligned with the starting point of the

positioning mark ( ) on the instrument.

2. Hold the outer edge of the mask, and turn it in the

direction of the arrow (clockwise). Turn the mask

until the cut in the outer edge is aligned with the “ ”

mark on the instrument and then secure the mask.

• Removal

Target Mask positioning mark

Section of the CM-700d/

600d to which the Target

Mask is attached.

1. Hold the outer edge of the mask, and turn it in the

opposite direction of the arrow (counterclockwise).

Turn the mask until the cut in the outer edge is

aligned with the starting point of the positioning

mark ( ) of the instrument.

2. Hold the outer edge of the mask and remove it.

E-15

Page 20

Preparation

Cleaning Parts

This section explains how to clean the White Calibration Cap, Target Mask and the inside of the

integrating sphere.

White Calibration Cap

• When the White Calibration Plate becomes dirty, gently wipe the dirt off with a soft dry cloth. If the dirt is difficult

to remove, wipe it off with a cloth dampened with commercially available lens cleaning solution. Then remove

the solution with a cloth dampened with water, and leave the plate to dry.

• When parts other than the White Calibration Plate become dirty, lightly wipe the dirt off with a cloth dampened

with water or soapy water. Never use solvents such as thinner or benzene.

Note

Be careful not to scratch the White Calibration Plate.

Target Mask

Use a blower to remove dirt and dust from the Target Masks.

Note

Do not touch the inner surface of the Target Masks with your fingers or wipe them with a cloth to remove dust.

If the inside is so dirty that dirt cannot be removed with a blower, contact the nearest KONICA MINOLTA

SENSING-authorized service facility.

Inside the Integrating Sphere

1. Remove the Target Mask.

M

emo

For the procedure of removing the Target Mask, refer to page E-15

“Attaching/Removing a Target Mask”.

2. Use a blower to remove dirt and dust from the

integrating sphere.

Note

Do not touch the white-coated inner surface of the integrating sphere,

wipe it with a cloth or put an object inside it. If the inside is so dirty that

dirt cannot be removed with a blower, contact the nearest KONICA

MINOLTA SENSING-authorized service facility.

E-16

Page 21

Preparation

Attaching Wrist Strap to the Instrument

When measuring by hand, attach Wrist Strap and put your arm through Wrist Strap to prevent dropping

of the instrument.

[Procedure]

Pass one end of Wrist Strap through the strap

1

holder of the instrument.

Pass other end of Wrist Strap through the ring,

2

and pass the strap that passed through the strap

holder through the ring too.

Ring

Pass one end of Wrist Strap that passed through

3

the ring through the buckle.

Pass other end of the strap through the buckle

4

from the other side.

M

emo

If necessary, after passing the arm through the strap, move the position of the ring so that the strap is snug your arm.

Buckle

E-17

Page 22

Preparation

Inserting the Batteries

For the CM-700d/600d, the supplied AC adapter (AC-A305) or four AA-size batteries (alkaline or

nickel-metal-hydride rechargeable batteries) must be used as a power supply. Use either the AC adapter

or batteries according to your application.

Note

• Do not use manganese batteries.

• If you are not going to use the CM-700d/600d for more than two weeks, the batteries must be removed. If the

batteries are left in the instrument for a long time, battery electrolyte may leak and damage the instrument.

• Do not use batteries of different types or mix new batteries with old ones. Doing so may result in battery

explosion or shorter battery life.

• Do not touch or short-circuit the terminals inside the battery chamber. Doing so may result in breakdown of

the instrument.

[Procedure]

Make sure that power is OFF (Power switch is set

1

to “ ”).

Press the battery chamber cover button on the

2

side of the instrument and slide the cover

downward to open it.

Place four AA-size batteries in the battery

3

chamber. Make sure that the batteries are placed

in the correct direction.

Align the grooves of the cover with the guides on

4

the edge of the battery chamber opening. Press

down lightly on the cover and slide it upward to

close it.

E-18

Page 23

Preparation

Connecting the AC Adapter

M

emo

When the external output terminal is used for data communication or printing, more power will be required. In this

case, it is recommended to use the AC adapter (AC-A305) rather than batteries.

Note

• To supply AC power to the instrument, always use the AC adapter (AC-A305) supplied with the instrument.

• Before connecting or disconnecting the AC adapter jack or plug, make sure that the instrument is turned OFF.

[Operating Procedure]

Make sure that power is OFF (Power switch is set

1

to “ ”.).

Open the connector protection cover of the AC

2

adapter terminal on the instrument.

Connect the AC adapter connector jack to the AC

3

adapter terminal.

Insert the AC adapter power plug to an AC outlet

4

(100 to 240 VAC, 50-60 Hz).

E-19

Page 24

Preparation

Turning Power ON/OFF

[Operating Procedure]

Turning power ON

Slide the Power switch to the “|” position.

1

The power will be turned ON (energized).

[Operating Procedure]

Turning power OFF

Slide the Power switch to the “ ” position.

1

The power will be turned OFF.

Power Save Function

The CM-700d/600d features a power save function which activates the power save mode when none of

the measuring and control buttons is operated for a specified period of time. In the power save mode, the

screen display is turned off and the flash circuit will not be charged.

You can return to the normal mode by pressing any of the measuring or control buttons.

M

emo

The period of time before the power save mode is activated can be set on the <Option> screen. For details, refer to

page E-70 “Setting the Power Save Mode”.

Note

The power save function is factory-set to OFF.

E-20

Page 25

System Diagram

Standard accessories

Optional accessories

Hard Case

CM-A176

* For storage

Personal computer

(Commercially

available)

USB Cable (2 m)

IF-A17

Color Data Software

CM-S100w

AC Adapter

AC-A305

White Calibration

Cap

CM-A177

CM-700d/600d

CM-600d

φ 8 mm

CM-A178

(w/ plate)

φ 8 mm

CM-A180

(w/o plate)

CM-700d

φ 3 mm

CM-A179

(w/ plate)

φ 3 mm

CM-A181

(w/o plate)

Wrist Strap

CR-A73

Target Mask

φ 8 mm (with glass)

CM-A183

Dust Cover Set

CM-A185

Replacement Dust Cover

(Polyolefin)

CM-A186

Zero Calibration Box

CM-A182

Granular-Materials

Attachment

CM-A184

E-21

Page 26

Items You Must Know

Initial Settings of the CM-700d/600d

When the instrument is turned ON, the <Calibration> screen will appear automatically in English. For

normal measurement, you do not need to change the initial settings.

It is recommended that you check the date and specify the power save mode in the <Option> screen

before using the instrument.

The display language can be selected from seven languages including Japanese.

For details, refer to page E-66 “Other Settings”.

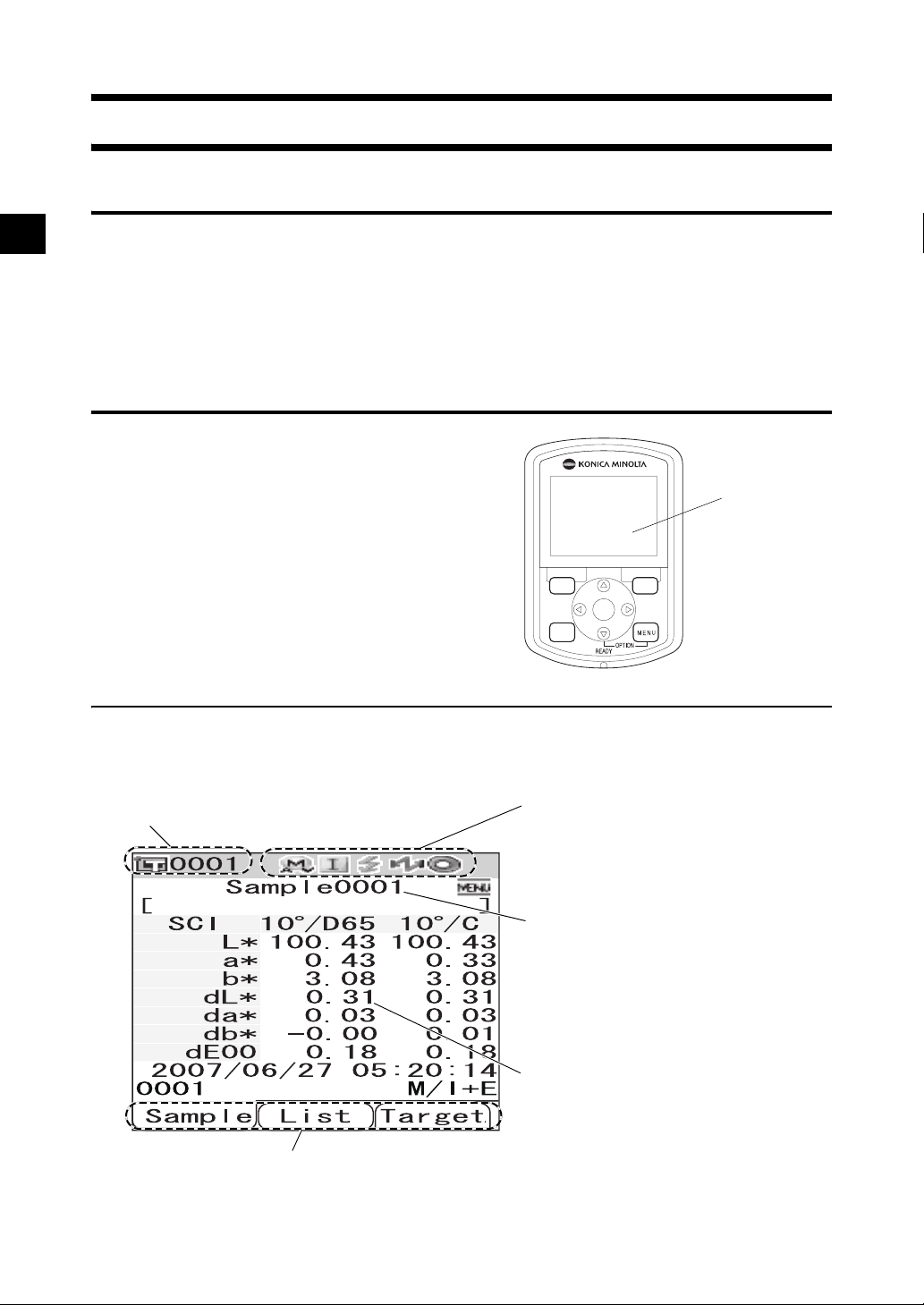

Control Panel

The top of the CM-700d/600d contains the LCD

screen on which the instrument displays

measurement results and messages, and the control

buttons which are used to set measurement options or

to change displays.

SAMPLE TARGET

SAVE

SEL

CAL

LCD

screen

Screen Display (LCD Screen)

The LCD screen displays measurement settings, measurement results and messages. It also indicates the

status of the instrument with icons.

The basic screen layout is shown below.

Target color No.

The functions assigned to the [SAMPLE], [SAVE/SEL] and [TARGET] buttons

are displayed respectively.

Status icons

The current settings and status of the

instrument are indicated with icons.

* For details, refer to the next page.

The screen title is displayed.

Measured values and setting

items are displayed.

E-22

Page 27

Items You Must Know

Status Icons

Status icon Description (Status) Meaning

Measurement area (Measurement

/

area selector setting)

* The CM-700d shows either the MAV or SAV icon. The CM-600d shows

MAV/SAV

only the MAV icon.

/ / Specular component mode setting SCI/SCE/I + E (SCI + SCE)

/ Bluetooth capability setting ON/OFF

Zero calibration required/White

/ / Calibration necessity

calibration required/User calibration

required

/ White calibration after power-on Performed/Not performed

/ Flash circuit charging Completed/Not completed

Control Buttons

Use these buttons to set items or change screens according to the guide on the LCD screen.

1

4

1 [SAMPLE] button:

Press this button to display the <Sample>

screen.

2 [TARGET] button:

Press this button to display the <Target>

screen.

3 [SAVE/SEL] button:

Use this button to determine the item indicated

by the cursor or to save the setting.

When the <Sample> or <Target> screen is

displayed, use this button to switch between

the detail display and list display.

4 [CAL] button:

SAMPLE TARGET

SAVE

SEL

CAL

5 [MENU] button:

Press this button to display the <Menu>

screen.

The screens and setting items for which menu

setting is available are indicated with

(MENU mark) at the top of the screen.

You can display the <Option> screen by

pressing the [MENU] button while holding

down the button of the cross key.

6 Cross key (///):

Use this key to move the cursor on the screen

or to change the selected value.

To determine the item indicated by the cursor,

press the [SAVE/SEL] button.

2

3

6

5

Press this button to display the <Calibration>

screen.

M

emo

The [SAMPLE], [SAVE/SEL] and [TARGET] buttons may be assigned different functions depending on the screen.

In this case, the guidance at the bottom of the screen indicates the current functions (Edit, etc.).

E-23

Page 28

Items You Must Know

Example of assigned functions

For example, when the screen shows the guidance

Edit

SEL] and [TARGET] buttons are assigned with the Edit, Save and

Back functions respectively. In this manual, when the button

name and the function assigned to the button are different, the

button name and function are described as “the [SAMPLE] (Edit)

button” or “[TARGET] (Back) button”.

Save Back

, the [SAMPLE], [SAVE/

Battery Alarm

The CM-700d/600d can be powered from the standard AC adapter (AC-A305) or AA-size alkaline or

nickel-metal-hydride rechargeable batteries. When the instrument is used with batteries, two types of

battery alarm indication will appear when battery power level is low. When the battery power is

sufficient, no battery alarm indication is displayed.

(Low battery indication)

When this indication appears, new batteries or the AC adapter should be prepared in the near future.

Even with this indication displayed, measurements are still possible.

If you continue using the instrument with the low battery indication being displayed, ER002 (low

battery voltage error) is displayed. When this error is displayed, replace the batteries immediately

with new ones or connect the AC adapter.

Data Saving

Data used with this instrument are saved automatically. The white calibration data stored in the internal

memory after you perform white calibration is retained even after the instrument is turned off.

Pairing Number

In addition to individual serial numbers, the instrument and White Calibration Cap bear 5-digit numbers

called “pairing number”. Before starting white calibration, confirm that the instrument and White

Calibration Cap have the same pairing number.

White Calibration Cap

Serial number of the

White Calibration Cap

CM-700d/600d

Pairing number

The instrument and White Calibration Cap to be used together must have the same

pairing number.

E-24

Page 29

Chapter 2

Preparation for Measurement

E-25

Page 30

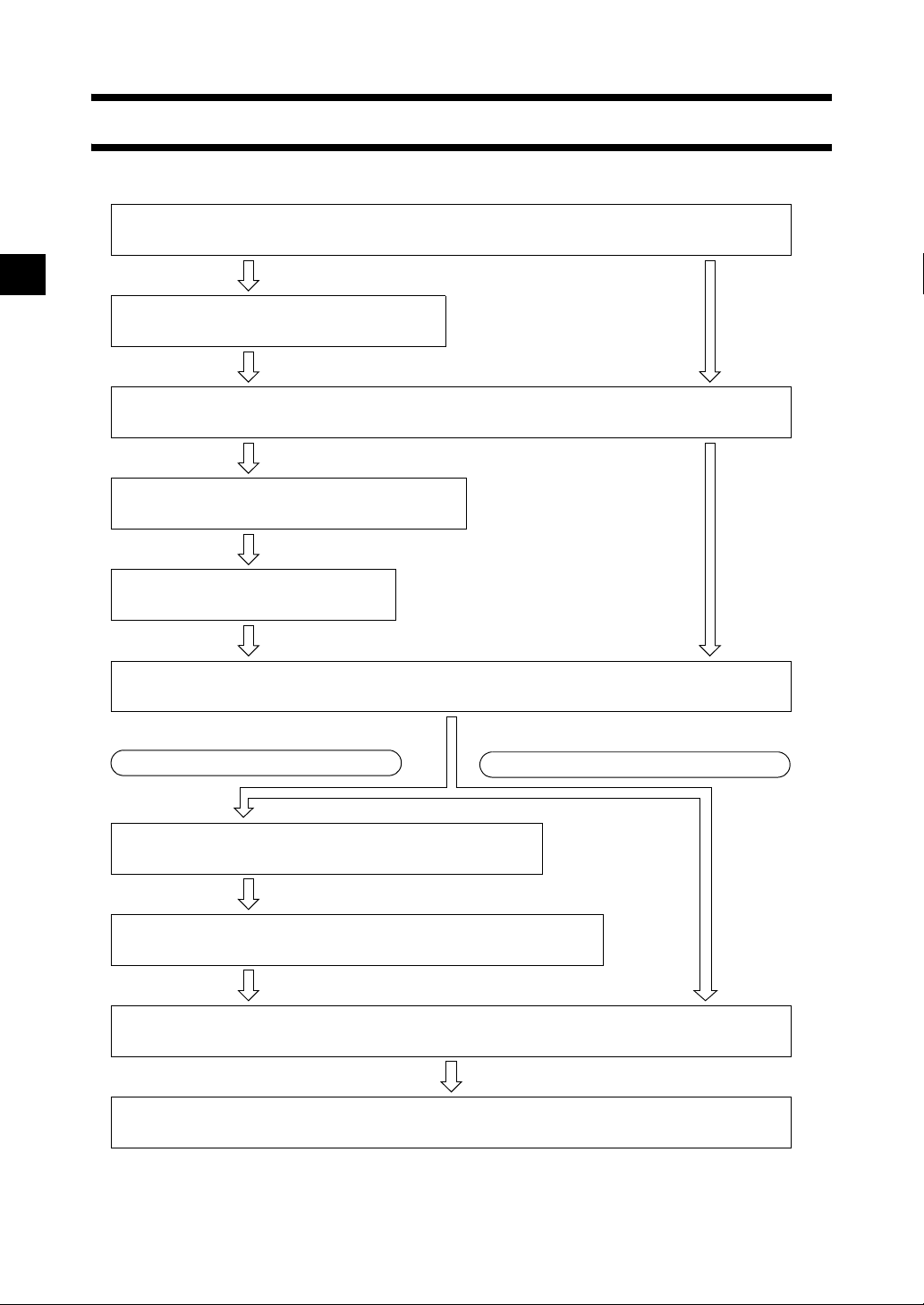

Flow of Measurement

■ Optional settings ■ Basic procedure

Turning Power ON/OFF (page E-20)

Setting the Display Language (page E-66)

Registering Conditions (Cond) (page E-56)

Attaching/Removing a Target Mask (page E-15)

Zero Calibration (page E-27)

White Calibration (page E-29)

When Checking Color Difference

* Perform this step if necessary

* Perform this step only if necessary,

such as after initialization.

such as after initialization.

* Perform this step if

necessary according to the

measurement conditions.

When Not Checking Color Difference

Color Difference Target Color Data Operation (page E-47)

Target Color Menu (page E-48)

Measurement (page E-74)

Completion of Measurement

E-26

Page 31

Calibration

Zero Calibration

Since the CM-700d/600d stores the data of the zero calibration performed at the factory, it is unnecessary

to repeat the zero calibration every time you turn ON the instrument. However, if the measurement

conditions change greatly, or if you use the optional dust cover set or Target Mask

you need to perform zero calibration before white calibration.

M

emo

• The effects of stray light inside the measuring part (i.e. light generated due to the flare characteristics of the optical

system) will be compensated for automatically by the zero calibration data.

• The amount of stray light may change because of dust or dirt which has collected in the optical system, humidity,

repeated operation, or vibration and shock exerted on the instrument. In this case, performing zero calibration

periodically is recommended.

• When I + E (SCI + SCE) is specified as the specular component mode (refer to page E-43 “Mode”), clicks caused

by opening and closing the optical trap may be heard during the measurement.

Note

• If the instrument is not used for long periods of time, the zero calibration data stored in the instrument may be

lost. If the data is lost, zero calibration must be performed again.

• When the instrument is used for the first time after purchase at a given measurement area setting (MAV or

SAV; SAV is available on CM-700d only), zero calibration must be performed.

• If you performed zero calibration using the optional dust cover set or Target Mask

must perform zero calibration again before starting measurement using the standard Target Mask.

φ

8 mm (with glass),

φ

8 mm (with glass), you

[Setting Procedure]

Confirm the type of attached target mask and the setting of the measurement area

1

selector of the instrument.

Turn the instrument ON.

2

The <Calibration> screen is displayed.

Note

Check the status icons displayed at the top of the screen to

verify that the lens position (MAV/SAV) icon is correct for

the measurement area selector setting and for the type of

attached Target Mask.

• If a different screen is displayed, press the [CAL] button.

E-27

Page 32

Calibration

Use the button of the cross key to move the

3

cursor to “Zero Cal.”

Direct the specimen measuring port to midair.

4

• Do not direct the specimen measuring port toward a light

source (including illumination such as a fluorescent lamp).

• Keep the specimen measuring port more than 1 m away

from any reflective items (hands, desks, walls etc.).

M

emo

Use of the optional Zero Calibration Box CM-A182 ensures

proper zero calibration.

Make sure that (Ready to measure) is

5

displayed or Ready lamp is green, and then

press the measuring button.

Zero calibration will be performed.

The Xe lamp flashes five times for each SCI and SCE

measurement.

During zero calibration, the screen shows the number of

flashes performed.

m

1

E-28

When zero calibration is finished, the screen returns to the

<Calibration> screen.

M

emo

When the screen is turned OFF by the power save function, press any of the measuring or control buttons to

turn ON the screen, confirm that (Ready to measure) is displayed or Ready lamp is green, and then press

the measuring button.

Note

• After zero calibration finished, perform white calibration. Go to step 3 of “White Calibration” on page

E-29.

• Even though you performed white calibration after turning ON the power, you need to perform it again

if you performed zero calibration after the first white calibration.

Page 33

Calibration

White Calibration

White calibration must be performed prior to start of measurement after the power is turned ON for the

first time after purchase at the current settings.

When white calibration finishes, <white calibration completed icon> is displayed.

Once white calibration is completed, measurement is possible without white calibration when the

instrument is turned ON the next time. However, the measurement result is not accurate.

M

emo

• The calibration data for the White Calibration Cap supplied with the instrument are stored in the instrument.

• Although the white calibration results stored in the internal memory are retained even after the instrument is turned

off, it is recommended that you repeat white calibration each time you switch the power back on.

• The reading may fluctuate slightly due to changes in the ambient temperature or due to heat generation caused by

repeated operation of the instrument. In this case, make sure to perform white calibration regularly.

• When I + E (SCI + SCE) is specified as the specular component mode (refer to page E-43 “Mode”), clicks caused

by opening and closing the optical trap may be heard during the measurement.

Note

• White calibration must be performed at the same temperature as the one at which measurement will be

performed.

• Before starting white calibration, make sure that the instrument is sufficiently acclimatized to the ambient

temperature.

• Whenever the measurement area setting has been changed between MAV and SAV, white calibration must be

performed.

[Setting Procedure]

Confirm the type of attached target mask and the setting of the measurement area

1

selector of the instrument.

Turn the instrument ON.

2

The <Calibration> screen is displayed.

Note

Check the status icons displayed at the top of the screen to

verify that the lens position (MAV/SAV) icon is correct for

the measurement area selector setting and for the type of

attached Target Mask.

• If a different screen is displayed, press the [CAL] button.

M

emo

• The <Calibration> screen shows two items: “Zero Cal.”

and “White Cal.” The date of the last calibration is

displayed under each item. If no calibration has been

performed yet, “None” is displayed.

• Under “White Cal.”, the serial number of the White

Calibration Cap to be used for the instrument is displayed.

If necessary, use the button of the cross

3

key to move the cursor to “White Cal.”

E-29

Page 34

Calibration

Properly attach the White Calibration Cap,

4

which has the same pairing number as the

instrument.

Make sure that (Ready to measure) is

5

displayed or Ready lamp is green, and then

press the measuring button.

White calibration will be performed.

The Xe lamp flashes five times for each SCI and SCE

measurement.

During white calibration, the screen shows the number of

flashes performed.

When white calibration finishes, the screen returns to the

<Calibration> screen.

Note

The instrument contains the data for the White Calibration Cap which has the same pairing number.

Therefore, you must use the instrument and corresponding White Calibration Cap for white calibration.

M

emo

• If you change the measurement area or change the specular component mode from a setting other than “I

+ E” after white calibration, you must perform white calibration under the changed conditions.

• If you performed white calibration in “I + E” mode and then switched the mode to “SCI” or “SCE”, it is

considered that white calibration has been completed and you do not need to repeat it.

• When the screen is turned OFF by the power save function, press any of the measuring or control buttons

to turn ON the screen, confirm that (Ready to measure) is displayed or Ready lamp is green, and then

press the measuring button.

E-30

Page 35

Calibration

User Calibration

You can perform calibration by using your own reference plate and calibration data instead of the white

calibration data. The calibration data for user calibration can be specified by connecting the instrument

to a PC and using the optional Color Data software “SpectraMagic™ NX”.

You can select whether to use the user calibration data for measurement on the <User Cal.> screen of the

instrument.

[Setting Procedure]

Turn the instrument ON.

1

The <Calibration> screen is displayed.

• If a different screen is displayed, press the [CAL] button.

Press the [MENU] button.

2

The <User Cal.> screen is displayed.

Use the button of the cross key to move the

3

cursor to “ON” and then press the [SAVE/

SEL] button.

Now you can perform white calibration using your own

calibration data.

Note

You need to prepare user calibration data and write it to the

instrument memory before you can set user calibration to

ON.

E-31

Page 36

Condition Setting

The CM-700d/600d requires condition settings (display and measurement conditions) before

measurement can be started.

M

emo

To configure condition settings, select “Disp. Cond.” (display conditions) or “Meas. Cond.” (measurement

conditions) from the <Option> screen to open an appropriate screen.

Note

If any predefined condition is selected, the condition setting (display/measurement conditions) is disabled. Set the

condition to OFF before starting condition setting.

Setting the Display Conditions

To set the display conditions, select “Disp. Cond.” on the <Option> screen.

You can select or specify the following seven items as the display conditions:

• Disp. Type: Specify items to be displayed as measurement results.

• Color Space: Select the color space to be used.

• Equation: Select the color difference formula to be used.

• Color Index: Select the index (WI, YI, etc.) to be used.

• Observer: Select the observer angle: 2° or 10°

• Illuminant 1: Select the illuminant used to measure colorimetric data.

• Illuminant 2: Select the secondary illuminant used for MI (metamerism index) calculation, etc.

[Setting Procedure]

Hold down the [MENU] button and press the

1

2

button of the cross key.

The <Option> screen is displayed.

Use the or button of the cross key to

move the cursor to “Disp. Cond.” and then

press the [SAVE/SEL] button.

The <Disp. Cond.> screen is displayed.

Note

When setting of “Cond” is “ON” (refer to page E-56),

“Disp. Cond” and “Meas. Cond” cannot be selected.

E-32

Page 37

Condition Setting

• The <Disp. Cond.> screen shows the current settings.

After you set the display conditions, press the [TARGET] (Back) button to return

3

to the <Option> screen.

E-33

Page 38

Condition Setting

Disp. Type

Specify items to be displayed as measurement results.

[Setting Procedure] Start the procedure from the <Disp. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Disp. Type.” and then

press the [SAVE/SEL] button.

The <Disp. Type> screen is displayed.

Use the or button of the cross key to

2

move the cursor to the desired item.

M

emo

• Press the [SAMPLE] (Edit) button to check or uncheck

the “Disp. Type” options indicated by the cursor.

• The checked option is currently selected.

Settings

❍Absolute: Display the absolute values of the colorimetric

data.

❍Difference:

Display the color difference from the target color. The measured data which failed the pass/fail judgment

based on the specified tolerances will be highlighted in red.

❍Abs. & Diff.:

Display the absolute value and the color difference from the target color. The measured data which

failed the pass/fail judgment based on the specified tolerances will be highlighted in red.

❍Judge:

Perform judgment of whether the color difference from the target color is within the range of the

predefined tolerances. “Pass” indicates that all the items passed the judgment, and “Fail” indicates at

least one item failed the judgment.

❍Graph Spec.: Display a spectral reflectance graph.

❍Graph Diff.: Display a graph indicating the color difference from the target color.

❍Pseudo Color: Display a pseudocolor.

❍Assessments: Display deviations in hue or other factors from the target color with specific words.

The table below shows the words to be used.

Δa*/Δb*/Hue (h, a*, b*) Lightness (L*) Chroma (C*)

+ RED - RED LIGHTER VIVID

+ GREEN - GREEN DARKER DULLER

+ YELLOW - YELLOW

+ BLUE - BLUE

* When the L*C*h color space is selected, the color assessment is indicated in the + direction only.

* The saturation is displayed only when the L*C*h color space is selected.

E-34

Page 39

Condition Setting

Note

The results for “Difference”, “Abs. & Diff.” and “Graph Diff.” will be displayed only when the target color has

been specified.

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the <Disp. Cond.> screen.

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Disp. Cond.> screen without changing the setting.

E-35

Page 40

Condition Setting

Color Space

Select the color space to be used.

[Setting Procedure] Start the procedure from the <Disp. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Color Space” and then

press the [SAVE/SEL] button.

The <Color Space> screen is displayed.

Use the or button of the cross key to

2

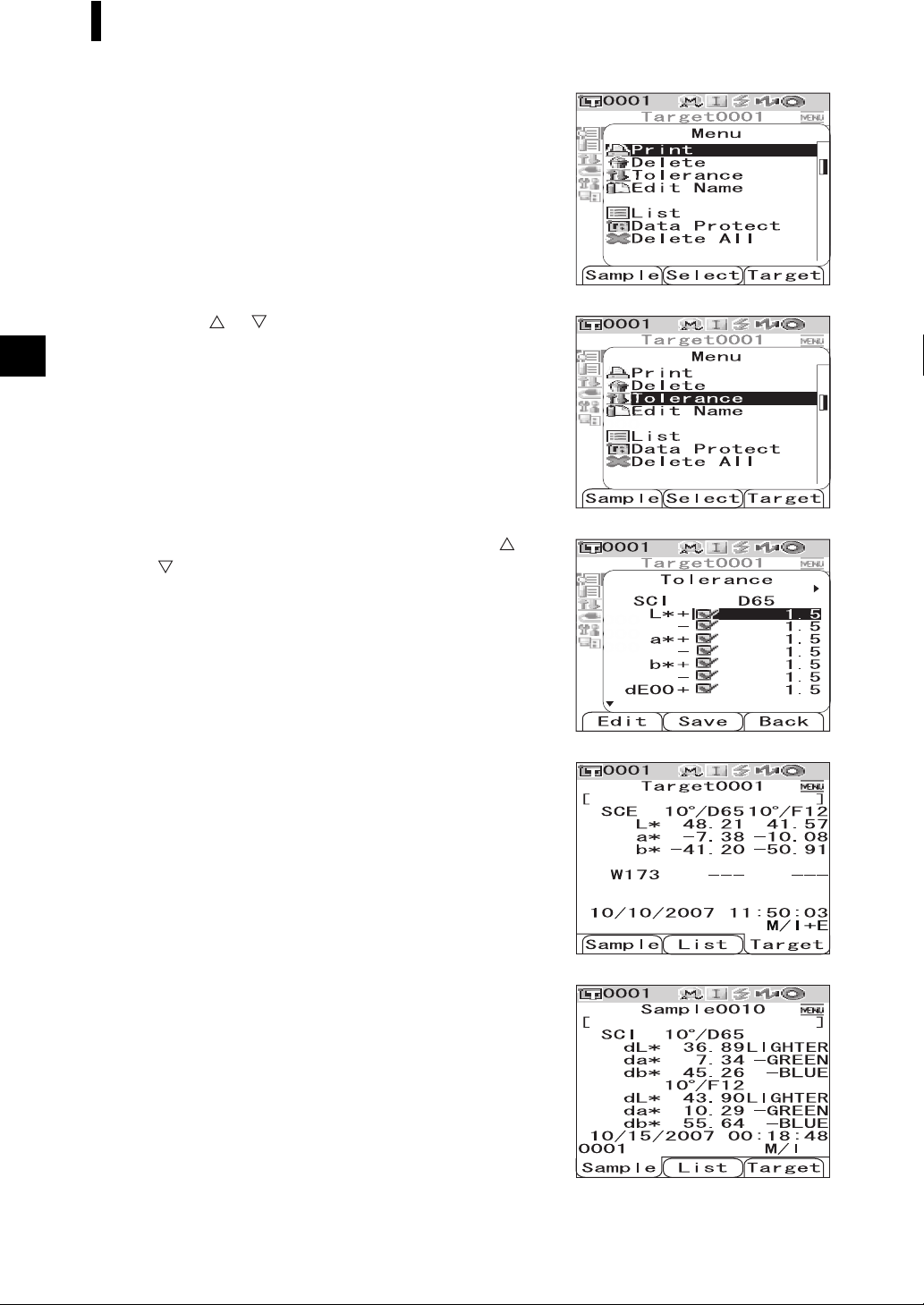

move the cursor to the desired item.

Settings

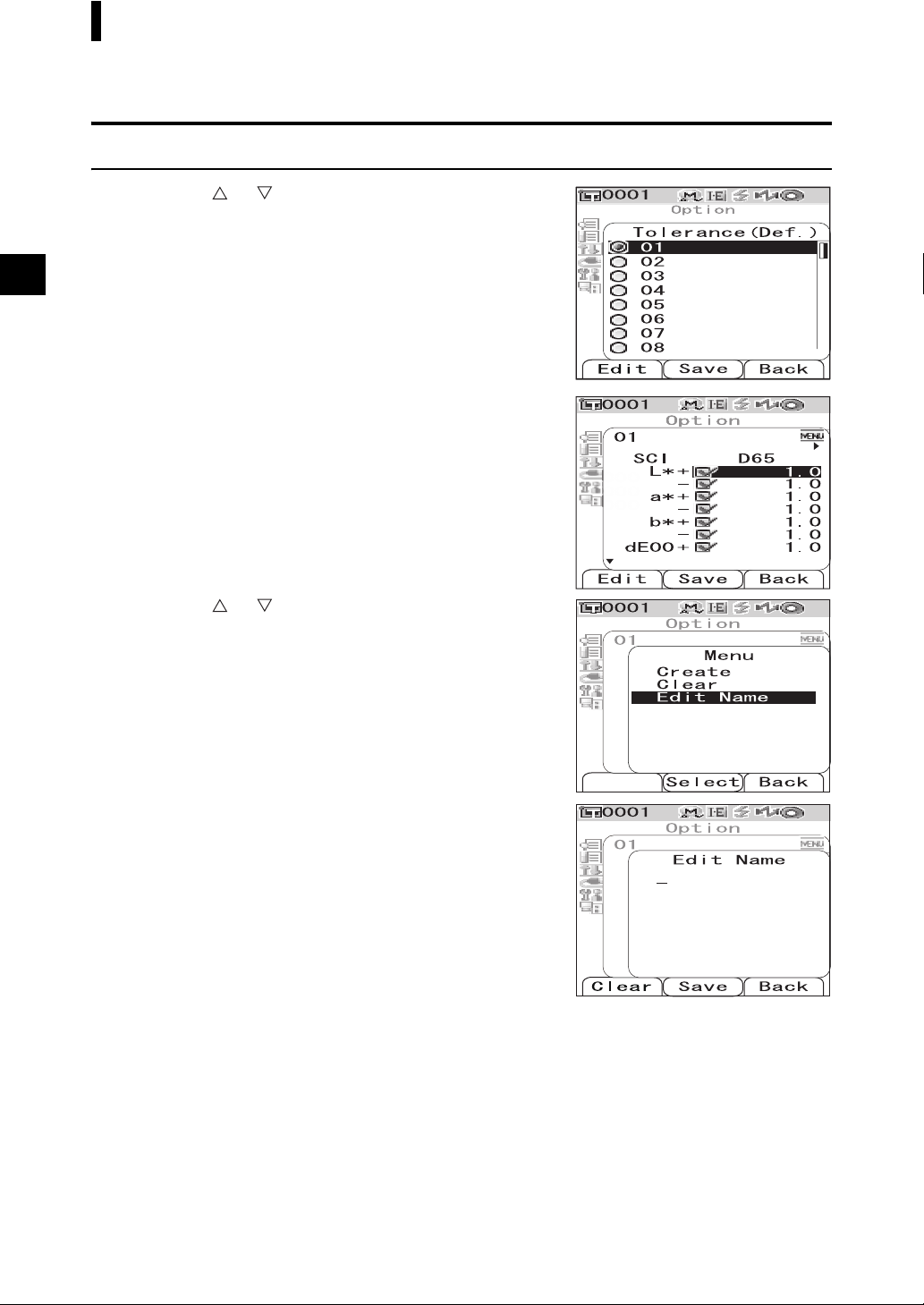

❍L✽a✽b✽: L*a*b* color space

✽C✽h: L*C*h color space

❍L

❍Hunter Lab: Hunter Lab color space

❍Yxy: Yxy color space

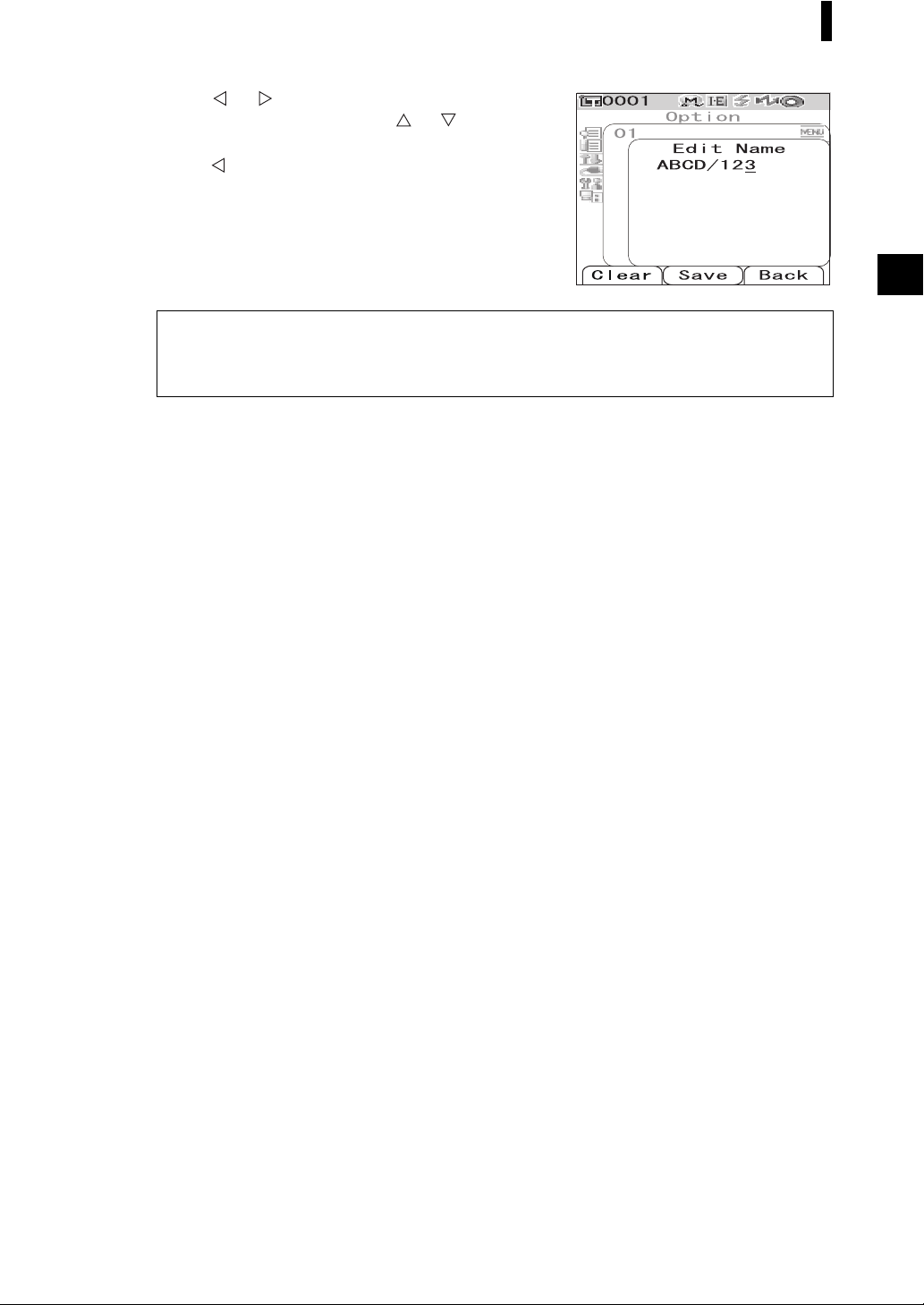

❍XYZ: XYZ color space

❍Munsell: Munsell color space

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the

<Disp. Cond.> screen.

E-36

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Disp. Cond.> screen without changing the setting.

Page 41

Condition Setting

Equation

Select the color difference formula to be used.

[Setting Procedure] Start the procedure from the <Disp. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Equation” and then press

the [SAVE/SEL] button.

The <Equation> screen is displayed.

Use the or button of the cross key to

2

move the cursor to the desired item.

Settings

❍dE*ab: ΔE*ab (CIE1976) color difference formula

❍CMC: CMC color difference formula

94: ΔE*94 (CIE1994) color difference formula

❍dE

*

❍dE00: ΔE00 (CIE2000) color difference formula

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the

<Disp. Cond.> screen.

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Disp. Cond.> screen without changing the setting.

E-37

Page 42

Condition Setting

Color Index

Select the index (WI, YI, etc.) to be used.

[Setting Procedure] Start the procedure from the <Disp. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Color Index” and then

press the [SAVE/SEL] button.

The <Color Index> screen is displayed.

Use the or button of the cross key to

2

move the cursor to the desired item.

Settings

❍None

❍WI (E313-73): Whiteness index (ASTM E313-73)

❍WI (E313-96): Whiteness index (ASTM E313-96)

❍YI (E313-73): Yellowness index (ASTM E313-73)

❍YI (D1925): Yellowness index (ASTM D1925)

❍ISO Bright.: ISO Brightness

❍8° Gloss: The gloss value calculated with the specular

reflection in the direction of 8. °. This value can be used

for relative management of glossiness.

E-38

M

emo

8° Gloss will be displayed when “I+E” for specular

component mode is selected.

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the <Disp. Cond.> screen.

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Disp. Cond.> screen without changing the setting.

Page 43

Condition Setting

Observer

Select the observer angle: 2° or 10°.

[Setting Procedure] Start the procedure from the <Disp. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Observer” and then

press the [SAVE/SEL] button.

The <Observer> screen is displayed.

Use the or button of the cross key to

2

move the cursor to the desired item.

Settings

❍2°: 2° observer (CIE1931)

❍10°: 10° observer (CIE1964)

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the

<Disp. Cond.> screen.

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Disp. Cond.> screen without changing the setting.

E-39

Page 44

Condition Setting

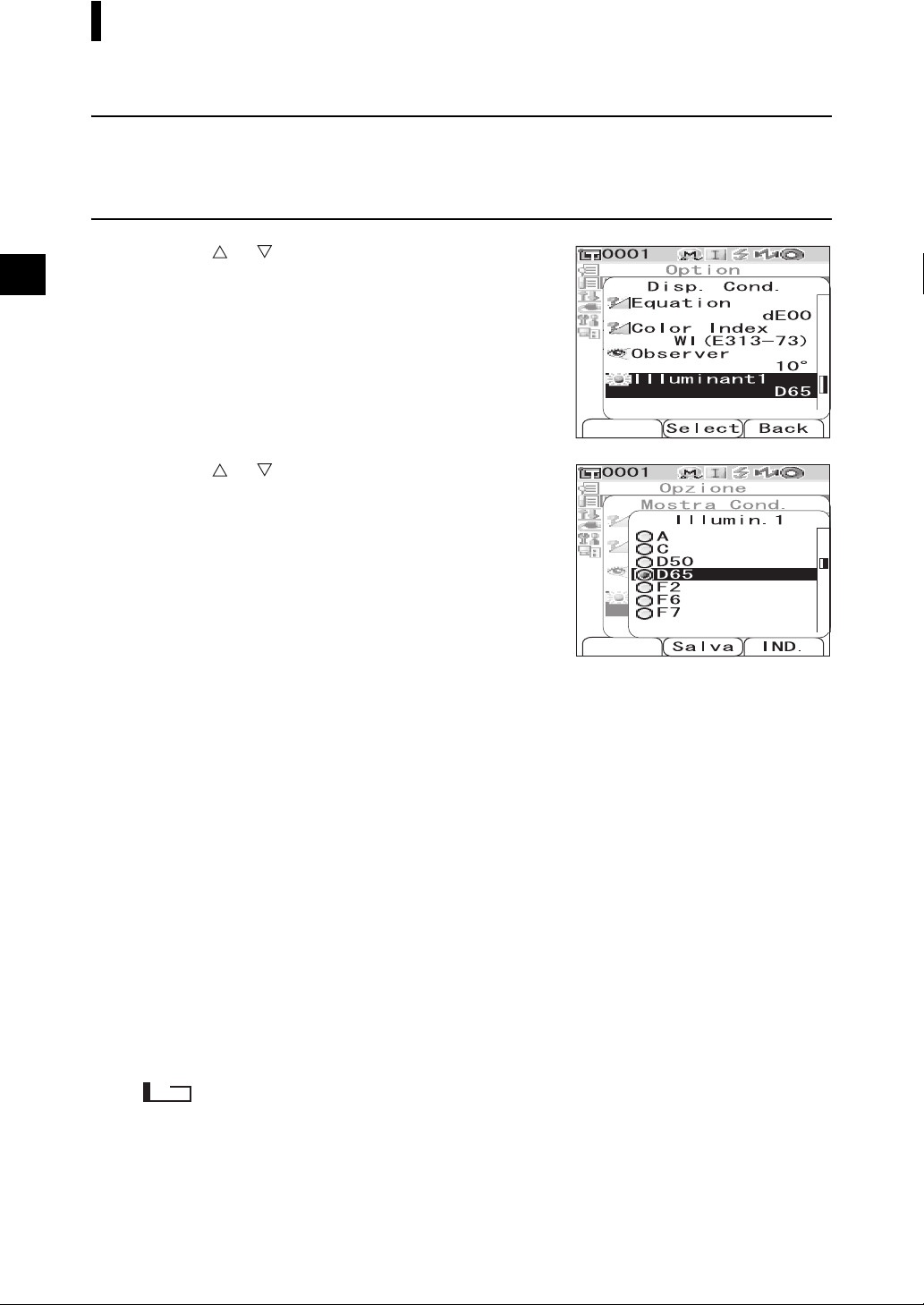

Illuminant 1

Select the illuminant used to measure colorimetric data.

[Setting Procedure] Start the procedure from the <Disp. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Illuminant 1” and then

press the [SAVE/SEL] button.

The <Illuminant 1> screen is displayed.

Use the or button of the cross key to

2

move the cursor to the desired item.

Settings

❍A: Standard illuminant A

temperature: 2856K)

❍C: Illuminant C

(Daylight, The relative value of the spectral

distribution in the ultraviolet region is small;

Color temperature: 6774K)

:Illuminant D50 (Daylight, Color temperature:

❍D

50

5003K)

:Standard illuminant D65 (Daylight, Color

❍D

65

temperature: 6504K)

❍F2: Cool white (fluorescent lamp)

❍F6: Cool white (fluorescent lamp)

❍F7: Color rendering A daylight white (fluorescent

lamp)

❍F8: Color rendering AAA natural white (fluorescent

lamp)

❍F10: 3-band type natural white (fluorescent lamp)

❍F11: 3-band type cool white (fluorescent lamp)

❍F12: 3-band type warm white (fluorescent lamp)

(Incandescent lamp, Color

E-40

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the

<Disp. Cond.> screen.

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Disp. Cond.> screen without changing the setting.

Page 45

Condition Setting

Illuminant 2

Select the secondary illuminant used for MI (metamerism index) calculation, etc.

[Setting Procedure] Start the procedure from the <Disp. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Illuminant 2” and then

press the [SAVE/SEL] button.

The <Illuminant 2> screen is displayed.

Use the or button of the cross key to

2

move the cursor to the desired item.

Settings

❍The setting values are the same as those for “Illuminant

1” and “None”.

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the

<Disp. Cond.> screen.

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Disp. Cond.> screen without changing the setting.

E-41

Page 46

Condition Setting

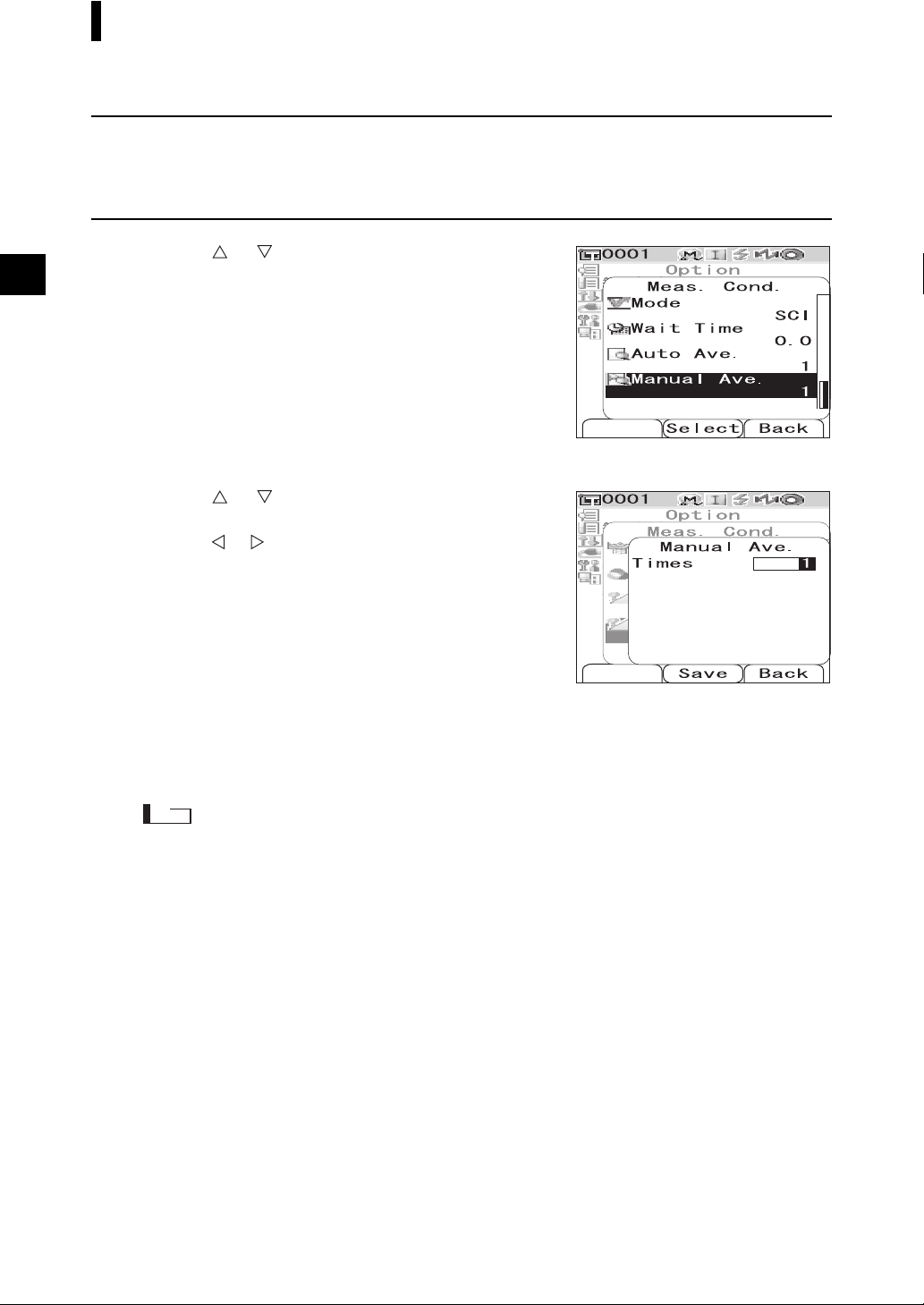

Setting the Measurement Conditions

To set measurement conditions, select “Meas. Cond.” from the <Option> screen.

You can select or specify the following four items as the measurement conditions:

• Mode: Select the specular component mode.

• Wait Time: Specify the delay between the press of the measuring button and the flash of the lamp.

• Auto Ave.: Specify the number of measurements for auto averaging.

• Manual Ave.: Specify the number of measurements for manual averaging.

[Setting Procedure]

Hold down the [MENU] button and press the

1

button of the cross key.

The <Option> screen is displayed.

Use the or button of the cross key to

2

move the cursor to “Meas. Cond.” and then

press the [SAVE/SEL] button.

The <Meas. Cond.> screen is displayed.

Note

When setting of “Cond” is “ON” (refer to page E-56),

“Disp. Cond” and “Meas. Cond” cannot be selected.

• The <Meas. Cond.> screen shows the current settings.

After you set the measurement conditions, press the [TARGET] (Back) button to

3

return to the <Option> screen.

E-42

Page 47

Condition Setting

Mode

Select the specular component mode.

[Setting Procedure] Start the procedure from the <Meas. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Mode” and then press the

[SAVE/SEL] button.

The <Mode> screen is displayed.

Use the or button of the cross key to

2

move the cursor to the desired item.

Settings

❍SCI: Specular component included

❍SCE: Specular component excluded

❍SCI+SCE: Automatic SCI/SCE switching

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the

<Meas. Cond.> screen.

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Meas. Cond.> screen without changing the setting.

E-43

Page 48

Condition Setting

Wait Time

Specify the delay between the press of the measuring button and the flash of the lamp.

[Setting Procedure] Start the procedure from the <Meas. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Wait Time” and then

press the [SAVE/SEL] button.

The <Wait Time> screen is displayed.

Use the or button of the cross key to

2

specify a value.

• Use the or button of the cross key to move the

cursor to the digit on the left or right.

Setting

❍Sec. [0.0 to 3.0]:

To eliminate the influence of instrument shake, provide a

period between the press of the measuring button and the

flash of the lamp for measurement in increments of 0.1

seconds. When 0.0 seconds is specified, measurement

starts immediately.

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the

<Meas. Cond.> screen.

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Meas. Cond.> screen without changing the setting.

E-44

Page 49

Condition Setting

Auto Averaging (Auto Ave.)

Specify the number of measurements for auto averaging.

[Setting Procedure] Start the procedure from the <Meas. Cond.> screen.

Use the or button of the cross key to

1

move the cursor to “Auto Ave.” and then

press the [SAVE/SEL] button.

The <Auto Ave.> screen is displayed.

Use the or button of the cross key to

2

specify a value.

• Use the or button of the cross key to move the

cursor to the digit on the left or right.

Setting

❍Times [1 to 10]:Specify the number of measurements,

from 1 to 10, to perform when using auto

averaging.

Press the [SAVE/SEL] button.

3

The selection is confirmed and the screen returns to the

<Meas. Cond.> screen.

Note

If you press the [TARGET] (Back) button without pressing the [SAVE/SEL] button, you return to the

<Meas. Cond.> screen without changing the setting.

E-45

Page 50

Condition Setting

Manual Averaging (Manual Ave.)