Page 1

2D Color Analyzer CA-2000 Series

Instruction Manual

Page 2

Safety Symbols

The following symbols are used in this manual to prevent accidents which may occur as a result of incorrect

use of the instrument.

Denotes a sentence regarding safety warning or precaution.

Read the sentence carefully to ensure safe and correct use.

Denotes a prohibited operation.

The operation must never be performed.

Denotes an instruction.

The instruction must be strictly adhered to.

Denotes an instruction.

Disconnect AC adapter from AC outlet.

Denotes a prohibited operation.

Never disassemble this instrument.

Notes on this manual

l Copying or reproduction of all or any part of the contents of this manual without KONICA MINOLTA

SENSING's permission is strictly prohibited.

l Contents of this manual are subject to change without prior notice.

l Every effort has been made in the preparation for this manual to ensure the accuracy of its contents.

However, should you have any questions or find any errors, contact the nearest KONICA MINOLTA

SENSING authorized service facility.

l KONICA MINOLTA SENSING will not accept any responsibility for consequences arising from the use of

this instrument.

Page 3

Safety Warnings and Cautions

To ensure correct use of this instrument, read the following points carefully and adhere to them. After you

have read this manual, keep it in a safe place where it can be referred to anytime a question arises.

Warning

Do not use this instrument in places where flammable or combustible gases (gasoline etc.) are

present. Doing so may cause fire.

Always use the AC adapter and power cord supplied as a standard accessory or optional (AC-A22),

and connect it to indoor AC outlet of rated voltage 100 V-240 V ~ and frequency 50 Hz-60 Hz. Failure to

follow either of these may result in damage to instrument or AC adapter, fire or electric shock.

If this instrument is not used for a long time, disconnect AC adapter from AC outlet. Accumulated

dirt or water on prongs of AC adapter plug may cause fire. Be sure to remove before use.

Do not forcibly pull any part on power cord when unplugging since this may damage power cord,

resulting in fire or electric shock. Gently disconnect by holding plug. Also, do not handle power

plug with wet hands. Doing so may cause electric shock.

Dust could enter inside this instrument from air duct. Do not leave such dust accumulated while using

for this may cause fire. Contact with the nearest KONICA MINOLTA SENSING authorized service

facility for periodical checkup.

Do not forcibly bend, twist or pull power cord. Also, do not place heavy object on power cord, or

damage or modify one. Any of these may cause fire or electric shock due to damage to power

cord.

Do not disassemble or modify this instrument or AC adapter. Doing so may cause fire or electric

shock.

(Failure to adhere to the following points may result in death or serious injury.)

Do not expose this instrument to liquid or metal object which may cause fire or electric shock.

Should either of these happen, switch power off immediately, unplug AC adapter, and contact the

nearest KONICA MINOLTA SENSING authorized service facility.

Should this instrument or AC adapter be damaged or smoke or odd smell be generated, do not

keep using one without correction. Doing so may cause fire. In such cases, switch power off

immediately, unplug AC adapter from AC outlet, and then contact the nearest KONICA MINOLTA

SENSING authorized service facility.

Caution

Use this instrument near AC outlet for easy plugging or unplugging in using AC adapter.

Do not place this instrument on unstable or sloping sur face which may drop or over turn it.

Dropping or overturning may injure someone around. Take care not to drop this instrument when

carrying.

(Failure to adhere to following points may result in injury or damage to this

instrument or other property.)

1

Page 4

Introduction

Thank you for purchasing our 2D Color Analyzer CA-2000 series. This instrument measures unevenness of

luminance and color on various display unit or projector, backlight and car instrument panel in 2 dimension.

Read this manual carefully before use.

"CA-2000" and CA-2000S are applied as representative examples for explanation and illustration

respectively in this instruction manual. Only those with different specification are indicated model by model.

Packaging material

Retain accompanying packaging materials (carton, protector, and plastic bag) for future use.

This is delicate measurement instrument. Use packaging materials supplied in purchasing in case this instrument

needs to be transferred for such purpose as maintenance in KONICA MINOLTA SENSING authorized service

facility. These packaging materials are useful for minimizing shock or vibration to this instrument in such situation.

Should any of these packaging materials be lost or broken, contact the nearest KONICA MINOLTA SENSING authorized service facility.

Note on use

Operating environment

l

Do not use this instrument outdoor since standard accessory AC adapter (AC-A22) is designed for indoor use.

l Never disassemble this instrument for being composed of delicate electronic components.

l Use this instrument at rated voltage of 100 V-240 V ~. Connect AC power cord to AC outlet with rated voltage 100

V-240 V ~ and frequency 50 Hz-60 Hz. Connected voltage should not be outside the range of ±10% of nominal.

l

This instrument is classified into a Pollution Degree 2 as instrument used mainly in manufacturing plant, laboratory,

warehouse or equivalents. Use this instrument in metal dust free and non condensing potential environment.

l This instrument is categorized into Installation Categor y II as equipment connected to commercially

available power source.

l If protective earth terminal is equipped with the PC to control this instrument, connect the PC terminal to a

protective earth outlet. If not, electric shock may occur due to earth leakage.

l Take care not to enter foreign substance like water or metal in this instrument. Operating in such state

causes serious danger.

l Do not use this instrument under direct sunlight or near heater. The internal temperature of this instrument

becomes much higher than ambient temperature which may break this instrument. Also, be sure to keep

good ventilation in using this instrument. Never cover air duct of this instrument.

l Avoid rapid change in ambient temperature which may form dew condensation.

l Avoid using this instrument in extremely dusty or humid place.

l Use this instrument at ambient temperature between 10ºC and 30ºC and relative humidity 70% or less

with no condensation. Operating this instrument outside specified temperature and humidity range may

unsatisfy its original performance.

l Even if the product is used within the specified operating temperature/humidity range, the displayed values

may be affected by long-term conditions of use. If you have any question about specification, please

contact the nearest KONICA MINOLTA SENSING authorized service facility.

This instrument

l Do not subject this instrument to strong impact or vibration.

l Do not forcibly pull, bend, or apply strong force to power cord for attached AC adapter or USB cable. This

may result in snapping.

l Connect this unit to power source with minimal noise.

l Should breakage or abnormality be found during operation, switch power off immediately and unplug.

Then, refer to "Error Check" on pages 35-37.

l Should this instrument break down, do not try to disassemble and repair it by yourself. Contact the nearest

2

Page 5

Lens and filter inside lens mount on body

l Be sure that there is no dirt on surface of lens and filter inside lens mount on body before measurement.

Correct measurement result cannot be obtained if dirt, dust or handsoil is left or uncleaned.

l Do not touch surface of lens and filter inside lens mount on body with hand.

l Lens and filter inside lens mount on body could become fogged up if ambient temperature fluctuates under

high humidity. Be careful not to generate such condition for correct measurement cannot be performed.

Storage

Body

Cover lens mount with standard accessory mount cover in storing lens in removed state.

l

Do not store this instrument under direct sunlight or near heater. The internal temperature of this

l

instrument could become much higher than ambient temperature which may break this instrument.

Store this instrument at ambient temperature between 0ºC and 30ºC and relative humidity 70% or less

l

with no condensation or between 30ºC and 35ºC and relative humidity 55% or less with no condensation.

Storage under high temperature and humidity may deteriorate performance of this instrument. For added

safety, we recommend storage with such drying agent as silica gel at room temperature.

Even if the product is stored within the specified storage temperature/humidity range, the displayed values

l

may be affected by long-term conditions of storage. If you have any question about specification, please

contact the nearest KONICA MINOLTA SENSING authorized service facility.

Take care not to form condensation. Avoid rapid change in ambient temperature when transferring body

l

for storage.

Put body in packaging box supplied when purchased or optional soft case (CA-A60) to store in safe place.

l

Lens

l Cover lens with lens cap, or lens hood with hood cap for storage.

l When you remove lens from body for storage, cover lens with lens cap and mount cap.

Temperature/Humidity conditions under which the instrument is used and stored

It is recommended that the instrument be used and stored under standard conditions (Temperature: 23ºC; Relative

humidity: 40%), and that areas subject to high temperature and/or humidity be avoided. In addition in order to maintain the

measurement accuracy of this instrument, it is recommenced that it be inspected regularly about once a year. For details

on having the instrument inspected, please contact the nearest Konica Minolta Sensing authorized service facility.

Even if the product is used within the specified operating temperature/humidity range or stored within the specified storage

temperature/humidity range, the displayed values may be affected by long-term conditions of use or storage.

If the instrument is left under the following high-temperature conditions for a long period of time, the displayed values may

change as follows:

Temperature: 30ºC; Relative humidity: 70%; Period under these conditions: 720 hours (30 days)

Accuracy: Luminance: ±0.4 %; Chromaticity: ±0.003

Inter-point error: Luminance: ±0.2 %; Chromaticity: ±0.0003

Temperature: 35ºC; Relative humidity: 55%; Period under these conditions: 336 hours (14 days)

Accuracy: Luminance: ±1 %; Chromaticity: ±0.006

Inter-point error: Luminance: ±0.5 %; Chromaticity: ±0.001

These differences in display values are due to the instrument materials and/or components being affected by the

temperature and humidity conditions of long-term use or storage. In particular, optical filters are easily affected by

temperature or humidity. Although measures have been taken to improve resistance to temperature/humidity changes, the

accumulated effect of long-term use or storage may affect the displayed values.

3

Page 6

Cleaning

Body

l If this unit becomes dirty, wipe with dry and soft cloth. Do not use organic solvent like benzine or thinner

and other chemical agent for cleaning. Should none of these methods be helpful, contact the nearest

KONICA MINOLTA SENSING authorized service facility.

Lens and filter inside lens mount on body

l Should it be gotten dirt or dust, wipe off with dry and soft cloth or lens cleaning paper. Do not use organic

solvent like benzine or thinner and other chemical agent for cleaning. Should none of these methods be

helpful, contact the nearest KONICA MINOLTA SENSING authorized service facility.

Notes on transfer

l Use packaging material supplied when purchased to minimize vibration or shock generated during transfer.

l Put all materials including unit and accessories together in original packaging material when returning this

instrument for service.

Maintenance

l Periodical checkup is recommended annually to maintain measurement accuracy of instrument. For details

on checkup, contact the nearest KONICA MINOLTA SENSING authorized service facility.

4

Page 7

CONTENTS

Safety Warnings and Cautions ………………… 1

Introduction …………………………………………2

Note on use ………………………………………… 2

Operating environment …………………………………… 2

This instrument …………………………………………… 2

Lens and filter inside lens mount on body ……………… 3

Storage ……………………………………………… 3

Body ………………………………………………………… 3

Lens ………………………………………………………… 3

Cleaning ……………………………………………… 3

Body ………………………………………………………… 3

Lens and filter inside lens mount on body ……………… 3

Notes on transfer …………………………………… 3

Maintenance ………………………………………… 3

Standard Accessory ……………………………… 6

Optional Accessory ……………………………… 7

System Configuration ……………………………8

Names and Functions of Parts ……………… 10

<Body> ……………………………………………………… 10

<Lens> ……………………………………………………… 11

Installing

<Preparation> ……………………………………………… 24

<Shutter speed adjustment> ……………………………… 25

<Focusing> ………………………………………………… 25

Caution ……………………………………………………… 26

Example of reference position to read distance

How to read distance in case of standard lens or telephoto lens

How to read distance in case of wide lens ……………… 27

…27

… 27

Description

Sync Measurement …………………………… 30

Backlight Cancellation ………………………… 31

User Calibration ………………………………… 31

Influence by viewing angle ……………………………… 31

LvTΔuv …………………………………………… 32

<Relation between correlated color temperature T and

color dif ference from blackbody locus Δuv> …………… 32

Dominant Wavelength and Excitation Purity

<Dominant wavelength and excitation purity of spectrum color>

<Complementary wavelength and excitation purity of

non-spectrum color> ……………………………………… 33

Outer Dimensions ……………………………… 34

Error Check ……………………………………… 35

… 33

… 33

Goods/Environment to Prepare on Customer's Side

Controlling PC ………………………………………14

Mounting stage ………………………………………14

Blackout curtain (To quickly make darkroom-like

condition) / Dark room …………………………… 14

… 14

Installing ………………………………………… 15

Placing Lens …………………………………… 16

Replacing lens ……………………………………… 17

Connecting AC Adapter ……………………… 18

Connection procedure …………………………… 18

ON (|) / OFF ( ○ ) of Power Switch …………… 19

To ON ……………………………………………………… 19

To OFF ……………………………………………………… 19

Connecting with PC …………………………… 19

Operation procedure ……………………………… 19

Measurement

Measuring Flow ………………………………… 22

Main Specification ……………………………… 38

Starting Up and Ending System …………… 23

Starting up ……………………………………………23

Connection recognition error …………………………… 23

Ending ………………………………………………… 23

Setting Measurement Distance …………… 24

Setting measurement distance ………………… 24

5

Page 8

Standard Accessory

Attached lens cap, mount cap, lens hood and hood cap corresponding with lens type for each model.

Lens Cap

l Place on lens for protection in not using this

instrument.

For standard or telephoto lens

For wide lens

For standard or

telephoto lens

Mount Cap

l Place on lens mount for protection when lens is

removed from body.

For standard or telephoto lens

For wide lens

For standard or

telephoto lens

Lens Hood

For standard or telephoto lens CA-A68

For wide lens CA-A69

For macro measurement CA-A70

For wide lens

For wide lens

Hood Cap

l Place on lens for protection in not using this

instrument.

For standard lens, telephoto lens, or macro measurement

For wide lens CA-A75

Mount Cover CA-A61

l Place for protection of lens mount of body when lens

is removed.

AC Adapter AC-A22

l Supplies power from AC outlet.

Input: 100 V-240 V

50 Hz-60 Hz

Output: 12 V 4.0 A

1.2 A

~

CA-A71

CA-A68 CA-A69 CA-A70

CA-A71 CA-A75

6

Page 9

Data Management Software CA-S20w

l For data management of this instrument from PC.

USB Cable (3 m) IF-A18

l Used for communication between this instrument

and PC.

Calibration Data DVD

Optional Accessory

Soft Case CA-A60

l Used to keep this instrument and accessories or

carry them with hand. Never use for transfer.

Tripod CS-A3

Pan Head CS-A4

7

Page 10

System Configuration

Wide lens CA-A73 Hood cap

(For wide)

CA-A75

Lens hood

(For wide)

CA-A69

Standard lens CA-A72

Hood cap

(For standard/telephoto, macro)

CA-A71

Lens hood

(For standard/

telephoto)

CA-A68

Telephoto lens CA-A74

Hood cap

(For standard/telephoto, macro)

CA-A71

Lens hood

(For standard/

telephoto)

CA-A68

Lens hood

(For macro)

CA-A70

Mount cover

CA-A61

Soft case

CA-A60

Tripod

CS-A3

Pan head

CS-A4

AC adapter

AC-A22

USB cable

IF-A18

CA-2000

Data management software

CA-S20w

PC

(on the market)

High

magnification

macro ring

Macro 2

Low

magnification

macro ring

Macro 1

Standard lens CA-A72 Hood cap

(For standard/telephoto, macro)

CA-A71

Lens hood

(For standard/

telephoto)

CA-A68

Mount cover

CA-A61

Soft case

CA-A60

Tripod

CS-A3

Pan head

CS-A4

AC adapter

AC-A22

USB cable

IF-A18

CA-2000

Data management software

CA-S20w

PC

(on the market)

Wide lens CA-A73

Hood cap (For wide)

CA-A75

Lens hood

(For wide)

CA-A69

Mount cover

CA-A61

Soft case

CA-A60

Tripod

CS-A3

Pan head

CS-A4

AC adapter

AC-A22

USB cable

IF-A18

CA-2000

Data management software

CA-S20w

PC

(on the market)

Telephoto lens CA-A74

Hood cap

(For standard/telephoto, macro)

CA-A71

Lens hood

(For standard/

telephoto)

CA-A68

Lens hood

(For macro)

CA-A70

High

magnification

macro ring

Macro 2

Low

magnification

macro ring

Macro 1

Mount cover

CA-A61

Soft case

CA-A60

Tripod

CS-A3

Pan head

CS-A4

AC adapter

AC-A22

USB cable

IF-A18

CA-2000

Data management software

CA-S20w

PC

(on the market)

CA-2000A (With all lenses)

CA-2000S (With standard lens)

CA-2000W (With wide lens)

CA-2000T (With telephoto lens)

8

Page 11

CA-2000SW (With standard and wide lenses)

CA-2000

Wide lens CA-A73

Hood cap (For wide)

CA-A75

Lens hood

(For wide)

CA-A69

Standard lens CA-A72

Hood cap

(For standard/telephoto, macro)

CA-A71

Lens hood

(For standard/

telephoto)

CA-A68

Mount cover

CA-A61

Soft case

CA-A60

Tripod

CS-A3

Pan head

CS-A4

AC adapter

AC-A22

USB cable

IF-A18

CA-200

Data management software

CA-S20w

PC

(on the market)

Wide lens CA-A73

Hood cap (For wide)

CA-A75

Lens hood

(For wide)

CA-A69

Telephoto lens CA-A74

Hood cap

(For standard/telephoto, macro)

CA-A71

Lens hood

(For standard/

telephoto)

CA-A68

Lens hood

(For macro)

CA-A70

Mount cover

CA-A61

Soft case

CA-A60

Tripod

CS-A3

Pan head

CS-A4

AC adapter

AC-A22

USB cable

IF-A18

CA-2000

Data management software

CA-S20w

PC

(on the market)

High

magnification

macro ring

Macro 2

Low

magnification

macro ring

Macro 1

Standard lens CA-A72

Hood cap

(For standard/telephoto, macro)

CA-A71

Lens hood

(For standard/

telephoto)

CA-A68

Telephoto lens CA-A74

Hood cap

(For standard/telephoto, macro)

CA-A71

Lens hood

(For standard/

telephoto)

CA-A68

Lens hood

(For macro)

CA-A70

Mount cover

CA-A61

Soft case

CA-A60

Tripod

CS-A3

Pan head

CS-A4

AC adapter

AC-A22

USB cable

IF-A18

CA-2000

Data management software

CA-S20w

PC

(on the market)

High

magnification

macro ring

Macro 2

Low

magnification

macro ring

Macro 1

CA-2000ST (With standard and telephoto lenses)

CA-2000WT (With wide and telephoto lenses)

Standard accessory

Optional accessor y

You can additionally purchase each lens regardless of your model.

9

Page 12

Names and Functions of Parts

Handle

<Body>

Lens attaching portion

Lens mount

Air duct

USB connector

AC adapter input terminal

Screw hole for xing (ISO screw)

Screw hole for xing (Tripod screw)

Power switch

Power switch Switches this instrument on/off. [|] side for ON; [ ○] side for OFF. Green LED

lights up while switched on. ……………………………………………… (p.19)

AC adapter input terminal

To which accessory AC adapter is connected. ………………………… (p.18)

USB connector To which USB cable is connected when used with PC. ……………… (p.19)

Air duct Air duct to air-cool interior. Do not cover here. Air-cooling fan built in this

instrument operates while switched on.

Lens mount To install lens on.

Lens attaching portion To which lens hood is attached.

Screw hole for fixing

Used to set this instrument on tripod or jig.

10

Page 13

<Lens>

Focus ring

Distance indicator

Lens hood

Lens

Body and lens arranged in a pair are calibrated. Pair those with identical numbers.

CA-2000A, CA-2000S, CA-2000SW, CA-2000ST

Standard lens

CA-2000A, CA-2000W, CA-2000SW, CA-2000WT

Aperture ring

Wide lens

CA-2000A, CA-2000T, CA-2000ST, CA-2000WT

(Low magnication) (High magnication)

Macro ringTelephoto lens

Lens hood Protects lens. Remove this once when replacing lens.

Focus ring Adjusts focus.

Aperture ring Being fixed, this should not be used. Do not operate by removing or revolving

screw for this would deteriorate the performance.

Macro ring Placed between telephoto lens and body when utilizing telephoto lens for

macro. You cannot place 2 types of macro ring simultaneously.

11

Page 14

12

Page 15

Installing

13

Page 16

Installing

Goods/Environment to Prepare on Customer's Side

Get prepared for below goods/environment before using this instrument.

Controlling PC

OS :

CPU : Pentium® 4 2.8 GHz or higher

Memory : 1024 MB or larger

Hard Disk : Needs free space of 80 MB at least on system drive (where OS is

In addition, each lens needs the following free spaces for installing

For standard lens: approx. 540 MB

For wide lens: approx. 470 MB

For telephoto lens: approx. 1.3 GB

Also, to save measurement data on hard disk, additional free space

Further empty space is required for temporary working area. For more

Display : Can display 1280 x 1024 dots / 65536 colors (High Color: 16 bits) at

Others : CD-ROM drive, 1 unit (required for installation)

DVD-ROM drive, 1 unit (required for installing calibration data)

(Instead of the above two drives, 1 unit of combo drive which can read

USB por t (2.0 compatible) (Type A connector specification), 1 unit

Excel 2003 (required for continuous measurement with the automation

Windows® XP Professional Service Pack 2

Windows® XP Professional x64 Edition

Windows® Vista Business 32-bit (x86)

Windows® Vista Business 64-bit (x64)

(English, Japanese and Korean versions

For Windows® XP Professional x64 Edition, English and Japanese versions only)

installed)

calibration data.

is required. (approx. 110MB for 10 measurement data in resolution

980x980)

details, see the instruction manual for data management software CA-

S20w.

least

both CD-R and DVD-R media is available.)

(required for connecting the measurement instrument)

function)

In addition, following items are useful.

Mounting stage

Table on which this instrument is installed. Below are recommended conditions.

l Can change measurement distance according to measurement object.

l Painted with black to prevent the entrance of light diffusely reflecting.

Blackout curtain (quickly prepared darkroom) / Dark room

Needed to block this instrument and measurement object from outside light.

Get prepared for blackout curtain for quickly prepared dark room or dark room.

14

Page 17

Installing

ISO screw hole

Optical axis

Tripod screw hole

UNC 1/4 Depth 6.5

95.2

186.2

68.2

125.2

Warning for safety

Do not use this instrument in places where flammable or combustible gases (gasoline etc.) are present.

Doing so may cause fire.

Caution for safety

Do not place this instrument on unstable or sloping surface which may drop or overturn it. Dropping or overturning

may injure someone around. Take care not to drop this instrument when carrying.

To set this instrument on tripod or jig, use screw hole for fixing at the bottom of this instrument.

2 type holes are available as follows;

Tripod screw hole: To set on tripod. Screw depth is 6.5 mm.

ISO screw hole: To set on jig. User ISO 5 mm screw and screw depth is 6.5 mm.

Installing

For further detail, see p.34.

*When standard lens and hood are placed

15

Page 18

Installing

Placing Lens

Below shows lens type accompanying respective CA-2000 series. Lens hood is ser ved as standard

corresponding to lens type.

CA-2000A Standard, wide and telephoto lenses, and 2 macro rings

CA-2000S Standard lens

CA-2000W Wide lens

CA-2000T Telephoto lens and 2 macro rings

CA-2000SW Standard and wide lenses

CA-2000ST Standard and telephoto lenses, and 2 macro rings

CA-2000WT Wide and telephoto lenses, and 2 macro rings

Operation procedure

Remove mount cover from lens

1.

mount on body.

Mount cover

Place lens on lens mount before

2.

rotating clockwise.

Be sure to insert lens straightly. If forcibly put

l

aslant, lens mount could be broken.

Revolve lens until fixed.

l

For CA-2000A, CA-2000T, CA-2000ST, or CA-2000WT

In using a macro ring for either of CA-2000A,

CA-2000T, CA-2000ST, or CA-2000WT,

sandwich it between lens and lens mount.

Align 2 pins of lens hood and 2 holes

3.

of body. Then, insert lens hood as if

it covers lens. Finally, rotate screw

portion of lens hood clockwise.

Sele ct appropriate l ens hood dep ending

l

on lens type. Inappropriate lens hood may

cause the lens head to be positioned back

from the lens hood, which leads to incorrect

measurement.

Hold the circumference of lens hood.

l

Rotate screw portion of lens hood until fixed.

l

Lens

Macro ring

Lens hood

Lens hood pin hole

16

Page 19

l Check whether body and lens have identical serial numbers.

警告:

カバーを開けないでください。

Serial number can be found on label of body and lens side respectively.

To pursue high-accuracy measurement, calibration was done on maker's

side for each unit before shipment combining with each accessory lens

for CA-2000 series. This means that attached calibration coefficient data

to each unit is valid exclusively for the packaged combination of unit and

lens.

l Set lens type to use in software CA-S20w.

(For detail, see the instruction manual for data management software CA-S20w.)

This enables the application of appropriate calibration coefficient data depending on usage condition

which would finally give correct measurement result.

Replacing lens

Follow reverse procedure to above to replace lens. First, remove lens hood and then lens.

Installing

17

Page 20

Installing

Connecting AC Adapter

Use accessory AC adapter for power source.

Warning

Always use the AC adapter and power cord supplied as a standard accessor y or optional (AC-A22), and

connect it to indoor AC outlet of rated voltage 100 V-240 V

either of these may result in damage to unit, fire or electric shock.

If this instrument is not used for a long time, disconnect AC adapter from AC outlet. Accumulated dirt or water

on prongs of AC adapter plug may cause fire and should be removed. Be sure to remove before use.

Do not forcibly pull any part on power cord when unplugging since this may cause fire or electric shock.

Gently disconnect by holding plug. Also, do not handle power plug with wet hands. Doing so may cause

electric shock.

Do not forcibly bend, twist or pull power cord. Also, do not place heavy object on power cord, or damage or

modify one. Any of these may cause fire or electric shock due to damage to power cord.

Do not disassemble or modify this instrument or AC adapter. Doing so may cause fire or electric shock.

Should this instrument or AC adapter be damaged or smoke or odd smell be generated, do not keep using

one without correction. Doing so may cause fire. Switch power off immediately, unplug AC adapter from

AC outlet in such case. If operated on battery, remove battery and contact the nearest KONICA MINOLTA

SENSING authorized service facility.

(Failure to adhere to the following points may result in death or serious injury.)

and frequency 50 Hz-60 Hz. Failure to follow

~

Caution

Use this instrument near AC outlet for easy plugging or unplugging in using AC adapter.

(Failure to adhere to following points may result in injur y or damage to instrument or other proper ty.)

Connection procedure

Be sure that power switch is OFF ([○]

1.

mark pressed).

Connect AC adapter plug to AC adapter

2.

input terminal of body.

Plug AC adapter to outlet (AC 100 V-240 V ~, 50 Hz-60 Hz).

3.

Insert AC adapter plug all the way seated in AC outlet.

l

18

Page 21

ON (|) / OFF ( ) of Power Switch

To ON

Press [|] side of power switch to

1.

ON.

To OFF

Press [○] side of power switch

2.

to OFF after completion of

measurement.

Installing

Connecting with PC

Before connecting CA-2000 body with PC, install software CA-S20w in PC. (For detail, see the instruction

manual for data management software CA-S20w.)

Use accessory USB cable (3 m) IF-A18 for this purpose.

No problem would occur if USB cable is plugged or unplugged while power is on, but instruction here

indicates the case when power is off.

Operation procedure

Switch power off.

1.

Connect USB cable to USB connector on body.

2.

Insert all the way to the end. Check whether

3.

the connection is secure.

Communication inter face of this instrument complies with

USB2.0.

Always hold plug portion of USB cable in unplugging. Never

hold cord portion to unplug.

Match the USB cable plug shape with the slot of either body or

PC before inserting.

Any USB port is usable on PC if it has multiple, but abnormal

operation could be detected on PC in case that it is used

together with other USB device than CA-2000.

19

Page 22

20

Page 23

Measurement

21

Page 24

Measuring Flow

1. Start up CA-2000 and PC. p.23

2. Attach lens corresponding to measurement target. p.16-17

Measurement

3. Start up software CA-S20w. p.24

4. Adjust CA-2000 position to measurement object. p.24-25

Ad j us t po si t i o n and dir e c t io n of C A - 2 0 0 0 t o

measurement object and focus while watching the

finder view on software CA-S20w.

Adjust shutter speed as needed if the finder view is

not good.

5. Set up measurement condition with software CA-S20w.

(For detail, see the instruction manual for data management software CA-S20w.)

l Lens

l Lens position (Distance) (p.25-27)

l Measuring range

l

Ex posure mode and light intensity adjustment

(Selection of shutter speed, signal amplification

circuit gain, and ND filter)

Light intensity can be adjusted with 3 factors; shutter

speed, signal amplification circuit gain, and ND filter for

this series. Adjustment of these is indispensable to gain

appropriate light intensity for measurement.

Shutter speed, signal amplification circuit gain, and ND

filter are automatically selected appropriately through

preliminary measurement at auto exposure mode.

No preliminary measurement is done at manual

ex posu re m ode. In thi s cas e, you are require d to

determine before meas ureme nt the combi natio n of

shutter speed, signal amplification circuit gain, and ND

filter which is shown on software CA-S20w display.

l Sync mode

In case of measuring object repeatedly and intermittently

emitting light like CRT or PDP, luminance and chroma

distributions can be measured by setting light emission

period.

6. Start measurement.

(For details on how to measure, see the instruction manual for data management software CA-S20w.)

22

Page 25

Starting Up and Ending System

Starting up

Switch power on as instructed. If not, erroneous operation could occur.

Switch power on for body. (Press [|] side.)

1.

Motor sounds indicating controller inside machine starts initialization.

l

Fan inside body starts to run.

l

15-minute warm-up at least (to leave in this state after switching on.) is recommended for accurate

l

measurement.

Start up Windows by turning on controlling PC.

2.

Connect PC and CA-2000 with USB cable.

3.

PC recognizes that CA-2000 has been connected.

l

Select "CA-S20w" from Start → [Program].

4.

CA-S20w starts to run.

l

Measurement

Connection recognition error

Sometimes, PC fails to recognize its connection with CA-2000 if CA-2000 was switched on after connected with

USB cable to PC which had already started up. Such condition could not allow control of CA-2000 from software.

Start up this instrument according to the procedure as above again.

l In case that PC has already started, unplug USB cable once and then connect after switching CA-2000

on.

l Switch CA-2000 on before PC if USB cable cannot be unplugged for some reason concerning setting.

Should connection error occur, unplug USB cable once and connect again. Then, both can star t up

normally.

Ending

Select "End CA-S20w" from "File" of menu bar.

1.

CA-S20w ends.

l

You can finish through standard application operation of OS.

l

Finish Windows and switch off PC.

2.

Switch off body. (Press [ ] side.)

3.

23

Page 26

Setting Measurement Distance

Setting measurement distance

Optical lens features in varying light intensity and illuminance distribution of imaging surface if focus ring

is rotated. Therefore, lens calibration has been done lens by lens according to the distance from lens to

measurement object (distance indicator of focus ring). Each has its own calibration coefficient.

Measurement

Correct calibration coefficient can be applied by selecting what kind of lens is used for which focusing

distance, in software CA-S20w.

<Preparation>

Start up system.

1.

Start up software CA-S20w.

2.

For detail, see the instruction manual for data management software CA-S20w.

l

Open Measure dialog of software CA-S20w.

3.

For detail, see the instruction manual for data management software CA-S20w.

l

Set measurement object on measuring stand.

4.

Set CA-2000 on appropriate position referring to below table.

5.

CA-2000A, CA-2000S, CA-2000SW, CA-2000ST

Standard lens

Size of measurement object

(One-side length of square)

98 mm approx.

210 mm approx.

440 mm approx. 1000 mm

890 mm approx.

CA-2000A, CA-2000W, CA-2000SW, CA-2000WT

Wide lens

Size of measurement object

(One-side length of square)

145 mm approx.

410 mm approx.

Measurement distance

250 mm

500 mm

2000 mm

Measurement distance

200 mm

500 mm

850 mm approx. 1000 mm

1770 mm approx.

2000 mm

24

Page 27

CA-2000A, CA-2000T, CA-2000ST, CA-2000WT

Telephoto lens With low-magnification macro ring (Macro 1)

Size of measurement object

(One-side length of square)

115 mm approx. 900 mm approx. 57 mm approx. 500 mm

275 mm approx. 2000 mm approx. With high-magnification macro ring (Macro 2)

Measurement distance

Size of measurement object

(One-side length of square)

Measurement distance

Measurement

420 mm approx. 3000 mm approx.

Size of measurement object

(One-side length of square)

27 mm approx. 300 mm

Measurement distance

<Shutter speed adjustment>

Select shutter speed to obtain the brightness under which focusing is easy

6.

while watching the finder view of software CA-S20w.

For detail, see the instruction manual for data management software CA-S20w.

l

<Focusing>

Rotate focus ring of lens for adjustment while watching the finder view of

7.

software CA-S20w.

If you use telephoto lens with a macro ring for focusing, fix the focus-ring position of telephoto lens to infinity

l

and adjust the distance between CA-2000 and the measurement object while checking the finder view.

Stripe-shape noise (moire) may be sometimes generated in the finder view. In this case, you can

l

change to the distance which hardly causes the moire stripe or obscure the focus to decrease

influence of the moire stripe.

Select the closest reading distance of focus ring among choices

8.

of "Lense Position" of Measure dialog of software.

Below shows reference position to read focus ring distance indicator.

l

CA-2000A, CA-2000S, CA-2000SW, CA-2000ST

Standard lens

Distance With distance label On indicator

0.25 m

0.3 m

0.5 m

1 m

○

○

○

○

○

Decimal point indicator position (See Figure 1-1.)

Intermediate indicator between previous and next

reference positions (Center) (See Figure 1-2.)

Decimal point indicator position

Intermediate indicator between previous and next

reference positions (Center)

Decimal point indicator position

Intermediate indicator between previous and next

reference positions (Center) (See Figure 1-3.)

Center of "1"

Intermediate indicator between previous and next

reference positions (Center)

End of focus-ring travel ([ ] side)

25

Page 28

CA-2000A, CA-2000S, CA-2000SW, CA-2000ST

Wide lens

Distance With distance label On indicator

0.2 m

Measurement

CA-2000A, CA-2000S, CA-2000SW, CA-2000ST

0.24 m

0.3 m

0.5 m

1 m

Distance With distance label On indicator

0.9 m

1 m

1.5 m

3 m

With low-magnification macro ring (Macro 1)

○

○

○

○

○

○

○

○

○

○

○

Wide lens

Decimal point indicator position (See Figure 2-1.)

Intermediate indicator between previous and next

reference positions (Center)

Intermediate indicator between previous and next reference

positions in 1:2 (short-distance side) (See Figure 2-2.)

Intermediate indicator between previous and next reference

positions in 2:1 (long-distance side) (See Figure 2-3.)

Intermediate indicator between previous and next

reference positions in 1:2 (short-distance side)

Intermediate indicator between previous and next

reference positions in 2:1 (long-distance side)

Intermediate indicator between previous and next

reference positions in 1:2 (short-distance side)

Intermediate indicator between previous and next

reference positions in 2:1 (long-distance side)

Indicator position (See Figure 3-1.)

Indicator position

Indicator position (See Figure 3-2.)

Indicator position

Indicator position

Indicator position

Center of "1"

Decimal point indicator position

Center of "3"

End of focus-ring travel ( [ ] side)

Distance With distance label Precise position on focus ring

○

With high-magnification macro ring (Macro 2)

Distance With distance label Precise position on focus ring

○

End of focus-ring travel ( [ ] side)

End of focus-ring travel ( [ ] side)

Caution

The 28 points listed above are the points for which the CA-2000 lenses have been calculated. Highest

measurement accuracy is assured only when measurements are taken at these listed conditions. When

measurements are taken at any distance other than the calibrated points listed above, use the calibration

coefficient for the calibration point closest to the measurement distance. However, the results in such case

may be less accurate than if measurements were taken at a calibration point distance.

26

Page 29

Example of reference position to read distance

0.30.5 0.24 0.21 0.30.5 0.24 0.21

0.30.25 0.30.25 0.5 1

10.9

1.510.9 1.51

How to read distance in case of standard lens or telephoto lens

The ring (focus ring) on which number values are written rotates in case of standard lens or telephoto lens.

If the "distance indicator" includes decimal point, "." is determined as reference position; and if it does not

include decimal point, the center of the number or [ ] is determined as reference position.

Standard lens

Measurement

Figure 1-1

Example when setting to "0.25"

Telephoto lens

Figure 2-1

Example when setting to "0.9"

Figure 1-2

Example when setting to "diverting

point between 0.25 and 0.3 in 1:1"

Set in reference of the 1/2

position between decimal

points of 0.25 and 0.3.

Figure 2-2

Example when setting to "diverting

point between 1 and 1.5 in 1:2"

Figure 1-3

Example when setting to "diverting

point between 0.5 and 1 in 1:1"

Set in reference of the 1/2

position between decimal point

of 0.5 and the center of 1.

Figure 2-3

Example when setting to "diverting

point between 1 and 1.5 in 2:1"

Set in reference of the 1/3

position between the center

of 1 and decimal point of 1.5.

Set in reference of the 2/3

position between the center

of 1 and decimal point of 1.5.

How to read distance in case of wide lens

The ring (focus ring) on which indicator position (the white circle in the figures below) is written rotates in case of wide lens.

Set the indicator position to the line of number value.

Wide lens

Figure 3-1

Example when setting to "0.2"

Figure 3-2

Example when setting to "0.3"

27

Page 30

Measurement

28

Page 31

Description

29

Page 32

Sync Measurement

-15.0%

-10.0%

-5.0%

0.0%

5.0%

10.0%

15.0%

1 2 3 4 5 6 7 8 9 10

Asynchronous

Synchronous

-0.025

-0.020

-0.015

-0.010

-0.005

0.000

0.005

0.010

0.015

0.020

0.025

1 2 3 4 5 6 7 8 9 10

-0.050

-0.040

-0.030

-0.020

-0.010

0.000

0.010

0.020

0.030

0.040

0.050

1 2 3 4 55 6 7 8 9 10

Asynchronous

Synchronous

Asynchronous

Synchronous

In case of measuring object repeatedly and intermittently emitting light like CRT or PDP, luminance and

chroma distributions can be measured steadily by setting light emission period.

Below shows an example of measurement result of CRT. Left is an image obtained light emission period

being ignored, and right with the most adequate exposure time matching light emission period. While striped

unevenness appears on the left due to the influence by CRT scanning, none of such phenomenon can be

seen on the right.

Description

Because light emission timing is different depending on the screen area for CRT, which emits light through

electron beam scanning, influence by intermittent light emission is found in the form of above shown

unevenness. On the other hand, no unevenness occurs like CRT when entire screen flashes simultaneously

like PDP, but measurement value varies with each measurement.

Below shows an example of measurement result of PDP. The graphs show both the synchronous and

asynchronous measurement results (the average value in 100 x 100 pixels of the center area) when the same

area was measured ten times in succession. While luminance and chromaticity are stable in synchronous

measurement, the values obtained by asynchronous measurement change remarkably.

Luminance Chromaticity

(Difference between the average value of ten (Difference between the average value of ten

times measurement and each measurement times measurement and each measurement value)

value is displayed in percentage)

x y

30

Page 33

Backlight Cancellation

To evaluate the evenness of optical part (optical waveguide for LCD, for example) which constitutes display,

evaluation object is put on some kind of light source like backlight.

However, this method gives negative impact for the light source itself generates unevenness.

You could evaluate fixing reference light source, but this does not realize objective evaluation of the

evenness of optical part. With backlight cancellation function of CA-2000, light source unevenness data

can be stored through previous measurement of light source or backlight to offset light source unevenness

element from the sum of measurement results of light source and optical part. Thus, objective measurement

result can be gained for optical part evenness without effect of light source unevenness.

User Calibration

Measurement error in luminance and chroma, or difference with the reference value controlled by the client

sometimes arise because of the gap between spectral sensitivity of this instrument and CIE1931 color-

matching function. In this case, you can use the user calibration function to calibrate measurement values.

CA-2000 applies roughly 2 types of calibration methods to calculate the calibration coefficient. One is

monotint calibration and the other RGB matrix one. You can use monotint calibration to perform the user

calibration relatively easily, because the calibration coefficient will be generated only by entering values of

luminance and chroma for one color (ex. white) before/after calibration. RGB matrix calibration is used to

calculate the calibration coefficient by entering values of luminance and chroma for two or more colors (ex.

RGB or RGBW) before/after calibration. This method has an advantage to obtain the high calibration result in

the wide rage of chroma.

CA-2000 uses the calibration coefficient calculated by either of monotint or RGB matrix calibration method to

make a calculation uniformly on entire screen, which enables to calibrate the measurement values for entire

screen.

Description

31

Page 34

LvTΔuv

v

u

Blackbody locus

Correlated temperature T

Correlated temperature T and ∆uv

13000K

5000K

3000K

2300

K

∆uv

0.35

0.30

0.20

0.25

0.30

Following factors can be acquired as measurement value with LVTΔuv as color space of this instrument.

LV : Luminance

T : Correlated color temperature

Δuv : Color difference from blackbody locus

While LV stands for luminance, T and Δuv for color in LVTΔuv.

<Relation between correlated color temperature T and color difference from blackbody locus Δuv>

Color temperature refers to the temperature of blackbody (perfect radiator) which has equal chromaticity

coordinates to certain light. However, color temperature only represents colors on blackbody locus.

Correlated color temperature, slightly wider interpretation of color temperature, is very useful to eliminate

such problem. Here, correlated color temperature covers those which are slightly outside the range of that of

Description

blackbody locus.

If a cer tain color positions on isotemperature line, the intersection point of isotemperature line and

blackbody locus is indicated as correlated color temperature for the color. Isotemperature line means line on

chromaticity coordinates which is a set of colors visually close to color temperature on blackbody locus.

However, since all colors on an isotemperature line are represented with equal correlated color temperature,

it is not possible to describe color only with correlated color temperature. To solve that, Δuv, deviation

of correlated color temperature T from blackbody locus, is to apply for that purpose. If Δuv exists above

blackbody locus, it is represented with "+", and below, with "-".

32

Page 35

Dominant Wavelength and Excitation Purity

Dominant wavelength in chromaticity diagram

y

0.8

0.6

0.4

0.2

0

0.2 0.4 0.6

x

550 nm

600 nm

780 nm

500 nm

380 nm

S

S

c

C

C'

S'

N

V

Spectrum locus

White point

R

Purple boundary

While curve VScSR indicates spectrum locus, point N white point (chromaticity point on complete diffusion

radiation sur face) in below chromaticity diagram (x, y). Spectrum color indicates the color of which

chromaticity point exists in the area surrounded by spectrum locus, lines VN and NR, and non-spectrum

color the color inside triangle NVR comprising purple boundary VR and white point N.

<Dominant wavelength and excitation purity of spectrum color>

Dominant wavelength indicates wavelength corresponding to S, intersection point of extension of NC and

spectrum locus (curve VScSR), if chromaticity point C is gained through measurement. Dominant wavelength

is represented with a symbol

represented with a symbol pe.

<Complementary wavelength and excitation purity of non-spectrum color>

λ

d. The ratio of line NC length to line NS is called excitation purity and

When chormacity point C' is gained through measurement, the extension of NC' to C' direction does not

cross with spectrum locus, but with purple boundary.

In this case, wavelength corresponding to Sc, intersection point of extension of NC' to N direction and

spectrum locus, is referred to as complementary wavelength which is symbolized with λc. The ratio of line

NC' length to NS' is called excitation purity and represented with a symbol pe'.

Excitation purities of spectrum and non-spectrum colors are derived with the following formula when (xn, yn)

is chromaticity coordinates of point N, (x, y) of point C, (x λ, y λ) of point S, (x' , y') of point C', and (x λ', y λ')

of point S'.

x - x

pe = =

n y - y n

x λ - xn yλ - y n

x’ - xn y’ - y n

pe’ = =

x λ’ - xn yλ’ - y n

Description

33

Page 36

Outer Dimensions

Description

34

Page 37

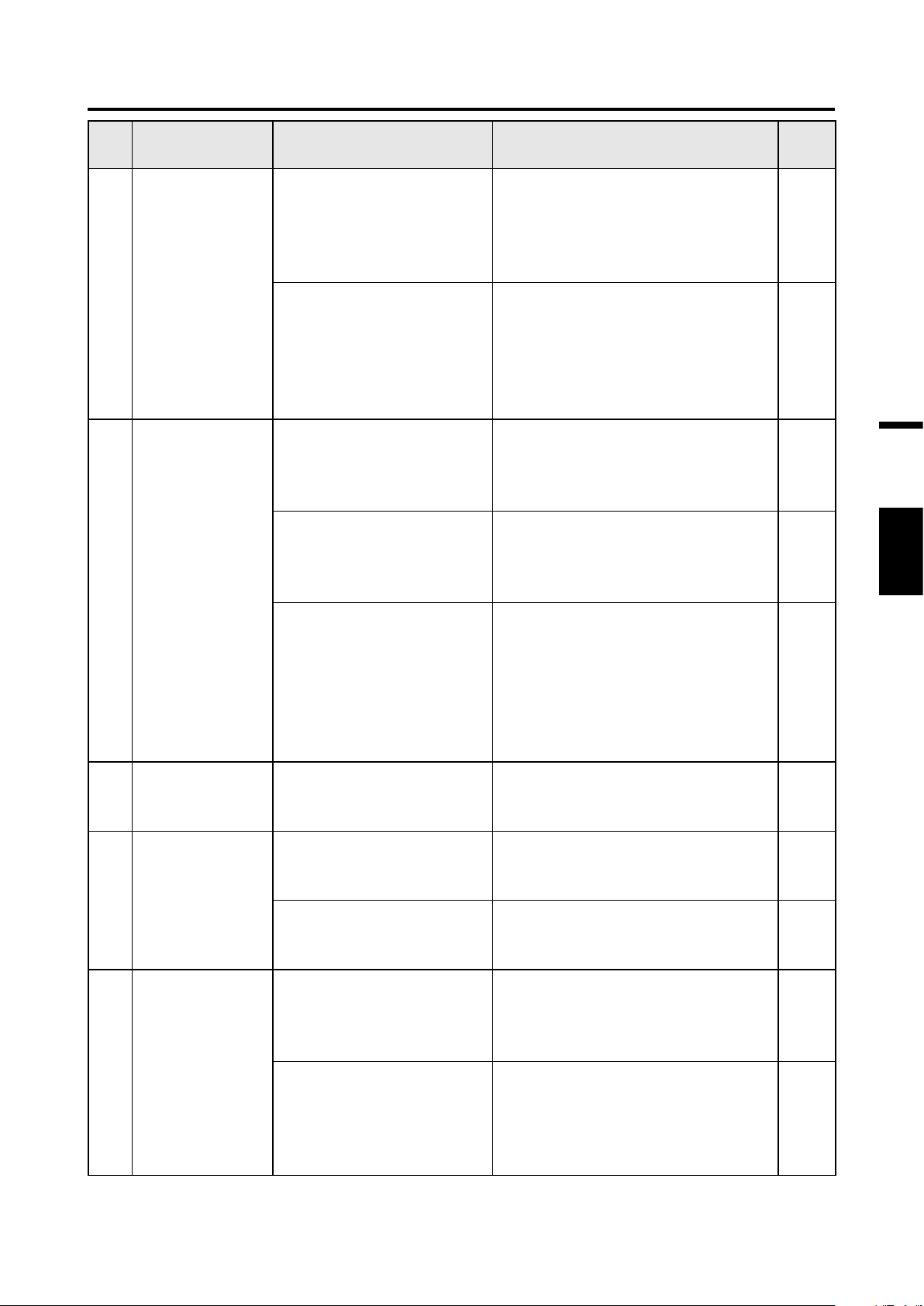

Error Check

Should error be found in this instrument, try corrective actions shown in the following table. If this does not

help, this instrument has possibly been broken. Please contact the nearest KONICA MINOLTA SENSING

authorized service facility with indicated error number.

Error

No.

1

2

3

Symptom Item to Check Corrective Action

Power does not turn

on.

Does not normally

start up.

Time for machine

initialization after

switched on varies.

Fan does not run

after switched on.

Has AC adapter been plugged in

outlet?

Has AC adapter been connected

with body?

Have you connected correct AC

adapter?

Is the AC power within rating? Be sure the AC power is within ±10% of the

It could vary depending on the

machine position when switched

on. It should not be regarded as

failure if it takes only a few

seconds.

Can hear sound if fan normally

rotates.

Connect AC adapter.

Connect AC adapter.

Use our specified standard accessory AC

adapter and power cord or optionally

offered AC adapter AC-A22.

nominal voltage.

If long time is needed, switch power off and

contact the nearest KONICA MINOLTA

SENSING authorized service facility.

If not, switch power off and contact the

nearest KONICA MINOLTA SENSING

authorized service facility.

Page to

Refer

18

18

6

-

-

-

Description

4

PC cannot

communicate

with CA-2000.

Check whether PC correctly

recognizes CA-2000.

Check whether device driver

normally operates with device

driver manager.

Has USB cable been connected

securely?

Check the standard for USB. Cannot use with those supporting except for

PC could not properly recognize this

instrument depending on PC type or how

CA-2000 was started up. Restart PC,

software, and CA-2000 according to each

instruction.

If not, uninstall software once for reinstallation.

See the instruction manual for CA-S20w.

Connect this instrument and PC securely.

USB2.0. Use PC with which USB2.0 is usable.

23

-

19

19

35

Page 38

Error

No.

5

Description

6

Symptom Item to Check Corrective Action

Takes much time

for measurement.

Abnormal data

indicated.

Check multiplication number. The higher set number is, the better

repeatability is, but the longer measurement it

takes. To cut measurement time rather than

better repeatability, set fewer number for

multiplication.

See the instruction manual for CA-S20w.

Is the object of low luminance? If so, shutter speed becomes slow needing

longer measurement time. This should not be

regarded as failure, but just accumulates

weak light for measurement with appropriate

light intensity.

If low luminance object is measured with

higher multiplication number, it takes

consumable time for measurement. Set lower

number for shorter measurement.

See the instruction manual for CA-S20w.

Has any foreign object adhered

to lens or lens mount filter?

Wipe these objects off with soft and clean

cloth.

Page to

Refer

-

-

3

Have you shut off outside light? Shut light off lest measurement area be

exposed to outside light.

Hasn't fluor lump reflected

on measurement object?

Is there any unexpected light

emission?

Haven't you used lens other than

supplied?

Haven't you used lens with

different serial number.

Have you selected correct lens

type?

Has the lens focus position been

correct?

Is the light exposure adequate? In case of manual exposure mode,

Shut light off to prevent light reflection on

measurement object. Just a little light

emission, leakage, or reflection severely

affects low luminance surface measurement

especially.

Look at measurement object closely. Just a

little light emission, leakage, or reflection

severely affects low luminance surface

measurement especially.

Use those supplied.

Use the lens of which serial number is

identical to instrument.

Select the type of using lens.

See the instruction manual for CA-S20w.

Set correct focus position information in

software for the usage condition.

See the instruction manual for CA-S20w.

select appropriate exposure.

-

-

-

6

17

24-25

25-27

-

Check for luminance unit, user

calibration and backlight

cancellation.

36

Set adequately depending on the purpose.

See the instruction manual for CA-S20w.

-

Page 39

Error

No.

7

8

9

10

11

Symptom Item to Check Corrective Action

Pattern-like

unevenness

appears.

Measurement values

vary quite largely.

Image looks rough.

User calibration has

not been functioned

as expected.

Backlight

cancellation does

not work correctly.

Small pixel number

for data. (Fewer than

980 x 980 pixels.)

Check whether stripe-like

unevenness fluctuates by slightly

changing the distance between

CA-2000 and measurement

object.

Is it round striped pattern?

Check whether pattern position

does not shift even after slight

migration of field angle of CA-2000

and measurement object up to

down or right to left.

Has the light exposure been

adequate?

Check whether the luminance

has been low.

Check whether the multiplication

has been set low.

Check whether the coefficient has

been correct.

Check whether the backlight data

has been correct.

Check whether the backlight

position has not been shifted.

Check data process range. Pixel

number tends to be smaller if set

up to process specified range data

of all measurement area.

Check resolution condition.

Resolution can be selected among

3 types; 980x980, 490x490

and 196x196 pixels. 490x490

pixels are set at shipment.

If so, Moire fringes could have generated. Adjust

the measurement distance of object to reduce

such phenomenon.

If not, it should not be regarded as failure, but

just unique pattern of this instrument. CA-2000

shows just slight pattern-like unevenness

originally. Apply lower display tone.

See the instruction manual for CA-S20w.

If light exposure is not enough under manual

exposure, fluctuation of measurement values

tends to be large. Set light intensity as large

as possible, but so as not to overexpose.

If it is close to the limit, noise from obtained

image signal becomes larger which generates

uneven values or rough image, but this is not

failure.

The lower multiplication is, the shorter

measurement time is, but values tend to be more

variant and image rougher. To reduce such

variance rather than to pursue shorter

measurement, set multiplication as high as

possible.

See the instruction manual for CA-S20w.

Select appropriate method and coefficient

depending on purpose.

See the instruction manual for CA-S20w.

Apply backlight cancellation data

corresponding to the backlight to use.

See the instruction manual for CA-S20w.

If the position and size (distance) has been

changed in measurement screen, take

backlight data again.

Set measurement range properly according

to purpose and condition.

See the instruction manual for CA-S20w.

Set the resolution properly according

to purpose and condition.

See the instruction manual for CA-S20w.

Page to

Refer

-

-

-

-

-

-

-

-

-

-

Description

37

Page 40

Main Specification

Model CA-2000S CA-2000W CA-2000T

Light receptor

Lens

Measurement points 980×980 (Available to select 490x490 or 196x196 by using Data Management Software CA-S20w.)

Color indication modes XYZ, Lvxy, Lvu’v’, T∆uv, Dominant wavelength, Excitation purity, Lv contrast

Display modes

CCD image sensor (monochrome); 2/3-inch; Effective number of pixels: 1,000 x 1,000 pixels;

Equipped with XYZ filter (closely matches CIE 1931 color-matching function) and ND filter

Interchangeable

Standard, wide, and telephoto lenses; low-magnification and high-magnification macro rings

(for use with telephoto lens)

Pseudo color, RGB image, 3D graph, Chromaticity diagram, Multi point display, Cross section,

Nonuniformity highlighting, Histogram

Measurement sizes (length

per side of square)*1

Description

Measurement size for typical

measurement distances

Measurement luminance

range (including ND filter use)

Measurement time (*2)

Luminance ±3 % ±3 % ±3 % ±3 % ±3 %

Accuracy (*3)

Repeatability

(*4)

Inter-point

error (*5)

Chromaticity ±0.005 ±0.005 ±0.005 ±0.005 ±0.005

Luminance 0.5 % 0.5 % 0.5 % 0.5 % 0.5 %

Chromaticity 0.001 0.001 0.001 0.001 0.001

Luminance (*6) ±2 % ±2 % ±2 % ±2 % ±2 %

Chromaticity (*6)

Luminance (*7) ±3 % ±3 % ±3 % ±3 % ±3 %

Standard lens Wide lens Telephoto lens

Approx. 98 mm or more

(depending on the distance)

98 mm/250 mm Approx. 145 mm/200 mm Approx. 115 mm/900 mm Approx.

210 mm/500 mm Approx. 410 mm/500 mm Approx.

440 mm/1,000 mm Approx. 850 mm/1,000 mm Approx.

890 mm/2,000 mm Approx.

0.1-100,000 cd/m

Single : Approx. 5 sec. or more; 4-time integration: Approx. 6 sec. or more; 16-time integration:

Approx. 10 sec. or more; 64-time integration : Approx. 28 sec. or more;

256-time integration : Approx. 98 sec. or more

Temperature/humidity characteristics (within the operating temperature/humidity range)

Luminance: ±2% of change compared to reference temperature and relative humidity of 23°C and 40%

Chromaticity: ±0.004 of change compared to reference temperature and relative humidity of 23°C and 40%

±0.002 ±0.002 ±0.002 ±0.002 ±0.002

Approx. 145 mm or more

(depending on the distance)

1,770 mm/2,000 mm Approx.

2

0.1-100,000 cd/m20.5-100,000 cd/m20.5-100,000 cd/m21-100,000 cd/m

Approx. 115 mm or more

(depending on the distance)

275 mm/2,000 mm Approx.

420 mm/3,000 mm Approx.

With low-magnification

macro ring

Approx. 57 mm

(Fixed)

57 mm/500 mm Approx.

(Fixed)

With high-magnification

macro ring

Approx. 27 mm

(Fixed)

27 mm/300 mm Approx.

(Fixed)

2

Chromaticity (*7)

Other functions

Interface USB 2.0

Operating temperature

and humidity range (*8)

Storage temperature and

humidity range (*8)

Body only 160 (W) × 164 (H) × 199 (D) mm (Height including handle: 211 mm)

Size

Weight 3.5 Kg approx. (when standard lens and hood are attached)

Power source Exclusive AC adapter (100 - 240 V~, 1.2 A, 50- 60 Hz)

Standard

accessories

Optional accessories Soft Case CA-A60, Tripod CS-A3, Pan Head CS-A4, Calibration certificate

When lens and

hood are attached

Lens Hood CA-A68 CA-A69 CA-A68 CA-A70

Hood Cap CA-A71 CA-A75 CA-A71

Calibration data DVD

Other

±0.003 ±0.003 ±0.003 ±0.003 ±0.003

Interval measurement, Measurement sync (Synchronization frequency selectable), Integration

function, Enhanced nonuniformity display, Conversion of enhanced nonuniformity image into

numerical values (statistical values, etc.)

10-30°C, Relative humidity 70% or less/No condensation

0-30°C, Relative humidity 70% or less/No condensation

30-30°C, Relative humidity 55% or less/No condensation

224 (D) mm 219 (D) mm 224 (D) mm 230 (D) mm 237 (D) mm

Included with each lens.

Mount Cover CA-A61, AC Adapter AC-A22, AC cable, USB Cable IF-A18, Data Management Software CA-S20w

38

Page 41

*1: Error in angle of view: 7%

*2: Measurement time differs depending on brightness of measurement object, PC performance, and data processing contents. The

specifications above were obtained under Konica Minolta's measurement conditions shown below:

PC CPU : Pentium 4, 2.8GHz

Data processing : Pseudocolor display of luminance data

Resolution : 490 x 490

Shutter speed : Y measurement: 1/64 sec., XZ measurement: 1/32 sec.

Measurement

subject brightness : Standard/wide lens: Approx. 80 cd/m2, Telephoto lens: Approx. 300 cd/m

2

Low-magnification macro ring and telephoto lens: Approx. 400 cd/m2, High-magnification macro ring and

telephoto lens: Approx. 600 cd/m

2

* The measurement time becomes longer when the object is dark. The longest measurement time is approx. 10 seconds with

1-time integration, approx. 27 seconds with 4-time integration, approx. 95 seconds with 16-time integration, approx. 6 minutes

and 8 seconds with 64-time integration and approx. 24 minutes and 19 seconds with 256 -time integration

*3: The specifications above were obtained under Konica Minolta's measurement conditions shown below:

Measurement

subject brightness : Standard/wide lens: Approx. 35 cd/m

2

, Telephoto lens: Approx. 140 cd/m

2

Low-magnification macro ring and telephoto lens: Approx. 250 cd/m2, High-magnification macro ring and

telephoto lens: Approx. 250 cd/m

2

Distance : Minimum distance of each lens

Evaluation : Based on the average obtained within 10% range at the center of the screen

Temperature : 23°C±2°C

Relative humidity : 40%±10%

Measuring light : White, reference light source

Integration : 64 times (Normal mode)

Description

*4: The specifications above were obtained under Konica Minolta's measurement conditions shown below:

Resolution : 196 x 196

Shutter speed : Y measurement: 1/64 sec., XZ measurement: 1/32 sec.

Gain : Normal (x1)

Light intensity level : Midpoint of appropriate light intensity range

Evaluation :Basedonthemaximumrepeatability(2σ)ofallpixels

Temperature : 23°C±2°C

Relative humidity : 40%±10%

Measuring subject : White, reference light source

Integration : 64 times (Normal mode)

*5: The specifications above were obtained under Konica Minolta's measurement conditions shown below:

Measurement

subject brightness : Standard/wide lens: Approx. 40 cd/m2, Telephoto lens: Approx. 160 cd/m

2

Low-magnification macro ring and telephoto lens: Approx. 200 cd/m2, High-magnification macro ring and

telephoto lens: Approx. 350 cd/m

2

Distance : Calibration distance of each lens

Resolution : 196 x 196

Evaluation (*6) : Based on the maximum/minimum values obtained in a square at the center of the screen measuring 60% of

the height and width of the entire screen

(*7) : Based on the maximum/minimum values obtained in the entire screen

Temperature : 23°C±2°C

Relative humidity : 40%±10%

Measurement subject

: White, reference light source

Integration : 64 times (Normal mode)

*8: Even if the instrument is stored within the specified usage (or storage) temperature humidity range, the displayed value may

change depending on long-period usage or storage conditions.

σIfyouhaveanyquestionsaboutspecifications,pleasecontactyourKonicaMinoltarepresentative.

σThespecificationsgivenherearesubjecttochangewithoutpriornotice.

39

Page 42

©

2005 KONICA MINOLTA SENSING, INC.

AHJDPX9222-1735-11

Loading...

Loading...