Page 1

C-101

SERVICE MANUAL

Page 2

CONTENTS

GENERAL, MECHANICAL/ELECTRICAL

1. SPECIFICATIO NS .............. ........... ................ ............... ............... ............... ..... M-1

2. PARTS IDENTIFICATION ...............................................................................M-1

3. CROSS-SECTIONAL VIEW ............................................................................M-2

4. DRIVE SYSTEM ............. .... .... .... ... ................ ... .... ................ ... ................ ... .....M-3

5. ELECTRICAL COMPONENT LAYOUT ...........................................................M-4

6. MECHANICAL DESCRIPTIONS .....................................................................M-5

6-1. Mechanical Operation and Control of Paper Plate Lifting ........................M-5

6-2. Mechanical Operatio n and Cont rol of Paper Take-Up, Separation,

and Transport ..........................................................................................M-7

6-3. Paper Empty Detecting Mechanism ........................................................M-9

6-4. Paper Dehumidifier Heater ......................................................................M-10

DIS/REASSEMBLY, ADJUSTMENT

1. DISASSEMBLY ...............................................................................................D-1

2. PAPER WIDTH CONVERSION .......................................................................D-3

3. IMAGE POSITION ADJUSTMENT ..................................................................D-5

MISFEED DETECTION&

MALFUNCTION DETECTION

1. PAPER MISFEED DETECTION ......................................................................T-2

1-1. Misfeed Dete c tio n Timin g ...... .... ............... ................ ............... ............... .T-2

1-2. Misfeed Trou b les h oot in g Proce du res ............... ........................... ............T-2

2. MALFUNCTION DETECTION .........................................................................T-4

2-1. Malfunction Detection Timing ..................................................................T-4

2-2. Malfunction Troubleshooting Procedures ................................................T-4

i

Page 3

GENERAL,

MECHANICAL/

ELECTRICAL

Page 4

1 SPECIFICATIONS

Name : C-101

Type : Cassette type large capacity tray

Installation : Fixed to the copier using a dedicated Base with Slide Rails

T y pe of Paper :

Size of Paper : A4 crosswise, B5 lengthwise, B5 crosswise, Letter

Capacity : 1,000 sheets

Power Supply : DC5V, DC24 V (supplied from the copier)

Power Consumpt ion : 30W or less

Dimensions : 358 (W) x 446 (D) x 289 (H) mm

Weight : 10.7 kg (main body + rails)

Environmental Requirements: Same as the copier

Plain paper weighing 60 to 90 g/m

crosswise

2

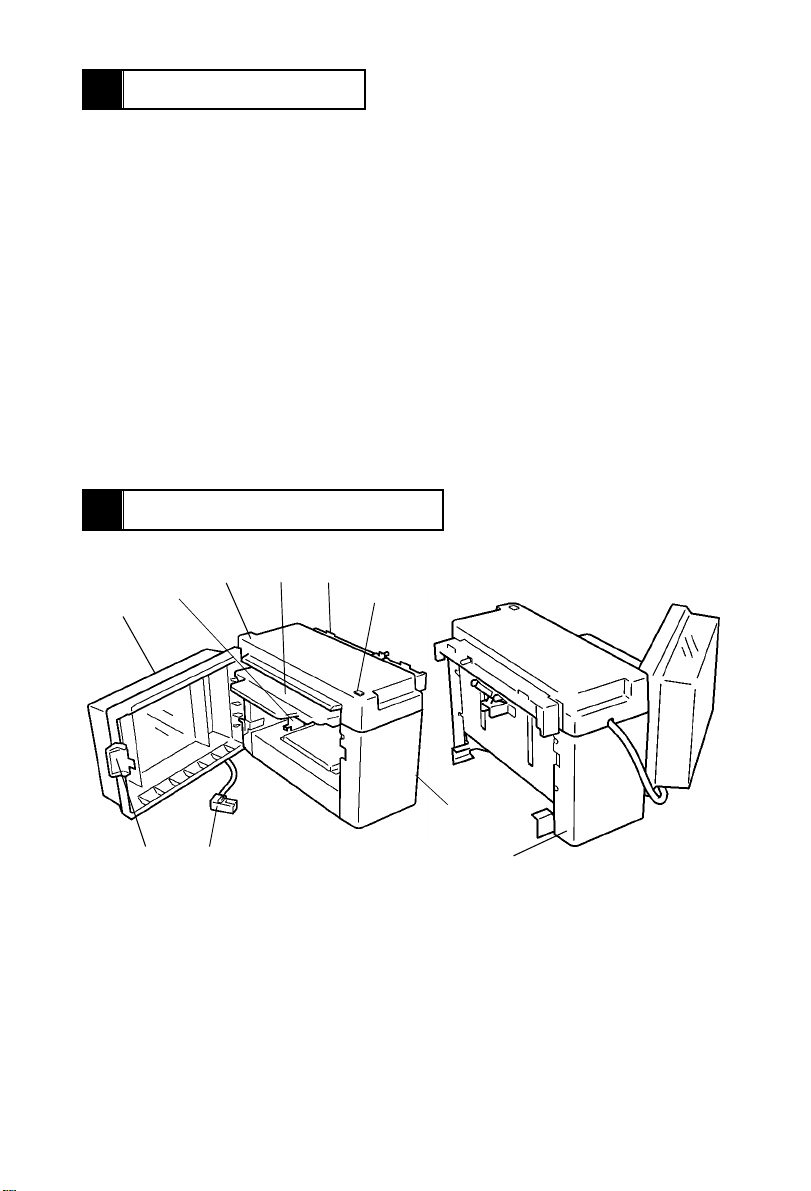

2 PARTS IDENTIFICATION

34

2

1

9

1. LCT Door

2. Edge Guide

3. Top Cover

4. Paper Plate

5. Paper Transport Port

8

5

4605M006AA

6

7

10

6. Paper Plate Descent Switch S1B

7. Front Cover

8. Relay Cord

9. Door Unlocki ng Lever

10. Rear Cover

M-1

4605M007AA

Page 5

3 CROSS-SECTIONAL VIEW

Paper Plate Upper Position Sensor PC2

Paper Empty Sensor PC3

LCT Door

Edge Guide

Paper Feed Roll

Paper Separator

Roll

Paper Take-Up Roll

Paper Plate

M-2

4605M008AA

Page 6

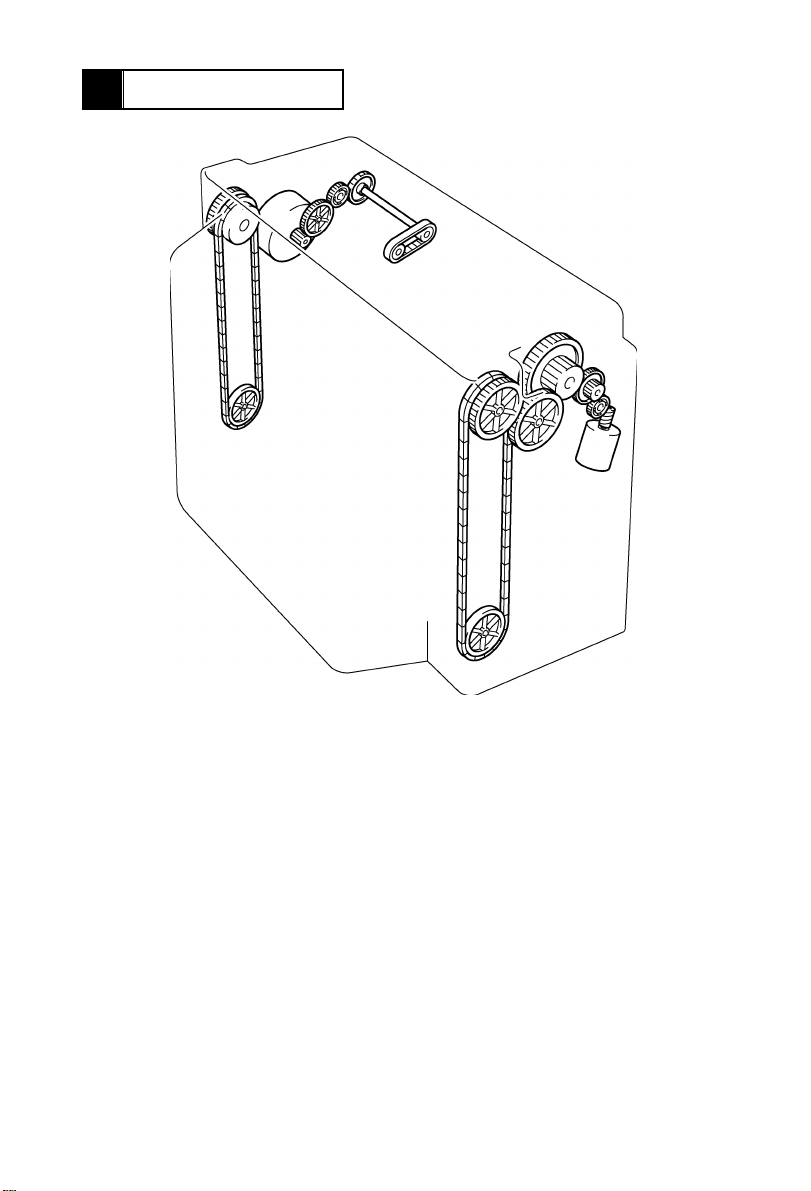

4 DRIVE SYSTEM

A

B

4605M009AA

A : Paper Take-Up Motor M2 : Drives the Paper Take-Up, Feed, and Separator Rolls.

B : Elevator Motor M1 : Moves the Paper Plate up and down.

M-3

Page 7

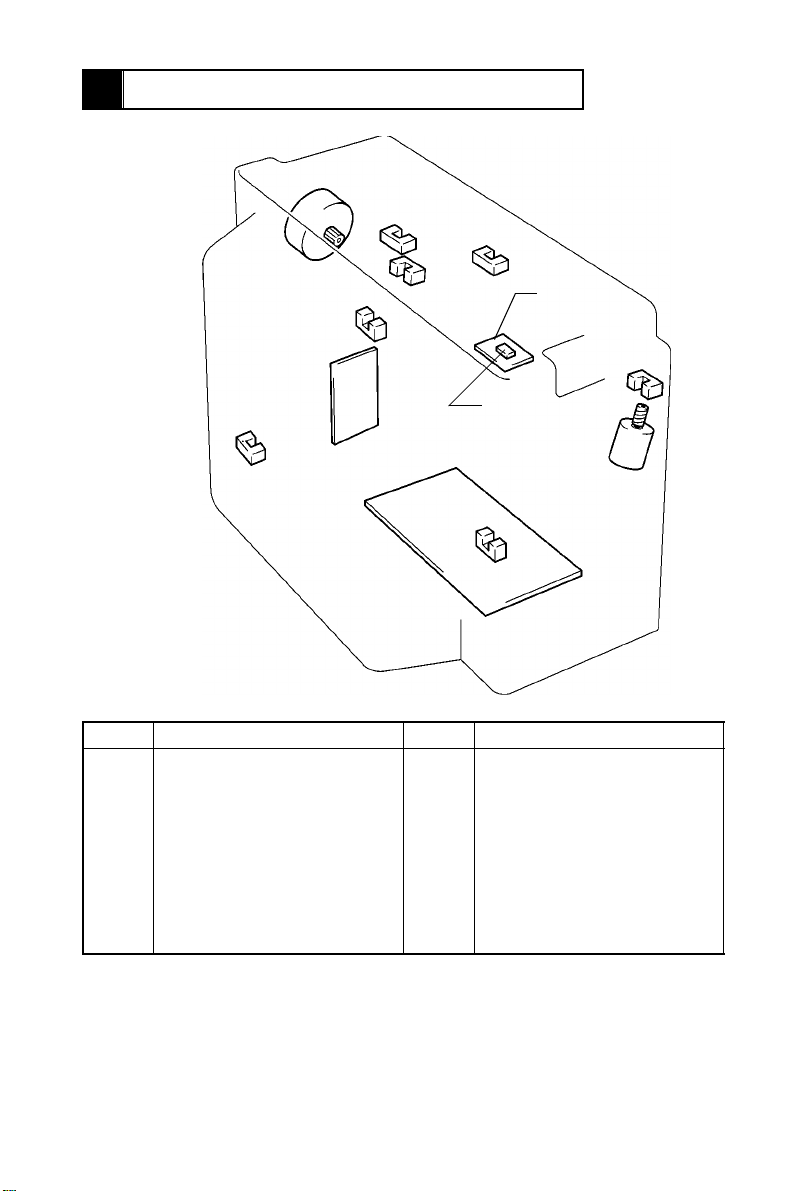

5 ELECTRICAL COMPONENT LAYOUT

M2

PC2

PC6

PWB-A

PC4

Symbol Name Symbol Location

PWB-A

PWB-B

M1

M2

H1

S1B

Master Board

Paper Plate Descent Switch

Board

Elev ator Motor

Paper Take-Up Motor

Paper Deh um i dif ie r Heate r

Paper Plate Descent Switch

PC1

PC2

PC3

PC4

PC5

PC6

PC7

PC5

PC3

H1

PC7

Elevator Pulse Sensor

Paper Plate Upper Position

Sensor

Paper Empty Sensor

Paper Plate Lower Position

Sensor

Paper Take-Up Sensor

LCT Set Detecting Sensor

LCT Door Ope n/C l os e Det ec ting

Sensor

PWB-B

S1B

M1

4605M010AA

PC1

M-4

Page 8

6 MECHANICAL DESCRIPTIONS

<

6-1. Mechanical Operation and Control of Paper Plate Li fting

• The Paper Plate is moved up and down by the chains and gears which are driven by Elevator Motor M1.

<M1 Turning Forward = Ascent>

Paper Plate Upper Position Sensor PC2

Elevator Motor M1

4605M011AA

M1 Turning Backward = Descent>

Paper Plate

Lower Position

Sensor PC4

4605M012AA

M-5

Page 9

<Mechanical Operation>

- Ascent Motion -

The LCT D oor is closed.

(LCT Door Open/Close Detecting Sensor PC7 is blocked L.)

Elevator Motor M1 turns forward. (The Paper Plate starts its ascent motion.)

The Paper Plate moves up and t he paper st ack blocks L Paper Plate

Upper Position Sensor PC2.

M1 is deen ergized. (The Paper Plate completes it s ascent motion.)

- Paper Take-Up Sequence -

Sheet s of pa pe r are tak en up.

The Paper Tak e-Up Roll gradually lowers to eventually unblock H PC2.

M1 turns forward to raise the Paper Take-Up Roll, thus blocking L PC2.

M1 is deenergiz ed.

✽ This sequence of operations is repeated to maintain a given pressure

between the paper stack and Paper Take-Up Roll.

- Descent Motion -

Paper Plate Descent Switch S1B is actuated or paper runs out.

M1 turns backward. (The Paper Plate starts its descent motion.)

The Paper Plate lowers to block L Paper Plate Lower Position Sensor PC4.

M1 is deenergiz ed. (The Paper Plate completes its descent motion.)

<Control>

• M1 is turned f orw ar d, backw a rd, stop pe d, a nd br ak ed by th e si gn al s out pu t fr o m IC 1A- 42

and 43 on Master Board PWB-A.

M1

Forward (Ascent) H L

Backward (Descent) L H

Stopped H H

Braked L L

IC1A

Pin 42 Pin 43

M-6

Page 10

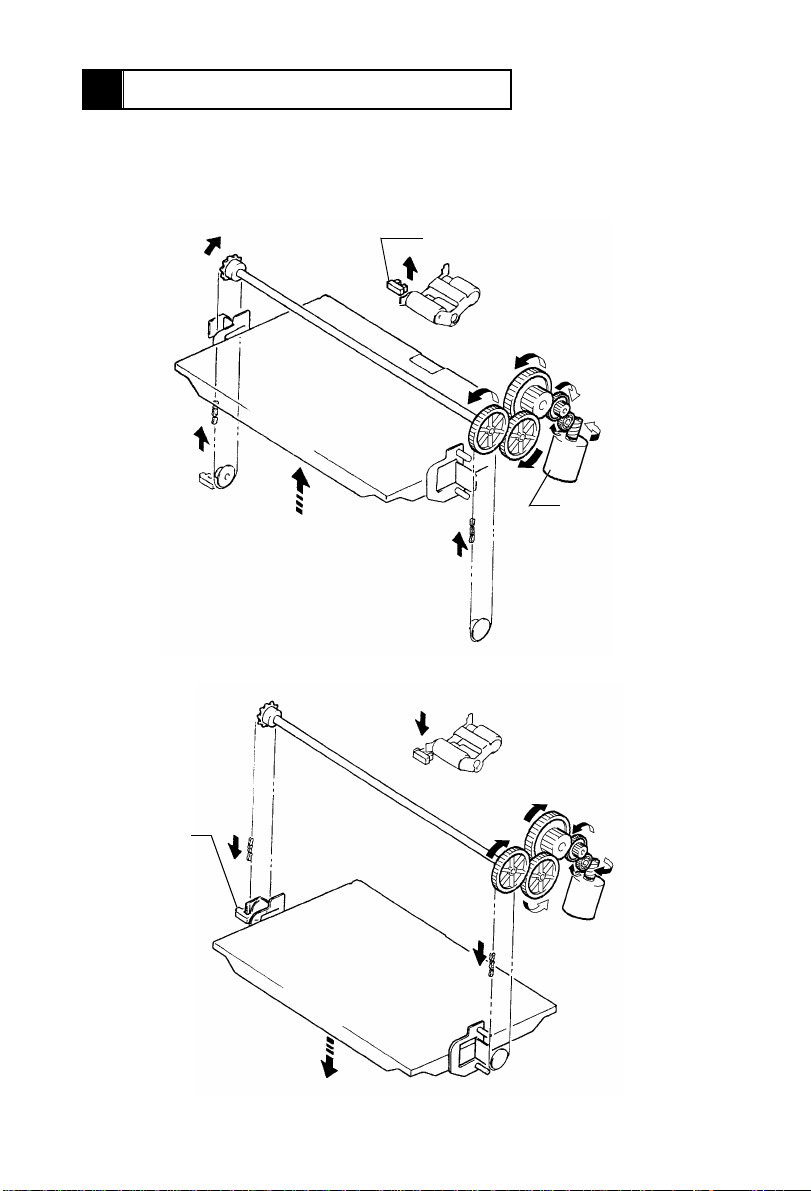

6-2. Mechanical Operation and Control of Paper Take-Up, Sep-

aration, and Transport

<Paper Take-U p Mecha nical Operation>

The Start key is pressed. (The copy cycle is started.)

Paper Take-Up Motor M2 is energized.

Drive from M2 is transmitted via gears and belt.

The Paper Feed, Separator, and Take-Up Rolls turn counterclockwise.

Paper is transp orted through the LCT.

Paper Take-Up Motor M2

Paper Ta ke-Up Roll

4605M013AA

Paper Feed Roll

Paper Separator Roll

4605M002AA

M-7

Page 11

<Paper Separation Mechanical Operat ion>

• When two or more sheets of paper are taken up by the Paper Take-Up Roll, the paper

separating mechanism prevents the second and subsequent sheets of paper from being

fed together with the first on e. The mechanism consists of the Paper Feed Roll, Pap er

Separator Roll, and torque limiter.

• When only one sheet of paper is taken up:

The turning torque of the Paper Feed Roll is transmitted to the Paper Separator Roll via

the sheet of paper being fed in; however, it is greater than the static torque of the Paper

Separator Roll (torque limiter), which causes the Paper Separator Roll to be turned by

the Paper Feed Roll, thus transporting the sheet of paper.

• When two or more sheets of paper are taken up at the same time:

The coefficient of friction between the first sheet and the second and subsequent sheets

of paper is small and the static torque of the torque limiter keeps the Paper Separator

Roll stationary.This stops the second and subsequent sheets of paper from being fed in,

allowing only the first sheet of paper to be fed in.

- Single-Sheet Feed - - Multiple-Sheet Feed -

1285M012

<Paper Take-U p Control>

• Rotation of Paper Take-Up Motor M2 is controlled by the pulse signals output from IC2A1, 2, 4, and 17 of Master Board PWB-A.

IC2A Rotation

1LLHH

2HHLL

17 L H H L

4HLLH

1285M013

M-8

Page 12

6-3. Paper Empty Detecting Mechanism

<Paper Empty De tection Timin g>

1. The LCT Door is opened.

2. Paper Plate Descent Switch S 1B is pressed unde r normal operatin g conditions.

3. Paper Empty Sensor PC3 is blocked.

If Paper Plate Upper Position Sensor PC2 is unblocked wh en PC3 is bl ocked, the Paper

Plate is then lowered until Paper Plate Lower Position Sensor PC4 is blocked.

<Resetting Paper Empty C ondition>

1. Close the LCT Door.

2. Add paper (if the LCT has run out of paper).

Paper Plate Upper Position Sensor PC2

Paper Empty Sensor PC3

1258M020AA

M-9

Page 13

<Paper Empty Sensor PC3>

When Paper is Present When Paper in not Present

4605M003AA

1258M021AA

Paper Plate Upper Position Sensor PC2

When Top Level is Detected When Top Level is not Detected

4605M004AA

4605M005AA

6-4. Paper Dehumidifier Heater

• When paper in the LCT grows damp, its electrical resistance is decreased, which aggravates the image transfer efficiency resulting in void image and other image problems.

The Paper Dehumidifier Heater (20W) is provided to prevent this problem.

• The heater is turned ON when the power cord of the copier is plugged in, and kept ON at

all times except while the copier Main Motor M1 remains energized.

M-10

Page 14

DIS/REASSEMBLY,

ADJUSTMENT

Precautions for Disassembly, Reassembly, and Adjustment

1. Before attempting to disassemble the LCT, always make sure that no p ower is being

supplied from the copier.

2. While power is being supplied to the LCT, do not attempt to remove/install the print

jacks from/to the PWBs or unplug/plug in the connectors.

3. If the LCT is run with its covers removed, use care not to allow your clothing to be

caught in revolving parts.

4. The basic rule is do n ot run the LCT with an y of its par ts removed.

5. A toothed washer is used with the screw that secures the ground wire to ensure positive

conduction. Do not forget to include th is washer at reassembly.

6. To reassemble the LCT, reverse the order of disassembly unless otherwise specified.

7. Do not attempt to re move or loosen the screws to which red paint has been applied.

8. Screws to which blue paint has been applied may be removed; however, be sure to

make an adjustment after reinstalling the screws.

Purpose of Application of Red Paint

Red paint is applied to the screws of parts that cannot be readjusted, set, or reinstalled in

the field.

Page 15

1 DISASSEMBLY

4605D001AA

4605D002AA

4605D003AA

4605D004AA

Important

The Paper Plate must be lowered be fore att empting to start the disassembly pr ocedures.

1. Removal of the Paper Take-Up/Feed Rolls

1. Remove the Top Cover.

NOTE:

Unplug the connector for Paper Plate Descent

Switch S1B.

2. Snap off the C-clip from the Paper Feed Roll shaft

and remove the timi ng belt.

3. Unhooking the springs in the P aper Separator Roll

unit, slide the Paper Take-Up Roll Assy and

remove the bushing to remove the Paper T ake-Up

Roll Assy.

NOTE:

When the Paper Take-Up Roll Assy, use care not to

allow it to hit against Paper Plate Upper Position Sensor PC2.

4. Remove the Paper Feed Roll and one-way cl utch.

D-1

Page 16

5. Snap off the C-clip and p ull out the Paper Take- Up

4605D005AA

4605D006AA

4605D007AA

1258D013AA

4605D008AA

2. Removal of the Paper Separator Roll

1. Remove one screw that secures the Paper Sepa-

2. Unhooking the springs in the P aper Separator Roll

Roll shaft to remove the Paper Take-Up Roll.

rator Roll Assy.

unit, remove the Paper Separator Roll Assy.

3. Snap off the E-rings and remove the bushings on

both ends. Then, remove the Paper Separator Roll

shaft.

4. Snap off the E-ring and remove the Paper Separator Roll.

D-2

Page 17

2 PAPER WIDTH CONVERSION

4605U011AA

4605U012AA

4605U013AA

4605U014AA

1. Bring the Paper Plate to its uppermost position.

Slide the LCT away from the copier and remove the LCT

Door.

2. Loosen the two screws. Then, with the Top Cover

slightly raised, unplug the connector of Paper Plate

Descent Switch S1B.

Remove the Top Cover.

3. Remove the position ing screws of Edge G uides.

4. Remove the Edge Guides.

D-3

Page 18

5. Fi t the Ed ge G uide s in to th e sl ots co r res pon di n g to

4605U015AA

B

AC D D CA

B

4605U013AA

4605U012AA

4605U011AA

the paper size to be used.

- Slot-to-Paper-Size Correspondence A ... A4 crosswise

B ... Letter crosswise

C ... B5 crosswise

D ... B5 lengthwise

6. Slightly raising the Edge Guides, tighten the positioning screws.

7. Connect the Top Cover conn ector and reinstall the

Top Cover.

8. Reinstall the LCT Door.

D-4

Page 19

3 IMAGE POSITION ADJUSTMENT

1. Set the copi er into the Service mode and select

“Machine Adjust.”

4605D021CA

2. Select “PRT Area.”

4605D022CA

3. Select “Left Margin.”

4605D023CA

4605D024CA

4. Select “LCT” and press the Start key to let the

copier start a test print cyc le.

D-5

Page 20

4605D024CA

4605D020AA

Feeding Direction

4605D019AA

5. Mea s ure the void image width on the test print.

Specifications.....3 mm±1.5 mm

6. If the measurement falls ou tside the specified

range, adjust the void image width using ▲or

▼key.

Make a test print again to check for correct adjustment.

7. If the void image width does not fal l within the

specified range even through these adjustments

on the Touch Pane l, move the Rail Assy to the rear

or front to make a mechanical adjustment.

D-6

Page 21

MISFEED DETECTION&

MALFUNCTION DETECTION

General Precautions

1. When servicing the LCT with i ts covers removed, use utmost care to prevent your

hands, clothing and tools from being caught in revolving parts.

2. Before attempting to replace parts and unplugging connectors, make sure that no

power is being supplied from the copier.

3. In whatev er situat ions, terminals and PWB patterns other than connectors spec ified in

the text must not be shorted.

4. When creating a closed circuit and measuring a voltage across connector pins specified in the text, be sure to use the green wire (GND).

5. Keep all disassembled parts in good order and keep to ols under control so that none

will be lost or da ma ge d.

Reading the Text

1. If a component on a PWB or any other functional unit inc luding a motor is defective, the

text only instructs you to replace the whole PWB or functional unit and does not give

troubleshooting pr ocedure applicable within the defectiv e unit.

2. The text assumes tha t there are no breaks and short s in the harnesses and all connectors are plugged into the right positions.

Page 22

- Sensor Check Procedure -

<Procedure>

1. When a paper misfeed or malfunction occurs, identify the possibly defective cont rolled

part or parts on the circuit diagram.

2. Open the “State Confirm” screen, as selected from the Service Mode menu. Then,

show the screen that contains the part or parts picked out in step 1) from among Switch

1 (Paper) or Switch 2 (Option).

3. Force to change the status of the sensor sel ected and check at that time that the signal

state changes on the screen.

Example

If Paper Take-Up Senso r PC5 is considere d defective when a paper misfeed occurs:

<Procedure>

1. Remove the sheet of misfed paper.

2. Select “Switch 2 (Option)” of “State Confirm” available from the Service mode.

4605D025CA

3. Check that Pap. Trans is Off on the screen.

4. Mo ve the PC5 actuator with a sheet of paper to block PC5.

5. Check that the state of Pap. Trans. has changed to On from Off.

On: PC5 is operational.

Set : L CT-to-copier connector

Path Set : LCT Set Detecting Sensor PC6

Cover Open : LCT Door Open/Close Detecting Sensor PC7

Pap. Empty : Paper Empty Sensor PC3

Upr. Limit : Paper Plate Upper Position Sensor PC2

Lwr. Limit : Paper Plate Lower Position Sensor PC4

Pap. Trans : Paper Take-Up Sensor PC5

Off: PC5 is defective

T-1

Page 23

1 PAPER MISFEED DET ECTION

1-1. Misfeed Detection Timing

Type Detection Timing

Paper left When the copier Power Switch is turned ON or a paper mis-

feed or malfunct ion is reset, Paper Take-Up Sensor PC5 or

Transport Roller Sensor PC19 is unblocked (H).

Paper take-up failure

detection

Paper take-up trailing

edge detection

1-2. Misfeed Troubleshooting Procedures

1. Misfeed Before Start of Copy Cycle (Paper Left)

Step Check Item Result Action

1 Is there a sheet of paper being fed

in the LCT, blocking the sensor?

LCT paper take-up section: Paper

Take-Up Sensor PC5

2 Is PC19 or PC5 mounted in a cor-

rect position, or does the sensor

actuator move cor rectly?

3 Does PWB-I receive the output sig-

nal of PC19 or PC5 properly ?

PC19: PWB-I on copier

PC5: PWB -I on copi er

PC19: If “Front Mid” fully operational when checked with Switch 1

(Paper)?

PC5: If “Pap. Trans.” fully operational when checked with Switch 2

(Option)?

PC5 is not unblocked (H) even after the lapse of about 1 sec.

after Paper Take-Up Motor M2 has been energized.

PC5 is not blocked (L) even after the lapse of about 4 .5 sec.

after it has been unblocked (H).

YES Remove the sheet of paper being

fed.

NO Check the mounting position or

actuator.

YES Replace PWB-A (C-101) or PWB-I

(copier).

NO Check the wiring between PWB-I

and sensor and, if it is intact,

change PC19 or PC 5.

T-2

Page 24

2. Misfeed After Copy Cycle Has Been Started

Step Check Item Result Action

1 Does the paper being used meet

product specifications?

2 Is the paper curled, waved, or

damp?

3 Does Paper Take-Up Motor M2 turn

when the Start key is pressed?

4 Is a drive voltage output from PWB-

A to M2?

Does the voltage across PJ6A-4

and GND change from approx.

DC0V whe n a paper misfeed is

reset and Start key pressed?

5 Is the Paper Take-Up/Fe ed/Sepa ra-

tor Roll dirty, worn, or deformed?

6 Is the guide plate along the paper

path di rty or deformed?

7 Is Transport Roller Sensor PC19 or

PC5 mounted at t he correct position? Does the sensor actuator

make a correct motion?

8 Does PWB-I receive the output sig-

nal of PC19 or PC5 properly ?

PC19: PWB-I on copier

PC5: PWB -I on copi er

PC19: If “Front Mid” fully operational when checked with Switch 1

(Paper)?

PC5: If “Pap. Trans.” fully operational when checked with Switch 2

(Option)?

NO Instruct the user to us e paper that

meets product specifications.

YES Change the paper. Instruct the

user in how to sto re the paper.

YES Check each part for possible over-

load.

YES Check the wiring between PWB-A

and M2 and, if it is intact, change

M2.

NO Change PWB-A.

YES Clean or change the defect ive roll.

YES Clean, correct, or change the

defective guide plate.

NO Check the mounting position or

actuator.

YES Replace PWB-A (C-101) or PWB-I

(copier).

NO Check the wiring between PWB-I

and sensor and, if it is intact,

change PC19 or PC 5.

✽ : If these procedures do not remedy the problem, check the copier. (See TROUBLE-

SHOOTING of the copier service manual.)

T-3

Page 25

2 MALFUNCTION DETECTION

2-1. Malfunction Detection Timing

Malfunction Code Malfunction Detail Detection Timing

Paper Plate Upper

Position Sensor PC2

is not activated.

C09XX

Elevator

malfunction

C0

Paper Plate Lower

C2

Position Sensor PC4

is not activated.

2-2. Malfu nc ti on Troub les hooting Procedures

1. C09C0

Step Check Item Result Act io n

1 Does the Paper Plate lower after the

malfunction has been reset?

2 Is PC2 or PC3 mounted at the correct

position? Does the sensor actuator

make a correct motion?

3 PC2: If “ Upr. Limit” fully o perational

when checked with Switch 2 (Option)?

4 Does PWB-I receive the output signal

from PC3 correctly?

Does the voltage across PJ4A-8B and

GND change from DC0V to DC5V

when PC3 is unblocked?

5 Does the drive transmission mecha-

nism from M1 remain intact?

6 Is a signal output from PWB-A to M1?

Does the voltage across ✽ and GND

change from DC0V to DC24V w hen

the malfunction is reset and the copier

Front Door opened and closed?

✽ During ascent: PJ2A-2

During descent: PJ2A-1

• PC2 is not blocke d (L) eve n aft er the la pse of

10 sec. a fter Elevator Motor M1 has be en

energized.

• PC2 is not blocke d (L) eve n aft er the la pse of

3 sec. after Paper Empty Sensor PC3 has

been un bl oc ke d ( H ).

• PC4 is not blocke d (L) eve n aft er the la pse of

10 sec. a fter M1 has been energized.

NO Go to step 5.

NO Check the mounting position or

actuator.

YES Change PWB-A (C-101) or

PWB-I (copier).

NO Check the wiring between

PWB-I and sensor and, if it is

intact, change PC2.

YES Change PWB-A (C-101) or

PWB-I (copier).

NO Check the wiring between

PWB-I and sensor and, if it is

intact, change PC3.

NO Check the drive tr ansmission

mechanism (gears, chains,

etc.) from M1.

YES Check the wiring between

PWB-A and sensor and, if it is

intact, change M1.

NO Change PWB-A.

✽ : If these procedures do not remedy the probl em, check the copier. (See TROUBLE-

SHOOTING of the copier service manual.)

T-4

Page 26

2. C09C2

Step Check Item Result Action

1 Does the Paper Plate lower after the malfunction

has been reset?

2 Is PC4 mounted at the correct position? Does

the sensor actuator make a correct motion?

3 PC4: If “ Lwr. Limit” fully o perational when

checked with Switch 2 (Option)?

4 Does the drive transmission mechani s m from

M1 remain intact?

5 Is a signal output from PWB-A to M1? Does the

voltag e ac ross ✽ and GND change from DC0V

to DC24 V when the malfunction is reset and the

copier Front Door opened and closed?

✽ During ascent : PJ2A-2

During descent : PJ2A-1

✽ : If these procedures do not remedy the probl em, check the copier. (See TROUBLE-

SHOOTING of the copier service manual.)

NO Go to step 5.

NO Check the mounting

position or actuator.

YES Change PWB-A.

NO Check the wiring

between PWB-A and

sensor and, if it is

intac t, change PC2.

NO Check the drive tr ans-

mission mechanism

(gears, chains, etc.)

from M1.

YES Check the wiring

between PWB-A and

sensor and, if it is

intact, change M1 .

NO Change PWB-A.

T-5

Loading...

Loading...