Page 1

ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1

OPERATOR’S MANUAL

Z 8805

Z 8805 T

Tedder

Part number 51514391

1st edition English

March 2019

Page 2

Contents

1GENERALINFORMATION

Notetotheowner...........................................................................1-1

Intendeduse................................................................................1-4

Prohibitedusage...........................................................................1-5

Electro-MagneticCompatibility(EMC).....................................................1-6

Manualscopeandrequiredtraininglevel..................................................1-7

ProductIdenticationNumber(PIN)........................................................1-9

Productidentication......................................................................1-11

Operator'smanualstorageonthemachine...............................................1-13

Implementorientation.....................................................................1-14

2SAFETYINFORMATION

Safetyrulesandsignalworddenitions....................................................2-1

Generalrecommendations.................................................................2-2

Illustrations.................................................................................2-3

Legalobligations...........................................................................2-4

Fireorexplosionprevention................................................................2-5

Hazardouschemicals.......................................................................2-6

Startinguptheimplementsafely...........................................................2-7

Travelingonpublicroads...................................................................2-8

Operatingtheimplementsafely...........................................................2-10

Stoppingtheimplementsafely............................................................2-11

Maintenance...............................................................................2-12

PersonalProtectiveEquipment(PPE)....................................................2-13

Safetyrequirementsforuidpowersystemsandcomponents-hydraulicsystems......2-14

Noiseemission............................................................................2-15

Vibrationlevels............................................................................2-16

Implementstability.........................................................................2-17

Ecologyandtheenvironment.............................................................2-18

Safetysigns...............................................................................2-19

3CONTROLSANDINSTRUMENTS

Information

Operatingprinciples....................................................................3-1

4OPERATINGINSTRUCTIONS

Commissioningtheunit

Preparingforoperation.................................................................4-1

Installationoftherotorarms............................................................4-2

Startingtheunit

Connectiontothetractor...............................................................4-3

Connectiontothetractor(forZ8805)..................................................4-6

Connectiontothetractor(forZ8805T).................................................4-8

Page 3

PowerTake-Off(PTO)shaft–Shorten................................................4-10

5TRANSPORTOPERATIONS

Roadtransport

Transportonpublicroads..............................................................5-1

Preparingforroadtransport

Conversionofthetedderfromtransporttoworkingposition...........................5-4

Shippingtransport

Transportonpallet......................................................................5-8

Connectionfromthepallet............................................................5-11

6WORKINGOPERATIONS

Generalinformation

Specialinstructions.....................................................................6-1

ConversionofthetedderfromtransporttoworkingpositionZ8805...................6-3

ConversionofthetedderfromtransporttoworkingpositionZ8805T.................6-7

Basicadjustment......................................................................6-12

Anti-wrapdiscforthewheelrim.......................................................6-15

Workingspeedandnumberofrevolutions............................................6-16

Disconnectionandparking............................................................6-17

Installationofoptionalequipment.....................................................6-19

7MAINTENANCE

Generalinformation

Maintenance............................................................................7-1

Torque..................................................................................7-2

Torqueforclass12.9...................................................................7-5

Fluidsandlubricants...................................................................7-6

Maintenanceplanning

Maintenancechart......................................................................7-7

Aftertherst3hoursofoperation

Boltsandttings........................................................................7-8

Every8hours

PowerTake-Off(PTO)shaft............................................................7-9

Every20hours

PowerTake-Off(PTO)shaft...........................................................7-11

Page 4

Every25hours

Hingepins.............................................................................7-13

Every40hours

PowerTake-Off(PTO)shaft...........................................................7-14

Every50hours

Tirepressure..........................................................................7-16

Jointpieceandboomarm.............................................................7-17

Steeringrod...........................................................................7-18

Oblonghole(guide)...................................................................7-19

Headstock.............................................................................7-20

Every200hours

Transportsafetybolt...................................................................7-22

Every6years

Hydraulichoses.......................................................................7-23

Asrequired

Gearboxes.............................................................................7-24

Fingerclutch...........................................................................7-25

Storage

Pressurewashing.................................................................7-26

Endofseasonservice.............................................................7-27

Orderingpartsand/oraccessories..............................................7-28

8TROUBLESHOOTING

Faultcoderesolution

Troubleshootingchart..............................................................8-1

9SPECIFICATIONS

Technicaldata..............................................................................9-1

Fluidsandlubricants.......................................................................9-2

10ACCESSORIES

Generalinformation.......................................................................10-1

Dualspeedgearbox.......................................................................10-2

Anti-wrapplateforwheelarm.............................................................10-2

Sparewheelkitwithholder................................................................10-3

Supportwheel.............................................................................10-4

Page 5

11FORMSANDDECLARATIONS

ECDeclarationofConformity.............................................................11-1

Page 6

Page 7

1-GENERALINFORMATION

1-GENERALINFORMATION###_1_###

Notetotheowner

Thismanualhasbeenpreparedtoassistyouinthecorrectproceduretorunin,todrive,tooperate,toadjustandto

maintainyournewimplement.

Thisimplementhasbeendesignedandbuilttogivemaximumperformance,economyandeaseofoperationunder

awidevarietyofconditions.

Priortodelivery,yourimplementwascarefullyinspectedbothatthefactoryandbyyourdealertomakesurethatit

reachesyouinoptimumcondition.T omaintainthisconditionandassuretrouble‐freeoperationitisimportantthat

routineservices,asspeciedinthismanual,arecarriedoutattherecommendedintervals.

Readthismanualcarefully(especiallyChapter2thatcoversthesafetyinformation)andkeepthismanualinaconvenientplaceforfuturereference.DONOToperateorpermitanyonetooperateorservicethisimplementuntilyou

and/orotherpersonshavereadthismanual.Readthemanual,itwillsaveyoutimeandhasslelater.Lackofknowledgecanleadtoaccidents.Employonlytrainedoperatorswhohavedemonstratedtheabilitytooperateandservice

thisimplementcorrectlyandsafely.Contactyourdealerforassistanceprovidingtherequiredtrainingtoyouroperators.Contactyourdealertoobtainadditionalmanualsoralternatelanguageversions.

Ifatanytimeyourequireadvicethatconcernsyourimplement,donothesitatetocontactyourauthorizeddealer.He

hasfactory‐trainedpersonnel,genuineservicepartsandthenecessaryequipmenttocarryoutyourservicerequirements.

NOTICE:ThisimplementhasbeendesignedandbuiltinlinewiththerequirementsputforwardbytheEuropean

Directives2006/42/ECand2014/30/EU.

AlwaysusegenuineKONGSKILDEServicePartsorpartsthatmatchatleastthesamequality,reliabilityandfunctionalityastheequivalentoriginalServicePartswhenyouserviceandrepairyourimplementanddonotmodifyyour

implementwithoutawrittenpermissionofthemanufacturer.Failuretodosowillvoidtheresponsibilityofthemanufacturer.

Checklocalroadlegislationbeforeyoudrivetheimplementonpublicroads.

Whenyouoperateinterchangeableimplement,makesurethattheimplementisCEapproved.

Asthispublicationisdistributedthroughoutourinternationalnetwork,theimplementillustrated,eitherasstandardor

asanaccessory,mayvaryaccordingtothecountryinwhichtheimplementistobeused.Lowspecicationcongurations,aschosenbythecustomer,maydeviatefromthespecicationsgiven.

Severalguresinthisoperator'smanualshowthesafetyguardingortheadditionalguards,legallyrequiredbycertain

countries,openorremovedtobetterillustrateaparticularfeatureoradjustment.Theimplementmustnotbeusedin

thiscondition.Foryourownsafety,makesurethatallguardsareclosedorreplacedbeforeyouoperatetheimplement.

1-1

Page 8

1-GENERALINFORMATION

OWNERASSISTANCE

WeatKONGSKILDEandyourKONGSKILDEdealerwantyoutobecompletelysatisedwithyourinvestment.Normally,yourdealer'sServiceDepartmentwillhandleanyproblemswithyourimplement.Sometimeshowever,misunderstandingcanoccur.Ifyourproblemhasnotbeenhandledtoyoursatisfaction,wesuggestyoutocontacttheowner

orGeneralManagerofthedealership,explaintheproblemandrequestassistance.Whenadditionalassistanceis

needed,yourdealerhasdirectaccesstoourbranchofce.

COMPANYPOLICY

Companypolicy,whichisoneofcontinuousimprovement,reservestherighttomakechangesindesignandspecicationatanytimewithoutnoticeandwithoutobligationtomodifyunitspreviouslybuilt.

Alldatagiveninthisbookissubjecttoproductionvariations.Theinformationinthispublicationisprovidedonthe

basisofinformationthatwasavailableatthetimethatthemanualwaswritten.Settings,proceduresandotheritems

canchange.Thesechangescanaffecttheservicethatisgiventotheimplement.

Dimensionsandweightsareapproximateonlyandtheillustrationsdonotnecessarilyshowtheimplementinstandard

condition.Forexactinformationaboutanyparticularimplementpleaseconsultyourdealer.Makesurethatyouhave

themostcurrentandcompleteinformationfromyourdealerbeforeyoustartanyjob.

ACCESSORIESANDOPTIONS

Yourimplementhasbeendesignedtooperateinawidevarietyofsoils/cropsandconditions.Neverthelessadditional

equipmentmay,incertaincases,berequiredtoimprovetheimplementperformance.Alistofthisadditionalequipmentisgiveninthe''Accessories”chapterinthismanual.Useonlythoseaccessoriesdesignedforyourimplement.

PARTSANDACCESSORIES

GenuineKONGSKILDEpartsandaccessorieshavebeenspecicallydesignedforKONGSKILDEimplements.

Wewouldliketopointoutthat''non-genuine”partsandaccessorieshavenotbeenexaminedandreleased

byKONGSKILDE.Theinstallationand/oruseofsuchproductscouldhavenegativeeffectsuponthedesign

characteristicsofyourimplementandtherebyaffectitssafety.KONGSKILDEisnotliableforanydamagecaused

bytheuseof''non-genuine”partsandaccessories.

RelyonyourauthorizeddealertosupplyyouwithgenuineKONGSKILDEpartsonly.Thesepartsarecoveredbyour

warrantyandwillgiveyouthebestperformance.

SeethepartscatalogorbrowsetheKONGSKILDEportaltondservicepartsforyourimplement.

Whenyouorderserviceparts,alwaysquotethemodelandserialnumberprintedontheProductIdenticationNumber

(PIN)plate.

1-2

Page 9

1-GENERALINFORMATION

LUBRICANTS

Yourdealersellsaselectionofspeciallyformulatedlubricantsbasedonownengineeringspecications.

Recommendedlubricantsforyourimplementarelistedinthemaintenancechapter.

WARRANTY

Yourimplementiswarrantedaccordingtolegalrightsinyourcountryandthecontractualagreementwiththeselling

dealer.Nowarrantyshall,however,applyiftheimplementhasnotbeenused,adjustedandmaintainedaccordingto

theinstructionsgiveninthisoperator'smanual.

Itisprohibitedtocarryoutanymodicationstotheimplementunlessspecicallyauthorized,inwriting,bya

KONGSKILDErepresentative.

CLEANINGYOURIMPLEMENT

Whenyouuseahighpressurewasher,donotstandtooclosetotheimplementandavoiddirectingthejetatelectronic

components,electricalconnections,breathers,seals,llercaps,andsoon.

Cleandecalsonlywithasoftcloth,waterandagentledetergent.DONOTusesolvent,gasolineorotherharsh

chemicalstocleandecals.Decalscouldberemovedorgetdamaged.

DISASSEMBLYORSCRAPPING

Whenyourimplementistakenoutofservicebecauseitisdamagedbeyondrepairorhasreachedtheendofits

usefullife,disassembly,scrappingand/orrecyclingofcomponentsmustbeperformedonlybyaqualiedtechnician

withserviceinstructions,andincompliancewithlocallawandregulations.

1-3

Page 10

Intendeduse

1-GENERALINFORMATION

TheKONGSKILDErotaryteddercanonlyperformthe

usualworkinagriculture.Onlyconnecttherotaryteddertoatractorwhichcorrespondswiththespecications

oftheimplementandislegaltouse.OnlythePower

Take-Off(PTO)ofthetractorcandrivetheattachedrotarytedder.

Theimplementmayonlyted,turn,cleartheeldboundaries,spreadwindrowsandsmallnightswathsofgreen

forage(alfalfa,clover,grass,etc.),hayandstraw.

Consideranyotherusecontrarytotheintendeduse.The

manufacturerisnotresponsibleforanydamagethatre-

sultsfromtheimproperuseoftheimplement.Theuser

bearsthatrisk.

Alwaysobservethefollowingsafetyinstructionsaswell

asthecommonrulesconcerningtechnicalsafety,working

practicesandroadsafety.

Ifyoumakechangestotheimplementanditsconstruction

withoutthepermissionfromthemanufacturer,themanufacturerdoesnotacceptanyresponsibilityfordamages

thatresultsfromthis.

1-4

Page 11

1-GENERALINFORMATION

Prohibitedusage

Sweepingofforexamplefarmyardswiththetinearmassemblyorbroomsfastenedtotheseisnotallowed.There

isariskthatforexamplestonesarethrownoutfromthe

workingareaoftheimplementwithdangerofpersonalinjuryordamagetoobjects.

Anyusebeyondtheintendeduseisregardedasforeseeablemisuse.

1-5

Page 12

1-GENERALINFORMATION

Electro-MagneticCompatibility(EMC)

ThismachinecompliesstrictlywiththeEuropeanRegulationsonelectro‐magneticemissions.However,interference

mayariseasaresultofadd‐onequipmentwhichmaynotnecessarilymeettherequiredstandards.Assuchinterferencecanresultinseriousmalfunctionoftheunitand/orcreateunsafesituations,youmustobservethefollowing:

Ensurethateachpieceofnon‐KONGSKILDEequipmentttedtothemachinebearstheCEmark.

•

Themaximumpowerofemissionequipment(radio,telephones,etc.)mustnotexceedthelimitsimposedbythe

•

nationalauthoritiesofthecountrywhereyouusethemachine.

Theelectro‐magneticeldgeneratedbytheadd‐onsystemshouldnotexceed24V/matanytimeandatanylo-

•

cationintheproximityofelectroniccomponents.

FailuretocomplywiththeseruleswillrendertheKONGSKILDEwarrantynullandvoid.

1-6

Page 13

1-GENERALINFORMATION

Manualscopeandrequiredtraininglevel

Introductiontothismanual

Thismanualgivesinformationabouttheuseofyour

KONGSKILDEmachineasintendedandunderthe

conditionsforeseenbyKONGSKILDEduringnormal

operation,routineservice,andmaintenance.

Thismanualdoesnotcontainalltheinformationthatrelatestoperiodicservice,conversions,andrepairsthat

onlytrainedservicepersonnelcanperform.Someof

theseactivitiesmayrequireappropriatefacilities,technicalskills,and/ortoolsthatKONGSKILDEdoesnotsupply

withthemachine.

ThemanualcontainsthechaptersasshownontheContentspages.SeetheIndexattheendofthismanualto

locatespecicitemsaboutyourKONGSKILDEmachine.

Normaloperation

Normaloperationconsistsoftheuseofthismachinefor

thepurposeKONGSKILDEintendsbyanoperatorthat:

Isfamiliarwiththemachineandanymountedequip-

•

mentortowedequipment

Complieswiththeinformationonoperationandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Normaloperationincludes:

Preparationandstorageofthemachine

•

Additionandremovalofballast

•

Connectionanddisconnectionofmountedequipment

•

and/ortowedequipment

Adjustmentandcongurationofthemachineand

•

equipmentforthespecicconditionsofthejobsite,

eld,and/orcrop

Movementofcomponentsintoandoutofworkingpo-

•

sitions

Routineserviceandmaintenance

Routineserviceandmaintenanceconsistsofthedaily

activitiesnecessarytomaintainthepropermachine

function.Theoperatormust:

Befamiliarwiththemachinecharacteristics

•

Complywiththeinformationonroutineserviceandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Routineservicecaninclude:

Fueling

•

Cleaning

•

Washing

•

Toppingupuidlevels

•

Greasing

•

Replacingconsumableitemssuchaslightbulbs

•

Periodicservice,conversions,andrepairs

Periodicserviceconsistsofactivitiesthatarenecessary

tomaintaintheexpectedlifeoftheKONGSKILDEmachine.Theseactivitieshavedenedintervals.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivitiesatthedened

intervals.Trainedservicepersonnelmustcomplywith

theinformationonperiodicserviceandsafepracticesas

partlyspeciedbyKONGSKILDEinthismanualand/or

othercompanyliterature.

Periodicserviceincludes:

Oilchangeservicefortheengine,hydrauliccircuits,or

•

transmission

Periodicexchangeofothersubstancesorcomponents

•

asrequired

ConversionactivitiesrebuildtheKONGSKILDEmachine

inacongurationthatisappropriateforaspecicjob

site,crop,and/orsoilconditions(e.g.,installationofdual

wheels).Conversionactivitiesmustbedone:

Bytrainedservicepersonnelfamiliarwiththemachine

•

characteristics

Bytrainedservicepersonnelthatcomplywiththe

•

informationonconversionaspartlyspeciedby

KONGSKILDEinthismanual,assemblyinstructions,

and/orothercompanyliterature

Repairactivitiesrestoreproperfunctiontoa

KONGSKILDEmachineafterafailureordegradation

ofperformance.Dismantlingactivitiesoccurduringthe

scrappingand/ordismantlingofthemachine.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivities.Trainedservice

personnelmustcomplywiththeinformationforrepairas

speciedbyKONGSKILDEintheservicemanual.

Beforeyouoperate

Readthismanualbeforeyoustarttheengineor

operatethisKONGSKILDEmachine.Contactyour

KONGSKILDEdealerif:

Youdonotunderstandanyinformationinthismanual

•

Youneedmoreinformation

•

Youneedassistance

•

Allpersonstrainingtooperate,orwhowilloperate

thisKONGSKILDEmachineshouldbeoldenoughto

possessavalidlocalvehicleoperatingpermit(ormeet

otherapplicablelocalagerequirements).Thesepersons

1-7

Page 14

1-GENERALINFORMATION

mustdemonstratetheabilitytooperateandservicethe

KONGSKILDEmachineinacorrectandsafemanner.

1-8

Page 15

1-GENERALINFORMATION

ProductIdenticationNumber(PIN)

TheProductIdenticationNumber(PIN)isaserialnumberthatidentiestheimplement.

Theserialnumber,modelandotherspecicationsareon

thePINplate.

ProvideyourKONGSKILDEdealerwiththemodelandthe

PINwhenyouorderparts.

Z8805

ZEIL18HT00546EA1

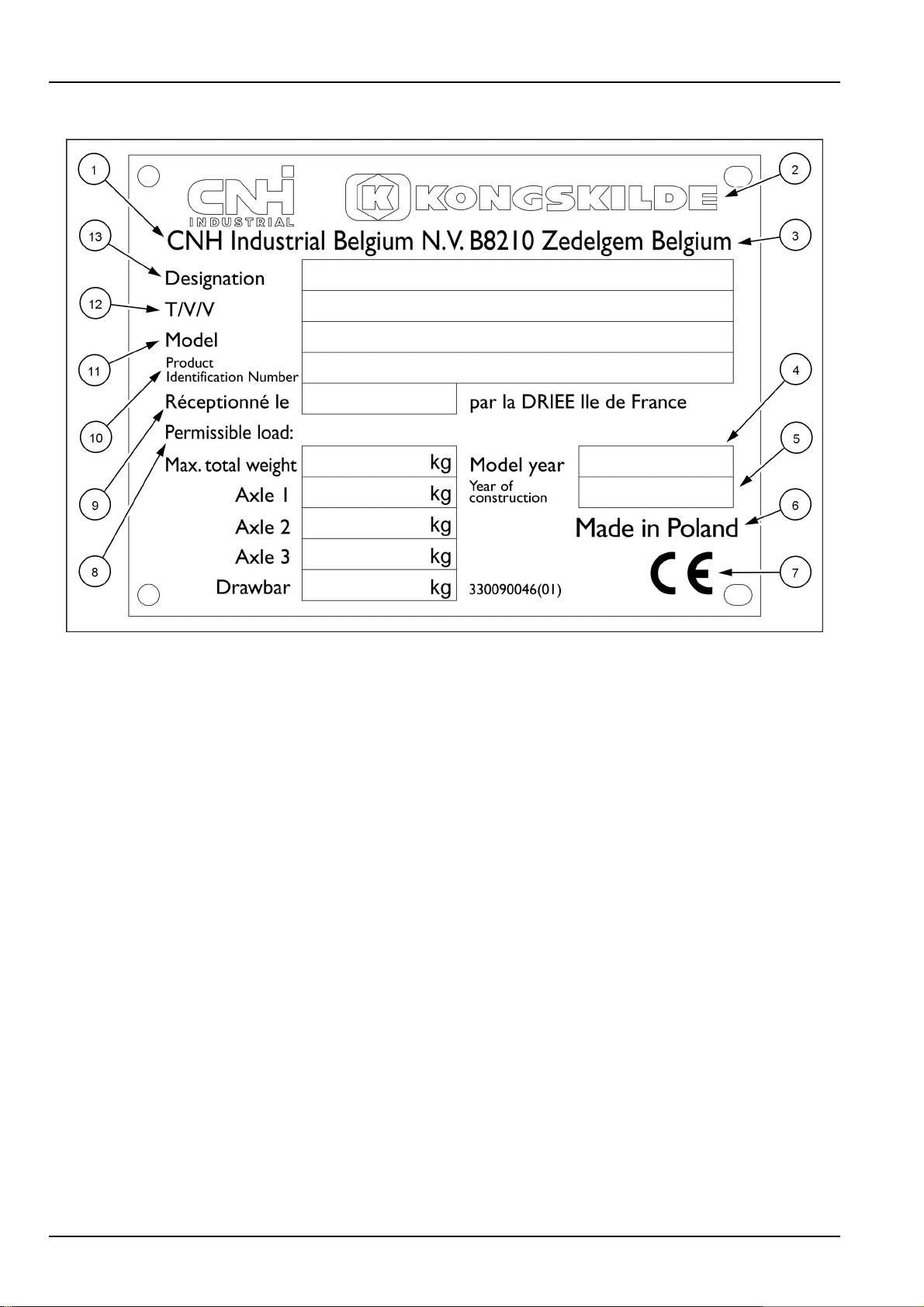

(1)Companyname(7)Yearofconstruction

(2)Brandidenticationlogo(8)Madein(countryoforigin)

(3)

(4)Type/Variant/Version(10)ProductIdenticationNumber(PIN)

(5)

(6)Certicationmark(12)

Mailaddress

Modelyear

(9)

(11)

Maximumweight

Model

Designation

1-9

Page 16

1-GENERALINFORMATION

Z8805T

ZEIL18HT00548FA2

(1)Companyname(8)

Maximumpermissibleloaddividedpereach

axleanddrawbar

(2)Brandidenticationlogo(9)

RéceptionnéleparlaDRIEEIledeFrance

(forFranceonly)

(3)

(4)

Mailaddress

Modelyear

(10)ProductIdenticationNumber(PIN)

(11)

Model

(5)Yearofconstruction(12)Type/Variant/Version

(6)Madein(countryoforigin)(13)

Designation

(7)Certicationmark

1-10

Page 17

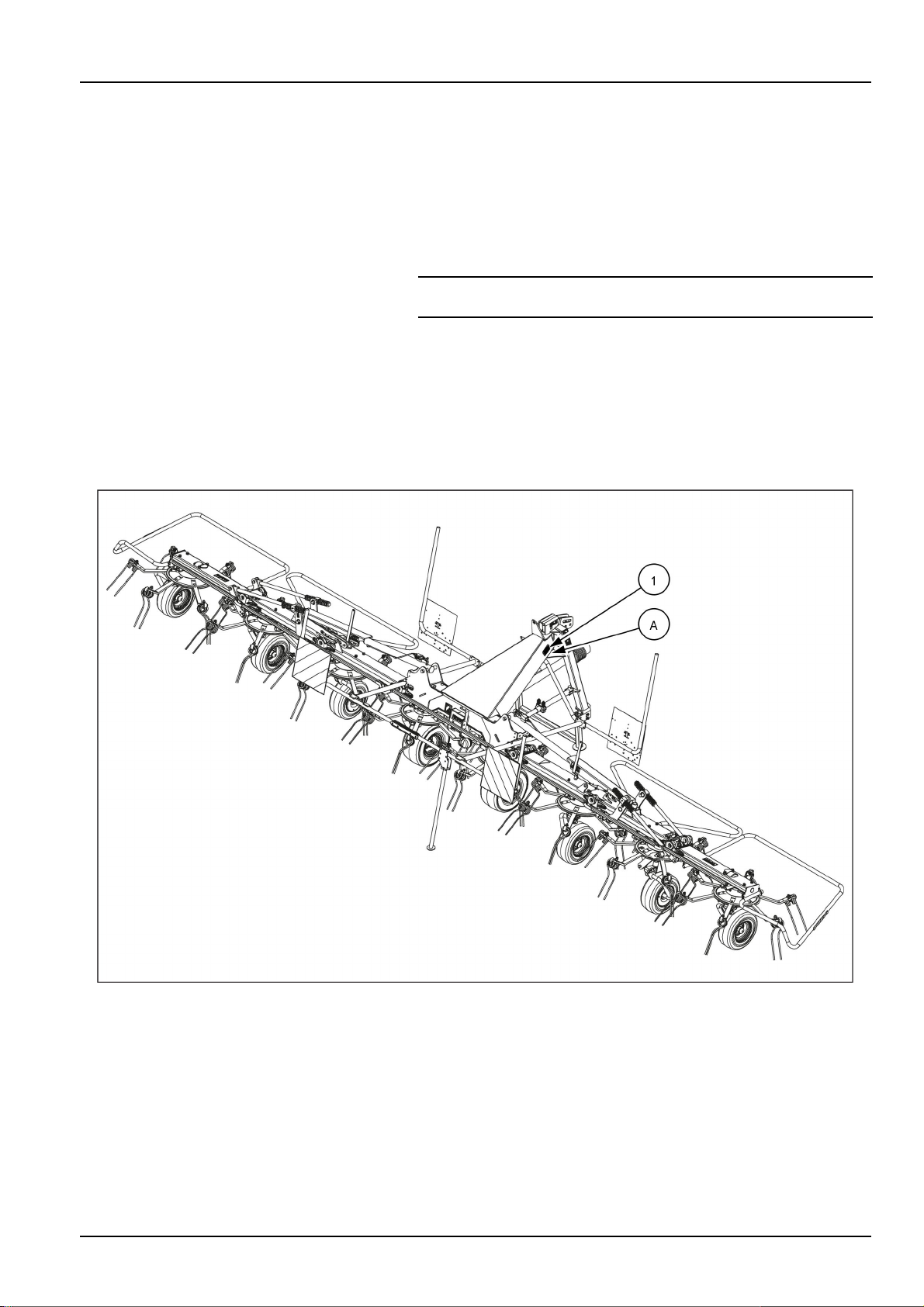

1-GENERALINFORMATION

Productidentication

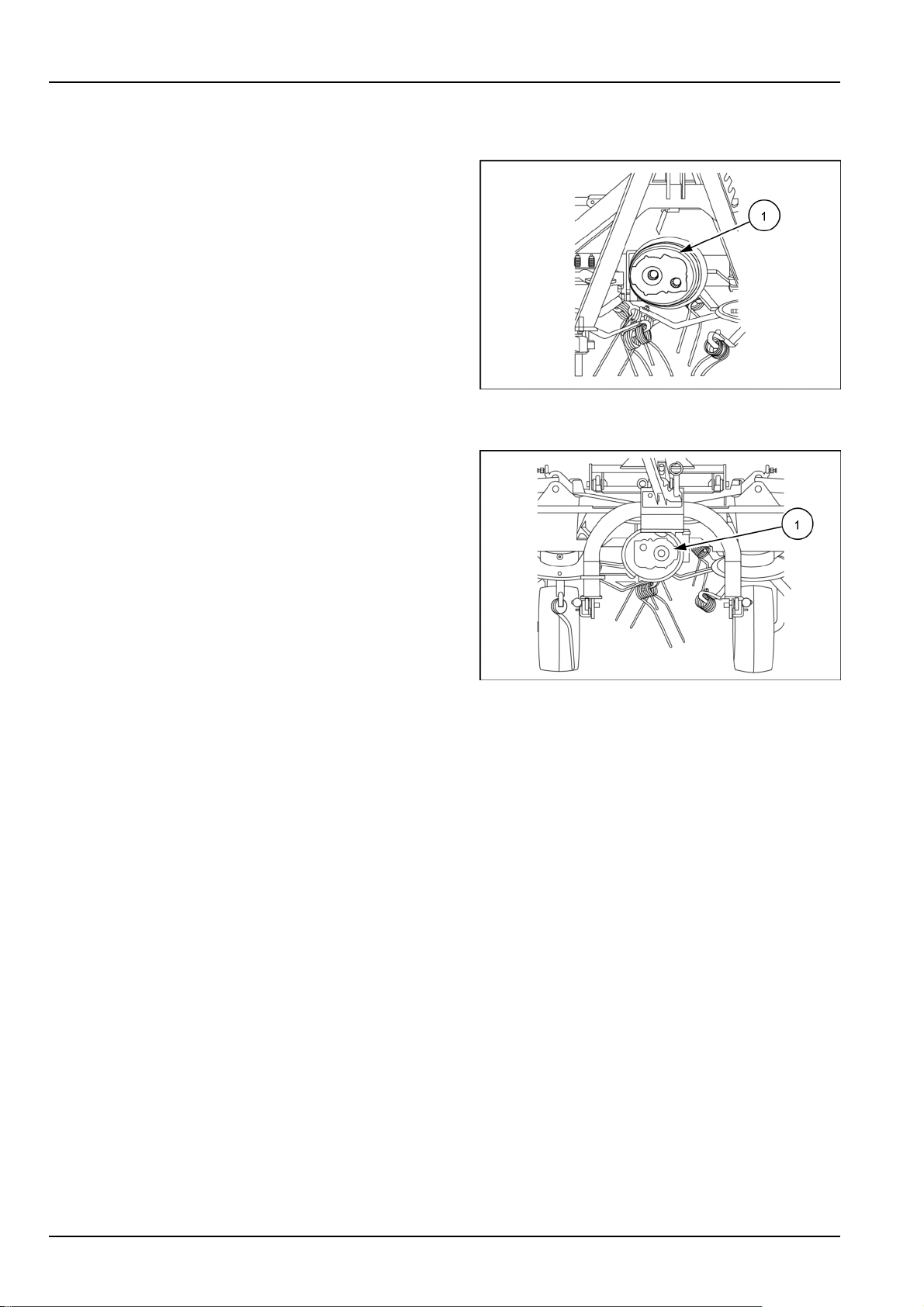

NOTE:DonotremoveorchangetheProductIdenticationNumber(PIN)plate(1)ontheimplement.

Forfuturereference,recordyourimplementmodeland

PINinthespacesbelow.

Model

ProductIdenticationNumber(PIN)

Z8805

ThePINplate(1)isplacedontheright-handsideofthe

implement.

ThePINisalsoengravedonthechassisat(A)belowthe

PINplate(1).

ZEIL18HT00835FA1

1-11

Page 18

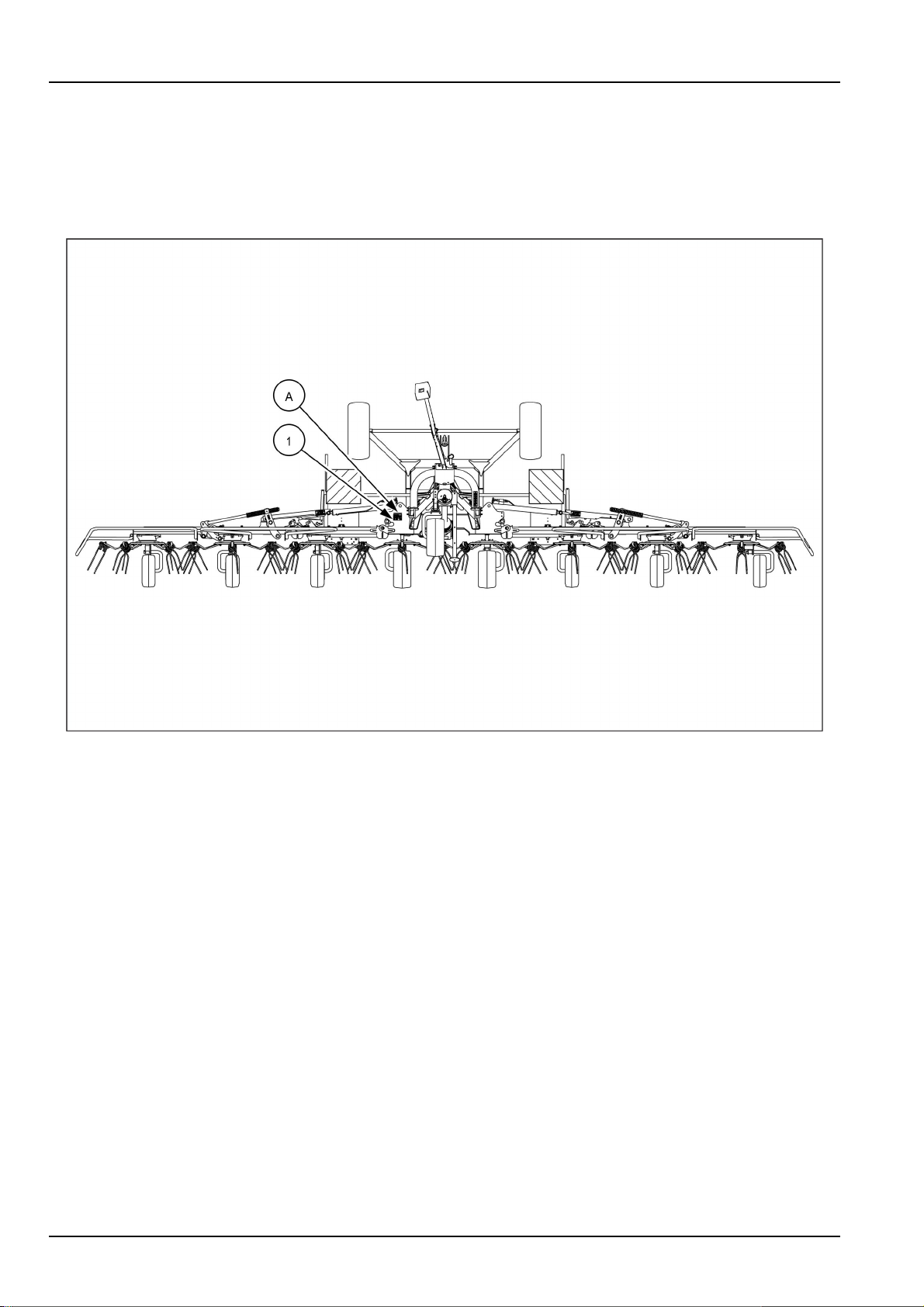

1-GENERALINFORMATION

Z8805T

ThePINplate(1)isplacedonthefrontsideoftheimple-

ment.

ThePINisalsoengravedonthechassisat(A)abovethe

PINplate(1).

ZEIL18HT00836FA2

1-12

Page 19

1-GENERALINFORMATION

Operator'smanualstorageonthemachine

Keepthisoperator'smanualprotectedandaccessibleon

thetractorwheneveryoutransportoroperatetheimplement.

1-13

Page 20

1-GENERALINFORMATION

Implementorientation

NOTE:T odeterminetheleft-handsideandtheright-hand

sideoftheimplement,standbehindtheimplementand

facethedirectionoftravelduringworkingoperation.

Thefollowingoverheadviewillustrationisageneralrepresentationoftheimplement.Theillustrationindicatesthe

sides,front,andrearorientationsoftheimplementasreferredtothroughouttheoperator’smanual.

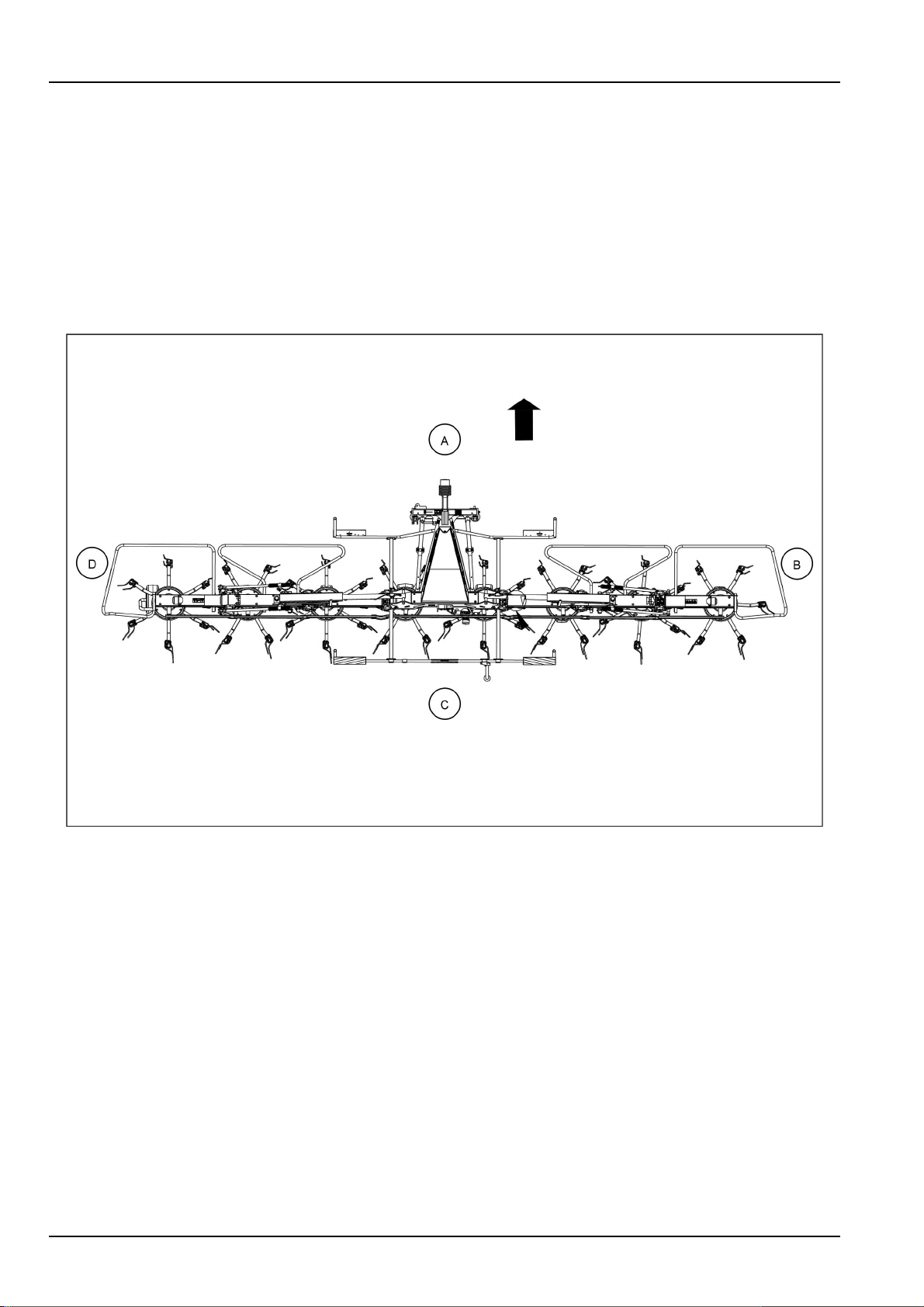

Z8805

NOTE:Thearrowindicatesthedirectionoftheimplement

duringworkingoperation.

(A)Frontoftheimplement.

(B)Right-handsideoftheimplement

(C)Rearoftheimplement..

(D)Left-handsideoftheimplement.

ZEIL18HT00838FA1

1-14

Page 21

1-GENERALINFORMATION

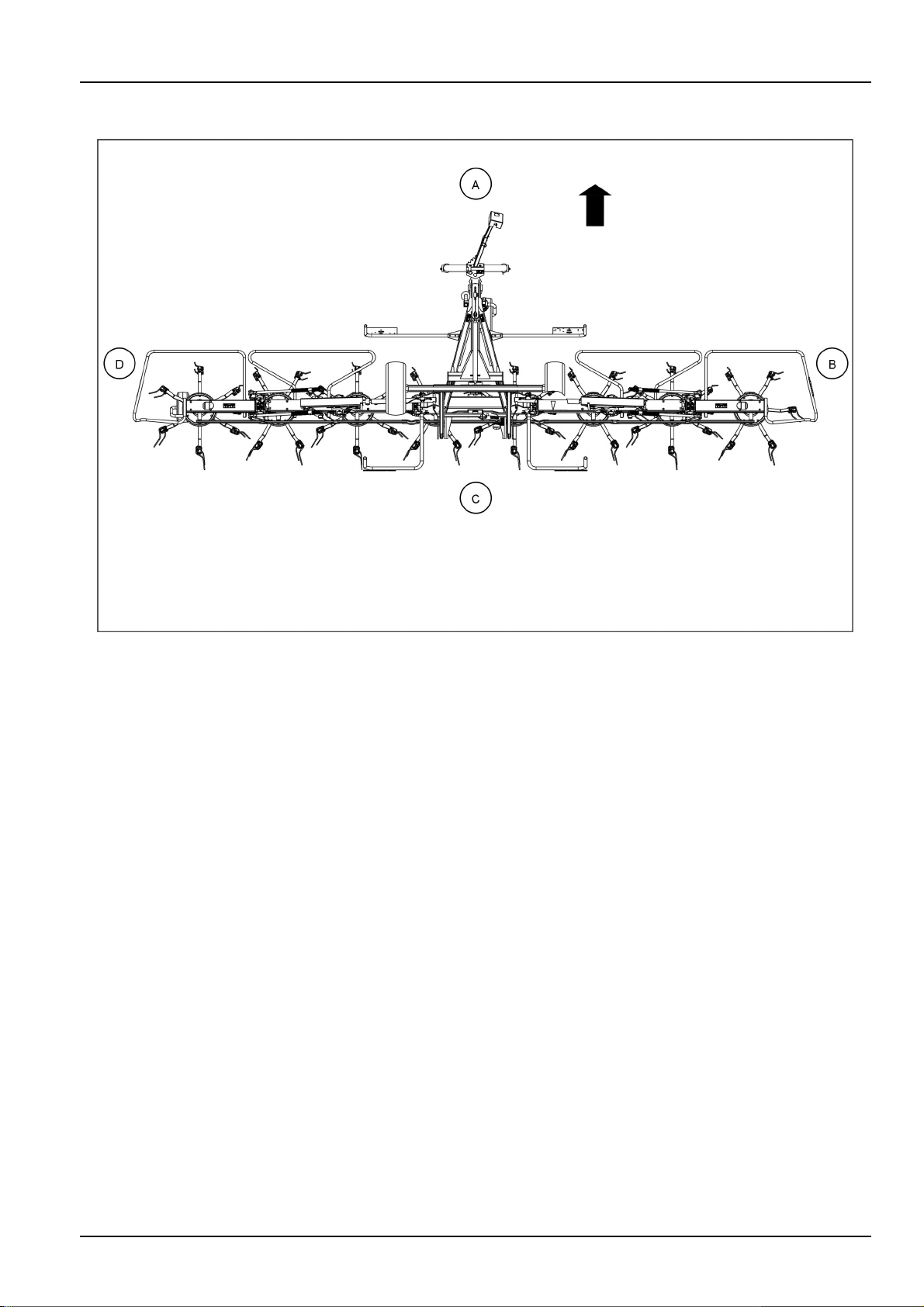

Z8805T

NOTE:Thearrowindicatesthedirectionoftheimplement

duringworkingoperation.

(A)Frontoftheimplement.

(B)Right-handsideoftheimplement.

(C)Rearoftheimplement.

(D)Left-handsideoftheimplement.

ZEIL18HT00839FA2

1-15

Page 22

1-GENERALINFORMATION

1-16

Page 23

2-SAFETYINFORMATION

2-SAFETYINFORMATION###_2_###

Safetyrulesandsignalworddenitions

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

ThroughoutthismanualyouwillndthesignalwordsDANGER,WARNING,andCAUTIONfollowedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworkingwithyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationthat,ifnotavoided,willresultindeathorseriousinjury.

WARNINGindicatesahazardoussituationthat,ifnotavoided,couldresultindeathorseriousinjury.

CAUTIONindicatesahazardoussituationthat,ifnotavoided,couldresultinminorormoderateinjury.

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESULT

INDEATHORSERIOUSINJURY .

Machinesafety

NOTICE:Noticeindicatesasituationthat,ifnotavoided,couldresultinmachineorpropertydamage.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachineor

propertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationthatclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

2-1

Page 24

2-SAFETYINFORMATION

Generalrecommendations

Mostfarmmachineryaccidentscanbeavoidedbythe

observanceofafewsimplesafetyprecautions.

Thisoperator’smanualcontainsimportantinformation

•

concerningoperation,maintenanceandadjustmentof

theimplement.Furthermore,thisoperator’smanual

mentionsandemphasizesallthesafetyinstructions.

Readtheoperator’smanualthoroughlybeforeyou

•

start,operate,service,orcarryoutanyotheroperation

ontheimplement.Eventhoughyouhavebeendriving

asimilarimplementbefore,youmustreadthemanual.

Thisisamatterofyourownandotherpeoplesafety.

Afewminutesreadingwillsaveyoutimeandhassle

later.Lackofknowledgecanleadtoaccidents.

Yourimplementwasdesignedwithsafetyinmind.

•

However,thereisnorealsubstituteforcautionand

attentionwhenyouneedtopreventanaccident.Once

anaccidenthasoccurred,itistoolatetothinkabout

whatyoushouldhavedone.Thismeansthatitis

veryimportantthatyouasuseroftheimplementpay

attentionandusetheimplementcorrectlyandthereby

avoidexposingyourselfandotherstounnecessary

danger.

Theimplementmustbeoperatedonlybyresponsible

•

personswhohavebeenadequatelytrainedandautho-

rizedtousetheimplement.Neverleavetheimplement

toothersbeforeyouhavemadesurethattheyhavethe

necessaryknowledgetooperatetheimplementsafely.

Neverlettheimplementrunwithoutsupervision.

•

Alwayskeeparstaidkithandy.

•

Takethenecessaryprecautions(forexampleassis-

•

tance)toalwaysbeawareofthepossiblepresenceof

bystandersandpets.

Keepchildrenawayfromandofftheimplementatall

•

times.

Donotusethisimplementasalift,ladderorplatform

•

toworkatheights.

Beforeyouworkontheimplement,disengageall

•

drives,stoptheengineandremovetheignitionkey.

Waitfortherotatingpartstorundown.

Neverworkaroundtheimplementwithlooseclothing,

•

jewelry,watches,longhairandotherlooseorhanging

itemscanbepulledinbythemovingpartsoftheimplement.

Keephandsawayfrommovingpartsoftheimplement.

•

Neverattempttocarryoutanyadjustmentsontheim-

•

plementwhiletheimplementisinmotionorwhilethe

PowerT ake-Off(PTO)shaftisengaged.

PTOdrivenimplementcancausedeathorseriousin-

•

jury.BeforeyouworkonornearthePTOshaftorser-

viceorclearthedrivenimplement,disengagethePTO,

stoptheengineandremovetheignitionkey.

2-2

Page 25

2-SAFETYINFORMATION

Illustrations

WARNING

Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment.

Replaceallshieldsbeforeoperatingthemachine.

Failuretocomplycouldresultindeathorseriousinjury .

NOTE:Someoftheillustrationsinthismanualhavebeen

obtainedbyphotographingprototypes.Standardproductionmachinesmaydifferinsomedetails.

W0012A

2-3

Page 26

2-SAFETYINFORMATION

Legalobligations

Yourmachinemaybeequippedwithspecialguardingor

otherdevicesincompliancewithlocallegislation.Some

oftheserequireactiveactionbytheoperator.

Therefore,checklocallegislationontheusageofthismachine.

2-4

Page 27

Fireorexplosionprevention

2-SAFETYINFORMATION

1.Cropmaterial,trash,debris,birdnestsorammable

materialcanigniteonhotsurfaces.

2.Inspecttheelectricalsystemforlooseconnectionsor

frayedinsulation.Repairorreplacelooseordamaged

parts.

3.Donotstoreoilyragsorotherammablematerialon

theimplement.

4.Donotweldoramecutanyitemsthatcontain

ammablematerial.Cleanitemsthoroughlywith

non-ammablesolventbeforeyouweldorcutwitha

ame.

5.Donotexposetheimplementtoames,burningbrush

orexplosives.

6.Promptlyinvestigateanyunusualsmellsorodorsthat

mayoccurduringtheoperationoftheimplement.

2-5

Page 28

Hazardouschemicals

2-SAFETYINFORMATION

1.Ifyouareexposedtoorcomeincontactwithhazardouschemicalsyoucanbeseriouslyinjured.

Theuids,lubricants,paints,adhesives,coolant,

etcetera.requiredforthefunctionofyourmachine

canbehazardous.Theymaybeattractiveandharmfulltodomesticanimalsaswellashumans.

2.MaterialSafetyDataSheets(MSDS)provideinformationaboutthechemicalsubstanceswithinaproduct,

safehandlingandstorageprocedures,rstaidmeasuresandprocedurestobetakenintheeventofaspill

oraccidentalrelease.MSDSareavailablefromyour

dealer.

3.BeforeyouserviceyourmachinechecktheMSDSfor

eachlubricant,uid,etcetera.usedinthismachine.

Thisinformationindicatestheassociatedrisksandwill

helpyouservicethemachinesafely.FollowtheinformationintheMSDS,onmanufacturercontainers,as

wellastheinformationinthismanualwhenyouservicethemachine.

4.Disposeofalluids,ltersandcontainersinanenvironmentallysafemannerinaccordancewithlocal

lawsandregulations.Checkwithlocalenvironmentalandrecyclingcentersoryourdealerforcorrectdisposalinformation.

5.Storeuidsandlterinaccordancewithlocallawsand

regulations.Useonlyappropriatecontainersforthe

storageofchemicalsorpetrochemicalsubstances.

6.Keepoutofreachofchildrenorotherunauthorized

persons.

7.Additionalprecautionsarerequiredforappliedchemicals.Obtaincompleteinformationfromthemanufacturerordistributorofthechemicalsbeforeyouuse

them.

2-6

Page 29

Startinguptheimplementsafely

2-SAFETYINFORMATION

Beforeyouattachtheimplementtothetractor,ensurethat

thetractorisingoodworkingorderandthatthebrakes

areefcient,particularlyifyouoperateonhillyground.

Also,ensurethatthehydraulicorpneumaticsystemis

compatiblewiththatoftheimplement.

Whenyouattachtheimplementtothetractor:

Neverallowanyonetostandbetweenthetractorand

•

theimplement.Anunintentionalmanoeuvrewiththe

tractormaycauseseriousinjury.

Nevergounderanunsupportedimplement.

•

Installalltheguardscorrectlybeforeyouusetheimplement.

Replacewornanddamagedcanvasesbeforeyouwork

withtheimplement.

MakesurethatyouarethoroughlyfamiliarwiththeinstrumentsandcontrolsbeforeyouengagethePowerT akeOff(PTO)driveforthersttime.

ThePTOshafthasitsowninstructionmanualthatthe

manufacturersupplywiththeimplement.T oensurethe

correctuseoftheshaft,followalltheinstructionsofthe

manufacturermanual.Payparticularlycloseattentionto

thesafetyandmaintenanceinstructions,inordertopreventunintentionalinjuryanddamage.

RepairimmediatelyadamagedPTOshaftbeforeyou

workwiththeimplement.

AlwaysstopthePTOandthetractorengineandremove

theignitionkeybeforeyouconnectthePTOdriveshafts.

Afteryouattachtheimplementtothetractor,ensurethat

thePowerTake-Off(PTO)lockpinisproperlyengaged

inthetractorPowerTake-Offshaft.Anincorrectlylocked

PTOshaftcouldworklooseandcauseaccidentsordamagetotheimplement.

MakesuretoinstallandsecurethePTOdriveshaftcorrectly.Checkthatthelockpinisinmesh.Fastenthe

supportchainatbothends.

Alwaysmakesurethattheguardtubesdonotseparate

atthemaximumworkingortransportlengthofthePTO

driveshaft.Checkalsothattheguardtubesdonotjamat

theminimumworkingortransportlengthofthePTOdrive

shaft.

Unlesstheprotectiveguards,thePTOdriveshaftmay

causeseriousinjury.Becarefulnottodamagetheguards

whenyouconnectthePTOdriveshafttoorfromthetractor.

FitcorrectlytheguardsonthePTOdriveshaft.Secure

theguardofthePTOshaftwiththechain.

DonotusePowerTake-Off(PTO)driveshaftswithother

specicationsthantheshaftwhichwassuppliedwiththe

implement.

BeforeyouinstallthePTOdriveshaft,checkthattheRevolutionsPerMinute(RPM)anddirectionofthePTOonthe

tractormatchthoseofthePTOontheimplement.

Beforeyoustartuptheimplement(forexampletherst

timeafteralongstandstillperiod),makesurethatthere

arenodetachedloosepartsonthedrivelineareaandon

themovingpartsoftheimplement.

2-7

Page 30

Travelingonpublicroads

2-SAFETYINFORMATION

Complywiththerelevanttrafcregulations

WARNING

Impacthazard!

Takecarewhenmakingturns.Themachine

rearendswingsoutwhenchangingdirection.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Lossofcontrolhazard!

Unevenbrakeforceexistsonleft-handand

right-handbrakes.Alwaysusebrakepedal

couplerwhentravelingonpublicroadstoensurebrakesareactuatedtogether.

Failuretocomplycouldresultindeathorseriousinjury.

Theimplementisbuiltaccordingtothehomologationrequirementsofyourcountry.Donotmodifytheimplement

inasensethatwouldconictwiththenationalregulations.

Ifyouwishtotransporttheimplementonthepublicroad,

makesurethatthecombinationtractorandimplement

observesthetrafcrulesinyourcountry.Thisgivesyou

andyoursurroundingsthebestpossiblesafety.

Passengers

Donotallowpassengerstorideinthetractorunlessa

specicseatisprovided.

Duringtransport,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

W0089A

W0081A

Transportsafety

Transporttheimplementonlyintransportposition.Securetheimplementfortransport.Alwaysactivatethemechanicaltransportsafetydevicesbeforetransport.

Makesuretotallthehitchpinswithretainingpinscorrectly.Mechanicallysecurethehydrauliccylinderstopreventcylindersfromcreeping.

Drivesafe

Donotdriveundertheinuenceofalcoholordrugs.

Nevertravelatspeedincrowdedareas.

Whenyoumaneuverthetractorwiththeimplement,alwaysbeawareandconsciousofitssize.

Thetractordrivermustnotleavethecabinduringtransport.

Theoperatorsmustobserverelevantstatutoryorother

nationalregulationsthatdealwithroadsafetyandlabor

safetyissues.

Beforeyoudrivetheimplementonpublicroads:

Checktheallowabletransportdimensionsandweights.

•

Installcorrectlythelightingandthewarningpanels.

•

Alwaysobservetheprinciplesforpermissibleaxleloads,

thetotalunitmassandthetransportgauge.

Observethetractormanufacturerregulationsandrecommendations,specicallythoserelatingtomaximumtransportloadsandmaximumspeed.

Eveninsimilarcircumstances,themaximumallowed

speedcanvarydependingonwhichcountryyoutravel

in.

Alwaysdrivewiththestatutorylightsandsafetymarking

duringtransportonpublicroadandatnight.

Installalltherequiredsignsthatindicatethevehiclewidth.

Alsoinstallalltherequiredlightsthatindicatethevehicle

widthduringthenightlytransport.Ifindoubt,contactyour

governmentdepartmentresponsibleforroadtransport.

Alwaysconsiderotherroadusers.

Alwaysadoptsafedrivingpractices.Slowdownandsignalbeforeturning.Givewaytooncomingtrafcinallsituations,includingnarrowbridges,intersectionsetcetera.

Pullovertoallowfastertrafctopass.

Iftheimplementismarkedwithamaximumspeedlimit,

neverexceedthismaximumspeedlimit.

Alwaysadjustthedrivingspeedtotheroadandweather

conditions.Incaseofbadroadconditionsandhighdrivingspeeds,bigforcesmayoccurandcauseoverloadof

tractorandimplement.

Driveatasafespeedtoensurecontrolandabilitytostop

inanemergency.

Lockthetractorbrakepedalstogether.Neveruseindependentbreakingattransportspeeds.

Mountedimplementsandballastweightsinuencethe

driving,steeringandbrakingcapacityofthetractor.Make

surethattheadditionalweightoftheimplementonthe

linkagedoesnotcompromisedriving,steeringandbrakingcapacityofthetractor.Installfrontweightsorrepair

thebrakesifthetractorisnotsafetodrive.

Travelmayberestrictedtocertainroadtypes.Transport

mayberestrictedtodaytimeoroutsidepeaktrafchours.

Howeverplanyourroutetoavoidheavytrafcandpeak

trafchours.

Reducespeedduringturns.Tractorshavenotbeendesignedforfastturning.Avoidthattherearendoftheimplementhitsanobstacle.

2-8

Page 31

2-SAFETYINFORMATION

Whenyouturnduringtransportpayattentiontotheoverhangand/oroscillatingweightoftheimplement.

Useenginebrakingwhenyoudrivedownhills.Donot

coast.

Watchforobstructions,particularlyifover-width.Observe

anyloadratingsapplicableonbridges.

Afteryounishthetransport,beforeyouleavethetractor,

alwayslowertheimplementtothegroundinparkingposition,turnoffthetractorengine,pulltheparkingbrake,

andremovethekeyfromtheignition.

2-9

Page 32

Operatingtheimplementsafely

WARNING

Hazardtobystanders!

Alwayssoundthehornbeforestartingthemachine.Makesuretheworkareaisclearof

otherpersons,domesticanimals,tools,etc.

beforeyouoperatethemachine.Neverallow

anyoneintheworkareaduringmachineoperation.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Rotatingparts!

Keepclearofalldrivesandrotatingcomponents.

Failuretocomplycouldresultindeathorseriousinjury.

2-SAFETYINFORMATION

Neverattempttoremoveresiduesfromtheimplement

whiletheimplementruns.Suchanimprudencecouldcost

lifeorlimb.AlwaysdisengagethePowerT ake-Off(PTO)

shaftmechanism,switchOFFthetractorengineandapplytheparkingbrakebeforeyouremoveresidues.

Duringthedailyworkyoumustconsiderthatloosestones

andforeignmatteronthegroundmightgetincontactwith

therevolvingpartsandgetthrownoutagainatavery

highspeed.Therefore,beforeyouoperatetheimplement

makesurethatallsafetyguardsareintact,properlytted

W0304A

W1101A

andsecured.

Beforeyouraiseorlowertheimplementwiththelinkarms

ofthetractor,checkthatnobodyisneartheimplementor

touchestheimplement.

Alwaysoperatetheimplementatasafespeedinaccordancewiththegroundconditions.Onunevenground,

proceedwiththeutmostcautiontoensureproperstability.

NOTE:Onlyputtheimplementintooperationaccording

totheinstructionsfromthedealer.

Neveroperatetheimplementundertheinuenceofalcohol,drugs,orwhileotherwiseimpaired.

Avoidusingtheimplementinunsuitableeldandweather

conditions.Itisbettertostopworktemporarilyratherthan

tooperateinsuchconditions.

Keeppeopleawayfromtheimplementduringoperation.

Askbystanderstoleavetheeld.Thereistheriskfor

bystanderstobeoverrunbytheimplement.Stoptheimplementimmediatelyifsomeoneapproaches.

Thetractororitsimplementmaystrikeorcrushagainsta

personorpetwithintheoperatorareaofthetractor.DO

NOTallowanyonetoentertheworkarea.Makesurethat

theareaisclearandoperationissafebeforeyoumove

theimplement.

Whenyouoperatetheimplement,alwaysremainseated

inthetractorcab.Operatecontrolsonlywhenseatedin

thetractorseat,exceptforthosecontrolsexpresslyintendedforusefromotherlocations.

Whenyouturnonhillsidesalwaysbecarefulwhenyoulift

theimplementwiththe3-pointlinkagebecausethereisa

riskofoverturning.Adjustthespeedtotheseconditions.

Driveinalowtractorgearifyouworkonhillsides.

Whenyoudriveupanddownandacrosshillsides,avoid

sharpturns.

Whenyouturnduringoperation,payattentiontotheoverhangand/oroscillatingweightoftheimplement.

Avoidchangingdirectionabruptly,especiallywhenyou

reverse,toavoiddangerouspitchingoftheimplement.

Whenyouworkwiththeimplementkeepasafedistance

fromsteepslopesandsimilargroundconditions,asthe

groundmaybeslipperyandpulltheimplementandthe

tractorsideways.Alsoremembertoadjustthespeedfor

sharpturnswhenyoudriveonhillsides.

Paythenecessaryattentionwhileyouoperatenextto

publicroadsorfootpaths.

Whileinoperation,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

2-10

Page 33

Stoppingtheimplementsafely

WARNING

Movingparts!

Somecomponentsmaycontinuetorunafter

disengagingthedrivesystems.Makesure

alldrivesystemsarefullydisengagedandall

movementhasstoppedbeforeservicingthe

machine.

Failuretocomplycouldresultindeathorseriousinjury.

2-SAFETYINFORMATION

thetractorcab,thenthefollowingprecautionsmustbe

followed:

•

•

•

•

Whenyouparktheimplementtherearesomeoperational

W0002A

riskswhichmaycausepersonalinjury.Therefore,you

must:

Bringthetractorenginetolowidlespeed.

Disengagealldrivesystems.

Shiftthetractortransmissionintoneutral.

Applytheparkingbrake.

Alwaysinterrupttheoperationoftheimplementbefore

youleavethetractorseat.

Forsafety'ssakeneverleavethetractorcabwithoutrst

todisengagethePowerT ake-Off(PTO)shaftmechanism

andtostopthetractorengine.Furthermore,ifyouleave

thetractorunattended,alwaysremovetheignitionkey.

StopthetractorengineandthePTOshaftandwaituntil

theimplementhascompletelystoppedbeforeyouopen

anyofthesafetyguards.Therearerotatingpartsunderthesafetyguardswhichmaycontinuerotatingafter

theimplementhasbeenstopped.Lookandlistenforevidenceofrotatingpartsbeforeyouopenanyofthesafety

guards.

Makesuretosecurethetractorbymeansofthehand

brakeand/orstopblocksifyouneedtostandbetween

thetractorandtheimplement.

When,duetoexceptionalcircumstances,youwould

decidetokeepthetractorenginerunningafterleaving

Makesurethatthegroundisrmandevenduringpark-

•

ing.

Makesurethattractorandimplementcannotmove.

•

Alwayslowertheimplementtotheground.

•

Stopthetractorengineandremovetheignitionkey.

•

Usecorrectsupportortransportsafetydevicewhenthe

•

implementisparked.Makesurethattheparkingstand

issecured.

Whenyoudetachtheimplementfromthetractor:

Alwaysdetachtheimplementcarefullyandonaat

•

surfacetopreventdamage.

Makesurethatnobodystandsinfrontoftheimplement.

•

Neverallowanyonetostandbetweenthetractorand

•

theimplement.

Nevergounderanunsupportedimplement.

•

2-11

Page 34

2-SAFETYINFORMATION

Maintenance

WARNING

Maintenancehazard!

Beforeyoustartservicingthemachine,attach

aDONOTOPERATEwarningtagtothemachineinavisiblearea.

Failuretocomplycouldresultindeathorseriousinjury.

Followthemaintenanceschedulewithregardtotheim-

•

plementservicingintervals.

Rememberthattheimplementrequiresattentionfrom

timetotime.Alsorememberthatthemaintenancewill

greatlyextendthelifeoftheimplement.

Takethenecessaryprecautions:nottospillanyoil,fuel

•

orgrease.

Toavoidoilandgreasecontactwithyourskin,wear

protectivegloves.

Servicetheimplementonarmlevelsurface.

•

Donotattempttoremovematerialfromanypartof

•

theimplement,clean,lubricateorcarryoutanyadjust-

mentsontheimplementwhileitisinuse.

Keephands,feetand/orgarmentsawayfromparts

•

whichmove.Checkthatallrotatingpartshavea

suitableprotectiveguard.

Raisedimplementand/orloadscanfallunexpectedly

•

andcrushpersonsunderneath.Neverenterorallow

anyonetoentertheareaunderneathraisedimplement

duringoperation.

Unsupportedhydrauliccylinderscanlosepressure

anddroptheimplementandcauseacrushinghazard.

Donotleavetheimplementinaraisedpositionwhile

parkedorduringservice,unlesssecurelyblockedon

woodenblocks.

Neverworkunderaraisedimplementunlessasupport

•

chainorothermechanicalsecuringdevicesecurethe

linkarmsofthetractorsothattheimplementcannot

movetoalowerpositionunintentionally.

Relievethepressure,stoptheengineandremovethe

•

ignitionkey,beforeyouconnectordisconnectuid

lines.

Beforeyouadjust,clean,lubricateoryoucarryoutre-

•

pairsontheimplement,stoptheengineandremove

W0004A

theignitionkey.

NeveradjusttheimplementwhilethePowerT ake-Off

•

(PTO)driveshaftisengaged.Donottoremovethe

guardsuntilallrevolvingpartshavestopped.

Anyleakageofhydraulicoilorfuelunderpressuremay

•

causesevereharm,soalwaysuseashielding,goggles

andgloveswhenyoutraceoilorfuelleaks.

Donotuseyourhandtocheckforleaks.Useapiece

ofcardboardorpaper.

Continuouslongtermcontactwithhydraulicuidmay

•

causeskincancer.Avoidlongtermcontactandwash

theskinpromptlywithsoapandwater.

Ifhydraulicuidordieselpenetratestheskin,seek

•

medicalcareimmediately.

Observeallrecommendationsthatarementionedin

•

thismanualsuchasserviceintervals,torques,lubri-

cants,etcetera.

Alwaysreplaceallpartsthathavedamageorwear.

•

Neverbuildexiblehoseassembliesfromhosesthat

•

werepreviouslypartofahoseassembly.

Neverweldtothetubes.

•

Alwaysusegloveswhenyouworkwithpartsonthe

•

implementasthepartscanhavesharpedges.

Transmissionandhydrauliclinesmaybecomehotdur-

•

ingoperation.Becarefulwhenyouservicesuchcom-

ponents.Allowsurfacestocoolbeforeyouhandleor

disconnecthotcomponents.Wearprotectiveequipmentwhenrequired.

2-12

Page 35

2-SAFETYINFORMATION

PersonalProtectiveEquipment(PPE)

WearPersonalProtectiveEquipment(PPE)suchasprotectiveclothing,eyeprotection,hearingprotection,dust

mask,hardhat,heavygloves,workboots,and/orany

otherPPEthatprovidesforthesafetyandprotectionof

theindividualthatoperatesthisequipment.

NHIL13RB00001AA1

2-13

Page 36

2-SAFETYINFORMATION

Safetyrequirementsforuidpowersystemsandcomponentshydraulicsystems

Beforeyoustarttheengineorpressurizethehydraulic

system,installandtightcorrectlyallthehydrauliccouplings.Checkthatallhosesandttingsarenotdamaged.

Replaceimmediatelydamagedcomponents.

Onlyconnectthehydraulichosestothetractoroutletsif

thetractorandtheimplementarepressure-free.Ifthe

hydraulicsofthetractorisactivateditmayleadtouncontrolledmovementswhichmaycausedamage.

Makesurethatnopersonsareneartheimplementwhen

youstarttheimplement,astheremightbeairinthehydraulicsystemwhichmightleadtosuddenmovements.

Whenthetractorenginehasstopped,activatethetractor

hydraulicspoolvalvestomakesurethatthereisnopressureinthehydraulichoses.

Toexpelalltheairfromtheoilinthehydrauliccylinders,

testallthefunctionsafteryouconnectthehydraulicconnectionstothetractor,especiallybeforeyouenterordrive

onthepublicroads.

2-14

Page 37

2-SAFETYINFORMATION

Noiseemission

ThemeasuringandreportingofthenoiselevelwerecarriedoutaccordingtoISO5131.

Thenoiselevelproducedbytheimplementisbelow

70dB.

Thenoiselevelwasmeasuredinthecabinofthetractor

wheretheheadoftheoperatorisusuallysituated.

Usehearingprotectorsifthenoisefromtheimplementis

annoyingorifyouworkwiththeimplementforaconsiderableperiodinatractorcabinthathasnotaadequate

soundproofcabin.

2-15

Page 38

2-SAFETYINFORMATION

Vibrationlevels

Installallrevolvingpartscorrectlybeforeyoustarttheimplement.Anunbalancecancreatevibrationsthatdamage

theimplement.

NOTE:Youmustcheckthattheallpartareinthecorrect

positionbeforestarttheimplement.

NOTE:Ifthevibrationsorthenoiseoftheimplementincreaseconsiderablyduringtheoperation,stopthework

immediately.Correctthefaultbeforeyoucontinuethe

work.

2-16

Page 39

2-SAFETYINFORMATION

Implementstability

Thecombinationofyourtractorandimplementcanbecomeunstable,duetotheadditionalweightthattheimplement

addstothetractor.

Inordertoguaranteestableandsafetransport,youmustcheckifyouneedballastweightsfortransportandeld

work.

Youmustalsocheckandguaranteethatyouhaveatleast20%fromthetractorweightonthefrontaxle.

Forrearmountedimplementsandfront-rearcombinations,theformulais:

ZEIL18HT00277FA1

Exampleofreferencestostabilityofthecombinationtractor–implement

Listofsigns

Te[kg]Thetractorownweight.

Tf[kg]

Tr[kg]Rearaxleloadwithemptytractor.

Ir[kg]

If[kg]Totalweightofthefront-mountedimplement/frontballast.

a[m]

b[m]Thetractorwheeldistance.

c[m]

d[m]

Frontaxleloadwithemptytractor.

Totalweightoftherear-mountedimplement/rearballast.

Distancebetweenthecenterofgravityofthefront-mountedimplement/frontballastandthe

middleofthefrontaxle.

Distancebetweenthemiddleoftherearaxleandthemiddleofthelinkarmballs.

Distancebetweenthemiddleofthelinkarmballsandthecenterofgravityoftherearmounted

implement/rearballast.

2-17

Page 40

Ecologyandtheenvironment

2-SAFETYINFORMATION

Soil,air,andwaterqualityisimportantforallindustries

andlifeingeneral.Whenlegislationdoesnotyetrulethe

treatmentofsomeofthesubstancesthatadvancedtechnologyrequires,soundjudgmentshouldgoverntheuse

anddisposalofproductsofachemicalandpetrochemical

nature.

Familiarizeyourselfwiththerelativelegislationapplicabletoyourcountry ,andmakesurethatyouunderstand

thislegislation.Wherenolegislationexists,obtaininformationfromsuppliersofoils,lters,batteries,fuels,

anti-freeze,cleaningagents,etc.,withregardtotheeffectofthesesubstancesonmanandnatureandhowto

safelystore,use,anddisposeofthesesubstances.Y our

KONGSKILDEdealercanalsoprovideassistance.

Helpfulhints

Avoidtheuseofcansorotherinappropriatepressur-

•

izedfueldeliverysystemstolltanks.Suchdelivery

systemsmaycauseconsiderablespillage.

Ingeneral,avoidskincontactwithallfuels,oils,acids,

•

solvents,etc.Mostoftheseproductscontainsub-

stancesthatmaybeharmfultoyourhealth.

Modernoilscontainadditives.Donotburncontami-

•

natedfuelsandorwasteoilsinordinaryheatingsys-

tems.

Avoidspillagewhenyoudrainuidssuchasuseden-

•

ginecoolantmixtures,engineoil,hydraulicuid,brake

uid,etc.Donotmixdrainedbrakeuidsorfuelswith

lubricants.Storealldraineduidssafelyuntilyoucan

disposeoftheuidsinaproperwaythatcomplieswith

alllocallegislationandavailableresources.

Donotallowcoolantmixturestogetintothesoil.Col-

•

lectanddisposeofcoolantmixturesproperly.

Donotopentheair-conditioningsystemyourself.It

•

containsgasesthatshouldnotbereleasedintotheat-

mosphere.YourKONGSKILDEdealerorair-conditioningspecialisthasaspecialextractorforthispurpose

andcanrechargethesystemproperly .

Repairanyleaksordefectsintheenginecoolingsys-

•

temorhydraulicsystemimmediately.

Donotincreasethepressureinapressurizedcircuitas

•

thismayleadtoacomponentfailure.

Batteryrecycling

Batteriesandelectricaccumulatorscontainseveral

substancesthatcanhaveaharmfuleffectontheenvironmentifthebatteriesarenotproperlyrecycledafter

use.Improperdisposalofbatteriescancontaminate

thesoil,groundwater,andwaterways.KONGSKILDE

stronglyrecommendsthatyoureturnallusedbatteries

toaKONGSKILDEdealer,whowilldisposeoftheused

batteriesorrecycletheusedbatteriesproperly.Insome

countries,thisisalegalrequirement.

NHIL14GEN0038AA1

Mandatorybatteryrecycling

NOTE:Thefollowingrequirementsaremandatoryin

Brazil.

Batteriesaremadeofleadplatesandasulfuricacidsolution.Becausebatteriescontainheavymetalssuchas

lead,CONAMAResolution401/2008requiresyoutoreturnallusedbatteriestothebatterydealerwhenyoureplaceanybatteries.Donotdisposeofbatteriesinyour

householdgarbage.

Pointsofsaleareobligedto:

Acceptthereturnofyourusedbatteries

•

Storethereturnedbatteriesinasuitablelocation

•

Sendthereturnedbatteriestothebatterymanufacturer

•

forrecycling

2-18

Page 41

2-SAFETYINFORMATION

Safetysigns

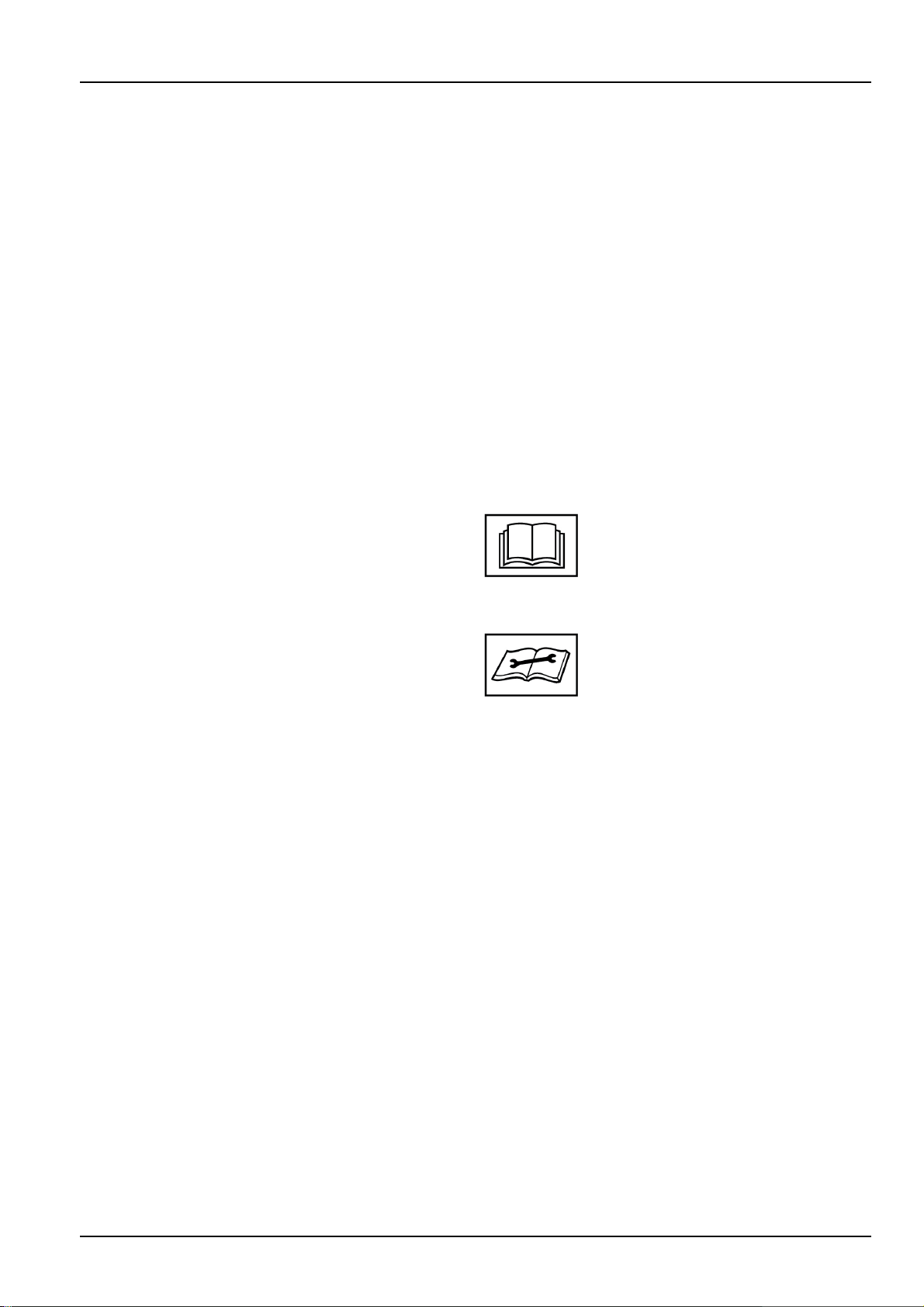

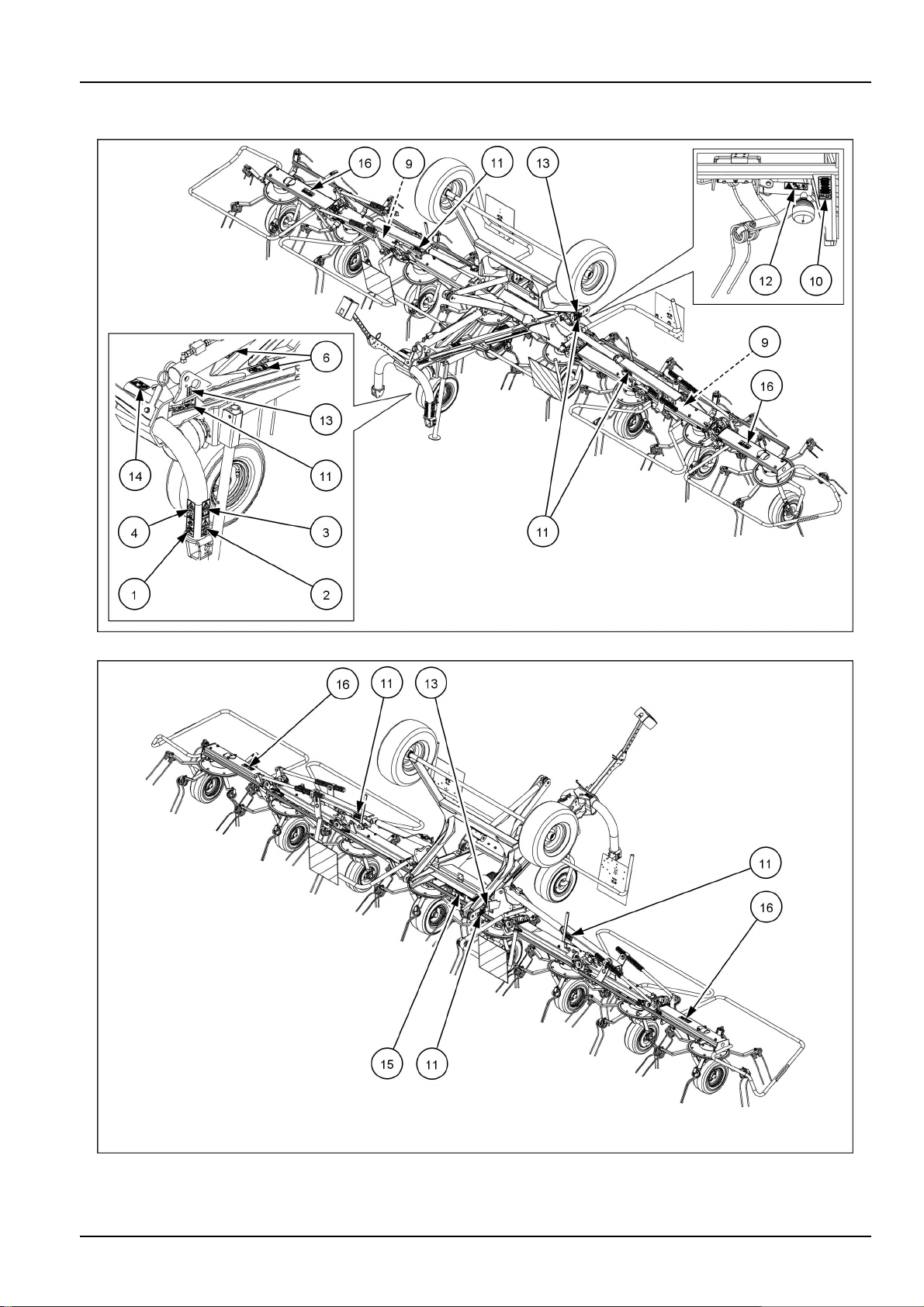

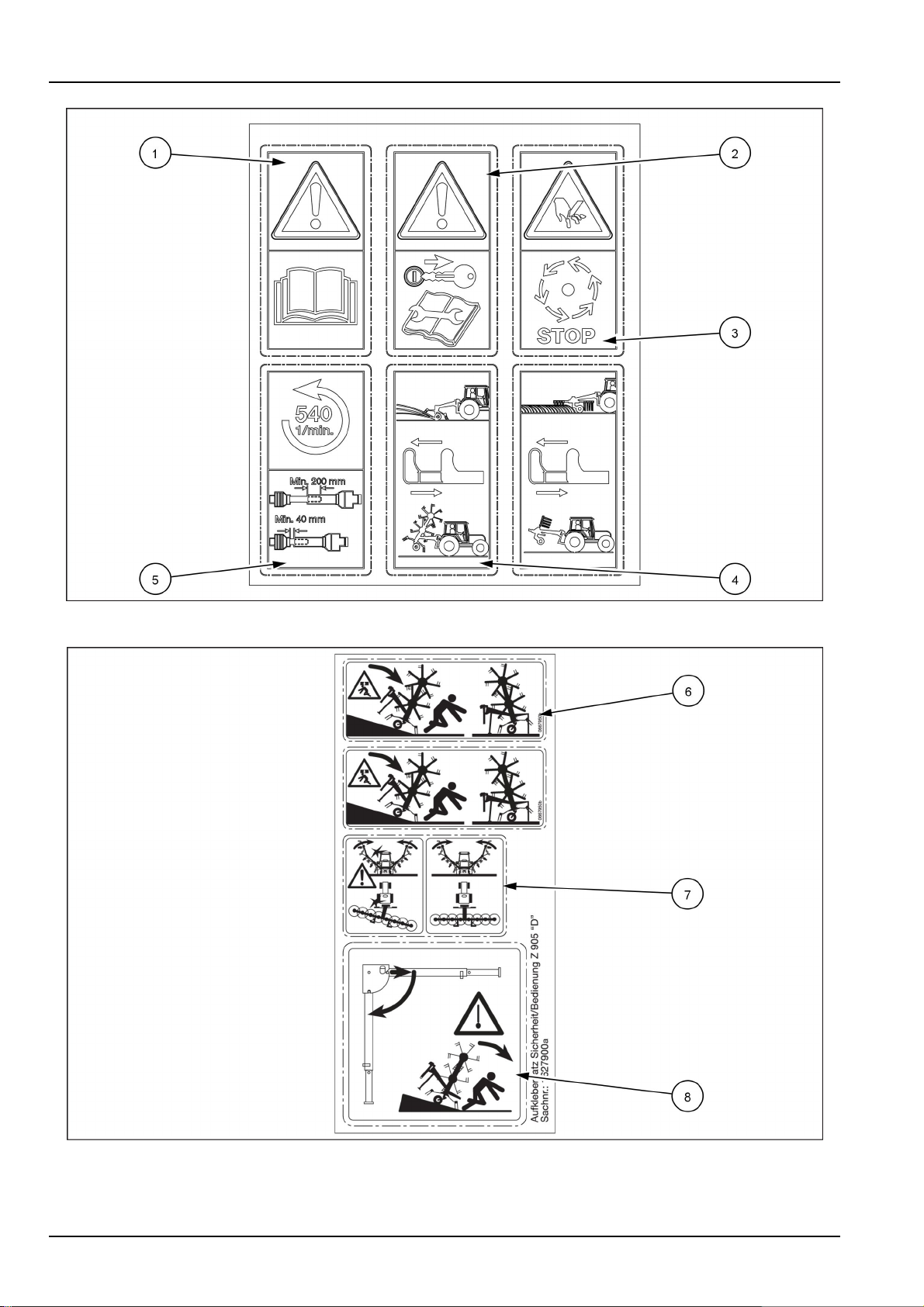

Thefollowingsafetysignsareonyourimplementasa

guideforyoursafetyandforthesafetyofthosewhowork

withyou.

Walkaroundyourimplementandnotethesignicance

andlocationofallsafetysignsbeforeyouoperateyour

implement.Readallthesafetysignsadheredtotheimplementandfollowtheinstructions.

Keepallsafetysignscleanandlegible.Cleansafetysigns

withasoftcloth,water,andagentledetergent.

NOTICE:Donotusesolvent,gasoline,orotherharsh

chemicals.Solvents,gasoline,andotherharshchemicalsmaydamageorremovethesafetysigns.

Replaceallsafetysignsthataredamaged,missing,

paintedover,orillegible.Ifasafetysignisonapartthat

youoryourdealerreplaces,makesurethatyouoryour

dealerinstallthesafetysignonthenewpart.Contact

yourdealerforthereplacementofthesafetysigns.

Safetysignsthatdisplaythe“Readoperator’smanual”

symboldirectyoutotheoperator’smanualforfurtherinformationregardingmaintenance,adjustments,orproceduresforparticularareasoftheimplement.Whenasafety

signdisplaysthissymbol,consulttheappropriatepageof

theoperator’smanual.

Safetysignsthatdisplaythe“Readservicemanual”symboldirectyoutotheservicemanual.Ifyoudoubtyour

abilitytoperformserviceoperations,contactyourdealer.

2-19

Page 42

2-SAFETYINFORMATION

Z8805

ZEIL18HT00508FA1

ZEIL18HT00509FA2

2-20

Page 43

2-SAFETYINFORMATION

Z8805T

ZEIL18HT00511FA3

ZEIL18HT00510FA4

2-21

Page 44

2-SAFETYINFORMATION

81PR80-08595

Partnumber:81PR80-0859

Partnumber:811627900

1627900A6

2-22

Page 45

2-SAFETYINFORMATION

Partnumber:811627030

Safetysign(1)

Readtheoperator'smanualandthesafetyinstructions.

Readtheoperator'smanualtooperatetheimplementand

toavoidunnecessaryaccidentsanddamagestotheimplement.

WARNING

IMPROPEROPERATIONOFTHISMACHINE

CANCAUSEDEATHORSERIOUSINJURY.

MAKESURETHA TEVERYOPERATOR:

-isinstructedinthesafeandproperuseofthis

machine.

-readsandunderstandstheoperator'smanual

forthismachine.

-readsandunderstandsALLsafetysignson

themachine.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:81PR80-0859

1627030A7

811650220_48

W0188A

2-23

Page 46

2-SAFETYINFORMATION

Safetysign(2)

Alwaysstopthetractorenginebeforeyouadjust,maintain,repair,orlubricatetheimplement.Alsorememberto

removetheignitionkey.Makesurethatnobodystartsthe

engine,untilyouhavenished.

Partofpartnumber:81PR80-0859

WARNING

Avoidinjury!Alwaysdothefollowingbefore

lubricating,maintaining,orservicingthemachine.

1.Disengagealldrives.

2.Engageparkingbrake.

3.Lowerallattachmentstotheground,or

raiseandengageallsafetylocks.

4.Shutoffengine.

5.Removekeyfromkeyswitch.

6.Switchoffbatterykey,ifinstalled.

7.Waitforallmachinemovementtostop.

Failuretocomplycouldresultindeathorseriousinjury.

W0047A

811650220_29

Safetysign(3)

Movingpartsaredangerousandifthemovingpartscome

incontacttoyourbodythemovingpartscanpinchyour

body.

Thehazardmaycausesevereinjuriestotheentirebody,

withpossiblelethaleffect.

Toavoidthehazards,waituntilallmovingelements

havecompletelystoppedbeforeyoutouchthemoving

elements.

WARNING

Pinchhazard!

Waitforallmovementtostopbeforeyouserviceoradjustthemachineorequipment.

Failuretocomplycouldresultindeathorseriousinjury.

W1420A

Partofpartnumber:81PR80-0859

Safetysign(4)

Pulloutthesafetyboltduringoperationintheeld.Push

inthesafetyboltduringthetransport.

Partofpartnumber:81PR80-0859

811650220_110

81PR80-0859_611

2-24

Page 47

2-SAFETYINFORMATION

Safetysign(5)

NOTE:ValidonlyforZ8805.

ThesignindicatesthemaximumRevolutionsPerMinute

(RPM)andthedirectionofrotationofthePowerT ake-Off

(PTO).

Referencetotheminimumoverlappingontheprole

tubesandtheminimumdistancerequirednottobottom

theshaft.

Partofpartnumber:81PR80-0859

Safetysign(6)

WARNING

Overturninghazard!

Beforeparkingthemachine,makesurethe

groundisstable.Plantheworksitesothatthe

groundisat,hard,andlevel.

Failuretocomplycouldresultindeathorseriousinjury.

W0258A

811650220_312

Partofpartnumber:811627900

Safetysign(7)

NOTE:ValidonlyforZ8805.

Partofpartnumber:811627900

Safetysign(8)

NOTE:ValidonlyforZ8805.

Partofpartnumber:811627900

1627900A_113

1627900A_214

1627900A_315

2-25

Page 48

2-SAFETYINFORMATION

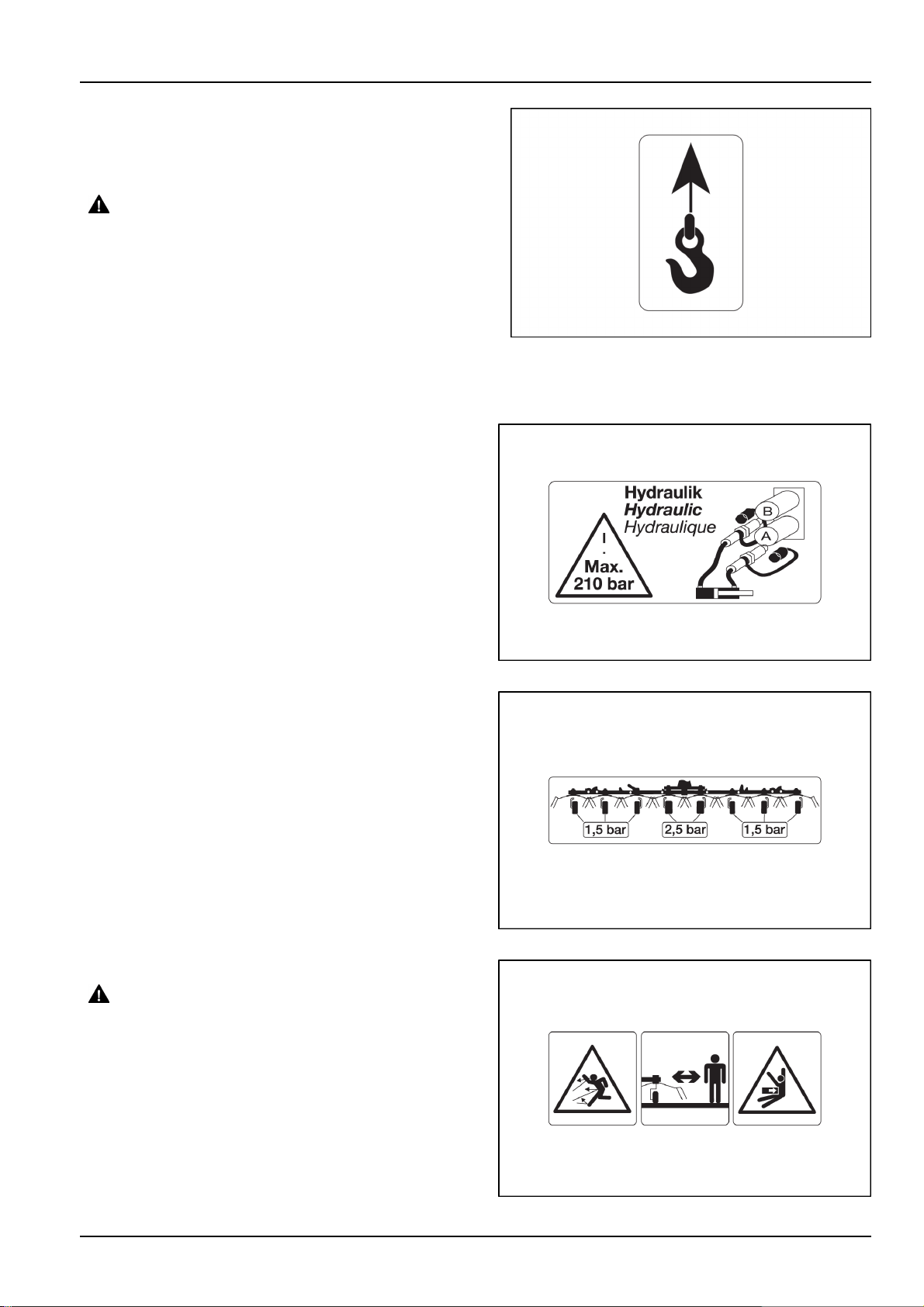

Safetysign(9)

Makesurethattherearenopersonsintheswivelareaof

theboomarms.Keepasafedistance.

Partofpartnumber:811627030

Safetysign(10)

Torqueagainallscrewsevery5hofoperation.

Partofpartnumber:811627030

1627030A_116

Safetysign(11)

Nevermoveyourhandintothedangerzoneaslongas

thepartscanmove.Thismaycauseseriousinjuryand,

atworst,resultindeath.

Partofpartnumber:811627030

Safetysign(12)

NOTE:ValidonlyforZ8805T.

Thepressuretankisundergasandoilpressure.

Partofpartnumber:811627030

1627030A_217

1627030A_318

1627030A_419

2-26

Page 49

2-SAFETYINFORMATION

Safetysign(13)

NOTE:ValidonlyforZ8805T.

Liftingpointsafetysign.

WARNING

Crushinghazard!

Usethemachineliftingpointswhenyoulift

and/ormovethemachinewithheavyhandling

equipment.Liftthemachineonlyfromtheindicatedliftingeyehookuppoints.Alwaysuse

adequateliftingequipment.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:811627030

Safetysign(14)

Thehydraulicpressuremustnotexceed210bar

(3045psi).

1627030A_520

W1432B

Partofpartnumber:811627030

Safetysign(15)

Tirepressuresafetysign.

Partofpartnumber:811627030

1627030A_621

1627030A_722

Safetysign(16)

WARNING

Rotatingparts!

Keepclearofalldrivesandrotatingcomponents.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:811627030

W1101A

1627030A_823

2-27

Page 50

2-SAFETYINFORMATION

2-28

Page 51

3-CONTROLSANDINSTRUMENTS

3-CONTROLSANDINSTRUMENTS###_3_###

Information

Operatingprinciples

Forallinformationrelatedtothedescriptionandthelocationofthecontrolstouseyourimplement,seechap-

ter“ControlsandInstruments”intheoperator’smanual

ofyourvehicle.

3-1

Page 52

3-CONTROLSANDINSTRUMENTS

3-2

Page 53

4-OPERATINGINSTRUCTIONS

4-OPERATINGINSTRUCTIONS###_4_###

Commissioningtheunit

Preparingforoperation

NOTICE:Onlyauthorizedandinformedpersonnelcan

mounttheimplement.

NOTICE:Thenecessarytoolsandadjustmenttoolsmust

beavailable.

NOTICE:Incorrectassemblyoftheimplementishighly

dangerous.Beforeyouperformthefunctionaltest,check

thecorrectassemblyoftheimplement.

NOTICE:Makesurethattherearenotoolsinthearea

aroundtheimplement.

Makesurethattherearenopersonsintheworkzone.

NOTE:Aftertheassemblyoftheimplement,performa

completefunctionaltest.

NOTE:Torqueallscrewjointsevery5hofoperation.

Theimplementisdisassembledintopartsanddelivered

onapallet.Forshipmentonabigpalletthewheelaxle

assemblyandsomearmsaredismounted.

Loosepartssuchasabagwithsmallparts(screws)and

thePowerTake-Off(PTO)shafthavebeentiedtothepalletortheimplementtosavespace.

4-1

Page 54

4-OPERATINGINSTRUCTIONS

Installationoftherotorarms

1.Thetinearm(1)ispre-assembledwiththeitemsas

follows:

Tinesupports(2)and(3).

○

Tine(4).

○

Bolt,washer,nut(5).

○

2.Torquethenut(5)to135N·m(100lbft).

3.Installthepre-assembledtinearm(1)onthehub(6)

usingtheboltsM12x40(7),thehexagonalheadbolts

12x35(8),andthelocknutsM12foreacharm.

NOTICE:Takenoticeofthesenseofrotation(A)of

therotors.

4.Afteryouinstallthetinearms(1),checkthatthetine

armsontheinnermostandtheoutermostrotorsare

exactlyoppositeeachother.

NOTICE:Donotusethebolts(8)insteadofthebolts(7).

ZEIL17HT00006AA1

ZEIL17HT00007AA2

4-2

Page 55

Startingtheunit

Connectiontothetractor

WARNING

Crushinghazard!

Usecarewhenyouconnectanddisconnect

themachines.Neverstandbetweenthetractorandtheimplementwhenyouconnectthe

linkarms.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Crushinghazard!

Donotstandorplaceanybodypartbetween

theimplementandamovingtractor.Stopthe

tractorengineandsettheparkingbrakebeforeyouattachcablesandhoses.

Failuretocomplycouldresultindeathorseriousinjury.

4-OPERATINGINSTRUCTIONS

W1545A

W1544A

WARNING

Hitchinghazard!

Alwayskeeptheareabetweenthetractorand

theimplementclearofallpersonswhilethe

tractororthree-pointhitchisinmotion.Lock

thetractortransmissioninParkandengage

theparkingbrake(s)beforeyouallowanyone

tocompletehitchingorunhitching.

Failuretocomplycouldresultindeathorseriousinjury.

Threepointsuspensiononthetractor

OnlyconnectthetedderZ8805tothethreepointsuspensionofthetractor(CategoryII).Theinstallationoftheballs

dependsontheequipmentofthetractor.

W1540A

ZEIL17HT00010AA1

4-3

Page 56

4-OPERATINGINSTRUCTIONS

ThetedderZ8805Tisequippedwithhitchpins(Category

II).Theinstallationoftheballsdependsontheequipment

ofthetractor.

Minimizethesidewaysmovementofthelinkarmsonthe

tractortoavoidoscillationoftheimplementduringwork

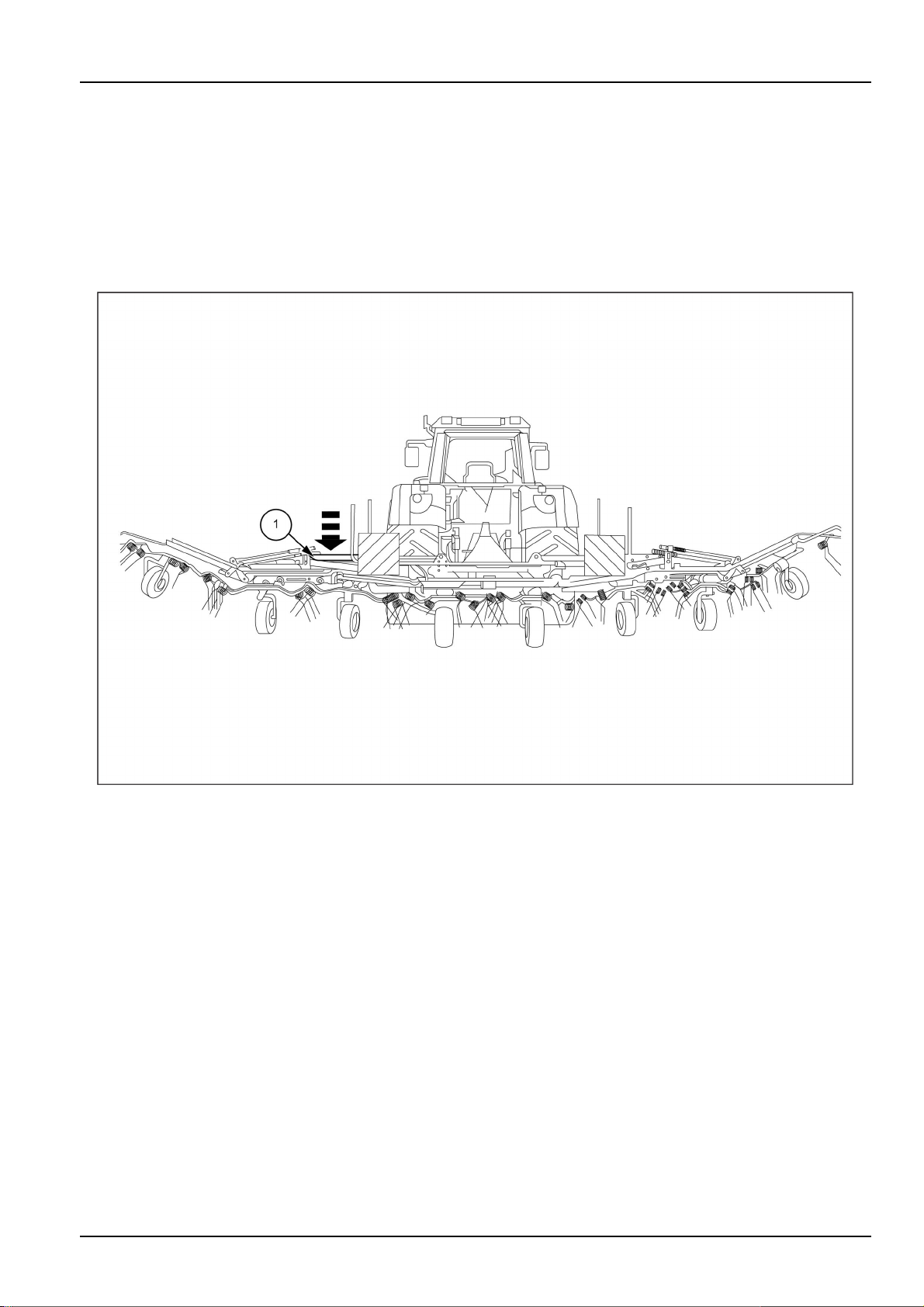

andtransport.Securethelinkarmswithlimitingchainsor

otherlockingdevice.

ZEIL17HT00112AA2

Placementofcord

Itshouldbepossibletooperatethecordforthelocking

pawlfromthetractorseat.Makesurethatthecorddoes

notgetjammedandisnotplacedonsharpedges.Relieve

thecordwhenyoulowerthepawls.

Hydraulicsystem(restriction)

Theliftingcylindersoftheimplementareequippedwith

restrictors.Donotmakeadjustmentonthetractor.

ZEIL18HT00270BA3

4-4

Page 57

4-OPERATINGINSTRUCTIONS

Electricsystem

Thelightingsystem(1)isequippedwithasevenpoleplug

forthetrailersocket.

Connectthisplugtothesocketattherearofthetractor.

NOTICE:Checkthelightingsystemaftertheconnection.

Dirtandmoisturecancausecontactproblemsorshort

circuit.Keepcleananddrytheplugconnection.Also

checkthatthesevenpinsocketofthetractorfusesare

inplaceandintact.

PowerTake-Off(PTO)connection

NOTICE:ToinstallandremovethePTOshaft,stopthe

engine.

NOTICE:OnlyusethesuppliedPTOshaftorthePTO

shaftthatthemanufacturerapprove.

AdjustthelengthofthePTOshafttothetractorbefore

youperformthefollowingsteps.Ifyouusetheimplement

withdifferenttractors,checkthatthePTOshafthasthe

correctlength.

ZEIL18HT00834AA4

NOTICE:Thesafetyguardsonthetractorsideandonthe

implementsidemustbeintact.

1.ReleasethePTOshaftfromthesupportchain.

2.PushthePTOshaftonthetractorPTOuntilyouengagethelockingballs.

3.ThesafetychainsecurethesafetyguardofthePTO

shaftsonthetractorside.Ontheimplementsidethere

isafull-coveringprotection.Theclampsecurethe

full-coveringprotection.

NOTICE:ThechainsecurethesafetyguardofthePTO

shaft.

4-5

Page 58

4-OPERATINGINSTRUCTIONS

Connectiontothetractor(forZ8805)

Connectiontothelinkarmsandtoplinkof

thetractor

NOTICE:Alwaysusethetransportlockwhenyoutransporttheimplement.

NOTICE:Theinstructionsarebasedonafullymounted

implementinlockedtransportpositionwiththesupport

foldeddown.

NOTICE:Neverstandbetweenthetractorandtheimplementduringconnectiontothetractor.

NOTICE:Makesurethattherearenopersonsinthe

swivelareaoftherotorarms.

1.Reversethetractortotheimplementandconnectthe

ballsonthepinsonthesuspensionoftheimplement

tothelinkarmsofthetractorandsecure.

2.Folddownthetoplinkonthetractorandconnectthe

toplinktotheupperballonthesuspensionofthetractorandsecure.

NOTICE:Securethetoplinkboltwithahairpincotter.The

chainofthehairpincottermusthangfreely .Securethe

linkarmballswithalynchpin.

3.Raisetheimplementwiththelinkarmsuntilthesupportisovertheground.

4.Toreleasethesupport,pulloutthehairpincotter(1).

5.Movethesupport90°totherearandlockthesupport

againwiththehairpincotter(1).

6.Makesuretopushinthetransportsafetybolt(2).Pull

andturnthetransportsafetybolt(2)toreleasethesplit

pin.

7.Pushthetransportsafetybolt(2)sofarinthatthesplit

pinreachestheendoftheguide.

ZEIL17HT00012AA1

NOTE:Thespringsupportstheprocedureandprevents

thetransportsafetyboltfromwanderingback.

ZEIL17HT00013AA2

4-6

Page 59

4-OPERATINGINSTRUCTIONS

NOTICE:Whentheimplementisliftedwiththerearhydraulics,makesuretoclosetherearwindowofthetractor.

NOTICE:Iftherearwindowisopenthereisariskthatthe

partsoftheimplementwilldamagetherearwindow.

Hydraulicconnection

Fortheconversionfromtransporttoworkingpositionthe

Z8805needsadouble-actingoutlet.

Tocleantheeldboundaries,useanadditionalsingleactingoutlet.

ZEIL17HT00014AA3

Openthestopvalveontheimplementside(ballvalve)aftertheconnectiontothetractorhydraulicsystem,sothat

thecouplingisnotunderpressure.Whentheimplement

isparkedthepressuremayadjust,forinstanceiftheoutdoortemperaturechanges.

Connectionoflightingequipment

Thelightingsystemisequippedwithasevenpoleplugat

thelightingcable.Connectthisplugtothesocketatthe

rearofthetractor.

NOTICE:Checkthelightingsystemfunctionaftertheconnection.

NOTICE:Dirtandmoisturecancausecontactproblems

orshortcircuit.

Keptcleananddrytheplugconnection.Alsocheckthat

thesevenpinsocketofthetractorfusesareinplaceand

intact.

4-7

Page 60

4-OPERATINGINSTRUCTIONS

Connectiontothetractor(forZ8805T)

Connectiontothelinkarmsandtoplinkof

thetractor

NOTICE:Alwaysusethetransportlockwhenyoutransporttheimplement.

NOTICE:Theinstructionsarebasedonafullymounted

implementinlockedtransportpositionwiththesupport

foldeddown.

NOTICE:Neverstandbetweenthetractorandtheimplementduringconnectiontothetractor.

NOTICE:Makesurethattherearenopersonsinthe

swivelareaoftherotorarms.

NOTICE:WaituntilthestabilizationofthePowerTake-Off

(PTO),theelectricconnections,andthehydraulicconnectionsbeforetopushupthesupportandbeforetoenterto

thedangerzone.

1.Raisetheimplementwiththelinkarmsuntilyouraise

thesupport(1)fromtheground.

2.Pulldownthehairpincotter(2)toreleasetheimple-

ment.

3.Pushupthesupportandlockitwiththehairpincotter.

NOTICE:Thepinsonthesuspensionoftheimplement

areconnectedtothelinkarmsofthetractorandsecured.

4.Atthelinkagethereisaholder(3)withacontrolbox

(4)foroperationoftheimplement.

Theholderhasmanyadjustmentpossibilities.

5.Loosenthetwoscrewontheholder.

6.Installthecontrolboxatabout30cm(12in)distance

fromthecabin.

7.Torqueagainthetwoscrews.

NOTICE:Installthecontrolboxatsufcientdistancefrom

thecabinrearwindow.

NOTICE:Reducethedistancebetweenthecontrolbox

andthetractorwhentheimplementisinheadlandposition,intransportposition,orinconditionofuneven

ground.

NOTICE:Ifyouusetheimplementwithdifferenttractors,

checkthatthecontrolboxhasthecorrectdistancefrom

thetractor.

ZEIL17HT00113AA1

ZEIL17HT00114AA2

4-8

Page 61

4-OPERATINGINSTRUCTIONS

Hydraulicconnection

Fortheconversionfromtransporttoworkingpositionthe

Z8805Tneedsadouble-actingoutlet.

Tocleantheeldboundariesisnecessaryanadditional

outletsingleacting.

Openthestopvalveontheimplementsideafteryou

makethehydraulicconnectionwhitthetractor,sothatthe

couplingisnotunderpressure.Whentheimplementis

parked,thepressuremaychange,forexamplebecause

oftheoutdoortemperaturechanges.

Thechange-overvalve(1)controltheallfunctions.The

change-overvalvehasfourpositions:

Blockingofthehydraulics(stopposition)(a).

•

Folding/unfoldingofsidearms(b).

•

Swivellingoftransportaxle(c).

•

Hydraulicclearingofeldboundaries(d).

•

Connectionoflightingequipment

Thelightingsystemisequippedwithasevenpoleplugat

thelightingcable.Connectthisplugtothesocketatthe

rearofthetractor.

NOTICE:Checkthelightingsystemfunctionaftertheconnection.

NOTICE:Dirtandmoisturecancausecontactproblems

orshortcircuit.Keptcleananddrytheplugconnection.

Alsocheckthatthesevenpinsocketofthetractorfuses

areinplaceandintact.

ZEIL17HT00108AA3

4-9

Page 62

4-OPERATINGINSTRUCTIONS

PowerTake-Off(PTO)shaft–Shorten

PowerTake-Off(PTO)shaftlength

NOTE:DonotshortenyournewPowerTake-Off(PTO)

shaftuntilyouarecertainthatitisnecessary .Fromthe

factorythedistancefromPTOtoPowerInputConnection

(PIC)isstandardonmosttractorbrands.

CheckthelengthofthePTOshaftforeachtractorpriorto

rstuse.

IfitisstillnecessarytoshortenthePTOshaft,theprole

tubesofthePTOshaftmustfullycomplywiththefollowing

overlappingmeasures.

Theslidingtubesmusthaveasmuchoverlapaspossi-

•

ble,withanacceptableminimumoverlap(b)of200mm

(7.87in)duringnormaloperation(TopSafeextension

linksinthenormalposition).

Theremustbeaminimumof40mm(1.6in)offree

•

PTOshaftlength(a)topreventtheshaftfrombottoming

out.

NHIL12HT00307AA1

Determiningtherequiredshaftlength

WhenyoudeterminethatyoumustshortenthePTOshaft,

selectthelengthsothatthetelescopingmembersnever

closecompletelyorbottomoutwheninuse.ThePTO

lengthmustneverbesmallerthantheminimumdistance

betweenthejoints.

1.AttachtheimplementtothetractorwithoutthePTO

shaft.

2.Adjustthethree-pointhitchsothatthePTOshaftis

parallelwiththeground.

3.Stopthetractorandengagetheparkingbrake.

4.DetermineifthePTOshaftbottomoutinthisposition.

IfthePTOshaftbottomsoutinthispositionorifthe

freelengthislessthan40mm(1.6in),proceedwith

theproceduretoshortenthePTOshaft.

4-10

Page 63

4-OPERATINGINSTRUCTIONS

ShorteningthePTOshaft

ToshortenthePTOshaftproceedasfollows.

1.FastenthePTOshafthalfpartstothePTO(onthe

tractor)andthePIC(ontheimplement).ThePTO

shafthalfpartsmustbeatthesamehorizontallevel,

oppositeeachotherattheshortestdistancefromthe

tractor.

2.Makesurethataminimumoverlapof200mm

(7.87in)exists.

3.CheckthatthePTOshaftdoesnotbottomoutatone

end.Keeptheshaftendsparalleltoeachotherand

marktheminimumdistanceof40mm(1.6in).Only

cutenoughPTOshaftofftoachievethisminimumfree

shaftlength.Thiswillmaintainthemaximumamount

ofPTOshaftoverlap.

4.Shortenallfourtubesequally .

5.Roundofftheendsoftheproletubesandremovethe

burrscarefully.

6.Removethemetalshavings.

ZEIL18HT00013AA2

NOTICE:Toavoidbigfrictionforces,greasethetube

carefullybeforeyoureassemblethetube.UseNLGI2.

NOTE:IfyoushortenthePTOshaft,thenyoumustcheck

theminimumoverlapandtheminimumdistanceagainif

youoperatetheimplementwithadifferenttractor.

4-11

Page 64

4-OPERATINGINSTRUCTIONS

4-12

Page 65

5-TRANSPORTOPERATIONS

5-TRANSPORTOPERATIONS###_5_###

Roadtransport

Transportonpublicroads

Installationofthewarningpanels

NOTICE:Thewarningpanelsarewarningofdangerson

theimplement.Youmustalwaysobservethesafetyreferences.Keptcleanandinreadableconditionthawarning

panels.Orderfromyourdealerthedamagedormissing

warningpanels.Positionthenewwarningpanelsonthe

correctpositionontheimplement.

Redandwhitereectingwarningpanel(1).

Yellowreectingwarningpanel(2).

NOTE:Theyellowreectingwarningpanel(2)islocated

atthecentersideoftheimplementfortheZ8805oratthe

right-handsideoftheimplement(whentheboomarms

arefoldedup)fortheZ8805T.

ZEIL18HT00279AA1

5-1

Page 66

5-TRANSPORTOPERATIONS

Z8805

ZEIL18HT00830FA2

Z8805T

ZEIL18HT00829FA3

5-2

Page 67

5-TRANSPORTOPERATIONS

Checkbeforetransport

NOTICE:ThetubeoverlapofthePowerTake-Off(PTO)

shaftmustbeinthecorrectpositionduringtransport.

NOTICE:BeforeyoustartthePTOcheckthatthenumber

ofRPMofthetractorPTOmatchesthenumberofRPM

oftheimplement.

NOTICE:WhenyouuseatravelspeedcontrolledPTO,

beawarethatthenumberofRPMdependsonthetravel

speedandthatthedirectionofrotationwillchangewhen

backing.

NOTICE:BeforeyoustartthePTOcheckthatthereare

nopersonsinthedangerzoneoftheimplement.

Followyourlocaltrafcrulesduringthetransportonpublic

roads.Applythelightingandwarningpanels.

Checkthatthetransportsafetybolt(1)ispushedincorrect

position.

Thestopvalvesofthehydraulicsystemmustbeclosed.

Duringthetransportyoumustdisconnectthetoplinkin

theoblongholeonthethreepointlinkage.Thereisarisk

thattheimplementtipsforward.

Alwaysadjustthedrivingspeedtotheconditionsofthe

road.Drivecarefullyonbadroadstoavoidthatthe

connectionforcesbetweenthetractorandtheimplement

causedamage.

Implementsandballastweightschangethedriving,steeringandbrakingcapacityofthetractor.Followtheinstructionofthemanufacturerofthetractorandoftheimplement.(seePage2-17).

Donotexceedthemaximumspeedof40km/h(25mph).

ZEIL17HT00016AA4

5-3

Page 68

5-TRANSPORTOPERATIONS

Preparingforroadtransport

Conversionofthetedderfromtransporttoworkingposition

NOTICE:T oconverttheimplementfromtheworkingpositiontotransportposition,placetheimplementinaeven

groundoruphill.

NOTICE:Donotplacetheimplementonslopes,toavoid

theriskofoverturning.

NOTICE:Makesurethattherearenopersonsinthe

swivelandworkingarea.

Z8805

NOTICE:Placetheimplementwithallrotorwheelsrmly

ontheground.DisconnectthePowerT ake-Off(PTO).

1.Pullthecord(1)forliftingthelockingpawls(2)untilthe

stopisreached.

2.Activatetheoutletonthetractorindirection“raise”.

3.Holdthecord(1)untiltheoutermostarmshavebeen

foldedinandthetensioninthecordyields.

4.Foldtheimplementfurtherintothenaltransportposition.

5.Makesurethatthehydraulicstopvalve(3)isinclose

position.

Openposition(A)

○

Closeposition(B)

○

ZEIL18HT00372AA1

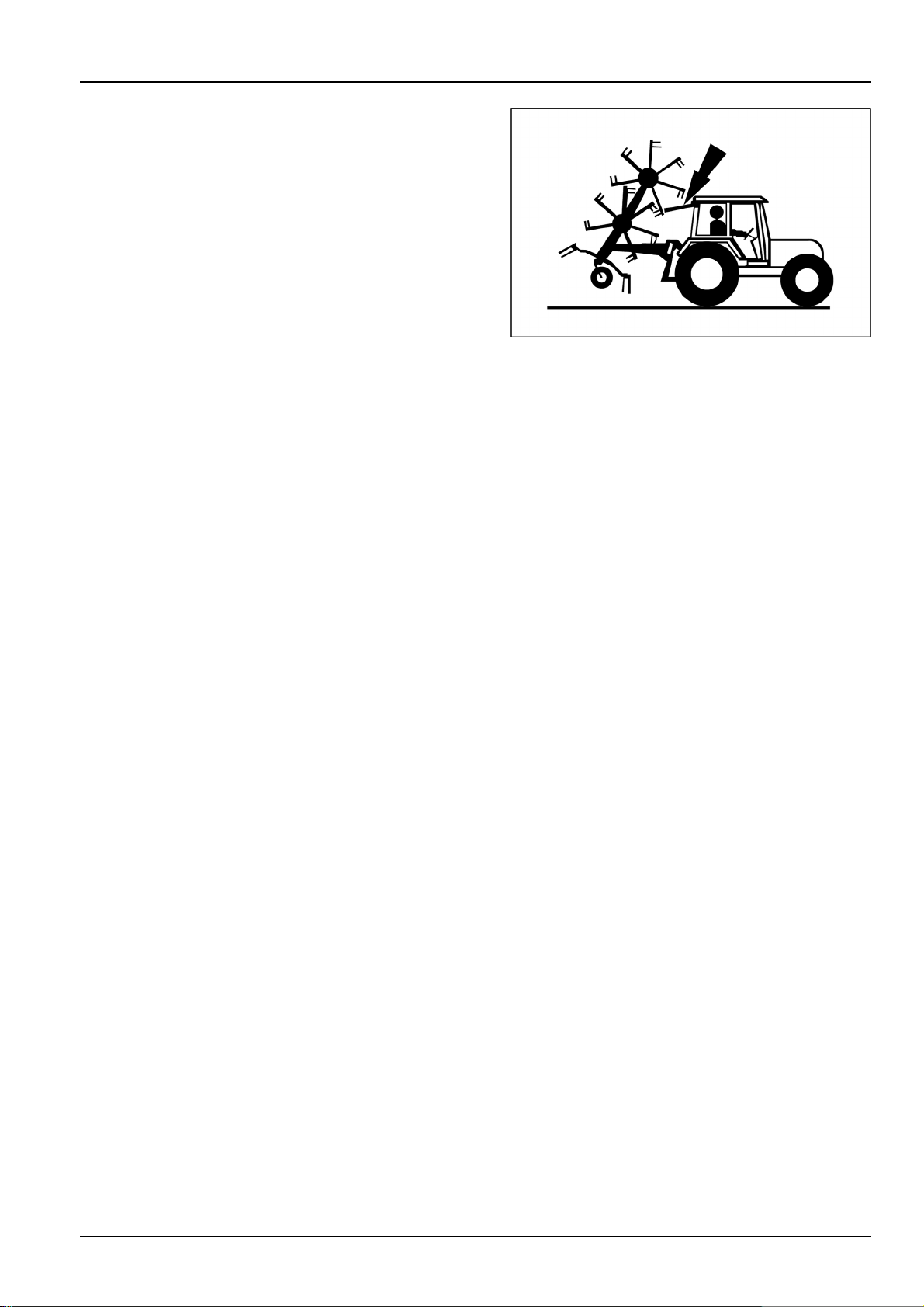

ZEIL17HT00017AA2

5-4

Page 69

5-TRANSPORTOPERATIONS

6.Lifttheimplementwiththelinkarmsuntilyouraisethe

wheelsfromtheground.

7.Brieypullthetransportsafetybolt(4)andturnthe

transportsafetybolt(4)toreleasethesplitpin(5).

8.Pushthetransportsafetybolt(4)untiltransportsafety

bolt(4)stopsothatthesplitpin(5)reachestheend

oftheguide.Thespringsupportstheprocedureand

preventsthetransportsafetybolt(4)fromwandering

back.

NOTICE:Toperformasafetransport,makesurethatthe

tractormaintainthesteeringandbrakingcapacityinspite

ofthemountedimplement.Observetheinstructionsofthe

tractormanufacturerwhenyouconnecttheimplementto

thetractor.

NOTE:Itisimportantmakeacorrectweightbalanceto

thefrontaxle.

ZEIL17HT00016AA3

5-5

Page 70

5-TRANSPORTOPERATIONS

Z8805T

NOTICE:Placetheimplementwithallrotorwheelsrmly

ontheground.DisconnectthePTO.

1.Turnthehandleofthechange-overvalvetothesymbol"folding/unfoldingofsidearms”or“swivellingof

transportaxle”.

2.Pullthecord(1)forliftingthelockingpawls(2)untilthe

cord(1)reachthestop.

3.Activatetheoutletonthetractorindirection“raise”.

4.Holdthecorduntiltheoutermostarmshavebeen

foldedinandthetensioninthecordyields.

5.Foldtheimplementfurtherintothenaltransportposition.

NOTICE:Completelylifttheimplementandfoldthe

transportaxleandthesidearms

ZEIL17HT00118AA4

6.Turnthehandle(1)ofthechange-overvalve(4)to

"STOP"position(a).

NOTICE:Toperformasafetransport,makesurethat

thetractormaintainthesteeringandbrakingcapacityinspiteofthemountedimplement.Observethe