Page 1

ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1

OPERATOR’S MANUAL

Z 685 Pro

Z 765 Pro

Tedder

Part number 51514380

1st edition English

March 2019

Page 2

Contents

1GENERALINFORMATION

Notetotheowner...........................................................................1-1

Intendeduse................................................................................1-4

Prohibitedusage...........................................................................1-5

Electro-MagneticCompatibility(EMC).....................................................1-6

Manualscopeandrequiredtraininglevel..................................................1-7

ProductIdenticationNumber(PIN)........................................................1-9

Productidentication......................................................................1-10

Operator'smanualstorageonthemachine...............................................1-11

Implementorientation.....................................................................1-12

2SAFETYINFORMATION

Safetyrulesandsignalworddenitions....................................................2-1

Generalrecommendations.................................................................2-2

Illustrations.................................................................................2-3

Legalobligations...........................................................................2-4

Fireorexplosionprevention................................................................2-5

Hazardouschemicals.......................................................................2-6

Startinguptheimplementsafely...........................................................2-7

Travelingonpublicroads...................................................................2-8

Operatingtheimplementsafely...........................................................2-10

Stoppingtheimplementsafely............................................................2-11

Maintenance...............................................................................2-12

PersonalProtectiveEquipment(PPE)....................................................2-13

Safetyrequirementsforuidpowersystemsandcomponents-hydraulicsystems......2-14

Noiseemission............................................................................2-15

Vibrationlevels............................................................................2-16

Implementstability.........................................................................2-17

Ecologyandtheenvironment.............................................................2-18

Safetysigns...............................................................................2-19

3CONTROLSANDINSTRUMENTS

Information

Operatingprinciples....................................................................3-1

4OPERATINGINSTRUCTIONS

Commissioningtheunit

Preparingforoperation.................................................................4-1

Installationoftherotorarms............................................................4-3

Startingtheunit

Connectiontothetractor...............................................................4-4

PowerTake-Off(PTO)shaft–Shorten.................................................4-6

Page 3

Parkingtheunit

Disconnectionandparking.............................................................4-8

5TRANSPORTOPERATIONS

Preparingforroadtransport

Conversionofthetedderfromworkingtotransportposition...........................5-1

Shippingtransport

Transportonpallet......................................................................5-2

6WORKINGOPERATIONS

Generalinformation

Descriptionofoperation................................................................6-1

DoublePTOjoints......................................................................6-3

Adjustabletinepositiontothearm.....................................................6-3

Doubletineswithasymmetrictinelength...............................................6-3

Basicadjustment.......................................................................6-4

Workingspeedandnumberofrevolutions.............................................6-6

Conversionofthetedderfromtransporttoworkingposition...........................6-7

Adjustmentofthesupportwheels......................................................6-8

7MAINTENANCE

Generalinformation

Maintenance............................................................................7-1

Torque..................................................................................7-2

Torqueforclass12.9...................................................................7-5

Fluidsandlubricants...................................................................7-6

Maintenanceplanning

Maintenancechart......................................................................7-7

Aftertherst3hoursofoperation

Boltsandttings........................................................................7-8

Everyday

PowerTake-Off(PTO)shaft............................................................7-9

Universaljoints.........................................................................7-9

Slideunits.............................................................................7-10

Slewing................................................................................7-11

Rotorbearings.........................................................................7-12

Bevelwheels..........................................................................7-13

Transmission..........................................................................7-14

Page 4

Everyweek

Headstock.............................................................................7-16

Every6years

Hydraulichoses.......................................................................7-17

Asrequired

Tirepressure..........................................................................7-18

Storage

Pressurewashing.................................................................7-19

Endofseasonservice.............................................................7-20

Orderingpartsand/oraccessories..............................................7-21

8TROUBLESHOOTING

Faultcoderesolution

Troubleshooting....................................................................8-1

9SPECIFICATIONS

Technicaldata..............................................................................9-1

Fluidsandlubricants.......................................................................9-2

10ACCESSORIES

Generalinformation.......................................................................10-1

Dualspeedgearbox.......................................................................10-1

Hydraulickitforadjustmentofbordertedding.............................................10-1

Anti-wrapdiscforthewheelrim...........................................................10-2

Anti-wrapplateforwheelarm.............................................................10-2

Sparewheelkitwithholder................................................................10-3

Frontgaugewheel.........................................................................10-3

Linkageequipmentforsteepslopes.......................................................10-3

Trafclightkit..............................................................................10-4

11FORMSANDDECLARATIONS

ECDeclarationofConformity.............................................................11-1

Page 5

1-GENERALINFORMATION

1-GENERALINFORMATION###_1_###

Notetotheowner

Thismanualhasbeenpreparedtoassistyouinthecorrectproceduretorunin,todrive,tooperate,toadjustandto

maintainyournewimplement.

Thisimplementhasbeendesignedandbuilttogivemaximumperformance,economyandeaseofoperationunder

awidevarietyofconditions.

Priortodelivery,yourimplementwascarefullyinspectedbothatthefactoryandbyyourdealertomakesurethatit

reachesyouinoptimumcondition.T omaintainthisconditionandassuretrouble‐freeoperationitisimportantthat

routineservices,asspeciedinthismanual,arecarriedoutattherecommendedintervals.

Readthismanualcarefully(especiallyChapter2thatcoversthesafetyinformation)andkeepthismanualinaconvenientplaceforfuturereference.DONOToperateorpermitanyonetooperateorservicethisimplementuntilyou

and/orotherpersonshavereadthismanual.Readthemanual,itwillsaveyoutimeandhasslelater.Lackofknowledgecanleadtoaccidents.Employonlytrainedoperatorswhohavedemonstratedtheabilitytooperateandservice

thisimplementcorrectlyandsafely.Contactyourdealerforassistanceprovidingtherequiredtrainingtoyouroperators.Contactyourdealertoobtainadditionalmanualsoralternatelanguageversions.

Ifatanytimeyourequireadvicethatconcernsyourimplement,donothesitatetocontactyourauthorizeddealer.He

hasfactory‐trainedpersonnel,genuineservicepartsandthenecessaryequipmenttocarryoutyourservicerequirements.

NOTICE:ThisimplementhasbeendesignedandbuiltinlinewiththerequirementsputforwardbytheEuropean

Directives2006/42/ECand2014/30/EU.

AlwaysusegenuineKONGSKILDEServicePartsorpartsthatmatchatleastthesamequality,reliabilityandfunctionalityastheequivalentoriginalServicePartswhenyouserviceandrepairyourimplementanddonotmodifyyour

implementwithoutawrittenpermissionofthemanufacturer.Failuretodosowillvoidtheresponsibilityofthemanufacturer.

Checklocalroadlegislationbeforeyoudrivetheimplementonpublicroads.

Whenyouoperateinterchangeableimplement,makesurethattheimplementisCEapproved.

Asthispublicationisdistributedthroughoutourinternationalnetwork,theimplementillustrated,eitherasstandardor

asanaccessory,mayvaryaccordingtothecountryinwhichtheimplementistobeused.Lowspecicationcongurations,aschosenbythecustomer,maydeviatefromthespecicationsgiven.

Severalguresinthisoperator'smanualshowthesafetyguardingortheadditionalguards,legallyrequiredbycertain

countries,openorremovedtobetterillustrateaparticularfeatureoradjustment.Theimplementmustnotbeusedin

thiscondition.Foryourownsafety,makesurethatallguardsareclosedorreplacedbeforeyouoperatetheimplement.

1-1

Page 6

1-GENERALINFORMATION

OWNERASSISTANCE

WeatKONGSKILDEandyourKONGSKILDEdealerwantyoutobecompletelysatisedwithyourinvestment.Normally,yourdealer'sServiceDepartmentwillhandleanyproblemswithyourimplement.Sometimeshowever,misunderstandingcanoccur.Ifyourproblemhasnotbeenhandledtoyoursatisfaction,wesuggestyoutocontacttheowner

orGeneralManagerofthedealership,explaintheproblemandrequestassistance.Whenadditionalassistanceis

needed,yourdealerhasdirectaccesstoourbranchofce.

COMPANYPOLICY

Companypolicy,whichisoneofcontinuousimprovement,reservestherighttomakechangesindesignandspecicationatanytimewithoutnoticeandwithoutobligationtomodifyunitspreviouslybuilt.

Alldatagiveninthisbookissubjecttoproductionvariations.Theinformationinthispublicationisprovidedonthe

basisofinformationthatwasavailableatthetimethatthemanualwaswritten.Settings,proceduresandotheritems

canchange.Thesechangescanaffecttheservicethatisgiventotheimplement.

Dimensionsandweightsareapproximateonlyandtheillustrationsdonotnecessarilyshowtheimplementinstandard

condition.Forexactinformationaboutanyparticularimplementpleaseconsultyourdealer.Makesurethatyouhave

themostcurrentandcompleteinformationfromyourdealerbeforeyoustartanyjob.

ACCESSORIESANDOPTIONS

Yourimplementhasbeendesignedtooperateinawidevarietyofsoils/cropsandconditions.Neverthelessadditional

equipmentmay,incertaincases,berequiredtoimprovetheimplementperformance.Alistofthisadditionalequipmentisgiveninthe''Accessories”chapterinthismanual.Useonlythoseaccessoriesdesignedforyourimplement.

PARTSANDACCESSORIES

GenuineKONGSKILDEpartsandaccessorieshavebeenspecicallydesignedforKONGSKILDEimplements.

Wewouldliketopointoutthat''non-genuine”partsandaccessorieshavenotbeenexaminedandreleased

byKONGSKILDE.Theinstallationand/oruseofsuchproductscouldhavenegativeeffectsuponthedesign

characteristicsofyourimplementandtherebyaffectitssafety.KONGSKILDEisnotliableforanydamagecaused

bytheuseof''non-genuine”partsandaccessories.

RelyonyourauthorizeddealertosupplyyouwithgenuineKONGSKILDEpartsonly.Thesepartsarecoveredbyour

warrantyandwillgiveyouthebestperformance.

SeethepartscatalogorbrowsetheKONGSKILDEportaltondservicepartsforyourimplement.

Whenyouorderserviceparts,alwaysquotethemodelandserialnumberprintedontheProductIdenticationNumber

(PIN)plate.

1-2

Page 7

1-GENERALINFORMATION

LUBRICANTS

Yourdealersellsaselectionofspeciallyformulatedlubricantsbasedonownengineeringspecications.

Recommendedlubricantsforyourimplementarelistedinthemaintenancechapter.

WARRANTY

Yourimplementiswarrantedaccordingtolegalrightsinyourcountryandthecontractualagreementwiththeselling

dealer.Nowarrantyshall,however,applyiftheimplementhasnotbeenused,adjustedandmaintainedaccordingto

theinstructionsgiveninthisoperator'smanual.

Itisprohibitedtocarryoutanymodicationstotheimplementunlessspecicallyauthorized,inwriting,bya

KONGSKILDErepresentative.

CLEANINGYOURIMPLEMENT

Whenyouuseahighpressurewasher,donotstandtooclosetotheimplementandavoiddirectingthejetatelectronic

components,electricalconnections,breathers,seals,llercaps,andsoon.

Cleandecalsonlywithasoftcloth,waterandagentledetergent.DONOTusesolvent,gasolineorotherharsh

chemicalstocleandecals.Decalscouldberemovedorgetdamaged.

DISASSEMBLYORSCRAPPING

Whenyourimplementistakenoutofservicebecauseitisdamagedbeyondrepairorhasreachedtheendofits

usefullife,disassembly,scrappingand/orrecyclingofcomponentsmustbeperformedonlybyaqualiedtechnician

withserviceinstructions,andincompliancewithlocallawandregulations.

1-3

Page 8

Intendeduse

1-GENERALINFORMATION

TheKONGSKILDErotaryteddercanonlyperformthe

usualworkinagriculture.Onlyconnecttherotaryteddertoatractorwhichcorrespondswiththespecications

oftheimplementandislegaltouse.OnlythePower

Take-Off(PTO)ofthetractorcandrivetheattachedrotarytedder.

Theimplementmayonlyted,turn,cleartheeldboundaries,spreadwindrowsandsmallnightswathsofgreen

forage(alfalfa,clover,grass,etc.),hayandstraw.

Consideranyotherusecontrarytotheintendeduse.The

manufacturerisnotresponsibleforanydamagethatre-

sultsfromtheimproperuseoftheimplement.Theuser

bearsthatrisk.

Alwaysobservethefollowingsafetyinstructionsaswell

asthecommonrulesconcerningtechnicalsafety,working

practicesandroadsafety.

Ifyoumakechangestotheimplementanditsconstruction

withoutthepermissionfromthemanufacturer,themanufacturerdoesnotacceptanyresponsibilityfordamages

thatresultsfromthis.

1-4

Page 9

1-GENERALINFORMATION

Prohibitedusage

Sweepingofforexamplefarmyardswiththetinearmassemblyorbroomsfastenedtotheseisnotallowed.There

isariskthatforexamplestonesarethrownoutfromthe

workingareaoftheimplementwithdangerofpersonalinjuryordamagetoobjects.

Anyusebeyondtheintendeduseisregardedasforeseeablemisuse.

1-5

Page 10

1-GENERALINFORMATION

Electro-MagneticCompatibility(EMC)

ThismachinecompliesstrictlywiththeEuropeanRegulationsonelectro‐magneticemissions.However,interference

mayariseasaresultofadd‐onequipmentwhichmaynotnecessarilymeettherequiredstandards.Assuchinterferencecanresultinseriousmalfunctionoftheunitand/orcreateunsafesituations,youmustobservethefollowing:

Ensurethateachpieceofnon‐KONGSKILDEequipmentttedtothemachinebearstheCEmark.

•

Themaximumpowerofemissionequipment(radio,telephones,etc.)mustnotexceedthelimitsimposedbythe

•

nationalauthoritiesofthecountrywhereyouusethemachine.

Theelectro‐magneticeldgeneratedbytheadd‐onsystemshouldnotexceed24V/matanytimeandatanylo-

•

cationintheproximityofelectroniccomponents.

FailuretocomplywiththeseruleswillrendertheKONGSKILDEwarrantynullandvoid.

1-6

Page 11

1-GENERALINFORMATION

Manualscopeandrequiredtraininglevel

Introductiontothismanual

Thismanualgivesinformationabouttheuseofyour

KONGSKILDEmachineasintendedandunderthe

conditionsforeseenbyKONGSKILDEduringnormal

operation,routineservice,andmaintenance.

Thismanualdoesnotcontainalltheinformationthatrelatestoperiodicservice,conversions,andrepairsthat

onlytrainedservicepersonnelcanperform.Someof

theseactivitiesmayrequireappropriatefacilities,technicalskills,and/ortoolsthatKONGSKILDEdoesnotsupply

withthemachine.

ThemanualcontainsthechaptersasshownontheContentspages.SeetheIndexattheendofthismanualto

locatespecicitemsaboutyourKONGSKILDEmachine.

Normaloperation

Normaloperationconsistsoftheuseofthismachinefor

thepurposeKONGSKILDEintendsbyanoperatorthat:

Isfamiliarwiththemachineandanymountedequip-

•

mentortowedequipment

Complieswiththeinformationonoperationandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Normaloperationincludes:

Preparationandstorageofthemachine

•

Additionandremovalofballast

•

Connectionanddisconnectionofmountedequipment

•

and/ortowedequipment

Adjustmentandcongurationofthemachineand

•

equipmentforthespecicconditionsofthejobsite,

eld,and/orcrop

Movementofcomponentsintoandoutofworkingpo-

•

sitions

Routineserviceandmaintenance

Routineserviceandmaintenanceconsistsofthedaily

activitiesnecessarytomaintainthepropermachine

function.Theoperatormust:

Befamiliarwiththemachinecharacteristics

•

Complywiththeinformationonroutineserviceandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Routineservicecaninclude:

Fueling

•

Cleaning

•

Washing

•

Toppingupuidlevels

•

Greasing

•

Replacingconsumableitemssuchaslightbulbs

•

Periodicservice,conversions,andrepairs

Periodicserviceconsistsofactivitiesthatarenecessary

tomaintaintheexpectedlifeoftheKONGSKILDEmachine.Theseactivitieshavedenedintervals.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivitiesatthedened

intervals.Trainedservicepersonnelmustcomplywith

theinformationonperiodicserviceandsafepracticesas

partlyspeciedbyKONGSKILDEinthismanualand/or

othercompanyliterature.

Periodicserviceincludes:

Oilchangeservicefortheengine,hydrauliccircuits,or

•

transmission

Periodicexchangeofothersubstancesorcomponents

•

asrequired

ConversionactivitiesrebuildtheKONGSKILDEmachine

inacongurationthatisappropriateforaspecicjob

site,crop,and/orsoilconditions(e.g.,installationofdual

wheels).Conversionactivitiesmustbedone:

Bytrainedservicepersonnelfamiliarwiththemachine

•

characteristics

Bytrainedservicepersonnelthatcomplywiththe

•

informationonconversionaspartlyspeciedby

KONGSKILDEinthismanual,assemblyinstructions,

and/orothercompanyliterature

Repairactivitiesrestoreproperfunctiontoa

KONGSKILDEmachineafterafailureordegradation

ofperformance.Dismantlingactivitiesoccurduringthe

scrappingand/ordismantlingofthemachine.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivities.Trainedservice

personnelmustcomplywiththeinformationforrepairas

speciedbyKONGSKILDEintheservicemanual.

Beforeyouoperate

Readthismanualbeforeyoustarttheengineor

operatethisKONGSKILDEmachine.Contactyour

KONGSKILDEdealerif:

Youdonotunderstandanyinformationinthismanual

•

Youneedmoreinformation

•

Youneedassistance

•

Allpersonstrainingtooperate,orwhowilloperate

thisKONGSKILDEmachineshouldbeoldenoughto

possessavalidlocalvehicleoperatingpermit(ormeet

otherapplicablelocalagerequirements).Thesepersons

1-7

Page 12

1-GENERALINFORMATION

mustdemonstratetheabilitytooperateandservicethe

KONGSKILDEmachineinacorrectandsafemanner.

1-8

Page 13

1-GENERALINFORMATION

ProductIdenticationNumber(PIN)

TheProductIdenticationNumber(PIN)isaserialnumberthatidentiestheimplement.

Theserialnumber,modelandotherspecicationsareon

thePINplate.

ProvideyourKONGSKILDEdealerwiththemodelandthe

PINwhenyouorderparts.

ZEIL18HT00546EA1

(1)Companyname(7)Yearofconstruction

(2)Brandidenticationlogo(8)Madein(countryoforigin)

(3)

(4)Type/Variant/Version(10)ProductIdenticationNumber(PIN)

(5)

(6)Certicationmark(12)

Mailaddress

Modelyear

(9)

(11)

Maximumweight

Model

Designation

1-9

Page 14

1-GENERALINFORMATION

Productidentication

NOTE:DonotremoveorchangetheProductIdenticationNumber(PIN)plate(1)ontheimplement.

NOTE:ThefollowinggureindicatesthePINplate(1)

localizationonZ685Pro.ThePINplatelocalizationon

Z765Proissimilar.

ThePINplate(1)isplacedintheright-handsideofthe

implement.

ThePINisalsoengravedonthechassis(A)abovethe

PINplate(1).

Forfuturereference,recordyourimplementmodeland

PINinthespacesbelow.

Model

ProductIdenticationNumber(PIN)

ZEIL18HT00823FA1

1-10

Page 15

1-GENERALINFORMATION

Operator'smanualstorageonthemachine

Keepthisoperator'smanualprotectedandaccessibleon

thetractorwheneveryoutransportoroperatetheimplement.

1-11

Page 16

1-GENERALINFORMATION

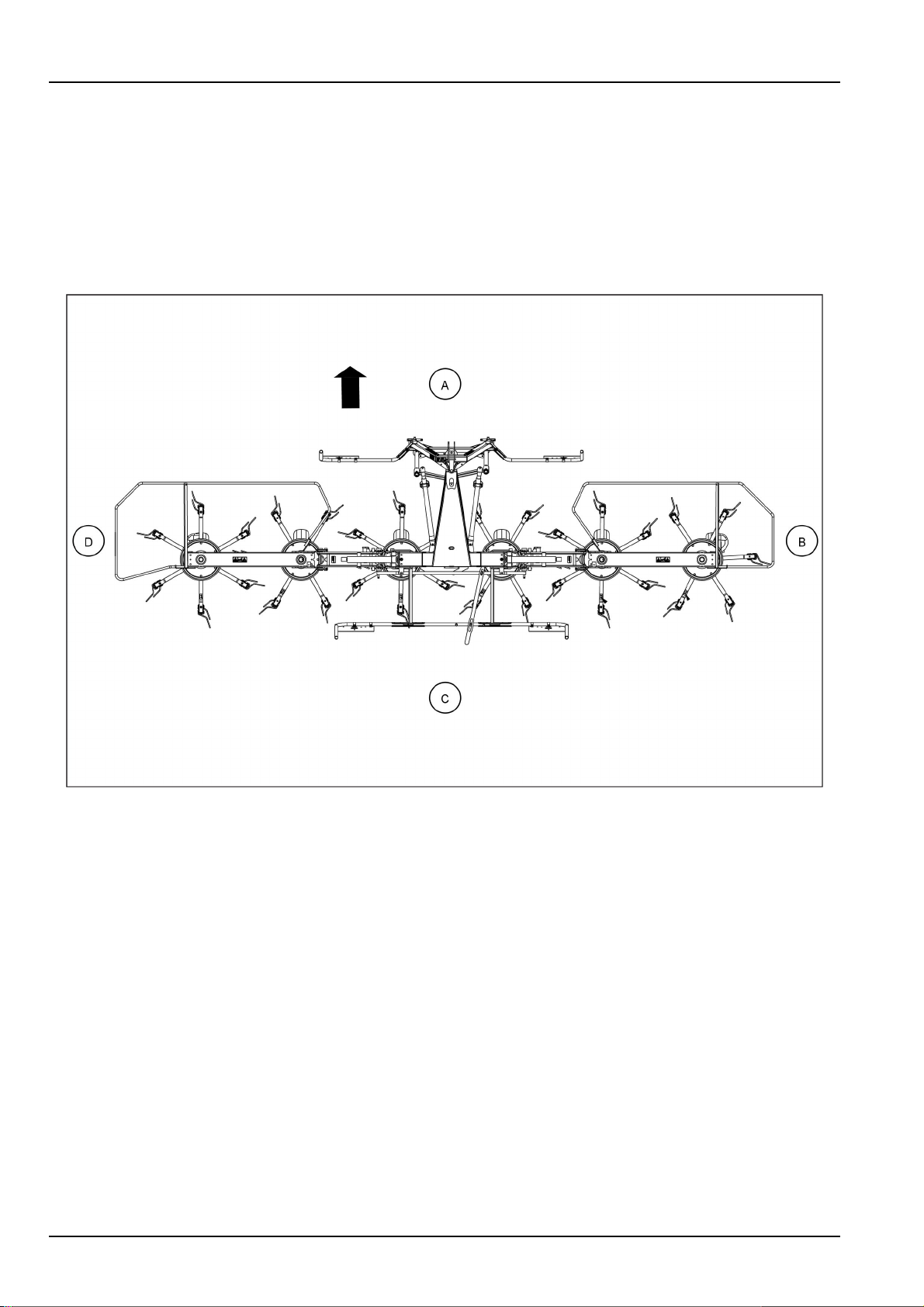

Implementorientation

NOTE:T odeterminetheleft-handsideandtheright-hand

sideoftheimplement,standbehindtheimplementand

facethedirectionoftravelduringworkingoperation.

Thefollowingoverheadviewillustrationisageneralrepresentationoftheimplement.Theillustrationindicatesthe

sides,front,andrearorientationsoftheimplementasreferredtothroughouttheoperator’smanual.

NOTE:Thearrowindicatesthedirectionoftheimplement

duringworkingoperation.

(A)Frontoftheimplement

(B)Right-handsideoftheimplement

(C)Rearoftheimplement

(D)Left-handsideoftheimplement

ZEIL18HT00827FA1

1-12

Page 17

2-SAFETYINFORMATION

2-SAFETYINFORMATION###_2_###

Safetyrulesandsignalworddenitions

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

ThroughoutthismanualyouwillndthesignalwordsDANGER,WARNING,andCAUTIONfollowedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworkingwithyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationthat,ifnotavoided,willresultindeathorseriousinjury.

WARNINGindicatesahazardoussituationthat,ifnotavoided,couldresultindeathorseriousinjury.

CAUTIONindicatesahazardoussituationthat,ifnotavoided,couldresultinminorormoderateinjury.

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESULT

INDEATHORSERIOUSINJURY .

Machinesafety

NOTICE:Noticeindicatesasituationthat,ifnotavoided,couldresultinmachineorpropertydamage.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachineor

propertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationthatclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

2-1

Page 18

2-SAFETYINFORMATION

Generalrecommendations

Mostfarmmachineryaccidentscanbeavoidedbythe

observanceofafewsimplesafetyprecautions.

Thisoperator’smanualcontainsimportantinformation

•

concerningoperation,maintenanceandadjustmentof

theimplement.Furthermore,thisoperator’smanual

mentionsandemphasizesallthesafetyinstructions.

Readtheoperator’smanualthoroughlybeforeyou

•

start,operate,service,orcarryoutanyotheroperation

ontheimplement.Eventhoughyouhavebeendriving

asimilarimplementbefore,youmustreadthemanual.

Thisisamatterofyourownandotherpeoplesafety.

Afewminutesreadingwillsaveyoutimeandhassle

later.Lackofknowledgecanleadtoaccidents.

Yourimplementwasdesignedwithsafetyinmind.

•

However,thereisnorealsubstituteforcautionand

attentionwhenyouneedtopreventanaccident.Once

anaccidenthasoccurred,itistoolatetothinkabout

whatyoushouldhavedone.Thismeansthatitis

veryimportantthatyouasuseroftheimplementpay

attentionandusetheimplementcorrectlyandthereby

avoidexposingyourselfandotherstounnecessary

danger.

Theimplementmustbeoperatedonlybyresponsible

•

personswhohavebeenadequatelytrainedandautho-

rizedtousetheimplement.Neverleavetheimplement

toothersbeforeyouhavemadesurethattheyhavethe

necessaryknowledgetooperatetheimplementsafely.

Neverlettheimplementrunwithoutsupervision.

•

Alwayskeeparstaidkithandy.

•

Takethenecessaryprecautions(forexampleassis-

•

tance)toalwaysbeawareofthepossiblepresenceof

bystandersandpets.

Keepchildrenawayfromandofftheimplementatall

•

times.

Donotusethisimplementasalift,ladderorplatform

•

toworkatheights.

Beforeyouworkontheimplement,disengageall

•

drives,stoptheengineandremovetheignitionkey.

Waitfortherotatingpartstorundown.

Neverworkaroundtheimplementwithlooseclothing,

•

jewelry,watches,longhairandotherlooseorhanging

itemscanbepulledinbythemovingpartsoftheimplement.

Keephandsawayfrommovingpartsoftheimplement.

•

Neverattempttocarryoutanyadjustmentsontheim-

•

plementwhiletheimplementisinmotionorwhilethe

PowerT ake-Off(PTO)shaftisengaged.

PTOdrivenimplementcancausedeathorseriousin-

•

jury.BeforeyouworkonornearthePTOshaftorser-

viceorclearthedrivenimplement,disengagethePTO,

stoptheengineandremovetheignitionkey.

2-2

Page 19

2-SAFETYINFORMATION

Illustrations

WARNING

Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment.

Replaceallshieldsbeforeoperatingthemachine.

Failuretocomplycouldresultindeathorseriousinjury .

NOTE:Someoftheillustrationsinthismanualhavebeen

obtainedbyphotographingprototypes.Standardproductionmachinesmaydifferinsomedetails.

W0012A

2-3

Page 20

2-SAFETYINFORMATION

Legalobligations

Yourmachinemaybeequippedwithspecialguardingor

otherdevicesincompliancewithlocallegislation.Some

oftheserequireactiveactionbytheoperator.

Therefore,checklocallegislationontheusageofthismachine.

2-4

Page 21

Fireorexplosionprevention

2-SAFETYINFORMATION

1.Cropmaterial,trash,debris,birdnestsorammable

materialcanigniteonhotsurfaces.

2.Inspecttheelectricalsystemforlooseconnectionsor

frayedinsulation.Repairorreplacelooseordamaged

parts.

3.Donotstoreoilyragsorotherammablematerialon

theimplement.

4.Donotweldoramecutanyitemsthatcontain

ammablematerial.Cleanitemsthoroughlywith

non-ammablesolventbeforeyouweldorcutwitha

ame.

5.Donotexposetheimplementtoames,burningbrush

orexplosives.

6.Promptlyinvestigateanyunusualsmellsorodorsthat

mayoccurduringtheoperationoftheimplement.

2-5

Page 22

Hazardouschemicals

2-SAFETYINFORMATION

1.Ifyouareexposedtoorcomeincontactwithhazardouschemicalsyoucanbeseriouslyinjured.

Theuids,lubricants,paints,adhesives,coolant,

etcetera.requiredforthefunctionofyourmachine

canbehazardous.Theymaybeattractiveandharmfulltodomesticanimalsaswellashumans.

2.MaterialSafetyDataSheets(MSDS)provideinformationaboutthechemicalsubstanceswithinaproduct,

safehandlingandstorageprocedures,rstaidmeasuresandprocedurestobetakenintheeventofaspill

oraccidentalrelease.MSDSareavailablefromyour

dealer.

3.BeforeyouserviceyourmachinechecktheMSDSfor

eachlubricant,uid,etcetera.usedinthismachine.

Thisinformationindicatestheassociatedrisksandwill

helpyouservicethemachinesafely.FollowtheinformationintheMSDS,onmanufacturercontainers,as

wellastheinformationinthismanualwhenyouservicethemachine.

4.Disposeofalluids,ltersandcontainersinanenvironmentallysafemannerinaccordancewithlocal

lawsandregulations.Checkwithlocalenvironmentalandrecyclingcentersoryourdealerforcorrectdisposalinformation.

5.Storeuidsandlterinaccordancewithlocallawsand

regulations.Useonlyappropriatecontainersforthe

storageofchemicalsorpetrochemicalsubstances.

6.Keepoutofreachofchildrenorotherunauthorized

persons.

7.Additionalprecautionsarerequiredforappliedchemicals.Obtaincompleteinformationfromthemanufacturerordistributorofthechemicalsbeforeyouuse

them.

2-6

Page 23

Startinguptheimplementsafely

2-SAFETYINFORMATION

Beforeyouattachtheimplementtothetractor,ensurethat

thetractorisingoodworkingorderandthatthebrakes

areefcient,particularlyifyouoperateonhillyground.

Also,ensurethatthehydraulicorpneumaticsystemis

compatiblewiththatoftheimplement.

Whenyouattachtheimplementtothetractor:

Neverallowanyonetostandbetweenthetractorand

•

theimplement.Anunintentionalmanoeuvrewiththe

tractormaycauseseriousinjury.

Nevergounderanunsupportedimplement.

•

Installalltheguardscorrectlybeforeyouusetheimplement.

Replacewornanddamagedcanvasesbeforeyouwork

withtheimplement.

MakesurethatyouarethoroughlyfamiliarwiththeinstrumentsandcontrolsbeforeyouengagethePowerT akeOff(PTO)driveforthersttime.

ThePTOshafthasitsowninstructionmanualthatthe

manufacturersupplywiththeimplement.T oensurethe

correctuseoftheshaft,followalltheinstructionsofthe

manufacturermanual.Payparticularlycloseattentionto

thesafetyandmaintenanceinstructions,inordertopreventunintentionalinjuryanddamage.

RepairimmediatelyadamagedPTOshaftbeforeyou

workwiththeimplement.

AlwaysstopthePTOandthetractorengineandremove

theignitionkeybeforeyouconnectthePTOdriveshafts.

Afteryouattachtheimplementtothetractor,ensurethat

thePowerTake-Off(PTO)lockpinisproperlyengaged

inthetractorPowerTake-Offshaft.Anincorrectlylocked

PTOshaftcouldworklooseandcauseaccidentsordamagetotheimplement.

MakesuretoinstallandsecurethePTOdriveshaftcorrectly.Checkthatthelockpinisinmesh.Fastenthe

supportchainatbothends.

Alwaysmakesurethattheguardtubesdonotseparate

atthemaximumworkingortransportlengthofthePTO

driveshaft.Checkalsothattheguardtubesdonotjamat

theminimumworkingortransportlengthofthePTOdrive

shaft.

Unlesstheprotectiveguards,thePTOdriveshaftmay

causeseriousinjury.Becarefulnottodamagetheguards

whenyouconnectthePTOdriveshafttoorfromthetractor.

FitcorrectlytheguardsonthePTOdriveshaft.Secure

theguardofthePTOshaftwiththechain.

DonotusePowerTake-Off(PTO)driveshaftswithother

specicationsthantheshaftwhichwassuppliedwiththe

implement.

BeforeyouinstallthePTOdriveshaft,checkthattheRevolutionsPerMinute(RPM)anddirectionofthePTOonthe

tractormatchthoseofthePTOontheimplement.

Beforeyoustartuptheimplement(forexampletherst

timeafteralongstandstillperiod),makesurethatthere

arenodetachedloosepartsonthedrivelineareaandon

themovingpartsoftheimplement.

2-7

Page 24

Travelingonpublicroads

2-SAFETYINFORMATION

Complywiththerelevanttrafcregulations

WARNING

Impacthazard!

Takecarewhenmakingturns.Themachine

rearendswingsoutwhenchangingdirection.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Lossofcontrolhazard!

Unevenbrakeforceexistsonleft-handand

right-handbrakes.Alwaysusebrakepedal

couplerwhentravelingonpublicroadstoensurebrakesareactuatedtogether.

Failuretocomplycouldresultindeathorseriousinjury.

Theimplementisbuiltaccordingtothehomologationrequirementsofyourcountry.Donotmodifytheimplement

inasensethatwouldconictwiththenationalregulations.

Ifyouwishtotransporttheimplementonthepublicroad,

makesurethatthecombinationtractorandimplement

observesthetrafcrulesinyourcountry.Thisgivesyou

andyoursurroundingsthebestpossiblesafety.

Passengers

Donotallowpassengerstorideinthetractorunlessa

specicseatisprovided.

Duringtransport,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

W0089A

W0081A

Transportsafety

Transporttheimplementonlyintransportposition.Securetheimplementfortransport.Alwaysactivatethemechanicaltransportsafetydevicesbeforetransport.

Makesuretotallthehitchpinswithretainingpinscorrectly.Mechanicallysecurethehydrauliccylinderstopreventcylindersfromcreeping.

Drivesafe

Donotdriveundertheinuenceofalcoholordrugs.

Nevertravelatspeedincrowdedareas.

Whenyoumaneuverthetractorwiththeimplement,alwaysbeawareandconsciousofitssize.

Thetractordrivermustnotleavethecabinduringtransport.

Theoperatorsmustobserverelevantstatutoryorother

nationalregulationsthatdealwithroadsafetyandlabor

safetyissues.

Beforeyoudrivetheimplementonpublicroads:

Checktheallowabletransportdimensionsandweights.

•

Installcorrectlythelightingandthewarningpanels.

•

Alwaysobservetheprinciplesforpermissibleaxleloads,

thetotalunitmassandthetransportgauge.

Observethetractormanufacturerregulationsandrecommendations,specicallythoserelatingtomaximumtransportloadsandmaximumspeed.

Eveninsimilarcircumstances,themaximumallowed

speedcanvarydependingonwhichcountryyoutravel

in.

Alwaysdrivewiththestatutorylightsandsafetymarking

duringtransportonpublicroadandatnight.

Installalltherequiredsignsthatindicatethevehiclewidth.

Alsoinstallalltherequiredlightsthatindicatethevehicle

widthduringthenightlytransport.Ifindoubt,contactyour

governmentdepartmentresponsibleforroadtransport.

Alwaysconsiderotherroadusers.

Alwaysadoptsafedrivingpractices.Slowdownandsignalbeforeturning.Givewaytooncomingtrafcinallsituations,includingnarrowbridges,intersectionsetcetera.

Pullovertoallowfastertrafctopass.

Iftheimplementismarkedwithamaximumspeedlimit,

neverexceedthismaximumspeedlimit.

Alwaysadjustthedrivingspeedtotheroadandweather

conditions.Incaseofbadroadconditionsandhighdrivingspeeds,bigforcesmayoccurandcauseoverloadof

tractorandimplement.

Driveatasafespeedtoensurecontrolandabilitytostop

inanemergency.

Lockthetractorbrakepedalstogether.Neveruseindependentbreakingattransportspeeds.

Mountedimplementsandballastweightsinuencethe

driving,steeringandbrakingcapacityofthetractor.Make

surethattheadditionalweightoftheimplementonthe

linkagedoesnotcompromisedriving,steeringandbrakingcapacityofthetractor.Installfrontweightsorrepair

thebrakesifthetractorisnotsafetodrive.

Travelmayberestrictedtocertainroadtypes.Transport

mayberestrictedtodaytimeoroutsidepeaktrafchours.

Howeverplanyourroutetoavoidheavytrafcandpeak

trafchours.

Reducespeedduringturns.Tractorshavenotbeendesignedforfastturning.Avoidthattherearendoftheimplementhitsanobstacle.

2-8

Page 25

2-SAFETYINFORMATION

Whenyouturnduringtransportpayattentiontotheoverhangand/oroscillatingweightoftheimplement.

Useenginebrakingwhenyoudrivedownhills.Donot

coast.

Watchforobstructions,particularlyifover-width.Observe

anyloadratingsapplicableonbridges.

Afteryounishthetransport,beforeyouleavethetractor,

alwayslowertheimplementtothegroundinparkingposition,turnoffthetractorengine,pulltheparkingbrake,

andremovethekeyfromtheignition.

2-9

Page 26

Operatingtheimplementsafely

WARNING

Hazardtobystanders!

Alwayssoundthehornbeforestartingthemachine.Makesuretheworkareaisclearof

otherpersons,domesticanimals,tools,etc.

beforeyouoperatethemachine.Neverallow

anyoneintheworkareaduringmachineoperation.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Rotatingparts!

Keepclearofalldrivesandrotatingcomponents.

Failuretocomplycouldresultindeathorseriousinjury.

2-SAFETYINFORMATION

Neverattempttoremoveresiduesfromtheimplement

whiletheimplementruns.Suchanimprudencecouldcost

lifeorlimb.AlwaysdisengagethePowerT ake-Off(PTO)

shaftmechanism,switchOFFthetractorengineandapplytheparkingbrakebeforeyouremoveresidues.

Duringthedailyworkyoumustconsiderthatloosestones

andforeignmatteronthegroundmightgetincontactwith

therevolvingpartsandgetthrownoutagainatavery

highspeed.Therefore,beforeyouoperatetheimplement

makesurethatallsafetyguardsareintact,properlytted

W0304A

W1101A

andsecured.

Beforeyouraiseorlowertheimplementwiththelinkarms

ofthetractor,checkthatnobodyisneartheimplementor

touchestheimplement.

Alwaysoperatetheimplementatasafespeedinaccordancewiththegroundconditions.Onunevenground,

proceedwiththeutmostcautiontoensureproperstability.

NOTE:Onlyputtheimplementintooperationaccording

totheinstructionsfromthedealer.

Neveroperatetheimplementundertheinuenceofalcohol,drugs,orwhileotherwiseimpaired.

Avoidusingtheimplementinunsuitableeldandweather

conditions.Itisbettertostopworktemporarilyratherthan

tooperateinsuchconditions.

Keeppeopleawayfromtheimplementduringoperation.

Askbystanderstoleavetheeld.Thereistheriskfor

bystanderstobeoverrunbytheimplement.Stoptheimplementimmediatelyifsomeoneapproaches.

Thetractororitsimplementmaystrikeorcrushagainsta

personorpetwithintheoperatorareaofthetractor.DO

NOTallowanyonetoentertheworkarea.Makesurethat

theareaisclearandoperationissafebeforeyoumove

theimplement.

Whenyouoperatetheimplement,alwaysremainseated

inthetractorcab.Operatecontrolsonlywhenseatedin

thetractorseat,exceptforthosecontrolsexpresslyintendedforusefromotherlocations.

Whenyouturnonhillsidesalwaysbecarefulwhenyoulift

theimplementwiththe3-pointlinkagebecausethereisa

riskofoverturning.Adjustthespeedtotheseconditions.

Driveinalowtractorgearifyouworkonhillsides.

Whenyoudriveupanddownandacrosshillsides,avoid

sharpturns.

Whenyouturnduringoperation,payattentiontotheoverhangand/oroscillatingweightoftheimplement.

Avoidchangingdirectionabruptly,especiallywhenyou

reverse,toavoiddangerouspitchingoftheimplement.

Whenyouworkwiththeimplementkeepasafedistance

fromsteepslopesandsimilargroundconditions,asthe

groundmaybeslipperyandpulltheimplementandthe

tractorsideways.Alsoremembertoadjustthespeedfor

sharpturnswhenyoudriveonhillsides.

Paythenecessaryattentionwhileyouoperatenextto

publicroadsorfootpaths.

Whileinoperation,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

2-10

Page 27

Stoppingtheimplementsafely

WARNING

Movingparts!

Somecomponentsmaycontinuetorunafter

disengagingthedrivesystems.Makesure

alldrivesystemsarefullydisengagedandall

movementhasstoppedbeforeservicingthe

machine.

Failuretocomplycouldresultindeathorseriousinjury.

2-SAFETYINFORMATION

thetractorcab,thenthefollowingprecautionsmustbe

followed:

•

•

•

•

Whenyouparktheimplementtherearesomeoperational

W0002A

riskswhichmaycausepersonalinjury.Therefore,you

must:

Bringthetractorenginetolowidlespeed.

Disengagealldrivesystems.

Shiftthetractortransmissionintoneutral.

Applytheparkingbrake.

Alwaysinterrupttheoperationoftheimplementbefore

youleavethetractorseat.

Forsafety'ssakeneverleavethetractorcabwithoutrst

todisengagethePowerT ake-Off(PTO)shaftmechanism

andtostopthetractorengine.Furthermore,ifyouleave

thetractorunattended,alwaysremovetheignitionkey.

StopthetractorengineandthePTOshaftandwaituntil

theimplementhascompletelystoppedbeforeyouopen

anyofthesafetyguards.Therearerotatingpartsunderthesafetyguardswhichmaycontinuerotatingafter

theimplementhasbeenstopped.Lookandlistenforevidenceofrotatingpartsbeforeyouopenanyofthesafety

guards.

Makesuretosecurethetractorbymeansofthehand

brakeand/orstopblocksifyouneedtostandbetween

thetractorandtheimplement.

When,duetoexceptionalcircumstances,youwould

decidetokeepthetractorenginerunningafterleaving

Makesurethatthegroundisrmandevenduringpark-

•

ing.

Makesurethattractorandimplementcannotmove.

•

Alwayslowertheimplementtotheground.

•

Stopthetractorengineandremovetheignitionkey.

•

Usecorrectsupportortransportsafetydevicewhenthe

•

implementisparked.Makesurethattheparkingstand

issecured.

Whenyoudetachtheimplementfromthetractor:

Alwaysdetachtheimplementcarefullyandonaat

•

surfacetopreventdamage.

Makesurethatnobodystandsinfrontoftheimplement.

•

Neverallowanyonetostandbetweenthetractorand

•

theimplement.

Nevergounderanunsupportedimplement.

•

2-11

Page 28

2-SAFETYINFORMATION

Maintenance

WARNING

Maintenancehazard!

Beforeyoustartservicingthemachine,attach

aDONOTOPERATEwarningtagtothemachineinavisiblearea.

Failuretocomplycouldresultindeathorseriousinjury.

Followthemaintenanceschedulewithregardtotheim-

•

plementservicingintervals.

Rememberthattheimplementrequiresattentionfrom

timetotime.Alsorememberthatthemaintenancewill

greatlyextendthelifeoftheimplement.

Takethenecessaryprecautions:nottospillanyoil,fuel

•

orgrease.

Toavoidoilandgreasecontactwithyourskin,wear

protectivegloves.

Servicetheimplementonarmlevelsurface.

•

Donotattempttoremovematerialfromanypartof

•

theimplement,clean,lubricateorcarryoutanyadjust-

mentsontheimplementwhileitisinuse.

Keephands,feetand/orgarmentsawayfromparts

•

whichmove.Checkthatallrotatingpartshavea

suitableprotectiveguard.

Raisedimplementand/orloadscanfallunexpectedly

•

andcrushpersonsunderneath.Neverenterorallow

anyonetoentertheareaunderneathraisedimplement

duringoperation.

Unsupportedhydrauliccylinderscanlosepressure

anddroptheimplementandcauseacrushinghazard.

Donotleavetheimplementinaraisedpositionwhile

parkedorduringservice,unlesssecurelyblockedon

woodenblocks.

Neverworkunderaraisedimplementunlessasupport

•

chainorothermechanicalsecuringdevicesecurethe

linkarmsofthetractorsothattheimplementcannot

movetoalowerpositionunintentionally.

Relievethepressure,stoptheengineandremovethe

•

ignitionkey,beforeyouconnectordisconnectuid

lines.

Beforeyouadjust,clean,lubricateoryoucarryoutre-

•

pairsontheimplement,stoptheengineandremove

W0004A

theignitionkey.

NeveradjusttheimplementwhilethePowerT ake-Off

•

(PTO)driveshaftisengaged.Donottoremovethe

guardsuntilallrevolvingpartshavestopped.

Anyleakageofhydraulicoilorfuelunderpressuremay

•

causesevereharm,soalwaysuseashielding,goggles

andgloveswhenyoutraceoilorfuelleaks.

Donotuseyourhandtocheckforleaks.Useapiece

ofcardboardorpaper.

Continuouslongtermcontactwithhydraulicuidmay

•

causeskincancer.Avoidlongtermcontactandwash

theskinpromptlywithsoapandwater.

Ifhydraulicuidordieselpenetratestheskin,seek

•

medicalcareimmediately.

Observeallrecommendationsthatarementionedin

•

thismanualsuchasserviceintervals,torques,lubri-

cants,etcetera.

Alwaysreplaceallpartsthathavedamageorwear.

•

Neverbuildexiblehoseassembliesfromhosesthat

•

werepreviouslypartofahoseassembly.

Neverweldtothetubes.

•

Alwaysusegloveswhenyouworkwithpartsonthe

•

implementasthepartscanhavesharpedges.

Transmissionandhydrauliclinesmaybecomehotdur-

•

ingoperation.Becarefulwhenyouservicesuchcom-

ponents.Allowsurfacestocoolbeforeyouhandleor

disconnecthotcomponents.Wearprotectiveequipmentwhenrequired.

2-12

Page 29

2-SAFETYINFORMATION

PersonalProtectiveEquipment(PPE)

WearPersonalProtectiveEquipment(PPE)suchasprotectiveclothing,eyeprotection,hearingprotection,dust

mask,hardhat,heavygloves,workboots,and/orany

otherPPEthatprovidesforthesafetyandprotectionof

theindividualthatoperatesthisequipment.

NHIL13RB00001AA1

2-13

Page 30

2-SAFETYINFORMATION

Safetyrequirementsforuidpowersystemsandcomponentshydraulicsystems

Beforeyoustarttheengineorpressurizethehydraulic

system,installandtightcorrectlyallthehydrauliccouplings.Checkthatallhosesandttingsarenotdamaged.

Replaceimmediatelydamagedcomponents.

Onlyconnectthehydraulichosestothetractoroutletsif

thetractorandtheimplementarepressure-free.Ifthe

hydraulicsofthetractorisactivateditmayleadtouncontrolledmovementswhichmaycausedamage.

Makesurethatnopersonsareneartheimplementwhen

youstarttheimplement,astheremightbeairinthehydraulicsystemwhichmightleadtosuddenmovements.

Whenthetractorenginehasstopped,activatethetractor

hydraulicspoolvalvestomakesurethatthereisnopressureinthehydraulichoses.

Toexpelalltheairfromtheoilinthehydrauliccylinders,

testallthefunctionsafteryouconnectthehydraulicconnectionstothetractor,especiallybeforeyouenterordrive

onthepublicroads.

2-14

Page 31

2-SAFETYINFORMATION

Noiseemission

ThemeasuringandreportingofthenoiselevelwerecarriedoutaccordingtoISO5131.

Thenoiselevelof70dBwasmeasuredinthecabinofthe

tractorwheretheheadoftheoperatorisusuallysituated.

Usehearingprotectorsifthenoisefromtheimplementis

annoyingorifyouworkwiththeimplementforaconsiderableperiodinatractorcabinthathasnotaadequate

soundproofcabin.

2-15

Page 32

2-SAFETYINFORMATION

Vibrationlevels

Installallrevolvingpartscorrectlybeforeyoustarttheimplement.Anunbalancecancreatevibrationsthatdamage

theimplement.

NOTE:Youmustcheckthattheallpartareinthecorrect

positionbeforestarttheimplement.

NOTE:Ifthevibrationsorthenoiseoftheimplementincreaseconsiderablyduringtheoperation,stopthework

immediately.Correctthefaultbeforeyoucontinuethe

work.

2-16

Page 33

2-SAFETYINFORMATION

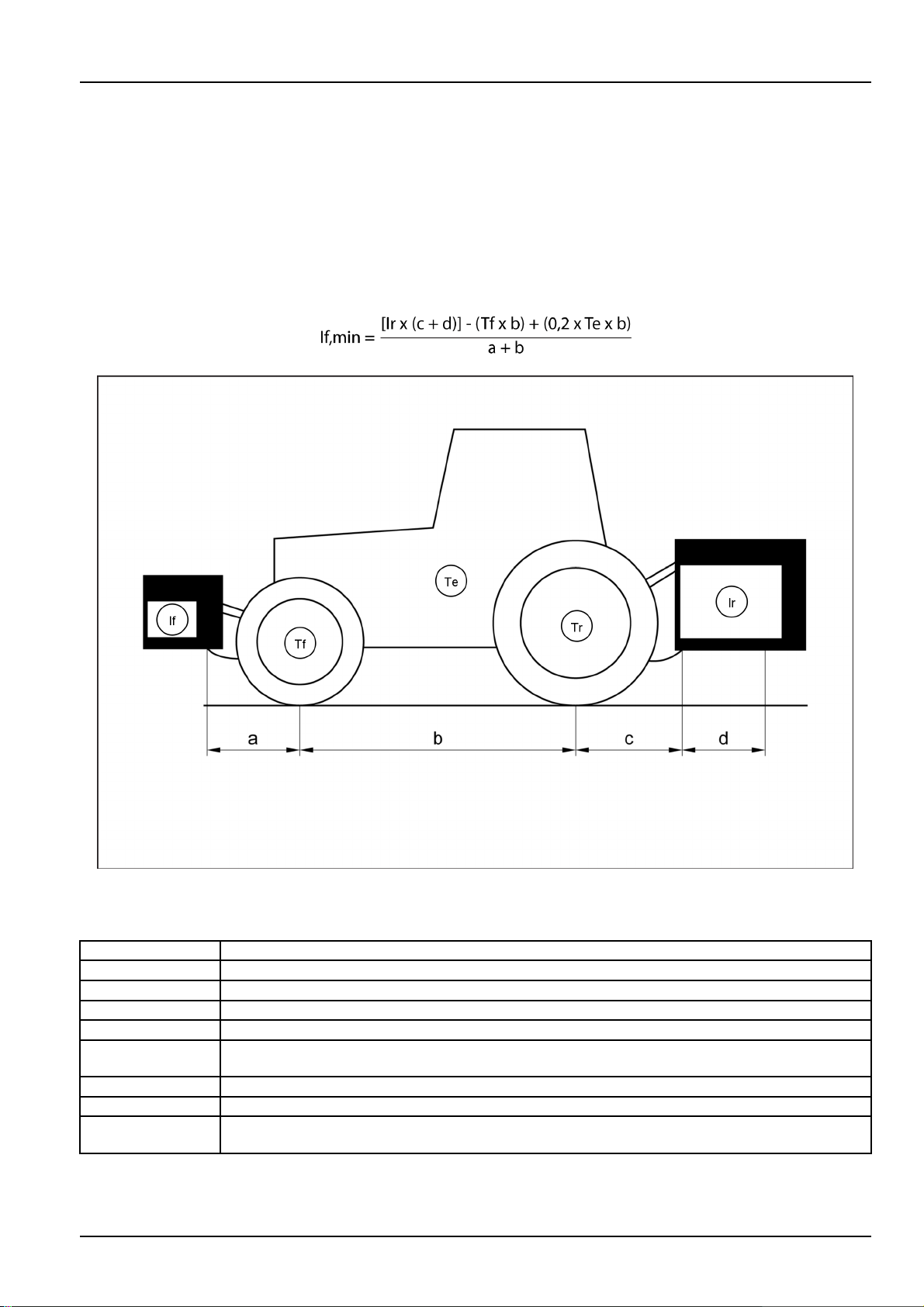

Implementstability

Thecombinationofyourtractorandimplementcanbecomeunstable,duetotheadditionalweightthattheimplement

addstothetractor.

Inordertoguaranteestableandsafetransport,youmustcheckifyouneedballastweightsfortransportandeld

work.

Youmustalsocheckandguaranteethatyouhaveatleast20%fromthetractorweightonthefrontaxle.

Forrearmountedimplementsandfront-rearcombinations,theformulais:

ZEIL18HT00277FA1

Exampleofreferencestostabilityofthecombinationtractor–implement

Listofsigns

Te[kg]Thetractorownweight.

Tf[kg]

Tr[kg]Rearaxleloadwithemptytractor.

Ir[kg]

If[kg]Totalweightofthefront-mountedimplement/frontballast.

a[m]

b[m]Thetractorwheeldistance.

c[m]

d[m]

Frontaxleloadwithemptytractor.

Totalweightoftherear-mountedimplement/rearballast.

Distancebetweenthecenterofgravityofthefront-mountedimplement/frontballastandthe

middleofthefrontaxle.

Distancebetweenthemiddleoftherearaxleandthemiddleofthelinkarmballs.

Distancebetweenthemiddleofthelinkarmballsandthecenterofgravityoftherearmounted

implement/rearballast.

2-17

Page 34

Ecologyandtheenvironment

2-SAFETYINFORMATION

Soil,air,andwaterqualityisimportantforallindustries

andlifeingeneral.Whenlegislationdoesnotyetrulethe

treatmentofsomeofthesubstancesthatadvancedtechnologyrequires,soundjudgmentshouldgoverntheuse

anddisposalofproductsofachemicalandpetrochemical

nature.

Familiarizeyourselfwiththerelativelegislationapplicabletoyourcountry ,andmakesurethatyouunderstand

thislegislation.Wherenolegislationexists,obtaininformationfromsuppliersofoils,lters,batteries,fuels,

anti-freeze,cleaningagents,etc.,withregardtotheeffectofthesesubstancesonmanandnatureandhowto

safelystore,use,anddisposeofthesesubstances.Y our

KONGSKILDEdealercanalsoprovideassistance.

Helpfulhints

Avoidtheuseofcansorotherinappropriatepressur-

•

izedfueldeliverysystemstolltanks.Suchdelivery

systemsmaycauseconsiderablespillage.

Ingeneral,avoidskincontactwithallfuels,oils,acids,

•

solvents,etc.Mostoftheseproductscontainsub-

stancesthatmaybeharmfultoyourhealth.

Modernoilscontainadditives.Donotburncontami-

•

natedfuelsandorwasteoilsinordinaryheatingsys-

tems.

Avoidspillagewhenyoudrainuidssuchasuseden-

•

ginecoolantmixtures,engineoil,hydraulicuid,brake

uid,etc.Donotmixdrainedbrakeuidsorfuelswith

lubricants.Storealldraineduidssafelyuntilyoucan

disposeoftheuidsinaproperwaythatcomplieswith

alllocallegislationandavailableresources.

Donotallowcoolantmixturestogetintothesoil.Col-

•

lectanddisposeofcoolantmixturesproperly.

Donotopentheair-conditioningsystemyourself.It

•

containsgasesthatshouldnotbereleasedintotheat-

mosphere.YourKONGSKILDEdealerorair-conditioningspecialisthasaspecialextractorforthispurpose

andcanrechargethesystemproperly .

Repairanyleaksordefectsintheenginecoolingsys-

•

temorhydraulicsystemimmediately.

Donotincreasethepressureinapressurizedcircuitas

•

thismayleadtoacomponentfailure.

Batteryrecycling

Batteriesandelectricaccumulatorscontainseveral

substancesthatcanhaveaharmfuleffectontheenvironmentifthebatteriesarenotproperlyrecycledafter

use.Improperdisposalofbatteriescancontaminate

thesoil,groundwater,andwaterways.KONGSKILDE

stronglyrecommendsthatyoureturnallusedbatteries

toaKONGSKILDEdealer,whowilldisposeoftheused

batteriesorrecycletheusedbatteriesproperly.Insome

countries,thisisalegalrequirement.

NHIL14GEN0038AA1

Mandatorybatteryrecycling

NOTE:Thefollowingrequirementsaremandatoryin

Brazil.

Batteriesaremadeofleadplatesandasulfuricacidsolution.Becausebatteriescontainheavymetalssuchas

lead,CONAMAResolution401/2008requiresyoutoreturnallusedbatteriestothebatterydealerwhenyoureplaceanybatteries.Donotdisposeofbatteriesinyour

householdgarbage.

Pointsofsaleareobligedto:

Acceptthereturnofyourusedbatteries

•

Storethereturnedbatteriesinasuitablelocation

•

Sendthereturnedbatteriestothebatterymanufacturer

•

forrecycling

2-18

Page 35

2-SAFETYINFORMATION

Safetysigns

Thefollowingsafetysignsareonyourimplementasa

guideforyoursafetyandforthesafetyofthosewhowork

withyou.

Walkaroundyourimplementandnotethesignicance

andlocationofallsafetysignsbeforeyouoperateyour

implement.Readallthesafetysignsadheredtotheimplementandfollowtheinstructions.

Keepallsafetysignscleanandlegible.Cleansafetysigns

withasoftcloth,water,andagentledetergent.

NOTICE:Donotusesolvent,gasoline,orotherharsh

chemicals.Solvents,gasoline,andotherharshchemicalsmaydamageorremovethesafetysigns.

Replaceallsafetysignsthataredamaged,missing,

paintedover,orillegible.Ifasafetysignisonapartthat

youoryourdealerreplaces,makesurethatyouoryour

dealerinstallthesafetysignonthenewpart.Contact

yourdealerforthereplacementofthesafetysigns.

Safetysignsthatdisplaythe“Readoperator’smanual”

symboldirectyoutotheoperator’smanualforfurtherinformationregardingmaintenance,adjustments,orproceduresforparticularareasoftheimplement.Whenasafety

signdisplaysthissymbol,consulttheappropriatepageof

theoperator’smanual.

Safetysignsthatdisplaythe“Readservicemanual”symboldirectyoutotheservicemanual.Ifyoudoubtyour

abilitytoperformserviceoperations,contactyourdealer.

NOTE:ThefollowinggureindicatesthesafetysignslocalizationforZ765Pro.Thesafetysignslocalizationfor

Z685Proissimilar.

2-19

Page 36

2-SAFETYINFORMATION

ZEIL18HT00809FA1

ZEIL18HT00811FA2

2-20

Page 37

2-SAFETYINFORMATION

Partnumber:1650220A

8116502203

2-21

Page 38

2-SAFETYINFORMATION

Partnumber:811627030

8116270304

2-22

Page 39

2-SAFETYINFORMATION

Safetysign(1)

Readtheoperator'smanualandthesafetyinstructions.

Readtheoperator'smanualtooperatetheimplementand

toavoidunnecessaryaccidentsanddamagestotheimplement.

WARNING

IMPROPEROPERATIONOFTHISMACHINE

CANCAUSEDEATHORSERIOUSINJURY.

MAKESURETHA TEVERYOPERATOR:

-isinstructedinthesafeandproperuseofthis

machine.

-readsandunderstandstheoperator'smanual

forthismachine.

-readsandunderstandsALLsafetysignson

themachine.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:1650220A

811650220_45

W0188A

Safetysign(2)

Alwaysstopthetractorenginebeforeyouadjust,maintain,repair,orlubricatetheimplement.Alsorememberto

removetheignitionkey.Makesurethatnobodystartsthe

engine,untilyouhavenished.

WARNING

Avoidinjury!Alwaysdothefollowingbefore

lubricating,maintaining,orservicingthemachine.

1.Disengagealldrives.

2.Engageparkingbrake.

3.Lowerallattachmentstotheground,or

raiseandengageallsafetylocks.

4.Shutoffengine.

5.Removekeyfromkeyswitch.

6.Switchoffbatterykey,ifinstalled.

7.Waitforallmachinemovementtostop.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:1650220A

W0047A

811650220_26

2-23

Page 40

2-SAFETYINFORMATION

Safetysign(3)

Movingpartsaredangerousandifthemovingpartscome

incontacttoyourbodythemovingpartscanpinchyour

body.

Thehazardmaycausesevereinjuriestotheentirebody,

withpossiblelethaleffect.

Toavoidthehazards,waituntilallmovingelements

havecompletelystoppedbeforeyoutouchthemoving

elements.

WARNING

Pinchhazard!

Waitforallmovementtostopbeforeyouserviceoradjustthemachineorequipment.

Failuretocomplycouldresultindeathorseriousinjury.

W1420A

Partofpartnumber:1650220A

Safetysign(4)

Pulloutthesafetyboltduringoperationintheeld.Push

inthesafetyboltduringthetransport.

811650220_17

Partofpartnumber:1650220A

Safetysign(5)

ThesignindicatesthemaximumRevolutionsPerMinute

(RPM)andthedirectionofrotationofthePowerT ake-Off

(PTO).

Referencetotheminimumoverlappingontheprole

tubesandtheminimumdistancerequirednottobottom

theshaft.

Partofpartnumber:1650220A

811650220_58

811650220_39

2-24

Page 41

2-SAFETYINFORMATION

Safetysign(6)

Makesurethattherearenopersonsintheswivelareaof

theboomarms.Keepasafedistance.

Partofpartnumber:811627030

Safetysign(7)

WARNING

Rotatingparts!

Keepclearofalldrivesandrotatingcomponents.

Failuretocomplycouldresultindeathorseriousinjury.

W1101A

811627030_110

Partofpartnumber:811627030

Safetysign(8)

Partofpartnumber:811627030

Safetysign(9)

Performthelubricationevery8h.

Partofpartnumber:811627030

811627030_411

811627030_212

811627030_313

2-25

Page 42

2-SAFETYINFORMATION

Safetysign(10)

Thehydraulicpressuremustnotexceed210bar

(3045psi).

Partofpartnumber:811627030

Safetysign(11)

Partofpartnumber:810652770B

811627030_514

Safetysign(12)

Partofpartnumber:811627030

Safetysign(13)

WARNING

Overturninghazard!

Beforeparkingthemachine,makesurethe

groundisstable.Plantheworksitesothatthe

groundisat,hard,andlevel.

Failuretocomplycouldresultindeathorseriousinjury.

810652770B15

811627030_616

W0258A

Riskofoverturning.

Beforeyoudisconnecttheimplement,pulldowntheparkingsupport.Makesurethatthegroundissolid.

Partofpartnumber:811627030

810667951A17

2-26

Page 43

3-CONTROLSANDINSTRUMENTS

3-CONTROLSANDINSTRUMENTS###_3_###

Information

Operatingprinciples

Forallinformationrelatedtothedescriptionandthelocationofthecontrolstouseyourimplement,seechapter“ControlsandInstruments”intheoperator’smanualof

yourvehicle.

3-1

Page 44

3-CONTROLSANDINSTRUMENTS

3-2

Page 45

4-OPERATINGINSTRUCTIONS

4-OPERATINGINSTRUCTIONS###_4_###

Commissioningtheunit

Preparingforoperation

1.Removethewirethatsecuresallloose,singleparts

fromthepalletsandtheimplement.

2.Settheheadstocktothecorrectheighttoconnect

theimplementtothetractorthree-pointlinkage.The

bottomhitchpinsmustbeapproximately350mm

(13.78in)abovetheground.Placethepalletwith

theimplementtoaplatformorrampofapproximately

250mm(9.84in)height.

NOTICE:Neverraisetheheadstockoftheimplement,

topreventtheimplementfromfalls.

3.Connecttheimplementtothethree-pointheadstockof

thetractor(seePage4-4).

4.Connectthehydraulichosesoftheimplementtothe

hydraulicsystemofthetractor.

5.Lifttheimplementslightly.

ZEIL17HT00125AA1

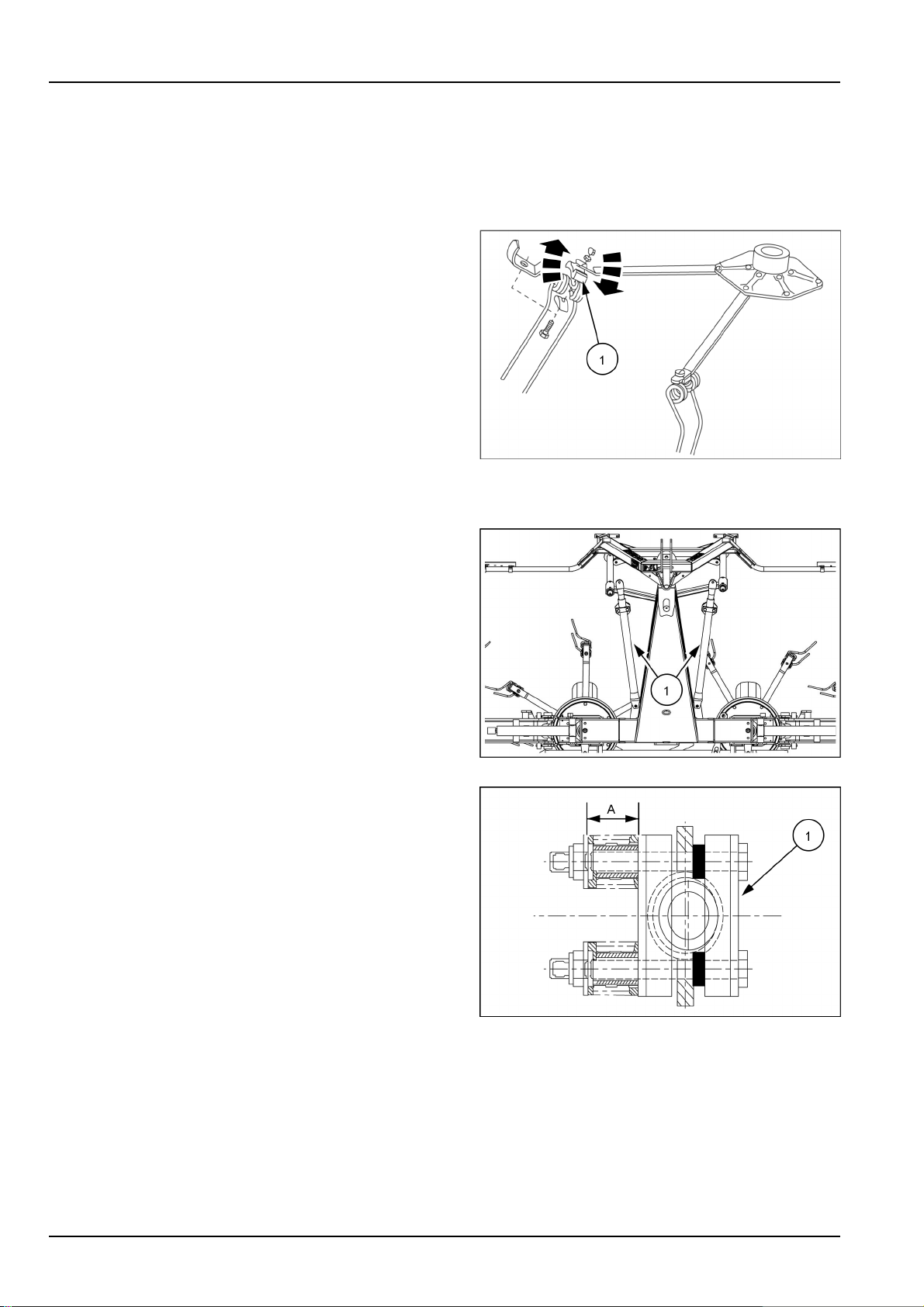

NOTICE:Performthefollowingstepsbeforeyouremovethesafetybarthatsecurestheliftedwingsduringtransport.

6.Folddownthelockingdevicestolockthewings.

7.Installthespringsbetweenthedevicesandthechas-

sis.

8.Installthepullropeprovidedforreleasingthede-

vices.

NOTICE:Operatingappliances(ropes,chains,rods,

etc.)ofremotecontrolledappliancesshouldnotbe

abletomovewhiletheimplementisintheworking

positionoroperatingposition.

9.Pulltheropeandkeepittautwhileyousetthecontrol

leverofthetractorhydraulictotheloweringposition,

toswingthejibarmsout.

NOTICE:Pulltheropetounlocklatchesofthetransportsafetyequipment.

10.Thepressurespringsmovesthejibarmsfromthe

verticalpositionandtheweightofthejibarmspush

thejibarmsinalowerposition.

NOTICE:Lowertheimplementslowly.

ZEIL17HT00126AA2

NOTICE:Checkthedispositionandtightnessofthe

hosesbeforeyouoperatethetractorhydraulicsystem.

NOTE:Ifyouneedtoreplacethehoses,onlyuse

hosesforapressureof225bar(3262.5psi).Only

useKONGSKILDEspareparts.

4-1

Page 46

4-OPERATINGINSTRUCTIONS

11.Installallthesupportwheelsintheworkingposition.

12.Reinstallallthedismountedtinecarrierarmstothe

rotordiscs.

13.Installthetwofoldabletinebarstotheouterrotorsso

thatthetwofoldabletinebarsfaceoutward.

NOTICE:Beforeyoupassthroughlow-heightdoorways,foldinthefoldabletinebarsandtheouter

safetyframes.

14.Usetheprovidedrubberlooptosecurethefoldedtine

bars.

15.Beforeyoustarttheoperations,unfoldthetinebars

andthesafetyframestotheworkingpositionand

securethemwiththeprovidedboltsandlockingdevices.

16.Swingouttheimplementtooperationalconguration

beforeyouinstallbothframesatright-handsideand

left-handsideoftheimplementwithwarningpanels.

17.Foldorraisetherotorsonlywhenthedirectionofthe

wheelsisdirectedtowardthefront.

ZEIL18HT00816AA3

NOTICE:Folduptheouterwingsandstoretherotary

tedderonarmandlevelarea.Ifyoustoretheimplement

ZEIL18HT00396FA4

onaninclinedorloosearea,anincreasedriskoftipping

mayoccur.

4-2

Page 47

4-OPERATINGINSTRUCTIONS

Installationoftherotorarms

1.UsetheboltsM12x45(5)toinstallthepre-assembled

rotorarm(2)onthehub(1).Usethehexagonalhead

boltsM12x35(3)andthelocknutsM12(4)foreach

arm.

NOTE:T akenoticeofthesenseofrotation(A)ofthe

rotors.

NOTE:DonotusetheboltsM12x30(6)insteadof

thebolts(5).UsetheboltsM12x30(6)forthetine

adjustment.SeePage6-4.

2.Aftertheinstallationoftherotorarms(2),checkthat

thearmsoftheinnerandouterrotorsareperfectly

alignedwitheachother.

ZEIL17HT00129AA1

ZEIL17HT00007AA2

4-3

Page 48

Startingtheunit

Connectiontothetractor

WARNING

Crushinghazard!

Usecarewhenyouconnectanddisconnect

themachines.Neverstandbetweenthetractorandtheimplementwhenyouconnectthe

linkarms.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Crushinghazard!

Donotstandorplaceanybodypartbetween

theimplementandamovingtractor.Stopthe

tractorengineandsettheparkingbrakebeforeyouattachcablesandhoses.

Failuretocomplycouldresultindeathorseriousinjury.

4-OPERATINGINSTRUCTIONS

W1545A

W1544A

WARNING

Hitchinghazard!

Alwayskeeptheareabetweenthetractorand

theimplementclearofallpersonswhilethe

tractororthree-pointhitchisinmotion.Lock

thetractortransmissioninParkandengage

theparkingbrake(s)beforeyouallowanyone

tocompletehitchingorunhitching.

Failuretocomplycouldresultindeathorseriousinjury.

NOTICE:Whenyouttheimplementtothethree-point

linkageofthetractor,turnallthecontrolleversintosucha

positionthatunintendedliftingorloweringisimpossible.

NOTICE:Whenyouttheimplementtothethree-point

linkage,themountingcategoriesatthetractorandthe

implementmustbecompatible.

NOTICE:Whenyouactivatethecontrolleversforthe

three-pointlinkagefromoutsidethetractorcab,never

stepbetweenthetractorandtheattachment.

W1540A

4-4

Page 49

4-OPERATINGINSTRUCTIONS

Beforeyouconnecttheimplementtothetractor

three-pointlinkageonsoftground,swingoutthe

implementtotheworkingposition.

1.Connectthehydraulicpipingoftheimplementtothe

tractorquick-actioncoupling.Coupletheelectroplug

oftheimplementtothetractor.

2.Foldorraisetherotorswiththerunningwheelsina

straightposition.

3.Beforeyouraisethelateralrotorstothetransportpo-

sition,alwaysswitchoffthetractorPowerTake-Off

(PTO).

4.Actuatethehydraulicvalveofthetractortoraisethe

lateralrotoroftheimplement.

5.Securethelateralrotorsautomaticallyforroadtrans-

portwiththesafetyhooks.

NOTICE:Beforeyoupassthroughlow-heightdoorways,foldinthefoldabletinebarsandtheoutersafety

frames.

6.Usetheprovidedrubberlooptosecurethefoldedtine

bars.

7.Beforeyoustarttheoperation,unfoldthetinebarsand

thesafetyframestotheworkingpositionandsecure

themwiththeprovidedboltsandlockingdevices.

8.Pulltheropeandkeepittautwhileyousetthecontrol

leverofthetractorhydraulictotheloweringposition

ZEIL17HT00127AA1

NOTICE:Lowertheimplementslowly.

NOTICE:Checkthedispositionandtightnessofthehoses

beforeyouoperatethetractorhydraulicsystem.

PowerTake-Off(PTO)connection

NOTICE:ToinstallandremovethePTOshaft,stopthe

engine.

NOTICE:OnlyusethesuppliedPTOshaftorthePTO

shaftthatthemanufacturerapprove..

AdjustthelengthofthePTOshafttothetractorbefore

youperformthefollowingsteps.Ifyouusetheimplement

withdifferenttractors,checkthatthePTOshafthasthe

correctlength.

NOTICE:Thesafetyguardsonthetractorsideandonthe

implementsidemustbeintact.

1.ReleasethePTOshaftfromthesupportchain.

2.PushthePTOshaftonthetractorPTOuntilyouen-

gagethelockingballs.

3.ThesafetychainsecurethesafetyguardofthePTO

shaftsonthetractorside.Ontheimplementsidethere

isafull-coveringprotection.Theclampsecurethe

full-coveringprotection.

NOTICE:ThechainsecurethesafetyguardofthePTO

shaft.

4-5

Page 50

4-OPERATINGINSTRUCTIONS

PowerTake-Off(PTO)shaft–Shorten

PowerTake-Off(PTO)shaftlength

NOTE:DonotshortenyournewPowerTake-Off(PTO)

shaftuntilyouarecertainthatitisnecessary .Fromthe

factorythedistancefromPTOtoPowerInputConnection

(PIC)isstandardonmosttractorbrands.

CheckthelengthofthePTOshaftforeachtractorpriorto

rstuse.

IfitisstillnecessarytoshortenthePTOshaft,theprole

tubesofthePTOshaftmustfullycomplywiththefollowing

overlappingmeasures.

Theslidingtubesmusthaveasmuchoverlapaspossi-

•

ble,withanacceptableminimumoverlap(b)of200mm

(7.87in)duringnormaloperation(TopSafeextension

linksinthenormalposition).

Theremustbeaminimumof40mm(1.6in)offree

•

PTOshaftlength(a)topreventtheshaftfrombottoming

out.

NHIL12HT00307AA1

Determiningtherequiredshaftlength

WhenyoudeterminethatyoumustshortenthePTOshaft,

selectthelengthsothatthetelescopingmembersnever

closecompletelyorbottomoutwheninuse.ThePTO

lengthmustneverbesmallerthantheminimumdistance

betweenthejoints.

1.AttachtheimplementtothetractorwithoutthePTO

shaft.

2.Adjustthethree-pointhitchsothatthePTOshaftis

parallelwiththeground.

3.Stopthetractorandengagetheparkingbrake.

4.DetermineifthePTOshaftbottomoutinthisposition.

IfthePTOshaftbottomsoutinthispositionorifthe

freelengthislessthan40mm(1.6in),proceedwith

theproceduretoshortenthePTOshaft.

4-6

Page 51

4-OPERATINGINSTRUCTIONS

ShorteningthePTOshaft

ToshortenthePTOshaftproceedasfollows.

1.FastenthePTOshafthalfpartstothePTO(onthe

tractor)andthePIC(ontheimplement).ThePTO

shafthalfpartsmustbeatthesamehorizontallevel,

oppositeeachotherattheshortestdistancefromthe

tractor.

2.Makesurethataminimumoverlapof200mm

(7.87in)exists.

3.CheckthatthePTOshaftdoesnotbottomoutatone

end.Keeptheshaftendsparalleltoeachotherand

marktheminimumdistanceof40mm(1.6in).Only

cutenoughPTOshaftofftoachievethisminimumfree

shaftlength.Thiswillmaintainthemaximumamount

ofPTOshaftoverlap.

4.Shortenallfourtubesequally.

5.Roundofftheendsoftheproletubesandremovethe

burrscarefully.

6.Removethemetalshavings.

ZEIL18HT00013AA2

NOTICE:Toavoidbigfrictionforces,greasethetube

carefullybeforeyoureassemblethetube.UseNLGI2.

NOTE:IfyoushortenthePTOshaft,thenyoumustcheck

theminimumoverlapandtheminimumdistanceagainif

youoperatetheimplementwithadifferenttractor.

4-7

Page 52

4-OPERATINGINSTRUCTIONS

Parkingtheunit

Disconnectionandparking

Parktheimplementonarmandevenground.

Toparktheimplement:

1.Placetheimplementonarmandlevelground.

2.Disconnectallthehydrauliccouplers.

3.Disconnecttheelectricalconnection.

4.DisconnectthePowerT ake-Off(PTO)shaftfromthe

tractor.SupportthePTOwiththechain.

5.Placewheelchocksasfollows:

Onaatsurface:oneinfrontof,andonebehinda

○

wheel.

Onaslope:onechockperwheel,eitherinfrontof,

○

orbehindthewheel,dependingontheincline.

6.Lowerthejacks(2).Securewiththelatchpins(1).

7.Releasetheimplementfromthetractor.

ZEIL18HT00926BA1

4-8

Page 53

5-TRANSPORTOPERATIONS

5-TRANSPORTOPERATIONS###_5_###

Preparingforroadtransport

Conversionofthetedderfromworkingtotransportposition

NOTICE:Adheretothemaximumpermissibleaxleloads,

totalweights.

NOTICE:Adheretothepermissibletransportmeasurements.

NOTICE:Fitandchecktransportgear,trafclights,warningandsafetysignalizationandsafetyguards.

NOTICE:Makesurethatinthetransportpositionofthe

implement,thetractorthree-pointlinkagedoesnotmove.

NOTICE:Whenyoudriveonpublicroadswithaliftedimplement,locktheliftingcontrollevertoavoidunintentional

lowering.

1.Raisetheimplementandlocktheheadstock.

2.Raisethejibarmsandcheckthesafetyhooks.

3.Theimplementisreadyfortransport.

ZEIL17HT00126AA1

Adjustmentoftheheadstockwithlateral

otationequipment

NOTICE:Raisetheimplementtoadjusttheheadstock.

Fortransportpositionlocktheheadstockasfollows:

1.Movethelever(1)totherear.

2.Inthisposition,thelatch(2)movesbeforethelocking

bolt(3),andtheheadstock(5)andthecarrierarm(4)

areinterlocked.

ZEIL17HT00125AA2

ZEIL17HT00131AA3

5-1

Page 54

5-TRANSPORTOPERATIONS

Shippingtransport

Transportonpallet

Theimplementiscompletelyassembledandsubmittedto

aruntestbeforetheimplementleavethefactory.

Beforetheimplementispalletizedforshipment,thesupportwheels,thewarningpanelsandthetinecarrierarms

arehoweverdismounted.

Theloosepartsandtheplasticbagwithhardwareare

wiredtothepalletorimplementinaemptyspace.

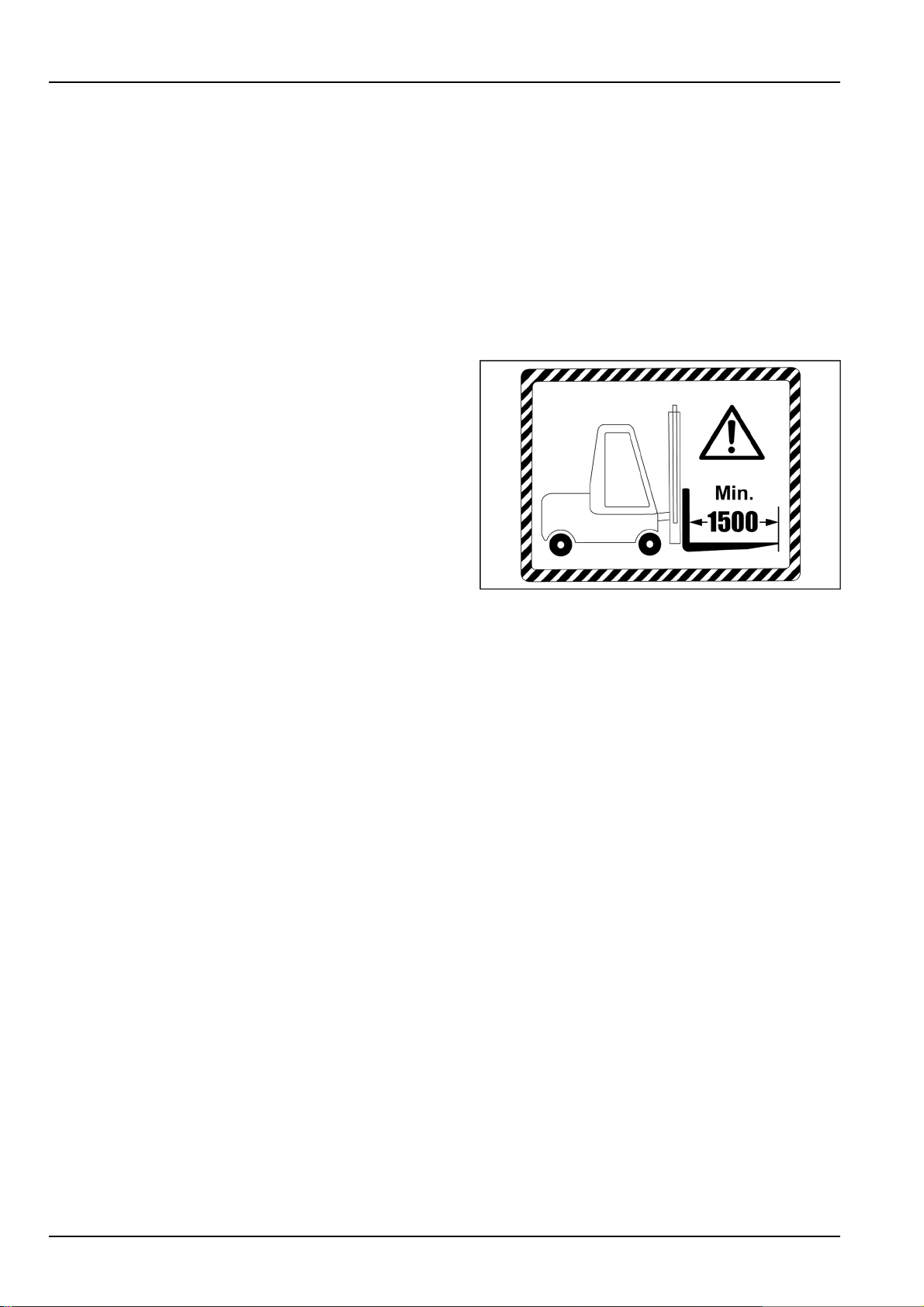

NOTICE:Onlytransportthepalletizedimplementwitha

forklifttruckiftheforksareatleast1500.0mm(59.1in)

long.Neveruseforklifttruckswithshorterforkstotransportthepalletizedimplement.

ZEIL17HT00137AA1

5-2

Page 55

6-WORKINGOPERATIONS

6-WORKINGOPERATIONS###_6_###

Generalinformation

Descriptionofoperation

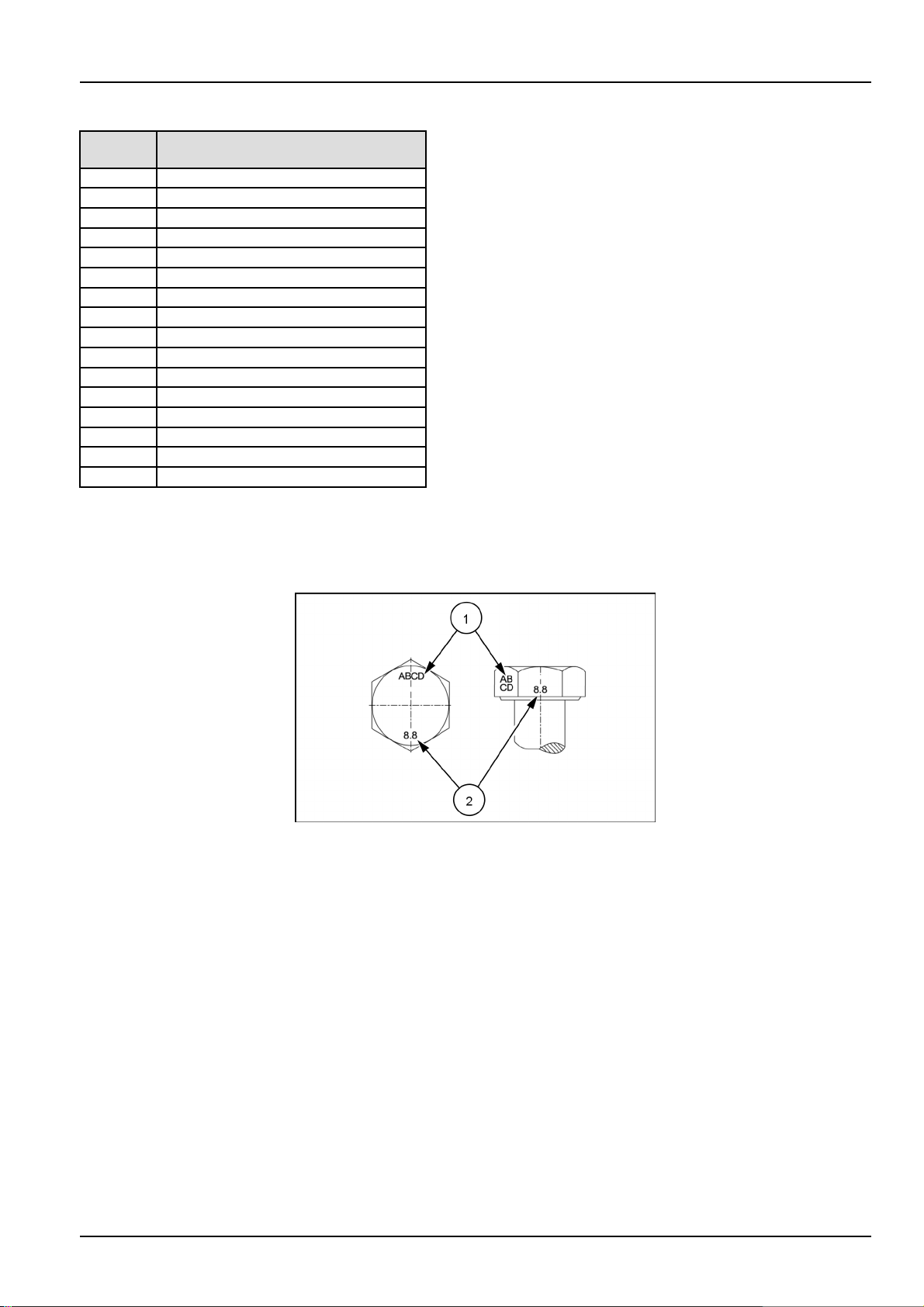

Thetedderisahaymakingimplementdesignedforthe

followingoperations:

Tedding.

•

Turning.

•

Clearingofeldboundaries.

•

Spreadingofwindrowsorsmallnightswaths.

•

Theimplementisequippedwithsixrotorsrotatingbypairs

inoppositedirections.

Forroadtransport,especiallyonnarrowroads,theimplementisequippedwithahydraulicallyoperateddevice

whichallowstheouterrotorstobebroughtinavertical

position.

Eachofthesixorsevenarmsoftherotorsisequipped

withdoublespringtineswhichcleanlytakeupthecrop

andleaveanevenscatterpatternbehindtheimplement.

Becausetheouterrotorsaremovableinheight,theimplementcanfollowgroundcontoursevenwhenyouworkon

unevenground,thusassuringexcellentworkingresultsat

alltimes.Arunningwheelsupportseachrotoroftheimplement.Therunningwheelscompensatejerkscaused

bygroundirregularities.

Thesmoothrunningoftheimplementallowshighworking

speedsandthus,incombinationwiththelargeworking

width,considerableacreage.

NOTICE:Beforeyouleavethetractor,lowertheimplementtotheground.Actuatetheparkingbrake,stopthe

engineandremovetheignitionkey.

NOTICE:Neverparktheimplementinthetransportpositiontransversetowaysorroadways.Theprojectingtines

cancauseinjuriesordamages.

Tedding/spreadingswaths

Whenspreadswathswiththeimplement,makesurethat

oneoftheswathsisbetweenthetractorwheels.

Alwaysselectthetravelspeedaccordingtothequalityof

thecroptobehandled.ThePowerT ake-Off(PTO)speed

shouldbeapproximately540RPM.

Toachieveacleanscatterpatternitmaybenecessaryto

mounttheimplementoffsetonthetractor.

Inanycaseyoumustarrangetheswathsinrelationtothe

rotorpairssothatthetractorwheelsdonotdriveoverthe

crop.

6-1

Page 56

6-WORKINGOPERATIONS

Turning

Topreventleafdamagelosseswhenyouturnthecrop

alreadyspread,selectalowPTOspeedwhileatthesame

timeyouincreasetheforwardspeed.

TomakesuretheratiobetweentravelandPTOspeedis

correct,checkthescatterpatternachieved.Ifnecessary,

adjusttheratio.

Spreadingwindrowsandsmallnightswaths

Whenyouspreadwindrowswiththeimplement,make

surethatoneofthewindrowsliesbetweenthetractor

wheels.

ReducingthePTOspeedachievesaminorscatteringeffectandaverygentlehandlingofthecrop.

Thetravelspeeddependsonthescatterpattern.Inparticularcases(forexampleinthecaseofcertainwindrow

widths)itmaybenecessarytomounttheimplementoffsetonthetractortoaligntheswathswiththerotorpairs.

6-2

Page 57

6-WORKINGOPERATIONS

DoublePTOjoints

ThedoublePowerTake-Off(PTO)joints(1)arelocatedin

thedrivelineofthemainframe.

ThepositionofthePTOpermittoturnandfoldtherotors

withoutdamagethedriveline.

ThedoublePTOjoints(1)aremaintenancefree.

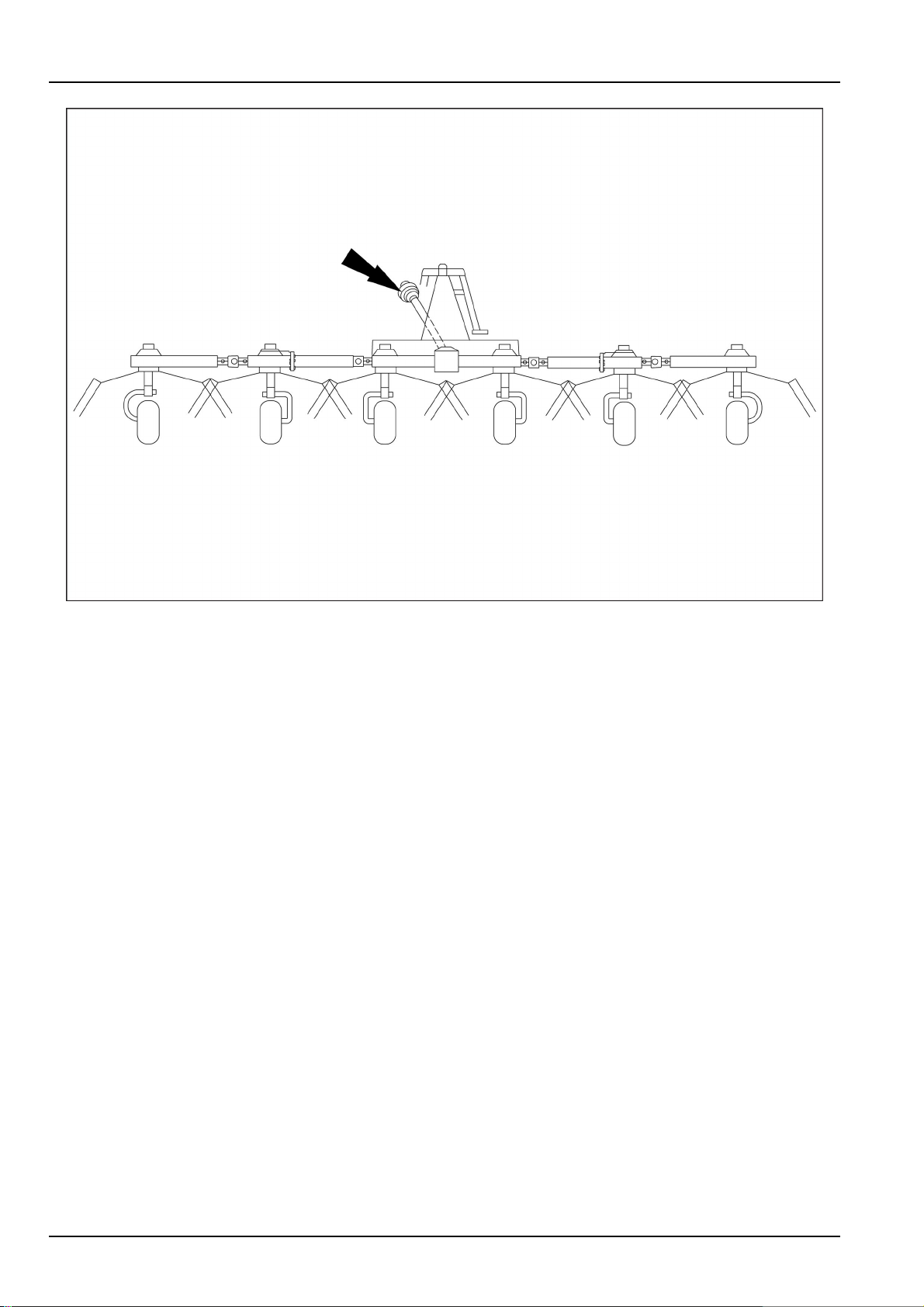

Adjustabletinepositiontothearm

Thetine(1)canbesetintwopositions:(X)8°and(Y)2°.

Withthetine(1)setto8°thecrophaveahigherdegree

ofsidewaysspreading.Usethistinesetincropsthatare

atunevenacrosstheeld.

ZEIL18HT00382AA1

Withthetine(1)setto2°thecropisthrownfurthertothe

rearandhaveabetterlengthwaysmixing.

Doubletineswithasymmetrictinelength

Thedoubletinesasymmetrictinelength(1)distributesthe

loadonthetinesevenlybetweenbothtines.Thewire

diameterofø9.5mm(0.4in)andthecoilouterdiameter

ofø69mm(2.7in)makethetinesturdyanddurable.

NOTE:Offset15mm(0.59in).

ZEIL18HT00383AA1

ZEIL18HT00384AA1

6-3

Page 58

6-WORKINGOPERATIONS

Basicadjustment

NOTICE:Alwaysstoptheimplementbeforeyouperform

anyadjustments.

Tineadjustment

Itispossibletochangethetineanglefromthestandard

angleof8°to2°.Stepperpositionoftinesgivemoregrip

ontheforagecrop.Tochangethetineangle,releasethe

securingboltsandturnthetinesupports(1)for180°on

thetinearms.

Shockabsorberadjustment

ZEIL17HT00129AA1

Twoshockabsorbers(1)stabilizethepositionofthe

rotarytedder.

Adjustthedampingintensityasfollows:

Torquethescrewstoincreasethedampingintensity.

•

Loosenthescrewstoreducethedampingintensity.

•

Adjustingdimension(A):32mm(1.26in).

ZEIL18HT00817AA2

ZEIL17HT00133AA3

6-4

Page 59

6-WORKINGOPERATIONS

Implementforpracticaloperationadjustment

1.Adjustthetiltingangleoftheimplementwithofthetop

link.Thedoublespringtinesmusttaptheground.

2.Withtheimplementsetwithtoolowposition,youwill

damagethecrop,thegrassstubbleandrisktodamagethedoublespringtines.

3.Checktheadjustmentatregularintervalsduringoper-

ation.

NOTICE:Thespreadingangledependsontheadjustmentofthesupportwheels(seePage6-8).

4.Ifyousetthespreadingangleofthesupportwheelsto

anotherspreadingangledifferentthantheangleadjustedbythefactory,actonthetoplinktobringthe

tinesinthecorrectpositionandtocorrecttheposition

oftheimplement.

Clearingtheedgesoftheeld

Itispossibletocleareldboundarieseitherontherighthandsideorontheleft-handside.

Tochangethepositionofthefourcenterwheels,move

theleverasfollows:

Levertotheleft-handsideposition:clearingontheleft-

•

handside.

Levertotheright-handsideposition:clearingonthe

•

right-handside.

Toswitchthepositionofthewheels,operatethehydraulic

controllever(optional)onthetractor.Thesteeringcylinderwillthenmovethefourcenterwheelstothepreselectedposition.

Whenyoumoveon,theimplementwillautomatically

movetotheselectedworkposition.

ZEIL17HT00135AA4

6-5

Page 60

6-WORKINGOPERATIONS

Workingspeedandnumberofrevolutions

NOTE:Adapttheworkingspeedtotheconditionsof

ground.Avoidabruptturningonslopedterrain.

Neverexceed25km/h(16mph)ontheroad.

NOTE:Whenyoudriveroundbendsbecarefulforwidth

ofthetractorandthechangeofthecenterofgravityofthe

implement.

Setacorrectforwardspeedtohavethecropcleanly.Set

acorrectPowerT ake-Off(PTO)speedtoavoiddamages

tothecrop.

YoumustalwaysadaptthePTOspeedtothecropconditions.Fordrycrop,lowthePTOspeed.

6-6

Page 61

6-WORKINGOPERATIONS

Conversionofthetedderfromtransporttoworkingposition

1.Raisetheimplementintheheadstock.

2.Swingoutthejibarms.

3.Unlocktheheadstockandlowertheimplement.

Workingposition

1.Movethelever(1)tothefront.

2.Themagnet(2)keepinUNLOCKEDpositionthelatch

(3).Theheadstock(5)isfreetomoveinrelationtothe

carrierarm(4).

ZEIL17HT00126AA1

ZEIL17HT00131AA2

6-7

Page 62

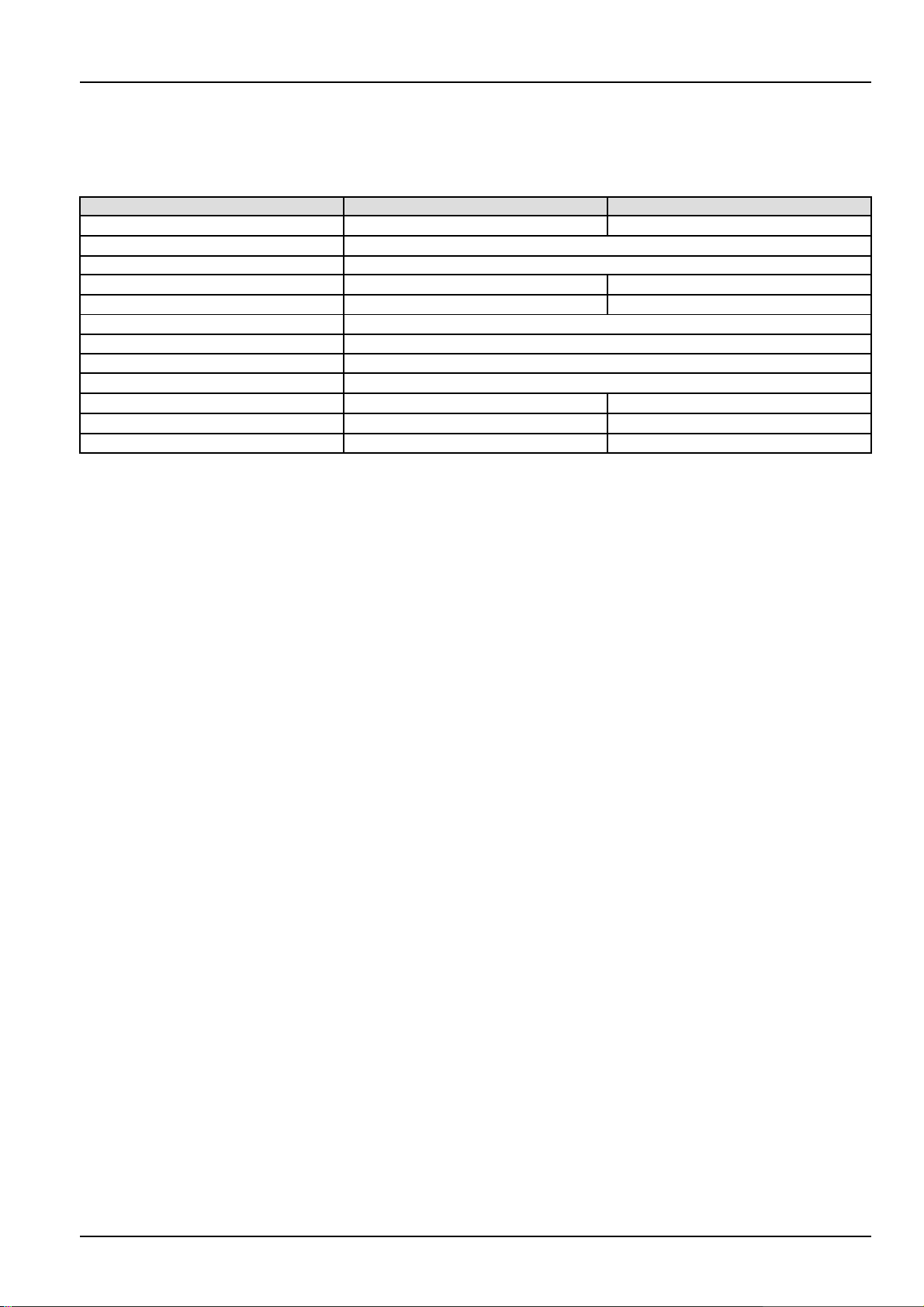

Adjustmentofthesupportwheels

NOTICE:Youcansetthesupportwheelstodifferent

spreadangles.

NOTICE:Thespreadingangledependsonandchanges

withtheworkingconditions.

1.Lifttheimplementtoadjustthespreadingangle.

2.Operatetheclevis(1)locatedonthewheelsupport,

andselectthespreadingangledesired.

6-WORKINGOPERATIONS

Setofholes(A)-Standardspreadingangle.

•

Setofholes(B)-Smallspreadinganglefordrymaterial.

•

ZEIL17HT00132BA1

ZEIL17HT00024AA2

ZEIL17HT00025AA3

6-8

Page 63

Setofholes(C)-Bigspreadingangle.

•

6-WORKINGOPERATIONS

ZEIL17HT00026AA4

6-9

Page 64

6-WORKINGOPERATIONS

6-10

Page 65

7-MAINTENANCE###_7_###

Generalinformation

Maintenance

Generalinformation

WARNING

Avoidinjury!

FollowALLoftheprecautionslistedbelow.

Failuretocomplycouldresultindeathorseriousinjury.

NOTICE:Dothemaintenance,theservice,thecleaning,

andtherepairwiththePowerTake-Off(PTO)shaftand

theengineOFF .Removetheignitionkey .

NOTICE:Takecarethatoilandgreasedonotgetincontactwithyourskin.

7-MAINTENANCE

W1091A

NOTICE:Youmustalwaysblockthetractorwheelsbefore