Kongskilde VCO-I 16-60, VCO-I 8-75, VCO-I 12-50, VCO-I 18-50, VCO-I 12-45 Operator's Manual

...Page 1

ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1

OPERATOR’S MANUAL

Vibro Crop

Vibro Crop Intelli

Inter-Row Cultivator

Part number 51601877

st

1

edition English

May 2019

Page 2

Contents

1GENERALINFORMATION

Notetotheowner...........................................................................1-1

Intendeduse................................................................................1-4

Prohibitedusage...........................................................................1-4

Electro-MagneticCompatibility(EMC).....................................................1-4

Manualscopeandrequiredtraininglevel..................................................1-5

ProductIdenticationNumber(PIN)........................................................1-6

Productidentication.......................................................................1-7

Operator'smanualstorageonthemachine................................................1-7

Implementorientation......................................................................1-8

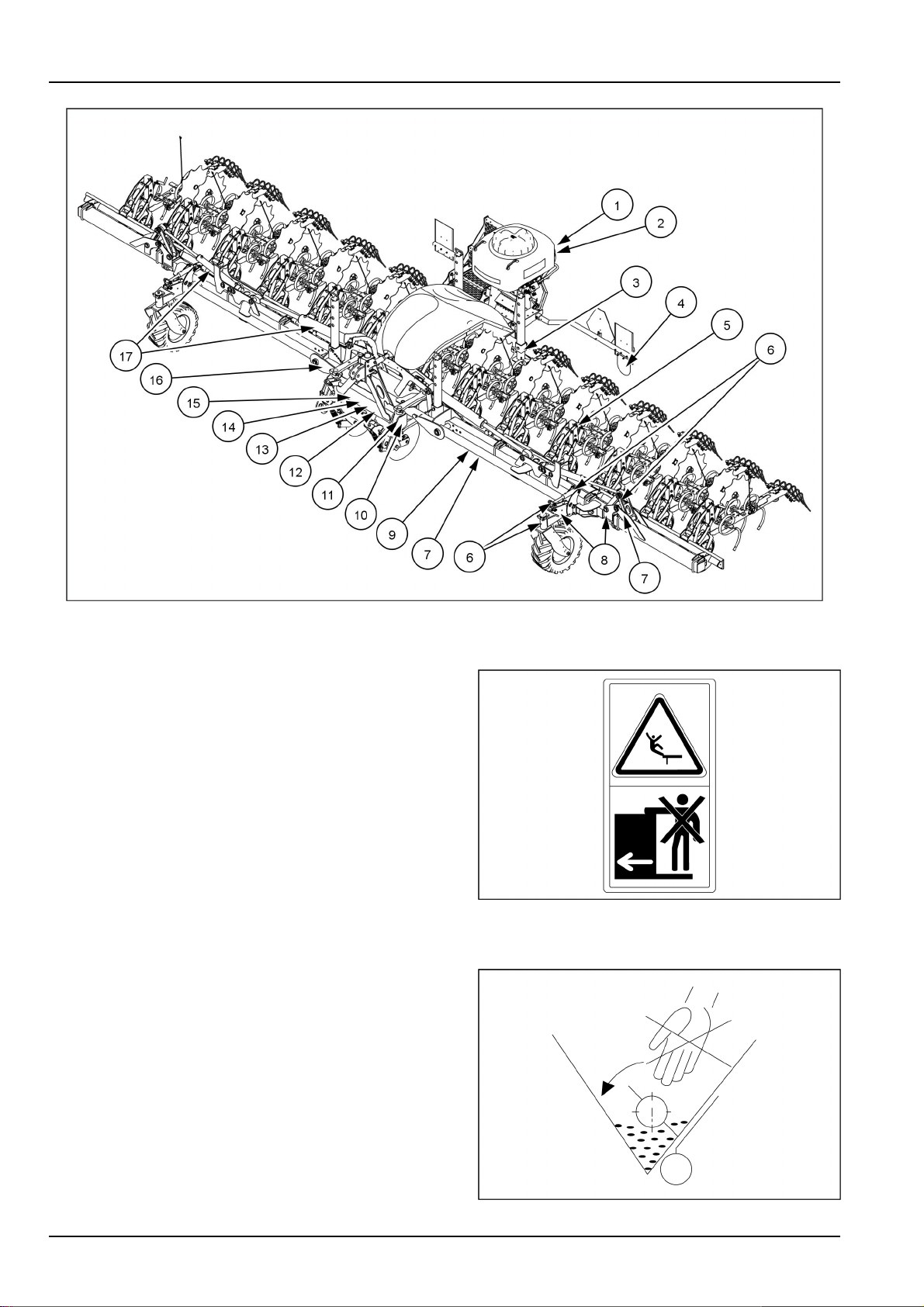

Implementcomponents.....................................................................1-9

2SAFETYINFORMATION

Safetyrulesandsignalworddenitions....................................................2-1

Generalrecommendations.................................................................2-2

Illustrations.................................................................................2-3

Localobligations............................................................................2-3

Fireorexplosionprevention................................................................2-3

Hazardouschemicals.......................................................................2-4

Startinguptheimplementsafely...........................................................2-4

Travelingonpublicroads...................................................................2-5

Operatingtheimplementsafely............................................................2-7

Maintenance................................................................................2-8

Personalprotectiveequipment(PPE)......................................................2-9

Safetyrequirementsforuidpowersystemsandcomponents-hydraulicsystems.......2-9

Noiseemission............................................................................2-10

Implementstability.........................................................................2-11

Ecologyandtheenvironment.............................................................2-12

Safetysigns...............................................................................2-13

3CONTROLSANDINSTRUMENTS

Information

Operatingprinciples....................................................................3-1

4OPERATINGINSTRUCTIONS

Commissioningtheunit

Choiceofthetractor....................................................................4-1

Checkbeforeuse.......................................................................4-2

Startingtheunit

Connectiontothetractor...............................................................4-3

HydraulicconnectionsforVibroCropIntelli............................................4-6

HydraulicconnectionsforVibroCrop..................................................4-6

Page 3

Parkingtheunit

Disconnectionandparking.............................................................4-7

5TRANSPORTOPERATIONS

Roadtransport

Transportposition......................................................................5-1

Transportonpublicroads..............................................................5-2

Shippingtransport

Liftingtheimplement...................................................................5-4

Transportonpallet......................................................................5-6

6WORKINGOPERATIONS

Generalinformation

Workingposition........................................................................6-1

Adjustmentofworkingsection..........................................................6-3

Adjustmentofworkingdepth...........................................................6-4

Hydraulicadjustment...................................................................6-5

Hydraulicblockadjustment.....................................................6-5

Operationmodeadjustment....................................................6-6

Oilowadjustment.............................................................6-6

Workingintheeld-VibroCropIntelli.................................................6-7

Workingintheeld-VibroCrop.......................................................6-9

Adjustmentofspacingofthetinesandprotectionshields............................6-10

Adjustmentofthestabilizingdisc......................................................6-1 1

Camerasteering.......................................................................6-12

FillingtheFSSeeder..................................................................6-13

Tines(VibroCroptinesforvulnerablecrops).........................................6-14

7MAINTENANCE

Generalinformation

General.................................................................................7-1

Torque..................................................................................7-3

Torqueforclass12.9...................................................................7-6

Fluidsandlubricants...................................................................7-6

Maintenanceplanning

Overview...............................................................................7-7

Aftertherst10hours

Nutsandbolts..........................................................................7-7

Every100hours

100hoursgreasettings...............................................................7-8

Nutsandbolts.........................................................................7-10

Page 4

Everysixyears

Hydraulichoses.......................................................................7-11

Storage

Pressurewashing.................................................................7-12

Endofseasonservice.............................................................7-13

Orderingpartsand/oraccessoriesand/oraccessories..........................7-14

8TROUBLESHOOTING

Faultcoderesolution

Troubleshooting....................................................................8-1

9SPECIFICATIONS

Technicaldata..............................................................................9-1

Fluidsandlubricants.......................................................................9-3

10ACCESSORIES

Sectioncontrols(GPS-system)...........................................................10-1

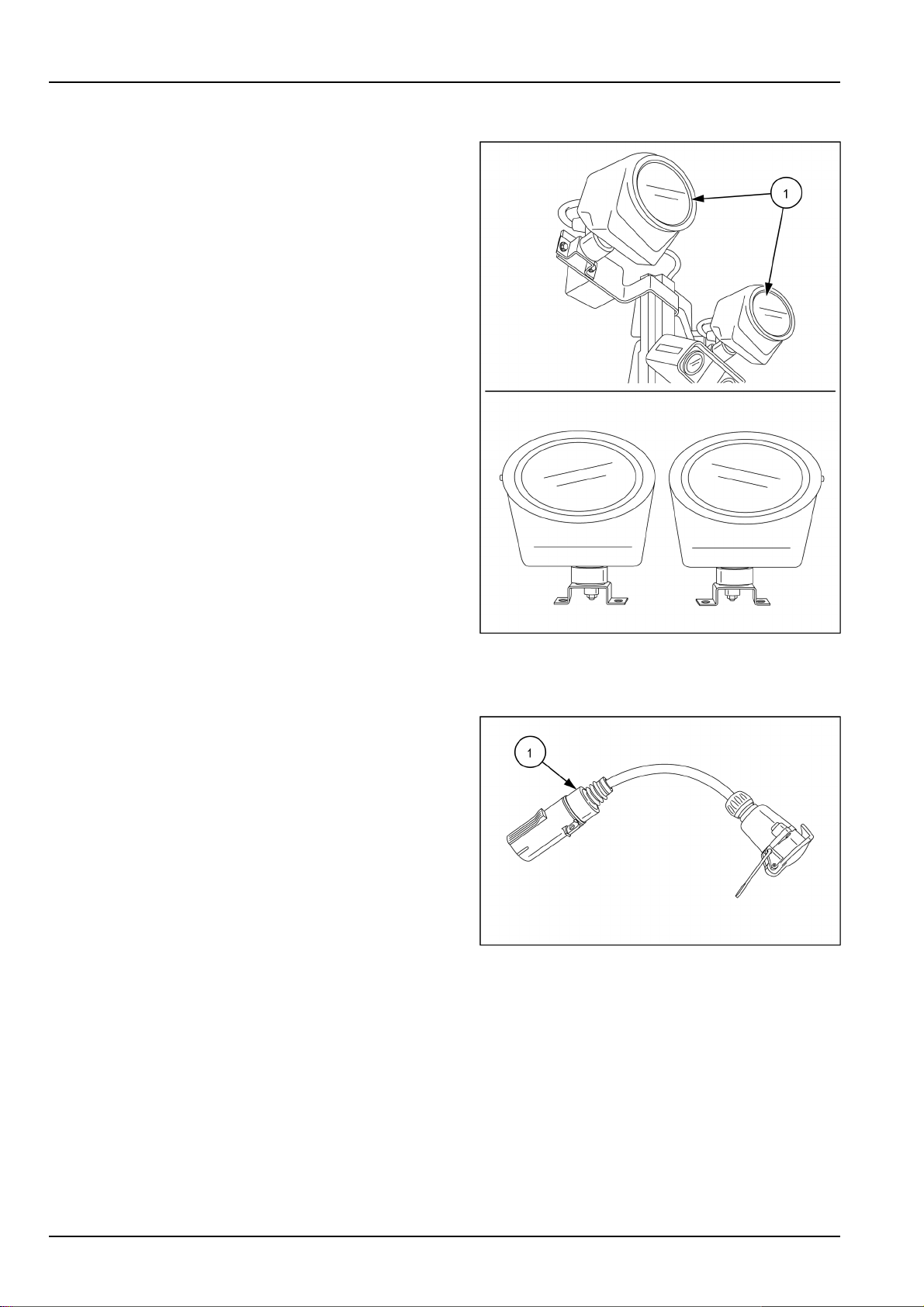

Lightkitforcamera(Completexenonlightkit)............................................10-2

Adapterforlightkit........................................................................10-2

Externalvideomonitor.....................................................................10-3

Rearharrow...............................................................................10-3

FSSeeder.................................................................................10-3

Loadsensingkit...........................................................................10-4

Hopperlevelsensor.......................................................................10-4

Wheels....................................................................................10-4

Splittercableandsensors.................................................................10-5

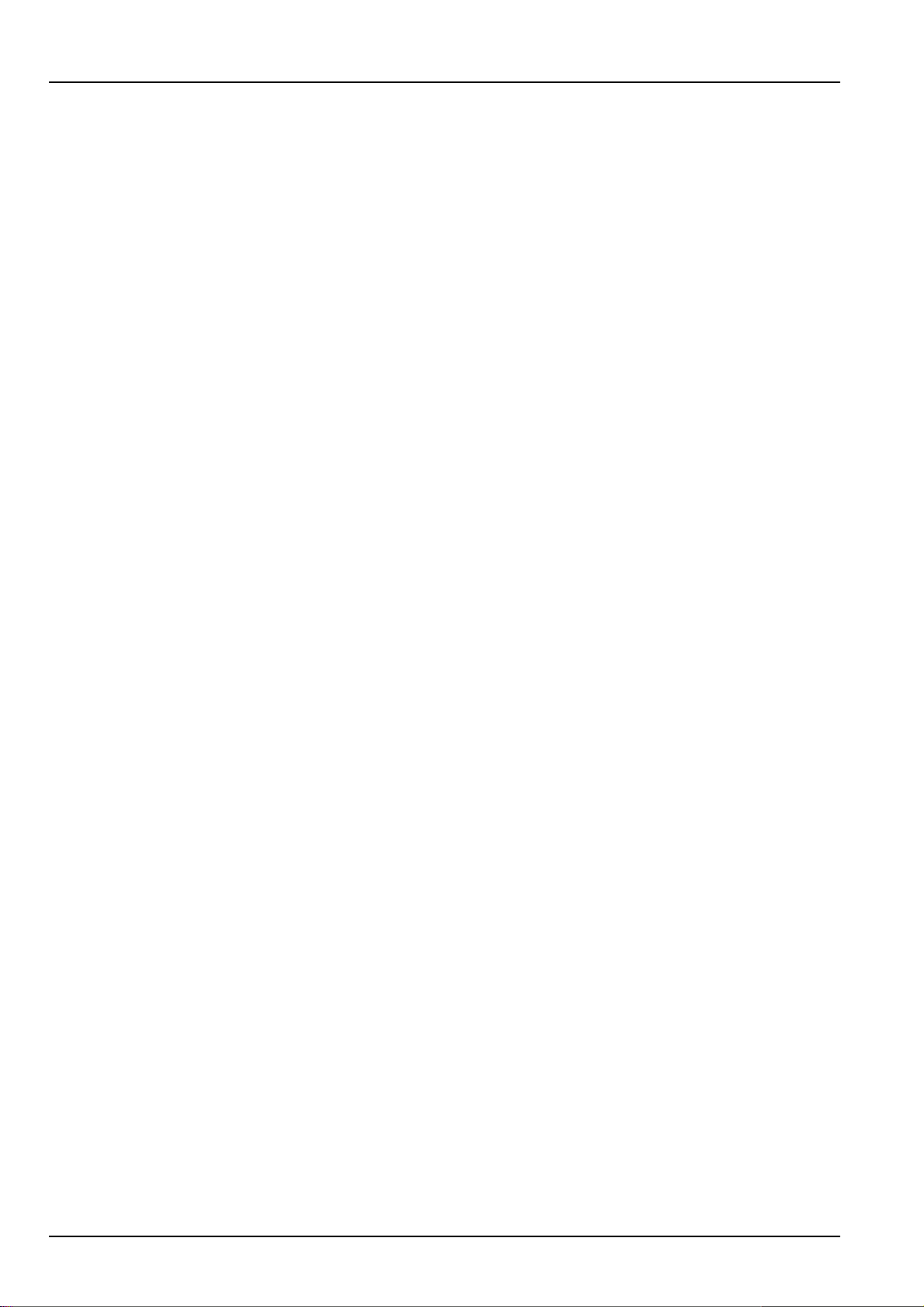

Connectorcable...........................................................................10-7

Adaptercablepowersupply...............................................................10-7

11FORMSANDDECLARATIONS

CEDeclarationofconformity..............................................................11-1

Page 5

1-GENERALINFORMATION

1-GENERALINFORMATION###_1_###

Notetotheowner

Thismanualhasbeenpreparedtoassistyouinthecorrectproceduretorunin,todrive,tooperate,toadjustandto

maintainyournewimplement.

Thisimplementhasbeendesignedandbuilttogivemaximumperformance,economyandeaseofoperationunder

awidevarietyofconditions.

Priortodelivery,yourimplementwascarefullyinspectedbothatthefactoryandbyyourdealertomakesurethatit

reachesyouinoptimumcondition.T omaintainthisconditionandassuretrouble‐freeoperationitisimportantthat

routineservices,asspeciedinthismanual,arecarriedoutattherecommendedintervals.

Readthismanualcarefully(especiallyChapter2thatcoversthesafetyinformation)andkeepthismanualinaconvenientplaceforfuturereference.DONOToperateorpermitanyonetooperateorservicethisimplementuntilyou

and/orotherpersonshavereadthismanual.Readthemanual,itwillsaveyoutimeandhasslelater.Lackofknowledgecanleadtoaccidents.Employonlytrainedoperatorswhohavedemonstratedtheabilitytooperateandservice

thisimplementcorrectlyandsafely.Contactyourdealerforassistanceprovidingtherequiredtrainingtoyouroperators.Contactyourdealertoobtainadditionalmanualsoralternatelanguageversions.

Ifatanytimeyourequireadvicethatconcernsyourimplement,donothesitatetocontactyourauthorizeddealer.He

hasfactory‐trainedpersonnel,genuineservicepartsandthenecessaryequipmenttocarryoutyourservicerequirements.

NOTICE:ThisimplementhasbeendesignedandbuiltinlinewiththerequirementsputforwardbytheEuropean

Directives2006/42/ECand2014/30/EU.

AlwaysusegenuineKONGSKILDEServicePartsorpartsthatmatchatleastthesamequality,reliabilityandfunctionalityastheequivalentoriginalServicePartswhenyouserviceandrepairyourimplementanddonotmodifyyour

implementwithoutawrittenpermissionofthemanufacturer.Failuretodosowillvoidtheresponsibilityofthemanufacturer.

Checklocalroadlegislationbeforeyoudrivetheimplementonpublicroads.

Whenyouoperateinterchangeableimplement,makesurethattheimplementisCEapproved.

Asthispublicationisdistributedthroughoutourinternationalnetwork,theimplementillustrated,eitherasstandardor

asanaccessory,mayvaryaccordingtothecountryinwhichtheimplementistobeused.Lowspecicationcongurations,aschosenbythecustomer,maydeviatefromthespecicationsgiven.

Severalguresinthisoperator'smanualshowthesafetyguardingortheadditionalguards,legallyrequiredbycertain

countries,openorremovedtobetterillustrateaparticularfeatureoradjustment.Theimplementmustnotbeusedin

thiscondition.Foryourownsafety,makesurethatallguardsareclosedorreplacedbeforeyouoperatetheimplement.

1-1

Page 6

1-GENERALINFORMATION

OWNERASSISTANCE

WeatKONGSKILDEandyourKONGSKILDEdealerwantyoutobecompletelysatisedwithyourinvestment.Normally,yourdealer'sServiceDepartmentwillhandleanyproblemswithyourimplement.Sometimeshowever,misunderstandingcanoccur.Ifyourproblemhasnotbeenhandledtoyoursatisfaction,wesuggestyoutocontacttheowner

orGeneralManagerofthedealership,explaintheproblemandrequestassistance.Whenadditionalassistanceis

needed,yourdealerhasdirectaccesstoourbranchofce.

COMPANYPOLICY

Companypolicy,whichisoneofcontinuousimprovement,reservestherighttomakechangesindesignandspecicationatanytimewithoutnoticeandwithoutobligationtomodifyunitspreviouslybuilt.

Alldatagiveninthisbookissubjecttoproductionvariations.Theinformationinthispublicationisprovidedonthe

basisofinformationthatwasavailableatthetimethatthemanualwaswritten.Settings,proceduresandotheritems

canchange.Thesechangescanaffecttheservicethatisgiventotheimplement.

Dimensionsandweightsareapproximateonlyandtheillustrationsdonotnecessarilyshowtheimplementinstandard

condition.Forexactinformationaboutanyparticularimplementpleaseconsultyourdealer.Makesurethatyouhave

themostcurrentandcompleteinformationfromyourdealerbeforeyoustartanyjob.

ACCESSORIESANDOPTIONS

Yourimplementhasbeendesignedtooperateinawidevarietyofsoils/cropsandconditions.Neverthelessadditional

equipmentmay ,incertaincases,berequiredtoimprovetheimplementperformance.Alistofthisadditionalequipmentisgiveninthe''Accessories”chapterinthismanual.Useonlythoseaccessoriesdesignedforyourimplement.

PARTSANDACCESSORIES

GenuineKONGSKILDEpartsandaccessorieshavebeenspecicallydesignedforKONGSKILDEimplements.

Wewouldliketopointoutthat''non-genuine”partsandaccessorieshavenotbeenexaminedandreleased

byKONGSKILDE.Theinstallationand/oruseofsuchproductscouldhavenegativeeffectsuponthedesign

characteristicsofyourimplementandtherebyaffectitssafety.KONGSKILDEisnotliableforanydamagecaused

bytheuseof''non-genuine”partsandaccessories.

RelyonyourauthorizeddealertosupplyyouwithgenuineKONGSKILDEpartsonly .Thesepartsarecoveredbyour

warrantyandwillgiveyouthebestperformance.

SeethepartscatalogorbrowsetheKONGSKILDEportaltondservicepartsforyourimplement.

Whenyouorderserviceparts,alwaysquotethemodelandserialnumberprintedontheProductIdenticationNumber

(PIN)plate.

1-2

Page 7

1-GENERALINFORMATION

LUBRICANTS

Yourdealersellsaselectionofspeciallyformulatedlubricantsbasedonownengineeringspecications.

Recommendedlubricantsforyourimplementarelistedinthemaintenancechapter.

WARRANTY

Yourimplementiswarrantedaccordingtolegalrightsinyourcountryandthecontractualagreementwiththeselling

dealer.Nowarrantyshall,however,applyiftheimplementhasnotbeenused,adjustedandmaintainedaccordingto

theinstructionsgiveninthisoperator'smanual.

Itisprohibitedtocarryoutanymodicationstotheimplementunlessspecicallyauthorized,inwriting,bya

KONGSKILDErepresentative.

CLEANINGYOURIMPLEMENT

Whenyouuseahighpressurewasher,donotstandtooclosetotheimplementandavoiddirectingthejetatelectronic

components,electricalconnections,breathers,seals,llercaps,andsoon.

Cleandecalsonlywithasoftcloth,waterandagentledetergent.DONOTusesolvent,gasolineorotherharsh

chemicalstocleandecals.Decalscouldberemovedorgetdamaged.

DISASSEMBLYORSCRAPPING

Whenyourimplementistakenoutofservicebecauseitisdamagedbeyondrepairorhasreachedtheendofits

usefullife,disassembly,scrappingand/orrecyclingofcomponentsmustbeperformedonlybyaqualiedtechnician

withserviceinstructions,andincompliancewithlocallawandregulations.

1-3

Page 8

Intendeduse

1-GENERALINFORMATION

KONGSKILDEimplementcanonlyperformtheusual

workinagriculture.Onlyconnecttheimplementtoa

tractorthatcorrespondswiththespecicationsofthe

implementandislegaltouse.

Theimplementrowcleanersaredevelopedforagriculturalwork.Connecttheimplementonlytoagricultural

tractorsanddrivebythehydraulicandelectricalsystem

ontheagriculturaltractor.

Theimplementareonlyintendedforworkthesoilinbetweenrowcropslikemaizeandsugarbeetsinorderto

mechanicallycleanoutbetweentherows.

Theimplementisarear-mountedrowcropcleaner

mountedonaparallelogramsideshiftframe,designed

formechanicalrowcropcleaning.Thenewintelligent

Prohibitedusage

NOTICE:DONOTusethisimplementforanotherpurposethanintendedbythemanufacturer(asdescribed

inthemanual,shownbythedecals,orinotherproduct

safetyinformationprovidedwiththeimplement).These

informationsourcesdenetheintendeduseoftheimplement.

Donotusethisimplement:

1.T operformotherworksthanfarmworksbasedonmechanicalrowcropcleaning.

2.Ifyouhavenotreadthisinstructionmanual.

3.Ifyouhavenotlearnthestructureandoperationofthe

implement.

solutionsprovidingincreasedcapacity,precisionand

userfriendliness.

Theimplementisself-adjustingduringtheworkintheeld

duetothecameracontrolledsideshiftframe.Theimplementidentiesandfollowstherowsintheeldand

adjustsitselfwhencameraisactive.Thesesolutionallowsincreasemaximumworkingspeedupto10km/h

(6.2mph).

Theworkmustoccurunderreasonableconditions,or

thoroughagriculturalknowledgeandauthorizedoperation,onanormalcultivationthathasareasonableextensionwithoutforeignmatterandthelike.Theperformance

oftheimplementwilldependonthecrop,theconditionof

theeld,theground,andnallytheweather.

Ifyouusetheunitinconsistentlywithitsdestination,

KONGSKILDEand/oritsrepresentativesshallnotbe

heldliableforanydamagesincurred.Insuchcase,full

responsibilityfortheimplementuse,transport,maintenance,repairs,etc.shallbebornebytheowner/user.

Anyandalldeparturesfrommanufacturerrequirements

andeffectivelegalregulations,aswellasperformingany

modicationsinimplementstructurewithoutobtaining

priormanufacturer’sapproval,usingsparepartsother

thanoriginalonesshallbeconstruedasusingtheunit

inconsistentlywiththerequirementsandshallresultina

waiverperformedbyKONGSKILDEwithrespecttothe

damages.

Electro-MagneticCompatibility(EMC)

ThismachinecompliesstrictlywiththeEuropeanRegulationsonelectro‐magneticemissions.However,interference

mayariseasaresultofadd‐onequipmentwhichmaynotnecessarilymeettherequiredstandards.Assuchinterferencecanresultinseriousmalfunctionoftheunitand/orcreateunsafesituations,youmustobservethefollowing:

Ensurethateachpieceofnon‐KONGSKILDEequipmentttedtothemachinebearstheCEmark.

•

Themaximumpowerofemissionequipment(radio,telephones,etc.)mustnotexceedthelimitsimposedbythe

•

nationalauthoritiesofthecountrywhereyouusethemachine.

Theelectro‐magneticeldgeneratedbytheadd‐onsystemshouldnotexceed24V/matanytimeandatanylo-

•

cationintheproximityofelectroniccomponents.

FailuretocomplywiththeseruleswillrendertheKONGSKILDEwarrantynullandvoid.

1-4

Page 9

1-GENERALINFORMATION

Manualscopeandrequiredtraininglevel

Introductiontothismanual

Thismanualgivesinformationabouttheuseofyour

KONGSKILDEmachineasintendedandunderthe

conditionsforeseenbyKONGSKILDEduringnormal

operation,routineservice,andmaintenance.

Thismanualdoesnotcontainalltheinformationthatrelatestoperiodicservice,conversions,andrepairsthat

onlytrainedservicepersonnelcanperform.Someof

theseactivitiesmayrequireappropriatefacilities,technicalskills,and/ortoolsthatKONGSKILDEdoesnotsupply

withthemachine.

ThemanualcontainsthechaptersasshownontheContentspages.SeetheIndexattheendofthismanualto

locatespecicitemsaboutyourKONGSKILDEmachine.

Normaloperation

Normaloperationconsistsoftheuseofthismachinefor

thepurposeKONGSKILDEintendsbyanoperatorthat:

Isfamiliarwiththemachineandanymountedequip-

•

mentortowedequipment

Complieswiththeinformationonoperationandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Normaloperationincludes:

Preparationandstorageofthemachine

•

Additionandremovalofballast

•

Connectionanddisconnectionofmountedequipment

•

and/ortowedequipment

Adjustmentandcongurationofthemachineand

•

equipmentforthespecicconditionsofthejobsite,

eld,and/orcrop

Movementofcomponentsintoandoutofworkingpo-

•

sitions

Routineserviceandmaintenance

Routineserviceandmaintenanceconsistsofthedaily

activitiesnecessarytomaintainthepropermachine

function.Theoperatormust:

Befamiliarwiththemachinecharacteristics

•

Complywiththeinformationonroutineserviceandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Routineservicecaninclude:

Fueling

•

Cleaning

•

Washing

•

Toppingupuidlevels

•

Greasing

•

Replacingconsumableitemssuchaslightbulbs

•

Periodicservice,conversions,andrepairs

Periodicserviceconsistsofactivitiesthatarenecessary

tomaintaintheexpectedlifeoftheKONGSKILDEmachine.Theseactivitieshavedenedintervals.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivitiesatthedened

intervals.Trainedservicepersonnelmustcomplywith

theinformationonperiodicserviceandsafepracticesas

partlyspeciedbyKONGSKILDEinthismanualand/or

othercompanyliterature.

Periodicserviceincludes:

Oilchangeservicefortheengine,hydrauliccircuits,or

•

transmission

Periodicexchangeofothersubstancesorcomponents

•

asrequired

ConversionactivitiesrebuildtheKONGSKILDEmachine

inacongurationthatisappropriateforaspecicjob

site,crop,and/orsoilconditions(e.g.,installationofdual

wheels).Conversionactivitiesmustbedone:

Bytrainedservicepersonnelfamiliarwiththemachine

•

characteristics

Bytrainedservicepersonnelthatcomplywiththe

•

informationonconversionaspartlyspeciedby

KONGSKILDEinthismanual,assemblyinstructions,

and/orothercompanyliterature

Repairactivitiesrestoreproperfunctiontoa

KONGSKILDEmachineafterafailureordegradation

ofperformance.Dismantlingactivitiesoccurduringthe

scrappingand/ordismantlingofthemachine.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivities.Trainedservice

personnelmustcomplywiththeinformationforrepairas

speciedbyKONGSKILDEintheservicemanual.

Beforeyouoperate

Readthismanualbeforeyoustarttheengineor

operatethisKONGSKILDEmachine.Contactyour

KONGSKILDEdealerif:

Youdonotunderstandanyinformationinthismanual

•

Youneedmoreinformation

•

Youneedassistance

•

Allpersonstrainingtooperate,orwhowilloperate

thisKONGSKILDEmachineshouldbeoldenoughto

possessavalidlocalvehicleoperatingpermit(ormeet

otherapplicablelocalagerequirements).Thesepersons

1-5

Page 10

1-GENERALINFORMATION

mustdemonstratetheabilitytooperateandservicethe

KONGSKILDEmachineinacorrectandsafemanner.

ProductIdenticationNumber(PIN)

TheProductIdenticationNumber(PIN)isaserialnumberthatidentiestheimplement.

Theserialnumber,modelandotherspecicationsareon

thePINplate.

ProvideyourKONGSKILDEdealerwiththemodelandthe

PINwhenyouorderparts.

ZEIL18HT00546EA1

(1)Companyname(7)Yearofconstruction

(2)Brandidenticationlogo(8)Madein(countryoforigin)

(3)

(4)Type/V ariant/Version(10)ProductIdenticationNumber(PIN)

(5)

(6)Certicationmark(12)

Mailaddress

Modelyear

(9)

(11)

Maximumweight

Model

Designation

1-6

Page 11

Productidentication

NOTE:DonotremoveorchangetheProductIdenticationNumber(PIN)plate(1)ontheimplement.

ThePINplate(1)isonthefrontoftheimplement.

1-GENERALINFORMATION

Forfuturereference,recordyourimplementmodeland

PINinthespacesbelow.

Model

ProductIdenticationNumber(PIN)

Operator'smanualstorageonthemachine

Keepthisoperator'smanualprotectedandaccessibleon

thetractorwheneveryoutransportoroperatetheimplement.

ZEIL19TIL0205FA1

1-7

Page 12

1-GENERALINFORMATION

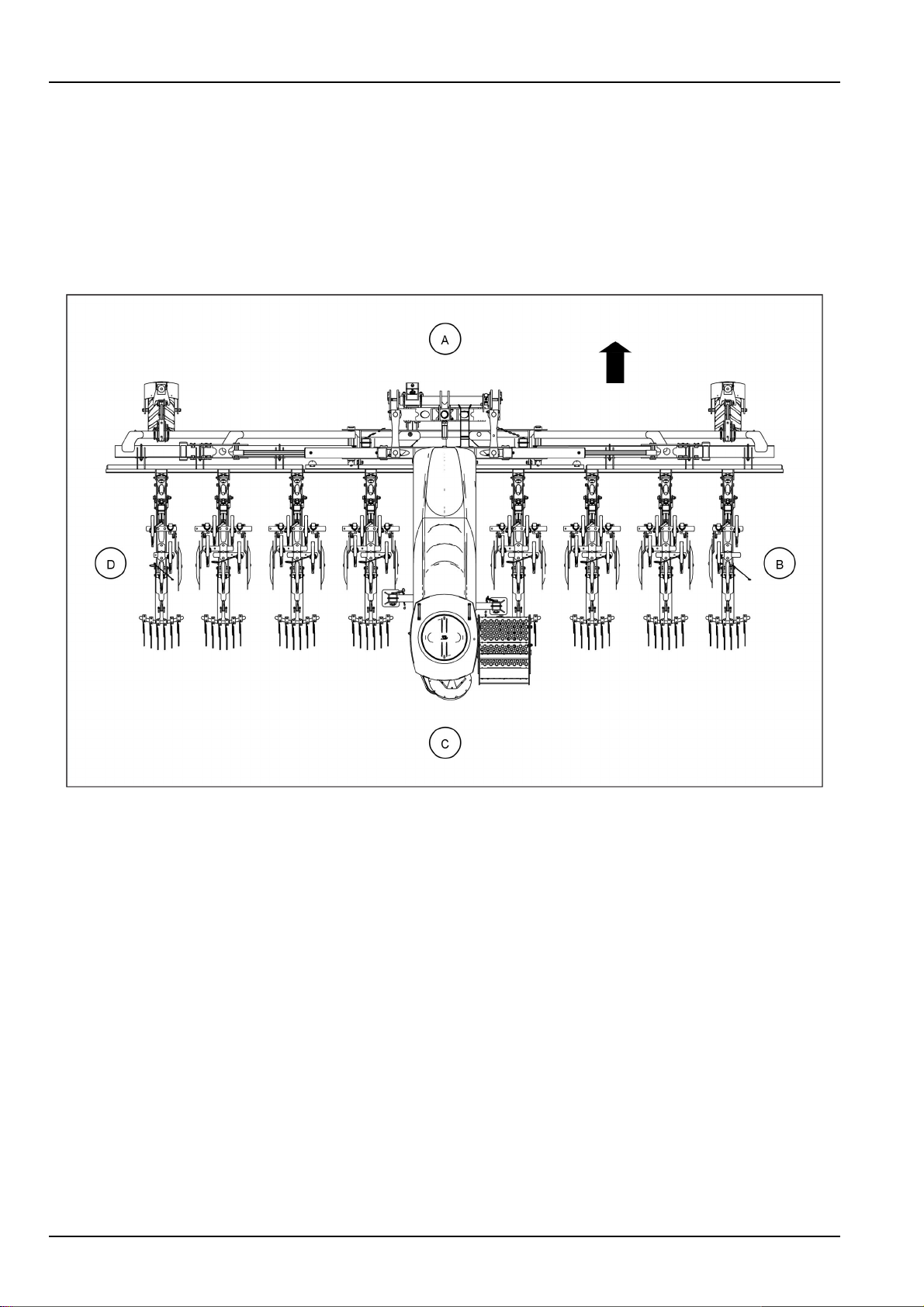

Implementorientation

NOTE:T odeterminetheleft-handsideandtheright-hand

sideoftheimplement,standbehindtheimplementand

facethedirectionoftravelduringworkingoperation.

Thefollowingoverheadviewillustrationisageneralrepresentationoftheimplement.Theillustrationindicatesthe

sides,front,andrearorientationsoftheimplementasreferredtothroughoutthisoperator’smanual.

NOTE:Thearrowindicatesthedirectionoftheimplement

duringworkingoperation.

(A)Frontoftheimplement

(B)Right-handsideoftheimplement

(C)Rearoftheimplement

(D)Left-handsideoftheimplement

ZEIL19TIL0202FA1

1-8

Page 13

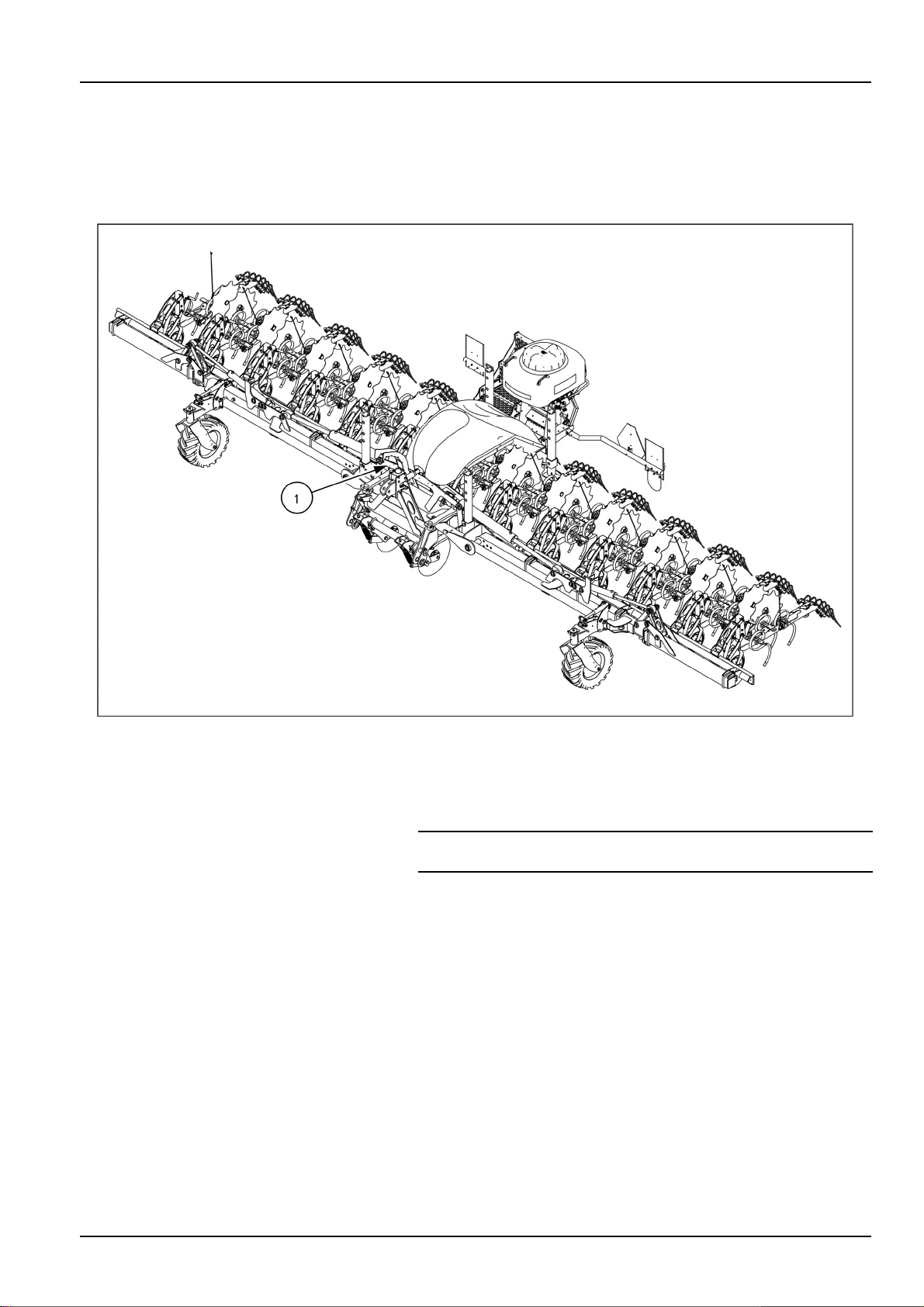

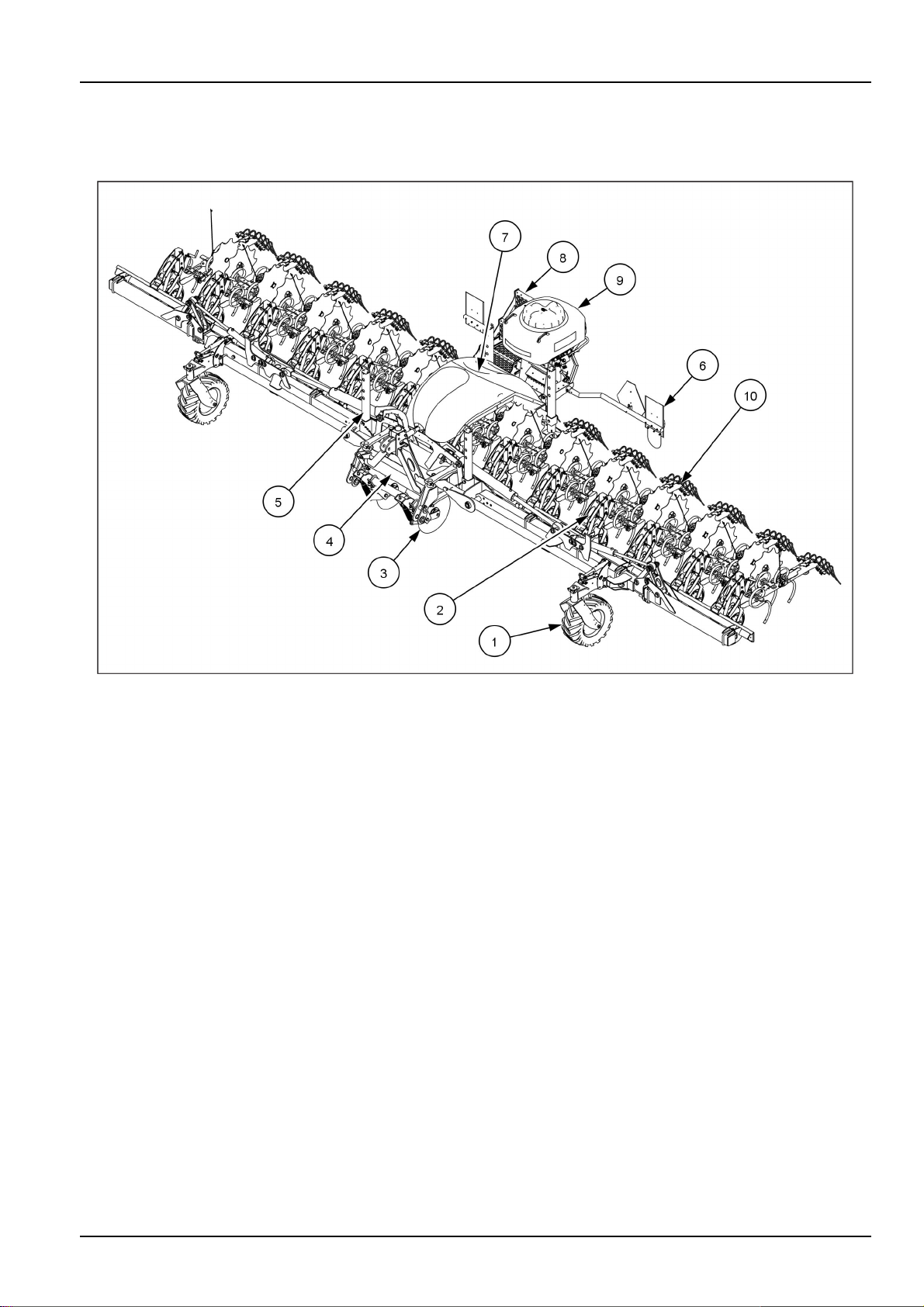

Implementcomponents

VibroCropIntelli

1-GENERALINFORMATION

ZEIL19TIL0205FA1

Standardequipment:Optionalequipment:

(1)Supportwheels(7)Sectioncontrol

(2)

(3)Stabilizingdisc(9)FSSEEDER

(4)Parallelogramsideshiftframe(10)

(5)Parkinglegs(frontandrear)

(6)

Workingsection

Lightset

(8)Loadingplatformwithsteps

Rearharrow

1-9

Page 14

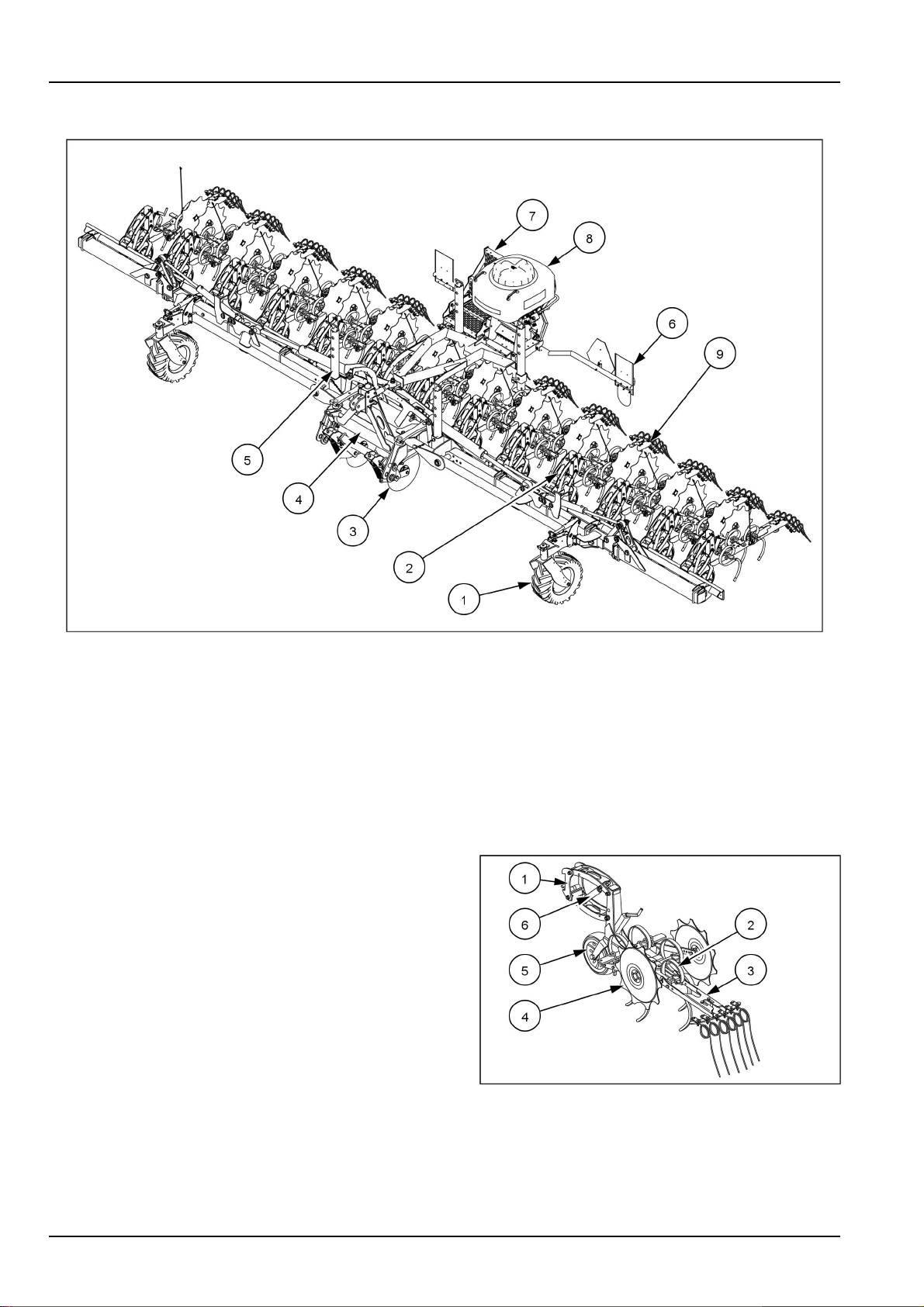

1-GENERALINFORMATION

VibroCrop

ZEIL19TIL0214FA2

Standardequipment:Optionalequipment:

(1)Mainframe(7)Loadingplatformwithsteps

(2)

(3)Stabilizingdisc(9)

Workingsection

(8)FSSEEDER

Rearharrow

(4)Parallelogramsideshiftframe

(5)Parkinglegs(frontandrear)

(6)

Lightset

Structureoftheworkingsection

Workingsection:

(1)

(2)VibroStineorVibroCroptine

(3)Rearharrow(optionalequipment)

(4)

(5)Supportwheel

(6)Hydrauliccylinderforsectioncontrolor

Parallelogram

Rollingshield

simpleliftingsystem

ZEIL19TIL0183AA3

1-10

Page 15

2-SAFETYINFORMATION

2-SAFETYINFORMATION###_2_###

Safetyrulesandsignalworddenitions

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

ThroughoutthismanualyouwillndthesignalwordsDANGER,WARNING,andCAUTIONfollowedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworkingwithyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationthat,ifnotavoided,willresultindeathorseriousinjury.

WARNINGindicatesahazardoussituationthat,ifnotavoided,couldresultindeathorseriousinjury.

CAUTIONindicatesahazardoussituationthat,ifnotavoided,couldresultinminorormoderateinjury .

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESUL T

INDEATHORSERIOUSINJURY .

Machinesafety

NOTICE:Noticeindicatesasituationthat,ifnotavoided,couldresultinmachineorpropertydamage.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachineor

propertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationthatclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

2-1

Page 16

2-SAFETYINFORMATION

Generalrecommendations

Mostfarmmachineryaccidentscanbeavoidedbythe

observanceofafewsimplesafetyprecautions.

Thisoperator’smanualcontainsimportantinformation

•

concerningoperation,maintenanceandadjustmentof

theimplement.Furthermore,thisoperator’smanual

mentionsandemphasizesallthesafetyinstructions.

Readtheoperator’smanualthoroughlybeforeyou

•

start,operate,service,orcarryoutanyotheroperation

ontheimplement.Eventhoughyouhavebeendriving

asimilarimplementbefore,youmustreadthemanual.

Thisisamatterofyourownandotherpeoplesafety.

Afewminutesreadingwillsaveyoutimeandhassle

later.Lackofknowledgecanleadtoaccidents.

Yourimplementwasdesignedwithsafetyinmind.

•

However,thereisnorealsubstituteforcautionand

attentionwhenyouneedtopreventanaccident.Once

anaccidenthasoccurred,itistoolatetothinkabout

whatyoushouldhavedone.Thismeansthatitis

veryimportantthatyouasuseroftheimplementpay

attentionandusetheimplementcorrectlyandthereby

avoidexposingyourselfandotherstounnecessary

danger.

Theimplementmustbeoperatedonlybyresponsible

•

personswhohavebeenadequatelytrainedandautho-

rizedtousetheimplement.Neverleavetheimplement

toothersbeforeyouhavemadesurethattheyhavethe

necessaryknowledgetooperatetheimplementsafely.

Neverlettheimplementrunwithoutsupervision.

•

Alwayskeeparstaidkithandy.

•

Takethenecessaryprecautions(forexampleassis-

•

tance)toalwaysbeawareofthepossiblepresenceof

bystandersandpets.

Keepchildrenawayfromandofftheimplementatall

•

times.

Donotusethisimplementasalift,ladderorplatform

•

toworkatheights.

Beforeyouworkontheimplement,disengageall

•

drives,stoptheengineandremovetheignitionkey.

Waitfortherotatingpartstorundown.

Neverworkaroundtheimplementwithlooseclothing,

•

jewelry,watches,longhairandotherlooseorhanging

itemscanbepulledinbythemovingpartsoftheimplement.

Keephandsawayfrommovingpartsoftheimplement.

•

2-2

Page 17

2-SAFETYINFORMATION

Illustrations

WARNING

Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment.

Replaceallshieldsbeforeoperatingthemachine.

Failuretocomplycouldresultindeathorseriousinjury.

NOTE:Someoftheillustrationsinthismanualhavebeen

obtainedbyphotographingprototypes.Standardproductionmachinesmaydifferinsomedetails.

Localobligations

W0012A

Yourmachinemaybeequippedwithspecialguardingor

otherdevicesincompliancewithlocallegislation.Some

oftheserequireactiveactionbytheoperator.

Fireorexplosionprevention

1.Cropmaterial,trash,debris,birdnestsorammable

materialcanigniteonhotsurfaces.

2.Inspecttheelectricalsystemforlooseconnectionsor

frayedinsulation.Repairorreplacelooseordamaged

parts.

3.Donotstoreoilyragsorotherammablematerialon

theimplement.

4.Donotweldoramecutanyitemsthatcontain

ammablematerial.Cleanitemsthoroughlywith

Therefore,checklocallegislationontheusageofthismachine.

non-ammablesolventbeforeyouweldorcutwitha

ame.

5.Donotexposetheimplementtoames,burningbrush

orexplosives.

6.Promptlyinvestigateanyunusualsmellsorodorsthat

mayoccurduringtheoperationoftheimplement.

2-3

Page 18

Hazardouschemicals

2-SAFETYINFORMATION

1.Ifyouareexposedtoorcomeincontactwithhazardouschemicalsyoucanbeseriouslyinjured.

Theuids,lubricants,paints,adhesives,coolant,

etcetera.requiredforthefunctionofyourmachine

canbehazardous.Theymaybeattractiveandharmfulltodomesticanimalsaswellashumans.

2.MaterialSafetyDataSheets(MSDS)provideinformationaboutthechemicalsubstanceswithinaproduct,

safehandlingandstorageprocedures,rstaidmeasuresandprocedurestobetakenintheeventofaspill

oraccidentalrelease.MSDSareavailablefromyour

dealer.

3.BeforeyouserviceyourmachinechecktheMSDSfor

eachlubricant,uid,etcetera.usedinthismachine.

Thisinformationindicatestheassociatedrisksandwill

helpyouservicethemachinesafely .FollowtheinformationintheMSDS,onmanufacturercontainers,as

Startinguptheimplementsafely

Beforeyouattachtheimplementtothetractor,ensurethat

thetractorisingoodworkingorderandthatthebrakes

areefcient,particularlyifyouoperateonhillyground.

Also,ensurethatthehydraulicorpneumaticsystemis

compatiblewiththatoftheimplement.

Whenyouattachtheimplementtothetractor:

Neverallowanyonetostandbetweenthetractorand

•

theimplement.Anunintentionalmaneuverwiththe

tractormaycauseseriousinjury.

Nevergounderanunsupportedimplement.

•

Beforeyoustarttheimplement,learnallcomponents

•

oftheimplementandserviceequipment.

wellastheinformationinthismanualwhenyouservicethemachine.

4.Disposeofalluids,ltersandcontainersinanenvironmentallysafemannerinaccordancewithlocal

lawsandregulations.Checkwithlocalenvironmentalandrecyclingcentersoryourdealerforcorrectdisposalinformation.

5.Storeuidsandlterinaccordancewithlocallawsand

regulations.Useonlyappropriatecontainersforthe

storageofchemicalsorpetrochemicalsubstances.

6.Keepoutofreachofchildrenorotherunauthorized

persons.

7.Additionalprecautionsarerequiredforappliedchemicals.Obtaincompleteinformationfromthemanufacturerordistributorofthechemicalsbeforeyouuse

them.

Beforeyoustarttheimplement,makesurethatallsub-

•

assembliesarefullyoperationalandcomplete.Pay

particularattentiontoalllocksandsafetydevices.

Beforeyoustarttheimplement,repairorreplaceall

•

malfunctioningelementswithnewones.

Neverstartthetractoruntilallpersonsaresafelyaway

•

fromthetractorandtheimplement.

Makesurethatalltoolshavebeenremovedfromthe

•

implementbeforestartingthetractor.

Makesurethatallsparepartandmovingequipment

•

areintactandhavebeenmountedcorrectly.

Donotstandneartheimplementwhileitisworking.

•

2-4

Page 19

Travelingonpublicroads

2-SAFETYINFORMATION

Complywiththerelevanttrafcregulations

WARNING

Impacthazard!

Takecarewhenmakingturns.Themachine

rearendswingsoutwhenchangingdirection.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Lossofcontrolhazard!

Unevenbrakeforceexistsonleft-handand

right-handbrakes.Alwaysusebrakepedal

couplerwhentravelingonpublicroadstoensurebrakesareactuatedtogether.

Failuretocomplycouldresultindeathorseriousinjury.

Theimplementisbuiltaccordingtothehomologationrequirementsofyourcountry.Donotmodifytheimplement

inasensethatwouldconictwiththenationalregulations.

Ifyouwishtotransporttheimplementonthepublicroad,

makesurethatthecombinationtractorandimplement

observesthetrafcrulesinyourcountry.Thisgivesyou

andyoursurroundingsthebestpossiblesafety .

Passengers

Donotallowpassengerstorideinthetractorunlessa

specicseatisprovided.

Duringtransport,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

W0089A

W0081A

Transportsafety

Transporttheimplementonlyintransportposition.Securetheimplementfortransport.Alwaysactivatethemechanicaltransportsafetydevicesbeforetransport.

Makesuretotallthehitchpinswithretainingpinscorrectly.Mechanicallysecurethehydrauliccylinderstopreventcylindersfromcreeping.

Drivesafe

Donotdriveundertheinuenceofalcoholordrugs.

Nevertravelatspeedincrowdedareas.

Whenyoumaneuverthetractorwiththeimplement,alwaysbeawareandconsciousofitssize.

Thetractordrivermustnotleavethecabinduringtransport.

Theoperatorsmustobserverelevantstatutoryorother

nationalregulationsthatdealwithroadsafetyandlabor

safetyissues.

Beforeyoudrivetheimplementonpublicroads:

Checktheallowabletransportdimensionsandweights.

•

Installcorrectlythelightingandthewarningpanels.

•

Alwaysobservetheprinciplesforpermissibleaxleloads,

thetotalunitmassandthetransportgauge.

Observethetractormanufacturerregulationsandrecommendations,specicallythoserelatingtomaximumtransportloadsandmaximumspeed.

Eveninsimilarcircumstances,themaximumallowed

speedcanvarydependingonwhichcountryyoutravel

in.

Alwaysdrivewiththestatutorylightsandsafetymarking

duringtransportonpublicroadandatnight.

Installalltherequiredsignsthatindicatethevehiclewidth.

Alsoinstallalltherequiredlightsthatindicatethevehicle

widthduringthenightlytransport.Ifindoubt,contactyour

governmentdepartmentresponsibleforroadtransport.

Alwaysconsiderotherroadusers.

Alwaysadoptsafedrivingpractices.Slowdownandsignalbeforeturning.Givewaytooncomingtrafcinallsituations,includingnarrowbridges,intersectionsetcetera.

Pullovertoallowfastertrafctopass.

Iftheimplementismarkedwithamaximumspeedlimit,

neverexceedthismaximumspeedlimit.

Alwaysadjustthedrivingspeedtotheroadandweather

conditions.Incaseofbadroadconditionsandhighdrivingspeeds,bigforcesmayoccurandcauseoverloadof

tractorandimplement.

Driveatasafespeedtoensurecontrolandabilitytostop

inanemergency .

Lockthetractorbrakepedalstogether.Neveruseindependentbreakingattransportspeeds.

Mountedimplementsandballastweightsinuencethe

driving,steeringandbrakingcapacityofthetractor.Make

surethattheadditionalweightoftheimplementonthe

linkagedoesnotcompromisedriving,steeringandbrakingcapacityofthetractor.Installfrontweightsorrepair

thebrakesifthetractorisnotsafetodrive.

Travelmayberestrictedtocertainroadtypes.Transport

mayberestrictedtodaytimeoroutsidepeaktrafchours.

Howeverplanyourroutetoavoidheavytrafcandpeak

trafchours.

Reducespeedduringturns.Tractorshavenotbeendesignedforfastturning.Avoidthattherearendoftheimplementhitsanobstacle.

2-5

Page 20

2-SAFETYINFORMATION

Whenyouturnduringtransportpayattentiontotheoverhangand/oroscillatingweightoftheimplement.

Useenginebrakingwhenyoudrivedownhills.Donot

coast.

Watchforobstructions,particularlyifover-width.Observe

anyloadratingsapplicableonbridges.

Afteryounishthetransport,beforeyouleavethetractor,

alwayslowertheimplementtothegroundinparkingposition,turnoffthetractorengine,pulltheparkingbrake,

andremovethekeyfromtheignition.

2-6

Page 21

2-SAFETYINFORMATION

Operatingtheimplementsafely

WARNING

Hazardtobystanders!

Alwayssoundthehornbeforestartingthemachine.Makesuretheworkareaisclearof

otherpersons,domesticanimals,tools,etc.

beforeyouoperatethemachine.Neverallow

anyoneintheworkareaduringmachineoperation.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Rotatingparts!

Keepclearofalldrivesandrotatingcomponents.

Failuretocomplycouldresultindeathorseriousinjury.

NOTE:Onlyputtheimplementintooperationaccording

totheinstructionsfromthedealer.

Neveroperatetheimplementundertheinuenceofalcohol,drugs,orwhileotherwiseimpaired.

Keeppeopleawayfromtheimplementduringoperation.

Askbystanderstoleavetheeld.Thereistheriskfor

bystanderstobeoverrunbytheimplement.Stoptheimplementimmediatelyifsomeoneapproaches.

Thetractororitsimplementmaystrikeorcrushagainsta

personorpetwithintheoperatorareaofthetractor.DO

NOTallowanyonetoentertheworkarea.Makesurethat

theareaisclearandoperationissafebeforeyoumove

theimplement.

Beforeyouraiseorlowertheimplementwiththelinkarms

ofthetractor,checkthatnobodyisneartheimplementor

touchestheimplement.

W0304A

W1101A

Whenyouoperatetheimplement,alwaysremainseated

inthetractorcab.Operatecontrolsonlywhenseatedin

thetractorseat,exceptforthosecontrolsexpresslyintendedforusefromotherlocations.

Whileinoperation,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

Avoidusingtheimplementinunsuitablecropandweather

conditions.Itisbettertostopworktemporarilyratherthan

tooperateinsuchconditions.

Alwaysoperatetheimplementatasafespeedinaccordancewiththegroundconditions.Onunevenground,

proceedwiththeutmostcautiontoensureproperstability.

Paythenecessaryattentionwhileyouoperatenextto

publicroadsorfootpaths.

Adjusttheworkingspeedtomakesurethatthesoilprocessedistransportedevenlybetweenparticularworking

elements.

Adjusttheprocessingdepthtothetypeofworkperformed

andtheamountofpost-croppingresidueinthefarmed

soil.

Intheeventtheimplementclogs:

Stopthetractorengineimmediatelyandlifttheimple-

•

ment.

Whenit’snecessarytostepontheimplementtore-

•

movejams,maintainparticularcaution–thereisarisk

ofslipping.

Whenit’snecessarytostepundertheimplementto

•

removejams,maintainparticularcautionandalways

makesuretheimplementwassecuredagainstautomaticlowering.

2-7

Page 22

2-SAFETYINFORMATION

Maintenance

WARNING

Maintenancehazard!

Beforeyoustartservicingthemachine,attach

aDONOTOPERATEwarningtagtothemachineinavisiblearea.

Failuretocomplycouldresultindeathorseriousinjury.

Followthemaintenanceschedulewithregardtotheim-

•

plementservicingintervals.

Rememberthattheimplementrequiresattentionfrom

timetotime.Alsorememberthatthemaintenancewill

greatlyextendthelifeoftheimplement.

Takethenecessaryprecautions:nottospillanyoil,fuel

•

orgrease.

Toavoidoilandgreasecontactwithyourskin,wear

protectivegloves.

Servicetheimplementonarmlevelsurface.

•

Donotattempttoremovematerialfromanypartof

•

theimplement,clean,lubricateorcarryoutanyadjust-

mentsontheimplementwhileitisinuse.

Raisedimplementand/orloadscanfallunexpectedly

•

andcrushpersonsunderneath.Neverenterorallow

anyonetoentertheareaunderneathraisedimplement

duringoperation.

Unsupportedhydrauliccylinderscanlosepressure

anddroptheimplementandcauseacrushinghazard.

Donotleavetheimplementinaraisedpositionwhile

parkedorduringservice,unlesssecurelyblockedon

woodenblocks.

Neverworkunderaraisedimplementunlessasupport

•

chainorothermechanicalsecuringdevicesecurethe

linkarmsofthetractorsothattheimplementcannot

movetoalowerpositionunintentionally.

Relievethepressure,stoptheengineandremovethe

•

ignitionkey ,beforeyouconnectordisconnectuid

lines.

Beforeyouadjust,clean,lubricateoryoucarryoutre-

•

pairsontheimplement,stoptheengineandremove

W0004A

theignitionkey .

Anyleakageofhydraulicoilorfuelunderpressuremay

•

causesevereharm,soalwaysuseashielding,goggles

andgloveswhenyoutraceoilorfuelleaks.

Donotuseyourhandtocheckforleaks.Useapiece

ofcardboardorpaper.

Continuouslongtermcontactwithhydraulicuidmay

•

causeskincancer.Avoidlongtermcontactandwash

theskinpromptlywithsoapandwater.

Ifhydraulicuidordieselpenetratestheskin,seek

•

medicalcareimmediately.

Observeallrecommendationsthatarementionedin

•

thismanualsuchasserviceintervals,torques,lubri-

cants,etcetera.

Alwaysreplaceallpartsthathavedamageorwear.

•

Neverbuildexiblehoseassembliesfromhosesthat

•

werepreviouslypartofahoseassembly.

Neverweldtothetubes.

•

Alwaysusegloveswhenyouworkwithpartsonthe

•

implementasthepartscanhavesharpedges.

Thehydrauliclinesmaybecomehotduringoperation.

•

Becarefulwhenyouservicesuchcomponents.Al-

lowsurfacestocoolbeforeyouhandleordisconnect

hotcomponents.Wearprotectiveequipmentwhenrequired.

2-8

Page 23

2-SAFETYINFORMATION

Personalprotectiveequipment(PPE)

WearPersonalProtectiveEquipment(PPE)suchasprotectiveclothing,eyeprotection,hearingprotection,dust

mask,hardhat,heavygloves,workboots,and/orany

otherPPEthatprovidesforthesafetyandprotectionof

theindividualthatoperatesthisequipment.

NHIL13RB00001AA1

Safetyrequirementsforuidpowersystemsandcomponentshydraulicsystems

Beforeyoustarttheengineorpressurizethehydraulic

system,installandtightcorrectlyallthehydrauliccouplings.Checkthatallhosesandttingsareundamaged.

Replaceimmediatelydamagedcomponents.

Onlyconnectthehydraulichosestothetractoroutletsif

thetractorandtheimplementarepressure-free.Ifthe

hydraulicsofthetractorisactivateditmayleadtouncontrolledmovementswhichmaycausesecondarydamage.

Makesurethatnopersonsareneartheimplementwhen

youstarttheimplement,astheremightbeairinthehydraulicsystemwhichmightleadtosuddenmovements.

Whenthetractorenginehasstopped,activatethetractor

hydraulicspoolvalvestomakesurethatthereisnopressureinthehydraulichoses.

Toexpelalltheairfromtheoilinthehydrauliccylinders,

testallthefunctionsafteryouconnectthehydraulic

connectionstothetractor,especiallybeforeyouenter

ordriveonthepublicroads.Otherwiseyouriskthatthe

cuttingunitsuddenlymovesdownwardafteryouhave

dismountedthetransportlock

2-9

Page 24

2-SAFETYINFORMATION

Noiseemission

ThemeasuringandreportingofthenoiselevelwerecarriedoutaccordingtoENISO3746:2005.Themeasurementuncertaintyisapproximately+/-2dB.

Thenoiseemissionsfortheimplementequippedwith

FSSeederare:

1.LPAemissionpressurelevel=maximum103dB

2.LWAemissionpressurelevel=109dB

Usehearingprotectorsifthenoisefromtheimplementis

annoyingorifyouworkwiththeimplementforaconsiderableperiodinatractorcabinthathasnotaadequate

soundproofcabin.

2-10

Page 25

2-SAFETYINFORMATION

Implementstability

Thecombinationofyourtractorandimplementcanbecomeunstable,duetotheadditionalweightthattheimplement

addstothetractor.

Inordertoguaranteestableandsafetransport,youmustcheckifyouneedballastweightsfortransportandeld

work.

Youmustalsocheckandguaranteethatyouhaveatleast20%fromthetractorweightonthefrontaxle.

Forrearmountedimplementsandfront-rearcombinations,theformulais:

ZEIL18HT00277FA1

Exampleofreferencestostabilityofthecombinationtractor–implement

Listofsigns

Te[kg]Thetractorownweight.

Tf[kg]

Tr[kg]Rearaxleloadwithemptytractor.

Ir[kg]

If[kg]Totalweightofthefront-mountedimplement/frontballast.

a[m]

b[m]Thetractorwheeldistance.

c[m]

d[m]

Frontaxleloadwithemptytractor.

Totalweightoftherear-mountedimplement/rearballast.

Distancebetweenthecenterofgravityofthefront-mountedimplement/frontballastandthe

middleofthefrontaxle.

Distancebetweenthemiddleoftherearaxleandthemiddleofthelinkarmballs.

Distancebetweenthemiddleofthelinkarmballsandthecenterofgravityoftherearmounted

implement/rearballast.

2-11

Page 26

Ecologyandtheenvironment

2-SAFETYINFORMATION

Soil,air,andwaterqualityisimportantforallindustries

andlifeingeneral.Whenlegislationdoesnotyetrulethe

treatmentofsomeofthesubstancesthatadvancedtechnologyrequires,soundjudgmentshouldgoverntheuse

anddisposalofproductsofachemicalandpetrochemical

nature.

Familiarizeyourselfwiththerelativelegislationapplicabletoyourcountry ,andmakesurethatyouunderstand

thislegislation.Wherenolegislationexists,obtaininformationfromsuppliersofoils,lters,batteries,fuels,

anti-freeze,cleaningagents,etc.,withregardtotheeffectofthesesubstancesonmanandnatureandhowto

safelystore,use,anddisposeofthesesubstances.Your

KONGSKILDEdealercanalsoprovideassistance.

Helpfulhints

Avoidtheuseofcansorotherinappropriatepressur-

•

izedfueldeliverysystemstolltanks.Suchdelivery

systemsmaycauseconsiderablespillage.

Ingeneral,avoidskincontactwithallfuels,oils,acids,

•

solvents,etc.Mostoftheseproductscontainsub-

stancesthatmaybeharmfultoyourhealth.

Modernoilscontainadditives.Donotburncontami-

•

natedfuelsandorwasteoilsinordinaryheatingsys-

tems.

Avoidspillagewhenyoudrainuidssuchasuseden-

•

ginecoolantmixtures,engineoil,hydraulicuid,brake

uid,etc.Donotmixdrainedbrakeuidsorfuelswith

lubricants.Storealldraineduidssafelyuntilyoucan

disposeoftheuidsinaproperwaythatcomplieswith

alllocallegislationandavailableresources.

Donotallowcoolantmixturestogetintothesoil.Col-

•

lectanddisposeofcoolantmixturesproperly .

Donotopentheair-conditioningsystemyourself.It

•

containsgasesthatshouldnotbereleasedintotheat-

mosphere.YourKONGSKILDEdealerorair-conditioningspecialisthasaspecialextractorforthispurpose

andcanrechargethesystemproperly.

Repairanyleaksordefectsintheenginecoolingsys-

•

temorhydraulicsystemimmediately .

Donotincreasethepressureinapressurizedcircuitas

•

thismayleadtoacomponentfailure.

Batteryrecycling

Batteriesandelectricaccumulatorscontainseveral

substancesthatcanhaveaharmfuleffectontheenvironmentifthebatteriesarenotproperlyrecycledafter

use.Improperdisposalofbatteriescancontaminate

thesoil,groundwater,andwaterways.KONGSKILDE

stronglyrecommendsthatyoureturnallusedbatteries

toaKONGSKILDEdealer,whowilldisposeoftheused

batteriesorrecycletheusedbatteriesproperly.Insome

countries,thisisalegalrequirement.

NHIL14GEN0038AA1

Mandatorybatteryrecycling

NOTE:Thefollowingrequirementsaremandatoryin

Brazil.

Batteriesaremadeofleadplatesandasulfuricacidsolution.Becausebatteriescontainheavymetalssuchas

lead,CONAMAResolution401/2008requiresyoutoreturnallusedbatteriestothebatterydealerwhenyoureplaceanybatteries.Donotdisposeofbatteriesinyour

householdgarbage.

Pointsofsaleareobligedto:

Acceptthereturnofyourusedbatteries

•

Storethereturnedbatteriesinasuitablelocation

•

Sendthereturnedbatteriestothebatterymanufacturer

•

forrecycling

2-12

Page 27

2-SAFETYINFORMATION

Safetysigns

Thefollowingsafetysignsareonyourimplementasa

guideforyoursafetyandforthesafetyofthosewhowork

withyou.

Walkaroundtheimplementandnotethecontentandlocationofallsafetysignsbeforeyouoperateyourimplement.

Readallthesafetydecalsadheredtotheimplementand

followtheinstructions.

Keepallsafetysignscleanandlegible.Cleansafetysigns

withasoftcloth,water,andagentledetergent.

NOTICE:Donotusesolvent,gasoline,orotherharsh

chemicals.Solvents,gasoline,andotherharshchemicalsmaydamageorremovethesafetysigns.

Replaceallsafetysignsthataredamaged,missing,

paintedover,orillegible.Ifasafetysignisonapartthat

youoryourdealerreplaces,makesurethatyouoryour

dealerinstallthesafetysignonthenewpart.Contact

yourdealerforthereplacementofthesafetysigns.

Safetysignsthatdisplaythe“Readoperator’smanual”

symboldirectyoutotheoperator’smanualforfurtherinformationregardingmaintenance,adjustments,orproceduresforparticularareasoftheimplement.Whenasafety

signdisplaysthissymbol,consulttheappropriatepageof

theoperator’smanual.

Safetysignsthatdisplaythe“Readservicemanual”symboldirectyoutotheservicemanual.Ifyoudoubtyour

abilitytoperformserviceoperations,contactyourdealer.

2-13

Page 28

2-SAFETYINFORMATION

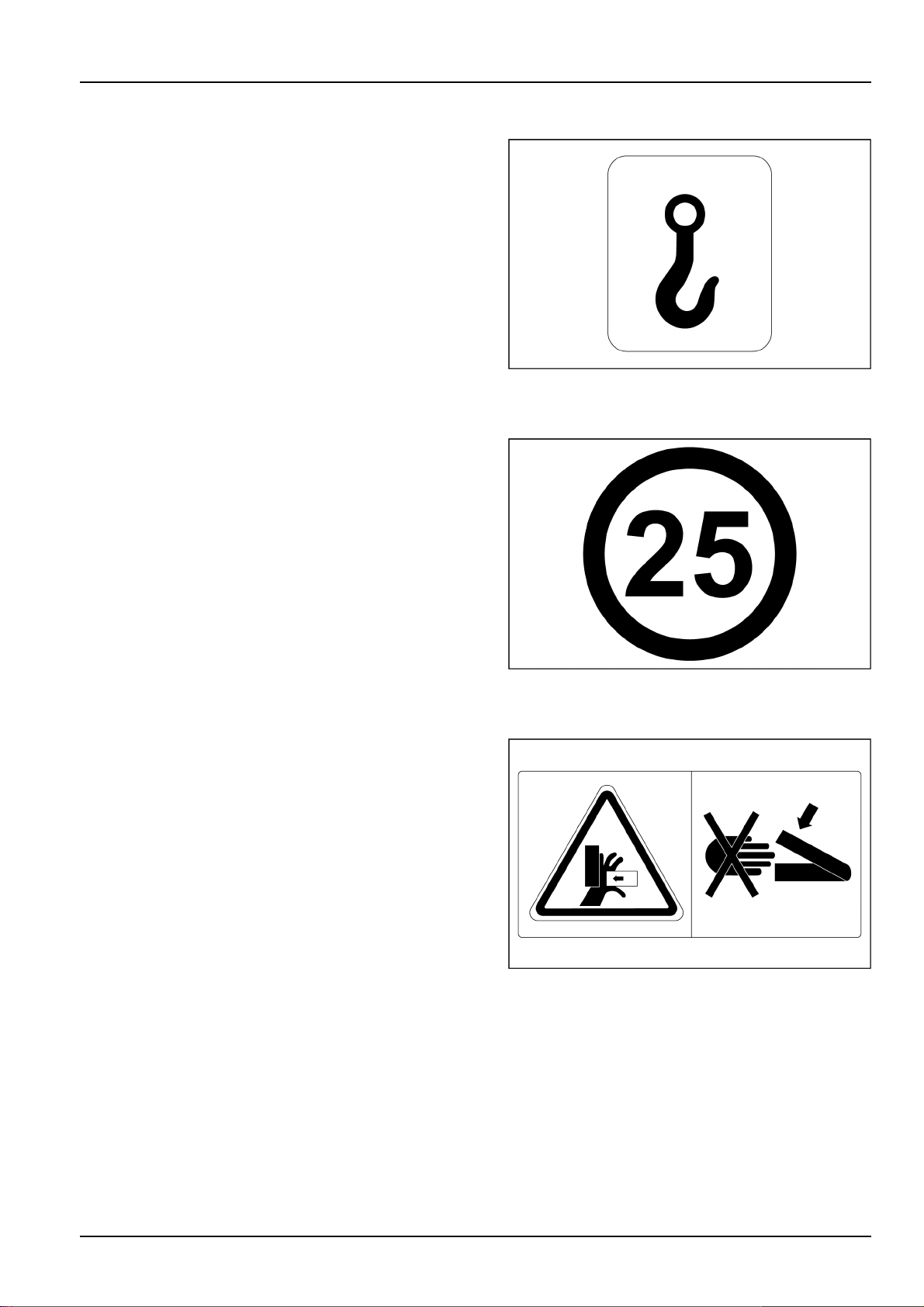

Safetysign(1)

Ahazardoffallingcausedbystandingontheimplement

whenworkingorintransport.Thehazardcouldresultin

deathorseriousinjury.

Travelingontheimplementorenteringtheimplement

whenworkingisstrictlyprohibited.Thisreservationrefers

toimplementwithwalkingsurfacesandplatformsaswell.

Makesurethatnooneistravelingontheimplement.

Partnumber:300007972

Safetysign(2)

Movingpartsintheseeddrilltank.

Nevermoveyourhandintothedangerzoneaslongas

thepartscanmove.

ZEIL19TIL0205FA1

3000079722

Thismaycauseseriousinjuryand,atworst,resultin

death.

Partnumber:7000045057

70000450573

2-14

Page 29

Safetysign(3)

Mounttransportbeltshere.

Partnumber:74000666103

Safetysign(4)

Speedlimit:25km/h.

Partnumber:300008277

2-SAFETYINFORMATION

740006661034

Safetysign(5)

Keephandsaway .

Nevermoveyourhandintothedangerzoneaslongas

thepartscanmove.Thehazardcouldresultindeathor

seriousinjury.

Partnumber:7002152848

3000082775

70021528486

2-15

Page 30

2-SAFETYINFORMATION

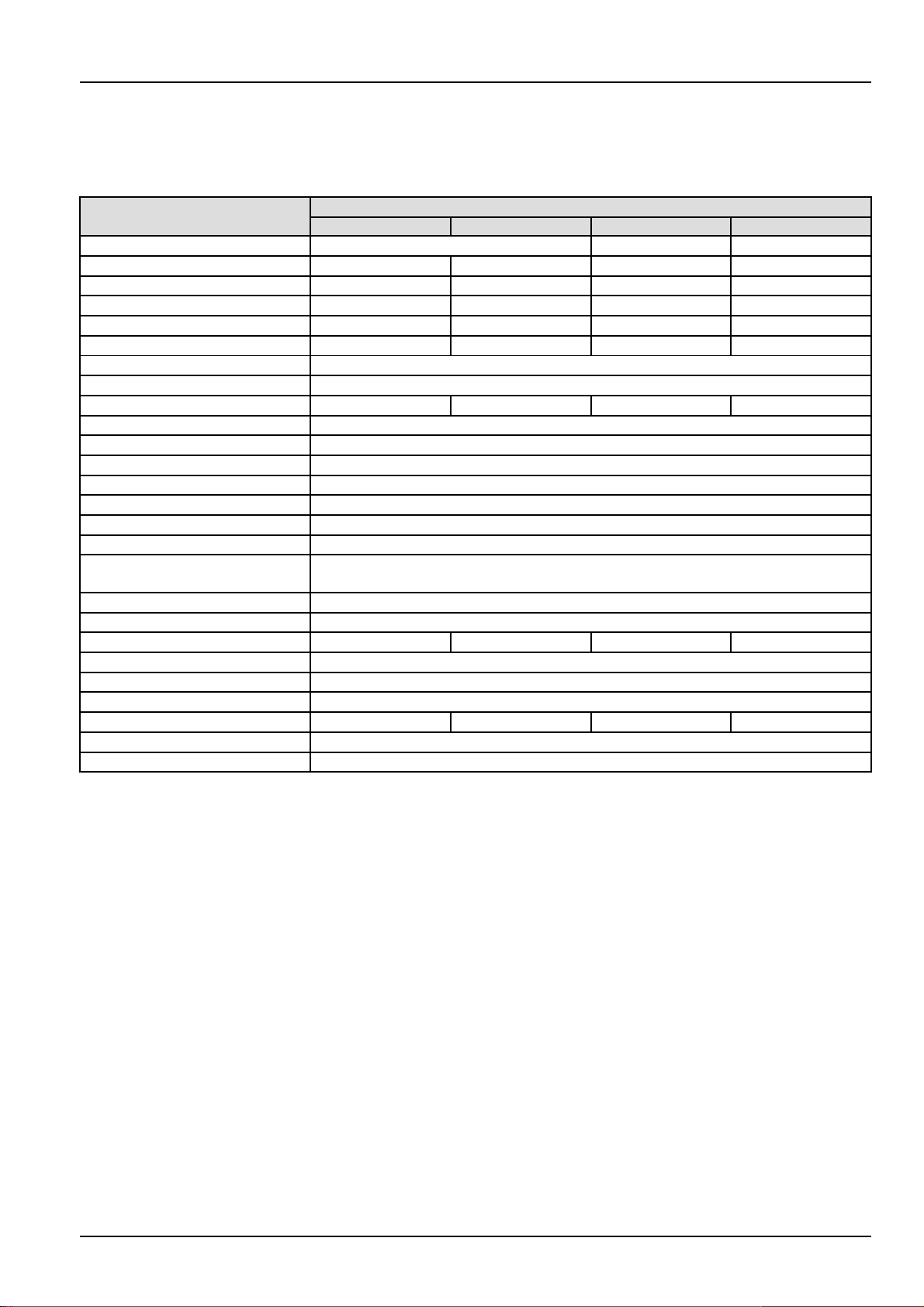

Safetysign(6)

Lubricationpoint.

Partnumber:74000667708

Safetysign(7)

Donotstandneartheimplementduringloweringorlevelingtheimplement.

Donotstandbetweenthetractorandtheimplementor

underneaththeimplementwhenoperatingtheequipment.

Itmaycourseseriousinjuries.

740006677087

Partnumber:101000336

Safetysign(8)

Keephandsaway .

Nevermoveyourhandintothedangerzoneaslongas

thepartscanmove.Thehazardcouldresultindeathor

seriousinjury.

Partnumber:71000629549

1010003368

710006295499

2-16

Page 31

2-SAFETYINFORMATION

Safetysign(9)

Hazardofbeingelectrocutedorrehazardcausedbyaccidentalhookingontooverheadelectricallinesorbyunauthorizedproximitytolive-currentoverheadelectricallines.

Thehazardcouldresultindeathorseriousinjury.

Maintainasafedistancetoanyelectricalwireswhenfolding,unfoldingandtravelinginthevicinityofelectricallines.

WARNING

Electrocutionhazard!

Contactwithoverheadpowerlinescancause

severeelectricalburnsordeathfromelectrocution.Makesurethereisenoughclearance

betweenequipmentandoverheadpower

lines.

Failuretocomplycouldresultindeathorseriousinjury.

Partnumber:303021278

30302127810

W0040A

Safetysign(10)

Keepaway.

Thereisadangerthatyoucanbecrushedbyloweringthe

implementelements.

Thedangermaycausesevereinjuriestotheentirebody .

Keepclearoftheimplement’sdangerzoneandpayattentiontoallotherpeoplestandingnexttotheimplement.

Partnumber:372003609

Safetysign(11)

Ahazardofyourbodybeingcrushedwhenstandingbetweenthetractorandtheimplementtobeconnected.

Thehazardcouldresultindeathorseriousinjury.

Whenconnectingtheimplementtoatractor,standingin

betweentheimplementandthetractorwiththetractorenginerunningandthetractornotsecuredagainstaccidentalrollingisstrictlyprohibited.

37200360911

Partnumber:300007974

30000797412

2-17

Page 32

2-SAFETYINFORMATION

Safetysign(12)

Maximumworkingpressureofthehydraulicsystem:

200bar(2900psi)

Partnumber:300007977

Safetysign(13)

Avoidpressurizedoutowingofliquid.

Dangergeneratedbyhydraulicoiloutowingunderpressure.

30000797713

Thedangermaycausesevereinjuriestotheentirebody ,

withpossiblelethaleffect.

Beforeproceedingtomaintenanceproceduresorrepairs

ofthehydraulicsystem,makesurethesystemisdepressurized.

Donottrytosealhydraulicoilleaksusingyourhandsor

ngers.

Partnumber:300007973

Safetysign(14)

WARNING

Avoidinjury!Alwaysdothefollowingbefore

lubricating,maintaining,orservicingthemachine.

1.Disengagealldrives.

2.Engageparkingbrake.

3.Lowerallattachmentstotheground,or

raiseandengageallsafetylocks.

4.Shutoffengine.

5.Removekeyfromkeyswitch.

6.Switchoffbatterykey,ifinstalled.

7.Waitforallmachinemovementtostop.

Failuretocomplycouldresultindeathorseriousinjury.

W0047A

30000797314

7100062955115

Stoptheengineandtakethekeyoutoftheignition.

Partnumber:71000629551

2-18

Page 33

2-SAFETYINFORMATION

Safetysign(15)

WARNING

IMPROPEROPERATIONOFTHISMACHINE

CANCAUSEDEA THORSERIOUSINJURY.

MAKESURETHA TEVERYOPERATOR:

-isinstructedinthesafeandproperuseofthis

machine.

-readsandunderstandstheoperator'smanual

forthismachine.

-readsandunderstandsALLsafetysignson

themachine.

Failuretocomplycouldresultindeathorseriousinjury.

Partnumber:200043774

Safetysign(16)

Attention!Foldedelements.

Thereisadangerthattheimplementunfoldedcouldcrush

thebody.

W0188A

20004377416

Thedangermaycausesevereinjuriestotheentirebody ,

withpossiblelethaleffect.

Toavoidthedanger,don’tstandwithintherangeofthe

foldingimplement.Beforeyoufold/unfoldtheimplement,

makesurethattherearenotpeoplestandinginitsrange.

Partnumber:71000629546

Safetysign(17)

Donotraisethesidearmsinanyotherwaythanthrough

thehydraulicsystemofthetractor.

Failuretocomplycanresultindamagetotheimplement.

Partnumber:101000337

7100062954617

10100033718

2-19

Page 34

2-SAFETYINFORMATION

2-20

Page 35

3-CONTROLSANDINSTRUMENTS

3-CONTROLSANDINSTRUMENTS###_3_###

Information

Operatingprinciples

Forallinformationrelatedtothedescriptionandthelocationofthecontrolstouseyourimplement,seechapter“ControlsandInstruments”intheoperator’smanualof

yourvehicle.

3-1

Page 36

3-CONTROLSANDINSTRUMENTS

3-2

Page 37

4-OPERATINGINSTRUCTIONS

4-OPERATINGINSTRUCTIONS###_4_###

Commissioningtheunit

Choiceofthetractor

Tooperatetheimplementincompliancewiththeintended

use,thetractormustfulllthefollowingrequirements.

Tractorenginepower

VCO-I18-50

VCO-I12-75

VCO-I18-45

VCO-I16-60

VCO18-50

VCO12-75

VCO18-45

VCO16-60

VCO-I12-50

VCO-I8-75

VCO-I12-45

VCO-I8-60

Electricalsystem

Batteryvoltage

Lightingsocket

Powersupplysocket3pinaccordingDIN9680

Hydraulicsystem

Maximumoperatingpressure

Tractorpumppower

ImplementhydraulicuidTransmission/hydraulicuidHLP68*

Maximumoiltemperature

HydraulicoutletsforVibroCropIntelli

Controlunit1

Controlunit2Single-actingcontrolunit

Controlunit3

Controlunit4

Controlunit5LSPort

HydraulicoutletsforVibroCrop

Controlunit1

Controlunit2Single-actingcontrolunit

Controlunit3

135–160kW(183.5–217.5Hp)

66–95kW(90–129Hp)

12V(volts)

7pinaccordingISO1724

200bar(2900psi)

Atleast60L/minat160bar(2320psi)

50°C(122°F)

Double-actingcontrolunit

Double-actingcontrolunit–withfreereturnforFSSeeder

Single-actingcontrolunit–forimplementwithoutsectioncontrol

Double-actingcontrolunit

Double-actingcontrolunit–withfreereturnforFSSeeder

*Theimplementhydraulic/transmissionuidissuitable

forthecombinedhydraulic/transmissionuidcircuitsof

allstandardmadeontractor.

4-1

Page 38

4-OPERATINGINSTRUCTIONS

Checkbeforeuse

Beforeyouoperatetheimplementforthersttime,performthefollowingitems:

Readthisoperator'smanualcarefully;especiallythe

•

chapterheaded”Safetyinformation”.

Checkthecorrectassemblyoftheimplement.Also

•

checkthattheimplementisundamaged.

Checkthatnopartshavebeentiedupinsidetheimple-

•

mentinconnectionwiththedeliveryoftheimplement.

Removeallthetoolsfromtheimplement.

•

Connecttheimplementtothetractorandcheckifthe

•

subassembliesworkproperly.

Checkthecorrectconnectionandtighteningofthehy-

•

drauliccomponents.

Checktheentirehydraulicsystem–allpipes,hoses

•

andconnections.Uponnoticinganytracesofdamages

oreventheslightestleaksmakesuretoreplacethese

parts.

Checkthatthehydraulichosesarelongenoughforthe

•

movementsoftheimplementinrelationtothetractor.

Checkthelengthofthehydraulichoseswhentheim-

•

plementisinworkingposition.Checkthatthehydraulic

hosesarenottootense.

Greasesufcientlytheimplement(seePage7-7).

•

Checkthepropertightnessofallthenutsandbolts.

•

Checkthetirepressureand,ifnecessary ,pumpthem

•

toreachtherequiredvalues.

Checkifthebrakesystemworksproperly.

•

Checkiftheelectricalinstallationworksproperly,includ-

•

ingthelights.

Checkthetines,shares,andprotectionshieldsforwear

•

andreplaceasneeded.

4-2

Page 39

Startingtheunit

Connectiontothetractor

4-OPERATINGINSTRUCTIONS

WARNING

Hitchinghazard!

Alwayskeeptheareabetweenthetractorand

theimplementclearofallpersonswhilethe

tractororthree-pointhitchisinmotion.Lock

thetractortransmissioninParkandengage

theparkingbrake(s)beforeyouallowanyone

tocompletehitchingorunhitching.

Failuretocomplycouldresultindeathorseriousinjury.

Useonlytractorsspeciedintheoperator’smanualas

recommendedforconnectingtheimplement.

Tomounttheimplementonthetractor,theimplementis

equippedwith3separatemovableconnectionbrackets

(1).Eachbracketcanbeadjustedintheoptimalwayin

relationtothetractormake,modeland3-pointhitchcategory.Correctlyadjustthelowerlinkarmbracketsofthe

implementsothattheimplementfollowsthetractorcorrectly.

Beforeyouconnecttheimplement,controlallcouplingelements,inspecttheimplementforcracks,loosescrews

ornuts,orpartsmissing.Alwaysmakesurethattheimplementwillnotaccidentallydisconnectfromthetractor

duringeldworks.

W1540A

WARNING

Pressurizedsystem!

Beforeremovingtheattachmentfromthe

machine,makesuretheairpressureandhydraulicoilpressureareatzero.

Failuretocomplycouldresultindeathorseriousinjury.

ZEIL19TIL0184AA1

W0284A

NOTICE:Duetotheweightoftheimplementanditsdistanceofthecenterofgravitybehindthetractor,thetoplinkishighloaded.Makesure,thattheusedtop-linkis

fullyfunctionalandthattherearenodamagesatitshook.

Incasesofdoubtreplacethetop-link.Onlyuseoriginal

spareparts.

Connecttheimplementtothetractorindedicatedplaces

only.

Installthepincersofthethree-pointimplementsuspensionsystemonthetractor.Securethepincersagainst

possibleunintentionaldisconnection.

Connectingtheimplementtothetractor

Beforeyouconnecttheimplementtothetractor:

Verifyiftheconnectionmatchesthethree-pointsuspen-

•

sionsystemoftheimplementandthetractor.

Performallthenecessaryadjustmentsiftheconnection

•

isinconsistent.

Makesurethattheimplementstandsonarmground.

•

ZEIL19TIL0235AA2

4-3

Page 40

4-OPERATINGINSTRUCTIONS

Toconnecttheimplementtoathree-pointsuspensionsystemofthetractor,proceedasfollows:

1.Lowerthelowerlinkagesandreversethetractorto

placethehooksofthelowerlinkagesundertheball

sleeves.

2.Placethecorrectballcouplingsonthepivotofthe

connectingrod.

3.Raisethejackuntilthehooksofthelowerlinkagegrab

theballsleeves.

4.Securealltheconnectionstoavoidunintentionaldisconnection.

5.Mountthetoplinksothatitisapproximatelyparallel

withthelinkarms.Herebyyouobtainthesmallest

changeintheimplementinclinationwhenraisedand

lowered,sothatitdoesnotinclineawayfromortowardsthetractor.

6.Makesurethatallhydraulicconnectionsarecleanand

thenmakeallthenecessaryhydraulicconnections.

7.Inspecttheimplementforanyleaksfromhydraulic

connections.

8.Connecttheimplementlighting.

9.Connecttheplug(2)ofthecamerasteeringsystemto

thesocket(3).

ZEIL19TL0053AA3

ZEIL19TL0054AA4

10.Connectthepowersupplyplug(1)oftheelectrical

installation.

11.Connecttheplugforsectioncontrol(4)whentheim-

plementisequippedwithoptionalsectioncontrol.

12.Checkifalldevicesarefullyoperational.

13.Lifttheimplementwiththetractorthreepointlinkage

sothatthejacksdonottouchtheground.

ZEIL19TL0055AA5

ZEIL19TL0056AA6

4-4

Page 41

4-OPERATINGINSTRUCTIONS

Liftthejackasfollows:

1.Removethepin(3)andpulloutthepivot(2).

2.Grabthehandle(1)andliftthejackuptohighestpo-

sition.

3.Re-insertthepivot(2)inholeandsecureitwithapin

(3).

4.RepeatStep1toStep3forallfourjacks.

NOTE:Adjustandlocksidewayssothattheimplement

issuspendedcenteredbehindthetractorandthereisno

playsideways.

ZEIL19TL0051BA7

ZEIL19TL0052BA8

4-5

Page 42

4-OPERATINGINSTRUCTIONS

HydraulicconnectionsforVibroCropIntelli

Hydraulicconnectionsaremarkedwiththefollowing

colors:

Black–thelineoperatingtheimplementfolding.

•

Red–thelineoperatingsideshiftandsectioncontrol

•

system.

Blue-singleactinglineforsimplesectionliftsystem(op-

•

tional).

Green–thelineoperatingtheloadsensing(optional).

•

NOTE:Makesurethathosesofthesamecolorsareconnectedtothesamepairsofhydraulicinletsontheengine.

Lineoperatingloadsensing(optional)mustbeconnected

intoloadsensecouplerintractor.

HydraulicconnectionsforVibroCrop

Hydraulicconnectionsaremarkedwiththefollowing

colors:

Black–thelineoperatingtheimplementfolding.

•

Blue-singleactinglineforsimplesectionliftsystem.

•

NOTE:Makesurethathosesofthesamecolorsareconnectedtothesamepairsofhydraulicinletsontheengine.

Lineoperatingloadsensing(optional)mustbeconnected

intoloadsensecouplerintractor.

4-6

Page 43

4-OPERATINGINSTRUCTIONS

Parkingtheunit

Disconnectionandparking

Todisconnectandparktheimplement,proceedasfollows:

1.Placetheimplementonarmandlevelground.

2.Disconnectallthehydrauliccouplers.

3.Disconnecttheelectricalconnection.

4.Placewheelchocksasfollows:

Onaatsurface:oneinfrontof,andonebehinda

○

wheel.

Onaslope:onechockperwheel,eitherinfrontof,

○

orbehindthewheel,dependingontheincline.

5.Removethelatchpin(1).Lowerthejack(2).Secure

withthelatchpin(1).

6.Closethehydraulicballvalves(3)onhydraulichoses

comingoutfromtractor.

7.Depressurizethehydraulicsystem.

8.Disconnectthehosesofthehydraulicsystemfromthe

tractor.

9.Disconnecttheelectricwireconnectedwiththetrac-

tor.

10.Disconnectthelightingequipment.

11.Dismountthetoplink.

12.Unlockandpulloutthehooksfromlowercouplings.

13.Lowerthejackarmsuntiltheyarereleasedfromthe

couplingsontheimplement.

WARNING

Escapinguid!

Donotconnectordisconnecthydraulicquick

couplerunderpressurizedconditions.Make

sureallhydraulicpressureisremovedfrom

thesystembeforeconnectingordisconnectinghydraulicquickcoupler .

Failuretocomplycouldresultindeathorseriousinjury.

ZEIL19TL0051BA1

W0095B

ZEIL19TL0061AA2

4-7

Page 44

4-OPERATINGINSTRUCTIONS

4-8

Page 45

5-TRANSPORTOPERATIONS

5-TRANSPORTOPERATIONS###_5_###

Roadtransport

Transportposition

Theimplementisequippedwithaspecialhydraulicfolding

beam.Foldingandunfoldingisachievedwith2double

actingcylinders(1),whichareactivatedfromthetractor.

Thesmallerimplementuntil6m(19.7ft)havesinglefold,

whereas9m(29.5ft)implementhavedoublefold.

Asimplefoldingmechanismensuresatransportwidthof

3m(9.8ft).

ZEIL19TIL0234BA1

5-1

Page 46

5-TRANSPORTOPERATIONS

Transportonpublicroads

WARNING

Transporthazard!

Ifthetractorhydraulicsystemaccidentally

engagesduringtransport,themachinecould

droptotheground,swingintoroadside

obstacles,orswingintooncomingtrafc.

Beforetransport,alwaysengagetheheader

liftlockvalveandthetongueswingcylinder

valveintheLOCKEDposition.

Failuretocomplycouldresultindeathorseriousinjury.

NOTICE:Whenyoudriveonslopingground,youmust

beawarethattheimplement’shighcenterofgravitywill

increasetheriskofoverturning,andalsoaffectstheroadholdingqualitiesaroundcornersetc.

NOTE:Thebehaviorofthetractorwhenyoudrivewiththe

implementmayvary.Adjustthestyleofdrivingtotheconditionsontheroad.Payspecialattentiontothelocationof

thecenterofgravityoftheseimplementelementswhich

arefoldedwiththeuseofhydrauliccylinders.Themaximumpermissiblespeedfordrivingwiththeimplementattachedis25km/h(15.5mph).

W1518A

NOTE:Makesurethattheimplementisequippedwith

thecorrectlightingsystemandothertrafcmarkingsin

accordancewiththecountry'scurrentrules.Theimplementmustbeequippedwithfrontlights(positionlights)

andrearlights(turnsignals,positionlights,brakinglights)

connectedtotheelectricalinstallationofthetractor.Plus

atrianglesignmustbemountedonaspecialgripforslow

vehicles.

NOTE:Inverticaltransportpositionthewingsmustbe

foldedinandthe3-pointlinkagemustbeliftedsothatthe

transportheightisbelow4metersandstillsafeclearance

abovetheroadfromthelowestpoint.Theexacttransport

heightfortheindividualimplementsisstatedundertechnicaldata(seePage9-1).

NOTE:Duringtransportandinoperation,transporting

peopleonthestructureoftheimplementisstrictlyprohibited.

NOTE:Beforeyoutransporttheimplementonapublic

road,makesurenottoexceedthetransportheightof4m

(13.1ft).

5-2

Page 47

5-TRANSPORTOPERATIONS

Onlytransporttheimplementbehindatractorinthetractor

linkagearms.

Transporttheimplementonlyinthetransportposition.

Beforeyoudriveonpublicroads,converttheimplement

fromtransporttoworkingpositionandbackagaintoensurethatthereisnoairinthehydraulicsystem.

Alwaysimmobilize(close)theballvalvethatsecurethe

implementbeforeyoudriveonpublicroad.

Liftthesectionsandputintotransportpositiontoobtain

thecorrecttransportwidthandinhibitthesectionsfrom

movingduringtransport

Placethejacksintothetransportposition.Liftthejacks

andsecurethesupportinthetransportpositionwitha

latchpin.Makesurethatthefourlatchpinsarereengaged.

Whenyoudrivewiththeimplementattachedonanypublicroads,railwaytracksorothersurfaces,neverexceed

thetransportwidththeimplement,speciedbyapplicable

regulations.Ifthemaximumpermissibletransportwidth

isexceeded,then,inextraordinaryconditions,theauthoritiesmayissueaspecialpermitforthetransportof

alarge-sizevehicle.

Alwaysobservetheprinciplesforpermissibleaxleloads,

thetotalimplementmassandthetransportgauge.

Whenyouturnsordrivenexttocorners,maintainasafe

distancetoaccountfortheinertiaoftheimplementand

locationofthecenterofgravityofthefoldedframe,which

isatheight.

Afteryounishthetransport,beforeyouleavethetractor,

alwayslowertheimplementtothegroundtotheparking

position(seePage4-7),turnoffthetractorengine,re-

movethekeyfromtheignitionandpullthehandbrake.

Tolowerthecenterofgravity,andtoensuremorestable

transportconditions,theimplementmustbeloweredto

thelowestpositionavailable,ensuringhoweverthatsufcientspaceisleftfromthesurfaceoftheroad.

Makesurethattheimplementissafeandthatnothingfalls

offitduringtransport,forinstancelargelumpsofsoil.

Controltheoperationoftheimplement’slampsandthe

conditionofwarningplates.

5-3

Page 48

Shippingtransport

Liftingtheimplement

WARNING

Fallingobjecthazard!

DONOTgounderneathahangingload.Make

suretheareaisclearofallbystanders.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Crushinghazard!

Usethemachineliftingpointswhenyoulift

and/ormovethemachinewithheavyhandling

equipment.Liftthemachineonlyfromtheindicatedliftingeyehookuppoints.Alwaysuse

adequateliftingequipment.

Failuretocomplycouldresultindeathorseriousinjury.

5-TRANSPORTOPERATIONS

W1129A

ZEIL19TL0049AA1

W1432B

Ifyoulifttheimplementwithacraneoraforklift,always

proceedaccordingtothefollowingguidelines:

Thecraneorforkliftusedtolifttheimplementmusthave

•

properliftingcapacityandisequippedwithproperbal-

last.

Lifttheimplementinthefoldedpositionorwithunfolded

•

onlymainfoldwings.

Alwaysusetransportbeltswithproperload-bearingca-

•

pacity.

Tolifttheimplementcorrectlyusetheliftingpointshown

•

intheFigure2.

5-4

Page 49

5-TRANSPORTOPERATIONS

Loadingandunloadingoftheimplement

withsuitableliftingdevice

Forloadingandunloadingtheimplement,useonly

•

asuitableliftingdevicewithanoperationaloperating

brakingsystem.

Beforeyouproceedtoloading/unloading,connectthe

•

implementtothetractorinthecorrectway.

Whenyouperformtheloading/unloadingprocedure,

•

askanadditionalpersonforhelpinpointingtheright

directions.

Whenyouloadtheimplement,disconnectitfromthe

•

tractorandsecureitforthedurationoftransport,ac-

cordingtoapplicableregulations.

ZEIL19TIL0205FA2

5-5

Page 50

5-TRANSPORTOPERATIONS

Transportonpallet

Theimplementisproperlyadaptedtoloadingontoany

meansoftransportaftersomepreparation.T otransport

theimplement,foldthewingsanddisassemblesomeof

equipment.

Topreparethetransportoftheimplement,disassemble

andpackthefollowingpartsoneuropallet:

Wheels(1)

•

Stabilizingdiscs(2)

•

Lightkit(3)

•

Steps(4)

•

FSseeder(5)

•

Rearharrows(6)

•

Beforeyouloadandunload,secureallcontactpoints

oftheimplementwiththeforkliftarestructuretoavoid

damagingthevarnishorequipment(cylinders,hydraulic

hoses).

ZEIL19TIL0205FA1

5-6

Page 51

6-WORKINGOPERATIONS

6-WORKINGOPERATIONS###_6_###

Generalinformation

Workingposition

Tounfoldtheimplementtotheworkingposition,proceed

asfollows:

1.Liftthejackstothetransportposition-highestposi-

tion.

2.Openthehydraulicballvalvesonhydraulichoses

comingoutfromtractorandinlinetostabilizingdisc.

3.Foldoutthesidewingsbybrieyactivatingthehy-

draulicoutlet.

4.Lowertheimplementwhileyouactivatethehydraulic

outletslowly(Ifthehydraulicoiliscold,itmayhappen

thattheloweringspeeddecreasesstrongly).

5.Lowerthesectionsusinghydraulicline.

6.Lowerthe3pointlinkageuntilthesectionsarein

workingposition-theparallelogramsarehorizontal

withtheeld.

7.Adjustthelinkagearmssothattheforemostendof

thebarisvertical.

8.Makesurethattherowspacingisadjustedcorrectly

-ifno,correctthedistance.

9.Adjustthewheelsonthesectionsinaccordancewith

therequiredworkingdepth-normally2–3cm(0.8

–1.2in).

NOTE:Ifyoufoldtheouterwings,the9m(29.5ft)version

canbeusedasa6m(19.7ft)implement.

ZEIL19TL0085EA1

6-1

Page 52

6-WORKINGOPERATIONS

Thesectionsmustbehorizontalwhenworkisstartedin

theeldandabletomovefreelyupanddownwithoutinterference.Eachindividualsectioncanmoveupwards

approximately25cm(9.8in)(A)anddownwardsapprox-

imately7cm(2.8in)(B)inrelationtothehorizontalposi-

tiontobeabletofollowthecontoursofanuneveneld.If

thetinesanddiscsontheworkingsectionsareblocked;

stopthetractorengine,activatetheparkingbrakeandremovetheforeignmatter.

ZEIL19TIL0192EA2

6-2

Page 53

6-WORKINGOPERATIONS

Adjustmentofworkingsection

Withproperspacingsection,thesupportwheelsmust

rollamiddleofinterrows.Thedistancebetweensections(measuredfromcenterofsupportwheel)mustbe

thesameandcorrespondtowidthsofinterrows(R).In

caseofirregularitiesthesectionsshouldbemoved.To

movethesection,proceedasfollows:

1.Loosenthebolt(1).

2.Liftandmovethesection(2)incorrectway,right-hand

sideorleft-handside(tomakethesettingsectioneasier,usethescalegluedontheinnerpartoftheframe).

3.Tightentheboltwithpropertorque(1).

ZEIL19TL0080AA1

ZEIL19TIL0185AA2

6-3

Page 54

6-WORKINGOPERATIONS

Adjustmentofworkingdepth

Positiontheboomcorrectlyinrelationtotheeld;horizontalsectionsandverticaltoolbarattheforemostend

ofthebar.Mountthecleaningsectionssothatthey

cleanbetweentherowsofcrops.

Theworkingsections(1)mustbehorizontalduringwork

toachievethebestpossibilityforthesectionstofollow

thesoilscontours.positiontheboomcorrectlyinrelationtotheeld.

Whileregulation,rememberthatthewheelsectionscollapseinthesoilforabout1–1.5cm(0.4–0.6in).To

setthecorrectworkingdepth,adjustthesupportwheel

attheheight(A).

ZEIL19TIL0405AA1

Eachindividualunitisaseparateselfcontainedcultivatorwithitsowndepthcontrolanparallelogramsuspension.Thedepthcontrolwheelmakesthesectionvery

stablewhilemaintainingtheuniformdepth.Thewheel

ismaintenancefreeandisadjustablebymeansofa

crank.

Tochangetheworkingdepth,proceedadfollows:

1.Turnthecrank(2)clockwisetoincreaseworkingdepth.

2.Turnthecrank(2)counter-clockwisetodecreasework-

ingdepth.

Thescaleandindicator(3)makeseasiertosetthe

sameworkingdepthforeachsection.

ZEIL19TIL0406AA2

ZEIL19TIL0404AA3

ZEIL19TIL0408AA4

6-4

Page 55

6-WORKINGOPERATIONS

Hydraulicadjustment

Hydraulicblock(1)tocontroltheparallelogramside

shiftframeallowstoworkin3modes,dependingonthe

requiredoperatingmodeadjustmentisnecessary:

ClosedCenter(CC)

•

OpenCenter(OC)

•

LoadSensing(LS)-asoption

•

Hydraulicblockadjustment

Toadjustthehydraulicblock,proceedasfollows:

1.Loosenthenut(2).

2.Screworunscrewthebolt(3).

3.Tightenthenut(2).

ZEIL19TL0069AA1

ZEIL19TL0070AA2

6-5

Page 56

6-WORKINGOPERATIONS

Operationmodeadjustment

ToadjustthehydraulicblockoperationmodeinOpen

Center,proceedasfollows:

Thebolt(4)shouldbeunscreweduntilthetensionofthe

springisundetectable.Thedimension(A)isapproxi-

mately24mm(0.9in).

ToadjustthehydraulicblockoperationmodeinClosed

CenterorLoadSensing,thebolt(4)shouldbescrewed

totheend.Thedimension(B)isapproximately11mm

(0.4in).

ZEIL19TL0071AA3

Oilowadjustment

Toadjustthespeedoftheframeshift,adjusttheoilow.

Toadjusttheoilow,proceedasfollows:

1.Loosennut(1).

2.Screworunscrewbolt(2).

3.Tightennut(1).

ZEIL19TL0072AA4

ZEIL19TIL0193AA5

6-6

Page 57

6-WORKINGOPERATIONS

Workingintheeld-VibroCropIntelli

Beforeyouworkintheeld,checkthattheimplement

hasbeenconnectedcorrectly,thattheimplementisinthe

workingpositionandthatequipmenthasbeenadjusted

correctlyasdescribedintheprevioussections.

Whenyougointooroutoftheheadland,haveaslower

speedthandrivingintheeld.Alwaysremembertolift

andlowerthelinkswhenyougoinandoutoftheheadlands.Theimplementwillautomaticallyself-centerwhen

itisbeingraisedduetoactivationofanimplementsensor

whentheimplementislifted.Thecamerawillthengoon

standby.

Loweringtheimplementwillactivatethecameraandit

needsafewmeterstoreadtherows.Ifthecamerais