ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1

OPERATOR’S MANUAL

R+ 760

R+ 820

Rotary rake

Part number 51514541

st

1

edition English

April 2019

Contents

1GENERALINFORMATION

Notetotheowner...........................................................................1-1

Intendeduse................................................................................1-4

Prohibitedusage...........................................................................1-4

Electro-MagneticCompatibility(EMC).....................................................1-5

Manualscopeandrequiredtraininglevel..................................................1-6

ProductIdenticationNumber(PIN)........................................................1-8

Productidentication.......................................................................1-9

Operator'smanualstorageonthemachine...............................................1-10

Implementorientation.....................................................................1-11

2SAFETYINFORMATION

Safetyrulesandsignalworddenitions....................................................2-1

Generalrecommendations.................................................................2-2

Illustrations.................................................................................2-3

Legalobligations...........................................................................2-3

Fireorexplosionprevention................................................................2-3

Hazardouschemicals.......................................................................2-4

Startinguptheimplementsafely...........................................................2-5

Travelingonpublicroads...................................................................2-6

Operatingtheimplementsafely............................................................2-8

Stoppingtheimplementsafely.............................................................2-9

Maintenance...............................................................................2-10

PersonalProtectiveEquipment(PPE)....................................................2-11

Safetyrequirementsforuidpowersystemsandcomponents-hydraulicsystems......2-12

Noiseemission............................................................................2-13

Vibrationlevels............................................................................2-13

Implementstability.........................................................................2-14

Ecologyandtheenvironment.............................................................2-15

Safetysigns...............................................................................2-16

3CONTROLSANDINSTRUMENTS

Information

Operatingprinciples....................................................................3-1

4OPERATINGINSTRUCTIONS

Commissioningtheunit

Preparingforoperation.................................................................4-1

Installationofwheels...................................................................4-2

Installationofswathcanvas............................................................4-3

Installationofrotors.....................................................................4-4

Installationofsafetyguard.............................................................4-5

Installationofhydrauliclock(optionalequipment)......................................4-6

Installationofextrawheelsonrotorchassis(optionalequipment).....................4-8

Adjustmentofworkingwidth............................................................4-9

Startingtheunit

Connectiontothetractor..............................................................4-10

PowerTake-Off(PTO)shaft–Shorten................................................4-15

5TRANSPORTOPERATIONS

Roadtransport

Travellingonpublicroads..............................................................5-1

Preparingforroadtransport

Conversionoftherakefromworkingtotransportposition.............................5-3

6WORKINGOPERATIONS

Generalinformation

Specialinstructions.....................................................................6-1

Conversionoftherakefromtransporttoworkingposition.............................6-3

Basicadjustment.......................................................................6-5

Startingtherotor........................................................................6-8

Workingspeedandnumberofrevolutions.............................................6-9

Disconnectionoftheattachment......................................................6-10

Turningofsteeringknucklesandinstallationofsteering..............................6-11

Furtherinstructionsforworkinganddrivingwiththeattachment......................6-12

7MAINTENANCE

Generalinformation

Maintenance............................................................................7-1

Torque..................................................................................7-2

Torqueforclass12.9...................................................................7-5

Fluidsandlubricants...................................................................7-5

Maintenanceplanning

Maintenancechart......................................................................7-6

Aftertherst3hoursofoperation

Boltsandttings........................................................................7-7

Every8hours

Universaljoint..........................................................................7-7

PowerTake-Off(PTO)shaft............................................................7-8

Rotorgear..............................................................................7-9

Every10hours

Hydraulicscrewjoints.................................................................7-10

Every20hours

PowerTake-Off(PTO)shaft...........................................................7-11

Every40hours

PowerTake-Off(PTO)shaft...........................................................7-12

Every50hours

Tirepressure..........................................................................7-13

Lockingpawlsandliftingcylinder......................................................7-14

Suspension............................................................................7-15

Every200hours

Steering................................................................................7-16

Every6years

Hydraulichoses.......................................................................7-18

Asrequired

Bearingarms..........................................................................7-19

Storage

Pressurewashing.................................................................7-20

Endofseasonservice.............................................................7-21

Orderingpartsand/oraccessories..............................................7-22

8TROUBLESHOOTING

Faultcoderesolution

Troubleshootingchart..............................................................8-1

9SPECIFICATIONS

Technicaldata..............................................................................9-1

Fluidsandlubricants.......................................................................9-2

10ACCESSORIES

Generalinformation.......................................................................10-1

Tandemcasterwheels.....................................................................10-1

Supportchainforlinkarms................................................................10-1

Kitforseparaterotorlift....................................................................10-1

11FORMSANDDECLARATIONS

ECDeclarationofConformity.............................................................11-1

1-GENERALINFORMATION

1-GENERALINFORMATION###_1_###

Notetotheowner

Thismanualhasbeenpreparedtoassistyouinthecorrectproceduretorunin,todrive,tooperate,toadjustandto

maintainyournewimplement.

Thisimplementhasbeendesignedandbuilttogivemaximumperformance,economyandeaseofoperationunder

awidevarietyofconditions.

Priortodelivery,yourimplementwascarefullyinspectedbothatthefactoryandbyyourdealertomakesurethatit

reachesyouinoptimumcondition.Tomaintainthisconditionandassuretrouble‐freeoperationitisimportantthat

routineservices,asspeciedinthismanual,arecarriedoutattherecommendedintervals.

Readthismanualcarefully(especiallyChapter2thatcoversthesafetyinformation)andkeepthismanualinaconvenientplaceforfuturereference.DONOToperateorpermitanyonetooperateorservicethisimplementuntilyou

and/orotherpersonshavereadthismanual.Readthemanual,itwillsaveyoutimeandhasslelater.Lackofknowledgecanleadtoaccidents.Employonlytrainedoperatorswhohavedemonstratedtheabilitytooperateandservice

thisimplementcorrectlyandsafely.Contactyourdealerforassistanceprovidingtherequiredtrainingtoyouroperators.Contactyourdealertoobtainadditionalmanualsoralternatelanguageversions.

Ifatanytimeyourequireadvicethatconcernsyourimplement,donothesitatetocontactyourauthorizeddealer.He

hasfactory‐trainedpersonnel,genuineservicepartsandthenecessaryequipmenttocarryoutyourservicerequirements.

NOTICE:ThisimplementhasbeendesignedandbuiltinlinewiththerequirementsputforwardbytheEuropean

Directives2006/42/ECand2014/30/EU.

AlwaysusegenuineKONGSKILDEServicePartsorpartsthatmatchatleastthesamequality,reliabilityandfunctionalityastheequivalentoriginalServicePartswhenyouserviceandrepairyourimplementanddonotmodifyyour

implementwithoutawrittenpermissionofthemanufacturer.Failuretodosowillvoidtheresponsibilityofthemanufacturer.

Checklocalroadlegislationbeforeyoudrivetheimplementonpublicroads.

Whenyouoperateinterchangeableimplement,makesurethattheimplementisCEapproved.

Asthispublicationisdistributedthroughoutourinternationalnetwork,theimplementillustrated,eitherasstandardor

asanaccessory,mayvaryaccordingtothecountryinwhichtheimplementistobeused.Lowspecicationcongurations,aschosenbythecustomer ,maydeviatefromthespecicationsgiven.

Severalguresinthisoperator'smanualshowthesafetyguardingortheadditionalguards,legallyrequiredbycertain

countries,openorremovedtobetterillustrateaparticularfeatureoradjustment.Theimplementmustnotbeusedin

thiscondition.Foryourownsafety,makesurethatallguardsareclosedorreplacedbeforeyouoperatetheimplement.

1-1

1-GENERALINFORMATION

OWNERASSISTANCE

WeatKONGSKILDEandyourKONGSKILDEdealerwantyoutobecompletelysatisedwithyourinvestment.Normally,yourdealer'sServiceDepartmentwillhandleanyproblemswithyourimplement.Sometimeshowever,misunderstandingcanoccur.Ifyourproblemhasnotbeenhandledtoyoursatisfaction,wesuggestyoutocontacttheowner

orGeneralManagerofthedealership,explaintheproblemandrequestassistance.Whenadditionalassistanceis

needed,yourdealerhasdirectaccesstoourbranchofce.

COMPANYPOLICY

Companypolicy,whichisoneofcontinuousimprovement,reservestherighttomakechangesindesignandspecicationatanytimewithoutnoticeandwithoutobligationtomodifyunitspreviouslybuilt.

Alldatagiveninthisbookissubjecttoproductionvariations.Theinformationinthispublicationisprovidedonthe

basisofinformationthatwasavailableatthetimethatthemanualwaswritten.Settings,proceduresandotheritems

canchange.Thesechangescanaffecttheservicethatisgiventotheimplement.

Dimensionsandweightsareapproximateonlyandtheillustrationsdonotnecessarilyshowtheimplementinstandard

condition.Forexactinformationaboutanyparticularimplementpleaseconsultyourdealer.Makesurethatyouhave

themostcurrentandcompleteinformationfromyourdealerbeforeyoustartanyjob.

ACCESSORIESANDOPTIONS

Yourimplementhasbeendesignedtooperateinawidevarietyofsoils/cropsandconditions.Neverthelessadditional

equipmentmay,incertaincases,berequiredtoimprovetheimplementperformance.Alistofthisadditionalequipmentisgiveninthe''Accessories”chapterinthismanual.Useonlythoseaccessoriesdesignedforyourimplement.

PARTSANDACCESSORIES

GenuineKONGSKILDEpartsandaccessorieshavebeenspecicallydesignedforKONGSKILDEimplements.

Wewouldliketopointoutthat''non-genuine”partsandaccessorieshavenotbeenexaminedandreleased

byKONGSKILDE.Theinstallationand/oruseofsuchproductscouldhavenegativeeffectsuponthedesign

characteristicsofyourimplementandtherebyaffectitssafety.KONGSKILDEisnotliableforanydamagecaused

bytheuseof''non-genuine”partsandaccessories.

RelyonyourauthorizeddealertosupplyyouwithgenuineKONGSKILDEpartsonly.Thesepartsarecoveredbyour

warrantyandwillgiveyouthebestperformance.

SeethepartscatalogorbrowsetheKONGSKILDEportaltondservicepartsforyourimplement.

Whenyouorderserviceparts,alwaysquotethemodelandserialnumberprintedontheProductIdenticationNumber

(PIN)plate.

1-2

1-GENERALINFORMATION

LUBRICANTS

Yourdealersellsaselectionofspeciallyformulatedlubricantsbasedonownengineeringspecications.

Recommendedlubricantsforyourimplementarelistedinthemaintenancechapter.

WARRANTY

Yourimplementiswarrantedaccordingtolegalrightsinyourcountryandthecontractualagreementwiththeselling

dealer.Nowarrantyshall,however,applyiftheimplementhasnotbeenused,adjustedandmaintainedaccordingto

theinstructionsgiveninthisoperator'smanual.

Itisprohibitedtocarryoutanymodicationstotheimplementunlessspecicallyauthorized,inwriting,bya

KONGSKILDErepresentative.

CLEANINGYOURIMPLEMENT

Whenyouuseahighpressurewasher,donotstandtooclosetotheimplementandavoiddirectingthejetatelectronic

components,electricalconnections,breathers,seals,llercaps,andsoon.

Cleandecalsonlywithasoftcloth,waterandagentledetergent.DONOTusesolvent,gasolineorotherharsh

chemicalstocleandecals.Decalscouldberemovedorgetdamaged.

DISASSEMBLYORSCRAPPING

Whenyourimplementistakenoutofservicebecauseitisdamagedbeyondrepairorhasreachedtheendofits

usefullife,disassembly,scrappingand/orrecyclingofcomponentsmustbeperformedonlybyaqualiedtechnician

withserviceinstructions,andincompliancewithlocallawandregulations.

1-3

Intendeduse

1-GENERALINFORMATION

TheKONGSKILDErotaryrakecanonlyperformtheusual

workinagriculture.Onlyconnecttherotaryraketoa

tractorwhichcorrespondswiththespecicationsofthe

implementandislegaltouse.OnlythePowerTake-Off

(PTO)shaftofthetractorcandrivetheattachedrotary

rake.

Therotaryrakemayonlybeusedforrakegrasshayand

strawcropsontheground.

Consideranyotherusecontrarytotheintendeduse.The

manufacturerisnotresponsibleforanydamagethatre-

Prohibitedusage

Sweepingofforexamplefarmyardswiththetinearmassemblyorbroomsfastenedtotheseisnotallowed.There

isariskthatforexamplestonesarethrownoutfromthe

workingareaoftheimplementwithdangerofpersonalinjuryordamagetoobjects.

Anyusebeyondtheintendeduseisregardedasforeseeablemisuse.

sultsfromtheimproperuseoftheimplement.Theuser

bearsthatrisk.

Alwaysobservethefollowingsafetyinstructionsaswell

asthecommonrulesconcerningtechnicalsafety,working

practicesandroadsafety.

Ifyoumakechangestotheimplementanditsconstruction

withoutthepermissionfromthemanufacturer,themanufacturerdoesnotacceptanyresponsibilityfordamages

thatresultsfromthis.

1-4

1-GENERALINFORMATION

Electro-MagneticCompatibility(EMC)

ThismachinecompliesstrictlywiththeEuropeanRegulationsonelectro‐magneticemissions.However,interference

mayariseasaresultofadd‐onequipmentwhichmaynotnecessarilymeettherequiredstandards.Assuchinterferencecanresultinseriousmalfunctionoftheunitand/orcreateunsafesituations,youmustobservethefollowing:

Ensurethateachpieceofnon‐KONGSKILDEequipmentttedtothemachinebearstheCEmark.

•

Themaximumpowerofemissionequipment(radio,telephones,etc.)mustnotexceedthelimitsimposedbythe

•

nationalauthoritiesofthecountrywhereyouusethemachine.

Theelectro‐magneticeldgeneratedbytheadd‐onsystemshouldnotexceed24V/matanytimeandatanylo-

•

cationintheproximityofelectroniccomponents.

FailuretocomplywiththeseruleswillrendertheKONGSKILDEwarrantynullandvoid.

1-5

1-GENERALINFORMATION

Manualscopeandrequiredtraininglevel

Introductiontothismanual

Thismanualgivesinformationabouttheuseofyour

KONGSKILDEmachineasintendedandunderthe

conditionsforeseenbyKONGSKILDEduringnormal

operation,routineservice,andmaintenance.

Thismanualdoesnotcontainalltheinformationthatrelatestoperiodicservice,conversions,andrepairsthat

onlytrainedservicepersonnelcanperform.Someof

theseactivitiesmayrequireappropriatefacilities,technicalskills,and/ortoolsthatKONGSKILDEdoesnotsupply

withthemachine.

ThemanualcontainsthechaptersasshownontheContentspages.SeetheIndexattheendofthismanualto

locatespecicitemsaboutyourKONGSKILDEmachine.

Normaloperation

Normaloperationconsistsoftheuseofthismachinefor

thepurposeKONGSKILDEintendsbyanoperatorthat:

Isfamiliarwiththemachineandanymountedequip-

•

mentortowedequipment

Complieswiththeinformationonoperationandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Normaloperationincludes:

Preparationandstorageofthemachine

•

Additionandremovalofballast

•

Connectionanddisconnectionofmountedequipment

•

and/ortowedequipment

Adjustmentandcongurationofthemachineand

•

equipmentforthespecicconditionsofthejobsite,

eld,and/orcrop

Movementofcomponentsintoandoutofworkingpo-

•

sitions

Routineserviceandmaintenance

Routineserviceandmaintenanceconsistsofthedaily

activitiesnecessarytomaintainthepropermachine

function.Theoperatormust:

Befamiliarwiththemachinecharacteristics

•

Complywiththeinformationonroutineserviceandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Routineservicecaninclude:

Fueling

•

Cleaning

•

Washing

•

Toppingupuidlevels

•

Greasing

•

Replacingconsumableitemssuchaslightbulbs

•

Periodicservice,conversions,andrepairs

Periodicserviceconsistsofactivitiesthatarenecessary

tomaintaintheexpectedlifeoftheKONGSKILDEmachine.Theseactivitieshavedenedintervals.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivitiesatthedened

intervals.Trainedservicepersonnelmustcomplywith

theinformationonperiodicserviceandsafepracticesas

partlyspeciedbyKONGSKILDEinthismanualand/or

othercompanyliterature.

Periodicserviceincludes:

Oilchangeservicefortheengine,hydrauliccircuits,or

•

transmission

Periodicexchangeofothersubstancesorcomponents

•

asrequired

ConversionactivitiesrebuildtheKONGSKILDEmachine

inacongurationthatisappropriateforaspecicjob

site,crop,and/orsoilconditions(e.g.,installationofdual

wheels).Conversionactivitiesmustbedone:

Bytrainedservicepersonnelfamiliarwiththemachine

•

characteristics

Bytrainedservicepersonnelthatcomplywiththe

•

informationonconversionaspartlyspeciedby

KONGSKILDEinthismanual,assemblyinstructions,

and/orothercompanyliterature

Repairactivitiesrestoreproperfunctiontoa

KONGSKILDEmachineafterafailureordegradation

ofperformance.Dismantlingactivitiesoccurduringthe

scrappingand/ordismantlingofthemachine.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivities.Trainedservice

personnelmustcomplywiththeinformationforrepairas

speciedbyKONGSKILDEintheservicemanual.

Beforeyouoperate

Readthismanualbeforeyoustarttheengineor

operatethisKONGSKILDEmachine.Contactyour

KONGSKILDEdealerif:

Youdonotunderstandanyinformationinthismanual

•

Youneedmoreinformation

•

Youneedassistance

•

Allpersonstrainingtooperate,orwhowilloperate

thisKONGSKILDEmachineshouldbeoldenoughto

possessavalidlocalvehicleoperatingpermit(ormeet

otherapplicablelocalagerequirements).Thesepersons

1-6

1-GENERALINFORMATION

mustdemonstratetheabilitytooperateandservicethe

KONGSKILDEmachineinacorrectandsafemanner.

1-7

1-GENERALINFORMATION

ProductIdenticationNumber(PIN)

TheProductIdenticationNumber(PIN)isaserialnumberthatidentiestheimplement.

Theserialnumber,model,andotherspecications,are

onthePINplate.

ProvideyourKONGSKILDEdealerwiththemodeland

PINwhenyouorderspareparts.

ZEIL18HT00548FA1

(1)Companyname(8)

(2)Brandidenticationlogo(9)

(3)

(4)

(5)Yearofconstruction(12)Type/Variant/Version

(6)Madein(countryoforigin)(13)

(7)Certicationmark

Mailaddress

Modelyear

(10)ProductIdenticationNumber(PIN)

(11)

Maximumpermissibleloaddividedpereach

axleanddrawbar

RéceptionnéleparlaDRIEEIledeFrance

(forFranceonly)

Model

Designation

1-8

1-GENERALINFORMATION

Productidentication

NOTE:DonotremoveorchangetheProductIdenticationNumber(PIN)plate(1)ontheimplement.

ThePINplate(1)isplacedontheright-handsideofthe

implement.

ThePINisalsoengravedonthechassisat(A)belowthe

PINplate(1).

Forfuturereference,recordyourimplementmodeland

PINinthespacesbelow.

Model

ProductIdenticationNumber(PIN)

ZEIL18HT00788FA1

1-9

1-GENERALINFORMATION

Operator'smanualstorageonthemachine

Keepthisoperator'smanualprotectedandaccessibleon

thetractorwheneveryoutransportoroperatetheimplement.

1-10

1-GENERALINFORMATION

Implementorientation

NOTE:T odeterminetheleft-handsideandtheright-hand

sideoftheimplement,standbehindtheimplementand

facethedirectionoftravelduringworkingoperation.

Thefollowingoverheadviewillustrationisageneralrepresentationoftheimplement.Theillustrationindicatesthe

sides,front,andrearorientationsoftheimplementasreferredtothroughouttheoperator’smanual.

NOTE:Thearrowindicatesthedirectionoftheimplement

duringworkingoperation.

(A)Frontoftheimplement

(B)Right-handsideoftheimplement

(C)Rearoftheimplement

(D)Left-handsideoftheimplement

ZEIL18HT00789FA1

1-11

1-GENERALINFORMATION

1-12

2-SAFETYINFORMATION

2-SAFETYINFORMATION###_2_###

Safetyrulesandsignalworddenitions

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

ThroughoutthismanualyouwillndthesignalwordsDANGER,WARNING,andCAUTIONfollowedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworkingwithyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationthat,ifnotavoided,willresultindeathorseriousinjury.

WARNINGindicatesahazardoussituationthat,ifnotavoided,couldresultindeathorseriousinjury.

CAUTIONindicatesahazardoussituationthat,ifnotavoided,couldresultinminorormoderateinjury.

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESULT

INDEATHORSERIOUSINJURY .

Machinesafety

NOTICE:Noticeindicatesasituationthat,ifnotavoided,couldresultinmachineorpropertydamage.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachineor

propertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationthatclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

2-1

2-SAFETYINFORMATION

Generalrecommendations

Mostfarmmachineryaccidentscanbeavoidedbythe

observanceofafewsimplesafetyprecautions.

Thisoperator’smanualcontainsimportantinformation

•

concerningoperation,maintenanceandadjustmentof

theimplement.Furthermore,thisoperator’smanual

mentionsandemphasizesallthesafetyinstructions.

Readtheoperator’smanualthoroughlybeforeyou

•

start,operate,service,orcarryoutanyotheroperation

ontheimplement.Eventhoughyouhavebeendriving

asimilarimplementbefore,youmustreadthemanual.

Thisisamatterofyourownandotherpeoplesafety.

Afewminutesreadingwillsaveyoutimeandhassle

later.Lackofknowledgecanleadtoaccidents.

Yourimplementwasdesignedwithsafetyinmind.

•

However,thereisnorealsubstituteforcautionand

attentionwhenyouneedtopreventanaccident.Once

anaccidenthasoccurred,itistoolatetothinkabout

whatyoushouldhavedone.Thismeansthatitis

veryimportantthatyouasuseroftheimplementpay

attentionandusetheimplementcorrectlyandthereby

avoidexposingyourselfandotherstounnecessary

danger.

Theimplementmustbeoperatedonlybyresponsible

•

personswhohavebeenadequatelytrainedandautho-

rizedtousetheimplement.Neverleavetheimplement

toothersbeforeyouhavemadesurethattheyhavethe

necessaryknowledgetooperatetheimplementsafely.

Neverlettheimplementrunwithoutsupervision.

•

Alwayskeeparstaidkithandy.

•

Takethenecessaryprecautions(forexampleassis-

•

tance)toalwaysbeawareofthepossiblepresenceof

bystandersandpets.

Keepchildrenawayfromandofftheimplementatall

•

times.

Donotusethisimplementasalift,ladderorplatform

•

toworkatheights.

Beforeyouworkontheimplement,disengageall

•

drives,stoptheengineandremovetheignitionkey.

Waitfortherotatingpartstorundown.

Neverworkaroundtheimplementwithlooseclothing,

•

jewelry,watches,longhairandotherlooseorhanging

itemscanbepulledinbythemovingpartsoftheimplement.

Keephandsawayfrommovingpartsoftheimplement.

•

Neverattempttocarryoutanyadjustmentsontheim-

•

plementwhiletheimplementisinmotionorwhilethe

PowerT ake-Off(PTO)shaftisengaged.

PTOdrivenimplementcancausedeathorseriousin-

•

jury.BeforeyouworkonornearthePTOshaftorser-

viceorclearthedrivenimplement,disengagethePTO,

stoptheengineandremovetheignitionkey.

2-2

2-SAFETYINFORMATION

Illustrations

WARNING

Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment.

Replaceallshieldsbeforeoperatingthemachine.

Failuretocomplycouldresultindeathorseriousinjury.

NOTE:Someoftheillustrationsinthismanualhavebeen

obtainedbyphotographingprototypes.Standardproductionmachinesmaydifferinsomedetails.

Legalobligations

W0012A

Yourmachinemaybeequippedwithspecialguardingor

otherdevicesincompliancewithlocallegislation.Some

oftheserequireactiveactionbytheoperator.

Fireorexplosionprevention

1.Cropmaterial,trash,debris,birdnestsorammable

materialcanigniteonhotsurfaces.

2.Inspecttheelectricalsystemforlooseconnectionsor

frayedinsulation.Repairorreplacelooseordamaged

parts.

3.Donotstoreoilyragsorotherammablematerialon

theimplement.

4.Donotweldoramecutanyitemsthatcontain

ammablematerial.Cleanitemsthoroughlywith

Therefore,checklocallegislationontheusageofthismachine.

non-ammablesolventbeforeyouweldorcutwitha

ame.

5.Donotexposetheimplementtoames,burningbrush

orexplosives.

6.Promptlyinvestigateanyunusualsmellsorodorsthat

mayoccurduringtheoperationoftheimplement.

2-3

Hazardouschemicals

2-SAFETYINFORMATION

1.Ifyouareexposedtoorcomeincontactwithhazardouschemicalsyoucanbeseriouslyinjured.

Theuids,lubricants,paints,adhesives,coolant,

etcetera.requiredforthefunctionofyourmachine

canbehazardous.Theymaybeattractiveandharmfulltodomesticanimalsaswellashumans.

2.MaterialSafetyDataSheets(MSDS)provideinformationaboutthechemicalsubstanceswithinaproduct,

safehandlingandstorageprocedures,rstaidmeasuresandprocedurestobetakenintheeventofaspill

oraccidentalrelease.MSDSareavailablefromyour

dealer.

3.BeforeyouserviceyourmachinechecktheMSDSfor

eachlubricant,uid,etcetera.usedinthismachine.

Thisinformationindicatestheassociatedrisksandwill

helpyouservicethemachinesafely.FollowtheinformationintheMSDS,onmanufacturercontainers,as

wellastheinformationinthismanualwhenyouservicethemachine.

4.Disposeofalluids,ltersandcontainersinanenvironmentallysafemannerinaccordancewithlocal

lawsandregulations.Checkwithlocalenvironmentalandrecyclingcentersoryourdealerforcorrectdisposalinformation.

5.Storeuidsandlterinaccordancewithlocallawsand

regulations.Useonlyappropriatecontainersforthe

storageofchemicalsorpetrochemicalsubstances.

6.Keepoutofreachofchildrenorotherunauthorized

persons.

7.Additionalprecautionsarerequiredforappliedchemicals.Obtaincompleteinformationfromthemanufacturerordistributorofthechemicalsbeforeyouuse

them.

2-4

Startinguptheimplementsafely

2-SAFETYINFORMATION

Beforeyouattachtheimplementtothetractor,ensurethat

thetractorisingoodworkingorderandthatthebrakes

areefcient,particularlyifyouoperateonhillyground.

Also,ensurethatthehydraulicorpneumaticsystemis

compatiblewiththatoftheimplement.

Whenyouattachtheimplementtothetractor:

Neverallowanyonetostandbetweenthetractorand

•

theimplement.Anunintentionalmanoeuvrewiththe

tractormaycauseseriousinjury.

Nevergounderanunsupportedimplement.

•

Installalltheguardscorrectlybeforeyouusetheimplement.

Replacewornanddamagedcanvasesbeforeyouwork

withtheimplement.

MakesurethatyouarethoroughlyfamiliarwiththeinstrumentsandcontrolsbeforeyouengagethePowerT akeOff(PTO)driveforthersttime.

ThePTOshafthasitsowninstructionmanualthatthe

manufacturersupplywiththeimplement.Toensurethe

correctuseoftheshaft,followalltheinstructionsofthe

manufacturermanual.Payparticularlycloseattentionto

thesafetyandmaintenanceinstructions,inordertopreventunintentionalinjuryanddamage.

RepairimmediatelyadamagedPTOshaftbeforeyou

workwiththeimplement.

AlwaysstopthePTOandthetractorengineandremove

theignitionkeybeforeyouconnectthePTOdriveshafts.

Afteryouattachtheimplementtothetractor,ensurethat

thePowerTake-Off(PTO)lockpinisproperlyengaged

inthetractorPowerT ake-Offshaft.Anincorrectlylocked

PTOshaftcouldworklooseandcauseaccidentsordamagetotheimplement.

MakesuretoinstallandsecurethePTOdriveshaftcorrectly.Checkthatthelockpinisinmesh.Fastenthe

supportchainatbothends.

Alwaysmakesurethattheguardtubesdonotseparate

atthemaximumworkingortransportlengthofthePTO

driveshaft.Checkalsothattheguardtubesdonotjamat

theminimumworkingortransportlengthofthePTOdrive

shaft.

Unlesstheprotectiveguards,thePTOdriveshaftmay

causeseriousinjury.Becarefulnottodamagetheguards

whenyouconnectthePTOdriveshafttoorfromthetractor.

FitcorrectlytheguardsonthePTOdriveshaft.Secure

theguardofthePTOshaftwiththechain.

DonotusePowerTake-Off(PTO)driveshaftswithother

specicationsthantheshaftwhichwassuppliedwiththe

implement.

BeforeyouinstallthePTOdriveshaft,checkthattheRevolutionsPerMinute(RPM)anddirectionofthePTOonthe

tractormatchthoseofthePTOontheimplement.

Beforeyoustartuptheimplement(forexampletherst

timeafteralongstandstillperiod),makesurethatthere

arenodetachedloosepartsonthedrivelineareaandon

themovingpartsoftheimplement.

2-5

Travelingonpublicroads

2-SAFETYINFORMATION

Complywiththerelevanttrafcregulations

WARNING

Impacthazard!

Takecarewhenmakingturns.Themachine

rearendswingsoutwhenchangingdirection.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Lossofcontrolhazard!

Unevenbrakeforceexistsonleft-handand

right-handbrakes.Alwaysusebrakepedal

couplerwhentravelingonpublicroadstoensurebrakesareactuatedtogether.

Failuretocomplycouldresultindeathorseriousinjury.

Theimplementisbuiltaccordingtothehomologationrequirementsofyourcountry.Donotmodifytheimplement

inasensethatwouldconictwiththenationalregulations.

Ifyouwishtotransporttheimplementonthepublicroad,

makesurethatthecombinationtractorandimplement

observesthetrafcrulesinyourcountry.Thisgivesyou

andyoursurroundingsthebestpossiblesafety.

Passengers

Donotallowpassengerstorideinthetractorunlessa

specicseatisprovided.

Duringtransport,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

W0089A

W0081A

Transportsafety

Transporttheimplementonlyintransportposition.Securetheimplementfortransport.Alwaysactivatethemechanicaltransportsafetydevicesbeforetransport.

Makesuretotallthehitchpinswithretainingpinscorrectly.Mechanicallysecurethehydrauliccylinderstopreventcylindersfromcreeping.

Drivesafe

Donotdriveundertheinuenceofalcoholordrugs.

Nevertravelatspeedincrowdedareas.

Whenyoumaneuverthetractorwiththeimplement,alwaysbeawareandconsciousofitssize.

Thetractordrivermustnotleavethecabinduringtransport.

Theoperatorsmustobserverelevantstatutoryorother

nationalregulationsthatdealwithroadsafetyandlabor

safetyissues.

Beforeyoudrivetheimplementonpublicroads:

Checktheallowabletransportdimensionsandweights.

•

Installcorrectlythelightingandthewarningpanels.

•

Alwaysobservetheprinciplesforpermissibleaxleloads,

thetotalunitmassandthetransportgauge.

Observethetractormanufacturerregulationsandrecommendations,specicallythoserelatingtomaximumtransportloadsandmaximumspeed.

Eveninsimilarcircumstances,themaximumallowed

speedcanvarydependingonwhichcountryyoutravel

in.

Alwaysdrivewiththestatutorylightsandsafetymarking

duringtransportonpublicroadandatnight.

Installalltherequiredsignsthatindicatethevehiclewidth.

Alsoinstallalltherequiredlightsthatindicatethevehicle

widthduringthenightlytransport.Ifindoubt,contactyour

governmentdepartmentresponsibleforroadtransport.

Alwaysconsiderotherroadusers.

Alwaysadoptsafedrivingpractices.Slowdownandsignalbeforeturning.Givewaytooncomingtrafcinallsituations,includingnarrowbridges,intersectionsetcetera.

Pullovertoallowfastertrafctopass.

Iftheimplementismarkedwithamaximumspeedlimit,

neverexceedthismaximumspeedlimit.

Alwaysadjustthedrivingspeedtotheroadandweather

conditions.Incaseofbadroadconditionsandhighdrivingspeeds,bigforcesmayoccurandcauseoverloadof

tractorandimplement.

Driveatasafespeedtoensurecontrolandabilitytostop

inanemergency.

Lockthetractorbrakepedalstogether.Neveruseindependentbreakingattransportspeeds.

Mountedimplementsandballastweightsinuencethe

driving,steeringandbrakingcapacityofthetractor.Make

surethattheadditionalweightoftheimplementonthe

linkagedoesnotcompromisedriving,steeringandbrakingcapacityofthetractor.Installfrontweightsorrepair

thebrakesifthetractorisnotsafetodrive.

Travelmayberestrictedtocertainroadtypes.Transport

mayberestrictedtodaytimeoroutsidepeaktrafchours.

Howeverplanyourroutetoavoidheavytrafcandpeak

trafchours.

Reducespeedduringturns.Tractorshavenotbeendesignedforfastturning.Avoidthattherearendoftheimplementhitsanobstacle.

2-6

2-SAFETYINFORMATION

Whenyouturnduringtransportpayattentiontotheoverhangand/oroscillatingweightoftheimplement.

Useenginebrakingwhenyoudrivedownhills.Donot

coast.

Watchforobstructions,particularlyifover-width.Observe

anyloadratingsapplicableonbridges.

Afteryounishthetransport,beforeyouleavethetractor,

alwayslowertheimplementtothegroundinparkingposition,turnoffthetractorengine,pulltheparkingbrake,

andremovethekeyfromtheignition.

2-7

Operatingtheimplementsafely

WARNING

Hazardtobystanders!

Alwayssoundthehornbeforestartingthemachine.Makesuretheworkareaisclearof

otherpersons,domesticanimals,tools,etc.

beforeyouoperatethemachine.Neverallow

anyoneintheworkareaduringmachineoperation.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Rotatingparts!

Keepclearofalldrivesandrotatingcomponents.

Failuretocomplycouldresultindeathorseriousinjury.

2-SAFETYINFORMATION

Neverattempttoremoveresiduesfromtheimplement

whiletheimplementruns.Suchanimprudencecouldcost

lifeorlimb.AlwaysdisengagethePowerTake-Off(PTO)

shaftmechanism,switchOFFthetractorengineandapplytheparkingbrakebeforeyouremoveresidues.

Duringthedailyworkyoumustconsiderthatloosestones

andforeignmatteronthegroundmightgetincontactwith

therevolvingpartsandgetthrownoutagainatavery

highspeed.Therefore,beforeyouoperatetheimplement

makesurethatallsafetyguardsareintact,properlytted

W0304A

W1101A

andsecured.

Beforeyouraiseorlowertheimplementwiththelinkarms

ofthetractor,checkthatnobodyisneartheimplementor

touchestheimplement.

Alwaysoperatetheimplementatasafespeedinaccordancewiththegroundconditions.Onunevenground,

proceedwiththeutmostcautiontoensureproperstability.

NOTE:Onlyputtheimplementintooperationaccording

totheinstructionsfromthedealer.

Neveroperatetheimplementundertheinuenceofalcohol,drugs,orwhileotherwiseimpaired.

Avoidusingtheimplementinunsuitableeldandweather

conditions.Itisbettertostopworktemporarilyratherthan

tooperateinsuchconditions.

Keeppeopleawayfromtheimplementduringoperation.

Askbystanderstoleavetheeld.Thereistheriskfor

bystanderstobeoverrunbytheimplement.Stoptheimplementimmediatelyifsomeoneapproaches.

Thetractororitsimplementmaystrikeorcrushagainsta

personorpetwithintheoperatorareaofthetractor.DO

NOTallowanyonetoentertheworkarea.Makesurethat

theareaisclearandoperationissafebeforeyoumove

theimplement.

Whenyouoperatetheimplement,alwaysremainseated

inthetractorcab.Operatecontrolsonlywhenseatedin

thetractorseat,exceptforthosecontrolsexpresslyintendedforusefromotherlocations.

Whenyouturnonhillsidesalwaysbecarefulwhenyoulift

theimplementwiththe3-pointlinkagebecausethereisa

riskofoverturning.Adjustthespeedtotheseconditions.

Driveinalowtractorgearifyouworkonhillsides.

Whenyoudriveupanddownandacrosshillsides,avoid

sharpturns.

Whenyouturnduringoperation,payattentiontotheoverhangand/oroscillatingweightoftheimplement.

Avoidchangingdirectionabruptly,especiallywhenyou

reverse,toavoiddangerouspitchingoftheimplement.

Whenyouworkwiththeimplementkeepasafedistance

fromsteepslopesandsimilargroundconditions,asthe

groundmaybeslipperyandpulltheimplementandthe

tractorsideways.Alsoremembertoadjustthespeedfor

sharpturnswhenyoudriveonhillsides.

Paythenecessaryattentionwhileyouoperatenextto

publicroadsorfootpaths.

Whileinoperation,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

2-8

Stoppingtheimplementsafely

WARNING

Movingparts!

Somecomponentsmaycontinuetorunafter

disengagingthedrivesystems.Makesure

alldrivesystemsarefullydisengagedandall

movementhasstoppedbeforeservicingthe

machine.

Failuretocomplycouldresultindeathorseriousinjury.

2-SAFETYINFORMATION

thetractorcab,thenthefollowingprecautionsmustbe

followed:

•

•

•

•

Whenyouparktheimplementtherearesomeoperational

W0002A

riskswhichmaycausepersonalinjury.Therefore,you

must:

Bringthetractorenginetolowidlespeed.

Disengagealldrivesystems.

Shiftthetractortransmissionintoneutral.

Applytheparkingbrake.

Alwaysinterrupttheoperationoftheimplementbefore

youleavethetractorseat.

Forsafety'ssakeneverleavethetractorcabwithoutrst

todisengagethePowerTake-Off(PTO)shaftmechanism

andtostopthetractorengine.Furthermore,ifyouleave

thetractorunattended,alwaysremovetheignitionkey.

StopthetractorengineandthePTOshaftandwaituntil

theimplementhascompletelystoppedbeforeyouopen

anyofthesafetyguards.Therearerotatingpartsunderthesafetyguardswhichmaycontinuerotatingafter

theimplementhasbeenstopped.Lookandlistenforevidenceofrotatingpartsbeforeyouopenanyofthesafety

guards.

Makesuretosecurethetractorbymeansofthehand

brakeand/orstopblocksifyouneedtostandbetween

thetractorandtheimplement.

When,duetoexceptionalcircumstances,youwould

decidetokeepthetractorenginerunningafterleaving

Makesurethatthegroundisrmandevenduringpark-

•

ing.

Makesurethattractorandimplementcannotmove.

•

Alwayslowertheimplementtotheground.

•

Stopthetractorengineandremovetheignitionkey.

•

Usecorrectsupportortransportsafetydevicewhenthe

•

implementisparked.Makesurethattheparkingstand

issecured.

Whenyoudetachtheimplementfromthetractor:

Alwaysdetachtheimplementcarefullyandonaat

•

surfacetopreventdamage.

Makesurethatnobodystandsinfrontoftheimplement.

•

Neverallowanyonetostandbetweenthetractorand

•

theimplement.

Nevergounderanunsupportedimplement.

•

2-9

2-SAFETYINFORMATION

Maintenance

WARNING

Maintenancehazard!

Beforeyoustartservicingthemachine,attach

aDONOTOPERATEwarningtagtothemachineinavisiblearea.

Failuretocomplycouldresultindeathorseriousinjury.

Followthemaintenanceschedulewithregardtotheim-

•

plementservicingintervals.

Rememberthattheimplementrequiresattentionfrom

timetotime.Alsorememberthatthemaintenancewill

greatlyextendthelifeoftheimplement.

Takethenecessaryprecautions:nottospillanyoil,fuel

•

orgrease.

Toavoidoilandgreasecontactwithyourskin,wear

protectivegloves.

Servicetheimplementonarmlevelsurface.

•

Donotattempttoremovematerialfromanypartof

•

theimplement,clean,lubricateorcarryoutanyadjust-

mentsontheimplementwhileitisinuse.

Keephands,feetand/orgarmentsawayfromparts

•

whichmove.Checkthatallrotatingpartshavea

suitableprotectiveguard.

Raisedimplementand/orloadscanfallunexpectedly

•

andcrushpersonsunderneath.Neverenterorallow

anyonetoentertheareaunderneathraisedimplement

duringoperation.

Unsupportedhydrauliccylinderscanlosepressure

anddroptheimplementandcauseacrushinghazard.

Donotleavetheimplementinaraisedpositionwhile

parkedorduringservice,unlesssecurelyblockedon

woodenblocks.

Neverworkunderaraisedimplementunlessasupport

•

chainorothermechanicalsecuringdevicesecurethe

linkarmsofthetractorsothattheimplementcannot

movetoalowerpositionunintentionally.

Relievethepressure,stoptheengineandremovethe

•

ignitionkey,beforeyouconnectordisconnectuid

lines.

Beforeyouadjust,clean,lubricateoryoucarryoutre-

•

pairsontheimplement,stoptheengineandremove

W0004A

theignitionkey.

NeveradjusttheimplementwhilethePowerTake-Off

•

(PTO)driveshaftisengaged.Donottoremovethe

guardsuntilallrevolvingpartshavestopped.

Anyleakageofhydraulicoilorfuelunderpressuremay

•

causesevereharm,soalwaysuseashielding,goggles

andgloveswhenyoutraceoilorfuelleaks.

Donotuseyourhandtocheckforleaks.Useapiece

ofcardboardorpaper.

Continuouslongtermcontactwithhydraulicuidmay

•

causeskincancer.Avoidlongtermcontactandwash

theskinpromptlywithsoapandwater.

Ifhydraulicuidordieselpenetratestheskin,seek

•

medicalcareimmediately.

Observeallrecommendationsthatarementionedin

•

thismanualsuchasserviceintervals,torques,lubri-

cants,etcetera.

Alwaysreplaceallpartsthathavedamageorwear.

•

Neverbuildexiblehoseassembliesfromhosesthat

•

werepreviouslypartofahoseassembly.

Neverweldtothetubes.

•

Alwaysusegloveswhenyouworkwithpartsonthe

•

implementasthepartscanhavesharpedges.

Transmissionandhydrauliclinesmaybecomehotdur-

•

ingoperation.Becarefulwhenyouservicesuchcom-

ponents.Allowsurfacestocoolbeforeyouhandleor

disconnecthotcomponents.Wearprotectiveequipmentwhenrequired.

2-10

2-SAFETYINFORMATION

PersonalProtectiveEquipment(PPE)

WearPersonalProtectiveEquipment(PPE)suchasprotectiveclothing,eyeprotection,hearingprotection,dust

mask,hardhat,heavygloves,workboots,and/orany

otherPPEthatprovidesforthesafetyandprotectionof

theindividualthatoperatesthisequipment.

NHIL13RB00001AA1

2-11

2-SAFETYINFORMATION

Safetyrequirementsforuidpowersystemsandcomponentshydraulicsystems

Beforeyoustarttheengineorpressurizethehydraulic

system,installandtightcorrectlyallthehydrauliccouplings.Checkthatallhosesandttingsarenotdamaged.

Replaceimmediatelydamagedcomponents.

Onlyconnectthehydraulichosestothetractoroutletsif

thetractorandtheimplementarepressure-free.Ifthe

hydraulicsofthetractorisactivateditmayleadtouncontrolledmovementswhichmaycausedamage.

Makesurethatnopersonsareneartheimplementwhen

youstarttheimplement,astheremightbeairinthehydraulicsystemwhichmightleadtosuddenmovements.

Whenthetractorenginehasstopped,activatethetractor

hydraulicspoolvalvestomakesurethatthereisnopressureinthehydraulichoses.

Toexpelalltheairfromtheoilinthehydrauliccylinders,

testallthefunctionsafteryouconnectthehydraulicconnectionstothetractor,especiallybeforeyouenterordrive

onthepublicroads.

2-12

2-SAFETYINFORMATION

Noiseemission

ThemeasuringandreportingofthenoiselevelwerecarriedoutaccordingtoISO5131.

Thenoiselevelproducedbytheimplementisbelow

70dB.

Thenoiselevelwasmeasuredinthecabinofthetractor

wheretheheadoftheoperatorisusuallysituated.

Usehearingprotectorsifthenoisefromtheimplementis

annoyingorifyouworkwiththeimplementforaconsiderableperiodinatractorcabinthathasnotaadequate

soundproofcabin.

Vibrationlevels

Installallrevolvingpartscorrectlybeforeyoustarttheimplement.Anunbalancecancreatevibrationsthatdamage

theimplement.

NOTE:Youmustcheckthattheallpartareinthecorrect

positionbeforestarttheimplement.

NOTE:Ifthevibrationsorthenoiseoftheimplementincreaseconsiderablyduringtheoperation,stopthework

immediately.Correctthefaultbeforeyoucontinuethe

work.

2-13

2-SAFETYINFORMATION

Implementstability

Thecombinationofyourtractorandimplementcanbecomeunstable,duetotheadditionalweightthattheimplement

addstothetractor.

Inordertoguaranteestableandsafetransport,youmustcheckifyouneedballastweightsfortransportandeld

work.

Youmustalsocheckandguaranteethatyouhaveatleast20%fromthetractorweightonthefrontaxle.

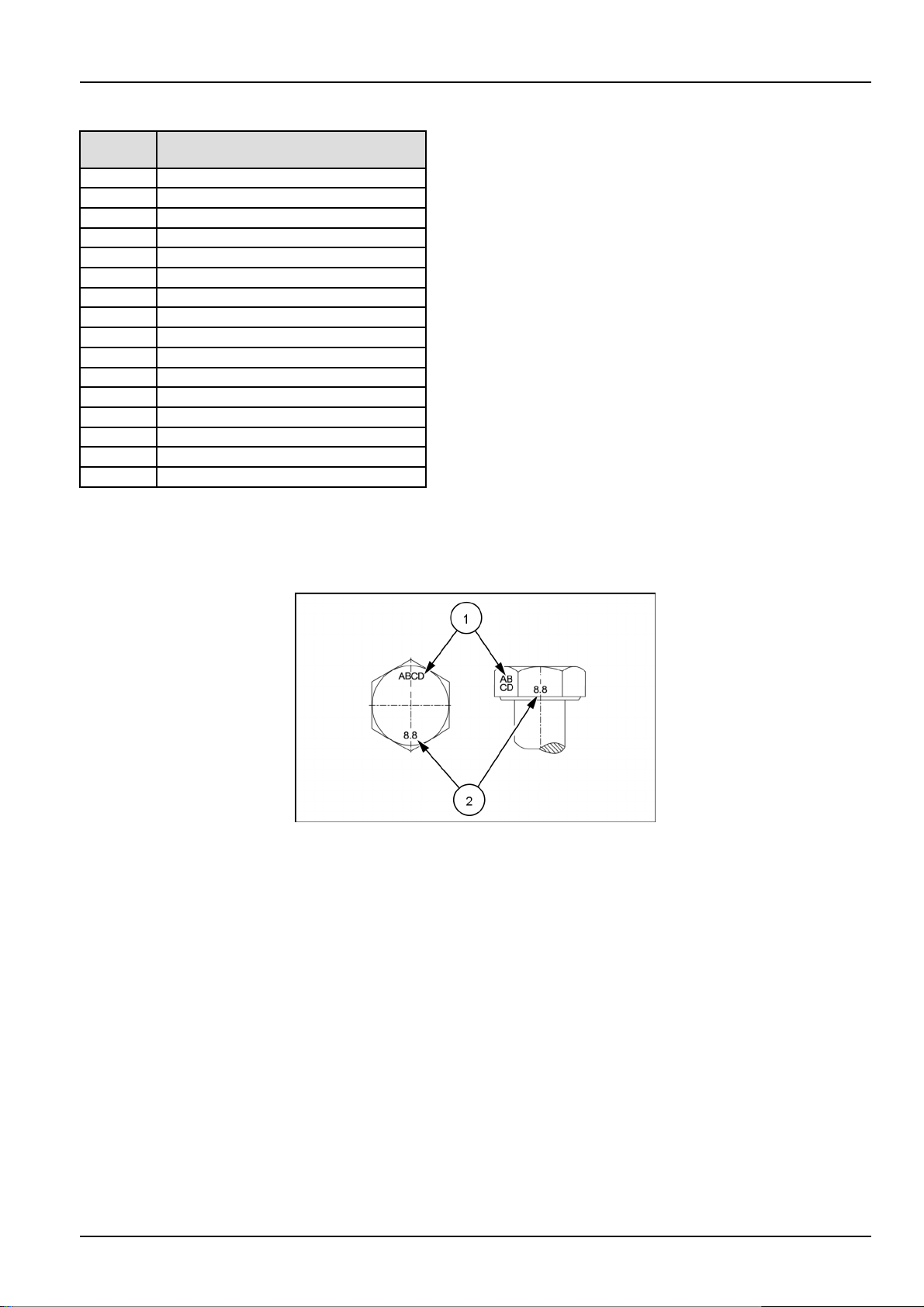

Forrearmountedimplementsandfront-rearcombinations,theformulais:

ZEIL18HT00277FA1

Exampleofreferencestostabilityofthecombinationtractor–implement

Listofsigns

Te[kg]Thetractorownweight.

Tf[kg]

Tr[kg]Rearaxleloadwithemptytractor.

Ir[kg]

If[kg]Totalweightofthefront-mountedimplement/frontballast.

a[m]

b[m]Thetractorwheeldistance.

c[m]

d[m]

Frontaxleloadwithemptytractor.

Totalweightoftherear-mountedimplement/rearballast.

Distancebetweenthecenterofgravityofthefront-mountedimplement/frontballastandthe

middleofthefrontaxle.

Distancebetweenthemiddleoftherearaxleandthemiddleofthelinkarmballs.

Distancebetweenthemiddleofthelinkarmballsandthecenterofgravityoftherearmounted

implement/rearballast.

2-14

Ecologyandtheenvironment

2-SAFETYINFORMATION

Soil,air,andwaterqualityisimportantforallindustries

andlifeingeneral.Whenlegislationdoesnotyetrulethe

treatmentofsomeofthesubstancesthatadvancedtechnologyrequires,soundjudgmentshouldgoverntheuse

anddisposalofproductsofachemicalandpetrochemical

nature.

Familiarizeyourselfwiththerelativelegislationapplicabletoyourcountry,andmakesurethatyouunderstand

thislegislation.Wherenolegislationexists,obtaininformationfromsuppliersofoils,lters,batteries,fuels,

anti-freeze,cleaningagents,etc.,withregardtotheeffectofthesesubstancesonmanandnatureandhowto

safelystore,use,anddisposeofthesesubstances.Your

KONGSKILDEdealercanalsoprovideassistance.

Helpfulhints

Avoidtheuseofcansorotherinappropriatepressur-

•

izedfueldeliverysystemstolltanks.Suchdelivery

systemsmaycauseconsiderablespillage.

Ingeneral,avoidskincontactwithallfuels,oils,acids,

•

solvents,etc.Mostoftheseproductscontainsub-

stancesthatmaybeharmfultoyourhealth.

Modernoilscontainadditives.Donotburncontami-

•

natedfuelsandorwasteoilsinordinaryheatingsys-

tems.

Avoidspillagewhenyoudrainuidssuchasuseden-

•

ginecoolantmixtures,engineoil,hydraulicuid,brake

uid,etc.Donotmixdrainedbrakeuidsorfuelswith

lubricants.Storealldraineduidssafelyuntilyoucan

disposeoftheuidsinaproperwaythatcomplieswith

alllocallegislationandavailableresources.

Donotallowcoolantmixturestogetintothesoil.Col-

•

lectanddisposeofcoolantmixturesproperly.

Donotopentheair-conditioningsystemyourself.It

•

containsgasesthatshouldnotbereleasedintotheat-

mosphere.YourKONGSKILDEdealerorair-conditioningspecialisthasaspecialextractorforthispurpose

andcanrechargethesystemproperly.

Repairanyleaksordefectsintheenginecoolingsys-

•

temorhydraulicsystemimmediately.

Donotincreasethepressureinapressurizedcircuitas

•

thismayleadtoacomponentfailure.

Batteryrecycling

Batteriesandelectricaccumulatorscontainseveral

substancesthatcanhaveaharmfuleffectontheenvironmentifthebatteriesarenotproperlyrecycledafter

use.Improperdisposalofbatteriescancontaminate

thesoil,groundwater,andwaterways.KONGSKILDE

stronglyrecommendsthatyoureturnallusedbatteries

toaKONGSKILDEdealer,whowilldisposeoftheused

batteriesorrecycletheusedbatteriesproperly.Insome

countries,thisisalegalrequirement.

NHIL14GEN0038AA1

Mandatorybatteryrecycling

NOTE:Thefollowingrequirementsaremandatoryin

Brazil.

Batteriesaremadeofleadplatesandasulfuricacidsolution.Becausebatteriescontainheavymetalssuchas

lead,CONAMAResolution401/2008requiresyoutoreturnallusedbatteriestothebatterydealerwhenyoureplaceanybatteries.Donotdisposeofbatteriesinyour

householdgarbage.

Pointsofsaleareobligedto:

Acceptthereturnofyourusedbatteries

•

Storethereturnedbatteriesinasuitablelocation

•

Sendthereturnedbatteriestothebatterymanufacturer

•

forrecycling

2-15

2-SAFETYINFORMATION

Safetysigns

Thefollowingsafetysignsareonyourimplementasa

guideforyoursafetyandforthesafetyofthosewhowork

withyou.

Walkaroundyourimplementandnotethesignicance

andlocationofallsafetysignsbeforeyouoperateyour

implement.Readallthesafetysignsadheredtotheimplementandfollowtheinstructions.

Keepallsafetysignscleanandlegible.Cleansafetysigns

withasoftcloth,water,andagentledetergent.

NOTICE:Donotusesolvent,gasoline,orotherharsh

chemicals.Solvents,gasoline,andotherharshchemicalsmaydamageorremovethesafetysigns.

Replaceallsafetysignsthataredamaged,missing,

paintedover,orillegible.Ifasafetysignisonapartthat

youoryourdealerreplaces,makesurethatyouoryour

dealerinstallthesafetysignonthenewpart.Contact

yourdealerforthereplacementofthesafetysigns.

Safetysignsthatdisplaythe“Readoperator’smanual”

symboldirectyoutotheoperator’smanualforfurtherinformationregardingmaintenance,adjustments,orproceduresforparticularareasoftheimplement.Whenasafety

signdisplaysthissymbol,consulttheappropriatepageof

theoperator’smanual.

Safetysignsthatdisplaythe“Readservicemanual”symboldirectyoutotheservicemanual.Ifyoudoubtyour

abilitytoperformserviceoperations,contactyourdealer.

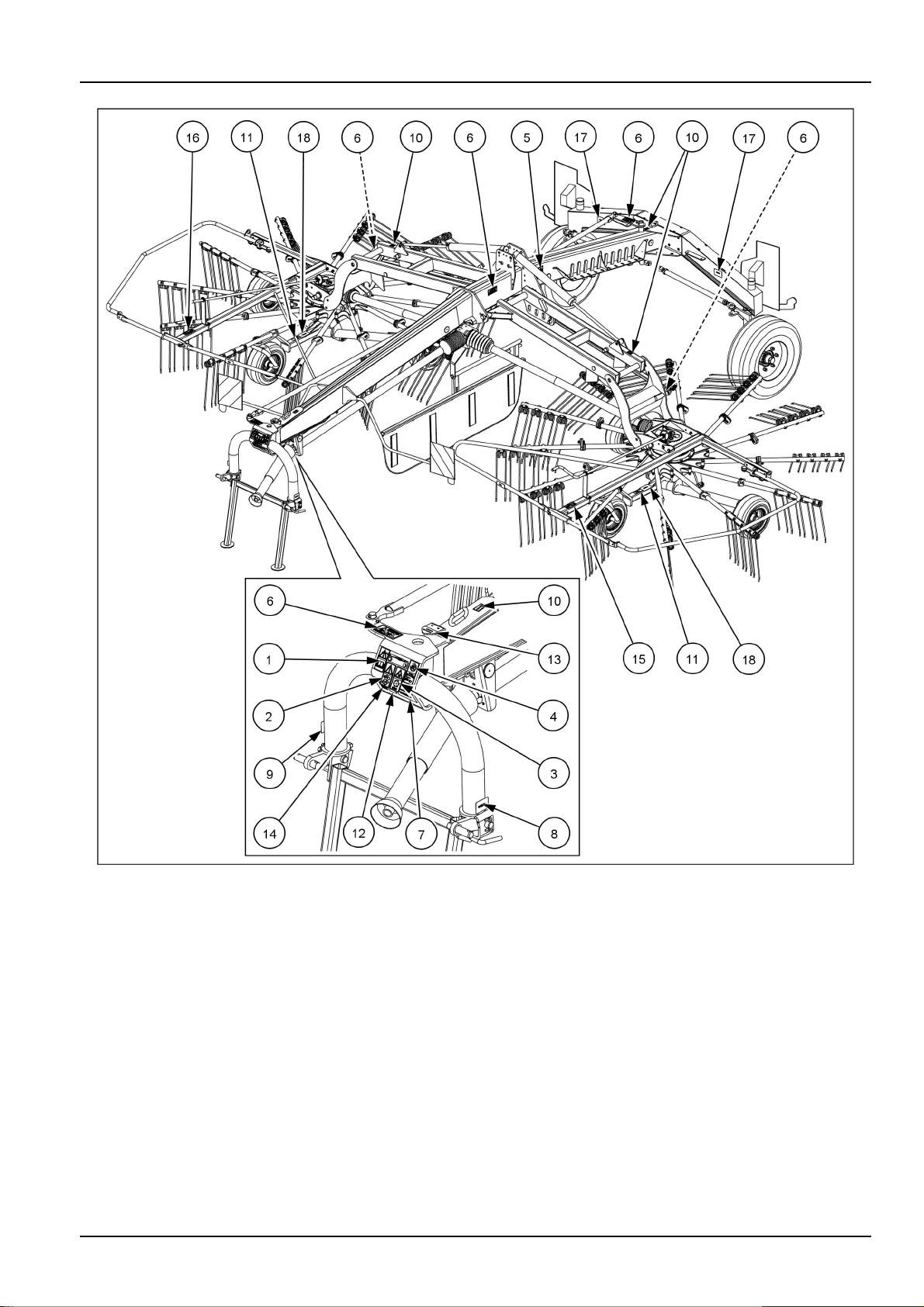

NOTE:ThefollowinggureindicatesthesafetysignslocalizationforR+760.ThesafetysignslocalizationforR+

820issimilar.

2-16

2-SAFETYINFORMATION

ZEIL18HT00778GA1

2-17

2-SAFETYINFORMATION

Partnumber:811650220

8116502202

PR80-08523

Partnumber:PR80-0852

2-18

2-SAFETYINFORMATION

Safetysign(1)

Readtheoperator'smanualandthesafetyinstructions.

Readtheoperator'smanualtooperatetheimplementand

toavoidunnecessaryaccidentsanddamagestotheimplement.

WARNING

IMPROPEROPERATIONOFTHISMACHINE

CANCAUSEDEATHORSERIOUSINJURY .

MAKESURETHA TEVERYOPERATOR:

-isinstructedinthesafeandproperuseofthis

machine.

-readsandunderstandstheoperator'smanual

forthismachine.

-readsandunderstandsALLsafetysignson

themachine.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:811650220

81PR80-0859_54

W0188A

Safetysign(2)

Alwaysstopthetractorenginebeforeyouadjust,maintain,repair,orlubricatetheimplement.Alsorememberto

removetheignitionkey.Makesurethatnobodystartsthe

engine,untilyouhavenished.

WARNING

IMPROPEROPERATIONOFTHISMACHINE

CANCAUSEDEATHORSERIOUSINJURY .

MAKESURETHA TEVERYOPERATOR:

-isinstructedinthesafeandproperuseofthis

machine.

-readsandunderstandstheoperator'smanual

forthismachine.

-readsandunderstandsALLsafetysignson

themachine.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:811650220

W0188A

81PR80-0859_25

2-19

2-SAFETYINFORMATION

Safetysign(3)

Movingpartsaredangerousandifthemovingpartscome

incontacttoyourbodythemovingpartscanpinchyour

body.

Thehazardmaycausesevereinjuriestotheentirebody,

withpossiblelethaleffect.

Toavoidthehazards,waituntilallmovingelements

havecompletelystoppedbeforeyoutouchthemoving

elements.

WARNING

Pinchhazard!

Waitforallmovementtostopbeforeyouserviceoradjustthemachineorequipment.

Failuretocomplycouldresultindeathorseriousinjury.

W1420A

Partofpartnumber:811650220

Safetysign(4)

ThesignindicatesthemaximumRevolutionsPerMinute

(RPM)(540RPM)andthedirectionofrotationofthe

PowerT ake-Off(PTO)shaft.

Referencetotheminimumoverlappingontheprole

tubesandtheminimumdistancerequirednottobottom

theshaft.

81PR80-0859_16

Partofpartnumber:811650220

Safetysign(5)

Keepasafedistancefromtherotatingpartsoftheimplement.

Neverstandintheswivelandfoldingareaoftherotors.

Checkthewearofthesafetypins.Replaceimmediately

thesafetypinsifthethicknessislessthan7mm(0.28in).

Partofpartnumber:PR80-0852

81PR80-0859_47

PR80-0852_058

2-20

2-SAFETYINFORMATION

Safetysign(6)

Nevermoveyourhandintothedangerzoneaslongas

thepartscanmove.Thismaycauseseriousinjuryand,

atworst,resultindeath.

Partofpartnumber:PR80-0852

Safetysign(7)

Torqueallscrewsevery5hofoperation.

Partofpartnumber:PR80-0852

PR80-0852_069

Safetysign(8)

Adjustmentoftheleft-handsideliftingheight.

Partofpartnumber:PR80-0852

Safetysign(9)

Adjustmentoftheright-handsideliftingheight.

Partofpartnumber:PR80-0852

PR80-0852_0710

PR80-0852_0811

PR80-0852_0912

2-21

Safetysign(10)

Liftingpointsafetysign.

WARNING

Crushinghazard!

Usethemachineliftingpointswhenyoulift

and/ormovethemachinewithheavyhandling

equipment.Liftthemachineonlyfromtheindicatedliftingeyehookuppoints.Alwaysuse

adequateliftingequipment.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:PR80-0852

Safetysign(11)

Referencelubricationofcamtrack.

Partofpartnumber:PR80-0852

2-SAFETYINFORMATION

W1432B

PR80-0852_1013

Safetysign(12)

Thehydraulicpressuremustbemaximum210bar

(3045psi).

Partofpartnumber:PR80-0852

Safetysign(13)

Turninganglesafetysign.

Partofpartnumber:PR80-0852

PR80-0852_1114

PR80-0852_1215

PR80-0852_1316

2-22

Safetysign(14)

Adjustmentofnumberofrevolutions.

Partofpartnumber:PR80-0852

Safetysign(15)

Adjustmentoftheleft-handsideworkingheight.

Partofpartnumber:PR80-0852

2-SAFETYINFORMATION

PR80-0852_1417

Safetysign(16)

Adjustmentoftheright-handsideworkingheight.

Partofpartnumber:PR80-0852

Safetysign(17)

Tirepressuresafetysign.

Partofpartnumber:PR80-0852

PR80-0852_1518

PR80-0852_1619

PR80-0852_1720

2-23

Safetysign(18)

Camtrackmodicationsafetysign.

Partofpartnumber:PR80-0852

2-SAFETYINFORMATION

PR80-0852_1821

2-24

3-CONTROLSANDINSTRUMENTS

3-CONTROLSANDINSTRUMENTS###_3_###

Information

Operatingprinciples

Forallinformationrelatedtothedescriptionandthelocationofthecontrolstouseyourimplement,seechap-

ter“ControlsandInstruments”intheoperator’smanual

ofyourvehicle.

3-1

3-CONTROLSANDINSTRUMENTS

3-2

4-OPERATINGINSTRUCTIONS

4-OPERATINGINSTRUCTIONS###_4_###

Commissioningtheunit

Preparingforoperation

NOTICE:Onlyauthorizedandinformedpersonnelcan

mounttheimplement.

NOTICE:Thenecessarytoolsandadjustmenttoolsmust

beavailable.

NOTICE:Incorrectassemblyoftheimplementishighly

dangerous.Beforeyouperformthefunctionaltest,check

thecorrectassemblyoftheimplement.

NOTICE:Makesurethattherearenotoolsinthearea

aroundtheimplement.

Makesurethattherearenopersonsintheworkzone.

NOTE:Aftertheassemblyoftheimplement,performa

completefunctionaltest.

NOTE:Torqueallscrewjointsevery5hofoperation.

Theimplementisdisassembledintopartsanddelivered

onapallet.Forshipmentonabigpalletthewheelaxle

assemblyandsomearmsaredismounted.

Loosepartssuchasabagwithsmallparts(screws)and

thePowerTake-Off(PTO)shafthavebeentiedtothepalletortheimplementtosavespace.

4-1

4-OPERATINGINSTRUCTIONS

Installationofwheels

NOTICE:Onlypersonnelwithsufcientknowledgecan

performthemountofthewheels.Mountingofwheels

requirestheuseofthecorrectmountingtools.

NOTICE:Whenyouperformthemaintenancetothe

wheels,youmustsecuretheimplementsothatthe

implementcannotmove.

Whenyouunloadtheimplement,replacethetransport

wheelsofsteelwiththeroadtireequipment.Youcan

mountthewheelsonwidetrackoronnarrowtrack,dependonwhichdirectionthecrankoftherimispointing.

Inbothcasestheouterwidthoftherakestaysunder3m

(118in).Whenyouworkonhillygroundisrecommend

tousethewidetracktoincreasethestabilityoftheimplement.

Thetorqueforthenutsofthewheelsis300N·m

(2655.2lbin).Checkandtorqueagainthenutsofthe

wheelsevery5hofoperation.

4-2

4-OPERATINGINSTRUCTIONS

Installationofswathcanvas

NOTE:Thedeliveryoftheswathcanvasisonapalletas

anassemblywiththeholder(2),theholder(4),andthe

controlrod(5).

1.Inserttheholder(2)underthegear.

2.Installtheholder(2)withthehardware(3).

3.Inserttheholder(4)ontheangeplate.Thespacers

(1)areplacedintheinnermostoblongholesforthe

spindles.

4.Installtheholder(4)withthehardware(6).

5.Placethecontrolrod(5)attheboom.

6.Installthecontrolrod(5)withthewasherandthetight-

eningpin.

NOTICE:Thehardware(4)andthehardware(6)areon

thescrewsbag.

ZEIL18HT00206FA1

4-3

4-OPERATINGINSTRUCTIONS

Installationofrotors

R+760

NOTICE:Forthetransportbylorrytherotorsareseparatedfromtheboom(5)atthecardinalsh-plates(1).The

steeringsh-plates(3),andthesteeringsh-plate(4)are

alsoseparatedfromtherotorandremainattheboom.

1.Installthesteeringsh-plate(3)(uppermostwithcam)

tothepinontheboomwhichisfurtheroutthanthe

oneforsteeringsh-plate(4).

2.Installthecardinalsh-plate(1)ontheboom.Install

thecardinalsh-platewiththefourscrewsM20x45,

thefourself-lockingnutsM20,andthefourbolts(6).

NOTE:Thetwocardinalsh-plates(1)areplacedonthe

insideoftheboom.

NOTE:Installthesh-platewiththeshortestslotatthe

frontinthedirectionoftravel.

NOTE:Theboltheads(6)mustpointinwards.

ZEIL18HT00207AA1

3.Installthesteeringsh-plate(3)andthesteeringsh-

plate(4)ontherotor.Installthesteeringsh-plate(3)

andthesteeringsh-plate(4)withthetwowashers

31x4,thetighteningpin5x50,andthetighteningpin

(5)8x50.

R+820

NOTE:Duringthetransportwithlorry,therotorsareseparatedfromtheboom(5)atthecardinalsh-plates(4).

Therotorsareseparatedfromthesteeringsh-plate(1),

andthesteeringsh-plate(6)thatremainattheboom(6).

1.Installthesteeringsh-plate(1)(uppermostwithcam)

tothepinontheboomwhichisfurtheroutthanthe

oneforsteeringsh-plate(6).

2.Installthecardinalsh-plate(4)ontheboom.Fixthe

cardinalsh-platewiththefourscrewsM20x45,the

fourself-lockingnutsM20,andthefourbolts(3).

NOTE:Thetwocardinalsh-plates(1)areplacedonthe

insideoftheboom(6).

NOTE:Installthesh-platewiththeshortestslotatthe

frontinthedirectionoftravel.

NOTE:Theboltheads(3)mustpointinwards.

ZEIL18HT00208AA2

3.Installthesteeringsh-plate(1)andsteeringsh-plate

(6)ontherotor.Installthesteeringsh-plate(1)and

steeringsh-plate(6)withthetwowashers31x4,the

tighteningpin5x50,andthetighteningpin(2)8x50.

4-4

4-OPERATINGINSTRUCTIONS

Installationofsafetyguard

Thesafetyguards(2)aresuppliedonapalletdismounted

fromtherotorheadascompleteunit.Thesafetyguards

(2)arefastenedtotherotorheadwithfourscrews(3)

each.

Thesafetyguard(2)shouldbeeasytoswivelbetween

thewashersinposition(1).

Partsperrotor

Screw

Nut

Washer

Partsperrotor

Screw

Washer

NutM123

NOTE:Duringtheinstallation,becarefultoplacecorrectly

thefoldablepartofthesafetyguards(2).Itmustbepos-

sibletofoldupthesafetyguards(2).

NOTE:Donotactivatethehydraulicallyfoldableframes

whentherearepersonsintheswivelarea.

Position(3)Quantity

M12x404

M12selflocking

Ø13x2.5

Position(1)Quantity

M12x601

Ø13x2.5

4

8

4

ZEIL18HT00777FA1

4-5

4-OPERATINGINSTRUCTIONS

Installationofhydrauliclock(optionalequipment)

FortherotaryrakesR+760andR+820ahydrauliclockingdeviceisavailableasoptionalequipmentforthelefthandsiderotor.Thelockingdevicemakepossibletowork

withonlyonerotor,forinstancealongtheeldboundary.

Theotherrotorremainslockedintheheadlandposition.

Inthissettinganhydraulicmagnetvalveblockthehydraulichosefortheliftingcylinder.Thevalveisopenwhen

thereisnocurrentonthevalveanddoesnotcloseuntil

thereisavoltage.

Fortheuseofthisequipmentthetractormustbeequipped

witha12Vsocket.Youcanusethisequipmentthrough

anadaptorforthecigarettelighter.

Anoperationunit,installedinthecabinofthetractor,

controlthevalve.Raisethetworotorstoheadlandposition.Inheadlandposition,inthedirectionoftravel,

theleft-handsiderotorislocked.Nowyoucanlowthe

right-handsiderotortoworkingposition.

NOTICE:Neverusethehydrauliclocktoblocktherotor

inheadlandpositiontomakethemaintenanceontheimplement.Ifthecurrentsupplyisunexpectedlycutoff,the

rotormaysuddenlyfolddown.Alsowhentheballvalveis

closedtheremaybeabalancingbetweentheliftingcylindersandtheblockedrotormayfolddownwhenthevalve

isopen.

NOTE:Thefactorydonotinstalltheoptionalequipment

"hydrauliclock”.Thedealerortheuserafterthedelivery

ofathenewimplement,mustinstallthehydrauliclock.

4-6

4-OPERATINGINSTRUCTIONS

1.RemovethehydraulichoselocatedontheT-pieceundertheframetotheleft-handsideliftingcylinder.

2.Separateintwopartsthestripslocatedonthelifting

cylinder.

3.Usethetwoscrews(2)M6x65,thewashers,andthe

nutsM6tofastenthevalve(1)totheframe.

NOTE:Thescrewsaresuppliedtogetherwiththe

equipment,theoblongholesareintheframeas

standard.

4.Installthescrew-jointsintothevalve.

5.Installthehose750mm(30in)(3)ontheT-pieceun-

dertheframeandthevalve.

6.Installthehose1100mm(43in)(4)betweenthevalve

andtheconnectionliftingcylinder.

7.Fastenthehose(4)totheliftingcylinderwithstrip.

Placethestrip120mm(5in)awayfromthepiston

headtoobtainasafehoseplacement.

8.Placethecableforcontrolboxundertheframealong

thehydraulichose.Placeandfastenthepluginthe

valve.

9.Fastentheholderforcontrolboxataneasilyaccessibleplaceinthetractorandontheimplement.

ZEIL18HT00210AA1

10.Aftermounting,carefullyraiseandlowerthehose

placementforcheckfunctionality.Thehosefromthe

liftingcylindertothevalveshouldnotgetcaughtor

squeezedanywhere.Thehosemustbeasshown

onthepicture.

ZEIL18HT00211AA2

4-7

4-OPERATINGINSTRUCTIONS

Installationofextrawheelsonrotorchassis(optionalequipment)

Insoftorweteldsitmaybenecessarytorelievethe

wheelsontherotorchassis.Youcandothiswhitthe

installationoftheextrawheels(1).Theextrawheels(1)

aresuppliedasoptionalequipment.Theextrawheels(1)

arespring-loadedandarticulated.

1.Installtheholder(2)ontheextendedbolt(3)which

replacestheexistingone.

2.Placethebushings(4)intheleft-handsideandright-

handsidewiththetighteningpins.

3.Installthetworods(5).

4.Tightenthesprings(6).

ZEIL18HT00212AA1

NOTICE:Thesafetydecals(7)showthetopossibledan-

gerinconnectionwithmounting,adjustmentandmaintenance.

ZEIL18HT00213FA2

4-8

4-OPERATINGINSTRUCTIONS

Adjustmentofworkingwidth

TherotaryrakesR+760andR+820canbesettothree

differentworkingwidths.Youcandothisadjustmentonly

whentheimplementisintransportposition.

NOTE:Closethestopcockofthehydraulichoseduring

theadjustment.

NOTE:Engagethelockingpawls.

1.Removethesplitpinandthediscontherod(1).

2.Placetherod(1)inthedesiredoblonghole.

3.Installthesplitpinandthedisc.

Thefollowingworkingwidthscanbepreset.

R+760

Outermost:7.6m(299.2in)

•

Middle:7.2m(283.5in)

•

Innermost:6.8m(267.7in)

•

ZEIL18HT00223AA1

R+820

Outermost:8.2m(322.8in)

•

Middle:7.8m(307.1in)

•

Innermost:7.4m(291.3in)

•

NOTE:Asymmetricadjustmentoftheworkingwidthsat

theleft-handsideandright-handsiderotorisalsoallowed.

NOTE:Thetransportheightisindependentoftheworking

width.

Alfalfapositionadjustment

Theimplementhaveafourthpositionforadjustment

oftheworkingwidth.Tomaketheadjustmentofthe

workingwidth,removeswathcanvas(1).Therotorsare

socloseinworkingpositionthatthereisnoroomforthe

safetyguard.Thispositionisintendedforcropswhich

areintertwinedinthestubblesandyoumustliftonce

fromthegroundinthewholeworkingwidth(forexample

alfalfagrass,alfalfaetc.)

1.Completelydisassembletheswathcanvas(1),the

holderatgear(2),andtheholder(3)atframeange

withspacer.

2.Removetherod(4).

Inthispositionitispossibletoobtainthefollowing

workingwidths.

R+760:6.45m(253.94in)

•

R+820:7m(276in)

•

ZEIL18HT00224AA2

NOTE:Dependingonthecropitmaybeanadvantageto

adjustthecropdeliveryonthecamtrackto"later"(see

Page6-5).

4-9

Startingtheunit

Connectiontothetractor

WARNING

Crushinghazard!

Usecarewhenyouconnectanddisconnect

themachines.Neverstandbetweenthetractorandtheimplementwhenyouconnectthe

linkarms.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Crushinghazard!

Donotstandorplaceanybodypartbetween

theimplementandamovingtractor.Stopthe

tractorengineandsettheparkingbrakebeforeyouattachcablesandhoses.

Failuretocomplycouldresultindeathorseriousinjury.

4-OPERATINGINSTRUCTIONS

W1545A

W1544A

WARNING

Hitchinghazard!

Alwayskeeptheareabetweenthetractorand

theimplementclearofallpersonswhilethe

tractororthree-pointhitchisinmotion.Lock

thetractortransmissioninParkandengage

theparkingbrake(s)beforeyouallowanyone

tocompletehitchingorunhitching.

Failuretocomplycouldresultindeathorseriousinjury.

W1540A

4-10

4-OPERATINGINSTRUCTIONS

Threepointsuspensiononthetractor

TherakesR+760andR+820areequippedwithhitch

pinscategoryII.Dependingontheequipmentofthetractor,ballscanbeinstalled.

Thesidewaysmovementofthebearingarmonthetractor

mustbeminimizedtoavoidoscillationoftheimplement

duringworkandtransport.Youmustsecurethebearing

armwithlimitingchainsorotherlockingdevice.Adjust

thebearingarmofthetractorsothattheyareatthesame

heightabovetheground.

ZEIL18HT00214AA1

ForR+760andR+820thisheightis68cm(27in).There

isalsoasignonthesuspensionregardingthis.

ZEIL18HT00270BA2

4-11

4-OPERATINGINSTRUCTIONS

Placementofcord

NOTICE:Youmustplacetheoperatingparts(cords,

chains,rodsetc.)forremotecontrolequipmentsothat

theoperatingpartsdonotcauseunintendedmovements

intransportandduringthework.

Itshouldbepossibletooperatethecordforthelocking

pawlfromthetractorseat.

Youmustcheckthatthecorddonotgetjammedandis

notplacedonsharpedges.

Relievethecordwhenthepawlsarelowered.

Hydraulicsystem(throttling)

Theliftingcylindersoftheimplementareequippedwith

throttlepieces.Donotmakeanyadjustmentsonthetractor.

Electricsystem

Thelightingsystemisequippedwitha7-poleplugforthe

trailersocket.Forthehydrauliclock(optionalequipment)

youneedalsoa12Vsocket.

Connectionoftheimplementtothetractor

NOTICE:Neverstandbetweenthetractorandtheimplementduringconnectiontothetractor.

NOTICE:Theoperatormustconnecttheelectriccables,

thehydraulichosesandthePowerT ake-Off(PTO)shaft

beforestepintothedangerzone.

NOTICE:Secureagainstunintendedusetheoperating

elementsofthetractorbeforeconnectionanddisconnection.

Theinstructionsarebasedonafullymountedimplement

inlockedtransportposition.

4-12

4-OPERATINGINSTRUCTIONS

Connectiontothebearingarmsofthetractor

NOTICE:Neverstandbetweenthetractorandtheimplementduringconnectiontothetractor.

NOTICE:Makesurethattherearenopersonsinthe

swivelareaofthetinearmsassembly .

Thepinsonthesuspensionoftheimplementareconnectedtothelinkarmsbearingofthetractorandsecured.

NOTICE:SetthePTOshaft,theelectricandhydraulic

connectionsbeforetofoldthesupportsincetheoperator

hastostepintothedangerzone.

1.Raisetheimplementabitsothatthesupportislifted

offtheground.

2.Pulltherod(1)toreleasethesupport.

3.Movethesupportapproximately115°totherearand

lockthesupportagain.Whenthesupportiscorrectly

locked,thetighteningpin(2)oftherodisinfullcontact

withthesideplateofthesupport.

Hydraulicconnection

Fortheconversionfromtransporttoworkingpositionof

therotaryrakesR+760andR+820itisnecessarya

single-actingoutlet.

Makesurethatthereisaoatingpositionsothattheimplementcanfollowthegroundduringoperation.

Thestopvalveontheimplementside(ballvalve)should

beopenedaftertheconnectiontothetractorhydraulics

sothatthecouplingisnotunderpressure.

Whentheimplementisparkedadjustthepressure,for

instanceiftheoutdoortemperaturechanges.

ZEIL18HT00216AA3

4-13

4-OPERATINGINSTRUCTIONS

PowerTake-Off(PTO)shaftconnection

NOTICE:ToinstallandremovethePTOshafttheengine

mustbeOFF .

NOTICE:OnlyusethesuppliedPTOshaftorthePTO

shaftthatthemanufacturerapprove.

DothelengthadjustedofthePTOshafttothetractorbeforetoperformthefollowsteps.Ifyouusetheimplement

withdifferenttractors,checkthatthePTOshafthasthe

correctlength.

NOTICE:Thesafetyguardsonthetractorsideandonthe

implementsidemustbeintact.

1.ReleasethePTOshaftfromthesupportchain.

2.PushthePTOshaftontothetractorPTOshaftuntil

youengagethelockingballs.

3.ThesafetychainsecurethesafetyguardofthePTO

shaftsonthetractorside.Ontheimplement,side

thereisafull-coveringprotection.Theclampsecure

thefull-coveringprotection.

NOTICE:ThechainsecurethesafetyguardofthePTO

shaft.

Functionaltest

Afterthepreparationoftheimplement,youmustdoa

functionaltest.

1.Therotorsmustcanfoldinandout.

2.Checkthattheimplementworkscorrectly.

3.Every50hofoperationallscrewsmustbetorque

again.

4-14

4-OPERATINGINSTRUCTIONS

PowerTake-Off(PTO)shaft–Shorten

PowerTake-Off(PTO)shaftlength

NOTE:DonotshortenyournewPowerTake-Off(PTO)

shaftuntilyouarecertainthatitisnecessary.Fromthe

factorythedistancefromPTOtoPowerInputConnection

(PIC)isstandardonmosttractorbrands.

CheckthelengthofthePTOshaftforeachtractorpriorto

rstuse.

IfitisstillnecessarytoshortenthePTOshaft,theprole

tubesofthePTOshaftmustfullycomplywiththefollowing

overlappingmeasures.

Theslidingtubesmusthaveasmuchoverlapaspossi-

•

ble,withanacceptableminimumoverlap(b)of200mm

(7.87in)duringnormaloperation(TopSafeextension

linksinthenormalposition).

Theremustbeaminimumof40mm(1.6in)offree

•

PTOshaftlength(a)topreventtheshaftfrombottoming

out.

NHIL12HT00307AA1

Determiningtherequiredshaftlength

WhenyoudeterminethatyoumustshortenthePTOshaft,

selectthelengthsothatthetelescopingmembersnever

closecompletelyorbottomoutwheninuse.ThePTO

lengthmustneverbesmallerthantheminimumdistance

betweenthejoints.

1.AttachtheimplementtothetractorwithoutthePTO

shaft.

2.Adjustthethree-pointhitchsothatthePTOshaftis

parallelwiththeground.

3.Stopthetractorandengagetheparkingbrake.

4.DetermineifthePTOshaftbottomoutinthisposition.

IfthePTOshaftbottomsoutinthispositionorifthe

freelengthislessthan40mm(1.6in),proceedwith

theproceduretoshortenthePTOshaft.

4-15

4-OPERATINGINSTRUCTIONS

ShorteningthePTOshaft

ToshortenthePTOshaftproceedasfollows.

1.FastenthePTOshafthalfpartstothePTO(onthe

tractor)andthePIC(ontheimplement).ThePTO

shafthalfpartsmustbeatthesamehorizontallevel,

oppositeeachotherattheshortestdistancefromthe

tractor.

2.Makesurethataminimumoverlapof200mm

(7.87in)exists.

3.CheckthatthePTOshaftdoesnotbottomoutatone

end.Keeptheshaftendsparalleltoeachotherand

marktheminimumdistanceof40mm(1.6in).Only

cutenoughPTOshaftofftoachievethisminimumfree

shaftlength.Thiswillmaintainthemaximumamount

ofPTOshaftoverlap.

4.Shortenallfourtubesequally.

5.Roundofftheendsoftheproletubesandremovethe

burrscarefully.

6.Removethemetalshavings.

ZEIL18HT00013AA2

NOTICE:Toavoidbigfrictionforces,greasethetube

carefullybeforeyoureassemblethetube.UseNLGI2.

NOTE:IfyoushortenthePTOshaft,thenyoumustcheck

theminimumoverlapandtheminimumdistanceagainif

youoperatetheimplementwithadifferenttractor.

4-16

5-TRANSPORTOPERATIONS

5-TRANSPORTOPERATIONS###_5_###

Roadtransport

Travellingonpublicroads

Connectionoflightingequipment

TherakesR+760andR+820areequippedwithlightingaccordingtocurrentrules.Thelightingsystemis

equippedwithasevenpoleplugatthelightingcable.This

plugisconnectedtothelightingsocketonthetractor.

NOTICE:Aftertheconnectioncheckthefunctionofthe

lightingsystem.Dirtandmoisturecancausecontact

problemsorevenshortcircuit.Youmustkeeptheplug

connectioncleananddry .

Installationofwarningpanels

Thefrontandrearwarningpanelsarefoldedinandfastenedfortransportonthelorry.Looseandplaceonthe

holestheupperscrewssothatyoucantightenagain.

NOTICE:Thewarningpanelsarewarningofdangerson

theimplement.Youmustalwaysobservethesafetyreferences.

Keptcleanandinreadableconditionthewarningpanels.

Orderfromyourdealerthedamagedormissingwarning

panels.Positionthenewwarningpanelsonthecorrect

positionontheimplement.

ZEIL18HT00279AA1

5-1

5-TRANSPORTOPERATIONS

Transport

Alwaysusethetransportsafetydeviceandthestop

valvesoftheliftingcylinderduringtransport.

NOTICE:Makesurethatthelockingpawlshavebeen

lockedcorrectlyintransportposition.

NOTICE:Theballvalveofthehydraulichosemustbe

closed.

NOTICE:Transportheightmaximum4m(157in)(see

Page9-1).

Observethecurrenttrafcruleswithregardtolighting

whenyoudriveonpublicroad.

NOTICE:Donotexceedthemaximumspeedof40km/h

(25mph).

NOTICE:Alwaysadjustthedrivingspeedtotheconditionsoftheroad.

NOTICE:ThetubeoverlapofthePowerT ake-Off(PTO)

shaftmustbeinthecorrectpositionduringtransportand

workingoperations.

NOTICE:BeforestartingthePTOshaftcheckthatthe

numberofRevolutionsPerMinute(RPM)ofthetractor