Page 1

ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1

OPERATOR’S MANUAL

R+ 420

R+ 460

Rake

Part number 81PIGB-184x

1st edition English

February 2018

Page 2

Page 3

PIGB-184X-02 R+420 R+460 0218

2

FOREWORD

DEAR CUSTOMER!

We appreciate the confidence you have shown to our company by investing in a

KONGSKILDE product and congratulate you with your new purchase. Of course, it is

our wish that you will experience complete satisfaction with the investment.

This instruction manual contains information about correct and safe use of the

machine.

When buying the machine you will receive information about use, adjustment and

maintenance.

However, this first introduction cannot replace a more thorough knowledge of the

different tasks, functions and correct technical use of the machine.

Therefore you should read this instruction manual very carefully before using

the machine. Pay special attention to the safety instructions.

This instruction manual is made so that the information is mentioned in the order you

will need it, i.e. from the necessary operation conditions to use and maintenance.

Besides this there are illustrations with text.

"Right" and "Left" are defined from a position behind the machine facing the direction

of travel.

All the information, illustrations and technical specifications in this instruction manual

describe the latest version at the time of publication.

Kongskilde Industries A/S reserves the right to make changes or improvements in the

design or construction of any part without incurring the obligations to install such

changes on any unit previously delivered.

Page 4

PIGB-184X-02 R+420 R+460 0218

3

Contents

1. In general

1.1 Intended use

1.2 Foreseeable misuse

1.3 General safety instructions

1.4 Technical data

1.4.1 Manufacturer’s address

1.4.2 Certificates

1.4.3 Marking of the machine

1.4.4 General technical data

2. Safety

2.1 Marking of safety instructions in the instruction manual

2.2 Safety rules and accident prevention

2.2.1 Power take-off

2.2.2 Tyres

2.2.3 Working near high-voltage lines

2.2.4 Maintenance

2.3 Placement of safety signs on the machine

2.4 Placement of normal reference signs on the machine

3. Mounting of the machine after delivery

3.1 Mounting of PTO drive shaft

3.2 Adjustment of PTO drive shaft

3.3 Mounting of optional equipment “Warning panel with lighting equipment”

3.4 Mounting of optional equipment “Support wheel, adjustable”

3.5 Mounting of optional equipment “4-wheel bogie axle” (R+420)

3.6 Mounting of optional equipment “3D bogie axle” (R+420)

3.7 Functional test

4. Mounting of the rake and preparation

4.1 Special instructions

4.2 Preparation of tractor

4.2.1 3-point suspension on the tractor

4.2.2 Electric system

4.3 Connection of the rotary rake to the tractor

4.3.1 Connection to the link arms of the tractor

4.3.2 Connection of lighting equipment

4.3.3 Connection of PTO shaft

4.4 Disconnection and parking of the rotary rake

4.5 Transport on public road

Page 5

PIGB-184X-02 R+420 R+460 0218

4

5. Handling of the rake during working

5.1 Conversion of the rake from transport to working position

5.1.1 Release of the transport lock

5.1.2 Mounting and securing of tine arms

5.1.3 Safety frame is placed in working position

5.1.4 Swath guard is placed in working position

5.2 Starting the rotor

5.3 Conversion of the rake from working to transport position

5.3.1 Dismounting of tine arms

5.3.2 Safety frame is placed in transport position

5.3.3 Swath guard is placed in transport position

5.3.4 Activating the transport lock

5.4 Further instructions for working and driving with the machine

6. Basic adjustment of the rake

6.1 Adjustment of working depth

6.2 Adjustment of the length of the top link

6.3 Adjustment of the rotor inclination in the direction of travel

6.4 Adjustment of the rotor inclination with extra support wheel (option)

6.5 Adjustment of the rotor inclination transverse to the direction of travel

6.6 Adjustment of working width and swath width

6.7 Adjustment of the cam track

6.8 Adjustment of shock absorber

6.9 Working speed and number of revolutions

7. Service and maintenance of the rake

7.1 Safety rules

7.2 General maintenance instructions

7.3 Cleaning of the machine and preparation for winter storage

7.3.1 Cleaning of the machine

7.3.2 Placement of the rake in the open

7.3.3 Winter storage

7.4 Wheels

7.4.1 Tyre pressure

7.5 PTO shafts

7.6 Replacement of bearing tubes

8. Maintenance - grease chart

8.1 PTO shaft

8.2 Rotor gear

8.3 Cam track

8.4 Swivel pin on suspension

8.5 Transport safety bolt

8.6 Universal joint

8.7 Grease chart overview

Page 6

PIGB-184X-02 R+420 R+460 0218

5

9. Machine disposal

10. Supplement

11. Warranty

Page 7

PIGB-184X-02 R+420 R+460 0218

6

1. In general

This instruction manual contains important information concerning operation,

maintenance and adjustment of the machine. Furthermore, all safety instructions are

mentioned and emphasized. Read the instruction manual carefully before using the

machine. The instruction manual should be accessible for the operator.

All safety instructions must be observed.

1.1 Intended use

The rotary rake is intended for raking grass hay and straw crops on the

ground.

The rotary rake is solely constructed for usual work in agriculture.

The rotary rake should only be connected to a tractor and driven by the PTO

of the tractor.

Any other use is regarded as not intended. The manufacturer is not

responsible for any damage resulting from such use, the user bears that risk.

Intended use also implies that the instructions and rules prescribed by the

manufacturer are observed.

The rotary rake should only be used, maintained and repaired by persons

who, through relevant instructions and after reading the instruction manual,

are familiar with the machine and, in particular, are informed of possible

dangers.

The following safety instructions as well as common rules concerning

technical safety, working practices and road safety must be observed

altogether.

If changes are made on the machine and its construction without permission

from the manufacturer, the manufacturer cannot be held responsible for any

damage resulting from this.

Intended use also implies that the rules prescribed by the manufacturer

concerning operation, maintenance and service are observed.

Page 8

PIGB-184X-02 R+420 R+460 0218

7

1.2 Foreseeable misuse

Sweeping of e.g. farmyards with the rake tines or brooms fastened to these is

not allowed. There is a risk that e.g. stones are thrown out from the working

area of the machine with danger of personal injury or damage to objects.

Any use beyond the intended use is regarded as foreseeable misuse.

1.3 General safety instructions

The following is a brief description of the measures, which should be a matter of

common knowledge to the operator.

1. Always disengage the PTO drive shaft, activate the parking brake and stop the

tractor engine before you

- lubricate the machine,

- clean the machine,

- maintain the machine.

- adjust the machine.

2. Always use the transport lock when transporting the machine.

3. Never work under a raised rotor unless it is secured by means of stop blocks

or other mechanical securing device.

4. Always block the tractor wheels before working on the machine.

5. Never start the tractor until all persons are safely away from the machine.

6. Make sure that all tools have been removed from the machine before starting

the tractor.

7. Make sure that all guards are intact and have been mounted correctly.

8. The clothes of the operator must be tight-fitting. During work never wear loose

clothes or have your hair hang down as it may be pulled in by the moving parts

of the machine.

9. Always drive with the statutory lights and safety marking during transport on

public road and at night.

10. Do not stand near the machine while it is working.

11. When mounting the PTO drive shaft check that the number and direction of

RPM of the tractor matches those of the machine.

12. Before raising or lowering the machine, check that no persons are near the

machine or touching it.

13. Do not stand near the safety frames of the rake until all revolving parts have

stopped moving.

14. Never use the machine for other purposes than what it has been constructed

for.

15. Do not allow any children to be near when you are working with the machine.

16. Never stand between the tractor and the machine during connection and

disconnection.

Page 9

PIGB-184X-02 R+420 R+460 0218

8

1.4 Technical data

1.4.1 Manufacturer’s address

Kongskilde Industries A/S

DK-6400 Sønderborg – Denmark

1.4.2 Certificates

-EC-Declaration of conformity (see page 46)

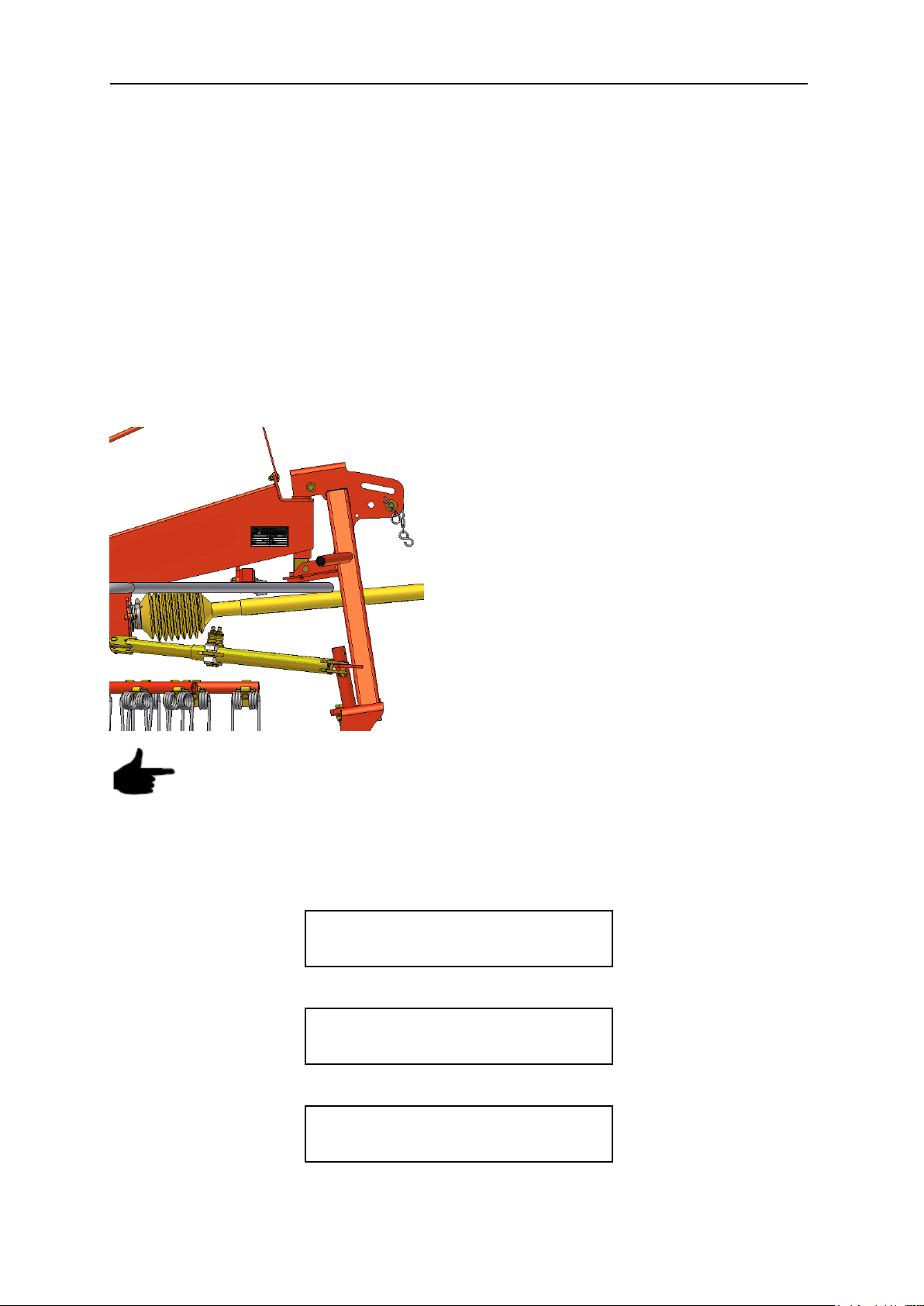

1.4.3 Marking of the machine

The machine data are printed on the.

machine plate. The machine plate is

placed in the right-hand side in the

direction of travelling behind the

suspension.

The marking on the machine should neither be changed nor removed!

The information on the machine plate can be written below so that it is always at

hand.

Machine type

Serial number

Manufacturing year

Page 10

PIGB-184X-02 R+420 R+460 0218

9

Technical data:

R+420

R+460

Rotor diameter:

3.20 m

3.50 m

Tine arms per rotor:

12

12

Double tines per tine arm:

4

4

Working width, max:

4.15 m

4.45 m

Minimum transport width:

1.90 m

2.18 m

Length (with tine arms / without PTO shaft):

3.70 m

4.00 m

Number of revolution, PTO:

540 RPM

540 RPM

Link arm category:

I + II

I + II

Suspension type:

3-point

3-point

Power requirement:

from 30/40 kW/HP

from 33/45 kW/HP

Number of rotor wheels:

2

4

Wheels, rotor:

18.5x8.50-8 (6PR)

18.5x8.50-8 (6PR)

Tyre pressure

2.2 bar

2.2 bar

Electricity (for extra lighting kit)

12 V

12 V

Equivalent sound pressure level

under 70 dB(A)

under 70 dB(A)

Weight, approx.:

570 kg

650 kg

In case of service questions and when ordering spare parts, please state machine

type, serial number and manufacturing year so that the inquiry can be treated as

soon as possible.

Only use original KONGSKILDE spare parts. The manufacturer

cannot be held responsible for any damage resulting from the use of

non-original spare parts.

1.5.4 General technical data

Page 11

PIGB-184X-02 R+420 R+460 0218

10

R+460

Page 12

PIGB-184X-02 R+420 R+460 0218

11

2. Safety

2.1 Marking of safety instructions in the instruction manual

In this instruction manual this symbol is used with reference to personal safety

directly and indirectly through maintenance of the machine.

This symbol (safety marking according to DIN 4844-W9) is supplemented with the

following references:

General references are marked with this symbol:

Reference signs on the machine must be observed and kept in a readable condition.

2.2 Safety rules and accident prevention

1. The safety instructions in this manual together with common rules concerning

safety and accident prevention must be observed!

2. The warning and reference signs provide important information on safe

operation and should be observed!

3. When driving on public road the current safety rules must be observed!

4. Before working with the machine you should make yourself familiar with all

devices, operating elements and functions. During work this will be too late!

5. The clothes of the operator must be tight-fitting. Avoid loose clothes.

6. The machine should always be kept clean! Hereby you avoid danger of fire.

7. Always check the area around the machine before working, especially for

children! Make sure that your view is sufficient!

8. Never allow anybody to be on the machine during work and transport.

9. The machine must be connected as per instructions and should only be

secured/fastened at the prescribed devices!

Page 13

PIGB-184X-02 R+420 R+460 0218

12

10. During connection and disconnection the supports must be in the prescribed

positions!

11. Particular care is required during connection and disconnection of machines!

12. The limits for allowable axle load, total weight and transport dimensions must

be observed!

13. Transport equipment, e.g. lighting and warning kit as well as protection

equipment must be checked and fitted.

14. Operating parts (cords, chains, rods etc.) for remote control equipment must

be placed so that they do not cause unintended movements in transport and

working position.

16. For road transport the machine must be prepared and locked according to the

instructions of the manufacturer!

17. Never leave the tractor seat when driving!

18. Always adjust the driving speed to the conditions of the ground. When driving

up and down and across hillsides, sharp turns should be avoided!

19. Driving, steering and braking capacity are influenced by mounted or trailed

implements and ballast weights. Therefore please be aware of sufficient

steering and braking capacity!

20. When turning pay attention to the overhang and oscillating weight of the

machine!

21. Only use the machine if all guards are mounted correctly!

22. Nobody should be allowed to stand in the working area!

23. Do not stand in the turning and swivel area of the machine!

24. Hydraulically foldable and pivotal frames should only be activated when there

are no persons in the swivel area!

25. Do not allow any person to stand under a raised machine when the machine is

not in locked position!

26. At remote-controlled (e.g. hydraulically controlled) units may be places where

there is danger of injury!

27. Lower the machine to the ground, stop the engine and remove the ignition key

before leaving the tractor!

28. Never stand between the tractor and the machine without securing the vehicle

by means of the hand brake and/or stop blocks!

29. Always interrupt the operation of the rake when leaving the tractor seat.

Page 14

PIGB-184X-02 R+420 R+460 0218

13

2.2.1 Power take-off

1. Only use the PTO drive shafts prescribed by the manufacturer!

2. The protection tube and cover of the PTO and the PTO guard – also on the

machine side – must be mounted and undamaged!

3. The tube overlap of the PTO shaft must be correct in transport and working

position!

4. Always stop the PTO and the tractor engine and remove the ignition key

before connecting or disconnecting the PTO drive shafts.

5. When using PTO shafts with overload or freewheel clutch which is not covered

by the protective devices of the tractor, the overload/freewheel clutches must

be placed on the machine side!

6. Always make sure that the PTO drive shaft has been mounted and secured

correctly!

7. The guard of the PTO shaft is secured with the chain!

8. Before starting the PTO check that the number of RPM of the tractor PTO

matches the number of RPM of the machine.

9. When using a travel speed controlled PTO, be aware that the number of rpm

is depending on the travel speed and that the direction of rotation will change

when backing!

10. Before starting the PTO check that there are no persons in the danger zone of

the machine!

11. Never connect the PTO if the engine has stopped!

12. When working with the PTO make sure that no persons stand near the

rotating PTO shaft.

13. Always stop the PTO if the deviation is too big or PTO is not used!

14. Caution! When the PTO has been stopped there will be a momentum! Do not

get too close to the machine. Do not carry out any work on the machine until it

has come to a complete stop!

15. Cleaning, greasing and adjustment of a PTO-driven machine or PTO shaft

should only take place when the PTO has been disconnected, the engine

stopped and the ignition key removed!

16. When the PTO shaft is disconnected from the tractor it must be fastened to

the suspension with the chain!

17. If the PTO shaft is damaged it must be repaired immediately before working

with the machine!

Page 15

PIGB-184X-02 R+420 R+460 0218

14

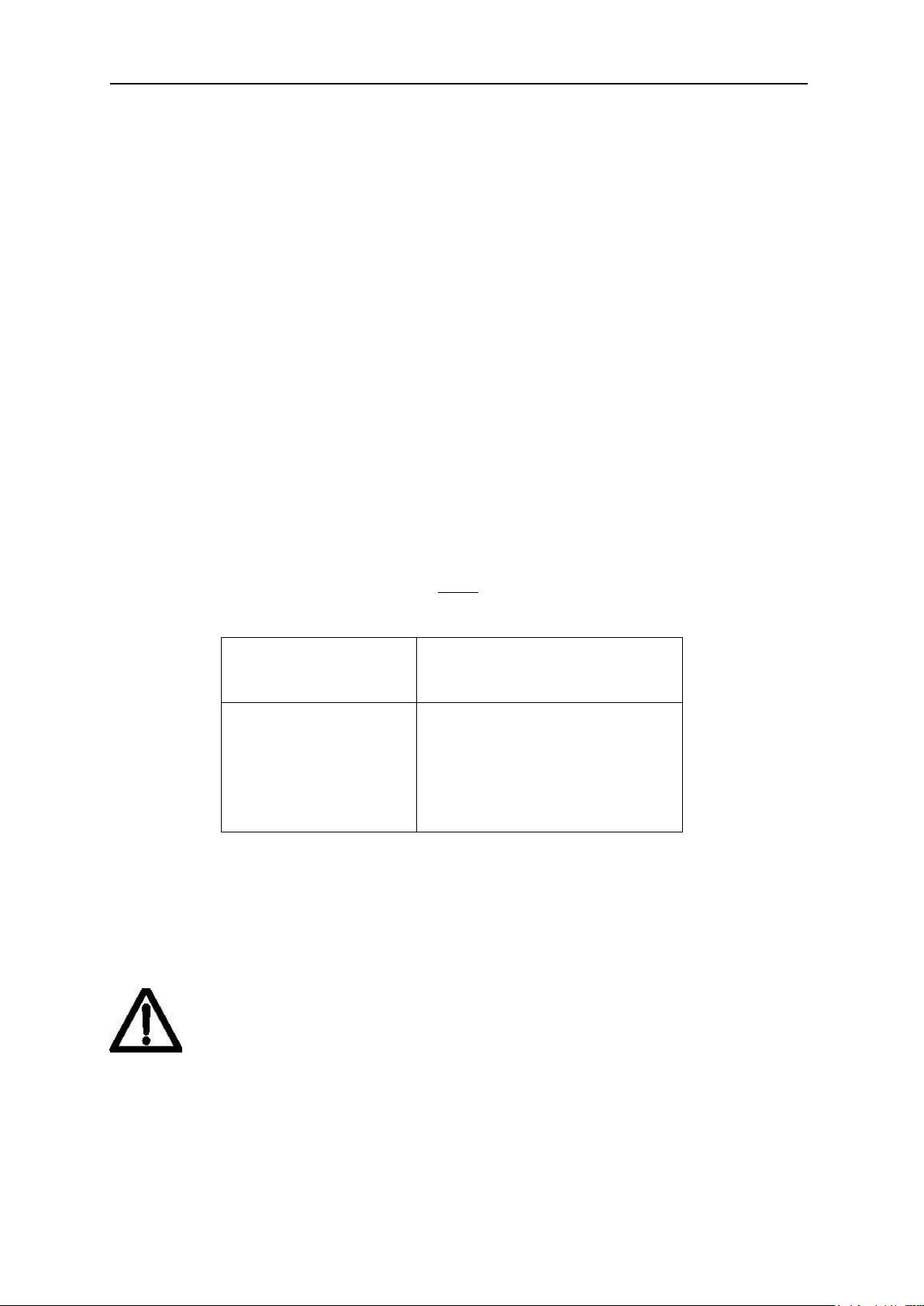

Rated voltage

kV

Safety distance from overhead lines

m

Op til 1

Over 1 til 110

Over 110 til 220

Over 220 til 380

1

2

3

4

2.2.2 Tyres

1. Before working on the tyres it must be ensured that the machine is stable and

cannot move (by means of stop blocks)!

2. Mounting of wheels requires sufficient knowledge and correct mounting tools!

3. Repair of tyres and wheels should only be made by experts and with correct

mounting tools!

4. Check the tyre pressure regularly! Observe the prescribed tyre pressure!

2.2.3 Working near high-voltage lines

1. Be very careful if working under or near high-voltage lines.

2. Make sure that the total height is as low as possible if working or transporting

the machine near high-voltage lines.

3. If driving under overhead lines the driver must contact the owner of the

overhead lines in order to get information on the rated voltage and minimum

height of the overhead lines.

4. The safety distances in the table must be observed.

2.2.4 Maintenance

In general:

When repairing or maintaining the machine it is especially important to

ensure correct personal safety. Therefore, always park the tractor (if

mounted) and the machine according to the GENERAL SAFETY

RULES, chapter 2.2, in the beginning of this instruction manual.

Page 16

PIGB-184X-02 R+420 R+460 0218

15

Torque measurement MA (if nothing else has been stated).

Screws and bolts on your new machine must be retightened after 5

hours of operation. This also applies if repairs have been made.

1. Maintenance, service, cleaning and repair must only take place when the PTO

and the engine have been stopped! - Remove the ignition key! - Apply the

hand brake of the tractor or secure the rake so that it cannot move!

2. Screws and nuts must be checked regularly and re-tightened if necessary!

3. If maintenance is going to be made on a machine in raised position, always

secure it by means of appropriate supports!

4. Oil and grease are disposed of as prescribed!

5. Cut off the power before working on the electric system!

6. If guards are exposed to wear they must be checked regularly and replaced in

time!

7. Before carrying out electric welding on tractor and mounted machine the cable

for generator and battery must be dismounted.

8. Spare parts must at least correspond to the technical requirements prescribed

by the manufacturer! Original spare parts observe these requirements!

Page 17

PIGB-184X-02 R+420 R+460 0218

16

2.3 Placement of safety signs on the machine

1. Read the instruction manual and

safety instructions carefully before

using the machine, and observe

the instructions!

2. Stop the PTO and the engine and

remove the ignition key

before carrying out maintenance,

repair and service!

Page 18

PIGB-184X-02 R+420 R+460 0218

17

3. Wait until all machine parts have come to

a complete stop before touching them!

4. Keep a safe distance from the rotating

parts of the machine!

5. Check the safety pins for wear.

If the thickness is less than 7 mm

they must be replaced immediately!

6. During operation in the field the safety bolt must

be pulled out and during transport it must be pushed in.

7. The prescribed number and direction of rotation.

Reference to the minimum overlapping on the profile tubes

and the minimum distance required in order not to bottom

the shaft.

Page 19

PIGB-184X-02 R+420 R+460 0218

18

8. Warning sign, reflecting

(not included)

Optional equipment ”Warning panel with

lighting equipment“

9. Reflector red (at the rear)

10. Reflector yellow (at the side when safety frames

are folded up)

The reference signs are warning of dangers of the machine. The safety references

must be observed at any time. Reference signs must be kept clean and in a readable

condition. Damaged or missing safety signs must be ordered from your dealer as

spare parts and must be placed at the correct positions!

2.4 Placement of normal reference signs on the machine

Page 20

PIGB-184X-02 R+420 R+460 0218

19

1. LOGO

2.

3. Mounting of the machine after delivery

Mounting of the rotary rake must only be carried out by experts.

The necessary tools and adjustment tools must be at disposal.

After mounting a complete functional test of the machine must be

carried out.

After 5 hours of operation all screw joints must be re-tightened!

The rakes R+420 and R+460 are separated into parts and delivered in a box.

A detailed mounting guide for the machine is supplied. The instructions in this guide

must be observed!

3.1 Mounting of PTO drive shaft

When the machine has been assembled, the PTO shaft can be connected.

The overload clutch must be positioned on the machine side.

The lock-pin on the PTO shaft must be properly engaged in the spline

on the machine’s drive shaft!

3.2 Adjustment of PTO drive shaft

It may be necessary to shorten the PTO shaft from tractor to machine in order to

prevent that it bottoms in the shortest position. On tractors with a short distance from

PTO to link arm connection, the PTO shaft may be too long.

Page 21

PIGB-184X-02 R+420 R+460 0218

20

Important: The profile tubes must have minimum 200 mm overlap! In

the shortest position there must be a distance of minimum 40 mm from

profile tube to universal joint!

The adjustment of the PTO drive shaft takes place as follows:

The rake and the tractor are placed in the position in which the PTO shaft has

the shortest length (e.g. during turning).

The two PTO shaft half parts are separated.

The one half part is pushed onto the tractor PTO, the other half part onto the

drive shaft of the rake.

See the instruction manual for the PTO drive shaft for further instructions.

If the rake is going to be connected to different tractors, it is important

to make sure that the 200 mm overlap and the distance of 40 mm are

observed. For tractors with very different distances between PTO and

link arm connection it is recommendable to have different PTO shafts in

stock.

After the adjustment the swivel area and clearance of the PTO shaft

must be checked. The PTO shaft should not in any position get in

contact with machine parts.

3.3 Mounting of optional equipment “Warning panel with lighting

equipment”

Mounting of this equipment is shown in the supplied spare parts book

3.4 Mounting of optional equipment “Support wheel, adjustable”

Mounting of this equipment is shown in the

supplied spare parts book.

The support wheel is mounted instead of the

bottom steering plate of the parking jack. The

parking jack is not used anymore.

The desired height is adjusted with the spring pin 1

and fixed with the ring screw 2 to avoid rattling sounds.

Page 22

PIGB-184X-02 R+420 R+460 0218

21

3.5 Mounting of optional equipment “4-wheel bogie axle”

Mounting of this equipment for R+420 is shown in the supplied spare parts book.

The stop screw on the lever arm at the right and left-hand side limits the

movement of the bogie axle so that the wheels cannot collide with the

tine arms.

This adjustment should not be made until the working height of the rake

tines has been adjusted roughly.

On R+460 this equipment is standard.

3.6 Mounting of optional equipment “3D bogie axle”

Mounting of this equipment for R+420 is shown in the supplied spare parts book.

The adjustment screws on the 3-wheel axle at the right and left-hand

side limits the movement of the bogie axle so that the wheels cannot

collide with the tine arms.

This adjustment should not be made until the working height of the rake

tines has been adjusted roughly.

3.7 Functional test

After the preparation of the machine, a functional test must be carried out.

Incorrect mounting of the machine is highly dangerous. Before the

functional test is carried out, please check that everything is mounted

correctly according to the instructions in the manual and the mounting

guide.

Make sure that there are no tools in the area around the machine!

Make sure that there are no persons in the danger zone!

After 5 hours of operation all screws must be re-tightened!

4. Mounting of the rake / preparation

Always disengage the PTO drive shaft before maintaining, repairing

and mounting. Stop the engine and remove the ignition key. Secure the

tractor and the machine so that they cannot move!

The maximum number of revolutions is 540 rpm.

The cable for the lighting equipment is placed so that unintended

contact with the tractor wheels is impossible! Check that the lighting

equipment is working!

During raising and lowering never stand between the tractor and the

machine or under the raised rotor arms. Risk of personal injury!

Page 23

PIGB-184X-02 R+420 R+460 0218

22

Before starting the PTO check that there are no persons in the danger

zone of the rotary rake. Danger!

Before work and transport on public road always make sure that all

guards are mounted correctly!

The operator should never leave the tractor during working! Make sure

that there are no persons in the danger zone!

4.1 Special instructions

In the area of the 3-point suspension there is a risk of personal injury

since there are places where you can get jammed or cut!

Be particularly careful during connection and disconnection of machines!

Never stand between the tractor and the rake during connection to the link arms. The

operator should not step into the danger zone until the electric cables, the hydraulic

hoses and the PTO are to be connected.

The operating elements of the tractor must be secured against unintended use

before connection and disconnection.

4.2 Preparation of tractor

4.2.1 3-point suspension on the tractor

The rakes R+420 and R+460 are designed

to be connected to the 3-point suspension

of the tractor - category I and II.

Hitch pins:

Inside = cat. I

Outside = cat. II

Page 24

PIGB-184X-02 R+420 R+460 0218

23

The sideways movement of the link arms on the tractor must be minimised in order to

avoid oscillation of the machine during work and transport. This means that the link

arms must be secured with limiting chains or other locking device.

Adjust the link arms of the tractor so that they are at the same height above the

ground at both sides.

4.2.4 Electric system

The lighting system (option) is equipped with a 7-pole plug for the trailer socket.

4.3 Connection of the rotary rake to the tractor

The instructions are based on a fully mounted rotary rake in locked

transport position with the support folded down.

4.3.1 Connection to the link arms and top link of the tractor

Never stand between the tractor and the rake during connection to

the tractor!

Reverse the tractor to the rake and connect the balls on the pins on the

suspension of the rake to the link arms of the tractor and secure.

Fold down the top link on the tractor and connect it to the upper ball on the

suspension of the tractor and secure.

- The top link bolt must be secured with spring pin. The chain of the spring

pin must hang freely.

- The link arm balls must be secured with linch pin (size 12).

Page 25

PIGB-184X-02 R+420 R+460 0218

24

Support

Raise the machine with the link arms

until the support is raised from the ground.

Remove the spring pin under the bottom steering plate

of the support and push up the support.

Place the spring pin in the bottom

hole of the support above the bottom

steering plate.

Make sure that the transport safety bolt

is pushed in!

This is done by briefly pulling the

transport safety bolt and turning it

so that the split pin is released. The transport

safety bolt is pushed so far in that the

split pin reaches the end of the guide. The

spring supports the procedure and

prevents the transport safety bolt from

wandering back.

4.3.2 Connection of lighting equipment (optional equipment)

The lighting system (option) is equipped with a 7-pole plug at the lighting cable.

Connect this plug to the socket at the rear of the tractor.

After the connection the function of the lighting system must be

checked! Dirt and moisture may result in contact problems or even short

circuit. Therefore the plug connection must be kept clean and dry.

4.3.3 Connection of PTO shaft

The description implies that the length of the PTO shaft is adjusted to

the tractor according to chapter 3.2.

If the machine is used with different tractors it must be checked that the

PTO shaft has the correct length.

On the tractor and machine side there must be an intact guard.

Only use the supplied PTO shaft or a PTO shaft that is approved by the

manufacturer!

Release the PTO shaft from the support chain.

Page 26

PIGB-184X-02 R+420 R+460 0218

25

Support chain

for PTO shaft

Spring pin for

top link bolt

Safety chain on

the tractor side

Push the PTO shaft onto the tractor PTO until the locking balls are engaged.

The guard of the PTO shafts is secured on the tractor side with the chains. On the

machine side there is a full-covering protection. This protection is secured with

clamp.

4.4 Disconnection and parking of the rotary rake

Raise the machine with the link arms.

Lower the support and place the spring pin under the bottom steering plate again.

Lower the machine with the link arms until it stands firmly with the wheels and the

support on the ground.

Disconnect the PTO shaft from the tractor and place it in the support chain.

Disconnect the electric cable for the lighting equipment (option) from the tractor

and place it on the machine.

Disconnect the top link and the link arms from the machine.

Fold up the top link and secure it on the tractor.

Lower the link arms further.

Drive the tractor forward, away from the machine.

Make sure that the machine is placed on firm and even ground so that it

is not in danger of turning over.

Make sure that the transport safety bolt is still pushed in while the

machine is parked.

Page 27

PIGB-184X-02 R+420 R+460 0218

26

Do not pull out the transport safety bolt when the machine is parked!

Risk of personal injury! The shock absorber would press the

suspension forward.

Machine in parked position

4.5 Transport on public road

During transport on public road the current traffic rules in the country in question

must be observed! This also applies to the rules regarding lighting and warning

panels.

Check that the transport safety bolt is pushed in correctly.

The safety frames of the rotors must be folded up and secured in transport

position.

When the safety frame is folded up the swath guard must be folded down to

vertical.

Always adjust the driving speed to the conditions of the road. Drive carefully on

bad roads and streets to ensure that the connection forces between the tractor

and the machine do not cause damage.

Driving, steering and braking capacity of the tractor are influenced by mounted

implements and ballast weights! Be aware of the instructions from the tractor

manufacturer and the supplement in chapter 10.

When turning pay attention to the overhang and oscillating weight of the machine.

Page 28

PIGB-184X-02 R+420 R+460 0218

27

Transport safety bolt

pulled out

Tightening pin engaged in the guide

5. Handling of the rake during working

The following description implies that the rake is completely mounted

according to chapter 3 and connected to the tractor according to

chapter 4.

The machine is in transport position, i.e.:

The safety frame is folded up

The swath guard is folded in vertically

The support is placed in folded position

The tine arms are placed on the holder and secured

The transport lock is engaged

5.1 Conversion of the rake from transport to working position

5.1.1 Release of the transport safety bolt

With raised machine the transport safety bolt is pulled towards the left to the end

of the guide of the tightening pin. Finally the transport safety bolt is turned so that

the tightening pin is engaged in the guide.

Page 29

PIGB-184X-02 R+420 R+460 0218

28

Bearing tube

Linch pin

Tine arm

Seal ring

5.1.2 The tine arms are placed on the bearing tubes and secured

The tine arms, which are dismounted for transport, can be found at the back of

the holder above the rotor gear.

Take off the linch pin on the tine arm.

Lift the tine arm from the holder and push it onto the bearing tube so that the

fishplate on the tine arm is led through the slot in the bearing tube.

Secure the tine arm by placing the linch pin in the fishplate of the tine arm and

folding it in.

All tine arms must be mounted before starting the machine in order not to create

an unbalance which may damage the machine.

Before starting the rake it must be checked that all linch pins are in the

correct position.

Risk of injury due to tine arms flying off!

Only use original linch pins!

Linch pins with round ring do not have

enough room and would be able to open!

Risk of injury due to tine arms flying off!

On each bearing tube there is a seal

ring which prevents dust and dirt from

getting between the bearing tube and

the tine arm.

Therefore the tine arm is always easy

to dismount.

Page 30

PIGB-184X-02 R+420 R+460 0218

29

Spring pin

Spring pin

Safety frame

Tightening screw

5.1.3 Safety frame is placed in working position

Remove the spring pin

Fold down the safety frame

Place the spring pin above the

support tube of the safety frame

in the same holes.

The safety frames must be folded

down at both sides.

5.1.4 Swath guard is placed in working position

Loosen the tightening screw

Pull the complete swath guard so

far out of the support tube of the

safety frame that the swath guard

is not lying above the tine arms

anymore.

Tighten the tightening screw again

Remove the spring pin

Push the swath guard forward until

the oblong hole in the swath guard

holder is free

Move the swath guard down to

vertical position

Push the swath guard to the rear

until the pin fixes the position

Place the spring pin again

5.2 Starting the rotor

Check that there are no persons near the machine before starting

the rotor!

Make sure that all tine arms have been secured correctly with split

pin!

Always start the PTO of the tractor with the engine at idle speed!

Page 31

PIGB-184X-02 R+420 R+460 0218

30

Holder

Fishplate of the

support tube

Spring pin

Locking pawl for

rotor

5.3 Conversion of the rake from working to transport position

5.3.1 Dismounting of tine arms

Take off the linch pin on the rake arm

Detach the tine arm from the bearing tube

and place it on the holder above the rotor

gear

Secure the tine arm with split pin so

that it cannot fall off

5.3.2 Safety frame is placed in transport position

Remove the spring pin

Fold up the safety frame to vertical position

Place the spring pin in the same hole

Make sure that the spring pin also goes

through the fishplate of the support tube so

that it secures the safety frame.

The two rakes, R+420 and R+460, are equipped with a locking pawl for rotor.

Fold up the safety frame holder, approx. 100˚, and turn the rotor so that

the end of the bearing tube fits into the locking pawl.

Swivel back the safety frame so that the spring pin fits into the fishplate

of the support tube.

The rake R+460 is also equipped with a

relief spring. This relief spring makes

it easier to lift the safety frame and the

swath guard.

Page 32

PIGB-184X-02 R+420 R+460 0218

31

Swath guard in

transport position

Transport safety bolt

Split pin

Spring pin

Tightening screw

5.3.3 Swath guard is placed in transport position

Loosen the tightening screw

Push the swath guard to the end of

support tube of the safety frame

Tighten the tightening screw again

Remove the spring pin

Push the swath guard forward and

move it down vertical

Push the swath guard to the rear

until it is fixed with the pin in the

oblong hole

Place the spring pin again

5.3.4 Activating the transport safety bolt

Lift the rake with the link arms until

the wheels are raised from the ground.

Briefly pull the transport safety bolt

and turn it so that the split pin is released.

Push the transport safety bolt so far

in that the split pin reaches the end of

the guide. The spring supports the

procedure and prevents the transport

safety bolt from wandering back.

The rotary rake is now ready for transport.

In order to obtain safe transport, the steering and braking capacity of

the tractor must be maintained in spite of the mounted machine. In this

connection the instructions of the tractor manufacturer should be

observed.

It may be necessary to ensure a better weight distribution to the front

axle.

This can be checked by means of chapter 10.

Page 33

PIGB-184X-02 R+420 R+460 0218

32

Spindle

2-4 mm space

6. Basic adjustment of the rake

6.1 Adjustment of working depth

The working depth of the rake tines is

adjusted by turning the spindle.

If the spindle is turned to the right (looking

backwards), the distance of the rake tines

to the ground is reduced. If it is turned to

the left, the distance to the ground is

increased.

Note:

If the rake tines are adjusted too low, there

is danger of contamination of the feed and

damage to the grass roots.

If the rake tines are adjusted too high,

clean raking cannot be obtained.

6.2 Adjustment of the length of the top link

Adjust the length of the top link

so that there is about 2-4 mm space

to the slide block at the end of the

guideway of the suspension.

The lever for adjustment of the

link arms must be in neutral

position, not in floating position!

Page 34

PIGB-184X-02 R+420 R+460 0218

33

Tightening screw

6.3 Adjustment of the rotor inclination in the direction of travel

In principle the rotor must be horizontal seen from the side.

This adjustment is obtained by regulating the height of the link arms.

In case of large amounts of crop, it may be an advantage if the rotor has a small

inclination forward. In this connection the link arms should only be lowered so much

that the rake tines do not damage the grass roots.

After the adjustment of the link arms, the adjustment of the top link should be

checked as described in chapter 6.2.

6.4 Adjustment of the rotor inclination with extra support wheel

(option)

If the rotary rake is equipped with a support wheel (option) at the suspension, the

rotor inclination is adjusted by means of this wheel.

With regard to the desired rotor inclination, the same criteria apply as in chapter 6.3.

Remember that the lever for adjustment of the link arms must be in floating position.

The support wheel maintains the raking height.

In mountainous areas it may be advantageous to use a chain top link.

During transport on public road the machine must be equipped with the

(normal) inflexible top link. Please note! Not in the oblong hole!

6.5 Adjustment of the rotor inclination transverse to the direction

of travel

The rotary rakes R+420 and R+460 are designed so that the rotor is horizontal

transverse to the direction of travel. This ensures perfect raking and optimal swath

shaping.

Only in case of very large amounts of crop it may be necessary to increase the

downwards inclination of the rotor in the swath guard side.

This can be done by reducing the tyre pressure in the left tyre (facing the direction of

travel). The tyre pressure should, however, not be lower than 1.2 bar.

6.6 Adjustment of working width and swath width

The working width and the swath width

are regulated by adjusting the swath

guard.

Loosen the tightening screw and push the

swath guard to the wanted position.

Tighten the tightening screw again.

Page 35

PIGB-184X-02 R+420 R+460 0218

34

Adjustment

Delivery time

earlier

Delivery time

later

Shock absorber

Friction damper

37

70

The swath guard can also be adjusted in height.

6.7 Adjustment of the cam track

The adjustment of the cam track determines

the crop delivery time and influences the

shape of the swath.

The rake is delivered with the factory setting

(70 mm) which in most cases gives a very

satisfactory result.

Depending on the crop it may be necessary

to make an adjustment. This is done by moving

the 2 nuts to the right or left-hand side.

6.8 Adjustment of shock absorber

The shock absorber ensures a

steady operation.

From the factory the springs of the shock

absorber are adjusted to 37 mm.

When driving on slopes under

extreme conditions it may

happen that the rake tines

are lifted from the ground

without raking the grass.

In this case the springs

must be tightened

(to maximum 32 mm).

Page 36

PIGB-184X-02 R+420 R+460 0218

35

6.9 Working speed and number of revolutions

The working speed and the number of rpm during raking depend on the type and

amount of crop, the dry matter content and the ground conditions.

The following can be used as a guide:

PTO number of revolutions, approx. 380 - 450 RPM

Driving speed, approx. 8 - 15 km/h

Both values must be adjusted to the working conditions.

Page 37

PIGB-184X-02 R+420 R+460 0218

36

7. Service and maintenance of the rake

7.1 Safety rules

Maintenance, service, cleaning and repair must only take place when

the PTO and the engine have been stopped. Remove the ignition key!

Take care that oil and grease do not get in contact with your skin.

After the first hours of operation all screws must be re-tightened!

7.2 General maintenance instructions

To obtain high operational safety and minimum wear there are certain

maintenance and service intervals which must be observed. This

includes e.g. cleaning, greasing and lubrication of parts and

components.

Screws and nuts must be checked after every 50 hours of operation

and re-tightened if necessary!

See the table for torque settings in chapter 2.2.5.

It is particularly important to check the fixing bolts of the rake tines on

the tine arms.

Only use original spare parts and equipment. There is no warranty on

non-original components. The manufacturer is not responsible for any

damage resulting from such use.

7.3 Cleaning of the machine and preparation for winter storage

7.3.1 Cleaning of the machine

When cleaning with a high pressure cleaner never spray directly on

bearings.

After cleaning, all bearings must be greased carefully until grease

comes out of the bearings to ensure that possible water is pressed out.

When cleaning with high pressure the paint may be damaged.

Therefore sufficient distance must be kept between the nozzle on the

high pressure cleaner and the machine.

Parts polished with use may get rusty.

7.3.2 Placement of the rake in the open

If the rake is placed in the open for a longer period, all bearings must be

greased according to the lubrication schedule.

Parts polished with use and the piston rods of the hydraulic cylinder must be

cleaned and brushed with grease to protect against wind and weather.

Page 38

PIGB-184X-02 R+420 R+460 0218

37

Wheels

Tyre pressure (bar)

Rotor chassis

18,5x8,50-8 (6PR)

2,2

Extra support wheel (option)

16x6,50-8 (6PR)

2,2

Bogie-axle (option)

18,5x8,50-8 (6PR)

2,2

7.3.3 Winter storage

Check the rake for damaged parts, loose screw-joints and leakage. If there is

any damage it may be forgotten during the winter and result in problems the

following year. Therefore the machine must be checked carefully before the

winter storage.

Grease the rake according to the lubrication chart.

Clean the machine carefully.

The machine must be stored in a place where it is protected against wind and

weather in the best possible way.

Parts polished with use must be greased to protect against rust.

The PTO shaft is dismounted and the inner and outer tubes are separated.

Grease the sliding surfaces and reassemble.

7.4 Wheels

The wheels must be checked regularly for damage and correct tyre

pressure.

Wheel-fixing bolts must be checked regularly and re-tightened if

necessary!

Repair of wheels should only be made by experts and with correct

tools!

Mounting of wheels requires correct mounting tools and must be

performed by persons with sufficient knowledge.

When working with the wheels the rake must be secured so that it

cannot move!

7.4.1 Tyre pressure

The tyre pressure must be checked regularly and adjusted if necessary.

The required tyre pressure is shown in the below table:

Caution: If the pressure is too high the tyres may crack. If the pressure is too low the

tyres may be damaged due to deformation of the tyre wall.

7.5 PTO shafts

When working with the PTO shafts:

Stop the engine!

Remove the ignition key!

Page 39

PIGB-184X-02 R+420 R+460 0218

38

Cover plate

A

Screws on

innermost

hole circle

Screws on

outermost

hole circle

Instructions regarding PTO shafts:

Never use PTO shafts without guards or if guards are damaged.

Risk of personal injury!

Missing or damaged protection tubes and covers must be replaced

immediately!

Only use PTO shafts that are approved by the manufacturer!

Grease the PTO shafts carefully according to the lubrication chart.

7.6 Replacement of bearing tubes

If a bearing tube has been damaged, it is easy to replace. It is not necessary to

disassemble the rotor.

Bearing tube A must be replaced.

First, check which cover plate the bearing tube A belongs to.

On this cover plate remove the 6 screws on the innermost hole circle and take out

the cover plate.

Page 40

PIGB-184X-02 R+420 R+460 0218

39

PR11-1877

Remove the screws on the defective bearing tube on the outermost hole circle.

Loosen the screws on the neighbouring bearing tubes as much as necessary.

Remove the defective bearing tube A.

Place the new bearing tube in same position.

Make sure that the roller runs correctly in the roller path of the cam track.

Mount the cover plate with the screws the same place as before.

All screws are placed and tightened loosely.

Finally all screws must be tightened firmly with the following torque settings:

o Innermost hole circle 160 Nm

o Outermost hole circle 145 Nm

8. Maintenance - grease chart

Maintenance, service, cleaning and repair must only take place when

the PTO and the engine have been stopped. Remove the ignition key!

Take care that oil and grease do not get in contact with your skin!

During greasing the rotary rake must be in working position and parked

safely and firmly on the ground!

This chapter describes all grease points as well as service intervals. The observance

of the following instructions is a precondition for the operational safety and long life of

the machine.

Drained oils and grease must be handed over to a destruction company!

8.1 PTO shaft

The rotary rakes R+420 and R+460 are equipped with a PTO shaft with overload

protection.

The grease spots on the PTO shaft must be greased with universal

grease according to the intervals indicated.

See also the instruction manual for PTO drive shaft.

Page 41

PIGB-184X-02 R+420 R+460 0218

40

Drain plug

8.2 Rotor gear

The bevel gear must be greased

every day with suitable amounts

of grease.

8.3 Cam track

To avoid squeaking noises, the cam track

in the roller path should occasionally be

greased.

The cam track can be made accessible

by removing the yellow drain plug.

8.4 Swivel pin on suspension

The swivel pin must be greased

once a week.

Page 42

PIGB-184X-02 R+420 R+460 0218

41

8.5 Transport safety bolt

The guides of the transport safety bolt

and the tightening pin must occasionally

be lubricated with oil.

This ensures that the transport safety bolt

keeps working optimally.

8.6 Universal joint

The connecting links of the

universal joint must be greased

occasionally.

8.7 Grease chart overview

Page 43

PIGB-184X-02 R+420 R+460 0218

42

The following plant-based oil and grease types can be used:

Grease:

SHELL ALVANIA RO

Oil:

SAE 80W-90 API-GL4 or GL5

9. Machine disposal

When the machine is worn-out it must be disposed of in a proper way. Observe the

following:

The machine must not be placed somewhere outside, - it must be

emptied of oil (gearboxes and hydraulic system). These oils must be

handed over to a destruction company.

Disassemble the machine and separate the individual parts, e.g.

tyres, hydraulic hoses, hydraulic valves etc.

Hand over the usable parts to an authorised recycling centre. The

large scrapping parts are handed over to an authorised breaker's

yard.

Page 44

PIGB-184X-02 R+420 R+460 0218

43

ANMÆRKNING Der er ved denne beregning taget hensyn til hækmonterede redskaber og

front/hæk kombinationer.

Supplement C

(informative)

Stability with the combination tractor – rotary tedder and rake

This supplement concerns 6.1.f) in this part of ISO 4254 which deals with the requirement of

informing of possible loss of the tractor’s stability due to the connection of the machine.

The following text is a suggestion to the manufacturer with the purpose of making it possible for him

to provide suitable and complete information.

The example concerns a rotary tedder and rake connected to a tractor.

Due to the own weight of the machine, the combination tractor – rotary tedder and rake can become

unstable. In order to test the total stability the following formula can be used for the calculation of the

minimum front ballast I

F,min

at a minimum front axle load of 20% of the tractor’s own weight:

ANNOTATION In this calculation rear-mounted implements and front/rear combinations have

been taken into consideration.

10. Supplement

Translation from Norm EN ISO 4254-10

Page 45

PIGB-184X-02 R+420 R+460 0218

44

List of signs

TE [kg] The tractor’s own weight 1)

TF [kg] Front axle load with empty tractor 1)

TR [kg] Rear axle load with empty tractor 1)

IR [kg] Total weight rear-mounted implement/rear ballast 2)

IF [kg] Total weight front-mounted implement/front ballast 2)

a [m] Distance between centre of gravity front-mounted implement/front ballast and middle of

front axle 2) 3)

b [m] The tractor’s wheel distance 1) 3)

c [m] Distance between middle of rear axle and middle of link arm balls 1) 3)

d [m] Distance between middle of link arm balls and centre of gravity rear mounted

implement/rear ballast 2)

1) see instruction manual for the tractor

2) see price list and/or instruction manual for the implement

3) to be measured

Picture B.1 Example of references to stability of the combination tractor – rotary tedder and

rake

Page 46

11. WARRANTY

Your machine is warranted according to legal rights in your country and the contractual

agreement with the selling dealer. No warranty shall, however, apply if the machine has

not been used, adjusted and maintained according to the instructions given in this

operator's manual.

It is prohibited to carry out any modifications to the machine unless specifically authorized,

in writing, by a NEW HOLLAND representative.

PIGB-184X-02 R+420 R+460 0218 45

Page 47

Maskine: La máquina: Masin:

Maschine: Maszyna: Stroj:

Machine: Машината: Η μηχανή:

Machine: Gép: Máquina:

La macchina: Stroj: Il-magna:

Machine: Mašina: Mašīna:

Maskin: Stroj:

Laite: Maşina:

Model/Type: R+420, R+460

Designation: Rake

Serial:

EF-overensstemmelseserklæring/ EG-Konformitätserklärung/ EC Declaration of Conformity/ Déclaration CE de

conformité/ Dichiarazione CE di conformita/ EG Verklaring van Overeenstemming/ EG-försäkran om överensstämmelse/

EY-vaatimustenmukaisuusvakuutus/ Declaración de conformidad CE/ Deklaracja Zgodności WE./ Декларация за

съответствие EO/ EK Megfelelőségi Nyilatkozat /ES Prohlášení o shodě/ EB Atitikties deklaracija/ ES prehlásenie o

zhode/ Declaraţia de conformitate CE/ Vastavuse Deklaratsioon EÜ /ES Izjava o skladnosti/ Δήλωση πιστότητας EK/

Declaração de fidelidade CE/ Dikjarazzjoni ta’ Konformità tal-KE/ EK Atbilstības deklarācija/

Fabrikant/ Hersteller/ Manufacturer/ Fabricant/ Produttore/ Fabrikant/ Fabrikant/ Valmistaja/ Fabricante/ Producent/

Производител/ Gyártó/ Výrobce/ Gamintojas/ Výrobca/ Producător/ Tootja/ Proizvajalec/ Κατασκευαστής/ Fabricante/

Fabbrikant/ Ražotājs

CNH INDUSTRIAL BELGIUM N.V.

Leon Claeysstraat 3a, 8210 Zedelgem, BELGIUM

Repræsenteret af Antoon Vermeulen, Leon Claeysstraat 3A, B8210 Zedelgem (Belgien), som også har tilladelse til at

indsamle teknisk dokumentation / vertreten durch Antoon Vermeulen, Leon Claeysstraat 3A, B8210 Zedelgem (Belgium),

der auch autorisiert ist, die technische Akte zu erarbeiten / represented by Antoon Vermeulen, Leon Claeysstraat 3A,

B8210 Zedelgem (Belgium), who is also authorised to compile the Technical File / Répresentés par Antoon Vermeulen,

Leon Claeysstraat 3A, B8210 Zedelgem (Belgique), également autorisé à constituer le dossier technique / rappresentati

da Antoon Vermeulen, Leon Claeysstraat 3A, B8210 Zedelgem (Belgio), autorizzato a compilare il File tecnico /

vertegenwoordigd door Antoon Vermeulen, Leon Claeysstraat 3A, B8210 Zedelgem (Belgium), die tevens is gemachtigd

om het Technisch Bestand samen te stellen / representerade av Antoon Vermeulen, Leon Claeysstraat 3A, B8210

Zedelgem (Belgien), som också har behörighet att sammanställa den tekniska dokumentationen / edustajamme Antoon

Vermeulenin, osoite Leon Claeysstraat 3A, B8210 Zedelgem (Belgium) välityksellä, jolla on myös oikeus laatia tekninen

tiedosto / representados por Antoon Vermeulen, Leon Claeysstraat 3A, B8210 Zedelgem (Bélgica), quien además está

autorizado para recopilar el documento técnico / której przedstawicielem jest Antoon Vermeulen, Leon Claeysstraat 3A,

B8210 Zedelgem (Belgia), który jest również upoważniony do sporządzania dokumentacji technicznej / представлявани

от Антоон Вермьолен, Leon Claeysstraat 3A, B8210 Zedelgem (Белгия), с упълномощение също да състави

Техническото досие / akiket képvisel: Antoon Vermeulen, Leon Claeysstraat 3A, B8210 Zedelgem (Belgium), aki

szintén jogosult a műszaki dokumentumok összeállítására / v zastoupení Antoon Vermeulen, Leon Claeysstraat 3A,

B8210 Zedelgem (Belgium), s autorizací k tvorbě technického souboru / atstovaujami Antoon Vermeulen, Leon

Claeysstraat 3A, B8210 Zedelgem (Belgija), taip pat turintis teisę sudaryti technines bylas / v zastúpení Antoonom

Vermeulenom, Leon Claeysstraat 3A, B8210 Zedelgem (Belgicko), ktorý je oprávnený zostavovať technickú

dokumentáciu / reprezentaţi de Antoon Vermeulen, Leon Claeysstraat 3A, B8210 Zedelgem (Belgia), care este, de

asemenea, autorizat să compileze dosarul ethnic / esindajatega Antoon Vermeulen, Leon Claeysstraat 3A, B8210

Zedelgem (Belgia), kellel on samuti luba tehnilise faili koostamiseks / ki nas zastopa Antoon Vermeulen, Leon

Claeysstraat 3A, B8210 Zedelgem (Belgija), ki je pooblaščen tudi za sestavo tehnične dokumentacije /

εκπροσωπούμενοι από τον Antoon Vermeulen, Leon Claeysstraat 3A, B8210 Zedelgem (Βέλγιο), με εξουσιοδότηση και

για τη σύνταξη του Τεχνικού φακέλου / representados por Antoon Vermeulen, Leon Claeysstraat 3A, B8210 Zedelgem

(Bélgica), que também tem autorização para compilar o Ficheiro Técnico / irrappreżentata minn Antoon Vermeulen Leon

Claeysstraat 3a, B8210 Zedelgem (Belġju), min huwa wkoll awtorizzat li tiġbor l-Fajl Tekniku / Antoon Vermeulen, Leon

Claeysstraat 3A, B8210, Zedelgem (Belgium), pārstāvēti, kas ir pilnvarots arī sastādīt tehnisko reģistru

Erklærer hermed, at/ Erklären hiermit, daß/ Hereby declare that/ Déclare par la présente que/ Dichiara che/ Verklaren

hierbij dat/ Försäkrar härmed, att/ Vakuuttaa täten, että tuote/ Por el presente declara que/ Niniejszym deklaruje, że/

Декларирам, че/ Az alábbiakban kijelentem, hogy/ Tímto prohlašuje, že/ Deklaruoja, kad/ Týmto prehlasujeme, že/ Prin

prezenta declar că/ Alljärgnevaga deklareerib, et/ Izjavljamo, da je/ Με το παρόν δηλώνω ότι/ Abaixo declara que /

Jiddikjaraw li / Apstiprinu, ka

- er i overensstemmelse med Maskindirektivets bestemmelser (Direktiv 2006/42/EF) og hvis relevant også

bestemmelserne i EMC-direktivet 2014/30/EU.

- In übereinstimmung mit den Bestimmungen der Maschinen-Richtlinie 2006/42/EG und wenn erforderlich auch mit der

EMC-Richtlinie 2014/30/EU hergestellt wurde.

- is in conformity with the provisions of the Machinery Directive 2006/42/EC and if relevant also the provisions of the

EMC Directive 2014/30/EU.

Page 48

- est conforme aux dispositions de la Directive relatives aux machines 2006/42/CE et également aux dispositions de la

Directive sur la Directive EMC 2014/30/UE.

- é in conformita' con la Direttiva Macchine 2006/42/CE e, se pertinente, anche alla Direttiva alla Direttiva EMC

2014/30/UE.

- in overeenstemming is met de bepalingen van de Machine richtlijn 2006/42/EG en wanneer relevant ook met de

bepalingen van de EMC richtlijn 2014/30/EU.

- är i överensstämmelse med Maskindirektivets bestämmelser (Direktiv 2006/42/EG) ock om relevant också

bestämmelserne EMC-direktivet 2014/30/EU.

- täyttää Konedirektiivin (Direktiivi 2006/42/EY) määräykset ja oleellisilta osin myös EMC-direktiivin 2014/30/EU.

- es conforme a la Directiva de Maquinaria 2006/42/CE y, si aplica, es conforme también a la Directiva EMC

2014/30/EU.

- pozostaje w zgodzie z warunkami Dyrektywy Maszynowej 2006/42/WE i jeżeli ma to zastosowanie również z

warunkami Dyrektywy dot. kompatybilności elektro magnetycznej EMC 2014/30/UE.

- отговаря на изискванията на Директивата за Машините 2006/42/EО и ако има приложение на изискванията на

Директивата за електромагнитна съвместимост 2014/30/EC.

- Megfelel a 2006/42/EK Gépi Eszközökre vonatkozó előírásoknak és amennyiben felhasználásra kerül, a 2014/30/EU

Elektromágneses kompatibilitás Irányelv feltételeinek.

- odpovídá základním požadavkům Strojní směrnice 2006/42/ES a jestliže to její uplatnění vyžaduje i s podmínkami

Směrnice 2014/30/EU týkající se elektromagnetické kompatibility.

- atitinka Mašinų direktyvos Nr. 2006/42/EB ir, jeigu taikoma, Elektromagnetinio suderinamumo direktyvos Nr.

2014/30/ES reikalavimus.

- je v súlade s podmienkami Smernice 2006/42/ES o strojných zariadeniach a pokiaľ si to jeho uplatnenie vyžaduje aj

s podmienkami Smernice 2014/30/EÚ o elektromagnetickej kompatibilite.

- îndeplineşte prevederilor Directivei de Maşini 2006/42/CE şi dacă este utilizată de asemenea cu prevederile Directivei

referitoare la compatibilitatea electro-magnetică EMC 2014/30/UE.

- on vastavuses Masinate Direktiivi tingimustega 2006/42/EÜ ning sammuti juhul, kui on tegemist sammuti on vastavuses

Elektromagnetilise kokkusobivuse Direktiivitingimustega EMC 2014/30/EL.

- z določili Direktive o strojih 2006/42/ES ter, če je to relevantno, tudi z določili EMC Direktive 2014/30/EU.

- παραμένει σύμφωνη με τους όρους της Οδηγίας περί Μηχανών 2006/42/ΕΚ και σε περίπτωση που αυτό εφαρμόζεται

και με τους όρους της Οδηγίας περί ηλεκτροµαγνητικής συµβατότητας (ΗΜΣ) 2014/30/EE.

- Está de acordo com exigências das Directivas das Maquínarias 2006/42/CE e no caso em que tiver igualmente

aplicação com as exigências das Directivas referentes a compatibilidade electromagnética EMC 2014/30/UE.

- tikkonforma mad-dispożizzjonijiet tad-Direttiva dwar il-Makkinarju 2006/42/KE u jekk rilevanti wkoll mad-dispożizzjonijiet

tad d-Direttiva EMC 2014/30/EU.

- atbilst mašīnu direktīvai 2006/42/EK, kā arī nepieciešamības gadījumā elektromagnētiskās saderības direktīvai EMC

2014/30/ES.

Zedelgem, date:

Antoon Vermeulen

Page 49

Page 50

Dealer’s stamp

CNH Industrial Belgium N.V. reserves the right to make improvements in design and changes in specifications

at any time without notice and without incurring any obligation to install them on units previously sold.

Specifications, descriptions, and illustrative material herein are as accurate as known

at time of publication, but are subject to change without notice.

Availability of some models and equipment builds varies according to the country

in which the equipment is being used. For exact information about any particular product,

please consult your Kongskilde dealer.

© 2018 CNH Industrial Belgium N.V. All Rights Reserved.

Kongskilde is a trademark registered in the United States and many other countries,

owned by or licensed to CNH Industrial N.V., its subsidiaries or affiliates.

Any trademarks referred to herein, in association with goods and/or services of companies, other than owned by or licensed to

CNH Industrial N.V., its subsidiaries or affiliates, are the property of those respective companies.

Loading...

Loading...