Page 1

ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1

OPERATOR’S MANUAL

R+ 1610 S

Rotary rake

Part number 51514543

st

1

edition English

April 2019

Page 2

Contents

1GENERALINFORMATION

Notetotheowner...........................................................................1-1

Intendeduse................................................................................1-4

Prohibitedusage...........................................................................1-5

Electro-MagneticCompatibility(EMC).....................................................1-6

Manualscopeandrequiredtraininglevel..................................................1-7

ProductIdenticationNumber(PIN)........................................................1-9

ProductIdentication......................................................................1-10

Operator'smanualstorageonthemachine...............................................1-11

Implementorientation.....................................................................1-12

2SAFETYINFORMATION

Safetyrulesandsignalworddenitions....................................................2-1

Generalrecommendations.................................................................2-2

Illustrations.................................................................................2-3

Legalobligations...........................................................................2-3

Fireorexplosionprevention................................................................2-3

Hazardouschemicals.......................................................................2-4

Startinguptheimplementsafely...........................................................2-5

Travelingonpublicroads...................................................................2-6

Operatingtheimplementsafely............................................................2-8

Stoppingtheimplementsafely.............................................................2-9

Maintenance...............................................................................2-10

PersonalProtectiveEquipment(PPE)....................................................2-11

Safetyrequirementsforuidpowersystemsandcomponents-hydraulicsystems......2-12

Noiseemission............................................................................2-13

Vibrationlevels............................................................................2-13

Implementstability.........................................................................2-14

Ecologyandtheenvironment.............................................................2-15

Safetysigns...............................................................................2-16

3CONTROLSANDINSTRUMENTS

Information

Operatingprinciples....................................................................3-1

4OPERATINGINSTRUCTIONS

Commissioningtheunit

Preparingforoperation.................................................................4-1

Installationofextrawheelsonrotorchassis(optionalequipment).....................4-2

Startingtheunit

Connectiontothetractor...............................................................4-3

PowerTake-Off(PTO)shaft–Shorten.................................................4-5

Page 3

Parkingtheunit

Disconnectionandparking.............................................................4-7

5TRANSPORTOPERATIONS

Preparingforroadtransport

Liftingtherotorsfortransport...........................................................5-1

6WORKINGOPERATIONS

Generalinformation

Descriptionofoperation................................................................6-1

Basicadjustment.......................................................................6-3

Conversionoftherakefromtransporttoworkingposition.............................6-6

7MAINTENANCE

Generalinformation

Maintenance............................................................................7-1

Torque..................................................................................7-2

Torqueforclass12.9...................................................................7-5

Fluidsandlubricants...................................................................7-6

Maintenanceplanning

Maintenancechart......................................................................7-7

Aftertherst3hoursofoperation

Boltsandttings........................................................................7-8

Everyday

Universaljoint..........................................................................7-8

Everyweek

PowerTake-Off(PTO)shaft............................................................7-9

Drivejoint..............................................................................7-11

Everymonth

Steeringknuckle.......................................................................7-13

Headstock.............................................................................7-14

Steeringrod...........................................................................7-15

Cylinder/Ratchet.......................................................................7-16

Rotorgear/Camtrack..................................................................7-17

Everyyear

Implementinspection..................................................................7-19

Page 4

Every6years

Hydraulichoses.......................................................................7-19

Asrequired

Tirepressure..........................................................................7-20

Transmission..........................................................................7-20

Bearingarm...........................................................................7-20

Storage

Pressurewashing.................................................................7-21

Endofseasonservice.............................................................7-22

Orderingpartsand/oraccessories..............................................7-23

8TROUBLESHOOTING

Faultcoderesolution

Troubleshooting....................................................................8-1

9SPECIFICATIONS

Technicaldata..............................................................................9-1

Fluidsandlubricants.......................................................................9-1

10ACCESSORIES

Generalinformation.......................................................................10-1

Tandemcasterwheels.....................................................................10-1

Supportchainforlinkarms................................................................10-1

Hydraulicvalveforsuccessiverotorlift....................................................10-1

Swathcanvasfortwosingleswaths.......................................................10-2

11FORMSANDDECLARATIONS

ECDeclarationofConformity.............................................................11-1

Page 5

1-GENERALINFORMATION

1-GENERALINFORMATION###_1_###

Notetotheowner

Thismanualhasbeenpreparedtoassistyouinthecorrectproceduretorunin,todrive,tooperate,toadjustandto

maintainyournewimplement.

Thisimplementhasbeendesignedandbuilttogivemaximumperformance,economyandeaseofoperationunder

awidevarietyofconditions.

Priortodelivery,yourimplementwascarefullyinspectedbothatthefactoryandbyyourdealertomakesurethatit

reachesyouinoptimumcondition.Tomaintainthisconditionandassuretrouble‐freeoperationitisimportantthat

routineservices,asspeciedinthismanual,arecarriedoutattherecommendedintervals.

Readthismanualcarefully(especiallyChapter2thatcoversthesafetyinformation)andkeepthismanualinaconvenientplaceforfuturereference.DONOToperateorpermitanyonetooperateorservicethisimplementuntilyou

and/orotherpersonshavereadthismanual.Readthemanual,itwillsaveyoutimeandhasslelater.Lackofknowledgecanleadtoaccidents.Employonlytrainedoperatorswhohavedemonstratedtheabilitytooperateandservice

thisimplementcorrectlyandsafely.Contactyourdealerforassistanceprovidingtherequiredtrainingtoyouroperators.Contactyourdealertoobtainadditionalmanualsoralternatelanguageversions.

Ifatanytimeyourequireadvicethatconcernsyourimplement,donothesitatetocontactyourauthorizeddealer.He

hasfactory‐trainedpersonnel,genuineservicepartsandthenecessaryequipmenttocarryoutyourservicerequirements.

NOTICE:ThisimplementhasbeendesignedandbuiltinlinewiththerequirementsputforwardbytheEuropean

Directives2006/42/ECand2014/30/EU.

AlwaysusegenuineKONGSKILDEServicePartsorpartsthatmatchatleastthesamequality,reliabilityandfunctionalityastheequivalentoriginalServicePartswhenyouserviceandrepairyourimplementanddonotmodifyyour

implementwithoutawrittenpermissionofthemanufacturer.Failuretodosowillvoidtheresponsibilityofthemanufacturer.

Checklocalroadlegislationbeforeyoudrivetheimplementonpublicroads.

Whenyouoperateinterchangeableimplement,makesurethattheimplementisCEapproved.

Asthispublicationisdistributedthroughoutourinternationalnetwork,theimplementillustrated,eitherasstandardor

asanaccessory,mayvaryaccordingtothecountryinwhichtheimplementistobeused.Lowspecicationcongurations,aschosenbythecustomer ,maydeviatefromthespecicationsgiven.

Severalguresinthisoperator'smanualshowthesafetyguardingortheadditionalguards,legallyrequiredbycertain

countries,openorremovedtobetterillustrateaparticularfeatureoradjustment.Theimplementmustnotbeusedin

thiscondition.Foryourownsafety,makesurethatallguardsareclosedorreplacedbeforeyouoperatetheimplement.

1-1

Page 6

1-GENERALINFORMATION

OWNERASSISTANCE

WeatKONGSKILDEandyourKONGSKILDEdealerwantyoutobecompletelysatisedwithyourinvestment.Normally,yourdealer'sServiceDepartmentwillhandleanyproblemswithyourimplement.Sometimeshowever,misunderstandingcanoccur.Ifyourproblemhasnotbeenhandledtoyoursatisfaction,wesuggestyoutocontacttheowner

orGeneralManagerofthedealership,explaintheproblemandrequestassistance.Whenadditionalassistanceis

needed,yourdealerhasdirectaccesstoourbranchofce.

COMPANYPOLICY

Companypolicy,whichisoneofcontinuousimprovement,reservestherighttomakechangesindesignandspecicationatanytimewithoutnoticeandwithoutobligationtomodifyunitspreviouslybuilt.

Alldatagiveninthisbookissubjecttoproductionvariations.Theinformationinthispublicationisprovidedonthe

basisofinformationthatwasavailableatthetimethatthemanualwaswritten.Settings,proceduresandotheritems

canchange.Thesechangescanaffecttheservicethatisgiventotheimplement.

Dimensionsandweightsareapproximateonlyandtheillustrationsdonotnecessarilyshowtheimplementinstandard

condition.Forexactinformationaboutanyparticularimplementpleaseconsultyourdealer.Makesurethatyouhave

themostcurrentandcompleteinformationfromyourdealerbeforeyoustartanyjob.

ACCESSORIESANDOPTIONS

Yourimplementhasbeendesignedtooperateinawidevarietyofsoils/cropsandconditions.Neverthelessadditional

equipmentmay,incertaincases,berequiredtoimprovetheimplementperformance.Alistofthisadditionalequipmentisgiveninthe''Accessories”chapterinthismanual.Useonlythoseaccessoriesdesignedforyourimplement.

PARTSANDACCESSORIES

GenuineKONGSKILDEpartsandaccessorieshavebeenspecicallydesignedforKONGSKILDEimplements.

Wewouldliketopointoutthat''non-genuine”partsandaccessorieshavenotbeenexaminedandreleased

byKONGSKILDE.Theinstallationand/oruseofsuchproductscouldhavenegativeeffectsuponthedesign

characteristicsofyourimplementandtherebyaffectitssafety.KONGSKILDEisnotliableforanydamagecaused

bytheuseof''non-genuine”partsandaccessories.

RelyonyourauthorizeddealertosupplyyouwithgenuineKONGSKILDEpartsonly.Thesepartsarecoveredbyour

warrantyandwillgiveyouthebestperformance.

SeethepartscatalogorbrowsetheKONGSKILDEportaltondservicepartsforyourimplement.

Whenyouorderserviceparts,alwaysquotethemodelandserialnumberprintedontheProductIdenticationNumber

(PIN)plate.

1-2

Page 7

1-GENERALINFORMATION

LUBRICANTS

Yourdealersellsaselectionofspeciallyformulatedlubricantsbasedonownengineeringspecications.

Recommendedlubricantsforyourimplementarelistedinthemaintenancechapter.

WARRANTY

Yourimplementiswarrantedaccordingtolegalrightsinyourcountryandthecontractualagreementwiththeselling

dealer.Nowarrantyshall,however,applyiftheimplementhasnotbeenused,adjustedandmaintainedaccordingto

theinstructionsgiveninthisoperator'smanual.

Itisprohibitedtocarryoutanymodicationstotheimplementunlessspecicallyauthorized,inwriting,bya

KONGSKILDErepresentative.

CLEANINGYOURIMPLEMENT

Whenyouuseahighpressurewasher,donotstandtooclosetotheimplementandavoiddirectingthejetatelectronic

components,electricalconnections,breathers,seals,llercaps,andsoon.

Cleandecalsonlywithasoftcloth,waterandagentledetergent.DONOTusesolvent,gasolineorotherharsh

chemicalstocleandecals.Decalscouldberemovedorgetdamaged.

DISASSEMBLYORSCRAPPING

Whenyourimplementistakenoutofservicebecauseitisdamagedbeyondrepairorhasreachedtheendofits

usefullife,disassembly,scrappingand/orrecyclingofcomponentsmustbeperformedonlybyaqualiedtechnician

withserviceinstructions,andincompliancewithlocallawandregulations.

1-3

Page 8

Intendeduse

1-GENERALINFORMATION

TheKONGSKILDErotaryrakecanonlyperformtheusual

workinagriculture.Onlyconnecttherotaryraketoa

tractorwhichcorrespondswiththespecicationsofthe

implementandislegaltouse.OnlythePowerTake-Off

(PTO)shaftofthetractorcandrivetheattachedrotary

rake.

Therotaryrakemayonlybeusedforrakegrasshayand

strawcropsontheground.

Consideranyotherusecontrarytotheintendeduse.The

manufacturerisnotresponsibleforanydamagethatre-

sultsfromtheimproperuseoftheimplement.Theuser

bearsthatrisk.

Alwaysobservethefollowingsafetyinstructionsaswell

asthecommonrulesconcerningtechnicalsafety,working

practicesandroadsafety.

Ifyoumakechangestotheimplementanditsconstruction

withoutthepermissionfromthemanufacturer,themanufacturerdoesnotacceptanyresponsibilityfordamages

thatresultsfromthis.

1-4

Page 9

1-GENERALINFORMATION

Prohibitedusage

Sweepingofforexamplefarmyardswiththetinearmassemblyorbroomsfastenedtotheseisnotallowed.There

isariskthatforexamplestonesarethrownoutfromthe

workingareaoftheimplementwithdangerofpersonalinjuryordamagetoobjects.

Anyusebeyondtheintendeduseisregardedasforeseeablemisuse.

1-5

Page 10

1-GENERALINFORMATION

Electro-MagneticCompatibility(EMC)

ThismachinecompliesstrictlywiththeEuropeanRegulationsonelectro‐magneticemissions.However,interference

mayariseasaresultofadd‐onequipmentwhichmaynotnecessarilymeettherequiredstandards.Assuchinterferencecanresultinseriousmalfunctionoftheunitand/orcreateunsafesituations,youmustobservethefollowing:

Ensurethateachpieceofnon‐KONGSKILDEequipmentttedtothemachinebearstheCEmark.

•

Themaximumpowerofemissionequipment(radio,telephones,etc.)mustnotexceedthelimitsimposedbythe

•

nationalauthoritiesofthecountrywhereyouusethemachine.

Theelectro‐magneticeldgeneratedbytheadd‐onsystemshouldnotexceed24V/matanytimeandatanylo-

•

cationintheproximityofelectroniccomponents.

FailuretocomplywiththeseruleswillrendertheKONGSKILDEwarrantynullandvoid.

1-6

Page 11

1-GENERALINFORMATION

Manualscopeandrequiredtraininglevel

Introductiontothismanual

Thismanualgivesinformationabouttheuseofyour

KONGSKILDEmachineasintendedandunderthe

conditionsforeseenbyKONGSKILDEduringnormal

operation,routineservice,andmaintenance.

Thismanualdoesnotcontainalltheinformationthatrelatestoperiodicservice,conversions,andrepairsthat

onlytrainedservicepersonnelcanperform.Someof

theseactivitiesmayrequireappropriatefacilities,technicalskills,and/ortoolsthatKONGSKILDEdoesnotsupply

withthemachine.

ThemanualcontainsthechaptersasshownontheContentspages.SeetheIndexattheendofthismanualto

locatespecicitemsaboutyourKONGSKILDEmachine.

Normaloperation

Normaloperationconsistsoftheuseofthismachinefor

thepurposeKONGSKILDEintendsbyanoperatorthat:

Isfamiliarwiththemachineandanymountedequip-

•

mentortowedequipment

Complieswiththeinformationonoperationandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Normaloperationincludes:

Preparationandstorageofthemachine

•

Additionandremovalofballast

•

Connectionanddisconnectionofmountedequipment

•

and/ortowedequipment

Adjustmentandcongurationofthemachineand

•

equipmentforthespecicconditionsofthejobsite,

eld,and/orcrop

Movementofcomponentsintoandoutofworkingpo-

•

sitions

Routineserviceandmaintenance

Routineserviceandmaintenanceconsistsofthedaily

activitiesnecessarytomaintainthepropermachine

function.Theoperatormust:

Befamiliarwiththemachinecharacteristics

•

Complywiththeinformationonroutineserviceandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Routineservicecaninclude:

Fueling

•

Cleaning

•

Washing

•

Toppingupuidlevels

•

Greasing

•

Replacingconsumableitemssuchaslightbulbs

•

Periodicservice,conversions,andrepairs

Periodicserviceconsistsofactivitiesthatarenecessary

tomaintaintheexpectedlifeoftheKONGSKILDEmachine.Theseactivitieshavedenedintervals.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivitiesatthedened

intervals.Trainedservicepersonnelmustcomplywith

theinformationonperiodicserviceandsafepracticesas

partlyspeciedbyKONGSKILDEinthismanualand/or

othercompanyliterature.

Periodicserviceincludes:

Oilchangeservicefortheengine,hydrauliccircuits,or

•

transmission

Periodicexchangeofothersubstancesorcomponents

•

asrequired

ConversionactivitiesrebuildtheKONGSKILDEmachine

inacongurationthatisappropriateforaspecicjob

site,crop,and/orsoilconditions(e.g.,installationofdual

wheels).Conversionactivitiesmustbedone:

Bytrainedservicepersonnelfamiliarwiththemachine

•

characteristics

Bytrainedservicepersonnelthatcomplywiththe

•

informationonconversionaspartlyspeciedby

KONGSKILDEinthismanual,assemblyinstructions,

and/orothercompanyliterature

Repairactivitiesrestoreproperfunctiontoa

KONGSKILDEmachineafterafailureordegradation

ofperformance.Dismantlingactivitiesoccurduringthe

scrappingand/ordismantlingofthemachine.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivities.Trainedservice

personnelmustcomplywiththeinformationforrepairas

speciedbyKONGSKILDEintheservicemanual.

Beforeyouoperate

Readthismanualbeforeyoustarttheengineor

operatethisKONGSKILDEmachine.Contactyour

KONGSKILDEdealerif:

Youdonotunderstandanyinformationinthismanual

•

Youneedmoreinformation

•

Youneedassistance

•

Allpersonstrainingtooperate,orwhowilloperate

thisKONGSKILDEmachineshouldbeoldenoughto

possessavalidlocalvehicleoperatingpermit(ormeet

otherapplicablelocalagerequirements).Thesepersons

1-7

Page 12

1-GENERALINFORMATION

mustdemonstratetheabilitytooperateandservicethe

KONGSKILDEmachineinacorrectandsafemanner.

1-8

Page 13

1-GENERALINFORMATION

ProductIdenticationNumber(PIN)

TheProductIdenticationNumber(PIN)isaserialnumberthatidentiestheimplement.

Theserialnumber,model,andotherspecications,are

onthePINplate.

ProvideyourKONGSKILDEdealerwiththemodeland

PINwhenyouorderspareparts.

ZEIL18HT00548FA1

(1)Companyname(8)

(2)Brandidenticationlogo(9)

(3)

(4)

(5)Yearofconstruction(12)Type/Variant/Version

(6)Madein(countryoforigin)(13)

(7)Certicationmark

Mailaddress

Modelyear

(10)ProductIdenticationNumber(PIN)

(11)

Maximumpermissibleloaddividedpereach

axleanddrawbar

RéceptionnéleparlaDRIEEIledeFrance

(forFranceonly)

Model

Designation

1-9

Page 14

1-GENERALINFORMATION

ProductIdentication

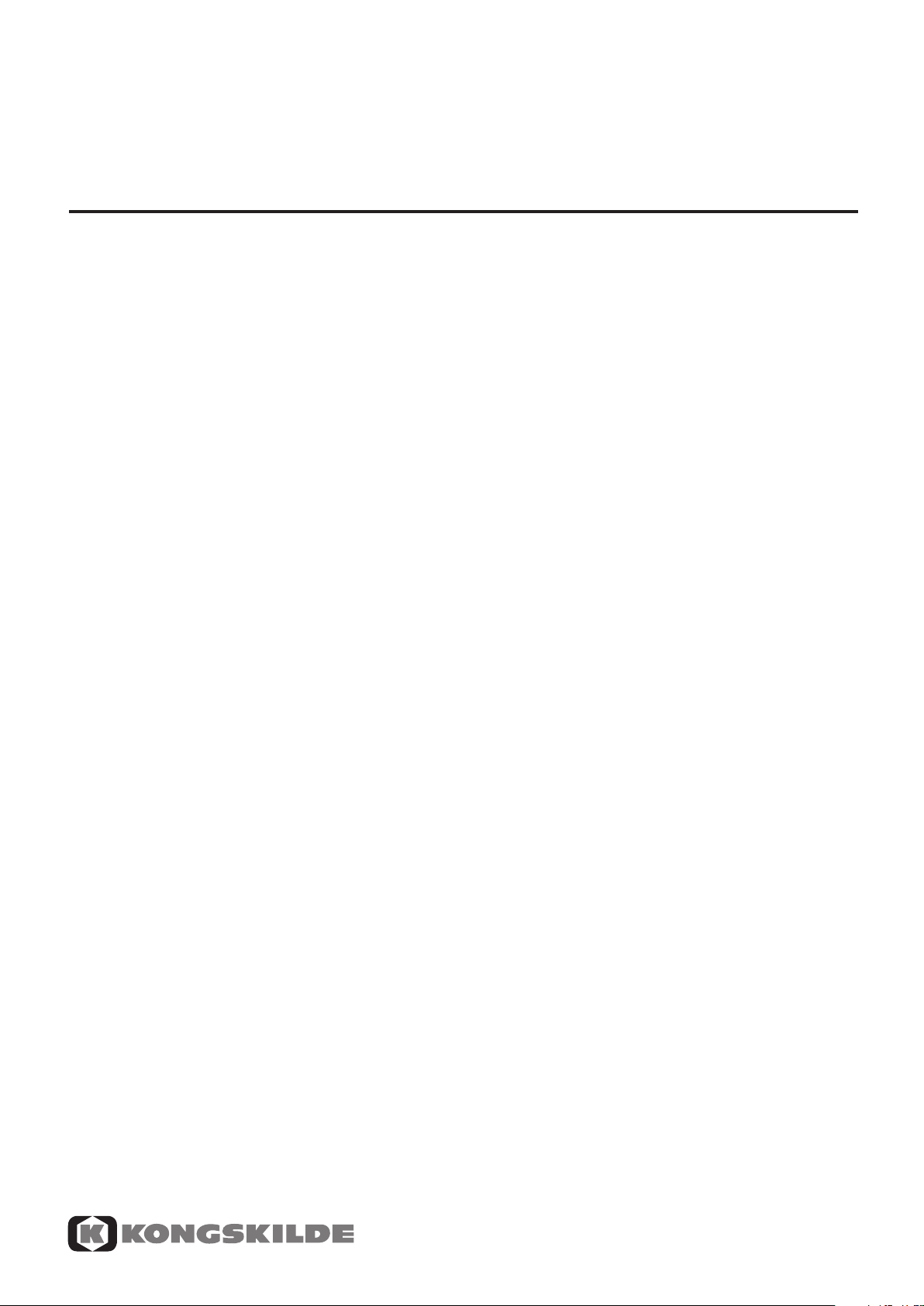

NOTE:DonotremoveorchangetheProductIdenticationNumber(PIN)plate(1)ontheimplement.

ThePINplate(1)isplacedontheright-handsideofthe

implement.

ThePINisalsoengravedonthechassisat(A)belowthe

PINplate(1).

Forfuturereference,recordyourimplementmodeland

PINinthespacesbelow.

Model

ProductIdenticationNumber(PIN)

ZEIL18HT00791FA1

1-10

Page 15

1-GENERALINFORMATION

Operator'smanualstorageonthemachine

Keepthisoperator'smanualprotectedandaccessibleon

thetractorwheneveryoutransportoroperatetheimplement.

1-11

Page 16

1-GENERALINFORMATION

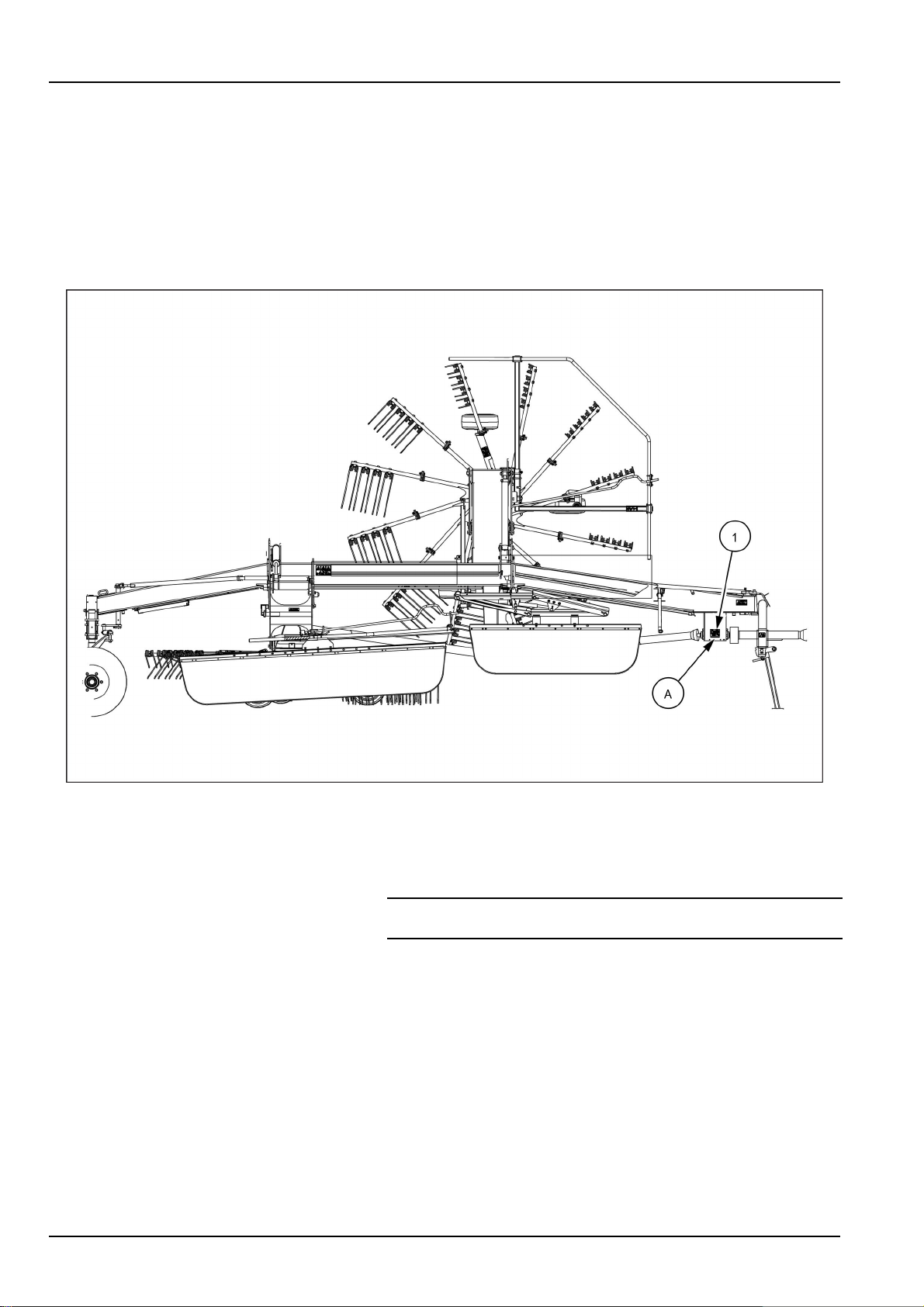

Implementorientation

NOTE:T odeterminetheleft-handsideandtheright-hand

sideoftheimplement,standbehindtheimplementand

facethedirectionoftravelduringworkingoperation.

Thefollowingoverheadviewillustrationisageneralrepresentationoftheimplement.Theillustrationindicatesthe

sides,front,andrearorientationsoftheimplementasreferredtothroughouttheoperator’smanual.

NOTE:Thearrowindicatesthedirectionoftheimplement

duringworkingoperation.

(A)Frontoftheimplement

(B)Right-handsideoftheimplement

(C)Rearoftheimplement

(D)Left-handsideoftheimplement

ZEIL18HT00790FA1

1-12

Page 17

2-SAFETYINFORMATION

2-SAFETYINFORMATION###_2_###

Safetyrulesandsignalworddenitions

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

ThroughoutthismanualyouwillndthesignalwordsDANGER,WARNING,andCAUTIONfollowedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworkingwithyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationthat,ifnotavoided,willresultindeathorseriousinjury.

WARNINGindicatesahazardoussituationthat,ifnotavoided,couldresultindeathorseriousinjury.

CAUTIONindicatesahazardoussituationthat,ifnotavoided,couldresultinminorormoderateinjury.

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESULT

INDEATHORSERIOUSINJURY .

Machinesafety

NOTICE:Noticeindicatesasituationthat,ifnotavoided,couldresultinmachineorpropertydamage.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachineor

propertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationthatclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

2-1

Page 18

2-SAFETYINFORMATION

Generalrecommendations

Mostfarmmachineryaccidentscanbeavoidedbythe

observanceofafewsimplesafetyprecautions.

Thisoperator’smanualcontainsimportantinformation

•

concerningoperation,maintenanceandadjustmentof

theimplement.Furthermore,thisoperator’smanual

mentionsandemphasizesallthesafetyinstructions.

Readtheoperator’smanualthoroughlybeforeyou

•

start,operate,service,orcarryoutanyotheroperation

ontheimplement.Eventhoughyouhavebeendriving

asimilarimplementbefore,youmustreadthemanual.

Thisisamatterofyourownandotherpeoplesafety.

Afewminutesreadingwillsaveyoutimeandhassle

later.Lackofknowledgecanleadtoaccidents.

Yourimplementwasdesignedwithsafetyinmind.

•

However,thereisnorealsubstituteforcautionand

attentionwhenyouneedtopreventanaccident.Once

anaccidenthasoccurred,itistoolatetothinkabout

whatyoushouldhavedone.Thismeansthatitis

veryimportantthatyouasuseroftheimplementpay

attentionandusetheimplementcorrectlyandthereby

avoidexposingyourselfandotherstounnecessary

danger.

Theimplementmustbeoperatedonlybyresponsible

•

personswhohavebeenadequatelytrainedandautho-

rizedtousetheimplement.Neverleavetheimplement

toothersbeforeyouhavemadesurethattheyhavethe

necessaryknowledgetooperatetheimplementsafely.

Neverlettheimplementrunwithoutsupervision.

•

Alwayskeeparstaidkithandy.

•

Takethenecessaryprecautions(forexampleassis-

•

tance)toalwaysbeawareofthepossiblepresenceof

bystandersandpets.

Keepchildrenawayfromandofftheimplementatall

•

times.

Donotusethisimplementasalift,ladderorplatform

•

toworkatheights.

Beforeyouworkontheimplement,disengageall

•

drives,stoptheengineandremovetheignitionkey.

Waitfortherotatingpartstorundown.

Neverworkaroundtheimplementwithlooseclothing,

•

jewelry,watches,longhairandotherlooseorhanging

itemscanbepulledinbythemovingpartsoftheimplement.

Keephandsawayfrommovingpartsoftheimplement.

•

Neverattempttocarryoutanyadjustmentsontheim-

•

plementwhiletheimplementisinmotionorwhilethe

PowerT ake-Off(PTO)shaftisengaged.

PTOdrivenimplementcancausedeathorseriousin-

•

jury.BeforeyouworkonornearthePTOshaftorser-

viceorclearthedrivenimplement,disengagethePTO,

stoptheengineandremovetheignitionkey.

2-2

Page 19

2-SAFETYINFORMATION

Illustrations

WARNING

Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment.

Replaceallshieldsbeforeoperatingthemachine.

Failuretocomplycouldresultindeathorseriousinjury.

NOTE:Someoftheillustrationsinthismanualhavebeen

obtainedbyphotographingprototypes.Standardproductionmachinesmaydifferinsomedetails.

Legalobligations

W0012A

Yourmachinemaybeequippedwithspecialguardingor

otherdevicesincompliancewithlocallegislation.Some

oftheserequireactiveactionbytheoperator.

Fireorexplosionprevention

1.Cropmaterial,trash,debris,birdnestsorammable

materialcanigniteonhotsurfaces.

2.Inspecttheelectricalsystemforlooseconnectionsor

frayedinsulation.Repairorreplacelooseordamaged

parts.

3.Donotstoreoilyragsorotherammablematerialon

theimplement.

4.Donotweldoramecutanyitemsthatcontain

ammablematerial.Cleanitemsthoroughlywith

Therefore,checklocallegislationontheusageofthismachine.

non-ammablesolventbeforeyouweldorcutwitha

ame.

5.Donotexposetheimplementtoames,burningbrush

orexplosives.

6.Promptlyinvestigateanyunusualsmellsorodorsthat

mayoccurduringtheoperationoftheimplement.

2-3

Page 20

Hazardouschemicals

2-SAFETYINFORMATION

1.Ifyouareexposedtoorcomeincontactwithhazardouschemicalsyoucanbeseriouslyinjured.

Theuids,lubricants,paints,adhesives,coolant,

etcetera.requiredforthefunctionofyourmachine

canbehazardous.Theymaybeattractiveandharmfulltodomesticanimalsaswellashumans.

2.MaterialSafetyDataSheets(MSDS)provideinformationaboutthechemicalsubstanceswithinaproduct,

safehandlingandstorageprocedures,rstaidmeasuresandprocedurestobetakenintheeventofaspill

oraccidentalrelease.MSDSareavailablefromyour

dealer.

3.BeforeyouserviceyourmachinechecktheMSDSfor

eachlubricant,uid,etcetera.usedinthismachine.

Thisinformationindicatestheassociatedrisksandwill

helpyouservicethemachinesafely.FollowtheinformationintheMSDS,onmanufacturercontainers,as

wellastheinformationinthismanualwhenyouservicethemachine.

4.Disposeofalluids,ltersandcontainersinanenvironmentallysafemannerinaccordancewithlocal

lawsandregulations.Checkwithlocalenvironmentalandrecyclingcentersoryourdealerforcorrectdisposalinformation.

5.Storeuidsandlterinaccordancewithlocallawsand

regulations.Useonlyappropriatecontainersforthe

storageofchemicalsorpetrochemicalsubstances.

6.Keepoutofreachofchildrenorotherunauthorized

persons.

7.Additionalprecautionsarerequiredforappliedchemicals.Obtaincompleteinformationfromthemanufacturerordistributorofthechemicalsbeforeyouuse

them.

2-4

Page 21

Startinguptheimplementsafely

2-SAFETYINFORMATION

Beforeyouattachtheimplementtothetractor,ensurethat

thetractorisingoodworkingorderandthatthebrakes

areefcient,particularlyifyouoperateonhillyground.

Also,ensurethatthehydraulicorpneumaticsystemis

compatiblewiththatoftheimplement.

Whenyouattachtheimplementtothetractor:

Neverallowanyonetostandbetweenthetractorand

•

theimplement.Anunintentionalmanoeuvrewiththe

tractormaycauseseriousinjury.

Nevergounderanunsupportedimplement.

•

Installalltheguardscorrectlybeforeyouusetheimplement.

Replacewornanddamagedcanvasesbeforeyouwork

withtheimplement.

MakesurethatyouarethoroughlyfamiliarwiththeinstrumentsandcontrolsbeforeyouengagethePowerT akeOff(PTO)driveforthersttime.

ThePTOshafthasitsowninstructionmanualthatthe

manufacturersupplywiththeimplement.Toensurethe

correctuseoftheshaft,followalltheinstructionsofthe

manufacturermanual.Payparticularlycloseattentionto

thesafetyandmaintenanceinstructions,inordertopreventunintentionalinjuryanddamage.

RepairimmediatelyadamagedPTOshaftbeforeyou

workwiththeimplement.

AlwaysstopthePTOandthetractorengineandremove

theignitionkeybeforeyouconnectthePTOdriveshafts.

Afteryouattachtheimplementtothetractor,ensurethat

thePowerTake-Off(PTO)lockpinisproperlyengaged

inthetractorPowerT ake-Offshaft.Anincorrectlylocked

PTOshaftcouldworklooseandcauseaccidentsordamagetotheimplement.

MakesuretoinstallandsecurethePTOdriveshaftcorrectly.Checkthatthelockpinisinmesh.Fastenthe

supportchainatbothends.

Alwaysmakesurethattheguardtubesdonotseparate

atthemaximumworkingortransportlengthofthePTO

driveshaft.Checkalsothattheguardtubesdonotjamat

theminimumworkingortransportlengthofthePTOdrive

shaft.

Unlesstheprotectiveguards,thePTOdriveshaftmay

causeseriousinjury.Becarefulnottodamagetheguards

whenyouconnectthePTOdriveshafttoorfromthetractor.

FitcorrectlytheguardsonthePTOdriveshaft.Secure

theguardofthePTOshaftwiththechain.

DonotusePowerTake-Off(PTO)driveshaftswithother

specicationsthantheshaftwhichwassuppliedwiththe

implement.

BeforeyouinstallthePTOdriveshaft,checkthattheRevolutionsPerMinute(RPM)anddirectionofthePTOonthe

tractormatchthoseofthePTOontheimplement.

Beforeyoustartuptheimplement(forexampletherst

timeafteralongstandstillperiod),makesurethatthere

arenodetachedloosepartsonthedrivelineareaandon

themovingpartsoftheimplement.

2-5

Page 22

Travelingonpublicroads

2-SAFETYINFORMATION

Complywiththerelevanttrafcregulations

WARNING

Impacthazard!

Takecarewhenmakingturns.Themachine

rearendswingsoutwhenchangingdirection.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Lossofcontrolhazard!

Unevenbrakeforceexistsonleft-handand

right-handbrakes.Alwaysusebrakepedal

couplerwhentravelingonpublicroadstoensurebrakesareactuatedtogether.

Failuretocomplycouldresultindeathorseriousinjury.

Theimplementisbuiltaccordingtothehomologationrequirementsofyourcountry.Donotmodifytheimplement

inasensethatwouldconictwiththenationalregulations.

Ifyouwishtotransporttheimplementonthepublicroad,

makesurethatthecombinationtractorandimplement

observesthetrafcrulesinyourcountry.Thisgivesyou

andyoursurroundingsthebestpossiblesafety.

Passengers

Donotallowpassengerstorideinthetractorunlessa

specicseatisprovided.

Duringtransport,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

W0089A

W0081A

Transportsafety

Transporttheimplementonlyintransportposition.Securetheimplementfortransport.Alwaysactivatethemechanicaltransportsafetydevicesbeforetransport.

Makesuretotallthehitchpinswithretainingpinscorrectly.Mechanicallysecurethehydrauliccylinderstopreventcylindersfromcreeping.

Drivesafe

Donotdriveundertheinuenceofalcoholordrugs.

Nevertravelatspeedincrowdedareas.

Whenyoumaneuverthetractorwiththeimplement,alwaysbeawareandconsciousofitssize.

Thetractordrivermustnotleavethecabinduringtransport.

Theoperatorsmustobserverelevantstatutoryorother

nationalregulationsthatdealwithroadsafetyandlabor

safetyissues.

Beforeyoudrivetheimplementonpublicroads:

Checktheallowabletransportdimensionsandweights.

•

Installcorrectlythelightingandthewarningpanels.

•

Alwaysobservetheprinciplesforpermissibleaxleloads,

thetotalunitmassandthetransportgauge.

Observethetractormanufacturerregulationsandrecommendations,specicallythoserelatingtomaximumtransportloadsandmaximumspeed.

Eveninsimilarcircumstances,themaximumallowed

speedcanvarydependingonwhichcountryyoutravel

in.

Alwaysdrivewiththestatutorylightsandsafetymarking

duringtransportonpublicroadandatnight.

Installalltherequiredsignsthatindicatethevehiclewidth.

Alsoinstallalltherequiredlightsthatindicatethevehicle

widthduringthenightlytransport.Ifindoubt,contactyour

governmentdepartmentresponsibleforroadtransport.

Alwaysconsiderotherroadusers.

Alwaysadoptsafedrivingpractices.Slowdownandsignalbeforeturning.Givewaytooncomingtrafcinallsituations,includingnarrowbridges,intersectionsetcetera.

Pullovertoallowfastertrafctopass.

Iftheimplementismarkedwithamaximumspeedlimit,

neverexceedthismaximumspeedlimit.

Alwaysadjustthedrivingspeedtotheroadandweather

conditions.Incaseofbadroadconditionsandhighdrivingspeeds,bigforcesmayoccurandcauseoverloadof

tractorandimplement.

Driveatasafespeedtoensurecontrolandabilitytostop

inanemergency.

Lockthetractorbrakepedalstogether.Neveruseindependentbreakingattransportspeeds.

Mountedimplementsandballastweightsinuencethe

driving,steeringandbrakingcapacityofthetractor.Make

surethattheadditionalweightoftheimplementonthe

linkagedoesnotcompromisedriving,steeringandbrakingcapacityofthetractor.Installfrontweightsorrepair

thebrakesifthetractorisnotsafetodrive.

Travelmayberestrictedtocertainroadtypes.Transport

mayberestrictedtodaytimeoroutsidepeaktrafchours.

Howeverplanyourroutetoavoidheavytrafcandpeak

trafchours.

Reducespeedduringturns.Tractorshavenotbeendesignedforfastturning.Avoidthattherearendoftheimplementhitsanobstacle.

2-6

Page 23

2-SAFETYINFORMATION

Whenyouturnduringtransportpayattentiontotheoverhangand/oroscillatingweightoftheimplement.

Useenginebrakingwhenyoudrivedownhills.Donot

coast.

Watchforobstructions,particularlyifover-width.Observe

anyloadratingsapplicableonbridges.

Afteryounishthetransport,beforeyouleavethetractor,

alwayslowertheimplementtothegroundinparkingposition,turnoffthetractorengine,pulltheparkingbrake,

andremovethekeyfromtheignition.

2-7

Page 24

Operatingtheimplementsafely

WARNING

Hazardtobystanders!

Alwayssoundthehornbeforestartingthemachine.Makesuretheworkareaisclearof

otherpersons,domesticanimals,tools,etc.

beforeyouoperatethemachine.Neverallow

anyoneintheworkareaduringmachineoperation.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Rotatingparts!

Keepclearofalldrivesandrotatingcomponents.

Failuretocomplycouldresultindeathorseriousinjury.

2-SAFETYINFORMATION

Neverattempttoremoveresiduesfromtheimplement

whiletheimplementruns.Suchanimprudencecouldcost

lifeorlimb.AlwaysdisengagethePowerTake-Off(PTO)

shaftmechanism,switchOFFthetractorengineandapplytheparkingbrakebeforeyouremoveresidues.

Duringthedailyworkyoumustconsiderthatloosestones

andforeignmatteronthegroundmightgetincontactwith

therevolvingpartsandgetthrownoutagainatavery

highspeed.Therefore,beforeyouoperatetheimplement

makesurethatallsafetyguardsareintact,properlytted

W0304A

W1101A

andsecured.

Beforeyouraiseorlowertheimplementwiththelinkarms

ofthetractor,checkthatnobodyisneartheimplementor

touchestheimplement.

Alwaysoperatetheimplementatasafespeedinaccordancewiththegroundconditions.Onunevenground,

proceedwiththeutmostcautiontoensureproperstability.

NOTE:Onlyputtheimplementintooperationaccording

totheinstructionsfromthedealer.

Neveroperatetheimplementundertheinuenceofalcohol,drugs,orwhileotherwiseimpaired.

Avoidusingtheimplementinunsuitableeldandweather

conditions.Itisbettertostopworktemporarilyratherthan

tooperateinsuchconditions.

Keeppeopleawayfromtheimplementduringoperation.

Askbystanderstoleavetheeld.Thereistheriskfor

bystanderstobeoverrunbytheimplement.Stoptheimplementimmediatelyifsomeoneapproaches.

Thetractororitsimplementmaystrikeorcrushagainsta

personorpetwithintheoperatorareaofthetractor.DO

NOTallowanyonetoentertheworkarea.Makesurethat

theareaisclearandoperationissafebeforeyoumove

theimplement.

Whenyouoperatetheimplement,alwaysremainseated

inthetractorcab.Operatecontrolsonlywhenseatedin

thetractorseat,exceptforthosecontrolsexpresslyintendedforusefromotherlocations.

Whenyouturnonhillsidesalwaysbecarefulwhenyoulift

theimplementwiththe3-pointlinkagebecausethereisa

riskofoverturning.Adjustthespeedtotheseconditions.

Driveinalowtractorgearifyouworkonhillsides.

Whenyoudriveupanddownandacrosshillsides,avoid

sharpturns.

Whenyouturnduringoperation,payattentiontotheoverhangand/oroscillatingweightoftheimplement.

Avoidchangingdirectionabruptly,especiallywhenyou

reverse,toavoiddangerouspitchingoftheimplement.

Whenyouworkwiththeimplementkeepasafedistance

fromsteepslopesandsimilargroundconditions,asthe

groundmaybeslipperyandpulltheimplementandthe

tractorsideways.Alsoremembertoadjustthespeedfor

sharpturnswhenyoudriveonhillsides.

Paythenecessaryattentionwhileyouoperatenextto

publicroadsorfootpaths.

Whileinoperation,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

2-8

Page 25

Stoppingtheimplementsafely

WARNING

Movingparts!

Somecomponentsmaycontinuetorunafter

disengagingthedrivesystems.Makesure

alldrivesystemsarefullydisengagedandall

movementhasstoppedbeforeservicingthe

machine.

Failuretocomplycouldresultindeathorseriousinjury.

2-SAFETYINFORMATION

thetractorcab,thenthefollowingprecautionsmustbe

followed:

•

•

•

•

Whenyouparktheimplementtherearesomeoperational

W0002A

riskswhichmaycausepersonalinjury.Therefore,you

must:

Bringthetractorenginetolowidlespeed.

Disengagealldrivesystems.

Shiftthetractortransmissionintoneutral.

Applytheparkingbrake.

Alwaysinterrupttheoperationoftheimplementbefore

youleavethetractorseat.

Forsafety'ssakeneverleavethetractorcabwithoutrst

todisengagethePowerTake-Off(PTO)shaftmechanism

andtostopthetractorengine.Furthermore,ifyouleave

thetractorunattended,alwaysremovetheignitionkey.

StopthetractorengineandthePTOshaftandwaituntil

theimplementhascompletelystoppedbeforeyouopen

anyofthesafetyguards.Therearerotatingpartsunderthesafetyguardswhichmaycontinuerotatingafter

theimplementhasbeenstopped.Lookandlistenforevidenceofrotatingpartsbeforeyouopenanyofthesafety

guards.

Makesuretosecurethetractorbymeansofthehand

brakeand/orstopblocksifyouneedtostandbetween

thetractorandtheimplement.

When,duetoexceptionalcircumstances,youwould

decidetokeepthetractorenginerunningafterleaving

Makesurethatthegroundisrmandevenduringpark-

•

ing.

Makesurethattractorandimplementcannotmove.

•

Alwayslowertheimplementtotheground.

•

Stopthetractorengineandremovetheignitionkey.

•

Usecorrectsupportortransportsafetydevicewhenthe

•

implementisparked.Makesurethattheparkingstand

issecured.

Whenyoudetachtheimplementfromthetractor:

Alwaysdetachtheimplementcarefullyandonaat

•

surfacetopreventdamage.

Makesurethatnobodystandsinfrontoftheimplement.

•

Neverallowanyonetostandbetweenthetractorand

•

theimplement.

Nevergounderanunsupportedimplement.

•

2-9

Page 26

2-SAFETYINFORMATION

Maintenance

WARNING

Maintenancehazard!

Beforeyoustartservicingthemachine,attach

aDONOTOPERATEwarningtagtothemachineinavisiblearea.

Failuretocomplycouldresultindeathorseriousinjury.

Followthemaintenanceschedulewithregardtotheim-

•

plementservicingintervals.

Rememberthattheimplementrequiresattentionfrom

timetotime.Alsorememberthatthemaintenancewill

greatlyextendthelifeoftheimplement.

Takethenecessaryprecautions:nottospillanyoil,fuel

•

orgrease.

Toavoidoilandgreasecontactwithyourskin,wear

protectivegloves.

Servicetheimplementonarmlevelsurface.

•

Donotattempttoremovematerialfromanypartof

•

theimplement,clean,lubricateorcarryoutanyadjust-

mentsontheimplementwhileitisinuse.

Keephands,feetand/orgarmentsawayfromparts

•

whichmove.Checkthatallrotatingpartshavea

suitableprotectiveguard.

Raisedimplementand/orloadscanfallunexpectedly

•

andcrushpersonsunderneath.Neverenterorallow

anyonetoentertheareaunderneathraisedimplement

duringoperation.

Unsupportedhydrauliccylinderscanlosepressure

anddroptheimplementandcauseacrushinghazard.

Donotleavetheimplementinaraisedpositionwhile

parkedorduringservice,unlesssecurelyblockedon

woodenblocks.

Neverworkunderaraisedimplementunlessasupport

•

chainorothermechanicalsecuringdevicesecurethe

linkarmsofthetractorsothattheimplementcannot

movetoalowerpositionunintentionally.

Relievethepressure,stoptheengineandremovethe

•

ignitionkey,beforeyouconnectordisconnectuid

lines.

Beforeyouadjust,clean,lubricateoryoucarryoutre-

•

pairsontheimplement,stoptheengineandremove

W0004A

theignitionkey.

NeveradjusttheimplementwhilethePowerTake-Off

•

(PTO)driveshaftisengaged.Donottoremovethe

guardsuntilallrevolvingpartshavestopped.

Anyleakageofhydraulicoilorfuelunderpressuremay

•

causesevereharm,soalwaysuseashielding,goggles

andgloveswhenyoutraceoilorfuelleaks.

Donotuseyourhandtocheckforleaks.Useapiece

ofcardboardorpaper.

Continuouslongtermcontactwithhydraulicuidmay

•

causeskincancer.Avoidlongtermcontactandwash

theskinpromptlywithsoapandwater.

Ifhydraulicuidordieselpenetratestheskin,seek

•

medicalcareimmediately.

Observeallrecommendationsthatarementionedin

•

thismanualsuchasserviceintervals,torques,lubri-

cants,etcetera.

Alwaysreplaceallpartsthathavedamageorwear.

•

Neverbuildexiblehoseassembliesfromhosesthat

•

werepreviouslypartofahoseassembly.

Neverweldtothetubes.

•

Alwaysusegloveswhenyouworkwithpartsonthe

•

implementasthepartscanhavesharpedges.

Transmissionandhydrauliclinesmaybecomehotdur-

•

ingoperation.Becarefulwhenyouservicesuchcom-

ponents.Allowsurfacestocoolbeforeyouhandleor

disconnecthotcomponents.Wearprotectiveequipmentwhenrequired.

2-10

Page 27

2-SAFETYINFORMATION

PersonalProtectiveEquipment(PPE)

WearPersonalProtectiveEquipment(PPE)suchasprotectiveclothing,eyeprotection,hearingprotection,dust

mask,hardhat,heavygloves,workboots,and/orany

otherPPEthatprovidesforthesafetyandprotectionof

theindividualthatoperatesthisequipment.

NHIL13RB00001AA1

2-11

Page 28

2-SAFETYINFORMATION

Safetyrequirementsforuidpowersystemsandcomponentshydraulicsystems

Beforeyoustarttheengineorpressurizethehydraulic

system,installandtightcorrectlyallthehydrauliccouplings.Checkthatallhosesandttingsarenotdamaged.

Replaceimmediatelydamagedcomponents.

Onlyconnectthehydraulichosestothetractoroutletsif

thetractorandtheimplementarepressure-free.Ifthe

hydraulicsofthetractorisactivateditmayleadtouncontrolledmovementswhichmaycausedamage.

Makesurethatnopersonsareneartheimplementwhen

youstarttheimplement,astheremightbeairinthehydraulicsystemwhichmightleadtosuddenmovements.

Whenthetractorenginehasstopped,activatethetractor

hydraulicspoolvalvestomakesurethatthereisnopressureinthehydraulichoses.

Toexpelalltheairfromtheoilinthehydrauliccylinders,

testallthefunctionsafteryouconnectthehydraulicconnectionstothetractor,especiallybeforeyouenterordrive

onthepublicroads.

2-12

Page 29

2-SAFETYINFORMATION

Noiseemission

ThemeasuringandreportingofthenoiselevelwerecarriedoutaccordingtoISO5131.

Thenoiselevelof70dBwasmeasuredinthecabinofthe

tractorwheretheheadoftheoperatorisusuallysituated.

Usehearingprotectorsifthenoisefromtheimplementis

annoyingorifyouworkwiththeimplementforaconsiderableperiodinatractorcabinthathasnotaadequate

soundproofcabin.

Vibrationlevels

Installallrevolvingpartscorrectlybeforeyoustarttheimplement.Anunbalancecancreatevibrationsthatdamage

theimplement.

NOTE:Youmustcheckthattheallpartareinthecorrect

positionbeforestarttheimplement.

NOTE:Ifthevibrationsorthenoiseoftheimplementincreaseconsiderablyduringtheoperation,stopthework

immediately.Correctthefaultbeforeyoucontinuethe

work.

2-13

Page 30

2-SAFETYINFORMATION

Implementstability

Thecombinationofyourtractorandimplementcanbecomeunstable,duetotheadditionalweightthattheimplement

addstothetractor.

Inordertoguaranteestableandsafetransport,youmustcheckifyouneedballastweightsfortransportandeld

work.

Youmustalsocheckandguaranteethatyouhaveatleast20%fromthetractorweightonthefrontaxle.

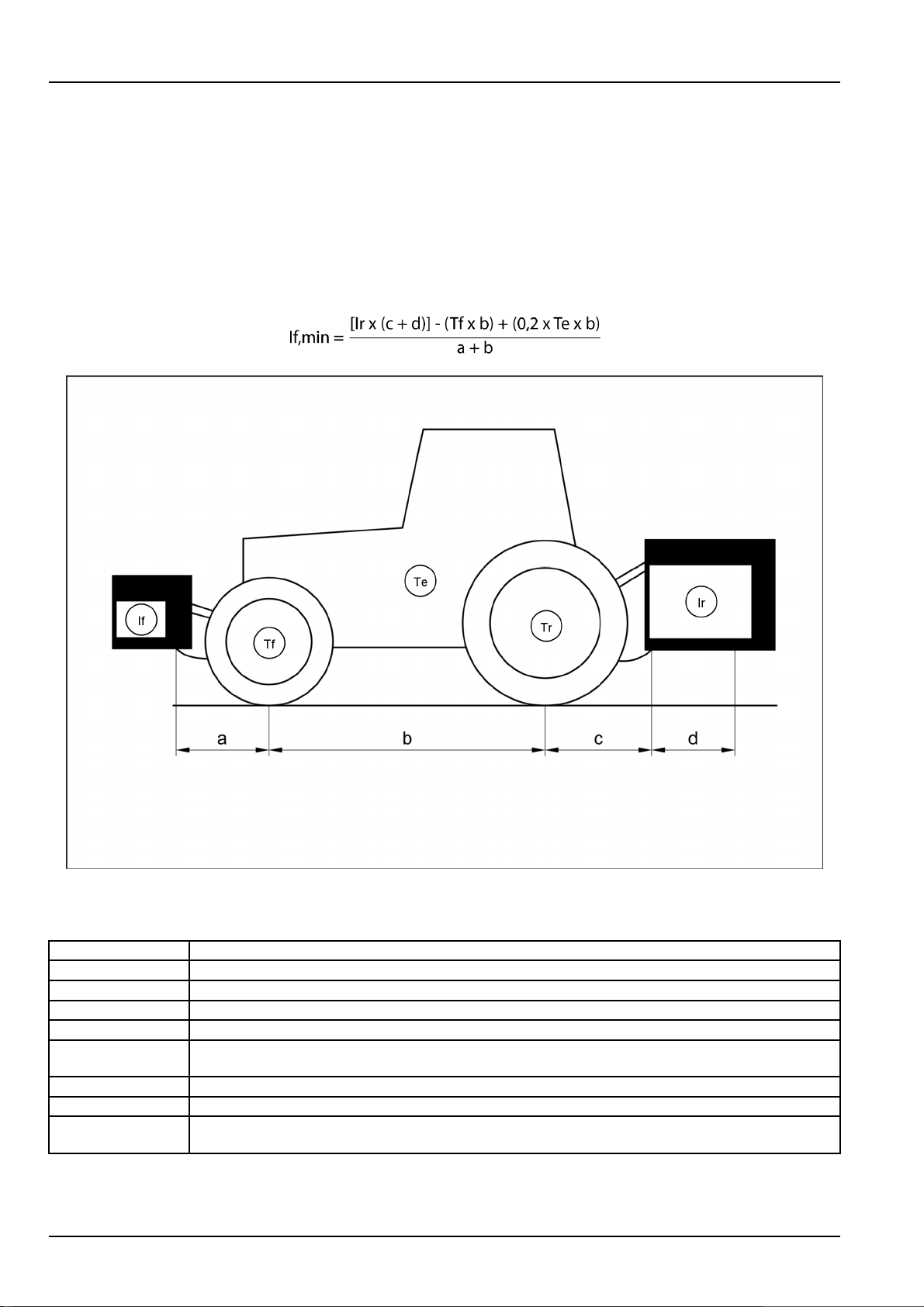

Forrearmountedimplementsandfront-rearcombinations,theformulais:

ZEIL18HT00277FA1

Exampleofreferencestostabilityofthecombinationtractor–implement

Listofsigns

Te[kg]Thetractorownweight.

Tf[kg]

Tr[kg]Rearaxleloadwithemptytractor.

Ir[kg]

If[kg]Totalweightofthefront-mountedimplement/frontballast.

a[m]

b[m]Thetractorwheeldistance.

c[m]

d[m]

Frontaxleloadwithemptytractor.

Totalweightoftherear-mountedimplement/rearballast.

Distancebetweenthecenterofgravityofthefront-mountedimplement/frontballastandthe

middleofthefrontaxle.

Distancebetweenthemiddleoftherearaxleandthemiddleofthelinkarmballs.

Distancebetweenthemiddleofthelinkarmballsandthecenterofgravityoftherearmounted

implement/rearballast.

2-14

Page 31

Ecologyandtheenvironment

2-SAFETYINFORMATION

Soil,air,andwaterqualityisimportantforallindustries

andlifeingeneral.Whenlegislationdoesnotyetrulethe

treatmentofsomeofthesubstancesthatadvancedtechnologyrequires,soundjudgmentshouldgoverntheuse

anddisposalofproductsofachemicalandpetrochemical

nature.

Familiarizeyourselfwiththerelativelegislationapplicabletoyourcountry,andmakesurethatyouunderstand

thislegislation.Wherenolegislationexists,obtaininformationfromsuppliersofoils,lters,batteries,fuels,

anti-freeze,cleaningagents,etc.,withregardtotheeffectofthesesubstancesonmanandnatureandhowto

safelystore,use,anddisposeofthesesubstances.Your

KONGSKILDEdealercanalsoprovideassistance.

Helpfulhints

Avoidtheuseofcansorotherinappropriatepressur-

•

izedfueldeliverysystemstolltanks.Suchdelivery

systemsmaycauseconsiderablespillage.

Ingeneral,avoidskincontactwithallfuels,oils,acids,

•

solvents,etc.Mostoftheseproductscontainsub-

stancesthatmaybeharmfultoyourhealth.

Modernoilscontainadditives.Donotburncontami-

•

natedfuelsandorwasteoilsinordinaryheatingsys-

tems.

Avoidspillagewhenyoudrainuidssuchasuseden-

•

ginecoolantmixtures,engineoil,hydraulicuid,brake

uid,etc.Donotmixdrainedbrakeuidsorfuelswith

lubricants.Storealldraineduidssafelyuntilyoucan

disposeoftheuidsinaproperwaythatcomplieswith

alllocallegislationandavailableresources.

Donotallowcoolantmixturestogetintothesoil.Col-

•

lectanddisposeofcoolantmixturesproperly.

Donotopentheair-conditioningsystemyourself.It

•

containsgasesthatshouldnotbereleasedintotheat-

mosphere.YourKONGSKILDEdealerorair-conditioningspecialisthasaspecialextractorforthispurpose

andcanrechargethesystemproperly.

Repairanyleaksordefectsintheenginecoolingsys-

•

temorhydraulicsystemimmediately.

Donotincreasethepressureinapressurizedcircuitas

•

thismayleadtoacomponentfailure.

Batteryrecycling

Batteriesandelectricaccumulatorscontainseveral

substancesthatcanhaveaharmfuleffectontheenvironmentifthebatteriesarenotproperlyrecycledafter

use.Improperdisposalofbatteriescancontaminate

thesoil,groundwater,andwaterways.KONGSKILDE

stronglyrecommendsthatyoureturnallusedbatteries

toaKONGSKILDEdealer,whowilldisposeoftheused

batteriesorrecycletheusedbatteriesproperly.Insome

countries,thisisalegalrequirement.

NHIL14GEN0038AA1

Mandatorybatteryrecycling

NOTE:Thefollowingrequirementsaremandatoryin

Brazil.

Batteriesaremadeofleadplatesandasulfuricacidsolution.Becausebatteriescontainheavymetalssuchas

lead,CONAMAResolution401/2008requiresyoutoreturnallusedbatteriestothebatterydealerwhenyoureplaceanybatteries.Donotdisposeofbatteriesinyour

householdgarbage.

Pointsofsaleareobligedto:

Acceptthereturnofyourusedbatteries

•

Storethereturnedbatteriesinasuitablelocation

•

Sendthereturnedbatteriestothebatterymanufacturer

•

forrecycling

2-15

Page 32

2-SAFETYINFORMATION

Safetysigns

Thefollowingsafetysignsareonyourimplementasa

guideforyoursafetyandforthesafetyofthosewhowork

withyou.

Walkaroundyourimplementandnotethesignicance

andlocationofallsafetysignsbeforeyouoperateyour

implement.Readallthesafetysignsadheredtotheimplementandfollowtheinstructions.

Keepallsafetysignscleanandlegible.Cleansafetysigns

withasoftcloth,water,andagentledetergent.

NOTICE:Donotusesolvent,gasoline,orotherharsh

chemicals.Solvents,gasoline,andotherharshchemicalsmaydamageorremovethesafetysigns.

Replaceallsafetysignsthataredamaged,missing,

paintedover,orillegible.Ifasafetysignisonapartthat

youoryourdealerreplaces,makesurethatyouoryour

dealerinstallthesafetysignonthenewpart.Contact

yourdealerforthereplacementofthesafetysigns.

Safetysignsthatdisplaythe“Readoperator’smanual”

symboldirectyoutotheoperator’smanualforfurtherinformationregardingmaintenance,adjustments,orproceduresforparticularareasoftheimplement.Whenasafety

signdisplaysthissymbol,consulttheappropriatepageof

theoperator’smanual.

Safetysignsthatdisplaythe“Readservicemanual”symboldirectyoutotheservicemanual.Ifyoudoubtyour

abilitytoperformserviceoperations,contactyourdealer.

2-16

Page 33

2-SAFETYINFORMATION

ZEIL18HT00798FA1

ZEIL18HT00799FA2

2-17

Page 34

2-SAFETYINFORMATION

Partnumber:811650220

8116502203

Partnumber:1642070a

1642070A4

2-18

Page 35

2-SAFETYINFORMATION

Safetysign(1)

Readtheoperator'smanualandthesafetyinstructions.

Readtheoperator'smanualtooperatetheimplementand

toavoidunnecessaryaccidentsanddamagestotheimplement.

WARNING

IMPROPEROPERATIONOFTHISMACHINE

CANCAUSEDEATHORSERIOUSINJURY .

MAKESURETHA TEVERYOPERATOR:

-isinstructedinthesafeandproperuseofthis

machine.

-readsandunderstandstheoperator'smanual

forthismachine.

-readsandunderstandsALLsafetysignson

themachine.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:811650220

81PR80-0859_55

W0188A

Safetysign(2)

Alwaysstopthetractorenginebeforeyouadjust,maintain,repair,orlubricatetheimplement.Alsorememberto

removetheignitionkey.Makesurethatnobodystartsthe

engine,untilyouhavenished.

WARNING

Avoidinjury!Alwaysdothefollowingbefore

lubricating,maintaining,orservicingthemachine.

1.Disengagealldrives.

2.Engageparkingbrake.

3.Lowerallattachmentstotheground,or

raiseandengageallsafetylocks.

4.Shutoffengine.

5.Removekeyfromkeyswitch.

6.Switchoffbatterykey,ifinstalled.

7.Waitforallmachinemovementtostop.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:811650220

W0047A

81PR80-0859_26

2-19

Page 36

2-SAFETYINFORMATION

Safetysign(3)

Movingpartsaredangerousandifthemovingpartscome

incontacttoyourbodythemovingpartscanpinchyour

body.

Thehazardmaycausesevereinjuriestotheentirebody,

withpossiblelethaleffect.

Toavoidthehazards,waituntilallmovingelements

havecompletelystoppedbeforeyoutouchthemoving

elements.

WARNING

Pinchhazard!

Waitforallmovementtostopbeforeyouserviceoradjustthemachineorequipment.

Failuretocomplycouldresultindeathorseriousinjury.

W1420A

Partofpartnumber:811650220

Safetysign(4)

ThesafetysignindicatesthemaximumRevolutionsPer

Minute(RPM)andthedirectionofrotationofthePower

Take-Off(PTO)shaft.

Referencetotheminimumoverlappingontheprole

tubesandtheminimumdistancerequiredinordernotto

bottomtheshaft.

81PR80-0859_17

Partofpartnumber:811650220

Safetysign(5)

Keepasafedistancefromtherotatingpartsoftheimplement.

Neverstandintheswivelandfoldingareaoftherotors.

Checkthewearofthesafetypins.Replaceimmediately

thesafetypinsifthethicknessislessthan7mm(0.28in).

Partofpartnumber:1642070a

81PR80-0859_48

PR80-0852_059

2-20

Page 37

2-SAFETYINFORMATION

Safetysign(6)

Nevermoveyourhandintothedangerzoneaslongas

thepartscanmove.Thismaycauseseriousinjuryand,

atworst,resultindeath.

Partofpartnumber:1642070a

Safetysign(7)

Turninganglesafetysign.

Partofpartnumber:1642070a

PR80-0852_0610

Safetysign(8)

Adjustmentoftheleft-handsideliftingheight.

Partofpartnumber:1642070a

Safetysign(9)

Adjustmentoftheright-handsideliftingheight.

Partofpartnumber:1642070a

PR80-0852_1311

PR80-0852_0812

PR80-0852_0913

2-21

Page 38

Safetysign(10)

Liftingpointsafetysign.

WARNING

Crushinghazard!

Usethemachineliftingpointswhenyoulift

and/ormovethemachinewithheavyhandling

equipment.Liftthemachineonlyfromtheindicatedliftingeyehookuppoints.Alwaysuse

adequateliftingequipment.

Failuretocomplycouldresultindeathorseriousinjury.

Partofpartnumber:1642070a

Safetysign(11)

Referencelubricationofcamtrack.

Partofpartnumber:1642070a

2-SAFETYINFORMATION

W1432B

PR80-0852_1014

Safetysign(12)

Thehydraulicpressuremustbemaximum210bar

(3045psi).

Partofpartnumber:1642070a

Safetysign(13)

Adjustmentofnumberofrevolutions.

Partofpartnumber:1642070a

PR80-0852_1115

PR80-0852_1216

PR80-0852_1417

2-22

Page 39

Safetysign(14)

Adjustmentoftheleft-handsideworkingheight.

Partofpartnumber:1642070a

Safetysign(15)

Adjustmentoftheright-handsideworkingheight.

Partofpartnumber:1642070a

2-SAFETYINFORMATION

PR80-0852_1518

Safetysign(16)

Tirepressuresafetysign.

Partofpartnumber:1642070a

Safetysign(17)

Camtrackmodicationsafetysign.

Partofpartnumber:1642070a

PR80-0852_1619

PR80-0852_1720

PR80-0852_1821

2-23

Page 40

2-SAFETYINFORMATION

2-24

Page 41

3-CONTROLSANDINSTRUMENTS

3-CONTROLSANDINSTRUMENTS###_3_###

Information

Operatingprinciples

Forallinformationrelatedtothedescriptionandthelocationofthecontrolstouseyourimplement,seechapter“ControlsandInstruments”intheoperator’smanualof

yourvehicle.

3-1

Page 42

3-CONTROLSANDINSTRUMENTS

3-2

Page 43

4-OPERATINGINSTRUCTIONS

4-OPERATINGINSTRUCTIONS###_4_###

Commissioningtheunit

Preparingforoperation

NOTICE:Onlyauthorizedandinformedpersonnelcan

mounttheimplement.

NOTICE:Thenecessarytoolsandadjustmenttoolsmust

beavailable.

NOTICE:Incorrectassemblyoftheimplementishighly

dangerous.Beforeyouperformthefunctionaltest,check

thecorrectassemblyoftheimplement.

NOTICE:Makesurethattherearenotoolsinthearea

aroundtheimplement.

Makesurethattherearenopersonsintheworkzone.

NOTE:Aftertheassemblyoftheimplement,performa

completefunctionaltest.

NOTE:Torqueallscrewjointsevery5hofoperation.

Theimplementisdisassembledintopartsanddelivered

onapallet.Forshipmentonabigpalletthewheelaxle

assemblyandsomearmsaredismounted.

Loosepartssuchasabagwithsmallparts(screws)and

thePowerTake-Off(PTO)shafthavebeentiedtothepalletortheimplementtosavespace.

4-1

Page 44

4-OPERATINGINSTRUCTIONS

Installationofextrawheelsonrotorchassis(optionalequipment)

Insoftorweteldsitmaybenecessarytorelievethe

wheelsontherotorchassis.Youcandothiswhitthe

installationoftheextrawheels(1).Theextrawheels(1)

aresuppliedasoptionalequipment.Theextrawheels(1)

arespring-loadedandarticulated.

1.Installtheholder(2)ontheextendedbolt(3)which

replacestheexistingone.

2.Placethebushings(4)intheleft-handsideandright-

handsidewiththetighteningpins.

3.Installthetworods(5).

4.Tightenthesprings(6).

ZEIL18HT00212AA1

NOTICE:Thesafetydecals(7)showthetopossibledan-

gerinconnectionwithmounting,adjustmentandmaintenance.

ZEIL18HT00213FA2

4-2

Page 45

Startingtheunit

Connectiontothetractor

WARNING

Crushinghazard!

Usecarewhenyouconnectanddisconnect

themachines.Neverstandbetweenthetractorandtheimplementwhenyouconnectthe

linkarms.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Crushinghazard!

Donotstandorplaceanybodypartbetween

theimplementandamovingtractor.Stopthe

tractorengineandsettheparkingbrakebeforeyouattachcablesandhoses.

Failuretocomplycouldresultindeathorseriousinjury.

4-OPERATINGINSTRUCTIONS

W1545A

W1544A

WARNING

Hitchinghazard!

Alwayskeeptheareabetweenthetractorand

theimplementclearofallpersonswhilethe

tractororthree-pointhitchisinmotion.Lock

thetractortransmissioninParkandengage

theparkingbrake(s)beforeyouallowanyone

tocompletehitchingorunhitching.

Failuretocomplycouldresultindeathorseriousinjury.

NOTICE:Whenyouattachorremovetheimplement,

checktobringthesupportingdevicesintothecorrespondingposition(standingsafety).

NOTICE:Neverexceedthemaximumpermissibleloadof

thecouplingdrawbarandofthehitch.

NOTICE:Theropemustneverbetautduringthetransport.

NOTE:Whenyouconnectthehitches,makesurethatthe

hitchpointcanmovefreely.

W1540A

4-3

Page 46

4-OPERATINGINSTRUCTIONS

1.Attachthehitchpinsofthe2-pointframetothebottom

linksofthetractor.

2.Slightlyliftthe2-pointframetoliftthejackstandsin

transportposition.Securethejackstands.

3.Connecttheconnectorofthelightingequipmenttothe

correctsocketonthetractor.

4.Connectthehydraulichosetoasingleactingcontrol

unitofthetractor.

NOTICE:Lockthelowerlinksofthetractoragainstlateral

oscillationtopreventanyhuntingofthesteeringsystem

oftheimplement.

NOTE:Adjustthedistancebetweenthelowerlinksof

thetractorandthegroundtoapproximately680mm

(26.77in).Thechassisoftheimplementwiththeadjust-

mentofthedistanceishorizontal.

5.Beforeyouraisetherotors,attachallprojectingtine

armsassemblytotheirsupportontherearcross

frame.Setthesafetyguardintotransportposition.

NOTE:Transportheightishigherthan3.5m(137.80in).

Payspecialattentiontooverhangingelectricalwires.

ZEIL18HT00258AA1

NOTE:Forlowerpassages,removethetinesarmsassemblyandputthetinesarmsassemblyintothetinecarriersupportonthereartraverseofthemainframe.To

adjustthesupportsforthesafetyguard,loosentheclamp

bolts.Putthesupportsintotheinnerpositionandsecure

thesupportswithalockingpin.Beforeusetheimplement,

securetobringthesafetyguardsinouterposition.

NOTE:Afterthestrawswathingoperation,puttherotors

backtothenormalworkingposition,toremainwithinthe

3m(118.11in)transportwidth.

PowerTake-Off(PTO)shaftconnection

NOTICE:ToinstallandremovethePTOshaft,stopthe

engine.

NOTICE:OnlyusethesuppliedPTOshaftorthePTO

shaftthatthemanufacturerapprove.

AdjustthelengthofthePTOshafttothetractorbefore

youperformthefollowingsteps.Ifyouusetheimplement

withdifferenttractors,checkthatthePTOshafthasthe

correctlength.

NOTICE:Thesafetyguardsonthetractorsideandonthe

implementsidemustbeintact.

1.ReleasethePTOshaftfromthesupportchain.

2.PushthePTOshaftonthetractorPTOshaftuntilyou

engagethelockingballs.

3.ThesafetychainsecurethesafetyguardofthePTO

shaftsonthetractorside.Ontheimplementsidethere

isafull-coveringprotection.Theclampsecurethe

full-coveringprotection.

NOTICE:ThechainsecurethesafetyguardofthePTO

shaft.

4-4

Page 47

4-OPERATINGINSTRUCTIONS

Functionaltest

Afterthepreparationoftheimplement,youmustdoa

functionaltest.

1.Therotorsmustcanfoldinandout.

2.Checkthattheimplementworkscorrectly.

3.Every50hofoperationallscrewsmustbetorque

again.

PowerTake-Off(PTO)shaft–Shorten

PowerTake-Off(PTO)shaftlength

NOTE:DonotshortenyournewPowerTake-Off(PTO)

shaftuntilyouarecertainthatitisnecessary.Fromthe

factorythedistancefromPTOtoPowerInputConnection

(PIC)isstandardonmosttractorbrands.

CheckthelengthofthePTOshaftforeachtractorpriorto

rstuse.

IfitisstillnecessarytoshortenthePTOshaft,theprole

tubesofthePTOshaftmustfullycomplywiththefollowing

overlappingmeasures.

Theslidingtubesmusthaveasmuchoverlapaspossi-

•

ble,withanacceptableminimumoverlap(b)of200mm

(7.87in)duringnormaloperation(TopSafeextension

linksinthenormalposition).

Theremustbeaminimumof40mm(1.6in)offree

•

PTOshaftlength(a)topreventtheshaftfrombottoming

out.

Determiningtherequiredshaftlength

WhenyoudeterminethatyoumustshortenthePTOshaft,

selectthelengthsothatthetelescopingmembersnever

closecompletelyorbottomoutwheninuse.ThePTO

lengthmustneverbesmallerthantheminimumdistance

betweenthejoints.

1.AttachtheimplementtothetractorwithoutthePTO

shaft.

2.Adjustthethree-pointhitchsothatthePTOshaftis

parallelwiththeground.

3.Stopthetractorandengagetheparkingbrake.

4.DetermineifthePTOshaftbottomoutinthisposition.

IfthePTOshaftbottomsoutinthispositionorifthe

freelengthislessthan40mm(1.6in),proceedwith

theproceduretoshortenthePTOshaft.

NHIL12HT00307AA1

4-5

Page 48

4-OPERATINGINSTRUCTIONS

ShorteningthePTOshaft

ToshortenthePTOshaftproceedasfollows.

1.FastenthePTOshafthalfpartstothePTO(onthe

tractor)andthePIC(ontheimplement).ThePTO

shafthalfpartsmustbeatthesamehorizontallevel,

oppositeeachotherattheshortestdistancefromthe

tractor.

2.Makesurethataminimumoverlapof200mm

(7.87in)exists.

3.CheckthatthePTOshaftdoesnotbottomoutatone

end.Keeptheshaftendsparalleltoeachotherand

marktheminimumdistanceof40mm(1.6in).Only

cutenoughPTOshaftofftoachievethisminimumfree

shaftlength.Thiswillmaintainthemaximumamount

ofPTOshaftoverlap.

4.Shortenallfourtubesequally.

5.Roundofftheendsoftheproletubesandremovethe

burrscarefully.

6.Removethemetalshavings.

ZEIL18HT00013AA2

NOTICE:Toavoidbigfrictionforces,greasethetube

carefullybeforeyoureassemblethetube.UseNLGI2.

NOTE:IfyoushortenthePTOshaft,thenyoumustcheck

theminimumoverlapandtheminimumdistanceagainif

youoperatetheimplementwithadifferenttractor.

4-6

Page 49

4-OPERATINGINSTRUCTIONS

Parkingtheunit

Disconnectionandparking

1.Placetheimplementonarmandevenground.

2.Foldtheimplement.

3.Disconnectallthehydrauliccouplers.

4.DisconnectthePowerTake-Off(PTO)shaftfromthe

tractor.SupportthePTOwiththechain.

5.Placewheelchocksasfollows:

Onaatsurface:oneinfrontof,andonebehinda

○

wheel.

Onaslope:onechockperwheel,eitherinfrontof,

○

orbehindthewheel,dependingontheincline.

6.pullthehandle(1)andturnthesupportlegs(2).

7.releasethehandle(1).

8.Releasetheimplementfromthetractor.

ZEIL18HT00258AA1

4-7

Page 50

4-OPERATINGINSTRUCTIONS

4-8

Page 51

5-TRANSPORTOPERATIONS

5-TRANSPORTOPERATIONS###_5_###

Preparingforroadtransport

Liftingtherotorsfortransport

NOTICE:Donotparktheimplementintransportposition

transversetowaysorroadways.

1.Drawintheswathcurtainforimplementheightlower

than4m(13.12ft).

2.Usethehydraulicpowertoraisethebearingarmswith

therotors.

3.Atthesametimepullthecontrolropeuntilthebearing

armsarelockedintheinnerratchetsofthelocking

hooks.

5-1

Page 52

5-TRANSPORTOPERATIONS

5-2

Page 53

6-WORKINGOPERATIONS

6-WORKINGOPERATIONS###_6_###

Generalinformation

Descriptionofoperation

Workingprinciple

NOTICE:Adheretothemaximumpermissibleaxleloads

andtotalweights.

NOTICE:Whenyoudrivetheimplementandturn,take

noteofthewidthandofthechangeofthecenterofgravity

oftheimplement.

NOTICE:Puttheimplementintooperationonlywhenall

thesafetyguardsarexedinposition.

NOTICE:Neverstayintheturningandslewingareaof

theimplement.

NOTICE:Donotapproachtherotatingrotorsfromtherear

side,nosafetyguardsprotectthisdirection

Thetinearmsassemblywithbearingarmsworktogether

withtheswathcanvastocreatethebestpossibleswaths.

The3-wheelrunninggearwithballoontiresisactingclose

tothetinearmsassembly.Thisallowsthetinearmsassemblytopreciselyfollowgroundcontourswhichmakes

forbestworkingresults.

Adjusttheworkingdepthwithadepthcontrolcrank.

Results

Thesefeaturescombinedwiththeconsiderableworking

widthandhighforwardspeed(upto12km/h(7.5mph))

permittocoveralargeareas.

Adjusttherotorspeedsoastoavoidanyunnecessary

scatteringoftheforagecrop.

Selecttheforwardspeedsoastoreceivegoodworking

results(cleanrakingandtidywindrows).

6-1

Page 54

6-WORKINGOPERATIONS

ZEIL18HT00252FA1

6-2

Page 55

6-WORKINGOPERATIONS

Basicadjustment

NOTE:Ifyouneedtodragcropmaterialoutsideswathto

therearandtowardthecenter,reducenumberofrevolutionsofthetinearmsassemblyandmoveforwardthe

camtrack.

Workingwidthadjustment

Dotheworkingwidthadjustmentonlywhentheimplement

isnotinoperation,androtorsareliftedandlockedintransportposition.Todotheworkingwidthadjustmentchange

thepositionoftherod,seegures.T odotheworking

widthadjustment,lockthearmoftheimplementwitha

ratchet.

Rodforinnercollet:smallworkingwidthforswathfrom

rsttosecondrotor.

Rodhastobeinouterposition:largeworkingwidthfor2

individualswaths.

Theswathwidthdependsontheforagecrop.

1.T ounfoldtherotorstoworkingpositionrelievestress

onthelockinghooksusinghydraulicpower.

2.Pulltheropeandkeepittautwhilesettingthecontrol

leverofthetractorhydraulicstoLOWERING.

3.Unfoldrotorsslowly.

4.Installremovedtinearmsassemblyandsafetyguards

intoprotectiveposition.

5.Bringtheswathcanvasintothedesiredswathwidth

andsecuretheswathcanvaswithatogglescrew.

NOTICE:Theropemustneverbetautduringthetransport.

NOTICE:Operatethetractorhydraulicsystemaswellas

thedispositionandtightnessofthehoses.

Rotorsliftingfortheheadlandturns

1.Usethehydraulicpowertoraisethetinearmsassemblywiththerotor,untilthetinearmsassemblybottom

againsttheoutercatchesofthelockinghooks.

Workingheightadjustment

ZEIL18HT00259AA1

ZEIL18HT00260AA2

NOTICE:Adjusttheworkingheightandadjusttheraking

width.DotheadjustmentonlywiththerotorsOFF .

IspossibledotheadjustmentoftheworkingheightseparatelyforbothrotorsusingacrankSK.

NOTE:Afterthestrawswathingoperation,puttherotors

backtothenormalworkingposition,toremainwithinthe

3m(118.11in)transportwidth.

ZEIL18HT00261AA3

6-3

Page 56

6-WORKINGOPERATIONS

Camtrackssetting

NOTE:Theimplementcanmatchindifferentconditions

offorage.Setthecamtrackssoastovarythemoment

atwhichthetinearmsassemblyareloweredandlifted

outsideswath.

NOTE:Anadjustingspindleisprovidedundereachrotor

ontheright-handsidetomatchthedifferentforageconditions.

1.T oadjustthecamtrack,turnthenutsinorouttorotate

thespindle(spanofthejaw30mm(1.2in)).

2.Aftertheadjustmenttorquethenuts.

Rotortiltadjustment

1.UsetheadjustspindlesS(245mm(9.65in))toadjust

therotortilt.

2.Positiontherotorslengthwise3cm(1.18in)lowerto

theground(inparkingposition)forcleaning.

NOTE:Ifcropremainsinthemiddleoftherotorwhile

raking,thefrontrotorcouldbeabittoohigh.Inthiscase

adjusttheadjustingspindles-turnbucklesS6(usewater

levelforhelp).

ZEIL18HT00556AA4

810689410_165

6-4

Page 57

6-WORKINGOPERATIONS

Lateraltiltsetting

NOTE:Aneccentricbolt(1)securetheright-handside

supportwheelofeachrotorwhichallowstomatchthe

implementtodifferenttypesofcrop.

NOTE:Onlyatrainedpersoncansetthelateraltilt.

Tomovethesupportwheelsoutsidecentralposition(factoryadjustment)doasfollows.

1.Removethesecuringboltandturnthelatter.

2.Introduceaspanner30mm(1.2in)oratoggle(diam-

eter10mm(0.4in))throughtheexpansionpinlocated

attheinnerendoftheaxlepin.

3.Turnthespannerorthetoggle.

4.Afteradjustmentlocktheeccentricboltusingthesecuringbolt.

ZEIL18HT00263AA6

6-5

Page 58

6-WORKINGOPERATIONS

Conversionoftherakefromtransporttoworkingposition

Introduction

NOTICE:Onlyanauthorizedspecialistworkshopcanassemblytheimplement.

Fortheshipmentsomecomponentsoftheimplementare

notinstallontheimplement,likeseveraltinearmsassembly,partsofthesafetyguardandwarningpanels.These

componentsareattachedtothecarryingframe.Remove

thecomponentsfromthecarryingframeandinstallthe

componentsinthecorrectpositionontheimplement.

1.Installthebearingpin(1)(eccentricinhorizontalpo-

sition)fortheouterwheelattheright-handsidedrive

chassisoftherotor.

2.InstalltheboltM12x40,thenut(2),andthesplitpinto

xthebearingpin(1).

3.Installthewasher30x42x2.0(3)onthebearingpinof

thewheelaxleassembly.

NOTE:Installthewasher(sealingside(4)tothewheel

axleassembly)onallbearingpins.

4.Securethewheelofthewheelaxleassemblywiththe

washer13x40x3(5)andtheboltM12x25(6),andthe

endcap(7).

ZEIL18HT00253FA1

6-6

Page 59

6-WORKINGOPERATIONS

5.Releasethetwowheelsofthewheelaxleassembly.

6.Swingtotherearandattachthesteeringrodsonthe

respectiveleversofthewheelaxleassembly.

7.Securewithrollpin.

ZEIL18HT00254AA2

8.Pulloutthefrontwarningpanelsandtheright-hand

sideprotectionrodtoawidthof3m(118.11in).

NOTE:Makesurethattheouterwarningpanelsaredirectedoutward.

Changingfromthetransporttotheworking

position

1.Connectthehydraulichoseoftheimplementtoasingleactinghydrauliccoupleronthetractor.

2.Keepthehydrauliccylinderforthewingsinretracted

position.Releasethelockingdevicesandslowlylower

thewings.

3.Re-installthebearingarmandusetheheightadjusting

spindletoperformacoarseadjustmentoftherotor

height.

4.Movethetwosafetyguardsoutward.Securethe

safetyguardswiththeclampboltsandthelocking

pins.

ZEIL18HT00255AA3

ZEIL18HT00554AA4

ZEIL18HT00257AA5

6-7

Page 60

6-WORKINGOPERATIONS

5.Fittheuniversaldriveshaftsupporttotheinsideofthe

headstocksothatitisfacingthetractor.

NOTE:Installtheuniversaldriveshaftbetweenthetractor

andtheimplementinawaythatthewideanglejoint(doubleuniversaljoint)isunderthepivotoftheimplement.

6.Useadjustableholdingchainifrequired.

ZEIL18HT00258AA6

6-8

Page 61

7-MAINTENANCE###_7_###

Generalinformation

Maintenance

Generalinformation

WARNING

Avoidinjury!

FollowALLoftheprecautionslistedbelow.

Failuretocomplycouldresultindeathorseriousinjury.

NOTICE:Dothemaintenance,theservice,thecleaning,

andtherepairwiththePowerT ake-Off(PTO)shaftand

theengineOFF .Removetheignitionkey .

NOTICE:Takecarethatoilandgreasedonotgetincontactwithyourskin.

7-MAINTENANCE

W1091A

NOTICE:Youmustalwaysblockthetractorwheelsbefore

youworkontheimplement.

NOTICE:Afterthersthoursofoperationyoumusttorque

againallthescrews.

NOTICE:Duringgreasing,theimplementmustbein

workingpositionandparkedsafelyandrmlyonthe

ground.

NOTICE:Duringmaintenanceonaliftedimplement,you

mustalwaysplacesuitablesupportsunderneath.

Checkthescrews,thebolts,andthenutsafter50hof

operationsandtorqueagainifnecessary.Seethetorque

table.Itisparticularlyimportanttocheckthexingbolts

oftheimplement.

Onlyuseoriginalsparepartsandequipment.Thereisno

warrantyonnon-originalcomponents.Themanufacturer

isnotresponsibleforanydamageresultingfromsuchuse.

NOTICE:T oreplaceanytoolswithcuttingedgesalways

usesuitabletoolsandprotectivegloves.

NOTICE:Beforeworkingontheelectricgear ,disconnect

thebatterycables.

NOTICE:Alwaysmakesurethatallthesafetyguardsof

theimplementareinplaceandfunctional.Immediatelyreplacethesafetyguardswornordamaged.Donotoperate

theimplementuntilyoureplaceallthewornordamaged

safetyguards.

Aftertherst10hofoperationstorqueagainallthehy-

draulicscrewjoints.Onlyuseoriginalsparepartsand

equipment.

7-1

Page 62

7-MAINTENANCE

Torque

Minimumhardwaretighteningtorques(inNmorlbin/lbft)fornormalassemblyapplicationsunlessotherwisestated

Theminimumhardwaretighteningtorqueondrawings,in

specications,etceterahavepriority.

Inthefollowingtables,torquespecicationsareshown

followingthestandardENS7001,applicableformaterial

class8.8andmaterialclass10.9.

Hexheadbolts

Class8.8inNm(lbinorlbft)Class10.9inNm(lbinorlbft)

Nominal

Size

M31.3N·m

M42.9N·m

M55.9N·m

M610.1N·m

M824.5N·m

M1048.7N·m

M1285N·m

M14135N·m

M16210N·m

M18299N·m

M20425N·m

M22579N·m

M24735N·m

M271073N·m

M301461N·m

PlatednutLocknutHardened

0.7N·m

(11.5lbin)

(25.7lbin)

(52.2lbin)

(89.4lbin)

(18.1lbft)

(35.9lbft)

(62.7lbft)

(99.6lbft)

(154.9lbft)

(220.5lbft)

(313.5lbft)

(427lbft)

(542.1lbft)

(791.4lbft)

(1077.6lbft)

(6.2lbin)

1.6N·m

(14.2lbin)

3.2N·m

(28.3lbin)

5.5N·m

(48.7lbin)

13.5N·m

(10.0lbft)

26.8N·m

(19.8lbft)

46.7N·m

(34.4lbft)

74.2N·m

(54.7lbft)

115.5N·m

(85.2lbft)

164.4N·m

(121.3lbft)

233.72N·m

(172.4lbft)

318.4N·m

(234.8lbft)

404.2N·m

(298.1lbft)

590.1N·m

(435.2lbft)

803.5N·m

(592.6lbft)

nut/Oiled

platednut

1.2N·m

(10.6lbin)

2.6N·m

(23.0lbin)

5.3N·m

(46.9lbin)

9.1N·m

(80.5lbin)

22N·m

(16.2lbft)

43.8N·m

(32.3lbft)

76.5N·m

(56.4lbft)

121.5N·m

(89.6lbft)

189N·m

(139.4lbft)

269.1N·m

(198.5lbft)

382.5N·m

(282.1lbft)

521.1N·m

(384.3lbft)

661.5N·m

(487.9lbft)

967.5N·m

(713.6lbft)

1315N·m

(969.9lbft)

PlatednutLocknutHardened

1.8N·m

(15.9lbin)

4.2N·m

(37.2lbin)

8.5N·m