Page 1

ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1

OPERATOR’S MANUAL

SMF 3005

Disc Mower

Part number 51505890

1st edition English

March 2019

Page 2

Contents

1GENERALINFORMATION

Notetotheowner...........................................................................1-1

Intendeduse................................................................................1-4

Prohibitedusage...........................................................................1-4

Electro-MagneticCompatibility(EMC).....................................................1-5

Manualscopeandrequiredtraininglevel..................................................1-6

ProductIdenticationNumber(PIN)........................................................1-7

Productidentication.......................................................................1-8

Operator'smanualstorageonthemachine................................................1-9

Implementorientation.....................................................................1-10

2SAFETYINFORMATION

Safetyrulesandsignalworddenitions....................................................2-1

Generalrecommendations.................................................................2-2

Illustrations.................................................................................2-3

Legalobligations...........................................................................2-3

Fireorexplosionprevention................................................................2-3

Hazardouschemicals.......................................................................2-4

Startinguptheimplementsafely...........................................................2-5

Travelingonpublicroads...................................................................2-6

Operatingtheimplementsafely............................................................2-8

Stoppingtheimplementsafely............................................................2-10

Maintenance...............................................................................2-11

PersonalProtectiveEquipment(PPE)....................................................2-12

Safetyrequirementsforuidpowersystemsandcomponents-hydraulicsystems......2-13

Noiseemission............................................................................2-14

Vibrationlevels............................................................................2-14

Implementstability.........................................................................2-15

Ecologyandenvironment.................................................................2-16

Safetysigns...............................................................................2-17

3CONTROLSANDINSTRUMENTS

Machinecomponents

Accesstoimplementcomponents......................................................3-1

4OPERATINGINSTRUCTIONS

Commissioningtheunit

Choiceoftractor........................................................................4-1

Checkbeforetestdriving...............................................................4-2

Testdrive...............................................................................4-4

Startingtheunit

Connectiontothetractor...............................................................4-5

PowerTake-Off(PTO)driveshaft–Shorten..........................................4-7

Page 3

Parkingtheunit

Disconnectionandparking.............................................................4-9

5TRANSPORTOPERATIONS

Preparingforroadtransport

Transportposition......................................................................5-1

Trafcmarking..........................................................................5-1

6WORKINGOPERATIONS

Generalinformation

Implementoverview....................................................................6-1

Frictionclutch...........................................................................6-2

Transmissionsecuringagainstoverload...............................................6-3

Twistedblades..........................................................................6-4

Discandblades–Q+system..........................................................6-5

Adjustmentofthereliefsystem.........................................................6-7

Stubbleheight..........................................................................6-8

Guards..................................................................................6-9

Swathdiscs............................................................................6-10

Doubledrumsystem–Option........................................................6-11

Workingintheeld....................................................................6-13

7MAINTENANCE

Generalinformation

Recommendations.....................................................................7-1

Torque..................................................................................7-4

Torqueforclass12.9...................................................................7-7

Fluidsandlubricants...................................................................7-7

Maintenanceplanning

Maintenancechart......................................................................7-8

Aftertherst3hoursofoperation

Boltsandttings........................................................................7-9

Aftertherst50hoursofoperation

Cutterbar-oilchange..................................................................7-9

Bevelgearboxabovethecutterbar-oilchange.......................................7-9

Bevelgearboxinthecenteroftheimplement-oilchange............................7-9

Dailyinspection

Cutterbar-oilcheck..................................................................7-10

Page 4

Every40hours

PowerTake-Off(PTO)-Grease.......................................................7-11

Every50hours

Lubricationchart.......................................................................7-12

Every80hours

Bevelgearboxabovethecutterbar-oilcheck........................................7-13

Bevelgearboxinthecenteroftheimplement-oilcheck.............................7-14

Every200hours

Cutterbar-oilchange.................................................................7-15

Every250hours

PowerTake-Off(PTO)-Grease.......................................................7-17

Every500hours

Bevelgearboxabovethecutterbar-oilchange......................................7-18

Bevelgearboxinthecenteroftheimplement-oilchange...........................7-19

8TROUBLESHOOTING

Everysixyears

Hydraulichoses.......................................................................7-20

Asrequired

Maintainingthefrictionclutch..........................................................7-21

PowerTake-Offforthecutterbar......................................................7-22

Controlofbalance.....................................................................7-23

Replacementofblades–Q+system.................................................7-24

Replacementofdiscs..................................................................7-26

Replacementofhubs..................................................................7-27

Storage

Pressurewashing.................................................................7-29

Endofseasonservice.............................................................7-30

Orderingpartsand/oraccessories..............................................7-31

Faultcoderesolution

Drivingtipsandfaultnding........................................................8-1

9SPECIFICATIONS

Dimensions.................................................................................9-1

Technicaldata..............................................................................9-2

Page 5

Fluidsandlubricants.......................................................................9-2

10ACCESSORIES

Generalinformation.......................................................................10-1

A-frametractorpart........................................................................10-1

Discdrumkitfornarrowswath............................................................10-1

Suspensionkitforcuttingunit.............................................................10-2

Highguideshoeset.......................................................................10-2

Lightkit....................................................................................10-3

TrafcpackageforFrance.................................................................10-3

11FORMSANDDECLARATIONS

ECDeclarationofConformity.............................................................11-1

Page 6

Page 7

1-GENERALINFORMATION

1-GENERALINFORMATION###_1_###

Notetotheowner

Thismanualhasbeenpreparedtoassistyouinthecorrectproceduretorunin,todrive,tooperate,toadjustandto

maintainyournewimplement.

Thisimplementhasbeendesignedandbuilttogivemaximumperformance,economyandeaseofoperationunder

awidevarietyofconditions.

Priortodelivery,yourimplementwascarefullyinspectedbothatthefactoryandbyyourdealertomakesurethatit

reachesyouinoptimumcondition.Tomaintainthisconditionandassuretrouble‐freeoperationitisimportantthat

routineservices,asspeciedinthismanual,arecarriedoutattherecommendedintervals.

Readthismanualcarefully(especiallyChapter2thatcoversthesafetyinformation)andkeepthismanualinaconvenientplaceforfuturereference.DONOToperateorpermitanyonetooperateorservicethisimplementuntilyou

and/orotherpersonshavereadthismanual.Readthemanual,itwillsaveyoutimeandhasslelater.Lackofknowledgecanleadtoaccidents.Employonlytrainedoperatorswhohavedemonstratedtheabilitytooperateandservice

thisimplementcorrectlyandsafely.Contactyourdealerforassistanceprovidingtherequiredtrainingtoyouroperators.Contactyourdealertoobtainadditionalmanualsoralternatelanguageversions.

Ifatanytimeyourequireadvicethatconcernsyourimplement,donothesitatetocontactyourauthorizeddealer.He

hasfactory‐trainedpersonnel,genuineservicepartsandthenecessaryequipmenttocarryoutyourservicerequirements.

NOTICE:ThisimplementhasbeendesignedandbuiltinlinewiththerequirementsputforwardbytheEuropean

Directives2006/42/ECand2014/30/EU.

AlwaysusegenuineKONGSKILDEServicePartsorpartsthatmatchatleastthesamequality ,reliabilityandfunctionalityastheequivalentoriginalServicePartswhenyouserviceandrepairyourimplementanddonotmodifyyour

implementwithoutawrittenpermissionofthemanufacturer.Failuretodosowillvoidtheresponsibilityofthemanufacturer.

Checklocalroadlegislationbeforeyoudrivetheimplementonpublicroads.

Whenyouoperateinterchangeableimplement,makesurethattheimplementisCEapproved.

Asthispublicationisdistributedthroughoutourinternationalnetwork,theimplementillustrated,eitherasstandardor

asanaccessory,mayvaryaccordingtothecountryinwhichtheimplementistobeused.Lowspecicationcongurations,aschosenbythecustomer,maydeviatefromthespecicationsgiven.

Severalguresinthisoperator'smanualshowthesafetyguardingortheadditionalguards,legallyrequiredbycertain

countries,openorremovedtobetterillustrateaparticularfeatureoradjustment.Theimplementmustnotbeusedin

thiscondition.Foryourownsafety,makesurethatallguardsareclosedorreplacedbeforeyouoperatetheimplement.

1-1

Page 8

1-GENERALINFORMATION

OWNERASSISTANCE

WeatKONGSKILDEandyourKONGSKILDEdealerwantyoutobecompletelysatisedwithyourinvestment.Normally,yourdealer'sServiceDepartmentwillhandleanyproblemswithyourimplement.Sometimeshowever,misunderstandingcanoccur.Ifyourproblemhasnotbeenhandledtoyoursatisfaction,wesuggestyoutocontacttheowner

orGeneralManagerofthedealership,explaintheproblemandrequestassistance.Whenadditionalassistanceis

needed,yourdealerhasdirectaccesstoourbranchofce.

COMPANYPOLICY

Companypolicy,whichisoneofcontinuousimprovement,reservestherighttomakechangesindesignandspecicationatanytimewithoutnoticeandwithoutobligationtomodifyunitspreviouslybuilt.

Alldatagiveninthisbookissubjecttoproductionvariations.Theinformationinthispublicationisprovidedonthe

basisofinformationthatwasavailableatthetimethatthemanualwaswritten.Settings,proceduresandotheritems

canchange.Thesechangescanaffecttheservicethatisgiventotheimplement.

Dimensionsandweightsareapproximateonlyandtheillustrationsdonotnecessarilyshowtheimplementinstandard

condition.Forexactinformationaboutanyparticularimplementpleaseconsultyourdealer.Makesurethatyouhave

themostcurrentandcompleteinformationfromyourdealerbeforeyoustartanyjob.

ACCESSORIESANDOPTIONS

Yourimplementhasbeendesignedtooperateinawidevarietyofsoils/cropsandconditions.Neverthelessadditional

equipmentmay,incertaincases,berequiredtoimprovetheimplementperformance.Alistofthisadditionalequipmentisgiveninthe''Accessories”chapterinthismanual.Useonlythoseaccessoriesdesignedforyourimplement.

PARTSANDACCESSORIES

GenuineKONGSKILDEpartsandaccessorieshavebeenspecicallydesignedforKONGSKILDEimplements.

Wewouldliketopointoutthat''non-genuine”partsandaccessorieshavenotbeenexaminedandreleased

byKONGSKILDE.Theinstallationand/oruseofsuchproductscouldhavenegativeeffectsuponthedesign

characteristicsofyourimplementandtherebyaffectitssafety.KONGSKILDEisnotliableforanydamagecaused

bytheuseof''non-genuine”partsandaccessories.

RelyonyourauthorizeddealertosupplyyouwithgenuineKONGSKILDEpartsonly.Thesepartsarecoveredbyour

warrantyandwillgiveyouthebestperformance.

SeethepartscatalogorbrowsetheKONGSKILDEportaltondservicepartsforyourimplement.

Whenyouorderserviceparts,alwaysquotethemodelandserialnumberprintedontheProductIdenticationNumber

(PIN)plate.

1-2

Page 9

1-GENERALINFORMATION

LUBRICANTS

Yourdealersellsaselectionofspeciallyformulatedlubricantsbasedonownengineeringspecications.

Recommendedlubricantsforyourimplementarelistedinthemaintenancechapter.

WARRANTY

Yourimplementiswarrantedaccordingtolegalrightsinyourcountryandthecontractualagreementwiththeselling

dealer.Nowarrantyshall,however,applyiftheimplementhasnotbeenused,adjustedandmaintainedaccordingto

theinstructionsgiveninthisoperator'smanual.

Itisprohibitedtocarryoutanymodicationstotheimplementunlessspecicallyauthorized,inwriting,bya

KONGSKILDErepresentative.

CLEANINGYOURIMPLEMENT

Whenyouuseahighpressurewasher,donotstandtooclosetotheimplementandavoiddirectingthejetatelectronic

components,electricalconnections,breathers,seals,llercaps,andsoon.

Cleandecalsonlywithasoftcloth,waterandagentledetergent.DONOTusesolvent,gasolineorotherharsh

chemicalstocleandecals.Decalscouldberemovedorgetdamaged.

DISASSEMBLYORSCRAPPING

Whenyourimplementistakenoutofservicebecauseitisdamagedbeyondrepairorhasreachedtheendofits

usefullife,disassembly,scrappingand/orrecyclingofcomponentsmustbeperformedonlybyaqualiedtechnician

withserviceinstructions,andincompliancewithlocallawandregulations.

1-3

Page 10

Intendeduse

1-GENERALINFORMATION

KONGSKILDEdiscmowercanonlyperformtheusual

workinagriculture.Onlyconnectthediscmowertoatractorthatcorrespondswiththespecicationsoftheimplementandislegaltouse.OnlythePowerT ake-Off(PTO)

ofthetractorcandrivetheattacheddiscmower.

Thediscmowercansolelycutonthegroundnatural

orplantedgrassandstemcropsforanimalfeeding

purposes.Thediscmowerlaysthematerialinaswath,

whichallowsthesubsequentpick-upofthematerial.

Theworkmustoccurunderreasonableconditions,or

thoroughagriculturalknowledgeandauthorisedoperation,onanormalcultivationthathasareasonableextensionwithoutforeignmatterandthelike.Theperformance

Prohibitedusage

NOTICE:DONOTusethisimplementforanotherpurposethanintendedbythemanufacturer(asdescribed

inthemanual,shownbythedecals,orinotherproduct

safetyinformationprovidedwiththeimplement).These

informationsourcesdenetheintendeduseoftheimplement.

Donotusethisimplement:

1.T ocutgrassinparkfacilitiesandlawns.

2.T ocutgrassonthesidesofpublicroadways.

3.T oharvestcorn.

4.T oclearforestordenselywoodedareas.

Anyotherusebeyondtheintendeduseisregardedas

misuseandrequirestheauthorizationofthemanufacturer.Themanufacturerisnotresponsibleforanydamagethatresultsfromtheimproperuseoftheimplement.

Theuserbearsthatrisk.

oftheimplementwilldependonthecrop,theconditionof

theeld,theground,andnallytheweather.

Intendeduseimpliesthatyouobservetheprescriptions

concerningadjustment,operationandmaintenanceinthe

instructionmanual.Observedaltogetherthesafetyinstructionsaswellascommonrulesconcerningtechnical

safety,workingpracticesandroadsafety.Alsoreadthe

sparepartscataloganduseoriginalspareparts.Ifnecessarycontactanauthorisedworkshop.

Ifyounoticedegradationofperformance,contactyour

dealerforassistance.Hemayhaveusefulinformation

forimprovements,orakitmaybeavailabletoenhance

theperformance.

Contactyourlocaldealerwhenyouarenotsureabout

theuseorfunctionofyourimplementinaparticularapplication(forexamplecrop,variety,uniqueconditions,

etcetera)oryoudonotknowifthereisaneedforspecialequipmentorspecialprecautions.

Nopartsmustbettedtothisimplement,whichhavenot

beenreleasedbyKONGSKILDE.Theymightaffectthe

implementoperation,safetyoftheuserorotherpeople,

stabilityorwearcharacteristicsoftheimplement.They

mayalsovoidthehomologationapprovalobtainedfor

yourcountryandcompliancewithECdirectives.

Donotmakechangestotheimplementanditsconstructionwithoutthepermissionfromthemanufacturer.The

manufacturerdoesnotacceptanyresponsibilityfordamagesthatresultsfromunauthorizedmodication.

1-4

Page 11

1-GENERALINFORMATION

Electro-MagneticCompatibility(EMC)

ThismachinecompliesstrictlywiththeEuropeanRegulationsonelectro‐magneticemissions.However,interference

mayariseasaresultofadd‐onequipmentwhichmaynotnecessarilymeettherequiredstandards.Assuchinterferencecanresultinseriousmalfunctionoftheunitand/orcreateunsafesituations,youmustobservethefollowing:

Ensurethateachpieceofnon‐KONGSKILDEequipmentttedtothemachinebearstheCEmark.

•

Themaximumpowerofemissionequipment(radio,telephones,etc.)mustnotexceedthelimitsimposedbythe

•

nationalauthoritiesofthecountrywhereyouusethemachine.

Theelectro‐magneticeldgeneratedbytheadd‐onsystemshouldnotexceed24V/matanytimeandatanylo-

•

cationintheproximityofelectroniccomponents.

FailuretocomplywiththeseruleswillrendertheKONGSKILDEwarrantynullandvoid.

1-5

Page 12

1-GENERALINFORMATION

Manualscopeandrequiredtraininglevel

Introductiontothismanual

Thismanualgivesinformationabouttheuseofyour

KONGSKILDEmachineasintendedandunderthe

conditionsforeseenbyKONGSKILDEduringnormal

operation,routineservice,andmaintenance.

Thismanualdoesnotcontainalltheinformationthatrelatestoperiodicservice,conversions,andrepairsthat

onlytrainedservicepersonnelcanperform.Someof

theseactivitiesmayrequireappropriatefacilities,technicalskills,and/ortoolsthatKONGSKILDEdoesnotsupply

withthemachine.

ThemanualcontainsthechaptersasshownontheContentspages.SeetheIndexattheendofthismanualto

locatespecicitemsaboutyourKONGSKILDEmachine.

Normaloperation

Normaloperationconsistsoftheuseofthismachinefor

thepurposeKONGSKILDEintendsbyanoperatorthat:

Isfamiliarwiththemachineandanymountedequip-

•

mentortowedequipment

Complieswiththeinformationonoperationandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Normaloperationincludes:

Preparationandstorageofthemachine

•

Additionandremovalofballast

•

Connectionanddisconnectionofmountedequipment

•

and/ortowedequipment

Adjustmentandcongurationofthemachineand

•

equipmentforthespecicconditionsofthejobsite,

eld,and/orcrop

Movementofcomponentsintoandoutofworkingpo-

•

sitions

Routineserviceandmaintenance

Routineserviceandmaintenanceconsistsofthedaily

activitiesnecessarytomaintainthepropermachine

function.Theoperatormust:

Befamiliarwiththemachinecharacteristics

•

Complywiththeinformationonroutineserviceandsafe

•

practicesasspeciedbyKONGSKILDEinthismanual

andbythesignsonthemachine

Routineservicecaninclude:

Fueling

•

Cleaning

•

Washing

•

Toppingupuidlevels

•

Greasing

•

Replacingconsumableitemssuchaslightbulbs

•

Periodicservice,conversions,andrepairs

Periodicserviceconsistsofactivitiesthatarenecessary

tomaintaintheexpectedlifeoftheKONGSKILDEmachine.Theseactivitieshavedenedintervals.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivitiesatthedened

intervals.Trainedservicepersonnelmustcomplywith

theinformationonperiodicserviceandsafepracticesas

partlyspeciedbyKONGSKILDEinthismanualand/or

othercompanyliterature.

Periodicserviceincludes:

Oilchangeservicefortheengine,hydrauliccircuits,or

•

transmission

Periodicexchangeofothersubstancesorcomponents

•

asrequired

ConversionactivitiesrebuildtheKONGSKILDEmachine

inacongurationthatisappropriateforaspecicjob

site,crop,and/orsoilconditions(e.g.,installationofdual

wheels).Conversionactivitiesmustbedone:

Bytrainedservicepersonnelfamiliarwiththemachine

•

characteristics

Bytrainedservicepersonnelthatcomplywiththe

•

informationonconversionaspartlyspeciedby

KONGSKILDEinthismanual,assemblyinstructions,

and/orothercompanyliterature

Repairactivitiesrestoreproperfunctiontoa

KONGSKILDEmachineafterafailureordegradation

ofperformance.Dismantlingactivitiesoccurduringthe

scrappingand/ordismantlingofthemachine.

Trainedservicepersonnelfamiliarwiththemachinecharacteristicsmustperformtheseactivities.Trainedservice

personnelmustcomplywiththeinformationforrepairas

speciedbyKONGSKILDEintheservicemanual.

Beforeyouoperate

Readthismanualbeforeyoustarttheengineor

operatethisKONGSKILDEmachine.Contactyour

KONGSKILDEdealerif:

Youdonotunderstandanyinformationinthismanual

•

Youneedmoreinformation

•

Youneedassistance

•

Allpersonstrainingtooperate,orwhowilloperate

thisKONGSKILDEmachineshouldbeoldenoughto

possessavalidlocalvehicleoperatingpermit(ormeet

otherapplicablelocalagerequirements).Thesepersons

1-6

Page 13

1-GENERALINFORMATION

mustdemonstratetheabilitytooperateandservicethe

KONGSKILDEmachineinacorrectandsafemanner.

ProductIdenticationNumber(PIN)

Theunitisidentiedbyaserialnumber.

Serialnumber,modelandotherspecicationscanbe

foundonthePINplate.

ProvideyourKONGSKILDEdealerthemodelandPIN

whenyouorderparts.

RecordthePINinthefrontofthismanualforquickreference.

ZEIL18HT00546EA1

(1)Companyname(7)Yearofconstruction

(2)

(3)

(4)ProductIdenticationNumber(PIN)(10)Type/Variant/Version

(5)

(6)Madein(countryoforigin)(12)Brandidenticationlogo

Designation

Model

Maximumweight

(8)Certicationmark

(9)

(11)

Modelyear

Mailaddress

1-7

Page 14

1-GENERALINFORMATION

Productidentication

NOTE:DonotremoveorchangetheProductIdenticationNumber(PIN)plate(1)ontheimplement.

ThePINplate(1)isonthetopoftheimplement.

ThePINisalsoengravesonthechassisat(A)belowthe

PINplate(1).

Forfuturereference,recordyourimplementmodeland

PINinthespacesbelow.

Model

ProductIdenticationNumber(PIN)

ZEIL18HT00474FA1

1-8

Page 15

1-GENERALINFORMATION

Operator'smanualstorageonthemachine

Keepthisoperator'smanualprotectedandaccessibleon

thetractorwheneveryoutransportoroperatetheimplement.

1-9

Page 16

1-GENERALINFORMATION

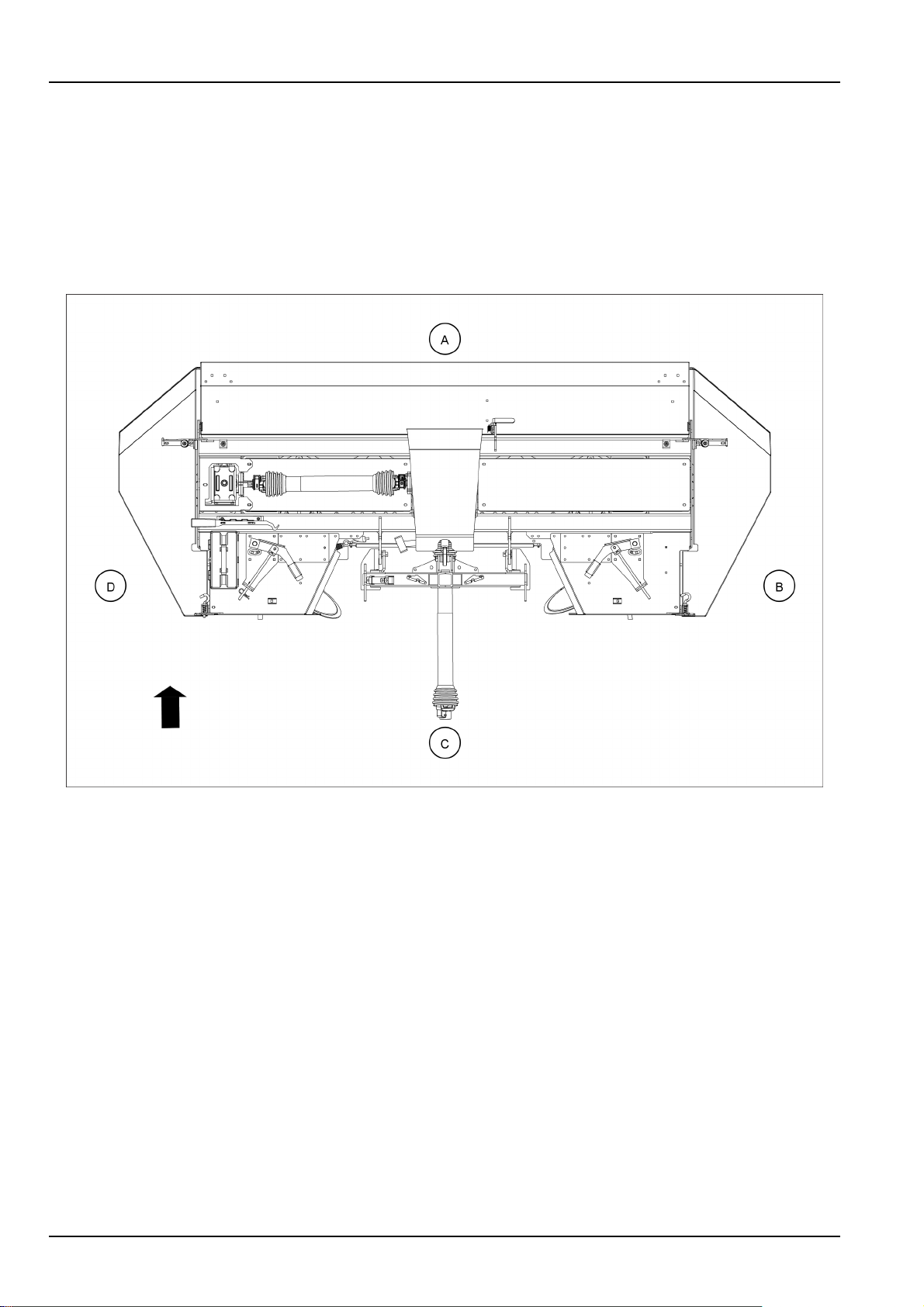

Implementorientation

NOTE:Todeterminetheleft-handsideandtheright-hand

sideoftheimplement,standbehindtheimplementand

facethedirectionoftravelduringworkingoperation.

Thefollowingoverheadviewillustrationisageneralrepresentationoftheimplement.Theillustrationindicatesthe

sides,front,andrearorientationsoftheimplementasreferredtothroughoutthisoperator’smanual.

NOTE:Thearrowindicatesthedirectionoftheimplement

duringworkingoperation.

(A)Frontoftheimplement

(B)Right-handsideoftheimplement

(C)Rearoftheimplement

(D)Left-handsideoftheimplement

ZEIL18HT00586FA1

1-10

Page 17

2-SAFETYINFORMATION

2-SAFETYINFORMATION###_2_###

Safetyrulesandsignalworddenitions

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

ThroughoutthismanualyouwillndthesignalwordsDANGER,WARNING,andCAUTIONfollowedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworkingwithyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationthat,ifnotavoided,willresultindeathorseriousinjury.

WARNINGindicatesahazardoussituationthat,ifnotavoided,couldresultindeathorseriousinjury.

CAUTIONindicatesahazardoussituationthat,ifnotavoided,couldresultinminorormoderateinjury.

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESULT

INDEATHORSERIOUSINJURY .

Machinesafety

NOTICE:Noticeindicatesasituationthat,ifnotavoided,couldresultinmachineorpropertydamage.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachineor

propertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationthatclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

2-1

Page 18

2-SAFETYINFORMATION

Generalrecommendations

Mostfarmmachineryaccidentscanbeavoidedbythe

observanceofafewsimplesafetyprecautions.

Thisoperator’smanualcontainsimportantinformation

•

concerningoperation,maintenanceandadjustmentof

theimplement.Furthermore,thisoperator’smanual

mentionsandemphasizesallthesafetyinstructions.

Readtheoperator’smanualthoroughlybeforeyou

•

start,operate,service,orcarryoutanyotheroperation

ontheimplement.Eventhoughyouhavebeendriving

asimilarimplementbefore,youmustreadthemanual.

Thisisamatterofyourownandotherpeoplesafety.

Afewminutesreadingwillsaveyoutimeandhassle

later.Lackofknowledgecanleadtoaccidents.

Yourimplementwasdesignedwithsafetyinmind.

•

However,thereisnorealsubstituteforcautionand

attentionwhenyouneedtopreventanaccident.Once

anaccidenthasoccurred,itistoolatetothinkabout

whatyoushouldhavedone.Thismeansthatitis

veryimportantthatyouasuseroftheimplementpay

attentionandusetheimplementcorrectlyandthereby

avoidexposingyourselfandotherstounnecessary

danger.

Theimplementmustbeoperatedonlybyresponsible

•

personswhohavebeenadequatelytrainedandautho-

rizedtousetheimplement.Neverleavetheimplement

toothersbeforeyouhavemadesurethattheyhavethe

necessaryknowledgetooperatetheimplementsafely.

Neverlettheimplementrunwithoutsupervision.

•

Alwayskeeparstaidkithandy.

•

Takethenecessaryprecautions(forexampleassis-

•

tance)toalwaysbeawareofthepossiblepresenceof

bystandersandpets.

Keepchildrenawayfromandofftheimplementatall

•

times.

Donotusethisimplementasalift,ladderorplatform

•

toworkatheights.

Beforeyouworkontheimplement,disengageall

•

drives,stoptheengineandremovetheignitionkey.

Waitfortherotatingpartstorundown.

Neverworkaroundtheimplementwithlooseclothing,

•

jewelry,watches,longhairandotherlooseorhanging

itemscanbepulledinbythemovingpartsoftheimplement.

Keephandsawayfrommovingpartsoftheimplement.

•

Neverattempttocarryoutanyadjustmentsontheim-

•

plementwhiletheimplementisinmotionorwhilethe

PowerT ake-Off(PTO)shaftisengaged.

PTOdrivenimplementcancausedeathorseriousin-

•

jury.BeforeyouworkonornearthePTOshaftorser-

viceorclearthedrivenimplement,disengagethePTO,

stoptheengineandremovetheignitionkey.

2-2

Page 19

2-SAFETYINFORMATION

Illustrations

WARNING

Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment.

Replaceallshieldsbeforeoperatingthemachine.

Failuretocomplycouldresultindeathorseriousinjury .

NOTE:Someoftheillustrationsinthismanualhavebeen

obtainedbyphotographingprototypes.Standardproductionmachinesmaydifferinsomedetails.

Legalobligations

W0012A

Yourmachinemaybeequippedwithspecialguardingor

otherdevicesincompliancewithlocallegislation.Some

oftheserequireactiveactionbytheoperator.

Fireorexplosionprevention

1.Cropmaterial,trash,debris,birdnestsorammable

materialcanigniteonhotsurfaces.

2.Inspecttheelectricalsystemforlooseconnectionsor

frayedinsulation.Repairorreplacelooseordamaged

parts.

3.Donotstoreoilyragsorotherammablematerialon

theimplement.

4.Donotweldoramecutanyitemsthatcontain

ammablematerial.Cleanitemsthoroughlywith

Therefore,checklocallegislationontheusageofthismachine.

non-ammablesolventbeforeyouweldorcutwitha

ame.

5.Donotexposetheimplementtoames,burningbrush

orexplosives.

6.Promptlyinvestigateanyunusualsmellsorodorsthat

mayoccurduringtheoperationoftheimplement.

2-3

Page 20

Hazardouschemicals

2-SAFETYINFORMATION

1.Ifyouareexposedtoorcomeincontactwithhazardouschemicalsyoucanbeseriouslyinjured.

Theuids,lubricants,paints,adhesives,coolant,

etcetera.requiredforthefunctionofyourmachine

canbehazardous.Theymaybeattractiveandharmfulltodomesticanimalsaswellashumans.

2.MaterialSafetyDataSheets(MSDS)provideinformationaboutthechemicalsubstanceswithinaproduct,

safehandlingandstorageprocedures,rstaidmeasuresandprocedurestobetakenintheeventofaspill

oraccidentalrelease.MSDSareavailablefromyour

dealer.

3.BeforeyouserviceyourmachinechecktheMSDSfor

eachlubricant,uid,etcetera.usedinthismachine.

Thisinformationindicatestheassociatedrisksandwill

helpyouservicethemachinesafely.FollowtheinformationintheMSDS,onmanufacturercontainers,as

wellastheinformationinthismanualwhenyouservicethemachine.

4.Disposeofalluids,ltersandcontainersinanenvironmentallysafemannerinaccordancewithlocal

lawsandregulations.Checkwithlocalenvironmentalandrecyclingcentersoryourdealerforcorrectdisposalinformation.

5.Storeuidsandlterinaccordancewithlocallawsand

regulations.Useonlyappropriatecontainersforthe

storageofchemicalsorpetrochemicalsubstances.

6.Keepoutofreachofchildrenorotherunauthorized

persons.

7.Additionalprecautionsarerequiredforappliedchemicals.Obtaincompleteinformationfromthemanufacturerordistributorofthechemicalsbeforeyouuse

them.

2-4

Page 21

Startinguptheimplementsafely

2-SAFETYINFORMATION

Beforeyouattachtheimplementtothetractor,ensurethat

thetractorisingoodworkingorderandthatthebrakes

areefcient,particularlyifyouoperateonhillyground.

Also,ensurethatthehydraulicorpneumaticsystemis

compatiblewiththatoftheimplement.

Whenyouattachtheimplementtothetractor:

Neverallowanyonetostandbetweenthetractorand

•

theimplement.Anunintentionalmanoeuvrewiththe

tractormaycauseseriousinjury.

Nevergounderanunsupportedimplement.

•

Installalltheguardscorrectlybeforeyouusetheimplement.

Replacewornanddamagedcanvasesbeforeyouwork

withtheimplement.

MakesurethatyouarethoroughlyfamiliarwiththeinstrumentsandcontrolsbeforeyouengagethePowerT akeOff(PTO)driveforthersttime.

ThePTOshafthasitsowninstructionmanualthatthe

manufacturersupplywiththeimplement.Toensurethe

correctuseoftheshaft,followalltheinstructionsofthe

manufacturermanual.Payparticularlycloseattentionto

thesafetyandmaintenanceinstructions,inordertopreventunintentionalinjuryanddamage.

RepairimmediatelyadamagedPTOshaftbeforeyou

workwiththeimplement.

AlwaysstopthePTOandthetractorengineandremove

theignitionkeybeforeyouconnectthePTOdriveshafts.

Afteryouattachtheimplementtothetractor,ensurethat

thePowerTake-Off(PTO)lockpinisproperlyengaged

inthetractorPowerTake-Offshaft.Anincorrectlylocked

PTOshaftcouldworklooseandcauseaccidentsordamagetotheimplement.

MakesuretoinstallandsecurethePTOdriveshaftcorrectly.Checkthatthelockpinisinmesh.Fastenthe

supportchainatbothends.

Alwaysmakesurethattheguardtubesdonotseparate

atthemaximumworkingortransportlengthofthePTO

driveshaft.Checkalsothattheguardtubesdonotjamat

theminimumworkingortransportlengthofthePTOdrive

shaft.

Unlesstheprotectiveguards,thePTOdriveshaftmay

causeseriousinjury.Becarefulnottodamagetheguards

whenyouconnectthePTOdriveshafttoorfromthetractor.

FitcorrectlytheguardsonthePTOdriveshaft.Secure

theguardofthePTOshaftwiththechain.

DonotusePowerT ake-Off(PTO)driveshaftswithother

specicationsthantheshaftwhichwassuppliedwiththe

implement.

BeforeyouinstallthePTOdriveshaft,checkthattheRevolutionsPerMinute(RPM)anddirectionofthePTOonthe

tractormatchthoseofthePTOontheimplement.

Beforeyoustartuptheimplement(forexampletherst

timeafteralongstandstillperiod),makesurethatthere

arenodetachedloosepartsonthedrivelineareaandon

themovingpartsoftheimplement.

2-5

Page 22

Travelingonpublicroads

2-SAFETYINFORMATION

Complywiththerelevanttrafcregulations

WARNING

Impacthazard!

Takecarewhenmakingturns.Themachine

rearendswingsoutwhenchangingdirection.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Lossofcontrolhazard!

Unevenbrakeforceexistsonleft-handand

right-handbrakes.Alwaysusebrakepedal

couplerwhentravelingonpublicroadstoensurebrakesareactuatedtogether.

Failuretocomplycouldresultindeathorseriousinjury.

Theimplementisbuiltaccordingtothehomologationrequirementsofyourcountry.Donotmodifytheimplement

inasensethatwouldconictwiththenationalregulations.

Ifyouwishtotransporttheimplementonthepublicroad,

makesurethatthecombinationtractorandimplement

observesthetrafcrulesinyourcountry.Thisgivesyou

andyoursurroundingsthebestpossiblesafety.

Passengers

Donotallowpassengerstorideinthetractorunlessa

specicseatisprovided.

Duringtransport,thetransportationofpeopleonthetop

oftheimplementisstrictlyforbidden.

W0089A

W0081A

Transportsafety

Transporttheimplementonlyintransportposition.Securetheimplementfortransport.Alwaysactivatethemechanicaltransportsafetydevicesbeforetransport.

Makesuretotallthehitchpinswithretainingpinscorrectly.Mechanicallysecurethehydrauliccylinderstopreventcylindersfromcreeping.

Drivesafe

Donotdriveundertheinuenceofalcoholordrugs.

Nevertravelatspeedincrowdedareas.

Whenyoumaneuverthetractorwiththeimplement,alwaysbeawareandconsciousofitssize.

Thetractordrivermustnotleavethecabinduringtransport.

Theoperatorsmustobserverelevantstatutoryorother

nationalregulationsthatdealwithroadsafetyandlabor

safetyissues.

Beforeyoudrivetheimplementonpublicroads:

Checktheallowabletransportdimensionsandweights.

•

Installcorrectlythelightingandthewarningpanels.

•

Alwaysobservetheprinciplesforpermissibleaxleloads,

thetotalunitmassandthetransportgauge.

Observethetractormanufacturerregulationsandrecommendations,specicallythoserelatingtomaximumtransportloadsandmaximumspeed.

Eveninsimilarcircumstances,themaximumallowed

speedcanvarydependingonwhichcountryyoutravel

in.

Alwaysdrivewiththestatutorylightsandsafetymarking

duringtransportonpublicroadandatnight.

Installalltherequiredsignsthatindicatethevehiclewidth.

Alsoinstallalltherequiredlightsthatindicatethevehicle

widthduringthenightlytransport.Ifindoubt,contactyour

governmentdepartmentresponsibleforroadtransport.

Alwaysconsiderotherroadusers.

Alwaysadoptsafedrivingpractices.Slowdownandsignalbeforeturning.Givewaytooncomingtrafcinallsituations,includingnarrowbridges,intersectionsetcetera.

Pullovertoallowfastertrafctopass.

Iftheimplementismarkedwithamaximumspeedlimit,

neverexceedthismaximumspeedlimit.

Alwaysadjustthedrivingspeedtotheroadandweather

conditions.Incaseofbadroadconditionsandhighdrivingspeeds,bigforcesmayoccurandcauseoverloadof

tractorandimplement.

Driveatasafespeedtoensurecontrolandabilitytostop

inanemergency.

Lockthetractorbrakepedalstogether.Neveruseindependentbreakingattransportspeeds.

Mountedimplementsandballastweightsinuencethe

driving,steeringandbrakingcapacityofthetractor.Make

surethattheadditionalweightoftheimplementonthe

linkagedoesnotcompromisedriving,steeringandbrakingcapacityofthetractor.Installfrontweightsorrepair

thebrakesifthetractorisnotsafetodrive.

Travelmayberestrictedtocertainroadtypes.Transport

mayberestrictedtodaytimeoroutsidepeaktrafchours.

Howeverplanyourroutetoavoidheavytrafcandpeak

trafchours.

Reducespeedduringturns.Tractorshavenotbeendesignedforfastturning.Avoidthattherearendoftheimplementhitsanobstacle.

2-6

Page 23

2-SAFETYINFORMATION

Whenyouturnduringtransportpayattentiontotheoverhangand/oroscillatingweightoftheimplement.

Useenginebrakingwhenyoudrivedownhills.Donot

coast.

Watchforobstructions,particularlyifover-width.Observe

anyloadratingsapplicableonbridges.

Afteryounishthetransport,beforeyouleavethetractor,

alwayslowertheimplementtothegroundinparkingposition,turnoffthetractorengine,pulltheparkingbrake,

andremovethekeyfromtheignition.

2-7

Page 24

Operatingtheimplementsafely

WARNING

Hazardtobystanders!

Alwayssoundthehornbeforestartingthemachine.Makesuretheworkareaisclearof

otherpersons,domesticanimals,tools,etc.

beforeyouoperatethemachine.Neverallow

anyoneintheworkareaduringmachineoperation.

Failuretocomplycouldresultindeathorseriousinjury.

WARNING

Entanglementhazard!

Makesureallpeopleandobstructionsare

clearoftheimplementbeforeengagingthe

tractorPowerTake-Off(PTO).

Failuretocomplycouldresultindeathorseriousinjury.

2-SAFETYINFORMATION

Beforeyouraiseorlowertheimplementwiththelinkarms

ofthetractor,checkthatnobodyisneartheimplementor

touchestheimplement.

Whenyouoperatetheimplement,alwaysremainseated

inthetractorcab.Operatecontrolsonlywhenseatedin

thetractorseat,exceptforthosecontrolsexpresslyintendedforusefromotherlocations.

Whileinoperation,thetransportationofpeopleontopof

theimplementisstrictlyforbidden.

W0304A

Avoidusingtheimplementinunsuitablecropandweather

conditions.Itisbettertostopworktemporarilyratherthan

tooperateinsuchconditions.

Neverattempttoremovecroporresiduesfromanimplementwhiletheimplementruns.Suchanimprudence

couldcostlifeorlimb.AlwaysdisengagethePower

Take-Off(PTO)mechanism,switchoffthetractorengine

andapplytheparkingbrakebeforeyouremovecropor

W1378A

residues.

WARNING

Rotatingparts!

Keepclearofalldrivesandrotatingcomponents.

Failuretocomplycouldresultindeathorseriousinjury.

NOTE:Onlyputtheimplementintooperationaccording

totheinstructionsfromthedealer.

Neveroperatetheimplementundertheinuenceofalcohol,drugs,orwhileotherwiseimpaired.

Keeppeopleawayfromtheimplementduringoperation.

Askbystanderstoleavetheeld.Thereistheriskfor

bystanderstobeoverrunbytheimplement.Stoptheimplementimmediatelyifsomeoneapproaches.

Thetractororitsimplementmaystrikeorcrushagainsta

personorpetwithintheoperatorareaofthetractor.DO

NOTallowanyonetoentertheworkarea.Makesurethat

theareaisclearandoperationissafebeforeyoumove

theimplement.

BeforeyouswitchonthePTOshaft,takecarethatnoone

staysinthedangerzoneoftheimplement.

Lowerthecuttingunittoworkingpositionbeforeyoustart

thepowertransmission.

Alwaysstarttheimplementwiththeenginerunningatlow

speed.

WheneveraPTOisinoperation,aguardmustbeinplace

topreventdeathorinjurytotheoperatororbystanders.

W1101A

AlwaysstopPTOwhenthePTOisnotneededorwhen

theshaftisinanadverseposition.

Duringthedailyworkyoumustconsiderthatloosestones

andforeignmatteronthegroundmightgetincontactwith

therevolvingpartsandgetthrownoutagainatavery

highspeed.Therefore,beforeyouoperatetheimplement

makesurethatallsafetyguardsareintact,properlytted

andsecured.

Relievecorrectlythecuttingunittoensureperfectoperationintheeldandtoreducetheriskofdamagingthe

cutterbar.Ifthecuttingunitisblockedbecauseofforeignmatter,stopthepowertake-offofthetractor,activatetheparkingbrakeandwaituntilallrevolvingparts

havestopped.Thentrytoremovetheforeignmatter.

Throughthesuspension,theimplementissecured

againstshocksinthedirectionoftravel.However,there

isnosecuringagainstshocksifyoudrivebackwithaloweredcuttingunitandyourisktodamagetheimplement.

Instonyeldsadjustthestubbleheighttomaximum(horizontalcutterbar)andreducethecuttingangleasmuch

aspossible.Thisresultsinlesswearofbladesandstone

guardsandreducestheriskofloosestonesbeingthrown

outfromtherotatingpartsoftheimplement.

Alwaysoperatetheimplementatasafespeedinaccordancewiththegroundconditions.Onunevenground,

proceedwiththeutmostcautiontoensureproperstability.

Whenyouturnonhillsidesalwaysbecarefulwhenyoulift

theimplementwiththe3-pointlinkagebecausethereisa

riskofoverturning.Adjustthespeedtotheseconditions.

Driveinalowtractorgearifyouworkonhillsides.

2-8

Page 25

2-SAFETYINFORMATION

Whenyoudriveupanddownandacrosshillsides,avoid

sharpturns.

Whenyouturnduringoperation,payattentiontotheoverhangand/oroscillatingweightoftheimplement.

Avoidchangingdirectionabruptly,especiallywhenyou

reverse,toavoiddangerouspitchingoftheimplement.

Whenyouworkwithamowerkeepasafedistancefrom

steepslopesandsimilargroundconditions,astheground

maybeslipperyandpullthemowerandthetractorsideways.Alsoremembertoadjustthespeedforsharpturns

whenyoudriveonhillsides.

Paythenecessaryattentionwhileyouoperatenextto

publicroadsorfootpaths.

2-9

Page 26

2-SAFETYINFORMATION

Stoppingtheimplementsafely

WARNING

Movingparts!

Somecomponentsmaycontinuetorunafter

disengagingthedrivesystems.Makesure

alldrivesystemsarefullydisengagedandall

movementhasstoppedbeforeservicingthe

machine.

Failuretocomplycouldresultindeathorseriousinjury.

Alwaysinterrupttheoperationoftheimplementbefore

youleavethetractorseat.

Forsafety'ssakeneverleavethetractorcabwithoutrst

todisengagethePowerTake-Off(PTO)drivemechanism

andtostopthetractorengine.Furthermore,ifyouleave

thetractorunattended,alwaysremovetheignitionkey.

StopthetractorengineandthePTOdriveandwaituntil

theimplementhascompletelystoppedbeforeyouopen

anyoftheguards.Therearerotatingpartsunderthe

guardswhichmaycontinuerotatingaftertheimplement

hasbeenstopped.Keepasafedistanceuntiltheimplementhascometoacompletestandstill.Lookandlisten

forevidenceofrotatingpartsbeforeyouopenanyofthe

guards.

Neverleavethetractorbeforethecuttingunitisrestingon

theground,theengineofthetractorhasstopped,andthe

parkingbrakehasbeenactivated.Thisistheonlywayto

performasafeoperation.

Donottrytolifttheguardofthecuttingunituntilallrevolvingpartshavestopped.

Makesuretosecurethetractorbymeansofthehand

brakeand/orstopblocksifyouneedtostandbetween

thetractorandtheimplement.

W0002A

Whenyouparktheimplementtherearesomeoperational

riskswhichmaycausepersonalinjury.Therefore,you

must:

Makesurethatthegroundisrmandevenduringpark-

•

ing.

Makesurethattractorandimplementcannotmove.

•

Alwayslowertheimplementtotheground.

•

Stopthetractorengineandremovetheignitionkey.

•

Usecorrectsupportortransportsafetydevicewhenthe

•

implementisparked.Makesurethattheparkingstand

issecured.

Whenyoudetachtheimplementfromthetractor:

Neverallowanyonetostandbetweenthetractorand

•

theimplement.Anunintentionalmanoeuvrewiththe

tractormaycauseseriousinjury.

AlwaysstopthePTOandthetractorengineandre-

•

movetheignitionkeybeforeyoudisconnectthePTO

driveshafts.

Unlesstheprotectiveguards,thePTOdriveshaftmay

•

causeseriousinjury.Becarefulnottodamagethe

guardswhenyoudisconnectthePTOdriveshaftfrom

thetractor.

NeverallowthePTOdriveshaftguardstofallintothe

•

implementordroptotheground,damagewillalmost

certainlyoccur.

AfteryouremovethePTOshaft,placetheguardonthe

•

tractorPTO.

Alwaysdetachtheimplementcarefullyandonaat

•

surfacetopreventdamage.

Nevergounderanunsupportedimplement.

•

When,duetoexceptionalcircumstances,youdecideto

keepthetractorenginerunningafteryouleavethetractor

cab,youmust:

Bringthetractorenginetolowidlespeed.

•

Disengagealldrivesystems.

•

Shiftthetractortransmissionintoneutral.

•

Applytheparkingbrake.

•

2-10

Page 27

2-SAFETYINFORMATION

Maintenance

WARNING

Maintenancehazard!

Beforeyoustartservicingthemachine,attach

aDONOTOPERATEwarningtagtothemachineinavisiblearea.

Failuretocomplycouldresultindeathorseriousinjury.

Followthemaintenanceschedulewithregardtotheim-

•

plementservicingintervals.

Rememberthattheimplementrequiresattentionfrom

timetotime.Alsorememberthatthemaintenancewill

greatlyextendthelifeoftheimplement.

Takethenecessaryprecautions:nottospillanyoil,fuel

•

orgrease.

Toavoidoilandgreasecontactwithyourskin,wear

protectivegloves.

Servicetheimplementonarmlevelsurface.

•

Donotattempttoremovematerialfromanypartof

•

theimplement,clean,lubricateorcarryoutanyadjust-

mentsontheimplementwhileitisinuse.

Keephands,feetand/orgarmentsawayfromparts

•

whichmove.Checkthatallrotatingpartshavea

suitableprotectiveguard.

Raisedimplementand/orloadscanfallunexpectedly

•

andcrushpersonsunderneath.Neverenterorallow

anyonetoentertheareaunderneathraisedimplement

duringoperation.

Unsupportedhydrauliccylinderscanlosepressure

anddroptheimplementandcauseacrushinghazard.

Donotleavetheimplementinaraisedpositionwhile

parkedorduringservice,unlesssecurelyblockedon

woodenblocks.

Neverworkunderaraisedimplementunlessasupport

•

chainorothermechanicalsecuringdevicesecurethe

linkarmsofthetractorsothattheimplementcannot

movetoalowerpositionunintentionally.

Relievethepressure,stoptheengineandremovethe

•

ignitionkey,beforeyouconnectordisconnectuid

lines.

Beforeyouadjust,clean,lubricateoryoucarryoutre-

•

pairsontheimplement,stoptheengineandremove

W0004A

theignitionkey.

NeveradjusttheimplementwhilethePowerTake-Off

•

(PTO)driveshaftisengaged.Donottoremovethe

guardsuntilallrevolvingpartshavestopped.

Anyleakageofhydraulicoilorfuelunderpressuremay

•

causesevereharm,soalwaysuseashielding,goggles

andgloveswhenyoutraceoilorfuelleaks.

Donotuseyourhandtocheckforleaks.Useapiece

ofcardboardorpaper.

Continuouslongtermcontactwithhydraulicuidmay

•

causeskincancer.Avoidlongtermcontactandwash

theskinpromptlywithsoapandwater.

Ifhydraulicuidordieselpenetratestheskin,seek

•

medicalcareimmediately.

Observeallrecommendationsthatarementionedin

•

thismanualsuchasserviceintervals,torques,lubri-

cants,etcetera.

Alwaysreplaceallpartsthathavedamageorwear.

•

Neverbuildexiblehoseassembliesfromhosesthat

•

werepreviouslypartofahoseassembly.

Neverweldtothetubes.

•

Alwaysusegloveswhenyouworkwithpartsonthe

•

implementasthepartscanhavesharpedges.

Transmissionandhydrauliclinesmaybecomehotdur-

•

ingoperation.Becarefulwhenyouservicesuchcom-

ponents.Allowsurfacestocoolbeforeyouhandleor

disconnecthotcomponents.Wearprotectiveequipmentwhenrequired.

2-11

Page 28

2-SAFETYINFORMATION

PersonalProtectiveEquipment(PPE)

WearPersonalProtectiveEquipment(PPE)suchasprotectiveclothing,eyeprotection,hearingprotection,dust

mask,hardhat,heavygloves,workboots,and/orany

otherPPEthatprovidesforthesafetyandprotectionof

theindividualthatoperatesthisequipment.

NHIL13RB00001AA1

2-12

Page 29

2-SAFETYINFORMATION

Safetyrequirementsforuidpowersystemsandcomponentshydraulicsystems

Beforeyoustarttheengineorpressurizethehydraulic

system,installandtightcorrectlyallthehydrauliccouplings.Checkthatallhosesandttingsareundamaged.

Replaceimmediatelydamagedcomponents.

Onlyconnectthehydraulichosestothetractoroutletsif

thetractorandtheimplementarepressure-free.Ifthe

hydraulicsofthetractorisactivateditmayleadtouncontrolledmovementswhichmaycausesecondarydamage.

Makesurethatnopersonsareneartheimplementwhen

youstarttheimplement,astheremightbeairinthehydraulicsystemwhichmightleadtosuddenmovements.

Whenthetractorenginehasstopped,activatethetractor

hydraulicspoolvalvestomakesurethatthereisnopressureinthehydraulichoses.

Toexpelalltheairfromtheoilinthehydrauliccylinders,

testallthefunctionsafteryouconnectthehydraulic

connectionstothetractor,especiallybeforeyouenter

ordriveonthepublicroads.Otherwiseyouriskthatthe

cuttingunitsuddenlymovesdownwardafteryouhave

dismountedthetransportlock

2-13

Page 30

2-SAFETYINFORMATION

Noiseemission

ThemeasuringandreportingofthenoiselevelwerecarriedoutaccordingtoISO5131.

Thenoiseismeasuredwiththeengineandallmechanismsengagedandrunningatnormaloperatingspeed

forthespecieduseoftheproduct.Thesearemaximum

valueswhichinnormaloperatingconditionswillneverbe

exceeded.

Themeasurementofthenoiseleveltookplaceinthetractorcabin,whereusuallyistheheadoftheoperator.

Toenablemeasurementofnoiselevelattheoperatorseat

producedbythetractor-implementcombination,itmust

benotedthattheairbornenoiseproducedbytheimplementattachedtothetractorismeasuredatadistance

of200mm(7.9in)behindtherearwindowpositionofan

averagetractorsuitableforoperatingtheimplement.

Twomeasurementswerecarriedout,bothwiththeRevolutionsPerMinute(RPM)ofthetractorengineadjusted

sothatthePowerT ake-Off(PTO)runsat1000RPM:

Implementconnected,tractorwindowclosed:66.5dB.

•

Implementconnected,tractorwindowopen:70.8dB.

•

Ontractorswithcabprovidedallwindows,doorsand

otherpossibleopeningsarekeptclosed;itisobviousthat

therealnoiselevelattheoperator'sseatwillbesignificantlylower.Theexactlevelwilldependonthenoise

insulationqualitiesofthecab.

Ontractorswithoutacaborwhenyouworkwiththecab

doorsorwindowsopen,itisrecommendedtouseearprotectionequipmentwhenthenoiselevelexceeds90dBa.

Inseveralcountriesthisismandatory,sochecklocallegislation.

Alwaysusehearingprotectorsifthenoisefromtheimplementisannoyingorifyouworkwiththeimplementfora

considerableperiodinatractorthathasnotanadequate

soundproofcabin.

NOTICE:Thelevelofnoisefortheoperatorcouldbeless

orgreaterdependinguponthetowingtractor.

Vibrationlevels

Allrevolvingpartsarebalancedbymeansofaspecial

machinewithelectronicsensors.Ifapartstillhasanunbalance,smallcounterweightsmustbefastened.

Asthediscsrunatupto3000RPM,eventheslightest

unbalancewillcausevibrationswhichmayleadtofatigue

fractures.

NOTE:Ifthevibrationsorthenoiseoftheimplementincreaseconsiderablyduringtheoperation,stopthework

immediately.Correctthefaultbeforeyoucontinuethe

work.

NOTE:Whenyoureplacetheblades,replaceboththe

bladesonthediscinquestionnottocreateanunbalance.

2-14

Page 31

2-SAFETYINFORMATION

Implementstability

Thecombinationofyourtractorandimplementcanbecomeunstable,duetotheadditionalweightthattheimplement

addstothetractor.

Inordertoguaranteestableandsafetransport,youmustcheckifyouneedballastweightsfortransportandeld

work.

Youmustalsocheckandguaranteethatyouhaveatleast20%fromthetractorweightonthefrontaxle.

Forrearmountedimplementsandfront-rearcombinations,theformulais:

ZEIL18HT00277FA1

Exampleofreferencestostabilityofthecombinationtractor–implement

Listofsigns

Te[kg]Thetractorownweight.

Tf[kg]

Tr[kg]Rearaxleloadwithemptytractor.

Ir[kg]

If[kg]Totalweightofthefront-mountedimplement/frontballast.

a[m]

b[m]Thetractorwheeldistance.

c[m]

d[m]

Frontaxleloadwithemptytractor.

Totalweightoftherear-mountedimplement/rearballast.

Distancebetweenthecenterofgravityofthefront-mountedimplement/frontballastandthe

middleofthefrontaxle.

Distancebetweenthemiddleoftherearaxleandthemiddleofthelinkarmballs.

Distancebetweenthemiddleofthelinkarmballsandthecenterofgravityoftherearmounted

implement/rearballast.

2-15

Page 32

2-SAFETYINFORMATION

Ecologyandenvironment

Soil,air,andwaterqualityisimportantforallindustries

andlifeingeneral.Whenlegislationdoesnotyetrulethe

treatmentofsomeofthesubstancesthatadvancedtechnologyrequires,soundjudgmentshouldgoverntheuse

anddisposalofproductsofachemicalandpetrochemical

nature.

Familiarizeyourselfwiththerelativelegislationapplicabletoyourcountry,andmakesurethatyouunderstand

thislegislation.Wherenolegislationexists,obtaininformationfromsuppliersofoils,lters,batteries,fuels,

anti-freeze,cleaningagents,etc.,withregardtotheeffectofthesesubstancesonmanandnatureandhowto

safelystore,use,anddisposeofthesesubstances.Your

KONGSKILDEdealercanalsoprovideassistance.

Helpfulhints

Avoidtheuseofcansorotherinappropriatepressur-

•

izedfueldeliverysystemstolltanks.Suchdelivery

systemsmaycauseconsiderablespillage.

Ingeneral,avoidskincontactwithallfuels,oils,acids,

•

solvents,etc.Mostoftheseproductscontainsub-

stancesthatmaybeharmfultoyourhealth.

Modernoilscontainadditives.Donotburncontami-

•

natedfuelsandorwasteoilsinordinaryheatingsys-

tems.

Avoidspillagewhenyoudrainuidssuchasuseden-

•

ginecoolantmixtures,engineoil,hydraulicuid,brake

uid,etc.Donotmixdrainedbrakeuidsorfuelswith

lubricants.Storealldraineduidssafelyuntilyoucan

disposeoftheuidsinaproperwaythatcomplieswith

alllocallegislationandavailableresources.

Donotallowcoolantmixturestogetintothesoil.Col-

•

lectanddisposeofcoolantmixturesproperly.

Donotopentheair-conditioningsystemyourself.It

•

containsgasesthatshouldnotbereleasedintotheat-

mosphere.YourKONGSKILDEdealerorair-conditioningspecialisthasaspecialextractorforthispurpose

andcanrechargethesystemproperly.

Repairanyleaksordefectsintheenginecoolingsys-

•

temorhydraulicsystemimmediately.

Donotincreasethepressureinapressurizedcircuitas

•

thismayleadtoacomponentfailure.

Batteryrecycling

Batteriesandelectricaccumulatorscontainseveral

substancesthatcanhaveaharmfuleffectontheenvironmentifthebatteriesarenotproperlyrecycledafter

use.Improperdisposalofbatteriescancontaminate

thesoil,groundwater,andwaterways.KONGSKILDE

stronglyrecommendsthatyoureturnallusedbatteries

toaKONGSKILDEdealer,whowilldisposeoftheused

batteriesorrecycletheusedbatteriesproperly.Insome

countries,thisisalegalrequirement.

NHIL14GEN0038AA1

Mandatorybatteryrecycling

NOTE:Thefollowingrequirementsaremandatoryin

Brazil.

Batteriesaremadeofleadplatesandasulfuricacidsolution.Becausebatteriescontainheavymetalssuchas

lead,CONAMAResolution401/2008requiresyoutoreturnallusedbatteriestothebatterydealerwhenyoureplaceanybatteries.Donotdisposeofbatteriesinyour

householdgarbage.

Pointsofsaleareobligedto:

Acceptthereturnofyourusedbatteries

•

Storethereturnedbatteriesinasuitablelocation

•

Sendthereturnedbatteriestothebatterymanufacturer

•

forrecycling

2-16

Page 33

2-SAFETYINFORMATION

Safetysigns

Thefollowingsafetydecalsareonyourimplementasa

guideforyoursafetyandforthesafetyofthosewhowork

withyou.

Walkaroundtheimplementandnotethecontentandlocationofallsafetydecalsbeforeyouoperateyourimplement.Readallthesafetydecalsadheredtotheimplementandfollowtheinstructions.

Keepallsafetydecalscleanandlegible.Cleansafety

decalswithasoftcloth,water,andagentledetergent.

NOTICE:Donotusesolvent,gasoline,orotherharsh

chemicals.Solvents,gasoline,andotherharshchemicalsmaydamageorremovethesafetydecals.

Replaceallsafetydecalsthataredamaged,missing,

paintedover,orillegible.Ifasafetydecalisonapartthat

youoryourdealerreplaces,makesurethatyouoryour

dealerinstallthesafetysignonthenewpart.Contact

yourdealerforthereplacementofthesafetydecals.

Safetysignsthatdisplaythe“Readoperator’smanual”

symboldirectyoutotheoperator’smanualforfurtherinformationregardingmaintenance,adjustments,orproceduresforparticularareasoftheimplement.Whenasafety

signdisplaysthissymbol,consulttheappropriatepageof

theoperator’smanual.

Safetysignsthatdisplaythe“Readservicemanual”symboldirectyoutotheservicemanual.Ifyoudoubtyour

abilitytoperformserviceoperations,contactyourdealer.

2-17

Page 34

2-SAFETYINFORMATION

Safetysign(1)

Riskofgettingjammed.

Neverletanyonestandbetweentheimplementandthe

tractoraftertheconnection.Anunintentionalmanoeuvre

maycauseseriousinjury.

Partnumber:81PR80-0809

ZEIL18HT00453FA1

81PR80-08092

2-18

Page 35

2-SAFETYINFORMATION

Safetysign(2)

WARNING

Entanglementhazard!

ThePowerTake-Off(PTO)guardmustbe

installedwhenoperatingPTO-drivenequipment.

Failuretocomplycouldresultindeathorseriousinjury.

Donotoperatewithout:

Alldriveline,tractorandequipmentshieldsinplace.

•

Drivelinessecurelyattachedatbothends.

•

Drivelineshieldsthatturnfreelyondriveline.

•

Failuretocomplywillresultindeathorseriousinjury.

Readtheinstructionmanualandthesafetyinstructions.

Partnumber:811340-9999

W0322A

811340-99993

Safetysign(3)

Thenumberandthedirectionofrotations.

CheckthatthePowerT ake-Off(PTO)driveshaftrunswith

therightRevolutionPerMinute(RPM)andintherightdirection.Awrongnumberofrotationsand/ordirectionof

rotationcandamagetheimplementwiththeriskofpersonalinjuryasaresult.

Partnumber:81PR80-0805

Safetysign(4)

Readtheoperator’smanualandthesafetyinstructions.

Readthedeliveredmanualstooperatetheimplementcorrectlyandtoavoidunnecessaryaccidentsandimplement

damage.

Partnumber:81PR80-0841

81PR80-08054

WARNING

IMPROPEROPERATIONOFTHISMACHINE

CANCAUSEDEATHORSERIOUSINJURY.

MAKESURETHATEVERYOPERATOR:

-isinstructedinthesafeandproperuseofthis

machine.

-readsandunderstandstheoperator'smanual

forthismachine.

-readsandunderstandsALLsafetysignson

themachine.

Failuretocomplycouldresultindeathorseriousinjury.

81PR80-08415

W0188A

2-19

Page 36

2-SAFETYINFORMATION

Safetysign(5)

WARNING

Avoidinjury!Alwaysdothefollowingbefore

lubricating,maintaining,orservicingthemachine.

1.Disengagealldrives.

2.Engageparkingbrake.

3.Lowerallattachmentstotheground,or

raiseandengageallsafetylocks.

4.Shutoffengine.

5.Removekeyfromkeyswitch.

6.Switchoffbatterykey,ifinstalled.

7.Waitforallmachinemovementtostop.

Failuretocomplycouldresultindeathorseriousinjury.

Stopthetractorengineandremovetheignitionkeybefore

youtouchtheimplement.

Alwaysremembertostopthetractorenginebeforeyou

adjust,maintain,repair,orlubricatetheimplement.Also

remembertoremovetheignitionkey.Makesurethatnobodystartstheengine,untilyouhavenished.

81PR80-08426

W0047A

Partnumber:81PR80-0842

Safetysign(6)

Operationwithoutcanvas.

Donotstarttheimplementunlesscanvasesandguards

areintactandintheirrightplace.Theimplementcan

throwoutstonesandotherforeignmatterduringoperation.Thepurposeofthecanvasesandtheguardsisto

reducesuchdanger.

Partnumber:81PR80-0808

Safetysign(7)

Children.

Neverletchildrenstandneartheimplementduringoperation.Especiallynotsmallchildrenastheyhaveatendencytodounforeseenthings.

81PR80-08087

Partnumber81PR80-0811

81PR80-08118

2-20

Page 37

2-SAFETYINFORMATION

Safetysign(8)

Rotatingblades.

Donotunderanycircumstancesletanyonegetnearor

standneartheimplementduringoperation.Therotating

bladesoftheimplementcanwithoutdifcultycauseseriousinjurytoanypartofthebodyifhitbysuchablade.

Partnumber:81PR80-0813

Safetysign(9)

WARNING

Rotatingparts!

Keepclearofalldrivesandrotatingcomponents.

Failuretocomplycouldresultindeathorseriousinjury.

W1101A

81PR80-08139

Rotatingparts.

AfterthePTOdriveshafthasstopped,thebladeswill

haveamomentumwheretheykeeprotatingforupto

2min.Waituntilthebladeshavecompletelystoppedbeforeyouremovethecanvasandtheguardsforinspection

andmaintenance.

Partnumber:81PR80-0807

Safetysign(10)

WARNING

Flyingdebris!

Themachinecanthrowstonesanddebristowardtheoperatororbystanders.Setthemachinetoclearobstructionsandstones.

Failuretocomplycouldresultindeathorseriousinjury.

Riskofstonesbeingthrown.

Eventhoughallcanvasesandguardsareintheright

place,thereisstillariskofstonesbeingthrownout.

Therefore,makesurethatnobodystandsneartheimplementduringoperation.

W0942A

81PR80-080710

81PR80-080611

Partnumber:81PR80-0806

2-21

Page 38

2-SAFETYINFORMATION

2-22

Page 39

3-CONTROLSANDINSTRUMENTS

3-CONTROLSANDINSTRUMENTS###_3_###

Machinecomponents

Accesstoimplementcomponents

WARNING

Rotatingparts!

Neverallowanyonetostandorhangontheattachmentwhileitisinmotion.Thefollowing

accesswaysareprovidedonlyforsafelyenteringandservicingtheattachmentwhileitis

stopped.

Failuretocomplycouldresultindeathorseriousinjury.

Right-handside

Opentheguard(1)tohaveaccessto:

Cutterbarandthediscdrum.

•

W1062A

Left-handside

Opentheguard(2)tohaveaccessto:

Cutterbarandthediscdrumwiththedrivelineshaft.

•

ZEIL18HT00652AA1

ZEIL18HT00650AA2

3-1

Page 40

Frontside

Opentheguard(3)tohaveaccessto:

Cutterbar.

•

Discdrumsystem(seePage10-1).

•

Removetheguard(4)tohaveaccessto:

Bevelgearboxatthecenteroftheimplement.

•

3-CONTROLSANDINSTRUMENTS

ZEIL18HT00648AA3

Rearside

Removethecanvas(5)tohaveaccessto:

Swathdisc.

•

ZEIL18HT00648AA4

ZEIL18HT00649AA5

3-2

Page 41

4-OPERATINGINSTRUCTIONS

4-OPERATINGINSTRUCTIONS###_4_###

Commissioningtheunit

Choiceoftractor

Alwaysfollowtherecommendationsspeciedintheinstructionmanualofthetractor.Ifthisisnotpossible,seek

authorisedtechnicalassistance.

ChooseatractorwithasuitablepoweronthePowerT akeOff(PTO).Ifthepowerofthetractorisconsiderablylarger

thantheprescribedpower,caretoavoidlong-termoverload.ThismaydamagethefrictionclutchinthePTOdrive

shaftwhichsecuresagainstoverload.

Theimplementisdesignedfor1000RPM.Therefore

makesurenottouseawrongnumberofrotationsonthe

PTObymistake.

Checkthattheimplementisintendedforthenumberand

thedirectionofrotationofthetractorPTOseeninthe

directionoftravelling.Awrongnumberofrotationsover

alongperiodmaydamagetheimplementandatworst

resultinejectionofparts.

Chooseatractorwithasuitableownweightandtrack

widthsothatitcandrivesteadilyontheground.

Makesurethattheliftsuspensionofthetractorisintended

tocarryimplementwiththeownweightinquestion.

However,thetractorspecicationsaredifferentwithinthe

individualtractorbrands.Therefore,itmaybenecessary

toadjusttheweightdistributionwithacounterweighton

thetractor.

Toapplythehydraulicfunctionoftheimplement,itisnecessarythatthetractorhasasingle-actinghydraulicoutlet

atthefrontorthatthereisaccesstooneoftheoutletsat

therear.Itisnecessarythatthefronthitchworksorcan

worklikesingle-acting.

Likewise,makesurethatthehydraulicsystemofthetractorhasapressureofmax210bar(3045psi).

Alwayschooseatractorwithaclosedcabinwhenyou

workwithadiscmower.

Useatractorwithacabinprovidedwithsafetyglass.Furthermoreitisadvisabletoprotecttheglassofthecabin

withpolycarbonateplatesinsideorwithaclosemeshed

netoutside.Closethecabinwhenyouworkintheeld.

81PR80-08031

4-1

Page 42

4-OPERATINGINSTRUCTIONS

Checkbeforetestdriving

Beforeyouoperatethediscmowerforthersttime,performthefollowingitems:

Readthisoperator'smanualcarefully;especiallythe

•

chapterheaded”Safetyinformation”.

Checkthecorrectassemblageoftheimplement.Also

•

checkthattheimplementisundamaged.

Checkthatnopartshavebeentiedupinsidetheimple-

•

mentinconnectionwiththedeliveryoftheimplement.

Checkthatthefronthitchissingle-acting.

•

Checkthattheprotection(guardsandcanvases)onthe

•

implementarecomplete,intactandcorrectlymounted,

andthatthesideguardsarefoldeddown.

Checkthecorrectinstallationofthediscsandthe

•

blades.

Ifyouplacethetoolforthereplacementoftheblades

•

ontheimplement,securethetoolwithaclippin.

Checkthecorrectinstallationofthesafetydevices.

•

Alsocheckifthesafetydevicesareintact.

Removeallthetoolsfromtheimplement.

•

CheckthatthePowerT ake-Off(PTO)speedoftheim-

•

plement(andofthetractor)iscorrect.T oohighPTO

speedcanbedangerous.ToolowPTOspeedcauses

badcutting,blockingofthediscmowerandhightorque

onthedriveshafts.

CheckthemovementsofthePTOdriveshaft.Ifthe

•

PTOshaftsistooshortortoolongitmaydamagethe

tractoraswellastheimplementconsiderably.Check

thattheprotectiontubesdonotgetjammedordamagedinanyposition.Securethesafetychainsofthe

protectiontubesproperly.Checkthatthesafetychains

donotinanypositiongettootightordamaged.

Checkthecorrectconnectionandtighteningofthehy-

•

drauliccomponents.

Checkthatthehydraulichosesarelongenoughforthe

•

movementsoftheimplementinrelationtothetractor.

Checkthelengthofthehydraulichoseswhentheim-

•

plementisinworkingposition.Checkthatthehydraulic

hosesarenottootense.

Greasesufcientlytheimplement(seePage7-8).

•

Checkthattheoillevelinthegearboxiscorrect(see

•

Page7-13and7-14).

Checkthattheoillevelinthecutterbariscorrect(see

•

Page7-10).

AirthefrictionclutchasdescribedonPage7-21.

•

Checkthepropertightnessofallthenutsandbolts.

•

4-2

Page 43

4-OPERATINGINSTRUCTIONS

Thetestsontherevolvingpartsoftheimplementfrom

thefactoryresulterrorfree.However,beforeyouusethe

implement,proceedasfollows:

1.Lowerthecuttingunittoworkingpositionbeforeyou

startthepowertransmission.

2.StarttheimplementatalownumberofRevolutions

PerMinute(RPM).

3.Withopenrearwindowandwithouthearingprotector,

checkthattherearenounusualscratchingorknocking

sounds.

4.IncreasethenumberofRPM.

5.AtthecorrectnumberofRPM,checkifthereareany

noticeablevibrations.Checktheguardsforunusual

vibrations.

NOTE:Ifthereisanydoubt,stopthetractorandtheimplementimmediately.

6.Turntherevolvingpartswithmanualpowertocheckif

theimplementcanturnfreely.

7.Checktheimplementvisuallytondpossibleerrors

(suchasburntorscrapedpaint).

8.Ifnecessary,seekauthorisedassistance.

NOTE:Becauseofthesmallercentrifugalforceatalow

numberofRPM,thebladescantouchtheguardplateson

thecutterbar.Thissoundmustdisappearatthenormal

numberofRPMduringwork.

NOTE:Thecutterbarunderthediscswillgetverywarm.

Thecolorofthecutterbargetsdarkeraftersomehours

ofoperation.

Afteryouchecktheimplement,ifyouwishtotestitfora

longtime,closetherearwindoworwearhearingprotector.

4-3

Page 44

4-OPERATINGINSTRUCTIONS

Testdrive

ConnectthePTOshaftcarefullyandlettheenginerunat

alownumberofRPMforsomeminutes.

Ifthereisnounintendednoiseorunusualvibrations,the

speedcangraduallyincreasetonormalnumberofRPM

of1000RPM.Apartfromthetractordrivernobodyshould

standneartheimplement.

Beforetheimplementsleavethefactory,theimplements

haveatestforvibrations.Thisisanessentialpartofthe

companyqualityassurance.

Itis,however,necessarytocheckregularlywhetherthe

implementhasunnaturalvibrations,especiallyduringtest

driving.

NOTICE:Whendiscsandbladesrotatewith3000RPM,

evenslightlydamagedrotatingparts(blades,discsand

caps)mayresultinvibrationswhichinthelongrunmay

leadtosecondarydamagesuchascracksorfractures.

Eventhoughyousecuretheimplementagainstimpacts

andvibrationdamage,therearealwaysacertainrisk,

thoughlimited.

Duringtheseasoncheckdailyifblades,discsandcaps

aredamagedandreplacepartsifnecessary.

4-4

Page 45

4-OPERATINGINSTRUCTIONS

Startingtheunit

Connectiontothetractor

Itispossibletoconnecttheimplementtothelowerlink

armsatthefrontofthetractorwithanA-frame(Accord

systemorsimilar).

Beforeyouconnecttheimplement,setthelinkarmsof

thetractortothesameheight.Installthetoplinkcorrectly

betweenthetractorandA-framesothattheA-frameis

verticalorhasasmallinclinationforward.

Transmission

TheimplementisconstructedforaPowerTake-Off(PTO)

speedfromthetractorof1000RPMandisintendedfor

tractorsonwhichthedirectionofrotationoftheshaft(1)

iscounterclockwise(A)whenyoulooktowardsthefront

ofthetractor.

Connection

Theimplementisconstructedforconnectiontothetractor

bymeansofquickconnectionwithA-frame(Accordsystemorsimilar).

WiththeA-frame(2)mountedonthetractor,drivestraight

totheimplementandlifttheA-frameupintheheadstock

(3)attherearoftheimplement.

ZEIL18HT00455AA1

ZEIL18HT00456AA2

4-5

Page 46

4-OPERATINGINSTRUCTIONS

TherearedifferenttypesofA-frames.Lockalltypesof

A-framesassoonastheimplementhasbeenconnected.

Ifyouusethetypewithlockingpawl(5),checktheclear-

ancebetweenthelockingpawlandthetractorframe.If

thereistoomuchclearancebetweenthelockingpawl

(5)andthelatch(6)ofthetractorframe,theimplement

maygetdisconnectedfromthetractorduringoperationor

transport.

Toavoidthedisconnection,adjustthelockingpawl(5)to

thesmallestpossibledistance.

Toadjustthelockingpawlproceedasfollows:

1.Lifttheimplementsothatithangsfromthetractor

frame.

2.Loosethenuts(4).

3.Movethelockingpawl(5).

4.Closetothelatch(6)sothatyoucanonlypulloutthe

latchwiththehandle.

5.Securethelatch(6)withthesafetypin(7)toprevent

thelatchfrombeingreleasedbyaccident.

NOTE:Thefronthitchmustbesingle-acting.

Adouble-actingfronthitchwilltransferthetractorweight

totheimplement.Thiswillloadtheimplement,especially

theA-frameandheadstock,muchmorethantheimplementisintendedfor.

Iftheimplementhasbeenoverloaded,checkifthereare

deformationsordamagedparts,especiallyattheA-frame

andtheheadstock.Replacethedamagedpartsandadjustagainthelockingpawl.

Severalelasticstrapsarettedontherearcurtain.The

purposeofthesestrapsistoensurethatthecurtainisin

thecorrectpositionduringtheoperation.

ZEIL18HT00457AA3

Thestraps(8)mustbettedaroundthetractorlinkarms.

Thestraps(9)mustbettedintheholders(10)atboth

sides.

ZEIL18HT00458AA4

4-6

Page 47

4-OPERATINGINSTRUCTIONS

PowerTake-Off(PTO)driveshaft–Shorten

PowerTake-Off(PTO)shaftlength

NOTE:DonotshortenyournewPowerTake-Off(PTO)

shaftuntilyouarecertainthatitisnecessary.Fromthe

factorythedistancefromPTOtoPowerInputConnection

(PIC)isstandardonmosttractorbrands.

CheckthelengthofthePTOshaftforeachtractorpriorto

rstuse.

IfitisstillnecessarytoshortenthePTOshaft,theprole

tubesofthePTOshaftmustfullycomplywiththefollowing

overlappingmeasures:

Theslidingtubesmusthaveasmuchoverlapaspossi-

•

ble,withanacceptableminimumoverlap(b)of200mm

(7.87in)duringnormaloperation(TopSafeextension

linksinthenormalposition).

Theremustbeaminimumof30mm(1.18in)offree

•

PTOshaftlength(a)topreventtheshaftfrombottoming

out.

NHIL12HT00307AA1

Determiningtherequiredshaftlength

WhenyoudeterminethatyoumustshortenthePTOshaft,

selectthelengthsothatthetelescopingmembersnever

closecompletelyorbottomoutwheninuse.ThePTO

lengthmustneverbesmallerthantheminimumdistance

betweenthejoints.

1.AttachtheimplementtothetractorwithoutthePTO

shaft.

2.Adjustthethree-pointhitchsothatthePTOshaftis

parallelwiththeground.

3.Stopthetractorandengagetheparkingbrake.

4.DetermineifthePTOshaftbottomoutinthisposition.

IfthePTOshaftbottomsoutinthispositionorifthe

freelengthislessthan30mm(1.18in),proceedwith

theproceduretoshortenthePTOshaft.

4-7

Page 48

4-OPERATINGINSTRUCTIONS

ShorteningthePTOdriveshaft

ToshortenthePTOshaftproceedasfollows.

1.FastenthePTOdriveshafthalfpartstothePTO(on

thetractor)andthePIC(ontheimplement).ThePTO

driveshafthalfpartsmustbeatthesamehorizontal

level,oppositeeachotherattheshortestdistancefrom

thetractor.

2.Makesurethataminimumoverlapof200mm

(7.87in)exists.

3.CheckthatthePTOshaftdoesnotbottomoutatone

end.Keeptheshaftendsparalleltoeachotherand

marktheminimumdistanceof30mm(1.18in).Only

cutenoughPTOshaftofftoachievethisminimumfree

shaflength.Thiswillmaintainthemaximumamount

ofPTOshaftoverlap.

4.Shortenallfourtubesequally.

5.Roundofftheendsoftheproletubesandremovethe

burrscarefully.

6.Removethemetalshavings.

ZEIL18HT00013AA2

NOTICE:Toavoidbigfrictionforces,greasethetube

carefullybeforeyoureassembleit.UseNLGI2.

NOTE:IfyoushortenthePTOshaft,thenyoumustcheck

theminimumoverlapandtheminimumdistanceagainif

youoperatetheimplementwithadifferenttractor.

4-8

Page 49

4-OPERATINGINSTRUCTIONS

Parkingtheunit

Disconnectionandparking

Todisconnecttheimplement,removethereliefsprings,

afterwardsremovethePowerTake-Off(PTO)driveshaft.

PlacethePTOdriveshaftontheholder(1)andswivelout

theholder(1).

Removetheelasticstrapsfastenedtothetractorlink

arms.WhenyouhavedeactivatedtheA-framelock,

lowerthelinkarmssothatthetractorA-frameisreleased

fromtheimplement.

NOTE:WhenyoulowertheA-frame,thepartsmaysuddenlyfallapart.Therefore,itisnecessarytokeepasafe

distance.

ZEIL18HT00464AA1

4-9

Page 50

4-OPERATINGINSTRUCTIONS

4-10

Page 51

5-TRANSPORTOPERATIONS

5-TRANSPORTOPERATIONS###_5_###

Preparingforroadtransport

Transportposition

Foldthesideguards(1)inposition(B)duringtransportto

minimizethetransportwidth.

Thesideguardsmustbeinposition(A)duringoperation.

Pulloutthehandle(1)tofoldthesideguards.

ZEIL18HT00462AA1

NOTE:Allguardsmustbeinplacebeforeyoustartthe

implement.

NOTE:Itisimportanttoblockthehydrauliccylinderon

theimplementwiththemechanicaltransportlock.Anunintentionaloperationofthehydraulichandleforthecylinder,suddenleakagefromhosesorttingsorairinthe

systemmaycausetheimplementtobeloweredandperhapshittheground.