Page 1

ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1

OPERATOR’S MANUAL

FCT 1360

Harvester

Part number 81PIGB-186x

1st edition English

February 2018

Page 2

Page 3

PIGB-186X-05 FCT1360 0218

- 3 -

FOREWORD

DEAR CUSTOMER!

We appreciate the confidence you have shown to our company by investing in a

KONGSKILDE product and congratulate you with your new purchase. Of course, it is

our wish that you will experience complete satisfaction with the investment.

This instruction manual contains information about correct and safe use of the

machine.

When buying the machine you will receive information about use, adjustment and

maintenance.

However, this first introduction cannot replace a more thorough knowledge of the

different tasks, functions and correct technical use of the machine.

Therefore you should read this instruction manual very carefully before using

the machine. Pay special attention to the safety instructions.

This instruction manual is made so that the information is mentioned in the order you

will need it, i.e. from the necessary operation conditions to use and maintenance.

Besides this there are illustrations with text.

"Right" and "Left" are defined from a position behind the machine facing the direction

of travel.

All the information, illustrations and technical specifications in this instruction manual

describe the latest version at the time of publication.

Kongskilde Industries A/S reserves the right to make changes or improvements in the

design or construction of any part without incurring the obligations to install such

changes on any unit previously delivered.

Page 4

PIGB-186X-05 FCT1360 0218

- 4 -

CONTENTS

FOREWORD ....................................................................................................................... 3

CONTENTS ......................................................................................................................... 4

INTRODUCTION ................................................................................................................. 6

INTENDED USE ................................................................................................. 6

PERFORMANCE ................................................................................................ 7

SAFETY .............................................................................................................. 9

Definitions .............................................................................................. 9

General safety instructions ................................................................... 10

Locking of guards ................................................................................. 11

Choice of tractor ................................................................................... 12

Connection and disconnection ............................................................. 12

Adjustment ........................................................................................... 13

Transport .............................................................................................. 14

Working ................................................................................................ 15

Parking ................................................................................................. 15

Greasing .............................................................................................. 15

Grinding ............................................................................................... 16

Maintenance ........................................................................................ 17

Replacement of wearing parts ............................................................. 17

Safety decals ....................................................................................... 19

TECHNICAL DATA ........................................................................................... 21

2. CONNECTION TO TRACTOR ...................................................................................... 22

THE HYDRAULIC SYSTEM ............................................................................. 22

Hydraulic connection ............................................................................ 22

Bypass valve ........................................................................................ 23

Connection of electric system .............................................................. 24

ELECTRO-HYDRAULIC CONTROL ................................................................ 25

Functions ............................................................................................. 26

DRAWBAR AND PTO DRIVE SHAFT .............................................................. 29

Shortening of the PTO drive shaft ........................................................ 31

Friction clutch ....................................................................................... 31

3. MOUNTING OF EQUIPMENT ....................................................................................... 32

HITCH FOR TRAILER ...................................................................................... 32

Combi-hitch .......................................................................................... 32

Hydraulic hitch hook (Auto-hitch) ......................................................... 33

PICK-UP ........................................................................................................... 34

TRANSPORT CONVERSION .......................................................................... 37

FITTING CHUTES ................................ ............................................................ 38

Chute turning ....................................................................................... 38

Standard chute ..................................................................................... 40

Foldable chute ..................................................................................... 40

Chute for parallel operation .................................................................. 41

LIGHTING KIT .................................................................................................. 43

Page 5

PIGB-186X-05 FCT1360 0218

- 5 -

4. ADJUSTMENTS ............................................................................................................ 45

PICK-UP ........................................................................................................... 45

OPENING OF ROTOR HOUSING.................................................................... 46

Collapsible chute .................................................................................. 49

ROTOR AND ROLLER SECTION .................................................................... 52

CUTTING LENGTHS ........................................................................................ 56

REPLACEMENT AND ADJUSTMENT OF BLADES ........................................ 57

GRINDING ........................................................................................................ 59

Grinding operation ............................................................................... 60

Rough grinding ..................................................................................... 62

REVERSE ........................................................................................................ 63

NEUTRAL POSITION ....................................................................................... 65

5. WORKING IN THE FIELD ............................................................................................. 66

GENERAL CONDITIONS ................................................................................. 66

Swathing before chopping .................................................................... 66

TRANSPORT POSITION ................................................................................. 67

STARTING IN THE FIELD ................................................................................ 68

Blockage in the machine ...................................................................... 69

After work ............................................................................................. 71

MISCELLANEOUS ........................................................................................... 71

WORKING POSITIONS .................................................................................... 71

6. MAINTENANCE ............................................................................................................ 73

IN GENERAL .................................................................................................... 73

GUARDS .......................................................................................................... 74

REPLACEMENT OF BLADES .......................................................................... 74

TYRE PRESSURE ........................................................................................... 75

FRICTION CLUTCH ......................................................................................... 76

FUSES .............................................................................................................. 79

MISCELLANEOUS ........................................................................................... 80

Rollers .................................................................................................. 80

Chain tightener for pick-up auger ......................................................... 80

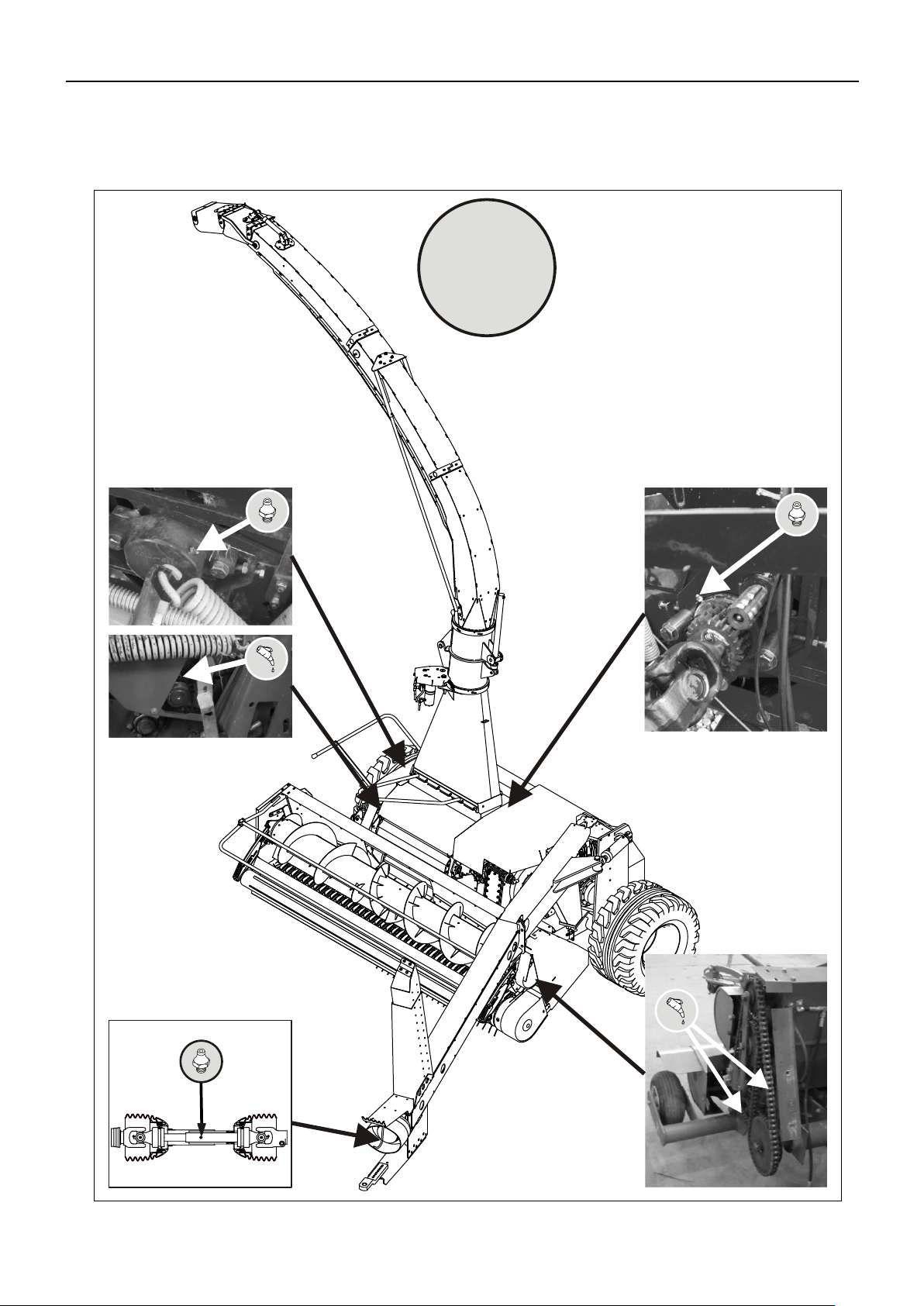

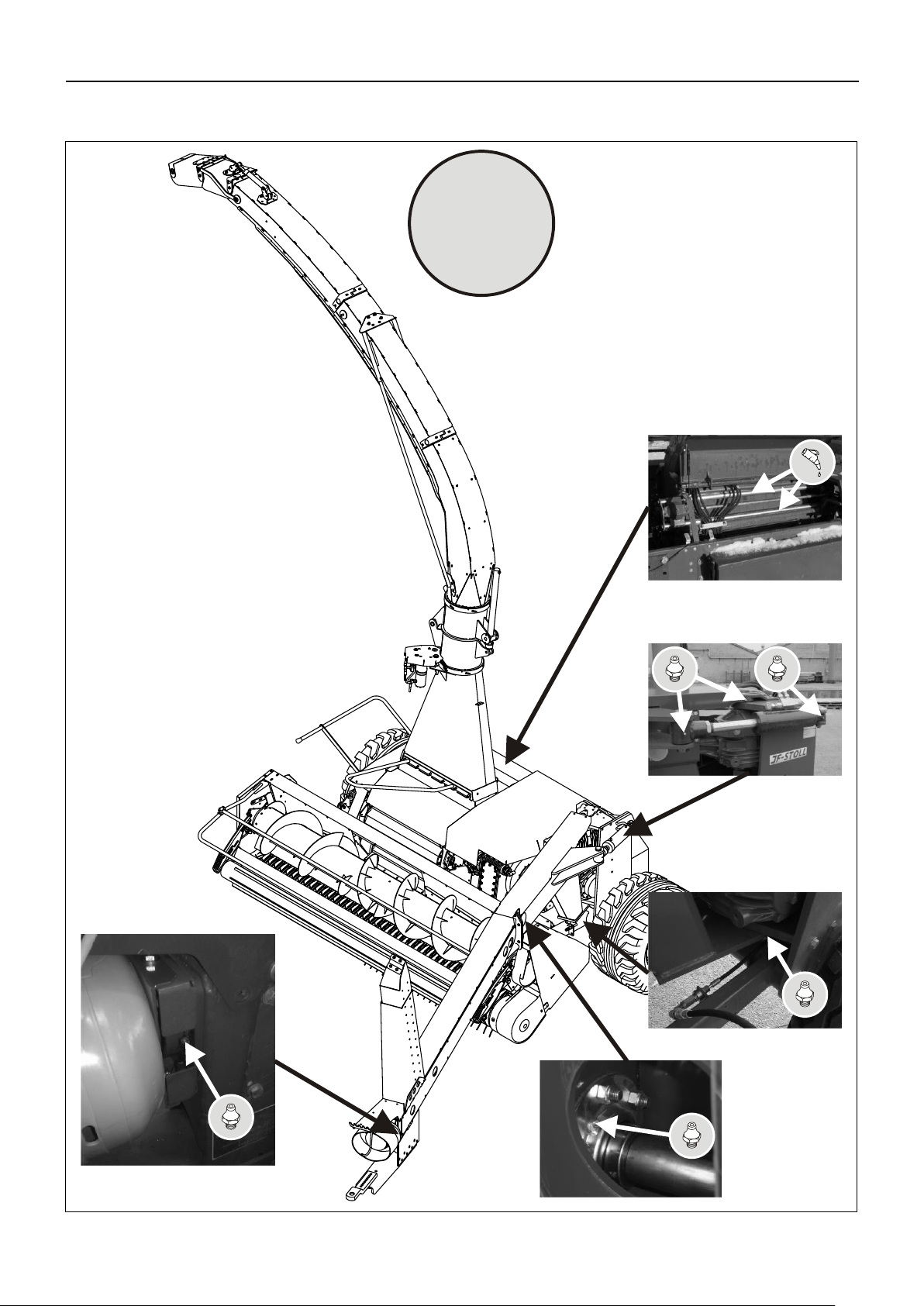

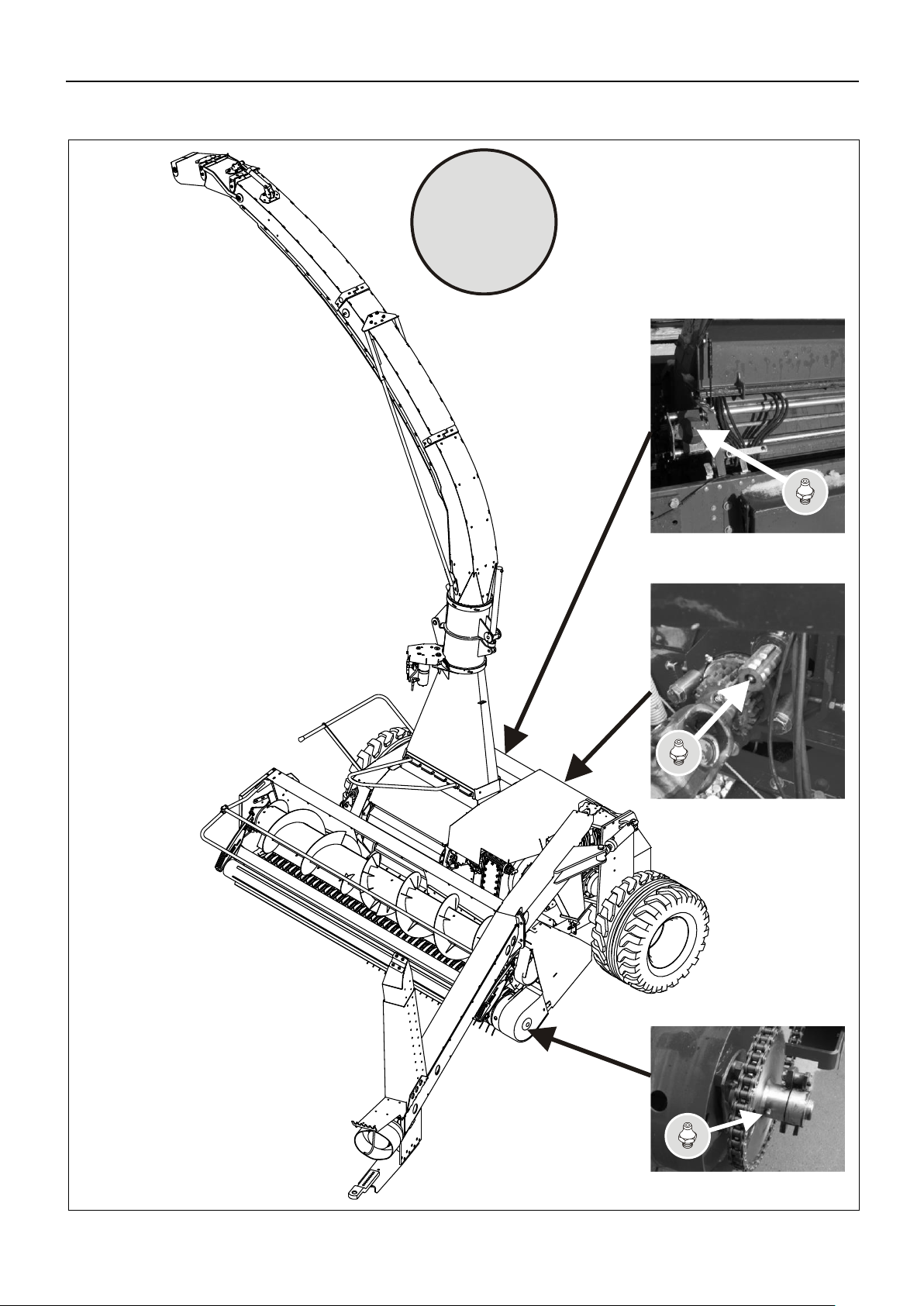

7. GREASING ................................................................................................................... 81

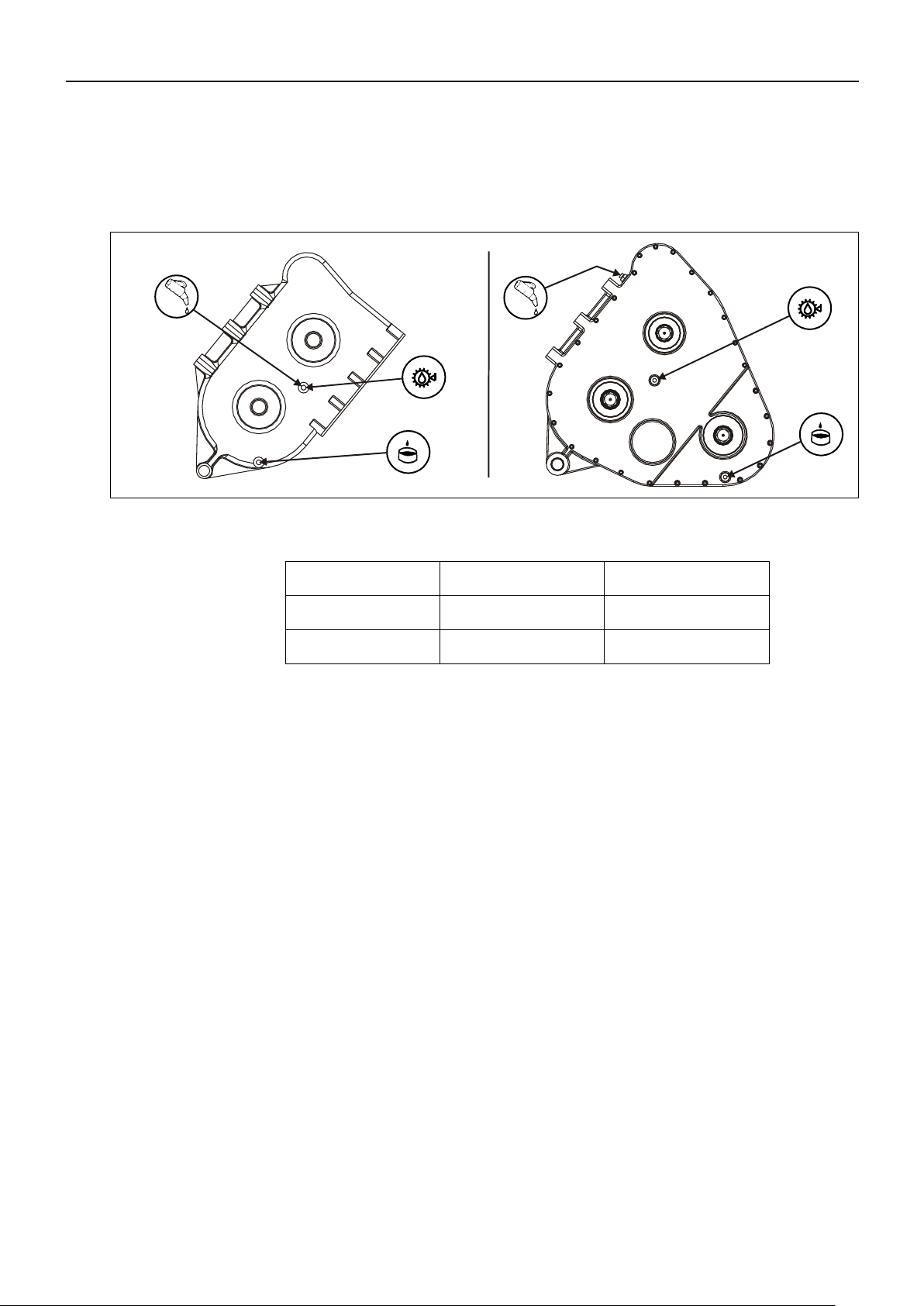

Oil in gearboxes ................................................................................... 89

8. STORAGE (WINTER STORAGE) ................................................................................. 91

9. SPARE PARTS ORDER ............................................................................................... 92

10. MACHINE DISPOSAL ................................................................................................. 93

11. MISCELLANEOUS ..................................................................................................... 94

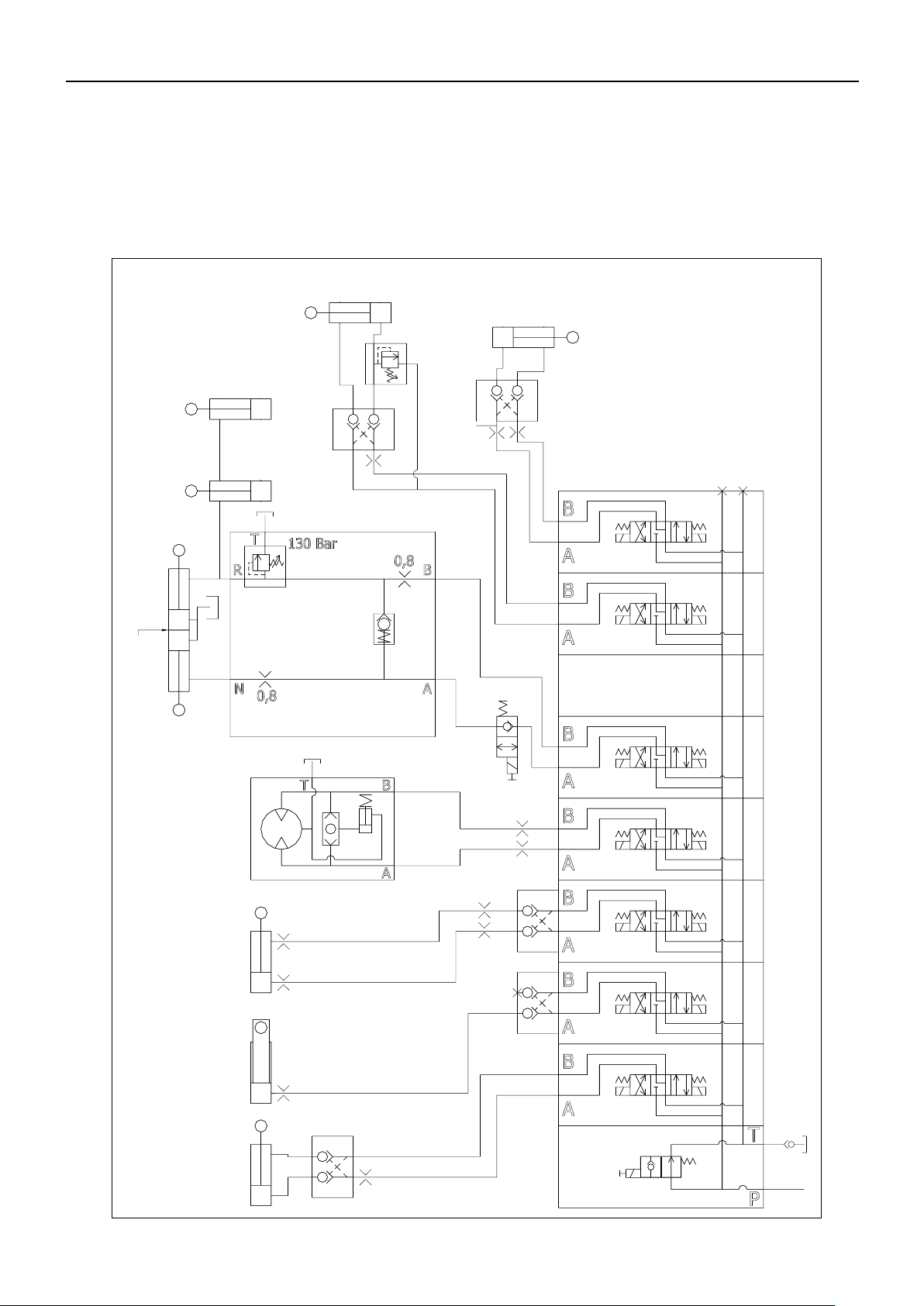

HYDRAULIC DIAGRAM FOR FCT 1360 .......................................................... 94

CONTROL SYSTEM ........................................................................................ 94

CONTROL BOX................................................................................................ 95

CONTROL UNIT ON THE MACHINE ............................................................... 97

CONTROL UNIT ON MACHINE, WIRING SYSTEM ........................................ 98

12. WARRANTY ................................................................................................................ 99

Page 6

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 6 -

INTRODUCTION

INTENDED USE

The precision chop forage harvester FCT 1360 is solely constructed and

manufactured for the usual work in agriculture, i.e.: Usual work in fields where

you want to cut/gather and chop green crops such as maize, grass or whole crop

which are to be used for silage production intended for coarse fodder for cattle.

The machine should only be connected to a tractor which corresponds with the

specifications of the product and is legal to use.

Any use beyond this is outside the intended use. Kongskilde Industries A/S is

not responsible for any damage resulting from such use, the user bears that

risk.

It is assumed that the work is performed under reasonable conditions, i.e. that the

fields are cultivated normally and to a reasonable extent kept clear of foreign matter

and the like.

Intended use also means that the instructions given by Kongskilde Industries A/S in

the instruction manual and the spare parts book are observed and that thorough

agricultural knowledge and technically correct use is a matter of course.

The precision chop forage harvester FCT 1360 should only be used, maintained

and repaired by persons who, through relevant instructions and after reading

the instruction manual, are familiar with the machine and, in particular, are

informed of possible dangers.

In the following there are a number of general and special safety instructions which

must be observed altogether.

If changes are made on the machine and its construction without permission from

Kongskilde Industries A/S, Kongskilde Industries A/S cannot be held responsible for

any damage resulting from this.

Page 7

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 7 -

Dry matter

Capacity

Dry matter

100%

18 ton/h

Wet new grass

15%

120 ton/h

Not pre-dried grass

18%

100 ton/h

Pre-dried grass – no outflow of sap from clamp

silo

25%

72 ton/h

Pre-dried grass – no outflow of sap from high

tower silo

33%

55 ton/h

Very pre-dried grass

50%

36 ton/h

Straw, very dry

90%

20 ton/h

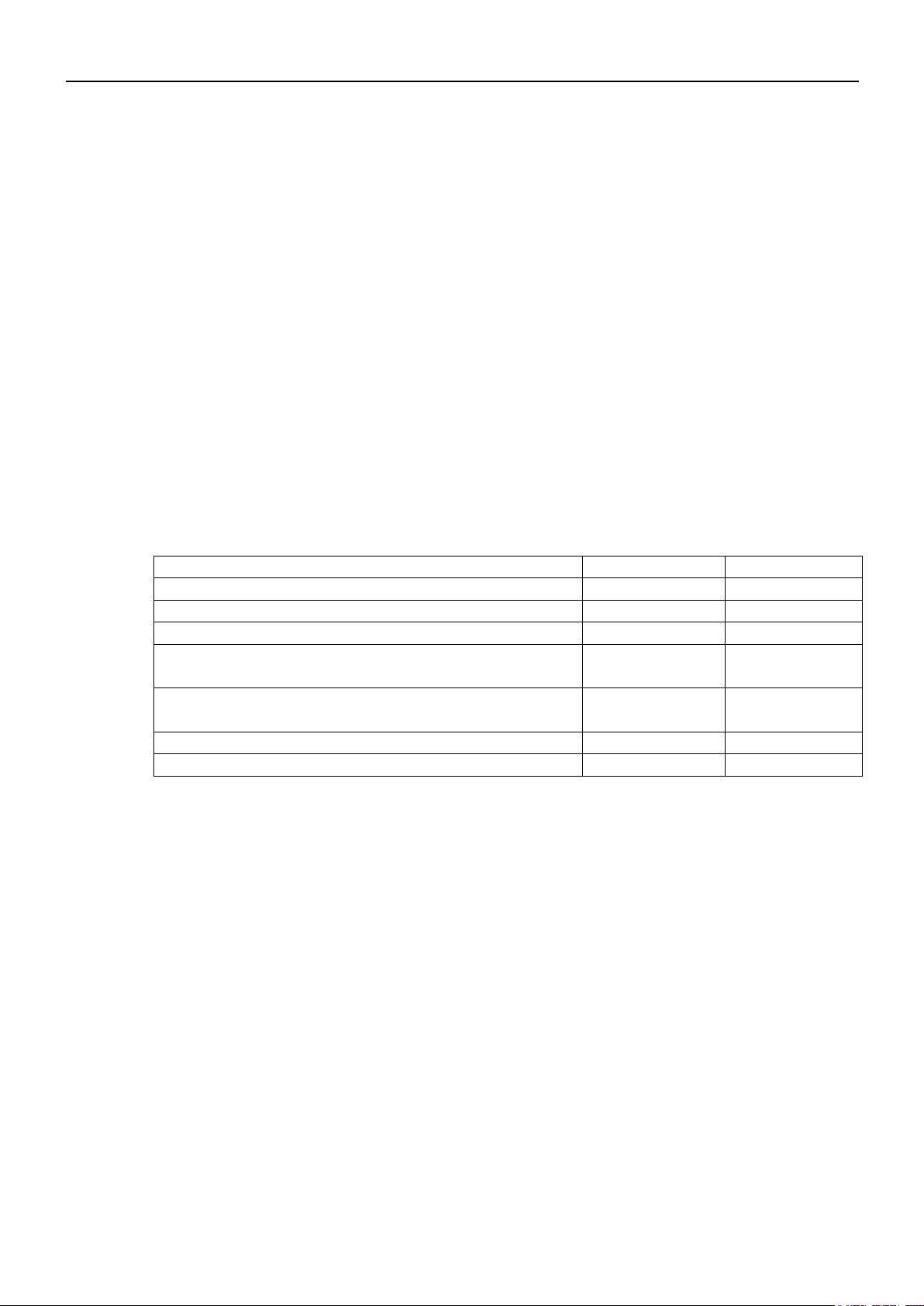

PERFORMANCE

The precision chop forage harvester FCT 1360 has a very versatile use which, with

the right equipment, makes it possible to chop grass, maize and whole crops. At the

same time FCT 1360 is capable of working alone or parallel with other machines.

FCT 1360 has a high capacity compared with other corresponding products as it

uses the “DIRECT CUT” system. “DIRECT CUT” gives a minimum loss of power

when cutting the material and thus ensures maximum utilisation of the accessible

tractor power.

Capacity, however, is difficult to define and compare as, for a forage harvester, it will

depend not just on which crop is being cut but also how the crop has been treated

before it is picked up or cut by the machine and finally which cutting length

adjustment the machine is working with.

If we take a forage harvester which, in fresh, not pre-dried grass, can work 100 tons

per hour, it is possible to calculate the capacity at different per cents of dry matter

depending on the pre-treatment before cutting, as shown in the following table.

It will probably surprise most people that the capacity can vary between 20 and 120

ton/h, as a result of varying water content.

In practice you want to drive the forage harvester in the highest possible tractor gear

without causing frequent blockage. However, the amount of grass in the field will

always vary, for instance where the mower conditioner has had to turn, change

forward speed or change direction of travel. Therefore it is often appropriate either to

drive with a power reserve so that the machine will not block, or to continuously

adapt the driving of the forage harvester to the conditions.

Page 8

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 8 -

The pick-up unit and the feed rollers are both secured against overloading. The pickup unit is secured by a friction clutch, the feed rollers by a shear bolt clutch. The

forage harvester also has a reverse function which makes it possible to remove a

blockage without having to leave the tractor seat.

The intention is that the inexperienced user increases the forward speed gradually in

the beginning until the pick-up is blocked; releases the blockage again by reversing

and chooses a tractor gear at a suitable lower level to remove the risk of blockage.

However, it is not the intention that the clutch function of the feed rollers releases. If

this happens, the clutch adjustment of the pick-up must be reduced. The same will

apply if the main friction clutch between the tractor and the machine releases during

normal working. If it is not the pick-up unit which is blocked, the adjustment of the

machine is incorrect.

Unfortunately it has been seen that the torque adjustment of the friction clutch of the

pick-up unit has been increased to the point where it is the friction clutch between the

machine and the tractor which releases frequently. The main friction clutch is not

intended to release frequently but only for starting shock or when foreign matter gets

into the machine. The same applies to the shear bolt clutch for the feed intake rollers.

The main clutch simply cannot absorb the heat which is generated during these long

releases. The power transmitted at the main clutch will be at least 10 times higher

than the power needed to drive the pick-up unit.

Only the pick-up unit can be seen from the tractor and therefore it should be released

first when there is a blockage. The experienced user will be able to adapt the driving

of the tractor to the amount of grass and thus work with less capacity reserve and, all

other things being equal, have a greater output.

The cutting length of the forage harvester can be adjusted and adapted to the crop in

question. The cutting length is usually reduced when cutting maize and whole crops

to ensure greater damage of the grains. The shorter cutting length will of course

require more power for which reason there will be a lower output when cutting maize

and whole crop than when cutting grass, though it is difficult to compare.

The power requirements are also increased when the blades are worn and the

shearbar adjustment thereby changes. It is necessary to sharpen the blades and

adjust the shearbar during the season.

Page 9

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 9 -

SAFETY

The safety of persons and machines is an integral part of Kongskilde’s development

work. We wish to ensure the safety of you and your family in the best possible

way, but this also requires and effort on your part. However, damage can occur as a

consequence of misuse and insufficient instruction.

A forage harvester cannot be constructed in such a way that it guarantees the full

safety of persons and at the same time performs an efficient piece of work. This

means that it is very important that you as user of the machine pay attention and use

the machine correctly and thereby avoid exposing yourself and others to

unnecessary danger.

As already mentioned the machine is only intended for one purpose, namely:

Chopping of grass and similar green crops, for feeding purposes.

It is assumed that the work is performed under reasonable conditions, i.e. that the

fields are cultivated normally and to a reasonable extent kept clear of foreign matter

and the like.

The machine demands skilled operation, which means that you should read the

instruction manual before you connect the machine to the tractor. Even though

you have been driving a similar machine before, you should read the manuals - this

is a matter of your own safety!

You should never leave the machine to others before you have made sure that they

have the necessary knowledge.

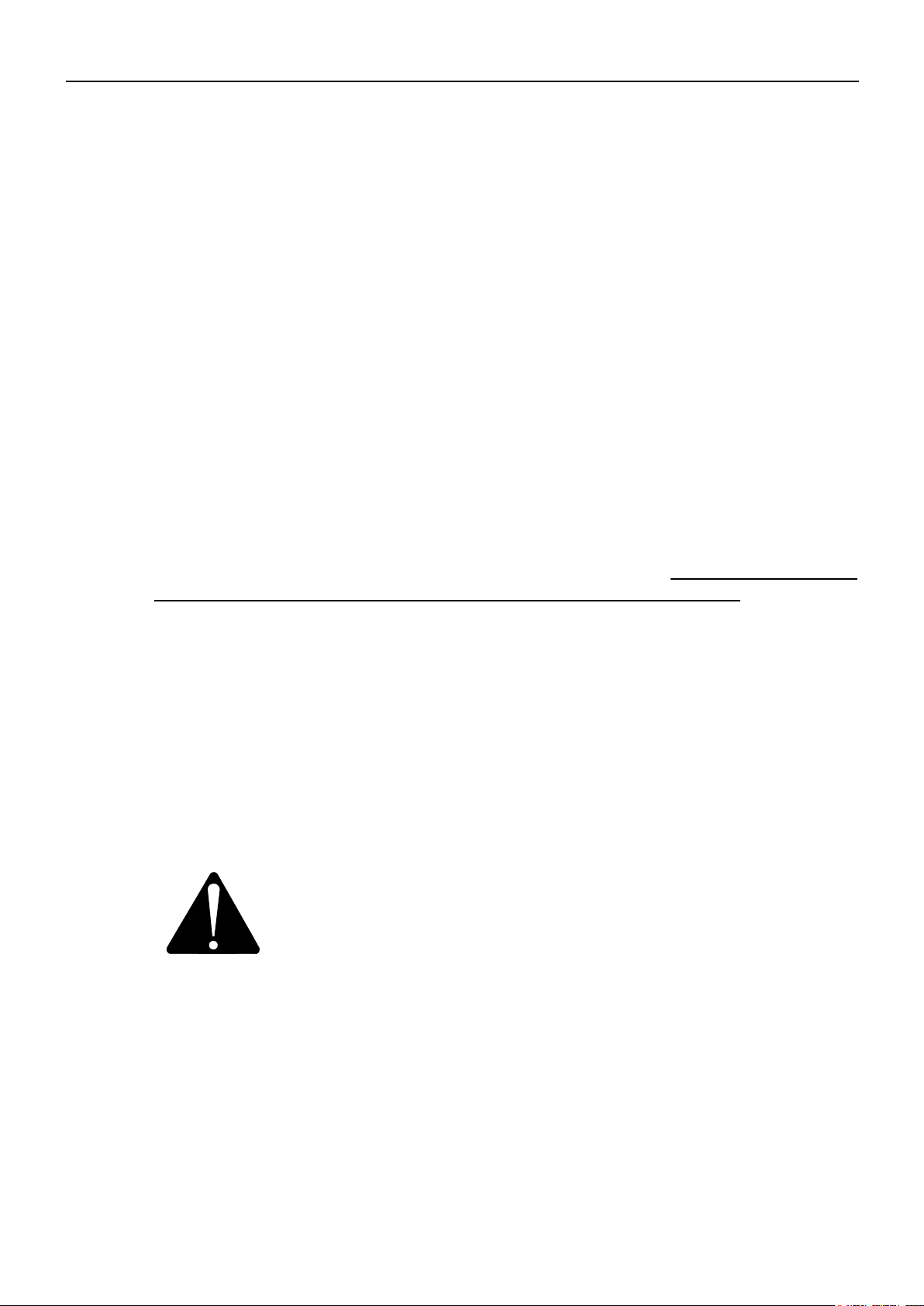

DEFINITIONS

The safety decals and the instruction manual of the machine contain a line of safety

notes. The safety notes mention certain measures, which we recommend you and

your colleagues to follow as to increase the personal safety as much as possible.

We recommend that you take the necessary time to read the safety instructions and

inform your staff to do the same.

In this instruction manual this symbol is used with reference to

personal safety directly or indirectly through maintenance of the

machine.

CAUTION: The word CAUTION is used to ensure that the operator follows the

general safety instructions or the measures mentioned in the

instruction manual to protect the operator and others against injuries.

WARNING: The word WARNING is used to warn against visible or hidden risks,

which might lead to serious personal injuries.

DANGER: The word DANGER is used to indicate measures which, according to

legislation, must be followed to protect oneself and others against

serious injuries.

Page 10

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 10 -

GENERAL SAFETY INSTRUCTIONS

The following is a brief description of the measures, which should be a matter of

common knowledge to the operator.

1. Always disengage the PTO drive shaft, activate the parking brake of the tractor,

stop the tractor engine and remove the ignition key before you:

- lubricate the machine,

- clean the machine,

- disassemble any part of the machine,

- adjust the machine.

2. Always block the wheels before working under the machine.

3. Never start the tractor until all persons are safely away from the machine.

4. Make sure that all tools have been removed from the machine before starting

the tractor.

5. Make sure that all guards have been mounted correctly.

6. During work never wear loose clothes or have your hair hang down as it may be

pulled in by the moving parts of the machine.

7. Always wear suitable shoes to avoid falling.

8. Do not change the guards or work with the machine when a guard is missing or

defective.

9. Always drive with the statutory lights and safety marking during transport on

public road and at night.

10. Limit the transport speed to maximum 30 km/h if the machine has not been

marked with another maximum speed limit.

11. Do not stand near the machine while it is working.

12. When mounting the PTO drive shaft check that the number and direction of

RPM of the tractor matches those of the machine.

13. Always use hearing protectors if the noise from the machine is annoying or if

you are working with the machine for a considerable period in a tractor cabin,

which has not been silenced sufficiently.

14. Never allow anybody to be on the machine during work or transport.

Page 11

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 11 -

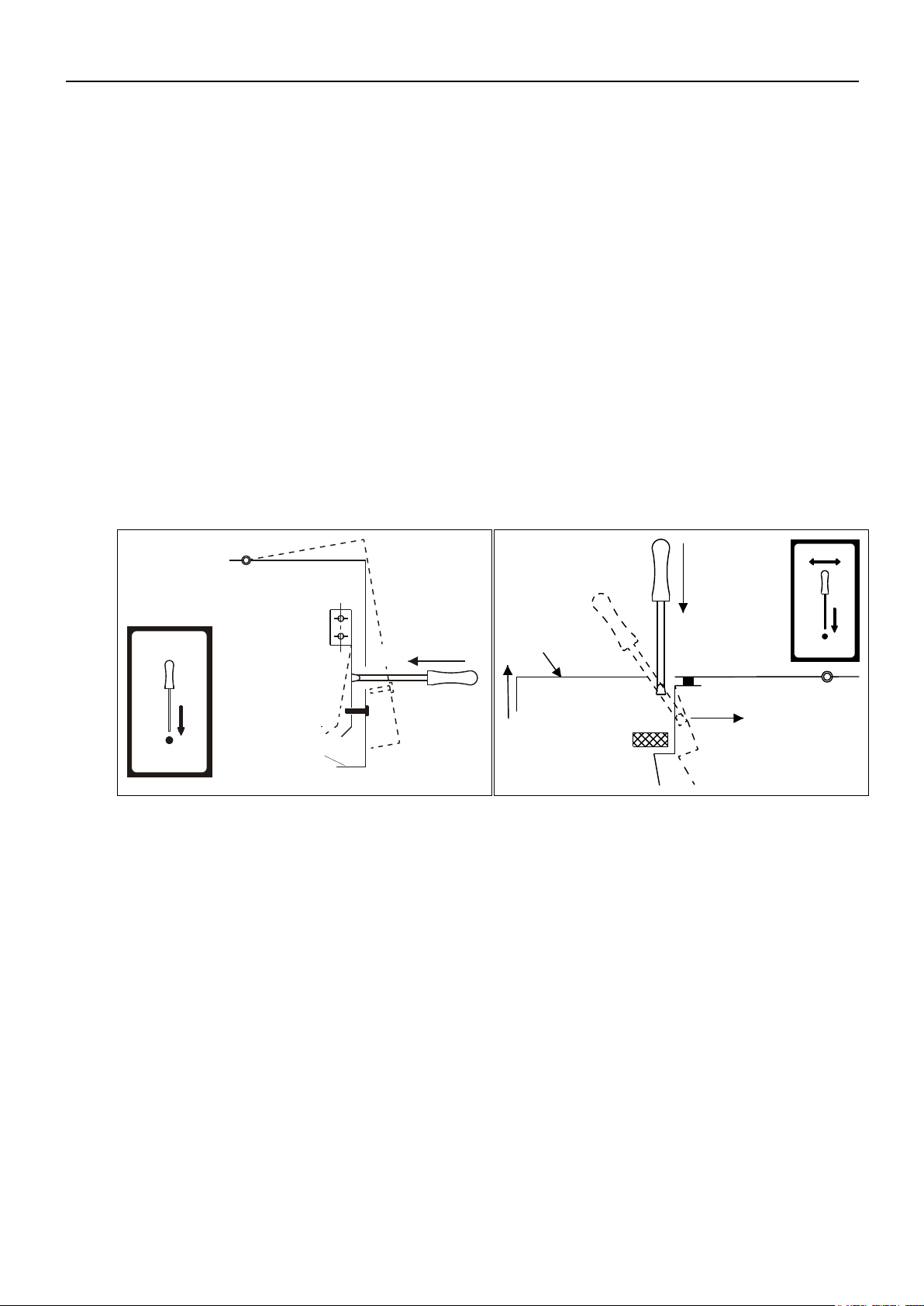

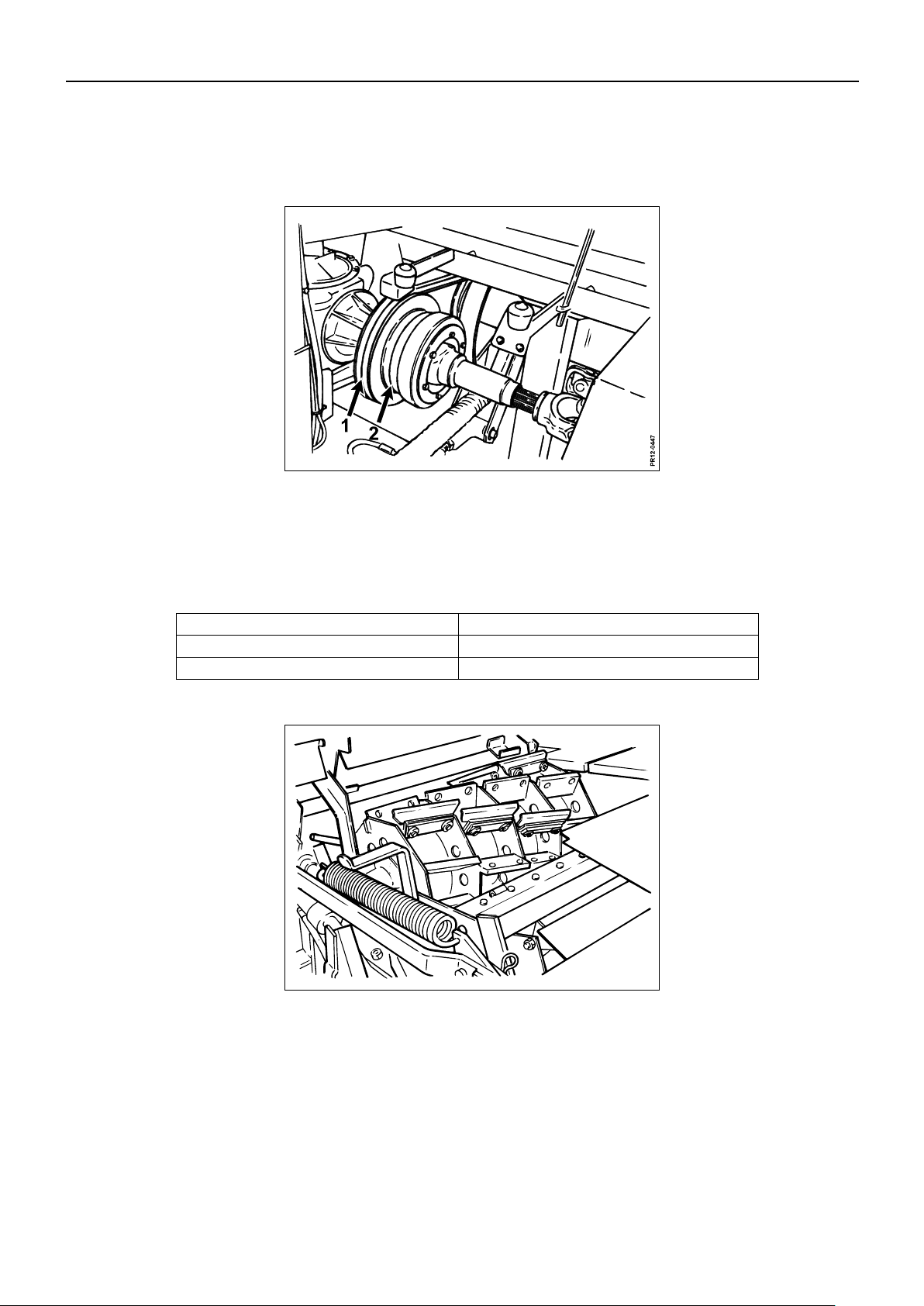

Fig. 1-1

P

R

1

1

-

0

2

4

3

PR80-0819

Guard

Fig. 1-2

PR11-0244

PR80-0820

Guard

15. Never use the machine for other purposes than what it has been constructed

for.

16. Do not allow any children to be near when you are working with the machine.

17. Never stand between the tractor and the machine during connection and

disconnection.

18. Do not feed material into the cutting unit, using hands or feet, while it is working.

19. Do not try to remove material from the cutting unit while it is working.

20. If material must be removed from the forage harvester, the PTO shaft must be

disconnected completely. Stop the engine and remove the ignition key.

LOCKING OF GUARDS

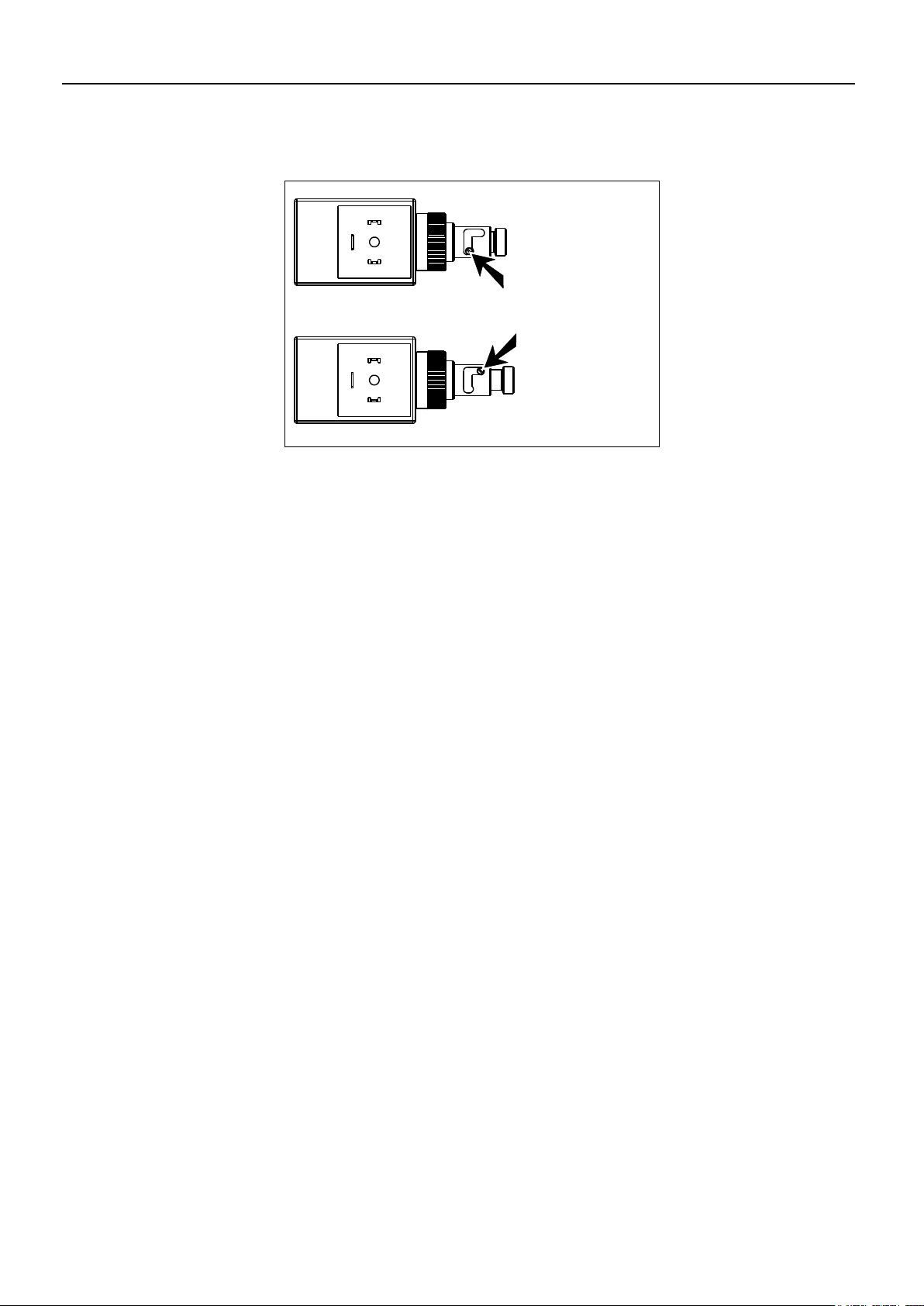

All hinged guards on the machine are equipped with a lock. The lock ensures that the

guard cannot be opened without tools. There are two different types of lock. Fig. 1-1

and 1-2 show the two locking principles and the corresponding transfers which

indicate and illustrate the locks on the machine.

Page 12

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 12 -

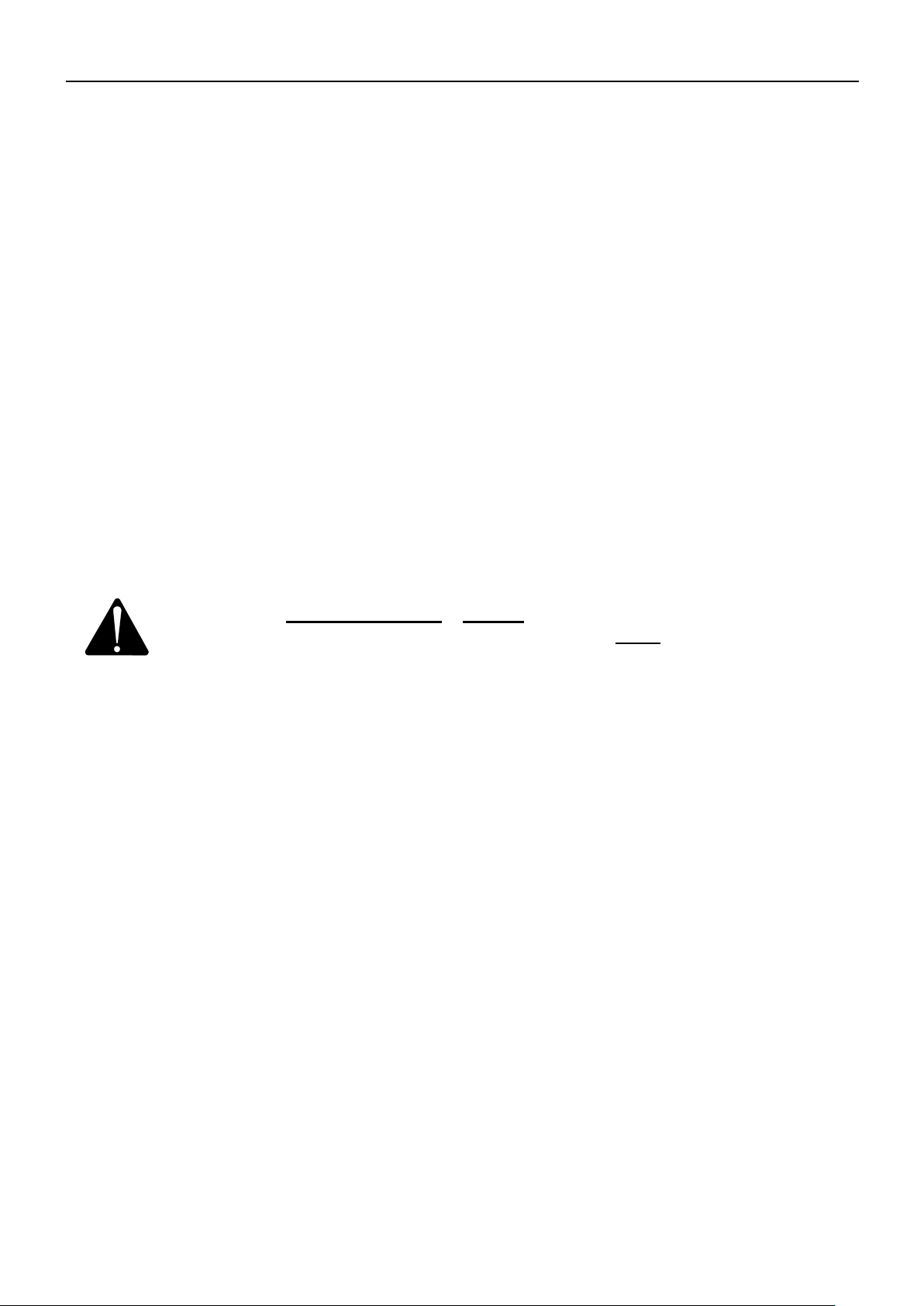

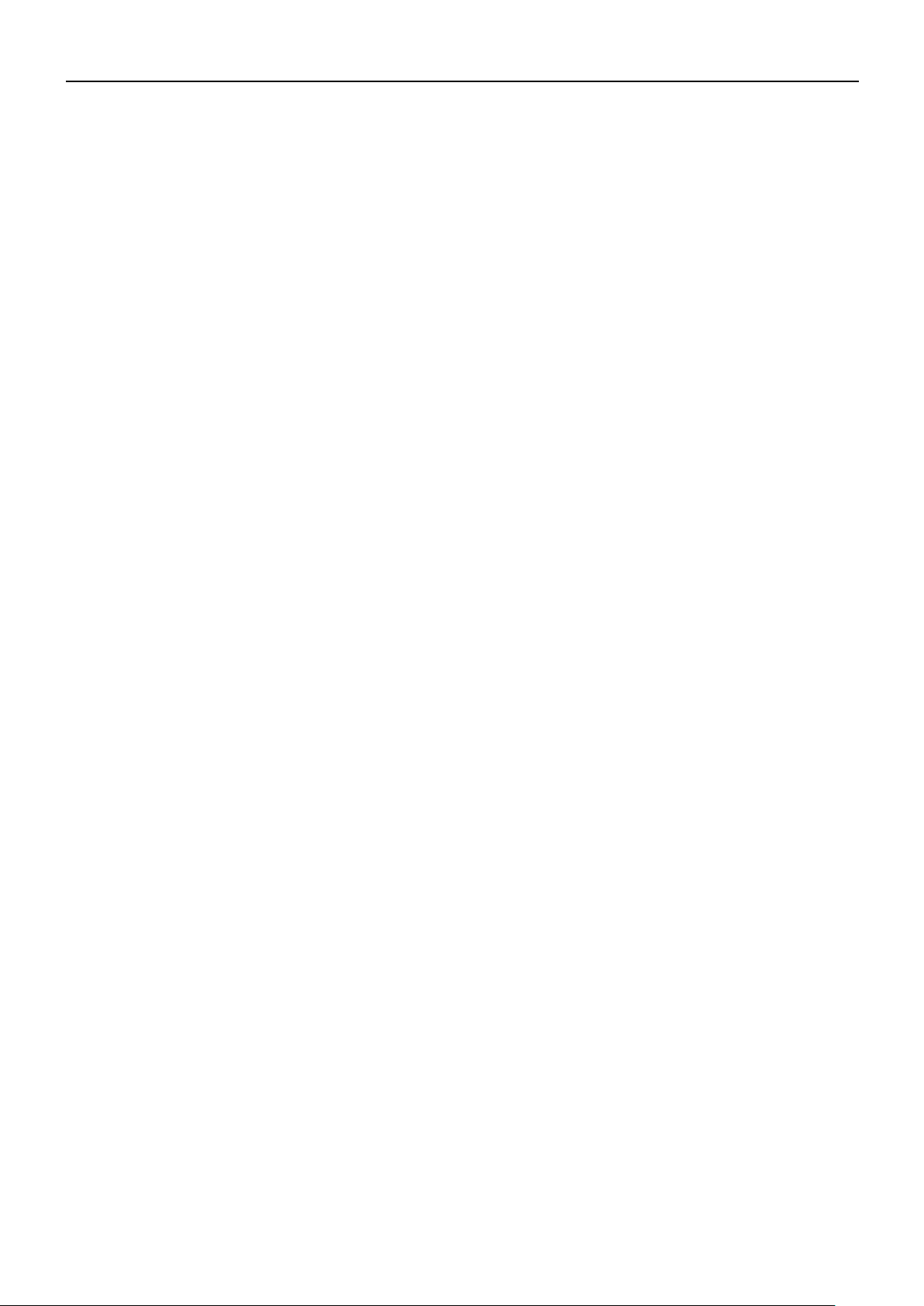

Fig. 1-3

CHOICE OF TRACTOR

Always follow the recommendations specified in the instruction manual of the tractor.

If this is not possible, technical assistance must be sought.

Legal transport of the machine on public road requires a tractor with sufficient mass

and braking capacity.

Choose a tractor which has minimum 103 KW/140 HP at the power take-off but

cannot deliver more than 165 KW/225 HP.

The machine is as standard constructed for 1000 RPM, and is delivered from the

factory with 1 3/4" PTO drive shaft with 20 splines yoke. As an alternative 1 3/4’’

yokes with 6 splines, 1 3/8” yokes with 6 splines and finally 1 3/8” yokes with 21

splines can be supplied for the PTO drive shaft of the machine

A suitable tractor will have a broad range of gears for driving speeds between 5 and

8 km/h.

The tractor hydraulic system should deliver at least 170 bar and the tractor’s

pressure relief valve should not allow more than 210 bar.

The drawbar of the forage harvester is delivered with a drawing eye, for which reason

the tractor should preferably have a clevis drawbar. The drawbar pin should be 30

mm diameter.

Always choose a tractor with a closed cabin when working with a precision chopper.

CONNECTION AND DISCONNECTION

Always make sure that nobody is standing between

the tractor and the machine during connection and

disconnection. An unintentional manoeuvre with the

tractor may cause serious injury (see Fig. 1-3).

When disconnecting it is important that the ground

is even and stable so that the machine does not

move and injure persons or cause damage to other

equipment.

The same precautions must be taken when connecting/disconnecting trailers by

means of the hydraulic hitch at the rear of the forage harvester.

Check that the machine is intended for the number and the direction of rotation of the

tractor PTO. A wrong number of rotations over a long period may damage the

machine and at worst result in ejection of parts through the delivery chute.

Page 13

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 13 -

Fig. 1-4

Make sure that the PTO drive shaft has been mounted correctly, i.e. that the lock pin

is in mesh and that the support chain has been fastened at both ends.

The PTO drive shaft must be correctly protected. If the guard is damaged it must be

replaced immediately.

IMPORTANT: Before connecting the trailer with the hydraulic hitch, always:

- Disengage the PTO from the tractor.

- Wait until all moving parts have stopped.

Check that all hydraulic couplings are tight and that all hoses and fittings are

undamaged before activating the hydraulic system.

Make sure that there is no pressure in the hydraulic hoses when these are

disconnected from the tractor.

Hydraulic oil under pressure can penetrate the skin

and cause serious infections. You should always

protect the skin and the eyes against oil splashes.

(see figure 1-4). If, by accident, hydraulic oil under

pressure hits you, consult a doctor immediately.

ADJUSTMENT

IMPORTANT: Before adjusting the machine, always:

- Disengage the PTO from the tractor.

- Stop the tractor engine

- Wait until all moving parts have stopped.

It is important not to remove the guards until all revolving parts have stopped. This

especially applies to the delivery chute above the blade cylinder.

If the cutting parts in the blade cylinder must be adjusted or replaced, it is important

to block the blade cylinder as the sharp blades can easily cause injury.

Before working, check that the feed rollers and the blade cylinder can move freely.

Also check that the blades are intact and without cracks. Damaged blades must be

replaced to prevent them from blocking or damaging the machine and to avoid metal

parts being thrown out from the delivery chute.

Check periodically if blades and blade bolts are worn according to the rules in the

instruction manual.

The first time you use the machine the blades and blade bolts may "bed in". For this

reason you must check and tighten the blade bolts after the first working hour.

Page 14

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 14 -

TRANSPORT

Limit the transport speed to maximum 30 km/h if the machine has not been marked

with another maximum speed limit.

When the machine has been prepared for transport, the control unit must be turned

off on the button at the side of the control box and the oil flow to the machine must be

interrupted. This prevents faulty operation during transport.

DANGER: Never let anyone stand or sit on the machine, especially not when

you are driving.

The machine has equipment for hydraulic conversion to transport position and the

cylinder for this is fitted with a hose breach valve. If there is air in the cylinder during

transport there is a risk that the machine moves to the opposite lane, the bicycle

track or the sidewalk.

IMPORTANT: If the machine is equipped with auto hitch, the mechanical lock on

the auto hitch must be activated when driving with a trailed wagon on

public road. This also applies if a hose breach valve is fitted on the

lifting cylinder of the auto hitch.

IMPORTANT: To ensure all the air has been expelled from the oil in the hydraulic

cylinders, test all the functions after the hydraulic connections are

connected to the tractor. Especially before you enter or drive on

public roads.

The attachments of the forage harvester (pick-up etc.) must be secured mechanically

before transport.

The statutory lighting and traffic markings must be placed correctly, on the forage

harvester as well as the trailer.

Reflectors and lighting must be cleaned regularly.

Page 15

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 15 -

WORKING

Before you start working make sure that no persons are behind the forage harvester

due to the danger of being hit by metal parts from damaged blades.

Also make sure that there are no persons in the trailer used for picking up. There is

danger of suffocating in the flow of material or getting hit by metal parts.

If the feed rollers or the blade cylinder are blocked, disengage the clutches and stop

the tractor engine immediately. Activate the parking brake and wait until the revolving

parts have stopped before removing the material or the foreign matter.

WARNING: This cannot be said often enough: Never remove material blocked in

the machine while the machine is running and never feed material

into the pick-up with your hands or feet as there is a serious danger

of getting caught and pulled into the harvester which would cause

dismemberment or death.

Never allow anyone to stand near the forage harvester while it is working, especially

not children who do not know the danger and do unforeseen things.

The chute is over 4 m high. Be aware of high-voltage lines and keep a safe distance

to these.

PARKING

Before parking the machine always lock the jack with the locking pin, otherwise the

machine may tip over during parking. Also remember to block the wheels if there is a

risk that the machine will move after parking

Remember to remove the hydraulic hoses and the control box before driving away

with the tractor.

GREASING

When greasing or maintaining the machine never let more than one person work at

the machine at a time. This reduces the risk of getting fingers caught because

another person by accident turns the revolving parts while you are still working with

them.

Never try to clean, grease or adjust the machine before the PTO has been

disengaged, the tractor engine has stopped and the parking brake been activated.

Remove the ignition key!

Page 16

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 16 -

GRINDING

When grinding always follow this procedure:

- Stop the tractor engine and remove the ignition key.

- Activate the parking brake.

- Wait until all moving parts have stopped.

Unfortunately it is necessary to remove some of the guards to change the direction of

rotation of the rotor when grinding the blades. As there are chain and belt

transmissions your hands may be injured if the revolving parts have not stopped

before the guards are removed.

Grinding is performed according to the following procedure:

1. Check if the grindstone is undamaged and if the device is able to move back

and forth easily.

2. Lower the guard behind the grinding device to give access to the blade cylinder.

3. Adjust the stone and guard the grinding device again.

4. Remove the guard above the blade cylinder transmission and change the

direction of rotation of the rotor.

5. Close the guard again and check that there are no persons near the machine.

6. Start the tractor again and keep the rpm at idle speed or a little above.

7. Perform the grinding carefully.

Always use safety glasses when grinding as small particles from the grindstone might

hit you.

When grinding has finished, stop the tractor engine, remove the ignition key, change

the direction of rotation and fasten all guards.

REMEMBER: Always grind with all guards closed.

Page 17

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 17 -

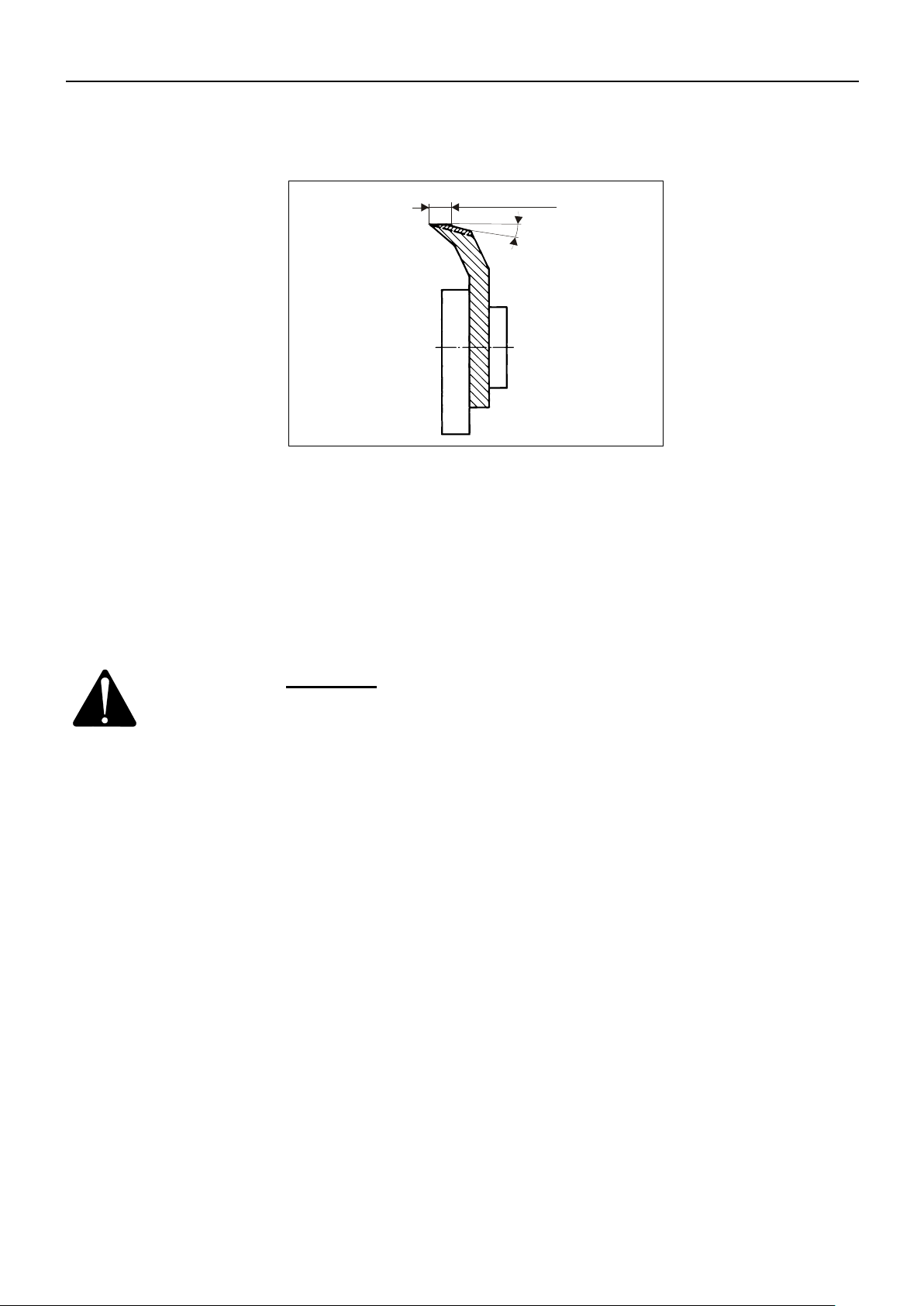

Fig. 1-5

MAINTENANCE

After approx. 2 days of operation, all bolts should be re-tightened. Always make sure

that the used spare parts are tightened to the correct torque.

When replacing parts in the hydraulic system always make sure that the pick-up rests

on the ground and/or the lifting cylinders are blocked.

Hydraulic hoses must be checked by an expert before use, and after that minimum

once a year. If necessary, they must be replaced. The working life of hydraulic hoses

should not exceed 6 years, including maximum 2 years of storage.

When replacing, always use hoses which comply with the requirements stated by the

manufacturer. All hoses are marked with date of production.

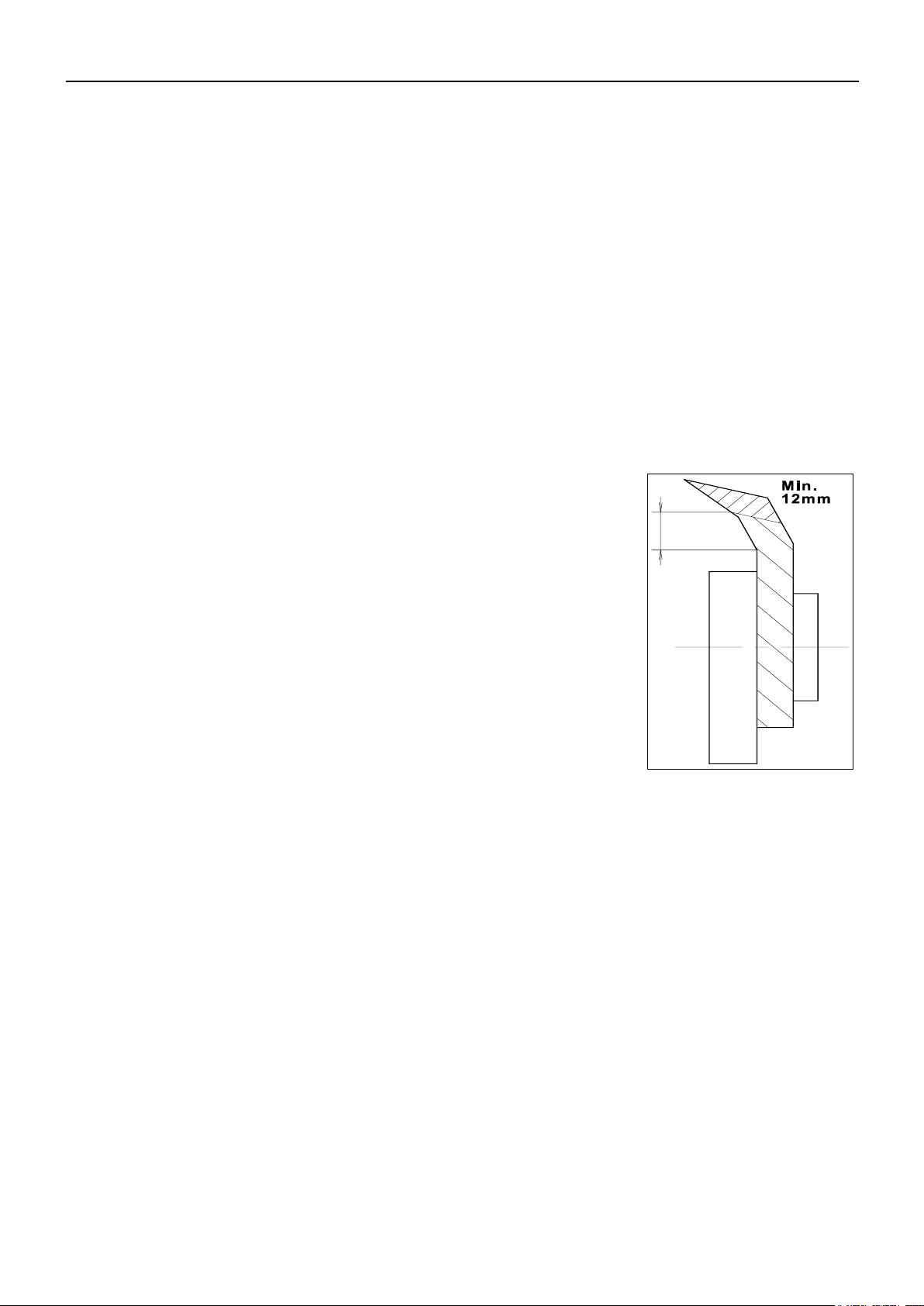

REPLACEMENT OF WEARING PARTS

Blades, blade bolts and shearbar are made of highalloyed, heat-treated materials. This heat treatment

provides especially hard and ductile material which is able

to withstand extreme stress. Damaged blades, blade bolts

or shearbars must be replaced by original KONGSKILDE

spare parts to ensure safe operation.

Blades and blade bolts must be checked every day during

the season.

The special blade bolts must be tightened with a torque

wrench to 40 kgm.

When the blades have been worn max. 8 mm or approx.

12 mm above the straight piece, they must be replaced

(see fig. 1-5).

After replacement of blades, blade bolts and the like, check that no tools have been

left in the machine.

Page 18

PIGB-186X-05 FCT1360 0218

- 18 -

3

5

10

12

9

4

6

8

7

STOP

PR80-0821

2 MIN

1

2

3

6

7

7

8

9

10

12

15

14

13

15

6

4

5

7

5

8

7

2

1

13

PR80-0837

15

PR80-0814

14

PR80-0861

11

PR80-0857

1. INTRODUCTION

Page 19

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 19 -

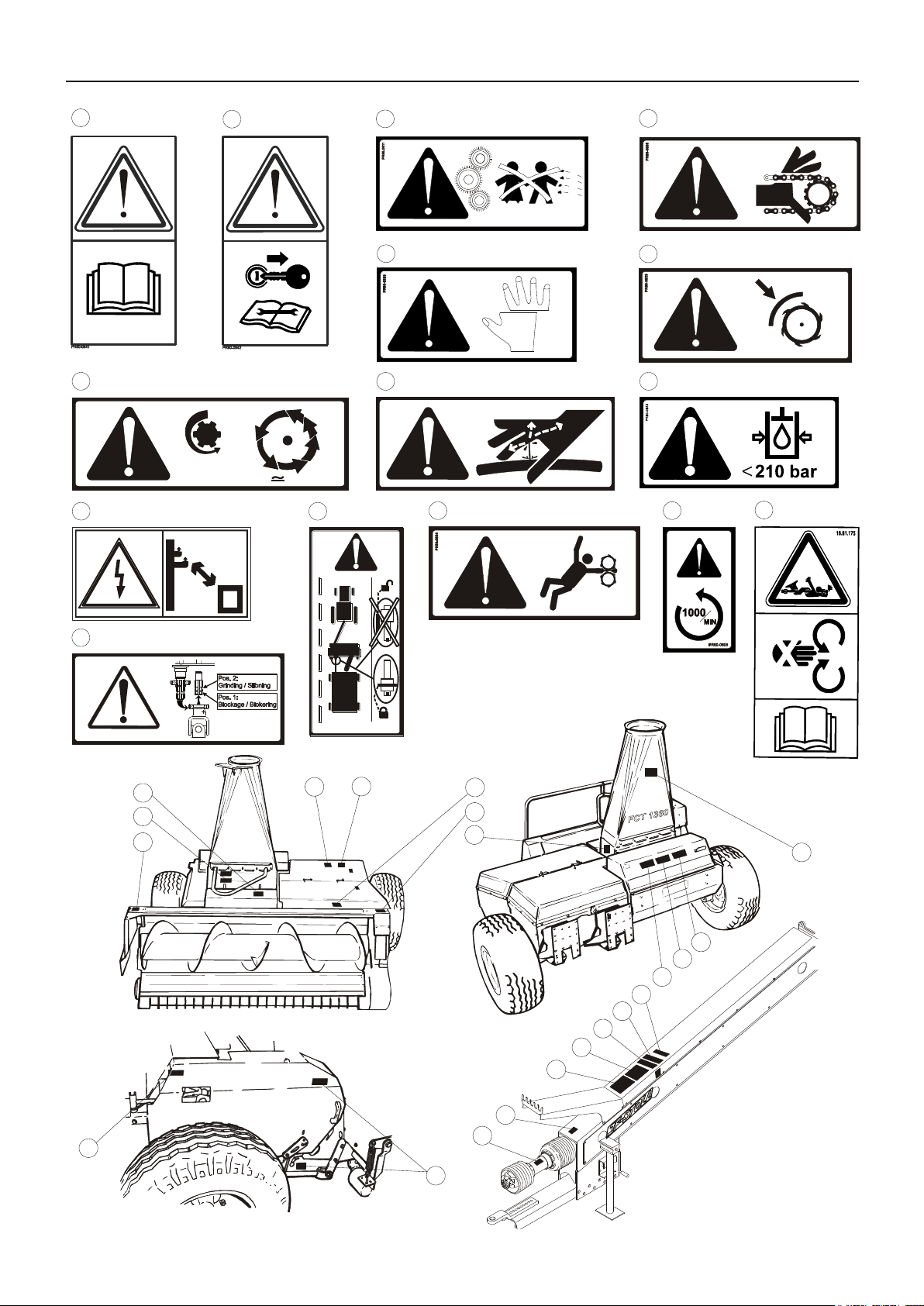

SAFETY DECALS

The safety decals shown on the previous page are positioned as shown on the

drawings. Before using the machine, check that all decals are present: if not, require

those missing. The decals have the following meaning:

1. Stop the tractor engine and remove the ignition key before touching the machine.

Always remember to stop the tractor engine before lubricating, adjusting, maintaining or repairing. Also

remember to remove the ignition key to ensure that nobody starts the engine until you have finished.

2. Read the instruction manual and the safety instructions.

This is to remind you to read the delivered documents to ensure the machine is operated correctly and to

avoid unnecessary accidents and machine damage.

3. Children.

Never let children stand near the machine during operation. Especially not small children as they have a

tendency to do unforeseen things.

4. Chain drive

One or more chain drives are placed under this guard. Make sure that the tractor engine has stopped

before opening the guard.

5. Risk of cutting.

There is a risk of getting fingers etc. caught several places on the machine. Be careful when the machine

is connected to the tractor and ready to work. The machine can easily crush or cut off any part of the body

that might get caught in the machine.

6. Remember the guards when grinding.

Remember to close ALL guards before grinding.

7. Rotating parts.

After the PTO drive shaft has stopped, the blades will have a momentum where they keep rotating for up

to 2 minutes. Wait until the blades have come to a complete stop before removing guards for inspection or

maintenance.

8. Risk of getting pulled into the machine.

Do not stand near the attachments or the feed rollers while the machine is running. Make sure that the

tractor engine has stopped first.

9. The number and the direction of rotations.

Check that the PTO drive shaft runs with the right RPM and in the right direction. A wrong number of

rotations and/or direction of rotation can damage the machine with the risk of personal injury as a result.

10. The PTO drive shaft.

This decal has the purpose to remind you how dangerous the PTO drive shaft can be if it is not correctly

mounted or protected.

11. Auto hitch.

Always block the hydraulic hitch with the supplied pin before driving with a trailed wagon on public road.

12. Maximum 210 bar.

Make sure that the hydraulic components are not exposed to more pressure than maximum 210 bar as

there could be a risk of explosive damage of parts. Hereby you expose yourself and others to serious

danger of getting hit by metal parts with high speed or oil under high pressure.

13. PTO drive shaft for rotor.

There is an alternative pin for the PTO drive shaft for the rotor. It is used when the rotor is disconnected

during reverse and when the rotor rotates in the opposite direction during grinding. Make sure that you

place the PTO drive shaft correctly on the pin when performing these operations.

14. High-voltage lines.

This decal has the purpose to remind you of the danger of getting too close to high-voltage lines.

15. Hydraulic oil under pressure.

Warning against hydraulic oil under pressure.

Page 20

PIGB-186X-05 FCT1360 0218

- 20 -

PR11-1746

5232

3569

3395

1. INTRODUCTION

Page 21

1. INTRODUCTION

PIGB-186X-05 FCT1360 0218

- 21 -

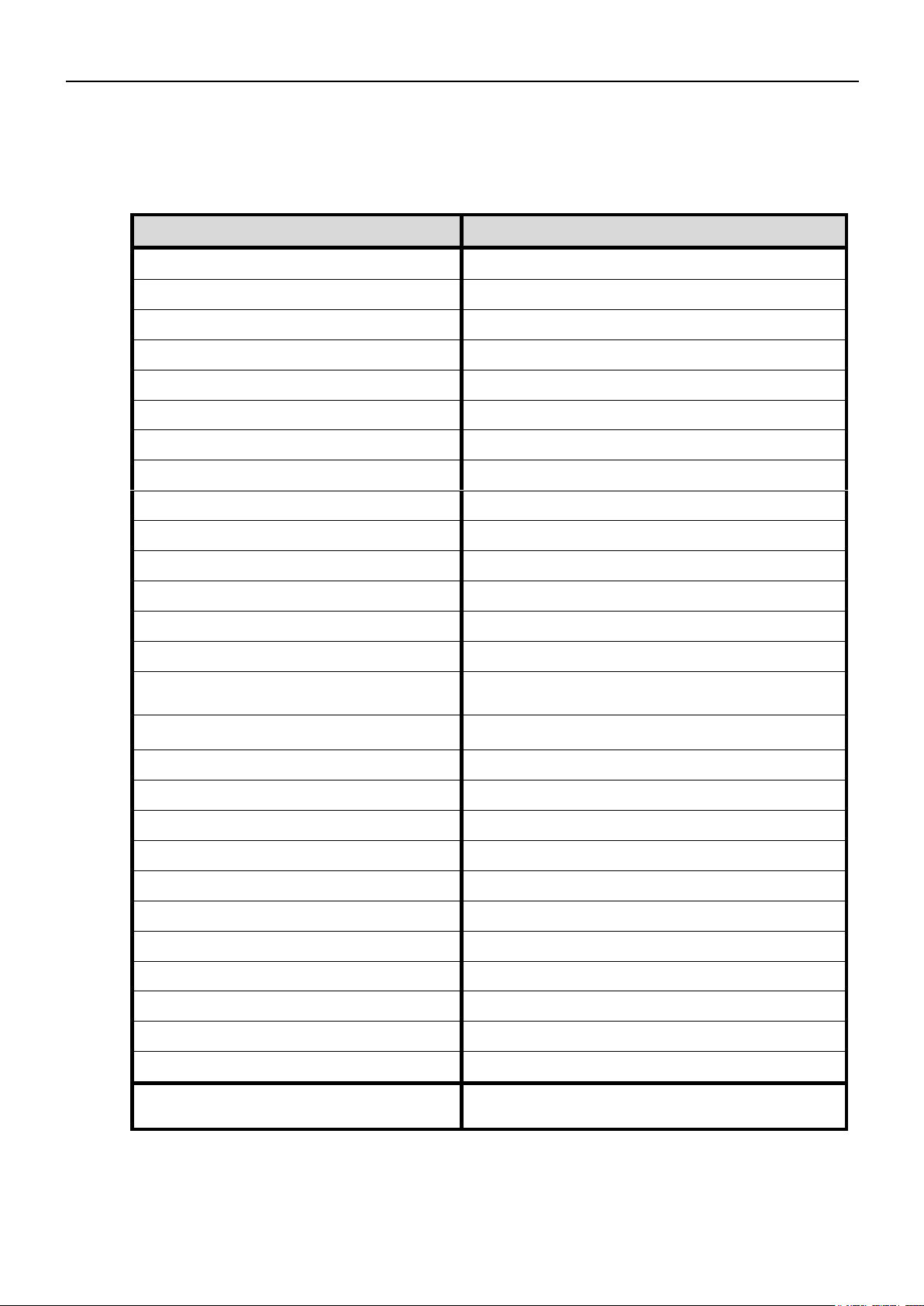

TECHNICAL DATA

FCT 1360

Pick-up width

3.1 m

Power requirement

103–165 kW/140-225 HP

Capacity (*)

35 - 100 t/hour

Blade rotor width

0.9 m

Rpm for rotor

1600 rpm

Number of blades, standard

40

HD blades

Standard

Grinding device

Grindstone with quick adjustment

Reverse grinding

Standard

Theoretical cutting length, standard

7 and 15mm

Reversible shearbar, tungsten-coated

Standard

Number of feed rollers

4

Reverse of feed intake

Standard, hydraulic

Hydraulic functions

Pick-up lifting, drawbar, chute swivelling,

deflector and reverse function

Turning angle for chute

260 degrees

Pick-up, pre-lubricated

Standard

Weight with pick-up

2995kg

Maximum length

5.2 m

Maximum width with pick-up

3.57 m

Transport height

3.4 m

Tyre dimension standard

19/45 x 17

Freewheeling clutch in PTO shaft

Standard

Friction clutch in PTO shaft

Standard, 3000 Nm

Steel wheels on pick-up

Standard

Rubber wheels on pick-up

Option (width 3.63 m)

Hydraulic Auto-Hitch

Option

Hitch for trailer: drawbar load/ total

weight

2000kg/ 15000kg

TECHNICAL DATA

(*) Depends on dry matter content, cutting length, the condition and the amount of crop.

We reserve the right to change the construction and specification details without

notice.

Page 22

PIGB-186X-05 FCT1360 0218

- 22 -

2. CONNECTION TO TRACTOR

THE HYDRAULIC SYSTEM

HYDRAULIC CONNECTION

DANGER: The hydraulic components must not be exposed to a higher

working pressure than 210 bar as a higher working pressure

may gradually cause parts to be damaged. Hereby a serious risk

of personal injury occurs.

CAUTION: It is important that the quick-release couplings are always carefully

cleaned before mounting to avoid that impurities get into the

hydraulic system and damage important valve functions. When the

hydraulic hoses are not connected to the tractor they should be

parked in the holder at the end of the drawbar.

The machine is equipped with its own hydraulic system, which must be supplied with

oil from the tractor.

The system is used for pick-up lifting, drawbar, chute swivelling, deflector and

reverse function. None of these functions use very much oil and are controlled in the

best way when the oil flow is low. Adjust the oil flow from the tractor to 15-20l/min., or

as low as possible.

Connect the hoses to a double-acting outlet on the tractor, or better: connect the

pressure hose to the A-port on the hydraulic outlet and the return hose to a free

return-port directly to tank or rear-axle assembly. Hereby you ensure that the return

pressure is sufficiently low. This is especially important if the oil flow from the tractor

cannot be adjusted to a sufficiently low level.

IMPORTANT: The hydraulic outlet of the chosen A-port must be locked in pressure

position to ensure continuous oil flow to the machine’s hydraulic

system.

2. CONNECTION TO TRACTOR

Page 23

2. CONNECTION TO TRACTOR

PIGB-186X-05 FCT1360 0218

- 23 -

P

R

1

1

-

1

7

4

3

Closed centre

Open centre

Fig. 2-1

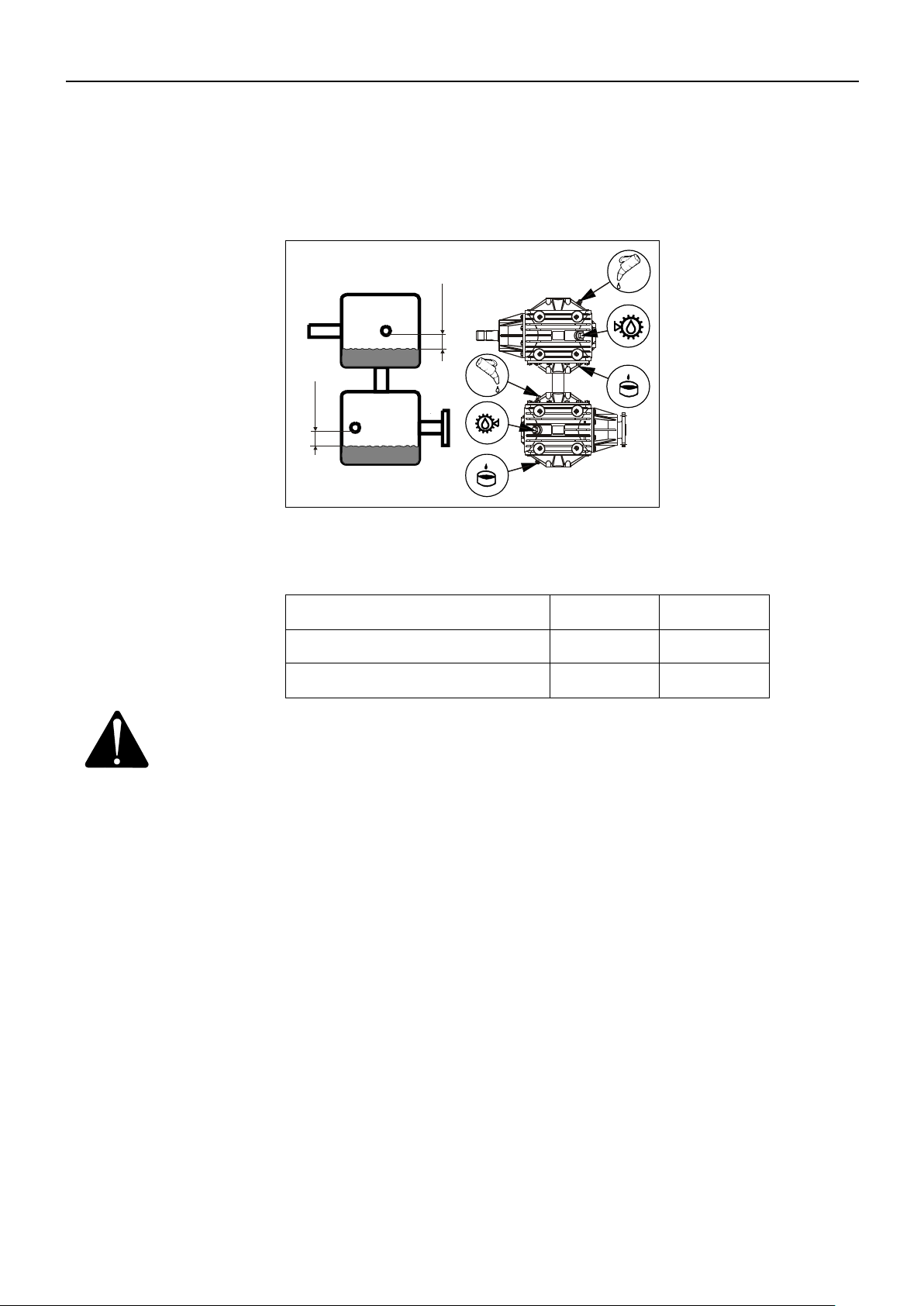

BYPASS VALVE

Fig. 2-1 We distinguish between two types of tractor hydraulic systems: “open centre

hydraulic” (also called “fixed pump”) and “closed centre hydraulic” (also called

“variable pump”).

If the tractor is of the “open centre” type, the bypass valve must be open in order to

allow passage of oil back to the tractor and should only be activated when a function

on the machine is activated. If the valve is not open, this can be changed at the

thumbscrew.

If the tractor is of the “closed centre” type, the bypass valve must be closed in

order to allow the tractor to close the oil flow automatically when no functions are

active. If the valve is not closed, this can be changed at the thumbscrew.

The bypass valve is placed at the bottom of the valve block.

None of the hydraulic functions use more than about 15 litres of oil per minute.

Therefore the oil flow from the tractor should be set to 15 litres of oil per minute, if

possible. The bypass valve is preset to maximum 40 l/min. If this limit is exceeded,

there will be a loss of pressure which may heat the oil and the valves.

Page 24

2. CONNECTION TO TRACTOR

PIGB-186X-05 FCT1360 0218

- 24 -

Fig. 2-2

CONNECTION OF ELECTRIC SYSTEM

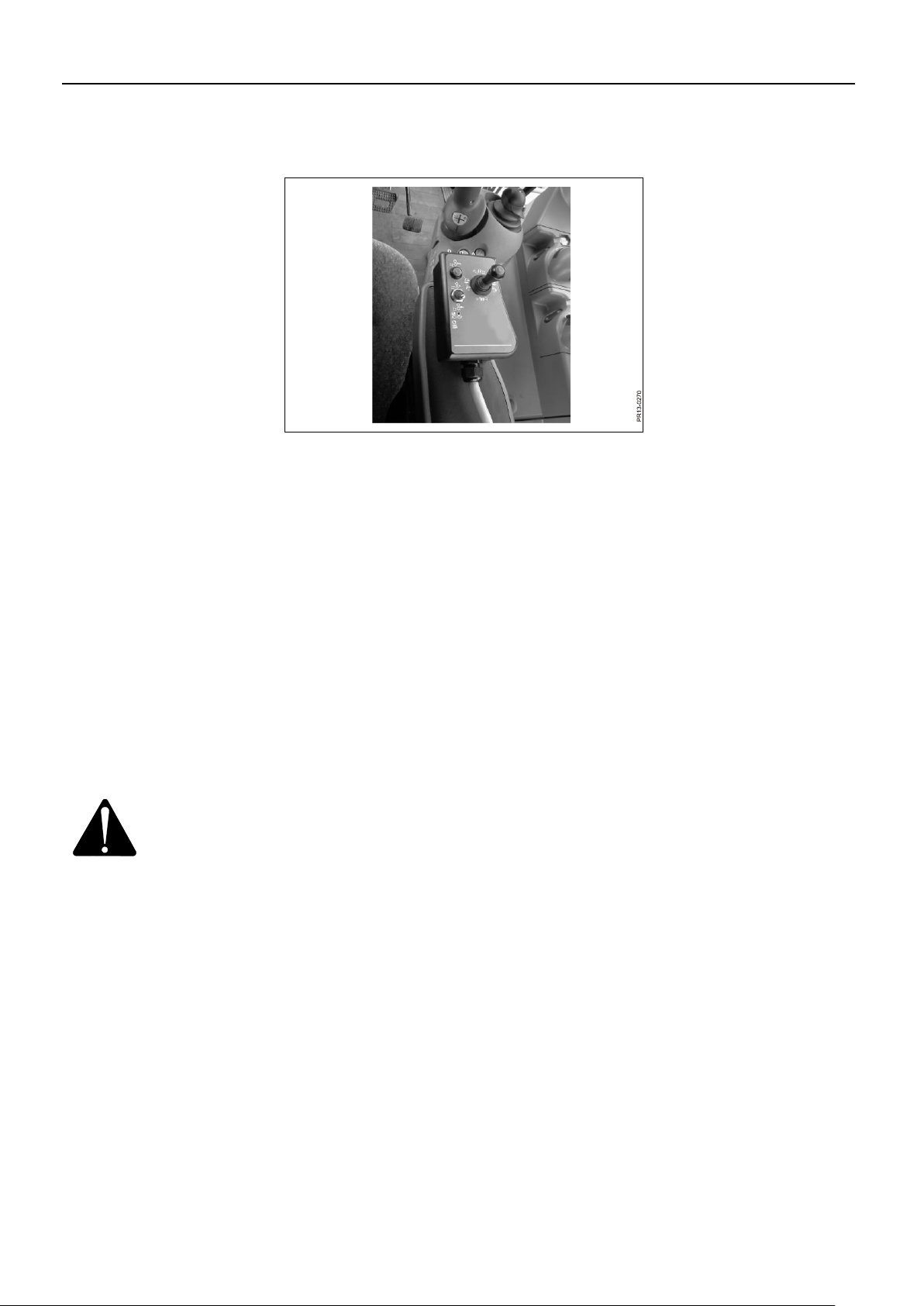

Fig. 2-2 The machine is equipped with full electronic operation of all the machine’s hydraulic

functions. The electronic operation consists of 2 units:

A control unit mounted on the machine together with the hydraulic system.

This unit activates the hydraulic valves.

A control box for operation of the hydraulic functions. This can be placed on

the right arm rest in the tractor cabin, allowing the driver easy access to it

while driving in the field, see figure 2-2.

The control box is equipped with detachable fittings which can be fastened in the

tractor cabin with screws, and it can subsequently be dismounted without tools.

The plug for the power supply is connected to a socket in the tractor cabin. This

should supply 12 V and allow minimum 15 A. If the tractor does not have the same

plug you should contact your dealer and get an adaptor.

IMPORTANT: When the machine is parked the control box should be placed in the

chute support on the drawbar.

Page 25

2. CONNECTION TO TRACTOR

PIGB-186X-05 FCT1360 0218

- 25 -

Fig. 2-3

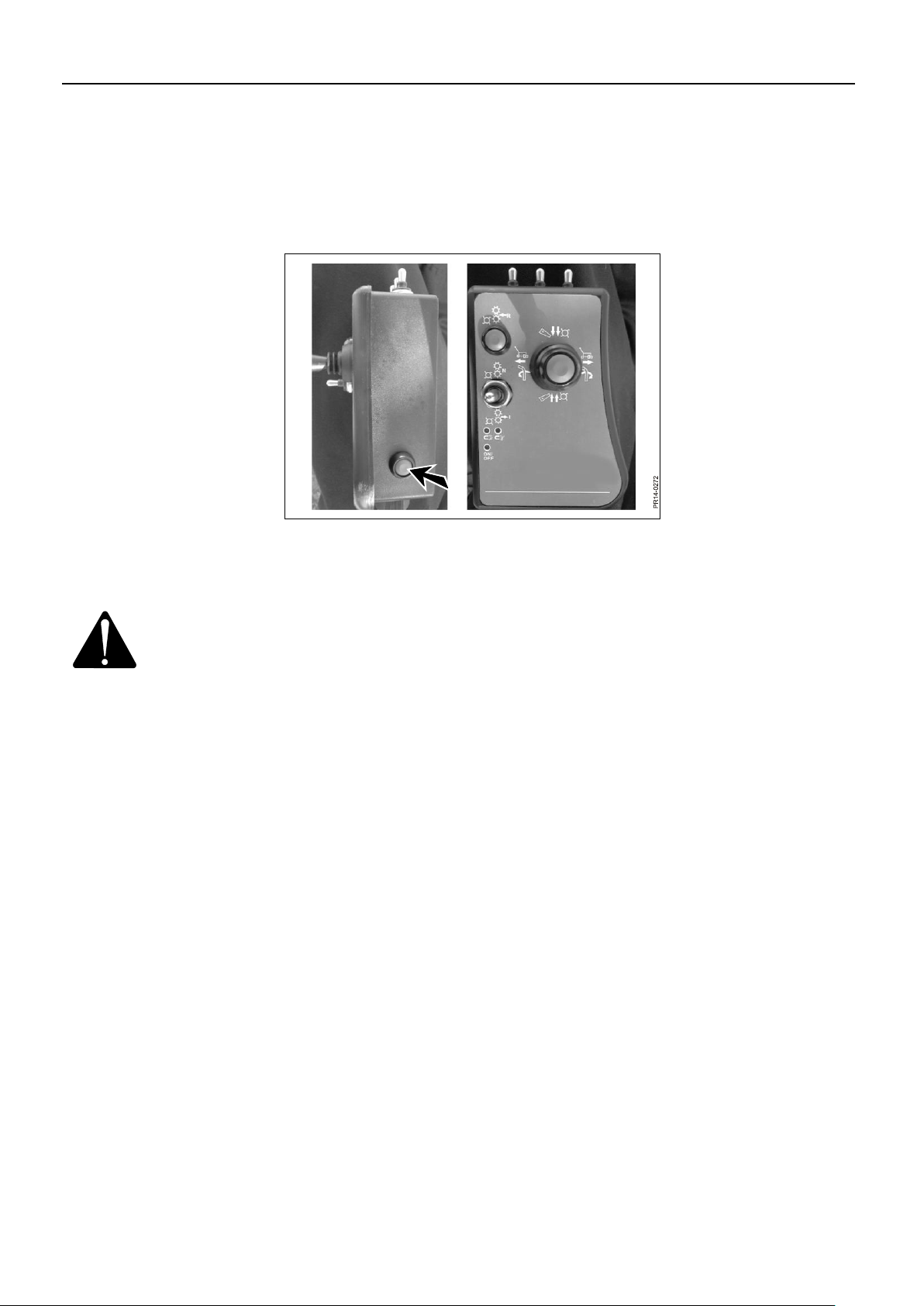

ELECTRO-HYDRAULIC CONTROL

The machine is operated from the control box which controls the electro-hydraulic

functions.

Fig. 2-3 The control is turned on and off on the side of the control box.

IMPORTANT: Remember to turn off the control box if the tractor is stopped for

some time. Although the machine is not in operation, several electric

coils may be activated. These will drain the tractor’s battery.

Page 26

PIGB-186X-05 FCT1360 0218

- 26 -

Fig. 2-5

Fig. 2-4

FUNCTIONS

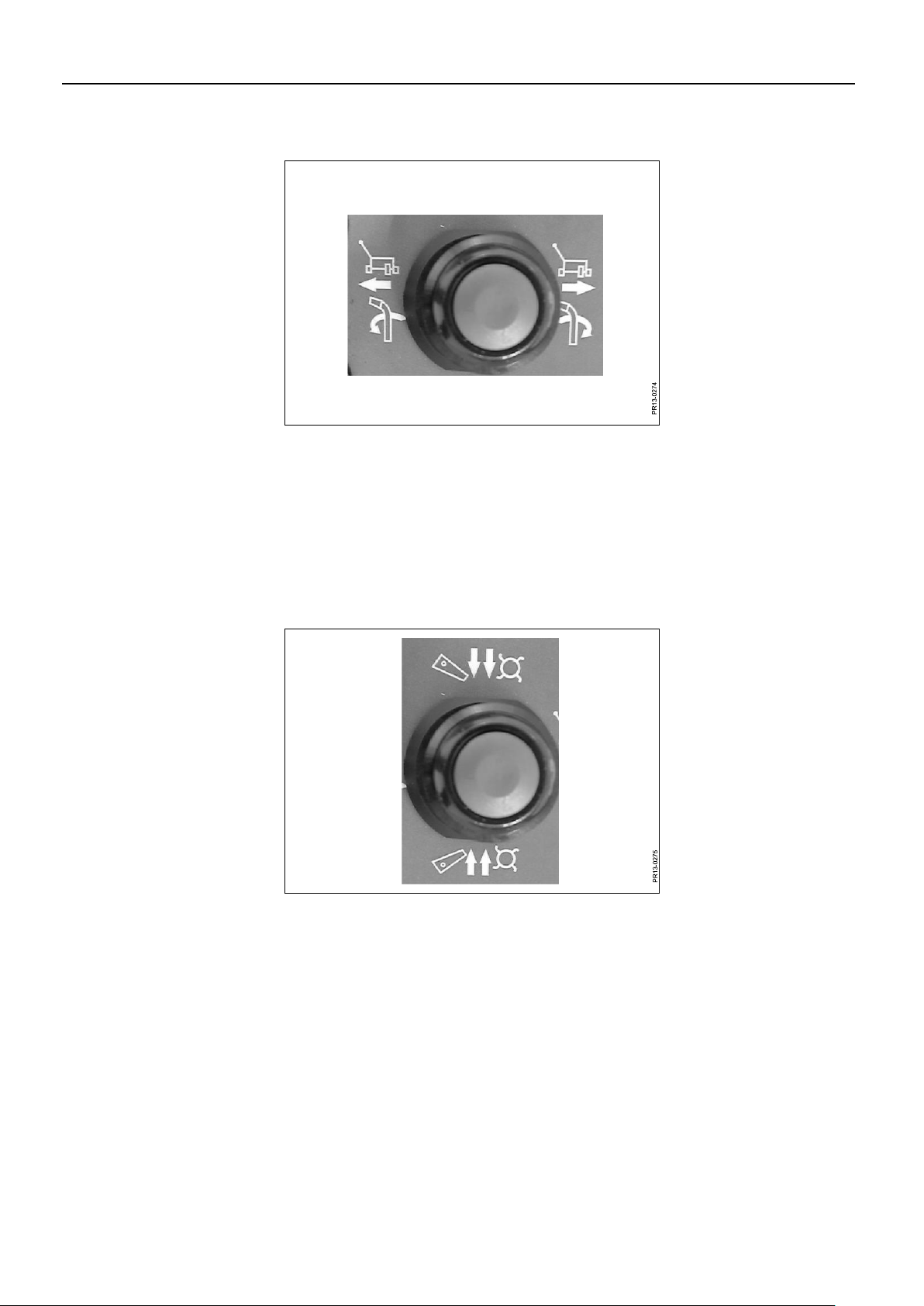

Fig. 2-4 On the joystick:

Chute: Push to the left: The chute turns anti-clockwise. Push to the right: The chute

turns clockwise.

Drawbar: While pushing the button: Push to the left: The machine moves behind the

tractor. Push to the right: The machine moves out to the swath.

2. CONNECTION TO TRACTOR

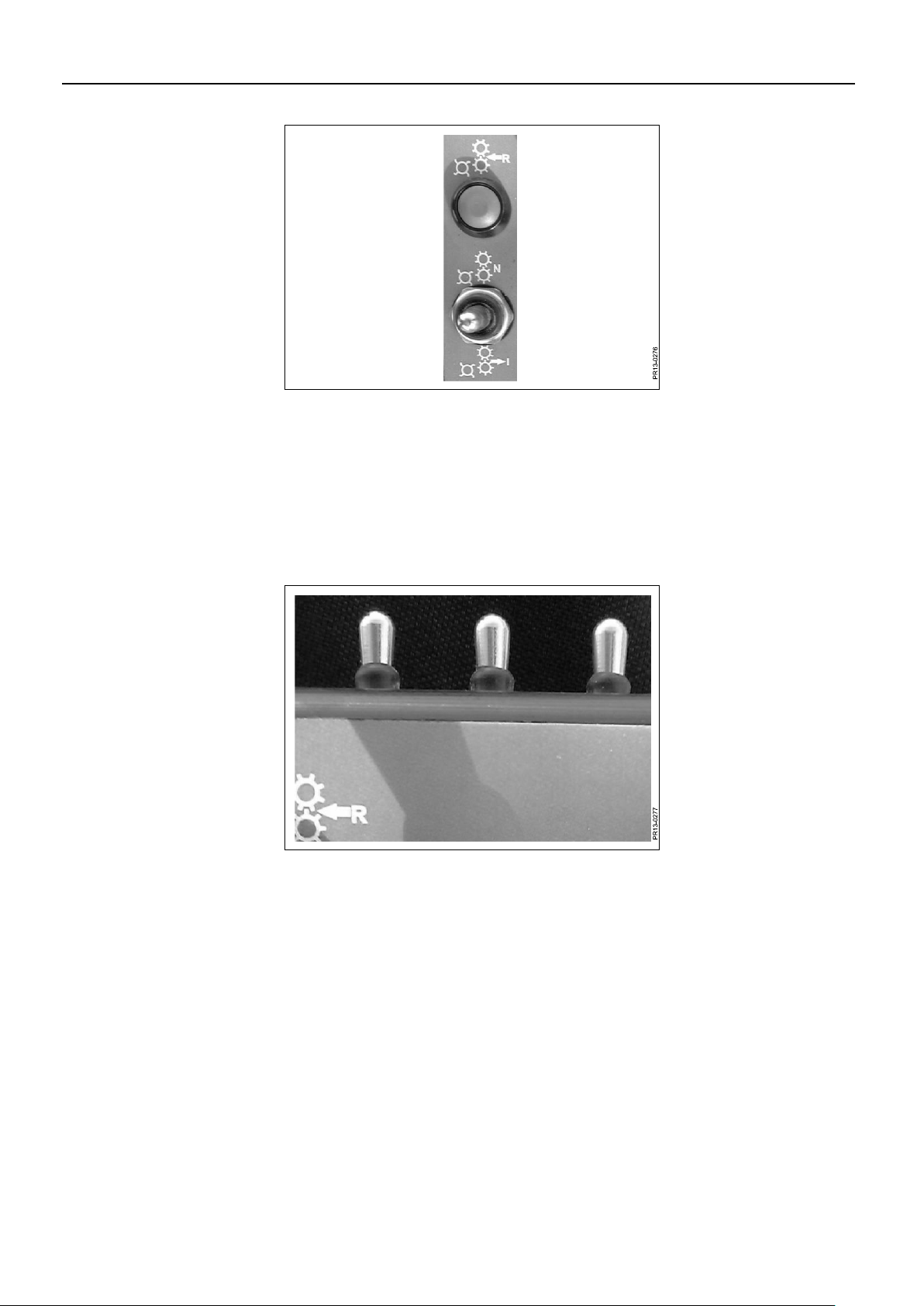

Fig. 2-5 On the joystick:

Chute: Push forward: The deflector points downward. Push to the rear: The deflector

points upward.

Pick-up: While pushing the button: Push forward: The pick-up is lowered. Push to

the rear: The pick-up is raised.

It takes about 2 seconds to lower the pick-up completely so that the support wheels

can follow the ground.

Page 27

2. CONNECTION TO TRACTOR

PIGB-186X-05 FCT1360 0218

- 27 -

Fig. 2-6

Fig. 2-7

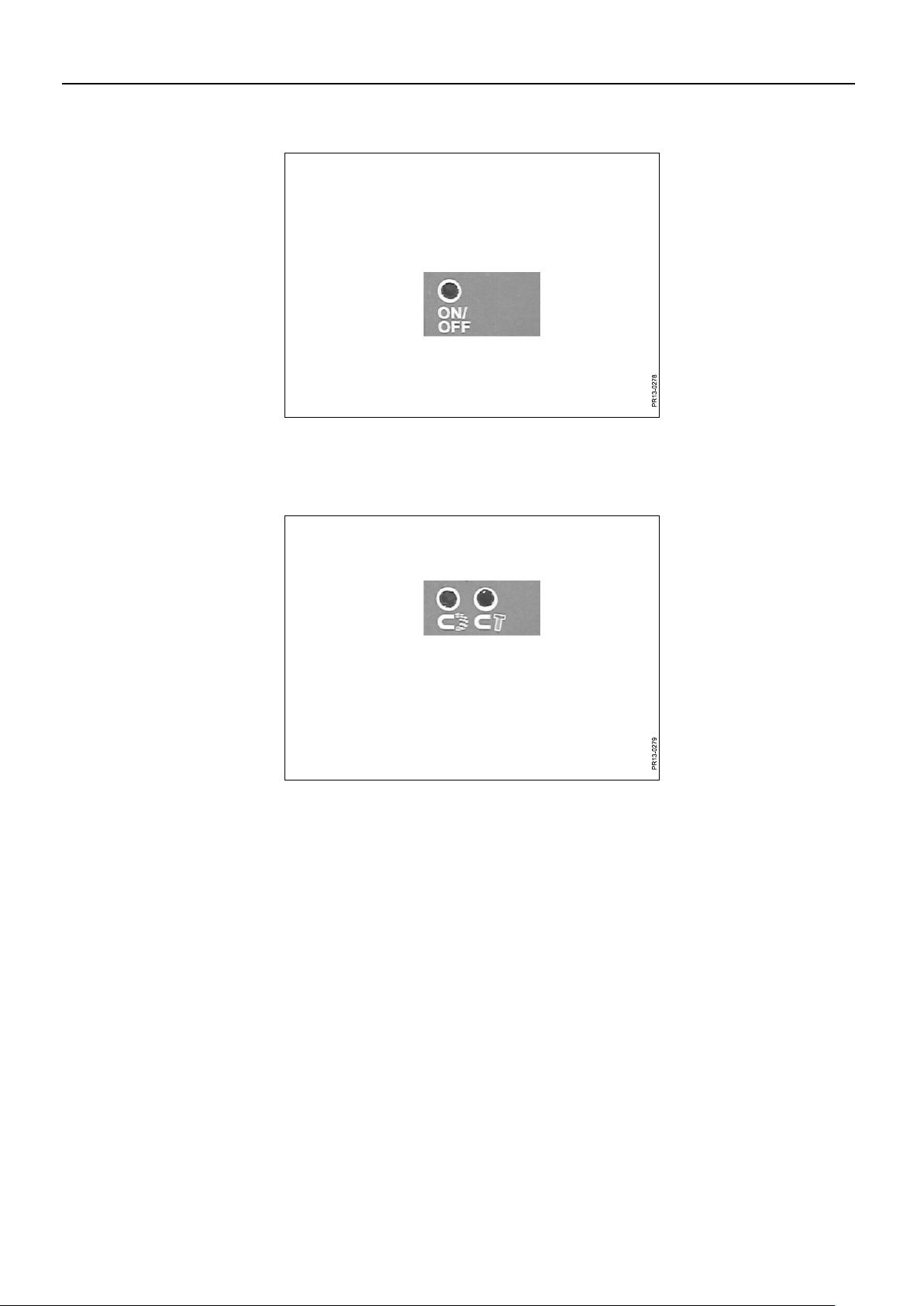

Fig. 2-6 Reverse function. Applies to feed rollers and pick-up.

Feed in: Move the toggle switch to the rear.

Neutral: Move the toggle switch forward for about 2 seconds and then back to the

middle position. Feed rollers and pick-up stay in neutral position.

Reverse: With the toggle switch in the middle position you reverse by holding down

the push-button. Reversing will stop when letting go of the button.

Fig. 2-7 There are 3 toggle switches at the front of the control box. One of them is used for

folding of the chute; the other two are intended for optional equipment. The toggle

switches automatically return to the neutral middle position after being activated.

Page 28

2. CONNECTION TO TRACTOR

PIGB-186X-05 FCT1360 0218

- 28 -

Fig. 2-8

Fig. 2-9

Control light

Fig. 2-8 This light is on when the control unit is switched on.

Fig. 2-9 Not used.

Page 29

PIGB-186X-05 FCT1360 0218

- 29 -

Fig. 2-10

PR11-5017

DRAWBAR AND PTO DRIVE SHAFT

The hitch eye of the drawbar is intended for a 30 mm hitch pin. The hitch pin must be

secured.

The drawbar load is 660kg.

2. CONNECTION TO TRACTOR

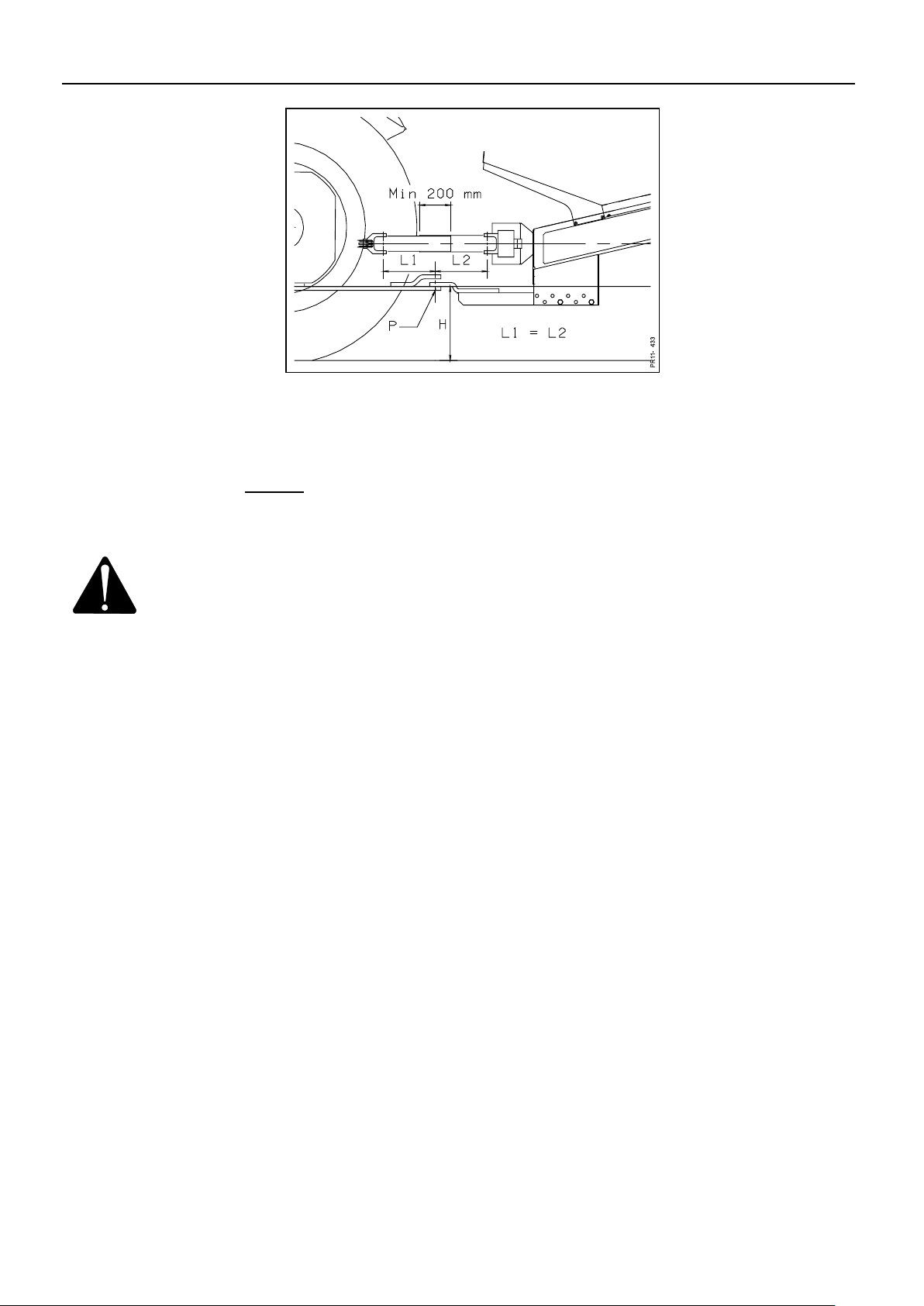

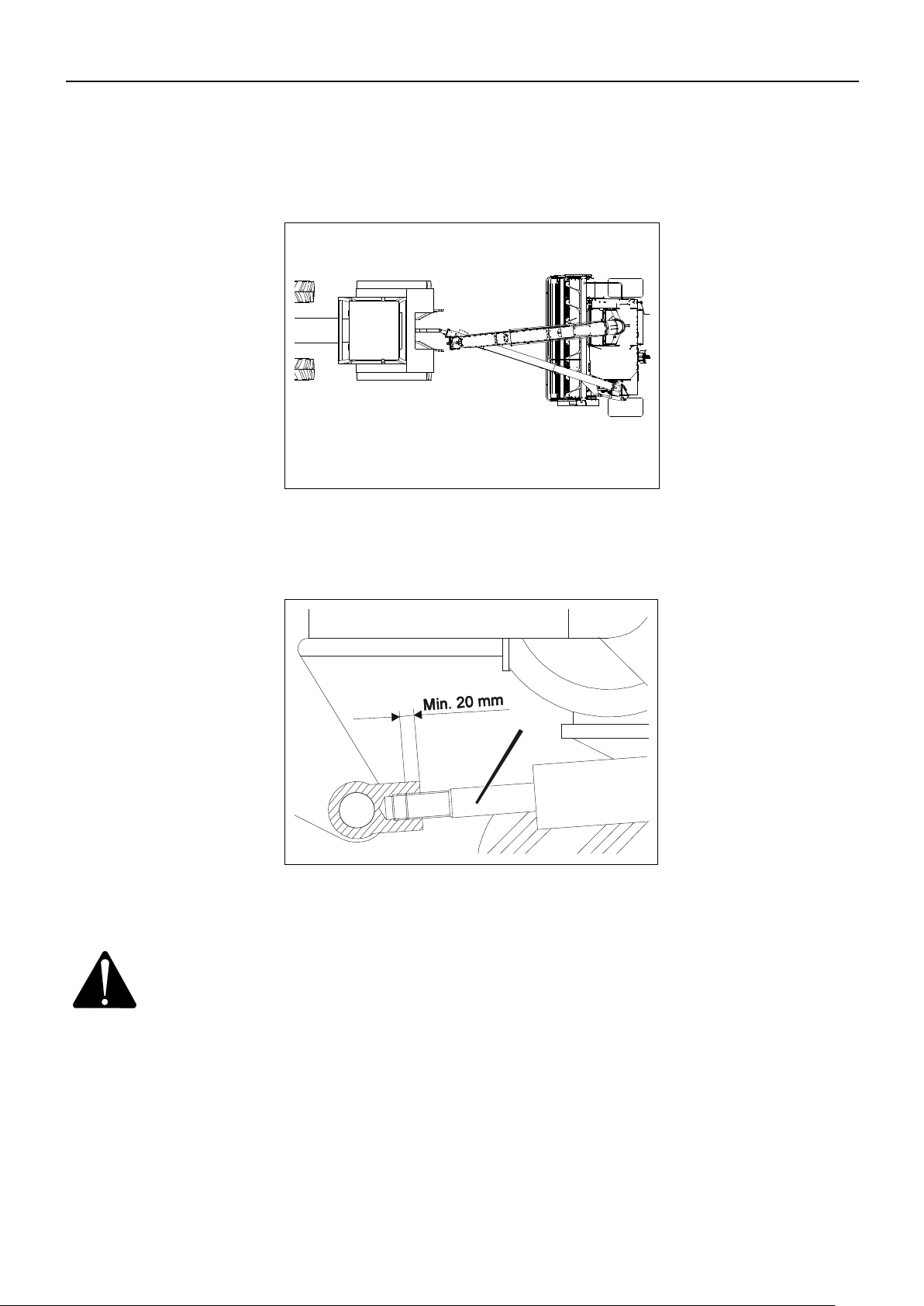

Fig. 2-10 Adjust the length of the PTO shaft so that it:

- in working position has minimum 200 mm overlap, see measure b.

- is not compressed more than the prescribed 30 mm in order not to bottom the shaft,

see measure a.

Adjustment of the length can take place by pulling out or pushing in the drawbar of

the tractor.

Page 30

2. CONNECTION TO TRACTOR

PIGB-186X-05 FCT1360 0218

- 30 -

Fig. 2-11

Fig. 2-11 The height H of the hitch eye must be adjusted so that the PTO shaft is horizontal.

The height can be changed by moving or turning the drawbar bracket.

To ensure longest possible life of the PTO shaft the following applies to standard

PTO shaft without wide angle: The length L1 must be equal to the length L2, i.e. the

centre of rotation P for the drawbar must be as close as possible under the centre

between the joints. The drawbar bracket on the chopper can be moved back and

forth in steps of 25 mm.

IMPORTANT: The drawbar must always be mounted and fastened with 2 bolts.

Page 31

2. CONNECTION TO TRACTOR

PIGB-186X-05 FCT1360 0218

- 31 -

Fig. 2-12

SHORTENING OF THE PTO DRIVE SHAFT

It is necessary to be very careful when shortening the PTO drive shaft. If the PTO

drive shaft is shortened too much, there is a risk that the profile tubes are drawn

apart which may cause serious damage.

Especially on hilly ground when the machine and the tractor have variable angles in

relation to each other. On the other hand, if the PTO drive shaft is not shortened

enough there is a risk of squeezing during sharp turns, which may cause high

frictional forces in the PTO drive shaft, which again will damage the axle joints.

Fig. 2-12 Fasten the halves of the shaft to PTO and PIC (fig. 2.10), respectively, when these

are right opposite each other with the machine in working position. (The longest

distance on this machine). Hold the shaft ends parallel to each other and mark the

wanted shortening, minimum 200 mm overlapping. Shorten all 4 tubes equally.

The ends of the profile tubes must be rounded off and burrs must be removed

carefully. It is very important that the tubes are smooth and clean before greasing.

Grease the tubes carefully before reassembling.

WARNING: Never turn so sharply that there are less than the prescribed 30

mm distance in order not to bottom the shaft. See measurement

a in fig. 2-10.

If the PTO drive shaft bottoms when turning sharply, there is a

risk that the shaft and/or other transmission parts are damaged.

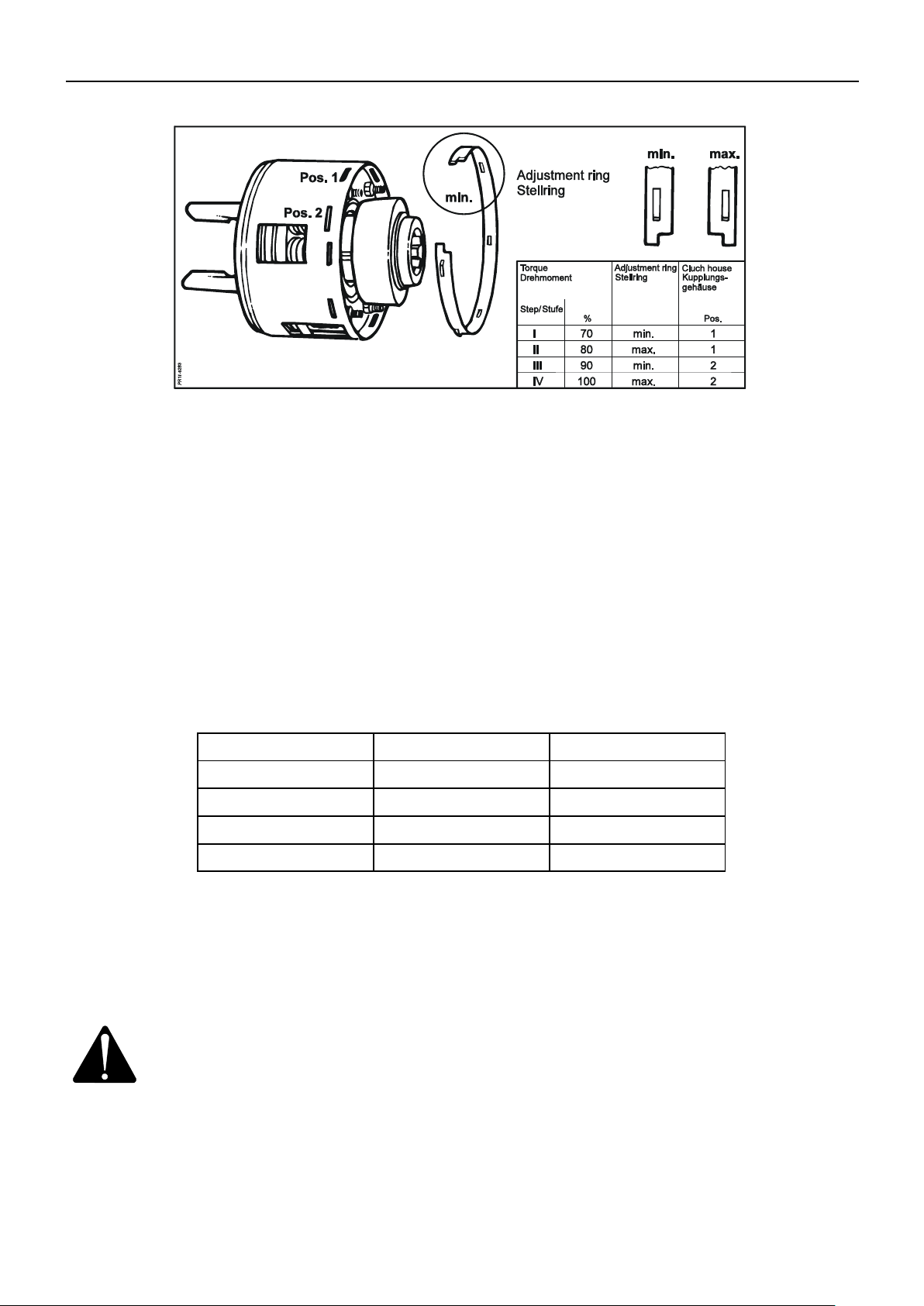

FRICTION CLUTCH

On the PTO drive shaft between the drawbar and the gearbox there is a friction

clutch which ensures that the machine is not overloaded during operation.

Before starting a new machine, the clutch must be "aired". See section concerning

the friction clutch in chapter 7 "MAINTENANCE".

Page 32

PIGB-186X-05 FCT1360 0218

- 32 -

Fig. 3-2

Fig. 3-1

P

R

1

2

-

0

2

0

8

A

3. MOUNTING OF EQUIPMENT

Mounting should take place in a workshop on even ground. The basic machine must

always be mounted correctly to the tractor according to section 2 "CONNECTION TO

TRACTOR" before equipment and accessories are mounted.

HITCH FOR TRAILER

The machine can be supplied with combi-hitch or hydraulic hitch for connection of

trailer. The maximum drawbar load is 2000 kg. Maximum total weight of trailed

wagon: 15000kg.

COMBI-HITCH

3. MOUNTING OF EQUIPMENT

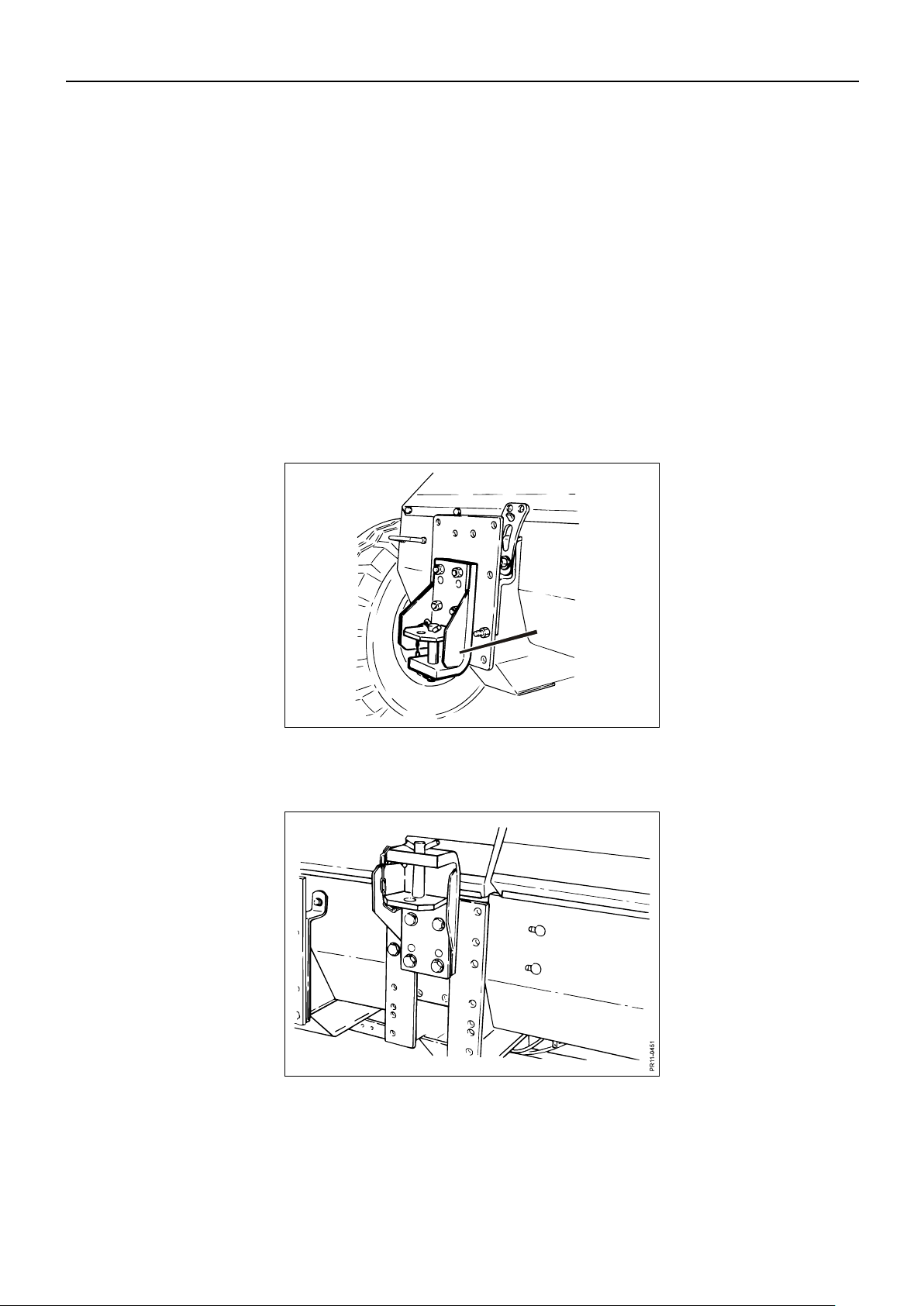

Fig. 3-1 Combi-hitch A mounted in lowest position.

Fig. 3-2 Combi-hitch mounted in uppermost position. This position is used for trailers with

overrun brake, e.g. in Germany.

Page 33

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 33 -

Fig. 3-3

PR12-1747

A

B

C

D

E

HYDRAULIC HITCH HOOK (AUTO-HITCH)

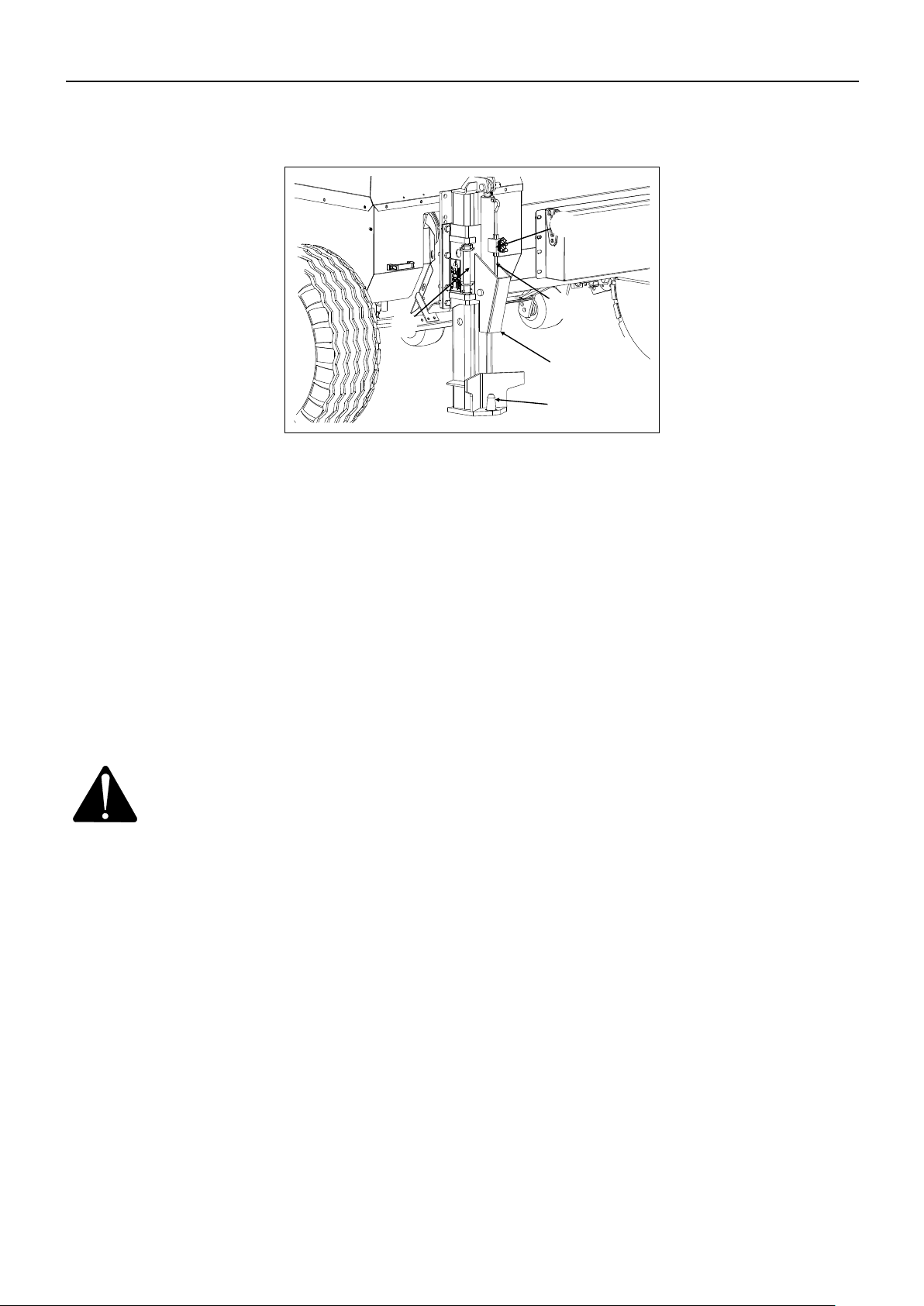

Fig. 3-3 The hydraulic hitch B is equipped with a hitch hook A which is raised and lowered

hydraulically by a double-acting cylinder C. The hoses from the cylinder C are

connected to a free valve on the valve block. Now the hydraulic hitch B can be

operated with one of the 3 toggle switches at the front of the control box.

Fig. 3-3 For connection of the trailer the machine must be reversed to the drawbar of the

trailer. The hitch hook A must be lowered and the hitch eye of the trailer is caught by

the hitch hook. Lift the trailer with the hydraulic cylinder C until it reaches its bottom

position. A hydraulic locking valve E which is mounted on the cylinder C ensures that

the hitch hook A stays in the raised position. If the trailer is equipped with plugs for

lighting and hoses for tipping and brakes these should be mounted subsequently.

IMPORTANT: When driving on public road with a trailer connected to the

hydraulic hitch B, the locking pin D MUST be removed from its

holder and lead through the frame on the hydraulic hitch B so

that the hitch hook A is locked mechanically, see fig. 3-4. This

must be done in order to observe the current traffic rules.

Page 34

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 34 -

Fig. 3-5

PR12-0212

A

B

Fig. 3-4

P

R

1

2

-

1

7

4

8

A

B

C

D

E

Fig. 3-4 The trailer is disconnected as follows: If the locking pin D is placed so that it locks the

hitch hook A, see figure 3-4, the locking pin D is removed and placed in the holder on

the hydraulic hitch B. Then the hitch hook A is lowered by activating the cylinder C.

When the hitch hook A has been lowered completely, the trailer is disconnected. Also

remember to disconnect plugs for lighting and hoses for tipping and brakes, if these

were mounted.

PICK-UP

Connection is preferably carried out on firm and even ground.

The basic machine is connected to the tractor according to section 2 “CONNECTION

TO TRACTOR”.

Fig. 3-5 Wheel the pick-up on the rollers to the machine so that the catch A is engaged.

Mount the 2 pins in order to fix the pick-up to the basic machine.

Attach the relief device to the pick-up at B.

Page 35

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 35 -

Fig. 3-7

Fig. 3-6

PR11-1402

A

Fig. 3-8

P

R

1

1

-

0

2

1

5

A

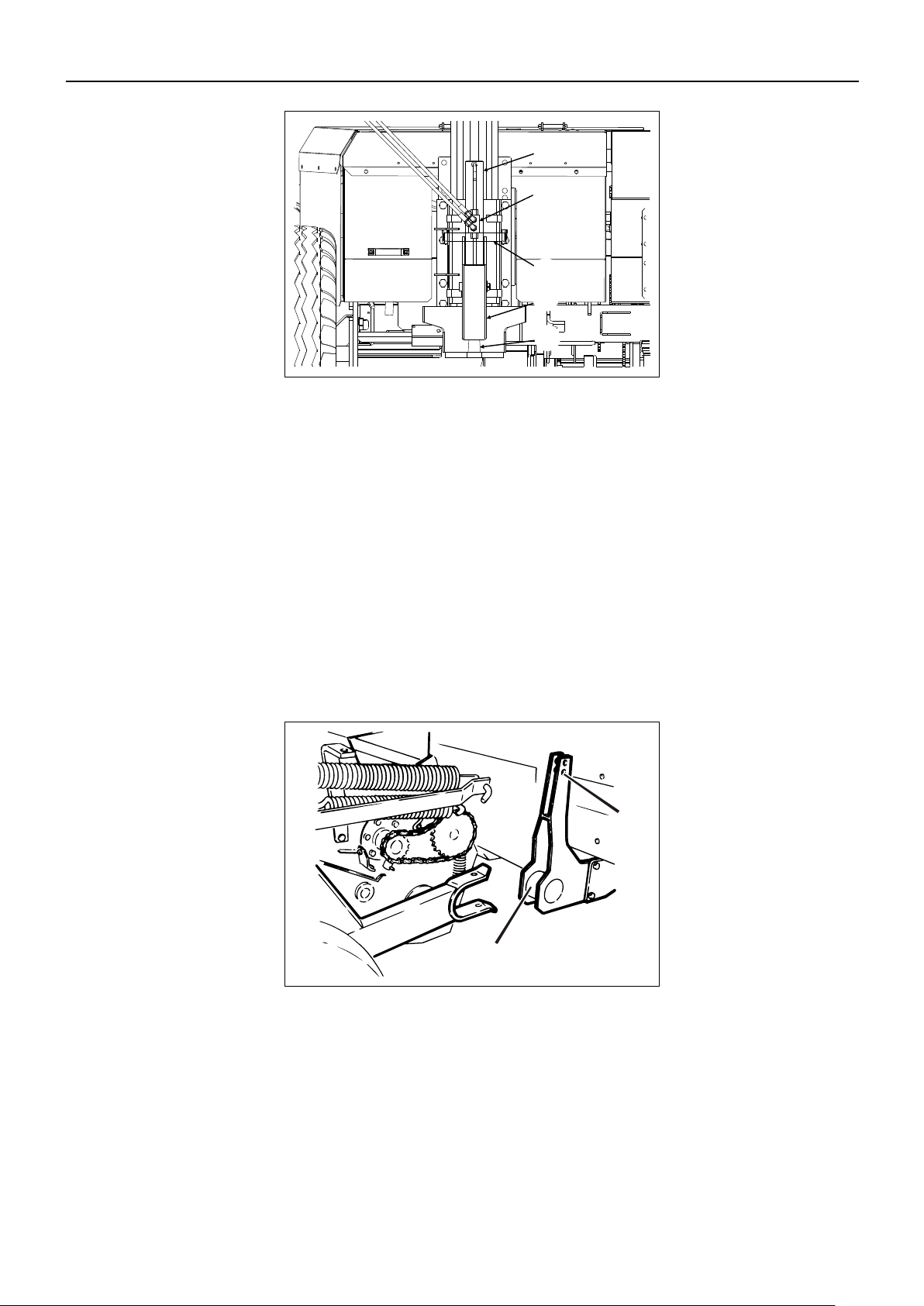

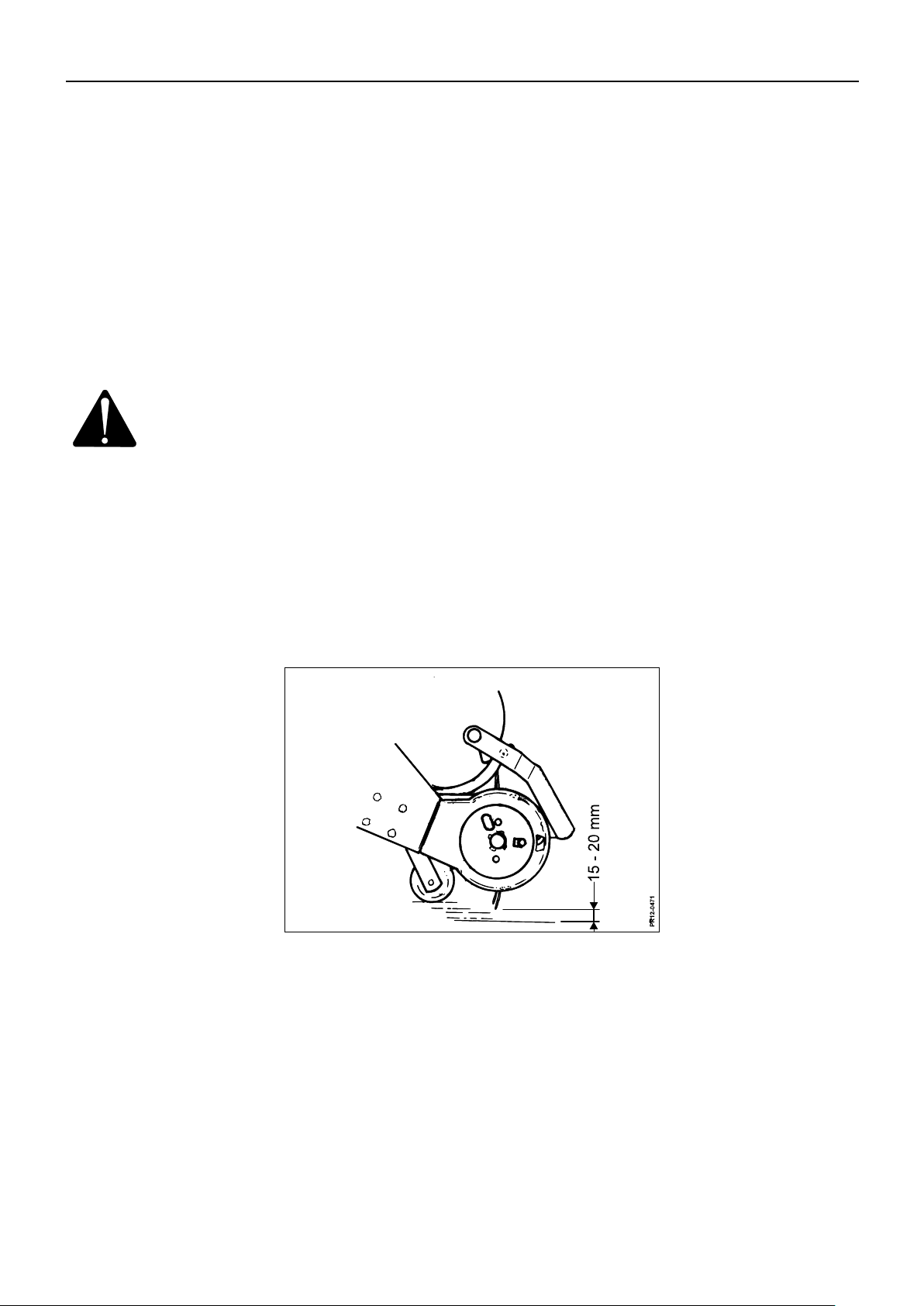

Fig. 3-6 Mount the PTO drive shaft A for the pick-up.

Fig. 3-7 The height of the rollers under the pick-up can be adjusted. Adjust the height so that

there is 15 – 20 mm distance between the point of the pick-up tines and the ground.

Fig. 3-8 Tighten the relief springs with the spindle A until the ground pressure for the pick-up

is maximum 30 kg.

Page 36

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 36 -

Fig. 3-9

PR12-1749

B

A

Fig. 3-10

PR12-1752

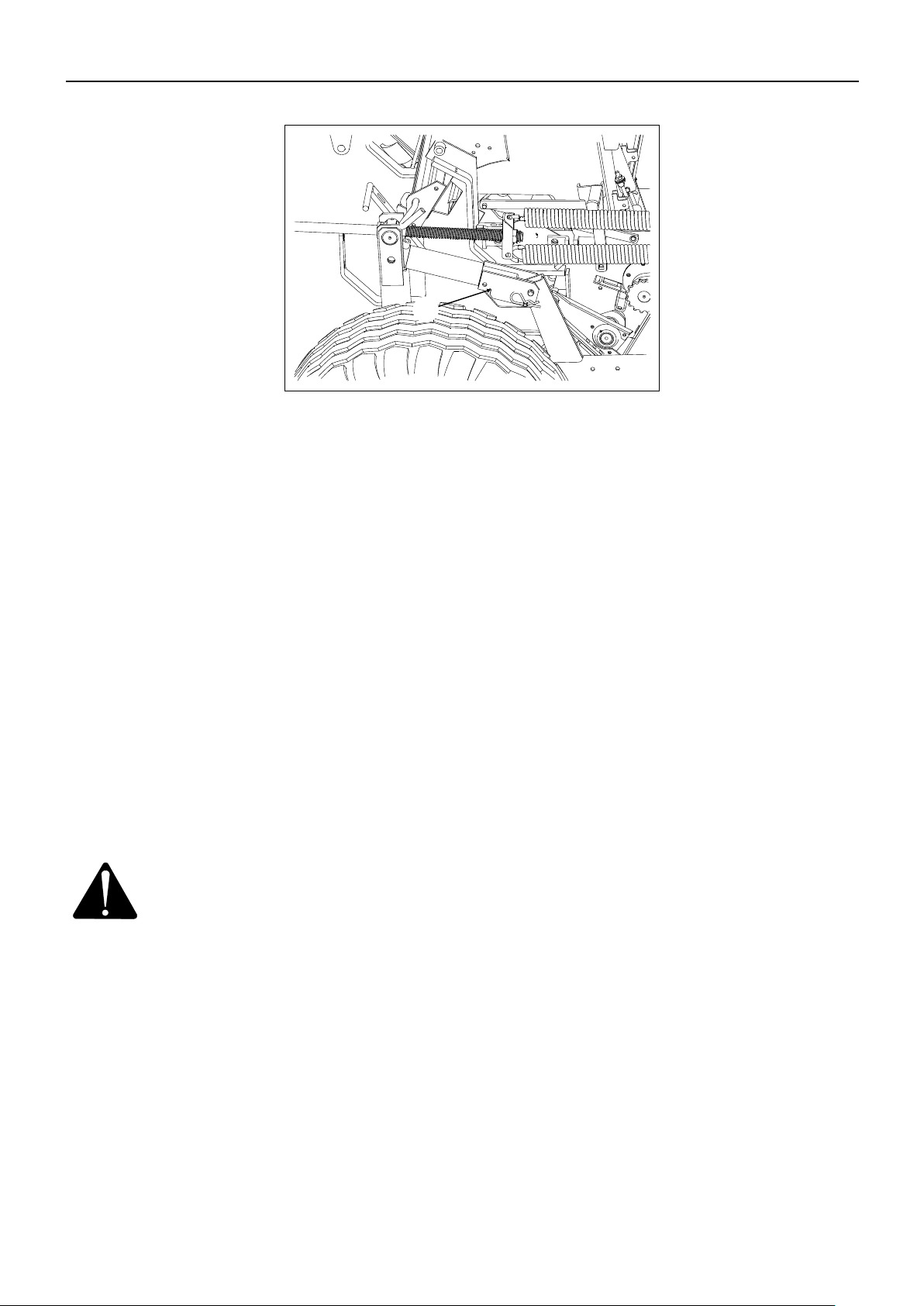

Fig. 3-9 Adjust the stop, B, for lift of the pick-up so that you obtain maximum lifting height but

also avoid that the pick-up collides with the drawbar at A.

Fig. 3-10 Connect the hydraulic hose for lift of auger and front roller to the quick-release

coupling at the left-hand catch.

Page 37

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 37 -

Fig. 3-11

PR12-0449a

B

A

TRANSPORT CONVERSION

Fig. 3-11 The drawbar is converted electro-hydraulically with the joystick on the control box.

The hydraulic cylinder A is equipped with a safety valve B which ensures that the

machine does not make any unintentional movements in case of leaking hoses.

Page 38

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 38 -

PR11-1855

Pos. 1

Pos. 2

Pos. 3

Fig. 3-12

FITTING CHUTES

There are 3 different chute options and 3 different positions of the bracket for chute

turning, in order to accommodate most needs.

NB! Not all machines offer the option for 3 positions of the bracket for chute turning.

CHUTE TURNING

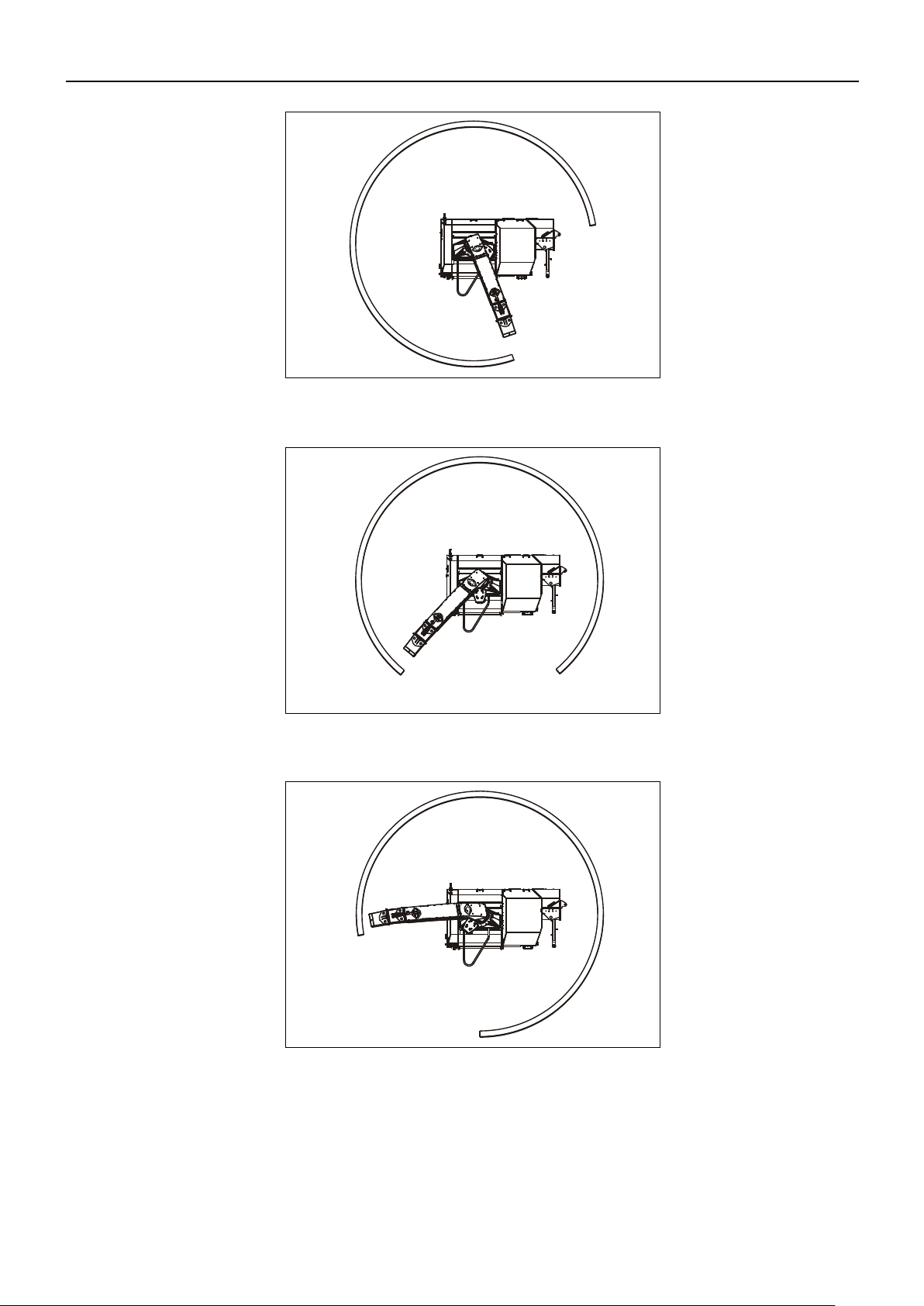

There are the following 3 positions for fitting the chute turning bracket, in order to

optimise unloading to a selected side.

Fig. 3-12 Pos. 1 for unloading to the right

Pos. 2 for unloading both sides. Cannot be used with the collapsible chute.

Pos. 3 for unloading to the left

When the chute is fitted, you must turn carefully from outer position to outer position

in order to ensure that the hydraulic hoses are fitted correctly and are long enough.

Page 39

PIGB-186X-05 FCT1360 0218

- 39 -

Fig. 3-13

PR11-1849

Fig. 3-14

PR11-1850

Fig. 3-15

PR11-1851

Fig. 3-13 Position 1

3. MOUNTING OF EQUIPMENT

Fig. 3-14 Position 2

Fig. 3-15 Position 3

NB! Not all machines offer the option for 3 positions of the bracket for

chute turning. Only position 3 is offered for these machines.

Page 40

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 40 -

Fig. 3-17

P

R

1

1

-

1

7

5

0

Fig. 3-16

PR11-1854

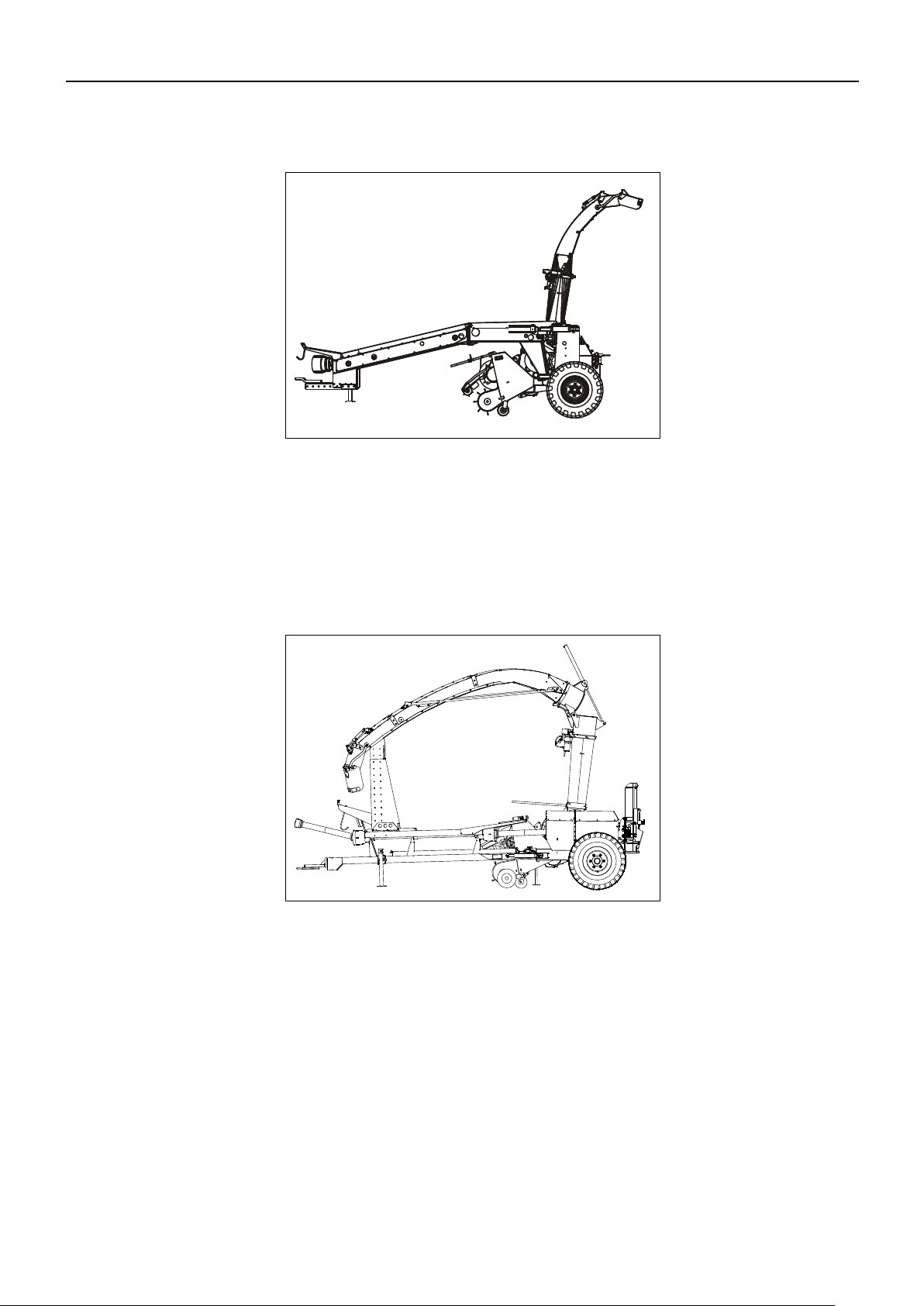

STANDARD CHUTE

Fig. 3-16 This is the standard chute that is supplied with the machine. It is approx. 3.8 metres

high in the transport position.

FOLDABLE CHUTE

Fig. 3-17 The machine can be fitted with a chute that permits loading of very high trailers. This

chute is over 4 m high. Therefore, and also because the chute/delivery chute will

otherwise be overloaded, it must be folded down during transport so that it rests on a

"chair" on the drawbar.

The chute is folded by a hydraulic cylinder which is operated by one of the toggle

switches at the front of the control box.

The chute is operated electro-hydraulically with the joystick and toggle switch on the

control box. Move the drawbar into transport position, turn the chute into a position

above the chair and fold it down until it rests on the chair.

Page 41

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 41 -

Fig. 3-18

PR11-1853

DANGER: The chute is over 4 m high. Be aware of high-voltage lines and keep

a safe distance to these.

WARNING: When you operate the chute make sure that persons keep a safe

distance from the machine. The hydraulic functions must be operated

from the tractor seat.

IMPORTANT: Be careful not to hit the tractor cabin.

IMPORTANT: Do not move the drawbar while the chute is resting on the chair.

IMPORTANT: Do not turn the chute while it is resting on the chair.

IMPORTANT: The chute must always rest on the chair during transport. This is due

to the Road Traffic Act and also because the chute/delivery chute

may get damaged, for instance if you drive fast on uneven ground.

CHUTE FOR PARALLEL OPERATION

Fig. 3-18 The machine can be fitted with a chute that has a transport height of 4.4 metres. This

chute cannot be folded for transport.

Page 42

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 42 -

Fig. 3-19

PR11-1852

A

B

Fig. 3-19 When this equipment is fitted, it is important that an extra spring A is fitted for chute

relief, in order to compensate for the added weight of the chute. Bracket B must be

moved to the indicated position so that the wire is not too short.

Page 43

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 43 -

Fig. 3-20

P

R

1

1

-

0

4

5

0

A

Fig. 3-21

P

R

1

2

-

0

4

5

6

A

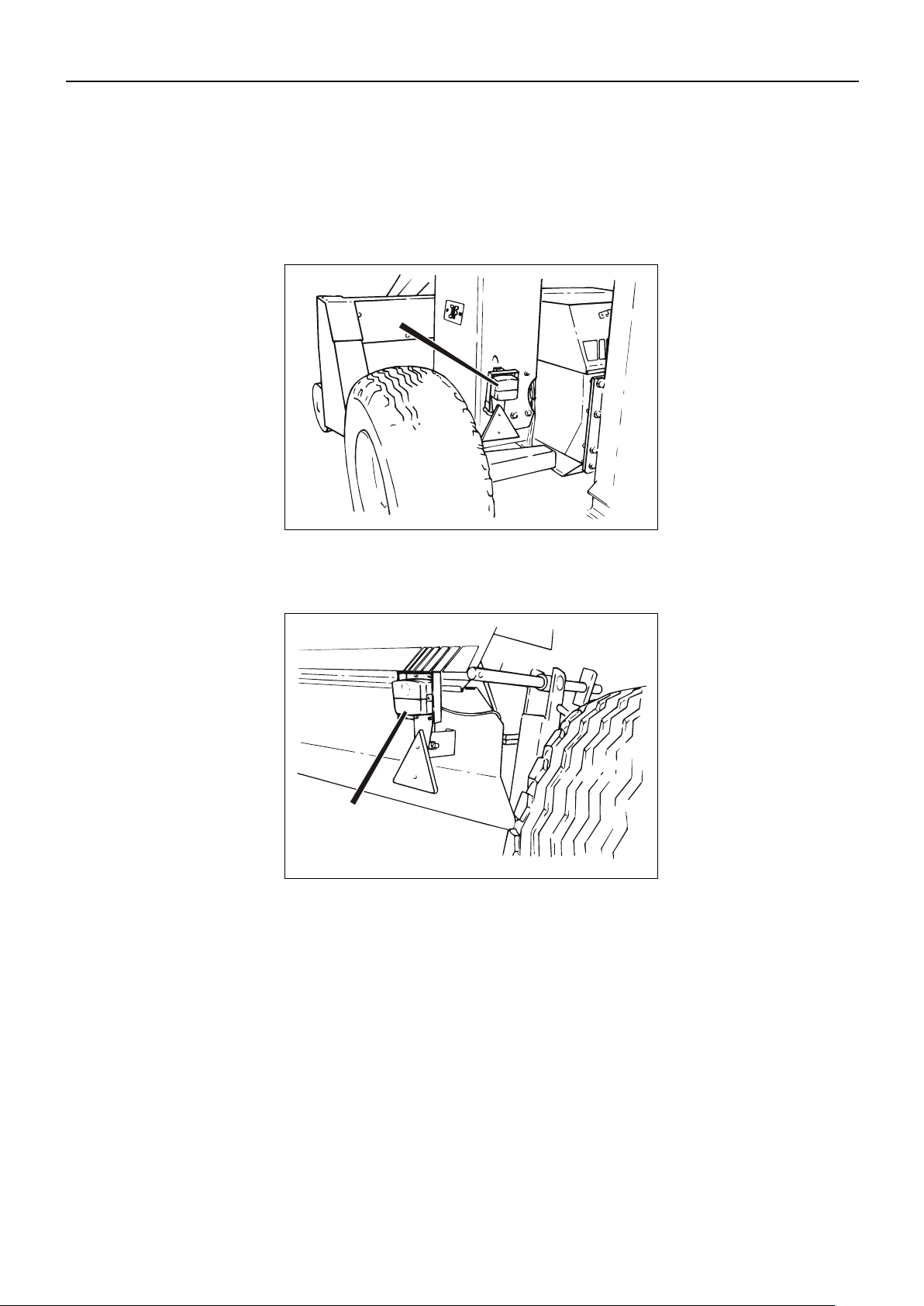

LIGHTING KIT

The machine can be equipped with universal lighting kit consisting of two light units

with tail light and flasher, fittings for assembling plugs and cables and wiring system

with plugs to the tractor. The equipment is easy to retro-fit on your machine.

Fig. 3-20 In the left-hand side the light A is mounted on the main frame right beside the left

wheel.

Fig. 3-21 In the right-hand side the light A is mounted on rear lower guard right beside the right

wheel.

Page 44

3. MOUNTING OF EQUIPMENT

PIGB-186X-05 FCT1360 0218

- 44 -

Fig. 3-22

P

R

1

2

-

0

4

4

9

C

Fig. 3-22 The fitting C with plugs for the 2 light units is placed rearmost at the top of the

bracket for the drawbar.

The cable with the plug for the tractor is placed along the drawbar together with the

hydraulic hoses.

Page 45

PIGB-186X-05 FCT1360 0218

- 45 -

PR12-1751

A

Fig. 4-2

Fig. 4-1

PICK-UP

4. ADJUSTMENTS

4. ADJUSTMENTS

Fig. 4-1 The pick-up is equipped with support rollers made of steel which are adjustable in

height. You should keep the pick-up at such a height that the tines do not hit the

ground and leave earth in the crop and can also pick up the grass without waste.

KONGSKILDE recommends a distance between the pick-up tines and the ground of

15 to 20 mm.

Fig. 4-2 The distance A between the pick-up roller and the crossbar is adjusted so that they

are as close as possible without colliding.

Page 46

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 46 -

Fig. 4-3

The auger on the pick-up is equipped with a slip clutch. The slip clutch of the auger is

adjusted so that it releases before the other friction clutches in the machine.

The highest capacity is obtained by working at a forward speed where you drive

without blockage in the auger. If there is a blockage around the auger you stop and

force the crop out of the machine by using the reverse function. See also chapter 6

"WORKING IN THE FIELD".

A continuous and even flow through pick-up and auger is the best way to avoid

blockages inside the machine, and thus avoid long operational stoppages.

The operator should always ensure spare friction discs for the slip clutch on the

auger are in the tool box. If this clutch has often been in operation, the coating of the

friction discs is worn and it cannot transfer sufficient transmission. It may therefore be

necessary to replace the friction discs, but remember they have to be of the same

number and quality.

OPENING OF ROTOR HOUSING

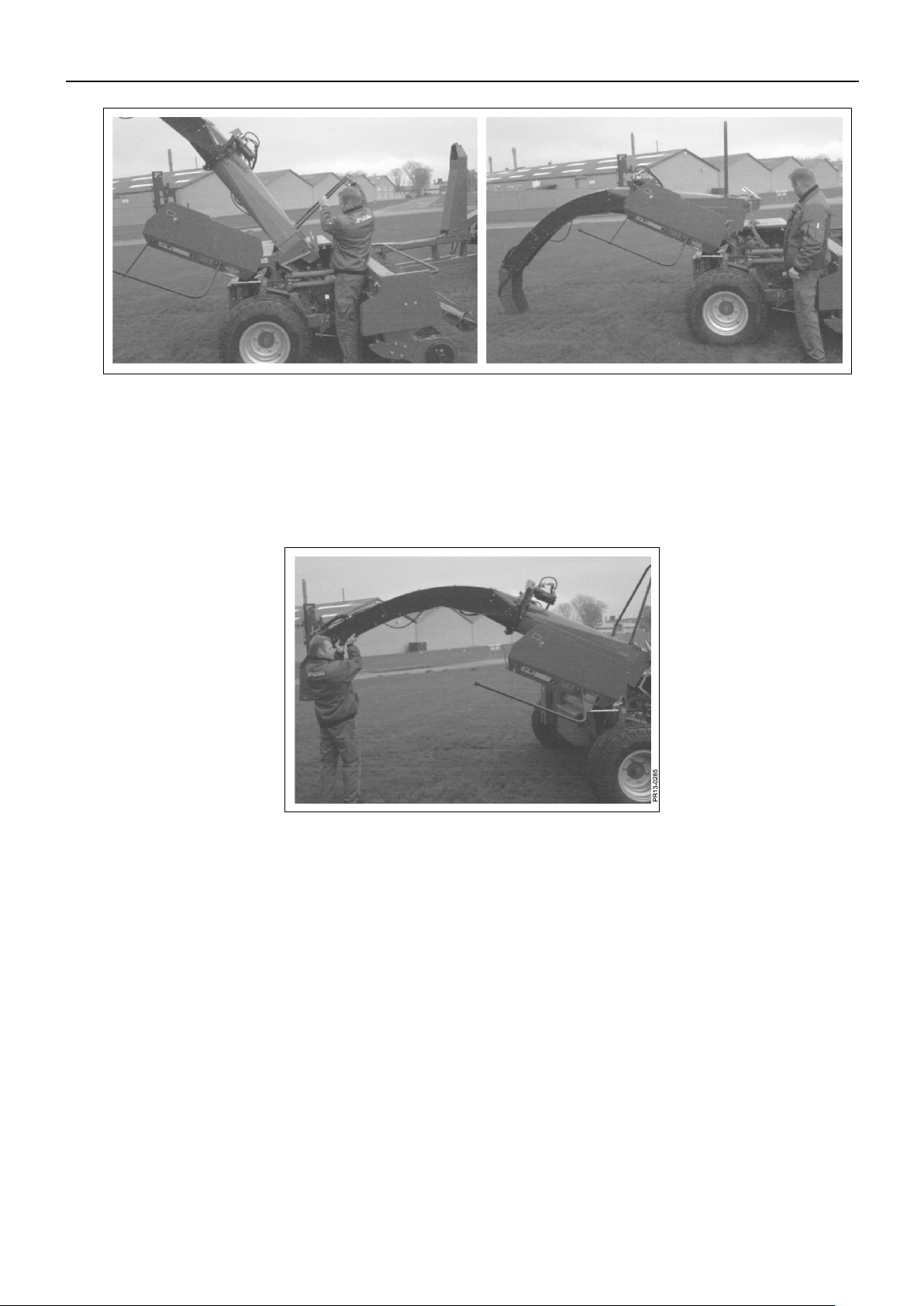

Fig. 4-3 The chute must be lowered in order to open the rotor housing. In order to make this

easier, the chute is relieved by strong springs.

DANGER: First ensure that no other persons than the operator are in the

vicinity.

WARNING: The hydraulically collapsible chute (accessory) is so heavy that

the rotor housing cannot be opened manually for access to the

chopping rotor. Instead, please use the procedure described in Fig.

4-9 – Fig. 4-13.

WARNING: The chute for parallel operation (accessory) requires two people to

open and close the rotor housing, as the weight of this exceeds the

permitted amount.

Page 47

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 47 -

PR11-1766

Fig. 4-4

Fig. 4-6

Fig. 4-5

Fig. 4-4 1) Turn the chute to the rear. Turn the deflectors to the middle of the working area.

Fig. 4-5 2) Open the cover of the rotor housing and the left cover.

Fig. 4-6 3) Open the clips on the front of the rotor housing.

Page 48

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 48 -

PR13-0284

Fig. 4-7

Fig. 4-8

Fig. 4-7 4) Using the handle, turn the chute backwards and down, which will open the rotor

housing.

5) The rotor housing is closed in the same way, although in the reverse order.

Fig. 4-8 When the rotor housing is closed, it is a good idea to lift the chute the first part of the

way.

Page 49

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 49 -

PR12-1753

A

Fig. 4-9

P

R

1

2

-

1

7

5

4

B

B

Fig. 4-10

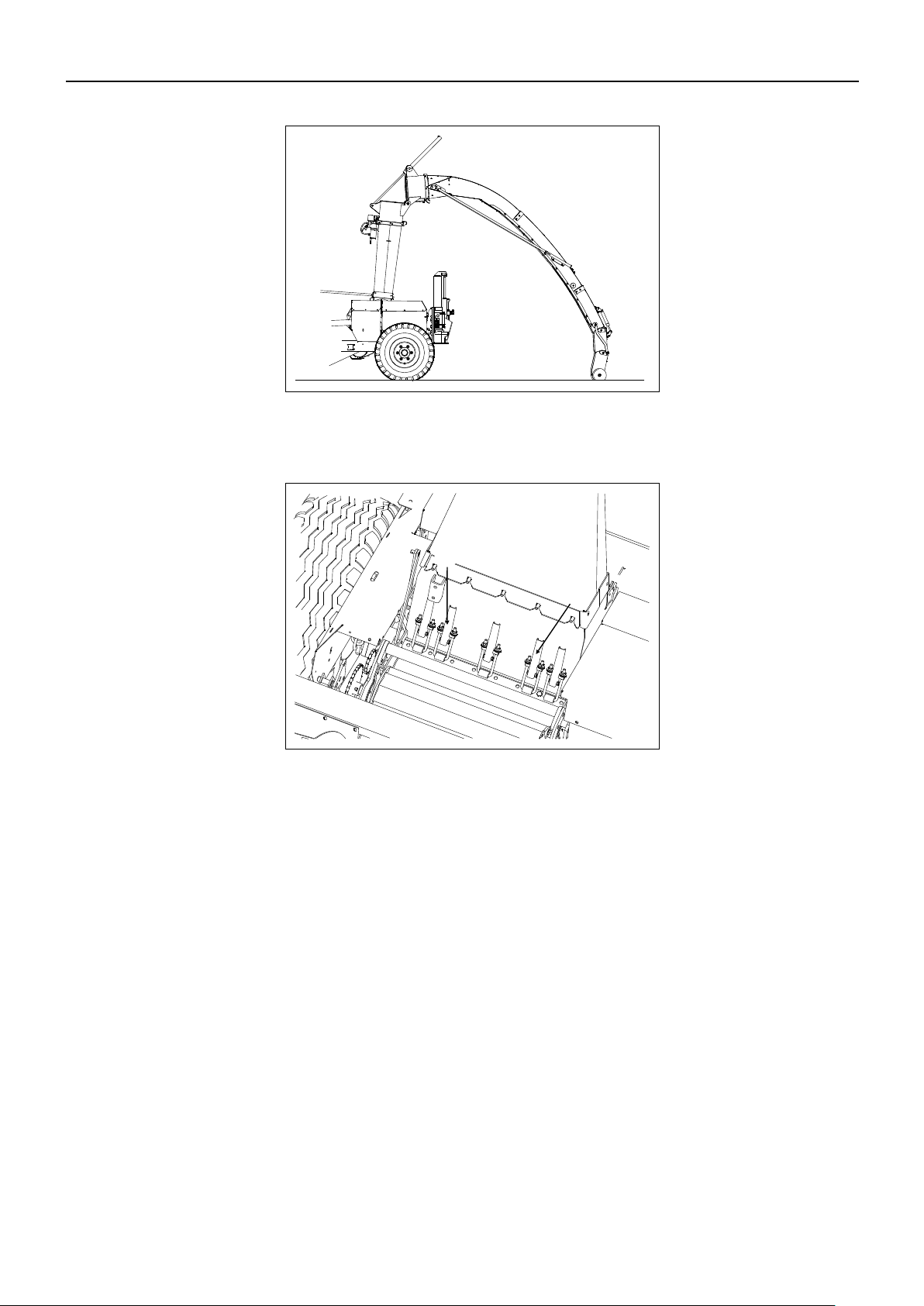

COLLAPSIBLE CHUTE

WARNING: The chute is so heavy that the rotor housing cannot be opened

manually when you want to get access to the chopping rotor. Use

this procedure instead:

DANGER: First, make sure that no persons are near. The hydraulic functions

must be operated from the tractor seat.

Fig. 4-9 Turn the chute to the rear. Adjust the deflectors A to the middle of the working area.

Fig. 4-10 Fold down the chute to about 1.5 m above the ground and mount the wheels B with

the pin and split pins.

Page 50

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 50 -

PR12-1756

C

C

Fig. 4-12

P

R

1

1

-

1

7

5

5

Fig. 4-11

Fig. 4-11 Fold down the chute until the wheels rest on the ground.

Fig. 4-12 Now the lock clamps C at the front of the rotor housing can be opened safely.

Page 51

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 51 -

PR12-1757

Fig. 4-13

Fig. 4-13 Move the chute cylinder in direction “Chute closed”, whereby the rotor housing is

opened.

When closing the rotor housing, follow the same procedure in reverse order.

Page 52

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 52 -

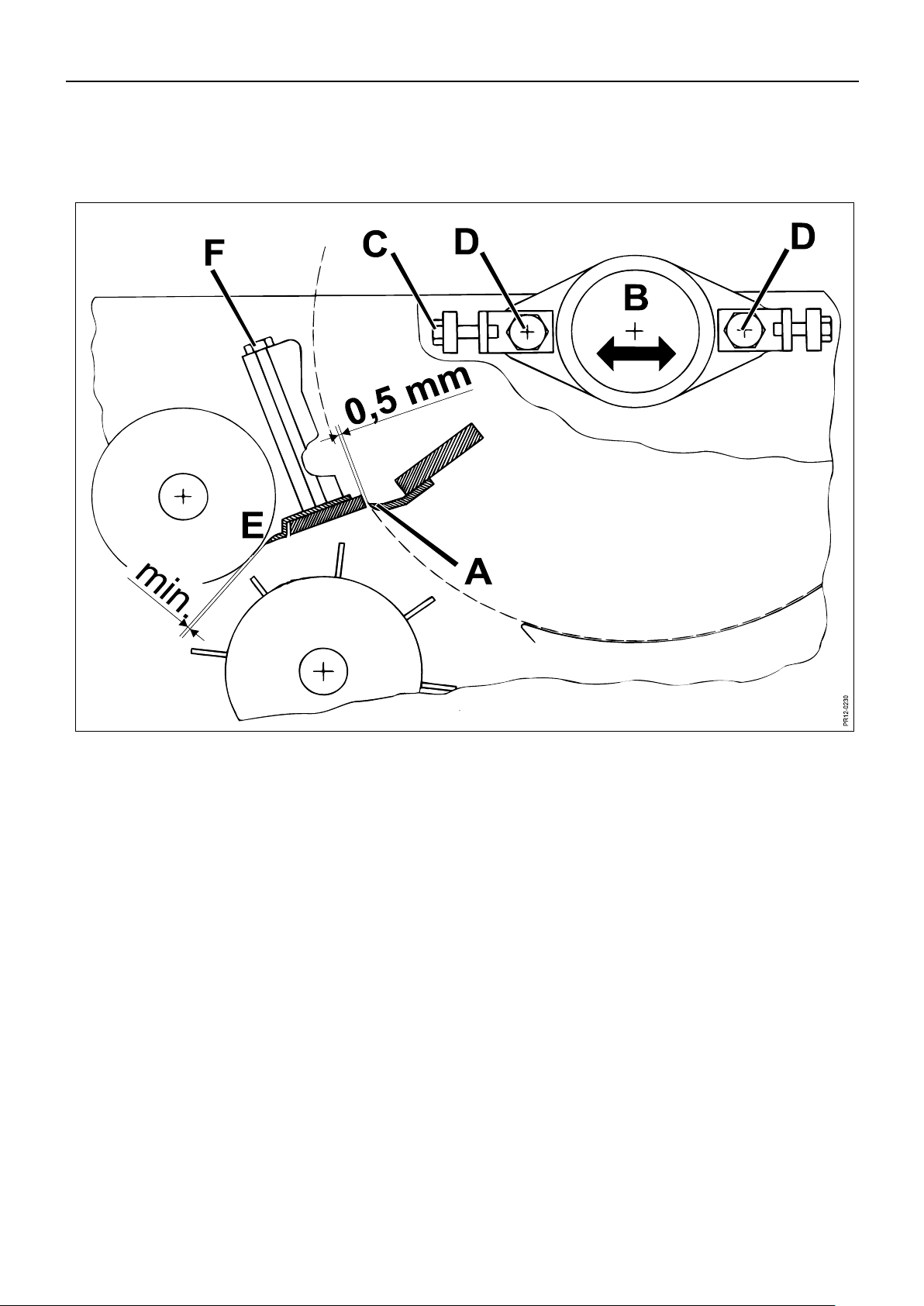

Fig. 4-14

ROTOR AND ROLLER SECTION

Fig. 4-14 The distance A between the blades of the rotor and the shearbar must be checked

regularly with the delivered gauge (distance measuring device). You should aim at a

distance of 0.5 mm. If it is necessary to adjust the distance, loosen the 2 bearing

housings B and adjust with the screws C. When the distance has been checked, the

bolts D of the bearing housings are tightened with a torque wrench to 40 kgm (400

Nm).

The machine is equipped with a scraper for the smooth roller E. The scraper is

mounted together with the reversible shearbar just mentioned.

The scraper is placed as close to the smooth roller E as possible without touching it.

The distance between the scraper and the smooth roller should be maximum 0.5

mm. Tighten the bolts F with a torque wrench to 10-12 kgm (100-120 Nm). Wrong

adjustment of the scraper may result in overheating of the smooth roller and

operational stoppage.

Page 53

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 53 -

Fig. 4-15

PR12-0458

A

B

Fig. 4-16

P

R

1

1

-

0

2

3

1

M

a

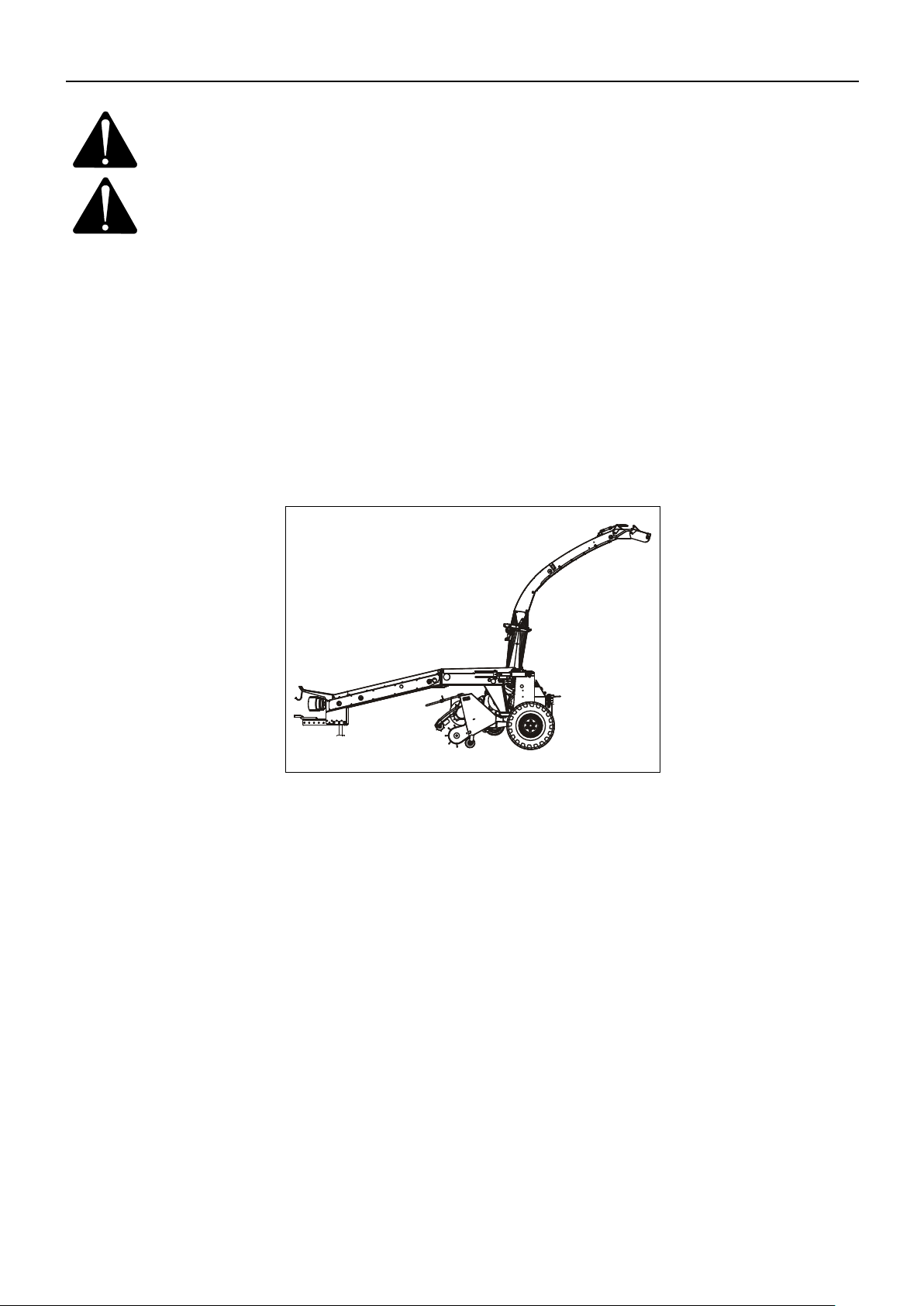

x

.

3

m

m

G

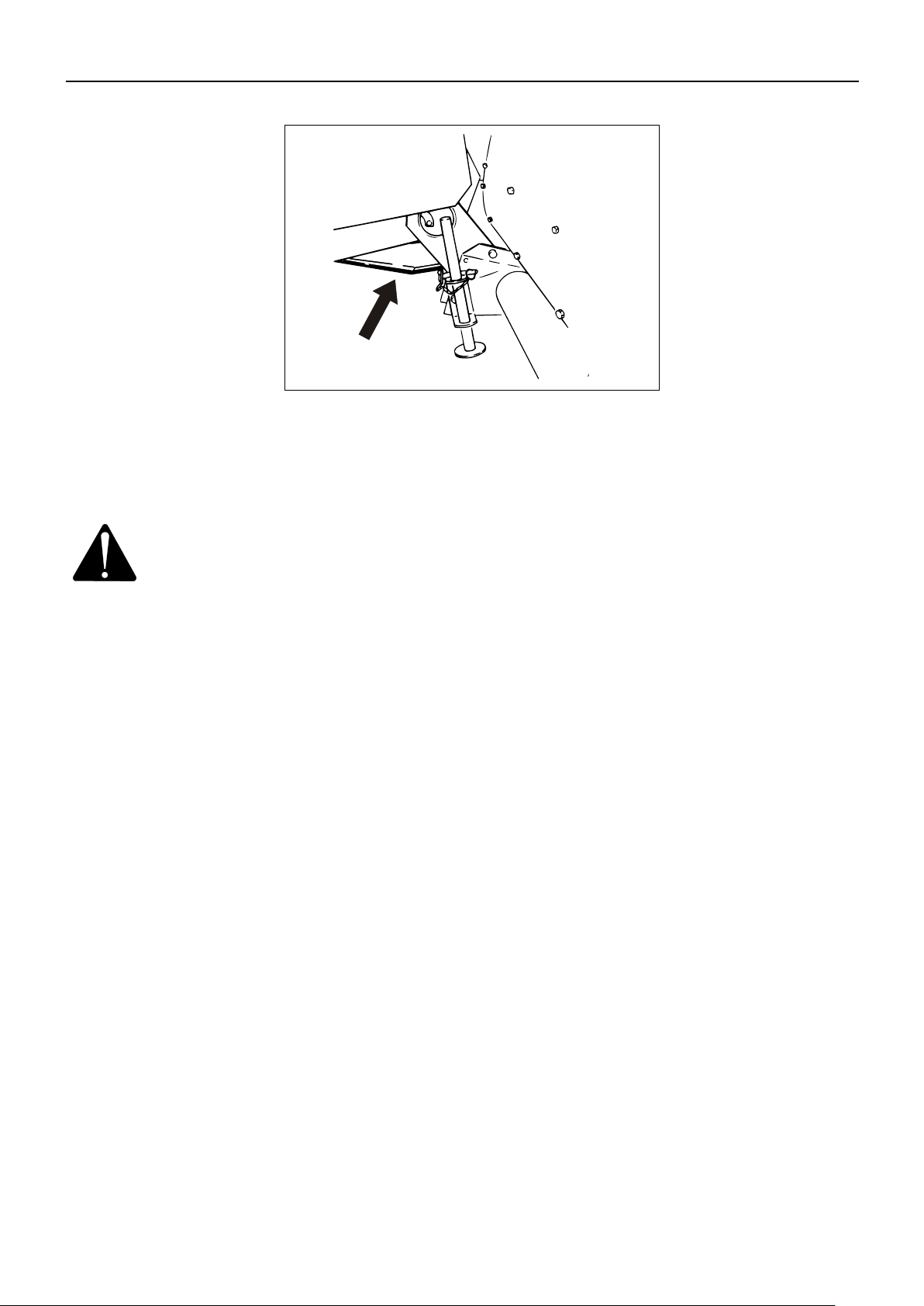

Fig. 4-15 The scraper is dismounted by removing the screws F (on fig. 4-14), which also

secure the shearbar, after which scraper and shearbar can be pulled out of the

opening A in the rotor housing. The spring B for the serrated roller must be loosened

or dismounted to get enough space.

If the shearbar has been worn, it can be reversed for a new sharp edge.

Fig. 4-16 The distance between the smooth roller and the serrated roller should be maximum 3

mm. Adjustment is made with the bolts G at both sides of the rotor housing.

Page 54

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 54 -

Fig. 4-17

PR11-0332

M

i

n

.

0

,

5

m

m

Fig. 4-18

PR11-1404

A

Fig. 4-17 Under some conditions, crop substance (small particles) can accumulate in the

shaded area and get so compact that this may result in an overloading of the

transmission driving the rollers.

Check the area after every 8 hours of operation and remove possible crop residue.

Check, and if necessary adjust, the distance between scraper and smooth roller. The

checking frequency can be reduced when the operator knows the machine under all

conditions.

Fig. 4-18 The roller chain for feed intake and pick-up, front left-hand side, should be kept

sufficiently tight. Chain adjustment takes place by means of spacers A.

Page 55

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 55 -

Fig. 4-19

P

R

1

2

-

0

2

2

2

B

Fig. 4-19 Under the roller section a bottom plate B can be mounted as option. This plate can

be mounted when working in very dry and/or short crops to avoid waste under the

rollers.

IMPORTANT: When working under normal conditions we recommend you to

drive without this bottom plate as, otherwise, material can

accumulate under the rollers causing reduced capacity and

unnecessary overload of the transmission.

However, when driving in a crop where there is an excessive

waste under the rollers, the bottom plate should be mounted.

Waste material should be removed on a regular basis.

Page 56

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 56 -

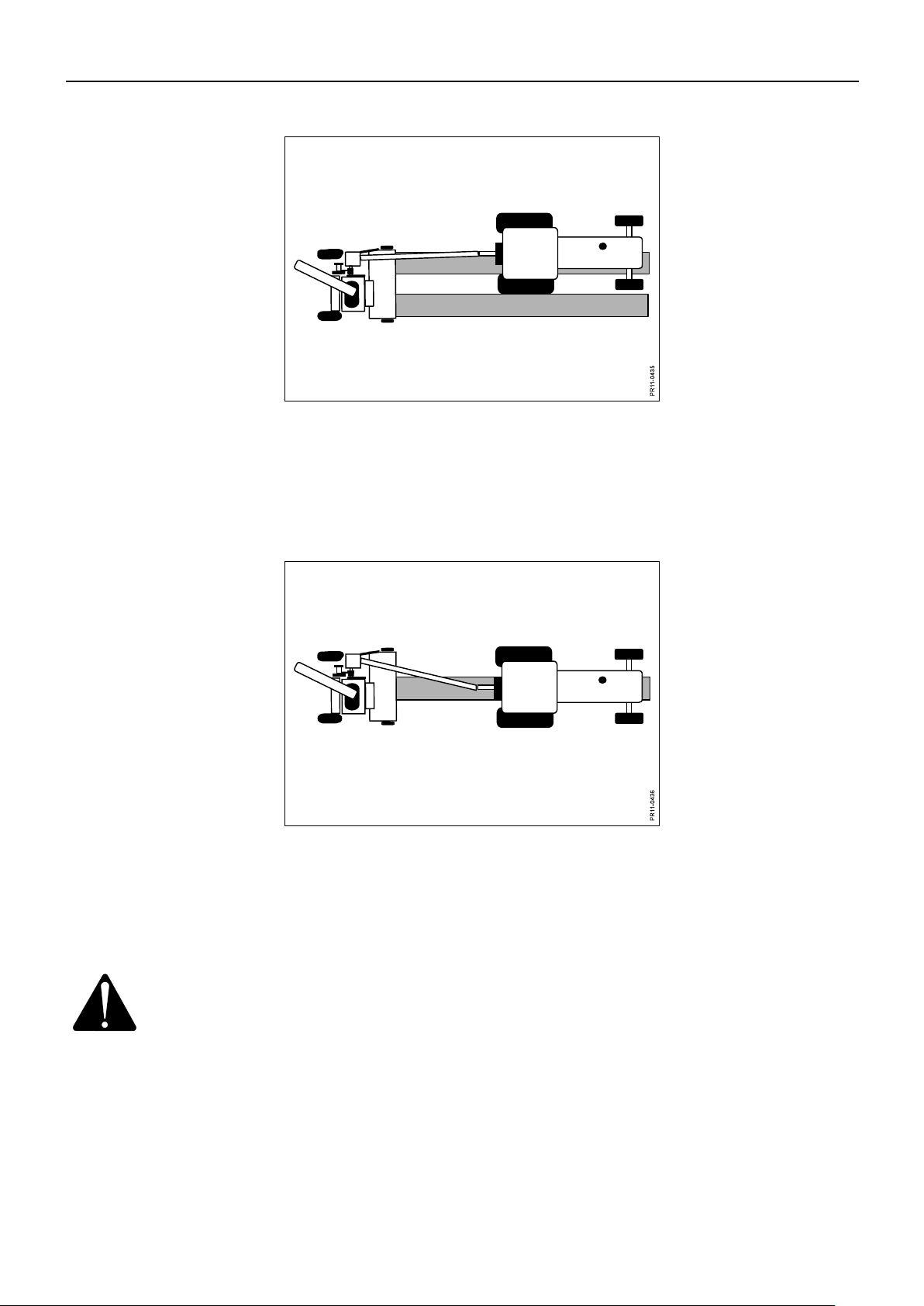

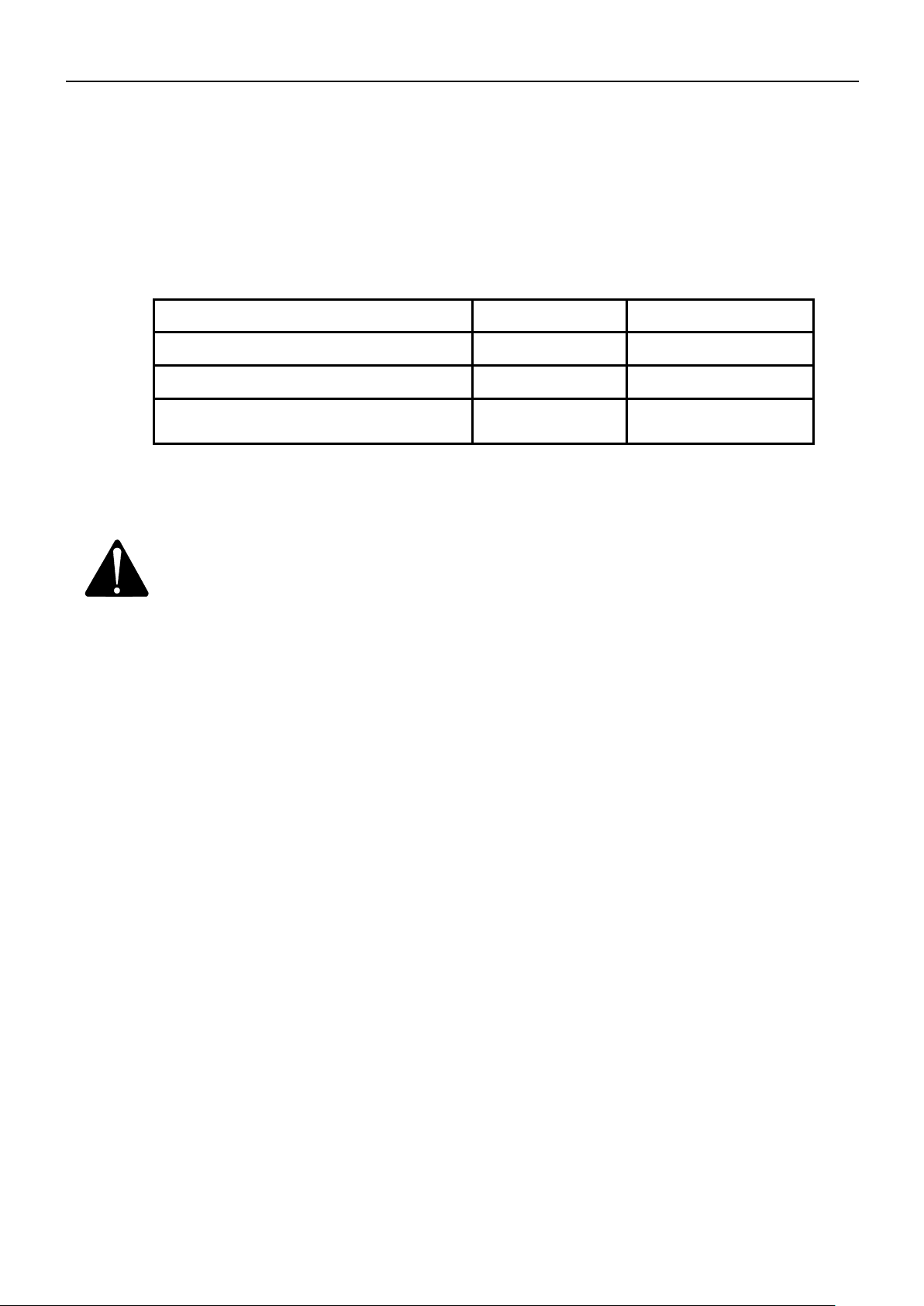

Adjustment

Theoretical cutting length

1

15 mm

2

9 mm

Fig. 4-21

PR11-0217

Fig. 4-20

CUTTING LENGTHS

Fig. 4-20 The cutting length is changed by shifting between 2 placements of the V-belts driving

the gearbox for the feed rollers.

The figures in the table indicate the theoretical cutting length in mm.

Fig. 4-21 The cutting lengths can be doubled by removing every second row of blades in the

rotor.

Page 57

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 57 -

Fig. 4-22

P

R

1

1

-

0

2

3

2

M

i

n

.

1

2

m

m

REPLACEMENT AND ADJUSTMENT OF BLADES

When replacing a single blade the blade must be placed at the same distance to the

shearbar as the existing blades. To ensure that the rotor is in balance it may be

necessary also to replace the opposite blade as a used blade has a different weight

compared to a new blade.

Even if there is no visible damage to the blade bolts, they should always be replaced

together with the blades as they might have been overloaded.

CAUTION: Check the distance between the blade and the shearbar (0.5

mm) with the supplied gauge before the bolts are tightened.

WARNING: Only use original blade bolts when replacing. Tighten the blade

bolts with a torque wrench to 40 kgm or with the supplied

spanner using approx. 40 kg leverage.

Fig. 4-22 When the blades have been worn max. 8 mm or to the first bend, i.e. approx. 12 mm

above the straight piece they must be replaced.

DANGER: When all blades on the rotor have been worn and the rotor

adjusted towards the shearbar, it MUST be adjusted back again

before new blades are mounted. Otherwise there is a risk that

the new blades collide with the shearbar when the rotor is

turned.

Page 58

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 58 -

Fig. 4-23

P

R

1

1

-

0

4

7

0

1

7

8

Ø

4

8

0

PR11-1881

A

Fig. 4-24

Fig. 4-23 When mounting new blades they must be pulled out so that the outer diameter on the

rotor is 480 mm (from rotor tube to blade point = 178mm).

Fig. 4-24 When replacing blade bolts, it is important to ensure that the area A under the bolt

heads is greased.

Page 59

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 59 -

GRINDING

Adjustment of the PTO drive shaft for the rotor to or from grinding position,

respectively, may only take place when the tractor and the machine have been

stopped and the rotor has come to a complete standstill. The rotor may only

rotate when the grinding device is in grinding position.

Check before grinding:

- that the grindstone is undamaged.

- that the device is easily sliding back and forth.

- that the device is parallel with the rotor.

The grinding device is correctly adjusted from the factory and therefore there is

normally no need for adjustment, but if it has been dismounted adjustment can be

made at the oblong holes of the lateral guides. The bolts must be tightened firmly

after the adjustment.

The stone is fed by turning the handle.

Normally you should grind the blades once a day – but avoid too much grinding

since it will reduce the life of the blades.

CAUTION: Protect your eyes – always use safety glasses when grinding.

The guard above the grinding device must be closed while

grinding.

Page 60

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 60 -

Fig. 4-25

P

R

1

1

-

0

2

1

8

Fig. 4-26

P

R

1

2

-

0

4

4

6

a

A

GRINDING OPERATION

1. Lift the guard above the grinding device.

Fig. 4-25 2. Lower the guard between the grinding device and the rotor so that there is free

space between the device and the rotor.

Fig. 4-26 3. Adjust the grindstone so that there is 2-3 mm clearance between the stone and

the blades by turning the handle A.

Page 61

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 61 -

Fig. 4-27

Fig. 4-28

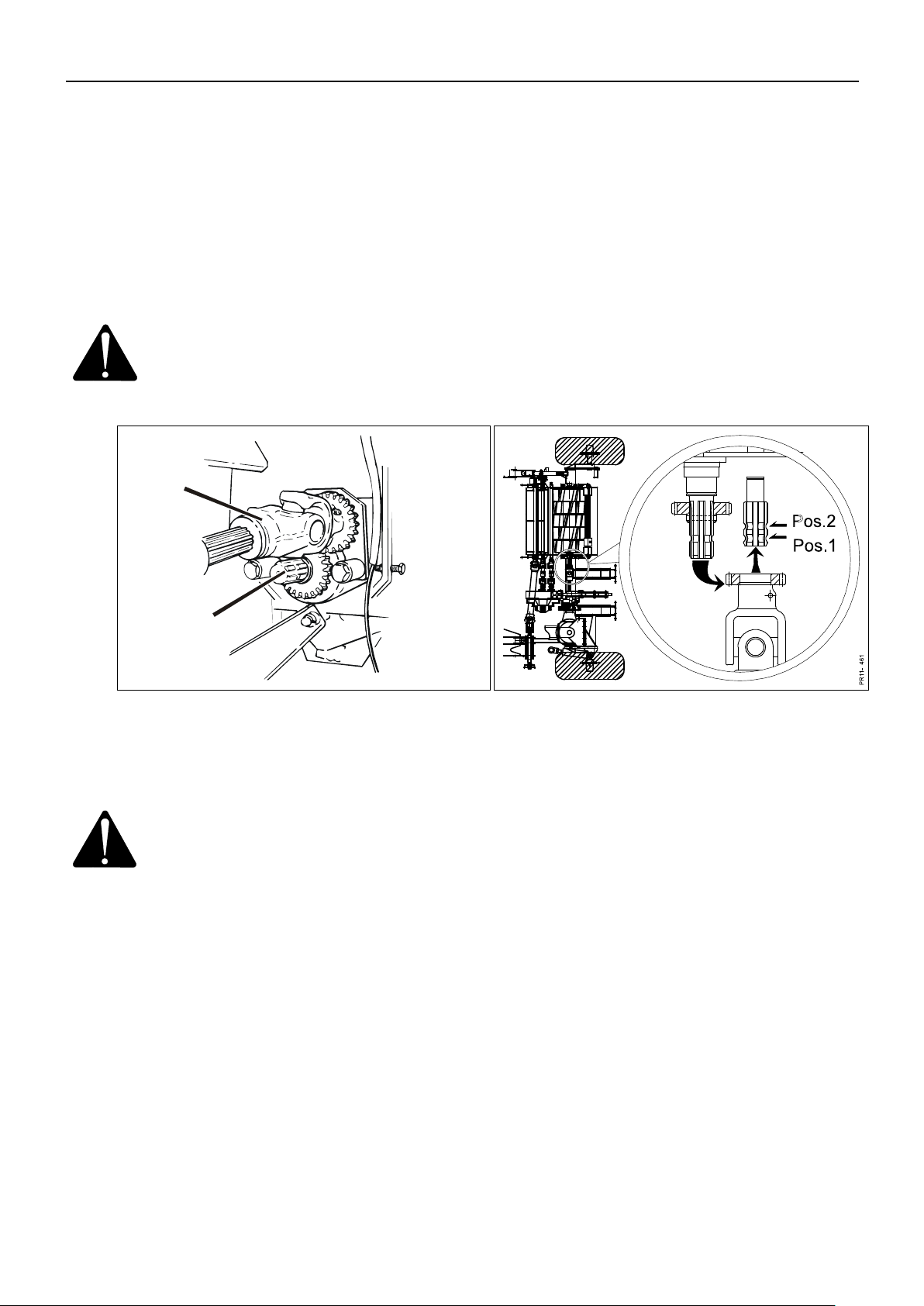

Fig. 4-27 4. Mount the PTO drive shaft for the rotor on the free pin on the rotor housing.

Fig. 4-28 The PTO drive shaft must be fixed at pos. 2 whereby the gear wheels are

engaged and the rotor will rotate in the opposite direction.

5. Close all guards.

6. Start the tractor and keep the rpm at a little above idle speed.

Fig. 4-26 7. Feed carefully by turning the handle A until the stone touches the blades. Move

the stone in a sliding movement across the whole rotor and back again. Feed

some more and repeat the movement across the whole width of the rotor so

that the blades in the whole width of the rotor are sharpened.

8. Push the handle in after grinding. Stop the tractor and when the rotor has come

to a complete stop, the guard between the device and the rotor must be lifted

back into its right position. The PTO drive shaft for the rotor must be moved

back to the pin for normal direction of rotation of the rotor.

WARNING: REMEMBER, only grind with CLOSED guards.

For safety's sake check the distance between blades and shearbars again with the

gauge.

Check wear of the grindstone regularly. If the stone has been worn down to a

thickness of 10 mm it must be replaced.

Page 62

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 62 -

Fig. 4-29

P

R

1

1

-

0

2

3

7

Max. 5 mm

1

5

º

ROUGH GRINDING

Fig. 4-29 To avoid unnecessary power consumption and excessive wear of the grindstone

when working with the harvester, it is necessary to make a rough grinding or

adjustment of the blades when the cutting edge is 5 mm wide or more. Grind the rear

edge to an angle of approx. 15°.

Rough grinding can be made by means of an angle grinder with the rotor and blades

positioned in the machine.

CAUTION: Be careful not to grind down the cutting edge (front edge) of the

blades.

Block the rotor with a firm object (a piece of wood or the like)

during rough grinding to make sure that the rotor does not

move during this operation.

Page 63

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 63 -

Fig. 4-30

PR12-0439

B

C

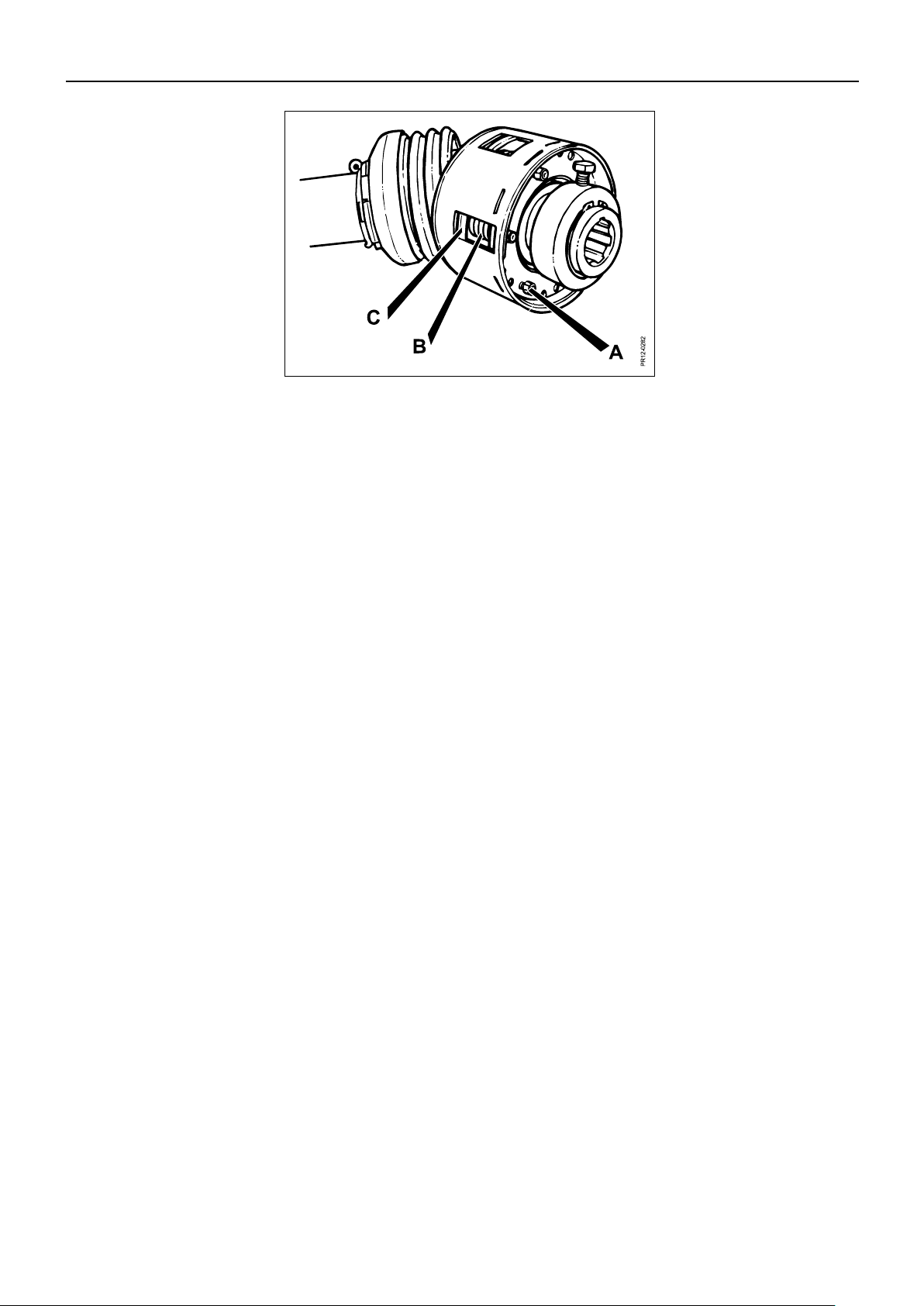

REVERSE

The reverse function can be used at full rpm (1000 rpm on the PTO), but we

recommend you to reduce the rpm to relieve the machine as much as possible

and reduce the wear of the rubber disc.

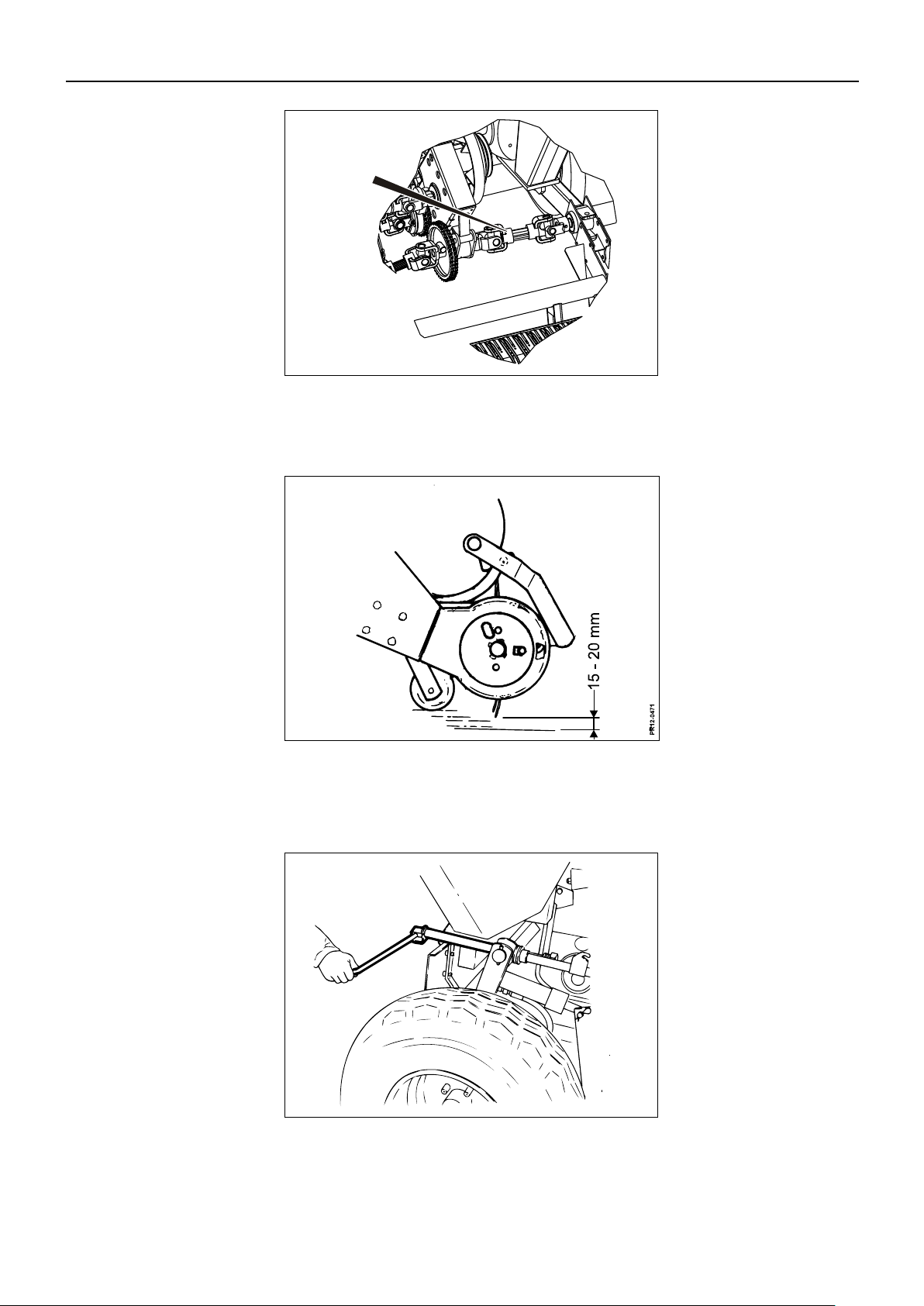

Fig. 4-30 During reverse, the overlap between the steel friction disc and the rubber disc is 5+/-

3mm. It is not necessary to make any adjustment in case of wear because the

cylinder always has the constant pressure which is determined by the pressure relief

valve.

CAUTION: Only use the reverse function shortly each time to ensure

correct functioning and long life of the rubber disc.

Page 64

4. ADJUSTMENTS

PIGB-186X-05 FCT1360 0218

- 64 -

Fig. 4-31

P

R

1

2

-

0

4

3

8

(430 mm)

450 mm

A B

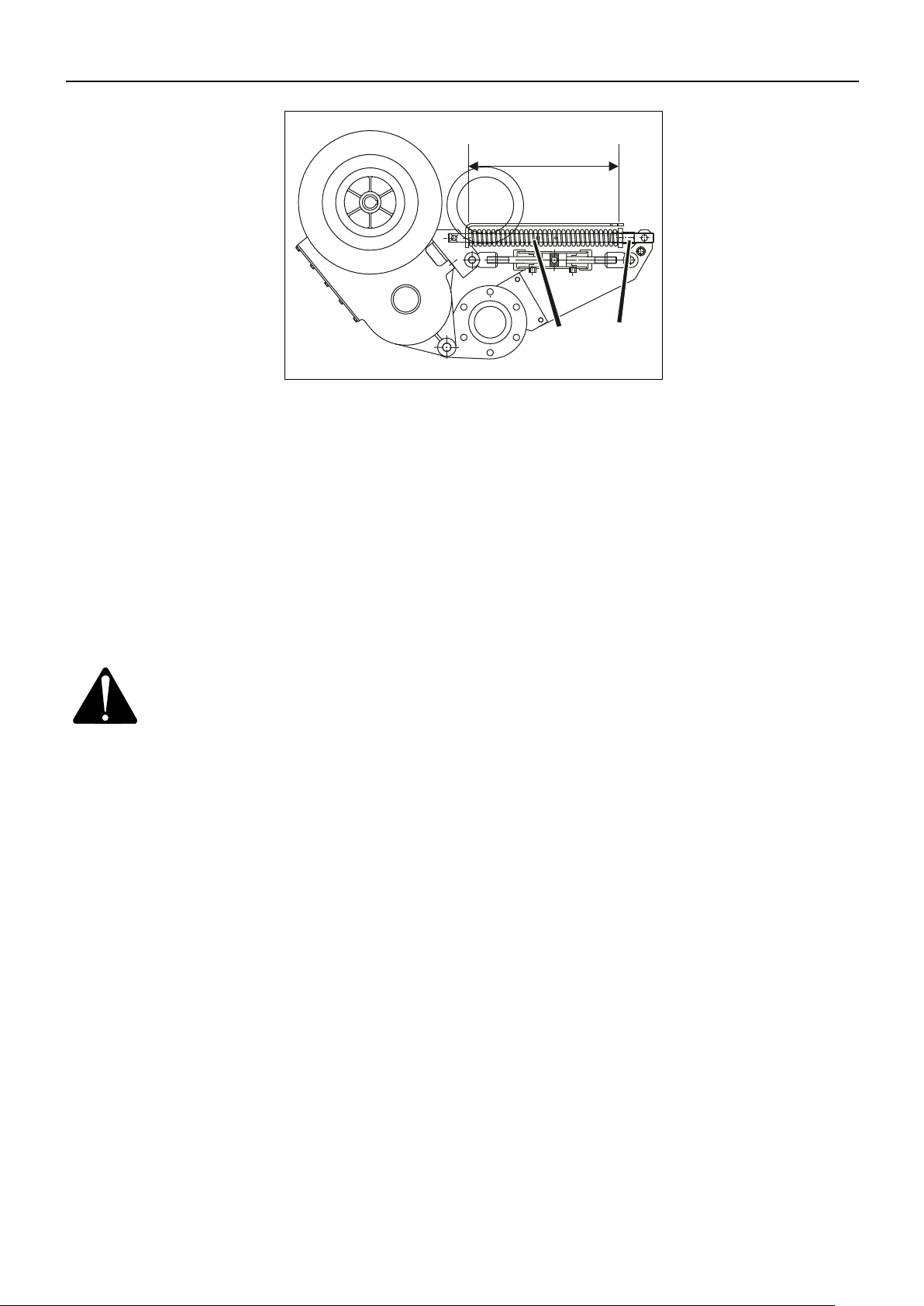

Fig. 4-31 The tightening of the V-belt drive is also adjusted automatically. It is determined by

the pressure relief spring A. The tightening of the V-belt drive can be changed by

turning the nut B on the spindle in the pressure relief spring until the spring has the

correct length:

In case of long chopping length, 15 mm, the length must be 450

mm.

In case of short chopping length, 9 mm, the length must be 430

mm.

The lengths apply to reserve function in “feed in”.

WARNING: The tightening of the spring should NOT be increased, in

relation to the indicated lengths, as this may overload the

transmission. The V-belt drive works as a belt clutch and slips if

the feed intake is overloaded.

With this clutch function the attentive operator can change into

a lower gear when the belts slip and thereby avoid blockage in

the feed intake section.

Page 65