Page 1

ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1

OPERATOR’S MANUAL

FCT 1260

FCT 1460

Harvester

Part number 81PIGB-206x

1st edition English

February 2018

Page 2

Page 3

PIGB-206B-02 FCT 1260-1460 0218

- 3 -

FOREWORD

DEAR CUSTOMER!

We appreciate the trust and confidence you have shown in our company by investing

in a KONGSKILDE product, and hope your new machine gives you many years of

reliable service. We want you to be completely satisfied with your investment.

This user manual contains information which when followed will ensure that the

machine is used safely and correctly.

When your machine was delivered, your dealer will have gone through the machine’s

operation, settings and maintenance with you.

However, this initial introduction is no substitute for a thorough understanding of

the various operations, functions and correct use of the machine.

You should therefore read this user manual thoroughly before using the machine

for the first time. Please pay particular attention to the safety references that are

given, as well as the section on safety.

The user manual is structured so that comprehensive information is provided in the

order in which you will logically need it when you receive your new machine, covering

everything from essential operating conditions via operation and use to maintenance

and general care. The subdivision of the various sections also follows the procedural

sequence, illustrated using sequential diagrams with associated text.

“Right” and “Left” are defined from a position standing behind the machine facing the

direction of travel.

All information, diagrams and technical specifications in this user manual describe

the most recent conditions at the time of publication.

Kongskilde Industries A/S reserves the right to alter and improve the design and

construction of each individual component of the machine without any obligation to

implement such changes on machines that have already been delivered.

Page 4

PIGB-206B-02 FCT 1260-1460 0218

- 4 -

CONTENTS

FOREWORD ....................................................................................................................... 3

CONTENTS ......................................................................................................................... 4

1. INTRODUCTION ............................................................................................................. 7

INTENDED USE ................................................................................................. 7

PERFORMANCE ................................................................................................ 8

SAFETY .............................................................................................................. 9

Definitions ............................................................................................ 10

General safety rules ............................................................................. 10

Locking of guards ................................................................................. 12

Choice of tractor ................................................................................... 12

Coupling and uncoupling ...................................................................... 13

Adjustments ......................................................................................... 14

Transport .............................................................................................. 15

Operation ............................................................................................. 16

Parking ................................................................................................. 16

Lubrication ........................................................................................... 16

Grinding ............................................................................................... 17

Maintenance ........................................................................................ 18

Replacing wearing components ........................................................... 18

Markings on the machine ..................................................................... 20

TECHNICAL DATA ........................................................................................... 22

2. CONNECTING TO THE TRACTOR .............................................................................. 23

HYDRAULICS .................................................................................................. 23

Connecting the hydraulics .................................................................... 23

Bypass valve ........................................................................................ 24

Adjustment of hydraulic flow ................................................................ 25

Connecting the electrical system ......................................................... 26

ELECTRO-HYDRAULIC CONTROL ................................................................ 27

Functions ............................................................................................. 28

DRAWBAR AND PTO DRIVE SHAFT .............................................................. 31

Standard PTO shaft ............................................................................. 31

Shortening the PTO shaft ..................................................................... 33

Friction clutch ....................................................................................... 34

Wide-angle PTO shaft .......................................................................... 34

3. COUPLING OF EQUIPMENT ....................................................................................... 37

PICK-UP ........................................................................................................... 37

TRANSPORT CONVERSION .......................................................................... 40

FITTING CHUTES ................................ ............................................................ 41

Chute turning ....................................................................................... 41

Standard chute ..................................................................................... 43

Folding chute ....................................................................................... 43

Chute for parallel operation .................................................................. 44

Page 5

PIGB-206B-02 FCT 1260-1460 0218

- 5 -

4. ADJUSTMENTS ............................................................................................................ 46

PICK-UP ........................................................................................................... 46

Change of speed of pick-up tines ......................................................... 47

OPENING THE ROTOR HOUSING ................................................................. 48

Collapsible chute .................................................................................. 51

ROTOR AND ROLLER SECTION .................................................................... 54

CUTTING LENGTHS ........................................................................................ 57

FCT 1260 ............................................................................................. 57

FCT 1260 MD and FCT 1460 MD ........................................................ 58

REPLACEMENT AND ADJUSTMENT OF BLADES ........................................ 60

GRINDING ........................................................................................................ 62

Grinding operation ............................................................................... 62

Rough grinding ..................................................................................... 64

REVERSING .................................................................................................... 65

FCT 1260 ............................................................................................. 66

FCT 1260MD and FCT 1460MD .......................................................... 67

NEUTRAL POSITION ....................................................................................... 68

Adjustment of BELT GUIDE ................................................................. 69

5. METAL DETECTOR (MD) ............................................................................................. 70

Magnetic tub (metal sensor) ................................................................. 70

Detection of metal ................................................................................ 71

Stopping the feed intake section .......................................................... 71

Resetting the metal detector ................................................................ 72

MD CONTROL.................................................................................................. 73

ADJUSTMENTS ............................................................................................... 75

Ratchet stop ......................................................................................... 75

Spring kit .............................................................................................. 76

FAULT FINDING FOR MD ............................................................................... 76

6. OPERATION IN THE FIELD ......................................................................................... 77

GENERAL CONSIDERATIONS ....................................................................... 77

Swathing before chopping .................................................................... 77

TRANSPORT POSITION ................................................................................. 78

STARTING IN THE FIELD ................................................................................ 79

Starting ................................................................................................. 79

Operation ............................................................................................. 80

Blockages in the machine .................................................................... 82

Following operation .............................................................................. 84

MISCELLANEOUS ........................................................................................... 84

WORKING POSITIONS .................................................................................... 84

HYDRAULIC TOW HITCH (AUTO-HITCH) ...................................................... 86

Page 6

PIGB-206B-02 FCT 1260-1460 0218

- 6 -

7. MAINTENANCE ............................................................................................................ 88

GENERAL ........................................................................................................ 88

GUARDS .......................................................................................................... 89

REPLACEMENT OF BLADES .......................................................................... 89

CHECKING THE PLAY IN THE WHEEL BEARING ................................ ......... 89

TYRE PRESSURE ........................................................................................... 90

FRICTION CLUTCH ......................................................................................... 91

FUSES .............................................................................................................. 94

MISCELLANEOUS ........................................................................................... 95

Rollers .................................................................................................. 95

Chain tightener for Pick-up auger ........................................................ 95

8. LUBRICATION .............................................................................................................. 96

PROGRESSIVE LUBRICATION BLOCK ......................................................... 96

Gearbox oil ......................................................................................... 105

LUBRICATING WHEEL HUBS ....................................................................... 107

9. STORAGE (WINTER STORAGE) ............................................................................... 108

10. ORDERING SPARE PARTS ..................................................................................... 109

11. DISPOSING OF THE MACHINE ............................................................................... 110

12. MISCELLANEOUS ................................................................................................... 111

HYDRAULIC DIAGRAM, FCT 1260 ............................................................... 111

HYDRAULIC DIAGRAM, FCT 1260MD AND FCT 1460MD ........................... 112

CONTROL SYSTEM ...................................................................................... 112

CONTROL BOX.............................................................................................. 114

CONTROL SYSTEM FOR THE MACHINE .................................................... 115

MD CONTROL SYSTEM ................................................................................ 116

CONTROL SYSTEM FOR THE MACHINE - WIRING .................................... 117

MD CONTROL - WIRING ............................................................................... 118

13. WARRANTY .............................................................................................................. 121

Page 7

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 7 -

1. INTRODUCTION

INTENDED USE

The precision chop forage harvesters FCT 1260 and FCT 1460 are solely designed

and manufactured for ordinary agricultural use, i.e.: Ordinary operation in fields

where green crops are being cut/collected, e.g. maize, grass or whole crops used for

silage production and intended for use as cattle fodder.

The machine should only be coupled to a tractor that both meets the product

specifications and can be used lawfully.

Any other use lies outside the intended use. Kongskilde Industries A/S accepts

no responsibility for any indirect loss or injury as a result of such use, and the

risk shall lie exclusively with the user.

It is assumed that the machine will be used under reasonable conditions, i.e. that the

land has been cared for normally and has been adequately cleared of any foreign

objects, etc.

"Intended use" also means that the information provided by Kongskilde Industries

A/S in the user manual and spare parts catalogue is followed, and that good

agricultural practice and technically correct operation is a matter of course.

The precision chop forage harvesters FCT 1260 and FCT 1460 must only be

used, maintained and repaired by persons who are familiar with the machine

concerned through relevant instruction and reading the user manual, and in

particular who have been informed of the hazards associated with the use of

the machine.

The following text provides a list of general and special safety instructions that must

be followed at all times.

Unauthorised modifications to the machine and its construction shall exempt

Kongskilde Industries A/S from all forms of liability in the event of any resultant

damage or injury.

Page 8

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 8 -

PERFORMANCE

The precision chop forage harvesters FCT 1260 and FCT 1460 offer highly versatile

performance, which, when used with the correct equipment, enables grass and whole

crops to be chopped.

The FCT 1260 and FCT 1460 have a high capacity compared with other similar

products because of the "DIRECT CUT" system that they use. "DIRECT CUT"

minimises power loss when cutting the material, thus ensuring maximum utilisation of

the available tractor power.

However, capacity is difficult to define and compare, as the capacity of a forage

harvester will be dependent not only on the type of crop being harvested, but also on

the way the crop has been treated prior to being harvested or cut by the machine, in

addition to the cutting length used by the machine.

In practice, it is desirable to operate the forage harvester in the highest possible

tractor gear without causing frequent blockages. However, the quantity of grass in a

field will always vary, for instance where the mower conditioner has had to turn or

change forward speed or direction of travel. Therefore, it is often appropriate either to

drive with a power reserve so that the machine will not become blocked, or to

continuously adapt the driving of the precision chop forage harvester to the

conditions.

The pick-up unit and feed rollers are both protected from overloading. The pick-up

unit is protected by means of a friction clutch, and the feed rollers with shear bolts in

the drive shafts. In addition, the entire feed intake section is protected against the

blocking of the pro-tec coupling driving the harvesting gearbox. The precision chop

forage harvester also has a reverse function, which allows blockages to be cleared

without you having to leave the tractor seat.

Inexperienced users should start by increasing the speed of travel gradually until the

pick-up becomes blocked, before then releasing the blockage by reversing and

choosing a tractor gear at a suitably lower level to eliminate the risk of blockage.

However, it is not the intention that the clutch function of the feed rollers be released.

The clutch adjustment of the pick-up must be reduced if this happens. The same

applies if the main friction clutch between the tractor and the machine releases

during normal operation. The machine is incorrectly adjusted if it is not the pick-up

unit that becomes blocked.

The torque setting of the friction clutch of the pick-up unit can unfortunately

sometimes be increased to the point when the main friction clutch between the

machine and the tractor releases frequently. The main friction clutch is not designed

to be released frequently, and is only intended to provide a starting shock or when

foreign objects enter the machine. The same applies to the shear bolt clutch for the

feed intake rollers. The main clutch simply cannot absorb the heat generated during

these long releases. The power transmitted at the main clutch will be at least 10

times greater than the output required to drive the pick-up unit.

Page 9

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 9 -

Only the pick-up unit can be seen from the tractor, and it should therefore not be

released until a blockage has occurred. The experienced user will be able to adjust

the driving of the tractor to the amount of grass and thus use a smaller capacity

reserve and, all other factors being equal, a higher output.

The cutting length of the precision chop forage harvester can be adjusted and

adapted to the crop concerned. The cutting length is usually reduced when cutting

maize and whole crops to ensure greater damage to the grains. Shorter cutting

settings will naturally require more power, hence the output for maize and whole

crops will be lower than for grass, although this is difficult to compare.

Similarly, the power requirement also increases as the blades become worn and the

shearbar setting must therefore be altered. It will be necessary to grind the blades

and adjust the shearbar during the season.

SAFETY

Many occupational injuries occur in the agricultural sector as a result of incorrect use

of machinery and inadequate instruction. Personal and mechanical safety is therefore

an integral part of Kongskilde’s development work. We want to protect you and

your family as much as possible, but to do this we need your wholehearted

cooperation.

A precision chop forage harvester cannot be constructed in such a way that it

guarantees the full safety of persons and operates efficiently at the same time. This

means that it is very important that you as a user of the machine pay attention and

use the machine correctly, and thereby avoid exposing yourself and others to

unnecessary danger.

As mentioned previously, the machine is intended for one purpose only, namely:

The chopping of grass and other similar green crops for use as fodder.

It is assumed that the machine will be used under reasonable conditions, i.e. that the

land has been cared for normally and has been adequately cleared of any foreign

objects, etc.

The machine requires skilled operation, i.e. you should read this safety and

operating manual before coupling the machine to the tractor. Even if you have

had a similar machine in the past, you should still read the manuals; your safety is at

stake after all.

You should never hand over the machine to anyone else until you have ensured that

they possess the knowledge necessary.

Page 10

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 10 -

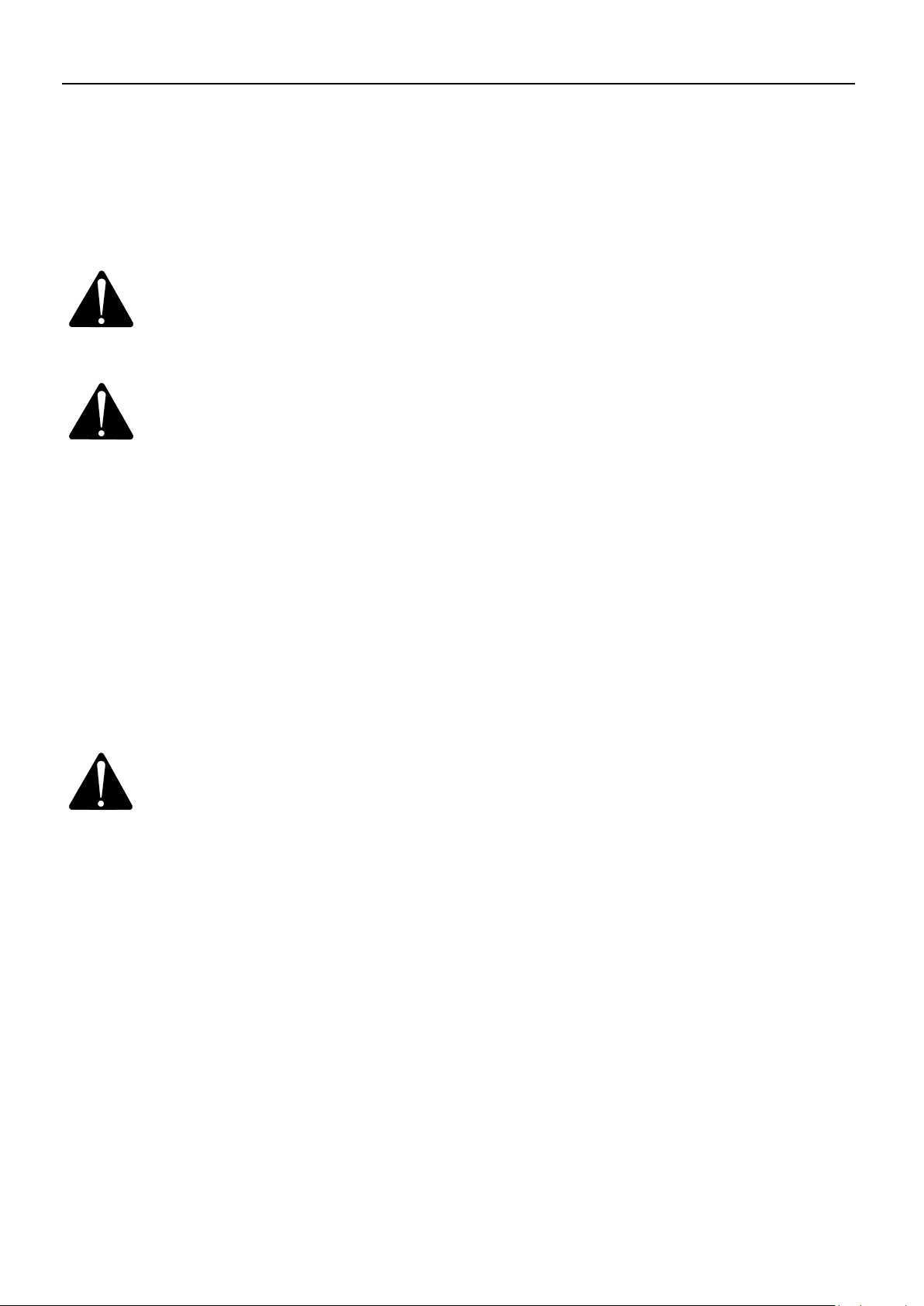

DEFINITIONS

The machine’s warning labels and user manual contain a number of safety notes.

These notes describe specific precautions which we recommend you and your

colleagues take in order to safeguard your personal safety as much as possible.

We recommend that you read these safety instructions thoroughly and ensure that

your employees do the same.

This symbol is used in the user manual with reference to personal

safety either directly, or indirectly through maintenance of the

machine.

CAUTION: The word CAUTION is used to ensure that the operator follows

general safety rules or the precautions described in the user manual

in order to protect themselves and others from injury.

WARNING: The word WARNING is used to warn against visible or hidden risks

which could result in serious personal injury.

DANGER: The word DANGER is used to specify precautions which must be

taken by law in order to protect both yourself and others against

serious injury.

GENERAL SAFETY RULES

The precautions with which the operator should generally be familiar are described

briefly below.

1. Always uncouple the power take-off (PTO) shaft, engage the tractor's parking

brake, and stop the tractor’s engine and remove the ignition key before you:

- lubricate the machine;

- clean the machine;

- disassemble any part of the machine;

- Adjust the machine.

2. Always lock the wheels before working under the machine.

3. Do not start the tractor until everyone is at a safe distance from the machine.

4. Ensure all tools have been removed from the machine before starting the

tractor.

5. Ensure all guards have been fitted correctly.

Page 11

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 11 -

6. Do not wear loose clothing or hair which could be drawn in by a moving part in

the machine.

7. Always ensure that you wear suitable footwear to avoid falling.

8. Do not modify guards or work on the machine if a part of a guard is missing.

9. Always follow statutory requirements concerning lights and safety labels when

towing the forage harvester on public roads and at night.

10. Limit the transport speed to a maximum of 30km/h if the machine is not marked

with another maximum permitted speed.

11. Do not stand near the machine while it is operating.

12. When attaching the PTO shaft, check that the RPM and direction of the tractor’s

shaft matches those of the machine.

13. Hearing protection should be worn if the noise from the machine is unpleasant

or you will be using the machine for long periods in a tractor cab without

sufficient sound insulation.

14. Never allow anybody to be on the machine during use or transport.

15. Never use the machine for any other purpose than its intended use.

16. Do not use the machine if there are children in the vicinity.

17. Never stand between the tractor and the machine during coupling and

uncoupling.

18. Do not feed material into the cutting unit using your hands or feet while it is

operating.

19. Do not attempt to remove material from the cutting unit while it is operating.

20. The PTO shaft must first be fully disconnected if material is to be removed from

the forage harvester. Turn off the engine and remove the ignition key.

Page 12

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 12 -

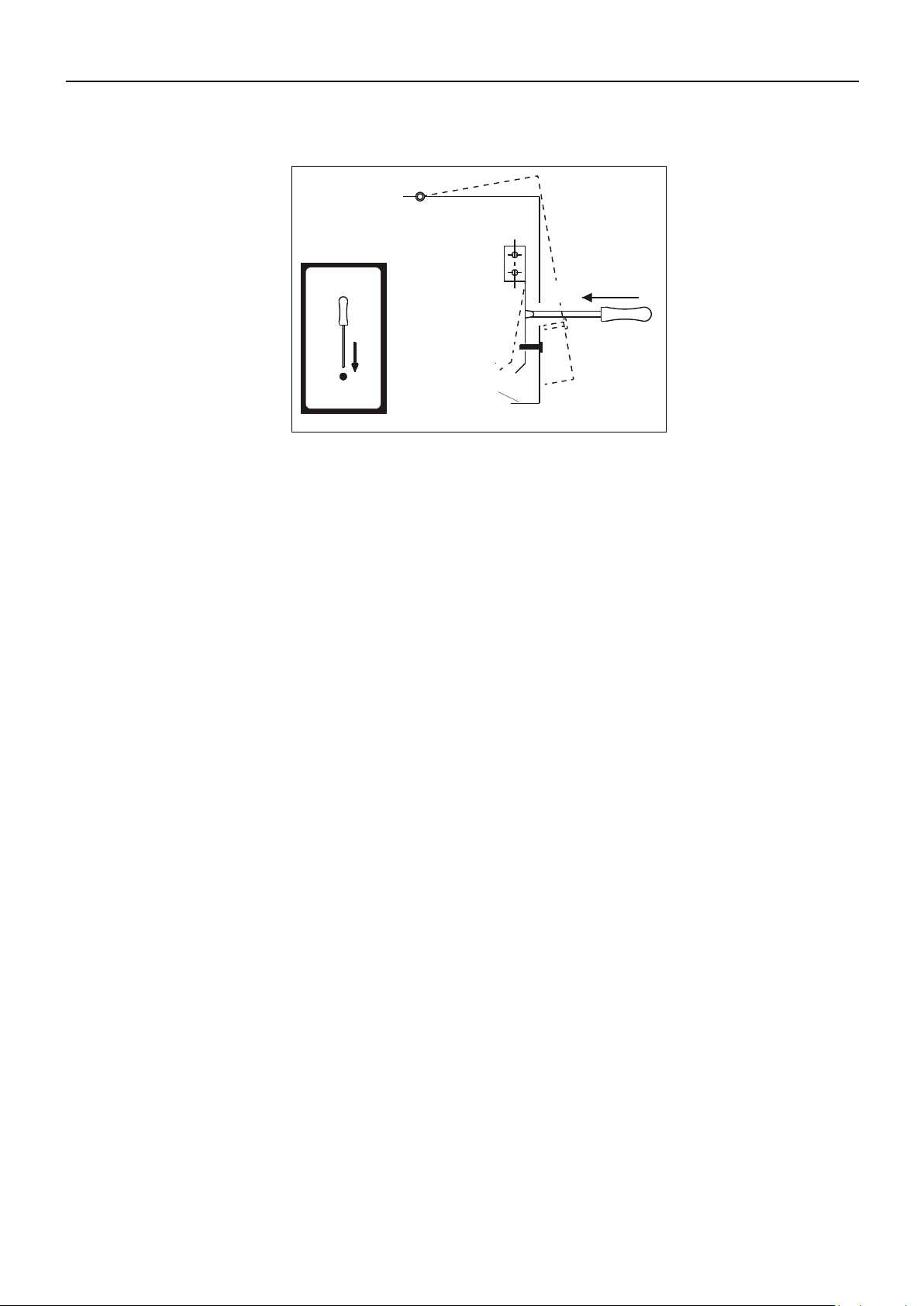

Fig. 1-1

P

R

1

1

-

0

2

4

3

PR80-0819

Guard

LOCKING OF GUARDS

All hinged guards on the machine are fitted with a lock. These locks ensure that the

guard cannot be opened without using a tool. Figure 1-1 illustrates the locking

principle and the corresponding transfers which indicate and illustrate the locks on

the machine.

CHOICE OF TRACTOR

You should always follow the recommendations laid down in the tractor's user

manual. If this is not possible, seek technical assistance.

The lawful transportation of the machine on public roads requires a tractor with

sufficient mass and braking capacity.

You should use a tractor which provides at least 103kW/140 HP at the PTO, but

which also cannot supply more than 200kW/280 HP.

The machine has a standard construction for 1,000 RPM, and is supplied from the

factory with a 1 3/4’’ PTO shaft with a 20-spline yoke.

A suitable tractor will have a good range of gears for travelling at speeds of between

5 and 12km/h.

The tractor's hydraulic system should supply at least 170 bar, and the adjustable

relief valve must not permit more than 210 bar.

The drawbar of the precision chop forage harvester has a hitch eye, and for this

reason the tractor should preferably have a clevis drawbar. The drawbar pin should

have a diameter of 30mm.

Always select a tractor with a closed cab when using a precision chop forage

harvester.

Page 13

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 13 -

Fig. 1-2

Fig. 1-3

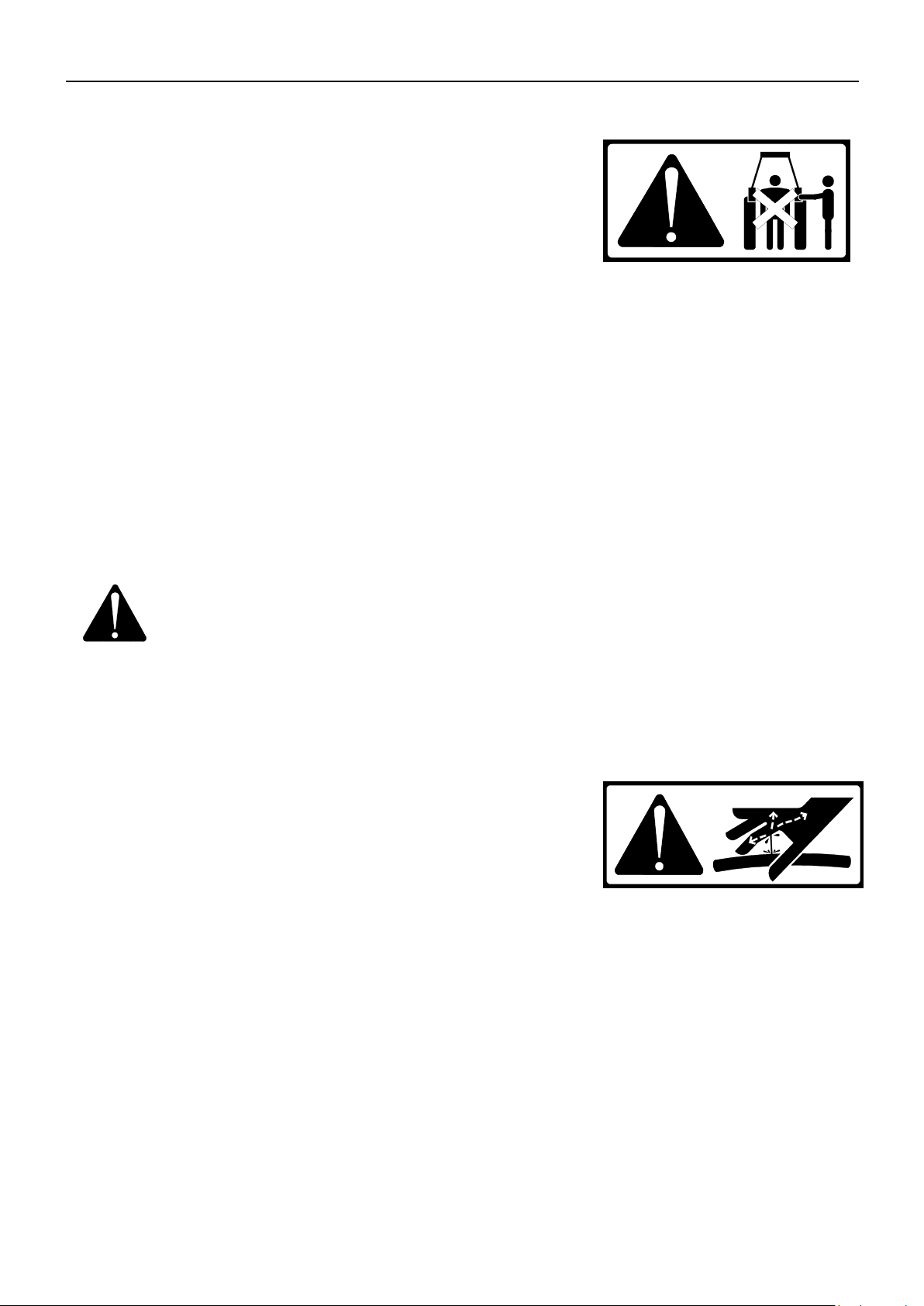

COUPLING AND UNCOUPLING

You should always ensure that no one is between

the tractor and the machine during coupling and

uncoupling. Any unintentional manoeuvre with the

tractor may cause serious injury (see fig. 1-2). When

uncoupling, it is important that the ground is even

and stable so that the machine does not move and

injure persons or cause damage to other equipment.

The same precautions must be taken when coupling and uncoupling trailers using a

hydraulic hitch attached to the rear of the forage harvester as an accessory.

Check that the machine is suitable for the RPM and direction of the tractor's PTO.

Using the wrong RPM may damage the machine over time, and in the worst case

scenario lead to the ejection of components through the delivery chute.

Ensure that the PTO shaft is fitted correctly, i.e. that the locking pin is engaged and

the support chain for the guard is fastened at both ends.

The PTO drive shaft must be protected correctly. Guards that are damaged must be

replaced immediately.

IMPORTANT: Before connecting the trailer to the hydraulic hitch, always:

- Disengage the PTO on the tractor;

- Wait until all moving parts have stopped.

Before activating the hydraulic system, always check that all hydraulic couplings are

correct and are tight and that all hoses and fittings are undamaged.

Ensure that the hoses are not under pressure when disconnecting them from the

tractor.

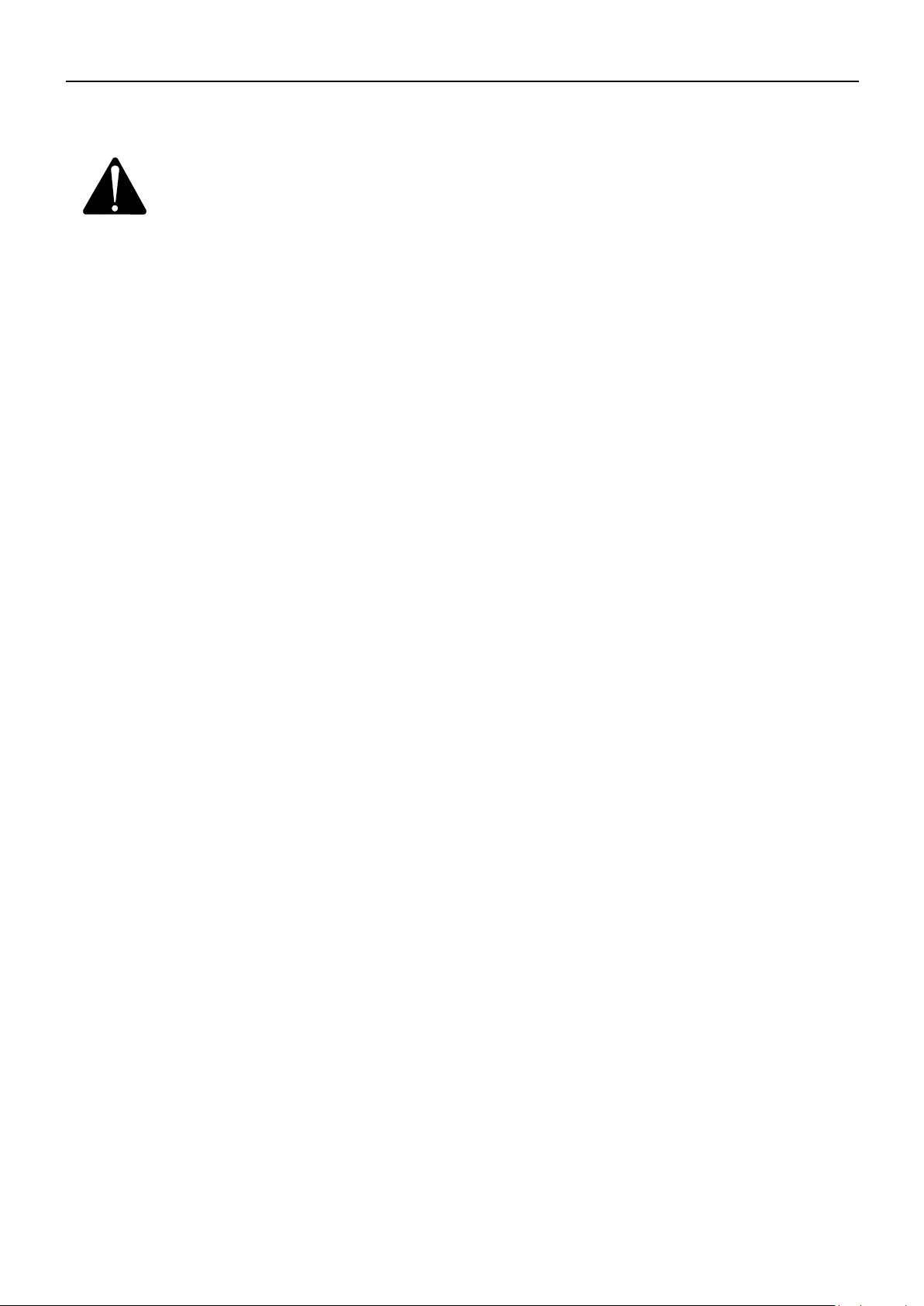

Hydraulic oil at high pressure can penetrate the skin

and cause serious inflammation. You should always

protect your skin and eyes from oil splashes. (see

Fig. 1-3) Seek medical assistance immediately if

you are splashed by hydraulic oil at high pressure.

Page 14

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 14 -

ADJUSTMENTS

IMPORTANT: Before adjusting the machine, you must always:

- Disengage the PTO on the tractor;

- Turn off the engine of the tractor.

- Wait until all moving parts have stopped.

It is important to wait until all rotating parts have stopped before removing the guards.

This particularly applies to the delivery chute above the blade cylinder.

If the cutting parts in the blade cylinder must be adjusted or replaced, it is important

to block the blade cylinder using a wooden wedge, as the sharp blades can easily

cause damage to multiple fingers because it is difficult to stop the rotor if started

accidentally by the operator.

Before starting work, you should check that the feed rollers and blade cylinder can

move freely. Also check that the blades are intact and without cracks. Damaged

blades must be replaced to prevent them from blocking or damaging the machine

and to avoid metal parts being thrown out from the delivery chute.

The first time you use the machine, the blade bolts may "bed in" and lead to

insufficient pretensioning of the blades. For this reason, you must check and tighten

the blade bolts after the first hour of use.

Check periodically whether the blades and blade bolts are worn according to the

rules in the user manual.

Page 15

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 15 -

TRANSPORT

Limit the transport speed to a maximum of 30km/h if the machine is not marked with

a different maximum permitted speed.

Once the machine has been prepared for transport, the control unit must be turned

off using the button on the side of the control box, and/or the oil supply to the

machine must be disconnected. This prevents faulty operation during transport. If the

machine has been fitted with an LS kit, the control unit for this must be turned off.

DANGER: Never allow anyone to climb or ride on the machine.

The machine is fitted with equipment for hydraulic conversion into the transport

position, and the cylinder for this is fitted a hose rupture valve. If there is air in the

cylinder during transport, there is a risk that the machine may drift into the opposite

lane or onto cycle lanes or in towards pavements.

IMPORTANT: If the machine is fitted with an auto-hitch, the mechanical lock on the

auto-hitch must be activated when driving while towing a trailer on

public roads. This also applies in cases where a hose rupture valve

has been fitted to the lifting cylinder of the auto-hitch.

IMPORTANT: Test all hydraulic cylinders following coupling to the tractor in order to

remove any air in the oil. This is particularly applicable when driving

on public roads.

The attachments for the forage harvester (pick-up, etc.) must be secured

mechanically prior to transport.

The statutory requirements concerning lights and traffic safety marking must be

positioned correctly, and any trailers attached must also be checked in addition to the

forage harvester.

Reflectors and lighting must be cleaned regularly.

Page 16

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 16 -

OPERATION

Before you start work, ensure there is nobody behind the discharge of the forage

harvester due to the danger of being hit by metal parts from damaged blades.

You should also make sure that there are no persons in the trailer used for pick-up.

There is a danger of suffocating in the flow of material or being hit by metal parts in

the discharge.

If the feed rollers or the blade cylinder are blocked, disengage the clutches and stop

the tractor engine immediately. Activate the parking brake and wait until the rotating

parts have stopped before attempting to remove the material or foreign object.

WARNING: The following cannot be said often enough: Never remove a material

blockage while the machine is running or feed material into the pickup using your hands or feet, as there is a serious risk of becoming

caught and pulled into the forage harvester, which could result in

dismemberment or death.

Never allow anyone to stand near the forage harvester while it is operating,

particularly children who are unaware of the danger and may behave unpredictably.

The chute may be more than 4 m high. Be aware of high-voltage lines. Keep a safe

distance from high voltage lines.

PARKING

The supporting leg must always be correctly fixed before the machine is parked,

otherwise the machine may tip over during parking. You should also remember to

place chocks under the wheels of the machine if there is a risk that the machine will

move after parking.

Remember to disconnect the hydraulic hoses and control box before driving away

with the tractor.

LUBRICATION

Never allow more than one person at a time to work on the machine when lubricating

or undertaking maintenance work. This reduces the risk of you getting your fingers

caught because another person turns rotating parts by accident while you are still

working with these parts.

Never attempt to clean, lubricate or adjust the machine until the PTO shaft has been

uncoupled, the tractor engine has stopped and the parking brake has been activated.

Remove the ignition key and wait until all moving parts have stopped!

Page 17

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 17 -

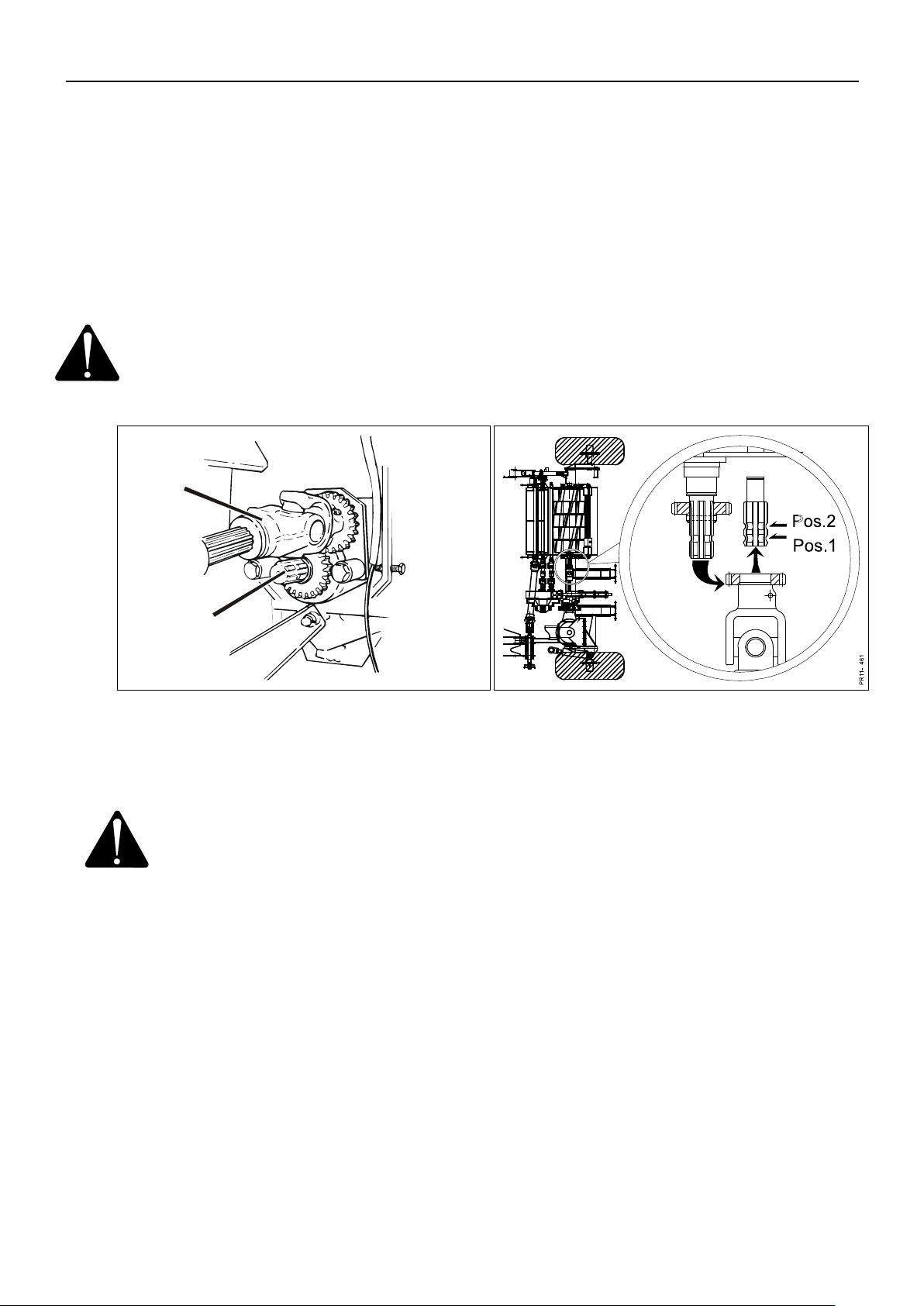

GRINDING

Always follow this procedure when switching to or from grinding:

- Stop the tractor engine and remove the ignition key;

- Activate the parking brake;

- Wait until all moving parts have stopped.

Unfortunately, it is necessary to remove some of the guards to change the direction

of rotation of the rotor when grinding the blades. As there are chain and belt

transmissions, your hands may be injured if the rotating parts have not stopped

before the guards are removed.

Grinding is performed using the following procedure:

1. Check to make sure that the grindstone is free from damage and that the device

can move backwards and forwards easily.

2. Lower the guard behind the grinding device to give free access to the blade

cylinder.

3. Adjust the stone before replacing the guard on the grinding device.

4. Remove the guard above the blade cylinder transmission and change the

direction of rotation of the rotor.

5. Close the guard again and check that no one is near the machine.

6. Start the tractor again and keep the RPM either at idling speed or slightly

above.

7. Perform the grinding carefully.

Always use safety glasses when grinding, as small particles may fly off the

grindstone.

Following grinding, stop the tractor engine again, remove the ignition key, change the

direction of rotation and fasten all guards.

REMEMBER: Always grind with all guards closed.

Page 18

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 18 -

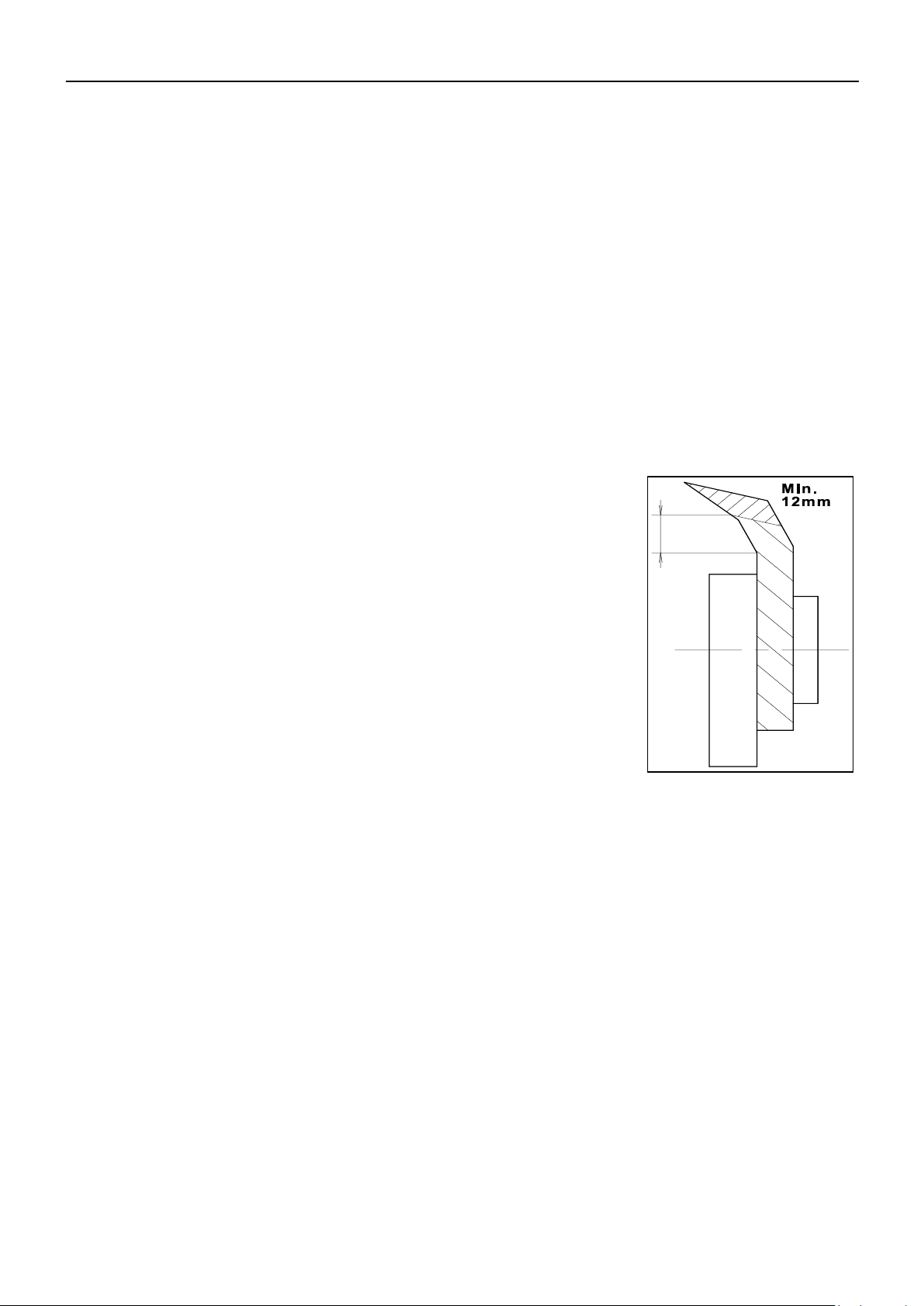

Fig. 1-4

MAINTENANCE

All bolts should be re-tightened after approximately two days of operation. Always

make sure that spare parts that have been fitted have been tightened with the correct

torque.

Always ensure that the pick-up is in contact with the ground and/or the lifting

cylinders are blocked when replacing parts in the hydraulic system.

Hydraulic hoses must be checked by suitably qualified personnel before they are

used for the first time and thereafter at least once a year. They must be replaced as

and when necessary. The working life of hydraulic hoses must not exceed six years,

including a maximum storage period of two years.

When replacing hoses, use hoses which meet the requirements specified by the

equipment manufacturer. All hoses are marked with their date of manufacture.

REPLACING WEARING COMPONENTS

Blades, blade bolts and the shearbar are made from high

alloy, heat-treated materials. This heat treatment

produces a particularly hard and tough material capable

of tolerating extreme stress. Damaged blades, blade bolts

or shearbars must be replaced by original KONGSKILDE

spare parts to ensure optimal reliability.

Blades and blade bolts must be checked every day during

the season.

The special blade bolts must be tightened using a torque

wrench to 40 kgm.

The blades must be replaced once they have worn to a

maximum of 8 mm or around 12 mm above the straight

piece (see Fig. 1-4).

Following the replacement of blades and blade bolts, etc., check that no tools have

been left in the machine.

Page 19

PIGB-206B-02 FCT 1260-1460 0218

- 19 -

3

5

10

12

9

4

6

8

7

STOP

PR80-0821

2 MIN

1

2

3

6

6

7

8

9

10

12

15

14

13

15

6

4

4

5

7

8

7

2

1

13

PR80-0837

15

PR80-0814

14

PR80-0861

11

PR80-0857

1. INTRODUCTION

Page 20

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 20 -

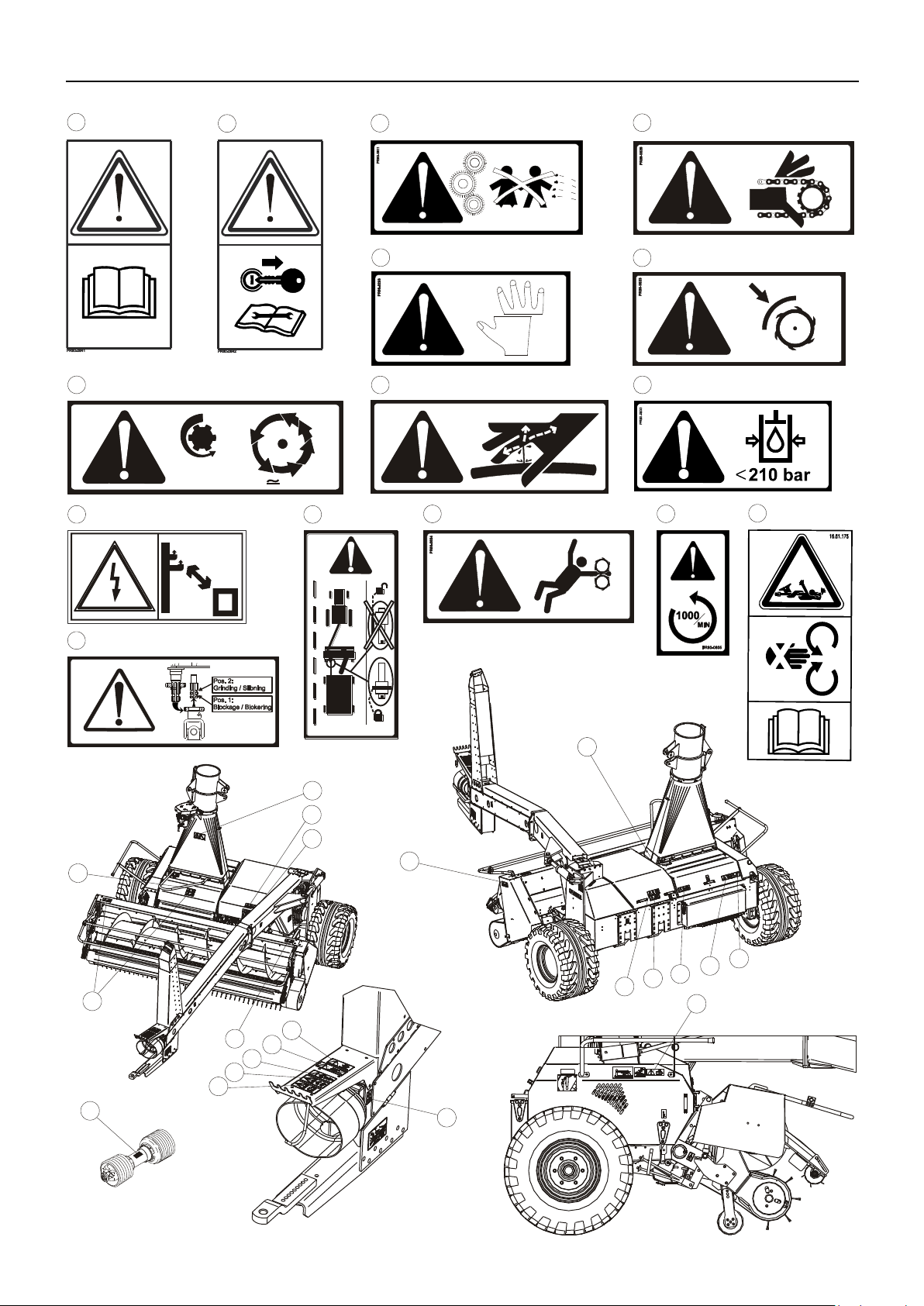

MARKINGS ON THE MACHINE

The warning labels shown on the previous page are positioned as shown on the

drawing at the bottom of the page. Before you start using the machine, ensure that all

labels are present; if not, replace any that are missing. The labels have the following

meaning:

1. Stop the tractor’s engine and remove the ignition key before touching the machine.

Always remember to stop the tractor’s engine before lubricating, adjusting, maintaining or repairing the

machine. Remove the ignition key so that you can be certain no one will start the tractor again until you

have finished.

2. Read the user manual and safety instructions.

This is a reminder that you must read the documents supplied to ensure that you operate the machine

correctly and avoid any unnecessary risk of accidents and mechanical damage.

3. Children.

Never allow children near the machine while it is in operation. Young children in particular have a tendency

to do unpredictable things.

4. Chain drives.

One or several chain drives are located beneath this guard. Ensure that the tractor's engine has been

turned off before opening the guard.

5. Risk of cutting.

There is a risk of fingers, etc. becoming crushed in various parts of the machine. Be careful when the

machine is coupled to the tractor and ready for use. The machine can easily crush or cut off any part of the

body that might get caught in the machine.

6. Remember the guards when grinding.

Remember to close ALL guards after switching to grinding mode before commencing grinding.

7. Rotating parts.

After the tractor's PTO drive shaft has stopped, the blades will have momentum which will keep them

rotating for up to two minutes. Wait until the blades have come to a complete stop before removing guards

for inspection or maintenance.

8. Risk of entanglement.

Keep away from the vicinity of any attachments and feed rollers while the machine running. Ensure that

the tractor's engine has stopped first.

9. RPM and direction of rotation.

Check that the PTO shaft is operating at the correct RPM and rotating in the correct direction. Using an

incorrect RPM and/or direction will damage the machine over time, resulting in a risk of personal injury.

10. PTO drive shaft.

This label is intended to remind you how dangerous the PTO shaft can be if it is not correctly coupled or

protected.

11. Auto-hitch.

Always block the hydraulic hitch using the pin supplied before driving on public roads with a trailer

attached.

12. Max. 210 bar.

Ensure that the hydraulic components are not subject to a pressure greater than the maximum of 210 bar,

as there could be a risk of explosive damage to components. This will result in both yourself and others

being at serious risk of being hit by metal components at high speed or oil under high pressure.

13. PTO drive shaft for rotor.

There is an alternative pin for the PTO drive shaft for the rotor. This is used both when the rotor is

disconnected for reversing and when the rotor rotates in the opposite direction for grinding. Ensure that

you place the PTO shaft correctly on the pin when performing these operations.

14. High-voltage lines.

This label is intended to warn of the danger of getting too close to high-voltage lines with the machine.

15. Hydraulic oil under pressure

Warning against hydraulic oil under pressure.

Page 21

PIGB-206B-02 FCT 1260-1460 0218

- 21 -

PR11-1810

1. INTRODUCTION

Page 22

1. INTRODUCTION

PIGB-206B-02 FCT 1260-1460 0218

- 22 -

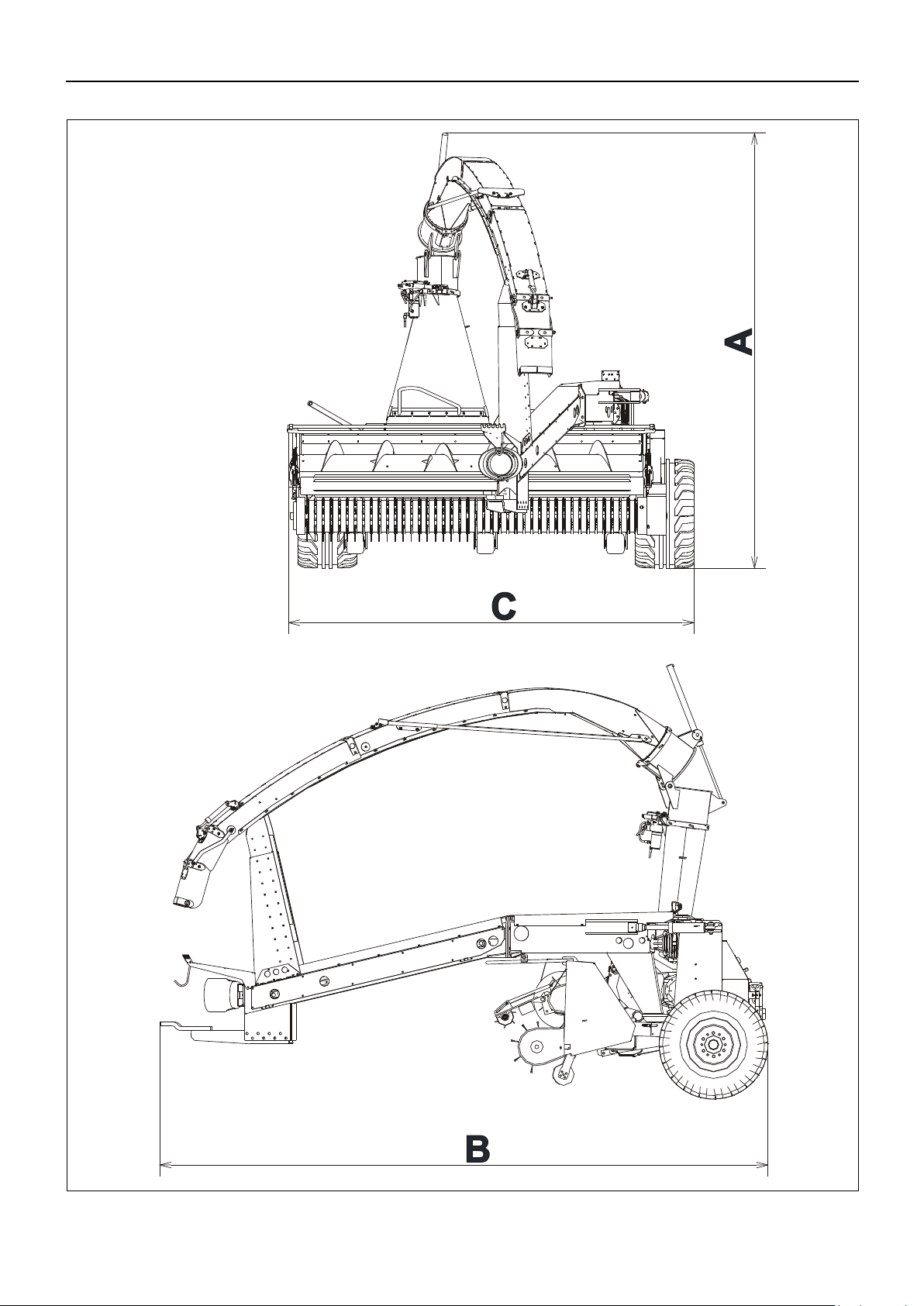

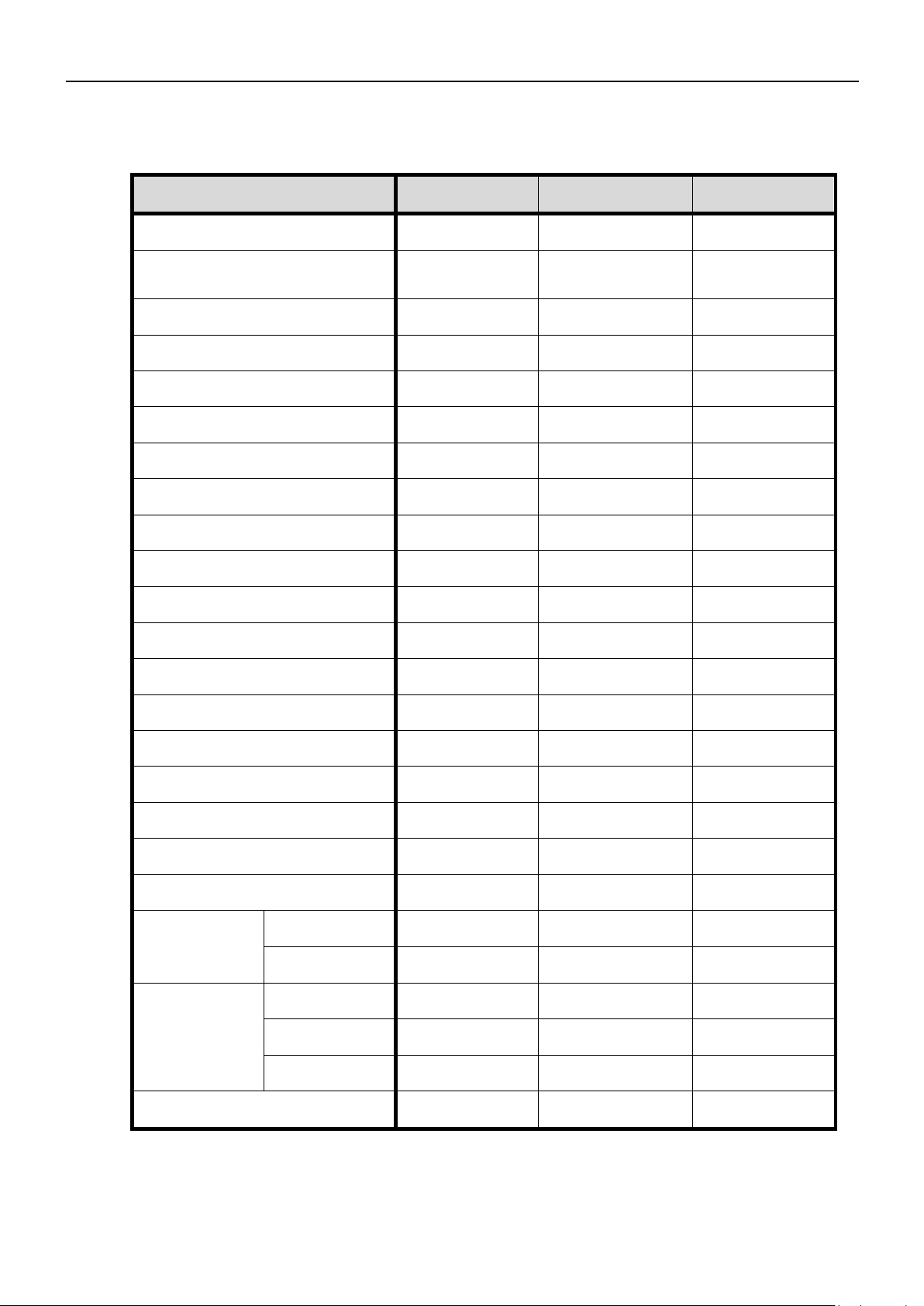

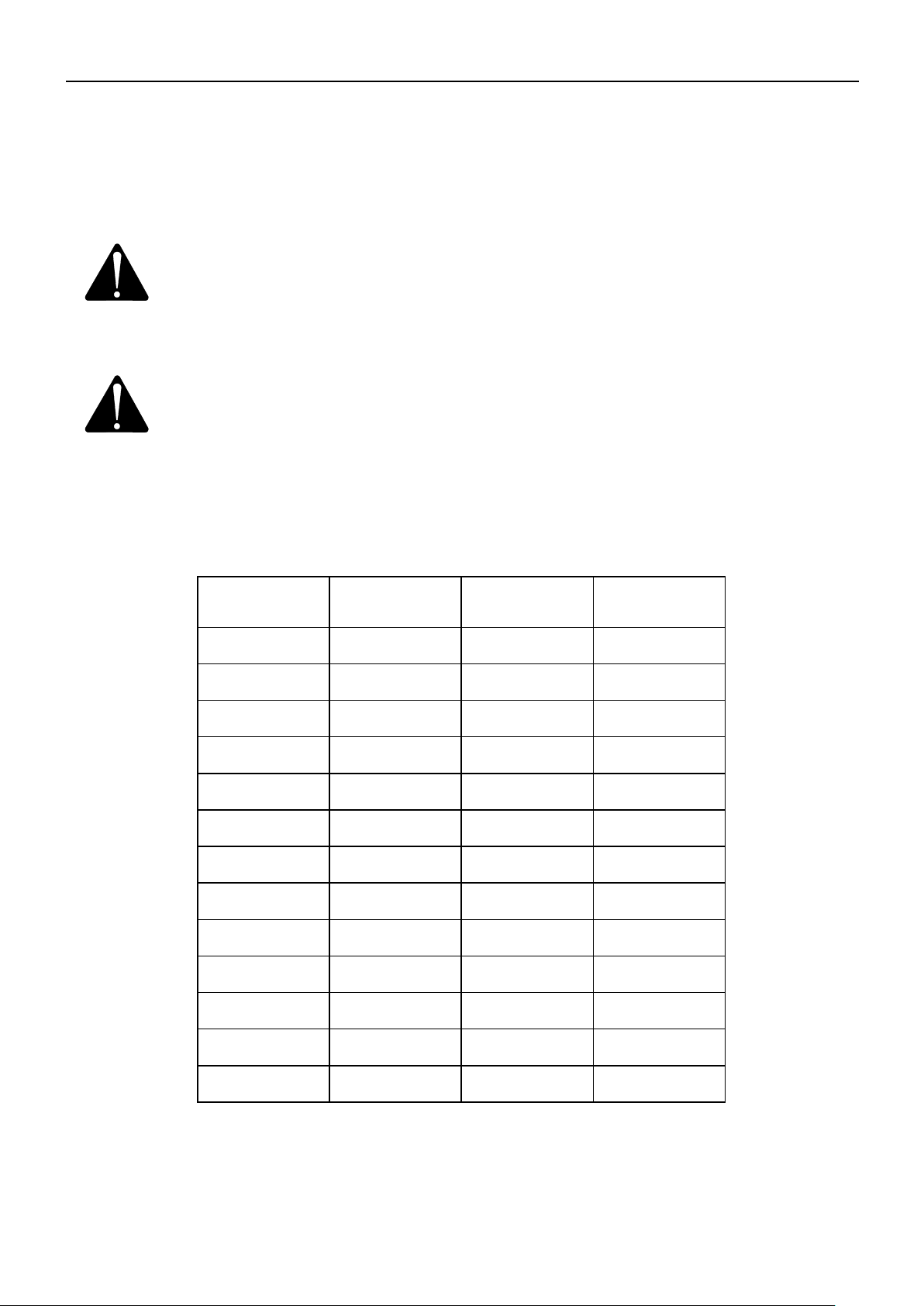

TECHNICAL DATA

FCT 1260

FCT 1260MD

FCT 1460MD

pick-up width

2.65 m

2.65 m

3.1 m

Power requirement

110–206 kW

/ 150-280 HP

110–206 kW

/ 150-280 HP

147–206 kW

/ 200-280 HP

Metal detector

-

Standard

Standard

Width of blade rotor

0.72 m

0.72 m

0.9 m

RPM for rotor

1600 RPM

1600 RPM

1600 RPM

Number of blades

24 / 32

24 / 32

40

Theoretical maximum cutting length

21 / 15 mm

21 / 16 mm

16 mm

Reversible shearbar

Standard

Standard

Standard

Number of feed rollers

4

4

4

Feed reversal

Electro-hydraulic

Electro-hydraulic

Electro-hydraulic

Turning angle for chute

280 degrees

280 degrees

280 degrees

Standard tyre size

13.5/75-430.9

13.5/75-430.9

500/50-17

Tyre size (Accessory)

500/50-17

500/50-17

-

Free-wheeling clutch in PTO shaft

Standard

Standard

Standard

Friction clutch in PTO shaft

3000 Nm

3000 Nm

3000 Nm

Steel wheels on pick-up

3 3 3

Weight with pick-up

3600 kg

3600 kg

3800 kg

Maximum axle load

2950 kg

2950 kg

3050 kg

Maximum length, B

5.31 m

5.31 m

5.31 m

Maximum width

with pick-up, C

Wheels,

Standard

3.0 m

3.0 m

3.57 m

Wheels,

Accessory

3.3 m

3.3 m

-

Transport height,

A

Standard

3.8 m

3.8 m

3.8 m

Parallel operation

4.4 m

4.4 m

4.4 m

Folding chute

3.8 m

3.8 m

3.8 m

Hitch for trailer: drawbar load/

total weight

2,000 kg/

15,000 kg

2,000 kg/

15,000 kg

2,000 kg/

15,000 kg

TECHNICAL DATA

Page 23

PIGB-206B-02 FCT 1260-1460 0218

- 23 -

2. CONNECTING TO THE TRACTOR

HYDRAULICS

CONNECTING THE HYDRAULICS

DANGER: The hydraulic components must not be exposed to a working

pressure in excess of 210 bar, as a higher working pressure

may gradually cause parts to be damaged. This poses a serious

risk of personal injury.

CAUTION: It is important that the quick-release couplings are always thoroughly

cleaned prior to fitting in order to prevent impurities from penetrating

the hydraulic system and damaging important valve functions. When

the hydraulic hoses are not connected to the tractor, these should be

positioned in the holder at the end of the drawbar.

The machine is equipped with its own hydraulic system, which must be supplied with

oil from the tractor.

The system is used for pick-up lifting, drawbar, chute swivelling, deflector, folding

chute and reverse function. None of these functions uses very much oil and are

controlled in the best way when the oil flow is low. You should therefore set the oil

flow from the tractor to 15-20 l/min., or as low as possible.

Connect the hoses to a double-acting outlet on the tractor, or better still: connect the

pressure hose to the A-port on the hydraulic outlet and the return hose to a vacant

return-port leading directly to the tank or rear-axle assembly. This ensures that the

return pressure is suitably low. This is especially important if the oil flow from the

tractor cannot be adjusted to a sufficiently low level.

IMPORTANT: The hydraulic port for the selected A port must be locked in the

pressure position to ensure a continuous oil flow to the machine's

hydraulic system.

The machine will control the oil pressure and flow itself if it has been fitted with LS.

2. CONNECTING TO THE TRACTOR

Page 24

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 24 -

PR11-1903

Closed centre

Load Sensing

Open centre

Fig. 2-1

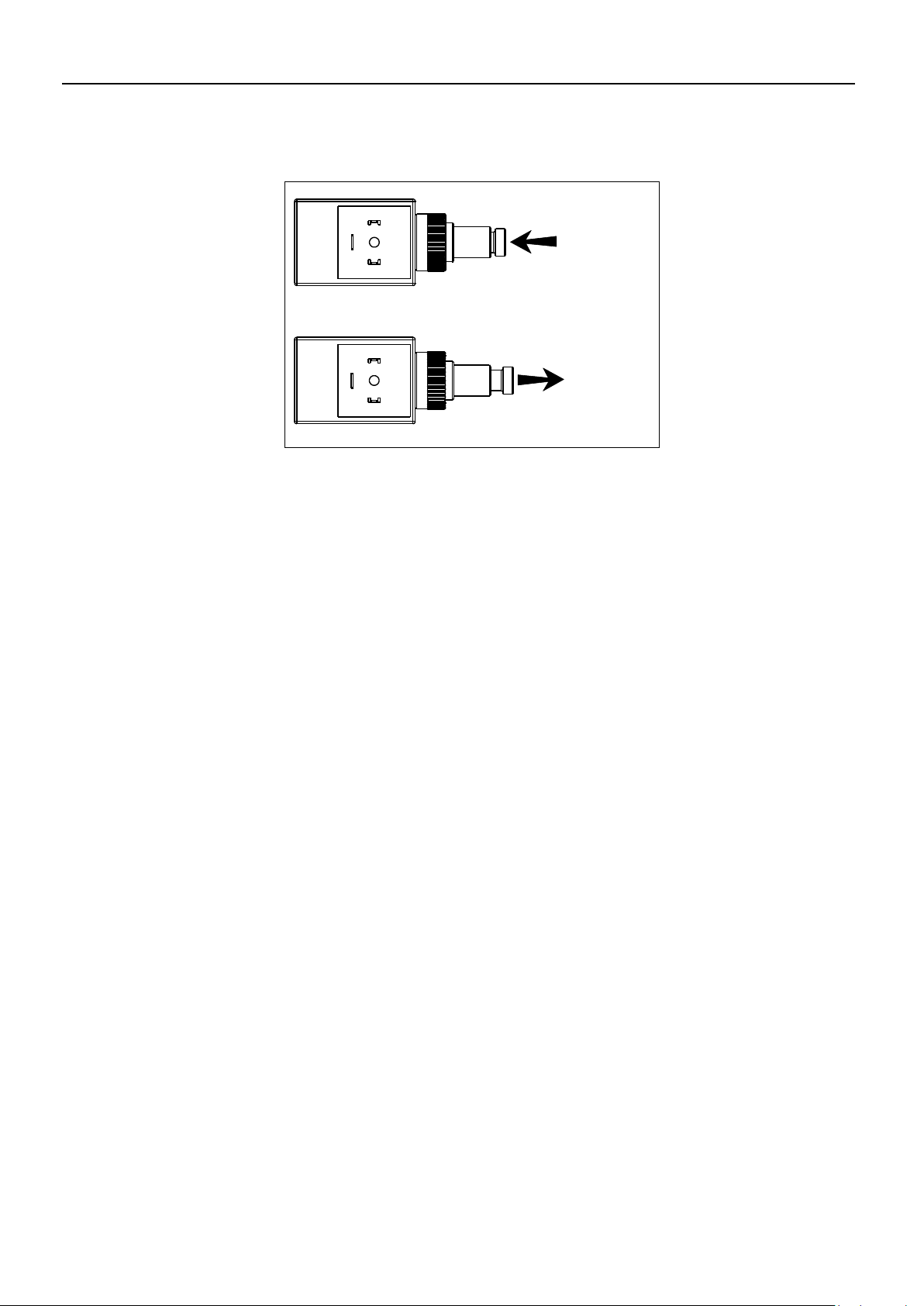

BYPASS VALVE

Fig. 2-1 A distinction is made between two types of tractor hydraulic systems: "open centre

hydraulics" (also known as "fixed pump") and "closed centre hydraulics" (also known

as "variable pump").

If the tractor is of the “open centre" type, the bypass valve must be open to permit

the passage of oil back to the tractor, and will only be activated when a function on

the machine is activated. The valve may be altered using the thumbscrew if it is not

open.

If the tractor is of the “closed centre" type, the bypass valve must be closed to

permit the tractor to close the oil flow automatically when no functions are active. The

valve may be altered using the thumbscrew if it is not closed.

The bypass valve is located on the left hand side of the valve block.

None of the hydraulic functions use more than around 10 litres of oil per minute.

You should therefore set the oil flow from the tractor to 10 l/min. of oil if possible. The

bypass valve has been designed for a maximum of 40 l/min. Pressure loss will occur

if this limit is exceeded, which can cause the temperature of the oil and valves to

increase.

The bypass valve must be set to closed centre if the machine has been fitted with

LS.

Page 25

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 25 -

PR12-1904

A

A

B

B

Fig. 2-2

ADJUSTMENT OF HYDRAULIC FLOW

The machine may be fitted with a hydraulic block allowing the adjustment of the flow

to the deflector and drawbar.

Fig. 2-2 The adjustment screws A are used to adjust the speed at the drawbar. The

adjustment screws B are used to adjust the deflector. The machine is supplied from

the factory with the flow adjusted to the recommended rate. Slacken the nuts and

turn the adjustment screws to change this. Tighten the nuts again when you are

happy with the level of adjustment.

IMPORTANT: It is possible to adjust the screw to such an extent that the function

works in the opposite way. Unscrew the adjustment screw again until

the function works correctly if this occurs.

Page 26

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 26 -

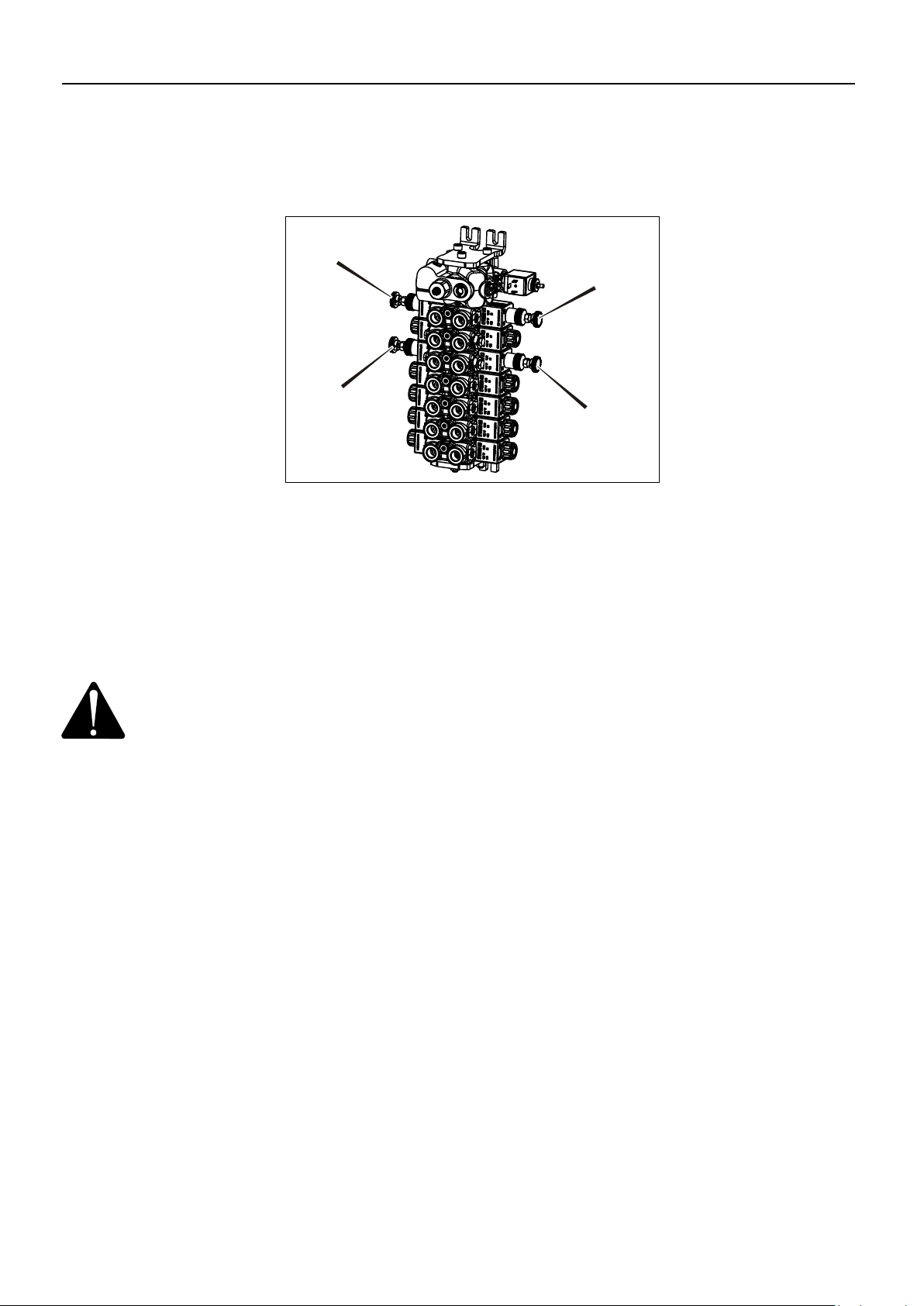

Fig. 2-3

CONNECTING THE ELECTRICAL SYSTEM

Fig. 2-3 The machine is equipped for complete electronic operation of all the machine's

hydraulic functions. The electronic operation consists of two units:

A control unit mounted on the machine together with the hydraulic system.

This unit activates the hydraulic valves;

A control box for operation of the hydraulic functions. This can be beneficially

positioned on the right armrest of the tractor seat for easy access while

working in the field.

The control box is equipped with detachable fittings that can be permanently screwed

into the cab, allowing subsequent dismantling without the use of a tool.

The male connector for the power supply connects to a female connector inside the

tractor cab. This provides 12 V of power and allows a minimum current of 15 A.

Contact your dealer for an adapter if your tractor does not use the same connectors.

IMPORTANT: When parking, position the control box in such a way as to prevent

the ingress of water.

Page 27

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 27 -

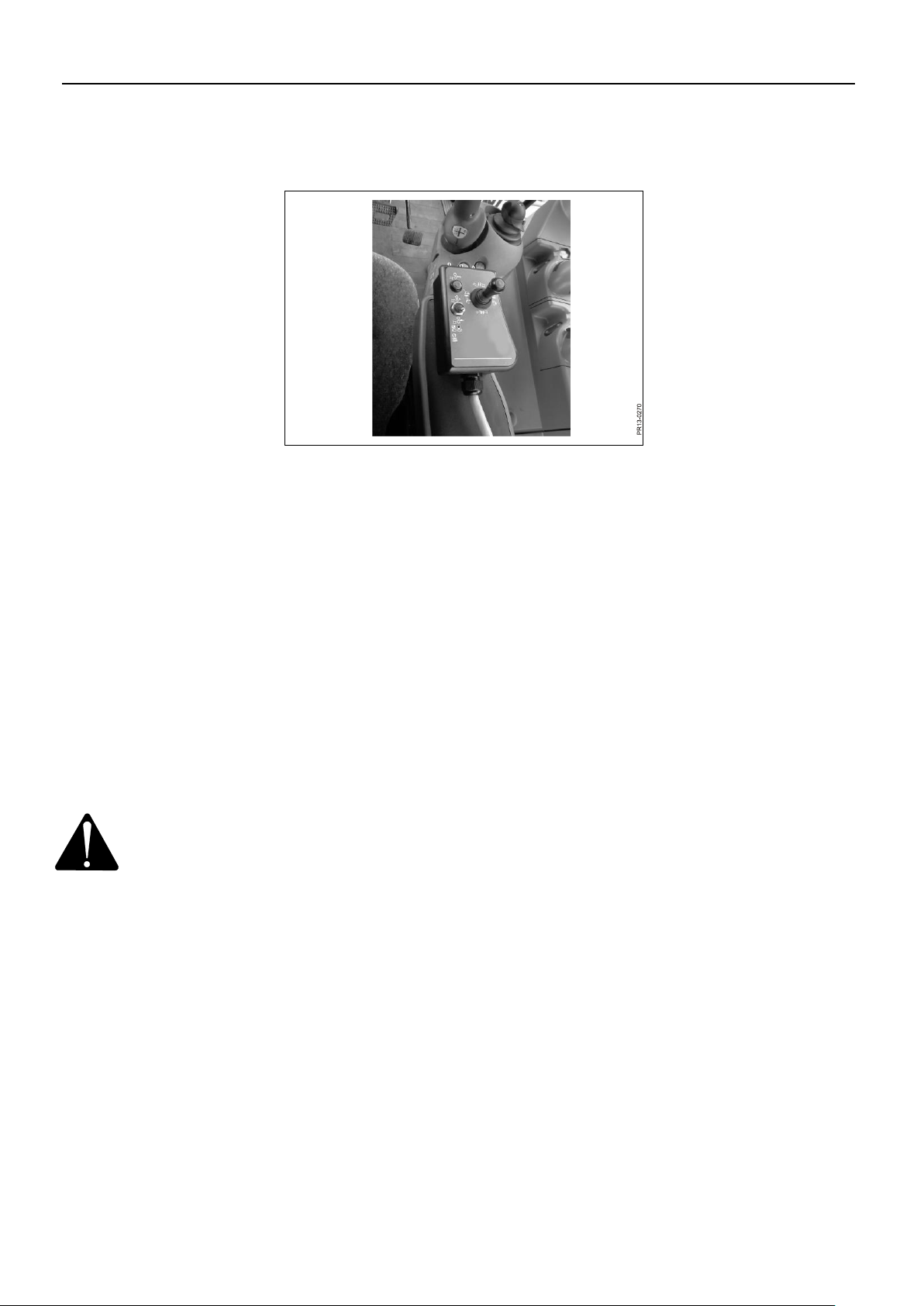

Fig. 2-4

ELECTRO-HYDRAULIC CONTROL

The machine is operated from the control box, which controls the electro-hydraulic

functions.

Fig. 2-4 The control is turned on and off on the side of the control box.

IMPORTANT: Remember to turn off the control box if the tractor is going to be

stopped for some time. Although the machine is not in operation,

several electric coils may be activated. These will drain the tractor’s

battery.

Page 28

PIGB-206B-02 FCT 1260-1460 0218

- 28 -

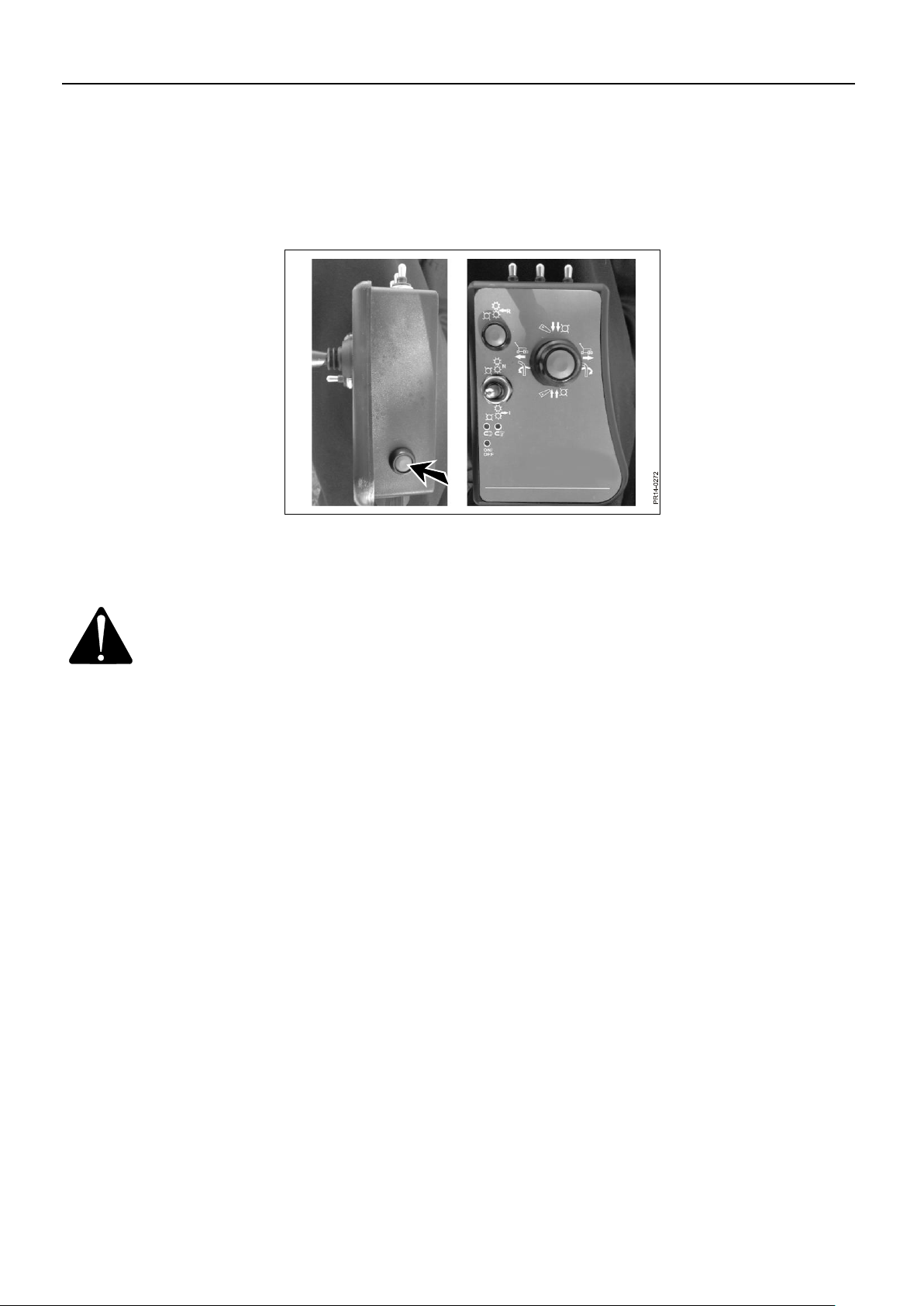

FUNCTIONS

Fig. 2-5

Fig. 2-6

Fig. 2-5 On the joystick:

Chute: Push to the left: The chute turns anti-clockwise. Push to the right: The chute

turns clockwise.

Drawbar: While pushing the button: Push to the left: The machine moves behind the

tractor. Push to the right: The machine moves out to the swath.

2. CONNECTING TO THE TRACTOR

Fig. 2-6 On the joystick:

Chute: Push forwards: The deflector points downward. Pull back: The deflector

points upward.

Pick-up: While pushing the button: Push forward: The pick-up is lowered. Pull back:

The pick-up is raised.

It takes around two seconds to lower the pick-up completely so that the supporting

wheels can follow the ground

Page 29

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 29 -

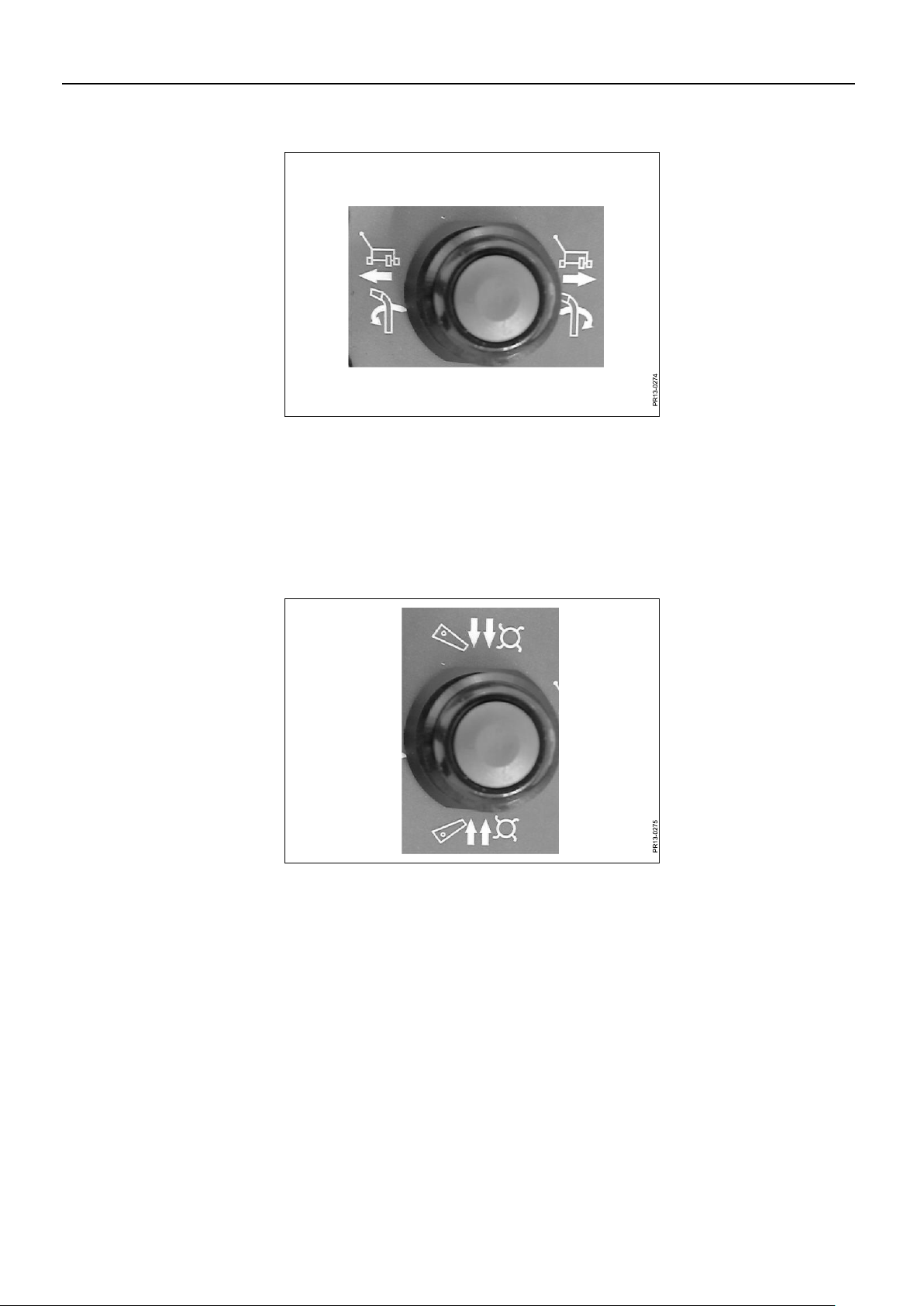

Fig. 2-7

Fig. 2-8

Fig. 2-7 Reverse function. Applies to feed rollers and pick-up.

Feed in: Move the toggle switch to the rear.

Neutral: Move the toggle switch forward for around two seconds and then back to

the centre position. Feed rollers and pick-up stay in neutral position.

Reverse: With the toggle switch in the centre position, you reverse by holding down

the push-button. Reversing will stop when you release the button.

Fig. 2-8 There are three toggle switches at the front of the control box. One of these controls

the folding of the chute, while the other two switches are for accessories. These

switches automatically return to the neutral centre position after being activated.

Page 30

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 30 -

Fig. 2-9

Fig. 2-10

Control lights

Fig. 2-9 This light will be illuminated when the control unit is switched on.

Fig. 2-10 The control light on the left is illuminated when the metal detector is active. It turns off

when there is a stoppage caused by metal or if the metal detector is turned off.

The control light on the right will illuminate constantly when there is a stoppage

caused by metal. If the light flashes, this indicates that the control box has been

turned off or there is a loose connection with the control box on the tractor.

The metal detector turns on each time the control unit is switched on. If you wish to

turn off the metal detector, this can be done by pushing the button on the MD control

unit on the machine.

Hold the button for about 5 seconds. The control light on the left of the control box

then extinguishes. The control light on the left of the control box will remain

illuminated until the metal detector is turned off.

See also the section: "MD-CONTROL"

Page 31

PIGB-206B-02 FCT 1260-1460 0218

- 31 -

Fig. 2-11

PR11-5017

DRAWBAR AND PTO DRIVE SHAFT

The hitch eye of the drawbar is intended for a 30 mm hitch pin. The hitch pin must be

secured.

The drawbar load is around 700 kg depending on equipment.

STANDARD PTO SHAFT

The machine can be supplied with a standard PTO shaft and a wide-angle shaft. This

section relates to the fitting of a standard PTO shaft. The subsequent section relates

to a wide-angle shaft.

2. CONNECTING TO THE TRACTOR

Fig. 2-11 Adjust the length of the PTO shaft so that:

- The operating position has minimum overlap of 200 mm, see measurement b.

- Under no circumstances should the shaft be closer to the block than 30 mm, see

measurement a.

The length may be adjusted both by pulling out or pushing in the drawbar of the

tractor.

Page 32

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 32 -

Fig. 2-12

Fig. 2-12 The height of the drawing eye H must be set in such a way that the PTO shaft is

horizontal. The height may be altered by moving or turning the drawbar bracket.

In order to ensure the longest possible lifetime of the PTO shaft in the case of the

standard PTO shaft without a wide-angle, the length L1 must be equal to the length

L2, i.e. the fulcrum P for the drawbar to be as close as possible beneath the centre

point between the intersections. The drawbar bracket on the forage harvester may be

moved back or forward in increments of 25 mm.

IMPORTANT: The drawbar must always be fitted and tightened with four bolts.

Page 33

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 33 -

Fig. 2-13

SHORTENING THE PTO SHAFT

Particular caution is required when shortening the PTO shaft. If the PTO drive shaft is

shortened too much, there is a risk that the profile tubes may be pulled apart, which

may cause serious damage.

This particularly applies in connection with operation on hilly ground, when the

machine and the tractor have varying angles in relation to each other. Conversely, if

the PTO drive shaft is not shortened enough, there is a risk of squeezing during

sharp turns, which may cause high frictional forces in the PTO drive shaft, which in

turn will damage the axle joints.

Fig. 2-13 Fasten the halves of the shaft to PTO and PIC (fig. 2.11) respectively when these are

immediately opposite each other with the machine in the operating position. (The

longest distance on this machine). Hold the shaft ends parallel to each other and

mark the desired amount to be shortened, but with an overlap of no less than 200

mm. Shorten all four tubes by the same amount.

Round off the ends of the tube profiles and carefully remove any burrs. It is very

important that the tubes are smooth and clean prior to lubrication. Lubricate the tubes

carefully before reassembling.

WARNING: To avoid bottoming the shaft, never turn so sharply that there is

less than the prescribed 30 mm distance. See measurement a in

fig. 2-11.

If the PTO drive shaft bottoms when turning sharply, there is a

risk that the shaft and/or other transmission parts will be

damaged.

Page 34

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 34 -

PR11-1878

Fig. 2-14

FRICTION CLUTCH

There is an integral friction clutch on the PTO drive shaft between the drawbar and

the gearbox, which ensures that the machine is not overloaded during operation.

The clutch must be "vented" before you start a new machine. See section concerning

the friction clutch in chapter 7 "MAINTENANCE".

WIDE-ANGLE PTO SHAFT

If the machine is supplied with a wide-angle PTO shaft, it must also be supplied with

an extension to the drawbar.

You must fit the wide-angle PTO shaft to the machine and the tractor before fitting

the extension. The tractor must be positioned directly in front of the drawbar so that

the PTO shaft is not at an angle, with the PTO shaft extruding between 125 and 175

mm.

Fig. 2-14 The height of the machine is adjusted using the support leg, so that the PTO shaft is

horizontal.

Page 35

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 35 -

PR12-1910

A

B

Fig. 2-15

PR11-1880

C

C

Fig. 2-16

Fig. 2-15 The tractor's drawbar B is then placed so that distance A is as small as possible.

The extension is then fitted to the machine and the tractor. It may be necessary to

adjust the height of the machine and the position of the tractor to make it fit.

Fig. 2-16 Crash pads C must be fitted in order to ensure that the wide-angle PTO shaft is not

damaged. They also prevent a collision with the folding chute in its transport position,

if you turn the machine too abruptly.

Page 36

2. CONNECTING TO THE TRACTOR

PIGB-206B-02 FCT 1260-1460 0218

- 36 -

D

C

Fig. 2-17

Fig. 2-17 The machine must be placed in the transport position to fit the pads and ensure that

the PTO shaft is properly installed. Turn the tractor so that there is a maximum of 70

degrees between the tractor and drawbar. While doing this, make sure that the PTO

shaft does not get blocked or the chute hits the tractor D; the PTO shaft must be min.

30 mm from the block. If this is not achieved, you must readjust the drawbar.

NOTE. At no point in time must the PTO shaft be extended more than

220 mm.

Finally, while the tractor has been turned, fit the crash pads in the same way on both

sides.

The PTO shaft must never be raised. In the event of blockage, please extend the

drawbar.

Page 37

PIGB-206B-02 FCT 1260-1460 0218

- 37 -

Fig. 3-1

PR12-0212

A

B

PR11-1811

Fig. 3-2

3. COUPLING OF EQUIPMENT

Coupling for the first time is easiest in a workshop on even ground. The basic

machine must always be coupled correctly to the tractor in accordance with section 2

"CONNECTING TO THE TRACTOR" before equipment and accessories are

connected up.

PICK-UP

Coupling is easiest on even ground.

The basic machine must be coupled to a tractor in accordance with section 2

"CONNECTING TO THE TRACTOR"

3. COUPLING OF EQUIPMENT

Fig. 3-1 Wheel the pick-up on the rollers to the machine so that catch A is engaged. The two

pins must be fitted in order to lock the pick-up to the basic machine.

Attach the relief device to the pick-up at B.

Fig. 3-2 The PTO shaft A for the pick-up drive must be coupled.

Page 38

3. COUPLING OF EQUIPMENT

PIGB-206B-02 FCT 1260-1460 0218

- 38 -

Fig. 3-3

PR11-1812

15-20 m

m

Fig. 3-4

PR11-1813

Fig. 3-3 The height of the rollers under the pick-up can be adjusted. Adjust the height so that

there is a distance of 15 – 20 mm between the points of the pick-up tines and the

ground.

Fig. 3-4 Tighten the relief springs using spindle A until the ground pressure for the pick-up is

a maximum of 30 kg. The spindle lock B must be pulled out to release the spindle,

and pushed in to lock it. Lift the lock to move this. Hold spindle A horizontal, so that

lock B can engage.

Page 39

3. COUPLING OF EQUIPMENT

PIGB-206B-02 FCT 1260-1460 0218

- 39 -

Fig. 3-5

PR12-1749

B

A

Fig. 3-6

PR12-1752

Fig. 3-5 The stop, B, for lifting the pick-up can be adjusted to achieve the maximum lifting

height without the pick-up colliding with the drawbar at A.

Fig. 3-6 The hydraulic hose for lifting an auger and front roller must be connected to the

quick-release coupling at the left hand catch.

Page 40

3. COUPLING OF EQUIPMENT

PIGB-206B-02 FCT 1260-1460 0218

- 40 -

Fig. 3-7

PR12-0449a

B

A

TRANSPORT CONVERSION

Fig. 3-7 The drawbar may be converted electro-hydraulically using the joystick on the control

box.

The hydraulic cylinder A is equipped with a safety valve B which ensures that the

machine does not make any unintentional movements in cases where there may be

a leaking hose.

Page 41

3. COUPLING OF EQUIPMENT

PIGB-206B-02 FCT 1260-1460 0218

- 41 -

PR11-1855

Pos. 1

Pos. 2

Pos. 3

Fig. 3-8

FITTING CHUTES

There are 3 different chute options and 3 different positions of the bracket for chute

turning, in order to accommodate most needs.

NOTE. Not all machines offer the option for 3 positions of the bracket for chute

turning.

CHUTE TURNING

There are the following 3 positions for fitting the chute turning bracket, in order to

optimise unloading to a selected side.

Fig. 3-8 Pos. 1 for unloading to the right

Pos. 2 for unloading both sides. Cannot be used with the collapsible chute.

Pos. 3 for unloading to the left

When the chute is fitted, you must turn carefully from outer position to outer position

in order to ensure that the hydraulic hoses are fitted correctly and are long enough.

Page 42

PIGB-206B-02 FCT 1260-1460 0218

- 42 -

Fig. 3-9

PR11-1849

Fig. 3-10

PR11-1850

Fig. 3-11

PR11-1851

Fig. 3-9 Position one

3. COUPLING OF EQUIPMENT

Fig. 3-10 Position two

Fig. 3-11 Position three

NB! Not all machines offer the option for 3 positions of the bracket for chute turning.

Only position 3 is offered for these machines.

Page 43

3. COUPLING OF EQUIPMENT

PIGB-206B-02 FCT 1260-1460 0218

- 43 -

Fig. 3-13

PR11-1750

Fig. 3-12

PR11-1854

STANDARD CHUTE

Fig. 3-12 This is the standard chute that is supplied with the machine. It is approx. 3.8 metres

high in the transport position.

FOLDING CHUTE

Fig. 3-13 The machine can be fitted with a chute that permits loading of very high trailers. This

chute must be folded down during transport, so that it rests on a stand on the

drawbar. This reduces the transport height to less than 4 metres.

The chute is collapsed by a hydraulic cylinder that is controlled from a toggle switch

on the front of the control box in the driver's cab.

The chute is operated electro-hydraulically with the joystick and toggle switch on the

control box. Move the drawbar into the transport position, turn the chute into position

above the stand and fold it down until it rests on the stand.

Page 44

3. COUPLING OF EQUIPMENT

PIGB-206B-02 FCT 1260-1460 0218

- 44 -

Fig. 3-14

PR11-1853

DANGER: The chute is more than 4 m high. Be aware of high-voltage lines.

Keep a safe distance from high voltage lines.

WARNING: Make sure that persons keep a safe distance from the machine when

moving the chute. The hydraulic functions must be operated from the

tractor.

IMPORTANT: Be careful not to hit the tractor cab.

IMPORTANT: Do not move the drawbar while the chute is resting on the stand.

IMPORTANT: Do not turn the chute while it is resting on the stand.

IMPORTANT: The chute must always rest on the stand during transport. This is

partly due to the Road Traffic Act and also because the

chute/delivery chute may get damaged, for instance if you drive fast

on uneven ground.

CHUTE FOR PARALLEL OPERATION

Fig. 3-14 The machine can be fitted with a chute that has a transport height of 4.4 metres. This

chute cannot be folded for transport.

Page 45

3. COUPLING OF EQUIPMENT

PIGB-206B-02 FCT 1260-1460 0218

- 45 -

Fig. 3-15

PR11-1852

A

B

Fig. 3-15 When this equipment is fitted, it is important that an extra spring A is fitted for chute

relief, in order to compensate for the added weight of the chute. Bracket B must be

moved to the indicated position so that the wire is not too short.

Page 46

PIGB-206B-02 FCT 1260-1460 0218

- 46 -

Fig. 4-2

PR12-1759

C

Fig. 4-1

PR11-1812

15-20 m

m

PICK-UP

4. SETTINGS

4. ADJUSTMENTS

Fig. 4-1 The underside of the pick-up is equipped with steel supporting rollers, which are

height-adjustable. You should keep the pick-up at such a height that the tines do not

hit the ground and get earth into the crop, but so that the tines can also pick up the

grass without waste.

Kongskilde A/S recommends a distance between the pick-up tines and the ground of

15 to 20 mm.

Fig. 4-2 Before making any adjustment, the cylinder stop C must be engaged and secured

using the pin.

Page 47

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 47 -

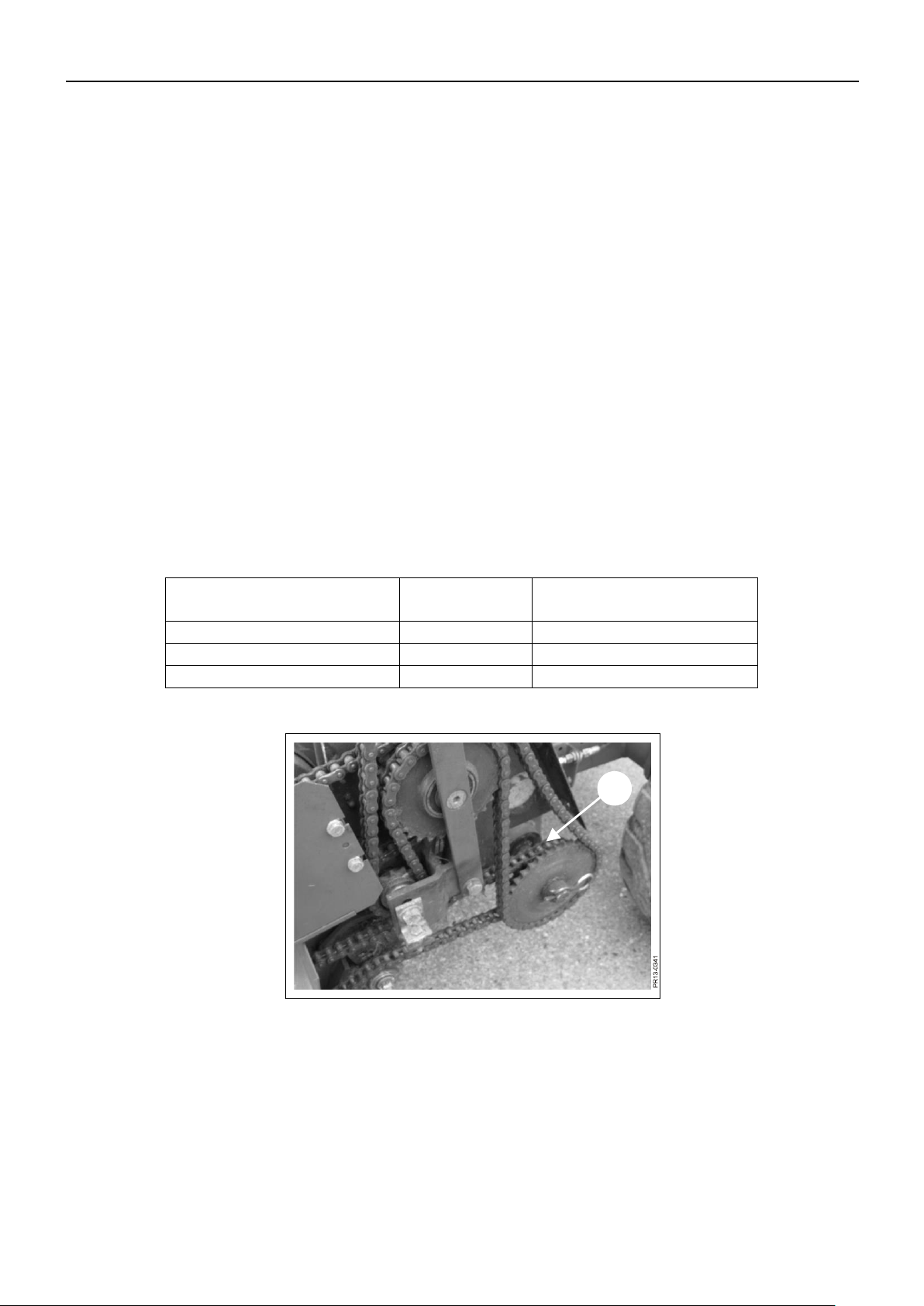

Sprocket no.

Number of

teeth Z

Speed

2064-720x

21

10 km/h

2065-897x (Standard)

25

12 km/h

2065-994x

30

14 km/h

A

Fig. 4-3

The auger on the pick-up is equipped with a slip clutch. The slip clutch of the auger is

adjusted so that it releases before the other friction clutches in the machine.

The highest capacity is obtained by operating at a forward speed where you drive

without causing blockages in the auger. If there is a blockage around the auger, stop

and force the crop out of the machine by using the reverse function. See also section

"6 OPERATION IN THE FIELD".

A continuous and even flow through the pick-up and auger is the best way to avoid

blockages inside the machine, which can lead to long operational stoppages.

The operator should always have spare friction discs for the slip clutch on the auger

are kept in the tractor. If this clutch has been in operation for a considerable period,

the coating on the friction discs will become worn and will be unable to transmit

sufficient torque. It may therefore be necessary to replace the friction discs, but

remember these must be of the same quantity and quality.

CHANGE OF SPEED OF PICK-UP TINES

Extra sprockets and chains are supplied in order to be able to change the speed of

the pick-up tines. This is an option that permits optimisation of material harvesting.

The stated speeds are the tines' peripheral speed on the ground with the maximum

cutting length.

Fig. 4-3 This is sprocket A, which is replaceable.

Page 48

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 48 -

Fig. 4-4

OPENING THE ROTOR HOUSING

Fig. 4-4 The chute must be lowered in order to open the rotor housing. In order to make this

easier, the chute is relieved by strong springs.

DANGER: First ensure that no one other than the operator is in the vicinity.

WARNING: The hydraulically folding chute (accessory) is so heavy that the

rotor housing cannot be opened manually for access to the blade

rotor. Instead, please use the procedure described in Fig. 4-10 – Fig.

4-14.

WARNING: The chute for parallel operation (accessory) requires two people to

open and close the rotor housing, as the weight of this exceeds the

permitted amount.

Page 49

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 49 -

PR11-1766

Fig. 4-5

Fig. 4-7

Fig. 4-6

Fig. 4-5 1) Turn the chute to the rear. Turn the deflectors to the centre of the operating range.

Fig. 4-6 2) Open the guard above the rotor housing and the left-hand guard.

Fig. 4-7 3) Open the lock clamps at the front of the rotor housing.

Page 50

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 50 -

PR13-0284

Fig. 4-8

Fig. 4-9

Fig. 4-8 4) Tilt the chute to the rear and down using the handle, which will open the rotor

housing.

5) Close the rotor housing following the same procedure in reverse order.

Fig. 4-9 When closing the rotor housing, it is an advantage to lift the chute initially.

Page 51

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 51 -

PR12-1753

A

Fig. 4-10

PR12-1754

B

B

Fig. 4-11

COLLAPSIBLE CHUTE

WARNING: The chute is so heavy that the rotor housing cannot be opened

manually for access to the blade rotor. Use the following procedure

instead:

DANGER: First ensure that no one is in the vicinity. The hydraulic functions

must be operated from the tractor.

Fig. 4-10 Turn the chute to the rear. Turn the deflectors A to the centre of the operating range.

Fig. 4-11 Fold down the chute to about 1.5 m above the ground and mount the wheels B using

the pin and split pins.

Page 52

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 52 -

PR11-1755

Fig. 4-12

Fig. 4-13

PR12-1756

C

C

Fig. 4-12 Fold down the chute until the wheels rest on the ground.

Fig. 4-13 3) The lock clamps C at the front of the rotor housing can now be opened safely.

Page 53

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 53 -

PR12-1757

Fig. 4-14

Fig. 4-14 Now move the chute cylinder in direction "Chute closed", which opens the rotor

housing.

Close the rotor housing following the same procedure in reverse order.

Page 54

PIGB-206B-02 FCT 1260-1460 0218

- 54 -

Fig. 4-15

ROTOR AND ROLLER SECTION

4. SETTINGS

Fig. 4-15 The distance A between the blades of the rotor and the shearbar must be checked

regularly using the gauge supplied (distance measuring device). A distance of 0.5

mm should be aimed for. If it is necessary to adjust the distance, loosen the two

bearing housings B and adjust using the screws C. When the distance has been

checked, tighten the bolts D of the bearing housings using a torque wrench to 40

kgm (400 Nm).

The machine is equipped with a scraper for the smooth roller E. The scraper is fitted

together with the reversible shearbar previously mentioned.

The scraper is placed as close to the smooth roller E as possible without touching it.

Therefore, the distance between the scraper and the smooth roller should be

between 0.2 and 0.5 mm. Then tighten the bolts F using a torque wrench to 10-12

kgm (100-120 Nm). Incorrect adjustment of the scraper may result in

overheating of the smooth roller and an operational stoppage.

Page 55

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 55 -

Fig. 4-16

PR12-0458

A

B

Fig. 4-17

PR11-0231

M

a

x

.

3

m

m

G

Fig. 4-16 The scraper is dismantled by removing the screws F (on Fig. 4-15), which also

secure the shearbar, after which the scraper and shearbar can be pulled out of the

opening A in the side of the rotor housing. The spring B for the serrated roller must

first be loosened or dismantled to allow sufficient space. If the shearbar has been

worn, it can be reversed to obtain a new sharp coulter.

Fig. 4-17 The distance between the smooth roller and the serrated roller should be a maximum

of 3 mm. Adjustment may be made using the bolts G at both sides of the rotor

housing.

Page 56

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 56 -

Fig. 4-18

PR11-0332

M

i

n

.

0

,

5

m

m

Fig. 4-19

PR11-1814

B

Fig. 4-18 Crop substances (small particles) can accumulate in the shaded area under certain

circumstances and become so compacted that it causes the transmission driving the

rollers to overload.

Check the area after every eight hours of operation and remove any crop residues.

Check, and if necessary adjust, the distance between the scraper and smooth roller.

The frequency of these checks may be reduced when the operator has become

familiar with the machine under all conditions.

Fig. 4-19 The bottom plate B may be mounted beneath the roller section as an additional piece

of equipment. This may be mounted when operating in very dry and/or short crops to

avoid waste under the rollers.

IMPORTANT: When operating under normal conditions, we recommend you

operate without this bottom plate, as material can otherwise

accumulate under the rollers, resulting in reduced capacity and

unnecessary overloading of the transmission.

However, the bottom plate may be mounted when operating in

crops where there is excessive waste beneath the rollers.

Page 57

PIGB-206B-02 FCT 1260-1460 0218

- 57 -

Adjustments

Theoretical cutting length

24 blades

Theoretical cutting length

32 blades

1

21 mm

15 mm

2

13 mm

9 mm

Fig. 4-20

Fig. 4-21

PR11-0217

CUTTING LENGTHS

FCT 1260

4. SETTINGS

Fig. 4-20 The cutting length may be altered by switching between the two positions of V-belts

operating the gear for the feed rollers.

The figures in the table specify the theoretical cutting length in mm.

Fig. 4-21 The cutting lengths can be doubled by removing every other row of blades in the

rotor.

Page 58

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 58 -

Adjustments

Theoretical cutting length

24 blades

Theoretical cutting length

32 blades

1

21 mm

16 mm

2

16 mm

12 mm

Adjustments

Theoretical cutting length

24 blades

Theoretical cutting length

32 blades

1

11 mm

8 mm

2

8 mm

6 mm

PR11-1816

A

Fig. 4-23

Fig. 4-22 Setting 1 Setting 2

PR11-1815

FCT 1260 MD AND FCT 1460 MD

Fig. 4-22 The cutting length may be altered using the harvesting gearbox, which has two

gears. This is done by removing the pin and moving the handle to the desired

position. Insert the pin again.

The following cutting lengths in mm may be obtained as standard:

Fig. 4-23 If a particularly short cutting length is desired, the outer belt pulley A must be moved

from the turning gear to the harvesting gear. This allows the following cutting lengths

to be obtained:

Page 59

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 59 -

Fig. 4-24

PR11-0217

Fig. 4-25

PR11-1817

Fig. 4-24 The cutting lengths can be doubled by removing every other row of blades in the

rotor.

Fig.4-25 The gear wheels of the harvesting gearbox are not engaged in the position

between setting 1 and setting 2.

Page 60

PIGB-206B-02 FCT 1260-1460 0218

- 60 -

Fig. 4-26

PR11-0232

Min. 12 mm

REPLACEMENT AND ADJUSTMENT OF BLADES

When replacing a single blade, the blade must be placed at the same distance from

the shearbar as the other blades. To ensure that the rotor is balanced, it may be

necessary to also replace the opposite blade because used blades have different

weights compared to new blades.

Even if there are no visible signs of damage to the blade bolts, they should always be

replaced together with the blades because they may have been overloaded.

CAUTION: Check the distance between the blade and the shearbar (0.5

mm) using the gauge supplied before the bolts are tightened.

WARNING: Only use original blade bolts when replacing. Tighten the blade

bolts using a torque wrench to 40 kgm or with the spanner

supplied using approx. 40 kg leverage.

4. SETTINGS

Fig. 4-26 When the blades have been worn by a maximum of 8 mm or to the first bend, i.e.

approx. 12 mm above the straight piece of the blade, they must be replaced.

DANGER: When all blades on the rotor have become worn and the rotor

has been adjusted towards the shearbar, it MUST be adjusted

back again before new blades are fitted. Otherwise there is a

risk that the new blades will collide with the shearbar when the

rotor is turned.

Page 61

4. SETTINGS

PIGB-206B-02 FCT 1260-1460 0218

- 61 -

Fig. 4-27

PR11-0470

1

7

8

Ø

4

8

0

PR11-1881

A

Fig. 4-28