Page 1

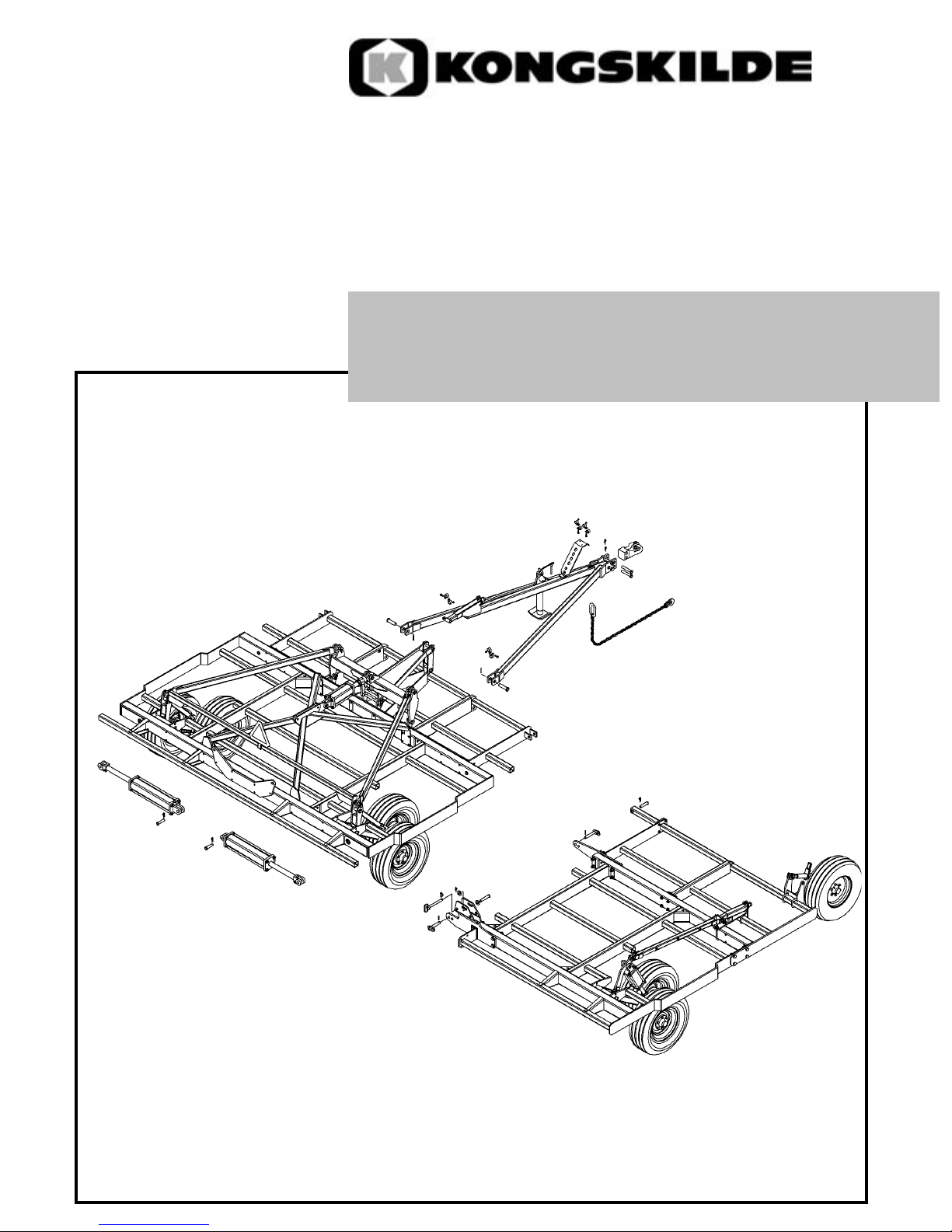

2800 VIBRO-TILL

FIELD CULTIVATOR

Kongskilde

2800 Series

*Model may not be exactly as shown.

Kongskilde reserves the right to make changes to product designs and specifications without notice or obligation to rework.

See your local Kongskilde representative for current product

specifications, instructions and options.

ASSEMBLY INSTRUCTIONS

Page 2

Introduction:

Please take the time to carefully read and review all instruction booklets provided with your

new Kongskilde product.

These instruction booklets have been developed to assist you in assembling, adjusting and

maintaining your new Kongskilde Product. To obtain optimal performance over the lifetime of

the product read and follow these instructions carefully.

A copy of the Spare Parts List has also been provided in order to identify the components

and hardware needed for each step of the assembly and to help you identify and obtain

replacement parts in the future.

When the assembly of the unit is completed, please refer to the Owners Manual before

attempting to adjust or use the product. The Owners Manual will provide you with further

instructions on the proper Field Settings, Adjustments and Maintenance Procedures for Safe

Operation of the unit.

If optional equipment or attachments have been ordered for your unit, please refer to the

instruction booklets provided for proper installation and adjustment of these accessories.

Please take the time to fill out and return the Owners Registration and Warranty Form provided

in the Owners Manual in order to activate the warranty coverage.

2

Page 3

Pre Assembly Instructions:

Assembly of Kongskilde products should only be undertaken by authorized Kongskilde Dealers

or an approved service provider who has the necessary tools, equipment and training for safe

handling and proper assembly of the unit.

Proper handling and assembly of the components is critical in order to validate the warranty

policy.

It is important to note that the frame components are heavy and somewhat awkward to handle.

Proper lifting devices such as overhead cranes, boom lifts or mobile lift trucks should be used

at all times when moving or handling the large frame components and must only be operated

by individuals who have had the proper safety training for using such devices. Proper steel

assembly stands or support jacks should also be used to support the frame components and

prevent them from falling during assembly.

Recommended assembly tools include:

A full set of standard open or box end wrenches and sockets; assorted sizes of pin punches;

a heavy hammer and/or sledge hammer; a pry bar; a large adjustable wrench; and pair of

visegrip or similar type pliers.

Optional tools could include an all purpose jack and a good quality air or electric drive impact

tool with heavy drive sockets.

The assembly area should be should be large enough to allow workers and equipment to

move around freely during assembly of the unit.

For example; to fully assemble a 2800-90 with 29' (9m) working width, a minimum area of

30' x 40' (10m x 12m) with 16' (5m) overhead clearance is required to assemble and fold the

machine.

If the unit is to be assembled and folded indoors, additional clearance may be needed in the

assembly area.

The ceiling height and the size of the building exit door must also be considered in order to

safely fold and move the cultivator outdoor after assembly.

The floor area should be relatively clean and level.

Proper lighting and ventilation should also be provided to allow the work to be carried out in

a safe and efficient manner.

3

Page 4

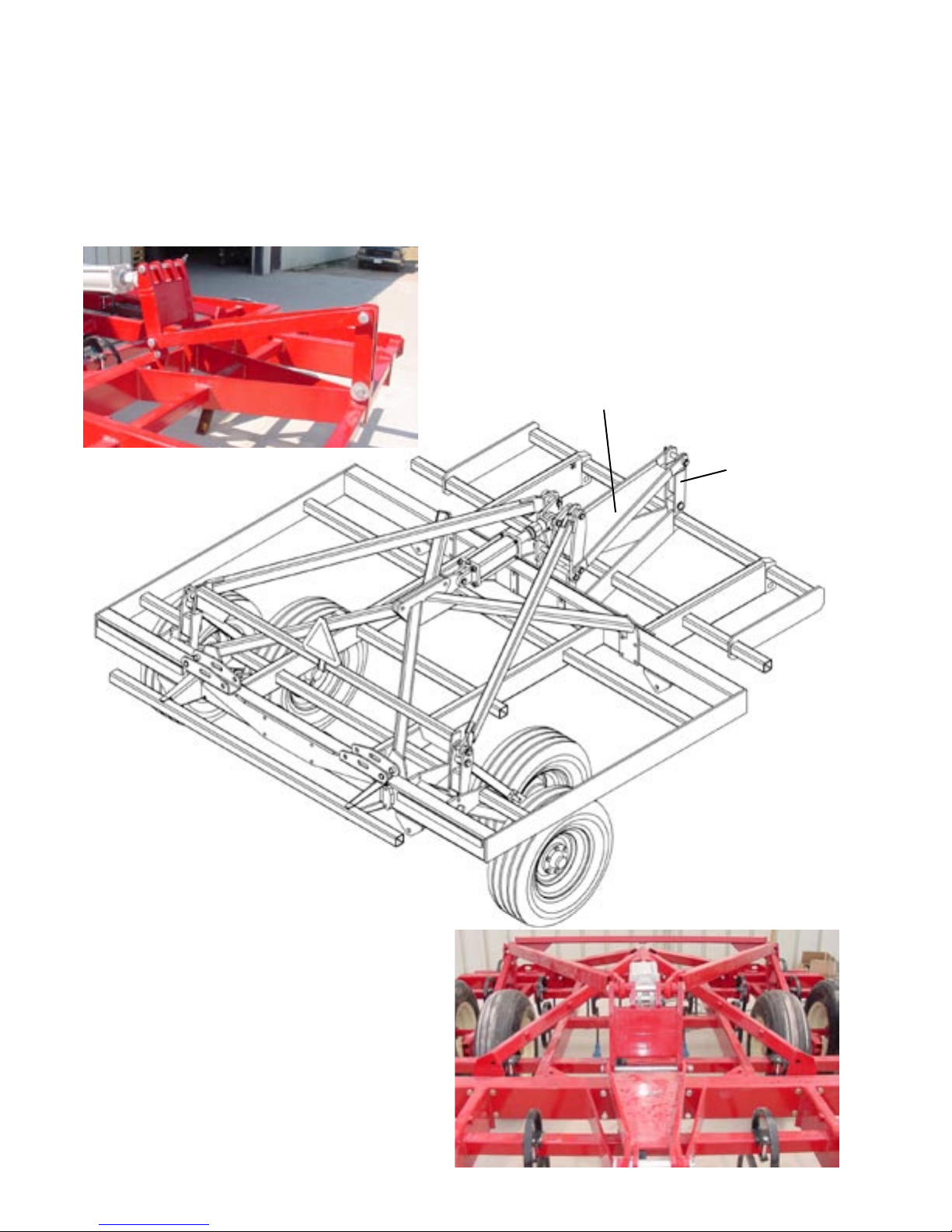

FRAME ASSMEBLY

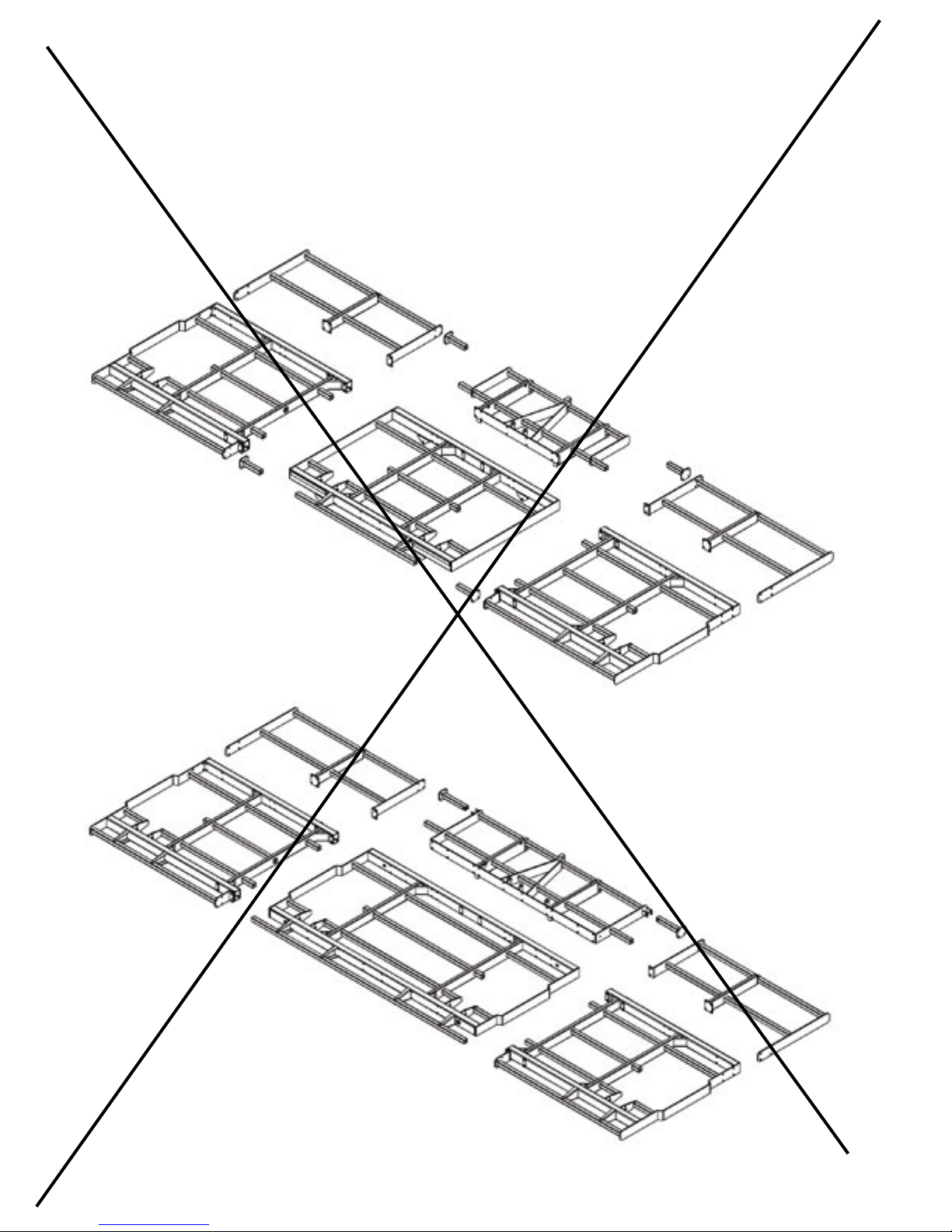

Sort out the frame sections for the size of cultivator you are assembling. Note that there are 2

different centre frame configurations as shown below: 1) 10' (3m) narrow transport model or

2) 13' (4m) wide transport model.

The main wing frames are the same for both the 3m and 4m models however, some compnents

are different such as the folding hinges, assembly hardware and hydraulic hose kits. Refer to

the spare parts list supplied for a full description of all of the different parts for both models.

Frame assembly with

10' (3m) centre section.

Frame assembly with

13' (4m) centre section.

4

Page 5

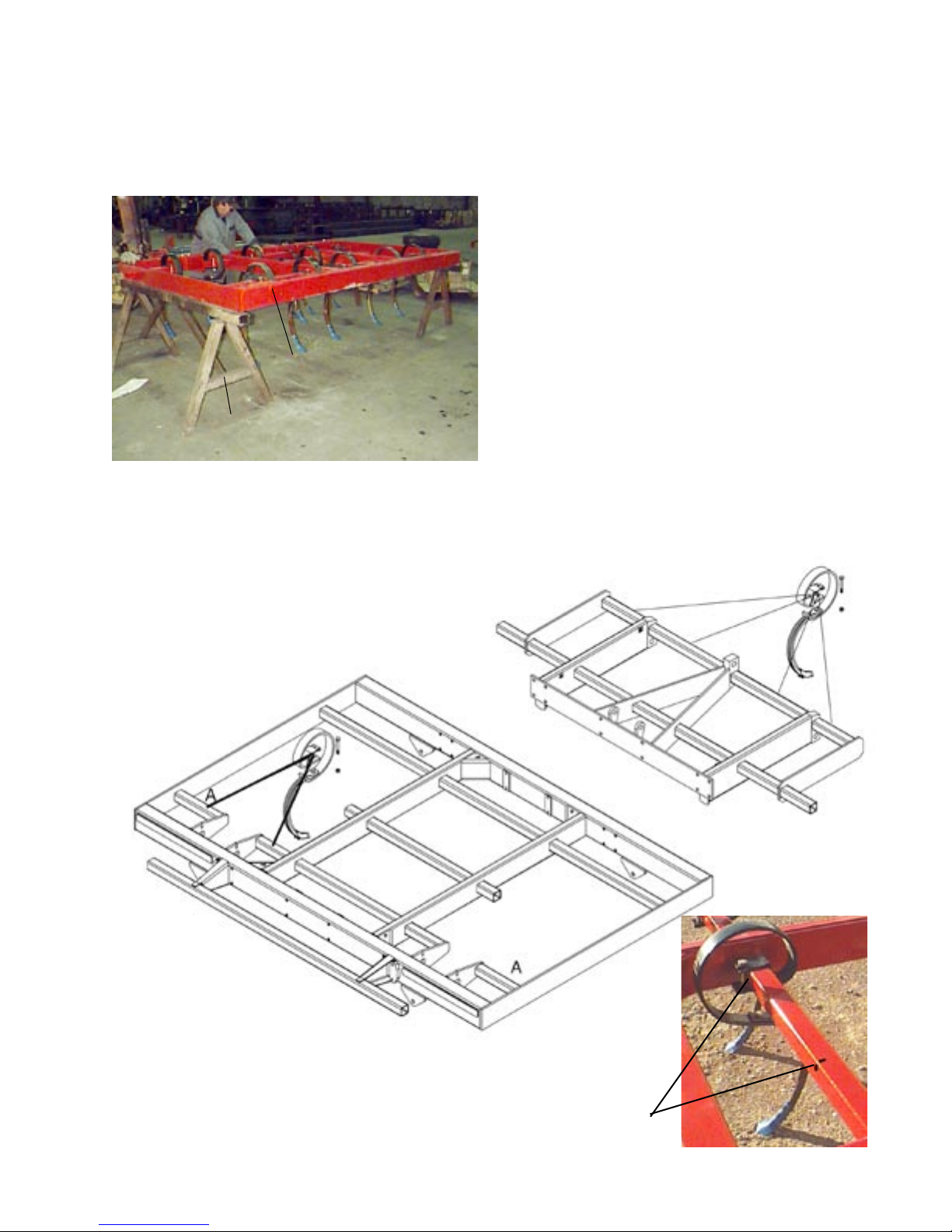

To ensure the stability of the frames and safety of the workers during assembly, place the

cultivator frames on surdy steel shop stands. Do not use construction blocks, tiles or supports

constructed of wood or other materials that could crush under continuous load. Position the

stands so they do not interfere with the mounting of frame components and tines.

Locate the tine patterns in the back of the

booklet for the model of cultivator you ordered

and begin measuring the tine locations on

each of the toolbar tubes.

Note that there are 2 standard tine patterns:

4" (100mm), and 6" (155mm). Tine quantities

delivered with the unit are based on the model

Cultivator frame.

size of cultivator and the tine spacing chosen

at time of order. Therefore, if you decide to

change the tine spacing after delivery of

Steel support stands.

the unit you may need to order extra tines

depending on the pattern you choose. Other

Tines mounted in the wheel area or near the

hinge points should be left loose until after the

tine spacings are available on request for

various special applications.

wheel arm assemblies and wing fold hinge

plates are installed. This will allow the tine to

move out of the way during assembly of the

wheels and hinge components.

Note: On 3m center, a 4 inch

sweep cannot be placed on

toolbar outside the wheel

(position A). Sweep will

interfere with tire.

Hook a tape measure on the "0" side of the cultivator frame and

put a mark on the front side or top of the toolbar tubes at the

dimensions shown on the tine pattern drawings. Mount the tines so

they are centred at the location marked. The mark will be covered

by the clamp and bolt.

5

Page 6

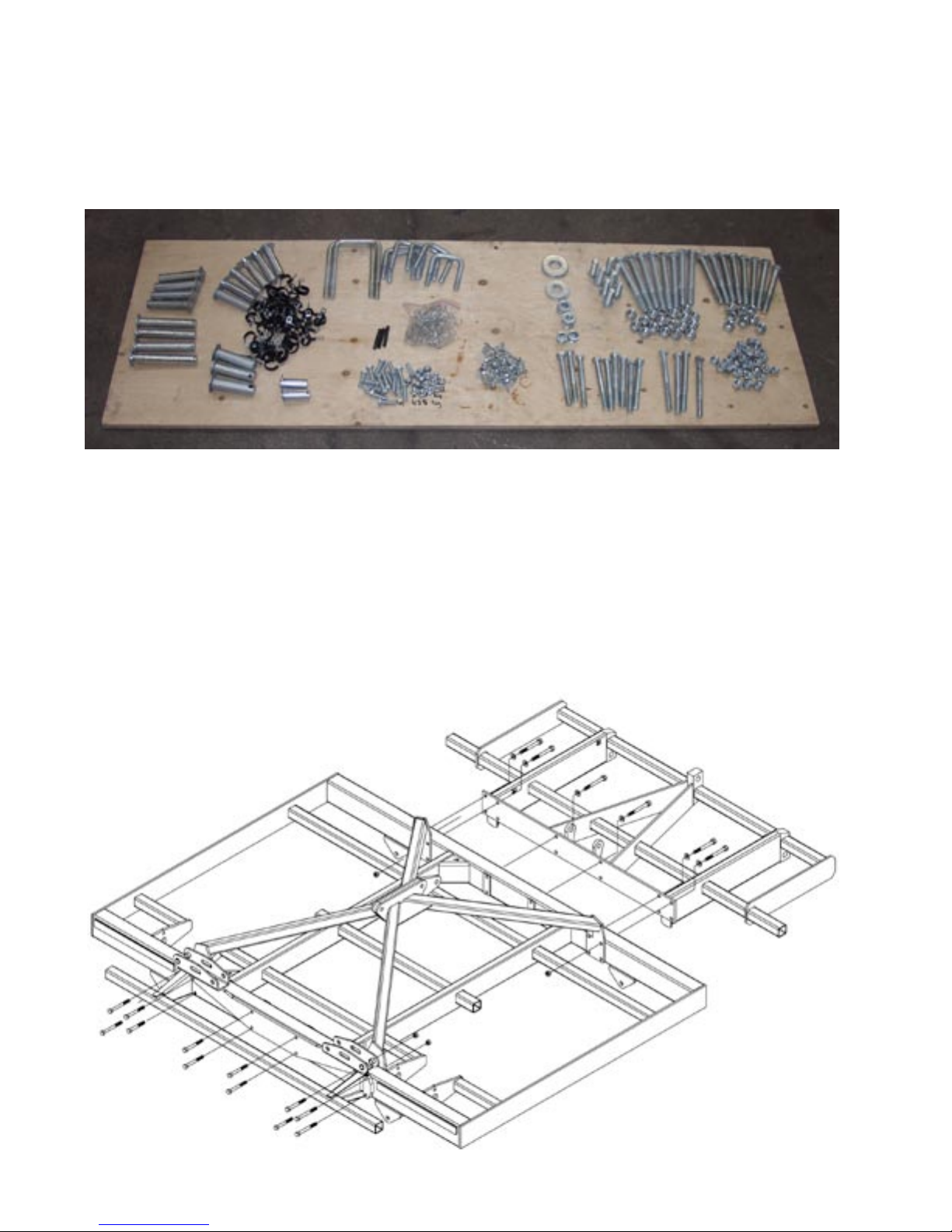

Carefully unpack and lay out all of the fasteners and hardware. (The empty shipping crate

and cardboard makes an excellent temporary work bench.) Assembling the cultivator is more

efficient if you take a few minutes to sort and organize the hardware by type and size instead

of dumping the bag or box in a pile on the floor. Place the assembly instructions and parts list

on the table for quick reference to help identify the parts for each step of the assembly.

When the tines are mounted to the main frame and front extension, move the 2 frame sections

together and assemble the centre section with the bolts, nuts, washers and pins shown in the

parts list.

Take care to insert the front frame bolts from the front and insert the back frame bolts from the

back so that the locknuts are all facing inside the machine. This will keep the frame assembly

looking neat and tidy and make the assembly more efficient.

(Note: The assembly diagrams do not show tines installed for easier viewing. In special

situations where the machine must be partly assembled and shipped to another location, the

tines may be mounted after assembly. But generally you will find it easier to mount the tines

as you assemble each frame section.)

Example:

10' (3m) Centre & Front Frame Assemby

6

Page 7

Frame assembly can be done while the frames are sitting on the assembly stands, or the

stands may be removed once the tines are mounted. Use a fork lift or overhead hoist to move

the heavy frame components into position for assembly.

7

Page 8

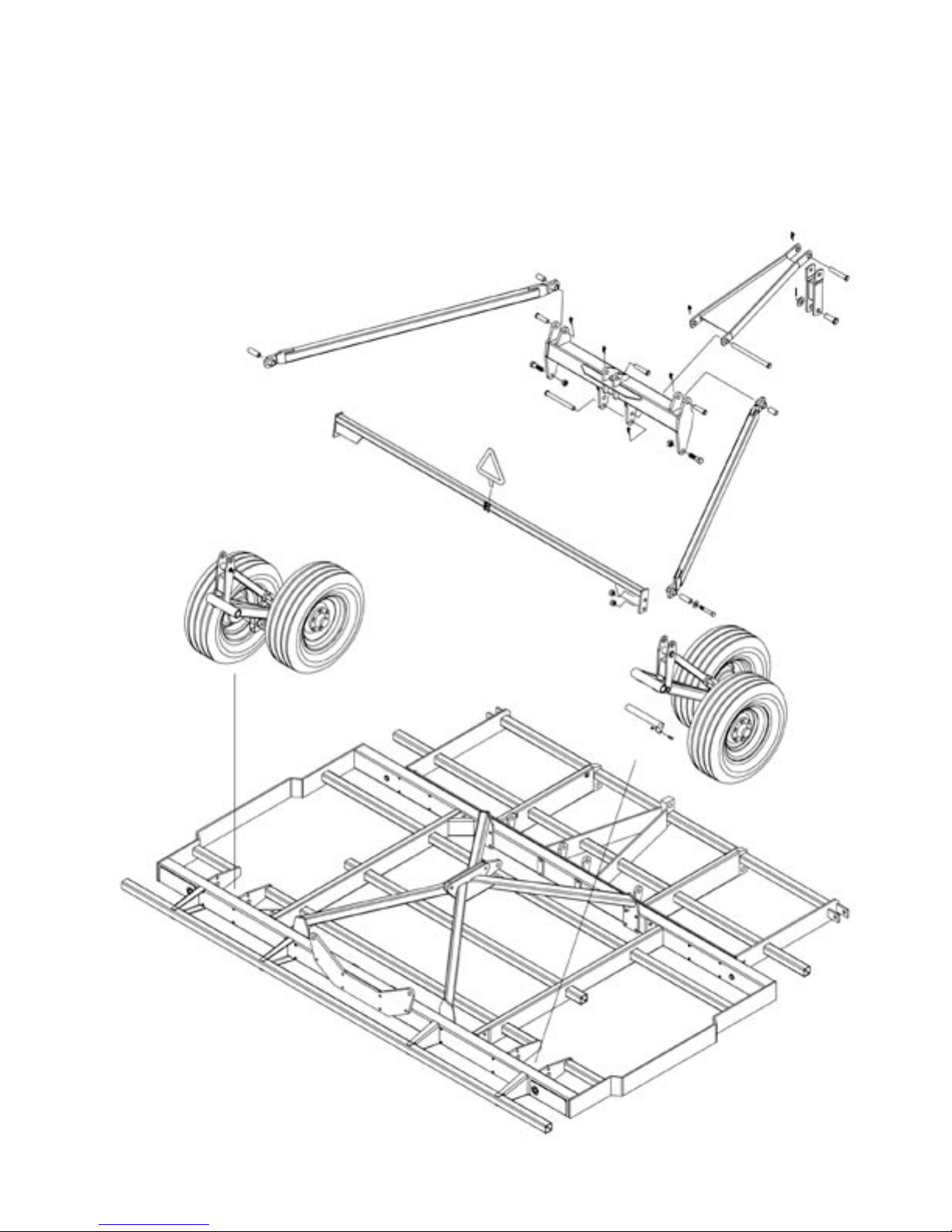

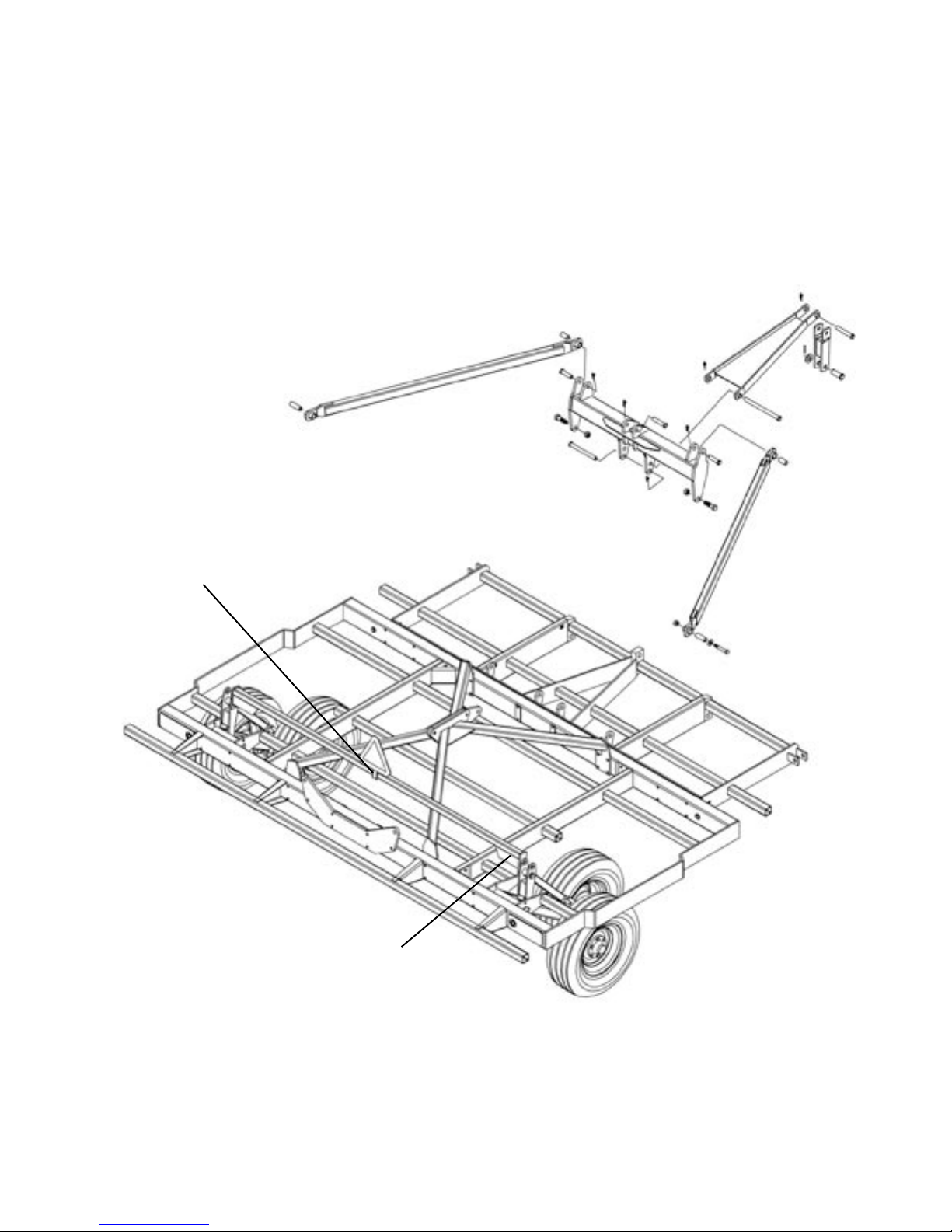

Although the 10' (3M) and 13' (4M) centre sections and self levelling wheel lift linkages have

some different components, they both have the same basic function and use the same order

of assembly as shown by the numbers below and opposite.

Sort out the pieces for the centre section self levelling linkages and wheel arms according to

the parts list and the diagram below for 10' (3m) or opposite on page 9 for the 13' (4m).

Important Note:

It is much easier to pre-assemble the right and left wheel arms according to the instructions

on page 10. The entire wheel assembly can then be lifted into the frame and secured with the

wheel axle.

The remaining steps for installing the linkages are outlined in detail beginning on page 11.

10' (3m) Self Levelling Linkage Assembly

3

1

8

7

6

5

4

2

8

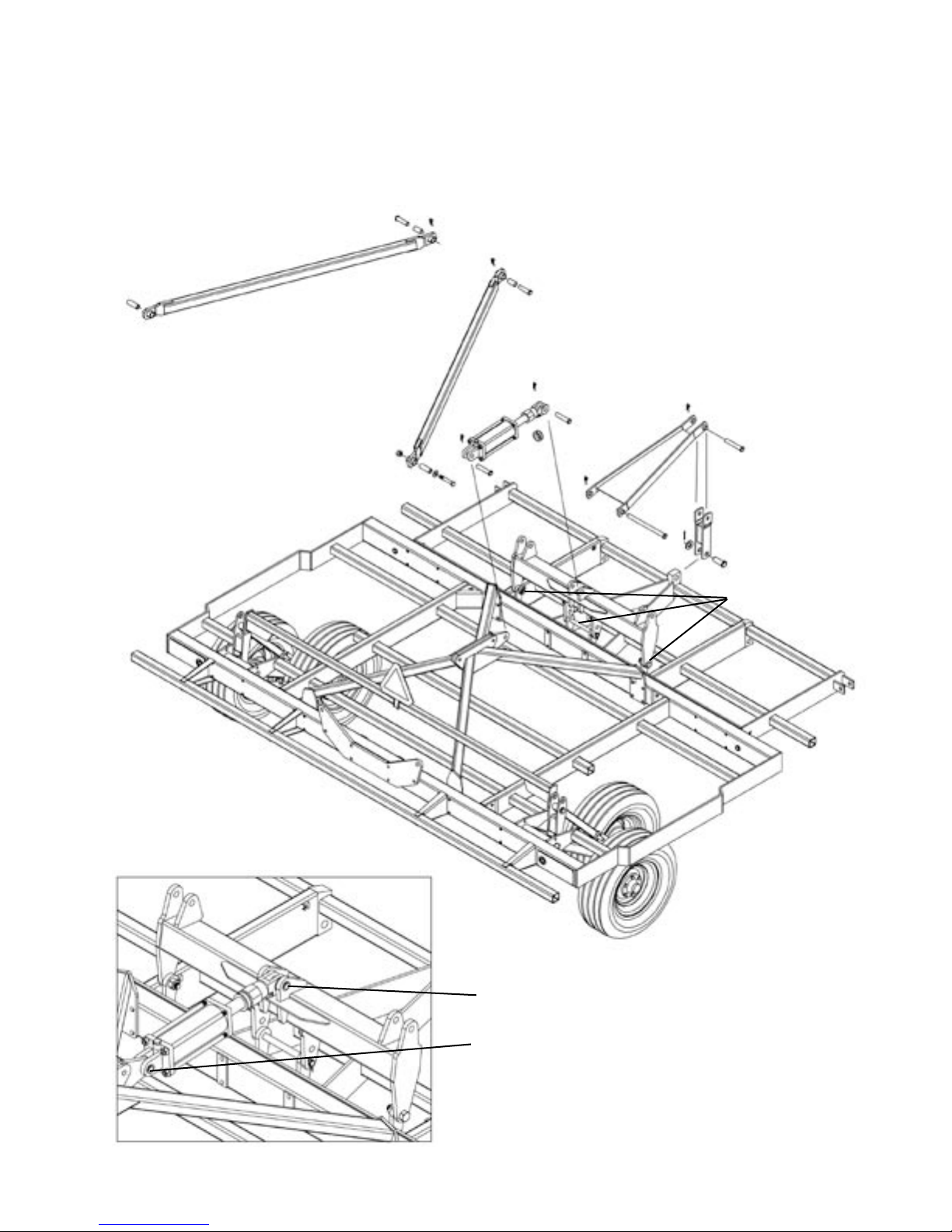

Page 9

After the wheel arm assemblies are installed, the self levelling linkages can be attached starting

with the wheel connection link at the back and work forward to the hitch. The numbers below

show the proper order of assembly. Refer to the detailed instructions beginning on page 10

for proper assembly of the wheel arms and self levelling lift linkages.

13' (4m) Self Levelling Linkage Assembly

8

7

6

4

5

1

3

2

9

Page 10

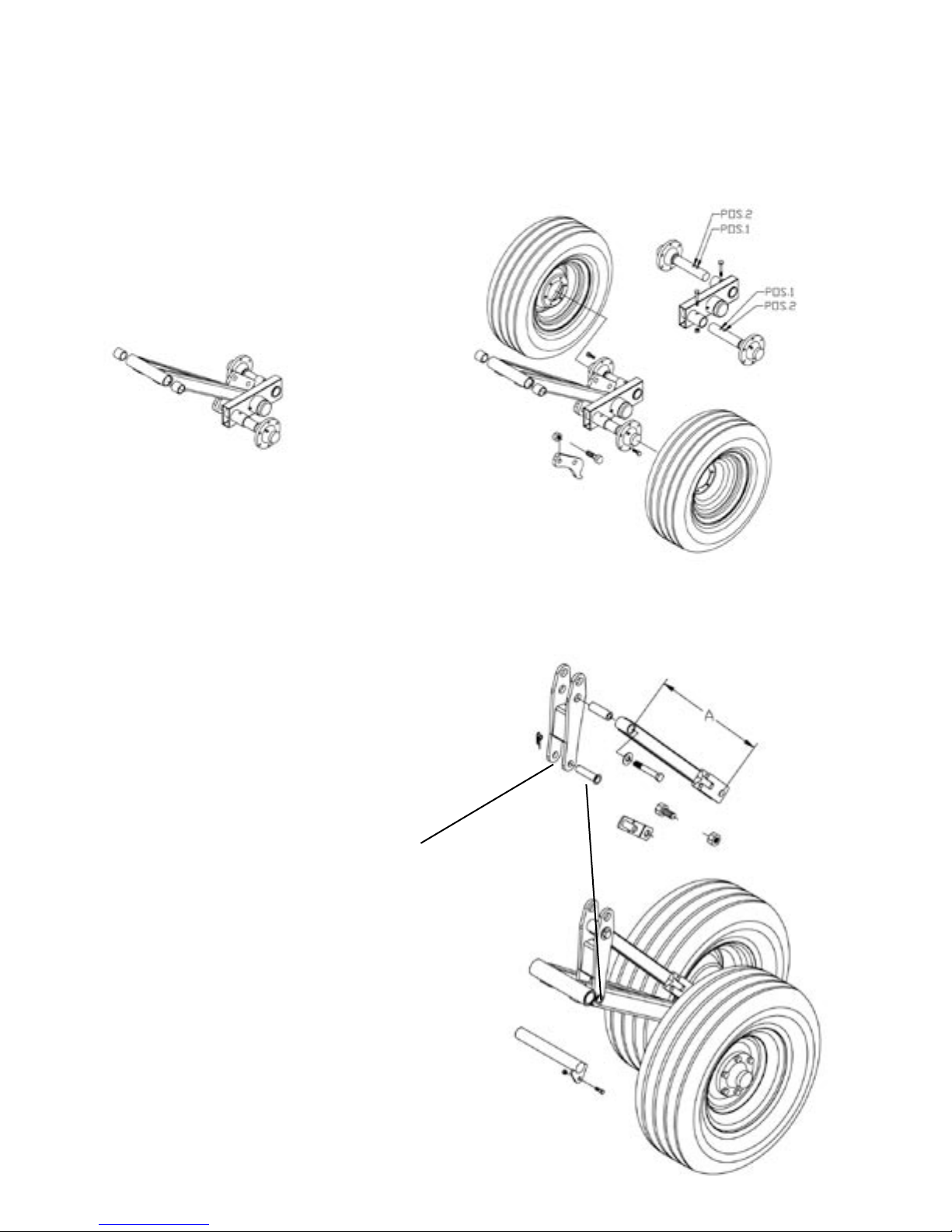

Carefully insert the wheel axle pivot bushings into the ends of the wheel arm tubes. Tap the

bushings into the ends of the tubes with a block of wood or rubberized hammer.

Before mounting the tires, install the wheel spindle bolts as shown. The front spindle must be in

the 1st hole or wide position for all centre machines. The rear spindle must be in the 2nd hole

on the 10' (3m) centre. The rear spindle should be in the 1st hole for the 13' (4m) center.

Never use a steel block or hammer

directly on the bushings as they are

from a material which can crack or

burr easily.

Assemble the wheel linkage as shown below with the pivot pins and bushings provided.

Note that the wheel pivot link shown below is a 2 piece adjustable linkage. This linkage can

be lengthened or shortened as necessary to provide proper under frame clearance for 20" or

24" tine options. This adjustable wheel link also provides side to side levelling for the centre

section.

The linkage length from centre to centre

"Dimension A" should be set at:

A = 28" (71cm) for 20" clearance tines.

A = 28.5" (73cm) for 24" clearance tines.

Take care to install the pins from

the outside as shown with the clip

pins on the inside of the wheel

arm.

10

Page 11

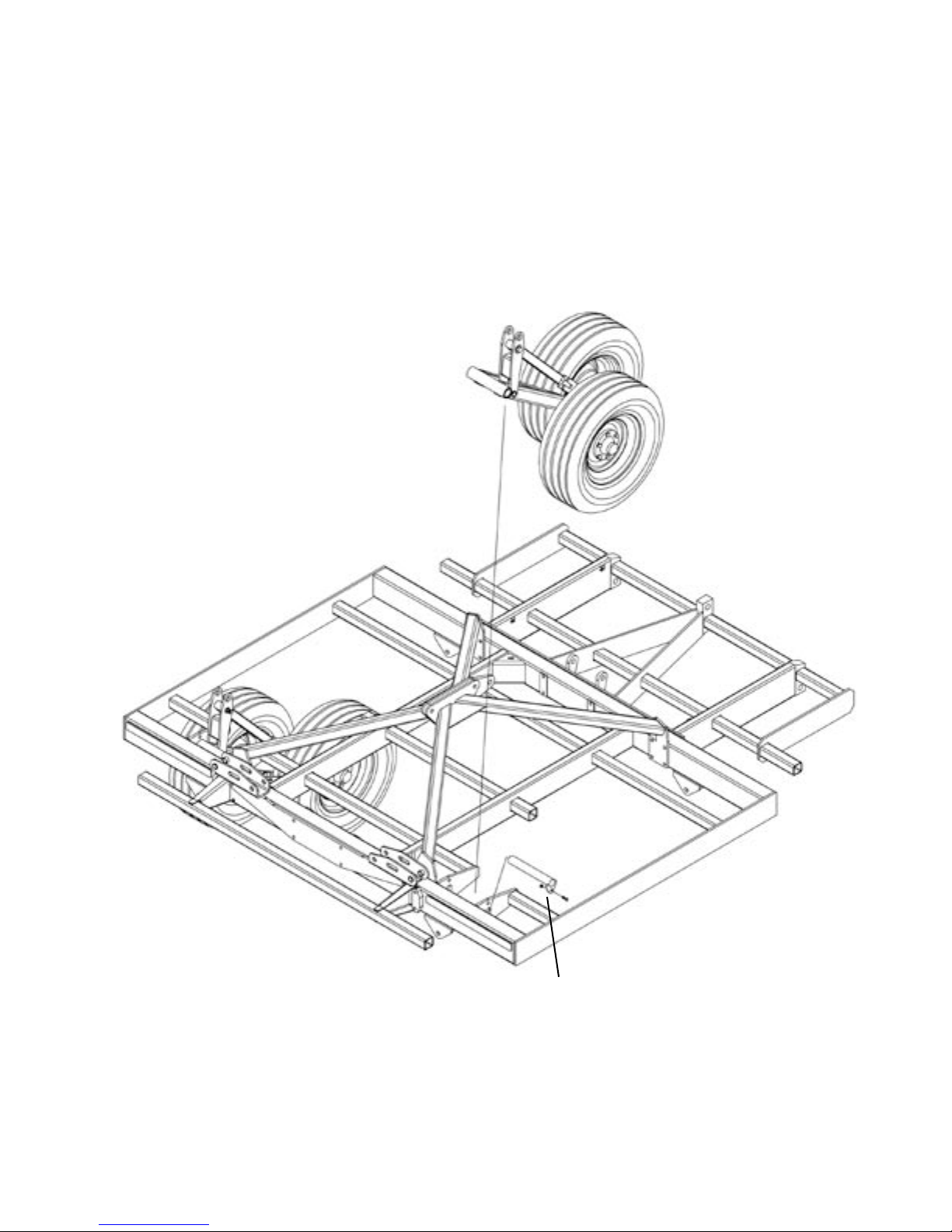

Using a lift truck or overhead hoist equipped with an approved lifting chain or strap, lift the

wheel arm assemblies one at a time into the centre frame as shown below before installing

the Self Levelling Wheel Arm Pivot Linkages.

The wheel arm pivots must be aligned with the holes in the frame and then secured with the

axle pin as shown in the detail below.

The pin can be coated with a light machine oil or grease to ease assembly but otherwise needs

no lubrication as the pivot bushings in the wheel arms are oil impregnated.

Install the axle pin with lock tab

pointing down and secure with the

bolt and locknut. Considerable force

is required to install the axle as the

tolerance is very close.

11

Page 12

For the 10' (3m) centre, attach the short Wheel Link Connector to the Wheel Arm Pivot Links

and A-Frame Wheel Links with the bolts provided. Remember to install the spacer bushings

so the upper pivot point will not bind when the bolts are tightened.

10' (3m) Self levelling

Pivot Links

A-Frame Wheel Links

The Wheel Link Conne ctor is

installed between centre wheels

with bu shings and bolt s wi th

locknuts.

Install the linkage with the SMV sign

bracket to the rear then insert the

SMV sign.

Centre Link Spacer Bushing

Must be installed in A-Frame

wheel Link before installing

bolt.

12

Page 13

For the 13' (4m) centre, the assembly is the same only the Wheel Link Connector is longer.

Attach the Wheel Link Connector to the Wheel Arm Pivot Links and A-Frame Wheel Links

with the bolts provided.

Once again, remember to install the spacer bushings so the upper pivot point will not bind

when the bolts are tightened.

13' (4m) Self levelling

Pivot Links

A-Frame Wheel Links

Install the linkage with the SMV sign

bracket to the rear then insert the

SMV sign.

The Wheel Link Conne ctor is

installed between centre wheels

with bu shings and bolt s wi th

locknuts.

13

Page 14

Install the 10' (3m) main pivot link with the long pin provided. When the main link is in place

install the 4.5" x 8" master cylinder as shown in the detail below. Do not install the other linkages

until both the main pivot link and cylinder are in place.

Install Main Pivot Link

and Master Cylinder

Attach the master cylin der with the pins

provided.

The rod clevis attaches to the lugs on the main

pivot link.

The butt end of the cylinder attaches to the lug

in the centre of the top cross frame.

Take care to turn the cylinder so the front or rod

end port is pointing down and the rear port is

facing to the left side.

Remove the protective port plugs so the cylinder

can be moved in or out during the assembly of

the remaining self levelling linkages.

14

Page 15

The 13' (4m) main pivot installs in much the same way as the 10' (3m) except that the 13' main

pivot is larger and requires a central pivot pin and additional mounting bolts to be installed in

the outside pivot mounts. The pivot bolts should not be tightened fully so that the pivot link can

move freely when the cylinder is extended or retracted. When the main link is in place install

the 4.5" x 8" master cylinder as shown in the detail below. Do not install the other linkages

until both the main pivot link and cylinder are in place.

Install Main Pivot Link

and Master Cylinder

Bolts and Pin

for 13' (4m)

Main Pivot Link

Attach the master cylin der with the pins

provided.

The rod clevis attaches to the lugs on the main

pivot link.

The butt end of the cylinder attaches to the lug

in the centre of the top cross frame.

Turn the cylinder so the front or rod end port is

pointing down and the rear port is facing to the

left side.

Remove the protective port plugs.

15

Page 16

Install the A-frame wheel links on the 10' (3m) centre as shown below. The wheel links are

identical so it does not matter which way you turn them.

Attach the front of the wheel linkages to the main pivot with the 1" (25mm) ID bushings and

insert the pins from the outside to secure both linkages to the main pivot link. It may be

necessary to extend or retract the cylinder rod by hand in order to line up the holes and install

the linkage pins. Take care to insert and lock the clip pins when finished.

Attach the rear of the wheel linkage to the upper hole of the wheel

pivot link with the 3/4" (20mm) ID bushing and secure with the

bolts, washers and locknuts provided.

16

Page 17

The A-Frame wheel links are the same for both the 10' and 13' centres, and are installed the

same way as shown below. The only difference is that the links are spaced wider apart on the

13' centre due to the wider frame and wheel spacing.

Attach the front of the wheel linkages to the main pivot with the 1" (25mm) ID bushings and

insert the pins from the outside to secure both linkages to the main pivot link. It may be

necessary to extend or retract the cylinder rod by hand in order to line up the holes and install

the linkage pins. Take care to insert and lock the clip pins when finished.

Attach the rear of the wheel linkage to the upper hole of the wheel

pivot link with the 3/4" (20mm) ID bushing and secure with the

bolts, washers and locknuts provided.

17

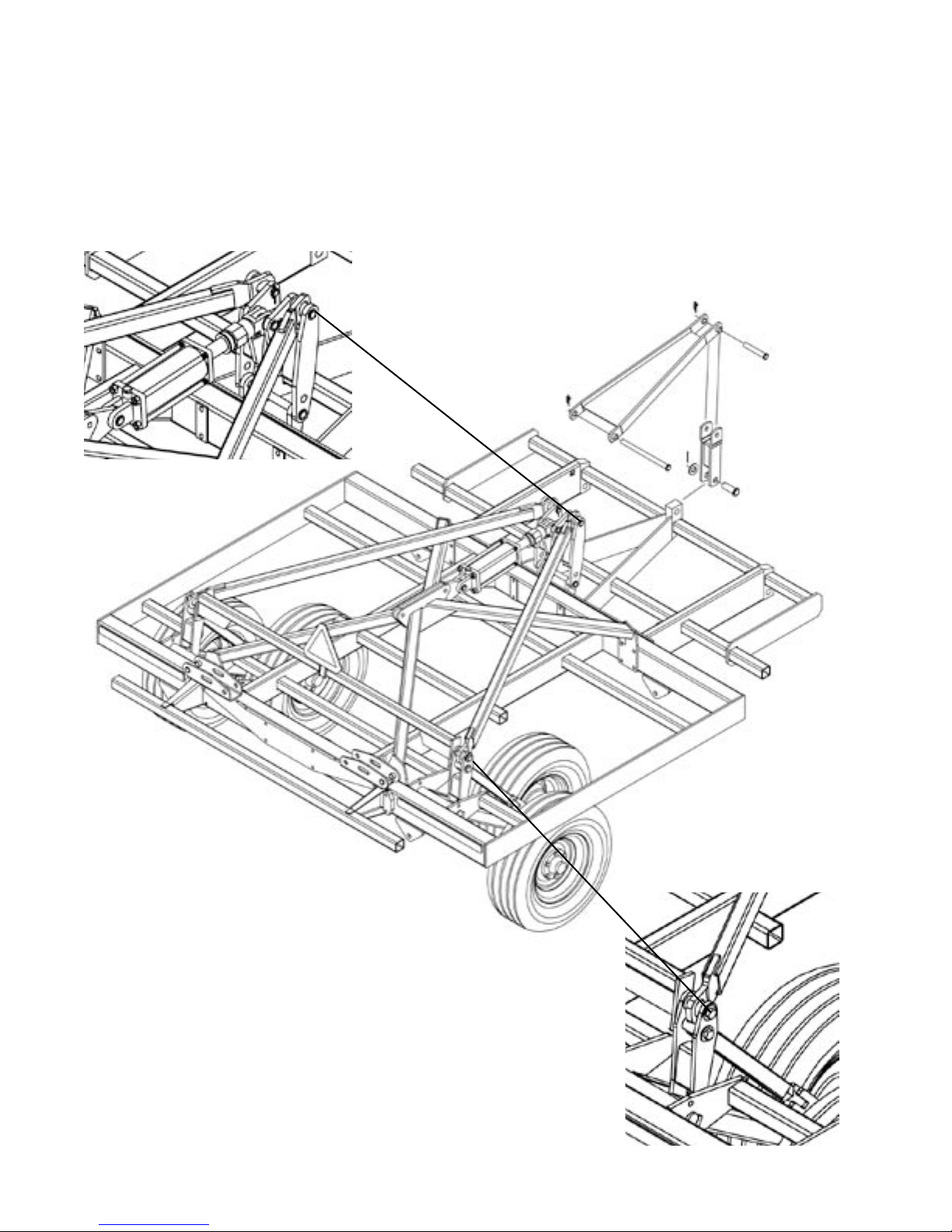

Page 18

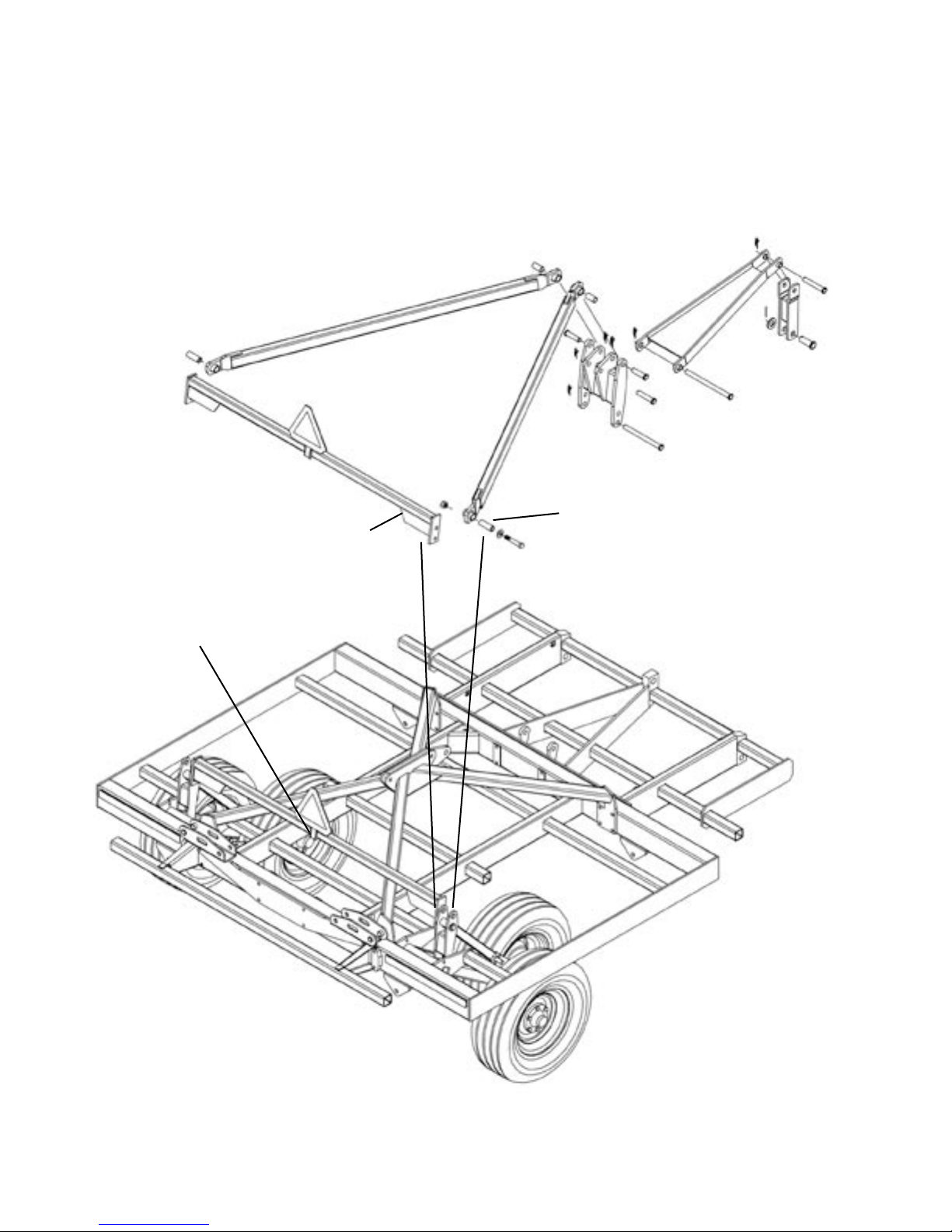

To complete the assembly of the self levelling wheel link system, install the front pivot link to

the lug in the centre of the front frame. Attach the wide end of the large triangular self levelling

link to the main pivot with the long pin provided and attach the narrow end to the front pivot

link with the shorter pin provided. These pieces are the same for both the 10' and 13' centres

and are installed in the same manner.

Check the assembly of the self levelling linkages and make sure all of the clip pins are installed

and locked.

Detail view of front linkages

on 10' (3m) centre

Self levelling link

Front hitch

pivot link

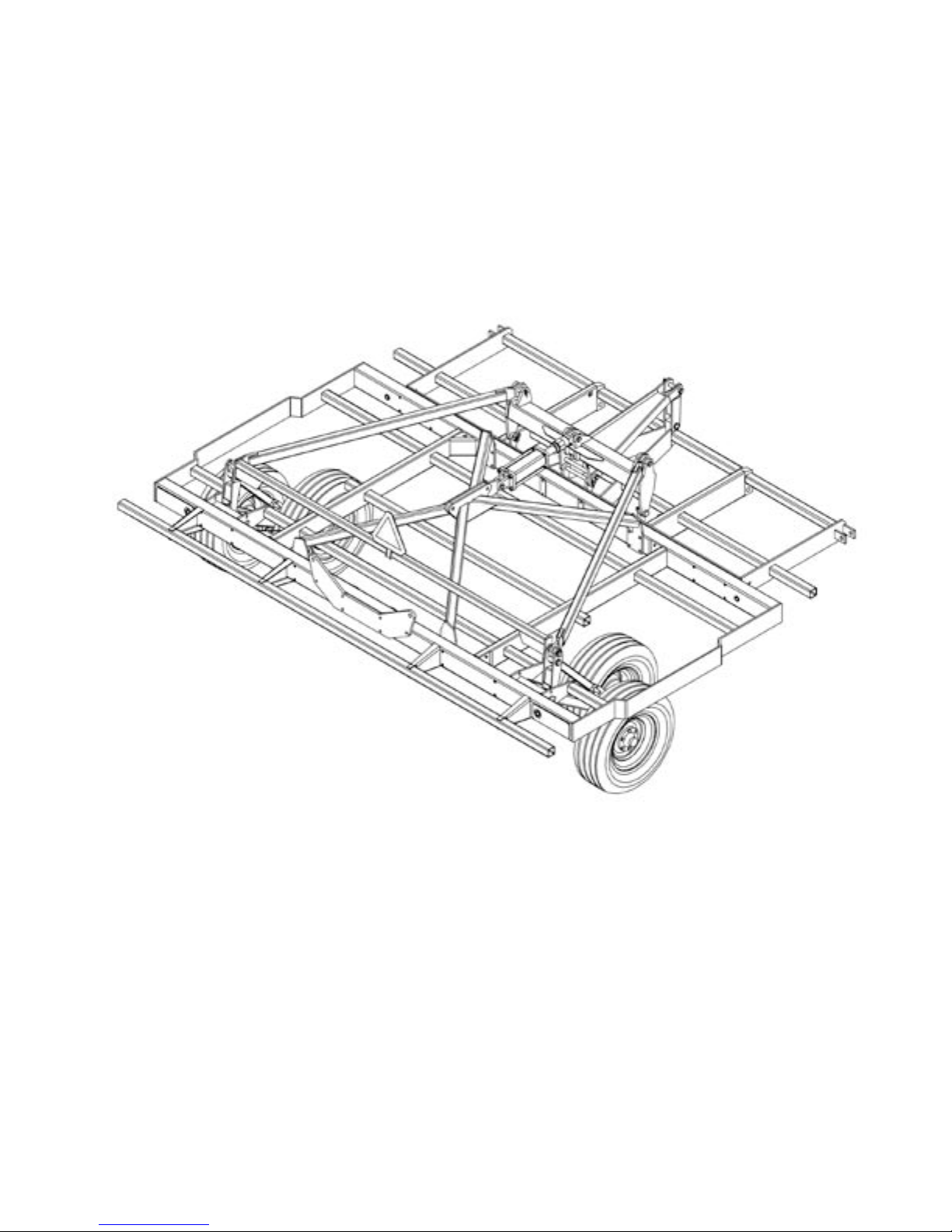

Overview of completed 10'

(3m) self levelling linkage

system.

18

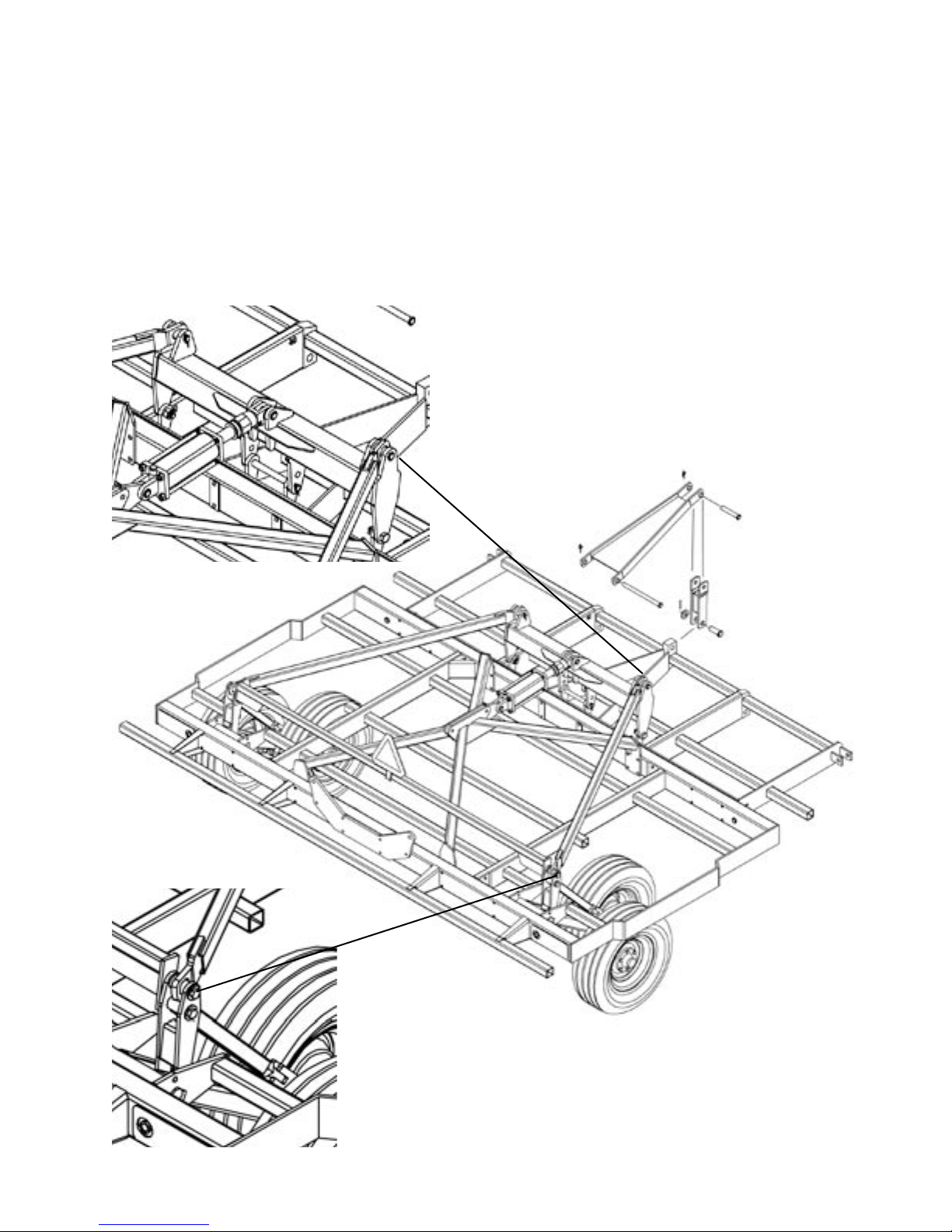

Page 19

The diagram below shows the completed 13' (4m) centre frame and self levelling wheel lift

linkage assembly.

Take care to go over the assembly of the centre section and linkage system to make sure that

all nuts and bolts are installed and tighened.

Check all pin connections and make sure the roll pins or clip pins are installed and locked.

If there is lots of room in the assembly area, the hitch can be assembled to the centre section

now. However if space is limited, the draw hitch can be assembled and attached later after

the wings are assembled and attached.

The hitch must be attached prior to installing the hydraulic lines and preparing the cultivator

to be raised and folded for transport.

19

Page 20

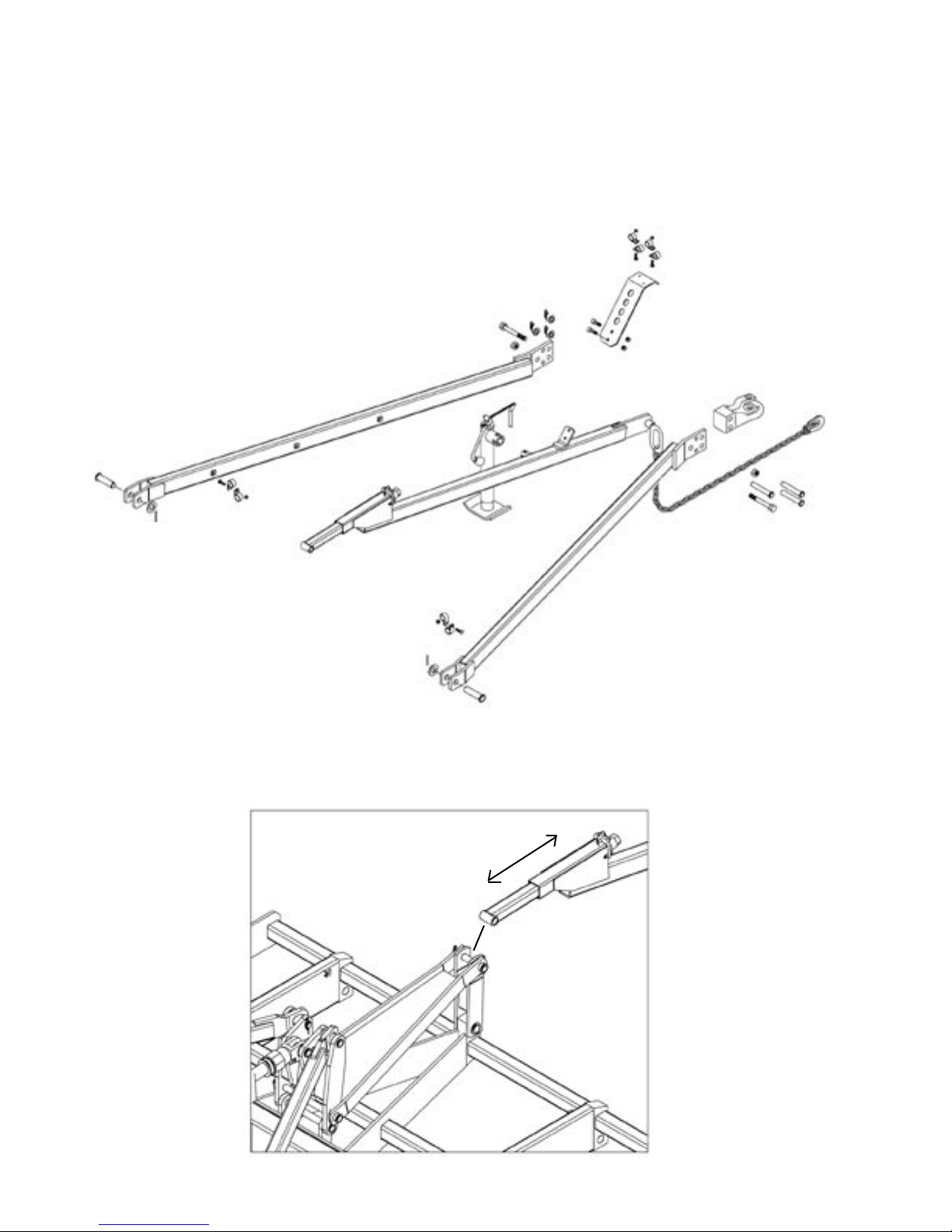

HITCH ASSEMBLY

The draw hitch components are identical for both the 10' and 13' centre sections and follow

the same order of assembly as shown on the numbered diagram below.

Gather the components and begin assembling the hitch with the hardware described in the

spare parts list.

Follow the numbers for the order of assembly on the diagram below and make the connections

with the pins and bolts provided.

4

5

3

1

2

The hitch adjuster, pivot link and self levelling link are all connected with the same pivot pin at

position 1 as shown below. To do this you will have to remove the clip pin and slide the pin to one

side to allow the hitch adjuster to be connected.The adjuster can be lengthened or shortened

as necessary to position the hitch at the tractor drawbar height for easier assembly.

1

20

Page 21

After connecting the hitch adjuster at position 1, attach the hitch side members with the 1-1/2"

pins with washers and roll pins at position 2 and 3. The side tubes are both the same and can

be flipped either way to make the left and right side member.

3

1

2

As shown in step 4 below, place the large eye of the saftey chain over the bushing at the front.

connect the hitch tubes togeather by inserting the the 2 long bolts from opposite sides and

tightening the locknuts. The hitch adjuster link and clevis casting are secured in place with the

long pins and clip pins. Install the jack and hose tower as shown in step 5.

The hook end of the saftey chain is for connecting the chain to the tractor hitch.

4

5

21

Page 22

WING ASSEMBLY

Gather the components for the wing frames and assemble using the hardware described in

the parts list booklet. The wing frame sections are basically the same for both 10' (3m) - shown

below, and 13'(4m) centre machine - shown opposite. The main difference between the wing

assembly of these 2 models is in the folding hinges and stub toolbars.

Note how the wing fold hinges for the 10' (3m) model below are different from the ones shown

on the opposite page, and how the model below has front and rear stub toolbars.

Please note that there are no right or left wing frame components. Therefore if you assemble

the right wing first as shown below, you will need to flip the frames over opposite to the diagram

below to assemble the left wing.

Mark the tine pattern on the wing frame tubes according to the locations given for each wing

frame section in the back of the book by hooking the tape measure on the side marked "0"

and measuring across the frame as you did for the centre section.

The frames should be placed on steel support stands during assembly and mounting of the

tines, then carefully lowered to the ground to rest on the tines for assembly of the wheel

components.

Note: Front and Rear

Bolt-on Stub Toolbars

Example:

Wing Assembly with 10' (3m)

Narrow Fold Hinges

Tines mounted near the hinge plates or in the wheel area

should be left loose until after the wheel arm assemblies

and hinge plates are installed to allow better access to the

mounting bolts with tools.

22

Page 23

The assembly diagram below shows the different folding hinges and front bolt on stub toolbar

used on the cultivator model with 13' (4m) centre section.

Also, Note how the front stub toolbar has a hinge pin that connects to the 13' centre front

frame and there is no rear stub toolbar on this model.

Refer to the parts list provided for complete discription of the components and hardware for

proper assembly of the wings.

The assembly diagrams do not show tines installed on the frames for easier viewing of the

components. You may choose to assemble the frames first and mount tines later, but generally

you will find it is easier to mount the tines as you assemble the frame sections.

Note: Front Bolt-on Stub

Example:

Toolbar with Hinge Pin

Wing Assembly with 13' (4m)

Wide Fold Hinges

Tines mounted near the hinge plates or in the wheel area

should be left loose until after the wheel arm assemblies

and hinge plates are installed to allow better access to the

mounting bolts with tools.

23

Page 24

Install the front and rear folding hinges to the frames at the same time as you assemble the

wing frames. The hinge pins and fold cylinder pins are installed later when connecting the wings

to the centre section. Take care to leave the nuts and bolts loose at the hinges as it makes it

easier to align the holes when attaching the wings to the centre section.

Stub Toolbar

Front folding hinge 10' (3m)

Front extension frame

Rear folding hinge 10' (3m)

Stub Toolbar

Front folding hinge 13' (4m)

Rear folding hinge 13' (4m)

Wing main frame

Stub Toolbar with

Hinge Pin

Front extension frame

Wing main frame

24

Page 25

When the wing frame is fully assembled and lowered to the ground resting on the tines, gather

the components for the wing tandem wheel and wheel adjustment linkages.

Before mounting the wheels on the hubs, install

the wheel spindle bolts as shown. The front

spindle must be in the wide position 1. The rear

spindle should be in the wide position 1.

Install the pivot bushings

into the ends of the wheel

arm tubes. Do not hammer

directly on the bushings,

tap them in using a wooden

block or rubber mallet.

Mount the wheels on the hubs and then lift the complete tandem wheel assembly into the wing

frame. Apply a little grease or machine oil to the axle pin to ease assembly and then insert

the pin through the holes in the wing frame and wheel arm.

Make sure the pin lock tab is pointing down before installing the lock nut and bolt.

Note it takes considerable force to install the axle pin as

the tolerance is very close.

The axle does not require any lubrication after assembly as

the wheel arm pivot bushings are oil impregnated.

Tab points down

25

Page 26

Mount the wing wheel tower and wheel lift cylinder with the pins, bolts and nuts described in

the parts list. The wheel cylinder upright attaches to the upper hole in the wheelarm tube with

the pin and clip pin supplied.

Note that the wing wheel lift cylinders are different sizes. One is 4.25 x 8 the other is 4 x 8.

Check the hydraulic layout in order to make sure you install the cylinders on the correct side

of the machine. The 4.25 x 8 cylinder is installed on the left wing and the 4 x 8 cylinder is

installed on the right wing as shown below. The ports on both cylinders should face into the

centre of the machine.

The butt end or top of the cylinder is connected to the wheel upright bar with one of the pins

and clip pins supplied. The rod end clevis connects to the lug on the lower end of the wheel

arm so the cylinder extends and retracts with the rod pointing down. The clevis pin is special

and has a mounting plate with bolt and locknut to secure it in place.

Wheel Cylinder Upright

NOTE: The lower cylinder pin

is special for this location and

is held in place with a bolt and

locknut.

4 x 8 Cylinder on Right Wing

- Cylinder Ports face inside

to Centre

26

Page 27

Install the wing wheel adjustment linkage with the pins, locking clip pins and U-bolts

supplied.

The wheel linkage tube should be mounted with the hose brackets on the inside as shown in

the detail photo below.

Take care to keep the linkages straight when tightening the U-Bolts so the adjustment slider

does not bind when adjusted in and out.

Note: Flip Linkage Tube

over so hose clips face

inside to centre.

27

Page 28

The adjustment linkage is used to adjust the wings so they are level with the centre section

when working in the field.

To adjust the linkage, remove the clip pin and turn the adjustment casting clockwise or counter

clockwise to lengthen or shorten the linkage. This in turn will raise or lower the wing wheel arm

position so the wings will run level at the same depth as the centre section. The adjustment

can be made with either a large adjustable wrench, or 1-1/2" socket, or a 3/4" drive socket

wrench handle only.

More information on the proper adjustment of these linkages is covered in the Owners Manual

under Field Settings and Adjustments.

Initially the adjustment slider can be set at 7' - 8" or (180 to 205mm). The distance is measured

from the edge of the outer housing tube to the centre of the pin.

Take care to replace the clip lock pin so the slider adjustment does not move from the set

position.

7" - 8"

(180 - 205mm)

28

Page 29

Mechanical Adjust Wheels on 3'3" (1.0m) Wings:

The mechanical adjusting wheel is used as the wing depth wheel on the 16' (5m) model

cultivator with 1m wings. It is also available as an accessory wing gauge wheel on all other

models.

On the small 3'3" (1.0m) Wing, the wheel is mounted inside the wing frame to the toolbar as

shown below. It should be assembled with the wheel mounted to the outside and positioned

to run about 1-1/2 to 2" away from the outside of the wing.

The mounting bracket and wheel arm are designed to allow the wheel to be assembled for

right or left hand use by turning the wheel arm over and mounting the turnbuckle adjuster on

the opposite side of the mounting bracket. The diagram below shows the wheel assembled

for the right side wing.

Adjustment of the working depth of the wing is accomplished using the mechanical ratchet

on the turnbuckle. An extension handle is provided for easier adjustment of the mechanical

ratchet.

29

Page 30

Mechanical Adjust Wheel used as Front Gauge Wheel:

When used as a front gauge wheel the gauge wheel mounting bracket is attached to the

front toolbar with the U-bolts provided. Again, the tire is usually mounted to the outside and

positioned near the front corner of the machine. The exact position will vary depending on the

tine pattern but the wheel should not stick out past the outside of the wing.

The mounting bracket and wheelarm are designed to allow the wheel to be assembled for

right or left hand use by turning the wheel arm over and mounting the turnbuckle adjuster on

the opposite side of the mounting bracket. The diagram below shows the wheel assembled

for the right side wing.

Adjustment of the gauge wheel is accomplished using the mechanical ratchet on the turnbuckle.

An extension handle is provided for easier adjustment of the mechanical ratchet.

Instructions for adjusting wheels and setting the working depth is explained in detail in the

Cultivator Owners Manual. When working in the field, the gauge wheels should only have light

contact with the ground in order to hold the depth accuracy of the wing and prevent it from

bouncing.

As a preliminary setting the wheels can be adjusted about 2" from the ground when the

cultivator is resting on the tines.

30

Page 31

Final Assembly of the 10' (3m) Centre Section and Wings:

Move the wing assemblies into position beside the centre section.

Install the wing hinge pins according to step 1 & 2 in the diagram below. The hinge plate bolts

should be loose to allow easier alignment and insertion of the hinge pins.

The main hinge pins are designed to lock in position and must be turned so that when they

are inserted thru the hinge plates and centre frame, the pin stub locks into the second hole

in the hinge plate before the roll pin can be installed.

When the pins are installed tighten the hinge plate bolts

1

2

31

Page 32

Folding Cylinders for 10' (3m) Centres:

When the wings are attached to the centre section the wing fold cylinders with hydraulic hose

lines and fittings can be installed.

The hydraulic assemblies are different for the 10' (3M) and 13' (4m) centre machines so make

sure you have the correct diagram for the machine model you are assembling.

The most noticeable difference is that the machines with 10' (3m) centres have a different

wing fold system to keep the machine as narrow as possible in road transport.

The wing fold hinge pivots are lower and the folding cylinders are installed to extend and retract

in reverse with cylinder rods pointing towards each other. The butt clevis are attached to the

folding hinge plates on the wings and the rod clevis are attached to slots in the centre section

fold bracket. (The slots allow the wings to float up and down in the field when the cylinders

are fully extended.)

Install the wings and fold cylinders as shown on the assembly diagram below and follow the

Hydraulic Hose layouts carefully for proper assembly of the hoses and fittings shown later in

this booklet.

32

Page 33

Detail Pictures of the 10' (3m) Fold Cylinders Installed:

Be sure to place four (4) 1" washers

at rod end of cylinder. The inside

two (2) keep the clevis centered.

Shown: Cylinders in extended

position. Fold lock pin goes in

storage hole when not being used.

Cylinders in folded position.

Insert fold lock pin as shown.

33

Page 34

Final Assembly of the 13' (4m) Centre Section and Wings:

Move the wing assemblies into position beside the centre section.

Install the wing hinge pins according to step 1, 2 & 3 in the diagram below. The hinge plate

bolts should be loose to allow easier alignment and insertion of the hinge pins. The main hinge

pins are designed to lock in position and must be turned so that when they are inserted thru

the hinge plates and centre frame, the pin stub locks into the second hole in the hinge plate

before the roll pin can be installed.

The front toolbar stub also acts as a 3rd hinge to provide greater stability for the front frame

extension on the wide fold models. Secure the front toolbar hinge pins in place with the locking

clip pin. When the pins are installed re-tighten the hinge plate bolts

Detail view of front frame

hinge pin with locking clip

pin installed.

1

13' (4M) Wing Fold

Lock Brackets

2

3

The 13' (4m) centre also has special wing lock brackets that must be installed before folding

the wings. The brackets are installed on the main frame tube behind the wheel arm. Mount

the lock brackets with the bolts provided but do not tighten the locknut. You will need to move

the brackets in order to allign the hole in the bushing with the hole in the wing hinge plates in

order to insert the wing fold lock pin.

Refer to the pages for the hydraulic assembly for further instructions.

34

Page 35

Folding Cylinders 13' (4m) Centres:

When the wings are attached to the centre section the wing fold cylinders with hydraulic hose

lines and fittings can be installed.

The hydraulic assembly is different for the 13' (4m) centre machines so make sure you have

the correct hose layout diagram for the machine model you are assembling.

The most noticeable difference is that the models with 13' (4m) centres have additional fold lock

brackets that must be installed in order to lock the wings in the folded position for transport.

The other difference is that the folding cylinders are installed so the cylinder rods extend and

retract pointing away from the centre. The cylinder butt clevis are attached to the centre fold

plate and the rod clevis are attached to the slot in the folding hinge brackets on the wings. (This

allows the wing to float up and down in the field when the cylinders are fully extended.)

Install the rear folding brackets and cylinders as shown on the assembly diagram below and

follow the Hydraulic Hose layouts carefully for proper assembly of the hoses and fittings shown

later in this booklet.

35

Page 36

Detail Pictures of the 13' (4m) Fold Cylinders Installed:

Cylinders in extended Position. Place fold lock pin in storage

hole when not being used.

With cylinders in folded position,

adjust fold lock plate so that the

fold locking holes lineup.

Insert fold lock pin as shown.

36

Page 37

Hydraulic Diagrams and Assembly Information:

For proper installation of the hose lines and fittings refer to the hose layout diagram provided

later in the booklet. The hydraulic hose lines and fittings are provided in the hose kit. Secure

the hoses to the frames with the hose clamps, carriage bolts and locknuts provided.

IMPORTANT NOTE:

DO NOT PLACE HOSE LINES ALONG FRAME IN FRONT OF TOP FRAME MOUNTING

PLATES AS SHOWN BELOW.

HOSE LINES CAN BECOME PINCHED BY THE FRONT WING FOLD STOP PLATE WHEN

FOLDING IF HOSES ARE LAYING ON TOP OF THE FRAME TUBE.

HOSES SHOULD BE BEHIND THE TOP

FRAME AND NEATLY CLAMPED SO

THEY DO NOT INTERFERE WITH THE

HINGES WHEN FOLDING.

KEEP HO S E S L I NES RUNNING

ACROSS THE CULTIVATOR BEHIND

THE FRAME TUBE AND NEATLY

CLAMPED TO THE FRAMES WITH

THE HOSE CLAMPS OR PLASTIC

TIE STRAPS PROVIDED.

37

Page 38

NOTE: On a 3m Center machine, fasten the

hoses to the wing frame and feed the cylinders

from there. Also, tie hoses to the rod port as

shown above

NOTE: On a 3m Center machine, route

the fold hoses in front of top frame leg

Charge the wheel lift hydraulics by fully

extending and retracting the wheel lift

hydraulic cylinders several times. Hold the

hydraulic lever open at the end of the stroke

to purge the air from the system.

The wheel lift cylinders are rephasing type

cylinders and must be fully extended at the

end of the field when turning to equalize the

oil pressure across the system.

This will ensure that the cultivator raises and

lowers evenly and stays at a uniform working

depth when working in the field.

38

Page 39

The wing fold cylinders must be charged with

oil before attempting to fold the cultivator.

Disconnect the cylinder rod clevis from the

fold bracket and place a block under the

cylinders as shown.

Connect the hoses to the tractor or portable

hydraulic unit and stroke the wing fold

cylinders in and out several times holding the

lever at the end of the stroke to remove the

air from the system and ensure the cylinders

and hoses are full of oil. Remove the block and

reconnect the cylinder to the fold bracket with

the cylinder pin, washer and clip pin.

Always insert the transport lock on the master

cylinder when ever the cultivator is placed in

the raised position for transport, maintenance

or stroage.

Secure with the lock pin and clip provided.

Always insert the wing fold lock pins and

secure the lynch pin when ever the wings

are raised in the folded position. Be sure to

remove the pins and store them in the storage

holes before unfolding the cultivator.

Never transport the cultivator on public road

ways without installing the transport safety

chain and SMV sign.

See the special instruction sheet for proper

placement of the cultivator identification

decals and safety warning decals

Refer to the Owners Manual for further

safety information before attempting to

operate or service the unit

39

Page 40

40

Page 41

Spare part list / 2800 Hydraulics. Date: 2003, 02.

Fig. Part no. Description

1 600470233 1/2" Hose 1/2" Pipe x 1/2" JIC - 240" all models (2 req'd on non fold models)

2 600470244 1/2" Hose 1/2" Pipe x 1/2" JIC - 397" (2800-6m-20')

600470235 1/2" Hose 1/2" Pipe x 1/2" JIC - 417" (2800-7m-23')

600470245 1/2" Hose 1/2" Pipe x 1/2" JIC - 437" (2800-8m-26')

600470234 1/2" Hose 1/2" Pipe x 1/2" JIC - 457" (2800-9m-30')

600470269 1/2" Hose 1/2" Pipe x 1/2" JIC - 477" (2800-10m-33')

3 600470182 1/2" Hose 1/2" JIC x 1/2" JIC - 175" (2800-6m-20')

600470239 1/2" Hose 1/2" JIC x 1/2" JIC - 195" (2800-7m-23')

600470177 1/2" Hose 1/2" JIC x 1/2" JIC - 215" (2800-8m-26')

600470137 1/2" Hose 1/2" JIC x 1/2" JIC - 235" (2800-9m-30')

600470272 1/2" Hose 1/2" JIC x 1/2" JIC - 255" (2800-10m-33')

4 600470147 1/2" Hose 1/2" JIC x 1/2" JIC - 310" (2800-6m-20')

600470149 1/2" Hose 1/2" JIC x 1/2" JIC - 350" (2800-7m-23')

600470151 1/2" Hose 1/2" JIC x 1/2" JIC - 390" (2800-8m-26')

600470153 1/2" Hose 1/2" JIC x 1/2" JIC - 430" (2800-9m-30')

600470273 1/2" Hose 1/2" JIC x 1/2" JIC - 470" (2800-10m-33')

5 600470049 Elbow 1/2" O-ring x 1/2" JIC - 90 Degree

6 600470232 3/8" Hose 1/2" Pipe x 3/8" JIC - 280" (All Folding Models)

7 600470270 3/8" Hose 3/8" JIC x 3/8" JIC - 62" (All narrow centre models -3m)

8 600470297 3/8" Hose 3/8" JIC x 3/8" JIC - 82 “ (All narrow centre models -3m)

9 600470003 Tee 3/8" JIC (All narrow centre models -3m)

9A 600470295 Tee 3/8" JIC x 3/8" JIC x 1/2" ORB (All wide centre models -4m)

9B 600470296 Tee 3/8" JIC x 3/8" JIC(FS) x 3/8" JIC (All wide centre models -4m)

10 600470124 Elbow 1/2" O-ring x 3/8 JIC

11 600470290 3/8" Hose 3/8" JIC x 3/8" JIC -102 “ (All narrow centre models -3m)

11A 600470294 3/8" Hose 3/8" JIC x 3/8" JIC - 100" (All wide centre models -4m)

12 600470289 3/8" Hose 3/8" JIC x 3/8" JIC -126 “ (All narrow centre models -3m)

12A 600470293 3/8" Hose 3/8" JIC x 3/8" JIC - 56" (All wide centre models -4m)

13 600474502 Cylinder 4.5 x 8 Rephasing with Mechanical Stroke Control - Midway

14 600474503 Cylinder 4.25 x 8 Rephasing - Midway

15 600474504 Cylinder 4 x 8 Rephasing - Midway

16 600474557 Cylinder 4 x 24 - Midway

17 600474513 Stop Collar 1"

18 606001331 Cylinder Transport Lock

19 601140780 Pin

20 600333011 Hair Pin Clip

21 600470007 Hose Clamp 3/8"

22 600470047 Hose Clamp 1/2"

23 Carriage Bolt 1/4" x 1"

24 Locknut 1/4"

41

Page 42

When the cultivator frame is fully assembled check all nuts and bolts and secure if loose.

Double check the hose layout and hydraulic connections according to the hydraulic

diagram.

Be sure to read the Owners Manual before attempting to fold or operate the cultivator. The

Owners Manual provides important instructions and safety precautions that must be followed

before attempting to hook up and move the cultivator after assembly.

If you have purchased optional levelling attachments such as the combi harrows shown on the

cultivator below, refer to the Manual provided with the Harrow Assembly for proper installation

and adjustment of the attachments.

*Model may not be exactly as shown.

Kongskilde reserves the right to make changes to product designs and specifications without notice or obligation to rework.

See your local Kongskilde representative for current product

specifications, instructions and options.

42

Page 43

Installing Safety Decals and Product Identification:

1) Install th e Kon gskilde Logo deca ls

#600475113 and Vibro-Till 2800 decals

#600475168 on both sides of the draw tongue

and wing frames as shown.

KONGSKILDE & Vibro-Till

2800 on both sides of hitch

KONGSKILDE & Vibro-Till

2800 on both side of wing

frames

2) Install a Kongskilde Decal #600475113

on both sides of the centre frame side bar

as shown below.

43

Page 44

3) Install Yellow Safety Reflectors #600475131 on both front corners and sides of the 2800

centre section.

YELLOW REFLECTORS

on both front corners and

side bars of front frame.

YELLOW REFLECTOR

front view

YELLOW REFLECTORS

side view

44

Page 45

4) Install Red Safety Reflectors #600475132 on bothrear fold brackets and sides of the 2800

centre section.

RED REFLECTORS on

Rear Hinges and side bar

If the rear reflector position could be blocked from view by harrow mounting brackets then

the reflector can be place in an alternate position on the rear corner of the toolbar to provide

better visibility.

RED REFLECTORS on

Rear Toolbar Tube and Side Bar

45

Page 46

5) The 3 safety decals #600475170, 600475169 & 600475160 are located on the front frame

side bar beside the serial number plate and the CE label as shown.

SERIAL #

PLATE

CE Label

ELECTROCUTION

DANGER

TOWING SAFETY

TIPPING HAZARD

6) Install the Wing Fold Lock Warning decals # 600475176 on the top of the centre section

frame tubes near the wing fold lock plates so it can be viewed with the wings in the folded or

unfolded position as shown below.

Wing Fold Lock

Warning Decal

46

Page 47

7) Install the WING FOLD SAFETY DECALS #600475039 on the front and rear main frame

tubes on the 2800 wing frames. The decals should be centred on the tube at about eye level

so they can be read clearly when the wings are folded as shown below.

WING SAFETY on

front wing frame tube

WING SAFETY on

rear wing frame tube

47

Page 48

Tine Pattern Reference Section:

Tines Patterns in this section are organized by machine model and spacing as follows:

10' (3m) Centre and Wings - 4" patterns

10' (3m) Centre and Wings - 6" patterns

13' (4m) Centre and Wings - 4" patterns

13' (4m) Centre and Wings - 6" patterns

Measure Centre Sections from Left side of frame as indicated by "0" line .

Measure Wings from outside of frame at front and rear as indicated by "0" lines.

48

Page 49

49

Page 50

50

Page 51

51

Page 52

52

Page 53

53

Page 54

54

Page 55

55

Page 56

56

Page 57

57

Page 58

58

Page 59

59

Page 60

60

Page 61

61

Page 62

62

Page 63

63

Page 64

601230008-2005

Printed in Canada

MARCH 2004

Loading...

Loading...