Page 1

PHKS 1450

2003

Page 2

Page 3

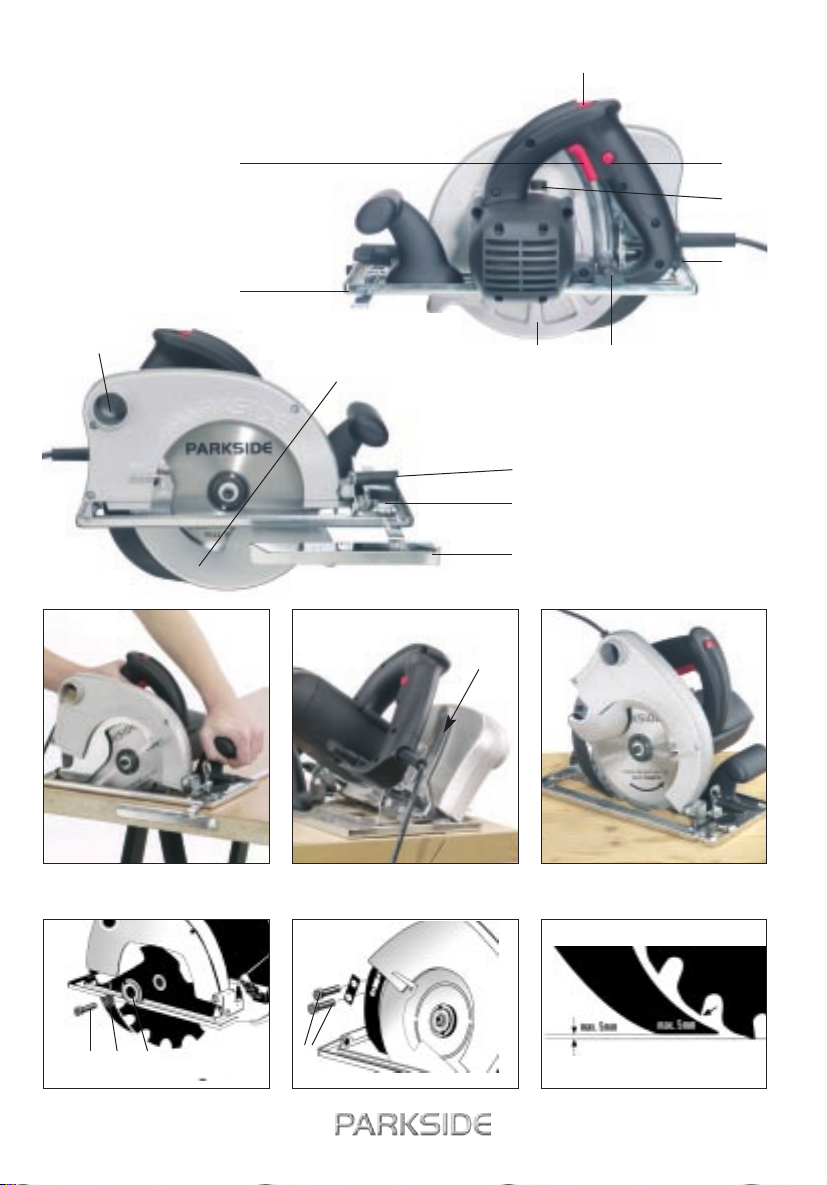

! @ # !

Page 4

CIRCULAR SAW PHKS 1450

Dear Customer, We are delighted that you have decided to purchase our high quality PHKS 1450

circular saw. Please make sure you familiarise yourself fully with the way the equipment works

before you use it for the first time and that you understand how to handle electrical power tools

correctly. Please read the instructions below and the accompanying safety advice carefully.

By doing this you will be able to work in complete safety and achieve better results. We hope you

enjoy using your circular saw.

PROPER USE

Sawing of solid wood, chipboard, plastic and aluminium. Please note that the blade pre-installed

in the saw as supplied is intended for sawing wood only. Any other use or modification to the saw

shall be considered as improper use and could give rise to considerable dangers.

FEATURES OF THE PHKS 1450

ON - OFF switch

Safety switch Parallel guide fence

Electronic speed control with millimetre scale

Adjustable depth stop Retractable guard

Sawdust outlet Spindle lock

Bevel cutting capacity Illustration showing operation

with angle gauge Depth of cut gauge

Guide plate Wing screw

TECHNICAL INFORMATION

Nom. power consumption: 1450 W Nom. voltage: 230 V 50 Hz

Output torque: 15 NM max. Weight: 6.75 kg

No load speed: 1800 - 5000 rpm The A-weighted noise level of the equipment

Blade: 210 x 30 x 1.8 x 2.6 mm is typically: Sound pressure level: 107.5 dB(A)

Cutting depth at 90°: 0 - 75 mm Sound power level : 120.5 dB(A)

Cutting depth at 45°: 0 - 50 mm Hand/arm vibration is typically less than 9.3 m/s

2

The PHKS 1450 circular saw has INTELLIGENT POWER CONTROL.

This automatic power delivery system ensures that for a particular

speed range the power output r

emains constant when working

on harder and more resistant materials.

SPECIFIC SAFETY ADVICE

To be read in conjunction with the advice in the accompanying booklet on safety.

The PHKS 1450 circular saw is fitted with an electronic soft start system. This provides a short

delay after the ON/OFF switch is actuated before the motor starts up.

Only actuate the spindle lock button after the saw has come to a standstill.

Before starting any

work on the machine, e.g. setting the guide plate etc., always take the plug

out of the socket.

Never remove chips or splinters while the equipment is operating - always remove the plug from

the socket first.

n

0

4

www.kompernass.com +++ www.kompernass.com +++ www.kompernass.com +++

Page 5

Always wear ear defenders and eye protection when working with the circular saw. In addition

we recommend wearing safety gloves, robust anti-slip footwear and an industrial apron.

Check the circular saw, power cable and plug for damage before every use. Always have any

damaged parts repaired or replaced at a specialist repair centre.

Always keep the power cable well out of the saw's working area and feed the cable from the rear

of the machine.

If you are working for long periods on wood or materials that give rise to a lot of dust, fit the saw

with a suitable tested vacuum extraction device.

Always use the saw's integrated safety devices, e.g. the safety switch and the retractable guard.

Check to see that the retractable guard moves freely before every use.

Persons under the age of 16 are not to use this equipment.

Only operate the retractable guard using the lever provided. As the saw comes into contact with

the material, the retractable guard automatically swings away. The guard is not to be fastened

back into the open position. In addition, please make sure all the moving parts on the guard

function without hindrance and all parts of the machine that cover the saw blade are working

properly.

When plunging make sure that the saw cannot kickback, e.g. clamp with a cross piece.

Secure round section wood on both sides of the saw blade against rotation.

Do not use on asbestos-based materials.

Make sure that the diameter, thickness and other saw blade parameters are suitable for use in the

circular saw.

Make sure the saw blade speed rating is suitable for the spindle rotation speed of the circular saw.

Cracked or distorted saw blades are not to be used.

HSS (High Speed Steel) saw blades are not to be used.

The distance between the reamer and the saw teeth is to be set to 5 mm maximum. The distance

between the point of the reamer and the deepest point of the saw blade is to be 5 mm maximum.

Always remove the reamer for plunging work.

When you switch off the saw, do not use any additional means of stopping the saw blade.

Do not lock the ON-OFF switch for hand fed work.

SETTING THE ANGLE OF CUT

You can use the angle gauge to set the angle of cut accurately. Slacken the wing nuts on each

side of the cut angle adjuster.

, set the required angle on the scale and tighten the wing nuts

again.

Caution - Check the angle of cut with a trial cut.

SETTING THE DEPTH OF CUT

Note: We recommend that the depth of cut is set if possible 5 mm greater than the material

thickness. This will ensure you have a clean cut. Release the wing nut on the depth stop ,

set the required depth of cut on the scale

and tighten the wing nut again.

SETTING THE WIDTH OF CUT / PARALLEL GUIDE

Release the wing screw on the parallel guide . Set the required width of cut on the parallel

guide fence scale and tighten the wing screw again.

HANDLING THE CIRCULAR SAW

1. Switch on the motor as described in the section "On/off switch" and then set the front edge

of the guide plate down on the material.

2. Align the circular saw with the parallel guide or with a drawn cutting line.

3. Hold the circular saw with both hands on the handles and saw using moderate force.

5

www.kompernass.com +++ www.kompernass.com +++ www.kompernass.com +++

Page 6

6

SETTING THE SPEED

Using the following advisory settings as a guide, set the rpm on the electronic control wheel

to an appropriate value. Turn the wheel until the required rpm setting is opposite the arrow

marking (

).

(1 = lowest rpm to 6 = highest rpm):

Material rpm setting

Hard- and softwoods (natural wood)

with & across grain 6

Chipboard, hardboard 6

Chipboard 6

Veneered plywood, plywood 6

Coated and veneered board 6

PVC board 3-5

Acrylic sheet, Plexiglas 2-4

Aluminium sheet 4-6

Aluminium sections 4-6

Plasterboard 1-2

Masonry veneered cladding board 1-2

Cement bound woodwool board 1-2

SAWDUST REMOVAL

The sawdust removal vent can be connected (* = not supplied with accessories)

• Connection spout • Sawdust collection system* • 35 mm dia. vacuum hose connection

to external suction equipment*

ON/OFF SWITCH

For safety purposes, the saw has a safety switch . The on/off switch will not self engage. To

switch the saw motor on, first press the safety switch and then (keeping the safety switch

pressed) press the on/off switch . Once the motor is running you can release the safety switch.

To turn off the saw motor, release the on/off switch

.

CHANGING THE SAW BLADE

1. First remove the parallel guide by unscrewing the wing screw .

2. Set the cutting depth (use the wing screw for cutting depth stop ) to the minimum position,

0 mm.

3. Swing back the retractable blade guard and place the saw down (see Fig. ).

4. Press the spindle lock button

(until it engages) and release the clamping screw using the

hexagonal socket screw key

!. Take off the washer @ and spring washer # (see Fig. ).

5. Remove the saw blade from the mounting flange.

6. Replacement of the saw blade takes place in the reverse order.

CAUTION: The arrow on the saw blade must point in the direction of rotation (marked with

an arrow on the saw body).

Further information:

The circumferential speeds at minimum and

maximum rotational speeds are approx.:

Setting 1 1,800 rpm

Circ. speed 20 metres/sec

Setting 6 5,000 rpm

Circ. speed 55 metres/sec

Make sure that the cutting speed resulting from the

effects of different saw blades, materials and the

force you apply to advance the saw always remains

less than the circumferential speed under no load.

www.kompernass.com +++ www.kompernass.com +++ www.kompernass.com +++

Page 7

7

FITTING/REMOVAL AND SETTING OF THE REAMER

Caution: The distance between the reamer and the saw blade is not to be more than 5 mm.

If the reamer is removed e.g. for plunging then this distance must be reset.

Fitting/r

emoval of the reamer (see Fig. ):

1. Release the wing nut on the depth stop and swing the saw to meet the stop. This reveals the

fastening screw for the reamer and loosens it.

2. Screw out the fastening screw ! and remove the reamer.

CAUTION / IMPORTANT: After plunging, the reamer must be refitted before further use.

Setting the r

eamer (see Fig. ):

The distance between the reamer and the saw blade teeth is to be set to 5 mm max. and the gap

between reamer and the deepest point of the saw blade is to be set to 5 mm max.

MAINTENANCE OF THE CIRCULAR SAW

1. Clean out the circular saw regularly (remove sawdust and splinters of wood etc.). For best

results do it immediately after use.

2. Do not allow liquids to get into the circular saw. Use a damp cloth to clean the housing. Do not

use petrol, solvents or cleaning fluids that attack plastic.

3. Keep the ventilation airways open and cleaned out.

TIPS AND TRICKS

When sawing at an angle to meet a stop, the stop (parallel stop /batten) must be accurately set.

To make sure use a trial cut beforehand.

If you are going to use a wider cut than the parallel guide allows, we recommend that you use a

guide rail or run the machine along a clamped-on batten.

If you are sawing towards a check with a drawn line use the appropriate value in the window:

right angled cut (reading "0"), 45° cut (reading "45") for each cutting angle

To avoid pulling away the coating on sensitive surfaces, e.g. coated plywood or doors, stick on

some rough paper tape along the cut line. This has the additional advantage of the cut line being

more easily seen on the tape than on a smooth surface. An even more effective way of avoiding

the surface pulling off at the cut edge is to attach a piece of thin wood which is then sawn at the

same time.

You can find other practical tips for electric power tools in the accompanying booklet and safety

advice.

We reserve the right to make changes to the equipment in the interests of developing improvements.

www.kompernass.com +++ www.kompernass.com +++ www.kompernass.com +++

Page 8

8

WARRANTY

This piece of equipment is covered by a 36-month warranty as of the date of purchase. The equipment was produced with the greatest of

care and underwent thorough testing before delivery. In the unlikely event of detecting a functional defect, please return the equipment in its

original packaging with the proof of purchase (if available) to the closest service address.

Damage caused due to improper handling as well as regular wear of the parts are not covered by this warranty.

Beaver Electronic Services · The Lodge, Premier Business Park

Long Street, Walsall · West Midlands, WS2 9DY

Tel.: 01922/72 5554 · Fax: 0 1922/7254 17

WARRANTY

This piece of equipment is covered by a 36-month warranty as of the date of purchase. The equipment was produced with the greatest of

care and underwent thorough testing before delivery. In the unlikely event of detecting a functional defect, please return the equipment in its

original packaging with the proof of purchase (if available) to the closest service address.

Damage caused due to improper handling as well as regular wear of the parts are not covered by this warranty.

Irish Web Specialists

1 Verbena Avenue · Dublin 13

Tel.: 01/8 3204 92 · Fax: 01/8 3968 29

Page 9

9

DECLARATION OF CONFORMITY

We, Kompernaß Handelsgesellschaft mbH, Burgstr. 21, D-44867 Bochum, Germany,

declare that this product complies with the following EU directives:

Machinery Directive (98/37 EC), Low Voltage Directive (73/23 EEC, 93/68 EEC), Electromagnetic

Compatibility (89/336 EEC, 93/68 EEC) in accordance with the applicable standards, and confirm

this with the CE mark.

Type/machine description: PARKSIDE CIRCULAR SAW PHKS 1450

Bochum, 31.01.2003

Hans Kompernaß

- Managing Director -

Page 10

Page 11

Page 12

© manual design, photos, translations

by ORFGEN Marketing & Communication

Essen · Germany

www.kompernass.com

Loading...

Loading...