Page 1

6

Overlock Sewing Machine

KH 4300

KOMPERNASS GMBH · BURGSTRASSE 21 · D-44867 BOCHUM

www.kompernass.com

ID-Nr.: KH4300-03/09-V3

Overlock Sewing Machine

Operating instructions

Page 2

KH 4300

q

w

z

e

r

dsapoi f

1

u

t

2

3

0

9

8

4

jhg k

5

6

7

Page 3

CONTENT PAGE

Intended Usage 3

Safety instructions 3

Technical Data 4

Items supplied 4

Description of the appliance 5

Preparation 5

Adjusting the thread tree .................................................................................................................5

Bobbin supports................................................................................................................................5

Bobbin caps ......................................................................................................................................6

Connecting the foot pedal .............................................................................................................6

Controlling the sewing speed..........................................................................................................6

Safety switch .....................................................................................................................................6

Fitting the waste container...............................................................................................................6

Handwheel........................................................................................................................................6

Front flap ...........................................................................................................................................6

Opening the free arm ......................................................................................................................7

Threading yarns into the looper......................................................................................................7

Threading yarns into the needle .....................................................................................................8

Trial run..............................................................................................................................................9

Setting the thread tension 10

Adjusting thread tension on the needle threads ........................................................................11

Adjusting thread tension on the looper threads..........................................................................11

Overview of the machine adjustments.........................................................................................12

Changing threads (binding together) 13

Setting the stitch length 13

Setting the cutting width 14

Exchanging needles 14

Replacing bulbs 15

Exchanging the upper blade 15

- 1 -

Page 4

Close and broad sewing with three threads 16

Sewing freehanded 16

Adjusting the sewing foot 16

Hemstitch and edging 17

Sewing hemstitch 17

Sewing narrow edging 17

Differential feed motion 18

Manner of operation .....................................................................................................................18

Setting the differential feed motion ..............................................................................................18

Uneven material edges and smoothness.....................................................................................19

Avoid ruffles by stretching.............................................................................................................19

Troubleshooting 20

Cleaning and care 21

Storage 21

Disposal 21

Warranty and Service 22

Importer 22

Read the operating instructions carefully before using the appliance for the first time and preserve this

booklet for later reference. Pass the manual on to whomsoever might acquire the appliance at a later date.

- 2 -

Page 5

OVERLOCK SEWING

MACHINE KH 4300

Intended Usage

This overlock sewing machine is intended ...

– for use as a portable machine,

– for the trimming of material edges (sewing) of

typical household textiles, and ...

– only for domestic household use.

This overlock sewing machine is not intended ...

- to be installed at a permanent location,

– for the processing of other materials (e.g. leather,

canvas, sailcloth and other heavy materials),

- for commercial or industrial use.

Safety instructions

• Arrange for defective power plugs and/or cables

to be replaced at once by qualified technicians

or our Customer Service Department.

• This appliance is not intended for use by individuals (including children) with restricted physical,

physio-logical or intellectual abilities or deficiences in experience and/or knowledge unless they

are supervised by a person responsible for their

safety or receive from this person instruction in

how the appliance is to be used.

• Children should be supervised to ensure that

they do not play with the appliance.

• Never use the machine when the ventilation

apertures are blocked. Keep the ventilation

apertures of the machine and the foot switch

free from fluff, dust and waste material.

• Should the cable connected to the foot pedal

become damaged, to avoid potential risks it must

be replaced by the manufacturer, his customers

services or a similarly qualified person.

Like any other electrical device, a sewing machine

can cause serious, even life-threatening injuries.

To avoid these, and to work safely:

• Always disconnect the power supply when leaving

the machine unattended. This will prevent the

risk of accidents if the machine is switched on

accidentally.

• First pull the power plug before changing the bulb

or performing maintenance work on the machine.

This will prevent possibly life-threatening electric

shocks.

• Do not pull the plug out of the wall socket by the

lead. When pulling out the plug, always hold the

plug, not the lead.

• Only use the sewing machine in dry rooms.

Warning about injuries and

material damages:

• Keep your work space tidy. An untidy workplace

can lead to accidents.

• Provide adequate lighting when working!

• Do not wear loose clothing or jewellery, as these

can be caught in moving parts. You should also

wear a hair net if you have long hair.

• Avoid adopting an unusual posture. Remain steady

and in a well-balanced position at all times.

• If accidents occur as a result of handling the machine with insufficient care, or failure to follow

the safety instructions in this manual, then the

manufacturer cannot accept liability.

• Never cover the ventilation slots! Risk of overheating!

- 3 -

Page 6

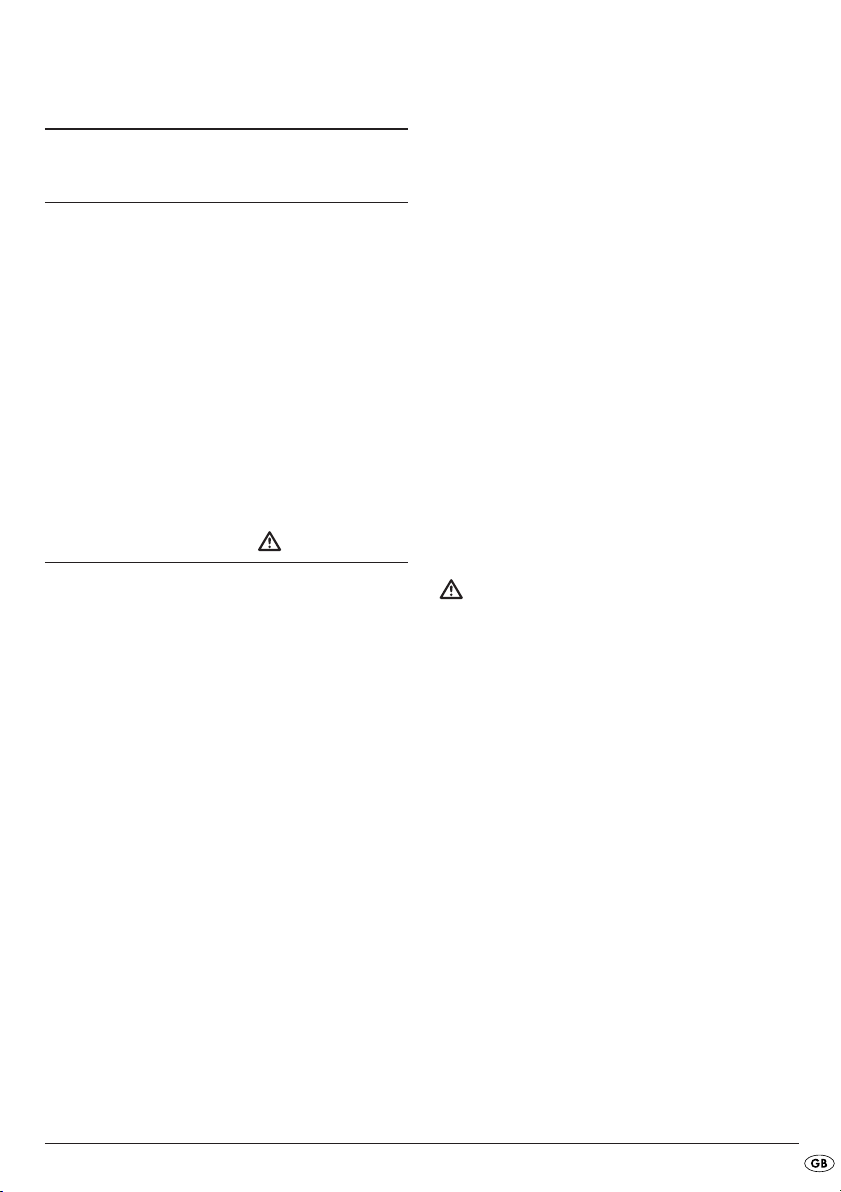

Technical Data

Items supplied

Number of threads 4 or 3

Number of needles 2 or 1

Sewing speed 1100 Revs/min

Stitch width 6 mm with 4 threads

6 mm or 4 mm with 3

threads

Stitch length 1 – 5 mm

Needles HA x 1 Nr. 11-14 or

130/705 Nr. 75-90

Power consumption : Motor: 90 W

Bulb: 15 W

Total: 105 W

Rated voltage: 230 V ~, 50Hz

Protection class: II

Bulb power: 15 W

Bulb voltage: 230 V / ~50 Hz

Bulb thread: E14 thread

The sound intensity level under normal operating

conditions amounts to 78dB(A).

Foot pedal

Use only the foot pedal originally supplied with this

sewing machine:

- ELECTRONIC FDM Speed Controller

- Type KD-2902

Overlock Sewing Machine

Oil

Waste container

Accessory box

Operating instructions

Replacement

(upper blade)

2 Needles Nr. 11

4 Needles Nr. 14

(2 in the machine,

pre-installed)

4 Bobbin caps

4 Spool pin

(preinstalled)

Allen key

Flat-headed screwdriver

Covering hood

Pincers

Brush

- 4 -

Page 7

Description of the appliance

Preparation

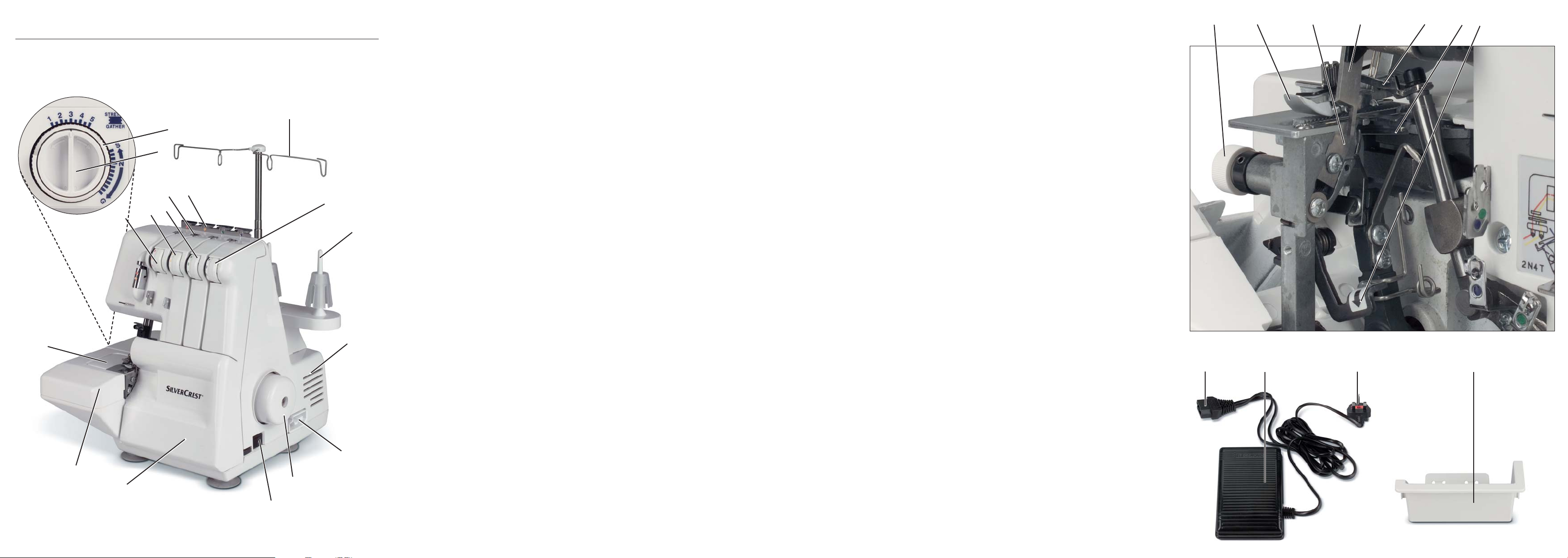

1 Thread tree

2 Thread tension selector (lower looper)

3 Spool support

4 Cold air intake

5 Connection Footpedal/Power supply

6 Handwheel

7 Power switch (On/Off switch)

8 Front flap

9 Arm support

0 Free arm

q Thread tension selector (left needle)

w Thread tension selector (right needle)

e Thread tension selector (upper looper)

r Thread guide

t Thread guide plate

z Adjustment wheel for stitch length

u Adjustment wheel for differential feed motion

i Adjustment wheel for cutting width

o Sewing foot

p Lower blade

a Upper blade

s Upper looper

d Lower looper

f Release lever PUSH

g Connection plug

h Foot pedal

j Power plug

k Waste container

Place the overlock sewing machine on a stable and

level surface. Ensure there is sufficient illumination at

your workplace.

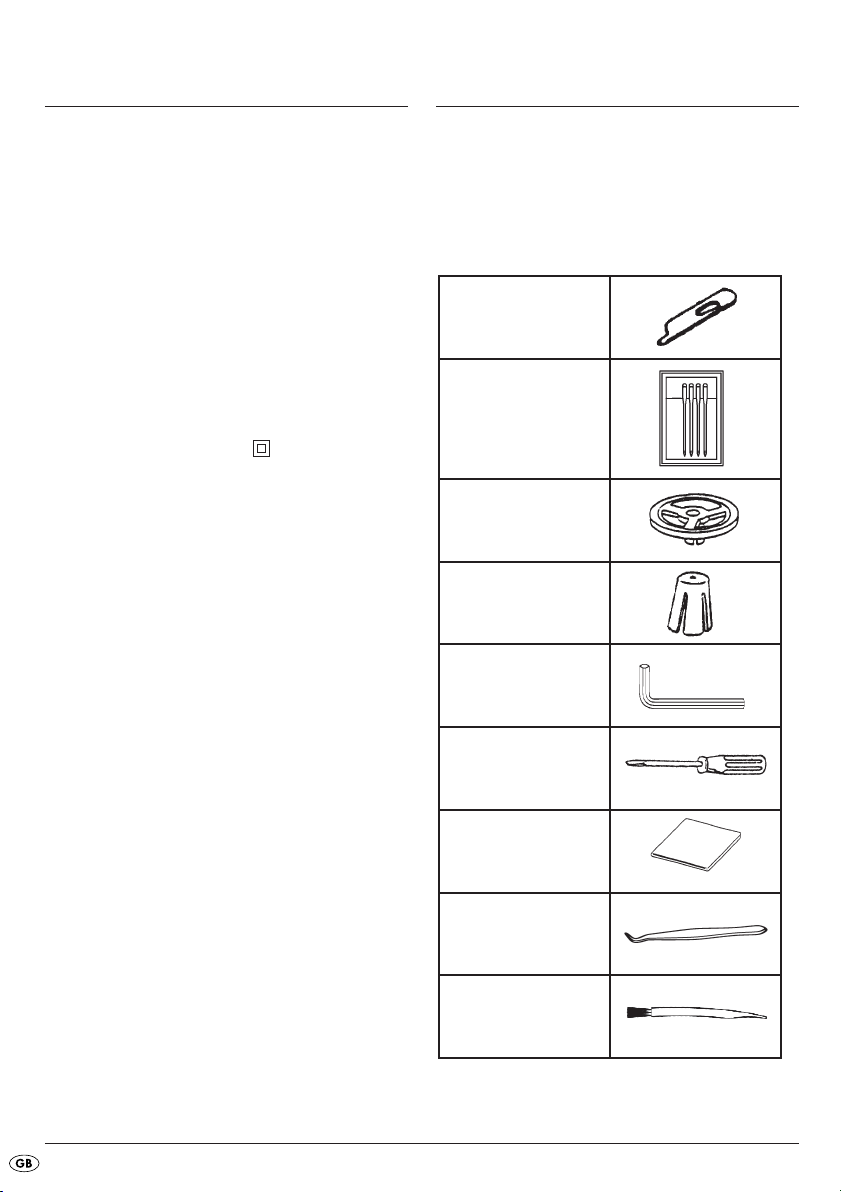

Adjusting the thread tree

Completely withdraw the thread tree 1 before

threading.

Turn the thread tree 1 so that the thread guides

stand exactly above the spool supports 3.

Bobbin supports

Both industrial bobbins and household bobbins can

be used with this machine.

For industrial bobbins with a large diameter place

the bobbins supports in with the broad end to the

top, for bobbins with a small diameter place the

support in with the narrow end to the top.

- 5 -

Page 8

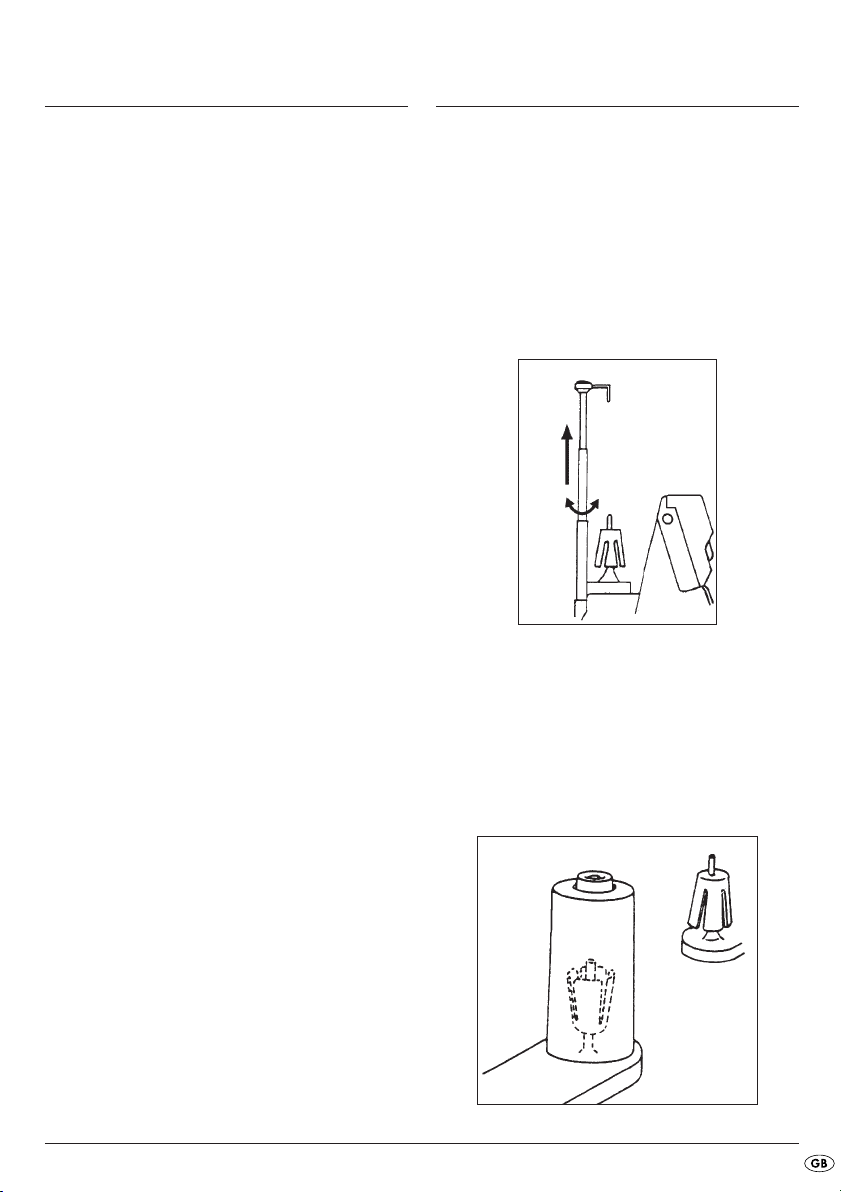

Bobbin caps

If using non-industrial thread bobbins, remove the

bobbin supports and place the bobbin caps on the

thread bobbins.

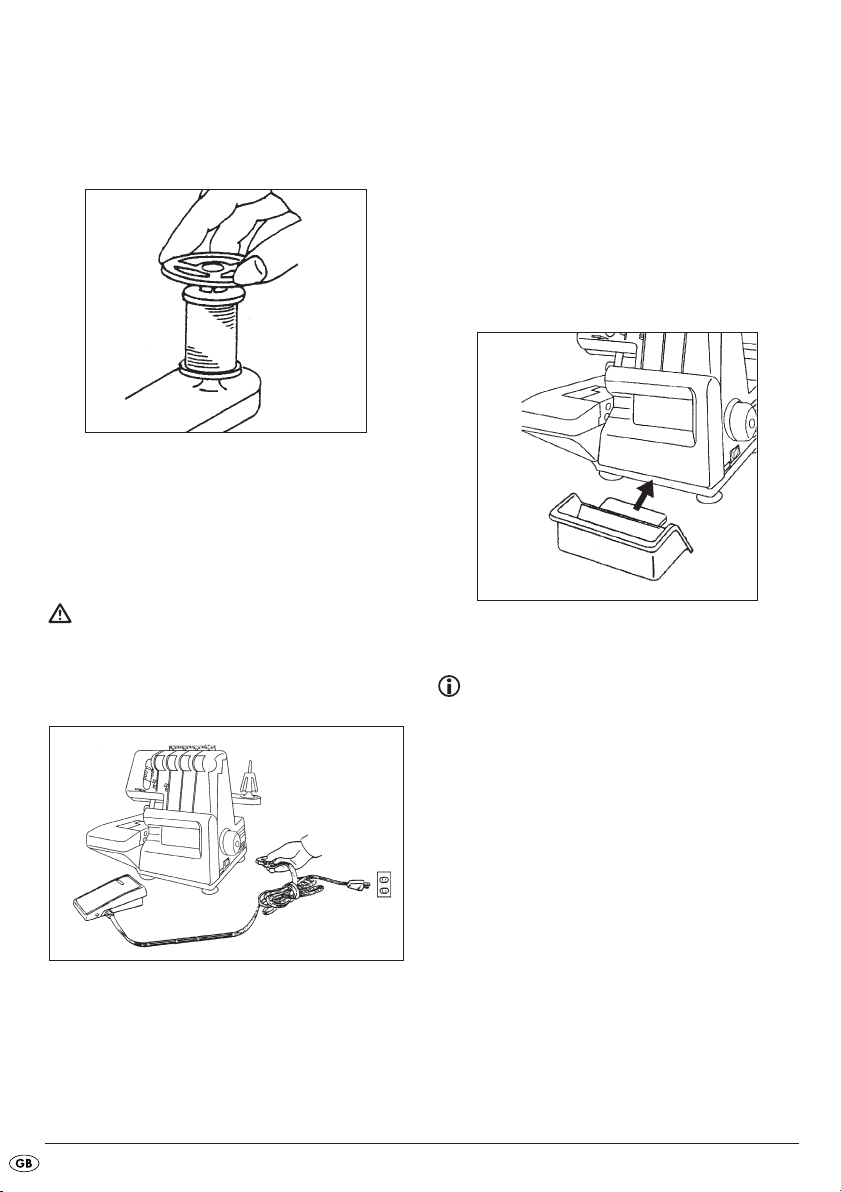

Connecting the foot pedal

Insert the plug of the footpedal g into the connection

for the footpedal 5 and the power plug j into a

mains power socket.

To switch the machine on, press the power switch 7.

Attention!

During absences from the machine or when doing

maintenance work, always remove the plug j from

the mains power socket. Injury hazard!

Safety switch

This machine is fitted with a micro safety switch. You

cannot start the machine if the front flap 8 is open.

Close the front flap 8 before you start to sew.

Fitting the waste container

The waste container k collects remnants during

sewing, so that your workplace stays tidy. Place the

waste container k between the machine and the

table.

Handwheel

Note:

Always turn the handwheel 6 towards yourself,

that is, in the same direction as with a domestic

sewing machine.

Controlling the sewing speed

The sewing speed is controlled by means of the

footpedal h. The sewing speed is changed by applying more or less pressure to the footpedal h.

Front flap

To open the front flap 8, slide it as far as possible

to the right and, at the same time, draw it towards

yourself.

- 6 -

Page 9

Opening the free arm

For threading the yarns the free arm 0 must be

opened.

1. Pull the arm support 9 off to the side.

2. Open the front flap 8.

3. Press the release lever "PUSH" f and, at the

same time, pull the free arm 0 downwards.

Correct threading is important, so that the stitches

are not irregular and that the yarn does not break.

On the inner side of the front flap 8 there is a guide

to threading. Additionally, the thread guides are

marked in various colours.

In the accessory box you will find pincers, the use

of which helps make threading easier.

Threading takes place in this sequence:

1. First step: Upper looper s (green)

2. Second step: Lower looper d (blue)

3. Third step: Right needle (yellow)

4. Fourth step: Left needle (red)

For simplification, the individual steps are numbered

on the illustrations (1

1. Open the front flap 8 and free arm 0.

2. Turn the handwheel 6 to yourself until the looper s

is in the most favourable position for threading.

3. Thread the upper and lower looper yarns as

shown.

, 2 w, 3 e, 4 r, ...).

q

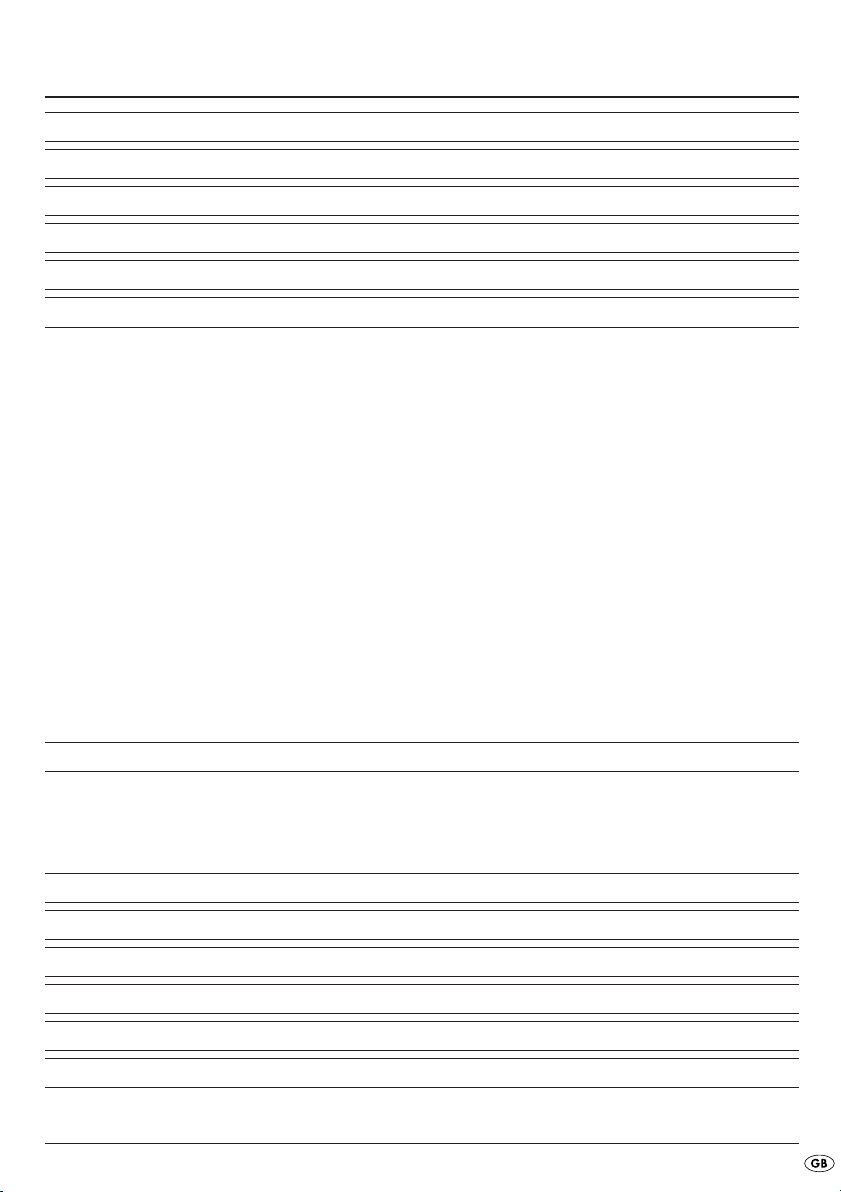

Threading yarns into the looper

Attention!

Before starting to thread yarns, ALWAYS place the

power switch 7 at OFF and remove the plug j.

This will prevent an unintentional starting of the appliance. If you do not, you run a risk of serious injury!

Thread tree 1 (on the right)

Thread guide r and thread guide plate t

(on the right)

Note:

The yarn must lie correctly between the two discs of

the thread tension selector 2/e.

- 7 -

Page 10

Thread tension selector 2 e

4. Pull the end of the thread about 10 cm (4”) out

from the looper eyelet.

5. Lift the sewing foot o and slide the thread under

it; then lower the sewing foot o back down. The

lever for lifting and lowering the sewing foot o

is located at the rear of the machine, above the

sewing lever rod system.

Position the lever to lift the sewing foot o

Thread routing on from the thread guide plate 8

Threading yarns into the needle

For simplification, the individual steps are numbered

on the illustrations (1

1. Turn the handwheel 6 to yourself until the needles

stand fully at the top.

2. Thread the left and right yarns as shown.

Thread tree 1 (on the left)

, 2 w, 3 e, 4 r, ...).

q

Thread routing behind the front flap 8

Thread guide r and thread guide plate t

(on the left)

- 8 -

Page 11

Note:

The yarn must lie correctly between the two discs of

the thread tension selector.

Thread tension selector q w

Thread routing on from the thread guide plate 8

4. Pull the end of the thread about 10 cm (4“ )

out from the eyes of the needles. Lift the sewing

foot o and slide the thread under it; then lower

the sewing foot o back down. The lever for lifting

and lowering the sewing foot o is located at the

rear of the machine, above the sewing lever rod

system.

further thread routing

3. Guide the yarn, as shown, from front to back

through the eyes of the needles.

Position the lever to lift the sewing foot o

Trial run

When yarn has been threaded for the first time,

or after a yarn breakage it must be rethreaded,

proceed as follows:

Lift the sewing foot o.

Hold the ends of the threads between the fingertips

of your left hand, slowly turn the handwheel 6 two

or three times towards yourself and then check the

threads once again.

- 9 -

Page 12

Lay the material for a trial run under the sewing

foot o and slowly start to sew.

The material will be automatically fed through.

Setting the thread tension

The thread tension required is variable, being dependant itself on the type and thickness of the thread

and fabric.

Check the seams and then adjust the appropriate

thread tension on the machine.

Tensioning the thread

When you turn the tensioning device to a lower

number, the tension reduces.

When you turn the tensioning device to a higher

number, the tension increases. The wheels of the

tensioning device have the following colours:

yellow

green

red

blue

When the task is complete, continue sewing until an

approximately 5cm (2") long length of threads has

formed at the end of the material.

Cut through the threads with scissors.

Correct thread tension:

Thread, right needle

Reverse

Thread, left needle

lower looper thread

upper looper thread

- 10 -

Page 13

Adjusting thread tension on the needle

threads

Adjusting thread tension on the looper

threads

The tread tension on the left needle

is too loose.

Adjust tension on the left thread.

The tread tension on the right needle

is too loose.

Adjust tension on the right thread.

The lower looper thread is firm and/or the

upper looper thread is loose.

Loosen the tension of the lower

looper thread and/or tighten the

upper looper thread.

The upper looper thread is firm and/or the

lower looper thread is loose.

Loosen the tension of the upper

looper thread and/or tighten the

lower looper thread.

- 11 -

Page 14

Overview of the machine adjustments

The most appropriate thread tension adjustment for one type of material is not necessarily the ideal adjustment for a different material.

The thread tensions required are dictated by the pliability and thickness of the material as well as the type

and thickness of the thread.

When necessary, adjust thread tensions as per this table:

Fabric Thread Needles Stitch length

Light:

• Georgette

• Muslin

• Batiste

• Dress fabric

• Crepe de Chine

• Silk

Medium weight:

• Cotton

• Poplin

• Waterproofed

cotton

• Corduroy

• Cotton

• Polyester

Nr. 80 - 100

• Cotton

• Polyester

Nr. 60 - 100

HA x 1

Nr. 11

130 / 705H

Nr. 80

HA x 1

Nr. 11 - 14

130 / 705H

Nr. 80 - 90

Thread tension

adjustment

2.0 - 3.5 mm

• Standard

2.5 mm

2.0 - 3.5 mm

• Standard

2.5 mm

Heavy:

• Denim

• Tweed

• Velour

• Cotton

• Polyester

Nr. 50 - 80

HA x 1

Nr. 14

130 / 705H

Nr. 90

- 12 -

2.5 - 4.0 mm

• Standard

3 mm

Page 15

Changing threads

(binding together)

With the following procedure, changing threads is

quite simple:

1. Cut the yarn above the spindle and knot the

ends of the new and the old thread together.

2. Place the thread tension selector 2/q/w/e

at "0" and lift the sewing foot o.

3. Pull on the other end of the yarn until the knot

passes under the sewing foot o.

4. For threading it in the needle, pull on the other

end until the knot is in the eye of the needle and

then cut the yarn to the left and right of the knot.

Then carry out the rethreading.

Setting the stitch length

The stitch length can be adjusted in nine steps, from

1.0 to 5.0 mm. Almost all overlock work is

carried out with a stitch length of 2.5 – 3.5 mm.

Turn on the inner adjustment wheel for stitch length

z to adjust the stitch length:

Stitch Stitch length

Normal seams

Narrow edgings 1.0 - 2.0 mm

Hemstitching 1.0 - 2.0 mm

2.0 - 5.0 mm

Standard: 3.0 mm

- 13 -

Page 16

Setting the cutting width

The appropriate cutting width is, from material to

material, variable. Each time test the seams and

adjust the cutting width as follows:

1. Turn the handwheel 6 towards yourself until the

needles are in the lowest position.

2. Open the front flap 8.

3. Press the lever PUSH f. The free arm 0 lowers

itself and the adjustment wheel for the cutting

width i can be seen.

4. Turn the djustment wheel for the cutting width i.

With this you move the lower blade p. Continue

turning it until the looper threads are lying at the

edge of the material. When you turn in the direction W (wide), the cutting width is broader.

When you turn in the direction N (narrow), the

cutting width is narrower.

Exchanging needles

Attention!

Before exchanging the needles, remove the power

plug. This prevents an unintended starting of the machine. If you do not, you run a risk of serious injury!

1. Turn the handwheel 6 towards yourself until the

needles are in the highest position.

2. Open the front flap 8 and lower the sewing

foot o.

3. Loosen the setscrew against the needle with the

Allen key from the accessories box and then remove the needle:

- upper left setscrew for the left needle

- lower right setscrew for the right needle.

Examples:

Select a narrower cutting width if the material edges

ruffle during sewing. For this, turn the adjustment

wheel for cutting width i to the right (N).

Select a larger cutting width if the yarn is being sewed

beyond the material edge. For this, turn the adjustment wheel for cutting width i to the left (W).

4. Insert the new needle, with the flat side to the

rear, into the needle mounting. Ensure that the

needle is inserted as far as is possible. Secure

the needle by retightening its setscrew.

When the needles have been correctly fitted, the

left needle stands a little higher than the right needle.

If the needles have not been correctly inserted, stitches

will occasionally be left out when sewing.

This machine is equipped with needles of the type

H.Ax1 (Needle system 130H) (for household machines).

- 14 -

Page 17

Replacing bulbs

Risk of electric shock

When changing bulbs, ALWAYS remove the plug j

from the mains power socket!

1. Remove the small round cover with a needle or

something similar.

2. Unscrew the screw completely.

3. Remove the lamp cover.

Note:

The lower blade p is manufactured from a special

material and normally does not need to be exchanged.

Should it at some time become nonetheless damaged,

please make contact with our Customer Services.

To exchange the upper blade a when it has become

blunt:

1. Open the front flap 8 and turn the handwheel 6

towards yourself until the needles are in the lowest

position.

2. Using the screwdriver, loosen the screw on the

upper blade holder and remove the upper

blade a.

Screwdriver

upper blade a

4. Exchange the bulb. Use a bulb of the type E14,

15 W.

5. Reassemble all of the parts in reverse order.

Exchanging the upper blade

Attention!

Before changing the blade a, ALWAYS remove the

plug j from the mains power socket. This prevents

an unintended starting of the machine. If you do

not, you run a risk of serious injury!

lower blade p

3. Insert a new upper blade a and lightly tighten

the screw on the blade holder.

4. Adjust the upper blade a to that its cutting edge

surmounts the cutting edge of the lower blade p

by about 0.5-1.0 mm.

5. Now firmly tighten the setscrew in the holder for

the upper blade a and close the front flap 8.

- 15 -

Page 18

Close and broad sewing with

three threads

When sewing with this machine you can adjust from

four to three threads.

Remove either the left or the right needle (see section

"Exchanging needles") and the appropriate thread.

The machine is now ready for sewing with three

threads.

With exclusive use of the right needle, the stitching

length amounts to 4 mm (0.16“).

Sewing freehanded

Freehand operation is excellently suited for the

sewing of trouser legs, sleeves and cuffs etc.

Remove the arm support 9, as shown in the illustration, to change from flatbed to free arm operation.

With exclusive use of the left needle, the stitching

length amounts to 6 mm (0.24“).

Adjusting the sewing foot

The special sewing foot o is adjusted to the position N on the countersunk screw at the front of the

sewing foot o for normal sewing operations.

Should you wish to sew a hemstitch, simply loosen

the large screw lightly and slide the small pin, which

protudes from the foot to the left, all the way in.

Now the letter R stands on the screw.

- 16 -

Page 19

Pin

Sewing hemstitch

With the sewing of hemstitches the loops of the upper

looper thread should be pulled back to the underside

of the material. This is achieved by adjustment of the

thread tension, as described in the section "Setting

the thread tension".

Hemstitch and edging

For these two tasks proceed as follows:

1. In the section "Adjusting the sewing foot" reread

the instructions for adjusting the sewing foot o.

2. Turn the handwheel 6 to yourself until the needles

stand fully at the top.

3. Open the front flap 8 and remove the left needle

(see section " Exchanging needles").

4. Adjust the stitching length to 1.0 - 2.0 mm. Ensure

that the adjustment wheel for the differential

feed motion u is placed at “N”.

5. Adjust the stitching width as described in the section “Setting the cutting width”.

6. If a yarn is not threaded, now rethread a new

yarn.

7. Lay your material under the sewing foot o and

start to sew.

Note:

Before you begin to sew on your actual workpiece,

always check the adjustments for stitching length

and thread tension on a material remnant.

Note:

Always remember to return the adjustment for the

sewing foot o from this special to normal operation

(sewing tasks) after the sewing of hems.

lower

looper thread

upper

looper thread

Sewing narrow edging

If you wish to sew very thin or light materials, select

a suitable thread tension, as described in the section "Setting the thread tension".

needle thread

upper

looper thread

lower

looper thread

- 17 -

Page 20

Important: If necessary, adjust the stitching length

and cutting width.

Hem stitching

Edging

Differential feed motion

With the differential feed motion uneven seams are

avoided in knitted materials, as well as the slippage

of textile positions. Additionally, the seams cause no

wrinkles in very light materials.

Manner of operation

The machine has two sets of toothed rack feeders,

one to the front and one to the rear. Both sets move

independant of each other. Through the differential

feed motion both toothed rack sets can move themselves at various speeds.

The toothed transport racks move themselves in an

elliptical motion and thus transport the material:

rear front

Setting the differential feed motion

The differential feed motion is adjusted to the desired direction simply by turning the adjustment

wheel for the differential feed motion u.

"N" = "Neutral Position", the toothed rack feeders

move the material forward evenly.

"G" ="Gather Position", the front toothed rack feeders

push the material forward faster than the rear

ones. Thereby, elasticated material is not extended.

"S" ="Stretch Position", the rear toothed rack feeders

push the material forward faster than the front

ones. Thereby, the front toothed rack feeders

hold the material tautly.

The differential feed motion can also be adjusted

during sewing.

- 18 -

Page 21

Uneven material edges and smoothness

To obtain precise flat edges when sewing elasticated

materials, the front toothed rack feeders must push

forward faster than the rear ones, so that the material

is not stretched. For smoothness the front toothed

rack feeders must also work faster than the rear

ones. With a larger stitching length the material

stays easily smooth. Place the differential feed

motion at "G".

Avoid ruffles by stretching

To avoid seams casting wrinkles in very light materials

or fine nylons, the rear toothed rack feeders must

work faster than the front ones. Thereby the front

toothed rack feeders hold the material taut so that

it does not ruffle. Place the differential feed motion

at "S".

- 19 -

Page 22

Troubleshooting

Problem Cause Solution

Needles break

Thread breaks

Stitches are omitted

Stitches are irregular

• Needles are bent, blunt or damaged at the points.

• Needles are not correctly inserted.

• You have pulled the material too

heftily.

• Yarn has not been correctly

threaded.

• Thread tension is too high. • Reduce the thread tension.

• Needles are not correctly inserted.

• Needles are bent, blunt or damaged at the points.

• Needles are not correctly inserted.

• Yarn has not been correctly

threaded.

• Incorrect needles are fitted.

• Thread tension is not correct. • Correct the thread tension.

• Thread is trapped.

• Fit new needles.

• Insert the needles into the retainers

correctly.

• Carefully guide the material with

both hands.

• Thread the yarn correctly.

• Insert the needles into the retainers

correctly.

• Fit new needles.

• Insert the needles into the retainers

correctly.

• Check the course of the individual

threads.

• Use the correct needles (HA x 1

or 130/705H)

• Check the course of the individual

threads.

Seams cause wrinkles

Material is not cut off cleanly

Material edges ruffle themselves

• Thread tension is too high. • Adjust the thread tension.

• Yarn has not been correctly

threaded.

• Thread is blocked.

• Differential feed motion not

adjusted.

• Upper blade a is blunt or in-

correctly inserted.

• Too much material in a stitch. • Alter the seam width.

- 20 -

• Thread the yarn correctly.

• Check the course of the individual

threads.

• Place the differential feed motion

at "S".

• Change the blade a or insert it

correctly.

Page 23

Cleaning and care

Attention:

ALWAYS remove the plug j from the mains power

socket before cleaning or lubricating the machine.

Otherwise there is the risk of you receiving an

electric shock!

To ensure that your machine works faultlessly at all

times, it must occasionally be cleaned with a brush.

This machine requires very little lubrication, as the

main components are manufactured from a special

material.

Only occasionally lubricate the designated positions:

Disposal

Do not dispose of the appliance in your

normal domestic waste. This product is

subject to the provisions of European

Directive 2002/96/EC.

Dispose of the appliance through an approved disposal centre or at your community waste facility.

Observe the currently applicable regulations.

In case of doubt, please contact your waste disposal centre.

Dispose of all packaging materials in an

environmentally friendly manner.

Storage

Attention:

ALWAYS remove the plug j from the mains power

socket before storageing the machine.

This prevents an unintended starting of the machine.

When the machine is not in use, always cover it with

the hood. This will protect the machine from dust.

Store the machine at a clean and dry location.

- 21 -

Page 24

Warranty and Service

Importer

This appliance comes with a 3 year warranty Purchase date. This appliance has been manufactured with

care and meticulously examined before delivery.

Please retain your receipt as proof of purchase. In

the case of a warranty claim, please make contact

by telephone with our service department. Only in

this way can a post-free despatch for your goods be

assured.

The warranty covers only claims for material and

maufacturing defects, not for wearing parts or for

damage to fragile components, e.g. buttons or batteries. This product is for private use only and is not

intended for commercial applications.

In the event of misuse and improper handling, use of

force and interference not carried out by our authorized service branch, the warranty will become

void. Your statutory rights are not restricted in any

way by this warranty.

DES Ltd

Units 14-15

Bilston Industrial Estate

Oxford Street

Bilston

WV14 7EG

Tel.: 0870/787-6177

Fax: 0870/787-6168

e-mail: support.uk@kompernass.com

KOMPERNASS GMBH

BURGSTRASSE 21

44867 BOCHUM, GERMANY

www.kompernass.com

Kompernass Service Ireland

Tel: 1850 930 412

Standard call rates apply. Mobile operators may vary.

e-mail: support.ie@kompernass.com

(0,082 EUR/Min.)

- 22 -

Loading...

Loading...