Komatsu D65EX-15E0, D65PX-15E0 User Manual

EEAM024400

Operation &

Maintenance Manual

D65EX

D65PX

BULLDOZER

SERIAL NUMBER

D65EX-15E0 - 69001

D65PX-15E0 - 69001

and up

and up

-15E0

-15E0

WARNING

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this

machine. This manual should be kept inside the cab for

reference and periodically reviewed by all personnel who

will come into contact with the machine.

FOREWORD

11

BEFORE READING THIS MANUAL FOREWORD

BEFORE READING THIS MANUAL 1

This manual gives details of the operation and methods of inspection and maintenance for this machine that must

be obeyed in order to use the machine safely. Most accidents are caused by the failure to follow fundamental

safety rules for the operation and maintenance of machines.

Read, understand and follow all precautions and warnings in this manual and on the machine before performing

operation and maintenance. Failure to do so may result in serious injury or death.

Komatsu cannot predict every circumstance that might involve a potential hazard when the machine is used.

Therefore, the safety messages in this manual and on the machine may not include all po ssible safety precautions. If you carry out any operation, inspection, or maintenance under conditions that are not described in this

manual, understand that it is your responsibility to take the necessary precautions to ensure safety. In no event

should you or others engage in the prohibited uses or actions described in this manual. Improper operation and

maintenance of the machine can be hazardous and could result in serious injury or death.

If you sell the machine, be sure to give this manual to the new owner toge th er with th e ma ch ine .

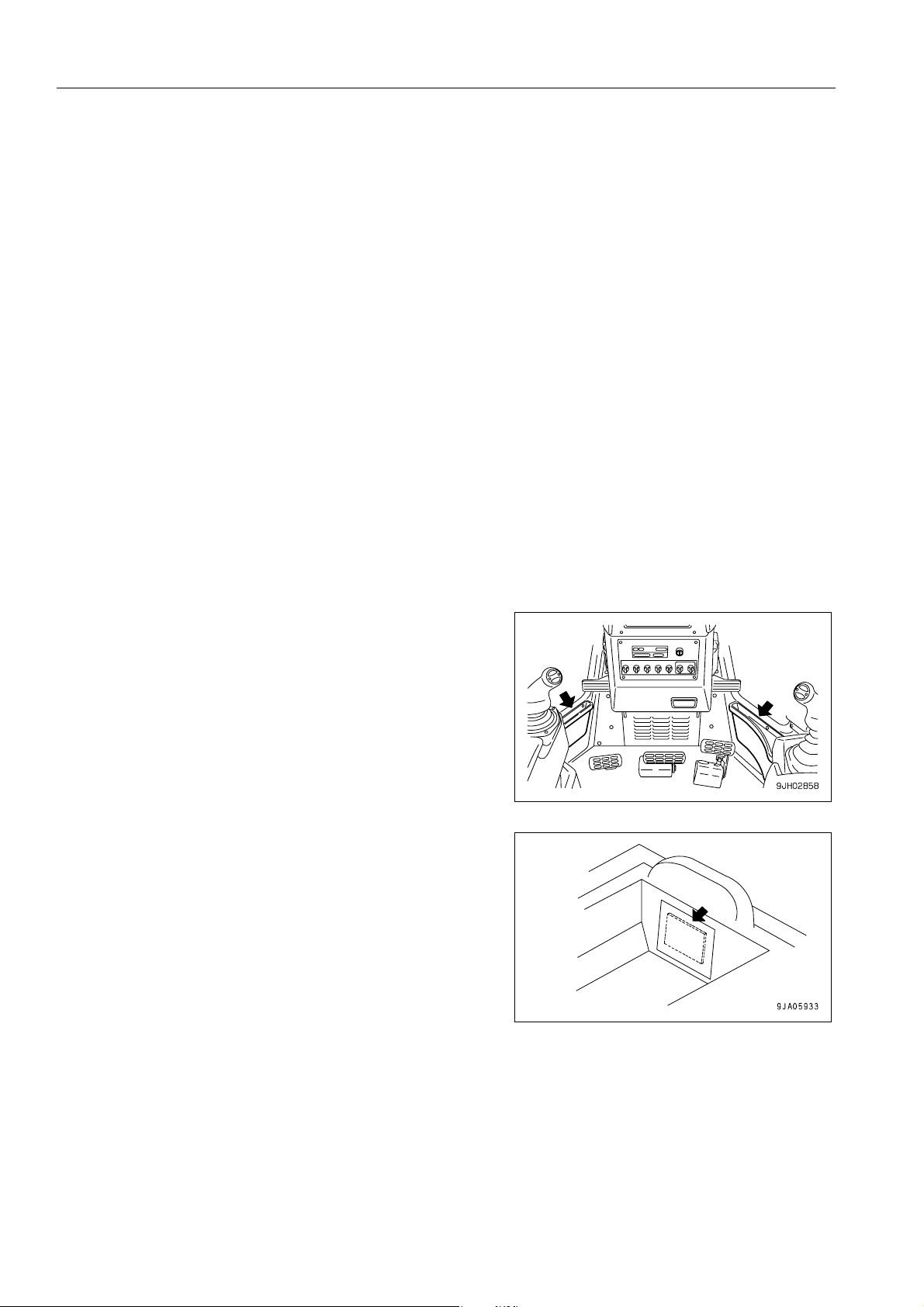

Always keep this Operation and Maintenance Manu al in the location shown on the r ight so that all relevant person-

nel can read it at any time.

Operation and Maintenance Manual Storing Place

For a machine with a cab, a pocket is provided on the inside of

both right and left doors.

For a machine with a ROPS canopy, a pocket is provided a t the

end of the floor.

If this manual is lost or damaged, contact your distributor immediately to arrange for its replacement. For details

regarding the machine serial No. you will need to provide your Komatsu distributor, see “TABLE TO ENTER

SERIAL NO. AND DISTRIBUTOR (1-13)“.

This manual uses the international units (SI) for units of measurement. For reference, unit s th at have been used in

the past are given in ( ).

1-2

FOREWORD BEFORE READING THIS MANUAL

The explanations, values, and illustrations in this manual have been prepared based on the latest information

available as of the date of its publication. Continuing imp rovement s in the desig n of this mach ine may le ad to ad ditional changes that are not reflected in this manual. Consult Koma tsu or your Komatsu distributor for the latest

available information concerning your mac hin e or with questions regarding information contai ned in this manual.

q The numbers in circles in the illustrations correspond to the numbers in ( ) in the text.

(For example:1 → (1))

Komatsu delivers machines that comply with all applicable regulatio ns and st andar ds of the country to which it h as

been shipped. If this machine has been purchased in anoth er country, it may lack certain safety devices and specifications that are necessary for use in you r country. If there is any question about whether your product complies

with the applicable standards and regulations of your country, consult Komatsu or your Komatsu distributor before

operating the machine.

1-3

IMPORTANT SAFETY INFORMATION FOREWORD

IMPORTANT SAFETY INFORMATION 1

To enable you to use the machine safely, and to prevent injury to operators, service personnel or bystanders, the

precautions and warnings included in this manual and the safety signs attached to the machine must always be

followed.

To identify important safety messages in the manual and on the machine labels, the following signal words are

used.

The “Safety Alert Symbol“ identifies important safety messages on machines, in manuals, and elsewhere. When

you see this symbol, be alert to the risk of personal injury or death. Follow the instructions in the safety message.

DANGER

WARNING

CAUTION

The following signal words are used to alert you to information that must be followed to avoid damage to the

machine.

NOTICE

REMARKS

This signal word indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury

This signal word indicates a potentially hazardous situation wh ich, if not avo id ed ,

could result in death or serious injury.

This signal word indicates a potentially hazardous situation exists which, if not

avoided, may result in minor or moderate injury.

This precaution is given where the machine may be damaged or the service life reduced if

the precaution is not followed.

This word is used for information that is useful to know.

1-4

FOREWORD IMPORTANT SAFETY INFORMATION

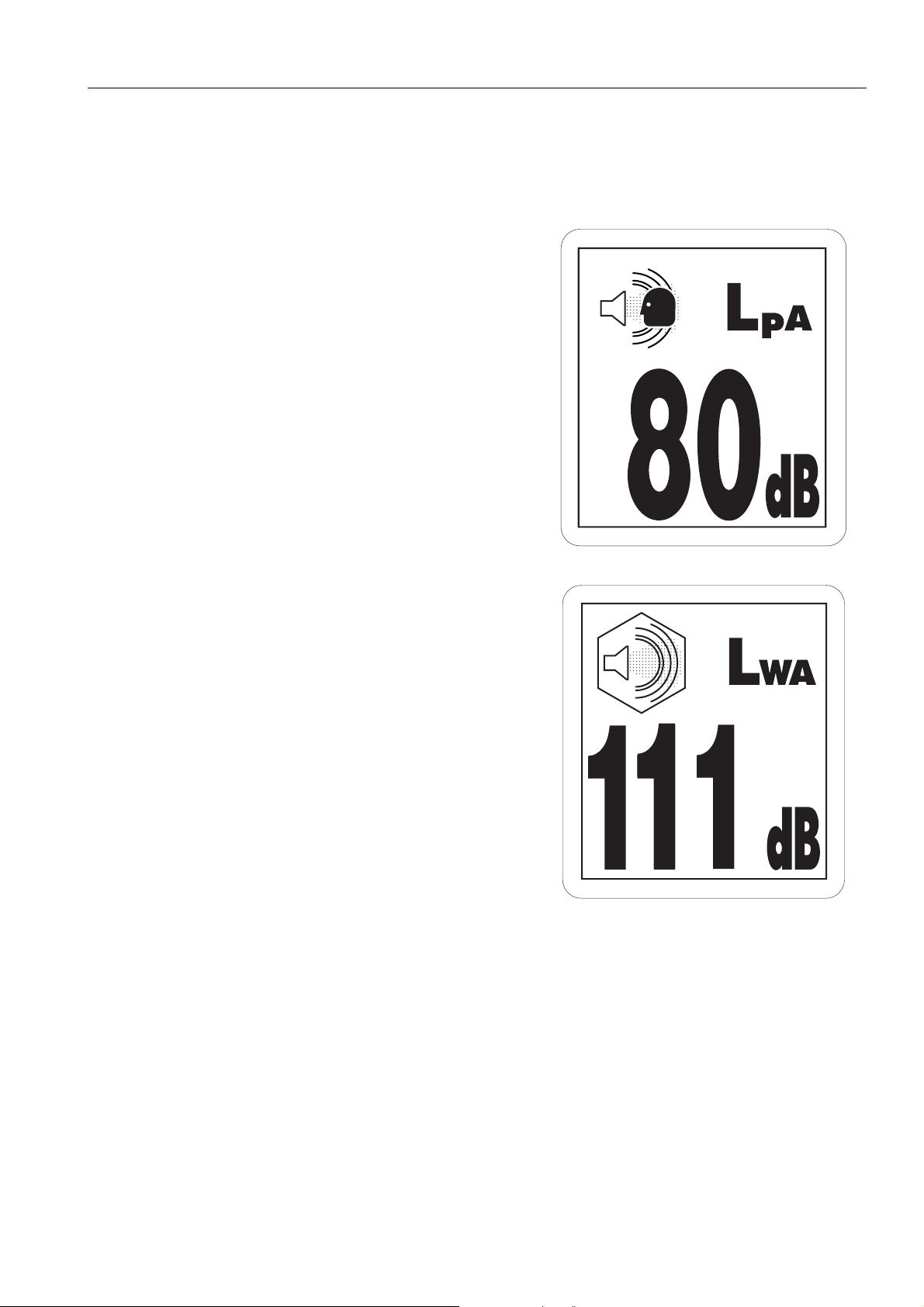

Noise emission levels 1

Two labels ind icating the machine noise level a re affixed on the

machine.

q Sound pressure level at the operator's station, measured

according to ISO6396 (Dynamic test method, simulated

working cycle)

q Sound power level emitted by the machine, measured

according to ISO 6395 (Dynamic test method, simulated

working cycle). This is the guaranteed value as specified

in European directive 2000/14/EC.

Vibration levels 1

When used for its intended purpose, levels of vibration for the earth-moving machine transmitted from the operator’s seat are lower than or equal to the tested vibrations for the relative machinery class in compliance with ISO

7096.

q If equipped with air suspension seat

The actual acceleration value for the hands and arms is less than or equal to 2.5 m/s². The actual acceleratio n

value for the body is less than or equal to 0.5 m/s².

q If equipped with mechanical suspension seat

The actual acceleration value for the hands and arms is less than or equal to 2.5 m/s².

D65EX-15 : the actual acceleration value for the body is 0.63 m/s².

D65EXL-15, D65PX-15 : the actual acceleration value for the body is 0.68 m/s².

1-5

IMPORTANT SAFETY INFORMATION FOREWORD

These values were determined using a representative machine and measured during the typical operating condition indicated below according to the measurement procedures that are defined in the standards ISO 2631/1 and

ISO 5349.

Operating condition:

(WHEEL LOADER:) V-shape loading

(HYDRAULIC EXCAVATORS:) Excavating (Digging-loading-rotating-unloading-rotating)

(TRACTOR DOZER:) Dozing and spreading material through forward/reversing motion

(Rigid/Articulate dumper:) Work cycle (including waiting, travelling, loading, travelling with load, unloading, and

travelling without load)

Guide to Reduce Vibration Levels on Machine 1

The following guides can help an operator of this machine to reduce the whole body vibration levels:

1. Use the correct equipment and attachments.

2. Maintain the machine according to this manual

q Tire pressures (for wheeled machines), tension of crawler (fo r crawler machines)

q Brake and steering systems

q Controls, hydraulic system and linkages

3. Keep the terrain where the machine is working and traveling in good condition

q Remove any large rocks or obstacles

q Fill any ditches and holes

q Site manager should provide machine operators with machine and schedule time to maintain terrain con-

ditions

4. Use a seat that meets ISO 7096 and keep the seat maintained and ad justed

q Adjust the seat and suspension for the weight and size of the operator

q Wear seat belt

q Inspect and maintain the seat suspension and adjustment mechanisms

5. Steer, brake, accelerate, shift gears (for wheeled machines), and move the attachment levers and pedals

slowly so that the machine moves smoothly

6. Adjust the machine speed and travel path to minimize the vibration level

q When pushing with bucket or blade, avoid sudden loading; load gradually

q Drive around obstacles and rough terrain conditions

q Slow down when it is necessary to go over rough terrain

q Make the curve radius of traveling path as large as possible

q Travel at low speed when traveling around sharp curves

7. Minimize vibrations for long work cycle or long distance traveling

q Reduce speed to prevent bounce

q Transport machines long distances between worksites

1-6

FOREWORD IMPORTANT SAFETY INFORMATION

8. The following guidelines can be effective to minimize risks of low back pain

q Operate the machine only when you are in good he alt h.

q Provide breaks to reduce long periods of sitting in the same posture

q Do not jump down from the cab or machine

q Do not repeatedly handle and lift loads.

1-7

INTENDED USE FOREWORD

INTENDED USE 1

USE OF MACHINE 1

This Komatsu machine is designed to be used mainly for the following work:

q Dozing

q Smoothing

q Cutting into hard or frozen ground or ditching

q Felling trees, removing stumps

See the section “WORK POSSIBLE USING BULLDOZER (3-88)“ for further details.

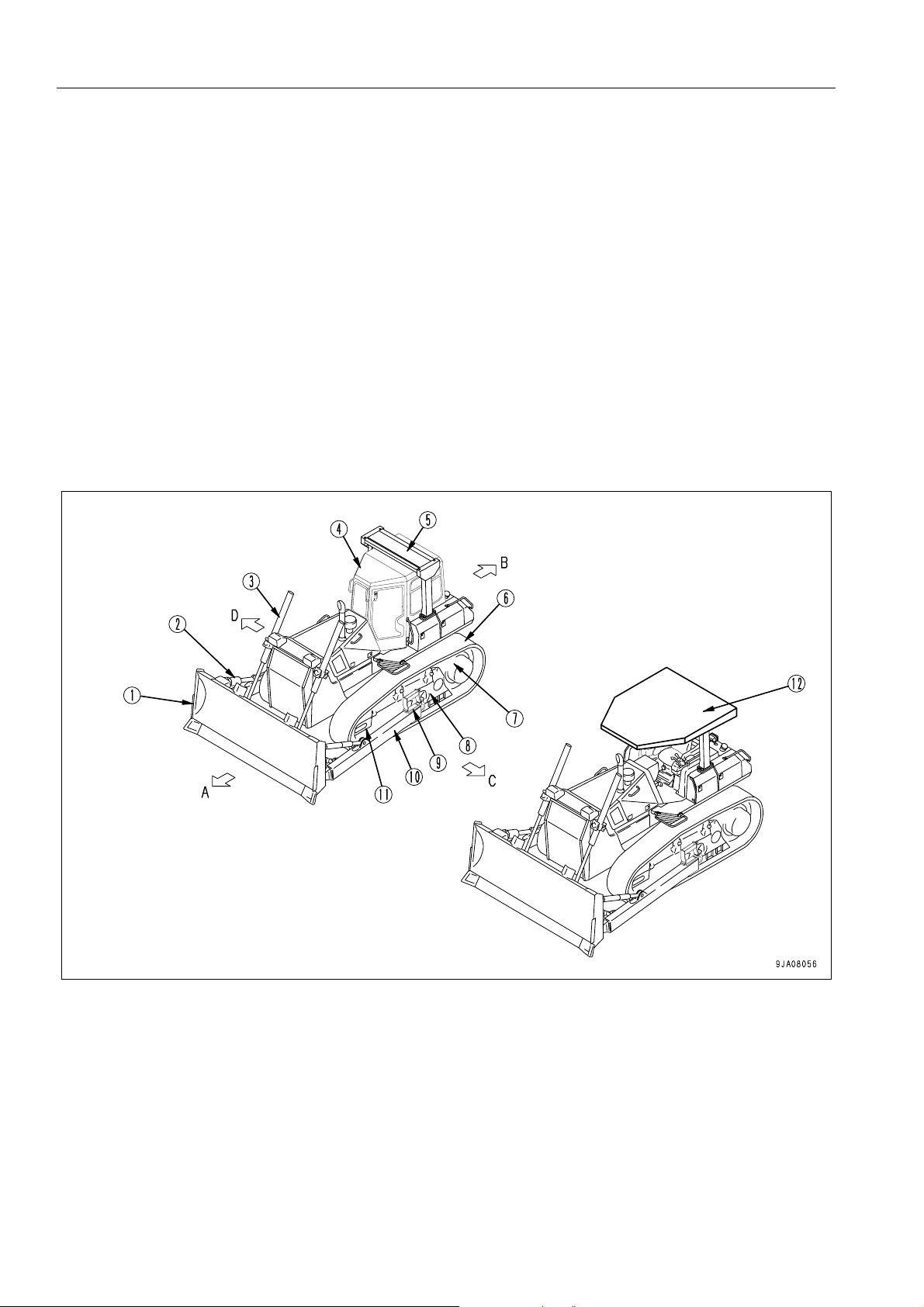

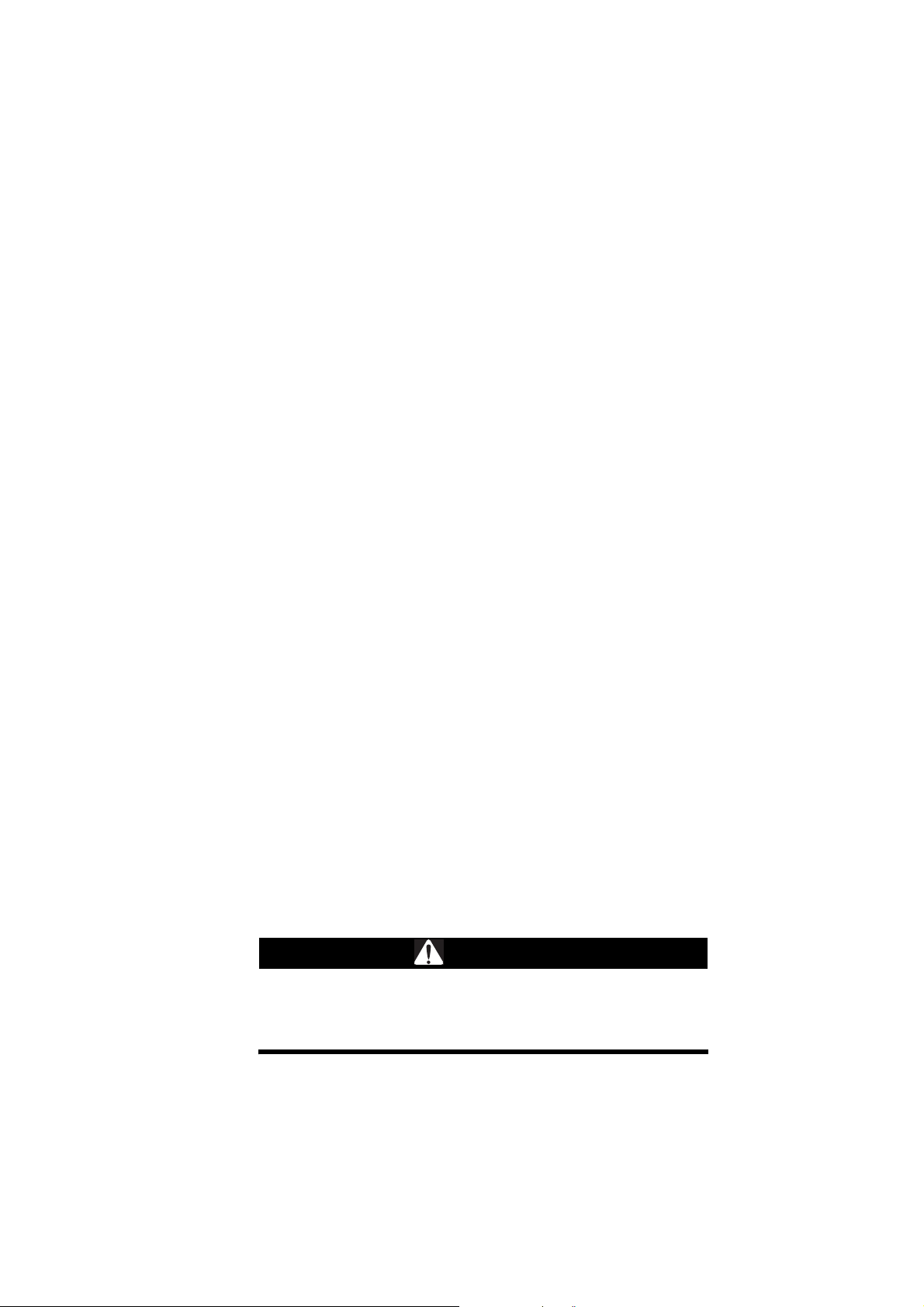

GENERAL VIEW AND DIRECTIONS OF MACHINE 1

In this manual, the directions of the machine (front,rear,left,right) are determined according to the view from the

operator's seat in the direction of travel (front) of the machine.

(1) Blade (7) Sprocket

(2) Tilt cylinder (8) Track frame

(3) Lift cylinder (9) Step

(4) Cab (10) Frame

(5) ROPS guard (11) Idler

(6) Track shoe (12) ROPS canopy

(A) Front (C) Left

(B) Rear (D) Right

1-8

FOREWORD INTENDED USE

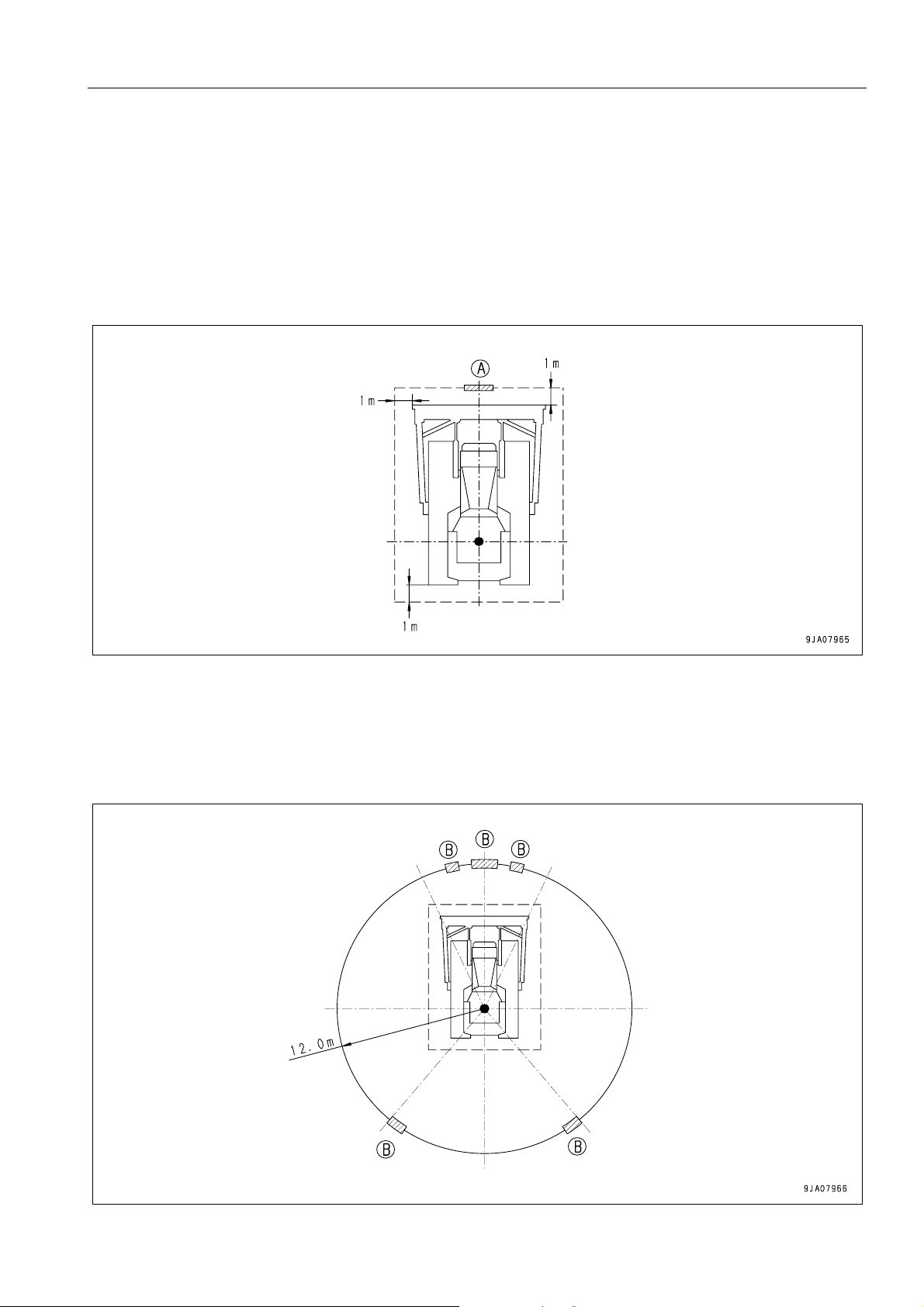

VISIBILITY FROM OPERATOR'S SEAT 1

The visibility standards (ISO 5006) for this machine require a view shown in the diagram below.

PROXIMITY VISIBILITY 1

The figure bellows shows a front visibility from the machine at a spot 1.0 m away from the side and 1.5 m above

the ground. Shaded area (A) in the figure shows an area whose view is blocked by part of the machine. Operate

the machine, fully aware that the machine has a portion that an operator cannot see.

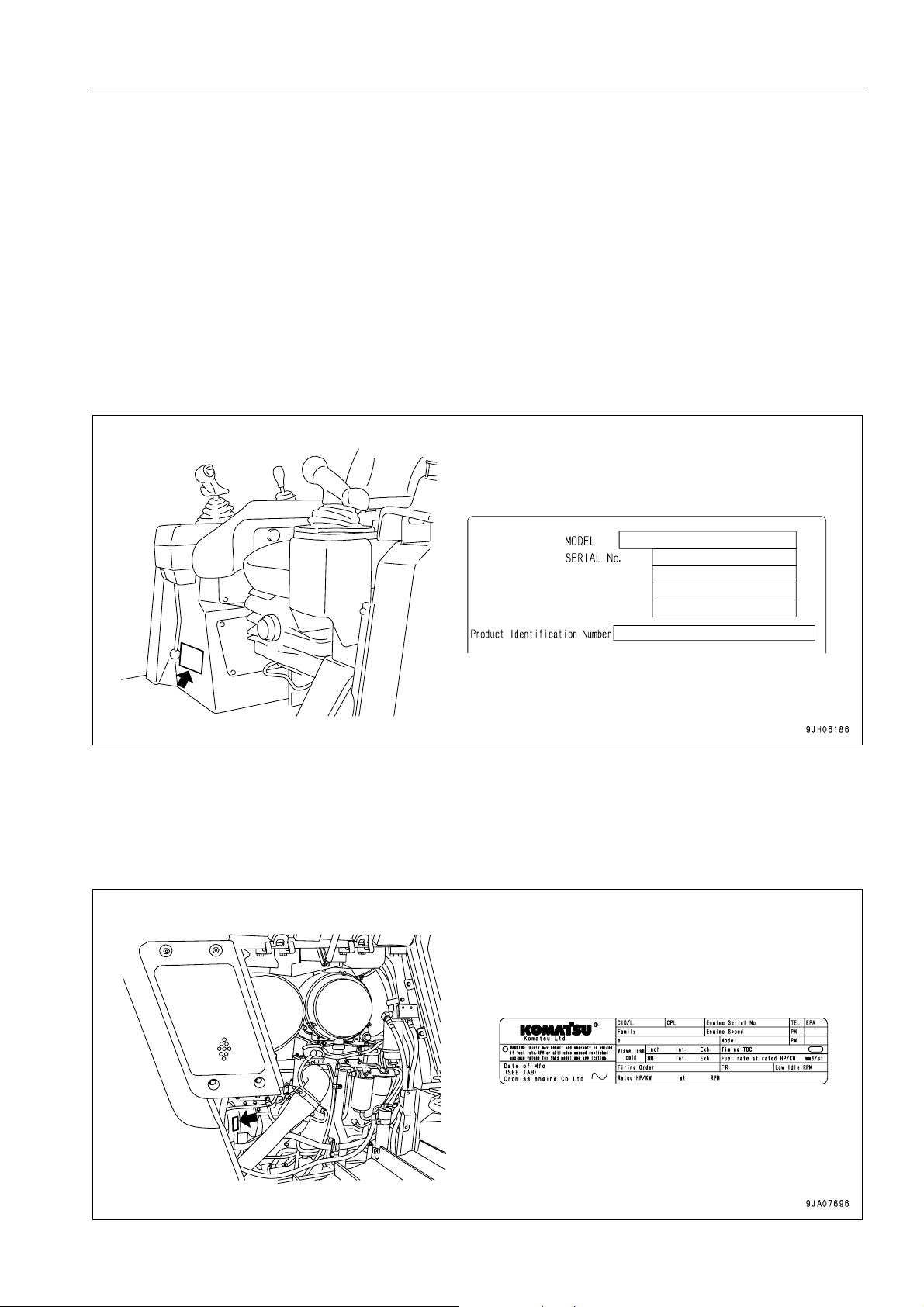

12M CIRCUMFERENCE VISIBILITY 1

The figure below shows a visibility from the machine within a circle of 12 m in radius. Shaded area (B) in the figure

shows an area whose view is blo cked by part of the machine. Operate the machine, fully aware that the machine

has a portion that an operator cannot see.

1-9

INTENDED USE FOREWORD

BREAKING-IN THE NEW MACHINE 1

NOTICE

Your Komatsu machine has been thoroughly adjusted and tested before shipment from the factory. However, ope rating the machine under full load before bre aking the machine in can adverse ly affect the perf ormance and shorten the machine life.

Be sure to break in the machine for the initial 100 hours (as indicated on the service meter).

Make sure that you fully understand the content of this manual, and pay careful attention to the following points

when breaking in the machine.

q Run the engine at idle for 15 seconds after star ting it. During this time, do not oper ate the control levers or fuel

control dial.

q Idle the engine for 5 minutes after starting it up.

q Avoid operation with heavy loads or at high speeds.

q Immediately after starting the engine, avoid sudden starts, sudden acceleration, unnecessary sudden stops,

and sudden changes in direction.

1-10

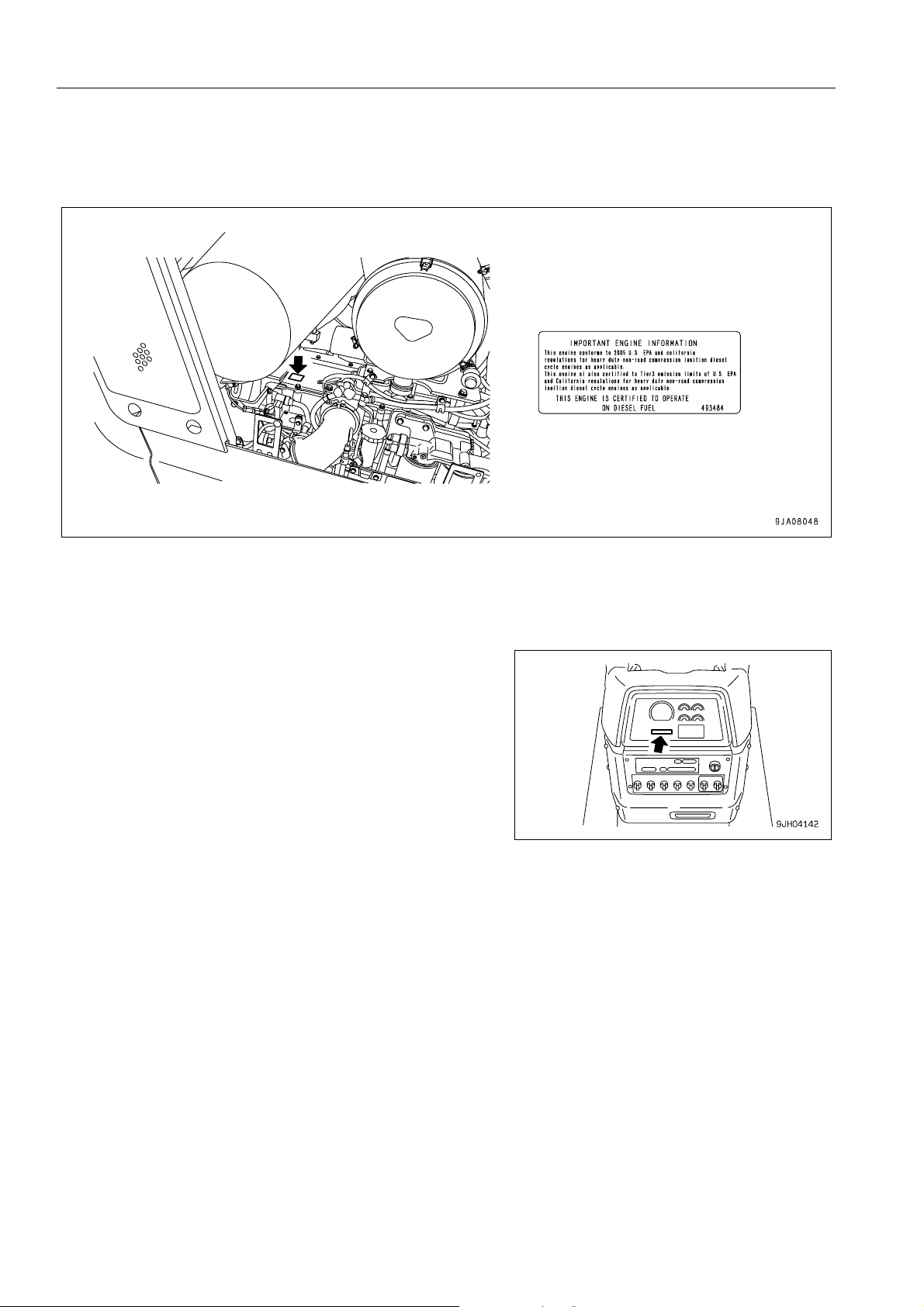

FOREWORD LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO.

AND DISTRIBUTOR 1

When ordering replacement parts, please inform your Komatsu distributor of the following.

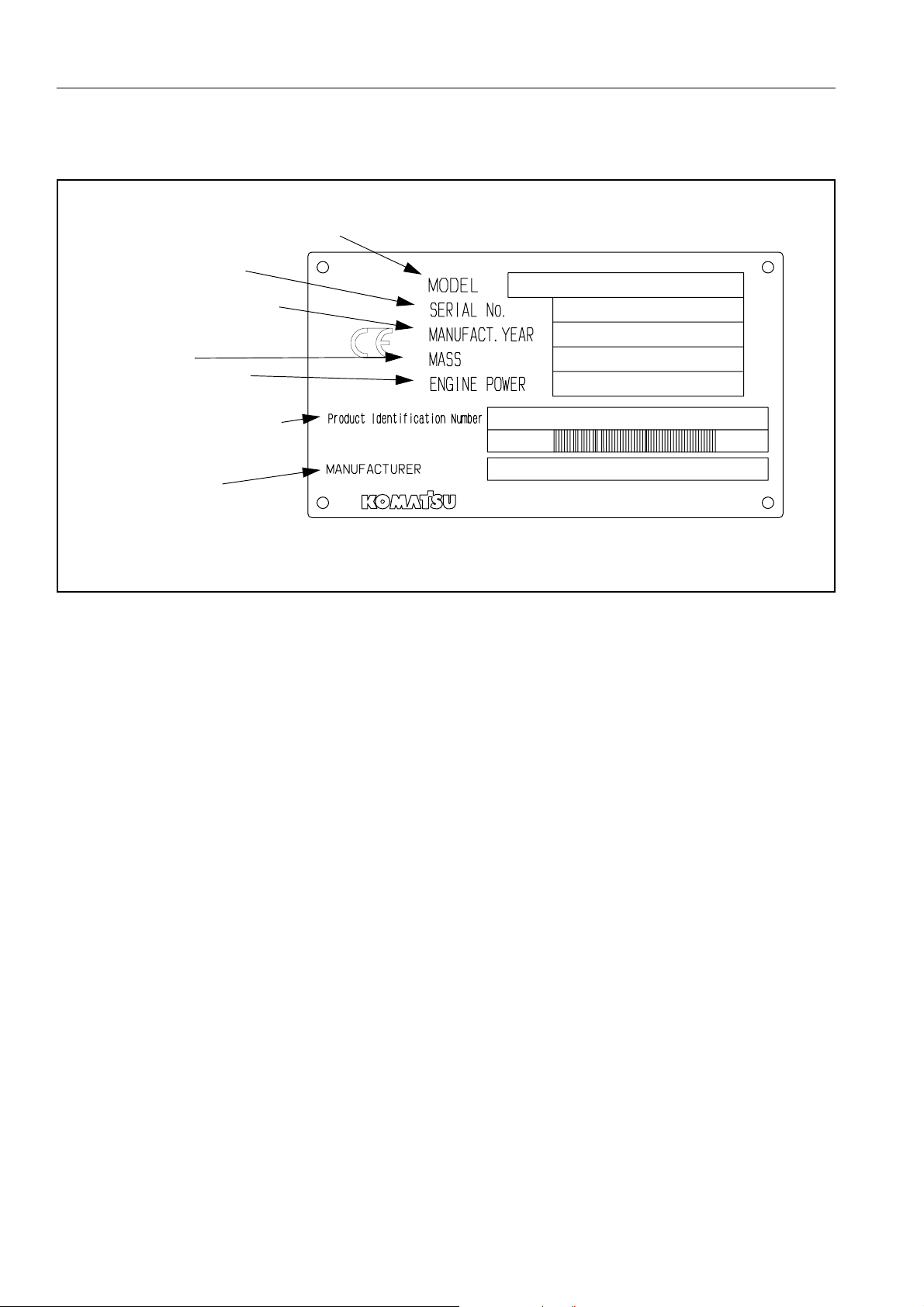

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE 1

This is at the front bottom right of the oper ator's seat.

The design of the nameplate differs according to the territory.

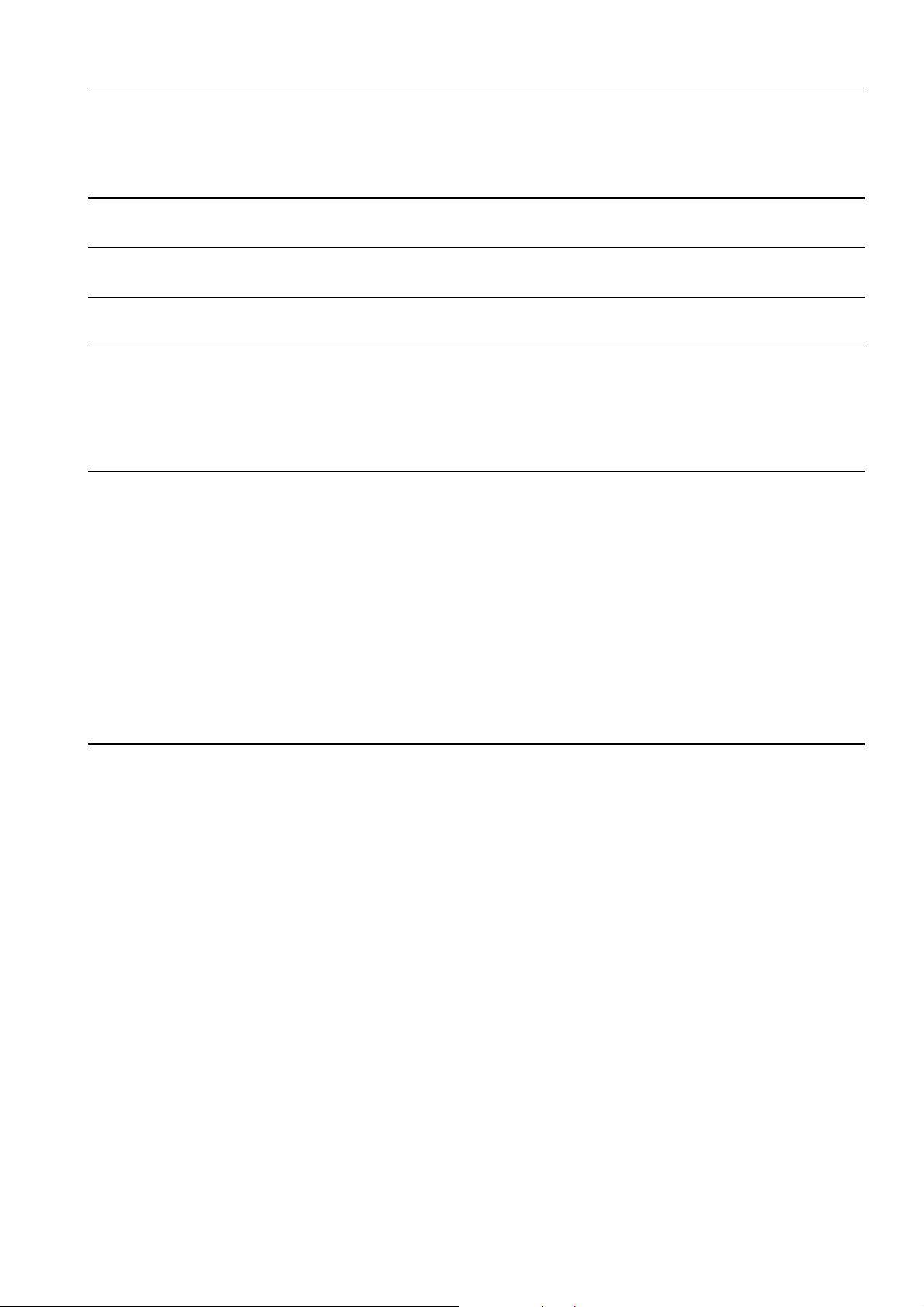

ENGINE SERIAL NO. PLATE POSITION 1

The engine serial No. plate is located on the side of the engine front cover on the left side of the machine.

1-11

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR FOREWORD

ADDITIONAL EPA NAMEPLATE 1

The additional EPA nameplate is located on top of the engine head cover on the left side of the machine.

EPA: Environmental Protection Agency, U.S.A.

SERVICE METER POSITION 1

The service meter is provided at the lower part of the monitor

panel.

1-12

FOREWORD LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR 1

Machine serial No.

Engine serial No.

Product Identification Number

(PIN)

Manufacturers name:

Address:

Distributor

Address

Phone

Service personnel for your

machine:

KOMATSU LTD.

3-6 Akasaka

Minato-ku, 101 Tokyo

Japan

1-13

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR FOREWORD

MACHINE SERIAL NUMBER PLATE 1

Model

Seriel Number

Manufacturing year

Weight

Engine power

Product Identification Number

Manufacturer

1-14

CONTENTS

CONTENTS

FOREWORD

BEFORE READING THIS MANUAL.................................................................................................................... 1-2

IMPORTANT SAFETY INFORMATION............................................................................................................... 1-4

Noise emission levels .................................................................................................................................1-5

Vibration levels................................ ... ... .... ... ... .......................................... ... ... .... ... ... ... ............................... 1-5

Guide to Reduce Vibration Levels on Machine.................................................................................. 1-6

INTENDED USE ................................................................................................................................................... 1-8

USE OF MACHINE..................................................................................................................................... 1-8

GENERAL VIEW AND DIRECTIONS OF MACHINE .. ... ... .... ... ... ... .... ... ............................................. ... ... .. 1-8

VISIBILITY FROM OPERATOR'S SEAT.................................................................................................... 1-9

PROXIMITY VISIBILITY.................................................................................................................... 1-9

12M CIRCUMFERENCE VISIBILITY ................................. ... .... ... ... ... ... .... ... ... ... .... ........................... 1-9

BREAKING-IN THE NEW MACHINE ....................................................................................................... 1-10

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR........................................... 1-11

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE ..................................... 1-11

ENGINE SERIAL NO. PLATE POSITION ................................................................................................1-11

ADDITIONAL EPA NAMEPLATE ............................................................................................................. 1-12

SERVICE METER POSITION ........................... ... .... ... ... ... .... ... ... .......................................... ... ... ............. 1-12

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR ............................................................................ 1-13

MACHINE SERIAL NUMBER PLATE....................................................................................................... 1-14

SAFETY

IMPORTANT SAFETY INFORMATION............................................................................................................... 2-2

SAFETY LABELS................................................................................................................................................. 2-4

POSITION FOR ATTACHING SAFETY LABELS.......................................................................................2-5

SAFETY LABELS ....................................................................................................................................... 2-5

PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE ............................................................... 2-10

PRECAUTIONS DURING OPERATION ............................................................................................................ 2-17

PRECAUTIONS FOR MAINTENANCE.............................................................................................................. 2-23

PRECAUTIONS FOR MACHINE........................................................................................................................ 2-29

OPERATION

GENERAL VIEW .................................................................................................................................................. 3-2

GENERAL VIEW OF MACHINE.. .......................................... ... ... ... .... ... ... ..................................................3-2

1-15

CONTENTS

GENERAL VIEW OF CONTROLS AND GAUGES..................................................................................... 3-3

EXPLANATION OF COMPONENTS.................................................................................................................... 3-6

FRONT PANEL........................................................................................................................................... 3-6

CHECK MONITOR SYSTEM ............................................................................................................3-7

EMERGENCY CAUTION ITEMS . ... ... .... ... .......................................... ... ... ... .... ... ... ... ........................ 3-8

CAUTION ITEMS...... .... ... ... ... .... ... ... ... .......................................... .... ... ... ... ... .... ... ............................3-10

METER GROUP..............................................................................................................................3-12

LAMPS............................................................................................................................................. 3-16

SWITCHES...................................................................................................................................... 3-18

METHOD OF USING MAINTENANCE MODE................................................................................3-22

SWITCHES............................................................................................................................................... 3-29

CONTROL LEVERS AND PEDALS ......................................................................................................... 3-33

CIRCUIT BREAKER .................................................................................................................................3-41

FUSE ........................................................................................................................................................3-41

FUSIBLE LINK..........................................................................................................................................3-43

ELECTRIC POWER TAKE-OUT ADAPTER ............................................................................................3-43

MACHINE EQUIPPED WITH CAB..................................................................................................3-43

MACHINE EQUIPPED WITH ROPS CANOPY ............................................................................... 3-44

DOOR - OPEN LOCK...............................................................................................................................3-44

SASH GLASS INTERMEDIATE LOCK.....................................................................................................3-45

DOOR POCKET ....................................................................................................................................... 3-45

OPENING AND CLOSING ENGINE SIDE COVER.................................................................................. 3-46

ASHTRAY................................................................................................................................................. 3-46

CUP HOLDER .......................................................................................................................................... 3-47

TOOL BOX................................................................................................................................................3-47

SHOVEL HOLDER ............ .... .......................................... ... ... ... .......................................... .... ..................3-47

AIR CONDITIONER, HANDLING ............................................................................................................. 3-48

GENERAL LOCATIONS AND FUNCTION OF CONTROL PANEL ................................................ 3-48

METHOD OF OPERATION................ .... ... ... ... ... .... ... ... ... .......................................... .... ... ... ... ... .... ..3-50

PRECAUTIONS WHEN USING ......................................................................................................3-51

SET SO THAT COLD AIR DOES NOT DIRECTLY BLOW ONTO THE GLASS SURFACE ..........3-51

INSPECTION DURING OFF-SEASON ...........................................................................................3-51

PROCEDURE FOR REPLACING RECEIVER ................................................................................ 3-51

CHECK COMPRESSOR BELT TENSION AND REFRIGERANT (GAS) LEVEL............................ 3-52

CLEANING AIR FILTER..................................................................................................................3-52

OPERATION....................................................................................................................................................... 3-53

CHECK BEFORE STARTING ENGINE, ADJUST..................................... ... ... ... ... .... ... ... ... .... ... ... ... ... .... .. 3-53

WALK-AROUND CHECK ................................................................................................................ 3-53

CHECK BEFORE STARTING ......................................................................................................... 3-54

ADJUSTMENT................................................................................................................................. 3-62

OPERATION AND CHECK BEFORE STARTING ENGINE............................................................3-66

STARTING ENGINE.................................................................................................................................3-68

NORMAL STARTING ................................... ... ... .... ... ... ... .... ... .......................................... ... ... ......... 3-68

STARTING IN COLD WEATHER....................................................................................................3-70

OPERATIONS AND CHECKS AFTER STARTING ENGINE................................................................... 3-73

WARMING UP OPERATIONS ........... .......................................... .... ... ... ... ... .... ... ... ... .... ... ... ............3-73

1-16

CONTENTS

STARTING IN COLD WEATHER.................................................................................................... 3-74

STOPPING ENGINE................................................................................................................................. 3-75

MACHINE OPERATION.............. ... ... ... .... ... ... ... .......................................... ... .... ... ... ... .... ... ...................... 3-77

MOVING MACHINE......................................................................................................................... 3-77

STOPPING MACHINE........................................................ ... .... ... .......................................... ......... 3-79

SHIFTING GEARS.................................................................................................................................... 3-79

GEARSHIFTING OPERATION........................................................................................................ 3-80

GEARSHIFTING OPERATION USING PRESET MODE FUNCTION ............................................ 3-80

AUTO DOWN SHIFT OPERATION................................................................................................. 3-82

SHIFTING BETWEEN FORWARD AND REVERSE................................................................................ 3-83

STEERING MACHINE.............................................................................................................................. 3-85

NORMAL TURNING........................................................................................................................ 3-85

PRECAUTIONS FOR OPERATION..... .... ... ... ... ... .... ... ... ... .......................................... .... ... ... ... ... .... ... ...... 3-86

PAY ATTENTION TO GAUGES...................................................................................................... 3-86

PERMISSIBLE WATER DEPTH...................... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ............................. 3-86

PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS.......................................................... 3-86

PRECAUTIONS ON SLOPES......................................................................................................... 3-87

METHOD OF USING BRAKES ....................................................................................................... 3-87

IT IS PROHIBITED TO KEEP THE DOOR OPEN DURING OPERATIONS................................... 3-87

IT IS PROHIBITED TO MODIFY THE CAB GLASS IN ANY WAY THAT WILL OBSTRUCT THE VIEW

3-87

PRECAUTIONS FOR BLIND SPOTS CAUSED BY CAB AND ROPS STRUCTURES.................. 3-88

WORK POSSIBLE USING BULLDOZER................................................................................................. 3-88

DOZING........................................................................................................................................... 3-88

SMOOTHING................................................................................................................................... 3-89

CUTTING INTO HARD OR FROZEN GROUND OR DITCHING.................................................... 3-89

FELLING TREES, REMOVING STUMPS....................................................................................... 3-89

ADJUSTING POSTURE OF WORK EQUIPMENT................................................................................... 3-90

ADJUST ANGLE OF BLADE EDGE................................................................................................ 3-90

ADJUSTING SHIMS IN ASSEMBLING WORK EQUIPMENT ........................................................ 3-91

ADJUSTING TENSION OF CENTER BRACE ................................................................................ 3-91

ADJUST AMOUNT OF TILT............................................................................................................3-92

METHOD OF ANGLING BLADE ..................................................................................................... 3-93

PARKING MACHINE................................................................................................................................ 3-94

CHECK AFTER FINISHING WORK .........................................................................................................3-95

BEFORE STOPPING ENGINE.............. ... ... .... ... ... ... .... .......................................... ... ... ... ... .... ... ... ... 3-95

AFTER STOPPING ENGINE....................... .... ... ... ... .......................................... .... ... ... ... ... .... ... ... ...3-95

LOCKING.................................................................................................................................................. 3-96

TIPS FOR LONGER UNDERCARRIAGE LIFE........................................... ... .... ... ... ... .... ... ... ... ... .... ... ...... 3-96

OPERATION METHOD................................................................................................................... 3-96

INSPECTION AND ADJUSTMENT....... .......................................................................................... 3-97

INSPECTION AND REPAIR ..........................................................................................................

.. 3-97

TRANSPORTATION......................................................................................................................................... 3-100

TRANSPORTATION MEANS................................................................................................................. 3-100

REMOVING CAB.................................................................................................................................... 3-100

PRECAUTIONS WHEN REMOVING WORK EQUIPMENT................................................................... 3-100

PRECAUTIONS WHEN REMOVING ROPS .......................................................................................... 3-101

1-17

CONTENTS

LOADING, UNLOADING WORK ............................................................................................................ 3-102

LIFTING MACHINE................................................................................................................................. 3-105

TRAVELING ON ROADS ....................................................................................................................... 3-107

COLD WEATHER OPERATION ...................................................................................................................... 3-108

PRECAUTIONS FOR LOW TEMPERATURE ........................................................................................ 3-108

AFTER COMPLETION OF WORK .................................. ... ... ... .... ... ... ... .... ... .......................................... 3-109

AFTER COLD WEATHER ........................................... .... ... ... ... .......................................... .... ... ... .......... 3-109

LONG-TERM STORAGE..................................................................................................................................3-110

BEFORE STORAGE . ... ... ... .... .......................................... ... ... ... .......................................... .... ................3-110

DURING STORAGE ........................................ ... ... ... ... .... .......................................... ... ... ... .... ................3-110

AFTER STORAGE.... ... ... ... .... ... .......................................... ... ... .... ... ... ... .... ............................................. 3-110

TROUBLESHOOTING...................................................................................................................................... 3-111

AFTER RUNNING OUT OF FUEL.......................................................................................................... 3-111

PROCEDURE FOR BLEEDING AIR............................................................................................. 3-111

METHOD OF TOWING MACHINE.........................................................................................................3-112

IF BATTERY IS DISCHARGED..............................................................................................................3-113

REMOVE AND INSTALL BATTERY ............................................................................................. 3-114

PRECAUTIONS FOR BATTERY CHARGING ..............................................................................3-114

STARTING ENGINE WITH BOOSTER CABLE ............................................................................3-115

OTHER TROUBLE ............ .......................................... .... ... ... ... .......................................... .... ................3-117

ELECTRICAL SYSTEM.................................................................................................................3-117

MONITOR PANEL..................... ... ... ... .... .......................................... ... ... ... ... .................................3-118

CHASSIS....................................................................................................................................... 3-119

ENGINE.........................................................................................................................................3-121

MAINTENANCE

GUIDE TO MAINTENANCE .................................................................................................................................4-2

OUTLINE OF SERVICE........................................................................................................................................ 4-5

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC......................................................4-5

OIL..................................................................................................................................................... 4-5

FUEL..................................................................................................................................................4-6

COOLANT AND WATER FOR DILUTION......................................................................................... 4-6

GREASE............................................................................................................................................ 4-7

CARRYING OUT KOWA (Komatsu Oil Wear Analysis) ....................................................................4-7

STORING OIL AND FUEL......... ... .......................................... ... ... .... ......................................... ........ 4-8

FILTERS............................................................................................................................................ 4-8

RELATING TO ELECTRIC SYSTEM .........................................................................................................4-8

HANDLING HYDRAULIC SYSTEM............................................................................................................ 4-9

WEAR PARTS LIST ...........................................................................................................................................4-10

WEAR PARTS LIST.................................................................................................................................. 4-10

RECOMMENDED FUEL, COOLANT, AND LUBRICANT .................................................................................4-12

1-18

CONTENTS

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE ............ 4-13

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU

GENUINE OIL........................................................................................................................................... 4-15

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS..................................................................... 4-16

TORQUE LIST.......................................................................................................................................... 4-16

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS .......................................................................... 4-17

SAFETY CRITICAL PARTS...................................................................................................................... 4-17

MAINTENANCE SCHEDULE CHART ............................................................................................................... 4-19

MAINTENANCE SCHEDULE CHART......................................................................................................4-19

WHEN REQUIRED.................................................................... ... ... ... ............................................. 4-19

CHECK BEFORE STARTING............ ... ... ... .... ... ... ... .... ... .......................................... ... ... ... .... ... ... ... 4-19

EVERY 50 HOURS SERVICE......................................................................................................... 4-19

EVERY 250 HOURS SERVICE....................................................................................................... 4-19

EVERY 500 HOURS SERVICE....................................................................................................... 4-19

EVERY 1000 HOURS SERVICE..................................................................................................... 4-19

EVERY 2000 HOURS SERVICE..................................................................................................... 4-20

EVERY 4000 HOURS SERVICE..................................................................................................... 4-20

EVERY 8000 HOURS SERVICE..................................................................................................... 4-20

SERVICE PROCEDURE .................................................................................................................................... 4-21

WHEN REQUIRED................................................................................................................................... 4-21

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT............................ .... ... ... ... ... .... ... ... ... 4-21

CLEAN INSIDE OF COOLING SYSTEM ........................................................................................ 4-24

CHECK TRACK SHOE TENSION, ADJUST...................... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ...... 4-27

CHECK AND TIGHTEN TRACK SHOE BOLTS.............................................................................. 4-29

REVERSE AND REPLACE END BITS AND CUTTING EDGES .................................................... 4-30

CLEANING AND INSPECTION OF FINS OF RADIATOR, OIL COOLER, CONDENSER AND AFTER-

COOLER.......................................................................................................................................... 4-32

CHECK, ADJUST AIR CONDITIONER........................................................................................... 4-35

GREASE DOOR HINGE.................................................................................................................. 4-36

CHECK DOOR LOCK STRIKER........................................ ... .... ... ... .......................................... ... ... 4-37

REPLACE DOOR DAMPER............................................................................................................ 4-37

CHECK DOOR LATCH.................... ... ... ... ... .... .......................................... ... ... ... .... ... ... ... ................ 4-37

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID.............................................................. 4-38

REPLACE WIPER BLADE ..............................................................................................................4-39

CHECK IDLER OIL LEVEL, ADD OIL............................................................................................. 4-40

ADJUST IDLER CLEARANCE........................................................................................................ 4-40

LUBRICATING UNIVERSAL JOINT......................... .............................................. ... ...................... 4-41

PROCEDURE FOR BLEEDING AIR IN HYDRAULIC SYSTEM........... .... ... ... ... .... ... ... ... ... .... ... ... ... 4-42

CHECK BEFORE STARTING .................................................................................................................. 4-43

EVERY 50 HOURS SERVICE.................................................................................................................. 4-43

DRAIN WATER, SEDIMENT FROM FUEL TANK........................................................................... 4-43

EVERY 250 HOURS SERVICE........................................................................................................

........ 4-44

LUBRICATING................................................................................................................................. 4-44

GREASE EQUALIZER BAR SIDE PIN............................................................................................ 4-45

GREASE EQUALIZER BAR CENTER PIN ..................................................................................... 4-46

1-19

CONTENTS

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL ..................................................................4-46

CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL....................................................................4-47

CHECK LEVEL OF BATTERY ELECTROLYTE ............................................................................. 4-48

CHECK, CLEAN ADDITIONAL FUEL STRAINER ..........................................................................4-49

CHECK BRAKE PERFORMANCE.................................................................................................. 4-50

CLEAN AIR CONDITIONER AIR FILTER (FRESH/RECIRC FILTER)............................................4-51

EVERY 500 HOURS SERVICE................................................................................................................4-52

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE.................... 4-52

REPLACE POWER TRAIN OIL FILTER ELEMENT........................................................................ 4-54

REPLACE FUEL PRE-FILTER CARTRIDGE..................................................................................4-54

EVERY 1000 HOURS SERVICE..............................................................................................................4-57

REPLACE FUEL MAIN FILTER CARTRIDGE ....................................... ... ... .... ... ... ... .... ... ... ... ... .... .. 4-57

CHANGE OIL IN POWER TRAIN CASE, CLEAN STRAINERS (POWER TRAIN PUMP STRAINER,

SCAVENGING PUMP STRAINER)................................................................................................. 4-60

CHECK OIL LEVEL IN DAMPER CASE, ADD OIL.........................................................................4-62

CHANGE OIL IN FINAL DRIVE CASE ............................................................................................4-63

CLEAN BREATHER ........................................................................................................................ 4-63

REPLACE CORROSION RESISTOR CARTRIDGE .......................................................................4-64

CHECK FOR LOOSE ROPS MOUNT BOLTS ................................................................................ 4-64

INSPECTION OF AFTER-COOLER CIRCUIT FOR LOOSENED BOLTS AND NUTS .................. 4-64

EVERY 2000 HOURS SERVICE..............................................................................................................4-65

CHANGE OIL IN HYDRAULIC TANK, REPLACE OIL FILTER ELEMENT.....................................4-65

REPLACE HYDRAULIC TANK BREATHER ELEMENT .................................................................4-66

CHECKING CHARGE PRESSURE OF NITROGEN GAS IN ACCUMULATOR (FOR CONTROL

CIRCUIT).........................................................................................................................................4-66

CHANGE OIL IN DAMPER CASE...................................................................................................4-69

CHECK VIBRATION DAMPER .......................................................................................................4-70

CHECK ENGINE VALVE CLEARANCE, ADJUST.......................................................................... 4-70

EVERY 4000 HOURS SERVICE..............................................................................................................4-71

REPLACE ACCUMULATOR (FOR CONTROL CIRCUIT).............................................................. 4-71

CHECK WATER PUMP...................................................................................................................4-71

CHECKING FOR LOOSENESS OF HIGH-PRESSURE CLAMP, HARDENING OF RUBBER ......4-72

CHECKING FOR MISSING FUEL SPRAY PREVENTION CAP, HARDENING OF RUBBER .......4-73

EVERY 8000 HOURS SERVICE..............................................................................................................4-74

REPLACE HIGH-PRESSURE PIPING CLAMP .............................................................................. 4-74

REPLACE FUEL SPLAY PREVENTION CAPS............................................................ ... ... ... ... .... .. 4-74

SPECIFICATIONS

SPECIFICATIONS................................................................................................................................................5-2

ATTACHMENTS, OPTIONS

GENERAL PRECAUTIONS .................................................................................................................................6-2

PRECAUTIONS RELATED TO SAFETY ...................................................................................................6-2

1-20

CONTENTS

HANDLING HYDRAULIC RIPPER....................................................................................................................... 6-3

GENERAL VIEW................................................................ .... ... ... ... ............................................................ 6-3

EXPLANATION OF COMPONENTS.......................................................................................................... 6-4

OPERATION............................................................................................................................................... 6-5

CHECK BEFORE STARTING ENGINE, ADJUST .......................... ... ... .... ... ... ... .... ... ... ... ... ............... 6-5

PRECAUTIONS WHEN OPERATING............................................................................................... 6-5

ADJUSTING POSTURE OF WORK EQUIPMENT ........................................................................... 6-5

TROUBLESHOOTING................................................................................................................................ 6-7

OTHER TROUBLE...... ... .... ... ... .......................................... ... .......................................... ... ............... 6-7

MAINTENANCE.......................................................................................................................................... 6-7

EVERY 250 HOURS SERVICE.........................................................................................................6-7

SPECIFICATIONS...................................................................................................................................... 6-8

AIR SUSPENSION SEAT..................................................................................................................................... 6-9

DELUXE SEAT................................................................................................................................................... 6-12

HEADREST ........................................................................................................................................................ 6-14

EQUIPPING FIRE EXTINGUISHER AND FIRST-AID KIT................................................................................. 6-15

INDEX

COLOPHON

1-21

CONTENTS

1-22

SAFETY

12

WARNING

Please read and make sure that you fully understand the

precautions discribed in this manual and the safety labels

on the machine. When operating or servicing the machine,

always follow these precaustions strictly.

IMPORTANT SAFETY INFORMATION SAFETY

IMPORTANT SAFETY INFORMATION 2

SAFETY LABELS................................................................................................................................................2-42

POSITION FOR ATTACHING SAFETY LABELS . .......................................... .... ... ... ......................................... 2-52

SAFETY LABELS...............................................................................................................................................2-52

PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE...............................................................2-102

FOR SAFE OPERATION.................................................................................................................................2-102

KNOW YOUR EQUIPMENT ............................................................................................................................ 2-102

PREPARE FOR SAFE OPERATION............................................................................................................... 2-102

CLOTHING AND PERSONAL PROTECTIVE ITEMS .....................................................................................2-112

FIRE EXTINGUISHER AND FIRST AID KIT ...................................................................................................2-112

KEEP THE MACHINE CLEAN.........................................................................................................................2-112

IF ABNORMALITIES ARE FOUND.................................................................................................................. 2-112

HANDRAILS AND STEPS ............................................................................................................................... 2-122

MOUNTING AND DISMOUNTING ..................................................................................................................2-122

INSIDE OPERATOR'S COMPARTMENT........................................................................................................ 2-122

PRECAUTIONS WHEN STANDING UP FROM OPERATOR'S SEAT ........................................................... 2-132

PRECAUTIONS WHEN LEAVING THE MACHINE.........................................................................................2-132

EMERGENCY ESCAPE FROM OPERATOR'S CAB ......................................................................................2-132

FIRE PREVENTION.........................................................................................................................................2-142

ACTION IF FIRE OCCURS..............................................................................................................................2-152

BATTERY HAZARD PREVENTION ................................................................................................................2-152

PRECAUTIONS RELATED TO VENTILATION OF EXHAUST GAS .............................................................. 2-162

BE CAREFUL ABOUT ASBESTOS DUST...................................................................................................... 2-162

PRECAUTIONS DURING OPERATION...........................................................................................................2-172

EXAMINATION AND CONFIRMATION OF WORKSITE.................................................................................2-172

WORKING ON LOOSE GROUND................................................................................................................... 2-172

DO NOT GO NEAR HIGH-VOLTAGE CABLES ..............................................................................................2-172

ENSURE GOOD VISIBILTY ............................................................................................................................2-182

CONFIRMATION OF MARK............................................................................................................................ 2-182

PRECAUTION FOR WARNING TAG ....................................... ... ... ... .... ... ... ... .... ............................................. 2-182

CHECK BEFORE STARTING ENGINE,ADJUST............................................................................................2-182

PRECAUTIONS WHEN STARTING................................................................................................................2-192

STARTING WITH BOOSTER CABLES....................... ... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... .............................2-192

CHECK BEFORE STARTING OPERATION ...................................................................................................2-202

PRECAUTIONS WHEN TRAVELING IN FORWARD OR REVERSE .............................................................2-202

PRECAUTIONS WHEN TRAVELING..............................................................................................................2-212

PRECAUTIONS FOR ACCUMULATED SNOW, AND ICE.................... ... ... ... .... ... ... ... ... ................................. 2-212

SHIPPING........................................................................................................................................................ 2-212

WHEN TOWING .............................................................................................................................................. 2-222

PRECAUTIONS FOR MAINTENANCE ............................................................................................................2-232

UNAUTHORIZED MODIFICATION .................................................................................................................2-232

WARNING TAG ...............................................................................................................................................2-232

KEEP WORK PLACE FOR MAINTENANCE CLEAN AND TIDY.................................................................... 2-232

REPAIR WELDING..........................................................................................................................................2-232

USE CAUTION WHEN FUELING....................................................................................................................2-232

PERSONAL MAINTENANCE .......................................................................................................................... 2-232

PROPER TOOLS............................................................................................................................................. 2-242

SELECTION WORK PLACE FOR MAINTENANCE........................................................................................ 2-242

STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE.......................................... 2-242

TWO WORKERS FOR INSPECTION AND MAINTENANCE WHEN ENGINE IS RUNNING.........................2-252

WORK UNDER THE MACHINE ......................................................................................................................2-252

PRECAUTIONS WHEN USING HAMMER.................................................................................................

.....2-262

2-2

SAFETY IMPORTANT SAFETY INFORMATION

PREVENTION BURNS FROM HOT WATER.................................................................................................. 2-262

PREVENTION BURNS FROM HOT OIL ......................................................................................................... 2-262

COMPRESSED AIR......................................................................................................................................... 2-262

HANDLING HIGH-PRESSURE HOSES, PIPING............................................................................................ 2-262

PRECAUTIONS WITH HIGH-PRESSURE OIL...............................................................................................2-272

PRECAUTIONS WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION..................... 2-272

DO NOT DISASSEMBLE RECOIL SPRING.................................................................................................... 2-272

ACCUMULATOR ............................................................................................................................................. 2-282

MAINTENANCE OF AIR CONDITIONER........................................................................................................2-282

WASTE MATERIALS.......................................................................................................................................2-282

PRECAUTIONS FOR MACHINE...................................................................................................................... 2-292

PRECAUTIONS WHEN USING ROPS (Roll Over Protective Structure)......................................................... 2-292

2-3

SAFETY LABELS SAFETY

SAFETY LABELS 2

The following safety labels are used on this machine.

q Make sure that you fully understand the location and content of each safety label, together with the means of

avoiding the danger shown.

q To ensure that the contents of safety labels can be read properly, be sure that they are in the correct place and

always keep them clean. When cleaning the labels, do not use organic solvents or gasoline. They may cause

the labels to peel off.

q If the labels are damaged, lost, or cannot be read properly, contact your Komatsu distributor immediately

regarding their replacement. For details concerning the part numbers for the labels, see this manual or the

actual label.

q There are also other labels on the machine in addition to the safety labels. Handle those labels in the same

way.

2-4

SAFETY SAFETY LABELS

POSITION FOR ATTACHING SAFETY LABELS 2

SAFETY LABELS 2

(1) Caution before operating or maintaining machine

(09651-A0641)

q Warning!

q Read manual before operation, maintaince, disassembly,

assembly and transportation.

2-5

SAFETY LABELS SAFETY

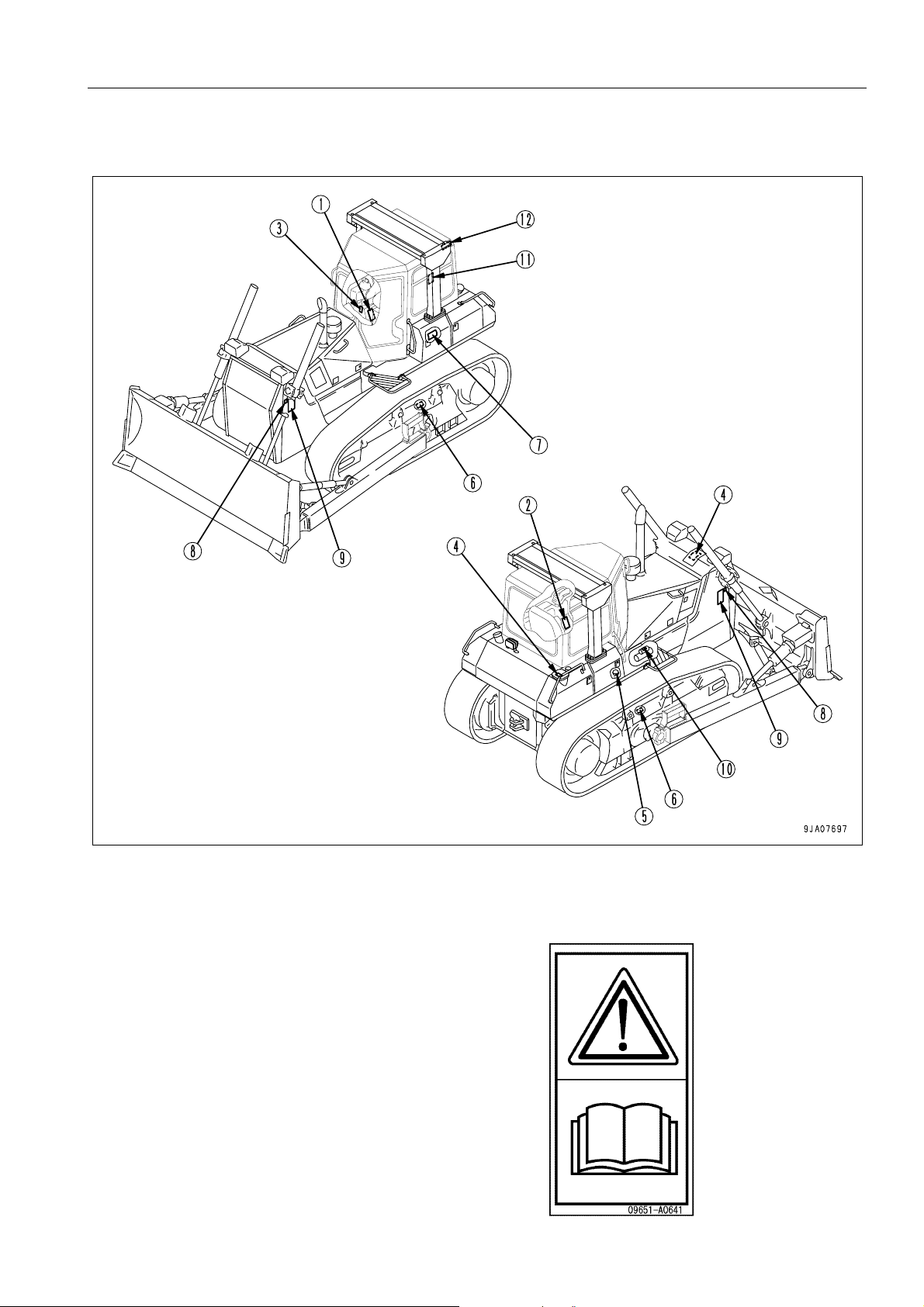

(2) Caution before moving in reverse (09802-B0750)

(3) Caution for leaving operator's seat (09654-B0641)

q Sign indicates a hazard of unexpected moving of stopped

machine.

q Lower working device to ground, move safety lever to lock

position and take engine key with you before leaving

machine.

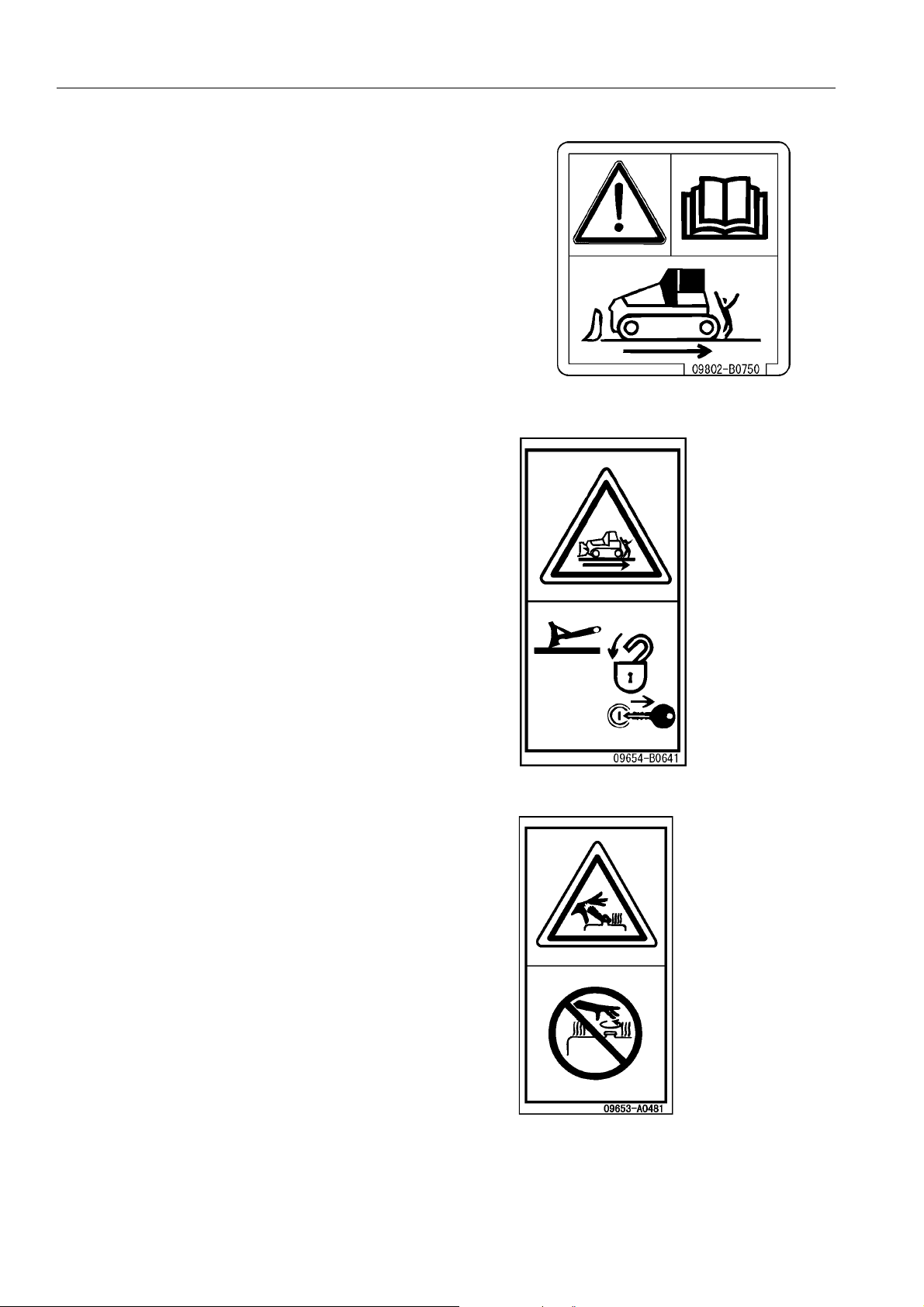

(4) Caution with high-temperature coolant, hydraulic oil

(09653-A0481)

q Never remove the cap when the engine is at operating

(high) temperature. Stream or high temperature oil blowing

up from the radiator or hydraulic tank, will cause personal

injury and / or burns.

q Never remove the radiator or hydraulic tank oil filler when

cooling water or hydraulic oil is at high temperatures.

2-6

Loading...

Loading...