komatsu D39PX-22, D39EX-22 SPECIFICATIONS

STANDARD EQUIPMENT FOR BASE MACHINE

OPTIONAL EQUIPMENT

Engine and related items

● Air cleaner, dry, double element type with

caution lamp on monitor

● Decelerator pedal

● Engine, KOMATSU SAA4D107E-1,

net output of 79 kW 105 HP direct

injection, turbocharged, air-to-air

aftercooler, EPA Tier 3 emissions certified

● Fan, hydraulic driven, electronic control

● Fuel pre-filter (10 micron) and fuel filter

(2 micron)

● Intake pipe with precleaner

● Radiator mask grid

● Radiator reserve tank

● Ribbon heater

● Water separator

Electric system

● Alternator, 35 amp (24 V)

● Back-up alarm

● Batteries, large capacity 92 Ah

● Starting motor, 5.5 kW

Power train and controls

● Brake pedal

● Counter rotation

● Electronically controlled Hydrostatic

Tr ansmission (HST) with Quick-shift and

variable speed settings

● Palm Command Control System (PCCS)

with electronic control for travel control

● Reverse speed presets

Undercarriage

● Idler cushions

● Sprockets, bolt-on

● Tr ack roller guards, end section

● Tr ack shoe assembly w/sealed and

lubricated link assembly:

—D39EX-22:

460 mm 18.1" single

grouser shoes

—D39PX-22: 635 mm 25.0" single

grouser shoes

Guards and covers

● Crankcase guard and underguard

● Engine hood and side panels

● ROPS/FOPS*

● Sprocket inner guard

Operator environment

● Cup holder

● Electronic monitor panel with on-board

diagnostics

● Foot rest, high mounted

● Horn

● Seat belt, 76 mm 3" retractable

● Seat, low back vinyl, suspension type

Dozer assembly

● Var iable pitch and power angle tilt dozer

assembly, inside arms (EX: 2710 mm

8'11" blade, PX: 3250 mm 10'8" blade)

Hydraulics and controls

● Accumulator for Proportional Pressure

Control (PPC)

● Hydraulics for PAT dozer

● Palm Command Control System (PCCS)

with Proportional Pressure Control (PPC)

for blade control

Vandalism protection

● Filler cap locks and cover locks

● Instrument panel lock and cover

(canopy only)

Other standard equipment

● Grease gun holder

● High altitude arrangement (no fuel

adjustment up to 2300 m 7,546 ft)

● Lighting package - (3 front, 1 rear

cab/canopy)

● Marks and plates, English

● Pullhook, front

Track shoe assembly with sealed and

lubricated link assembly

● D39PX-22

– 700 mm 27.6" single grouser, link

Track rail assembly with Abrasion

Resistant (AR) bushings and sealed and

lubricated link assembly

● D39EX-22

– 460 mm 18.1" single grouser,

shoe with AR link

– 510 mm 20" single grouser,

with AR link

● D39PX-22

– 635 mm 25.0" single grouser,

with AR link

– 700 mm 27.6" single grouser,

with AR link

Dozer assembly

● D39PX-22 – 2980 mm 9'9" blade

Track roller guards

● Tr ack roller guards, segmented, full

length

Operator environment

● 12 amp (12V) power port (cab only)

● Cab machine

– Cigarette lighter (24 V, standard for cab)

– Lunch box holder (standard for cab)

– Provision for radio (cab only)

– Seat, suspension type, fabric, high back

– Seat, suspension type, fabric low back

– Seat, air suspension type, fabric high

back

● Lunch box holder (option for canopy)

Rear equipment and hydraulics

● Rear, hydraulics (D39EX/PX-22)

● Ripper, multi-shank (D39EX-22 only)

● Hitch

ROPS canopy and ROPS cab equipment

● ROPS cab (includes air conditioner with

heater, defroster, pressurizer)

– Optional radio, AM/FM, cassette

● ROPS canopy with lower heater

Operator environment

● Forestry guards for cab and canopy

www.Komatsu.com Printed in Japan 200803 IP.AD (10)

CEN00321-00

Materials and specifications are subject to change without notice.

is a trademark of Komatsu Ltd. Japan.

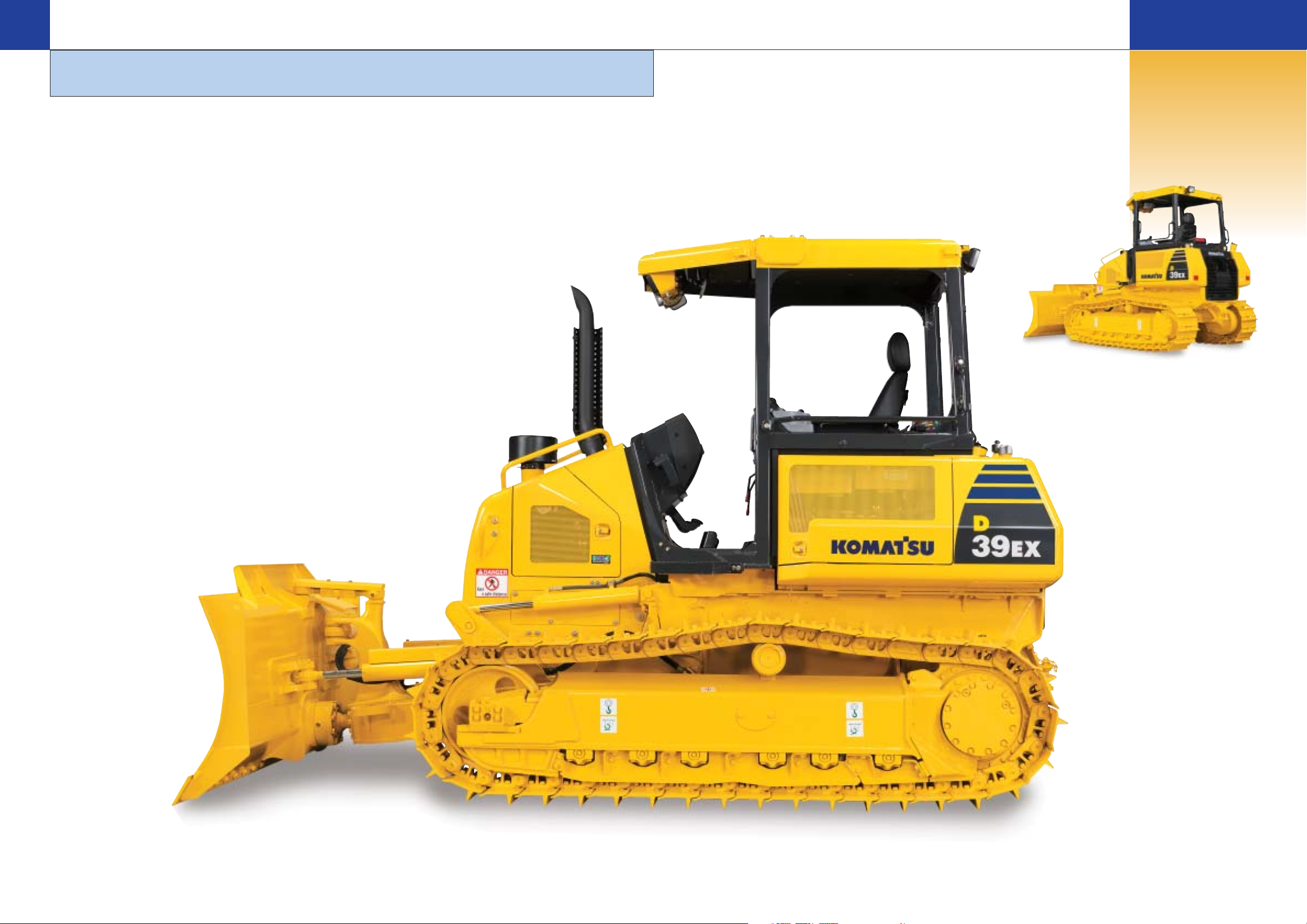

NET HORSEPOWER

79 kW

105 HP @ 2200 rpm

OPERATING WEIGHT

D39EX-22: 9040 kg 19,930 lb

D39PX-22:

9480 kg 20,900 lb

D39E X-22

D39PX-22

C

RAWLER

D

OZER

Photo may include optional equipment.

D

39

*ROPS cab or ROPS canopy must be ordered for

all machines. Cab and canopy FOPS Level 2.

ROPS/FOPS meets all OSHA/MSHA standards

and regulations criteria.

Dozer assembly and rear-mounted equipment are

not included in base machine price.

2 3

D275AX-5

CRAWLER DOZER

W

ALK

-A

ROUND

D39-22

CRAWLER DOZER

D39-22 C RAWLER D OZER

NET HORSEPOWER

79 kW 105 HP @ 2200 rpm

OPERATING WEIGHT

D39EX-22: 9040 kg 19,930 lb

D39PX-22: 9480 kg 20,900 lb

All-around visibility

● Super-slant nose design

● Cab-forward design

● Integrated ROPS/FOPS

Increased productivity

● Highest HP in its class

● Electronically-controlled hydraulically-driven fan

● In-shoe final drive

● High capacity Pitch- Adjustable Power-Angle-Tilt

dozer blade

Easy operation/Increased operator

comfort

● Hydrostatic Transmission (HST) with electronic

control

● Palm Command Control System (PCCS)

● Large and quiet pressurized cab (optional)

● New cab damper mounting system (for cab)

Improved durability

● Heavy-plate steel used throughout

● Modular design

Easy maintenance

● Electronic monitor panel with on-board diagnostics

● Rear-mount radiator with swing-up hydraulically-

driven fan

● Ground-level daily service checks

Photo may include optional equipment.

Loading...

Loading...