Page 1

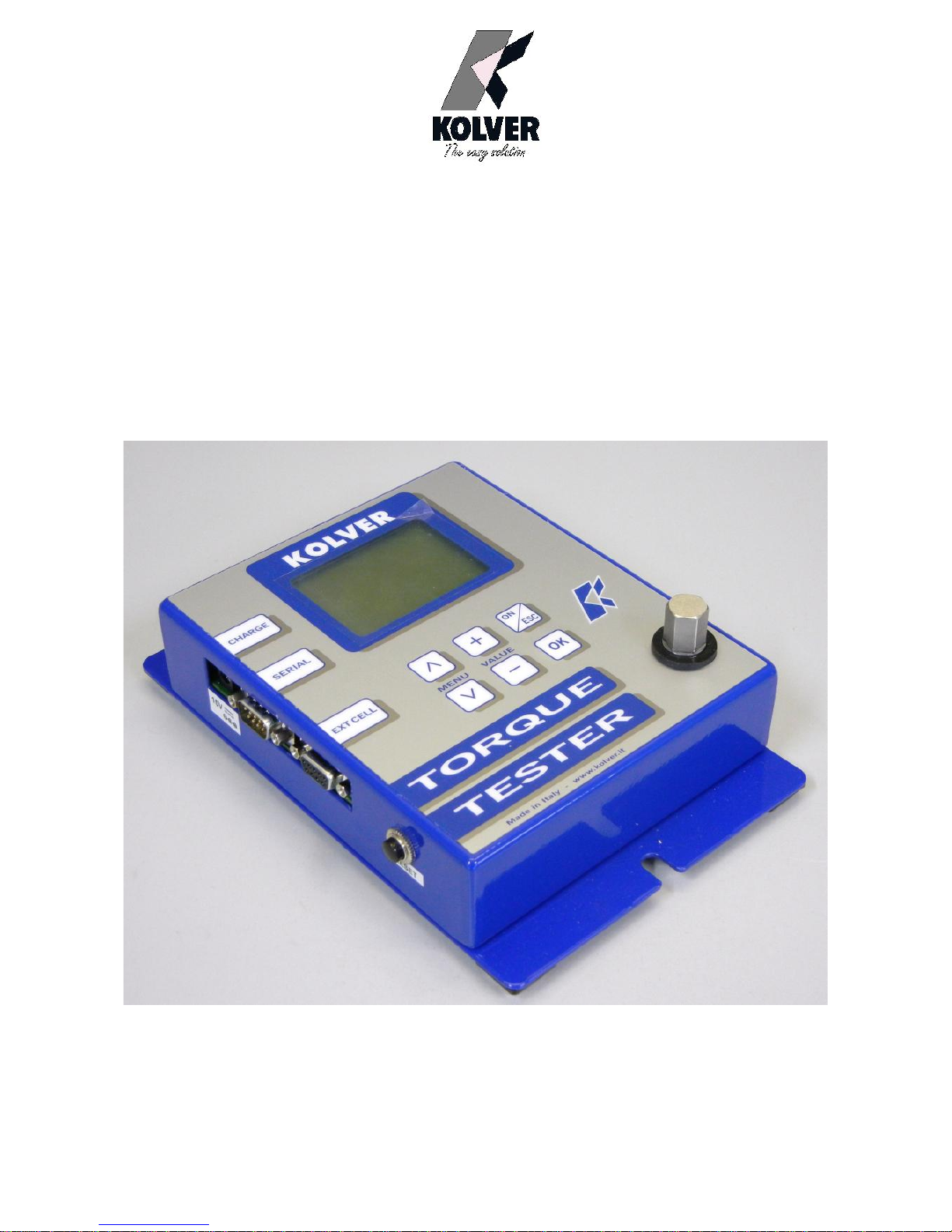

K1 - K5 - K20

TORQUE TESTER

OPERATOR’S HANDBOOK

KOLVER S.r.l - Via Corner, 19/21 - 36016 THIENE - ITALY - tel. +39 0445 371068 fax. +39 0445 371069

kolver@kolver.it - www.kolver.it

Page 2

2

1.FEATURES OVERVIEW

Controlling torque is quintessential for companies to ensure that product's quality, safety and

reliability isn't compromised. Insufficiently torqued fasteners can vibrate loose overtime and when

excessively torqued the threaded fasteners can strip. Using a quality torque tester has become

increasingly important for many companies to secure that proper torque is being applied.

The K1.K5.K20 Torque Tester is built for accuracy and reliability ever demanded for these

kinds of products. This tester accurately measures torque for most tools, meeting the

demands to test multiple torque ranges for various tools used in production. The analyser

features a built-in transducer and supports most external size transducers. Utilizing a highperformance circuitry system, the tester can store and download torque readings to a

computer at high speeds. This allows a powerful collection of analytical data to be stored for

future reference and statistical analysis of tools. Offering three modes of operation (Track,

Peak + and Peak -) this versatile analyser provides the operator a variety of ways to

smoothly verify torque applied with a selection of four measuring units. Models ranging in

torque up to 20 Nm with the built-in transducer and up to 999 Nm with the external

transducer.

Recommended for all hand screwdrivers, wrenches, or power tools.

Measuring range with built in transducer:

K1 0.05-1 Nm, K5 0.3-5 Nm, K20 0.5-20 Nm

Accuracy K1 = ± 1 cNm

K5 = ± 2 cNm

K20 = ± 3 cNm

Selection from the menu of three operation modes: (Track, Peak +, Peak -) and four units of

torque measurements: (N.m, cN.m, lbf.in, kgf.cm).

Port for external transducers.

<, =, > signals to indicate validity of torque readings with buzzer for audible user feedback.

RS-232 interface to download values stored in memory (500 values capacity).

Manual and auto reset functions to clear displayed values.

Calibration will allow for both a fast calibration (using mV/V transducers rated output) and

a true (dead weight) calibration.

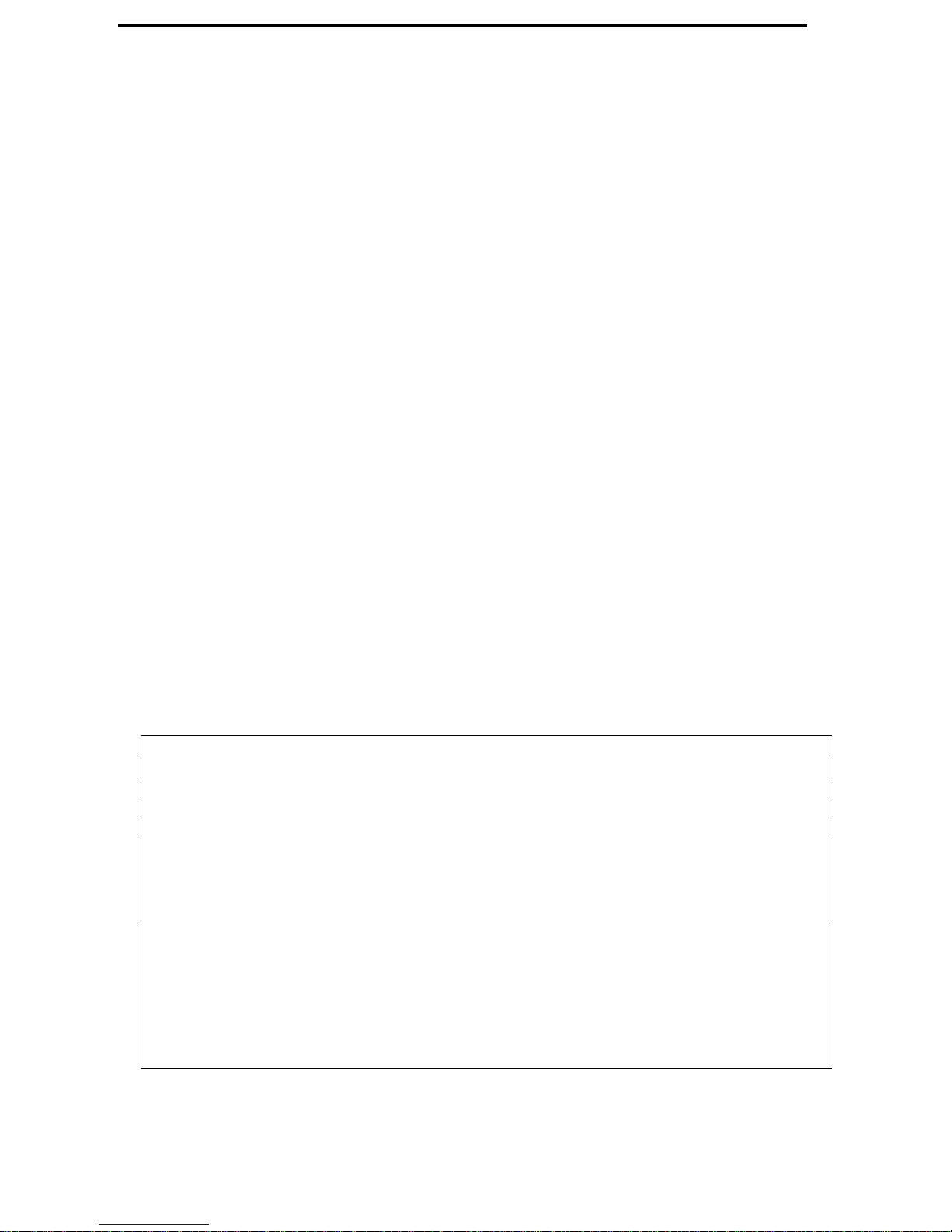

2. DESCRIPTION AND USER INTERFACE

1. Mounting holes

2. Display with 8 lines/ 16 digits

3. CHARGE: External power supply 5,5 – 2,5mm and battery charger port

4. SERIAL: RS232 output

5. EXT CELL: External transducer input and GO signal output

6. MENU keys to move through the menu. Key ^ to enter the menu.

7. Key “ON/ESC” :

Press for 3 seconds to switch the tester on or off.

Press to return to the previous screen

8. Keys: VALUE + and - to increase or decrease values when setting numbers

9. Key OK : press once

To enter a sub-menu

To save settings

To reset torque values displayed when in MANUAL clear mode

10. Internal transducer: 13mm hex male to accept the joint simulator

Page 3

3

3. MOUNTING

It is strongly recommend securing the tester through slots “1” to a workbench before operating.

Immobilizing the tester when checking torque values over 3 Nm is critical for the safety the

operator as well as for the accuracy of torque measurements during operation.

4. JOINT SIMULATOR (run down adapter)

The Joint Simulator (JS) consists of a screw compressing a series of washers (see §11). The way the

washers are mounted can simulate soft or hard joint. The screw comes with a ¼” hex male head for

proper fit to any ¼” hex female screwdriver drive. Hardened thread components increase accuracy

and life. One semi-elastic JS included. Hard joint simulator available on request.

NB. It is suggested to grease the JS each 1000 cycles.

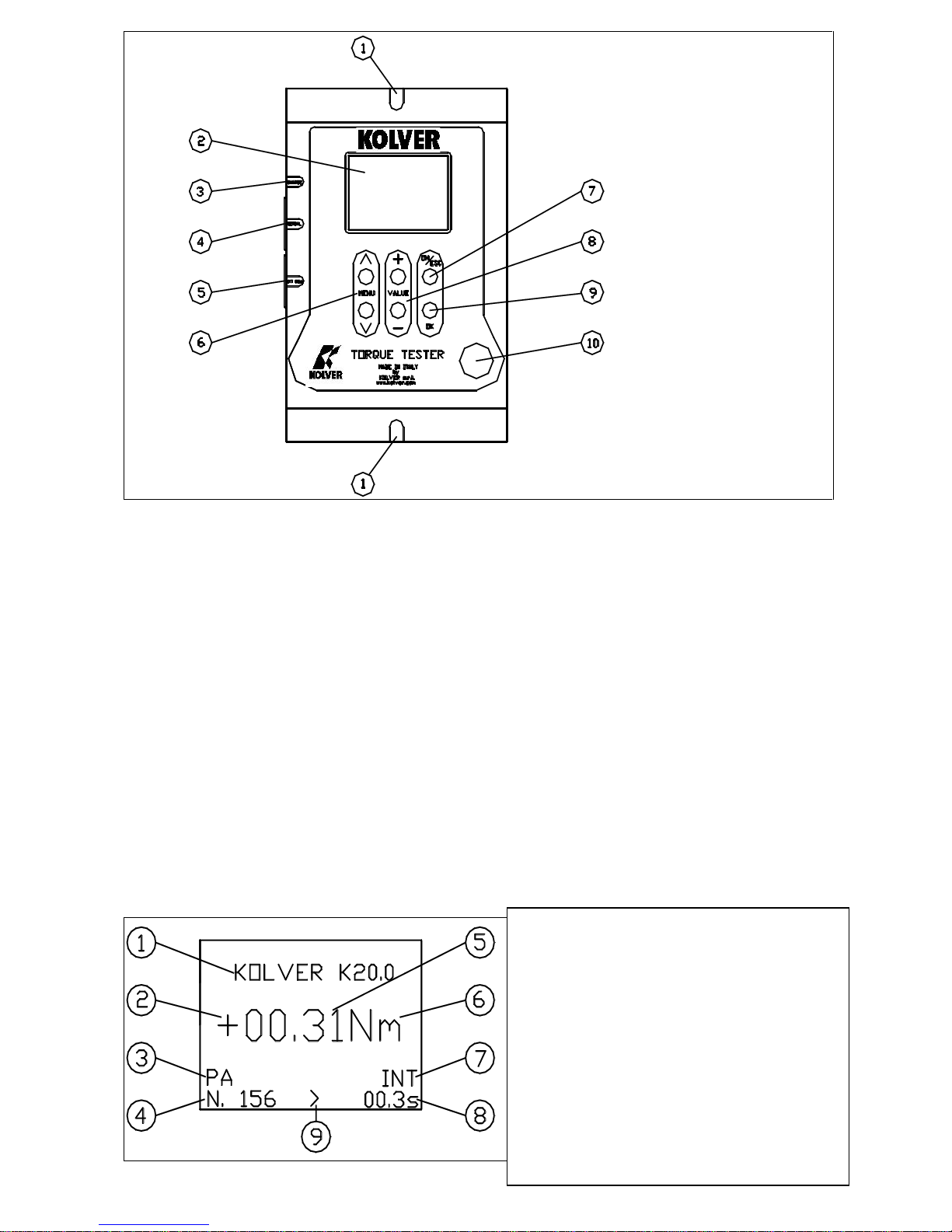

5. STARTING AND OPERATING THE TESTER

Connect the battery charger/power supply unit.

Push the “ON/ESC” key. The display will show the main screen.

1. Model

2. “+” tightening, “-“ untightening.

3. Mode of operation: PA (peak +), PS

(peak -), Track

4. Number of measures since last reset

5. Torque value measured

6. Measuring unit

7. Transducer in use : INT or EXT

8. Time of tightening cycle

9. = GO, > < NO GO used to

monitor lower and upper torque limit

and receive a visual and audible

warning

Page 4

4

Push the ^ key to enter the menu and adjust the various settings to your requirements.

Insert the joint simulator into its 13mm hex. seat and make sure the screw is in its upper

position (if not run the driver anticlockwise to unscrew it). The tester is ready.

Run the joint simulator screw all the way down until it stops and read the torque value on

the display. Run the screw up to be ready for the next cycle.

Press the “ON/ESC” key for 3 seconds to switch the tester off. The Tester features a built-in

auto shut off mode function to save power when not in use. If there is no activity for 5

minutes, such as key press or no torque input, the tester will shut down. To restore power

press the “ON/ESC” key for 3 seconds.

In case of a deadlock, press the Reset button and restart the tester.

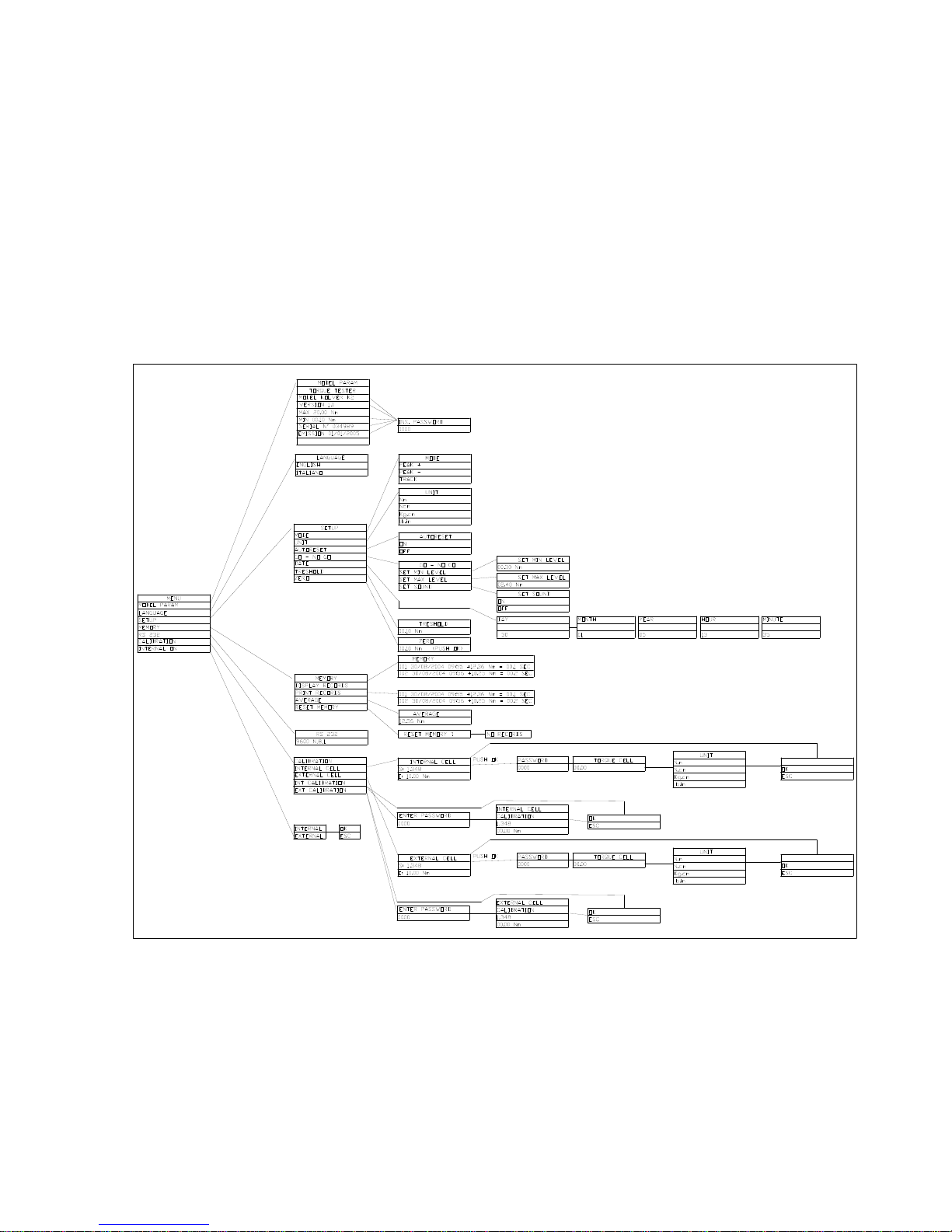

6. PROGRAM MENU

The flow chart below shows the complete menu options.

Push ^ key to enter the menu from the main screen. To move through the menus push ^ or v keys.

The indicator < on the right side of the screen will signal the selected option. Push “OK” key to

confirm the desired option.

Use + or - key to active digits when setting numbers and push OK to save them.

Protected parameters (such as calibration) need a password from Kolver or Kolver authorized

distributor.

Page 5

5

MENU OPTIONS

MODEL

This screen gives you information on the unit you are using, like serial number, software

version etc. Such data are password protected.

LANGUAGE

You can choose between English and Italian.

SETUP

The following is a quick reference for the Set-Up menu structure. If lost within the menu, you

can turn the analyser OFF and ON at any time.

MODE:

The Torque Tester offers three different mode of displaying torque information during operation.

The user will determine which mode is best suited for the application.

Key sequence to change mode:

Mode

^ o v.

OK

PEAK +

The display retains the highest torque applied clockwise.

Use this mode during calibration or testing of any power tools as well as hand type torque wrench

(dial, beam, and screwdriver).

PEAK The display retains the highest torque applied anticlockwise.

Use this mode when checking the torque needed to unscrew a tightened fastener.

TRACK

This mode constantly tracks increasing or decreasing torque variations. Use this mode to monitor

varying torque on motors and machinery. Also for calibrating and testing Dial type wrenches on a

loading bench.

MEASURING UNIT: Nm, Ncm, Kg.cm and lb.in

Key sequence to change unit:

unit

^ o v.

OK.

AUTORESET: When off push OK to remove readings from the display and reset all values to zero.

When on this process occurs automatically with any new measure.

GO - NO GO: The Torque Tester is equipped with visual (>, <, =) and audible (buzzer) signals to

provide the user instant torque status during operation. These signals operate in conjunction with

the tolerance (high limit, low limit) settings. Example: let us assume we want to calibrate our

screwdriver in the range between 0.8 and 1.0 Nm. We will then set the Low limit to 0.8 and the

High limit to 1.0. If our measure will fall inside the pre set limits the display will show =, if the

measure is below 0.8 Nm we will see <, if over 1.0 Nm we will see >. A buzzer will also signal the

measure was out of the required range. Push OK to stop the buzzer.

Note: When the values are within the pre set range an electric GO signal will be sent to pin 8 (pin 4

of 4N35) and 9 (pin 5 of 4N35) of connector EXT CELL, as per following diagram:

Page 6

6

DATE: You can set day, month, year, hour and minute.

Key sequence to change values:

date

+ or -.

OK

TRESHOLD: The parameter “threshold” indicates the minimum torque level you need to measure.

Values below this level will not be displayed. This setting enables the system to have excellent

immunity to spurious signals. Key sequence to change values:

Treshold

+ or - .

OK

ZERO: All transducers can experience some drift in the “zero” or “zero offset” point when shifting

torque from clockwise to counter clockwise or vice versa and when the transducer has not been

used for a certain time. This is a normal characteristic of transducers due to a hysteresis or lack of

“retrace”. As a result, the display may not zero and show a torque value. Key sequence to reset the

zero:

Zero

Push OK until you see 00.00

MEMORY

The memory menu will give you access to the stored values, to display and print them. You

can also see the average value of all the measure taken since you last reset the memory.

DISPLAY MEASURE: Push “OK” key and the screen will display all the data of the last measure

taken: sequence number, torque value, unit, duration of detected torque, date, hour, signals = > <

(see GO- NO GO). Push v e ^ keys to move through stored values. Push “ESC” to exit.

PRINT MEASURE: Push “OK” to send all data to the 232 serial port.

DATA DOWNLOADING

If you desire to download and display data on a computer, you can do so by using any serial

communications software. One such program is Hyperterminal accessory, standard to Windows 95,

NT, Windows 98, 2000 or XP. A description of operation is given below. This procedure may vary

slightly depending on the Windows software version being used. This is just an example, if you

have problems consult Windows Help files.

Select “Start”, “Programs”, “Accessories”, and then “Hyperterminal”. Then select

HyperTerminal.exe.

When the program starts you will be asked to choose an icon and assign a name. Choose any

icon you prefer and choose a name such as “Data_K5”, for example. Click OK.

Page 7

7

The “Connect To” screen will appear. Just click OK, or if you want to change the COM

port, select the appropriate COM port and click OK.

The “COM2 Properties” screen will appear. Choose 9600 Bits per second. Leave the default

values for character format (8 Data Bits, Parity – None, and Stop Bits 1). Change the Flow

Control to “None”. Click OK.

Click “File” on the Menu Bar and select “Properties”. When the “Data_K5 Properties”

screen appears choose the “Settings” tab and then choose “ASCII setup”. In “ASCII

receiving” check the box “Append line feeds to incoming line ends”. Click OK then OK

again.

Hyperterminal is now configured to allow torque values to be displayed on your computer screen.

If you want to capture data to a file as it is downloaded, you must enable the file capture option. To

capture to a file, select “Transfer” from the Menu Bar and select “Capture Text”. Then select the

folder and file you wish to save it as.

You can also connect the 232 serial port to a serial printer for direct data printing.

MEDIA: Push “OK” to see the average value of all the measures taken since you last reset the

memory. Please note that the program will consider the numerical values only and not the unit so

make sure all the measures have been taken under the same unit and sense of rotation.

Push “ESC” to go back to the previous screen.

RESET MEMORY: Push “OK” , the screen will display: reset memory? to ask the operator for a

further confirmation. Pushing the “OK” will delete the stored data and the screen will dispaly: no

values in memory. Push “ESC” to exit.

RS232

The Configuration of the RS 232 port is: 9600 (bits per second), 8 (data bits), n (no parity), 1 (stop

bits 1).

CALIBRATION

The torque tester comes with a calibration certificate. Further calibrations should be performed by

Kolver or authorized personnel. This menu section is password protected.

INTERNAL

This option allows the user to select the transducer to be used during operation.

Although the Torque Tester features one internal transducer, it has the unique feature to be also

used with an external transducer (optional). Key sequence to select the transducer:

OK

^ o v.

OK

The main screen will show the selected option (INT or EXT) .

7. EXTERNAL TRANSDUCER

The K tester are the unique feature to support an external rotary transducer with Wheatstone bridge

strain gauge. The tester can read rotary torque up to 20.00 Nm. External transducer for higher torque

on request. The Internal/External parameter must be set to external as outlines in section (6) for the

K tester to read the torque value from the external transducer.

PIN

FUNCTION

2

TX

Serial transmission

5

GND

0Vdc

Page 8

8

The external transducer should be connected as follows:

“EXT CELL” INPUT

PIN

DESCRIPTION

1

OUTPUT: + 2,5 V

2

INPUT: + SIGNAL FROM TRANSDUCER

3

OUTPUT: 0 V

4

INPUT: - SIGNAL FROM TRANSDUCER

8. MAINTENANCE

The K testers are maintenance free. The electronics and the internal transducer have no wearing parts.

The internal transducer should be calibrated every 12 to 30 months, depending on the frequency of

use.

WARNING: The overload protection of the internal transducer is limited to 125% of nominal value.

Damages due to overloading will result in inaccurate readings and will not be covered by our

warranty.

9. GUARANTEE

1. This KOLVER product is guaranteed against defective workmanship or materials, for a maximum

period of 12 months following the date of purchase from KOLVER, provided that its usage is limited

to single shift operation throughout that period. If the usage rate exceeds of single shift operation, the

guarantee period shall be reduced on a prorata basis.

2. If, during the guarantee period, the product appears to be defective in workmanship or materials, it

should be returned to KOLVER or its distributors, transport prepaied, together with a short

description of the alleged defect. KOLVER shall, at its sole discretion, arrange to repair or replace

free of charge such items.

3. This guarantee does not cover repair or replacement required as a consequence of products which

have been abused, misused or modified, or which have been repaired using not original KOLVER

spare parts or by not authorized service personnel.

4. KOLVER accepts no claim for labour or other expenditure made upon defective products.

5. Any direct, incidental or consequential damages whatsoever arising from any defect are expressly

excluded.

6. This guarantee replaces all other guarantees, or conditions, expressed or implied, regarding the

quality, the marketability or the fitness for any particular purpose.

7. No one, whether an agent, servant or employee of KOLVER, is authorized to add to or modify the

terms of this limited guarantee in any way. However it’s possible to extend the warranty with an

extra cost. Further information at kolver@kolver.it.

Page 9

9

10. PARTS LIST

K1

Page 10

10

REF

DESCRIPTION

CODE

1

Plastic support (4 pcs)

800016/B

2

Screw M4 x 14 (6 pcs)

240006

3

Base

240013

4

Screw M3 x 6 (2 pcs)

231504

5

Screw M3 x 22

241012

6

Screw M4 x 8 (3 pcs)

241011

7

Internal transducer 1Nm (K1)

240405

8

Washer M4 (7 pcs)

241015

9

Screw M4 x 20

241014

10

Washer ( 3 pcs)

800041

11

Screw M3 (3 pcs)

800056

12

Screw M3 x 5 (4 pcs)

240605

13

Metal housing

240001

14

PVC Washer

240017

15

Membrane

240008

16

Board and display

240002

17

Battery support (2 pcs)

800169

18

Battery 9,6V 1500mAh

240007

19

Turret M3 x 18 (4 pcs)

240016

Joint simulator M6 (K1)

240600

Case

240000

Battery charger 15V 360mA

240003/N

External transducer

ON REQUEST

Page 11

11

K5 – K20

Page 12

12

REF

DESCRIPTION

CODE

1

Plastic support (4 pcs)

800016/B

2

Screw M4 x 14 (6 pcs)

240006

3

Base

240013

4

Screw M3 x 6 (2 pcs)

231504

5

Screw M3 x 22

241012

6

Screw M4 x 8 (3 pcs)

241011

7

Internal transducer 5Nm (K5)

240503

Internal transducer 20Nm (K20)

240504

8

Washer ( 3 pcs)

800041

9

Screw M3 (3 pcs)

800056

10

Screw M3 x 5 (4 pcs)

240605

11

Metal housing

240001

12

PVC Washer

240017

13

Membrane

240008

14

Board and display

240002

15

Battery support (2 pcs)

800169

16

Battery 9,6V 1500mAh

240007

17

Turret M3 x 18 (4 pcs)

240016

Joint simulator M6 (K5)

240600

Joint simulator M8 (K20)

240800

Case

240000

Battery charger 15V 360mA

240003/N

External transducer

ON REQUEST

Page 13

13

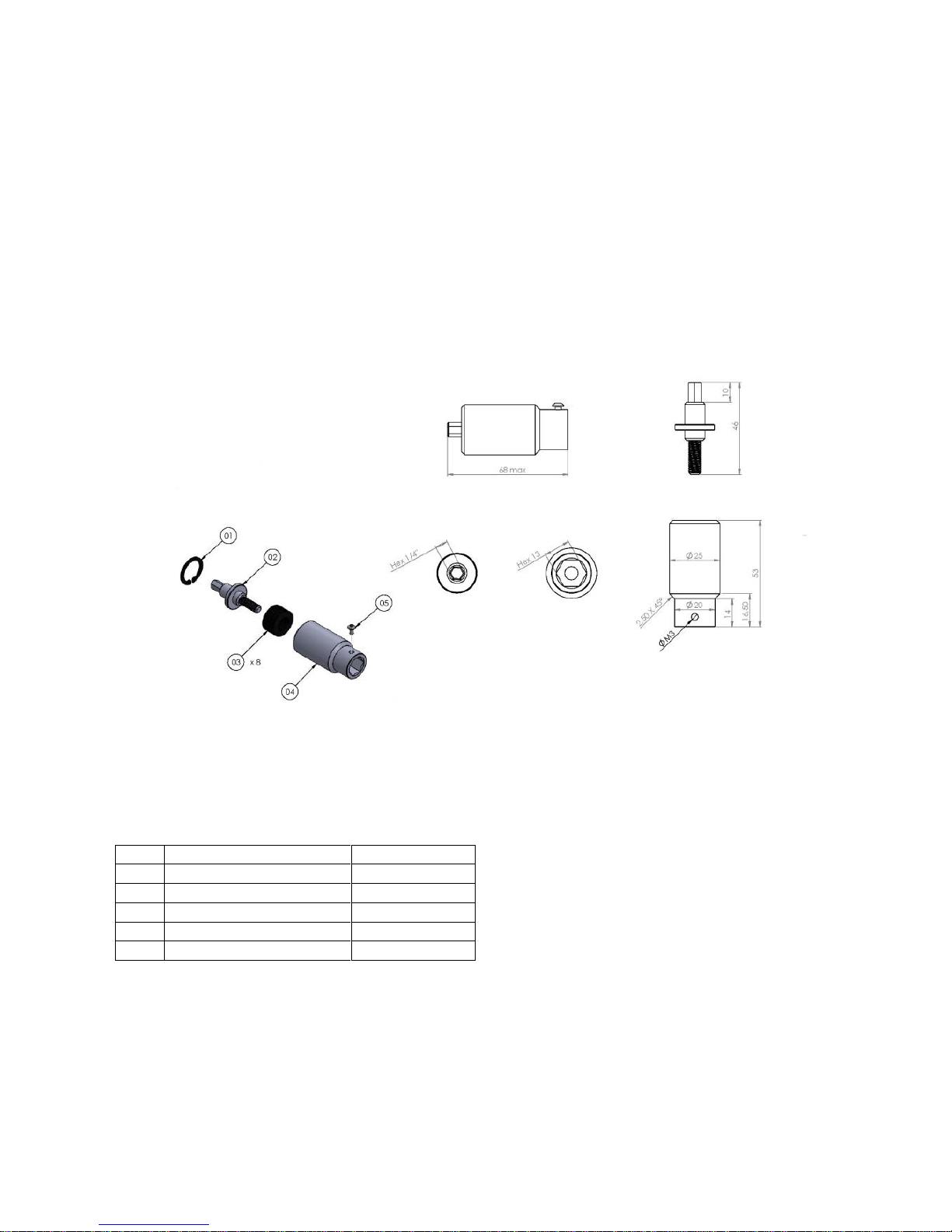

M6 (code 240600) – K1 & K5

Pos.

Description

Code

01

Seiger

240601

02

Joint shaft

240602

03

Washer spring (8)

240603

04

Joint housing

240604

05

Screw M3x5

872443/ZN

Page 14

14

M8 (code 240800) – K20

Pos.

Description

Code

01

Seiger

240801

02

Joint shaft

240802

03

Washer spring (12)

240803

04

Joint housing

240804

05

Screw M3x5

872443/ZN

Page 15

15

DECLARATION OF CONFORMITY

KOLVER S.r.l.

VIA MARCO CORNER, 19/21

36016 THIENE (VI) ITALIA

Declare that the new tool here described: Torque tester:

K1

020402

K5

020403

K20

020404

Is in conformity with the following standards and other normative documents: 2006/42/CE, LVD 2014/35/UE, EMCD 2014/30/UE,

EN 60745-1, EN 60204-1, EN 61000-6-1, EN 61000-6-3.

It is also in conformity with RoHS II normative (2011/65/UE).

Name: Giovanni Colasante

Position: General Manager

Person authorized to compile the technical file in Kolver

Thiene, Jan. 1st 2018 Giovanni Colasante

Loading...

Loading...