Page 1

DECLARATION OF CONFORMITY

KOLVER S.r.l.

VIA MARCO CORNER, 19

36016 THIENE (VI) ITALIA

Declare that the new tool here described:

Electric screwdriver:

ACC2210 141910

ACC2220 141920

ACC2222 151222

ACC2230 151930

ACC2245 151945

Is in conformity with the following standards and other

normative documents: 2006/42/CE, LVD 2014/35/UE,

EMCD 2014/30/UE, EN 60745-1, EN 60204-1, EN 610006-1, EN 61000-6-3.

It is also in conformity with RoHS II normative

(2011/65/UE).

Name: Giovanni Colasante

Position: General Manager

Person authorized to compile the technical file

in Kolver

Thiene, Jan. 1st 2017 Giovanni Colasante

Operator’s Handbook

IDENTIFICATION DATA OF THE MANUFACTURER

KOLVER S.r.l.

VIA MARCO CORNER, 19/21

36016 THIENE (VI) - ITALIA

IDENTIFICATION DATA OF THE PRODUCT

ELECTRIC SCREWDRIVER MODEL:

ACC2210 141910

ACC2220 141920

ACC2222 151222

ACC2230 151930

ACC2245 151945

THECNICAL DATA OF THE PRODUCT

TENSION: 230V DC

POWER: 30W

SPEED RPM: 950; 2222: 2400; 2245: 450

TORQUE RANGE Nm: 2210: 0,2-1; 2220: 0,7-2

2222: 0,9-2; 2230: 1-3; 2245: 1-4,5

Page 2

GENERAL SAFETY RULES

WARNING: when using electric screwdrivers, basic safety precautions should always be

followed to reduce the risk of fire, electric shock and personal injury. Read all the instructions

below before using the screwdriver and save them.

1. Keep the work area clean and well lit.

2. Do not use the electric screwdrivers in dampt or wet locations or in presence of

flammable liquid or gases.

3. Avoid body conctact with grounded surfaces as pipes, radiators, refigerators etc.

4. Keep children and visitors away from work area.

5. When not in use screwdrivers should be stored in dry and locked-up place and out of

the reach of children.

6. Do not use the screwdrivers for purposes or works not intended.

7. Dress properly. Do not wear loose clothing and jewelry. Wear protective hair

covering to contain long hair.

8. Never carry the screwdriver by cable or pull it to disconnect it from socket.

9. Use clamps or a vice to hold work.

10. Keep proper footing and balance at all times.

11. Inspect tool cable periodically and, if damaged, have it repaired or replaced by

authorized service facility. Always keep handles dry, clean and free from oil and

grease.

12. Disconnect tools from power supply before any operation of servicing, when changing

accessories and when you do not use them.

13. When screwdriver is used outdoors,only operate with extension cords intended for use

outdoors and so marked.

14. Pay attention while working. Do not operate screwdriver when you are tired.

15. Always check the screwdriver is not damaged before using it. Defective switches must

be replaced by authorized service center. Never use tools that cannot be turned on or

off by the switch.

16. The use of any other accessory other than recommended in this operating instruction

may represent a risk of personal injury.

17. Have the screwdriver repaired only by authorized and expert people.

Failing to do so may represent a serious danger.

WARNING: before connecting the control unit and power supply to the socket, please check

the voltage you are using is the same indicated on the label of the unit itself.

1. APPLICATIONS

Kolver electric screwdrivers are designed to tighten to preset torque values any fasteners up to

M5. Tabel 1 will help you to identify the capacity and the torque range of each model.

Precision assembly industries in the field of electronics, electric appliances, toys, glasses frame

and so on, are the natural users of electric screwdrivers.

Model

Capacity

Speed RPM

Torque range [Nm]

ACC2210M3950

0,2 - 1,0

ACC2220M4950

0,7 - 2,0

ACC2222M42400

0,9 - 2,0

ACC2230M5950

1,0 - 3,0

ACC2245M5450

1,0 – 4,5

Page 3

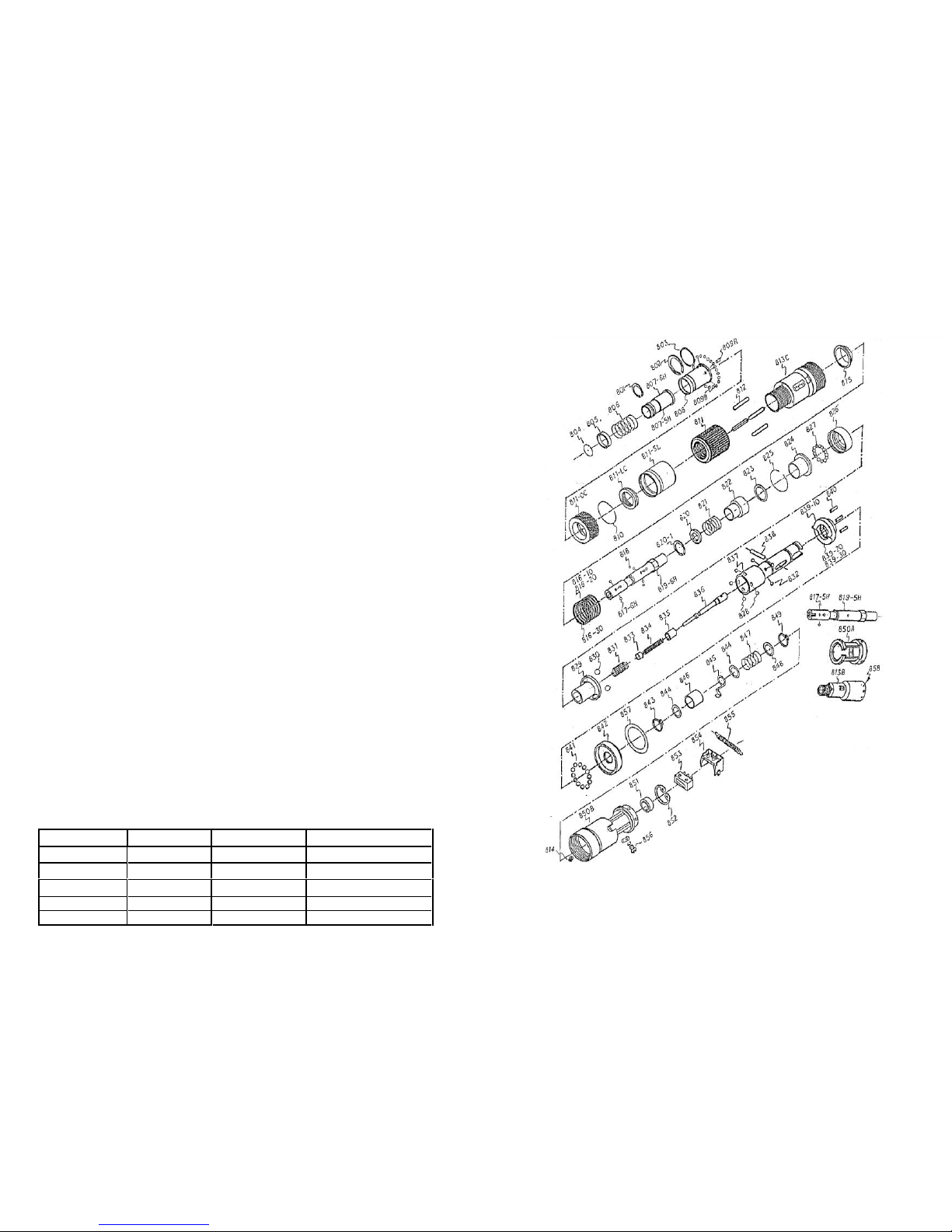

SPARE PARTS LIST ACC

REF

DESCRIPTION

CODE

REF

DESCRIPTION

CODE

M3076-10

Motor 2210

219210

961

Fixing screw

200039

M3076-20

Motor 2220

219220

962

Isolation washer

219962

M3076-30

Motor 2230 & 2222

219230

963

Shell (base)

219963

M-301

Motor cover

219301

964

Shell (cover)

219964

M-302

Bering

220080

965

Trigger start

219965

M-303

Washer

219303

966

Spring

219966

M-304/1

Magnet 2210

219304

967

Flat screw

219967

M-304/2

Magnet 2220

219314

968

Screw

219968

M-304/3

Magnet 2230 & 2222

219324

969

Hanger

219969

M-305

Steel housing 2210 &2220

219305

970

Microswitch

219970

M-305/1

Steel housing 2230 & 2222

219350

971

Start switch

219971

M-306

Rotor 2210 & 2220

219306

972

For-Rev slide switch

219972

M-306/1

Rotor 2230 & 2222

219360

973

P.C.B.

219973

M-307

Carbon brush

219307

974

Cable joiner

219974

M-308

Carbon brush cover

219308

975

Cable

219975

M-309

Brushes seat 2210 & 2220

219309

976

Plug

219976

M-309/1

Brushes seat 2230 & 2222

219390

M-310

Stop spring 2210 & 2220

219310

G602836

Internal gear

219836

G-154

Upper reduction plater

219154

G-155

Planet gear

219155

G-156

Washer

219156

G-157

Lower reduction plate

219157

G-191

Main gear

219191

G-192

Planet gear

219192

G-193

Washer

219193

G-194

Steel washer

219194

G-195

Washer ring

219195

F1

Separate seat

219957

F2

Bearing

210080

F3

Fan

219959

F4

Washer

219960

Page 4

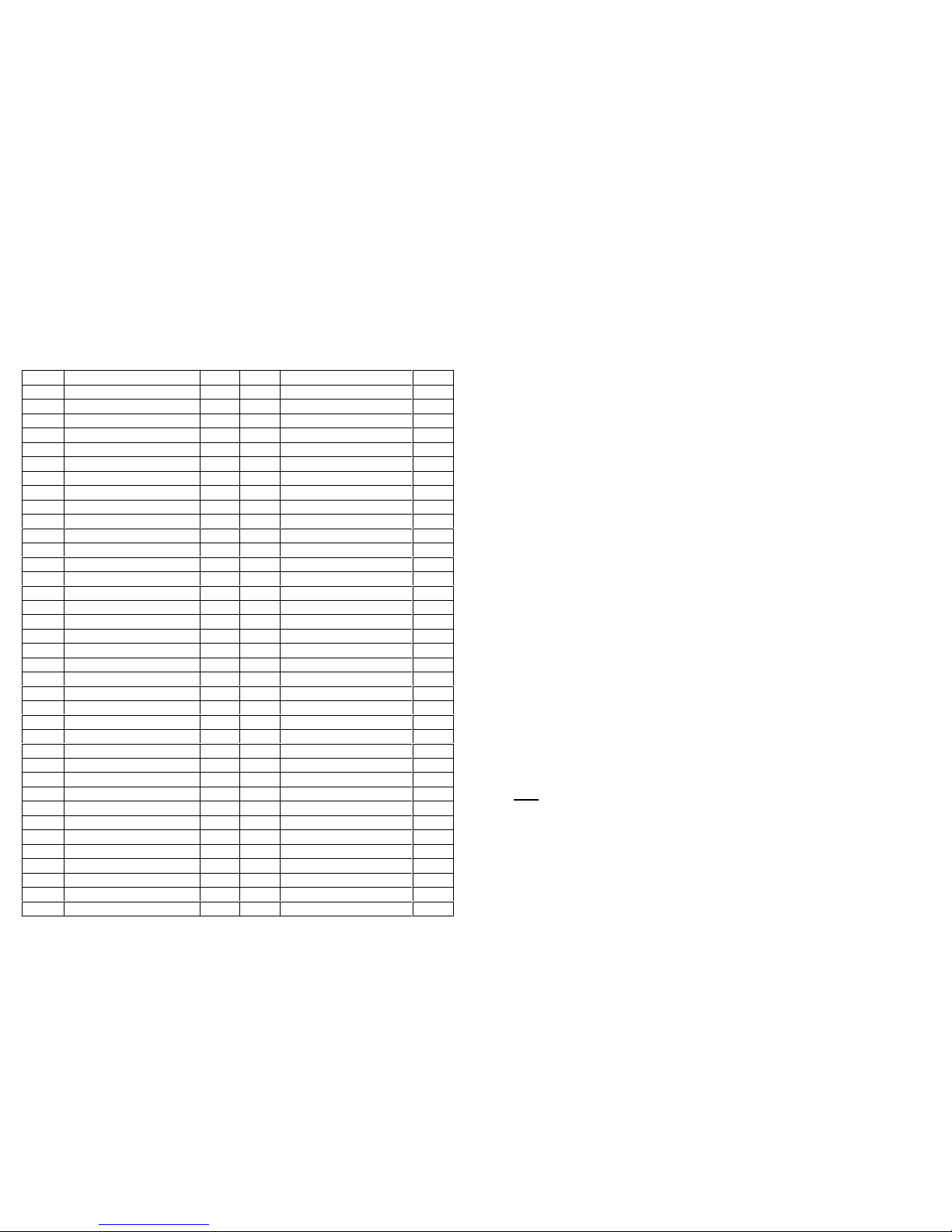

SPARE PARTS LIST ACC

REF

DESCRIPTION

CODE

REF

DESCRIPTION

CODE

801

Clip

219801

826

Thrust sheet

219826

802

Clip

219802

827

Steel ball

219827

803

Washer

219803

828

Steel ball

219828

804

Clip

219804

829

Idling ring

219829

805

Lining ring

219805

830

Steel ball d. 5mm

219830

806

Spring

219806

831

Main shaft return spring

219831

807-5H

Bit control ring 5mm

219807

832

Steel ball

219832

807-6H

Bit control ring 1/4

219880

833

Stopping ball

219833

808-5H

Main shaft thrust sleeve 5mm

219808

834

Central control rod spring

219834

808-6H

Main shaft thrust sleeve 1/4

219881

835

Control rod sliding sleeve

219835

809-B

Steel ball

219809

836

Central control rod

219836

809-R

Roller ball

219882

837

Main shaft-output

219837

810

Stop ring

219810

838

Pin

219838

811

Torque nut fixing type

219811

839-10

Upper clutch

219839

811-LC

Thread of torque nut

219883

839-20

Upper clutch

219893

811-SL

Torque nut outer slide sleeve

219884

839-30

Upper clutch

219894

811-0C

Torque adjusting locker

219885

840

Roller ball

219840

812

Pin

219812

841

Steel ball

219841

813-B

Torque nut seat

219813

842

Upper clutch thrust cover

219842

813-C

Torque nut seat

219892

843

Clip

219843

814

Fixing screw

219814

844

Washer

219844

815

Torque spring bottom seat

219815

845

Hook

219845

816-10

Torque spring 10 Kg/cm

219816

846

Shaft liner

219846

816-20

Torque spring 20 Kg/cm

219886

847

Spring

219847

816-30

Torque spring 30 Kg/cm

219887

848

Washer

219848

817-5H

Steel ball d. 2.5mm

219817

849

Clip

219849

817-6H

Steel ball d. 2mm

219888

850-A

Upper mechanical seat

219850

818

Steel ball d. 2.38mm

219818

850-B

Upper m. seat wear improved

219891

819-5H

Main shaft output 5mm

219819

851

Bearing

219851

819-6H

Main shaft output 1/4

219889

852

Stop ring

219852

820

Release ring spring seat

219820

853

Micro switch

219853

820-1

Stop ring

219890

854

Micro switch seat

219854

821

Release ring spring

219821

855

M. switch seat pull spring

219855

822

Release ring

219822

856

Earth connection screw set

219856

823

Washer

219823

857

Schock absorber

219857

824

Lower clutch thrust sleeve

219824

858

Screw

219858

825

Stop ring

219825

2. USE

The screwing system is composed by a screwdriver and a cable with schuko plug. To install

it please follow the instructions.

a. Pull the collect ring of the quick change chuck, insert the desired bit into the ¼” seat and

release the ring. The bit is automatically locked into position .

b. Connect the screwdriver plug to a mains supply socket 230v- 50Hz .

c. Put the bit head firmly into the fastener head, position the forward/ reverse selector upside

.

- PUSH AND LEVER COMBINATION FUNCTION (switch on the PL position).

Apply axial pressure through the tool onto the fastener. Then, press the trigger to start

tightening the fastener. When the preset torque is reached, the tool stops automatically.

- PUSH START FUNCTION (switch on the P position) .

Make sure to keep the tool bit straight onto the fastener. Then, push to start tightening

(same as PL function but no need to press the trigger).

IMPORTANT: For each second of operation the motor needs 3 seconds of rest, as

indicated on the tool label (1s/3s). Failure to do so may result in motor overheating and

eventually damage and will be considered as a misuse. Our warranty will not apply.

3. ACCESSORIES

Use only ¼” ISO 1173 bits and power bits.

4. ADJUSTING THE CLUTCH

The torque values is adjusted by changing the tension of the clutch spring. The torque can be

increased by turning nut #811 clockwise and decreased by turning it anticlockwise.

To check the torque value we suggest the use of KOLVER K and miniK torque tester series.

4. MAINTENANCE

The D.C. motor is equipped with two carbon brushes 8mm long. When their lenght is about

5mm it is time to replace them with new ones as per the following instructions.

a. Unscrew cover # M-308 and let the carbon brush come out of its seat.

b. Insert a new carbon brush and screw back cover # M-308.

The average life of carbon brushes is approx 1 milion cycles.

Note

The sound level generated by Kolver electric screwdrivers is always lower than 70dB(A).

The vibrations transmitted to operator’s hand are lower than 2,5m/s². In particular the

exposition to vibrations is lower than 1m/s² for operators who make up to 4200 screwing

cycles per day.

Page 5

GUARANTEE

1. This KOLVER product is guaranteed against defective workmanship or materials,

for a maximum period of 12 months following the date of purchase from

KOLVER, provided that its usage is limited to single shift operation throughout

that period. If the usage rate exceeds of single shift operation, the guarantee period

shall be reduced on a prorata basis.

2. If, during the guarantee period, the product appears to be defective in

workmanship or materials, it should be returned to KOLVER or its distributors,

transport prepaied, together with a short description of the alleged defect.

KOLVER shall, at its sole discretion, arrange to repair or replace free of charge

such items.

3. This guarantee does not cover repair or replacement required as a consequence of

products which have been abused, misused or modified, or which have been

repaired using not original KOLVER spare parts or by not authorized service

personnel.

4. KOLVER accepts no claim for labour or other expenditure made upon defective

products.

5. Any direct, incidental or consequential damages whatsoever arising from any

defect are expressly excluded.

6. This guarantee replaces all other guarantees, or conditions, expressed or implied,

regarding the quality, the marketability or the fitness for any particular purpose.

7. No one, whether an agent, servant or employee of KOLVER, is authorized to add

to or modify the terms of this limited guarantee in any way. However it’s possible

to extend the warranty with an extra cost. Further information at kolver@kolver.it

Loading...

Loading...