Page 1

I/O Terminal

Installation Manual

Revision 1.1, June 2011

AKT-PRB-000-000 PROFIBUS Coupler

Keep all manuals as a product component during the life span of the product.

Pass all manuals to future users / owners of the product.

Page 2

Record of Document Revisions

Revision Remarks

1.0 Preliminary edition

1.1 Added dimensions to technical data table and mechanical drawing to

Appendix B. For more information, see “Technical Data” page 8 and

“Appendix B” page 76.

IMPORTANT NOTICE

Copyright© Kollmorgen™2010–2011. All rights reserved. Kollmorgen holds the copyright to this manual. All rights are

reserved and no part of this publication may be reproduced or transmitted in any form or by any means without prior

written consent from Kollmorgen.

Disclaimer

The information in this manual was accurate and reliable at the time of its release. However, Kollmorgen. reserves

the right to change the specifications of the product described in this manual without notice at any time.

This document contains proprietary and confidential information of Kollmorgen. The contents of the document may

not be disclosed to third parties, translated, copied or duplicated in any form, in whole or in part, without the express

written permission of Kollmorgen.

Registered Trademarks

Kollmorgen is a registered trademark of Danaher Corp.

Technical changes which improve the performance of the device may be made without prior notice! Printed in the

Federal Republic of Germany. All rights reserved. No part of this work may be reproduced in any form (by printing,

photocopying, microfilm or any other method) or stored, processed, copied or distributed by electronic means without

the written permission of Kollmorgen. All other proprietary names mentioned in this manual are the trademarks of

their respective owners.

June 2011

Page 3

Safety Precautions

1

1.1 Safety Rules............................................................................................6

1.2 State at Delivery......................................................................................6

1.3 Personnel Qualification...........................................................................6

1.4 Description of Notes and Warnings ........................................................6

2 Overview

2.1 PROFIBUS Coupler (AKT-PRB-000-000) ..............................................7

2.1.1 Technical Data........................................................................................8

2.2 System Overview....................................................................................9

2.2.1 Bus Terminal System..............................................................................9

2.3 PROFIBUS DP......................................................................................11

2.4 PROFIBUS DPV1 .................................................................................12

3 Mounting and Wiring

3.1 Dimensions ...........................................................................................13

3.2 Installation.............................................................................................14

3.3 Wiring....................................................................................................15

3.3.1 Potential Groups ...................................................................................15

3.3.2 Insulating Testing..................................................................................16

3.3.3 PE Power Contacts...............................................................................16

3.4 Power Supply........................................................................................17

3.4.1 Power Contacts Supply (Up).................................................................18

3.4.2 Power Contacts.....................................................................................18

3.4.3 Configuration and Programming Interface............................................18

3.4.4 Electrical Isolation.................................................................................19

3.5 PROFIBUS Connection ........................................................................19

3.5.1 M12 Circular Connector........................................................................19

3.5.2 Nine Pole D-Sub ...................................................................................20

3.5.3 PROFIBUS Conductor Colors...............................................................20

3.5.4 Connection of Fieldbus Box Modules ...................................................21

3.6 PROFIBUS Cabling...............................................................................21

3.6.1 Cable-Based Transmission...................................................................21

3.6.2 Cabling for Profibus DP and Profibus FMS ..........................................22

3.6.3 Distances ..............................................................................................23

3.6.4 Bus Segments.......................................................................................23

3.6.5 Installation Guidelines...........................................................................23

3.6.6 Checking the Profibus Wiring................................................................24

I/O Terminal / CONTENTS

4 Start-up Behavior of the Bus Coupler

4.1 Self-Test................................................................................................25

5 Automatic Configuration

5.1 Scan Devices........................................................................................26

3

Page 4

Manual Configuration

6

6.1 The Bus Coupler’s UserPrmData..........................................................28

6.2 Configuration.........................................................................................31

6.2.1 Configuration: CfgData .........................................................................31

6.2.2 Configuration of the Coupler Modules ..................................................31

6.2.3 Configuration of Complex Modules.......................................................32

6.3 Cyclic Data Exchange...........................................................................33

6.3.1 Process Data and Image ......................................................................33

6.3.2 Standard-Bus Cycle..............................................................................35

6.4 DPV1 – Acyclic Data Transfer ..............................................................39

6.4.1 DPV1 Interface......................................................................................39

6.4.2 DPV1 at the Coupler.............................................................................41

7 Extended Functions

7.1 2-byte PLC Interface.............................................................................47

7.2 Word Alignment.....................................................................................47

7.3 Deactivating the CfgData Check...........................................................48

7.4 Multi-Configuration Mode......................................................................49

7.4.1 Creating a DP Configuration for Various Implementation Levels.........49

7.4.2 Reserved Bus Terminals.......................................................................49

7.4.3 Assign Bus Terminals to Freely Choose Process Image Addresses...49

7.4.4 Setting the Multi-configuration Mode ....................................................49

7.4.5 Rules for Multi-configuration Mode.......................................................49

7.4.6 Enabling/disabling Bus Terminals.........................................................50

7.5 Changing the Size of the Process Data................................................53

7.5.1 Exceeding the Input Data Length (InputData) ......................................53

7.5.2 Exceeding the Output Data Length (OutputData).................................53

7.5.3 Exceeding the Configuration Data Length (CfgData) ...........................53

I/O Terminal / CONTENTS

8 Error Handling and Diagnosis

8.1 Fieldbus LEDs.......................................................................................55

8.1.1 DIA-LED Blink Codes............................................................................56

8.1.2 Standard-Bus LEDs (Local Errors) .......................................................57

8.2 DP Diagnostic .......................................................................................58

8.2.1 DP Diagnostic Data (DiagData)............................................................58

8.2.2 Errors During DP Start-up.....................................................................62

8.2.3 Reaction to PROFIBUS Error ...............................................................64

8.3 Standard-Bus Diagnostic......................................................................64

8.3.1 Standard-Bus Interruption.....................................................................64

8.3.2 Terminal Diagnostics.............................................................................65

Appendix A

A.1 GSE File................................................................................................67

4

Page 5

Appendix B

B.1 AKT-PRB-000-000 Mechanical Drawing...............................................76

Performance Box Controllers / INTRODUCTION

5

Page 6

1 SAFETY PRECAUTIONS

This chapter provides safety information for the I/O terminal.

1.1 Safety Rules

The appropriate staff must ensure that the application or use of the products described satisfy all

the requirements for safety, including all the relevant laws, regulations, guidelines and stan dards.

1.2 State at Delivery

All the components are supplied in particular hardware and software configurations appropriate

for the application. Modifications to hardware or software configurations other than those

described in the documentation are not permitted, and nullify any liability from Kollmorgen.

1.3 Personnel Qualification

This description is only intended for the use of trained specialists in control and automation

engineering who are familiar with the applicable national standards.

I/O Terminal / SAFETY PRECAUTIONS

1.4 Description of Notes and Warnings

The following notes and warnings are used in this manual. They are intended to alert the reader

to the associated safety instructions.

Danger — This note is intended to highlight risks for the life or health of personnel.

Warning — This note is intended to highlight risks for equipment, materials or the environment.

Note — Indicates information that contributes to better understanding.

6

Page 7

2 OVERVIEW

This section provides an overview of the PROFIBUS Coupler.

Note: For information about configuring the PROFIBUS Coupler, see the Kollmorgen Automation

Suite™ IDE software and online help system.

2.1 PROFIBUS Coupler (AKT-PRB-000-000)

The Bus Coupler connects the PROFIBUS system to the electronic terminal blocks, which can be

extended in modular fashion. One unit consists of the Bus Coupler, any number of up to 64

terminals and one end terminal. Up to 64 digital input/output terminals can be connected.

The Bus Coupler recognizes the connected terminals and automatically genera tes the affiliations

of the inputs/outputs to the bytes of the process image. The first input/output signal is inserted in

the first bit of one byte (LSB), beginning from the left. The Bus Coupler inserts further signals in

this byte. Inputs and outputs are clearly separated. The Bus Coupler automatically begins a

further byte if the number of inputs or outputs exceeds 8 bits.

The Bus Coupler supports the operation of all Bus Terminals. As far as the user is concerned,

handling of the analog inputs/outputs is not different to other series. The information is available

in the process image of the controller for processing in the form of a byte array.

I/O Terminal / OVERVIEW

The Bus Terminals can be controlled by the control system. Via function blocks (FBs), the

programmable logic controller (PLC) or the handles configuration of the complete periphery

during the start up phase. If required, the controller can upload the de-centrally created

configuration data in order to centrally manage and store this data. Therefore, new adjustments

are not necessary in the event of replacement of a Bus Terminal. The controller automatically

sets the required setting on power up.

Figure 2.1 PROFIBUS Coupler (Front View)

7

Page 8

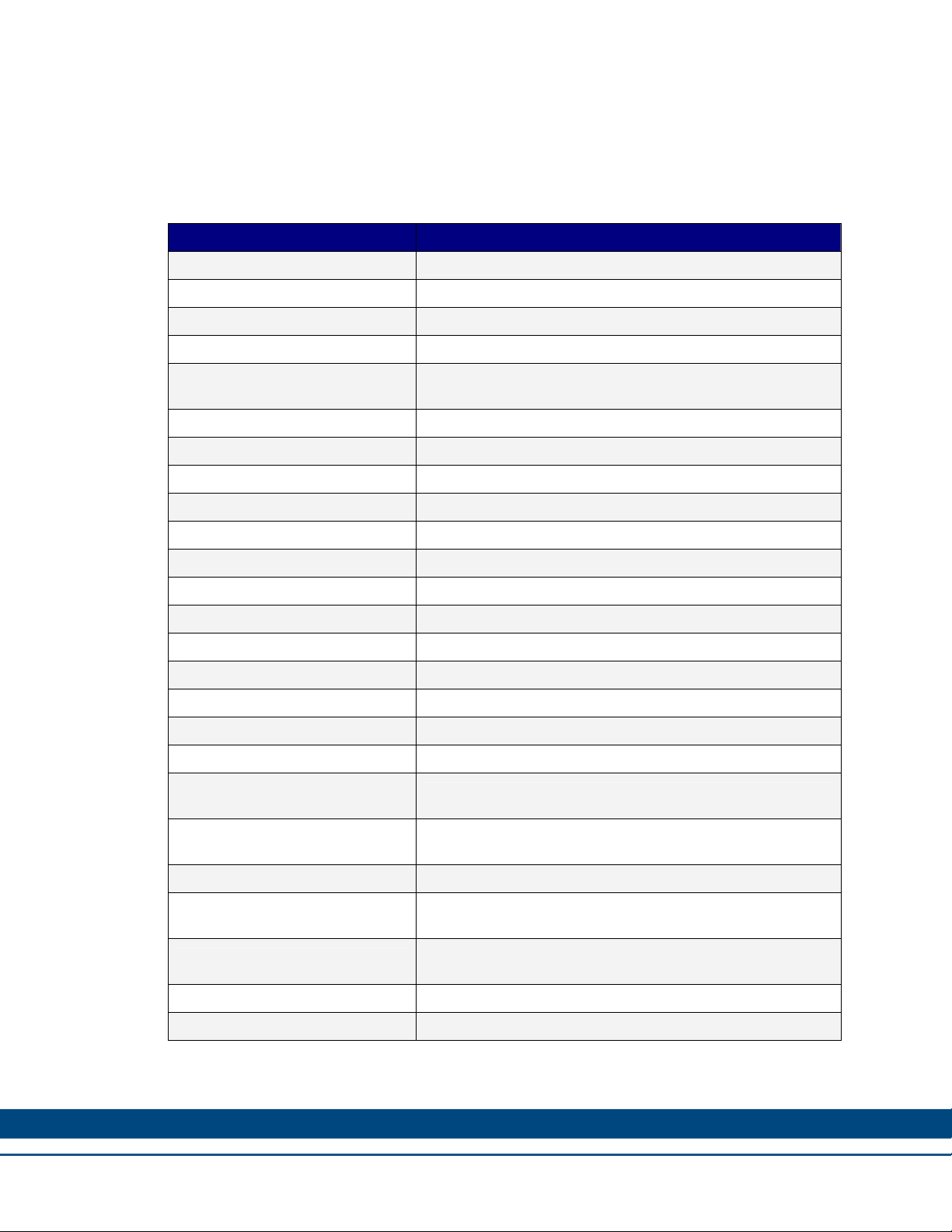

2.1.1 Technical Data

This section provides the technical details for the ETHERCAT Coupler.

Parameters (AKT-PRB-000-000)

Number of Bus Terminals 64

Digital peripheral signals 512 inputs/outputs

Analog peripheral signals 128 inputs/outputs

Configuration possibility IDE software or controller

I/O Terminal / OVERVIEW

Maximum number of bytes

64 bytes (DP and FMS operation)

128 bytes (DP operation only)

Baud rate (automatic detection) Up to max. 12 MBaud

Bus connection 1 x D-sub plug, 9-pin with shielding

Power supply 24 VDC (-15 % /+20 %)

Input current 70 mA + (total Standard-Bus current)/4, max. 500 mA

Starting current 2.5 x continuous current

Standard-Bus current up to 1750 mA (BK3x00)

Power contact voltage (Up) Maximum 24 VDC

Power contact current load (Up) Maximum 10 A

Recommended fuse (Up) Maximum 10 A

Electrical isolation Power contact / supply / fieldbus

Dielectric strength 500 V

(power contact / supply / fieldbus)

rms

Dimensions (H × W ) 100 × 51 mm

Weight ~150 g

Permissible ambient temperature

(operation)

0 °C … +55 °C

Permissible ambient temperature

(storage)

-25 °C … +85 °C

Permissible relative humidity 95 % (no condensation)

Vibration / shock resistance

EMC resistance Burst / ESD

According to EN 60068-2-6 / EN 60068-2-27,

EN 60068-2-29

According to EN 61000-6-2 (EN 50082) /

EN 61000-6-4 (EN 50081)

Protection class IP 20

Installation position Variable

8

Page 9

2.2 System Overview

This section provides a system overview for the PROFIBUS Coupler.

2.2.1 Bus Terminal System

Up to 64 Bus Terminals each having 2 I/O Channels for each Signal Form

The Bus Terminal system is the universal interface between a fieldbus system and the

sensor / actuator level. A unit consists of a Bus Coupler as the head station, and up to 64

electronic series terminals, the last one being an end terminal. For each technical signal form,

terminals are available each having two I/O channels, and these can be mixed in any order. All

the terminal types have the same mechanical construction, so that difficulties of planning and

design are minimized. The height and depth match the dimensions of compact terminal boxes.

Decentralized Wiring of Each I/O Level

Fieldbus technology allows more compact forms of controller to be used. The I/O level does not

have to be brought to the controller. The sensors and actuators can be wired de-centrally, using

minimum cable lengths. The controller can be installed at any location within the plant.

Programmable Automation Controllers (PAC)

I/O Terminal / OVERVIEW

The use of a PAC as the controller means that the operating and observing element can be

implemented in the controller’s hardware. The controller can therefore be located at an operating

panel, in a control room, or at some similar place. The Bus Terminals form the decentralized

input/output level of the controller in the control cabinet and the subsidiary terminal boxes. The

power sector of the plant is also controlled over the bus system in addition to the sensor/actuator

level. The Bus Terminal replaces the conventional series terminal as the wiring level in the control

cabinet. The control cabinet can have smaller dimensions.

Bus Couplers for all Usual Bus Systems

The Bus Terminal system unites the advantages of a bus system with the possibilities of the

compact series terminal. Bus Terminals can be driven within all the usual bus systems, thus

reducing the controller parts count. The Bus Terminals then behave like conventional connections

for that bus system. All the performance features of the particular bus system are supported.

Assembly on Standardized C Mounting Rails

The easy, space-saving, assembly on a standardized C-rail, and the direct wiring of actuators and

sensors, without cross-connections between the terminals, standardizes the installation. The

consistent labeling scheme also contributes.

The small physical size and the great flexibility of the Bus Terminal system allow it to be used

wherever a series terminal is also used. Every type of connection, such as analog, digital, serial

or the direct connection of sensors can be implemented.

9

Page 10

I/O Terminal / OVERVIEW

Modularity

The modular assembly of the terminal strip with Bus Terminals of various functi ons limits the

number of unused channels to a maximum of one per function. The presence of two channels in

one terminal is the optimum compromise of unused channels and the cost of each channel. The

possibility of electrical isolation through potential feed terminals also helps to keep the number of

unused channels low.

Display of the Channel State

The integrated LEDs show the state of the channel at a location close to the sensors and

actuators.

Standard-Bus

The Standard-Bus is the data path within a terminal strip. The Standard--Bus is led through from

the Bus Coupler through all the terminals via six contacts on the terminals’ side walls. The end

terminal terminates the Standard-Bus. The user does not have to learn anything about the

function of the Standard-Bus or about the internal workings of the terminals and the Bus Coupler.

Many software tools that can be supplied make project planning, configuration and operation

easy.

Potential Feed Terminals for Isolated Groups

The operating voltage is passed on to following terminals via three power contacts. You can

divide the terminal strip into arbitrary isolated groups by means of potential feed terminals. The

potential feed terminals play no part in the control of the terminals, and can be inserted at any

locations within the terminal strip.

Up to 64 terminals can be used within one terminal strip. This count does include potential feed

terminals, but not the end terminal.

Bus Couplers for Various Fieldbus Systems

Various Bus Couplers can be used to couple the electronic terminal strip quickly and easily to

different fieldbus systems. It is also possible to convert to another fieldbus system at a later time.

The bus coupler performs all the monitoring and control tasks that are necessary for operation of

the connected Bus Terminals. The operation and configuration of the Bus Terminals is carried out

exclusively by the Bus Coupler. Nevertheless, the parameters that have been set are stored in

each Bus Terminal, and are retained in the event of voltage drop-out. Fieldbus, Standard--Bus

and I/O level are electrically isolated.

If the exchange of data over the fieldbus is prone to errors or fails for a period of time, register

contents (such as counter states) are retained, digital outputs are cleared, and analog outputs

take a value that can be configured for each output when commissioning. The default setting for

analog outputs is 0 V or 0 mA. Digital outputs return in the inactive state. The timeout periods for

the Bus Couplers correspond to the usual settings for the fieldbus system. When conve rting to a

different bus system it is necessary to bear in mind the need to change the timeout periods if the

bus cycle time is longer.

The Interfaces

A Bus Coupler has six different methods of connection. These interfaces are designed as plug

connectors and as spring-loaded terminals.

10

Page 11

2.3 PROFIBUS DP

In PROFIBUS DP systems, a master (PLC, PC etc.) usually communicates with a large number

of slaves (I/Os, drives etc.). Only the master may here actively access the bus (send telegrams

on its own initiative), while a DP slave only sends telegrams when it is requested to do so by a

master.

DP StartUp

Before the master and slave can cyclically exchange data, the parameter and configuration data

is transmitted from the master to the slaves during the DP StartUp phase. After the parameter

and configuration data has been sent, the master interrogates the slave's diagnostic data until the

slave indicates that it is ready for data exchange. Depending on the extent of the calculations that

the slave must carry out after receiving the parameter and configuration data, it can take up to a

few seconds before it is ready for data exchange. For this reason the slave possesses the

following states:

Parameter Data

The parameter data is sent from the master to the slave in the SetPrmLock request telegram. The

SetPrmLock response telegram does not contain any data, and therefore consists of a singl e

byte, the short acknowledgement. The parameter data consists of DP parameters (e.g. the setting

of the DP watchdog or checking the IdentNumber (unique to each DP device)), of DPV1-/DPV2

parameters and of application-specific parameters that only have to be transmitted once during

the StartUp. If an error is found in the parameter data, this is indicated in the diagnostic data, and

the slave either remains in or enters the WAIT-PRM state.

I/O Terminal / OVERVIEW

Configuration Data

The configuration data is sent from the master to the slave in the ChkCfg request telegram. The

ChkCfg response telegram does not contain any data, and therefore consists of a single byte, the

short acknowledgement. The configuration data describes the assignment of the DP modules to

the cyclic I/O data that is to be exchanged between the master and slave via the Data_Exchange

telegram in the cyclic data exchange phase. The sequence of the DP modules added to a slave

in the DP configuration tool determines the sequence of the associated I/O data in the

Data_Exchange telegram.

Diagnostic data

The diagnostic data is requested by the master using a SlaveDiag request telegram without any

data. The slave replies with the diagnostic data in a SlaveDiag response telegram. The diagnostic

data consists of the standard DP diagnostics (e.g. the state of the slave, the IdentNumber) and of

application-specific diagnostic data.

Cyclic Data Exchange

The heart of the PROFIBUS DP protocol is cyclic data exchange, during which the master carries

out an exchange of I/O data with every slave during a PROFIBUS DP cycle. This involves the

master sending the outputs to each slave with a DataExchange request telegram, while the slave

replies with the inputs in a DataExchange response telegram. This means that all the output

and/or input data is transmitted in one telegram, in which the DP configuration (the sequence of

DP modules) specifies the assignment of the output and/or input data to the slave's actual

process data.

11

Page 12

I/O Terminal / OVERVIEW

Diagnosis During Cyclic Data Exchange

A slave can send a diagnostics signal to the master during cyclic data exchange. In this case, the

slave sets a flag in the DataExchange response telegram, whereby the master recognizes that

there is new diagnostic data in the slave. It then fetches that data in the SlaveDiag telegram. This

means that diagnostic data is not transmitted to the controller with the cyclic I/O data in real-time,

but is always at least one DP cycle later.

Synchronization with Sync and Freeze

The Sync and Freeze commands in the GlobalControl request telegram (b roadcast telegram)

allow the master to synchronize the activation of the outputs (Sync) or the reading of the inputs

(Freeze) in a number of slaves. When the Sync command is used, the slaves are first switched

into Sync mode (a process that is acknowledged in the diagnostic data). The I/O data is then

exchanged sequentially with the slaves in the DataExchange telegram. Transmitting the Sync

command in the GlobalControl telegram then has the effect of causing the slaves to generate the

most recently received outputs. In Freeze operation a Freeze command is first sent in the

GlobalControl telegram, in response to which all the slaves latch their inputs. These are then

fetched sequentially by the master in the DataExchange telegram.

States in the Master

The master distinguishes between the CLEAR state (all outputs are set to the Fail_Safe value)

and the OPERATE state (all outputs have the process value). The Master is usually switched into

the CLEAR mode when, for instance, the PLC enters STOP.

Class 1 and Class 2 DP Masters

The Class 1 master refers to the controller that carries out cyclic I/O data exchange with the

slaves, while a Class 2 master is a B&B device that generally only has read access to the slaves'

I/O data.

2.4 PROFIBUS DPV1

PROFIBUS DPV1 refers primarily to the acyclic read and write telegrams, with which data sets in

the slave are cyclically accessed. A distinction between a Class 1 and a Class 2 master is also

made for DPV1. The difference between acyclic Class 1 (C1) and Class 2 (C2) connections is

that the acyclic C1 connection is established during the DP StartUp phase of cyclic DP operati on.

Once the slave has reached the WAIT-CFG state it is possible for acyclic DPV1-C1 read and

write telegrams to be sent from the master to the slave, whereas the C2 connection is established

separately, independently of the cyclic DP connection. This is usually carried out by a second

(C2) master so that, for instance, a manufacturer-specific project configuration and diagnostic tool

can access the slave's data.

When two masters are used, however, is must always be borne in mind that these share bus

access (a token is exchanged), so that time relationships are less favorable than in the case of a

single master system.

12

Page 13

3 MOUNTING AND WIRING

This section provides mounting and wiring information for the PROFIBUS Coupler.

Note: For information about configuring the PROFIBUS Coupler, see the Kollmorgen Automation

Suite™ IDE software and online help system.

3.1 Dimensions

The system of the Bus Terminals is characterized by low physical volume and high modularity.

When planning a project it must be assumed that at least one Bus Coupler and a number of Bus

Terminals will be used. The mechanical dimensions of the Bus Couplers are independent of the

fieldbus system.

I/O Terminal / MOUNTING AND WIRING

The total width in practical cases is composed of the width of the Bus Coupler with the Bus End

Terminal and the width of the Bus Terminals in use. Depending on function, the Bus Terminals

are 12 or 24 mm wide. The front wiring increases the total height of 68 mm by about 5 to 10 mm,

depending on the wire thickness.

13

Page 14

3.2 Installation

The Bus Coupler and all the Bus Terminals can be clipped, with a light press, onto a 35 mm

mounting rail. A locking mechanism prevents the individual housings from bei ng pulled off again.

For removal from the mounting rail the orange colored tension strap releases the latching

mechanism, allowing the housing to be pulled off the rail without any force.

I/O Terminal / MOUNTING AND WIRING

Up to 64 Bus Terminals can be attached to the Bus Coupler on the right hand side. When

plugging the components together, be sure to assemble the housings with gro ove and tongue

against each other. A properly working connection can not be made by pushing the housings

together on the mounting rail. When correctly assembled, no significant gap can be seen bet ween

the attached housings.

WARNING!! Insertion and removal of Bus Terminals is only permitted when switched off. The

electronics in the Bus Terminals and in the Bus Coupler are protected to a large

measure against damage, but incorrect function and damage cannot be ruled out

if they are plugged in under power.

14

Page 15

I/O Terminal / MOUNTING AND WIRING

The right hand part of the Bus Coupler can be compared to a Bus Terminal. Eight connections at

the top enable the connection with solid or fine wires from 0.08 mm² to 2.5 mm². The connection

is implemented with the aid of a spring device. The spring-loaded terminal is opened with a

screwdriver or rod, by exerting gentle pressure in the opening above the terminal. The wire can

be inserted into the terminal without any force. The terminal closes automatically when the

pressure is released, holding the wire securely and permanently.

3.3 Wiring

The section provides potential groups, insulation testing, and PE information for the

PROFIBUS Coupler.

3.3.1 Potential Groups

The Bus Terminals stations usually have three different potential groups:

The fieldbus interface is electrically isolated (except for individual Low Cost cou plers) and

forms the first potential group

Bus Coupler / Bus Terminal Controller logic, Standard-Bus a nd terminal logic form a

second galvanically separated potential group

The inputs and outputs are supplied via the power contacts and form further potential

groups.

Groups of I/O terminals can be consolidated to further potential groups via potential supply

terminals or separation terminals.

15

Page 16

3.3.2 Insulating Testing

The connection between the Bus Coupler / Bus Terminal Controller and the Bus Terminals is

automatically realized by pushing the components together. The transfer of the data and the

supply voltage for the intelligent electronics in the Bus Terminals is performed by the

Standard-Bus. The supply of the field electronics is performed through the power contacts.

Plugging together the power contacts creates a supply rail. Since some Bus Terminals (e.g.

analog Bus Terminals or 4-channel digital Bus Terminals) are not looped through these

power contacts (or not completely) the Bus Terminal contact assignments must be

considered.

The potential feed terminals interrupt the power contacts, and represent the start of a new

supply rail. The Bus Coupler / Bus Terminal Controller can also be made use of to feed the

power contacts.

3.3.3 PE Power Contacts

The power contact labeled PE can be used as a protective earth. For safety reasons this

contact mates first when plugging together, and can ground short-circuit currents of up to 125

A.

I/O Terminal / MOUNTING AND WIRING

It should be noted that, for reasons of electromagnetic compatibility, the PE contacts are

capacitively coupled to the mounting rail. This can both lead to misleading results and to

damaging the terminal during insulation testing (e.g. breakdown of the insulation from a 230

V power consuming device to the PE conductor). The PE conductor to the Bus Coupler / Bus

Terminal Controller must be disconnected for the insulation testing. In order to uncouple

further feed locations for the purposes of testing, the feed terminals can be pulled at least 10

mm out from the connected group of other terminals. In that case, the PE conductors do not

have to be disconnected.

The PE power contact must not be used for other potentials.

16

Page 17

3.4 Power Supply

The Bus Coupler / Bus Terminal Controller require a 24 VDC supply for their operation.

The connection is made by means of the upper spring-loaded terminals labeled 24 V and 0 V.

This supply voltage feeds the Bus Coupler / Bus Terminal Controller electronics and, over the

Standard-Bus, the electronics of the Bus Terminals. It is electrically separated from the

potential of the field level.

I/O Terminal / MOUNTING AND WIRING

DANGER!! For the compliance of the UL requirements Us should only be supplied:

By a 24 VDC supply voltage, supplied by an isolating source and protected by means of

a fuse (in accordance with UL248), rated maximum 4 Amp.

By a 24 VDC power source, that has to satisfy NEC class 2.

A NEC class 2 power supply shall not be connected in series or parallel with another

(class 2) power source!

17

Page 18

3.4.1 Power Contacts Supply (Up)

The bottom six connections with spring-loaded terminals can be used to feed the supply for the

peripherals. The spring-loaded terminals are joined in pairs to a power contact. The feed for the

power contacts has no connection to the voltage supply for the Bus Coupler / Bus Terminal

Controller.

The spring-loaded terminals are designed for wires with cross-sections between 0.08 mm² and

2.5 mm².

The assignment in pairs and the electrical connection between feed terminal contacts allows the

connection wires to be looped through to various terminal points. The current drawn from the

power contact must not exceed 10 A for long periods. The current carrying capacity between two

spring-loaded terminals is identical to that of the connecting wires.

3.4.2 Power Contacts

On the right hand face of the Bus Coupler / Bus Terminal Controller there are three spring

contacts for the power contact connections. The spring contacts a re hidd en in slots so that they

can not be accidentally touched. By attaching a Bus Terminal the blade contacts on the left hand

side of the Bus Terminal are connected to the spring contacts. The tongue and groove guides on

the top and bottom of the Bus Coupler / Bus Terminal Controller and of the Bus Terminals

enables that the power contacts mate securely.

I/O Terminal / MOUNTING AND WIRING

3.4.3 Configuration and Programming Interface

The Bus Coupler / Bus Terminal Controller have an RS232 interface at the bottom of the front

face. The miniature connector can be joined to a PC IDE software with the aid of a connecting

cable. The interface permits the Bus Terminals to be configured, for example adjusting the

amplification factors of the analog channels. The interface can also be used to change the

assignments of the bus terminal data to the process image in the Bus Coupler. The functionality

of the configuration interface can also be reached via the fieldbus using string communication

facility.

18

Page 19

3.4.4 Electrical Isolation

The Bus Coupler / Bus Terminal Controller operate by means of three independent potential

groups. The supply voltage feeds the Standard-Bus electronics and the Standard-Bus itself. The

supply voltage is also used to generate the operating voltage for the fieldbus interface.

Remark: All the Bus Terminals are electrically isolated from the Standard-Bus. The Standard-Bus

is thus electrically isolated from everything else.

I/O Terminal / MOUNTING AND WIRING

3.5 PROFIBUS Connection

This section provides information about the PROFIBUS connection for the PROFIBUS

Coupler.

3.5.1 M12 Circular Connector

The M12 socket is inverse coded, and has five pins. Pin 1 is 5 VDC and 3 is GND for the

active termination resistor. These must never be misused for other functions, as this can lead

to destruction of the device. Pin 2 and pin 4 are the Profibus signals. These must never be

swapped over, as this will prevent communication. Pin 5 is the shield, and this is

capacitatively coupled to the Fieldbus Box chassis.

M12 Socket Pin Assignment

19

Page 20

3.5.2 Nine Pole D-Sub

Pin 6 is 5 VDC und Pin 5 is GND for the active termination resistor. These must never be

misused for other functions, as this can lead to destruction of the device. Pin 3 and pin 8 are

the Profibus signals. These must never be swapped over, as this will prevent communication.

Shield is connected to the D-Sub housing that is coupled with low-resistance to the mounting

rail.

D-Sub Socket Assignment

3.5.3 PROFIBUS Conductor Colors

I/O Terminal / MOUNTING AND WIRING

PROFIBUS

Conductors

B Red Pin 4 Pin 3

A Green Pin 2 Pin 8

M12 D-Sub

20

Page 21

3.5.4 Connection of Fieldbus Box Modules

The connection of the Fieldbus Box modules is done direct or via a T-piece (or Y-piece).

The B318 series does have a male and female connector, that means no external T-piece is

required. The supply voltage (+5VDC) for the termination resistor is only supplied via the

female M12 connector. The termination resistor is only available with male connector,

therefore the incoming PROFIBUS line should end in a female connector.

I/O Terminal / MOUNTING AND WIRING

Two T-pieces are available:

+5VDC on male and female connector for the termination resistor

+5VDC only on the female connector

3.6 PROFIBUS Cabling

Physical aspects of the data transmission are defined in the Profibus standard (see Profibus

layer 1: Physical Layer).

The types of area where a fieldbus system can be used is largely determined by the choice of

the transmission medium and the physical bus interface. In addition to the requirements for

transmission security, the expense and work involved in acquiring and installing the bus cable

is of crucial significance. The Profibus standard therefore allows for a variety of

implementations of the transmission technology while retaining a uniform bus protocol.

3.6.1 Cable-Based Transmission

This version, which accords with the American EIA RS-485 standard, was specified as a

basic version for applications in production engineering, building management and drive

technology. A twisted copper cable with one pair of conductors is used. Depending on the

intended application area (EMC aspects should be considered) the screening may be

omitted.

21

Page 22

I/O Terminal / MOUNTING AND WIRING

Two types of conductor are available, with differing maximum conductor lengths (see the RS485 table).

RS485 - Fundamental Properties

RS-485 Transmission According to the Profibus Standard

Network topology

Medium

Number of stations

Maximum bus length

without repeater

Maximum bus length with

repeater

Transmission speed

(adjustable in steps)

Plug connector

Linear bus, active bus terminator at both ends, stubs are

possible.

Screened twisted cable, screening may be omitted,

depending upon the environmental conditions (EMC).

32 stations in each segment with no repeater. Can be

extended to 127 stations with repeater

100 m at 12 MBit/s

200 m at 1500 KBit/s, up to 1.2 km at 93.75 KBit/s

Line amplifiers, or repeaters, can increase the bus length up

to 10 km. The number of repeaters possible is at least 3, and,

depending on the manufacturer, may be up to 10.

9.6 kBit/s; 19.2 kBit/s; 93.75 kBit/s; 187.5 kBit/s; 500 kBit/s;

1500 kBit/s; 12 MBit/s

9-pin D-Sub connector for IP20

M12 round connector for IP65/67

3.6.2 Cabling for Profibus DP and Profibus FMS

Note the special requirements on the data cable for baud rates greater than 1.5 MBaud. The

correct cable is a basic requirement for correct operation of the bus system. If a simple 1.5

Mbaud cable is used, reflections and excessive attenuation can lead to some surprisi ng

phenomena. It is possible, for instance, for a connected Profibus station not to achieve a

connection, but for it to be included again when the neighboring station is disco nnected. Or

there may be transmission errors when a specific bit pattern is transmitted. The result of this

can be that when the equipment is not operating, Profibus works without faults, but that there

are apparently random bus errors after start-up. Reducing the baud rate (< 93,75 kBaud)

corrects this faulty behavior.

If reducing the baud rate does not correct the error, then in many cases this can indicate a

wiring fault. The two data lines maybe crossed over at one or more connectors, or the

termination resistors may not be active, or they may be active at the wrong locations.

Note: Installation is made a great deal more straightforward if pre-assembled cables are

used! Wiring errors are avoided, and commissioning is more rapidly completed. The range

includes fieldbus cables, power supply cables, sensor cables and accessories such as

terminating resistors and T-pieces. Connectors and cables for field assembly are

nevertheless also available.

22

Page 23

Note: In systems with more than two stations all devices are wired in parallel. It is essential

that the bus cables are terminated with resistors at the conductor ends in order to avoid

reflections and associated transmission problems.

3.6.3 Distances

The bus cable is specified in EN 50170. This yields the following lengths for a bus segment.

I/O Terminal / MOUNTING AND WIRING

Baud Rate in kbits/sec 9.6 19.2 93.75 187.5 500 1500 12000

Cable length in m 1200 1200 1200 1000 400 200 100

Stubs up to 1500 kbaud <6.6 m; at 12 Mbaud stub segments should not be used.

3.6.4 Bus Segments

A bus segment consists of at most 32 devices. 126 devices are permitted in a Profibus

network. Repeaters are required to refresh the signal in order to achieve this number. Each

repeater is counted as one device.

IP-Link is the subsidiary bus system for Fieldbus Boxes, whose topology is a ring structure.

There is an IP master in the coupler modules to which up to 120 extension modules may be

connected. The distance between two modules may not exceed 5 m. When planning and

installing the modules, remember that because of the ring structure the IP-Link master must

be connected again to the last module.

3.6.5 Installation Guidelines

When assembling the modules and laying the cables, observe the technical guidelines

provided by the Profibus User Organization for Profibus DP/FMS (see www.profibus.com).

23

Page 24

3.6.6 Checking the Profibus Wiring

A Profibus cable (or a cable segment when using repeaters) can be chec ked with a few

simple resistance measurements. The cable should meanwhile be removed from all stations:

1. Resistance between A and B at the start of the lead: approx. 110 Ohm

2. Resistance between A and B at the end of the lead: approx. 110 Ohm

3. Resistance between A at the start and A at the end of the lead: approx. 0 Ohm

4. Resistance between B at the start and B at the end of the lead: approx. 0 Ohm

5. Resistance between screen at the start and screen at the end of the lead: approx. 0

Ohm

If these measurements are successful, the cable is okay. If, in spite of this, bus malfunctions

still occur, this is usually a result of EMC interference. Observe the installation notes from the

Profibus User Organization (www.profibus.com

I/O Terminal / MOUNTING AND WIRING

).

24

Loading...

Loading...