Page 1

I/O Terminal

Installation Manual

Revision 1.1, June 2011

AKT-ENC-000-000 Incremental Encoder Inputs

Keep all manuals as a product component during the life span of the product.

Pass all manuals to future users / owners of the product.

Page 2

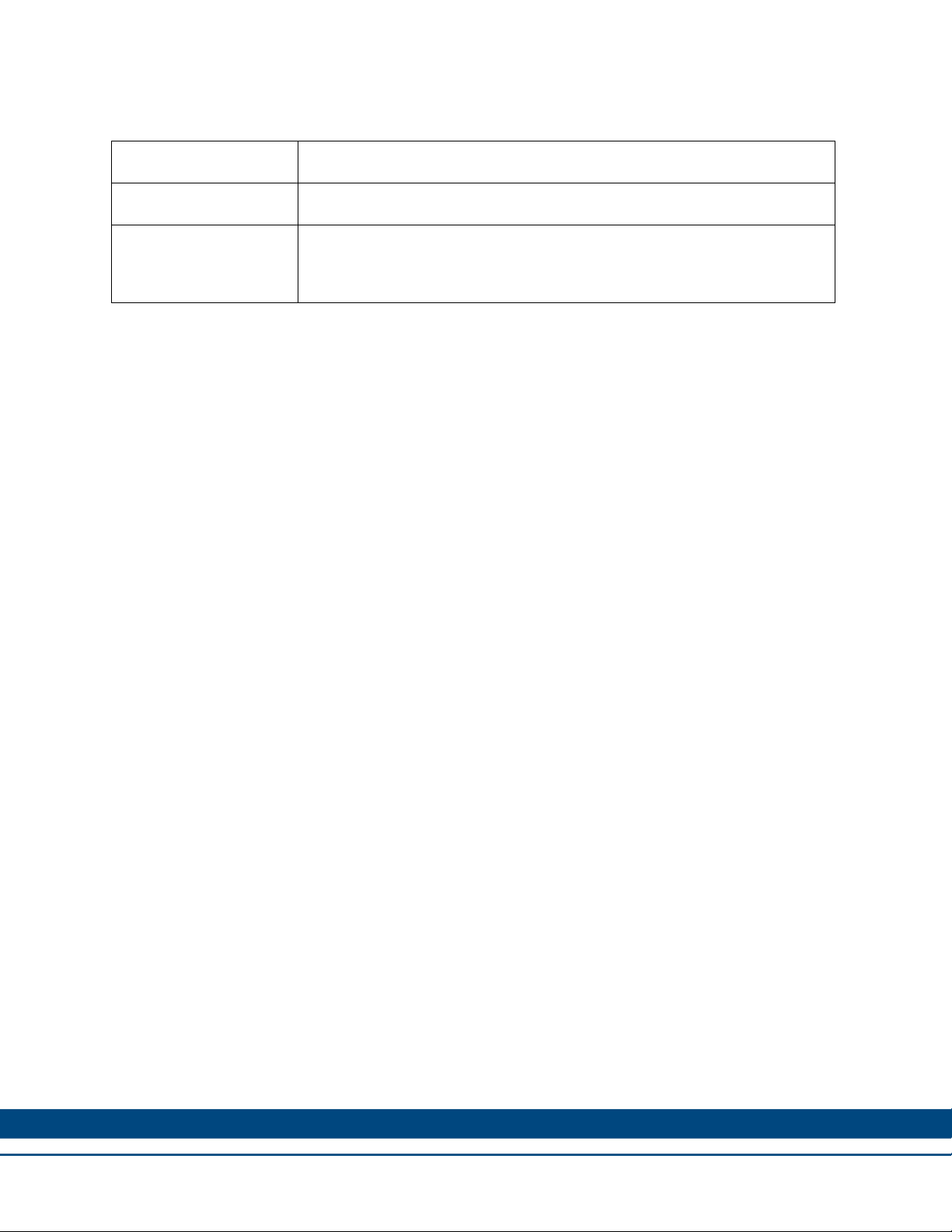

Record of Document Revisions

Revision Remarks

1.0 Preliminary edition

1.1 Added dimensions to technical data table and mechanical drawing to

Appendix A. For more information, see “Technical Data” page 8 and

“Appendix A” page28 .

IMPORTANT NOTICE

Copyright© Kollmorgen™2010-2011. All rights reserved. Kollmorgen holds the copyright to this manual. All rights are

reserved and no part of this publication may be reproduced or transmitted in any form or by any means without prior

written consent from Kollmorgen.

Disclaimer

The information in this manual was accurate and reliable at the time of its release. However, Kollmorgen. reserves

the right to change the specifications of the product described in this manual without notice at any time.

This document contains proprietary and confidential information of Kollmorgen. The contents of the document may

not be disclosed to third parties, translated, copied or duplicated in any form, in whole or in part, without the express

written permission of Kollmorgen.

Registered Trademarks

Kollmorgen is a registered trademark of Danaher Corp.

Technical changes which improve the performance of the device may be made without prior notice! Printed in the

Federal Republic of Germany. All rights reserved. No part of this work may be reproduced in any form (by printing,

photocopying, microfilm or any other method) or stored, processed, copied or distributed by electronic means without

the written permission of Kollmorgen. All other proprietary names mentioned in this manual are the trademarks of

their respective owners.

June 2011

Page 3

1

Safety Precautions

1.1 Safety Rules............................................................................................5

1.2 State at Delivery......................................................................................5

1.3 Personnel Qualification...........................................................................5

1.4 Description of Notes and Warnings ........................................................5

2 Overview

2.1 AKT-ENC-000-000 Incremental Encoder Inputs.....................................6

2.1.1 Technical Data........................................................................................8

2.1.2 Assignments of Terminal Contact...........................................................9

2.1.3 Operating Modes...................................................................................10

2.1.4 Functions...............................................................................................10

2.1.5 LED Display ..........................................................................................11

2.1.6 Process Data.........................................................................................11

3 Mounting and Wiring

3.1 Installation of Bus Terminals on Mounting Rails...................................12

3.1.1 Assembly...............................................................................................12

3.1.2 Disassembly..........................................................................................12

3.1.3 Connections Within a Bus Terminal Block............................................12

3.1.4 PE Power Contact.................................................................................13

3.1.5 Wiring....................................................................................................13

3.2 AKT-ENC-000-000 Connections...........................................................14

I/O Terminal / CONTENTS

4 Automatic Configuration

4.1 Scan Device..........................................................................................15

4.2 Setting I/O Values.................................................................................15

5 Manual Configuration

5.1 Mapping in the Bus Coupler..................................................................17

5.2 Control and Status Byte........................................................................18

5.2.1 Control Byte in Process Transfer..........................................................18

5.2.2 Status Byte in Process Data Transfer...................................................20

5.3 Register Overview.................................................................................21

5.4 Register Description..............................................................................22

5.4.1 General Register Description................................................................22

5.4.2 Process Variable...................................................................................22

5.4.3 Type Registers......................................................................................23

5.4.4 Manufacturer Parameters.....................................................................24

5.4.5 User Parameters...................................................................................24

5.4.6 Extended Application Region................................................................25

5.5 Terminal-Specific Register Description.................................................25

5.5.1 Application Parameters.........................................................................25

5.6 Register Communication.......................................................................26

3

Page 4

5.6.1

Appendix A

A.1 I/O 12.0mm Mechanical Drawing..........................................................28

Graphic Operator Terminal / CONTENTS

Control Byte in Register Mode..............................................................26

4

Page 5

1 SAFETY PRECAUTIONS

This chapter provides safety information for the I/O terminal.

1.1 Safety Rules

The appropriate staff must ensure that the application or use of the products described satisfy all

the requirements for safety, including all the relevant laws, regulations, guidelines and stan dards.

1.2 State at Delivery

All the components are supplied in particular hardware and software configurations appropriate

for the application. Modifications to hardware or software configurations other than those

described in the documentation are not permitted, and nullify any liability from Kollmorgen.

1.3 Personnel Qualification

This description is only intended for the use of trained specialists in control and automation

engineering who are familiar with the applicable national standards.

I/O Terminal / SAFETY PRECAUTIONS

1.4 Description of Notes and Warnings

The following notes and warnings are used in this manual. They are intended to alert the reader

to the associated safety instructions.

Danger — This note is intended to highlight risks for the life or health of personnel.

Warning — This note is intended to highlight risks for equipment, materials or the environment.

Note — Indicates information that contributes to better understanding.

5

Page 6

2 OVERVIEW

This section provides an overview of the I/O terminal.

Note: For information about configuring the I/O terminal, see the Kollmorgen Automation Suite™

IDE software and online help system.

2.1 AKT-ENC-000-000 Incremental Encoder Inputs

The incremental encoder interface terminal enables the connection of any incremental encoders

to the bus coupler or the PLC. A 16-bit counter with a quadrature decoder and a 16-bit latch can

be read, set or activated. Besides the decoder inputs A, B, C, an additional latch input G1 (24 V)

and a gate input G2 (24 V) for disabling the counter are available.

The 16-bit up / down counter mode can also be selected. In this mode of operation, input B is the

counting input.

1-fold, 2-fold or 4-fold evaluation of the encoder signals A, B, C in simple or complementary form

can be parameterized via the field bus.

The terminal is supplied as a 4-fold quadrature decoder with complementary evaluation of the

encoder signals A, B, C. For operation of the encoder interface, the operating voltage of 24 V DC

must be connected to the terminal contacts in addition to the encoder inputs.

I/O Terminal / OVERVIEW

Additional features include:

The incremental encoder with fault alarm outputs can be connected to the Status input of the

AKT-ENC-000-000.

A period measurement with a resolution of 200 ns can also be performed.

6

Page 7

I/O Terminal / OVERVIEW

Figure 2.1 Top View and Contact Assembly

7

Page 8

2.1.1 Technical Data

This section provides the technical details for the 2-channel thermocouple module.

Parameters AKT-ENC-000-000

I/O Terminal / OVERVIEW

Sensor connection

Sensor operating voltage 5 V DC

Sensor output current 0.5 A

Counter 16 bits binary

Cut off frequency 1 MHz (at 4 time evaluation)

Quadrature decoder 1-2-4 time evaluation

Zero pulse latch 16 bits

Commands Read, set, activate

Supply voltage 24 V DC (20 V ... 29 V)

Current consumption from

power contacts

Bit width in the process image I/O: 2 x 16 bits data, 1 x 8 bits control/status

Current consumption from

Standard-Bus

Weight ~85 g

Dimensions (W x H) ~12 mm x 100 mm

Permissible ambient

temperature range during

operation

A, A(inv), B, B(inv), zero, zero(inv),

difference signal (RS 485); Status input

0.1 A (without sensor load current)

25 mA

0°C ... +55°C

Permissible ambient

temperature range during

storage

Relative humidity 95%, no condensation

Vibration / Shock resistance

EMC resistance burst / ESD Conforms to EN 61000-6-2 / EN 61000-6-4

Installation position Any

Type of protection IP20

-25°C ... +85°C

Conforms to EN 60068-2-6 / EN 60068-2-27,

EN 60068-2-29

8

Page 9

2.1.2 Assignments of Terminal Contact

I/O Terminal / OVERVIEW

Inputs A, /A

Pulse input in the terminal’s encoder and counter mode.

Inputs B, /B

Phase-shifted pulse input in the terminal’s encoder mode.

Counting direction input in the terminal’s counter mode.

Counting direction:

+ 5 V (or open contact): up

0 V: down

Inputs C, /C

Zero point pulse input for the terminal’s latch register.

This input is activated via the EN_LATC bit in the terminal’s control byte.

External Latch 24 V

Additional latch input of the terminal.

The counter value is latched when this input is alerted and an edge change takes place from 0 V

to 24 V.

External Gate 24 V

9

Page 10

I/O Terminal / OVERVIEW

A high level at this contac

Status Input 5 V

Incremental encoder with fault alarm outputs can be connected to the Status input of the

AKT-ENC-000-000.

Ue

Voltage supply for the encoder (+5 V).

Uo

Voltage supply for the encoder (0 V).

0 V, 24 V

A supply of 0 V and 24 V voltage must be applied to these contacts for operation of the terminal.

2.1.3 Operating Modes

A, B, zero pulse incremental encoder (default)

Up/down counter with:

A = Count , the positive edges of the input pulses are counted

t suppresses counting by the terminal.

B = Up/down input

B = 0: up counting direction

B = 1: down counting direction

C = Gate input

C = 0: counter enabled

C = 1: counter disabled

2.1.4 Functions

Counting

Counter setting

Arming the zero pulse and storing the valid value

Determining the period between two pulses with a resolution of two 200 ns (the time between

two positive edges of the input signal A is evaluated)

Indication of a counter overflow or underflow.

10

Page 11

2.1.5 LED Display

The signal LEDs indicate the status of the encoder inputs A, B, C, Status input and of the logic

inputs of the gate and of the additional external latch.

The RUN LED indicates cyclic data transfer with the higher-level controlle r.

The RUN LED goes off if no process data is exchanged for 100 ms.

2.1.6 Process Data

The AKT-ENC-000-000 always occupies 6 bytes of input data and 6 bytes of output data. The

control / status byte is at the least significant byte offset.

The data word D0/D1 contains the counter value (read/set) and the data word D3/D4 contains the

latch word (read).

In the period measurement mode the value can be found in D2 together with D3 and D4.

I/O Terminal / OVERVIEW

11

Page 12

I/O Terminal / MOUNTING AND WIRING

3 MOUNTING AND WIRING

This section provides mounting and wiring information for the operator terminal.

Note: For information about configuring the I/O terminal, see the Kollmorgen Automation Suite™

IDE software and online help system.

3.1 Installation of Bus Terminals on Mounting Rails

DANGER!! Bring the bus terminal system into a safe, powered down state before starting

installation, disassembly or wiring of the Bus Terminals!

3.1.1 Assembly

The Bus Coupler and Bus Terminals are attached to commercially available 35 mm mounting

rails (DIN rails according to EN 50022) by applying slight pressure:

1. First attach the Fieldbus Coupler to the mounting rail.

2. The Bus Terminals are now attached on the right-hand side of the Fieldbus Coupler. Join the

components with tongue and groove and push the terminals against the mounting rail, until

the lock clicks onto the mounting rail.

If the Terminals are clipped onto the mounting rail first and then pushed together without

tongue and groove, the connection will not be operational! When correctly assembled, no

significant gap should be visible between the housings.

During the installation of the Bus Terminals, the locking mechanism of the terminals must not

come into conflict with the fixing bolts of the mounting rail.

3.1.2 Disassembly

Each terminal is secured by a lock on the mounting rail, which must be relea se d for disassembly:

1. Carefully pull the orange-colored lug approximately 1 cm out of the disassembled terminal,

until it protrudes loosely. The lock with the mounting rail is now released for this terminal, and

the terminal can be pulled from the mounting rail without excessive force.

2. Grasp the released terminal with thumb and index finger simultaneous at the upper and lower

grooved housing surfaces and pull the terminal away from the mounting rail.

3.1.3 Connections Within a Bus Terminal Block

The electric connections between the Bus Coupler and the Bus Terminals are automatically

realized by joining the components:

The six spring contacts of the Standard Bus/Performance Bus deal with the transfer of the

data and the supply of the Bus Terminal electronics.

The power contacts deal with the supply for the field electronics and thus represent a supply

rail within the bus terminal block. The power contacts are supplied via terminals on the Bus

Coupler.

12

Page 13

Note

: During the design of a bus terminal block, the pin assignment of the individual Bus

Terminals must be taken account of, since some types (e.g. analog Bus Terminals or digital

4-channel Bus Terminals) do not or not fully loop through the power contacts. Power Feed

Terminals interrupt the power contacts and thus represent the start of a new supply rail.

3.1.4 PE Power Contact

The power contact labeled PE can be used as a protective earth. For safety reasons this contact

mates first when plugging together, and can ground short-circuit currents of up to 125 A.

WARNING!! Note that, for reasons of electromagnetic compatibility, the PE contacts are

For insulation testing, disconnect the PE supply line at the Bus Coupler or the

Note: The PE power contact must not be used for other potentials!

I/O Terminal / MOUNTING AND WIRING

capacitatively coupled to the mounting rail. This may lead to incorrect results

during insulation testing or to damage on the terminal (e.g. disruptive discharge

to the PE line during insulation testing of a consumer with a nominal voltage of

230 V).

Power Feed Terminal! In order to decouple further feed points for testing, these

Power Feed Terminals can be released and pulled at least 10 mm from the

group of terminals.

3.1.5 Wiring

Up to eight connections enable the connection of solid or finely stranded cables to the Bus

Terminals. The terminals are implemented in spring force technology. Connect the cables as

follows:

1. Open a spring-loaded terminal by slightly pushing with a screwdriver or a rod into the square

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal closes automatically when the pressure is released, holding the wire securely

Note: Analog sensors and actors should always be connected with shielded, twisted

paired wires.

opening above the terminal.

and permanently.

13

Page 14

3.2 AKT-ENC-000-000 Connections

The section describes the connections for the Counter module.

I/O Terminal / MOUNTING AND WIRING

Figure 3.1 Terminal Connections

14

Page 15

I/O Terminal / AUTOMATIC CONFIGURATION

4 AUTOMATIC CONFIGURATION

This chapter describes the basics of automatic configuration within the KAS Integrated

Development Environment (IDE).

4.1 Scan Device

For ease-of-use the KAS IDE Scan Device feature provides automatic integration of I/O devices.

This allows you to automatically locate and add I/O terminals to the application project:

4.2 Setting I/O Values

After the I/O slice is mapped it can be selected in the application project and the offset and gain

values can be set. Additionally, the IDE allows you to map the I/O points to variables in your

application:

15

Page 16

I/O Terminal / AUTOMATIC CONFIGURATION

For more detailed information on these procedures refer to the section “EtherCAT Scan Device”

in the KAS IDE online help.

16

Page 17

5 MANUAL CONFIGURATION

Kollmorgen strongly recommends automatic configuration using the KAS IDE over manual

configuration. For automatic configuration refer to chapter 4. Manual configuration is for advanced

procedures only. The following sections provide the necessary configuration information to

manually map the I/O device.

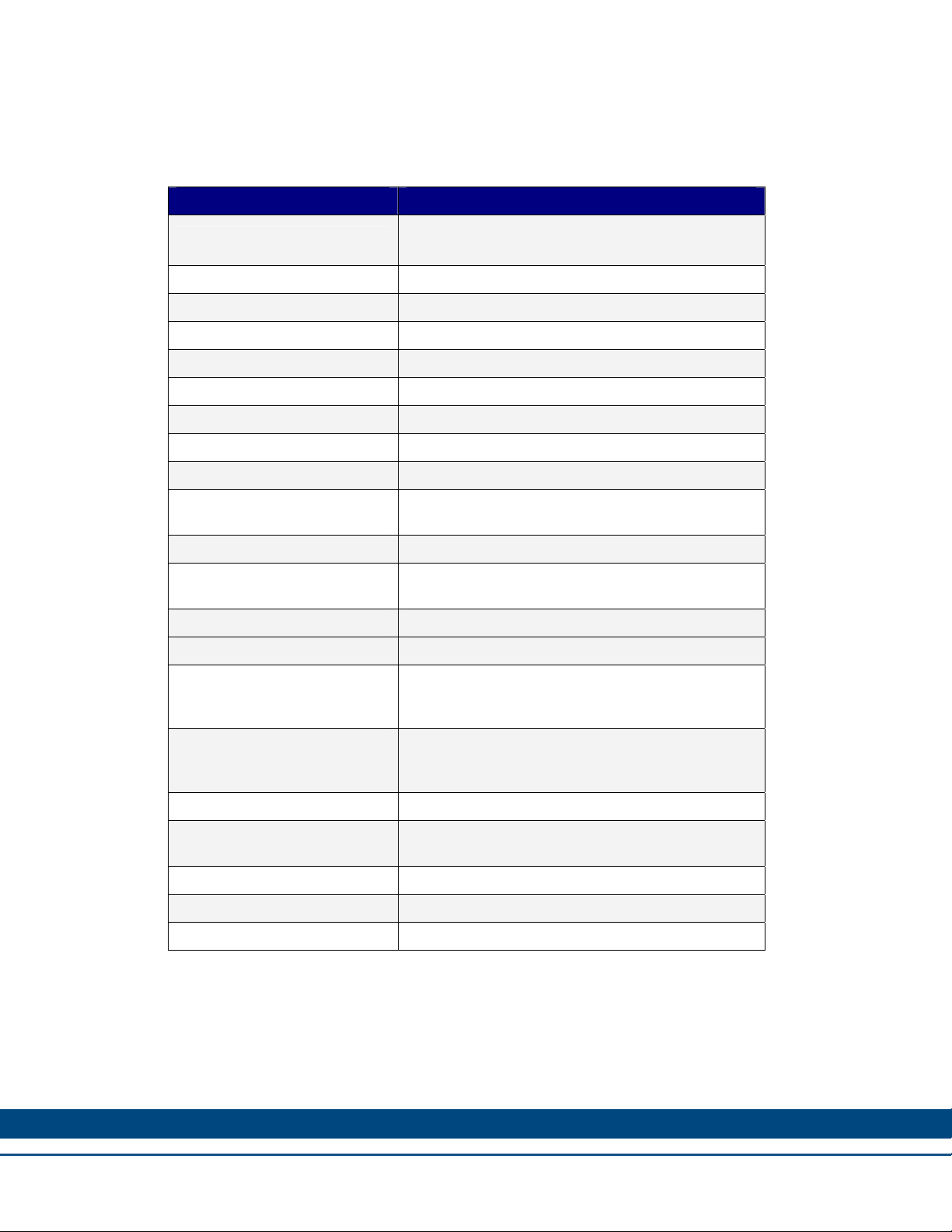

5.1 Mapping in the Bus Coupler

Each terminal channel is mapped in the bus coupler. In the standard case, this mapping is done

with the default setting in the bus coupler / bus terminal. The following tables provide information

on how the AKT-ENC-000-000 maps itself in the bus coupler depending on the set parameters.

The AKT-ENC-000-000 is mapped in the bus coupler depending on the set parameters. The

terminal is always evaluated completely, the terminal occupies memory space in the process

image of the input and outputs.

Default mapping for CANopen

Conditions Word offset High byte Low byte

I/O Terminal / MANUAL CONFIGURATION

Complete evaluation: any

Motorola format: no

Word alignment: no

Default mapping for Profibus Coupler

Conditions Word offset High byte Low byte

Complete evaluation: any

Motorola format: yes

Word alignment: no

Default mapping for EtherCAT

Conditions Word offset High byte Low byte

Complete evaluation: any

Motorola format: no

Word alignment: yes

0 D0 CB/SB

1 D2 D1

2 D4 D3

0 D1 CB/SB

1 D2 D0

2 D3 D4

0 – CB/SB

1 D1 D0

2 – D2

3 D4 D3

17

Page 18

I/O Terminal / MANUAL CONFIGURATION

Conditions Word offset High byte Low byte

Complete evaluation: any

Motorola format: yes

Word alignment: yes

Key Complete evaluation: The terminal is mapped with control / status byte.

Motorola format: The Motorola or Intel formal can be set.

Word alignment: The terminal is at a word limit in the bus coupler.

CB: Control- Byte (appears in the process image of the outputs).

SB: Status- Byte (appears in the process image of the inputs).

D0/D1: Counter word (read/set)

(D2): contains the period, together with 3/D4

D3/D4: Latch word (read)

5.2 Control and Status Byte

The following section describes the control and status bytes.

5.2.1 Control Byte in Process Transfer

0 – CB/SB

1 D0 D1

2 – D2

3 D3 D4

Bit

name

The control byte is transferred from the controller to the terminal. It can be used in the register

mode (REG = 1) or in process data transfer (REG = 0). Various actions are triggered in the AKTENC-000-000 with the control byte:

7 6 5 4 3 2 1 0

REG = 0 - - - En_Latch_Ext_n Cnt_Set EN_LAT_EXT/

RD_PERIOD

Bit Bit Function

3 En_Latch_Ext_n The external latch input is activated for

negative edge. With the first external

latch impulse after validity of the

EN_Latch_Ext_n bit, the counter value

in the latch register is stored. The

pulses that follow have no influence on

the latch register when the bit is set.

Attention must be paid to ensuring that

the corresponding latch valid bit

(Latch_Ext_Val) has been removed

from the terminal before alerting of the

zero pulse. This functionality is

EN_LATC

18

Page 19

I/O Terminal / MANUAL CONFIGURATION

Bit Bit Function

adjustable in the feature register

(default).

2 Cnt_Set The counter is set to the value that is

specified via the process data with the

rising edge of Cnt_Set.

1

En_Latch_Ext The external latch input is activated for

positive edge. With the first external

latch impulse after validity of the

En_Latch_Ext bit, the counter value in

the latch register is stored. The pulses

that follow have no influence on the

latch register when the bit is set.

Attention must be paid to ensuring that

the corresponding latch valid bit

(Latch_Ext_Val) has been removed

from the terminal before alerting of the

zero pulse. This functionality is

adjustable in the feature register

(default).

RD_Period The periods between two positive

edges of the input A are measured with

a resolution of 200 ns. When the bit is

set, this period is output in the data

bytes D2, D3, D4. This functionality is

adjustable in the feature register.

0 En_Latch The zero point latch (C input) is

activated. The counter value is stored in

the latch register with the first external

latch pulse after validity of the En_Latch

bit (this has priority over En_Latch_Ext).

The pulses that follow have no

influence on the latch register when the

bit is set. Attention must be paid to

ensuring that the corresponding latch

valid bit (Latch_Val) has been removed

from the terminal before the zero pulse

is alerted (the Latch_Val bit cannot be

removed from the terminal until the C

pulse has a low level).

Note: For the external latch input: The activation of the positive edge (En_Latch_Ext = 1) has

priority to the activation of the negative edge (En_Latch_Ext_n = 1).

19

Page 20

5.2.2 Status Byte in Process Data Transfer

The status byte is transferred from the terminal to the controller. The status byte contains various

status bits of the AKT-ENC-000-000.

I/O Terminal / MANUAL CONFIGURATION

Bit

name

7 6 5 4 3 2 1 0

REG = 0 - State_Input Overflow Underflow Cnt_Set_

Acc

Bit Name

5 State_Input The state of the Status input is mapped

in this Bit (adjustable via feature

register)

4 Overflow This bit is set if an overflow (65535 to 0)

of the 16-bit counter occurs. It is reset

when the counter exceeds a third of the

measurement range (21845 to 21846)

or as soon as an underflow occurs.

3 Underflow This bit is set if an underflow (0 to

65535) of the 16-bit counter occurs. It is

reset when the counter drops below two

thirds of the measurement range

(43690 to 43689) or as soon as an

overflow occurs.

Latch_Ext

_Val/RD_

Period_Q

Latch_Val

2 CntSet_Acc The data for setting the counter has

been accepted by the terminal.

1

0 Latch_Val A zero point latch has occurred. The

RD_Period_Q The data bytes 2, 3, 4 contain the

period time

Latch_Ext_Val An external latch pulse has occurred.

The data D2,D3 in the process image

corresponds to the latched value when

the bit is set. To activate the latch input

again, En_Latch_Ext must first be

removed and then set again.

data D2, D3 in the process image

corresponds to the latched value when

the bit is set. To activate the latch input

again, En_Latch must first be removed

and then set again.

20

Page 21

5.3 Register Overview

The terminal can be configured and parameterized by using the internal regi ster structure.

Address Description Default Value R/W Storage Medium

R0 Reserved 0x0000 R

… … … … …

R5 Reserved 0x0000 R

I/O Terminal / MANUAL CONFIGURATION

R6

R7

R8 Terminal type 5101 R ROM

R9

R10

R11 Signal channels 0x0130 R ROM

R12 Minimum data length 0x3030 R ROM

R13 Data structure 0x0000 R ROM

R14 Reserved 0x0000 R

R15 Alignment register Variable R/W RAM

R16

R17 Reserved

… … … … …

Diagnostic

register – not used

Command

register - not used

Software version

number

Multiplex shift

register

Hardware version

number

0x0000 R

0x0000 R

0x???? R ROM

0x0218/0130 R ROM

0x???? R/W SEEROM

R31 Code word register Variable R/W RAM

R32 Feature register 0x2200 R/W SEEROM

R33 Reserved 0x0000 R/W SEEROM

… … … … …

R61 Reserved 0x0000 R/W SEEROM

21

Page 22

5.4 Register Description

The complex terminals can be adjusted to different operating modes or functionalities. The "

general description of register " describes the contents of the registers, which are identical for all

complex terminals.

The terminal-specific registers are explained in the following section following.

The access to the internal registers of the terminal is described in the section "Register

Communication ".

5.4.1 General Register Description

Complex terminals that possess a processor are capable of bidirectionally ex-changing data with

the higher-level control system. Below, these terminals are referred to as intelligent bus terminals.

They include the analog inputs (0-10V, -10-10V, 0-20mA, 4-20mA), the analog outputs (0-10V, 10-10V, 0-20mA, 4-20mA), serial interface terminals (RS485, RS232, TTY, data transfer

terminals), counter terminals, encoder interfaces, SSI interfaces, PWM terminals and all other

configurable terminals.

Internally, all intelligent terminals possess a data structure that is identical in terms of it's essential

characteristics. This data area is organized in words and embra ce s 64 memory locations. The

essential data and parameters of the terminal can be read and adjusted by way of the structure.

Function calls with corresponding parameters are also possible. Each logical channel of an

intelligent terminal has such a structure (therefore, 4-channel analog terminals have 4 regi ster

sets.

I/O Terminal / MANUAL CONFIGURATION

This structure is broken down into the following areas:

Register Application

0 to 7 Process variables

8 to 15 Type register

16 to 30 Manufacturer parameters

31 to 47 User parameters

48 to 63 Extended user area

5.4.2 Process Variable

R0 - R7: Registers in the terminal’s internal RAM – The process variables can be used in

additional to the actual process image and their functions are specific to the terminal.

R0 - R5: These registers have a function that depends on the terminal type.

22

Page 23

I/O Terminal / MANUAL CONFIGURATION

R6: Diagno

In the case of serial interface terminals, for example, parity errors that have occurred during data

transfer are indicated.

R7: Command register

High-Byte_Write = function parameter

Low-Byte_Write = function number

High-Byte_Read = function result

Low-Byte_Read = function number

5.4.3 Type Registers

R8 - R15 Registers in the terminal's internal ROM

The type and system parameters are programmed permanently by the manufacturer and can only

be read by the user but cannot be modified.

R8: Terminal type:

The terminal type in register R8 is needed to identify the terminal.

R9: Software version X.y

stic register – The diagnostic register may contain additional diagnostic information.

The software version can be read as an ASCII character string.

R10: Data length

R10 contains the number of multiplexed shift registers and their length in bits. The bus coupler

recognizes this structure.

R11: Signal channels

In comparison with R10, the number of logically existing channels is located here. For example,

one physically existing shift register may consist of several signal channels.

R12: Minimum data length

The respective byte contains the minimum data length of a channel to be transferred. If the MSB

is set, then the control/status byte is not necessarily needed for the function of the terminal and,

with appropriate configuration of the coupler, is not transferred to the control system. 3.2.1.1

R13: Data type register

Data Type Register Description

0x00 Terminal with no valid data type

0x01 Byte array

0x02 Structure 1 byte n bytes

0x03 Word array

23

Page 24

I/O Terminal / MANUAL CONFIGURATION

Data Type Register Description

0x04 Structure 1 byte n words

0x05 Double word array

0x06 Structure 1 byte n double words

0x07 Structure 1 byte 1 double word

0x08 Structure 1 byte 1 double word

0x11 Byte array with variable logical channel length

0x12 Structure 1 byte n bytes with variable logical channel length (e.g.

60xx)

0x13 Word array with variable logical channel length

0x14 Structure 1 byte n words with variable logical channel length

0x15 Double word array with variable logical channel length

0x16 Structure 1 byte n double words with variable logical channel length

R14: Reserved

R15: Alignment bits (RAM) – The alignment bits are used to place the analog terminal in the

Bus Coupler on a byte boundary.

5.4.4 Manufacturer Parameters

R16 to R30: Manufacturer parameter area (SEEROM) – The manufacturer parameters are

specific for each type of terminal. They are programmed by the manufacturer, but can also be

modified by the controller. The manufacturer parameters are stored in a serial EEPROM in the

terminal, and are retained in the event of voltage drop-out. These registers can only be altered

after a code-word has been set in R31.

5.4.5 User Parameters

R31 to R47: User parameter area (SEEROM) – The application parameters are specific for each

type of terminal. They can be modified by the programmer. The application parameters are stored

in a serial EEPROM in the terminal, and are retained in the event of voltage drop-out. The user

area is write-protected by a code-word.

R31: Code-word register in RAM – The code-word 0x1235 must be entered here so that

parameters in the user area can be modified. If any other value is entered into this register, the

write-protection is active. When write protection is not active, the code word is returned when the

register is read. If the write protection is active, the register contains a zero value.

R32: Feature register – This register specifies the terminal's operating modes. Thus, for

instance, a user-specific scaling can be activated for the analog I/Os.

R33 to R47 Terminal-specific Registers – The function of these registers depends on the

respective terminal type (see terminal-specific register description).

24

Page 25

5.4.6 Extended Application Region

R47 to R63 – These registers have not yet been implemented.

5.5 Terminal-Specific Register Description

This section contains the description for terminal specific registers.

5.5.1 Application Parameters

R32: Feature register:

[0x2200]

The feature register determines the operating modes of the terminal.

Feature bit no. Mode Description

Bit 0 0 Reserved, don’t change

Bit 1 0/1 0: Counter inhibit with high-level at Gate

I/O Terminal / MANUAL CONFIGURATION

input [0]

1: Counter inhibit with low-level at Gate-

input

Bit 3, Bit 2

Bit 6 – Bit 4

Bit 7 – 9 0 Reserved, don’t change

Bit 11, Bit 10

0 0 Status input (active-low) is mapped into

the status-byte.5 (ST.5) [00]

0 1 Reserved

1 0 ST.5 = Status input, ST.6 = Status input

1 1 ST.5 = Status input, ST.6 = Status input

0 0 0 External Latch function active [000]

0 0 1 Period measurement active

0 1 0

…

1 1 1

0 0 4-fold evaluation of the encoder signals

0 1 1-fold evaluation of the encoder signals

Reserved

A,B,C,

i.e. both rising and falling edges of the

encoder signals A, B are counted. [00]

A, B, C.

i.e. every period of the encoder signal A

is counted.

1 0 2-fold evaluation of the encoder signals

A, B, C,

i.e. every edge of the encoder signal A

is counted.

25

Page 26

Feature bit no. Mode Description

1 1 4-fold evaluation of the encoder signals

Bit 14 – 12 0 Reserved, don’t change

Bit 15 0/1 0: Encoder interface. [0]

5.6 Register Communication

Register Access Via Process Data Exchange | Bit 7=1bin: Register Mode

If bit 7 of the control byte is set, then the first two bytes of the user data are not used for

exchanging process data, but are written into or read from the terminal's register set.

I/O Terminal / MANUAL CONFIGURATION

A, B, C

1: Counter mode is activated.

16-bit up/down counter

Input A: Counter

Input B: Counting direction (5 V or open

= up, 0 V= down)

Input C: Latch

Bit 6=0

: read | Bit 6=1

bin

bin

Bit 6 of the control byte specifies whether a register should be read or written. If bit 6 is not set,

then a register is read out without modifying it. The value can then be taken from the input

process image.

If bit 6 is set, then the user data is written into a register. As soon as the status byte has supplied

an acknowledgement in the input process image, the procedure is completed (see example).

Bit 0 to 5: Address

The address of the register that is to be addressed is entered into bits 0 to 5 of the control byte.

5.6.1 Control Byte in Register Mode

Bit

name

REG = 0bin: Process data exchange

REG = 1bin: Access to register stru ct ure

W/R = 0bin: Read register

7 6 5 4 3 2 1 0

REG = 0 W/R A5 A4 A3 A2 A1 A0

: write

W/R = 1bin: Write register

A5...A0 = register address

Address bits A5 to A0 can be used to address a total of 64 registers.

26

Page 27

I/O Terminal / MANUAL CONFIGURATION

The control or status byte occupies the lowest address of a logical channel. The corresponding

register values are located in the following 2 data bytes.

27

Page 28

APPENDIX A

This section provides the mechanical drawing of the I/O Terminal.

A.1 I/O 12.0mm Mechanical Drawing

I/O Terminal / APPENDIX A

28

Page 29

About Kollmorgen

Kollmorgen is a leading provider of motion systems and

components for machine builders. Through world-class

knowledge in motion, industry-leading quality and

deep expertise in linking and integrating standard and

custom products, Kollmorgen delivers breakthrough

solutions that are unmatched in performance, reliability

and ease-of-use, giving machine builders an irrefutable

marketplace advantage.

For assistance with your application needs, contact

us at: 540-633-3545, contactus@kollmorgen.com

or visit www.kollmorgen.com

North America

Kollmorgen

203A West Rock Road

Radford, VA 24141 USA

Phone: 1-540-633-3545

Fax: 1-540-639-4162

Europe

Kollmorgen

Wacholderstraße 40 – 42

40489 Düsseldorf Germany

Phone: + 49 (0) 203-9979-235

Fax: + 49 (0) 203-9979-3314

Loading...

Loading...