Kollmorgen AKM13C, AKM13D, AKM21C, AKM21E, AKM22E Technical Description, Installation, Setup

...Page 1

www.DanaherMotion.com

Synchronous servomotors

AKM

Technical description, Installation, Setup

Edition 05/2006

File akm_e.xxx

Page 2

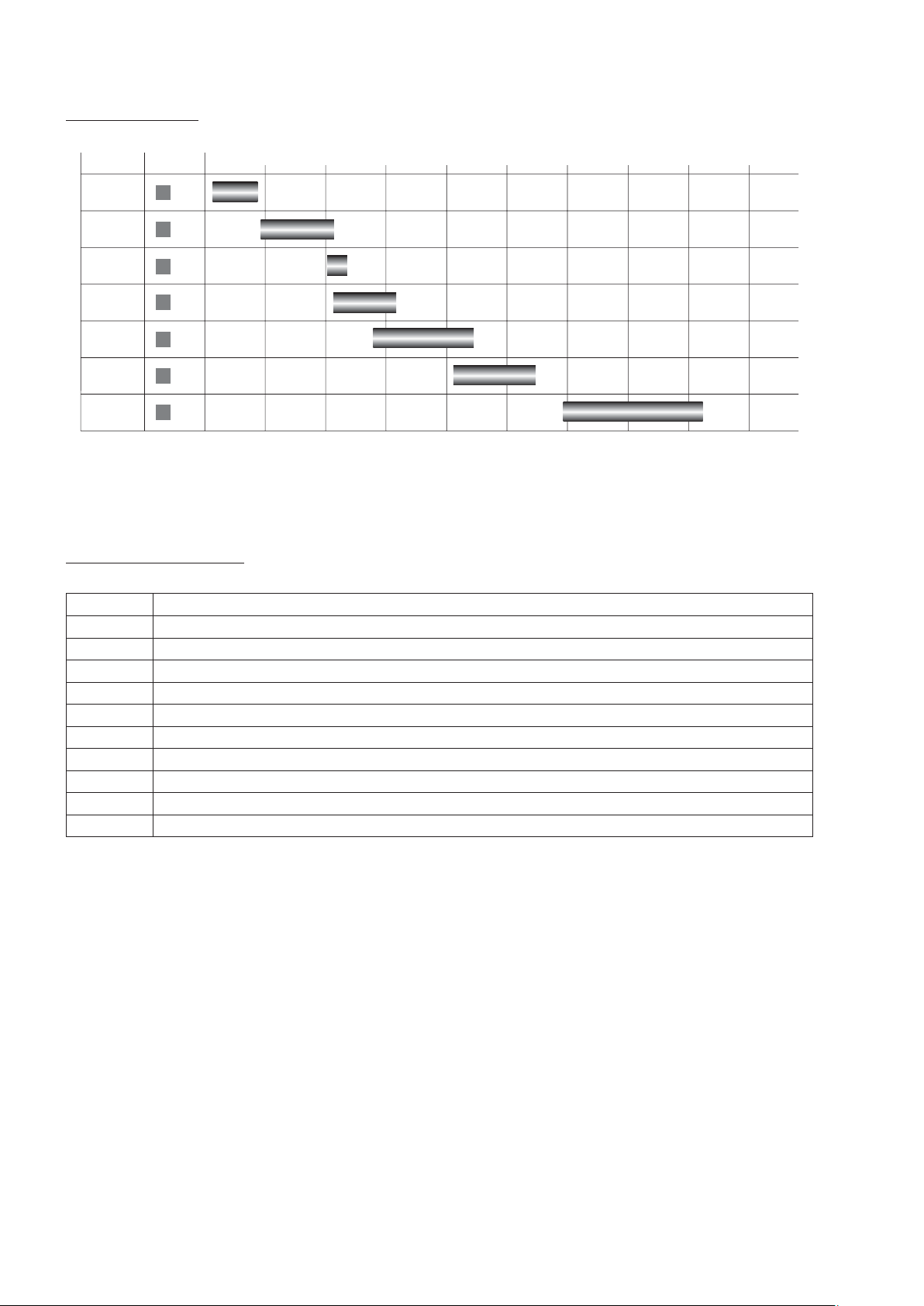

Choose your Motor:

Typ

AKM1

AKM2

AKM3

AKM4

AKM5

AKM6

AKM7

Flange

Standstill torque

40 0,18..0,41

58 0,48..1,42

70 1,15..2,88

84 1,95..6

108 4,7..14,4

138 11,9..25

188 29,4..53

0105020 70130540

0,5

Already published editions

Edition Comments

03 / 2004 First edition

12 / 2004 Performance curves corrected, polenumbers, gearhead mounts, several corrections

09 / 2005 centering AKM7, chapter 1, several corrections, BISS interface, protection class

05 / 2006 Performance curves deleted, order numbers cables, new label

Page

Þ 24

Þ 26

Þ 28

Þ 30

Þ 32

Þ 34

Þ 36

Nm

Technical changes to improve the performance of the equipment may be made without prior notice!

Printed in the Federal Republic of Germany

All rights reserved. No part of this work may be reproduced in any form (by printing, photocopying, microfilm or any

other method) or stored, processed, copied or distributed by electronic means without the written permission of

Danaher Motion.

Page 3

Kollmorgen 05/2006 Contents

Page

NewTableof Contents

1 General

1.1 About this manual ....................................................................... 5

1.2 Use as directed ......................................................................... 5

1.3 Symbols used in this manual:............................................................... 5

1.4 Safety Notes ........................................................................... 6

1.5 Important Notes ......................................................................... 7

1.6 Design of the motors ..................................................................... 8

1.7 General technical data .................................................................... 8

1.8 Standard features........................................................................ 9

1.8.1 Style............................................................................. 9

1.8.2 Shaft end, A-side ................................................................... 9

1.8.3 Flange ........................................................................... 9

1.8.4 Protection class .................................................................... 9

1.8.5 Protective device ................................................................... 9

1.8.6 Insulation material class.............................................................. 9

1.8.7 Vibration class .................................................................... 10

1.8.8 Connection method ................................................................ 10

1.8.9 Feedback unit .................................................................... 10

1.8.10 Holding brake..................................................................... 10

1.8.11 Pole numbers..................................................................... 10

1.9 Options............................................................................... 11

1.10 Selection criteria........................................................................ 11

1.10.1 Model number description ........................................................... 12

1.10.2 Nameplate ....................................................................... 12

2 Installation / Setup

2.1 Important notes ........................................................................ 13

2.2 Assembly / Wiring ...................................................................... 14

2.2.1 Connection of the motors with preassembled cables....................................... 16

2.2.1.1 Wiring diagram for motors with resolver .............................................17

2.2.1.2 Wiring diagram for motors with encoder ............................................. 18

2.2.1.3 Wiring diagram for motors with SFD ................................................ 19

2.2.1.4 Wiring diagram for motors with ComCoder ........................................... 20

2.2.1.5 Wiring diagram for motors with BISS................................................ 21

2.3 Setup ................................................................................ 22

3 Technical Data

3.1 Definitions ............................................................................ 23

3.2 AKM1 ................................................................................ 24

3.3 AKM2 ................................................................................ 26

3.4 AKM3 ................................................................................ 28

3.5 AKM4 ................................................................................ 30

3.6 AKM5 ................................................................................ 32

3.7 AKM6 ................................................................................ 34

3.8 AKM7 ................................................................................ 36

4 Appendix

4.1 Assignment of RediMount gearhead mounts .................................................. 38

4.2 Delivery package, transport, storage, maintenance, disposal ..................................... 39

4.3 Removing faults ........................................................................ 40

4.4 Index ................................................................................ 41

Servomotors AKM 3

Page 4

Manufacturer declaration

According to the EG-Machine-guideline 98/37/EC, appendix II B

We, the company

Danaher Motion GmbH

Wacholderstrasse 40-42

40489 Düsseldorf

declare, that the product

Motor series AKM

(Types AKM1, AKM2, AKM3, AKM4, AKM5, AKM6, AKM7)

05/2006 Kollmorgen

is intended exclusively, in its standard version, for installation in another machine and that its setup is forbid

den until it has been established that the machine into which this product is to be installed conforms to the pro

visions of the EC Directive in its version 98/37/ECW.

We confirm that the above-mentioned product conforms to the following standards:

73/23/EEC Low voltage directive

VDE 0530 / DIN 57530 Provisions for rotating machinery

DIN EN 60034-7 Design

DIN 748 Cylindrical shaft ends

DIN 6885 Keyway and Key

DIN 42955 True running, coaxiality and concentricity

DIN EN 60034-14 Vibration class

Issued by: Management

Michel van Roozendaal

-

-

This Declaration does not contain any assurance of properties. The notes on safety and protection in the ope

rating instructions must always be observed.

4 Servomotors AKM

-

Page 5

Kollmorgen 05/2006 General

1 General

1.1 About this manual

This manual describes the AKM series of synchronous servomotors (standard

version). Among other things, you find information about:

General description, standard version of the motors Chapter 1

l

Installation, Setup, Wiring Chapter 2

l

Technical data, dimensions Chapter 3

l

Notes on Transport, Storage, Maintenance, Disposal Chapter 4

l

This Manual is intended for the use of qualified staff with professional knowledge of electri

cal and mechanical engineering.

The motors are operated in drive systems together with servo amplifiers SERVOSTAR. Please

observe the entire system documentation, consisting of:

— Installation and setup instructions for the servo amplifier

— Installation and setup instructions for any expansion card which is connected

— Operating manual for the Operator Software of the servo amplifier

— Technical description of the AKM series of motors

1.2 Use as directed

The AKM series of synchronous servomotors is designed especially for drives for industrial robots,

machine tools, textile and packing machinery and similar with high requirements for dynamics.

The user is only permitted to operate the motors under the ambient conditions which are defined in

this documentation.

The AKM series of motors is exclusively intended to be driven by servo amplifiers from the

SERVOSTAR series under speed and / or torque control.

The motors are installed as components in electrical apparatus or machines and can only be commissioned and put into operation as integral components of such apparatus or machines.

The motors must never be connected directly to the mains supply.

The thermal contact which is integrated in the motor windings must be observed and evaluated.

-

The conformity of the servo-system to the standards mentioned in the manufacturers

declaration on page 4 is only guaranteed when the components (servo amplifier, motor, cables etc.)

that are used have been supplied by us.

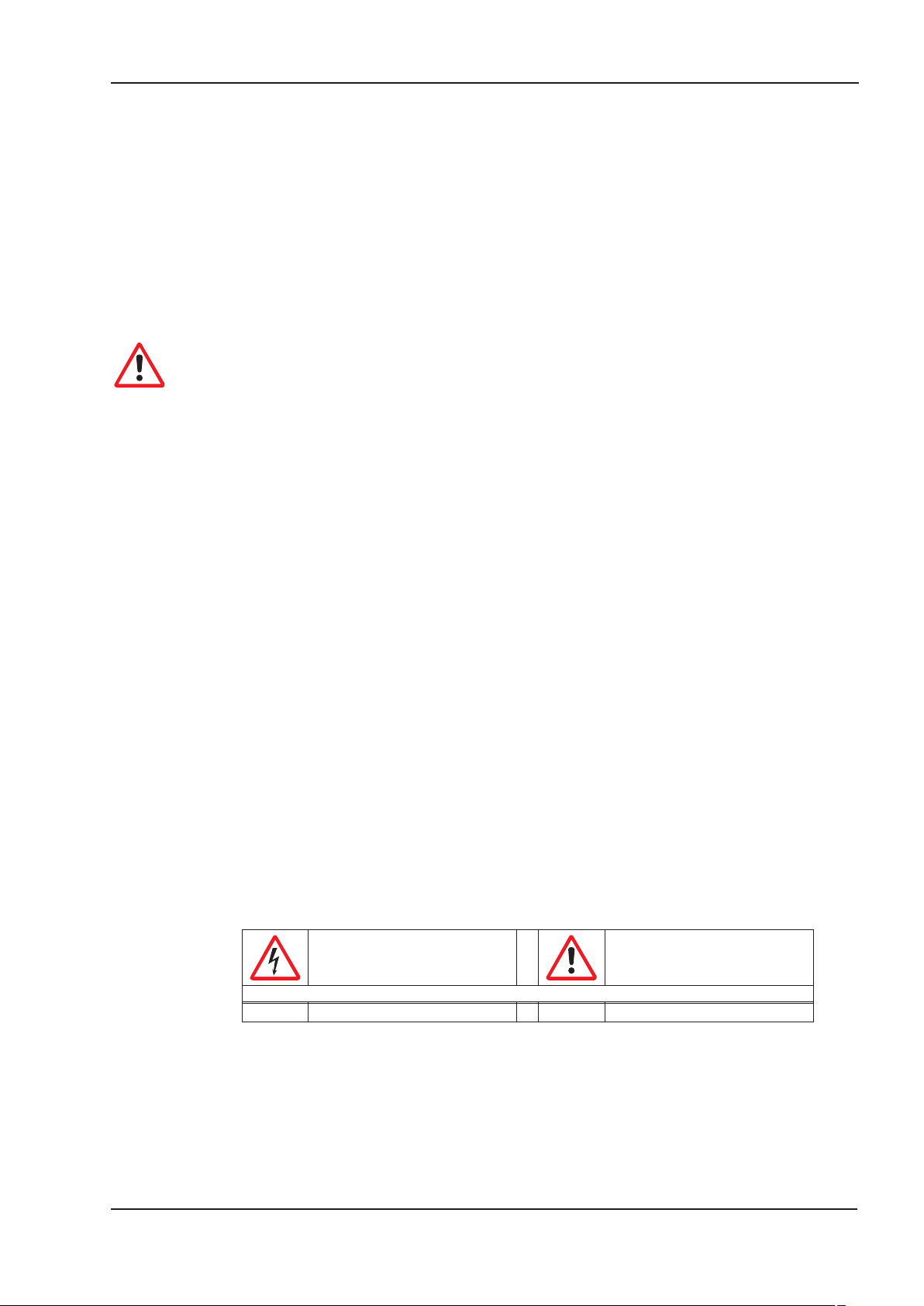

1.3 Symbols used in this manual:

Danger to personnel from electricity

and its effects

see page/chapter (cross reference) l special emphasis

Þ

General warning

general instruction

mechanical hazard

Servomotors AKM 5

Page 6

General 05/2006 Kollmorgen

1.4 Safety Notes

Only properly qualified personnel are permitted to perform such tasks as transport,

l

assembly, setup and maintenance. Properly qualified personnel are persons who are

familiar with the transport, assembly, installation, setup and operation of motors, and

who have the appropriate qualifications for their jobs. The qualified personnel must

know and observe the following standards and regulations:

IEC 364 resp. CENELEC HD 384 or DIN VDE 0100

IEC-report 664 or DIN VDE 0110

national regulations for safety / accident prevention or BGV A3

Read the available documentation before assembly and setup. Incorrect handling of

l

the motors can result in injury and damage to persons and machinery. Keep strictly

to the technical data and the information on the connection requirements (nameplate

and documentation).

The manufacturer of the machine must generate a hazard analysis for the machine,

l

and take appropriate measures to ensure that unforeseen movements cannot cause

injury or damage to any person or property.

It is vital that you ensure that the motor housing is safely earthed to the PE(protective

l

earth) busbar in the switch cabinet. Electrical safety is impossible without a low-re

sistance earth connection.

Do not unplug any connectors during operation. This creates the danger of death, se

l

vere injury, or extensive material damage.

-

-

Power connections may be live even when the motor is not rotating. Never discon-

l

nect the power connections of the motor while the equipment is energised. This can

cause flashovers with resulting injuries to persons and damage to the contacts.

After disconnecting the servo amplifier from the supply voltage, wait at least five mi-

l

nutes before touching any components which are normally live (e.g. contacts, screw

connections) or opening any connections.

The capacitors in the servo amplifier can still carry a dangerous voltage up to five minutes after switching off the supply voltages. To be quite safe, measure the DC-link

voltage and wait until the voltage has fallen below 40V.

l

The surfaces of the motors can be very hot in operation, according to their protection

category. The surface temperature can exceed 100°C. Measure the temperature, and

wait until the motor has cooled down below 40°C before touching it.

l

Remove any fitted key (if present) from the shaft before letting the motor run indepen

dently, to avoid the dangerous results of the key being thrown out by centrifugal for

ces.

-

-

6 Servomotors AKM

Page 7

Kollmorgen 05/2006 General

1.5 Important Notes

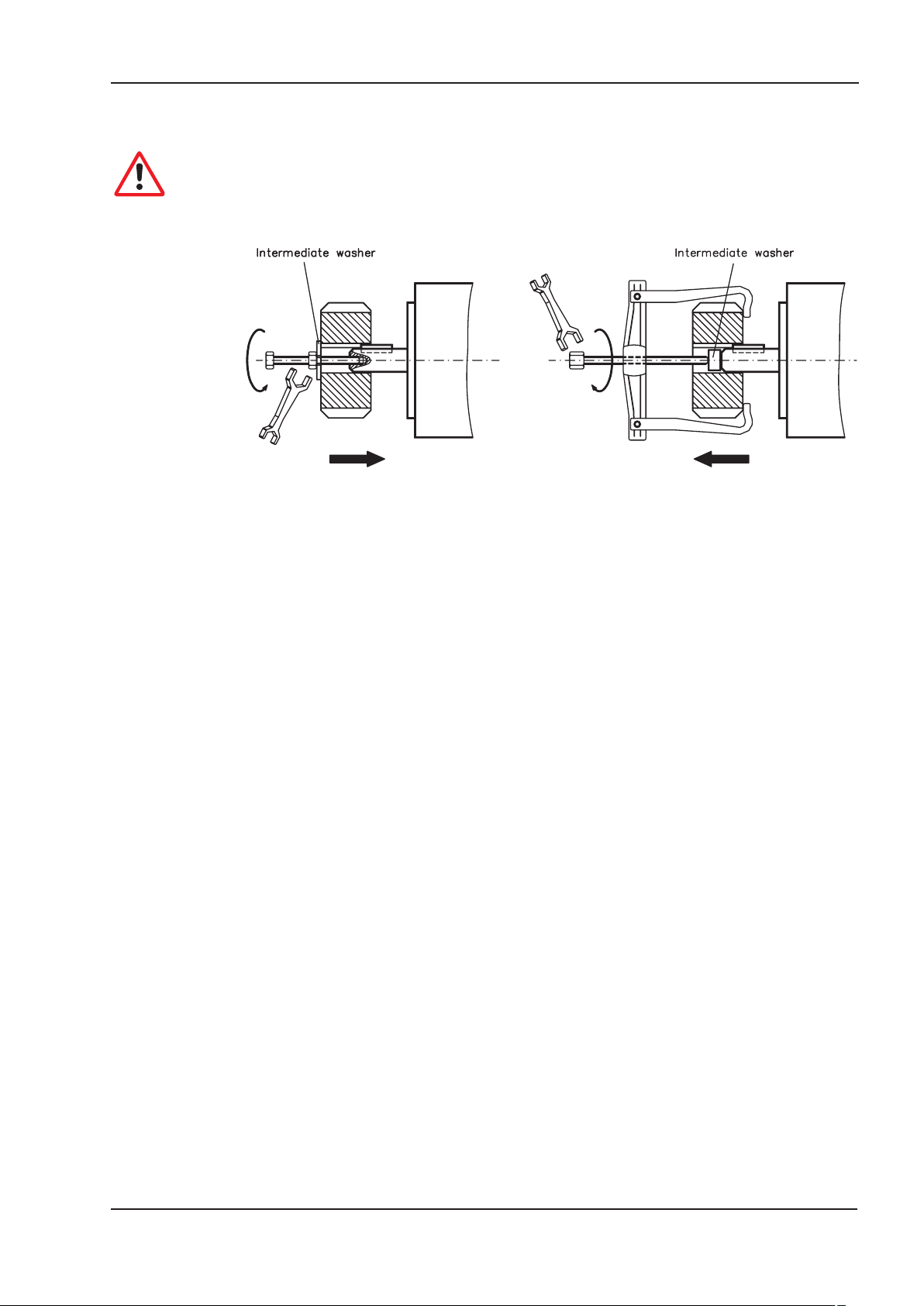

Servomotors are precision equipment. The flange and shaft are especially vulnerable

l

during storage and assembly — so avoid brute force. Precision requires delicacy. It is

important to use the locking thread which is provided to tighten up couplings, gear

wheels or pulley wheels and warm up the drive components, where possible. Blows

or the use of force will lead to damage to the bearings and the shaft.

Wherever possible, use only backlash-free, frictionally-locking collets or couplings.

l

Ensure correct alignment of the couplings. A displacement will cause unacceptable

vibration and the destruction of the bearings and the coupling.

For toothed belts, it is vital to observe the permissible radial forces. An excessive ra

l

dial load on the shaft will significantly shorten the life of the motor.

Avoid axial loads on the motor shaft, as far as possible. Axial loading significantly

l

shortens the life of the motor.

In all cases, do not create a mechanically constrained motor shaft mounting by using

l

a rigid coupling with additional external bearings (e.g. in a gearbox).

l

For mounting style V3 (shaft end upwards), make sure that no liquid can enter the upper bearing.

l

Take note of the no. of motor poles and the no. of resolver poles, and ensure that the

correct setting is made in the servo amplifier which is used. An incorrect setting can

lead to the destruction of the motor, especially with small motors.

-

Servomotors AKM 7

Page 8

General 05/2006 Kollmorgen

1.6 Design of the motors

Synchronous servomotors in the AKM series are brushless DC motors for demanding servo appli

cations. When combined with our digital servo amplifiers they are especially suited for positioning

tasks in industrial robots, machine tools, transfer lines etc. With high requirements for dynamics and

stability.

The servomotors have permanent magnets in the rotor. The rare earth neodymium -iron-boron

magnetic material is an important factor in making it possible to drive these motors in a highly dyna

mic fashion. A three-phase winding which is driven by the servo amplifier is integrated into the sta

tor. The motor does not have any brushes since commutation is performed electronically by the

servo amplifier

The temperature of the winding is monitored by temperature sensors in the stator windings and is

signalled via an electrically isolated thermistor (PTC, £550W / ³1330W).

A resolver is built into the motors as standard feedback element. The servo amplifiers in the

SERVOSTAR series evaluate the resolver position and supply sinusoidal currents to the motors.

The alternatively offered feedback systems partly cause a change of the motor length and cannot

be retrofitted.

The motors can be delivered with or without a built-in holding brake. Retrofitting of the brake is not

possible.

The motors are enamelled in matt black (RAL 9005). This finish is not resistant against solvents

(e.g. trichlorethylene, nitro-thinners, or similar).

1.7 General technical data

Climate category 3K3 to EN 50178

-

-

-

Ambient temperature 5...+40°C for site altitude up to 1000m amsl (at rated values) It is vital to consult our applications department for

ambient temperatures above 40°C and encapsulated

mounting of the motors.

Permissible humidity 95% rel. humidity, no condensation

(at rated values)

Power derating 1%/Kinrange 40°C...50°C up to 1000m amsl (currents and torques) for site altitude above 1000m amsl and 40°C

6% up to 2000m amsl

17% up to 3000m amsl

30% up to 4000m amsl

55% up to 5000m amsl

No derating for site altitudes above 1000m amsl

with temperature reduction of 10K / 1000m

Ball-bearing life ³ 20.000 operating hours

Technical data Þ p.23

Storage data Þ p.39

8 Servomotors AKM

Page 9

Kollmorgen 05/2006 General

1.8 Standard features

1.8.1 Style

The basic style for the AKM synchronous motors is style IM B5 according to DIN EN 60034-7. The

permitted mounting positions may be read from the technical data of the motor series.

1.8.2 Shaft end, A-side

Power transmission is made through the cylindrical shaft end A, fit k6 (AKM1: h7) to DIN 748, with a

locking thread but without a fitted-keyway.

If the motors drive via pinions or toothed belts, then high radial forces will occur. The permissible

values at the end of the shaft may be read from the diagrams in chapter 3. The maximum values at

rated speed you will find at the technical data. Power take-off from the middle of the free end of the

shaft allows a 10% increase in F

The curves are based on a bearing life of 20.000 operating hours.

The axial force F

Double-coned collets have proved to be ideal zero-backlash coupling devices, combined, if required, with metal bellows couplings.

.

R

must not exceed FR/3.

A

1.8.3 Flange

Flange dimensions to IEC standard, fit j6 (AKM1: h7), accuracy according to DIN 42955.

Tolerance class: N

1.8.4 Protection class

Standard version IP65

Standard shaft bushing IP54

Shaft bushing with shaft-sealing ring IP67

1.8.5 Protective device

The standard version of each motor is fitted with an electrically isolated PTC. The switching point is

at 155°C ± 5%. The thermostat does not provide any protection against short, heavy overloading.

Provided that our preassembled resolver cable is used, the thermostat contact is integrated into the

monitoring system of the digital servo amplifier SERVOSTAR.

1.8.6 Insulation material class

The motors come up to insulation material class F according to DIN 57530. - E.4.929.4/09

Servomotors AKM 9

Page 10

General 05/2006 Kollmorgen

1.8.7 Vibration class

The motors are made to vibration class N according to DIN EN 60034-14.

1.8.8 Connection method

The motors are equipped with angular connectors (AKM1: straight connectors at cable ends) for

power supply and feedback signals .

The mating connectors are not part of the delivery package. We can supply preassembled resolver

and power cables. On page 16 you will find notes on the cable materials.

1.8.9 Feedback unit

Standard

Option

Option

Option

Option

Option

Resolver Two-pole hollow-shaft EnDat Encoder, Single-Turn AKM2-AKM4: ECN 1113, AKM5-AKM7: ECN1313 EnDat Encoder, Multi-Turn AKM2-AKM4: EQN 1125, AKM5-AKM7: EQN1325

ComCoder

SFD fully digital resolver interface

BiSS Encoder, Single-/Multi-Turn AKM2-AKM4: AD36, AKM5-AKM7: AD58

The motor length depends on the mounted feedback unit. Retrofitting is not possible.

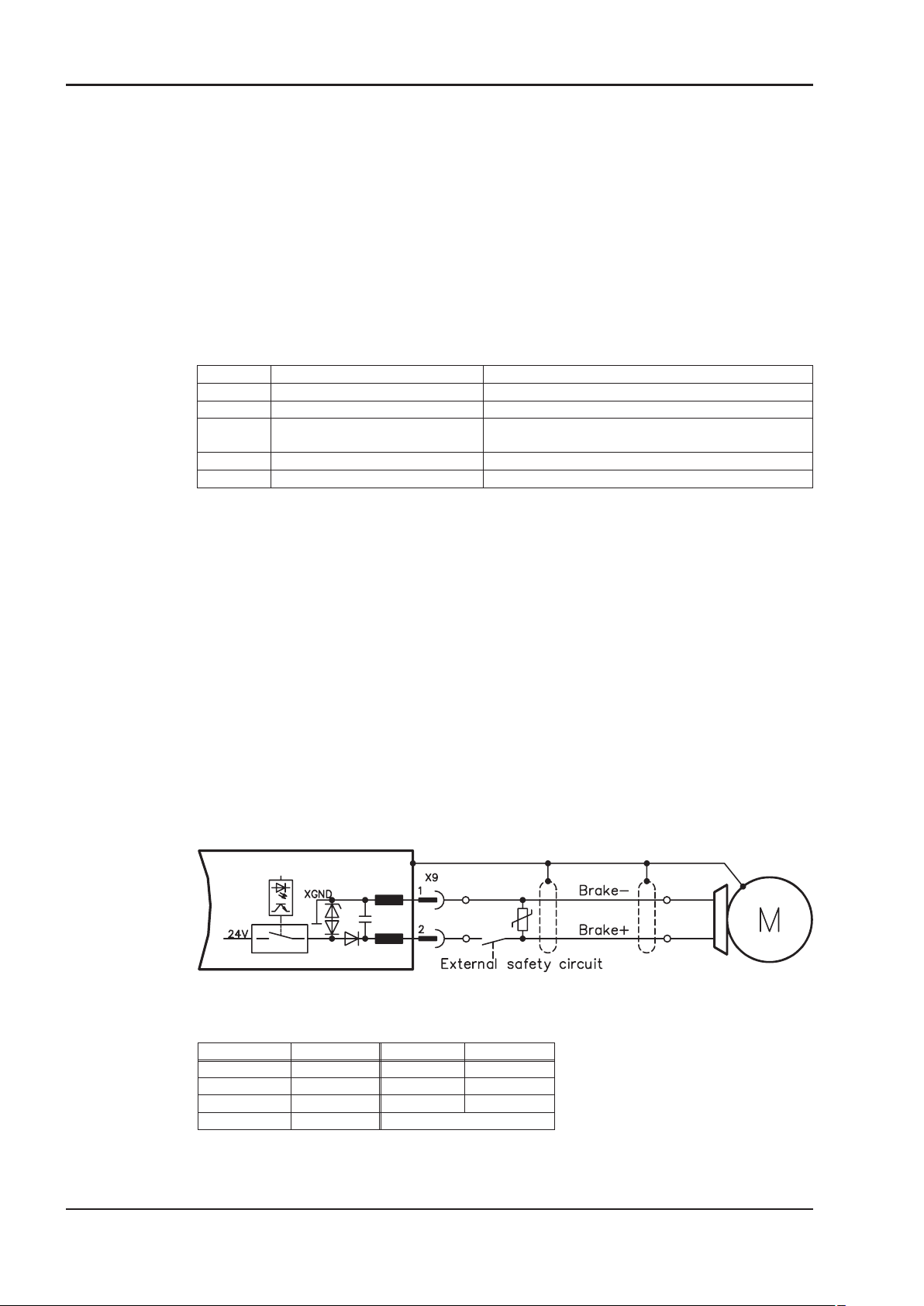

1.8.10 Holding brake

The AKM2-AKM7 motors are optionally available with a holding brake.

A spring applied brake (24V DC) is integrated into the motors. When this brake is de-energized it

blocks the rotor. The holding brakes are designed as standstill brakes and are not suited for

repeated operational braking. If the brake is released then the rotor can be moved without a remanent torque. The motor length increases when a holding brake is mounted.

The holding brake can be controlled directly by SERVOSTAR-servo amplifier (no personal safety !),

the winding is suppressed in the servo amplifier — additional circuitry is not required.

If the holding brake is not controlled directly by the servo amplifier, an additional wiring (e.g. varistor) is required. Consult our applications department beforehand.

A personal safe operation of the holding brake requires an additional contact (normally opened) in

the braking circuit and an anti-surge-device (e.g. Varistor) for the brake.

Wiring example for SERVOSTAR 600

Incremental encoder with commutation,

resolution 500-10000 lines

SERVOSTAR 600

1.8.11 Pole numbers

Motor Poles Motor Poles

AKM1 6 AKM5 10

AKM2 6 AKM6 10

AKM3 8 AKM7 10

AKM4 10

- A.4.031.1/35

10 Servomotors AKM

Page 11

Kollmorgen 05/2006 General

1.9 Options

— Holding brake

Built-in holding brake.

Motor length increases by the holding brake.

— Radial shaft-sealing rings

A radial shaft-sealing ring can be supplied at extra charge to seal against oil mist

and oil spray. This increases the protection rating of the shaft bushing to IP67.

— Keyway

The motors are available with keyway and key inserted according to DIN6885

The shaft is balanced with a short (half) key.

— EnDat, BISS, ComCoder, SFD

Another feedback system is mounted instead of the resolver. The motor length

can increase by the alternative feedback.

With exception of the radial shaft seal the options cannot be retrofitted. Options such as radial shaft

seal, holding brake, EnDat or Comcoder can lead to a reduction of rated data.

1.10 Selection criteria

The three-phase servomotors are designed to operate with SERVOSTAR servo amplifiers. Toget

her, both units form a closed speed or torque control loop.

The most important selection criteria are:

— Standstill torque M

— Rated speed n

— Moment of inertia of motor and load J [kgcm²]

— Effective torque (calculated) M

When calculating the motors and servo amplifiers which are required, take account of the static load

and the dynamic load (acceleration/braking). Collected formulae and examples of the calculations

are available from our applications department.

0

n

rms

[Nm]

[min-1]

[Nm]

-

Servomotors AKM 11

Page 12

General 05/2006 Kollmorgen

1.10.1 Model number description

AKM62P- ANCNDA-00

Flange size

1 40mm

2 58mm

3 70mm

4 84mm

5 108mm

6 138mm

7 188mm

Rotor length

1

2

3

4

5

Winding type

A..Z

S special

Flange

A IEC

B NEMA

C alternative IEC standard

D other standard

G alternative IEC standard

H alternative IEC standard

S special

Shaft

C keyway

K open keyway

N smooth shaft

S special

Customization

00 standard

01 with shaft seal

xx special

Feedback

1 Comcoder with 1024 PPR

2 Comcoder with 2048 PPR

AA Acuro(Biss) Single Turn

AB Acuro(Biss) Multi Turn

C Smart Feedback Device

DA ECN1x13

DB EQN1x25

R Resolver

S special

Brake

2 24V holding brake

N w/o brake

S special

Connectors

B angular connectors

rotatable (AKM2)

C 0.5m shielded cable with

IP65 connector (AKM1/2),

angular connectors

rotatable (AKM3..7)

D single aangular connector,

rotatable (AKM3/4

with SFD, w/o brake)

M 0.5m shielded cable with

IP20 connectors (In < 6A)

P 0.5m shielded cable with

single IP20 connector

(In < 6A and SFD)

S special

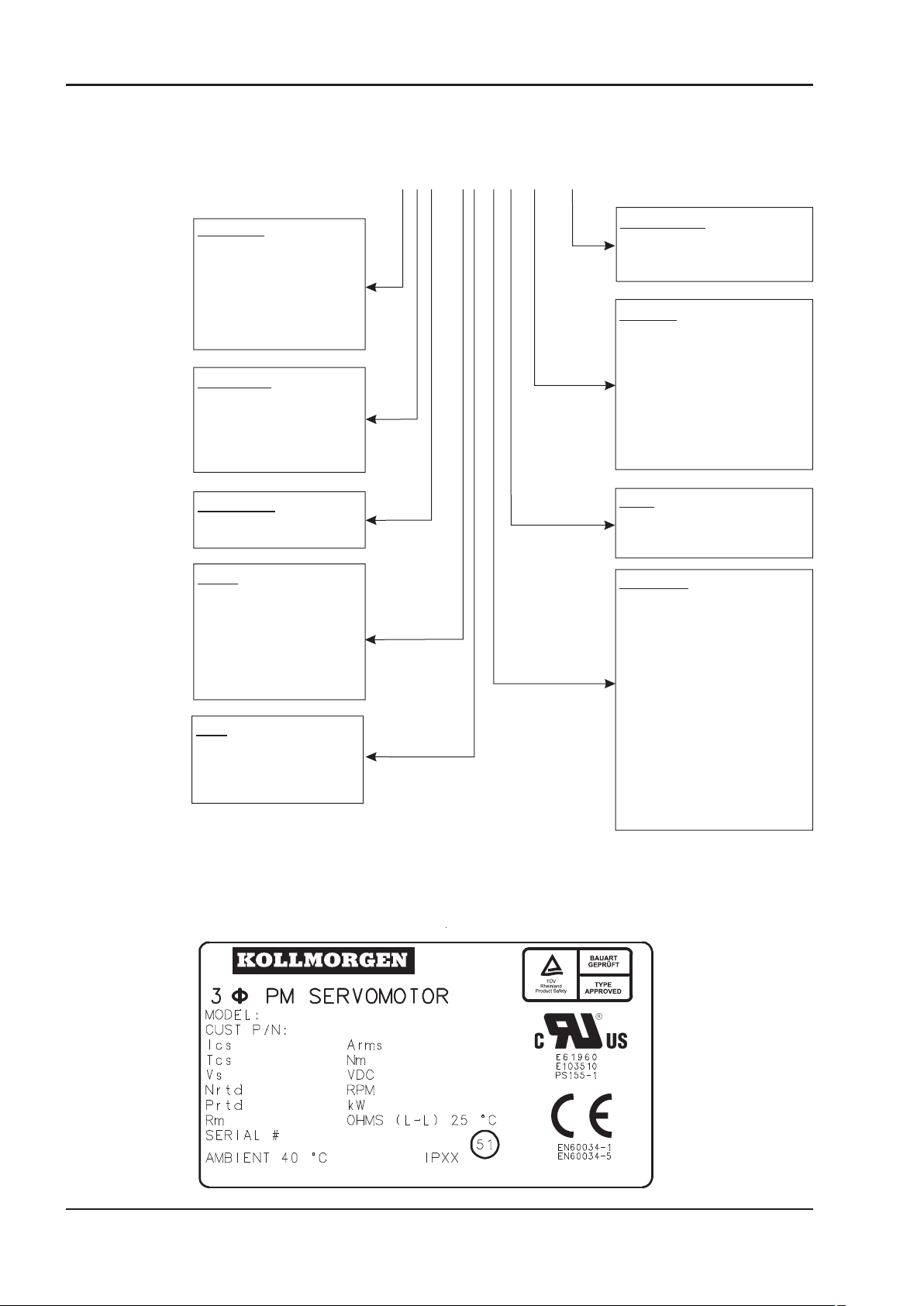

1.10.2 Nameplate

- A.4.028.6/44

12 Servomotors AKM

Page 13

Kollmorgen 05/2006 Installation / Setup

2 Installation / Setup

2.1 Important notes

Check that the servo amplifier and motor match each other. Compare the rated voltage and

l

rated current of the unit. Carry out the wiring according to the wiring diagram in the Installati

on and Setup Instructions for the servo amplifier. The connections to the motor are shown

on pages 17f. Notes on the connection methods can be found on page 16.

Ensure that there is proper earthing of the servo amplifier and the motor.

l

Route the power and control cables as separately as possible from one another (separation

l

> 20 cm). This will improve the immunity of the system to electromagnetic interference.

If a motor power cable is used which includes integral brake control leads, then these brake

control leads must be shielded. The shielding must be connected at both ends (see under

Installation Instructions for the servo amplifier).

Install all cables carrying a heavy current with an adequate cross-section, as per EN 60204.

l

The recommended cross-section can be found in the Technical data.

Caution!

If a servo amplifier of the series SERVOSTAR is used and the motor cable exceeds

25m, a motor choke (type 3YLNxx, see manual of the servo amplifier) and motor leads

with the following diameters must be used:

-

Rated output current of the servo amplifier

1...6 A 4 x 1mm²

10...20 A 4 x 2,5mm²

l Connect up all shielding via a wide surface-area contact (low impedance) and metallized

Maximum lead diameter of the motor cable

(cable length > 25m and motor choke)

connector housings or EMC-cable glands.

l

Check the compliance to the permitted radial and axial forces FRand FA.

When you use a toothed belt drive, the minimal permitted diameter of the pinion e.g. follows

M

from the equation:

d

min

³´02

.

F

R

Caution!

Never undo the electrical connections to the motor while it is energised. A dangerous

voltage, resulting from residual charge, can be still present on the capacitors up to 5

minutes after switch-off of the mains supply.

Measure the DC-link voltage and wait until it has fallen below 40V.

Even when the motor is not rotating, control and power leads may be live.

Servomotors AKM 13

Page 14

Installation / Setup 05/2006 Kollmorgen

2.2 Assembly / Wiring

Only qualified staff with knowledge of mechanical engineering are permitted to assemble

the motor.

Only staff qualified and trained in electrical engineering are allowed to wire up the motor.

The procedure is described as an example. A different method may be appropriate or necessary,

depending on the application of the equipment.

Warning!

Protect the motor from unacceptable stresses.

Take care, especially during transport and handling, that components are not bent and that

insulation clearances are not altered.

Always make sure that the motors are de-energized during assembly and wiring, i.e. No vol

tage may be switched on for any piece of equipment which is to be connected.

Ensure that the switch cabinet remains turned off (barrier, warning signs etc.).

The individual voltages will only be turned on again during setup.

-

Note!

The ground symbol

must provide an electrical connection, with as large a surface area as possible, between the

unit indicated and the mounting plate in the switch cabinet. This connection is to suppress

HF interference and must not be confused with the PE (protective earth) symbol (protective

measure to EN 60204).

To wire up the motor, use the wiring diagrams in the Installation and Setup Instructions of

the servo amplifier which is used.

X, which you will find in the wiring diagrams, indicates that you

14 Servomotors AKM

Page 15

Kollmorgen 05/2006 Installation / Setup

The following notes should help you to carry out the assembly and wiring in an appropriate

sequence, without overlooking anything.

The site must be free of conductive and aggressive material. For

Site

V3-mounting (shaft end upwards), make sure that no liquids can enter

the bearings. If an encapsulated assembly is required, please consult

our applications department beforehand

.

Ventilation

Assembly

Cable selection

Earthing / Shielding

Wiring

Check

Ensure an unhindered ventilation of the motors and observe the permis

sible ambient and flange temperatures. For ambient temperatures abo

ve 40°C please consult our applications department beforehand

During assembly, take care that the motor is not overstressed when it is

fixed in place

Select cables according to EN 60204.

See the table on page 13 when cable length exceeds 25m.

Use correct earthing and EMC-shielding according to the Installation in

structions for the servo amplifier which is used. Earth the mounting pla

te and motor casing. For connection methods see chapter 2.2.1

— Route power cables as separately as possible from control cables

— Connect up the resolver or encoder.

— Connect the motor cables, install motor chokes close to the

servo amplifier, connect shields to shielding terminals or EMC

connectors at both ends

— Connect the holding brake, if used, Connect shielding at both ends

Final check of the installed wiring, according to the wiring diagram

which was used

.

.

.

-

-

-

-

.

Servomotors AKM 15

Page 16

Installation / Setup 05/2006 Kollmorgen

2.2.1 Connection of the motors with preassembled cables

Carry out the wiring in accordance with the valid standards and regulations.

l

Only use our preassembled shielded cables for the resolver and power connections.

l

Connect up the shielding according to the wiring diagrams in the installation instructions for

l

the servo amplifier.

Incorrectly installed shielding inevitably cables to EMC interference.

l

In the table below you find all cables supplied by us. Further information referring to

chemical, mechanical and electrical qualities can be received from our applications department.

Insulating material

Sheathing PUR (Polyurethane, identification 11Y)

core insulation PETP (Polyesteraphtalate, identification 12Y)

Capacity

Motor cable less than 150 pF/m Resolver cable less than 120 pF/m

Technical Data

— All cables are UL-listed. The UL-Style-number is printed on the sheathing.

— All cables are suitable for trailing. Technical data refer to mobile usage of cables.

Life time: 1 Million bending cycles

— The temperature range refers to the operation temperature.

— N=number, F=color acc. to DIN 47100, ()= shielding

Cores

[mm²]

(4x1,0) N -30 / +80 10 100

(4x2,5) N -30 / +80 12,6 125

(4x1,0+(2x0,75)) F -30 / +80 10,5 100

(4x1,5+(2x0,75)) N -30 / +80 11,5 120

(4x2,5+(2x1)) F -30 / +80 14,2 145

(4x2x0,25) F -30 / +80 7,7 70 Resolver cable

(7x2x0,25) F -30 / +80 9,9 80 Encoder cable

(8x2x0,25) F -30 / +80 10,5 100 Comcoder cable

Identifi-

cation

Temperature

range

[°C]

Cable

diameter

[mm]

Bending

radius

[mm]

Remarks

Motor cable(4x1,5) N -30 / +80 10,5 105

Motor cable with integral

brake control leads

Feedback cables with connectors

Article EU order code

Resolver cable 5m (4x(2x0.25))

Resolver cable 10m (4x(2x0.25))

Resolver cable 15m (4x(2x0.25))

Resolver cable 20m (4x(2x0.25))

Resolver cable 25m (4x(2x0.25))

Encoder cable 5m (7x(2x0.25))

Encoder cable 10m (7x(2x0.25))

Encoder cable 15m (7x(2x0.25))

Encoder cable 20m (7x(2x0.25))

Encoder cable 25m (7x(2x0.25))

Comcoder cable 5m (8x(2x0.25))

Comcoder cable 10m (8x(2x0.25))

Comcoder cable 15m (8x(2x0.25))

Comcoder cable 20m (8x(2x0.25))

Comcoder cable 25m (8x(2x0.25))

DE-84972

DE-84973

DE-84974

DE-84975

DE-87655

DE-90287

DE-91019

DE-91811

DE-91807

DE-92205

DE-107915

DE-107916

DE-107917

DE-107918

DE-107919

other lengths on request,

16 Servomotors AKM

Page 17

Kollmorgen 05/2006 Installation / Setup

2.2.1.1 Wiring diagram for motors with resolver

- A.4.050.4/09

SERVOSTAR

Servomotors AKM 17

Page 18

Installation / Setup 05/2006 Kollmorgen

2.2.1.2 Wiring diagram for motors with encoder

- A.4.050.4/10

SERVOSTAR

18 Servomotors AKM

Page 19

Kollmorgen 05/2006 Installation / Setup

2.2.1.3 Wiring diagram for motors with SFD

- A.4.050.4/26

SERVOSTAR

Servomotors AKM 19

Page 20

Installation / Setup 05/2006 Kollmorgen

2.2.1.4 Wiring diagram for motors with ComCoder

-A.4.050.4/27

SERVOSTAR

20 Servomotors AKM

Page 21

Kollmorgen 05/2006 Installation / Setup

2.2.1.5 Wiring diagram for motors with BISS

SERVOSTAR

Servomotors AKM 21

Page 22

Installation / Setup 05/2006 Kollmorgen

2.3 Setup

The procedure for setup is described as an example. A different method may be appropriate or

necessary, depending on the application of the equipment.

Only specialist personnel with extensive knowledge in the areas of electrical engineering / drive

technology are allowed to commission the drive unit of servo amplifier and motor.

Check that all live connection points (terminal boxes) are safe against accidental contact.

Deadly voltages can occur, up to 900V.

Never undo the electrical connections to the motor when it is live. The residual charge in the

capacitors of the servo amplifier can produce dangerous voltages up to 5 minutes after the

mains supply has been switched off.

The surface temperature of the motor can exceed 100°C in operation.

Check (measure) the temperature of the motor. Wait until the motor has cooled down below

40°C before touching it.

Make sure that, even if the drive starts to move unintentionally, no danger can result for per

sonnel or machinery.

Check the assembly and orientation of the motor.

l

Check the drive components (clutch, gear unit, belt pulley) for the correct seating and

l

setting (observe the permissible radial and axial forces).

Check the wiring and connections to the motor and the servo amplifier. Check that

l

the earthing is correct.

Test the function of the holding brake, if used. (apply 24V, the brake must be relea-

l

sed).

l

Check whether the rotor of the motor revolves freely (release the brake, if necessary).

Listen out for grinding noises.

l

Check that all the required measures against accidental contact with live and moving

parts have been carried out.

l

Carry out any further tests which are specifically required for your system.

l

Now commission the drive according to the setup instructions for the servo amplifier.

l

In multi-axis systems, individually commission each drive unit (servo amplifier and

motor).

-

22 Servomotors AKM

Page 23

Kollmorgen 05/2006 Technical Data

3 Technical Data

All data valid for 40°C environmental temperature and 100K overtemperature of the winding. The

data can have a tolerance of +/- 10%.

3.1 Definitions

Standstill torque M0[Nm]

The standstill torque can be maintained indefinitely at a speed n<100 min

-1

and rated ambient con

ditions.

Rated torque M

n

[Nm]

The rated torque is produced when the motor is drawing the rated current at the rated speed. The

rated torque can be produced indefinitely at the rated speed in continuous operation (S1).

Standstill current I

The standstill current is the effective sinusoidal current which the motor draws at n<100 min

0rms

[A]

-1

to

produce the standstill torque.

Peak current (pulse current) I

The peak current (effective sinusoidal value) is approximately equivalent to 4-times the rated cur

0max

[A]

-

rent. The actual value is determined by the peak current of the servo amplifier which is used.

Torque constant K

The torque constant defines how much torque in Nm is produced by the motor with 1A r.m.s. cur

rent. The relationship is M=I x K

Voltage constant K

Trms

Erms

[Nm/A]

(uptoI=2xI0)

T

[mV/min-1]

-

The voltage constant defines the induced motor EMF, as an effective sinusoidal value between two

terminals, per 1000 rpm

Rotor moment of inertia J [kgcm²]

The constant J is a measure of the acceleration capability of the motor. For instance, at I

leration time t

from 0 to 3000 rpm is given as:

b

ts

[]=

b

´

3000 2

Msmcm

´

60 10

0

p

´

42

´

2

with M

J

´

in Nm and J in kgcm²

0

the acce-

0

-

Thermal time constant t

The constant t

defines the time for the cold motor, under a load of I0, to heat up to an overtempe

th

th

[min]

rature of 0.63 x 105 Kelvin. This temperature rise happens in a much shorter time when the motor is

loaded with the rated current.

Release delay time t

[ms] / Application delay time t

BRH

These constants define the response times of the holding brake when operated with the rated vol

[ms] of the brake

BRL

-

tage from the servo amplifier.

Servomotors AKM 23

Page 24

Technical Data 05/2006 Kollmorgen

3.2 AKM1

Technical data

Data

Symbol

[Unit]

11B 11C 11E 12C 12E 13C 13D

Electrical data

Standstill torque* M

Standstill current I

max. Mains voltage U

[Nm] 0,18 0,18 0,18 0,31 0,31 0,41 0,40

0

[A] 1,16 1,45 2,91 1,51 2,72 1,48 2,40

0rms

[VAC] 230VAC

N

Rated speed nn[min-1] — — 6000 — 3000 — 2000

Rated torque* M

Rated power

U = 75VDC

[Nm] — — 0,18 — 0,31 — 0,40

n

[kW]

P

n

— — 0,11 — 0,10 — 0,08

Rated speed nn[min-1] 4000 6000 — 4000 8000 3000 7000

Rated torque* M

= 115V

N

Rated power

U

[Nm] 0,18 0,18 — 0,30 0,28 0,41 0,36

n

[kW]

P

n

0,08 0,11 — 0,13 0,23 0,13 0,27

Rated speed nn[min-1] 8000 — — 8000 — 8000 —

Rated torque* M

= 230V

N

Rated power

U

[Nm] 0,17 — — 0,28 — 0,36 —

n

[kW]

P

n

0,14 — — 0,23 — 0,30 —

Rated speed nn[min-1] ———————

Rated torque* M

= 400V

N

Rated power

U

[Nm] ———————

n

P

n

[kW]

———————

Rated speed nn[min-1] ———————

Rated torque* M

= 480V

N

Rated power

U

Peak current I

Peak torque M

Torque constant K

Voltage constant K

Winding resistance Ph-Ph

[Nm] ———————

n

[kW]

P

n

[A] 4,65 5,79 11,6 6,06 10,9 5,93 9,6

0max

[Nm] 0,61 0,61 0,61 1,08 1,08 1,46 1,44

0max

[Nm/A] 0,16 0,13 0,06 0,21 0,11 0,28 0,17

Trms

[mVmin] 10,2 8,3 4,1 13,3 7,2 17,9 10,9

Erms

R

[W]

25

———————

20,2 13,1 3,3 12,4 3,9 13,5 5,2

Winding inductance Ph-Ph L [mH] 12,5 8,3 2,0 9,1 2,7 10,3 3,8

Mechanical data

Rotor moment of inertia J [kgcm²] 0,017 0,031 0,045

Pole number 6 6 6

Static friction torque M

Thermal time constant t

[Nm] 0,0011 0,0021 0,0031

R

[min] 4 6 7

TH

Weight standard G [kg] 0,35 0,49 0,63

Radial load permitted at shaft

end @ 8000 min

Axial load permitted at shaft

end @ 8000 min

-1

-1

FR[N]

FA[N]

* reference flange Aluminium 254mm * 254mm * 6,35mm

AKM

30

12

Connections and cables

Data AKM1

Power connection 4 + 4 poles, round, on Cable 0,5m

Motorcable, shielded 4 x 1

Motor cable with control leads,

shielded

4x1+2x0,75

Resolver connection 12 poles, round, on Cable 0,5m

Resolver cable, shielded 4x2x0,25mm²

Comcoder connection (option) 17 poles, round, on Cable 0,5m

24 Servomotors AKM

Page 25

Kollmorgen 05/2006 Technical Data

Dimensions (drawing in principle)

Radial-/axial forces at the shaft end

Servomotors AKM 25

Page 26

Technical Data 05/2006 Kollmorgen

3.3 AKM2

Technical data

Data

Symbol

[Unit]

21C 21E 21G 22C 22E 22G 23C 23D 23F 24C 24D 24F

Electrical data

Standstill torque* M

Standstill current I

max. Mains voltage U

[Nm] 0,48 0,50 0,50 0,84 0,87 0,88 1,13 1,16 1,18 1,38 1,41 1,42

0

[A] 1,58 3,11 4,87 1,39 2,73 4,82 1,41 2,19 4,31 1,42 2,21 3,89

0rms

[VAC] 480

N

Rated speed nn[min-1] — 2000 4000 — 1000 2500 — — 1500 — — 1000

Rated torque* M

Rated power

U = 75VDC

[Nm] — 0,48 0,46 — 0,85 0,83 — — 1,15 — — 1,39

n

[kW]

P

n

— 0,10 0,19 — 0,09 0,22 — — 0,18 — — 0,15

Rated speed nn[min-1] 2500 7000 — 1000 3500 7000 1000 1500 4500 — 1500 3000

Rated torque* M

= 115V

N

Rated power

U

[Nm] 0,46 0,41 — 0,83 0,81 0,74 1,11 1,12 1,07 — 1,36 1,33

n

[kW]

P

n

0,12 0,30 — 0,09 0,30 0,54 0,12 0,18 0,50 — 0,21 0,42

Rated speed nn[min-1] 8000 — — 3500 8000 — 2500 5000 8000 2000 4000 8000

Rated torque* M

= 230V

N

Rated power

U

[Nm] 0,39 — — 0,78 0,70 — 1,08 1,03 0,94 1,32 1,29 1,12

n

[kW]

P

n

0,32 — — 0,29 0,59 — 0,28 0,54 0,79 0,28 0,54 0,94

Rated speed nn[min-1] — — — 8000 — — 5500 8000 — 4500 8000 —

Rated torque* M

= 400V

N

Rated power

U

[Nm] — — — 0,68 — — 0,99 0,92 — 1,25 1,11 —

n

P

n

[kW]

— — — 0,57 — — 0,57 0,77 — 0,59 0,93 —

Rated speed nn[min-1] — — — 8000 — — 7000 8000 — 5500 8000 —

Rated torque* M

= 480V

N

Rated power

U

Peak current I

Peak torque M

Torque constant K

Voltage constant K

Winding resistance Ph-Ph

[Nm] — — — 0,68 — — 0,95 0,92 — 1,22 1,11 —

n

[kW]

P

n

[A] 6,3 12,4 19,5 5,6 10,9 19,3 5,6 8,8 17,2 5,7 8,8 15,6

0max

[Nm] 1,47 1,49 1,51 2,73 2,76 2,79 3,77 3,84 3,88 4,73 4,76 4,82

0max

[Nm/A] 0,30 0,16 0,10 0,61 0,32 0,18 0,80 0,52 0,27 0,97 0,63 0,36

Trms

[mVmin] 19,5 10,2 6,6 39 20,4 11,7 51,8 33,8 17,6 62,4 40,8 23,4

Erms

R

[W]

25

— — — 0,57 — — 0,70 0,77 — 0,70 0,93 —

13,0 3,42 1,44 19,4 5,09 1,69 20,3 8,36 2,23 20,4 8,4 2,77

Winding inductance Ph-Ph L [mH] 19 5,2 2,18 35,5 9,7 3,19 40,7 17,3 4,68 43,8 18,7 6,16

Mechanical data

Rotor moment of inertia J [kgcm²] 0,11 0,16 0,22 0,27

Pole number 6666

Static friction torque M

Thermal time constant t

[Nm] 0,002 0,005 0,007 0,01

R

[min] 8 9 10 11

TH

Weight standard G [kg] 0,82 1,1 1,38 1,66

Radial load permitted at shaft

end @ 5000 min

Axial load permitted at shaft

end @ 5000 min

-1

-1

FR[N]

FA[N]

* reference flange Aluminium 254mm * 254mm * 6,35mm

AKM

145

60

Brake data

Data Symbol [Unit] Value

Holding torque @ 120°C M

Operating voltage

electrical power P

Moment of inertia J

Release delay time t

Application delay time t

Weight of the brake G

[Nm] 1,42

BR

U

[VDC]

BR

[W] 8,4

BR

[kgcm²] 0,011

BR

[ms] 20

BRH

[ms] 18

BRL

[kg] 0,27

BR

24 ± 10 %

Typical backlash [ °mech.] 0,46

26 Servomotors AKM

Page 27

Kollmorgen 05/2006 Technical Data

Connections and cables

Data AKM2

Power connection 4 + 4 poles, round, angular

Motorcable, shielded 4 x 1

Motor cable with control leads, shielded 4x1+2x0,75

Resolver connection 12 poles, round, angular

Resolver cable, shielded 4x2x0,25mm²

Encoder connection (option) 17 poles, round, angular

Encoder cable, shielded 7x2x0,25mm²

Dimensions (drawing in principle)

Radial-/axial forces at the shaft end

- A.4.043.4/01, 13

Servomotors AKM 27

Page 28

Technical Data 05/2006 Kollmorgen

3.4 AKM3

Technical data

Data

Symbol

[Unit]

31C 31E 31H 32C 32D 32H 33C 33E 33H

Electrical data

Standstill torque* M

Standstill current I

max. Mains voltage U

[Nm] 1,15 1,20 1,23 2,00 2,04 2,10 2,71 2,79 2,88

0

[A] 1,37 2,99 5,85 1,44 2,23 5,50 1,47 2,58 5,62

0rms

[VAC] 480

N

Rated speed nn[min-1] — 750 2000 — — 1200 — — 800

Rated torque* M

Rated power

U = 75VDC

[Nm] — 1,19 1,20 — — 2,06 — — 2,82

n

[kW]

P

n

— 0,09 0,25 — — 0,26 — — 0,24

Rated speed nn[min-1] — 2500 6000 — 1000 3000 — — 2500

Rated torque* M

= 115V

N

Rated power

U

[Nm] — 1,17 0,97 — 2,00 1,96 — — 2,66

n

[kW]

P

n

— 0,31 0,61 — 0,21 0,62 — — 0,70

Rated speed nn[min-1] 2500 6000 — 1500 2500 7000 1000 2000 5500

Rated torque* M

= 230V

N

Rated power

U

[Nm] 1,12 0,95 — 1,95 1,93 1,45 2,64 2,62 2,27

n

[kW]

P

n

0,29 0,60 — 0,31 0,51 1,06 0,28 0,55 1,31

Rated speed nn[min-1] 5000 — — 3000 5500 — 2000 4500 —

Rated torque* M

= 400V

N

Rated power

U

[Nm] 1,00 — — 1,86 1,65 — 2,54 2,34 —

n

P

n

[kW]

0,52 — — 0,58 0,95 — 0,53 1,10 —

Rated speed nn[min-1] 6000 — — 3500 6000 — 2500 5000 —

Rated torque* M

= 480V

N

Rated power

U

Peak current I

Peak torque M

Torque constant K

Voltage constant K

Winding resistance Ph-Ph

[Nm] 0,91 — — 1,83 1,58 — 2,50 2,27 —

n

[kW]

P

n

[A] 5,5 12,0 23,4 5,7 8,9 22,0 5,9 10,3 22,5

0max

[Nm] 3,88 4,00 4,06 6,92 7,05 7,26 9,76 9,96 10,2

0max

[Nm/A] 0,85 0,41 0,21 1,40 0,92 0,39 1,86 1,10 0,52

Trms

[mVmin] 54,5 26,1 13,7 89,8 59,0 24,8 120 70,6 33,4

Erms

R

[W]

25

0,57 — — 0,67 0,99 — 0,65 1,19 —

21,4 4,58 1,25 23,0 9,57 1,64 25,4 8,36 1,82

Winding inductance Ph-Ph L [mH] 37,5 8,6 2,4 46,5 20,1 3,55 53,6 18,5 4,1

Mechanical data

Rotor moment of inertia J [kgcm²] 0,33 0,59 0,85

Pole number 8 8 8

Static friction torque M

Thermal time constant t

[Nm] 0,014 0,02 0,026

R

[min] 14 17 20

TH

Weight standard G [kg] 1,55 2,23 2,9

Radial load permitted at shaft

end @ 3000 min

Axial load permitted at shaft

end @ 3000 min

-1

-1

FR[N]

FA[N]

* reference flange Aluminium 254mm * 254mm * 6,35mm

AKM

195

65

Brake data

Data Symbol [Unit] Value

Holding torque @ 120°C M

Operating voltage

electrical power P

Moment of inertia J

Release delay time t

Application delay time t

Weight of the brake G

[Nm] 2,5

BR

U

[VDC]

BR

[W] 10,1

BR

[kgcm²] 0,011

BR

[ms] 25

BRH

[ms] 10

BRL

[kg] 0,35

BR

24 ± 10 %

Typical backlash [ °mech.] 0,46

28 Servomotors AKM

Page 29

Kollmorgen 05/2006 Technical Data

Connections and cables

Data AKM3

Power connection 4 + 4 poles, round, angular

Motorcable, shielded 4 x 1

Motor cable with control leads, shielded 4x1+2x0,75

Resolver connection 12 poles, round, angular

Resolver cable, shielded 4x2x0,25mm²

Encoder connection (option) 17 poles, round, angular

Encoder cable, shielded 7x2x0,25mm²

Dimensions (drawing in principle)

Radial-/axial forces at the shaft end

- A.4.043.4/02, 13 - A.4.043.3/02, 044.3/05, 09, 10

Servomotors AKM 29

Page 30

Technical Data 05/2006 Kollmorgen

3.5 AKM4

Technical data

Data

Symbol

[Unit]

41C 41E 41H 42C 42E 42G 42J 43E 43G 43K 44E 44G 44J

Electrical data

Standstill torque* M

Standstill current I

max. Mains voltage U

[Nm] 1,95 2,02 2,06 3,35 3,42 3,53 3,56 4,70 4,80 4,90 5,76 5,88 6,00

0

[A] 1,46 2,85 5,60 1,40 2,74 4,80 8,40 2,76 4,87 9,60 2,90 5,00 8,80

0rms

[VAC] 480

N

Rated speed nn[min-1] — — 1000 ——————————

Rated torque* M

Rated power

U = 75VDC

[Nm] — — 1,99 ——————————

n

[kW]

P

n

— — 0,21 ——————————

Rated speed nn[min-1] — 1200 3000 — — — 3000 — — 2500 — — —

Rated torque* M

= 115V

N

Rated power

U

[Nm] — 1,94 1,86 — — — 3,03 — — 4,08 — — —

n

[kW]

P

n

— 0,24 0,58 — — — 0,95 — — 1,07 — — —

Rated speed nn[min-1] 1200 3000 6000 — 1800 3500 6000 1500 2500 6000 1200 2000 4000

Rated torque* M

= 230V

N

Rated power

U

[Nm] 1,88 1,82 1,62 — 3,12 2,90 2,38 4,24 4,00 2,62 5,22 4,90 3,84

n

[kW]

P

n

0,24 0,57 1,02 — 0,59 1,06 1,50 0,67 1,05 1,65 0,66 1,03 1,61

Rated speed nn[min-1] 3000 6000 — 1500 3500 6000 — 2500 5000 — 2000 4000 6000

Rated torque* M

= 400V

N

Rated power

U

[Nm] 1,77 1,58 — 3,10 2,81 2,35 — 3,92 3,01 — 4,80 3,76 2,75

n

P

n

[kW]

0,56 0,99 — 0,49 1,03 1,48 — 1,03 1,58 — 1,01 1,57 1,73

Rated speed nn[min-1] 3500 6000 — 2000 4000 6000 — 3000 6000 — 2500 5000 6000

Rated torque* M

= 480V

N

Rated power

U

Peak current I

Peak torque M

Torque constant K

Voltage constant K

Winding resistance Ph-Ph

[Nm] 1,74 1,58 — 3,02 2,72 2,35 — 3,76 2,57 — 4,56 3,19 2,75

n

[kW]

P

n

[A] 5,8 11,4 22,4 5,61 11,0 19,2 33,7 11,0 19,5 38,3 11,4 20,0 35,2

0max

[Nm] 6,12 6,28 6,36 11,1 11,3 11,5 11,6 15,9 16,1 16,3 19,9 20,2 20,4

0max

[Nm/A] 1,34 0,71 0,37 2,40 1,26 0,74 0,43 1,72 0,99 0,52 2,04 1,19 0,69

Trms

[mVmin] 86,3 45,6 23,7 154 80,9 47,5 27,5 111 63,9 33,2 132 76,6 44,2

Erms

R

[W]

25

0,64 0,99 — 0,63 1,14 1,48 — 1,18 1,61 — 1,19 1,67 1,73

21,7 5,7 1,51 27,5 7,22 2,38 0,80 8,04 2,61 0,70 8,08 2,65 0,88

Winding inductance Ph-Ph L [mH] 66,1 18,4 5,0 97,4 26,8 9,2 3,1 32,6 10,8 2,9 33,9 11,5 3,8

Mechanical data

Rotor moment of inertia J [kgcm²] 0,81 1,5 2,1 2,7

Pole number 10 10 10 10

Static friction torque M

Thermal time constant t

[Nm] 0,014 0,026 0,038 0,05

R

[min] 13 17 20 24

TH

Weight standard G [kg] 2,44 3,39 4,35 5,3

Radial load permitted at shaft

end @ 3000 min

Axial load permitted at shaft

end @ 3000 min

-1

-1

FR[N]

FA[N]

* reference flange Aluminium 254mm * 254mm * 6,35mm

AKM

450

180

Brake data

Data Symbol [Unit] Value

Holding torque @ 120°C M

Operating voltage

electrical power P

Moment of inertia J

Release delay time t

Application delay time t

Weight of the brake G

[Nm] 6

BR

U

[VDC]

BR

[W] 12,8

BR

[kgcm²] 0,068

BR

[ms] 35

BRH

[ms] 15

BRL

[kg] 0,63

BR

24 ± 10 %

Typical backlash [ °mech.] 0,37

30 Servomotors AKM

Page 31

Kollmorgen 05/2006 Technical Data

Connections and cables

Data AKM4

Power connection 4 + 4 poles, round, angular

Motorcable, shielded 4 x 1,5

Motor cable with control leads, shielded 4x1+2x0,75

Resolver connection 12 poles, round, angular

Resolver cable, shielded 4x2x0,25mm²

Encoder connection (option) 17 poles, round, angular

Encoder cable, shielded 7x2x0,25mm²

Dimensions (drawing in principle)

Radial-/axial forces at the shaft end

- A.4.043.4/03, 13 - A.4.043.3/03, 044.3/12, 15, 16

Servomotors AKM 31

Page 32

Technical Data 05/2006 Kollmorgen

3.6 AKM5

Technical data

Data

Symbol

[Unit]

51E 51G 51K 52E 52G 52K 52M 53G 53K 53M 53P 54G 54K 54L 54N

Electrical data

Standstill torque* M

Standstill current I

max. Mains voltage U

Rated speed nn[min-1]

Rated torque* Mn[Nm]

Rated power

U = 75VDC

Rated speed nn[min-1]

Rated torque* Mn[Nm]

= 115V

N

Rated power

U

Rated speed nn[min-1]

Rated torque* Mn[Nm]

= 230V

N

Rated power

U

[Nm] 4,70 4,75 4,90 8,34 8,43 8,60 8,60 11,4 11,6 11,4 11,4 14,3 14,4 14,1 14,1

0

[A] 2,75 4,84 9,4 2,99 4,72 9,3 13,1 4,77 9,4 13,4 19,1 5,0 9,7 12,5 17,8

0rms

[VAC] 480

N

P

[kW]

n

P

[kW]

n

P

[kW]

n

———————————————

———————————————

———————————————

— — 2500 ————————————

— — 4,15 ————————————

— — 1,09 ————————————

1200 2500 5500 — 1500 3000 4500 1000 2000 3000 5000 — 1800 2500 3500

4,41 4,02 2,35 — 7,69 6,80 5,20 10,7 10,1 8,72 5,88 — 12,7 11,5 9,85

0,55 1,05 1,35 — 1,21 2,14 2,45 1,12 2,12 2,74 3,08 — 2,39 3,00 3,61

Rated speed nn[min-1] 2500 5000 — 1500 2500 5500 — 2000 4000 — — 1500 3500 4500 —

Rated torque* M

= 400V

N

Rated power

U

Rated speed nn[min-1]

[Nm] 3,98 2,62 — 7,61 7,06 3,90 — 9,85 7,65 — — 12,9 10,0 8,13 —

n

P

[kW]

n

1,04 1,37 — 1,20 1,85 2,25 — 2,06 3,20 — — 2,03 3,68 3,83 —

3000 6000 — 2000 3000 6000 — 2400 4500 — — 2000 4000 — —

Rated torque* Mn[Nm] 3,80 1,94 — 7,28 6,66 3,25 — 9,50 6,85 — — 12,3 9,25 — —

= 480V

N

Rated power

U

Peak current I

Peak torque

Torque constant

Voltage constant

Winding resistance Ph-Ph

[kW]

P

n

0max

M

0max

[Nm]

K

Trms

[Nm/A]

K

Erms

[mVmin]

R

25

1,19 1,22 — 1,52 2,09 2,04 — 2,39 3,23 — — 2,57 3,87 — —

[A] 8,24 14,5 28,3 9,00 14,2 27,8 39,4 14,3 28,1 40,3 57,4 14,9 29,2 37,5 53,4

11,6 11,7 12,0 21,3 21,5 21,9 21,9 29,7 30,1 29,8 29,8 37,8 38,4 37,5 37,6

1,72 0,99 0,52 2,79 1,79 0,93 0,66 2,39 1,24 0,85 0,60 2,88 1,50 1,13 0,80

110 63,6 33,5 179 115 60,1 42,4 154 79,8 54,7 38,4 185 96,6 72,9 51,3

8,47 2,75 0,75 8,59 3,47 0,93 0,48 3,75 1,00 0,51 0,27 3,80 1,02 0,63 0,33

[W]

Winding inductance Ph-Ph L [mH] 36,6 12,1 3,40 44,7 18,5 5,00 2,50 21,3 5,70 2,70 1,30 22,9 6,20 3,50 1,80

Mechanical data

Rotor moment of inertia J [kgcm²] 3,4 6,2 9,1 12

Pole number 10 10 10 10

Static friction torque M

Thermal time constant t

[Nm] 0,022 0,04 0,058 0,077

R

[min] 20 24 28 31

TH

Weight standard G [kg] 4,2 5,8 7,4 9

Radial load permitted at

shaft end @ 3000 min

Axial load permitted at

shaft end @ 3000 min

FR[N]

-1

FA[N]

-1

* reference flange Aluminium 305mm * 305mm * 12,7mm

AKM

450

180

Brake data

Data Symbol [Unit] Value

Holding torque @ 120°C M

Operating voltage

electrical power P

Moment of inertia J

Release delay time t

Application delay time t

Weight of the brake G

[Nm] 14,5

BR

U

[VDC]

BR

[W] 19,5

BR

[kgcm²] 0,173

BR

[ms] 80

BRH

[ms] 15

BRL

[kg] 1,1

BR

24 ± 10 %

Typical backlash [ °mech.] 0,31

32 Servomotors AKM

Page 33

Kollmorgen 05/2006 Technical Data

Connections and cables

Data AKM5

Power connection 4 + 4 poles, round, angular

Motorcable, shielded 4 x 1,5 4 x 2,5

Motor cable with control leads, shielded 4 x 1,5+2x0,75 4 x 2,5+2x1

Resolver connection 12 poles, round, angular

Resolver cable, shielded 4x2x0,25mm²

Encoder connection (option) 17 poles, round, angular

Encoder cable, shielded 7x2x0,25mm²

Dimensions (drawing in principle)

Radial-/axial forces at the shaft end

- A.4.043.4/04, 13

Servomotors AKM 33

Page 34

Technical Data 05/2006 Kollmorgen

3.7 AKM6

Technical data

Data

Symbol

[Unit]

62G 62K 62M 62P 63G 63K 63M 63N 64K 64L 64P 65K 65M 65N

Electrical data

Standstill torque* M

Standstill current I

Mains voltage U

[Nm] 11,9 12,2 12,2 12,3 16,5 16,8 17,0 17,0 20,8 21,0 20,4 24,8 25,0 24,3

0

[A] 4,9 9,6 13,4 18,8 4,5 9,9 13,8 17,4 9,2 12,8 18,6 9,8 13,6 17,8

0rms

[VAC] 230-480

N

Rated speed nn[min-1] ——————————————

Rated torque* M

Rated power

U = 75VDC

[Nm] ——————————————

n

[kW]

P

n

——————————————

Rated speed nn[min-1] ——————————————

Rated torque* M

= 115V

N

Rated power

U

[Nm] ——————————————

n

[kW]

P

n

——————————————

Rated speed nn[min-1] — 2000 3000 4500 — 1500 2000 3000 1200 1500 2500 1000 1500 2000

Rated torque* M

= 230V

N

Rated power

U

[Nm] — 10,4 9,50 8,10 — 14,9 14,3 13,0 18,8 18,4 16,0 22,8 21,9 19,8

n

[kW]

P

n

— 2,18 2,98 3,82 — 2,34 2,99 4,08 2,36 2,89 4,19 2,39 3,44 4,15

Rated speed nn[min-1] 1800 3500 6000 — 1200 3000 4000 5000 2000 3000 4500 2000 2500 3500

Rated torque* M

= 400V

N

Rated power

U

[Nm] 10,4 9,00 5,70 — 14,9 12,9 11,3 9,60 17,2 15,6 11,9 20,2 19,2 16,0

n

P

n

[kW]

1,96 3,30 3,58 — 1,87 4,05 4,73 5,03 3,60 4,90 5,61 4,23 5,03 5,86

Rated speed nn[min-1] 2000 4500 6000 — 1500 3500 4500 6000 2500 3500 5500 2200 3000 4000

Rated torque* M

= 480V

N

Rated power

U

Peak current I

Peak torque M

Torque constant K

Voltage constant

Winding resistance Ph-Ph

[Nm] 10,2 8,00 5,70 — 14,6 12,0 10,5 7,00 16,3 14,4 9,00 19,7 18,1 14,7

n

[kW]

P

n

[A] 14,6 28,7 40,3 56,5 13,4 29,7 41,4 52,2 27,5 38,4 55,9 29,4 40,9 53,3

0max

[Nm] 29,8 30,1 30,2 30,4 41,8 42,6 43,0 43,0 53,5 54,1 52,9 64,5 65,2 63,7

0max

[Nm/A] 2,47 1,28 0,91 0,66 3,70 1,71 1,24 0,98 2,28 1,66 1,10 2,54 1,85 1,38

Trms

K

Erms

[mVmin]

R

[W]

25

2,14 3,77 3,58 — 2,29 4,40 4,95 4,40 4,27 5,28 5,18 4,54 5,69 6,16

159 82,1 58,8 42,2 238 110 79,9 63,3 147 107 71,0 164 119 88,8

3,94 1,05 0,55 0,30 5,16 1,09 0,58 0,38 1,34 0,71 0,36 1,27 0,68 0,42

Winding inductance Ph-Ph L [mH] 31,7 8,5 4,4 2,2 43,5 9,3 4,9 3,1 11,8 6,2 2,8 11,4 6,1 3,4

Mechanical data

Rotor moment of inertia J [kgcm²] 17 24 32 40

Pole number 10 10 10 10

Static friction torque M

Thermal time constant t

[Nm] 0,05 0,1 0,15 0,2

R

[min] 20 25 30 35

TH

Weight standard G [kg] 8,9 11,1 13,3 15,4

Radial load permitted at

shaft end @ 3000 min

Axial load permitted at

shaft end @ 3000 min

FR[N]

-1

FA[N]

-1

* reference flange Aluminium 457mm * 457mm * 12,7mm

AKM

770

280

Brake data

Data Symbol [Unit] Value

Holding torque @ 120°C M

Operating voltage

electrical power P

Moment of inertia J

Release delay time t

Application delay time t

Weight of the brake G

[Nm] 25

BR

U

[VDC]

BR

[W] 25,7

BR

[kgcm²] 0,61

BR

[ms] 105

BRH

[ms] 20

BRL

[kg] 2

BR

24 ± 10 %

Typical backlash [ °mech.] 0,24

34 Servomotors AKM

Page 35

Kollmorgen 05/2006 Technical Data

Connections and cables

Data AKM6

Power connection 4 + 4 poles, round, angular

Motorcable, shielded 4 x 2,5

Motor cable with control leads, shielded 4 x 2,5+2x1

Resolver connection 12 poles, round, angular

Resolver cable, shielded 4x2x0,25mm²

Encoder connection (option) 17 poles, round, angular

Encoder cable, shielded 7x2x0,25mm²

Dimensions (drawing in principle)

Radial-/axial forces at the shaft end

- A.4.043.4/05, 13

Servomotors AKM 35

Page 36

Technical Data 05/2006 Kollmorgen

3.8 AKM7

Technical data

Data

Symbol

[Unit]

72K 72M 72P 73M 73P 74L 74P

Electrical data

Standstill torque* M

Standstill current I

max. Mains voltage U

[Nm] 29,7 30,0 29,4 42,0 41,6 53,0 52,5

0

[A] 9,3 13,0 18,7 13,6 19,5 12,9 18,5

0rms

[VAC] 480

N

Rated speed nn[min-1] ———————

Rated torque* M

Rated power

U = 75VDC

[Nm] ———————

n

[kW]

P

n

———————

Rated speed nn[min-1] ———————

Rated torque* M

= 115V

N

Rated power

U

[Nm] ———————

n

[kW]

P

n

———————

Rated speed nn[min-1] — — 1800 — 1300 — —

Rated torque* M

= 230V

N

Rated power

U

[Nm] — — 23,8 — 34,7 — —

n

[kW]

P

n

— — 4,49 — 4,72 — —

Rated speed nn[min-1] 1500 2000 3000 1500 2400 1200 1800

Rated torque* M

= 400V

N

Rated power

U

[Nm] 25,1 23,6 20,1 33,8 28,5 43,5 39,6

n

P

n

[kW]

3,94 4,94 6,31 5,31 7,16 5,47 7,46

Rated speed nn[min-1] 1800 2500 3500 1800 2800 1400 2000

Rated torque* M

= 480V

N

Rated power

U

Peak current I

Peak torque M

Torque constant K

Voltage constant K

Winding resistance Ph-Ph

[Nm] 24,0 22,1 18,2 32,1 26,3 41,5 35,9

n

[kW]

P

n

[A] 27,8 38,9 56,1 40,8 58,6 38,7 55,5

0max

[Nm] 79,2 79,7 78,5 113 111 143 142

0max

[Nm/A] 3,23 2,33 1,58 3,10 2,13 4,14 2,84

Trms

[mVmin] 208 150 102 200 137 266 183

Erms

R

[W]

25

4,52 5,79 6,67 6,05 7,71 6,08 7,52

1,22 0,64 0,33 0,68 0,35 0,85 0,43

Winding inductance Ph-Ph L [mH] 20,7 10,8 5,0 12,4 5,9 16,4 7,7

Mechanical data

Rotor moment of inertia J [kgcm²] 65 92 120

Pole number 10 10 10

Static friction torque M

Thermal time constant t

[Nm] 0,16 0,24 0,33

R

[min] 46 53 60

TH

Weight standard G [kg] 19,7 26,7 33,6

Radial load permitted at shaft

end @ 1000 min

Axial load permitted at shaft

end @ 1000 min

-1

-1

FR[N]

FA[N]

* reference flange Aluminium 457mm * 457mm * 12,7mm

AKM

1300

500

Brake data

Data Symbol [Unit] Value

Holding torque @ 120°C M

Operating voltage

electrical power P

Moment of inertia J

Release delay time t

Application delay time t

Weight of the brake G

[Nm] 53

BR

U

[VDC]

BR

[W] 35,6

BR

[kgcm²] 1,64

BR

[ms] 110

BRH

[ms] 35

BRL

[kg] 2,1

BR

24 ± 10 %

Typical backlash [ °mech.] 0,2

36 Servomotors AKM

Page 37

Kollmorgen 05/2006 Technical Data

Connections and cables

Data AKM7

Power connection 4 + 4 poles, round, angular

Motorcable, shielded 4 x 2,5

Motor cable with control leads, shielded 4 x 2,5+2x1

Steueradern, geschirmt 4 x 1

Resolver connection 12 poles, round, angular

Resolver cable, shielded 4x2x0,25mm²

Encoder connection (option) 17-polig, rund

Encoder cable, shielded 7x2x0,25mm²

Dimensions (drawing in principle)

Radial-/axial forces at the shaft end

- A.4.043.4/10, 14

Servomotors AKM 37

Page 38

Appendix 05/2006 Kollmorgen

4 Appendix

4.1 Assignment of RediMount gearhead mounts

Motor RediMount Flange length [mm] Motor RediMount Flange length [mm]

AKM1xx-A RM060-130 35,1

AKM1xx-C RM060-XXX in preparation RM090-124 44,1

RM060-6 31,0 RM100-124 43,7

AKM2xx-A

AKM2xx-C

AKM3xx-A

AKM3xx-C

AKM4xx-A

RM075-6 in preparation RM115-124 48,9

RM090-6 62,7

RM100-6 in preparation RM100-71 43,7

RM060-17 31,0 RM115-71 48,9

RM075-17 42,9 RM142-71 69,6

RM090-17 44,1 RM180-71 91,4

RM100-17 62,7

RM115-17 48,9 RM100-53 in preparation

RM060-19 31,0 RM115-53 59,9

RM075-19 42,9 RM142-53 in preparation

RM090-19 44,1 RM180-53 in preparation

RM100-19 58,9

RM060-XXX in preparation RM142-92 81,5

RM075-XXX in preparation RM180-92 91,4

RM090-XXX in preparation RM220-92 69,5

RM100-XXX in preparation

RM075-40 42,9 RM180-114 91,4

RM090-40 44,1 RM220-114 69,6

RM100-40 43,7

RM115-40 48,9

AKM4xx-C

AKM5xx-A

AKM5xx-C

AKM6xx-A

AKM7xx-A

RM075-124 42,9

RM090-71 62,7

RM090-53 in preparation

RM115-92 in preparation

RM142-114S 85,3

These gearheads can be fitted to RediMount:

RM060: DT60, DTR60, DTRS60, DTRH60, NT23, NTP23, NT60, NTR23, UT006,

UTR006, EQ23, EQ60

RM075: UT075, UTR075, UT090, UTR090

RM090: DT90, DTR90, DTRS90, DTRD90, DTRH90, NT34, NTP34, NT90, NTR34

RM100: UT010, UTR010, ET010, UT115, UTR115

RM115: DT115, DTR115, DTRS115, DTRD115, DTRH115, NT42, NTP42, NT115,

NTR42

RM142: DT142, DTR142, DTRS142, DTRD142, DTRH142, NT142, UT014, UTR014,

ET014

RM180: UT018, UTR018, ET018

RM220: UT220

You can find further information on Redimount and gearheads on our website.

38 Servomotors AKM

Page 39

Kollmorgen 05/2006 Appendix

4.2 Delivery package, transport, storage, maintenance, disposal

Delivery package: — Motor from the AKM series

— Technical description (documentation), 1 copy per delivery

— Motor package leaflet (short info)

Transport: — Climate category 2K3 to EN 50178

— Transport temperature -25...+70°C, max. 20K/hr change

— Transport humidity rel. humidity 5% - 95% , no condensation

— only by qualified personnel

— only in the manufacturer’s original recyclable packaging

— avoid shocks

— if the packaging is damaged, check the motor for visible damage.

— Inform the carrier and, if appropriate, the manufacturer.

®

Packaging: — Cardboard packing with Instapak

— You can return the plastic portion to the supplier or a certified

— disposal company. Ask us for addresses.

Motor type Carton Max.stacking height

AKM1 X 10

AKM2 X 10

AKM3 X 6

AKM4 X 6

AKM5 X 5

AKM6 X 1

AKM7 X 1

foam cushion.

Storage: — Climate category 1K4 to EN 50178

— Storage temperature -25...+55°C, max. variation 20K/hr. — Humidity rel. humidity 5% - 95%, no condensation

— only in the manufacturer’s original recyclable packaging

— max. stacking height see table under Packaging

— Storage time unlimited

Maintenance: — Only by qualified personnel

— The ball bearings have a grease packing which is adequate for

— 20,000 hours of operation under normal conditions. The bearings

— should be replaced after 20,000 hours of operation under rated

— conditions.

— Check the motor for bearing noise every 2500 operating hours,

— respectively each year. If any noises are heard, then the operation

— of the motor must stop, the bearings must be replaced.

— Opening the motor invalidates the warranty.

Cleaning: — If the housing is dirty: clean with Isopropanol or similar.

do not immerse or spray

Disposal : In accordance to the WEEE-2002/96/EG-Guidelines we take old devices and

accessories back for professional disposal, if the transport costs are taken

over by the sender. Send the devices to:

Danaher Motion GmbH

Robert-Bosch-Straße 10

D-64331 Weiterstadt

Germany

Servomotors AKM 39

Page 40

Appendix 05/2006 Kollmorgen

4.3 Removing faults

The following table is to be seen as a “First Aid” box. There can be a large number of different rea

sons for a fault, depending on the particular conditions in your system. The fault causes described

below are mostly those which directly influence the motor. Peculiarities which show up in the control

loop behaviour can usually be traced back to an error in the parameterization of the servo amplifier.

The documentation for the servo amplifier and the setup software provides information on these

matters.

For multi-axis systems there may be further hidden reasons for faults.

Our applications department can give you further help with your problems.

Fault Possible cause

— Servo-amplifier not enabled

Motor doesn’t

rotate

Motor runs away

Motor oscillates

Error message:

brake

Error message:

output stage fault

Error message:

resolver

Error message:

motor temperature

Brake does not

grip

— Break in setpoint lead

— Motor phases in wrong sequence

— Brake not released

— Drive is mechanically blocked

— Motor phases in wrong sequence — Correct the phase sequence

— Break in the shielding of the resolver cable

— amplifier gain to high

— Short-circuit in the supply voltage lead to

the motor holding brake

— Faulty motor holding brake

— Motor cable has short-circuit or earth short

— Motor has short-circuit or earth short

— Resolver connector is not properly plugged

in

— Break in resolver cable, cable crushed or

similar

— Motor thermostat has switched

— Loose resolver connector or break in

resolver cable

— Required holding torque too high

— Brake faulty

— Motor shaft axially overloaded

Measures to remove the cause of the

fault

— Supply ENABLE signal

— Check setpoint lead

— Correct the phase sequence

— Check brake controls

— Check mechanism

— Replace resolver cable

— use motor default values

— Remove the short-circuit

— Replace motor

— Replace cable

— Replace motor

— Check connector

— Check cables

— Wait until the motor has cooled

down. Then investigate why the

motor becomes so hot.

— Check connector, replace resolver

cable if necessary

— Check the dimensioning

— Replace motor

— Check the axial load, reduce it.

Replace motor, since the bearings

have been damaged

40 Servomotors AKM

Page 41

Kollmorgen 05/2006 Appendix

4.4 Index

IndexA AKM1 ..................24

AKM2 .................. 26

AKM3 .................. 28

AKM4 .................. 30

AKM5 .................. 32

AKM6 .................. 34

AKM7 .................. 36

Ambient temperature ........... 8

Axial force .................9

B BISS ...................21

Break response times ..........23

C ComCoder ................ 20

Connection method ........... 10

Coupling .................. 9

D Delivery package .............39

Disposal ................. 39

E Earthing ................. 15

Encoder .................10

F Feedback unit .............. 10

G Gearhead mount .............38

Ground symbol ..............14

H Holding brake ..............10

I Insulation material class ..........9

M Maintenance ............... 39

Manufacturer declaration .........4

Model number ..............12

Motor cable................16

N Nameplate ................ 12

O Options..................11

P Peak current ...............23

Pole numbers .............. 10

Power derating .............. 8

Protection class .............. 9

Protective device .............9

R Radial force ................9

Rated torque ...............23

Resolver ................. 10

Resolver cable ..............16

Rotor moment of inertia .........23

S Safety notes ................6

Servo amplifier ..............8

Setup...................22

SFD ...................19

Shielding .................15

Standstill current .............23

Standstill torque .............23

Storage.................. 39

Storage humidity .............39

Storage temperature ...........39

Storage time ............... 39

Style ....................9

T Thermal time constant ..........23

Torque constant .............23

Transport.................39

V Ventilation ................ 15

Vibration class .............. 10

Voltage constant .............23

W Wiring .................. 15

Servomotors AKM 41

Page 42

www.DanaherMotion.com

Sales and Service

We are committed to quality customer service. In order to serve in the most effective way,

please contact your local sales representative for assistance.

If you are unaware of your local sales representative, please contact us.

Europe

Visit the European Danaher Motion web site at www.DanaherMotion.net for Setup Software upgrades,

application notes, technical publications and the most recent version of our product manuals.

Danaher Motion Customer Support - Europe

Internet www.DanaherMotion.net

E-Mail support@danahermotion.net

Phone: +49(0)203 - 99 79 - 0

Fax: +49(0)203 - 99 79 - 155

North America

Visit the North American Danaher Motion web site at www.DanaherMotion.com for Setup Software

upgrades, application notes, technical publications and the most recent version of our product manuals.

Danaher Motion Customer Support North America

Internet www.DanaherMotion.com

E-Mail DMAC@danahermotion.com

Phone: +1 - 540 - 633 - 3400

Fax: +1 - 540 - 639 - 4162

Loading...

Loading...