Page 1

GraphicOperatorTerminal

Installation

Manual

ionA,April2017

Edit

AKI2G-CDB-MOD-12T-00012.1”TouchscreenHMI

Keepallmanualsasaproductcomponentduringthelifespanoftheproduct.

Passallmanualstofutureusers/ownersoftheproduct.

Page 2

RecordofDocumentRevisions

Revision Remarks

A,04/2017

Preliminaryedition

IMPORTANTNOTICE

Technicalchangeswhichimprovetheperformanceofthedevicemaybe made withoutpriornotice!

PrintedintheUn ited StatesofAmerica. Thisdocument istheintellectualpropertyofKollmorgen™. Allrightsreserved. No

partofthi

copiedordistributed byelectronicmea ns withoutthewr ittenpermissionofKollmorgen™.

sworkmaybe reproducedina ny form(byphotocopying,microfilmoranyothermethod)orstored,processed,

ky

Kollmorgen|April2017

2

Page 3

AKI2G-CDB-MOD-12T-000|CONTENTS

1 General

1.1 AboutThisM

2 SafetyPrecau

anual .......................................................................

tions

2.1 General ................................................................................... 5

2.2 DisposalR

2.3 ULandcULI

2.4 DuringIns

2.5 DuringUse

2.6 Servicea

2.7 Dismantl

2.8 Appearan

3Installati

3.1 SpaceRe

3.1.1 AKI2G

3.2 Install

3.2.1 Conne

3.2.2 Othe

4 Technica

5Chemical

5.1 MetalC

5.2 TouchS

5.2.1 Aut

5.2.2 Tou

5.2.3 Tou

6Operato

6.1 Conn

6.2 Comm

6.3 Digi

talOutputs ............................................................................

6.4 AKI2

7Additi

onalInstallationTips

7.1 Gro

7.2 Eth

undingtheHMI panel ................................................................

ernet Connectionin theOperatorPanel ............................................

7.3 ToA

7.4 Amb

7.5 Saf

7.6 Ga

7.7 Ca

ety .....................................................................................

lvanicIsolation ........................................................................

bleandBusTermination RS485 .....................................................

equirementsUnderWEEE Regulations ...................................

nstallation ..................................................................

tallation ........................................................................

................................................................................

nd Maintenance ...............................................................

ingandScrapping ..............................................................

ce of Airin TouchScreen .....................................................

on

quirements ....................................................................

-CDB-MOD-12T-000 ....................................................

ation Process ......................................................................

ctionsto theController ...................................................

rConnectionsand Peripherals ............................................

lData

Resistance

asing .............................................................................

creen andOverlayMaterial .....................................................

oflex EBA 180L ...............................................................

ch ScreenSurface(for12”Panels) .........................................

ch ScreenProtector .........................................................

rPanelDrawings

ectors ...............................................................................

unicationPorts ....................................................................

G-CDB-MOD-12T-000Outline ....................................................

chieveBetterEMC Protection ......................................................

ientTemperature ....................................................................

4

5

5

7

7

7

8

8

9

9

10

11

11

14

15

15

15

16

17

18

19

20

21

22

23

24

25

26

27

ky

Kollmorgen|April2017

3

Page 4

1 GENERAL

1.1 AboutThisManual

AllAdvancedKollmorgenInterfacesaredevelopedtosatisfythedemandsofhuman-machine

communication. Built-infu nctionssuchasdisplayingandcontrollingtext,dynamicindication,time

channels,alarmandrecipehandlingareincluded.

TheAdvancedKollmorgenInterfacesworks primarilyinanobject-orientedway,makingiteasyto

understandanduse. ConfigurationiscarriedoutonaPCusingth e KollmorgenVisualizationBuilder

configurationtool. Theprojectcanthenbe transferredandstoredintheoperatorpanelitself.

VarioustypesofautomationequipmentsuchasPLCs,servosordrivescanbeconnectedtothe

AdvancedKollmorgenInterfaces. Inthismanual,theterm“thecontroller”referstotheconnected

equipment.

Thismanualexplainshowtoinstalltheoperatorpanel. PleaserefertotheKollmorgenVisualizationBuilderProgrammingandInstallationmanualforfurtherinformation.

AKI2G-CDB-MOD-12T-000|GENERAL

ky

Kollmorgen|April2017

4

Page 5

2 SAFETYPRECAUTIONS

Boththeinstallerandtheownerand/oroperatoroftheoperatorpanelmustreadandunderstand

thisinstallationmanual.

2.1 General

• Readthesafetyprecautionscarefully.

• Checkthedeliveryfortransportationdamage. Ifdamageisfound,notifythesupplierassoonas

possible.

• DonotusetheHMIpanelinanenvironmentwithhighexplosivehazards.

• Thesupplierisnotresponsibleformodified,alteredorreconstructedequipment.

• Useonlypartsandaccessoriesmanufacturedaccordingtospecificationsofthesupplier.

• Readtheinstallationandoperatinginstructionscarefullybeforeinstalling,usingorrepairing

theHMIpanel.

• Neverallow fluids,metalfilingsorwiringdebristoenteranyopeningsintheHMIpanel. Thismay

causefireorelectricalshock.

•OnlyqualifiedpersonnelmayoperatetheHMIpanel.

• StoringtheHMIpanelwherethetemperatureislower/higherthanrecommendedinthismanual

cancausetheLCDdisplayliquidtocongeal/becomeisotropic.

• TheLCDdisplayliquidcontainsapowerfulirritant. Incaseofskincontact,washimmediately

withplentyofwater. Incaseofeyecontact,holdtheeyeopen,flushwithplentyofwater andget

medicalattention.

•Thefiguresinthismanua l serveanillustrativepurpose. Becauseofthema ny variables

associatedwithanyparticula r installation,thesuppliercannota ssumeresponsibilityforactual

usebased ont he figures.

• ThesupplierneitherguaranteesthattheHMIpanelissuitableforyourparticularapplication,nor

assumesresponsibilityforyourproductde s ign,installationoroperation.

• Itisrecommendedtoturnonandshutdown theHMI panelatleastoncebeforeinstallinga ny

components/cardsorbeforeconnectingtheoperatorpaneltoexternaldevices;forexample

serialdevices.

• ForMarinepanelsonly:

– TheHMIpanelmustbeinstalledandoperatedasdescribedinthisdocumenttomeetthis

certification.

– Observeprecautionsforhandlingelectrostaticdischargesensitivedevices

AKI2G-CDB-MOD-12T- 000|SAFETYPRECAUTIONS

2.2 DisposalRequirementsUnderWEEERegulations

rofessionalusersinthe EuropeanUnion: Ifyouwishtodiscardelectricalandelectronic

Forp

pment(EEE),pleasecontactyourdealerorsupplierforfurtherinformation.

equi

FordisposalincountriesoutsideoftheEuropeanUnion: Ifyouwishtodiscardthisproduct

pleasecontactyourlocalauthoritiesordealerandaskforthecorrectmethodofdisposal.

2.3 ULandcULInstallation

Caution:

Thissectionisonly validforUL labeledpanels.

ky

Kollmorgen|April2017

5

Page 6

AKI2G-CDB-MOD-12T- 000|SAFETYPRECAUTIONS

• ThisequipmentissuitableforuseinClass2non-hazardouslocationsonly. [Combinationsof

equipmentinyoursystemaresubjecttoinvestigationbythelocalauthorityhavingjurisdiction

atthetimeofinstallation].

• AlldeviceshavetobesuppliedbyaClass2powersupply.

OnlyULand cULapprovedexpansionunitsareallowedto beconnectedto theportdesignated

“EXPANSION”. Atthemomentthere arenosuchunitsevaluatedor allowed.

SEULESLESUNITÉSD'EXTENSION CERTIFIÉESUL ET

cULPEUVENTÊTRERACCORDÉES AUPORTDÉSIGNÉ«EXPANSION».

ÀL'HEUREA CTUELLE, AUCUNEU NITÉ DECE TYPEN'A ÉTÉTESTÉE

OUAUTORISÉE.

•Thisequip

equipment

atthetime

• Alldevice

mentissuitableforuseinClass2non-hazardouslocationsonly. [Combinationsof

inyoursystemaresubjecttoinvestigationbythelocalauthorityhavingjurisdiction

ofinstallation].

shavetobesuppliedbyaClass2powersupply.

OnlyULand cULapprovedexpansionunitsareallowedto beconnectedto theportdesignated

“EXPANSION”. Atthemomentthere arenosuchunitsevaluatedor allowed.

SEULESLESUNITÉSD'EXTENSION CERTIFIÉESUL ET

cULPEUVENTÊTRERACCORDÉES AUPORTDÉSIGNÉ«EXPANSION».

ÀL'HEUREA CTUELLE, AUCUNEU NITÉ DECE TYPEN'A ÉTÉTESTÉE

OUAUTORISÉE.

• Thisproductcontainsabattery;thismustonlybechangedinanareaknowntobenon-hazardous.

• ReplacethebatterywithaBR2032battery. Useofanothertypeofbatterymaypresentariskof

fireorexplosion.

rymayexplodeifmistreated. Donotrecharge,disassembleor disposeofin fire.

Batte

roductcontainsaBR2330A batterythatisnotuserreplaceable.

Thisp

LABAT

NELA

PASD

CEPR

REMP

TERIEPEUTEXPLOSERENCASDEMAUVAISEMANIPULATION.

RECHARGEZPAS,NELADÉMONTEZ PASETNELAJETEZ

ANSLEFEU.

ODUITCONTIENTUNE PILEBR2330A QUINE PEUTPASÊTRE

LACÉEPARL'UTILISATEUR.

• Foruseonaflatsurfaceofatype4Xenclosureindooruseonly.

• Useminimum75°Ccopperconductorsonly.

• Tomakewiringconnectionstothepowersupplyconnector,followthetablewithcableandtorque

specificationsbelow:

ky

Kollmorgen|April2017

6

Page 7

AKI2G-CDB-MOD-12T- 000|SAFETYPRECAUTIONS

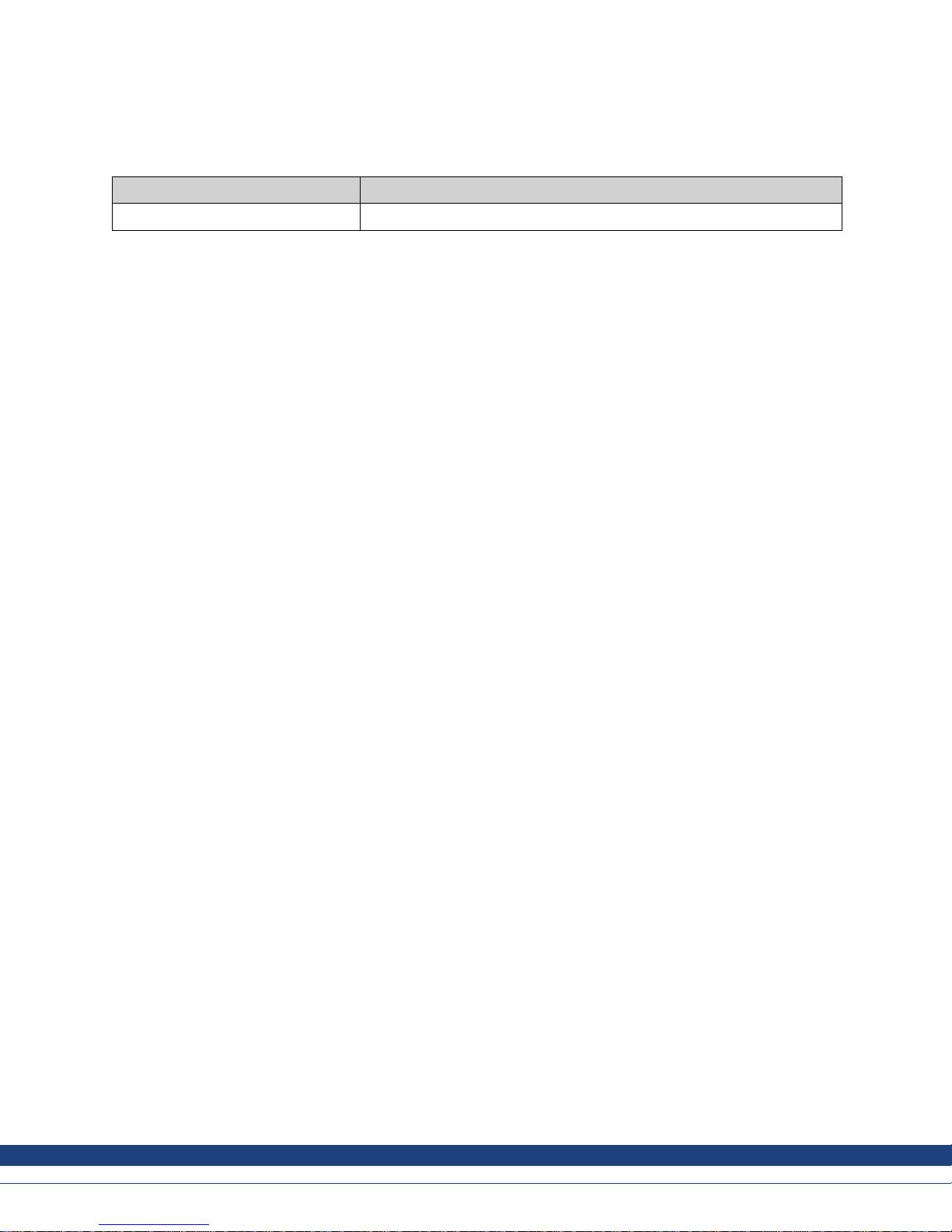

TerminalBlockConnector WireSizeAWG TQLb.In.

X1/X100Phoen

X1/X100Anytekconnectors AWG24–12

X1/X100DECA

• ThesedevicesareClass2suppliedprogrammablecontrollers(industrialPCs)fortheusein

industrialcontrolequipmentandareintendedtobe(front)panelmounted(Type12and4xfor

indooruseonly).

Caution:

Theenclosureprovidesa degreeofprotectionofatleastIP20, butwheninstalledinan

apparatus,itshouldmeetIP65..

LEBOÎTIEROFFR E UNDEGRÉ DEPROTECTION D'AUMOINS IP20,MAIS

LORSQU'ILESTIN STALLÉDANSUN APPAREIL,ILDOITÊTRE DECLASSE IP65..

2.4 DuringInstallation

• TheHMIpanelisdesignedforstationaryinstallationonaplanarsurface,wherethefollowing

conditionsarefulfilled:

– nohighexplosiverisks

– nostrongmagneticfields

– nodirectsunlight

– nolarge,suddentemperaturechanges

ixconnectors

connectors

AWG30–12

AWG24–12

5–7

3.5

7

• InstalltheHMIpanelaccordingtotheaccompanyinginstallationinstructions.

• GroundtheHMIpanelaccordingtothe accompanyinginstallationinstructions.

•OnlyqualifiedpersonnelmayinstalltheHMIpanel.

• Separatethehighvoltage,signal,andsupplyc ables.

• MakesurethatthevoltageandpolarityofthepowersourceiscorrectbeforeconnectingtheHMI

• Peripheralequipmentmustbeappropriatefortheapplicationandlocation.

2.5 DuringUse

• Keep

•Emer

•Don

2.6 Ser

viceandMaintenance

•Onlyqualifiedpersonnelshouldcarryoutrepairs.

• Theagreedwarrantyapplies.

• Beforecarryingoutanycleaningormaintenanceoperations,disconnecttheequipmentfrom

• Cleanthedisplayandsurroundingfrontcoverwitha softclothandmilddetergent.

paneltothepoweroutlet.

theHMIpanelclean.

gencystopandothersafetyfunctionsmaynotbecontrolledfromthe HMIpanel.

otuseexcessiveforceorsharpobjectswhenoperatingthe touchscreen.

theelectricalsupply.

ky

Kollmorgen|April2017

7

Page 8

• Replacingthebatteryincorrectlymayresultinexplosion. Onlyusebatteriesrecommended

bythesupplier. Duringthewarrantyperiod,thebatteryneedstobereplacedbyanauthorized

Kollmorgenservicecenter.

2.7 DismantlingandScrapping

AKI2G-CDB-MOD-12T- 000|SAFETYPRECAUTIONS

• TheHMIpanel

• Thefollowin

environment

2.8 Appearance

Thelayerstructureofthetouchscreencontainsair. Inrarecases,theappearanceofbubblescan

arise. ThisispurelycosmeticanddoesnotaffectthefunctionalityoftheHMIpanel. Theappearance

canoccurundercertainenvironmentalconditionssuchastemperature,humidity,andatmospheric

pressure.

orpartsthereofshallberecycledaccordingtolocalregulations.

gcomponentscontainsubstancesthatmightbehazardoustohealthandthe

: lithiumbattery, electrolyticcapacitor,anddisplay.

ofAirinTouchScreen

ky

Kollmorgen|April2017

8

Page 9

3INSTALLATION

3.1 SpaceRequirements

• Maximuminstallationplatethickness12”: 8mm

• Thefollowingdrawingsshowthespacerequirementsinmillimeterswheninstalling theoperator

panel. Thedrawings areonlyillustrativeandmay beoutofproportion.

AKI2G-CDB-MOD-12T-000|INSTALLATION

3.1.1 AKI2G-CDB-

242 mm

MOD-12T-000

50 mm

100 mm

100 mm

340 mm

50 mm

100 mm

49 mm

ky

Kollmorgen|April2017

9

Page 10

3.2 InstallationProcess

AKI2G-CDB-MOD-12T-000|INSTALLATION

Thefollowing

isneeded:

• APhillips/slotscrewdriver

1.

Unpackandche

Note:

PlacetheHMIpanel onastablesurfaceduringinstallation.

DroppingtheHMI panelorletting itfallmaycausedamage.

2.

TocutacorrectopeningfortheHMIpanel,usethecutoutdimensionsintheoutlinedrawing. For

ckthedelivery. Ifdamageisfound,notifythesupplier.

moreinformation,seesectionsOperatorPanelDrawingsandTechnicalData.

3. InstalltheHMIpanelintothecutout.

4.

SecuretheHMIpanelinpositionby screwingtheslottedthumbscrewclockwise,allowingthe

built-inbrackettoflipoutandtightenagainstthecabinet.

Figure 3-1: Tightenthescrewsto0.7Nm± 0.2Nm.

5.

Incaseswherethefrontpanelseal(IP54orgreater,NEMA-4X)iscritical,useatorquewrenchto

ensureallscrewsaretorquedwithinthespecificationabove.

ky

Kollmorgen|April2017

10

Page 11

AKI2G-CDB-MOD-12T-000|INSTALLATION

6.

Connectthecab

lesinthespecifiedorder,accordingtothedrawingandstepsbelow.

Caution:

TheHMIpanelmust bebroughtto ambienttemperaturebefore itisstartedup. Ifcondensation forms,ensure

•

thattheHMIpanel isdrybeforeconnecting ittothep oweroutlet.

• EnsurethattheHMIpanel andthecontrollersystemhave thesameelectricalgrounding(reference voltage

level),otherwiseerrorsincommunicationmay occur.

• Ensurethatthe voltageandpolarityofthepowersourceiscorrect.

• Separatehighvoltage cablesfromsig nalandsupplycables.

• Shieldedcommunicationcables arerecommended.

B

RS232/

RS422/

RS485

24V DC

C

Power

Controller

24V DC

D

A

Ethernet

Figure 3-2: Theimageisillustrativeonly andmaydifferslightly fromtheactual panel.

– ConnectcableA.

– ConnectcableB,usinganM5screwandagroundingconductor(asshortaspossible),thatis

sizedcorrectlyaccordingtolocalelectricalcodes.

– ConnectcableC.

– ConnectcableD. Therecommendedcross-sectionofthecableis1.5mm.

7.

Carefullyremove theprotec tive filmovertheHMIpaneldisplay,takecaretoavoidstaticelectricity

thatcoulddamagethepanel.

3.2.1 ConnectionstotheController

informationaboutthecablestobeusedwhenconnectingtheHMIpaneltothecontroller,please

For

ertothehelpfileforthedriverinquestion.

ref

3.2.2 OtherConnectionsandPeripherals

Cables,peripheralequipmentandaccessoriesmustbesuitablefortheapplicationandits

environment. Forfurtherdetailsorrecommendations,pleaserefertothesupplier.

ky

Kollmorgen|April2017

11

Page 12

4 TECHNICALDATA

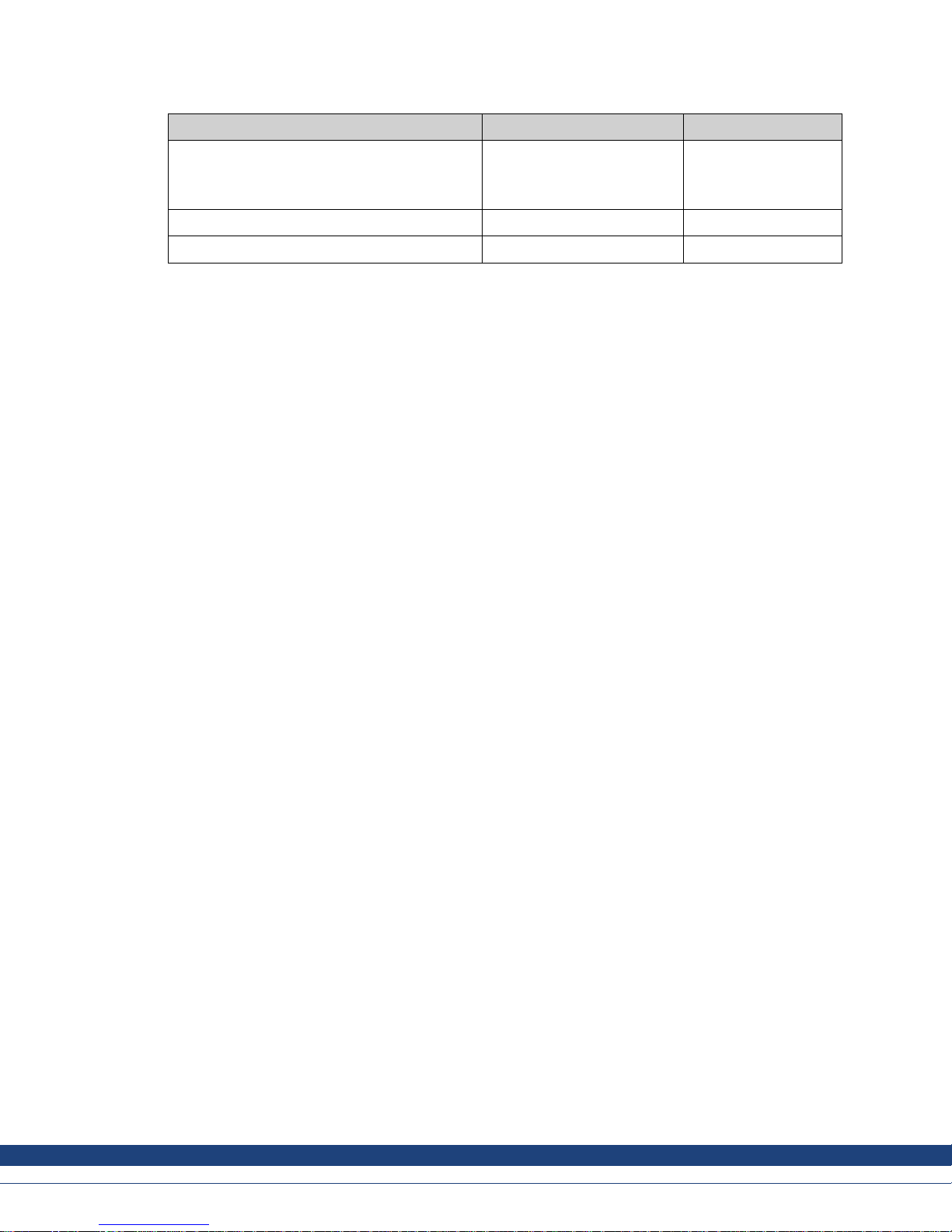

Parameter AKI2G-CDB-MOD-12T-000

Frontpanel,WxHxD 340x242x8mm

AKI2G-CDB-MOD-12T-000|TECHNICALDATA

Cutoutdimensions,W×H

Mountingdepth

Standalonemounting VESA75x75Note: Maximumscrewlengthfor

Frontpanelseal IP65

Rearpane

Touchs creenmaterial

Frameov

Touchs creenoperations

Reversesidematerial Powder-coatedaluminum

Framematerial Powder-coatedaluminum

Weigh

CPU

SerialportforCOM1RS232,COM2

RS422/RS485andCOM3RS485

lseal

erlay

t

324x226mm

49mm(149mm

VESAmountingis4mm. Usageoflongerscrews

mayleadtodamage.

IP20

Polyesteronglass,ITOfilm,resistive

AutoflexEBA180L

nfingertouchoperations

1millio

2.6kg

i.MX6DualLite

DualCortex-A9

1.0GHz

512kBL2 cache

9-pinD-subcontactwithRS232RTS/CTS,

chassis-mountedfemalewithstandardlocking

screws4-40UNC

includingclearance)

EthernetLANA

EthernetLANB

USB 2×USB Host2.0,maxoutputcurrent500mA

DIO(outputs,potentialfree) N/A

Externalstoragemedia

Flashmemory(applicationmemory) 1.5GBSSD(eMMC)

MemoryRAM

NVRAM

LED 1×Multicolor

Realtimeclock Yes

Battery LithiumbatterytypeBR2032,exchangeable

Powerconsumptionatratedvoltage 28.8W

Fuse

ky

10/100Mbit/s(shieldedRJ45)

10/100Mbit/s(shieldedRJ45)

1×SDcard

1GB(DDR3)

N/A

InternalDCfuse,4 AT,5×20mm

Kollmorgen|April2017

12

Page 13

AKI2G-CDB-MOD-12T-000|TECHNICALDATA

Parameter AKI2G-CDB-MOD-12T-000

Powersupply

+24VDC(18to3

CE:Thepowersupplymustconformwiththe

requirementsaccordingtoIEC60950and

IEC61558-2-4.

ULandcUL:Th

entsforclassIIpowersupplies.

Display

therequirem

TFT-LCDwithLEDbacklight

1280×800pixels,262kcolors

Activeareaofdisplay,W×H

Pixelerrors

Backlightbrightness

Backlightlifetime

261.1x163.2mm

ClassI(ISO9241-307)

400cd/m

2

50,000hours

Operatingtemperature -10°Cto+60°C

Storagetemperature -20°Cto+70°C

Relativehumidityinoperation

Vibration

Mechanicalshock

5%–85%non-condensation

1g,accordingtoIEC60068-2-6,TestFc

15g,half-sine,11msaccordingtoIEC60068-2-27

Approvalsandcertifications CE/FCC/KC

Informationisavailableonwww.kollmorgen.com

2VDC)

epowersupplymust conformwith

ULapproval

,informationavailableatUL.com

Yes

Marinecert ificates Informationisavailableonwww.kollmorgen.com

ky

Kollmorgen|April2017

13

Page 14

5 CHEMICALRESISTANCE

5.1 MetalCasing

Theframeandcasingmaterialispowder-coatedaluminum. Thispowderpaintwithstandsexposure

tothefollowingchemicalswithoutvisiblechange:

Aceticacid10% Phosphoricacid4%

Citricacid10% Phosphoricacid10%

AKI2G-CDB-MOD-12T-000|CHEMIC AL RESISTANCE

Diesel

Distilledwater

Edibleoi

Fueloil

Hydrogenperoxide3%

Thepowderpaintshowslimitedresistancetothefollowingchemicalsatroomtemperature:

Butanol

Hydrochloricacid5% Nitricacid10%

Isopropylalcohol

Sodiumhypochlorite10%

Note:

Ifexposuretoany oftheabovechemicalsisdemanded,itisrecommendedtofirsttest the

chemicalinahidden spotofthemetalcasing.

Thepowderpaintshowslittleornoresistancetothefollowingchemicalsatroomtemperature:

l

Seawater

Sodiumchloride2%

Sodiumchloride20%

Sulphur

Tapwater

Nitricacid3%

Phosphoricacid43%

Turpentine

icacid20%

Aceticacid,conc. Methyl-ethylketone Toluene

Acetone

Ammonia5%

Ammonia,conc.

Ethylacetate

ky

Nitricacid30%

Phenol Xylene

Sodiumhydroxide5%

Sodiumhydroxide30%

Trichlorethylene

97octaneunleadedpetrol

98octaneleadedpetrol

Kollmorgen|April2017

14

Page 15

5.2 TouchScreenandOverlay Material

AKI2G-CDB-MOD-12T-000|CHEMIC AL RESISTANCE

5.2.1 AutoflexEBA18

AutoflexEBA180Lcoverstheoverlaysurroundingthescreen.

SolventResistance

AutoflexEBA1

thefollowin

Acetonitrile Diesel Petroleumspirit

Ajax/Viminsolution Downy/Lenor

Alkalicarbonatesolution

Ammonia(<40%)

Aceticacid(<50%) Glycol

Arielpowderinsolution

Bleach

Castoroil

Caust

Cuttingoil Nitricacid(<10%) WhiteSpirit

Cyclohexanol Paraffinoil

Diacetonealcohol Persilpowderinsolution

(1)

(1)

icsoda(<40%)

Extremelyfaintglossingof thetexturewas noted.

0L

80Lwithstandsexposureofmorethan24hoursdurationunderDIN42115Part2to

gchemicalswithoutvisiblechange:

(1)

(1)

(1)

(1)

(1)

(1)

Ethanol

Glycerine Potassiumhyd roxide(<30%)

(1)

Gumptio

n

Hydrochloricacid(<36%) Sulfuricacid(<10%)

doil

Linsee

Methanol

(1)

Phosphoricacid(<30%)

Potassium

PureTurp

SBP60/9

Tomato

Trich

Wind

ferricyanide

entine

(1)

5

ketchup

loroaceticacid(<50%)

(1)

ex

AutoflexEBA180LwithstandsDIN42115Part2exposureofupto1hourdurationtoglacialacetic

acidwithoutvisiblechan ge.

oflexEBA180Lisnotresistanttohighpressuresteamatover100°Corthefollowingchemicals:

Aut

centratedmineralacids

Con

Concentratedcausticsolution

5.2.2 TouchScreenSurface(for 12”Panels)

hetouchscreensurfaceontheoperatorpanelwithstandsexposuretothefollowingsolventswithout

T

isiblechange:

v

Thescreensurfaceontheoperatorpanelwithstandsexposuretothefollowingsolventswithout

visiblechange:

Solvents

Acetone 10minutes

Isopropanol 10minutes

Toluene 5hours

Benzylalcohol

Methylenechloride

Time

ky

Kollmorgen|April2017

15

Page 16

5.2.3 TouchScreenProtector

AKI2G-CDB-MOD-12T-000|CHEMIC AL RESISTANCE

Forharshenvi

filmtoguardth

ronmentsandexposuretooutdoorconditions,itisrecommendedtouseaprotective

etouchscreenfromdamage. Thisoptionalpartcan beorderedfromKollmorgen.

ky

Kollmorgen|April2017

16

Page 17

AKI2G-CDB-MOD-12T-000|OPERATORPANELDRAWINGS

6 OPERATORPANELDRAWINGS

6.1 Connectors

Figure 6-1: AKI2G-CDB-MOD-12T-000

Pos. Connector Description

1 Powersupply

2

3LANA

4LANB

5

USB USBHost2.0,maxoutputcurrent500mA

COM Serialc

+24VDC (18-32V DC)

10/100Base-T(shieldedRJ45)

10/100Base-T(shieldedRJ45)

ommunicationport

ky

Kollmorgen|April2017

17

Page 18

6.2 CommunicationPorts

AKI2G-CDB-MOD-12T-000|OPERATORPANELDRAWINGS

Pin

Serialport,9-pin female

COM1 COM2 COM3

1

-

2RS232RxD

3

4

5

6

7

8

9

Note:

Inordertoutilizetwocommunicationports,theY-splitcableCAB109mustbeused.

Inordertoutilizethreecommunicationportsthe splitcableCAB150 mustbeused.

To use232+422,use CAB109.

To use232+485,use CAB150.

RS232TxD

-

GND GND

-

RS232RT

S

RS232CTS

-

RS422Tx+

RS485Tx+/Rx+

--

--

RS422Rx+ RS485Tx+/Rx+

RS422Tx-

RS485Tx-/Rx-

--

--

RS422Rx- RS485Tx-/Rx-

-

-

-

ky

Kollmorgen|April2017

18

Page 19

6.3 DigitalOutputs

Ratings

AKI2G-CDB-MOD-12T-000|OPERATORPANELDRAWINGS

Maximumsupplyvoltage

Maximumloadcurrent

32.0V(DC)/22Vrms(AC)

0.5A(DC)/0

.5Arms(AC)

Isolation

Channelto

Channel

1000V(DC)

/550Vrms(AC)

ChanneltoSystem 1000V(DC)/550Vrms(AC)

ky

Kollmorgen|April2017

19

Page 20

6.4 AKI2G-CDB-MOD-12T-000Outline

AKI2G-CDB-MOD-12T-000|OPERATORPANELDRAWINGS

Figure 6-2: AKI2G-CDB-MOD-12T-000

ky

Kollmorgen|April2017

20

Page 21

AKI2G-CDB-MOD-12T-000|A DDITION AL INSTALLATIONTIPS

7 ADDITIONALINSTALLATIONTIPS

Whenexperiencingcommunicationproblemsinnoisyenvironmentsorwhenoperatingcloseto

temperaturelimits,thefollowingrecommendationsaretobenoticed.

7.1 GroundingtheHMIpanel

Door

Operator panel

1

Ferrite core

6

3

2

5

4

Mounting plate in the cabinet

Power supply

24 V DC

5350

ThemountingclampsoftheHMIpaneldonotprovideasecuregroundingconnectionbetweenthe

panelandthedevicecabinet,see1indrawingabove.

1.

Connectawire,thatissizedcorrectlyaccordingtolocale lectricalcodes,betweenthe

quick-connectterminalconnectorontheoperatorpanelandthechassisofthepanel,see 2in

drawingabove.

2.

Connectawireorgroundingbraid,thatissizedcorrectlyaccordingtolocalelectricalc odes,

betweenthechassisoftheHMIpaneland theclosestgroundingpointonthedoor,see3in

drawingabove.

3.

4.

ectastrongbutshortgroundingbraidbetweenthedoorandthedevicecabinet,see4in

Conn

ingabove.

draw

Twistthecablesontothe24VDCfeed,see5indrawingabove.

2turnsaroundtheferritecoreprovide4timesthesuppressionof1turn.

3turnsaroundtheferritecoreprovide9timesthesuppressionof1turn.

Aferritecoresuppressesdisturbancestothe24Vfeed,see6indrawingabove.

e:

Not

groundingwiresshould beshortand theconductorshould havealarge area.

The

ong,thingrounding wirehasaveryhighimpedance(resistance)athighfrequenciesanddoesnotgui de

Al

sturbancestotheground.

di

lti-wireconductorsarebetter thansinglewire conductorswiththe samearea.

Mu

raidedconductorwirewiththesameareaisevenbetter. Thebestisashort, thickgroundingbraid.

Ab

ky

Kollmorgen|April2017

21

Page 22

7.2 EthernetConnectioninthe OperatorPanel

AKI2G-CDB-MOD-12T-000|A DDITION AL INSTALLATIONTIPS

Industrial Ethernet

RJ45

RJ45

1

RJ45

RJ45

Operator panel

Shielded

0.1 μF

250 V

Insome

capaci

industrialunitsforEthernet,theRJ45contact’sshieldisconnectedtothechassisviaa

tor,see1indrawingabove.

RJ45

3

4

1-1

2-2

3-3

8-8

Short and

unshielded

5

Operator panel

RJ45

Operator panel

RJ45

Operator panel

RJ45

2

Theoperatorpanel’sEthernetshieldis directlyconnectedtothechassis,see2indrawingabove.

1.

CheckwhethertheotherEthernetunithasitsshielddirectlygroundedorgroundedviaacapacitor.

Note:

ycases,connecting theshieldedEthernet cablingtothe chassisatbothendsisinappropriate. Humor

Inman

dingloopscanoccur. Unshieldedcabling mayevenresult infewercommunication errors.

groun

Agoodsolutionmaybetouse ashieldedEthernetcable,buttoconnecttheshieldatoneendonly.

Oneoptionistobreakthe shield,see3indrawingabove.

AmoreelegantmethodistoexpandtheshieldedEthernetcablingwithapieceofunshieldedEthernet

cable,see4indrawingabove.

Theshieldcanbe groundedviaanexternal0.1µF/250Vplasticcapacitor,see5indrawingabove.

ThisconnectstheHFtransientstoground.

ky

Kollmorgen|April2017

22

Page 23

7.3 ToAchieveBetterEMCProtection

AKI2G-CDB-MOD-12T-000|A DDITION AL INSTALLATIONTIPS

• Initially,us

etheoriginalcabling fromKollmorgenprimarily.

• UseshieldedcablesforRS232communication.

• Usetwisted pa

irandshieldedcablingforRS422andRS485.

• Usethecablingintendedforthebustype;Ethernet,Profibus,CC -Link, CAN,Device Netetc.

• Installandco

nnectaccordingtoapplicablespecificationsfortherelevantbusstandard.

• UseshieldedcablingforEthernet,preferablywithfoiland abraidedshield.

• D-subcoverss

thecableent

houldbeshielded,andtheshieldshouldbeconnectedtothecover360°where

ers.

• Connecttheshieldatbothends.

Shielded cable

0.1 μF/250 V

Ground plane 1 Ground plane 2

Ground plate Ground plate in another building

Not same potential

Withlongerdistances,thereisariskthatthegroundpotentialmaybedifferent. Inthatcase,theshield

shouldonlybeconnectedatoneend. Agoodalternativeistoconnecttheotherendoftheshieldtothe

groundviaa0.1µF/250Vplasticcapacitor. Bothendsarethenconnectedtothegroundintermsof

HF,butonlyconnectedtothegroundatoneendintermsofLF,thusavoidingthe50/60Hzgrounding

loops.

Metal cabinet Metal cabinet

Terminal or connector Terminal or connector

Cable clamp

in steel

Short distance

EMC cable gland

Shielded cable

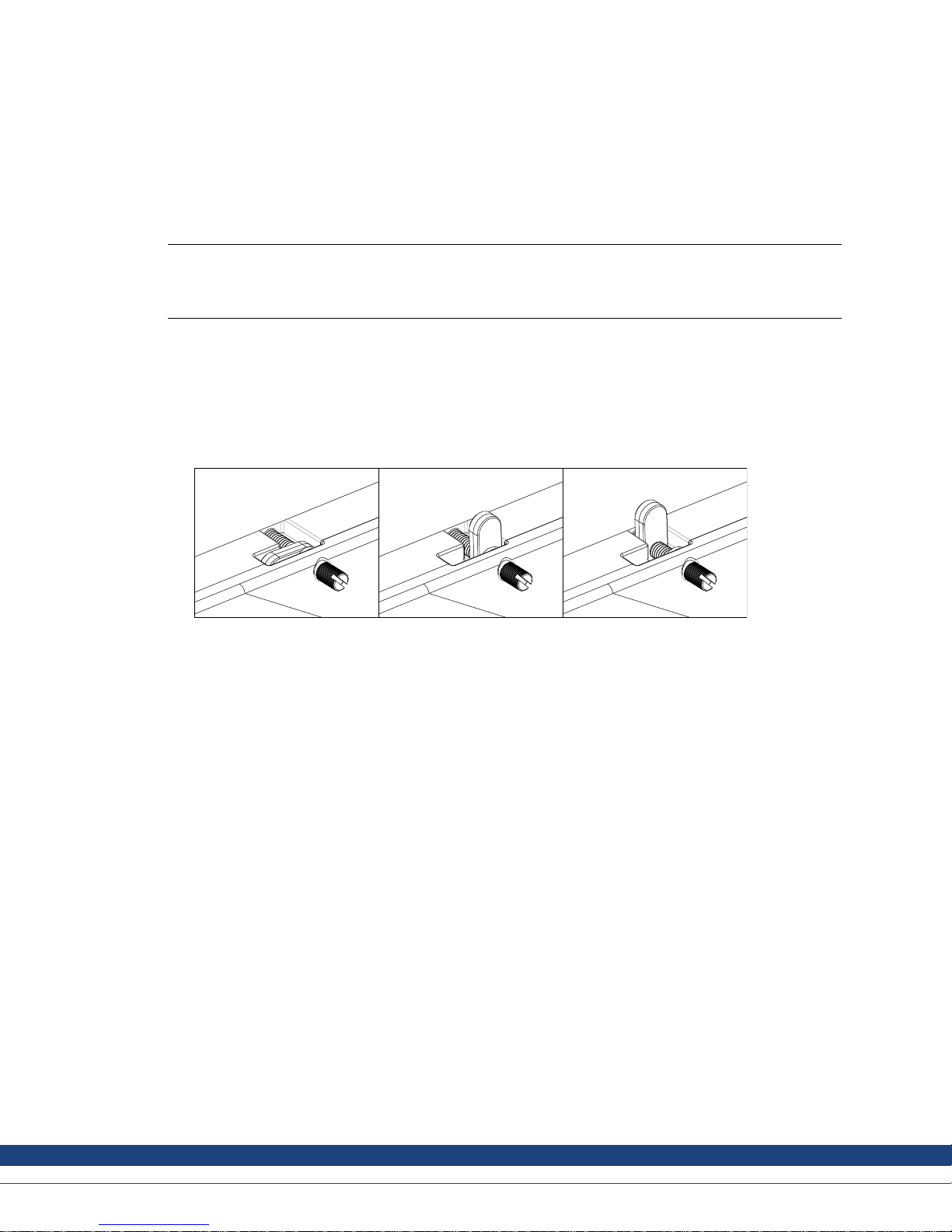

1.

UseanEMC cableglandorregularplasticcablegland,removetheouterjacketandconnectthe

Shielded cable

Plastic cable gland

shieldtotheinstallation platewitha360°metal cableclamp.

2.

Placethe24V DCandcommunicationscablinginonecabletrunk/cableductand230/380VAC

inanother. Ifthecablesneedtobecrossed,crossthemat90°only. Avoidcombiningthecabling

forstronger24VDCoutputswiththecommunicationcabling.

Ferritecoresthataresnappedontotheshieldedcablingmayremoveminordisturbances. Large

ferritepiecesthataresnappedontounshieldedcablingandwherethewiresgo2-4timesaroundthe

coresareapproximately5-25timesmoreefficient.

ky

Kollmorgen|April2017

23

Page 24

7.4 AmbientTemperature

AKI2G-CDB-MOD-12T-000|A DDITION AL INSTALLATIONTIPS

Themaximumam

ambienttempe

bienttemperaturefortheoperatorpanelisprovidedinthespecifications. The

raturereferstothetemperatureinthedevicecabinetwhichcoolstheoperatorpanel’s

electronics.

To p

50 °C inside

Operator

panel

30 °C outside

Middle

45 °C inside

Bottom

40 °C inside

Powe r

Powe r

Powe r

Axial fan

120 x 120 mm

Airflow

Inmostcases,theambienttemperaturefortheoperatorpanelissignificantlyhigherthanthedevice

cabinet’sambienttemperature.

Ifthecabinetistallandthereareanumberofheat-generatingdevices,thetemperatureatthe

topofthecabinetisconsiderablyhigherthanthetemperatureincreasethatwouldbeexpected.

Allelectronicsaresensitivetoheat. Thelifespanofanelectrolyticcapacitoriscutinhalfwithan

8-10°Cincreaseintemperature. A15-20°Ctemperatureincreaseresultsinaquarterofthelifespan

etc.

Rittalhasagoodprogramforestimatingtheanticipatedaveragetemperatureinthecabinetaswellas

alargeprogramforcontrollingthetemperature inth e devicecabinet.

Anenamel-coatedsteelcabinethasaradiantheatvalueof5.5W/m

2

perdegreesC.

Installingafaninsidethecabine t evensoutthetemperature,whilemovingairprovidesconsiderably

bettercoolingthanstillair.

Installthefansothatitsitsinacoolerareaandblowscoldairagainsttheoperatorpanel. Ifthefanis

mountedatthetopandsuckswarmairupwards,theambienttemperatureofthefanbecomeshigher,

resultinginashorterlifespan.

AnapproximatevalueofthenetpowerconsumptionfortheHMIpanelcanbe calculatedbymultiplying

thesupplyvoltagewiththecurrentdrawnbytheHMIpanel. Thisisassumingthatallsuppliedpoweris

transformedtoheat.

ky

Kollmorgen|April2017

24

Page 25

7.5 Safety

AKI2G-CDB-MOD-12T-000|A DDITION AL INSTALLATIONTIPS

Mostoftheope

Power supply

230 V AC to 24 V DC

1

Power supply

230 V AC to 24 V DC

2

Power supply

230 V AC to 24 V DC

3

230 V AC

ratorpanelsarefedwith24VDC.

+24 V

0 V

4

+24 V

0 V

4

Distance?

+24 V

0 V

4

Operator panel

Operator panel

Operator panel

Small controller with expansion unit

COM1

COM100

Ch0

Ch1

Ch100

Ch101

5355

Ifapow

proble

ersupplythatmeetssafetystandardsisusedandonlyfeedstheoperatorpanel,thereisno

m. See1indrawingabove.

However,ifa24Vunitthatalsofeedsotherunitsisused,thereisreasontobecautious,see2in

drawingabove. Theoperatorpaneldoesnothaveinsulationthatmeetssafetyrequirementsinthe

eventofapotentialshortcircuitbetween230VACand24VDC.Itisassumedthatthe24Vfeedis

secure,forexample,SELVaccordingtoEN60950(protectionagainstelectricshock)andUL950.

Note:

Hereisanexamplethatexplainswhyasecure24VDCfeedcanberuinedbymixing24Vrelaycontactswith

230VACrelay contactsina smallercontroller. Checkthattheclearances andcreepagedistancesbetween

24VDCand 230VACfulfillEN60950orUL950. Ifnot,inputaseparate24Vunitintotheoperator panel.

Ifthereisasubstantiald istancebetweentherelaycont actsfor24V DCand230VAC,itisOKto use

thesame24Vdevicesforallfeeds. See3indrawingabove.

Connect0Vonthe24 Vfeedtotheground,see 4indrawingabove. Thisoffersthreeadvantages:

• Safetyisincreased. The24Vfeedisnotliveintheeventofafaultyconnectionorshortcircuit

between0V(24V)and230Vphase.

• Transientsonthe24Vfeedareconnectedtotheground.

• Noriskthatthe24Vfeedisatahighlevelinrelationshiptotheground. Thisisnotunusualsince

thereishighstatic electricity.

ky

Kollmorgen|April2017

25

Page 26

7.6 GalvanicIsolation

r

AKI2G-CDB-MOD-12T-000|A DDITION AL INSTALLATIONTIPS

Internal electronics

Ethernet

DC/DC

Filter

+24 V DC

0 V

galvanic isolation

VCC

0 V (GND)

DC/AC

CFL

1.5 m

RS232RS422/485

USB

USB

Theoperatorpanelhasgalvanicisolationagainstthe24VDC feedbutnogalvanicisolationbetween

thecommunicationportsforR S232,RS422/485andUSB.OnlytheEthernetconnectionhasgalvanic

isolation.

Operator panel Modular controller Printe

Power CPU COM COM2

RS422 RS232 USB

* *

**

*

Different ground potential

***

*

PCPC

* = Internal 0 V (GND) connection

WhenaPCisconnectedtotheHMIpanel,theinternal0V(GND)ofthepanelisconnectedtothe

protectivegroundviathePC.

AnumberofUSBdevicescanhavetheshieldconnectedtogetherwiththeprotectiveground. Here,

the0V(GND)oftheHMIpanelisconnectedtotheprotectivegroundwhen,forexample,aUSB

memorystick,keyboard,or similardeviceispluggedin.

Ifanumberofunitsareconnectedthathavea0Vandagroundconnection,andtheseareconnected

tovariousgroundingpoints,thereisasubstantialriskofproblems. Groundingcurrentsgothrough

communicationcables,therearplateofthecontroller,internallyintheoperatorpanel,andcancause

errors.

Useexternalunitstoimprovecommunicationandachievegalvanicisolation. Westermohasgood

industry-standardinsulatorsthatarealsoinsulatedfromthe24VDCfeed.

Note:

Itisveryimportant tomakesure thatthe24 Vfeedinthe externalinsulationunitisnotcon nectedtooneofthe

communicationoutlets. Ifitdoes nothave100% insulationagainst the24Vfeed,disturbancesandgrounding

currentsfromthe0 Vonthe24 Vsidedisrupt thecommunication.

Usingthistypeof unitsolvesone problembutcreates alargerproblem! Asubstandardinstallationmayworknow,

butproblemsmayarisewhenotherdevicesareconnected.

ky

Kollmorgen|April2017

26

Page 27

7.7 CableandBusTerminationRS485

AKI2G-CDB-MOD-12T-000|A DDITION AL INSTALLATIONTIPS

• Ifmaximum tra

cableshouldb

shouldbeatle

• 0V,therefere

communicatio

• Theshield mu

distancesor

totheground

Anumberofma

manufactur

nsferdistanceandmaximumtransferspeedisneeded,shieldedandtwistedpair

eused. Themutualcapacitancemaynotexceed52.5pF/m,andthecablearea

ast0.25mm

2

(AWG24).

ncevoltageforcommunicationshouldbeincludedinthecabling. Withtwo-way

nusetwopairs;onepairforcommunicationandonepairfor0V.

stbegroundedatoneend. Theotherendisusuallygrounded,butwithlonger

whenthereisadifferenceinthegroundpotential,theshieldshouldbeconnected

via0.1µF/250Vplasticcapacitortopreventgroundcurrentinthebraidedshield.

nufacturersrecommendthattheshieldbegroundedateachnode. Various

ershavedifferentsystemsforbustermination.

Dependingontherecipients’design,thebuswiresmaybeonthesamelevelorrequirepull-upor

pull-downtoensurethatnofaultysignalsaredetectedwhenthebusisinrestingmode(alltransmitters

aredisconnected).

ky

Kollmorgen|April2017

27

Page 28

Kollmorgen | April 2017

8 APPENDIX

This appendix provides information for accessing the HMI service menu and

interfacing an AKI to an AKD PxMM .

8.1 AKI Panel Service Menu

The HMI provides a service setting menu to perform touch calibration, IP

settings,

self-tests, and other options. After a project is loaded onto a panel, the service

menu is accessible by following the procedures described below.

1. Apply power to the panel.

2. When the hourglass displays, press a finger on the screen and hold for

approximately 20 seconds.

3. Enter a PIN code if the service menu is password protected.

4. The touch calibration screen displays the following message:

“Tap anywhere on screen or touch calibrate will start in 10 seconds.”

5. Press finger on screen again to enter the service menu.

The Service Menu displays:

AKI2G | APPENDIX

Note: Additional information about the Service Menu options are available in the

Kollmorgen Visualization Builder (KVB) online help: HMI Panel System

Software/Service Menu

8.2 KVB Installation

Programming the AKI panels requires the KVB software to be install on a PC

work station. When installed on the same PC as the KAS IDE, KVB can be

opened from inside the KAS IDE. This facilitates a KAS IDE project file (.kas) to

include the KVB project.

Page 29

Kollmorgen | April 2017

8.3 HMI to PDMM Connection and Programming

Modbus TCP is used to communicate from the AKI panel’s Ethernet port to the

X32 connector on the top of an AKD PxMM, also referred to as an PxMM

Ethernet service port. If the AKD PxMM is connected to a network, switch, or hub

you can have Modbus communication active at the same time as you are

programming the AKD PDMM with your computer through KAS Integrated

Development Environment software (KAS IDE). This is also appropriate for TCP,

HTTP, Profinet, or Ethernet IP communication that also uses the X32 port and

any combination can be active simultaneously.

When incorporating an AKI HMI panel into a KAS IDE Proje ct , variables that are

planned to be used inside the KVB software are designated by checking the KVB

column box in the KAS Dictionary.

AKI2G | APPENDIX

The Modbus tag addresses are defined automatically in the KAS IDE when the

project is compiled, then transferred into KVB when the KVB project is opened

from inside the IDE. Global or local variables can now be selected to share over

Modbus. Each time the KAS IDE project is compiled the share list is updated.

If both software packages are installed on your computer, use the KAS IDE by

right-clicking on the System option in the Project Explorer and select “Add HMI

Device” to display a list of HMI panels that are available.

Page 30

AKI2G | APPENDIX

Kollmorgen | April 2017

This selection is transferred into KVB when it is opened from inside the KAS IDE.

KAS IDE KVB

Additionally, the PxMM’s IP address is also transferred into the KVB project when

it is opened from within the KAS IDE.

To open KVB from inside the KAS IDE, double-click on the project to launch

KVB.

Page 31

AKI2G | APPENDIX

Kollmorgen | April 2017

Note when starting with a KAS Template Project, some of the template projects

will contain a KVB Project.

Double-clicking on it will also launch KVB. In this scenario tags and the target IP

address are imported into KVB but the AKI Panel selection is not made in the

IDE and must be configured in KVB:

Page 32

AboutKOLLMORGEN

Kollmorgenisaleadingproviderofmotionsystemsandcomponentsformachinebuilders. Throughworldclass

knowledgeinmotion,industry-leadingqualityanddeepexpertiseinlinkingandintegratingstandardandcustom

products,Kollmorge n deliversbreakthroughsolutionsthatareunm atchedinperformance,reliabilityand ease-of-use,

givingmachinebuildersanirrefutablemarketplaceadvantage.

NorthAmerica

KOLLMORGEN

203AWestRockRoad

Radford,VA24141USA

www.kollmorgen.com

Web:

support@kollmorgen.com

Mail:

Jointhe

questio

improv

KollmorgenDevelopmentNetwork

ns,searchtheknowledgebaseforanswers,getdownloads,andsuggest

ements.

Europe

KOLLMORGENEuropeGmbH

Pempelfurtstraße1

40880Ratingen,Germany

www.kollmorgen.com

Web:

technik@kollmorgen.com

Mail:

forproductsupport. Askthecommunity

Tel.: +1-540-633-3545 Tel.: +49-2102-9394-0

Fax: +1-540-639- 4162 Fax: +49-2102-9394-3155

SouthAmerica ChinaandSEA

KOLLMORGEN KOLLMORGEN

AvenidaTamboré-1077TamboréBarueri—SPBrasil

CEP:06460–000,Brazil

www.kollmorgen.com

Web:

support@kollmorgen.com

Mail:

Room202,Building3,Lane168

LinHongRoad,ChangningDistrict

Shanghai,China

www.kollmorgen.cn

Web:

sales.china@kollmorgen.com

Mail:

Tel.: +55114191-4771 Tel.: +98-4006612802

.

Loading...

Loading...