Kollmorgen AKD-x00306, AKD-x00606, AKD-x01206, AKD-x02406, AKD-x00307 Installation Manual

...Page 1

AKD™

Installation Manual

Edition March 2010

Valid for Hardware Revision A

Original Document

Patents Pending

Keep all manuals as a product component

during the life span of the product. Pass all manuals to

future users/owners of the product.

Page 2

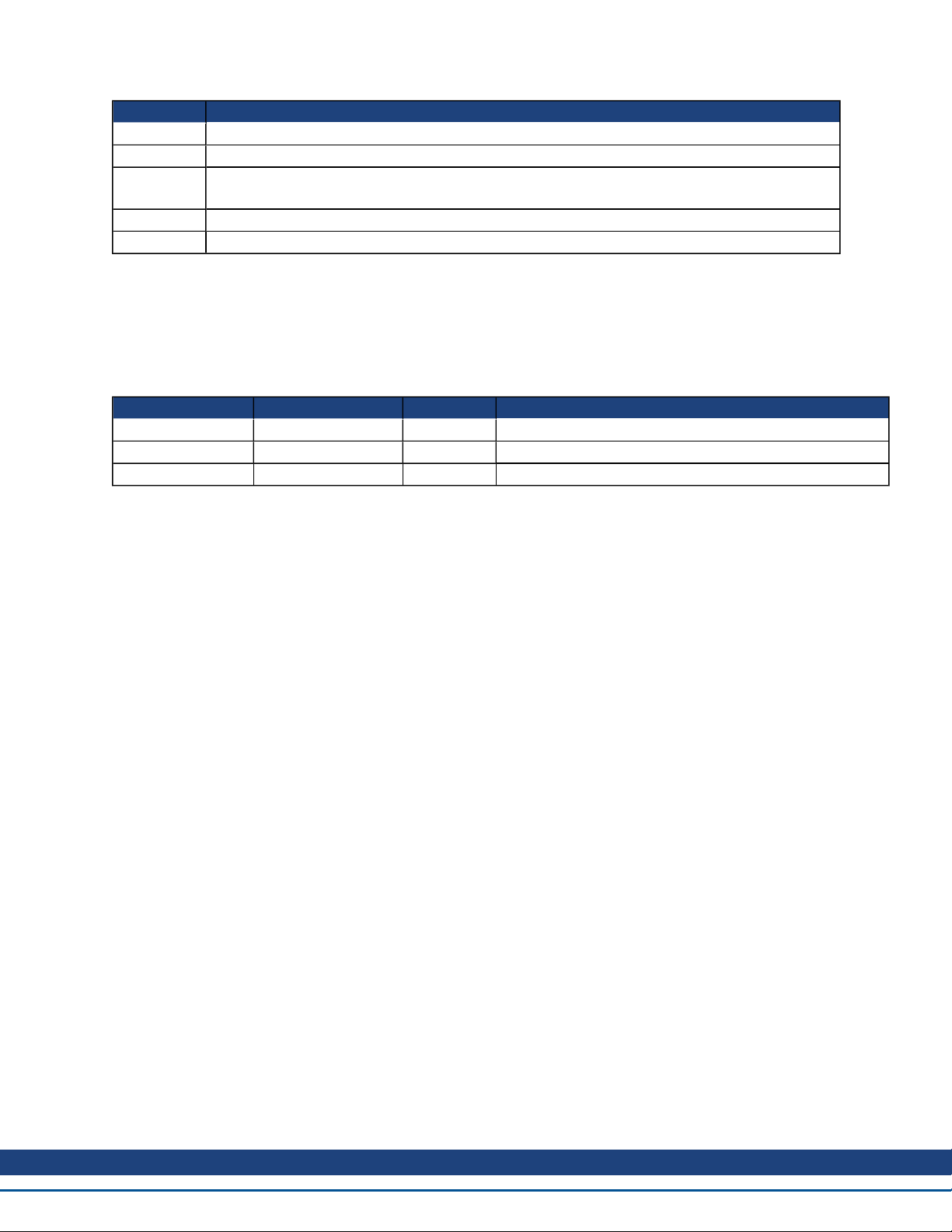

Record of Document Revisions:

Revision Remarks

11/2009 Beta launch version

12/2009 Digital I/O corrections, several updates

03/2010

CAN terminationconnector "optional", data dynamic brake updated, resolver signals renamed,

CE certificate, X9 description updated, technical data completed

Hardware Revision (HR)

Hardware Revision Firmware WorkBench Remarks

A M_01-02-00-000 1.2.0

EnDat is a registered trademark of Dr. Johannes Heidenhain GmbH

EtherCAT is a registered trademark of EtherCAT Technology Group

HIPERFACE is a registeredtrademark of Max Stegmann GmbH

WINDOWS is a registeredtrademark of Microsoft Corporation

AKD is a registered trademark of Kollmorgen Corporation

Current patents:

US Patent 5,646,496 (used in control card R/D and1 Vp-p feedback interface)

US Patent 5,162,798 (used in control card R/D)

US Patent 6,118,241 (used in control card simple dynamic braking)

Technical changes which improve the performance of the device may be made without prior notice!

Printedin the United States of America

This document is the intellectual property of Kollmorgen™. All rights reserved. No part of this work may be

reproduced in any form (by photocopying, microfilm or any other method) orstored, processed, copied or distributed by electronic means without the written permission of Kollmorgen™.

2 Kollmorgen | March 2010

Page 3

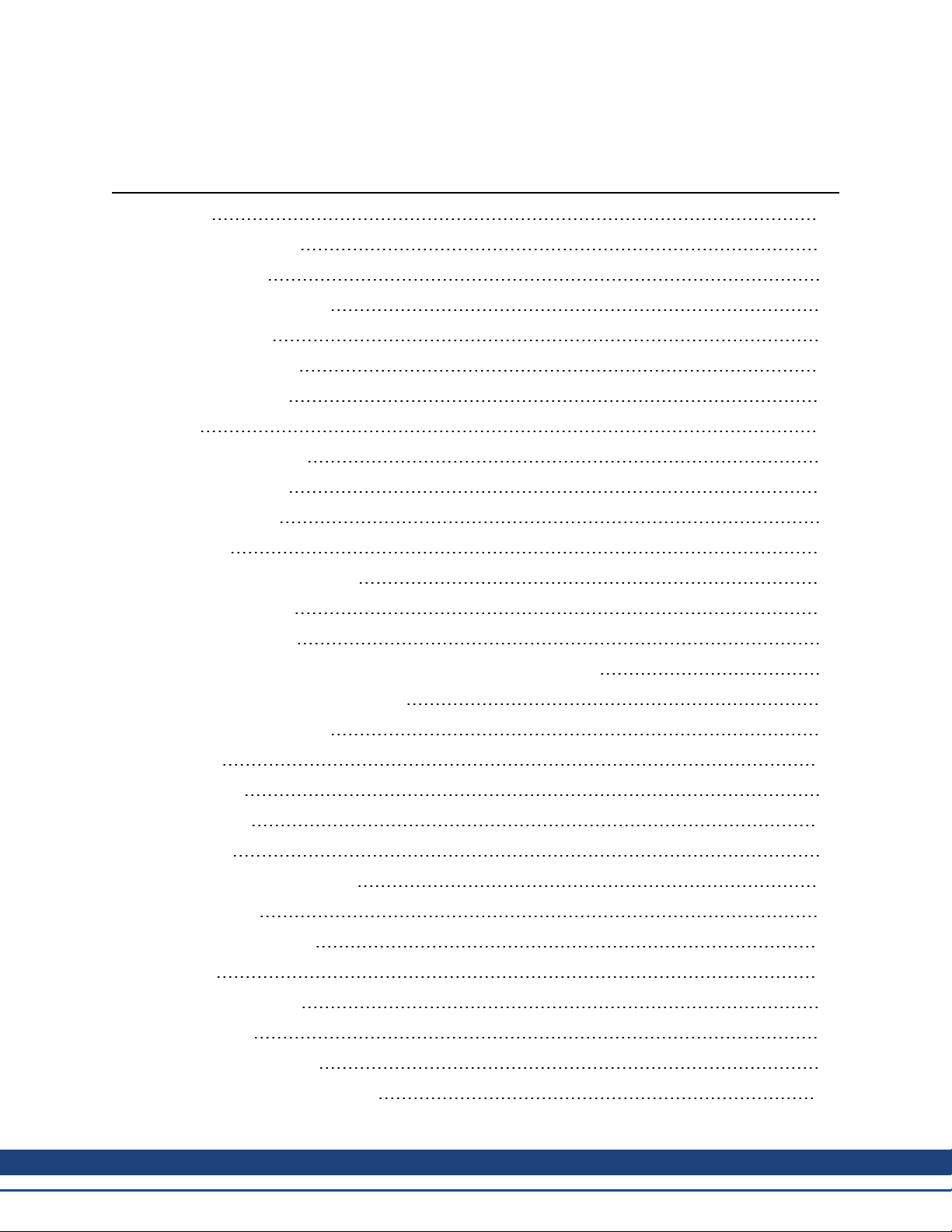

Table of Contents

1 General 11

1.1 About this Manual 12

1.2 Target Group 12

1.3 Using the PDF Format 12

1.4 Abbreviations 13

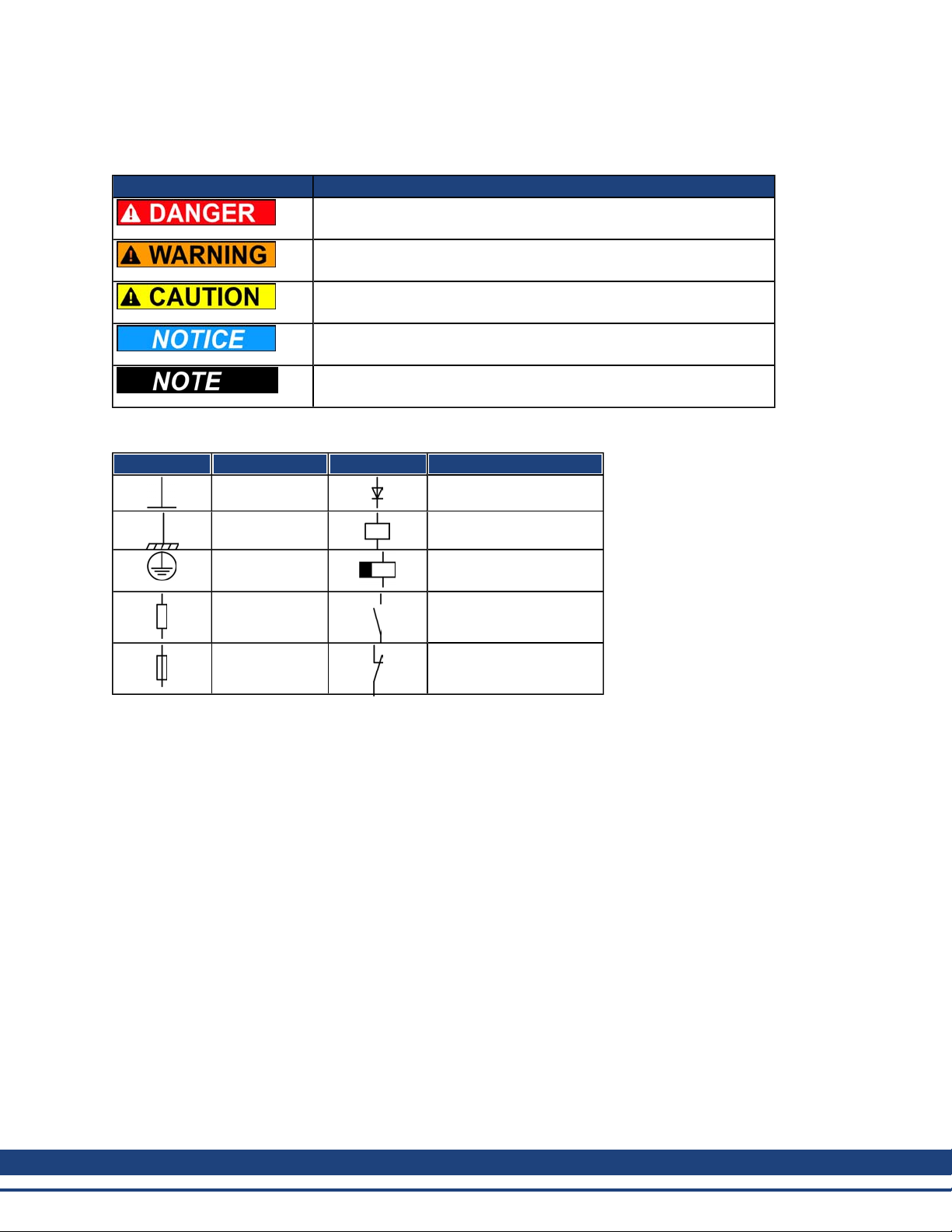

1.5 Warning Symbols 14

1.6 Standards Used 15

2 Safety 16

2.1 Safety Instructions 17

2.2 Use as Directed 18

AKD Installation|

2.3 ProhibitedUse 18

3 Approvals 19

3.1 Conformance with UL/cUL 20

3.1.1 UL Markings 20

3.2 CE Conformance 22

3.2.1 EuropeanDirectives and Standards for the machinebuilder 23

3.2.2 EC Declaration of Conformity 24

3.3 Safe TorqueOff (STO) 25

4 Handling 26

4.1 Transport 27

4.2 Packaging 27

4.3 Storage 27

4.4 Maintenance andCleaning 28

4.5 Uninstalling 28

4.6 Repair and Disposal 28

5 Package 29

5.1 Package Supplied 30

5.2 Nameplate 30

5.3 Part numberscheme 31

6 Technical description and data 32

Kollmorgen | March 2010 3

Page 4

AKD Installation|

6.1 The AKD Family of Digital Drives 33

6.2 Ambient Conditions, Ventilation, and Mounting Position 35

6.3 Mechanical Data 35

6.4 Inputs/Outputs 36

6.5 Electrical Data AKD-xzzz06 37

6.6 Electrical Data AKD-xzzz07 38

6.7 Performance Data 39

6.8 Recommended tightening torques 39

6.9 Fusing 40

6.9.1 External Power Supply fusing 40

6.9.2 External 24 V supply fusing 40

6.9.3 External Brake Resistor fusing 40

6.10 Connectors 41

6.10.1 AKD-xzzz06 Types (120V to 240V Mains Voltage Supply) 41

6.10.2 AKD-xzzz07 Types (240V to 480V Mains Voltage Supply) 41

6.11 Cable and Wire Requirements 42

6.11.1 General 42

6.11.2 Cable Cross Sections and Requirements 42

6.12 LED display 43

6.13 Grounding System 43

6.14 Dynamic Braking 44

6.14.1 Functional description 44

6.14.2 Technical Data for AKD-xzzz06 45

6.14.3 Technical Data for AKD-xzzz07 46

6.15 Switch-on and Switch-off Behavior 47

6.15.1 Behavior in Standard Operation 48

6.15.2 Behavior in the event of a fault (with standard setting) 49

6.16 Stop-/Emergency Stop- Function 50

6.16.1 Stop: Standards 50

6.16.2 Emergency Stop: Standards 51

6.16.3 Implementation of the Stop Category 0 52

6.16.4 Implementation of Stop Category 1 53

4 Kollmorgen | March 2010

Page 5

AKD Installation|

6.16.5 Implementation of Stop Category 2 54

6.17 Safe Torque Off (STO) 55

6.17.1 Safety instructions 56

6.17.2 Use as directed 56

6.17.3 Prohibited Use 57

6.17.4 Technical data and pinning 57

6.17.5 Enclosure 57

6.17.6 Wiring 57

6.17.7 Functional description(in process) 58

6.17.7.1 Signal diagram (sequence) 59

6.17.7.2 Control circuit (example) 60

6.17.7.3 Functional test 61

6.17.7.4 Mains supply circuit (example) 61

6.18 Shock-hazard Protection 62

6.18.1 LeakageCurrent 62

6.18.2 Residual Current Protective Device (RCD) 62

6.18.3 Isolating Transformers 63

7 Mechanical Installation 64

7.1 Safety Instructions 65

7.2 Guide to Mechanical Installation 65

7.3 Control Cabinet Layout AKD-xzzz06 66

7.4 Control Cabinet Layout AKD-xzzz07 67

7.5 Dimensions, AKD-x00306 to x00606 68

7.6 Dimensions, AKD-x01206 69

7.7 Dimensions, AKD-x02406 70

7.8 Dimensions, AKDx00307 to 01207 71

7.9 Dimensions, AKDx02407 72

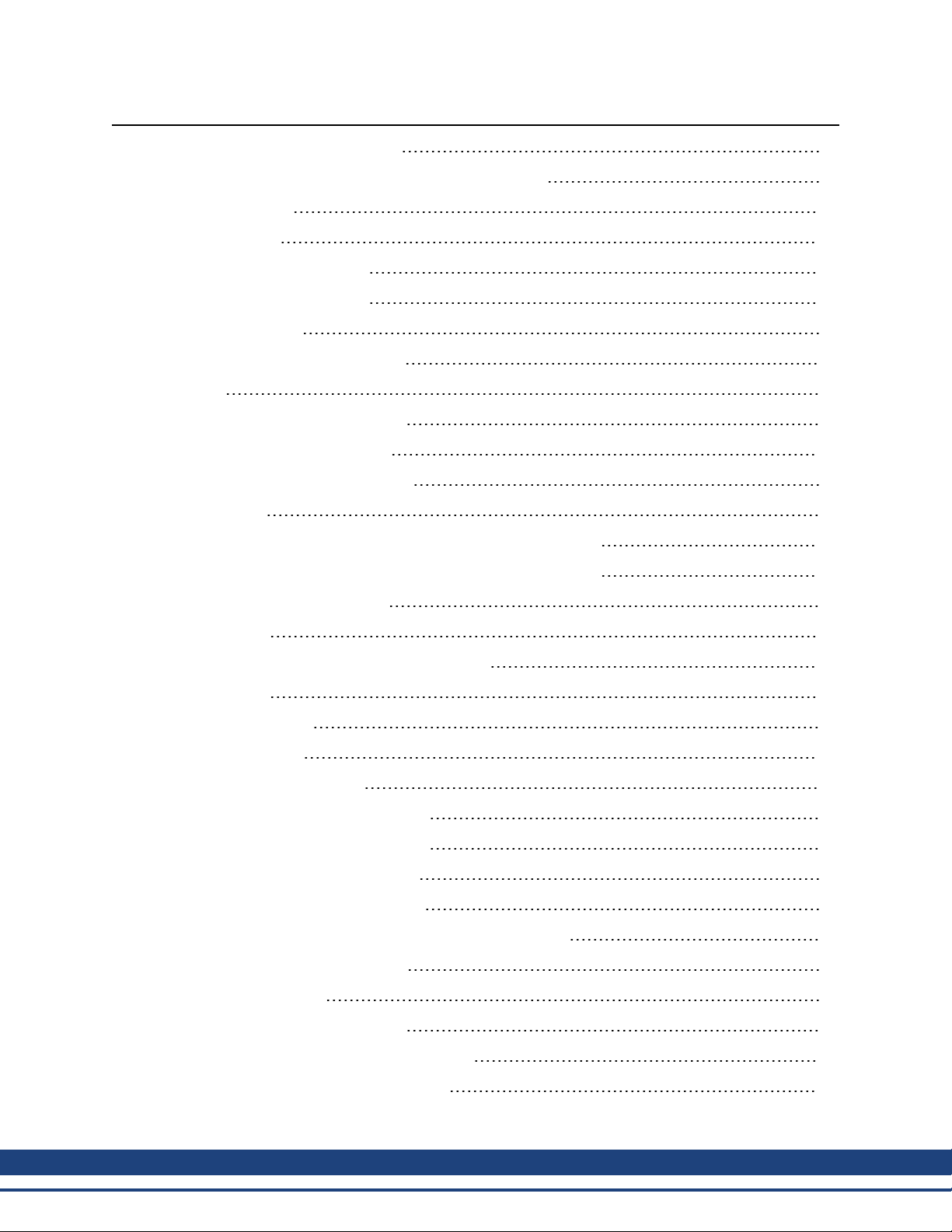

8 Electrical Installation 73

8.1 Safety Instructions 74

8.2 Guide to electrical installation 75

8.3 Wiring 76

8.4 Components of a servosystem 77

Kollmorgen | March 2010 5

Page 6

AKD Installation|

8.5 Connector Assignments, AKD-x00306 to x00606 78

8.6 Connector Assignments, AKD-x01206 78

8.7 Connector Assignments, AKD-x02406 andAKD-xzzz07 79

8.8 Connection Diagram, AKD-x00306 to x00606 80

8.9 Connection Diagram, AKD-x01206 81

8.10 Connection Diagram, AKD-x02406and AKD-xzzz07 82

8.11 EMI Noise Reduction 83

8.11.1 Recommendations for EMI Noise Reduction 83

8.11.2 Shielding with External Shielding Busbar 84

8.11.2.1 Shielding Concept 84

8.11.2.2 Shielding Busbar 85

8.11.3 Shielding Connection to the Drive 86

8.11.3.1 Grounding Plates 86

8.11.3.2 Shieldconnection clamps 86

8.11.3.3 MotorConnector X2 with shieldingconnection 87

8.12 Electrical Supply Connection 88

8.12.1 Connection to Various Mains Supply Networks AKD-xzzz06 (120V to 240V) 88

8.12.2 Connection to Various Mains Supply Networks AKD-xzzz07 (240V to 480V) 89

8.12.3 24 V Auxiliary Supply (X1) 90

8.12.4 Mains Supply Connection (X3, X4) 91

8.12.4.1 Three Phase connection (all AKD types) 91

8.12.4.2 Singlephase connection (AKD-xzzz06 only) 92

8.12.5 External Brake Resistor (X3) 93

8.12.6 DC Bus Link (X3) 94

8.13 Motor Connection 96

8.13.1 Motor Power (X2) 97

8.13.1.1 Cable Length ≤ 25 m 97

8.13.1.2 Cable length >25 m 97

8.13.2 Motor Holding Brake (X2) 98

8.14 Feedback Connection 99

8.14.1 Feedback Connector (X10) 100

8.14.2 Resolver 101

6 Kollmorgen | March 2010

Page 7

AKD Installation|

8.14.3 SFD 102

8.14.4 Encoder with BiSS 103

8.14.5 Sine Encoder with EnDat 2.1 104

8.14.6 Encoder with EnDat 2.2 105

8.14.7 Sine Encoder with Hiperface 106

8.14.8 Sine Encoder with Hall Encoder 107

8.14.9 Incremental Encoder with Hall Switches 108

8.15 Encoder Emulation Connector (X9) 109

8.15.1 Input Modes 109

8.15.1.1 Pinout Input X9 109

8.15.1.2 Pulse/Direction input (5 V) 110

8.15.1.3 Up/Down input (5 V) 111

8.15.1.4 Incremental Encoder (A quadB and Index) input (5 V) 111

8.15.2 Output Modes 112

8.15.2.1 Pinout Output X9 112

8.15.2.2 Emulated Encoder Output (EEO) - A quad B 113

8.15.3 Master-Slave Control 114

8.16 I/O Connection 115

8.16.1 I/O Connectors (X7 and X8) 115

8.16.2 Analog Input (X8) 116

8.16.3 Analog Output (X8) 117

8.16.4 Digital Inputs (X7/X8) 118

8.16.4.1 Digital Inputs 1 and 2 120

8.16.4.2 Digital Inputs 3 to 7 120

8.16.4.3 Digital Input 8 (ENABLE) 120

8.16.5 Digital Outputs (X7/X8) 121

8.16.5.1 Digital Outputs 1 and2 121

8.16.5.2 FAULT relay contacts 122

8.17 Service Interface (X11) 123

8.17.1 Possible Network Configurations 123

8.17.2 Setting the IP Address with Rotary Switches 124

8.18 CANbus Interface (X12/X13) 125

Kollmorgen | March 2010 7

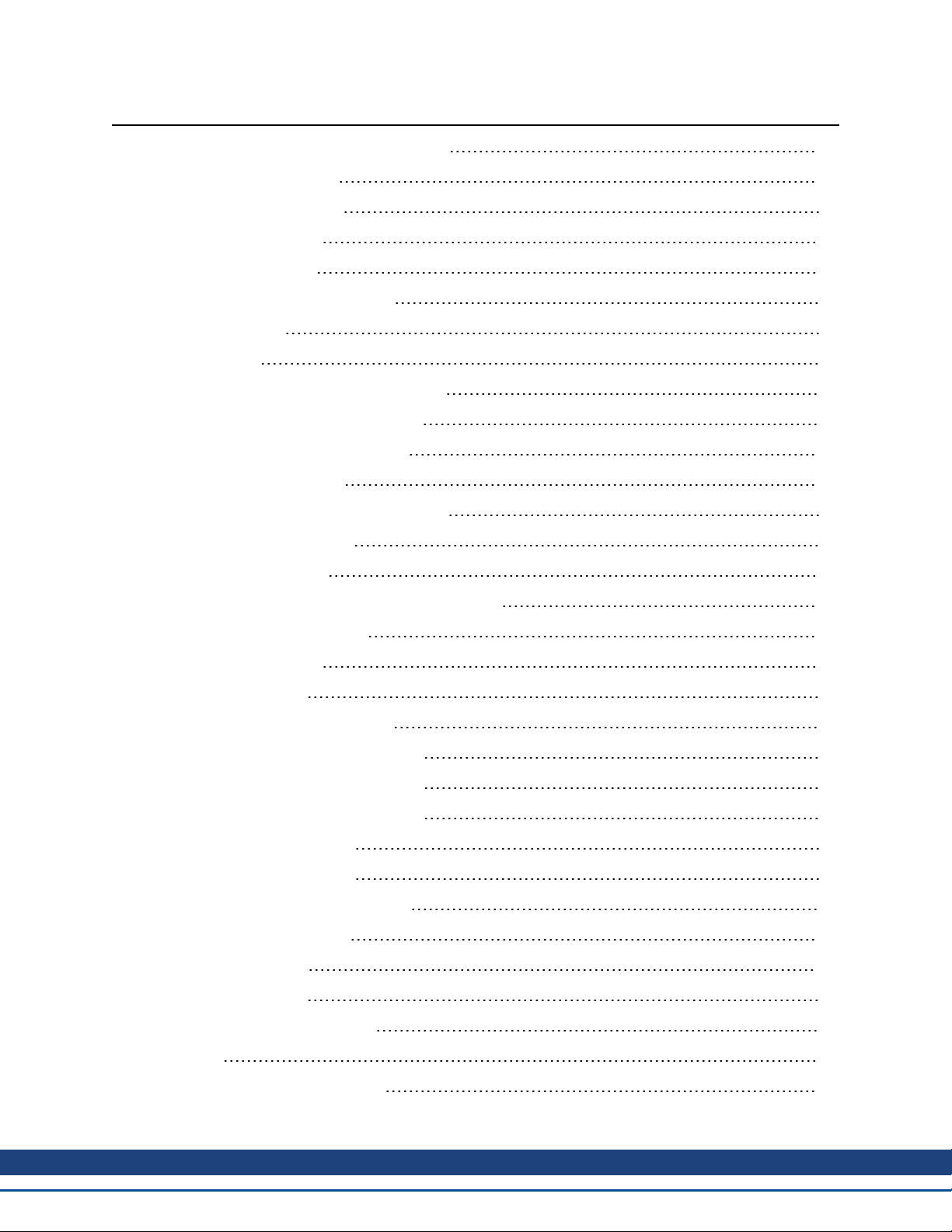

Page 8

AKD Installation|

8.19 Motion Bus Interface (X5/X6) 129

8.18.1 Transmission Rate for CANbus 125

8.18.2 Node Address for CANbus 126

8.18.3 CANbus Termination 126

8.18.4 CAN Bus Wiring 127

8.18.5 CANbus Cable 128

8.19.1 Pinout X5/X6 129

8.19.2 Optional Motion Bus Protocols 129

8.19.3 EtherCAT 130

8.19.4 SynqNet (in process) 130

8.19.5 Motion Busses in Process 130

8.19.5.1 PROFINET CBA/RT/IRT (in process) 130

8.19.5.2 SERCOS III (in process) 130

8.19.5.3 Ethernet IP (A-B, in process) 130

8.19.5.4 Powerlink (in process) 130

8.19.5.5 Modbus TCP/IP (in process) 130

9 Setup 131

9.1 Safety Instructions 132

9.2 Setup software (WorkBench) 133

9.2.1 Use as directed 133

9.2.2 Software description 134

9.2.3 Hardware requirements 134

9.2.4 Operating systems 134

9.2.5 Installation under WINDOWS 2000/XP/VISTA/7 135

9.3 Basic Drive Test 136

9.3.1 Unpacking, Mounting, andWiring the Drive 136

9.3.2 Minimum Wiring for Drive Test without Load 136

9.3.3 Testing Procedure 137

9.3.3.1 Confirm Connections 137

9.3.3.2 Install and Start WorkBench 137

9.3.3.3 Set Drive IP Address in WorkBench 138

9.3.3.4 Enable the Drive Using the Setup Wizard. 138

8 Kollmorgen | March 2010

Page 9

AKD Installation|

9.4 Fault and Warning Messages 139

9.5 Troubleshooting the AKD 146

10 Option Cards 147

11 Order Codes 148

11.1 Cables, brake resistors, filters, chokes 148

11.2 Drives 148

11.3 Mating connectors 148

11.3.1 AKD-xzzz06 148

11.3.2 AKD-xzzz07 148

12 Index 149

Kollmorgen | March 2010 9

Page 10

This page intentionally left blank.

10 Kollmorgen | March 2010

Page 11

AKD Installation| 1 General

1 General

1.1 About this Manual 12

1.2 Target Group 12

1.3 Using the PDF Format 12

1.4 Abbreviations 13

1.5 Warning Symbols 14

1.6 Standards Used 15

Kollmorgen | March 2010 11

Page 12

AKD Installation| 1 General

1.1 About this Manual

This manual, AKD Installation Manual, describes the AKD series of digital drives and includes information

needed to safely install an AKD. A digital version of this manual (pdf format) is available on the CD-ROM

included with your drive. Manual updates can be downloaded from the Kollmorgen website (www.kol-

lmorgen.com).

This document fulfills all requirements for an "Instructions Manual" underthe EC Machinery Directive

(2006/42/EC).

Additional documents on the accompanying CD-ROM include the following:

l AKD Quick Start (also provided in hardcopy). This guide provides instructions for basic drive setup

andconnection to a network.

l AKD Users Manual. This manual describes how to use your drive in common applications. It also pro-

vides tips for maximizing your system performance with the AKD.

l AKD Parameter and Command Reference Guide. This guide provides documentationfor the param-

eters andcommands used to program the AKD.

l AKD Accessories Manual. This manual includes technical data anddimensional drawings of acces-

sories such as cables, brake resistors, andmains supplies.

1.2 Target Group

This manual addresses personnel with the following qualifications:

l Transport: only by personnel with knowledge of handling electrostatically sensitive components.

l Unpacking: only by electrically qualified personnel.

l Installation: only by electrically qualified personnel.

l Basic tests: only by qualified personnel with extensive knowledge of electrical engineering and drive

technology

The qualified personnel must know and observe the following standards:

l ISO 12100, IEC 60364 andIEC 60664

l National accident preventionregulations

During operation, hazards exist that can cause death, severe injury, or material

damage. To safely operate the AKD, you must follow all safety instructions in

this manual. The operator of systems using the AKD must require that all personnel who work with the drive read and understand the manual before using the

drive.

1.3 Using the PDF Format

This document includes several features for ease of navigation

Cross References Table of contents and index include active cross references.

Table of contents and index Lines are active cross references. Click on the line andthe appropriate page

Page/chapter numbers in

the text

12 Kollmorgen | March 2010

is accessed.

Page/chapternumbers with cross references are active links.

Page 13

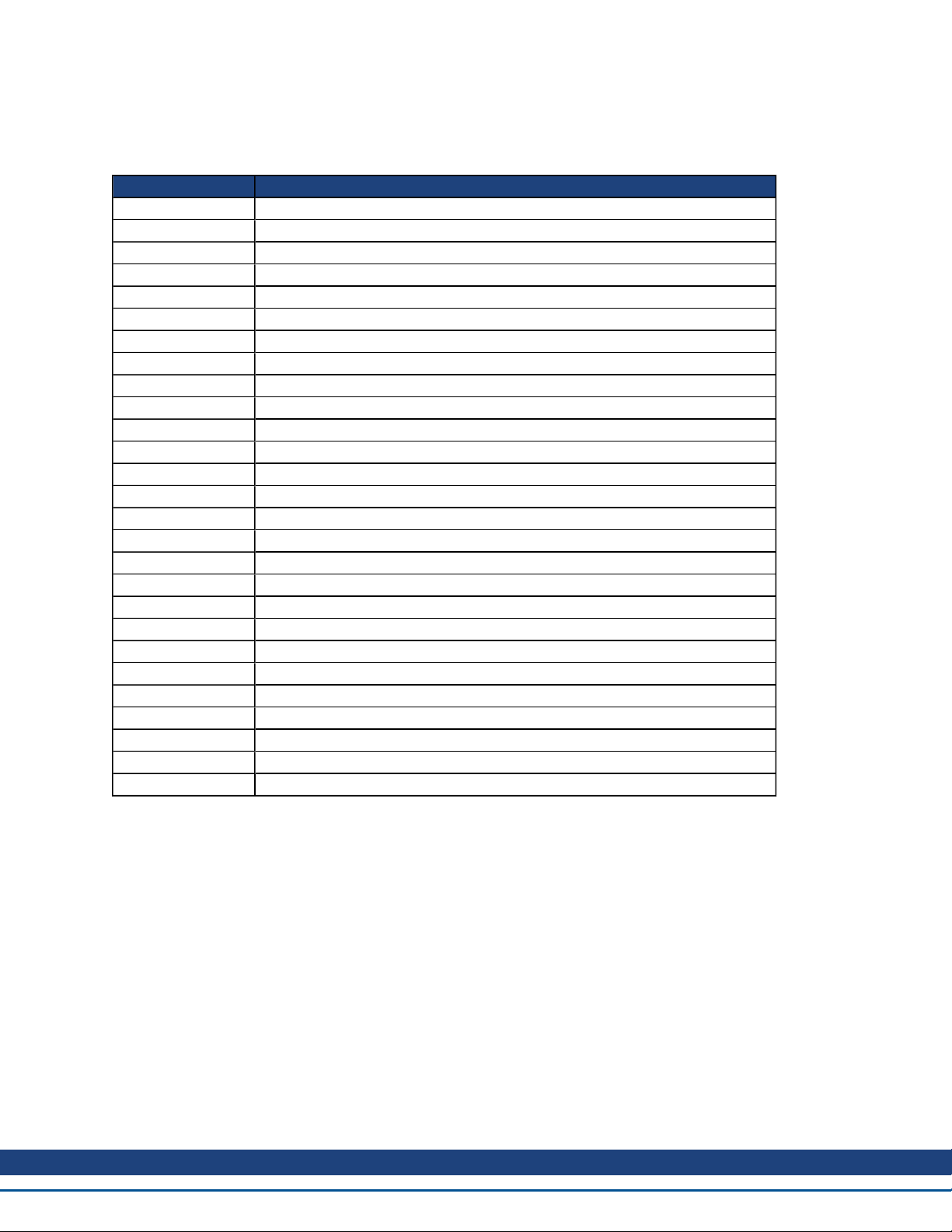

1.4 Abbreviations

Abbreviation Meaning

AGND Analog ground

CE Communité Européenne

COM Serial interface for a personal computer

DCOMx Communication line for digital inputs (with x=7 or 8)

Disk Magnetic storage (diskette, hard disk)

EEPROM Electrically erasable programmable memory

EMC Electromagnetic compatibility

F-SMA Fiber optic cable connector according to IEC 60874-2

LED Light-emitting diode

LSB Low significant byte (orbit)

MSB Main significant byte (or bit)

NI Zero pulse

PC Personal computer

PE Protective earth

PLC Programmable logic control

PWM Pulse-width modulation

RAM Random access memory (volatile memory)

R

Brake/RB

RBext External brake resistor

RBint Internal brake resistor

RCD Residual current device

RES Resolver

ROD Incremental encoder (A quad B)

S1 Continuous operation

STO Safe torque off

Vac Volts, alternating current

Vdc Volts, direct current

Brake resistor (also called a regen resistor)

AKD Installation| 1 General

Kollmorgen | March 2010 13

Page 14

AKD Installation| 1 General

1.5 Warning Symbols

Symbol Indication

Drawing symbols

Symbol Description Symbol Description

Signal ground Diode

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Indicates situations which, if not avoided, couldresult in property

damage.

This is not a safety symbol.

This symbol indicates important notes.

Chassis ground Relays

Protective earth Relays switch off

delayed

Resistor Normal open contact

Fuse Normal closed contact

14 Kollmorgen | March 2010

Page 15

AKD Installation| 1 General

1.6 Standards Used

Standard Content

ISO 4762 Hexagon socket head cap screws

ISO 11898 Road vehicles — Controller area network (CAN)

ISO 12100 Safety of machinery: Basic concepts, general principles for design

ISO 13849 Safety of machinery: Safety-related parts of control systems

IEC 60085 Electrical insulation - Thermal evaluation anddesignation Maintenance

IEC 60204 Safety of Machinery: Electrical equipment of machinery

IEC 60364 Low-voltage electrical installations

IEC 60439 Low-Voltage Switchgear and Controlgear Assemblies

IEC 60529 International protection rating (IP code)

IEC 60664 Insulationcoordinationfor equipment within low-voltage systems

IEC 60721 Classification of environmental conditions

IEC 61000 Electromagnetic compatibility (EMC)

IEC 61131 Programmable controllers

IEC 61491 Electrical equipment of industrial machines – Serial data link for real-time com-

munications between controls anddrives.

IEC 61508 Functional safety of electrical/electronic/programmableelectronic safety-related sys-

tems

IEC 61800 Adjustable speed electrical power drive systems

IEC 62061 Functional safety of electrical/electronic/programmableelectronic safety-related sys-

tems

IEC 62079 Preparationof instructions - Structuring, content and presentation

ANSI Z535 Product safety (symbols, colors, information)

UL 840 UL Standard for Safety for InsulationCoordination Including Clearances and Creep-

ageDistances for Electrical Equipment

UL 508C UL Standard for Safety Power Conversion Equipment

ANSI - AmericanNational StandardInstitute, Inc.

IEC - International Electrotechnical Commission

ISO - International Organizationfor Standardization

UL - Underwriters Laboratories

Kollmorgen | March 2010 15

Page 16

AKD Installation| 2 Safety

2 Safety

2.1 Safety Instructions 17

2.2 Use as Directed 18

2.3 Prohibited Use 18

16 Kollmorgen | March 2010

Page 17

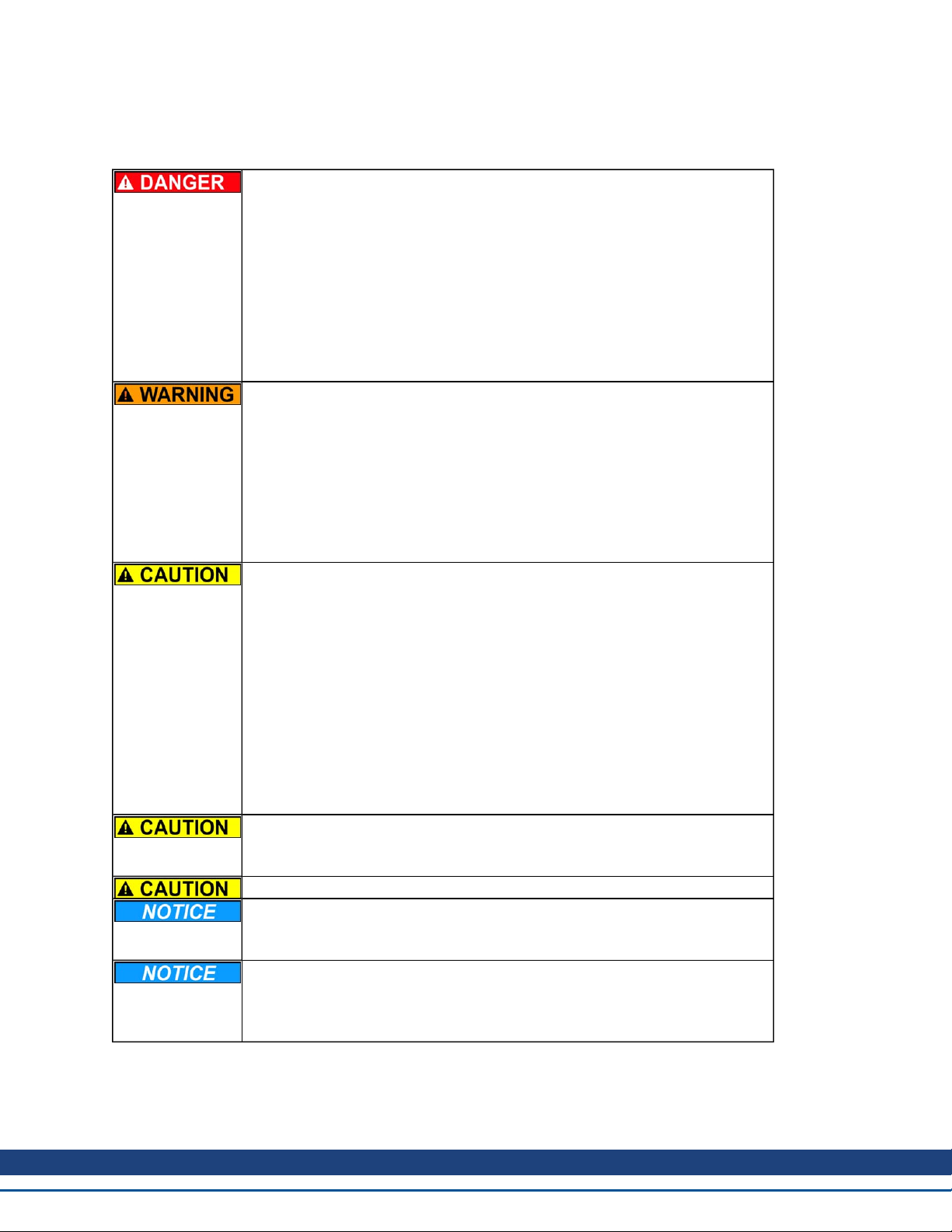

2.1 Safety Instructions

Duringoperation, hazards exist that can cause death, severe injury, or material

damage. Do not open or touch the equipment during operation. Keep all covers

andcabinet doors closed during operation. Only properly qualified persons may

handle the equipment during installation and commissioning .

l Duringoperation, drives may have uncovered live components, depend-

ing on their level of enclosureprotection.

l Control and power connections may be live, even though the motoris not

rotating.

l Drives may have hot surfaces during operation. The heat sink can reach

temperatures above 80°C.

The danger of electrical arcing is present. Electrical arcing can damage contacts and injure personnel. Never undo any electrical connections to the drive

while it is live.

Wait at least 7 minutes after disconnecting the drive from the main supply

powerbefore touching potentially live sections of the equipment (such as contacts) or removing any connections.

Capacitors can have dangerous voltages present up to seven minutes after

switching off the supply power. Always measurethe voltagein the DC bus link

andwait until the voltage is below 40 V before handling components.

Incorrect handling of the drive can lead to personnel injury or material damage.

Read this documentation before installing and commissioning the drive. It is

vital that you keep to the technical data and information on connection requirements (nameplate and documentation).

Only properly qualified personnel may perform activities such as transport,

installation, commissioning, andmaintenance. Properly qualified persons are

those who are familiar with the transport, assembly, installation, commissioning

andoperation of the product, and who have the appropriate qualifications for

their job. The qualified personnel must know and observe the following standards:

AKD Installation| 2 Safety

l IEC 60364 and IEC 60664

l national accident preventionregulations

The manufacturer of the machine must produce a hazard analysis for the

machine and take appropriate measures to ensure that unforeseen movements

do not result in personnel injury or material damage.

It is not allowed to modify this device without permission by the manufacturer.

Check the Hardware Revision Number of the product (see product label). This

revision number must match the Hardware Revision Number on the cover page

of the manual.

The drives contain electrostatically sensitive components which may be damaged by incorrect handling. Electrostatically discharge your body before touching the drive. Avoid contact with highly insulating materials (artificial fabrics,

plastic film etc.). Place the drive on a conductive surface.

Kollmorgen | March 2010 17

Page 18

AKD Installation| 2 Safety

2.2 Use as Directed

Drives arecomponents that are built into electrical plants or machines and can only be operated as integral

components of these plants or machines. The manufacturer of the machine used with a drive must generate a

hazard analysis for the machine and take appropriate measures to ensure that unforeseen movements cannot

cause personnel injury or property damage.

Cabinet and wiring

Drives must only be operated in a closed control cabinet suitablefor the ambient conditions see page 32. Ventilation or coolingmay be necessary to keepthe temperaturewithin the cabinet below 40 °C.

Use only copper conductors for wiring. The conductor cross-sections can be derived from the standard IEC

60204 (alternatively for AWG cross-sections: NEC Table 310-16, 75 °C column).

Power supply

Drives in the AKD series can be supplied as follows:

l AKD-xzzz06: 1 or 3 phase industrial supply networks

(not more than 42 kA symmetrical rated current at 120 V and 240 V).

l AKD-xzzz07: 3 phase industrial supply networks

(not more than 42 kA symmetrical rated current at 240 V, 400 V and 480 V).

Connection to other voltage types of supply networks is possible with an additional isolating transformer (see

page 88).

Periodic overvoltages between phases (L1, L2, L3) and the housing of the drive must not exceed 1000V peak.

In accordance with IEC 61800, voltage spikes (< 50 µs) between phases must not exceed 1000 V. Voltage

spikes (< 50 µs) between a phase and the housing must not exceed 2000 V.

EMC filter measures must be implemented by the user.

Motor voltage rating

The AKD family of drives is exclusively intended for driving suitable synchronous servomotors with closedloopcontrol of torque, speed, and/or position. The rated voltage of the motors must be at least as high as the

DC bus link voltage divided by √2 producedby the drive (U

nMotor

>=UDC/√2).

Safe torque off and restart lock

Review the section "Use as Directed" in the safe torqueoff (STO) chapter (see page56) before using the personnel safe restart lock (accordingto ISO 13849 category 3).

2.3 Prohibited Use

Otheruse than that described in chapter “Use as directed” is not intended andcan lead to personnel injuries

andequipment damage. The drive may not be used with a machine that does not comply with appropriate

national directives or standards. The use of the drive in the following environments is also prohibited:

l potentially explosive areas

l environments with corrosive and/orelectrically conductive acids, alkaline solutions, oils, vapors, dusts

l ships or offshore applications

18 Kollmorgen | March 2010

Page 19

AKD Installation| 3 Approvals

3 Approvals

3.1 Conformance with UL/cUL 20

3.2 CE Conformance 22

3.3 Safe Torque Off (STO) 25

Kollmorgen | March 2010 19

Page 20

AKD Installation| 3 Approvals

3.1 Conformance with UL/cUL

This drive is listed under UL (Underwriters Laboratories Inc.) file number E141084 Vol.3 Sec.5.

USL, CNL – Power conversion equipment (NMMS, NMMS7) – Models AKD followed by B,P,S,M or F, followed by 003, 006, 012, and024, followedby 06 or 07, followed by additional suffixes.

USL

Indicates Investigated to United States Standard for Power Conversion Equipment, UL 508C, Third Edition,

Revised February 15, 2008.

CNL

Indicates investigation to Canadian Standard for Industrial Control Equipment, CAN/CSA - C22.2 No. 142005, Second Edition, Revised April 2008.

Note:

CNL = Canadian National Standards - Listed.

USL = United States Standards - Listed.

3.1.1 UL Markings

l These drives are open type adjustable frequency motor drives that providevariable speed control to

motors andprovides overload protection andcurrent limit control.

l These devices are intended to be used in a pollution degree2 environment.

l Identification of the terminals on the controller are codedso they may be identified in the instructions.

The instructions shall identify powerconnections for power supply, load, control, and ground.

l Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit pro-

tection must be provided in accordance with the National Electrical Code and any additional local

codes, or the equivalent.

l This product is suitable for use on a circuit capable of delivering not more than 200,000rms sym-

metrical amperes, 240 V (AKD-xzzz06) / 480 V (AKD-xzzz07) volts maximum, when protected by ”

Fuses", or equivalant.

l The following fuse types arerecommended:

Model Fuse class Rating Max. Fuse Rating

AKD-x00306 J 600 Vac, 200 kA 10 A

AKD-x00606 J 600 Vac, 200 kA 15 A

AKD-x01206 J 600 Vac, 200 kA 15 A

AKD-x02406 J 600 Vac, 200 kA 30 A

AKD-x00307 J 600 Vac, 200 kA 6 A

AKD-x00607 J 600 Vac, 200 kA 10 A

AKD-x01207 J 600 Vac, 200 kA 15 A

AKD-x02407 J 600 Vac, 200 kA 30 A

l These drives provide solid state motor overload protection at 125% of the rated FLA Current.

l Use minimum 75°C copper wire.

20 Kollmorgen | March 2010

Page 21

AKD Installation| 3 Approvals

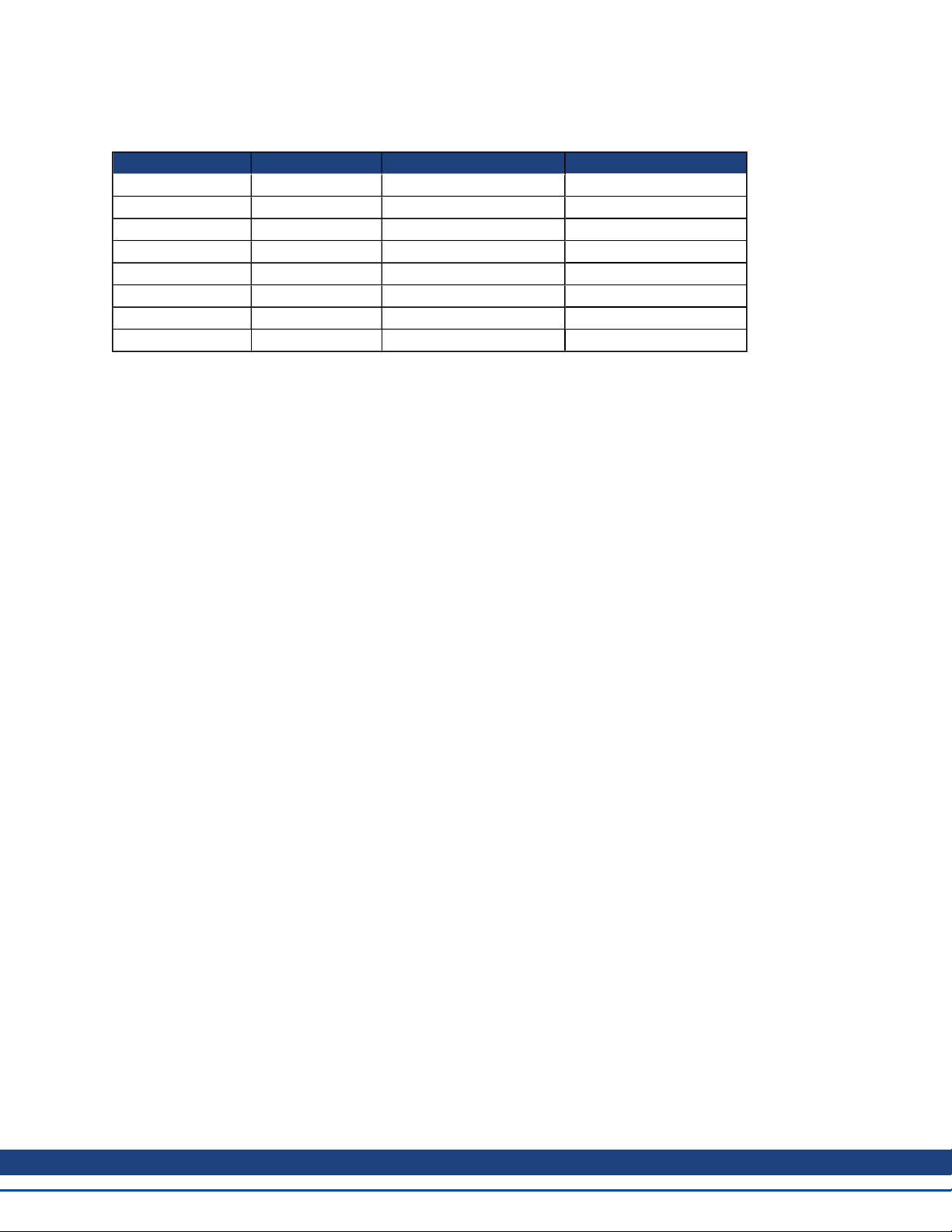

l The following tableillustrates the torque requirements for the field wiring connectors:

Model Mains Connector Motor Phase Connector 24 Vdc Input Connector

AKD-x00306 5-7in-lbs 5-7 in-lbs 4 in-lbs

AKD-x00606 5-7in-lbs 5-7 in-lbs 4 in-lbs

AKD-x01206 5-7in-lbs 7 in-lbs 4 in-lbs

AKD-x02406 7 in-lbs 7 in-lbs 4 in-lbs

AKD-x00307 7 in-lbs 7 in-lbs 4 in-lbs

AKD-x00607 7 in-lbs 7 in-lbs 4 in-lbs

AKD-x01207 7 in-lbs 7 in-lbs 4 in-lbs

AKD-x02407 7 in-lbs 7 in-lbs 4 in-lbs

l Maximum surrounding air temperature of 40°C” or equivalent.

Kollmorgen | March 2010 21

Page 22

AKD Installation| 3 Approvals

3.2 CE Conformance

Conformance with the EC EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC is mandatory for the supply of drives within the European Community.

The drives have been tested by an authorized testing laboratory in a defined configuration, using the system

components that are described in this documentation. Any divergence from the configuration and installation

described in this documentationmeans that the user will be responsiblefor carrying out new measurements to

ensure conformance with regulatory requirements.

AKD-xzzz06

With external EMC filters for noise emission the drives meet the noise immunity requirements of the second

environmental category (industrial environment) to a product of the category C2 (motor cable < 10 m).

Withamotorcablelengthof10morlongerandexternalEMC filters,thedrivemeetstherequirementofcategoryC3.

AKD-xzzz06 drives do not have integrated EMC filters. These drives can cause

high-frequency interferences and may require measures for interference suppression (such as additional external EMC filters).

AKD-xzzz07

AKD-xzzz07 drives have integrated EMC filters.

The drive meets the noise immunity requirements to the 2nd environmental category (industrial environment).

For noise emission the drive meets the requirement to a product of the Category C2 (motor cable < 10 m).

With a motor cable length of 10 m or longer, the servo drive meets the requirement to the Category C3.

22 Kollmorgen | March 2010

Page 23

AKD Installation| 3 Approvals

3.2.1 European Directives and Standards for the machine builder

Drives arecomponents that are intendedto be incorporated into electrical plant and machines for industrial

use. Whenthe drives are built into machines or plant, the drive must not be used until it has been established

that the machine or equipment fulfills the requirements of the

l EC Machinery Directive (2006/42/EC)

l EC EMC Directive (2004/108/EC)

l EC Low Voltage Directive (2006/95/EC)

Standards to be applied for conformance with the EC Machinery Directive (2006/42/EC)

l IEC 60204-1 (Safety and Electrical Equipment in Machines)

l ISO 12100(Safety of Machines)

The manufacturer of the machine must generate a hazard analysis for the

machine, and must implement appropriate measures to ensure that unforeseen

movements cannot cause injury or damage to any person or property.

Standards to be applied for conformance with the EC Low VoltageDirective(2006/95/EC)

l IEC 60204-1 (Safety and Electrical Equipment in Machines)

l IEC 60439-1 (Low-voltage switchgear and controlgear assemblies)

Standards to be applied for conformance with the EC EMC Directive (2004/108/EC)

l IEC 61000-6-1/2 (Interference Immunity in Residential & Industrial Areas)

l IEC 61000-6-3/4 (Interference Generation in Residential & Industrial Areas)

The manufacturer of the machine/plant is responsible for ensuring that it meets the limits required by the EMC

regulations. Advice on the correct installation for EMC (such as shielding, grounding, treatment of connectors

andcable layout) is shown in this manual.

The machine/plant manufacturer must check whether other standards or EC Directives must be applied to the machine/plant.

Kollmorgen only guarantees the conformance of the servosystem with the standards cited in this chapter if the

components (motor, cables, chokes etc.) are those supplied by Kollmorgen.

Kollmorgen | March 2010 23

Page 24

AKD Installation| 3 Approvals

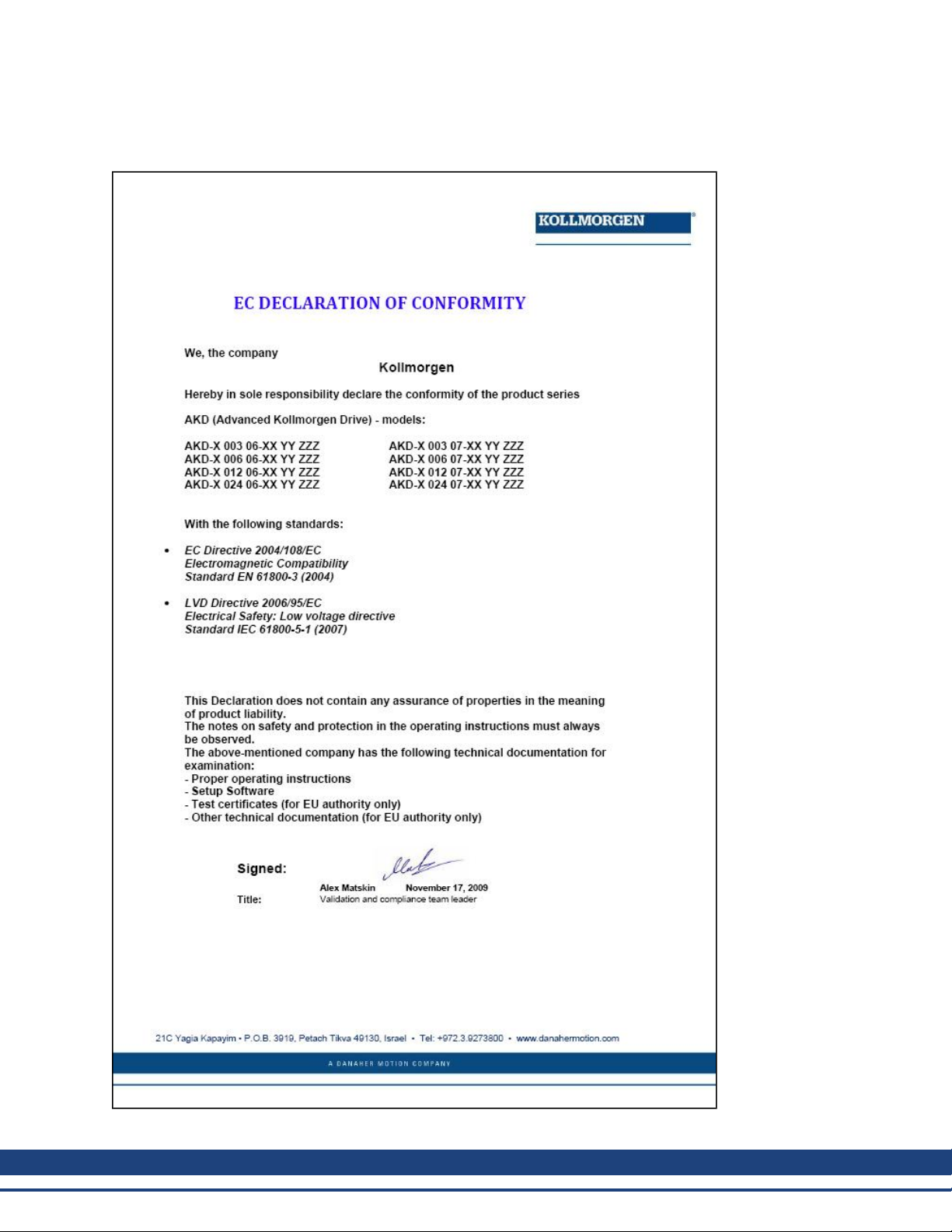

3.2.2 EC Declaration of Conformity

24 Kollmorgen | March 2010

Page 25

AKD Installation| 3 Approvals

3.3 Safe Torque Off (STO)

STO Input X1/3

TheAKD drive’s STO functionality is not certified, yet. The circuit concept is going to be examinedby theTÜV.

We cannot ensure the functionality of the STO function until the certification

process is complete.

We expect theSTO functionality certified in July 2010.To ensureproduct is certified, pleasecontact Kollmorgenfor updatedinformation. Connect the STO input X1/3 with +24Vdc. This deactivates theSTO function.

STO Eingang X1/3

Die STO Funktionalität des AKD Servoverstärkers ist nicht zertifiziert. Das Schaltungskonzept wird zur Zeit

vom TÜV geprüft.

Bis zum Abschluss der Prüfung können wir die Funktionalität der STO Funktion

nicht gewährleisten.

Wir erwarten dieZertifizierung der STO Funktionalität im Juli 2010. Setzen Sie sich mit Kollmorgenfür

aktuelle Informationen zur Zertifizierung in Verbindung. Verbinden Sie den STO Eingang X1/3 fest mit +24

VDC. Dies deaktiviert die STO Funktion.

Ingresso STO X1/3

La funzionalità STO del servoazionamento AKD non è ancora certificata. Il principio di collegamento verrà

esaminato dal TÜV.

Fino a quando non sarà concluso il procedimento di certificazione non possiamo garantire la funzionalità della funzione STO.

La certificazione della funzionalità STO è prevista per il mese di luglio 2010. Per accertarsi che il prodotto sia

certificato, metta in contatto con Kollmorgen per riceverele informazioni aggiornate. Collegare l'ingresso STO

X1/3 a +24 Vdc. In questo modo la funzione STO viene disattivata.

Entrée STO X1/3

La fonctionnalité STO du variateur AKD n’est pas encore certifiée. Le concept du circuit va être examinépar le

TÜV.

Nous ne pouvons garantir la fonctionnalité pour la fonction STO, tant que le

processus de certification n’est pas achevé.

Nous prévoyons que la fonctionnalité STO sera certifiée en juillet 2010. Pours'assurer quele produit est certifié, entrez en contact avec Kollmorgen pour l'information mise à jour. Connectez l’entrée STO X1/3 avec +24

Vcc. Ceci désactive la fonction STO.

Kollmorgen | March 2010 25

Page 26

AKD Installation| 4 Handling

4 Handling

4.1 Transport 27

4.2 Packaging 27

4.3 Storage 27

4.4 Maintenance and Cleaning 28

4.5 Uninstalling 28

4.6 Repair and Disposal 28

26 Kollmorgen | March 2010

Page 27

AKD Installation| 4 Handling

4.1 Transport

Transport the AKD in accordance with IEC 61800-2 as follows:

l Transport only by qualified personnel in the manufacturer’s original recyclable packaging.

l Avoid shocks while transporting.

l Transport only within specified temperature ranges: -25 to +70 °C, max. rate of change20 K/hour,

class 2K3.

l Transport only within specifiedhumidity: max. 95% relative humidity, no condensation, class 2K3.

The drives contain electrostatically sensitive components that can be damaged

by incorrect handling. Electrostatically discharge yourself before touching the

drive. Avoid contact with highly insulating materials, such as artificial fabrics

and plastic films. Place the drive on a conductive surface.

If the packagingis damaged, check the unit for visible damage. Inform the shipperand the manufacturer of

any damage to the package or product.

4.2 Packaging

The AKD packaging consists of recyclable cardboard with inserts and a label on the outside of the box.

Model

Package Dimensions (mm)

HxWxL

Total Weight (kg)

AKD-x00306 and AKD-x00606 77 x 280 x 222 1.7

AKD-x01206 153x 394x 229 3.4

AKD-x02406 153x 394x 229 5

AKD-x00307 and AKD-x00607 153x 394x 229 4.3

AKD-x01207 153x 394x 229 4.3

AKD-x02407 153x 394x 229 6.7

4.3 Storage

Store the AKD in accordance with IEC 61800-2 as follows:

l Store only in the manufacturer’s original recyclable packaging.

l Store at or below maximum stacking height:

l AKD-x0306to 0606 models: 8 cartons

l All other models: 6 cartons

l Store only within specified temperature ranges: -25to +55 °C, max.rate of change 20 K/hour, class

1K4.

l Storage only within specified humidity: 5 to 95% relative humidity, no condensation, class 1K3.

l Store in accordance with the following duration requirements:

l Less than 1 year: without restriction.

l More than 1 year: capacitors must be re-formed before setting up and operating the drive. To re-

form the capacitors, remove all electrical connections andapply single-phase 120 Vac for about 30

minutes to the L1/L2 terminals.

Kollmorgen | March 2010 27

Page 28

AKD Installation| 4 Handling

4.4 Maintenance and Cleaning

The drive does not require maintenance. Opening the drive voids the warranty.

The inside of the unit can only be cleaned by the manufacturer. To clean the drive exterior:

l Casing: Cleanwith isopropanol or similar cleaningsolution.

l Protective grill on fan: Clean with a dry brush.

4.5 Uninstalling

If a drive must be uninstalled (such as for replacement), remove the drive as follows:

1. Switch off the main switch of the switchgear cabinet andthe fuses that supply the system.

Do not immerse or spray the drive.

Wait at least seven minutes after disconnecting the drive from the main supply

power before touching potentially live sections of the equipment (e.g. contacts)

or undoing any connections. Always measure the voltage in the DC bus link and

wait until the voltage is below 40 V before touching or handling the drive.

2. Remove the connectors. Disconnect the potential earth connection last.

3. Check temperature.

During operation, the heat sink of the drive may reach temperatures above 80°C

(176°F). Before touching the device, check the temperature and wait until it has

cooled below 40°C (104°F).

4. Uninstall. Remove the drive andpower supply from the conductive, grounded mounting plate in the cabinet.

4.6 Repair and Disposal

Onlythe manufacturercan repairthe drive.Opening thedevice voidsthe warranty. Uninstall the drive as

describedin "Uninstalling" (page28)andsend it in theoriginal packagingto themanufacturer (seetable below).

In accordance with the WEEE-2002/96/EC-Guidelines andsimilar, the manufactureraccepts returns of old

devices and accessories for professional disposal. Transport costs are the responsibility of the sender. Send

the devices to the manufacturer addresses shown in the table below.

USA Europe

Kollmorgen

201West Rock Road

Radford, VA 24141

DanaherMotion GmbH

Wacholderstr. 40-42

D-40489Düsseldorf

28 Kollmorgen | March 2010

Page 29

AKD Installation| 5 Package

5 Package

5.1 Package Supplied 30

5.2 Nameplate 30

5.3 Part number scheme 31

Kollmorgen | March 2010 29

Page 30

AKD Installation| 5 Package

5.1 Package Supplied

WhenadrivefromtheAKD seriesis ordered(seepage148), thefollowingitemsareincludedinthedrivepackage:

l AKD drive

l Printedcopy of AKD Installation Manual (EU only)

l Printedcopy of AKD Quick Start

l Printedcopy of fault and warning card

l CD-ROM containing the setup software, WorkBench, and all product documentation in digital format.

l Mating connectors X1, X2, X3, X4 (if required), X7, andX8

l Grounding plate, L-shape or Flat depending on AKD voltage tye

Accessories Sold Separately

Accessories must be orderedseparately if required; refer to your regional accessories manual:

l EMC filters for 24 V andmains supply voltage, categories C2 or C3

l External brake resistor

l Motor cable. Assembled motor cables are available for all regions. EU customers may also order motor

cable at custom lengths and assemble the cable with power connectors ordered separately.

l Feedback cable. Assembled feedback cables areavailable for all regions. EU customers may also

orderfeedback cable at custom lengths and assemble the cablewith power connectors ordered separately.

l Motor choke, for motor cables longer than 25m

l CAN terminationconnector (with CAN drives only)

l Service cable to the network

l Power cable, control cables, and fieldbus cables (as cutoff lengths)

The mating SubD and RJ45 connectors are not included in the package.

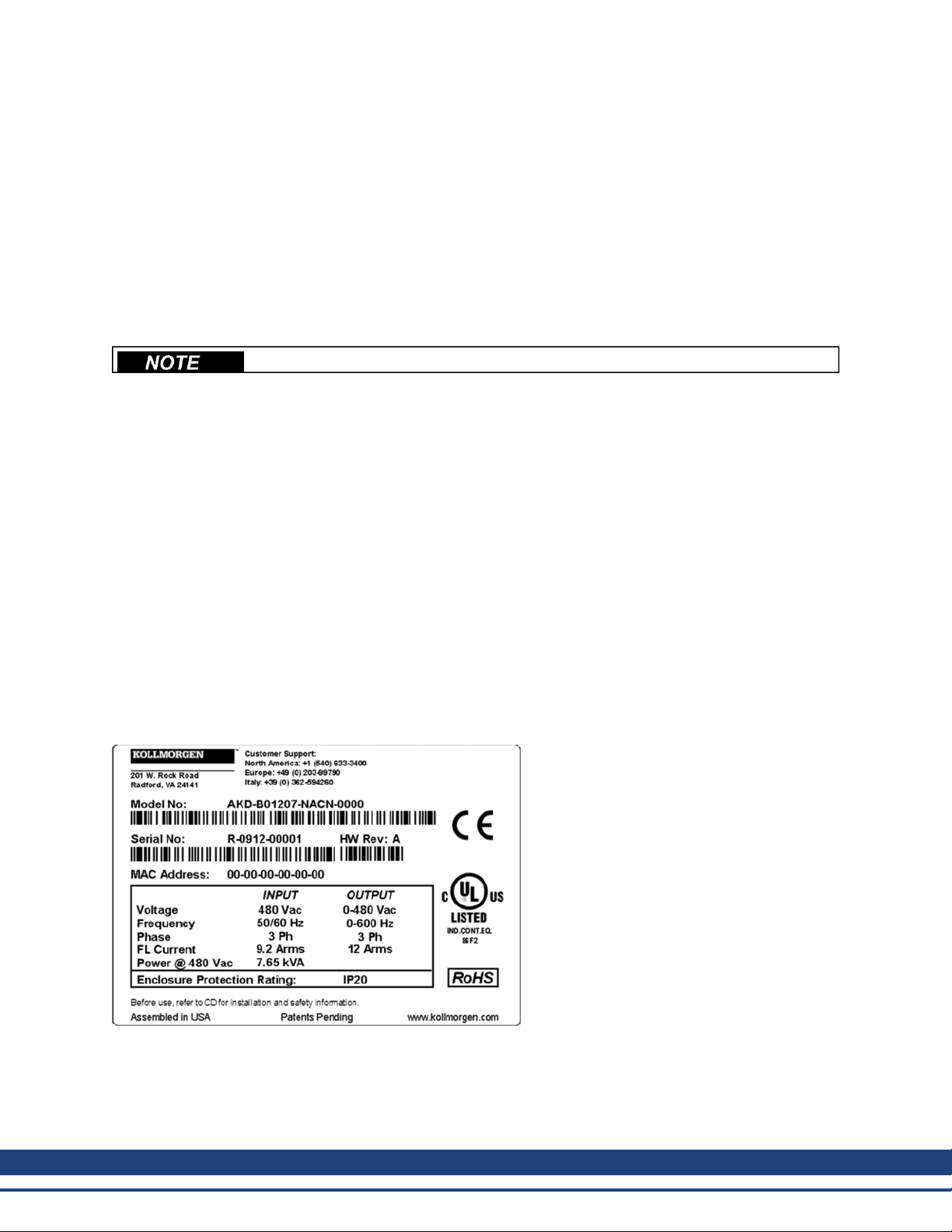

5.2 Nameplate

The nameplate depicted below is attached to the side of the drive, sample data entries are for a 12A type.

30 Kollmorgen | March 2010

Page 31

5.3 Part number scheme

The part number is identical to the ordercode.

AKD Installation| 5 Package

Customization code includes language versionof printed material for Europeancountries:

l D000 for German

l E000 for English

l F000 for French

l I000 for Italian

Presently the AKD-xzzz07 models only support operation at levels above 270Vac. Updates to the AKD firmware are in process to allow the operation of the AKD-xzzz07 models drives at 240Vac. These updates will

only requirea firmware modification and will be backwards compatible with all AKD-xzzz07 hardware."

Kollmorgen | March 2010 31

Page 32

AKD Installation| 6 Technical description and data

6 Technical description and data

6.1 The AKD Family of Digital Drives 33

6.2 Ambient Conditions, Ventilation, and Mounting Position 35

6.3 Mechanical Data 35

6.4 Inputs/Outputs 36

6.5 Electrical Data AKD-xzzz06 37

6.6 Electrical Data AKD-xzzz07 38

6.7 Performance Data 39

6.8 Recommended tightening torques 39

6.9 Fusing 40

6.10 Connectors 41

6.11 Cable and Wire Requirements 42

6.12 LED display 43

6.13 Grounding System 43

6.14 Dynamic Braking 44

6.15 Switch-on and Switch-off Behavior 47

6.16 Stop-/Emergency Stop- Function 50

6.17 Safe Torque Off (STO) 55

6.18 Shock-hazard Protection 62

32 Kollmorgen | March 2010

Page 33

AKD Installation| 6 Technical description and data

6.1 The AKD Family of Digital Drives

Standard features

l Supply voltage range 95 Vac to 480 Vac ±10%.

l Several housingdimensions, dependingon current and hardware options.

l Motion bus onboard.

l TCP/IP service channel onboard.

l SFD, Resolver, Comcoder, 1Vp-p Sin-Cos encoders, incremental encoders support onboard.

l Support for ENDAT 2.1 & 2.2, BISS or HIPERFACE protocols onboard.

l Encoder emulation onboard.

l Secondfeedback support.

l Safe Torque Off (STO) according to IEC 61508 SIL 2 onboard.

l Use with Synchronous servomotors, linear motors, and induction machines can be used.

Available AKD versions

l B - Base drive is controlledby analog torque andvelocity commands (electronic gearing).

l P - Position Indexer drive adds the ability to command multiple motions, process I/O, make decisions,

addtime delays, andmodify drive process variables to the base drive.

l T - (in process) Structured Text drive adds simple programmability (similar to Basic) to the base drive.

l S - (in process) Single Axis KMS is a one-axis programmable drive features KMS software built in to

the drive. Includes all five IEC 61131 languages, PLC Open and Pipes Network.

l M - (in process) Multi Axis KMS master drive runs two to four axes. Includes all five IEC 61131lan-

guages, PLC Open and Pipes Network.

Power section

l Oneorthree phase supply, voltage range95to 480 V, 50/60 Hz.

l Connection to highervoltage mains only via isolatingtransformer, see page 89

l B6 bridge rectifier, integral soft-start circuit.

l Single phase supply possible with output power derating.

l Fusing to be provided by the user.

l Shielding star point close to the drive.

l DC bus link voltage range 120 to 375Vdc, can be connected in parallel.

l Output stage IGBT module with floatingcurrent measurement.

l Brake circuit with dynamic distribution of the generated power between several drives on the same

DC bus link circuit.

l Internal brake resistor for all 240/480 Vac AKD-xzzz07 models (only 120/240 Vac 3 A and 6 A AKD-

xzzz06 models lack internal brake resistors.), external brake resistors if required.

Kollmorgen | March 2010 33

Page 34

AKD Installation| 6 Technical description and data

Integrated safety

l Appropriate insulation/creepage distances and electrical isolation for safe electrical separation, per

IEC 61800-5-1, between the power input/motor connections and the signal electronics.

l Soft-start, overvoltage detection, short-circuit protection, phase-failure monitoring.

l Temperature monitoring of the drive and motor.

l Motor overload protection: foldback mechanism

l SIL 2 safe torque off in accordance with IEC 61508, see page 55.

l Optional safety functions for the safe operation of drive shafts in accordance with IEC 61800-5-2 (in

process).

Auxiliary supply voltage 24V DC

l From an external, safety approved24 V ±10% power supply.

Operation and parameter setting

l Using the setup softwareWorkBench, for setup via TCP/IP.

Full digital control

l Digital current controller (670 ns)

l Adjustabledigital velocity controller (62.5 µs)

l Software optionposition controller (125 µs)

Inputs/Outputs

l 1 programmable analog input see page 116

l 1 programmable analog output see page 117

l 7 programmable digital inputs see page 118

l 2 programmable digital outputs see page 121

l 1 Enableinput see page 118

l 1 STO input see page 55

Option Cards (in process)

Several option cards arein process. These options will affect the device width.

Connectivity

l Analog +/- 10 V control with encoder feedback output.

Onboard Serial Interface (see page 125), optional

l CANopen see page 125

Onboard Ethernet interface (see page129), optional

l SynqNet see page 129

l EtherCAT see page129

34 Kollmorgen | March 2010

Page 35

AKD Installation| 6 Technical description and data

6.2 Ambient Conditions, Ventilation, and Mounting Position

Storage see page 26

Transport seepage 26

Ambient temperature

in operation

Humidity in operation Relative humidity 5 to 85%, no condensation, class 3K3

Site altitude Up to 1000meters AMSL without restriction

Pollution level Pollution level 2 as per IEC 60664-1

Vibrations Class 3M1 according to IEC 60721-3-3

Enclosure protection IP 20 according to IEC 60529

Mounting position Vertical, see page 66

Ventilation Built-in fan

0 to +40 °C underrated conditions

+40 to +55 °C with continuous current derating 4 % per °C

1,000 to 2,500 meters AMSL with power derating 1.5%/100 m

The drive shuts down (fault F234, see page 139, motor has no

torque) in case of excessively high temperature in the control cabinet. Make sure sufficient forced ventilation is supplied within the

control cabinet.

AMSL = above mean sea level

6.3 Mechanical Data

Mechanical data Units AKD-x00306 AKD-x00606 AKD-x01206 AKD-x02406

Weight, standard kg 1.1 2 3.7

Weight, delivery package kg 1.7 3.4 5

Height, without connectors mm 168 195 250

Height, with service connector mm 200 225 280

Width front/back, standard mm 53/57 74/76 97/100

Depth, without connectors mm 153 186 230

Depth, with connectors mm < 205 < 255 <300

Mechanical data Units AKD-x00307 AKD-x00607 AKD-x01207 AKD-x02407

Weight, standard kg 2.7 5.3

Weight, delivery package kg 4.3 6.7

Height, without connectors mm 256 306

Height, with service connector mm 290 340

Width front/back, standard mm 65/70 100/105

Depth, without connectors mm 185 228

Depth, with connectors mm <225 <265

Kollmorgen | March 2010 35

Page 36

AKD Installation| 6 Technical description and data

6.4 Inputs/Outputs

Interface Electrical Data

Analog input (resolution16 bit) ±10Vdc

Max. common-mode voltage ±10 Vdc

Analog output (resolution 16 bit) ±10 Vdc

Digital inputs min. 3.5 Vdc, max. 30 Vdc

Digital outputs max. 30 Vdc, 100 mA

FAULT output, relay contacts max. 30 Vdc, max 42 Vac, 1 A

min. 2 mA, max. 15 mA

36 Kollmorgen | March 2010

Page 37

AKD Installation| 6 Technical description and data

6.5 Electrical Data AKD-xzzz06

Electrical Data Units AKD-x00306 AKD-x00606 AKD-x01206 AKD-x02406

Rated supply voltage, 50/60 Hz V~

Rated input powerfor S1 operation kVA 1.2 2.38 3.82 7.6

Rated input current

at 1x120 V A 5.0 9.9 12 N/A

at 1x240 V A 5.0 9.9 12 N/A

at 3x120 V A 2.3 4.6 9.2 N/A

at 3x240 V A 2.3 4.6 9.2 18.3

Permitted switch on/off frequency 1/h 30

Max. inrush current A 10 10 10 20

Rated DC bus link voltage

(Bus Turn onDelay 3ph 1 sec)

Continuous output current ( ± 3%)

at 120 V Arms 3 6 12 N/A

at 240 V Arms 3 6 12 24

Peak output current (for approx.5 s, ± 3%) Arms 9 18 30 48

Continuous output power

at 1x120 V W 312.5 625 1250 N/A

at 1x240 V W 625 1250 2500 N/A

at 3x120 V W 312.5 625 1250 N/A

at 3x240 V W 625 1250 2500 5000

Peak output power(for approx.5 s)

at 1x120 V kVA 0.937 1.875 3.125 N/A

at 1x240 V kVA 1.875 3.750 6.250 N/A

at 3x120 V kVA 0.937 1.875 3.125 N/A

at 3x240 V kVA 1.875 3.750 6.250 10

Technical data for brake circuit — see page 44

Motor inductance min.

at 120 V mH 1.3 0.6 0.5 0.3

at 240 V mH 2.5 1.3 1 0.6

Motor inductance max. mH 250 125 100 60

Thermal dissipation, output stage disable W max. 20 max. 20 max. 20 max. 25

Thermal dissipation at rated current W 31 57 137 175

Noise emission (low speed/high speed fan) dB(A) N/A 33/39 37/43 41/56

Aux. voltage supply V 24 V (±10%, check voltage drop)

-current w/o motor brake, w/o option card A 0.5 0.6 0.7 1.0

-current w/o motor brake with option card A 1.2 1.3 1.4 1.7

-current with motor brake, w/o option card A 1.7 1.8 1.9 2.5

-current with motor brake and option card A 2.4 2.5 2.6 3.2

V 170 to 340

3 x 120 V to 240 V ±10%

1 x 120 V to 240 V ±10%

3x240 V

±10%

Kollmorgen | March 2010 37

Page 38

AKD Installation| 6 Technical description and data

6.6 Electrical Data AKD-xzzz07

Electrical data Units AKD-x00307 AKD-x00607 AKD-x01207 AKD-x02407

Rated supply voltage, 50/60Hz V~ 3 x 240 V to 480 V ±10%

Rated input powerfor S1 operation kVA 2.24 4.49 7.65 15.2

Rated input current

at 3x240 V A 2.7 5.4 9.2 18.3

at 3x400 V A 2.7 5.4 9.2 18.3

at 3x480 V A 2.7 5.4 9.2 18.3

Permitted switch on/off frequency 1/h 30

Max. inrush current A 10 10 10 20

Rated DC bus link voltage

(Bus Turn onDelay 3ph 1 sec)

Continuous output current ( ± 3%)

at 240 V Arms 3 6 12 24

at 400 V Arms 3 6 12 24

at 480 V Arms 3 6 12 24

Peak output current (for approx.5 s, ± 3%) Arms 9 18 30 48

Continuous output power

at 3x240 V kVA 0.6 1.25 2.5 5

at 3x400 V kVA 1 2 4.2 8.3

at 3x480 V kVA 1.2 2.5 5 10

Peak output power(for approx.5 s)

at 3x240 V kVA 1.8 3.75 6.25 10

at 3x400 V kVA 3 6.75 10.4 16.7

at 3x480 V kVA 3.6 7.5 12.5 20

Technical data for brake circuit — see page 44

Motor inductance min.

at 240 V mH 3.2 1.6 1.3 0.6

at 400 V mH 5.3 2.6 2.1 1

at 480 V mH 6.3 3.2 2.5 1.2

Motor inductance max. mH 600 300 250 120

Thermal dissipation, output stage disable W max. 20 max. 20 max. 20 max. 25

Thermal dissipation at rated current W 102 129 153 237

Noise emission (low speed/high speed fan) dB(A) 34/43 34/43 44/52 48/58

Aux. voltage supply V= 24 V (±10%, check voltage drop)

- current w/o motor brake, w/o option card A= 1 1 1 2

- current w/o motor brake with option card A= 1.7 1.7 1.7 2.7

- current with motor brake, w/o optioncard A= 2.5 2.5 2.5 4

- current with motor brake and optioncard A= 3.2 3.2 3.2 4.7

V= 340 to 680

Presently the AKD-xzzz07 models only support operation at levels above 270Vac. Updates to the AKD firmware are in process to allow the operation of the AKD-xzzz07 models drives at 240Vac.

38 Kollmorgen | March 2010

Page 39

6.7 Performance Data

AKD-xzzz06

AKD Installation| 6 Technical description and data

Performance Data Units

Switching frequency of output stage kHz 10 10 8 8

Voltagerise speed dU/dt kV/µs 2.5 4.3

Bandwidth of current controller kHz 2.5 to 4 2 to 3

Bandwidth of velocity controller (scalable) Hz 0 to 1000 0 to 800 0 to 600

Bandwidth of position controller (scalable) Hz 1 to 250

AKD-xzzz07

Performance Data Units

Switching frequency of output stage kHz 8 8 6 8

Voltagerise speed dU/dt kV/µs 7.2

Bandwidth of current controller kHz 2.5 to 4 2 to 3

Bandwidth of velocity controller (scalable) Hz 0 to 800 0 to 600

Bandwidth of position controller (scalable) Hz 1 to 250

AKDx

00306

AKDx

00307

AKDx

00606

AKDx

00607

AKDx

01206

AKDx

01207

AKDx

02406

AKDx

02407

6.8 Recommended tightening torques

TighteningTorque/Nm

Connector AKD-x00306 to 00606 AKD-x01206 AKD-x02406 and AKD-xzzz07

X1 0.22 to 0.25 0.22 to 0.25 0.7 to 0.8

X2 0.5 to 0.6 0.7 to 0.8 0.7 to 0.8

X3 0.5 to 0.6 0.5 to 0.6 0.7 to 0.8

X4 - - 0.7 to 0.8

X7, X8 0.2 to 0.25 0.2 to 0.25 0.2 to 0.25

PE block 1.7 1.7 1.7

See "Conformance with UL/cUL" (page 20) for in-lbs values.

Kollmorgen | March 2010 39

Page 40

AKD Installation| 6 Technical description and data

6.9 Fusing

US fuses:

Class J, 600 Vac 200 kA, time-delay. The fuse must be UL and CSA listed, UL recognized is not sufficient.

EU fuses:

types gRL or gL, 400 V/500 V, time-delay

Fuse holders

Combined with the standard fuse blocks, finger safe fuse holders must be used according to IEC 60529.

Examples:

Bussmann: CH Series Modular Fuse Holders, fuse size 0 to 30A class J, 3 poles: CH30J3

Ferraz: Ultrasafe Fuse holders, fuse size 0 to 30A class J, 3 poles: US3J3I

6.9.1 External Power Supply fusing

Drive

Model

AKD-X00306 10A (Time-Delay) LPJ101/DFJ102 AJT101/HSJ102

AKD-X00606 15A (Time-Delay) LPJ151/DFJ152 AJT151/HSJ152

AKD-X01206 15A (Time-Delay) LPJ151/DFJ152 AJT151/HSJ152

AKD-X02406 30A (Time-Delay) LPJ301/DFJ302 AJT301/HSJ302

AKD-X00307 6A (Time-Delay) LPJ61/DFJ62 AJT61/HSJ62

AKD-X00607 10A (Time-Delay) LPJ101/DFJ102 AJT101/HSJ102

AKD-X01207 15A (Time-Delay) LPJ151/DFJ152 AJT151/HSJ152

AKD-X02407 30A (Time-Delay) LPJ301/DFJ302 AJT301/HSJ302

6.9.2 External 24 V supply fusing

Drive

Model

all AKD 8A (Time-Delay) LPJ81/DFJ82 AJT81/HSJ82

6.9.3 External Brake Resistor fusing

Drive

Model

all AKD 6A (Time-Delay) in process

Max.

Ampere rating

Max.

Ampere rating

Max.

Ampere rating

Example class J

Cooper Bussmann

Example class J

Cooper Bussmann

Example class KLM-xx

Cooper Bussmann

Example class J

Ferraz Shawmut

Example class J

Ferraz Shawmut

40 Kollmorgen | March 2010

Page 41

AKD Installation| 6 Technical description and data

6.10 Connectors

Given voltage and current data are the lowest values allowed by UL andCE. Order codes see page 148

6.10.1 AKD-xzzz06 Types (120V to 240V Mains Voltage Supply)

Connector Type Max. Cross Sec-

1

tion

Allowed

Current

2

Allowed

Voltage

Control signals X7, X8 Weidmüller BL3.5/10F SN 1.5 mm², 16 awg 10 A 250 V

Aux. voltage X1 Phoenix, MC1.5/3-STF-3.81 1.5 mm², 16 awg 8 A 160 V

Motor X2 (3 to 6 A) Phoenix, IC 2.5/6-STF-5.08 2.5 mm², 14 awg 10 A 300V

Motor X2 (12to 24A) Phoenix, PC 5/6-STF-7.62 10 mm², 10 awg 30 A 600 V

Power X3 (3 to 6A) Phoenix, MVSTBW2.5/7-STF-5.08 2.5 mm², 12 awg 10 A 300 V

Power X3 (12A) Phoenix, MSTB2,5HC/8-STF-5,08 2,5 mm², 12 awg 16 A 300 V

Power X3 (24A) Phoenix, PC 5/4-STF-7,62 10 mm², 10 awg 30 A 600V

Power X4 (24A) Phoenix, PC 5/4-STF-7,62 10 mm², 10 awg 30 A 600V

Feedback X10 SubD 15pinHD (female) 0,5 mm², 21 awg 1 A <100 V

Service Port X11 RJ45 0,5 mm², 21 awg 1 A <100 V

Motion Bus X5, X6 RJ45 0,5 mm², 21 awg 1 A <100V

CAN In/Out X12/13 RJ25 0,5 mm², 21 awg 1 A <100 V

Encoder EmulationX9 SubD 9pin (male) 0,5 mm², 21 awg 1 A <100V

1

single-line connection

2

single-line connection with recommendedconductor cross section (see page 42)

3

rated voltage with pollution level 2

6.10.2 AKD-xzzz07 Types (240V to 480V Mains Voltage Supply)

3

Connector Type Max. Cross Sec-

1

tion

Allowed Cur-

2

rent

Allowed Volt-

age

Control signals X7, X8 Weidmüller BL3.5/10F SN 1.5 mm², 16 awg 10 A 250 V

Aux. voltage X1 Phoenix, MC1.5/3-STF-3.81 1.5 mm², 16 awg 8 A 160 V

Motor X2 Phoenix, PC 5/6-STF-7.62 10 mm², 10 awg 30 A 600 V

Power X3 Phoenix, PC 5/4-STF-7,62 10 mm², 10 awg 30 A 600 V

Power X4 Phoenix, PC 5/4-STF-7,62 10 mm², 10 awg 30 A 600 V

Feedback X10 SubD 15pinHD (female) 0,5 mm², 21 awg 1 A <100 V

Service Port X11 RJ45 0,5 mm², 21 awg 1 A <100 V

Motion Bus X5, X6 RJ45 0,5 mm², 21 awg 1 A <100 V

CAN In/Out X12/13 RJ25 0,5 mm², 21 awg 1 A <100 V

Encoder EmulationX9 SubD 9pin (male) 0,5 mm², 21 awg 1 A <100V

1

single-line connection

2

single-line connection with recommendedconductor cross section (see page 42)

3

rated voltage with pollution level 2

Kollmorgen | March 2010 41

3

Page 42

AKD Installation| 6 Technical description and data

6.11 Cable and Wire Requirements

6.11.1 General

For informationon the chemical, mechanical, and electrical characteristics of the cables please refer to the

accessories manual or contact customer support.

To reach the maximum permitted cable length, you must use cable material with

the following capacitance (phase to shield) requirements:

l Motor cable: less than 150 pF/m

l Resolver/Encoder cable: less than 120 pF/m

Motor cables longer than 25 m may require the use of a motor choke.

6.11.2 Cable Cross Sections and Requirements

The table below describes the recommended interface cross sections and cable requirements for single-axis

systems in accordance with IEC 60204. For multi-axis systems, observe the specific operating conditions for

your system.

Interface Cross Section CableRequirements

AC connection AKD-x003 to 6: 1.5 mm² (16 awg)

600V,minimum 75°C

AKD-x012: 2.5 mm² (14 awg)

AKD-x024: 4 mm² (12 awg)

DC bus link,

Brake resistor

Motor cables without

choke, max. 25 m

AKD-x003 to 6: 1.5 mm² (16 awg)

AKD-x012 to 24: 2.5 mm² (14 awg)

AKD-x003 to 6: 1.5 mm² (16 awg)

AKD-x012: 2.5 mm² (14 awg)

1000 V, minimum 75°C, shielded

for lengths >0.20 m

600V,minimum 75°C, shielded,

capacitance <150 pF/m

AKD-x024: 4 mm² (12 awg)

Motor cables with

choke, 25 - 50 m

AKD-x003 to 6: 1.5 mm² (16 awg)

AKD-x012: 2.5 mm² (14 awg)

600V,minimum 75°C, shielded,

capacitance <150 pF/m

AKD-x024: 4 mm² (12 awg)

Resolver, max.100 m 4x2x0.25 mm² (24awg) twisted pairs, shielded,

capacitance <120 pF/m

SFD, max. 50 m 1x2x0.25 mm² (24 awg)

twisted pairs, shielded

1x2x0.25 mm² (21 awg)

Encoder, max. 50 m 7x2x0.25 mm² (24 awg) twisted pairs, shielded

ComCoder, max. 25 m 8x2x0.25mm² (24 awg) twisted pairs, shielded

Analog I/Os, max. 30 m 0.25 mm² (24 awg) twisted pairs, shielded

Digital I/Os, max. 30 m 0.5 mm² (21 awg) single line

Holdingbrake (motor) min. 0.75 mm² (19 awg) 600 V,minimum 75°C, shielded

+24 V/GND, max 30 m max. 2.5 mm² (14 awg) single line

42 Kollmorgen | March 2010

Page 43

AKD Installation| 6 Technical description and data

6.12 LED display

A two-character, LED seven-segment display indicates the status of the drive after the 24 V supply is

switched on. Fault codes or warning codes are displayed constantly if present. The IP address can be flashed

across the LED display if the B1 button is pressed, or if the RJ45 cable is re-inserted into the X11 connection.

6.13 Grounding System

There are four ground networks in the drive:

AGND analog ground

DCOMx commonlinefor digital inputs (with x=7 or 8 coding the I/O connectors X7/X8)

GND 24 V supply, STO input, holding brake

0 V internal digital ground, encoder emulation output, service channel

Kollmorgen | March 2010 43

Page 44

AKD Installation| 6 Technical description and data

6.14 Dynamic Braking

Dynamic braking is a normal operation for a servo system with a large load to decelerate. The AKD uses a

dynamic braking resistor (also called a regen resistor) for dynamic braking whenthe energy required to decelerate the load exceeds the voltage threshold of the DC bus. In this situation, the AKD braking resistor circuit

engages, and the excess energy is output to an internal or external braking resistor. The AKD can also use a

braking resistor during anemergency stop if the drive disablemode (DRV.DISMODE2) is used to perform a

controlled stop or dynamic brake action.

AKD-x00306 to AKD-x00606

These units do not have an internal brake resistor. Depending on the application requirements, an external

resistor can be connected.

AKD-x01206 to AKD-x02406 and AKD-xzzz07

These units have an internal resistor plus the capability to connect an external resistor.

Suitable external brake resistors are described in the AKD Accessories Manual.

6.14.1 Functional description

1. Individual drives, not coupled through the DC bus link circuit (+DC, -DC)

When the energy fed back from the motor has an averageorpeak power that exceeds the preset level for the

brake power rating, the drive generates the warning "n521Regen Over power”. After the warning is issued, if

the power increases past the fault level, the brake circuit will switch off.

With the braking circuit switched off, the drive internal DC bus link voltage is checked. The drive reports an

over-voltage fault if the DC bus threshold is exceeded. The drive power stageis disabled and the load coasts

to a stop with the fault message “F501 Bus Over voltage" (see page 139). The Fault contact (terminals X8/9-

10)is opened (see page 122) dueto this fault.

2. Several drives coupled through the DC bus link (+DC, -DC)

Using the built-in brake circuit, several drives of the same series can be operatedfrom a common DC-bus link

(see page 94), without any additional measures. 90% of the combined power of all the coupled drives is

always available for peak and continuous power. The switch-off on over voltage takes place as described

under 1. (above) for the drive that has the lowest switch-off threshold (resulting from tolerances).

Observe the regeneration time (some minutes) for the dynamic brake circuit after

full load with peak brake power.

44 Kollmorgen | March 2010

Page 45

AKD Installation| 6 Technical description and data

6.14.2 Technical Data for AKD-xzzz06

Technical data for the brake circuits depends on the drive type and the mains voltage.

Supply voltages, capacitances, and switch-on voltages are all nominal values.

Brake circuit Supply voltage

Type Rated data Units 120 V / 240 V

AKD-xzzz06

all types

Switch-on threshold of brake circuit V 400

Switch-off threshold of brake circuit V 420

Maximum brake duty cycle % 15*

Type Rated data Units 120 V / 240 V

AKD-x00306 External brake resistor Ohm 33

Maximum continuous brake power, external resistor kW 0.77

Peak brake power, external (1s) kW 5.4

Storeable energy in capacitors (+/- 20%) Ws 60 / 20

DC Bus Capacitance µF 940

AKD-x00606 External brake resistor Ohm 33

Maximum continuous brake power, external resistor kW 1.5

Peak brake power, external resistor (1s) kW 5.4

Storeable energy in capacitors (+/- 20%) Ws 60 / 20

DC Bus Capacitance µF 940

AKD-x01206 Internal brake resistor Ohm 15

Continuous power, internal resistor W 100

Peak brake power, internal resistor (0.5s) kW 11.7

External brake resistor Ohm 33

Maximum continuous brake power, external resistor kW 3

Peak brake power, external resistor (1s) kW 5.4

Storeable energy in capacitors (+/- 20%) Ws 160 / 55

DC Bus Capacitance µF 2460

AKD-x02406 Internal brake resistor Ohm 8

Continuous power, internal resistor W 200

Peak brake power, internal resistor (0.5s) kW 22

External brake resistor Ohm 15

Maximum continuous brake power, external resistor kW 6

Peak brake power, external resistor (1s) kW 11.8

Storeable energy in capacitors (+/- 20%) Ws 180 / 60

DC Bus Capacitance µF 2720

* depends on connected brake resistor power

Kollmorgen | March 2010 45

Page 46

AKD Installation| 6 Technical description and data

6.14.3 Technical Data for AKD-xzzz07

Brake circuit Supply voltage

Type Rated data Units 240 V 400 V / 480V

AKD-xzzz07

all types

Switch-on threshold of brake circuit V 400 800

Switch-off threshold of brake circuit V 420 840

Maximum brake duty cycle % 15*

Type Rated data Units 240 V 400 V / 480 V

AKD-x00307 Internal brake resistor Ohm 32

Continuous power, internal resistor W 80

Peak brake power, internal resistor (0.5s) kW 5.5 22.1

External brake resistor Ohm 33

Maximum continuous brake power, external resistor kW 0.77 1.5

Peak brake power, external (1s) kW 5,4 21.4

Storeable energy in capacitors (+/- 20%) Ws 5 35 / 20

DC Bus Capacitance µF 235

AKD-x00607 Internal brake resistor Ohm 33

Continuous power, internal resistor W 100

Peak brake power, internal resistor (0.5s) kW 5.4 21.4

External brake resistor Ohm 33

Maximum continuous brake power, external resistor kW 1.5 3

Peak brake power, external resistor (1s) kW 5.4 21.4

Storeable energy in capacitors (+/- 20%) Ws 5 35 / 20

DC Bus Capacitance µF 235

AKD-x01207 Internal brake resistor Ohm 33

Continuous power, internal resistor W 100

Peak brake power, internal resistor (0.5s) kW 5.4 21.4

External brake resistor Ohm 33

Maximum continuous brake power, external resistor kW 3 6

Peak brake power, external resistor (1s) kW 5.4 21.4

Storeable energy in capacitors (+/- 20%) Ws 10 70 / 40

DC Bus Capacitance µF 470

AKD-x02407 Internal brake resistor Ohm 23

Continuous power, internal resistor W 200

Peak brake power, internal resistor (0.5s) kW 7.7 30.6

External brake resistor Ohm 23

Maximum continuous brake power, external resistor kW 6 12

Peak brake power, external resistor (1s) kW 7.7 30.6

Storeable energy in capacitors (+/- 20%) Ws 15 110 / 60

DC Bus Capacitance µF 680

* depends on connected brake resistor power

Presently the AKD-xzzz07 models only support operation at levels above 270Vac. Updates to the AKD firmware are in process to allow the operation of the AKD-xzzz07 models drives at 240Vac."

46 Kollmorgen | March 2010

Page 47

AKD Installation| 6 Technical description and data

6.15 Switch-on and Switch-off Behavior

This chapter describes the switch-on and switch-off behavior of the AKD and the steps required to achieve

operational stopping or emergency stop behavior that complies with standards.

The drive’s 24 V supply must remain constant. The command DRV.DISMODE

dictates how the drive behaves.

DRV.DISMODE Disable mode. Consult the AKD User Guide for configuring this parameter.

0 Disable axis immediately, if velocity drops below threshold brake is closed.

2 Use active disable to disable drive, if velocity drops below threshold brake is closed.

In all cases, the holding brake is appliedif velocity drops below the threshold (CS.VTHRESH).

Behavior when undervoltage threshold is reached

The behavior in an undervoltage conditiondepends on the VBUS.UVMODE setting.

VBUS.UVMODE DC Bus Undervoltage Mode. Consult the AKDUser Guide for configuring the parameter.

0 The drive will report a F502undervoltage fault any time an undervoltage condition occurs.

1 (default) The drive will report a warning n502 if not enabled. The drive will report a fault if the drive

is enabled when the condition occurs, or an attempt is made to enablewhile an under voltagecondition occurs.

Behavior with enabled “holding brake” function

Drives with an enabled holding brake function have a special procedure for switching off the output stage (see

page 98). Removingthe ENABLE signal triggers electrical braking. As with all electronic circuits, the general

ruleapplies that there is a possibility of the internal holding brake module failing. Bringing a motor to a standstill using a holdingbrake in a way that is personnel safe also requires an electromechanical “make” contact

for the holding equipment and a suppressor device for the brake.

Behavior of the restart lock STO

With the personnel safe restart lock STO, the drive can be secured on standstill using its internal electronics

so that even when power is beingsupplied, the drive shaft is protected against unintentional restart. The chapter “Personnel Safe Restart Lock STO” describes how to use the restart lock STO (see page55).

Kollmorgen | March 2010 47

Page 48

AKD Installation| 6 Technical description and data

6.15.1 Behavior in Standard Operation

The behavior of the drive always depends on the current setting of a number of different parameters (DRV.DISMODE, VBUS.UVFTHRESH, CS.VTHRESH and others; see the AKDUser Guide or WorkBench help for

more details). The diagram below illustrates the correct functional sequence for switching the drive on andoff.

Devices which areequipped with a selected “brake” function use a special sequence for switching off the output stage (see page 98).

The built-in restart lock STO can be used to switch off the drive, to provide personnel safety at the motor shaft

(see page 55).

48 Kollmorgen | March 2010

Page 49

AKD Installation| 6 Technical description and data

6.15.2 Behavior in the event of a fault (with standard setting)

The behavior of the drive always depends on the current setting of a number of different parameters

(DRV.DISMODE, VBUS.UVFTHRESH, CS.VTHRESH, and others; see the AKDUser Guide or Work-

Bench helpfor moredetails). The diagram shows the startupprocedure and the procedurethat the internal control system follows in the event of one or more electrical supply phases failing, assuming that the standard

parameter settings apply.

When main power drops out, the drive continues to operate until the DC bus reaches VBUS.UVFTHRESH,

which causes an undervoltage condition (F502).

Kollmorgen | March 2010 49

Page 50

AKD Installation| 6 Technical description and data

6.16 Stop-/Emergency Stop- Function

With the personnel safe, approved restart lock STO (see page 55) the drive can

be secured on standstill (torque-free) using its internal electronics so that even

when power is being supplied, the drive shaft is protected against unintentional

restart (IEC 61508 SIL 2).

If the “Safety” option card is integrated, it provides safe drive functions in

accordance with IEC 61800-5-2 (in process)

6.16.1 Stop: Standards

The stop function shuts down the machine in normal operation. The following stop functions aredefinedby

IEC 60204:

l Category 0:

Shut-down by immediate switching-off the energy supply to the drive machinery (this is an uncontrolled

shut-down).

l Category 1:

A controlled shut-down, whereby the energy supply to the drive machinery is maintained to perform the

shut-down, and the energy supply is only interrupted when the shut-down has been completed.

l Category 2:

A controlled shut-down, whereby the energy supply to the drive machinery is maintained.

The parameter DRV.DISMODE must be set to 2 to implement the different stop

categories. Consult the User Guide for configuring the parameter.

The stop category must be determined by a risk evaluation of the machine. In addition, suitable means must

be providedto guarantee a reliable shut-down.

Category 0 andCategory 1 stops must be operable independently of the operating mode, whereby a Category

0 stop must have priority. Stop functions must be implemented by disconnection of the appropriate circuitry

andhave priority over assigned start functions.

If necessary, provision must be made for the connection of protective devices andlock-outs. If applicable, the

stop function must signal its status to the control logic. A reset of the stop function must not create a hazardous situation.

50 Kollmorgen | March 2010

Page 51

AKD Installation| 6 Technical description and data

6.16.2 Emergency Stop: Standards

The emergency stop function is used for the fastest possible shutdown of the machine in a dangerous situation. The emergency stop function can be triggered by the actions of a singleperson. It must be fully functional and available at all times. The user must understand instantly how to operate this mechanism (without

consulting references or instructions).

The emergency stop function is defined by IEC 60204.

In addition to the requirements for stop, the emergency stop must fulfil the following requirements:

l Emergency stop must have priority over all other functions and controls in all operating situations.

l The energy supply to any drive machinery that could cause dangerous situations must be switched off

as fast as possible, without causing any further hazards (such as by using mechanical latching

devices that do not require an external supply of energy or by counter-current braking in Stop Category

1).

l The reset must not initiate a restart.

If necessary, provisionmust bemade forthe additionalconnection of emergency stopdevices (seeIEC 60204,

"Requirements for emergency stop devices"). The emergencystop must be effective as a stop of eitherCategory0 orCategory 1. The emergency stop categorymust bedetermined bya risk evaluation of the machine.

Category 0

Only hard-wired, electromechanical components may be used for the Category 0 Emergency Stop function. It

must not be triggered using switching logic (hardware or software), by transferring commands via a communication network, or via a data link.

The drive must be shut down using anelectromechanical circuit. If the connected servomotor has an integrated brake, this brake must always be controlled by an electromechanical circuit as well.

Category 1

With the Category 1 emergency stop function, the final power supply switch-off must be ensured by using

electromechanical components. Additional external emergency stop equipment may be connected. The motor

is stoppedby interruptingthe mains supply and usingcontrolledelectronic braking. The 24 V supply for the

drive must remain constant. The issue of which circuit shouldbe used highly depends on the requirements of

the application at hand.

In most servomotors, a brake has only the function of a holdingbrake. To ensure an emergency stop function,

the braking torque that is requiredmust be checked. If the holding brake fulfills the dynamic requirements, it

must be taken into account that this application will cause increased wear.

The parameter DRV.DISMODE must be set to 2 to implement the different stop

categories. Consult the AKD User Guide for configuring the parameter.

Kollmorgen | March 2010 51

Page 52

AKD Installation| 6 Technical description and data

6.16.3 Implementation of the Stop Category 0 Bringing the motor to a standstill by immediately switching off the drive powersupply (DRV.DISMODE must

be set to 2). The switching sequence is precisely determined by this circuit in order to avoid undesirable fault

messages anddrive failures.

It is not possible to achieve a Category 0 shut-down with the drive alone, since hard-wiredelectromechanical

components arecompulsory for this type of disconnection.

A brake that is built into the motor must have an additional electromechanical control circuit, as well as the

control through the AKD, in order to meet Category 0.

In most servomotors a brake has only the function of a holding brake. To ensure an emergency stop function,

the braking torque that is requiredmust be checked. If the holding brake fulfills the dynamic requirements, it

must be taken into account that this application will cause increased wear.

Circuit suggestion (with EMERGENCY STOP Category 0, control function with contactor relays)

52 Kollmorgen | March 2010

Page 53

AKD Installation| 6 Technical description and data

6.16.4 Implementation of Stop Category 1

Bringing the motor to a standstill by interrupting the mains supply andusing controlled electronic braking

(DRV.DISMODE must be set to 2). The 24 V supply for the AKD must remain constant.

The drive is braked in a controlled manner during the stopping (disabling) procedure. If the speed

CS.VTHRESH (sequence diagram: see page1)is undershot, the holding brake is applied and the output

stage is disabled. As soon as two separate time periods (set at the time relay) have elapsed, the mains supply

andthe holding brake are electrically isolated.

Should an internal AKD fault occur, the motor is forced to a standstill once the

AKD drops out. Make sure that the machinery cannot be damaged by forced braking. Forced braking with the built-in motor holding brake can damage the brake.

Circuit suggestion (with EMERGENCY STOP Category 1, control function with contactor relays)

Kollmorgen | March 2010 53

Page 54

AKD Installation| 6 Technical description and data

6.16.5 Implementation of Stop Category 2

The machine receives an operational stop (disable) command and brakes the drive using the set braking ramp

(DRV.DISMODE must be set to 2).

The drive is braked in a controlled manner during the stopping (disabling) procedure. If the speed

CS.VTHRESH (sequence diagram: see page96is undershot, the holding brake is applied and the output

stage is disabled. In this case, there is no interruption of the electrical supply.

If the electrical supply is switched off, not only will thecontrolled brakingprocedurebeperformed, butthe mains

supply and theholding brakewill alsobe electrically isolated followinga time period set at thetime relay.

Circuit suggestion (with EMERGENCY STOP Category 1, control function with contactor relays)

54 Kollmorgen | March 2010

Page 55

AKD Installation| 6 Technical description and data

6.17 Safe Torque Off (STO)

STO Input X1/3