Page 1

AKD™

AKD™ Positioner Training Manual

Rev 4.2.0

This training module is intended to provide a full understanding of AKD. This manual will help

the user to become familiar with setting up an AKD. This workbook is the prerequisite to the AKD

BASIC training manual.

Material is subject to change based on firmware and WorkBench™ design development.

Page 2

Table of Contents

Introduction to AKD™ Advanced Kollmorgen Drive™ .................................................. 4

Features of AKD ....................................................................................................... 4

Benefits of AKD ........................................................................................................ 4

Wiring the Drive for Training ........................................................................................ 6

Power Connections ...................................................................................................... 6

Digital Inputs and Outputs ............................................................................................ 7

Overview ..................................................................................................................... 8

Connect to the AKD Drive ........................................................................................ 8

WorkBench Help .................................................................................................... 10

Drive Setup Screens .................................................................................................. 10

Opmode/Source/Enabled/Running ............................................................................ 11

DRV.OPMODE ....................................................................................................... 11

DRV.CMDSOURCE ............................................................................................... 11

IP Address ................................................................................................................... 8

Units ....................................................................................................................... 13

Terminal ................................................................................................................. 14

Watch Window ....................................................................................................... 14

Scope Tool ............................................................................................................. 15

Service Motion ....................................................................................................... 15

Motion Task ........................................................................................................... 16

Servo Gains ........................................................................................................... 16

Save & Print ........................................................................................................... 16

Measure ................................................................................................................. 16

Cursor .................................................................................................................... 17

Display ................................................................................................................... 17

Settings .................................................................................................................. 18

AKD™ Motion Task ..................................................................................................... 19

Homing ...................................................................................................................... 19

Home Mode Types ................................................................................................. 19

Home Type 0 ......................................................................................................... 19

Home Types 1, 2 & 3.............................................................................................. 20

Home Types 4, 5 & 6.............................................................................................. 20

Home Types 7 & 11 ............................................................................................... 21

Home Types 8, 9 & 10 ............................................................................................ 21

Home Type 12........................................................................................................ 22

Motion Task ............................................................................................................... 22

Absolute Move ....................................................................................................... 22

Relative Move ........................................................................................................ 22

Motion Task ........................................................................................................... 23

Electronic Gearing ..................................................................................................... 25

Leader .................................................................................................................... 26

Follower ................................................................................................................. 27

Tuning .......................................................................................................................... 28

Introduction ................................................................................................................ 28

Slider Tuning ............................................................................................................. 29

Bandwidth .............................................................................................................. 29

2

Page 3

Slider Tuner – How it Works ................................................................................... 30

Limitations of Slider Tuner ...................................................................................... 31

Appendix A – Under Construction ............................................................................. 33

Under Construction ....................................................... Error! Bookmark not defined.

Appendix B – Under Construction ............................................................................. 35

3

Page 4

Introduction to AKD™ Advanced Kollmorgen Drive™

The AKD Servo Drive is designed with the end user in mind. The AKD provides to

the customer the fastest current and velocity loops on the market. The WorkBench

graphical user interface, or GUI, makes setup fast and intuitive.

Kollmorgen servomotors with intelligent feedback devices become Plug & Play,

removing the need for any motor setup. Tuning can be completed using either the

Automatic mode or Manual mode. The Bode Tool can provide important information

about the system to which the drive is connected.

Features of AKD

• Ease of Use

• Plug & Play motor combinations

• Advance Tuning

• Intuitive Graphical User Interface

• Fastest Current and Velocity Loop on the market

• Versatile Connectivity

• Robust Design

Benefits of AKD

• Fast Setup

• Highest Throughput

• Reduced Down Time

4

Page 5

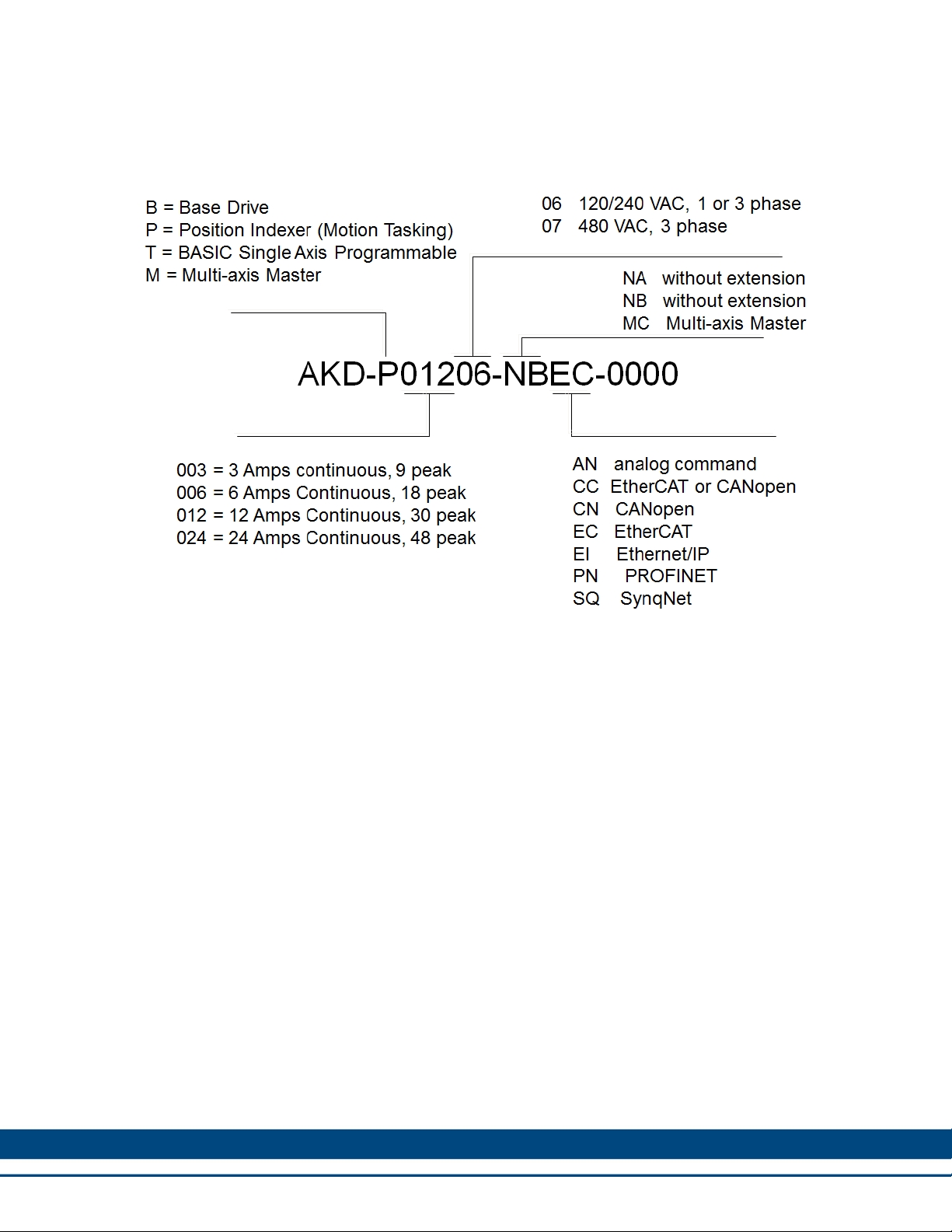

Part Number Break Down

Support Materials Available

• User Guide (in WorkBench Help)

• WorkBench & firmware

• Sample Motion Task & Setup

5

Page 6

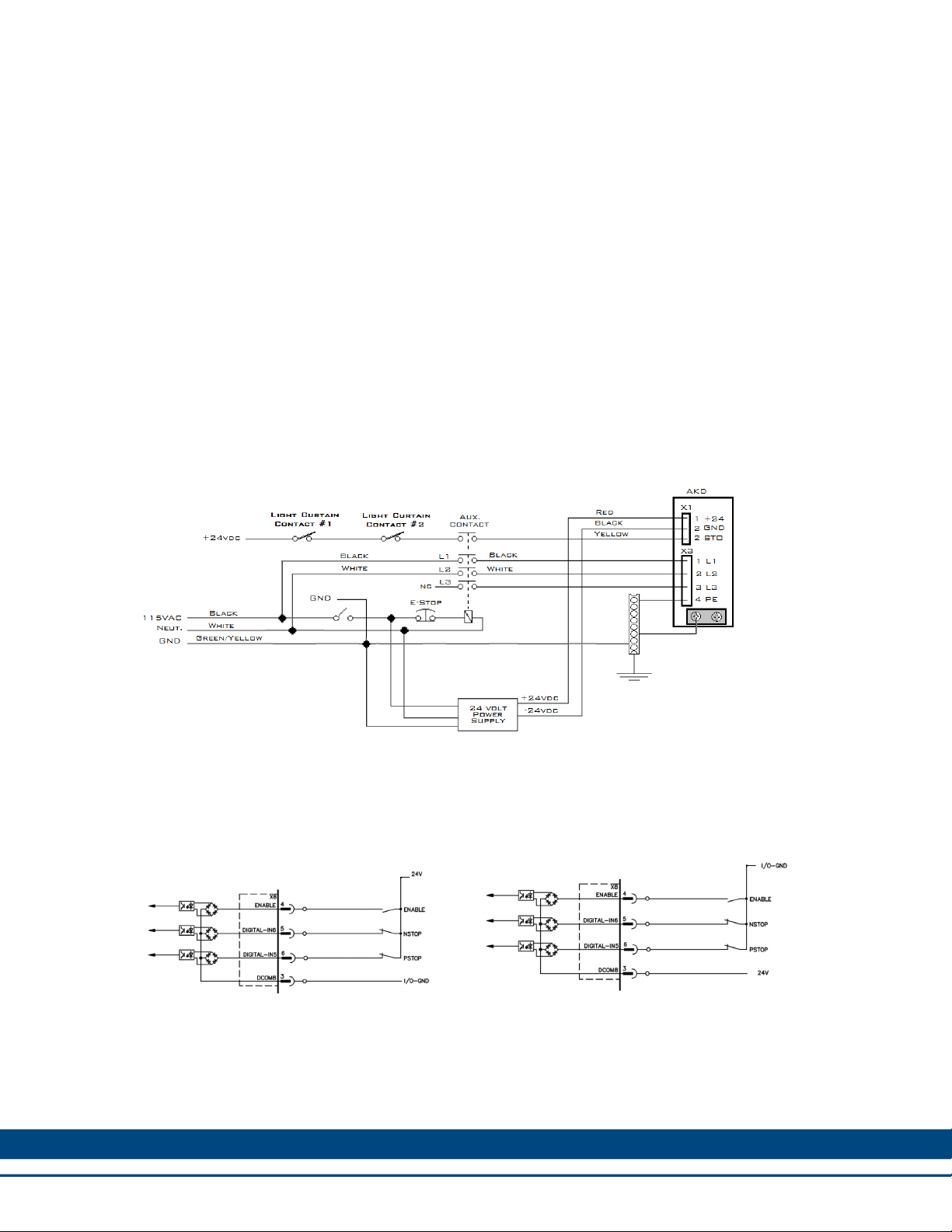

Wiring the Drive for Training

The AKD Servo Drive is mounted on the base plate and wired to 115vac for training.

The following schematic is provided since the base plate is prewired for simulation of an

electrical cabinet.

Power Connections

Include on the base plate are:

115vac Circuit Breaker

24vdc Power Supply

Emergency Stop Button

Power Contactor

Auxiliary Contacts for STO

Terminal Strip for easy connection

Ground Bar

Note: Not included on the base plate are the Light Curtain Contacts. They have

been added to show where the contacts could be added in a real world

application.

The I/O connections are made using the manual control I/O box, part number: AKDCONTROLBOX-A. The AKD I/O is Optically Isolated and can be configured for either

Sinking or Sourcing, but not both on the same connector.

Input is sourcing – Drive is sinking Input is sinking – Drive is sourcing

Note: X7 & X8 have individual DC Commons that must be wired up. These DC Commons are

not connected internally. This allows X7 & X8 to be connected as either sourcing or sinking

independently of each other. For example, X7 can be sourcing and X8 can be sinking. But all

the connections on X7 & X8 must be connected in the same configuration.

6

Page 7

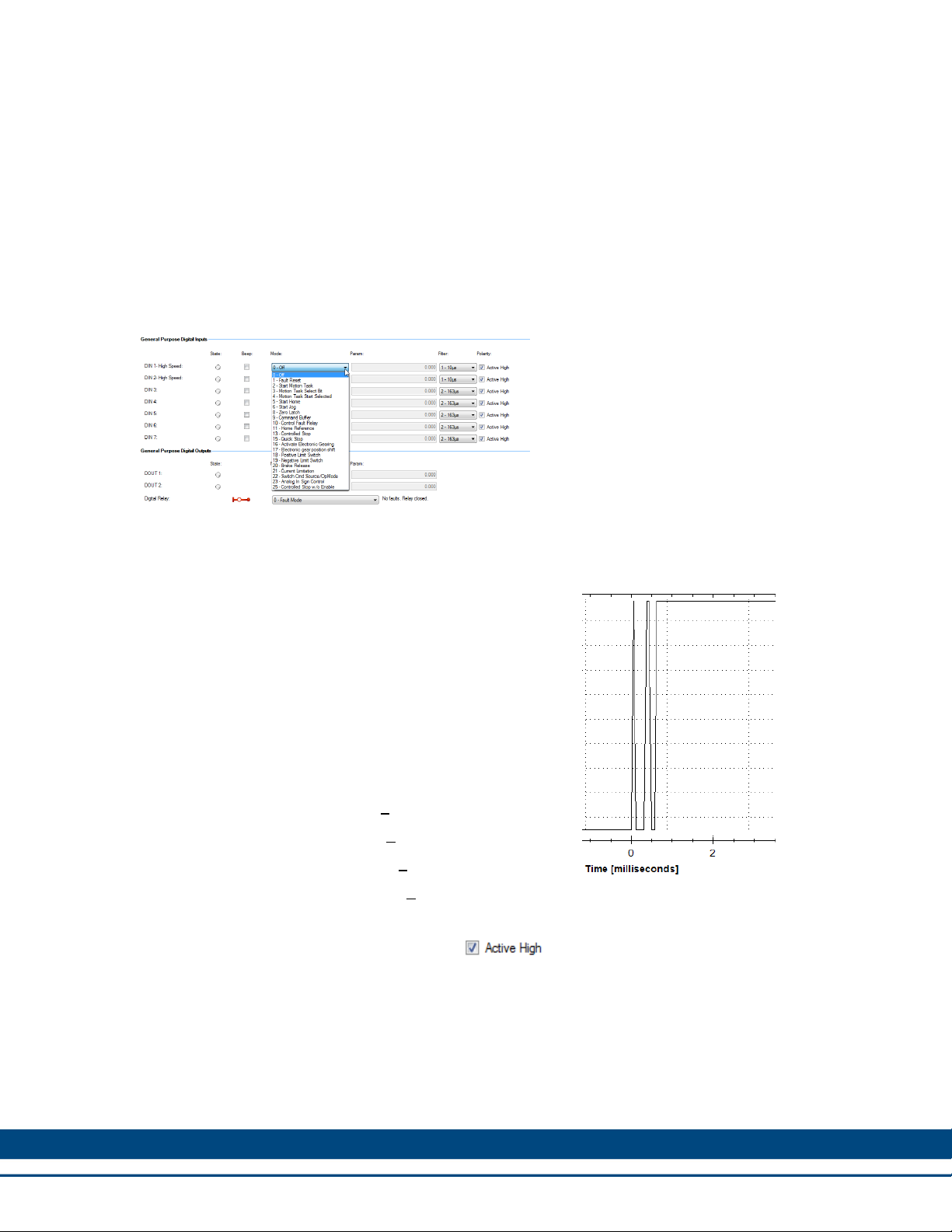

Digital Inputs and Outputs

The Digital I/O connections are made on connectors X7 & X8. Once the connections are

properly made, they can be configured in WorkBench. Digital Inputs 1 & 2 both are high

speed inputs with update rates of 2µs. Digital Inputs 3 to 7 are standard programmable

inputs with update rates of 250 µs.

The function of the input can be programmed in WorkBench and selecting one of the

twenty-one available modes. Each input has a drop down box with the available mode.

The mode selected will depend on

the application requirements.

Keep in mind End Of Travel limits

are, in most cases, Normally

Closed, and Home Switches are

Normally Open.

All of the inputs can have Filters add, or the Polarity changed. Adding filters can be very

helpful when the input is from a mechanical switch that may bounce when closing or

opening.

Setting the filter to 0 – Off will allow all inputs to be

detected. The image to the right is a scope plot of

Digital Input 1 with filters off. The input is coming

from a snap action switch. The bounce of the

switch is clearly visible in the scope plot.

A bouncing input can trigger more than one move.

Adding a filter can insure the trigger will be

acknowledged only once.

The available filters are:

0 – Off (detects all inputs >40ns wide)

1 - 10µs (detects all inputs >10.24µs wide)

2 – 162µs (detects all inputs >163µs wide)

3 – 2.62ms (detects all inputs >2.62ms wide)

Digital Input with filters off.

Polarity allows the input to be changed from Active High to Active Low. Polarity can be

changed in Workbench by clicking Polarity, , or by setting the parameter. The

parameter is, DINx.INV, and will be set as follows.

0 – Input is Active High

1 – Input is Active Low

CAUTION: Changing the Polarity with the drive enabled can cause unexpected motion.

7

Page 8

WorkBench - AKD™ Positioner

Overview

The Advanced Kollmorgen Drive is the most advanced servo drive on the market. The

WorkBench software used to set-up and program the drive is an intuitive graphical user

interface. The power of the AKD comes for its high level features such as:

• Plug-and-Play compatibility with Kollmorgen motors

• Digital Signal Processor Control

• Optically Isolated I/O

• Highest Current Loop & Velocity Loop Bandwidth

• Fastest Digital Current Loop on the market

• Wide Feedback Range

• Multiple Bus choices

The AKD is a powerful, yet easy to set-up and use, digital servo drive. Its compact

design makes it the industry leader in power density.

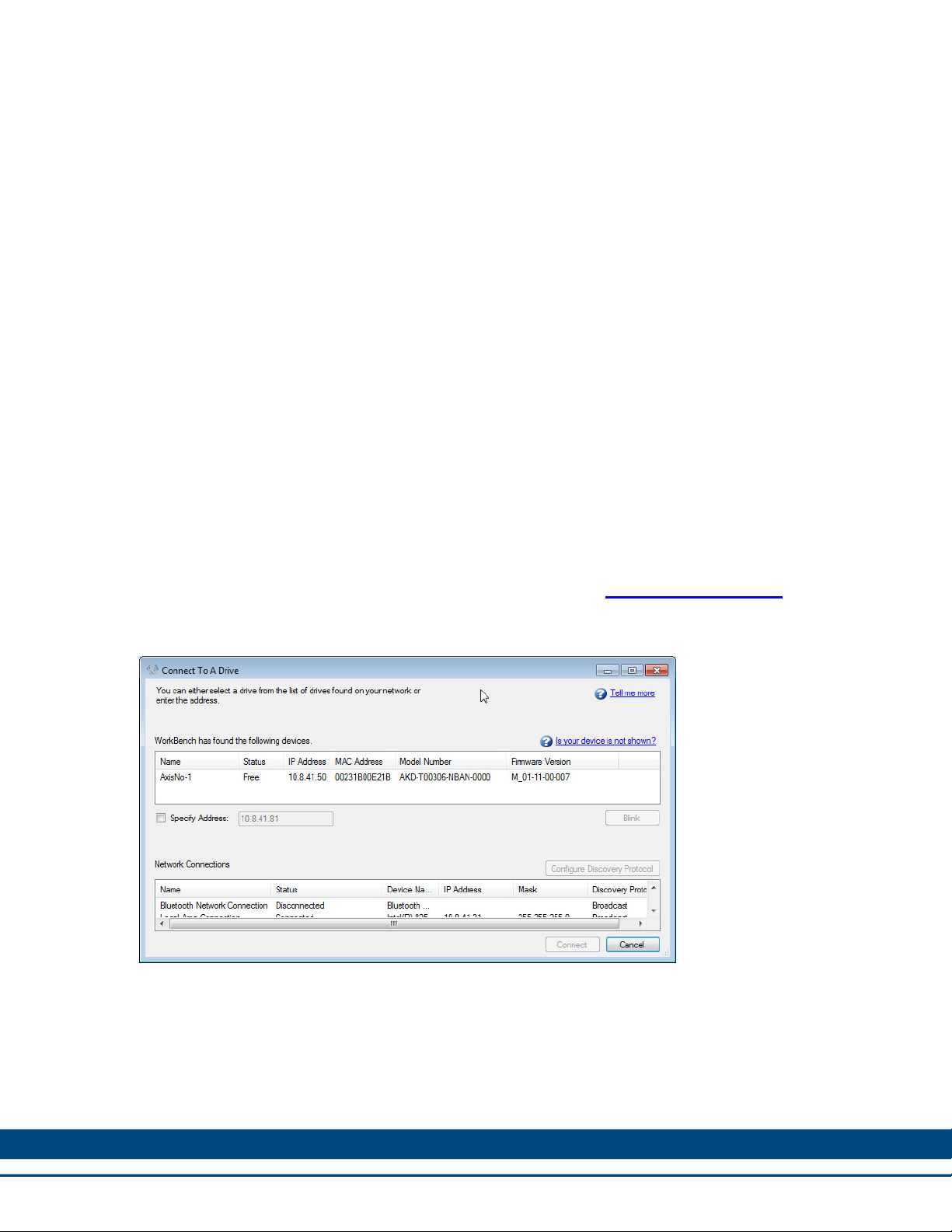

Connect to the AKD Drive

To communicate the AKD Servo Drive, the WorkBench graphical user interface is

provided. The most recent released version can be found at: www.kollmorgen.com.

The current versions of Workbench are compatible with the AKD and AKD BASIC.

Open WorkBench™.

8

Page 9

IP Address

In order to use the AKD, you must be able to communicate with the device using

WorkBench and an Ethernet connection. The AKD uses TCP/IP. Both the AKD and the

PC must connect through this standard in order to communicate.

Automatic (Dynamic) IP Address

The IP Address for each drive can be set automatically, or

dynamically. This is using the Dynamic Host Configuration

Protocol (DHCP). To set the drive to Automatic IP Address

set switches S1 and S2 to 0. Either power the drive up or

cycle power.

The drive will display an I-P on the display followed by the

address. This address can change each time the logic

power is cycled.

Static IP Address

A Static (fixed) IP Address can be set using rotary switches S1 and S2. The IP address

for the drive will be set to 192.168.0x1x2. The last two numbers, x1 and x2, are set by

S1 and S2.

Example:

We want to set the drive address to reflect its location in the system. This drive

is Axis No. 15.

S1 is set to 1 & S2 is set to 5

The IP address of the drive is now: 192.168.015

For your computer to see the drive it must be setup in the same domain. To set your

computer up, go into your control panel. Here you will find either Local Are Connection

or Network and Sharing Center. If it is Network and Sharing Center enter this to find

Local Area Connection. Note that your screen may look differently depending on your

version of Windows.

In the Local Area Connection click, on Properties then scroll down to TCP/IP version 4

and click on Properties again. Set Use the following IP address and enter:

IP Address: 192.168.0.100

Subnet mask: 255.255.255.0

Then click OK.

At this point the drives IP Address will appear in the screen and the PC can connect to

drive. This address will not change until you decide to make a change.

9

Page 10

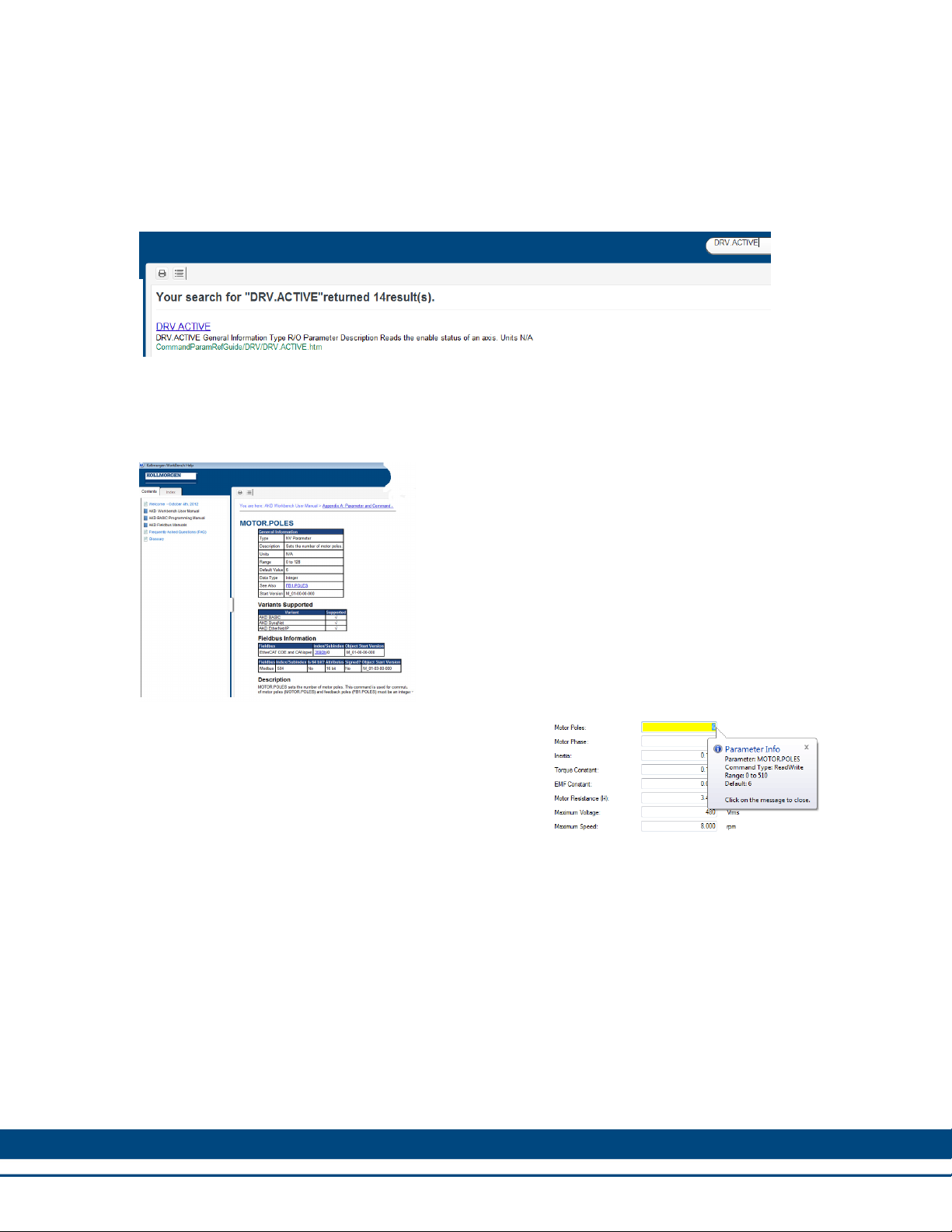

WorkBench Help

parameter, Units, Range, and Data Type.

Within WorkBench is provided quick access to the help screens. These can be

accessed using the Help tab, or the F1 key. If the Help tab is used the search screen

within Help will allow you search on a specific topic. In the example a search of

DRV.ACTIVE was made returning 14 results.

Using the F1 key can take the user to a specific section by clicking on the screen, or

within a specific parameter to narrow the search. For example, from the Motor screen

and clicking in the Motor Poles then F1 brings up the Help screen specific to

MOTOR.POLES, the parameter name.

At this point all the general information about

this parameter is displayed. Some of the

important information displayed is Type of

Also include is the Variants Supported which

is helpful if the parameter is to be changed in

other drive types. The Fieldbus Information

provides the format and for this parameter in

EtherCAT COE, CANopen, and Modbus. A

detailed description of the parameter is also

provided as well as Related Topics.

Another helpful feature is using the Right Click in

the parameter box. A drop down box will appear

in which is the selection, “Parameter Info” is

available. When this is click a box with a brief

description about parameter will appear. At times

this is enough information to help complete the

current setup task.

Drive Setup Screens

Drive Overview

Settings

• Motor • Units

• Feedback 1 • Modulo

• Feedback 2 • Limits

• Brake • Home

10

Page 11

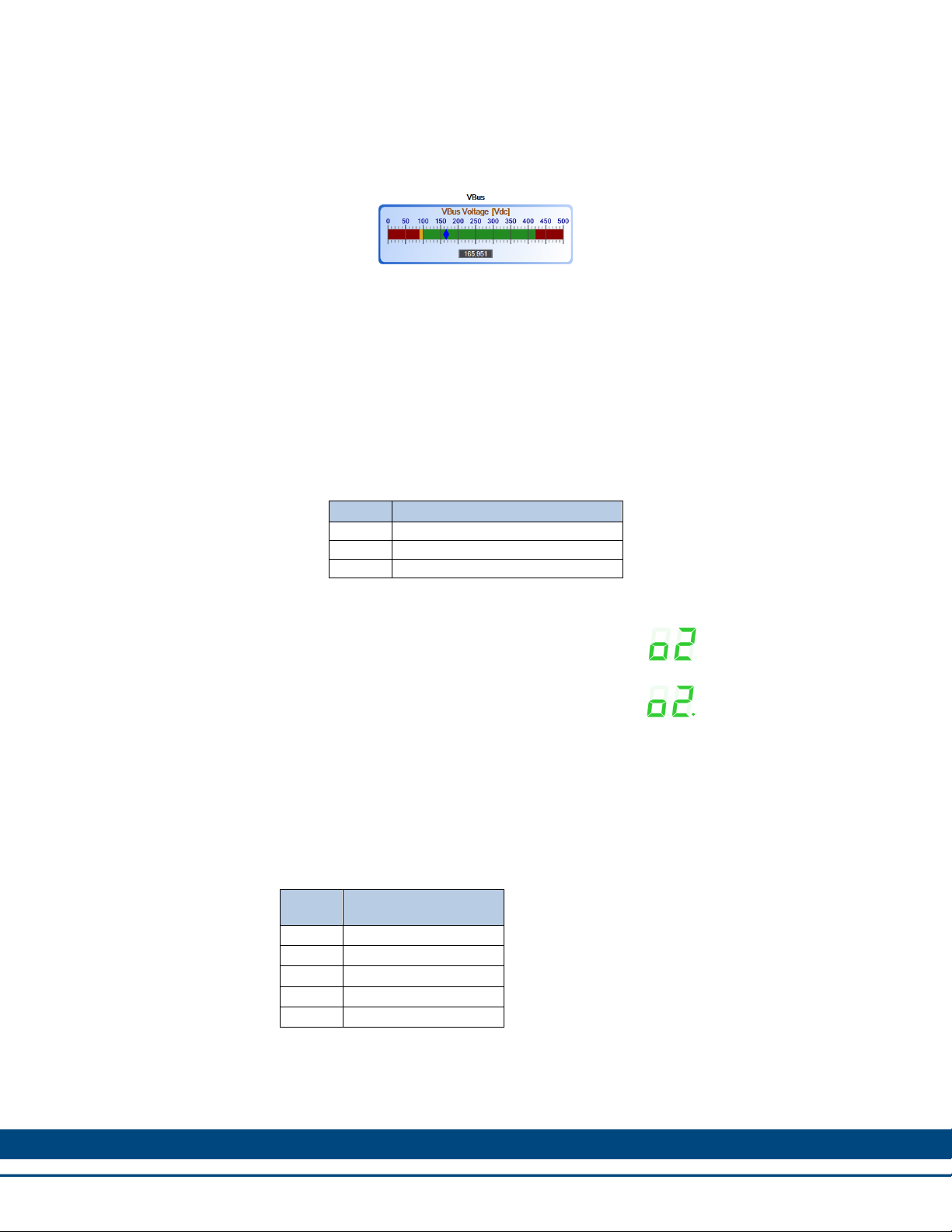

Power

The Power screen allows the bus voltage to be monitored, the DC-bus Over-Voltage

threshold, DC-bus Under-Voltage threshold, Under-Voltage Fault Mode, and the

Operating voltage.

Opmode/Source/Enabled/Running

DRV.OPMODE

The AKD™ servo drive has three operation modes in which it can function. The

operation mode, or DRV.OPMODE, of the drive is selected for the application in which

the drive is being used. The “Opmode” ranges are 0 to 2.

Mode Description

0 Current or Torque mode

1 Velocity mode

2 Position mode

The display is indicating that the drive is in position

mode and not enabled.

The display indicates that the drive is in position

mode and the drive is enabled and active.

DRV.CMDSOURCE

The Command Source sets the method with which the drive will be communicated.

During setup of the drive the command source is usually set to 0 for Service mode.

Value Description

0 Service/TCP/IP

1 Fieldbus

2 Electronic Gearing

3 Analog

5 Program

DRV.CMDSOURCE 5 is only available in the AKD BASIC servo drive and is used in the

programming mode.

11

Page 12

The command source can be changed from the Workbench setup screen, or from the

terminal screen.

If the DRV.CMDSOURCE is changed in the terminal screen while the drive

is enabled the system can experience a step change in command. This can result in

unexpected motion.

The AKD™ servo drive has to two states when operating. The drive can be enabled or

disabled. This is displayed by two LED’s located on the front of the drive, and in GUI.

There times that the drive can be enabled but not active. For the drive to be active both

the Hardwar enable, HW, and Software enable, SW, must be true, and no faults can

have occurred.

The diagram above is the Boolean representation for DRV.ACTIVE to be true. There

are no faults and the Software Enable (SW) and Hardware Enable (HW) are true.

Below the DRV.ACTIVE is false and the Power Stage is off. Missing are the Software

Enable (SW) and Hardware Enable (HW).

12

Page 13

Units / Terminal / Watch window / Scope Tool

Units

The Units screen is used to set the three primary drive parameters of acceleration,

velocity and position into user defined application specific units. This will allow the user

to work in clear understandable units. Motion Task will reflect the units as they are

established in this section.

For a motor only we can still set the units to our desired values.

In this example the position units are set to

degrees of the motor shaft, velocity is in RPM

(Revolutions Per Minute) of the motor shaft, and

acceleration is being set to RPS/s (Revolutions

Per Second per Second).

The range of available units allows the system to

duplicate any mechanical scenario found in

industry.

For a motor connected to a lead/ball screw with a lead of 0.5 inches/revolution of the

screw, we can set up our units as follow.

In our example the motor is connected to

the screw directly. The input has be set to

turns to show that this can be expressed

as a turns 1 to 1.

The Lead is set to 0.5”/rev of the motor.

Velocity will be in Inches/second, and acceleration

will be in Inches/second/second.

Workbench provides many examples of

mechanical devices. Each one has a

pictorial of the device to assist the operator

to correctly enter the information.

The gear ratios are entered the same way

for each unit. Either as none, Turns, or

Teeth.

Position units are set the mechanics of the

device. Since our lead screw was defined

in inches, the position will be provided in

inches as well. Also velocity and

acceleration will be mechanically

dependent.

13

Page 14

Terminal

Terminal Screen allows parameter or command to be check and entered directly

from the drive and to the drive. In most training sessions the terminal screen will be the

first stop. From here the drive can be set back to factory defaults.

Note: It is important to make sure you back up the parameter files before resetting the drive as all

values will be overwritten.

DRV.RSTVAR will restore the drive to its

default values. As you begin typing the

parameter into the terminal screen it will

begin to auto fill. To the right will be a

short explanation of the parameter or

F1 can be used at any time in any screen. This will be the fast way to the help section of

Workbench. While in the terminal screen hitting F1 will take you the section on the

Terminal Screen.

Watch Window

The watch window allows selected parameters to be view in real time such as the

VL.FB, or the velocity feedback of the motor. The watch window can be turn on in three

different ways. The first is from the View tab at the top-left of Workbench.

command.

From the tree:

View-

- Toggle Watch Pane

At the bottom of Workbench will appear the Watch Window. In the example below we

are monitoring Position Feedback (PL.FB), Current Feedback (IL.FB), Velocity Feedback

(VL.FB), and the state of Digital Input 1 (DIN1.STATE).

If more than one drive is connected to Workbench Device can be setup for additional

axis and different Parameters can be set for each. This provides a simple solution to

monitor the different elements of motion.

While the watch window is providing the parameter information in real time, it is not

recorded and cannot be played back or viewed at a later time.

Ctrl +W will open and close

the watch window. Or the

Icon of the glasses can be

clicked to alternate between

open and closed.

14

Page 15

Scope Tool

The Scope tool allows the user to collect and view six channels of data from the

drive. Using the trigger mode will allow data to be collect at the same points in a move

when repeated.

In the Scope Tool, Channels allows the selection of parameters to be monitored,

displayed, and saved for later recall. Parameters can be selected from the Source

section. Clicking in the box will bring up a list of parameters. Below we see the default

parameters: Current Feedback (IL.FB), Velocity Command (VL.CMD), and Velocity

Feedback (VL.FB).

Clicking in the Source section will pull up a list of standard parameters that can be

select. Not all the parameters available are on the list so an <User Defined> parameter

is available.

Time-base and Trigger allow the Recording time and

Trigger to be setup. The Recording time can be set by

simply adjusting the time in milliseconds. If, however,

there is a need to increase the number of samples within

a given time the button can be click to provide

access to the Sampling frequency and Number of

samples.

The Trigger is used to begin the recording at the same

place in the move every time. The most common

Trigger Type is VL.CMD. Since a position move will

generate a velocity command, VL.CMD, it is a very good

trigger point. The level is set slightly above the ambient

velocity command, or that which holds position.

The slope indicates the direction of the command off which the trigger will occur. If our

first move is positive this will be set to 1-Positive, and if negative it will be set to 0Negative. Position is the amount of record time that will be kept in advance of the

trigger. When the system is armed it basically recording data at that point and will keep

the amount of data based on the Position time.

Service Motion

Service Motion allows a move or motion to

be created from the scope screen. This

can be very useful during the tuning or

troubleshooting process. The motion can

be a single pulse, Reversing motion, or a

continuous move.

15

Page 16

Motion Task

From the scope screen a motion task can

be called. Using the motion task in the

scope will allow the exact motion required

for the application to be triggered and

captured. A plot of the motion task can

show any problems in the motion that may

be occurring.

Servo Gains

Servo Gains, Observer, All Gains, and AR Filter will be addressed in another class. All

of these can be seen from the scope screen and changed to improve the system

performance. As always, care should be taken when changings gains and filters as

systems can become unstable.

Save & Print

After a scope plot has been taken it may

be important to share the scope plot with

your colleagues commissioning purposes,

troubleshooting or bragging right.

The scope plot can be saved as an image

in BMP, JPG, PNG, EMF or WMF format.

The plot can also be saved in a csv (Comma Separated Values) file format which will

allow the data points to be brought into an Excel Spread sheet. This can be very useful

when evaluating the data collected.

The scope plot can also be sent to a print to create a hard copy. Associated with the

print tab is the Page Setup tab which allows the page to be set to the most practical

format for display. For example, Landscape or Portrait.

Measure

The measure tab allows basic information to be displayed. The data displayed is that

set in the Channels tab and will indicated the Average, Minimum, Maximum, Peak to

Peak, and RMS values. The data will be displayed in the units set for the system.

The average value is based on the sum of the data points divided by the number of data

points. The minimum and maximum values are the highest and lowest data points. The

Peak to Peak value is the value from the minimum to maximum values.

RMS (Root Mean Square) is the geometric average of the value.

16

Page 17

Cursor

To measure the values between two points the

cursor can be used. The left Right Cursors can

be moved to their positions and the distance

between them in Time and the set units can be

displayed.

In the example the left cursor is set on the rising

edge of the digital input 1 state. The right cursor

is set at the end of the last motion task before the

return move. Between the two cursors is the

measured time, Position, Velocity Commanded

and Velocity.

We can see from the measured data that the move time is 1,065.000 milliseconds, or

approximately 1 second.

Since the motion task is set to move out 1,550 degrees and returning to zero, the

position is measure just before the return move. If it was measured after the return

move it would read approximately zero. We measure the distance moved as 1,549.581

degrees.

Display

The Display tab allows adjustments to the displayed data to make the interpretation of

the data easier. Controls allow the viewer to zoom In and Out, Pan Left and Right,

display the current data along with the last three.

The legend can be removed, the Font enlarged, Horizontal and Vertical grids added or

removed, and a Zero Line displayed. The data points can be marked as well, but with a

large number of data points the display can be cluttered.

Show Data will display the individual data points and their magnitude.

Zoom Out All will return the display to its original state.

17

Page 18

Settings

Settings allows for a series of Preset Scope settings to be created. These settings can

be retrieved and used as needed.

Clicking on the Reload Current tab will bring down the list of preset scope settings.

Loading a preset will set the Channels to be recorded, the recording time, triggers etc.

The preset scope settings can be exported to the computer’s memory and shared as you

would any other file. Files can also be Imported and used. This is very helpful during

long distance troubleshooting where the data being collected will need to be as close as

possible.

18

Page 19

AKD™ Motion Task

Homing

Before a position move can be executed, the home position must be established.

Workbench provides fifteen different methods to home a system and the type selected

will depend on the application and mechanics to which the motor is connected. Each

home mode provides flexibility when working with the application.

To select the proper home mode, HOME.MODE, will require an understanding of the

application. If the application does not require a known starting point, such as the case

for a conveyor that must index a set distance on a trigger, then a simple home type can

be used. Home mode 0, “Home using current position”, can be used. This will basically

allow the current position to be the starting point.

Mode Description

0 Home using current position

1 Find limit input

2 Find limit input then find zero angle

3 Find limit then find index

4 Find home input, including hardware limit switches

5 Find home input then find zero angle, including hardware limit switches

6 Find home input then find index, including hardware limit switches

7 Find zero angle

8 Move until position error exceeded

9 Move until position error exceeded, then find zero angle

10 Move until position error exceeded, then find index

11 Find index signal, without any precondition

12 Homing to a home-switch, including mechanical stop detection

13 Home using the feedback position

14 Find home input – Only in given direction

Home Mode Types

The home mode types can be broken into: use current position, find the limit switch, find

the home input, move until position error exceeded, and find zero angle or index. Each

of these can be modified to provide an offset from the home position.

Home Type 0

Mode Type 0, use current position, will make the current position the home point.

Although a very basic home type, it can be modified using Offset and Position. This

means the current position doesn’t have to be defined as zero, but can be given any

desired position, and the load can be moved from this position.

Mode Type 0 is very useful when you have a device that is not concerned with the actual

starting point such as a conveyor that will index a defined distance once an input has

been triggered. In other words, where it is beginning is not as important as where it is

going.

19

Page 20

Home Types 1, 2 & 3

Using Mode types 1, 2, and 3 we see that this is basically looking for the limit input, or

End-Of-Travel switch (EOT). Modes 2 and 3 have the added “… then find zero angle”

and “… then find index.” Each feedback device will have either the zero-angle or the

index. SFD, EnDat Sine Encoder, BiSS, and Resolver will have the zero-angle. The

incremental encoder with and without Halls will have the index. These are precise

positions in the feedback device that do not change unless the motor or feedback is

changed.

Home Types 4, 5 & 6

Using Mode Types 4, 5, and 6 will be looking for a dedicated input specifically for the

Home Reference. This input can be a snap action switch, which is inherently inaccurate,

or a non-contact type switch such as Hall Effect, Inductive Proximity, Capacitive

Proximity, or Photo-detector Proximity switch. As with Mode Types 1, 2, and 3, finding

the Home Reference input can increase the accuracy by adding the zero-angle or index.

Homing to a limit switch, home input switch, or a physical hard stop can provide a

position that may fluctuate depending on the switch type, ambient temperature, or other

environmental or material changes. For example if the machine is using home mode 8,

which will drive the mechanical components into a hardstop, and the hardstop is a piece

of rubber the position will change with temperature as the rubber softens or hardens.

To remove this inaccuracy due to temperature, the load can move to the hardstop then

move off to the zero angle or index of the feedback device. This will make the homing

very repeatable.

In most cases when homing to a limit switch or hardstop an offset is desired. The Home

setup screen provides for this offset. The example below is for homing to a limit switch

with an offset.

Homing Example:

Units have been setup for connection to a

Lead Screw. The lead is 0.5”/rev. The

Position Unit is 3-Custom (mechanics

dependent) which will provide position in

inches when Custom Position Unit is set to

inches; Velocity Unit 3-Custom (mechanics

dependent) which be in inches/second;

Acceleration Unit is 3-Custom (mechanics

dependent) which will be in inches/s².

For this example the load will be homed in the negative direction, a 1-inche offset will be

provided, and the final position will be zero.

20

Page 21

Velocity, Acceleration, and Deceleration

have been set to moderate values. The

Home Mode is set to type 3-Find limit

input then find index (feedback is

incremental encoder). The direction is

set to 0-Negative; this will allow the

moves to be positive from home. The

position is set to -1, and distance is set to

1. This means when the limit switch is

found the system will move off to the

index position. This point is now defined

as -1, then the system will move positive

1 inch. The Position Feedback now

reads 0.00 inches.

When homing to a limit switch the switch must be made long enough for the

system to decelerate to zero and the switch still triggered. The switch can be overshot if

the deceleration rate is very low and velocity is very high. A homing error will occur.

Home Types 7 & 11

Home Types 7 and 11 are very similar. Both use the feedback device’s internal

reference point for homing. Homing using the zero angle or index and adding an offset

can be used with each of the other Home Modes.

Home Types 8, 9 & 10

Home Types 8, 9, and 10, Move until position error exceeded, are commonly called

Homing to a Hard-stop. Basically the current will be reduced to prevent damage and

the load will be moved in one direction or another until the position error increases above

the set value. Care needs to be taken to prevent damage of the mechanical system.

The Peak Current limit set in the Homing screen needs to be high enough to overcome

all frictions in the system, yet low enough to not damage the components.

A common mistake when using Home Modes 8, 9, & 10 is to have an offset move in the

same direction as the home direction. For example using Direction: 0-Negative and

Distance: -1. Since the system was moving in the negative direction when it

encountered the hardstop, it cannot move -1 as this will be beyond the hardstop. The

system will generate an Error as seen below.

21

Page 22

Home Type 12

Home Type 12, Find home input (account for mechanical end stops) will allow a system

to travel to a hard-stop, turn around, and continue looking for the Home Reference input.

This home type removes the need for adding End Of Travel limit switches to the system.

It is important to be aware that this system works similar to the Home Types 8, 9 and 10,

except the hard-stop is the EOT. Peak Current will need to be reduced enough to

prevent damage, but high enough to overcome frictions in the system.

Motion Task

In many applications point to point moves are all that is needed. AKD and

Workbench can allow simple to complex profiles to be entered into the drive and moves

triggered by the I/O.

There are two basic types of move available in the motion task. These are Absolute and

Relative moves. While both are motion types, when and how they are used is

application dependent.

Absolute Move

Absolute moves are excellent when working in a finite space such as an actuator. Since

the travel is limited to the length of travel in the actuator, Absolute moves help prevent

an accidental move beyond the travel limits.

If the systems begins at 0 degrees and an absolute move is commanded for 360

degrees, the system will move to that point. There is only one point that is 360 degrees.

If the move is repeated two more times the system will not move since it is already at

360.

Relative Move

Relative move, or Incremental move, is based on making a move of a certain distance.

The starting point is irrelevant, since the move is starting from whatever point it is

located at the time the move is initiated.

If the system begins at 0 degrees and a command to make a relative move is given the

system will move to 360 degrees. If the command is given two more times the system

will make two more moves each equaling a distance of 360 degrees. The final position

is 1080 degrees.

22

Page 23

Relative moves are used in applications were the system can make repeated moves

without coming to the end of travel such as indexing tables or conveyor systems.

A clear understanding of Absolute and Relatives is required to insure that the correct

move type is used in the application. As we can see from the two examples, if

connected to an actuator with a travel limit of 360 degrees, the Relative move would

have found the end of travel and possibly damaged the actuator.

Motion Task

There are two ways create a motion task. The first is to enter the data into the

data spreadsheet. Below we see that a move of 360-degrees at 1000-rpm has been

created. The spreadsheet can be expanded to the right to add the column for the

Following Task, which is the task that will be executed after the current task, the Start

Condition and Dwell Time if the Start Condition calls for a Dwell between the Motion

Task.

The second method is to double-click the Motion Task number which will bring up the

Motion Task screen. The Motion Task screen is for a single task. It provides a visual

representation of the move and allows all the parameters to be edited in one place.

The type of move can be selected as:

Absolute

Relative to command position (PL.CMD)

Relative to previous target position

Relative to feedback position

The units for Position, Velocity, Acceleration,

and Deceleration are defined in the Units

Screen. It is important to set the Units

appropriately for the application.

Following Task is the task to be completed

after this Motion Task. They do not need go in

order and jump around as needed.

One move can blend into the next as defined in drop down section. One task can blend

into the acceleration or velocity of the next task. Scope plots of each Blend type can be

found in Appendix A.

23

Page 24

Exercise

Objective: to create a series of motion task connected together using different start

conditions and blending that will be trigger from an I/O condition and captured using the

Scope tool.

Setup the following motion task all of which will Absolute moves, Trapezoidal Profiles,

and Acceleration /Deceleration 10,000 rpm/s:

Task No. Position (degrees) Velocity (rpm) Next Task Start Condition Dwell Time

0 1200 300 1 Dwell Time 250

1 2400 600 2 Dwell Time 250

2 3600 1200 3 Dwell Time 250

3 0 2000 none

Set the scope to record VL.FB, PL.FB, and DINx.STATE for the digital input selected to

start the motion task. In example, digital input 1 will be DIN1.STATE.

Set the scope to record 2.5 seconds of data, while triggering off the velocity command

going greater than 5 rpm. Remember to set the slope to 1 – Positive to catch the rising

edge. Arm the scope then trigger the motion task.

The example below is similar to what you should have displayed. The shape of the

move profiles may vary due to tuning and load. The blue line is the digital input that

triggered the move. The red line is the velocity profile for the moves. The green line is

position during the moves.

24

Page 25

PLS – Programmable Limit Switches

To connect the states to the OR gate, the box must be

checked. The state indicator will illuminate when that point

is true, and will not be illuminated when not true.

PLS.EN enables the programmable limit switch. The range is 0 to 255, and is a binary

representation of the 8 programmable points. PLS.EN 255 will be for all points on, while

PLS.EN 0 is for all points off. Any combination of points can be enabled based on the

binary value of PLS.EN. PLS1 is the least significant bit, and PLS8 is the most

significant bit.

The above scope plot shows Digital Output 1 firing at the six set points.

25

Page 26

Electronic Gearing

Electronic gearing allows two axis to be connected together digitally. Usually there is at

least two axis involved, but it is not uncommon to have several follower axis. One axis is

the Master, or Leader. The other axis, or multiple axis if more than one, is the Follower.

The AKD can be setup as either the Leader or the Follower, but not both. Each axis will

be setup individually. When using AKD connector X9, the connection will be one to one.

One to one connection means pin-1 on

one connector is connected to pin-1 on the

other connector. Pin-2 is connected to pin2, and so on and so forth.

It is important to observe all grounding,

shielding and bonding procedures to insure

good performance of the system.

AKD connector X7 can also be used for electronic gearing. It can be used for 24 volt

signals to provide an up-down control. This commonly used when a third-party controller

is being used to deliver the signal.

It is important to note that this configuration is single ended and provides very little noise

rejection. It is very important to shield and ground the signal carrying cable.

Leader

The leader is the easier of the axis to setup. This will basically consist of setting up the

Emulated Encoder Output (EEO). The EEO is set in the Encoder Emulation screen.

Emulation Mode is the type of output

the AKD will generate. The more

common is mode 1-Output A/B with

once per rev index. This simulates

an A quad B encoder. The Emulation

Resolution is here in lines/rev.

The leader Emulation Resolution is from 0 to 16,777,125 lines/rev. Lines/rev is before

quadrature. Post is found by taking the resolution time four (lines/rev x 4 = counts/rev).

26

Page 27

Follower

The Follower has a more complex setup compared to the Leader. Because the Follower

will be receiving the input, Encoder Emulation is set to 0-Input (No EEO Output).

The Follower Axis will be setup for the example below. The connection will be from X9

to X9 through a 9-pin Sub-D female-to-female cable. The cable is shielded and the

shield is tied to ground.

Feedback 2 will be setup for X9.

Feedback mode is 0-Input A/B Signals.

Resolution is set to 262,140 counts/rev.

The Follower must be setup for DRV.CMDSOURCE 2-Electronic Gearing. When the

command source is set Electronic Gearing an additional branch will appear on the tree.

The Input Type and Input Source will

reflect that which was set in the

Feedback 2 screen.

The ratio between the Leader and the

Follower can be set here in the In = Out

tabs. A 2:1 ratio can be set as In: 2,

Out: 1, or In: 200, Out: 100, or any

combination that will be equal 2:1. This

flexibility becomes helpful when ratios

such as 15.5:1 are required. The

values for In and Out must be integers,

so this will be set as In: 155, Out: 10.

While In (GEAR.IN) has a range of 1 to 65,535, Out (GEAR.OUT) has a range from

-32,768 to 32,767. Since Out can be negative it can be used to counter rotate two axis,

or correct for axis in which one motor is mounted opposite another.

Limit can be set for the Follower axis using the Maximum Velocity, Maximum

Acceleration, and Maximum Deceleration. In most cases it is best to set Acceleration

and Deceleration as high as possible. Limiting Acc and Dec and adversely affect the

system performance.

The Gearing Type defines how gearing will start if the Leader is

already in motion. Since the electronic gearing can be used to

synchronize two axis, it should understood relationship

between the Leader and Follower.

If the follower is only meant to come up to the same speed as the Leader then Velocity

Matching will be used. Position Matching is used when the Leader and Follower need to

be lock together by their position. When engaged, the Follower will speed up and

recover the steps lost during the acceleration.

27

Page 28

Tuning

Introduction

In a perfect world tuning a system would not be required. In the “Real World” tuning a

system is a necessity.

A servo system is a closed loop system which will continually monitor and adjust torque,

velocity, and position to achieve the desired trajectory. A servo system can operate in

torque mode, or velocity mode, or position mode. In the diagram above can be seen a

simplified diagram of these three loops.

The tuning begins at the right with the current loop which is tuned for the motor. The

current loops function is to insure that as much current as possible can get into and out

of the motor as quickly as possible. The current loop does take into account the load

and doesn’t even care if a load is connected or not.

The velocity loop is added to the current loop. The velocity loop is tuned after the

current loop and is tuned specifically for the load. The tuning is basically telling the drive

how it needs to react to any change in velocity. If the load is very small, JL/JM=1:1 or

less, a slight change in velocity does not warrant a huge injection of error into the system

to correct for this change.

At the other end of the spectrum is a large load, JL/JM =1,000:1. Since the load will

create a large opposition to motor, a larger error will need to be injected into the system

to insure enough torque is generated to overcome the load and correct the change in

velocity.

The position loop can be added to the velocity loop and current loop after they have

been tuned. The position loop is now monitoring the position as well as velocity and will

need to be tuned for the load for the same reasons the velocity loop is tuned for the load.

The AKD provides several paths for tuning the system from the Slider Tuner to the

Performance Servo Tuner which can tune in Automatic Mode or Manual Mode. Accept

for the most extreme cases, the AKD can be tuned to provide excellent performance with

high inertial loads, systems resonance, and poor mechanical components.

The Key to good servo performance is to begin with a sound mechanical system!

28

Page 29

Slider Tuning

The slider tuner is a simple easy to use tool that can get most servo systems up and

running in just a few minutes. It requires two pieces of information:

Load inertia

Bandwidth

The desired bandwidth can be entered by using the gentle/medium/stiff settings which

represents 25Hz, 75Hz, or 200Hz respectively. You can also type in the desired

bandwidth, or use the slider bar itself to increase the value.

The “More>>” button opens the screen to identify what specific gains are being set, and

to what values.

Important Notes: The slider tuner does modify one of the digital filters (Biquads) and

tunes a low pass filter based on the bandwidth selected. It is important to keep track of

any filters that are present to maintain stability. The Slider tuner does not configure any

feed-forwards (current, friction, velocity, acceleration, etc.). Manual set up may be

required to optimize motion profiles.

What Bandwidth is required?

The simple answer is based on just how fast you need the system to settle from

disturbances or motion. Knowing your desired settling time allows you to calculate your

system bandwidth:

System Bandwidth = 1/Settling Time (seconds)

Desired bandwidth

29

Page 30

Slider Tuner – How it Works

How does the slider tuner know what the tuning gains should be just from the bandwidth

and load inertia? Slider tuner will set four parameters, VL.KP (velocity proportional gain),

VL.KI (velocity integral gain), PL.KP (position proportional gain), IL.KP (current

proportional gain), and one biquad filter, AR1. Let’s look at each one individually:

First – VL.KP, or Velocity Proportional Gain

ܸܮ.ܭܲ = 2ߨ∗ܤܹ∗ܬܯ∗(1+ܬܮ)∗0.0001*ܭݐ

JM and JL are in units of kg-cm2, BW in in Hz, and Kt is N-m/A

rms

VL.KP will bring the gain of the system up to a specific performance rating (bandwidth).

Therefor it is based on how strong the motor is (Kt – the motor torque constant) and how

much mass is attached to the motor (JM – motor shaft mass and JL – load mass).

Next we look at VL.KI, or Velocity Integral Gain

VL.KI = BW * tan(2.5°)

BW and VL.KI are in units of Hz

There is no standard to how much velocity integral gain is needed on a system. The

slider tuner makes a conservative assumption and sets the Velocity Integral gain to

contribute only 2.5 degrees of phase loss at the bandwidth requested.

Next, we look at PL.KP, or the Position Proportional Gain

PL.KP = BW * tan(2.5°) * 2π

BW is in units of Hz, PL.KP is in (rev/s)/rev (can be converted to Hz by dividing by 2ߨ)

The required Position Proportional gain will also vary from system to system. The slider

tuner sets the Position Proportional gain to contribute only 2.5 degrees of phase loss at

the bandwidth requested.

Our next parameter is IL.KP, or the Current Proportional Gain.

IL.KP = IL BW * tan(2.5°) *2π * Motor Inductance (mH)

Where BW is in units of Hz

First a current loop bandwidth must be calculated:

IL BW = 75 Hz / tan 5 = 857 Hz

30

Page 31

Next, IL BW (Current Loop Bandwidth) is clamped between 1000 Hz and 2000 Hz to

݂݂݂݂

݅݅݅݅

݈݈݈݈

ݐݐݐݐ

݁݁݁݁

ݎݎݎݎ

ܨܨܨܨ

ݎݎݎݎ

݁݁݁݁

ݍݍݍݍ

ࢎࢎࢎࢎ

ݖݖݖݖ

====

((((

−(

−(−(

−(

܋܋܋܋

ܗܗܗܗ

ܛܛܛܛ

∗∗∗∗

ܾܾܾܾ

ݓݓݓݓ

−−−−

∗∗∗∗

ܾܾܾܾ

ݓݓݓݓ

∗∗∗∗

++++

−−−−

∗∗∗∗

ܛܛܛܛ

ܑܑܑܑ

ܖܖܖܖ

∗∗∗∗

܋܋܋܋

ܗܗܗܗ

ܛܛܛܛ

∗∗∗∗

ܾܾܾܾ

ݓݓݓݓ

∗∗∗∗

ܾܾܾܾ

ݓݓݓݓ

−−−−

∗∗∗∗

∗∗∗∗

++++

∗∗∗∗

((((

ܾܾܾܾ

ݓݓݓݓ

−−−−

ܾܾܾܾ

ݓݓݓݓ

∗∗∗∗

++++

))))

−−−−

܋܋܋܋

ܗܗܗܗ

ܛܛܛܛ

∗∗∗∗

ܾܾܾܾ

ݓݓݓݓ

−−−−

−−−−

ܛܛܛܛ

ܑܑܑܑ

ܖܖܖܖ

∗∗∗∗

ܾܾܾܾ

ݓݓݓݓ

∗∗∗∗

∗∗∗∗

))))

∗∗∗∗

ܾܾܾܾ

ݓݓݓݓ

∗∗∗∗

܋܋܋܋

ܗܗܗܗ

ܛܛܛܛ

ܘܘܘܘ

∗∗∗∗

܊܊܊܊

ܟܟܟܟ

∗∗∗∗

−−−−

ܛܛܛܛ

ܑܑܑܑ

ܖܖܖܖ

ܘܘܘܘ

∗∗∗∗

܊܊܊܊

ܟܟܟܟ

−−−−

∗∗∗∗

maintain numerical accuracy and stability.

IL BW = 1000 Hz

Note: Default tuning will leave the current loop with ~1000 Hz bandwidth. If manual

tuning is used to achieve more than a few hundred Hertz, IL.KP will need to be manually

increased appropriately.

Finally, AR1 is set as a low pass with a cutoff frequency calculated to cause no more

than 8.5 degrees phase loss at the requested frequency.

Yes – this is a BIG equation and very cumbersome than most would like. However,

since the slider tuner is limited over a small frequency range (no larger than 300 Hz

bandwidth), an acceptable substitute is:

AR1 Frequency = 9 * BW

Important Note: All systems are different. Integral gains can be sensitive to

mechanical oscillations and friction. The slider tuner may not be appropriate for some

applications.

Limitations of Slider Tuner

Why use anything else? The slider tuner is very simple to use as it can get simple

mechanical assemblies tuned reasonably well with little fine tuning. When mechanical

systems get beyond a simple rigid load, more tuning finesse is often required to handle

the complex resonances created by complicated mechanics.

Common systems that may not be able to be optimized using the slider tuner:

Belt driven loads High friction mechanics

Multi-staged loads (multiple resonant loads) Low resolution feedback

Linear motors Unknown inertia loads

Unfortunately, the slider Tuner won’t work for every system. This is primarily because

the slider tuner does not measure any part of your motor or mechanics and assumes the

ideal case. It also assumes the load inertia you entered includes all of your loads.

Rarely are mechanical systems ideal – there is always something unexpected like

friction, imprecise manufacturing of components, belt tensioning, and even variations

from machine to machine.

In these cases, solving advanced problems will require just a bit more work. Using the

AKD Performance Tuner feature, it is possible to measure your physical system and

tune on what is actually, physically there, even if there are variations from machine to

machine. The Performance Tuner allows you to visualize these problems and adjust

tuning accordingly.

31

Page 32

Projects

Project #1 Bode Tool & Tuning

On your hard drive create a folder called: AKD Projects.

1. Take a Bode Plot of your system and save it to your project folder.

2. Set the tuning using the Slider Tuning.

32

Page 33

Appendix A – Always Under Construction

Blending Moves

When a more complex move is require, moves can be connected together using the

Blend feature. The move can be connected without any blending, or blended into the

acceleration or velocity of the next move. It should be noted this will only work for those

motion task of the same direction.

250 millisecond dwell between moves. The distance, acceleration, and decelerations

are the same for the motion task, but the velocity is different. The results are three

moves with the acceleration and distance covered, but different times to complete the

move.

Motion Task 0 blended into the acceleration of Motion Task 1.

33

Page 34

Motion Task 0 blended into the velocity of Motion Task 1.

34

Page 35

Appendix B – Under Construction

North America

Europe

Under Construction

About Kollmorgen

Kollmorgen is a leading provider of motion systems and

components for machine builders. Through world-class

knowledge in motion, industry-leading quality and

deep expertise in linking and integrating standard and

custom products, Kollmorgen delivers breakthrough

solutions that are unmatched in performance, reliability

and ease-of-use, giving machine builders an irrefutable

marketplace advantage.

For assistance with your application needs, contact

us at: 540-633-3545, contactus@kollmorgen.com

or visit www.kollmorgen.com

Kollmorgen

203A West Rock Road

Radford, VA 24141 USA

Phone: 1-540-633-3545

Fax: 1-540-639-4162

Kollmorgen

Wacholderstraße 40 – 42

40489 Düsseldorf Germany

Phone: + 49 (0) 2039979235

Fax: + 49 (0) 20399793314

35

Loading...

Loading...