Page 1

AKD™

EtherCAT Communication

Edition December 2009

Valid for Hardware Revision A

Original Documentation

Keep all manuals as a product component

during the life span of the product.

Pass all manuals to future users / owners

of the product.

Page 2

Record of Document Revisions:

Revision Remarks

11/2009 Beta launch version

12/2009 Minor formatting changes

Hardware Revision (HR)

Hardware Revision Firmware WorkBench Remarks

A 1.1.0 1.1.0 launch version

EnDat is a registered trademark of Dr. Johannes Heidenhain GmbH

EtherCAT is a registered trademark of EtherCAT Technology Group

HIPERFACE is a registered trademark of Max Stegmann GmbH

WINDOWS is a registered trademark of Microsoft Corporation

AKD is a registered trademark of Kollmorgen Corporation

Current patents:

US Patent 5,646,496 (used in control card R/D and 1 Vp-p feedback interface)

US Patent 5,162,798 (used in control card R/D)

US Patent 6,118,241 (used in control card simple dynamic braking)

Technical changes which improve the performance of the device may be made without prior notice!

Printed in the United States of America

This document is the intellectual property of Kollmorgen™. All rights reserved. No part of this work may be

reproduced in any form (by photocopying, microfilm or any other method) or stored, processed, copied or distributed by electronic means without the written permission of Kollmorgen™.

2 Kollmorgen | December 2009

Page 3

Table of Contents

1 General 5

1.1 About this Manual 6

1.2 Target Group 6

1.3 Warning Symbols 7

1.4 Abbreviations used 8

2 Safety 9

2.1 Safety Instructions 10

2.2 Use as directed 11

2.3 Prohibited use 11

3 Installation and Setup 12

AKD EtherCAT |

3.1 Safety Instructions 13

3.2 EtherCAT Onboard 14

3.2.1 LED functions 14

3.2.2 Connection technology 14

3.2.3 Network Connection Example 14

3.3 Guide to Setup 15

3.4 Setup via TwinCAT NC/PTP System Manager 15

3.4.1 Scan devices 15

3.4.2 Select the device 17

3.4.3 Scan for boxes 17

3.4.4 Add Slaves to NC tasks 18

3.4.5 Enable the network configuration 19

3.4.6 Enable the axis and move the axis 20

4 EtherCAT Profile 21

4.1 Slave Register 22

4.2 AL Event (Interrupt Event) and Interrupt Enable 23

4.2.1 Interrupt Enable Register (Address 0x0204:0x0205) 23

4.2.2 AL Event Request (Address 0x0220:0x0221) 24

4.3 Phase Run-Up 25

Kollmorgen | December 2009 3

Page 4

AKD EtherCAT |

4.4 CANopen over EtherCAT (CoE) Status Machine 27

4.5 Fixed PDO Mappings 30

4.6 Supported Cyclical Setpoint- and Actual Values 30

4.7 Supported Operation Modes 30

4.8 Adjusting EtherCAT Cycle Time 31

4.3.1 AL Control (Address 0x0120:0x0121) 25

4.3.2 AL Status (Address 0x0130:0x0131) 25

4.3.3 AL Status Code (Address 0x0134:0x0135) 26

4.3.4 EtherCAT communication phases 26

4.4.1 Status Description 27

4.4.2 Commands in the Control Word 28

4.4.3 Status Machine Bits (status word) 29

4.9 Maximum Cycle Times depending on operation mode 31

4.10 Synchronization 31

4.11 Latch Control Word and Latch Status Word 32

4.12 Mailbox Handling 33

4.12.1 Mailbox Output 34

4.12.2 Mailbox Input 35

4.12.3 Example: Mailbox Access 36

4.13 Fieldbus Parameters 37

5 Index 39

4 Kollmorgen | December 2009

Page 5

AKD EtherCAT | 1 General

1 General

1.1 About this Manual 6

1.2 Target Group 6

1.3 Warning Symbols 7

1.4 Abbreviations used 8

Kollmorgen | December 2009 5

Page 6

AKD EtherCAT | 1 General

1.1 About this Manual

This manual, AKD EtherCAT Communication, describes the installation, setup, range of functions, and soft-

ware protocol for the EtherCAT AKD product series. All AKD EtherCAT drives have built-in EtherCAT functionality; therefore an additional option card is not required.

A digital version of this manual (pdf format) is available on the CD-ROM included with your drive. Manual

updates can be downloaded from the Kollmorgen website.

Related documents for the AKD series include:

l AKD Quick Start (also provided in hard copy). This guide provides instructions for basic drive setup

and connection to a network.

l AKD Installation Manual (also provided in hard copy). This manual provides instructions for installation

and drive setup.

l AKD Parameter and Command Reference Guide. This guide provides documentation for the param-

eters and commands used to program the AKD.

l AKD Accessories Manual. This manual includes technical data and dimensional drawings of acces-

sories such as cables, brake resistors, and mains supplies.

l AKD CANopen Communication. This manual includes setup information for the CAN interface and

describes the CANopen profile.

1.2 Target Group

This manual addresses personnel with the following qualifications:

l Installation: only by electrically qualified personnel.

l Setup : only by qualified personnel with extensive knowledge of electrical engineering

and drive technology

l Programming:Software developers, project-planners

The qualified personnel must know and observe the following standards:

l ISO 12100, IEC 60364 and IEC 60664

l National accident prevention regulations

During operation there are deadly hazards, with the possibility of death, severe

injury or material damage. The operator must ensure that the safety instructions

in this manual are followed. The operator must ensure that all personnel responsible for working with the servo drive have read and understand the manual.

6 Kollmorgen | December 2009

Page 7

1.3 Warning Symbols

Symbol Indication

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Indicates situations which, if not avoided, could result in property

damage.

This is not a safety symbol.

This symbol indicates important notes.

Drawing symbols

Symbol Description Symbol Description

Signal ground Diode

AKD EtherCAT | 1 General

Chassis ground Relays

Protective earth Relays switch off

delayed

Resistor Normal open contact

Fuse Normal closed contact

Kollmorgen | December 2009 7

Page 8

AKD EtherCAT | 1 General

1.4 Abbreviations used

Abbreviation Meaning

AL Application Layer: the protocol that directly used by the process entities.

Cat Category – classification for cables that is also used in Ethernet.

DC Distributed Clocks Mechanism to synchronize EtherCAT slaves and master

DL Data Link(=Layer 2). EtherCAT uses Ethernet, which is standardized as IEEE 802.3.

FPGA Field Programmable Gate Array

FTP File Transfer Protocol

HW Hardware

ICMP Internet Control Message Protocol: Mechanisms for signaling IP errors.

IEC International Electrotechnical Commission: The international standards

IEEE Institute of Electrical and Electronics Engineers, Inc.

LLDP Lower Layer Discovery Protocol

MAC Media Access Control

MII Media Independent Interface: Standardized interface Ethernet controller <-> routing equipment.

MDI Media Dependant Interface: Use of connector Pins and Signaling.

MDI-X Media Dependant Interface (crossed): Use of connector Pins and Signaling with crossed lines.

OSI Open System Interconnect

OUI Organizationally Unique Identifier – the first 3 Bytes of an Ethernet-Address, that will be assign

to companies or organizations and can be used for protocoll identifiers as well (e.g. LLDP)

PDI Physical Device Interface: set of elements that allows access to ESC from the process side.

PDO Process Data Object

PDU Protocol Data Unit: Contains protocol information transferred from a protocol instance of trans-

parent data to a subordinate level

PHY Physical interface that converts data from the Ethernet controller to electric or optical signals.

PLL Phase Locked Loop

PTP Precision Time Protocol in accordance with IEEE 1588

RSTP Rapid Spanning Tree Protocol

RT Real-time, can be run in Ethernet controllers without special support.

RX Receive

RXPDO Receive PDO

SNMP Simple Network Management Protocol

SPI Serial Peripheral Interface

Src Addr Source Address: Source address of a message.

STP Shielded Twisted Pair

TCP Transmission Control Protocol

TX Transmit

TXPDO Transmit PDO

UDP User Datagram Protocol: Non-secure multicast/broadcast frame.

UTP Unshielded Twisted Pair

ZA ECAT Access mode EtherCAT

ZA Drive Acces mode Drive

8 Kollmorgen | December 2009

Page 9

AKD EtherCAT | 2 Safety

2 Safety

2.1 Safety Instructions 10

2.2 Use as directed 11

2.3 Prohibited use 11

Kollmorgen | December 2009 9

Page 10

AKD EtherCAT | 2 Safety

2.1 Safety Instructions

During operation there are deadly hazards, with the possibility of death, severe

injury or material damage. Do not open or touch the equipment during operation.

Keep all covers and cabinet doors closed during operation. Touching the equipment is allowed during installation and commissioning for properly qualified persons only.

l During operation, drives may have uncovered live components, depend-

ing on their level of enclosure protection.

l Control and power connections may be live, even though the motor is not

rotating.

l Drives may have hot surfaces during operation. Heat sink can reach tem-

peratures above 80°C.

Electronic equipment is basically not failure-proof. The user is responsible for

ensuring that, in the event of a failure of the servo amplifier, the drive is set to a

state that is safe for both machinery and personnel, for instance with the aid of a

mechanical brake.

Drives with servo amplifiers and EtherCAT expansion cards are remote-controlled machines. They can start to move at any time without previous warning.

Take appropriate measures to ensure that the operating and service personnel

is aware of this danger.

Implement appropriate protective measures to ensure that any unintended startup of the machines cannot result in dangerous situations for personnel or

machinery. Software limit-switches are not a substitute for the hardware limitswitches in the machine.

Install the drive as described in the Installation Manual. The wiring for the

analog setpoint input and the positioning interface, as shown in the wiring diagram in the Installation Manual, is not required. Never break any of the electrical

connections to the drive while it is live. This action can result in destruction of

the electronics

Do not connect the Ethernet line for the PC with the set up software to the EtherCAT interface X5/X6. The set up Ethernet cable must be connected to the service interface on X11

10 Kollmorgen | December 2009

Page 11

AKD EtherCAT | 2 Safety

2.2 Use as directed

Drives are components that are built into electrical plants or machines and can only be operated as integral

components of these plants or machines. The manufacturer of the machine used with a drive must generate a

hazard analysis for the machine and take appropriate measures to ensure that unforeseen movements cannot

cause personnel injury or property damage.

Please observe the chapters "Use as directed” and "Prohibited use" in the AKD Installation Manual.

The EtherCAT interface serves only for the connection of the AKD Drive to a master with EtherCAT connectivity.

2.3 Prohibited use

Other use than that described in chapter “Use as directed” is not intended and can lead to personnel injuries

and equipment damage. The drive may not be used with a machine that does not comply with appropriate

national directives or standards. The use of the drive in the following environments is also prohibited:

l potentially explosive areas

l environments with corrosive and/or electrically conductive acids, alkaline solutions, oils, vapors, dusts

l ships or offshore applications

The connectors X5 and X6 of the AKD EtherCAT drive may not be used for any ethernet protocol except EtherCAT (CoE, Can over EtherCAT).

Kollmorgen | December 2009 11

Page 12

AKD EtherCAT | 3 Installation and Setup

3 Installation and Setup

3.1 Safety Instructions 13

3.2 EtherCAT Onboard 14

3.3 Guide to Setup 15

3.4 Setup via TwinCAT NC/PTP System Manager 15

12 Kollmorgen | December 2009

Page 13

3.1 Safety Instructions

Never undo any electrical connections to the drive while it is live. There is a danger of

electrical arcing with damage to contacts and serious personal injury. Wait at least

seven minutes after disconnecting the drive from the main supply power before touching

potentially live sections of the equipment (e.g. contacts) or undoing any connections.

Capacitors can still have dangerous voltages present up to 7 minutes after switching off

the supply power. To be sure, measure the voltage in the DC Bus link and wait until it

has fallen below 40 V.

Control and power connections can still be live, even if the motor is not rotating.

Electronic equipment is basically not failure-proof. The user is responsible for ensuring

that, in the event of a failure of the servo amplifier, the drive is set to a state that is safe

for both machinery and personnel, for instance with the aid of a mechanical brake.

Drives with servo amplifiers and EtherCAT are remote-controlled machines. They can

start to move at any time without previous warning. Take appropriate measures to

ensure that the operating and service personnel is aware of this danger.

Implement appropriate protective measures to ensure that any unintended start-up of the

machines cannot result in dangerous situations for personnel or machinery. Software

limit-switches are not a substitute for the hardware limit-switches in the machine.

Install the drive as described in the Installation Manual. The wiring for the analog setpoint

input and the positioning interface, as shown in the wiring diagram in the Installation Man-

ual, is not required. Never break any of the electrical connections to the drive while it is

live. This action can result in destruction of the electronics.

The drive's status must be monitored by the PLC to acknowledge critical situations.

Wire the FAULT contact in series into the emergency stop circuit of the installation. The

emergency stop circuit must operate the supply contactor.

AKD EtherCAT | 3 Installation and Setup

It is permissible to use WorkBench to alter the settings of the drive. Any other alterations

will invalidate the warranty.

Because of the internal representation of the position-control parameters, the position

controller can only be operated if the final limit speed of the drive does not exceed:

rotatory

at sinusoidal² commutation: 7500 rpm

at trapezoidal commutation: 12000 rpm.

linear

at sinusoidal² commutation: 4 m/s

at trapezoidal commutation: 6.25 m/s

All the data on resolution, step size, positioning accuracy etc. refer to calculatory values.

Non-linearities in the mechanism (backlash, flexing, etc.) are not taken into account.If

the final limit speed of the motor must be altered, then all the parameters that were previously entered for position control and motion blocks must be adapted.

Kollmorgen | December 2009 13

Page 14

AKD EtherCAT | 3 Installation and Setup

3.2 EtherCAT Onboard

Connection to the EtherCAT Network via X5 (in port) and X6 (out port).

3.2.1 LED functions

The communication status is indicated by the built-in LEDs.

Connector LED# Name Function

X5 LED1 IN port Link ON = active

LED2 RUN ON = running

X6 LED3 OUT port Link ON = active

LED4 - -

OFF= not active

OFF = not running

OFF = not active

3.2.2 Connection technology

You can connect to the EtherCAT network using RJ-45 connectors.

3.2.3 Network Connection Example

14 Kollmorgen | December 2009

Page 15

AKD EtherCAT | 3 Installation and Setup

3.3 Guide to Setup

Only professional personnel with extensive knowledge of control and drive

technology are allowed to setup the drive.

Make sure that any unintended movement of the drive cannot endanger

machinery or personnel.

1. Check assembly/installation. Check that all the safety instructions in the product manual for the drive

and this manual have been observed and implemented. Check the setting for the station address and

baud rate.

2. Connect PC,start WorkBench. Use the setup software WorkBench to set the parameters for the drive.

3. Setup basic functions. Start up the basic functions of the drive and optimize the current, speed and

position controllers. This section of the setup is described in the in the online help of the setup software.

4. Save parameters. When the parameters have been optimized, save them in the drive.

3.4 Setup via TwinCAT NC/PTP System Manager

Before you set up the drive, make sure the following have been completed:

l The AKD is configured with WorkBench and the servomotor is able to move

l A correctly configured EtherCAT card is present in the master.

l TwinCAT software from Beckhoff (NC/PTP-Mode setup) is installed.Install first the TwinCAT System

Manager, restart your PC, then install the option package NC/PTP-Mode.

l The XML description of the Drive is available (the XML file on the CD-ROM or on the Kollmorgen web-

site).

l An AKD EtherCAT slave is connected to the EtherCAT master PC.

l The TwinCAT system manager resides in Config-Mode. The current mode of the system manager is

displayed of the bottom right side of the TwinCAT main-screen window.

Copy the XML description of the drive to the TwinCAT system (usually to the folder c:\TwinCAT\IO\EtherCAT) and restart the TwinCAT system since TwinCAT analyzes all device description files

during start-up.

The following example explains the automatic EtherCAT network setup. The network setup can also be done

manually; please refer to the TwinCAT manual for more details.

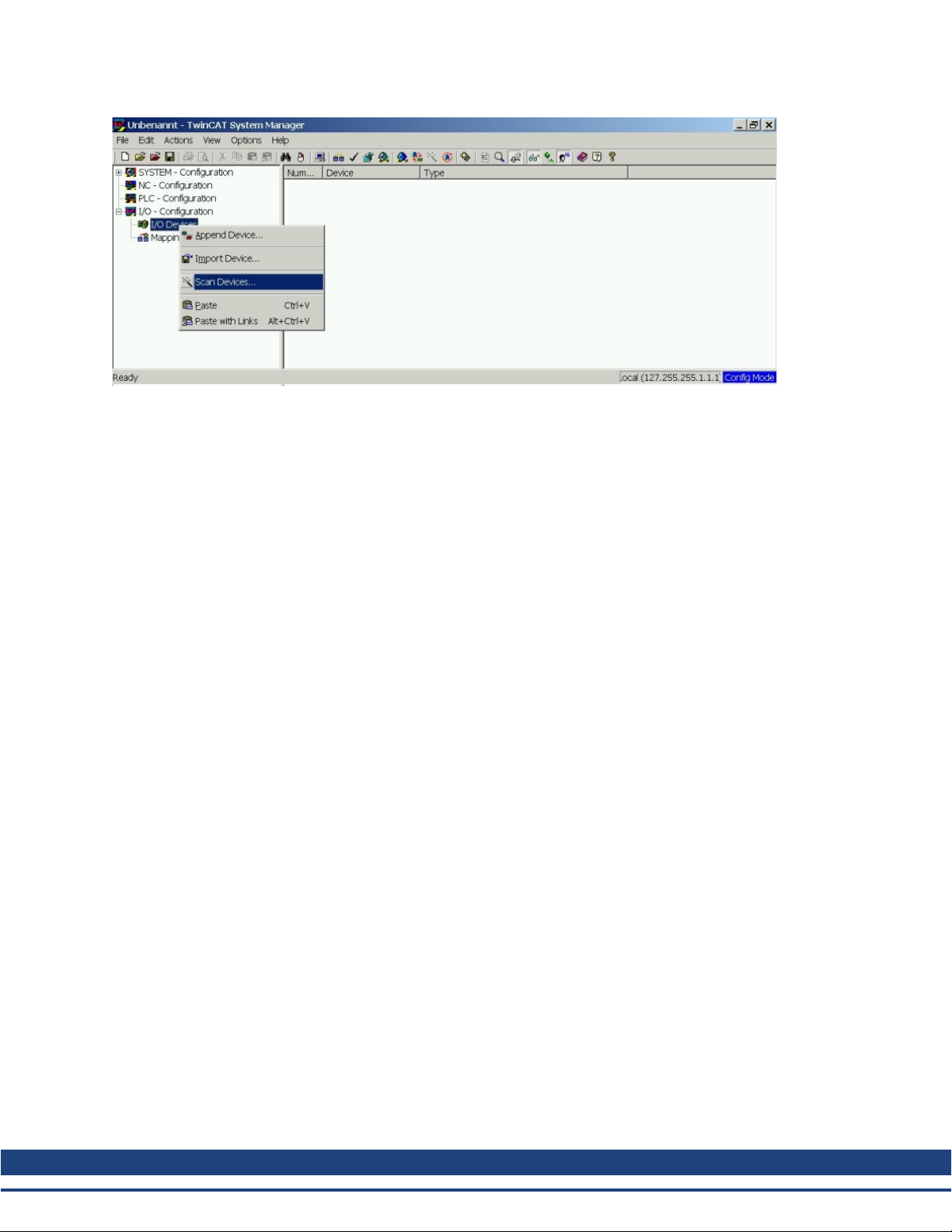

3.4.1 Scan devices

First ensure that the EtherCAT master is physically connected to the EtherCAT AKD Drive. Create a new

(empty) project. Right click I/O-Devices and scan for the devices. An example is included in the EtherCAT network card, which is plugged into the PC.

Kollmorgen | December 2009 15

Page 16

AKD EtherCAT | 3 Installation and Setup

A pop-up window informs you that not all devices can be detected by the TwinCAT software.

Click OK to continue.

16 Kollmorgen | December 2009

Page 17

AKD EtherCAT | 3 Installation and Setup

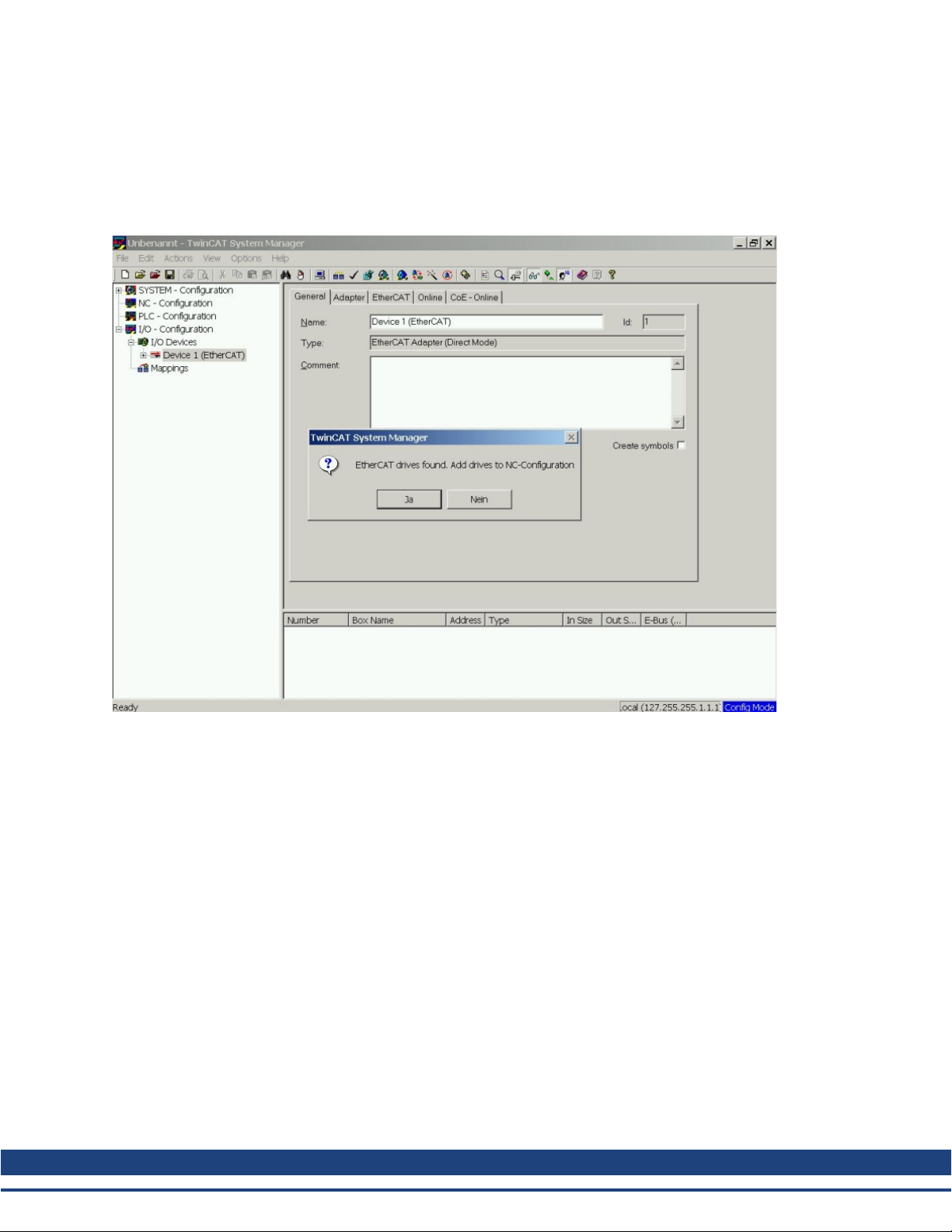

3.4.2 Select the device

TwinCAT must beableto findthe EtherCAT network card.An EtherCAT slave must beconnectedto the network

card; otherwise TwinCAT will find a real-timeEtherNET cardinsteadof theEtherCAT card. Press theOK button.

3.4.3 Scan for boxes

Click Yes to allow TwinCat to scan for boxes. A box is an alias for a slave device and is always used in Beckhoff software products.

Kollmorgen | December 2009 17

Page 18

AKD EtherCAT | 3 Installation and Setup

3.4.4 Add Slaves to NC tasks

TwinCAT should now have identified the AKD according to the Device Description file. TwinCAT next asks if

the slaves should be connected to NC tasks. Click Yes to continue. An NC task can, for example, contain a

PLC program, which can be programmed by the user.

18 Kollmorgen | December 2009

Page 19

AKD EtherCAT | 3 Installation and Setup

3.4.5 Enable the network configuration

Confirm that the AKD appears in the device tree. Next, enable the network configuration Press first the

button in order to generate the mappings, afterwards press the button in order to let TwinCAT check the

configuration and use finally the button in order to step into run-mode.

Confirm afterwards that TwinCAT is allowed to jump into run-mode.

Kollmorgen | December 2009 19

Page 20

AKD EtherCAT | 3 Installation and Setup

3.4.6 Enable the axis and move the axis

The Axis can be enabled by a mouse-click on the Set button within the Online window inside of each Axis, see

also the next picture.

Afterwards a pop-up window appears.

The following setting enables the drive and allows command values in both directions.

Afterwards the motor should move in positive or negative direction as soon as the clicks on the following yellow buttons within the Online window:

20 Kollmorgen | December 2009

Page 21

AKD EtherCAT | 4 EtherCAT Profile

4 EtherCAT Profile

4.1 Slave Register 22

4.2 AL Event (Interrupt Event) and Interrupt Enable 23

4.3 Phase Run-Up 25

4.4 CANopen over EtherCAT (CoE) Status Machine 27

4.5 Fixed PDO Mappings 30

4.6 Supported Cyclical Setpoint- and Actual Values 30

4.7 Supported Operation Modes 30

4.8 Adjusting EtherCAT Cycle Time 31

4.9 Maximum Cycle Times depending on operation mode 31

4.10 Synchronization 31

4.11 Latch Control Word and Latch Status Word 32

4.12 Mailbox Handling 33

4.13 Fieldbus Parameters 37

Kollmorgen | December 2009 21

Page 22

AKD EtherCAT | 4 EtherCAT Profile

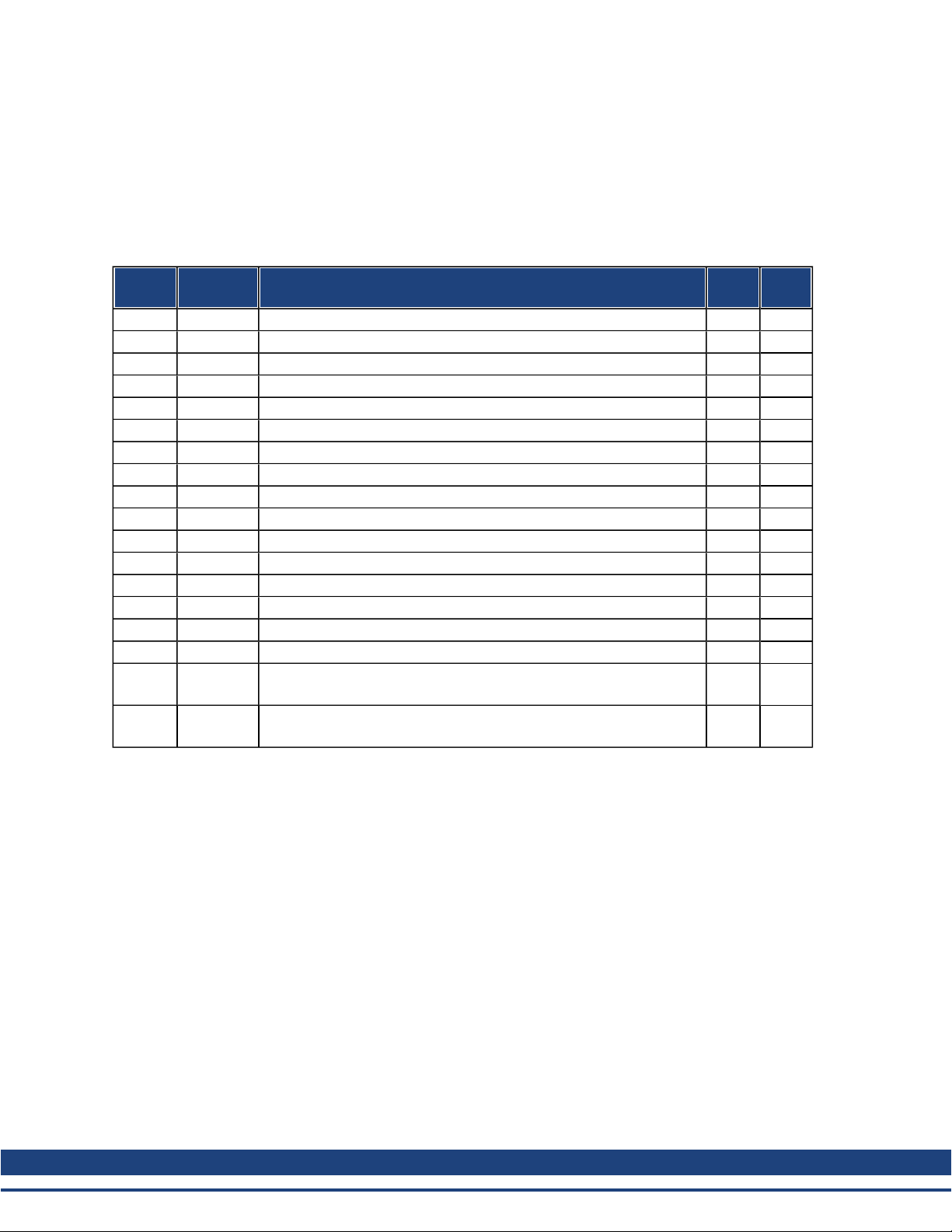

4.1 Slave Register

The table below gives the addresses of individual registers in the FPGA memory. The data is provided in littleendian format, with the ’least significant byte’ occupying the lowest address. A detailed description of all registers and FPGA memory locations is available in the “EtherCAT Slave Controller” description of the EtherCAT user organization (www.EtherCAT.org).

Length

Address

0x0120 2 AL Control R/W R/O

0x0130 2 AL Status R/O R/W

0x0134 2 AL Status Code R/O R/W

0x0204 2 Interrupt Enable Register R/O R/W

0x0220 2 AL Event (IRQ Event) R/W R/O

0x0800 8 Sync Manager 0 (Mail Out Control Register) R/W R/O

0x0808 8 Sync Manager 1 (Mail In Control Register) R/W R/O

0x0810 8 Sync Manager 2 (Process data Output Control Register) R/W R/O

0x0818 8 Sync Manager 3 (Process data Input Control Register) R/W R/O

0x0820 8 Sync Manager 4 R/W R/O

0x0828 8 Sync Manager 5 R/W R/O

0x0830 8 Sync Manager 6 R/W R/O

0x0838 8 Sync Manager 7 R/W R/O

0x0840 8 Sync Manager 8 R/W R/O

0x1100 Max. 64 ProOut Buffer (Process data Output, setpoints ECAT) R/W R/O

0x1140 Max. 64 ProIn (Process data Input, act. values ECAT) R/O R/W

0x1800 512 Mail Out Buffer (Object Channel Buffer ECAT,

0x1C00 512 Mail In Buffer (Object Channel Buffer Drive,

(Byte) Description

byte-length is specified in the device description file)

byte-length is specified in the device description file)

ZA

ECAT*ZADrive*

R/W R/O

R/O R/W

* ZA ECAT = Access mode EtherCAT

* ZA Drive = Access mode Drive

22 Kollmorgen | December 2009

Page 23

AKD EtherCAT | 4 EtherCAT Profile

4.2 AL Event (Interrupt Event) and Interrupt Enable

Communication between the drive and the EtherCAT FPGA can be interrupt-driven. The interrupt enable register and the AL event register are responsible for the EtherCAT interface interrupt functionality.

There are two events which lead also to a HW interrupt within the Drive, the EEPROM emulation event and

the SyncManager 2 event. The actual values of the Drive (SyncManager 3 data) are written without any AL

event request during each HW IRQ, e.g. triggered by a SyncManager 2 event. The Mailbox exchange

between the master and the AKD is completely handled by polling the AL event register within the background

task of the Drive.

The drive activates individual EtherCAT interface events when the corresponding bit of the interrupt enable

register is set to 1. When it is set to 0, the hardware interrupts for the specific events are deactivated.

4.2.1 Interrupt Enable Register (Address 0x0204:0x0205)

Parameter Address BitZADriveZAECAT Description

AL Control Event 0x204 0 R/W R/O Activation of AL control event for phase run-up

- 0x204 1 R/W R/O Reserved

Sync0 DC Distributed

Clock

Sync1 DC Distributed

Clock

SyncManager activation

register change

EEPROM emulation

event

- 0x204 3 to 7 R/W R/O Reserved

Sync Manager 0 Event

(Mail Out Event)

Sync Manager 1 Event

(Mail In Event)

Sync Manager 2 Event

(Pro Out Event)

Sync Manager 3 Event

(Pro In Event)

- 0x205 4 to 7 R/W R/O Reserved

0x204 2 R/W R/O Activation of distributed clock (DC) sync 0 inter-

rupts for entire communication

0x204 3 R/W R/O Activation of distributed clock (DC) sync 1 inter-

rupts for entire communication

0x204 4 R/W R/O Activation of ‘SyncManager activation register

change’ IRQ.

0x204 5 R/W R/O Activation of the EEPROM emulation interrupts.

0x205 0 R/W R/O Activation of output event mailbox (SDO, Sync

Manager 0) for object channel.

0x205 1 R/W R/O Activation of input event mailbox (SDO, Sync Man-

ager 1) for object channel.

0x205 2 R/W R/O Activation of output event process data (PDO,

card's cyclical setpoints)

0x205 3 R/W R/O Activation of input event process data (PDO,

drive's cyclical actual values)

Kollmorgen | December 2009 23

Page 24

AKD EtherCAT | 4 EtherCAT Profile

4.2.2 AL Event Request (Address 0x0220:0x0221)

When the relevant bit of the AL event request register is set to 1, the EtherCAT interface tells the drive which

event it should process by the AKD.

Parameter Address BitZADriveZAECAT Description

AL Control Event 0x220 0 R/O R/W Processing of AL control event for phase run-

Sync0 Distributed

0x220 2 R/O R/W Processing of a distributed clock (DC) event

Clock (DC) Event

Sync1 Distributed

0x220 3 R/O R/W Processing of a distributed clock (DC) event

Clock (DC) Event

SyncManager acti-

0x220 4 R/O R/W The content of the SyncManager activation

vation register change

EEPROM emulation

0x220 5 R/O R/W Processing of an EEPROM emulation event in

event

- 0x220 6 to 7 R/O R/W Reserved

Sync Manager 0

0x221 0 R/O R/W Mailbox request (SDO, Sync Manager 0) for

Event

Sync Manager 1

0x221 1 R/O R/W Mailbox response (SDO, Sync Manager 1) for

Event

Sync Manager 2

0x201 2 R/O R/W Process data output (PDO, card's cyclical set-

Event

Sync Manager 3

0x201 3 R/O R/W Process data input (PDO, drive's cyclical

Event

Sync Manager 4 –

Sync Manager 7

0x221 4 to 7 R/O R/W Reserved

Event

Sync Manager 8 –

Sync Manager 15

0x222 0…7 R/O R/W Reserved

Event

up

register has been changed.

order to identify the AKD within the network.

object channel.

object channel.

points)

actual values)

24 Kollmorgen | December 2009

Page 25

AKD EtherCAT | 4 EtherCAT Profile

4.3 Phase Run-Up

The AL control, AL status and AL status code registers are responsible for communication phase run-up (also

referred to as EtherCAT status change), for current status display and for any fault messages. The drive

responds to every EtherCAT interface transition request made by the AL control register via the AL Status and

AL Status Code registers. Any fault messages are displayed in the AL status code register.

A status change within the AL control register is polled within the AKD, which means that an AL control event

does not lead to a HW interrupt within the Drive.

4.3.1 AL Control (Address 0x0120:0x0121)

Parameter Address BitZADriveZAECAT Description

Status 0x120 3 to 0 R/O W/O 0x01: Init Request

0x02: PreOperational Request

0x03: Bootstrap Mode Request

0x04: Safe Operational Request

0x08: Operational Request

Acknowledgement 0x120 4 R/O W/O 0x00: No fault acknowledgement

0x01: Fault acknowledgement (positive edge)

Reserved 0x120 7 to 5 R/O W/O Applic. specific 0x120 15 to 8 R/O W/O -

4.3.2 AL Status (Address 0x0130:0x0131)

Parameter Address BitZADriveZAECAT Description

Status 0x130 3 to 0 W/O R/O 0x01: Init

0x02: PreOperational

0x03: Bootstrap Mode

0x04: Safe Operational

0x08: Operational

Status change 0x130 4 W/O R/O 0x00: Acknowledgement

0x01: Error, e.g. forbidden transition

Reserved 0x130 7 to 5 W/O R/O Applic. specific 0x130 15 to 8 W/O R/O -

Kollmorgen | December 2009 25

Page 26

AKD EtherCAT | 4 EtherCAT Profile

4.3.3 AL Status Code (Address 0x0134:0x0135)

Parameter Address Bit ZA Drive ZA ECAT Description

Status 0x134 7 to 0 W/O R/O See table below

Status 0x135 7 to 0 W/O R/O See table below

Code Description

0x0000 No error All Current Status

0x0011 Invalid requested state change I -> S, I -> O, P -> O,

0x0017 Invalid sync manager configuration I -> P, P -> S Current Status + E

No other codes are supported.

4.3.4 EtherCAT communication phases

Current Status

(Status change) Resulting Status

Current Status + E

O -> B, S -> B, P -> B

INIT:

Initialization, no communication. EEPROM emulation will be activated.

PRE-OP:

Mailbox active, slave parameterization and startup parameters

SAVE-OP:

Cyclical actual values are transferred and the drive tries to synchronize.

OPERATIONAL:

Cyclical setpoints are processed, torque enable can be activated

and the drive must be synchronized.

Individual communication transitions

AL Control

Transition

(Bit 3 to 0) Description

(IB) 0x03 (BI) - (IP) 0x02 AKD reads the SyncManager 0 & 1 configuration and verifies the value of the start-

address and the length. The AKD prepares itself for handling SyncManager 0 events.

(PI) 0x01 -

(PS) 0x04 AKD reads the SyncManager 2 & 3 configuration and verifies the value of the start-

address and the length.

(SP) 0x02 -

(SI) 0x01 -

(SO) 0x08 The SnycManager 2 hardware interrupt will be enabled by the Drive.

(OS) 0x04 Deactivation of SyncManager 2 hardware interrupt.

(OP) 0x02 Deactivation of SyncManager 2 hardware interrupt..

(OI) 0x01 Deactivation of SyncManager 2 hardware interrupt.

26 Kollmorgen | December 2009

Page 27

AKD EtherCAT | 4 EtherCAT Profile

4.4 CANopen over EtherCAT (CoE) Status Machine

The status machine for the control and status words corresponds to the CANopen status machine in accordance with DS402. CANopen control and status words are captured in every instance of fixed PDO mapping

(see chapter entitled ‘Fixed PDO Mapping‘, page ).

4.4.1 Status Description

Status Description

Not Ready to SwitchOnThe drive is not ready to switch on; the controller has not indicated readiness for

service. The drive is still in the boot phase or in fault status.

Switch On Disable In 'Switch On Disable' status, the amplifier cannot be enabled via the EtherCAT

interface, because (for example) there is no connection to a power source.

Ready to Switch On In 'Ready to Switch On' status, the drive can be enabled via the control word.

Switched On In 'Switched On' status, the amplifier is enabled, but the setpoints of the EtherCAT-

interface are not yet transferred. The amplifier is idle, and a positive edge in bit 3 of

the control word activates setpoint transfer (transition to 'Operation Enable' status).

Operation Enable In this status, the drive is enabled and setpoints are transferred from the EtherCAT

interface.

Quick Stop Active The drive follows a quick stop ramp.

Fault Reaction Active The drive responds to a fault with an emergency stop ramp.

Fault A fault is pending, the drive is stopped and disabled.

Kollmorgen | December 2009 27

Page 28

AKD EtherCAT | 4 EtherCAT Profile

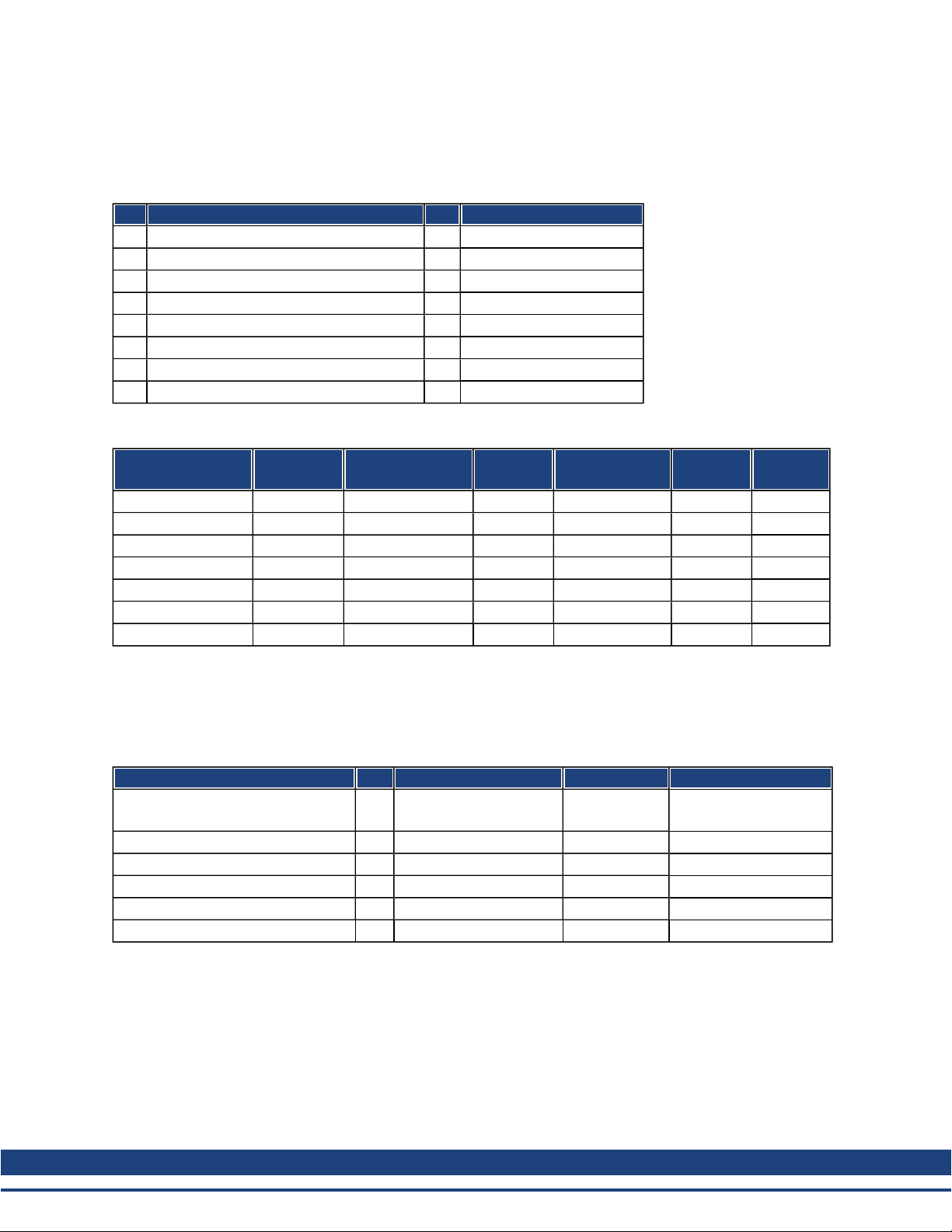

4.4.2 Commands in the Control Word

Bit assignment in the control word

Bit Name Bit Name

0 Switch on 8 Pause/halt

1 Disable Voltage 9 reserved

2 Quick Stop 10 reserved

3 Enable Operation 11 reserved

4 Operation mode specific 12 reserved

5 Operation mode specific 13 Manufacturer-specific

6 Operation mode specific 14 Manufacturer-specific

7 Reset Fault (only effective for faults) 15 Manufacturer-specific

Commands in the control word

Command

Bit 7

Fault Reset

Bit 3

Enable Operation

Bit 2

Quick Stop

Bit 1

Disable Voltage

Bit 0

Switch on Transitions

Shutdown X X 1 1 0 2, 6, 8

Switch on X X 1 1 1 3

Disable Voltage X X X 0 X 7, 9, 10, 12

Quick Stop X X 0 1 X 7, 10, 11

Disable Operation X 0 1 1 1 5

Enable Operation X 1 1 1 1 4, 16

Fault Reset 1 X X X X 15

Bits labeled X are irrelevant. 0 and 1 indicate the status of individual bits.

Mode-dependent bits in the control word

The following table shows the mode-dependent bits in the control word. Only manufacturer-specific modes are

supported at present. The individual modes are set by Object 6060h Modes of operation.

Operation mode No. Bit 4 Bit 5 Bit 6

Profile Position Mode (pp) 01h new_set_point change_set_

absolute/relative

immediately

Profile Velocity Mode (pv) 03h reserved reserved reserved

Profile Torque Mode (tq) 04h reserved reserved reserved

Homing Mode (hm) 06h homing_operation_start reserved reserved

Interpolated Position Mode (ip) 07h reserved reserved

Cyclic synchronous position mode 08h reserved reserved reserved

Description of the remaining bits in the control word

Bit 8: (Pause) If Bit 8 is set, then the drive halts (pauses) in all modes. The setpoints (speed for homing or jog-

ging, motion task number, setpoints for digital mode) for the individual modes are retained.

Bit 9,10: These bits are reserved for the drive profile (DS402).

Bit 13, 14, 15: These bits are manufacturer-specific, and reserved at present.

28 Kollmorgen | December 2009

Page 29

4.4.3 Status Machine Bits (status word)

Bit assignment in the status word

Bit Name Bit Name

0 Ready to switch on 8 Manufacturer-specific (reserved)

1 Switched on 9 Remote (always 1)

2 Operation enable 10 Target reached

3 Fault 11 Internal limit active

4 Voltage enabled 12 Operation mode specific (reserved)

5 Quick stop 13 Operation mode specific (reserved)

6 Switch on disabled 14 Manufacturer-specific (reserved)

7 Warning 15 Manufacturer-specific (reserved)

States of the status machine

AKD EtherCAT | 4 EtherCAT Profile

State

Bit 6

switch on

disable

Bit 5

quick

stop

Bit 3

fault

Bit 2

operation

enable

Bit 1

switched

on

Bit 0

ready to

switch on

Not ready to switch on 0 X 0 0 0 0

Switch on disabled 1 X 0 0 0 0

Ready to switch on 0 1 0 0 0 1

Switched on 0 1 0 0 1 1

Operation enabled 0 1 0 1 1 1

Fault 0 X 1 0 0 0

Fault reaction active 0 X 1 1 1 1

Quick stop active 0 0 0 1 1 1

Bits labeled X are irrelevant. 0 and 1 indicate the status of individual bits.

Description of the remaining bits in the status word

Bit 4: voltage_enabled The DC-link voltage is present if this bit is set.

Bit 7: warning There are several possible reasons for Bit 7 being set and this warning being produced. The rea-

son for this warning can be revealed by using the Object 20subindex manufacturer warnings.

Bit 9:remoteis always set to1, i.e.thedrivecan always communicate andbe influencedvia theRS232-interface.

Bit 10: target_reached This is set when the drive has reached the target position.

Bit 11: internal_limit_active This bit specifies that a movement was or is limited. In different modes, different

warnings cause the bit to be set.

Kollmorgen | December 2009 29

Page 30

AKD EtherCAT | 4 EtherCAT Profile

4.5 Fixed PDO Mappings

Various ready-to-use mappings can be selected for cyclic data exchange via SDO’s of the object 0x1C12 and

0x1C13. Using object 0x1C12 subindex 1 (Sync Manager 2 assignment), a fixed mapping for the cyclic command values can be set with the values 0x1701 … 0x1702. Using object 0x1C13 subindex 1 (Sync Manager 3

assignment), a fixed mapping for the cyclic actual values can be set via the data 0x1B01 … 0x1B02.

The following sequence describes how to select the fixed command value mapping 0x1701 via SDO’s:

1. SDO write access to object 0x1C12Sub0 Data:0x00

2. SDO write access to object 0x1C12Sub1 Data:0x1701

3. SDO write access to object 0x1C12Sub0 Data:0x01

The following fixed mappings are supported:

Position interface:

0x1701: Position command value (4 bytes), Control word (2 bytes), total (6 bytes)

0x1B01: Position actual value (4 bytes), Status word (2 bytes), total (6 bytes)

Velocity interface:

0x1702: Velocity command value (4 bytes), Control word (2 bytes), total (6 bytes)

0x1B02: Position actual value (4 bytes), Status word (2 bytes), total (6 bytes)

4.6 Supported Cyclical Setpoint- and Actual Values

Supported cyclical setpoint values

Name CANopen object number Data type Description

Position command value 0x60C1 sub 1 INT32 interpolation data record in IP-mode

Velocity command value 0x60FF sub 0 INT32

CANopen control-word 0x6040 Sub 0 UINT16 CANopen control word.

Supported cyclical actual values

Name CANopen object number Data type Description

Position actual value 0x6063 sub 0 INT32

Velocity actual value 0x606c sub 0 INT32

CANopen status-word 0x6041 Sub 0 UINT16 CANopen status word.

4.7 Supported Operation Modes

CANopen mode of operation AKD mode of operation Description

Profile velocity DRV.OPMODE 2

DRC.CMDSOURCE 1

Interpolated position DRV.OPMODE 2

DRV.CMDSOURCE 1

0x6060Sub0 Data: 3

In this mode of operation the EtherCAT master

sends cyclic velocity command values to the AKD.

0x6060Sub0 Data: 7

In this mode of operation the EtherCAT master

sends cyclic position command values to the AKD.

These command values are interpolated by the AKD

according to the fieldbus sample rate.

30 Kollmorgen | December 2009

Page 31

AKD EtherCAT | 4 EtherCAT Profile

4.8 Adjusting EtherCAT Cycle Time

The cycle time to be used in the drive for the cyclical setpoints and actual values can either be stored in the

FBUS.SAMPLEPERIOD parameter in the amplifier or configured in the startup phase.

This takes place via SDO mailbox access (see chapter) to CANopen objects 60C2 subindex 1 and 2.

Subindex 2, known as the interpolation time index, defines the power of ten of the time value (e.g. -3 means

10-3 or milliseconds) while subindex 1, known as interpolation time units, gives the number of units (e.g. 4

means 4 units).

If you wish to run a 2 ms cycle, this can be achieved by means of various combinations. For example,

Index = -3, Units = 2

or

Index = -4, Units = 20 etc.

The FBUS.SAMPLEPERIOD parameter is counted in multiples of 62.5us microseconds within the device.

This means, for example that 2 ms equates to FBUS.SAMPLEPERIOD value of 32.

4.9 Maximum Cycle Times depending on operation mode

The minimum cycle time for the drive is largely dependent on the drive configuration (second actual position

value encoder latch functionality enabled and so on)

Interface Cycle time AKD

Position ≥ 0.25 ms (≥ 250 µs)

Velocity ≥ 0.25 ms (≥ 250 µs)

Torque ≥ 0.25 ms (≥ 250 µs)

4.10 Synchronization

On all drives, the internal PLL is theoretically able to even out an average deviation of up to 4800 ppm in the

cycle time provided by the master. The Drive checks once per fieldbus cycle a counter within the Drive internal FPGA, which is cleared by a Sync0 (Distributed clock) event. Depending of the counter value, the Drive

extends or decrease the 62.5[µs] MTS signal within the Drive by a maximum of 300[ns].

The theoretical maximum allowed deviation can be calculated by using the following formula:

The synchronization functionality within the Drive can be enabled via setting bit 0 of the FBUS.PARAM02

parameter to high. Therefore FBUS.PARAM02 must be set to the value of 1. Furthermore the distributed clock

functionality must be enabled by the EtherCAT master in order to activate cyclic Sync0 events.

Kollmorgen | December 2009 31

Page 32

AKD EtherCAT | 4 EtherCAT Profile

4.11 Latch Control Word and Latch Status Word

Latch Control word (2 Byte)

Bit Value (bin) Value (hex) Description

0 00000000 00000001 xx01 Enable extern latch 1 (positive rise)

1 00000000 00000010 xx02 Enable extern latch 1 (negative rise)

2 00000000 00000100 xx04 Enable extern latch 2 (positive rise)

3 00000000 00001000 xx08 Enable extern latch 2 (negative rise)

4

5-7 Reserve

8-12 00000001 00000000 01xx Read external latch 1 (positive rise)

00000010 00000000 02xx Read external latch 1 (negative rise)

00000011 00000000 03xx Read external latch 2 (positive rise)

00000100 00000000 04xx Read external latch 2 (negative rise)

13-15 Reserve

Latch Status word (2 Byte)

Bit Value (bin) Value (hex) Description

0 00000000 00000001 xx01 External latch 1 valid (positive rise)

1 00000000 00000010 xx02 External latch 1 valid (negative rise)

2 00000000 00000100 xx04 External latch 2 valid (positive rise)

3 00000000 00001000 xx08 External latch 2 valid (negative rise)

4

5-7 Reserve

8-11 00000001 00000000 X1xx Acknowledge value external latch 1 (positive rise)

00000010 00000000 X2xx Acknowledge value external latch 1 (negative rise)

00000011 00000000 X3xx Acknowledge value external latch 2 (positive rise)

00000100 00000000 X4xx Acknowledge value external latch 2 (negative rise)

12-15 00010000 00000000 1xxx Zustand Digital Input 4

00100000 00000000 2xxx Zustand Digital Input 3

01000000 00000000 4xxx Zustand Digital Input 2

10000000 00000000 8xxx Zustand Digital Input 1

32 Kollmorgen | December 2009

Page 33

AKD EtherCAT | 4 EtherCAT Profile

4.12 Mailbox Handling

With EtherCAT, acyclical data traffic (object channel or SDO channel) is called mailbox. This system is

based around the master:

Mailbox Output:

The master (EtherCAT controller) sends data to the slave (drive). This is essentially a (read/write) request

from the master. Mailbox output operates via Sync Manager 0.

Mailbox Input:

The slave (drive) sends data to the master (EtherCAT controller). The master reads the slave's response. Mailbox input operates via Sync Manager 1.

Timing diagram

The timing diagram illustrates the mailbox access process:

1. The EtherCAT master writes the mailbox request to the mail-out buffer.

2. On the next interrupt, the EtherCAT interface activates a Sync Manager 0 event (mailbox output event)

in the AL event register.

3. The drive reads 16 bytes from the mail-out buffer and copies them to the internal mailbox output array.

4. The drive identifies new data in the internal mailbox output array and performs an SDO access to the

object requested by the EtherCAT interface. The response from the drive is written to an internal mailbox input array.

5. The drive deletes all data in the internal mailbox output array so that a new mailbox access attempt can

be made.

6. The drive copies the response telegram from the internal mailbox input array to the mail-in buffer of the

EtherCAT interface.

Kollmorgen | December 2009 33

Page 34

AKD EtherCAT | 4 EtherCAT Profile

4.12.1 Mailbox Output

An interrupt by the EtherCAT-interface with a Sync Manager 0 - Event starts a Mailbox Output Process. A 1 in

the Mail Out Event-Bit of the AL Event register signalizes the drive, that the EtherCAT-interface wants to send

a Mailbox message and that it has already stored the required data in the Mail Out Buffer. Now 16 Byte data

are read by the drive with the IRQ process. The bytes are defined as follows

Address 0x1800 Address 0x180F

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

CAN over EtherCAT specific data

(CoE Header)

Byte 0 Length of the data (Low Byte)

Byte 1 Length of the data (High Byte)

Byte 2 Address (Low Byte)

Byte 3 Address (High Byte)

Byte 4 Bit 0 to 5: Channel

Bit 6 to 7: Priority

Byte 5 Bit 0 to 3: Type 1 = Reserved: ADS over EtherCAT

Bit 4 to 7: Reserved

Byte 6 PDO Number (with PDO transmissions only, Bit 0 = LSB of the PDO number, see Byte 7 for MSB)

Byte 7 Bit 0: MSB of the PDO number, see Byte 6

Bit 1 to 3: Reserved

Bit 4 to 7: CoE specific type 0: Reserved

Byte 8 Control-Byte in the CAN telegram:

write access: 0x23=4Byte, 0x27=3Byte, 0x2B=2Byte, 0x2F=1Byte

read access: 0x40

Byte 9 Low Byte of the CAN object number (Index)

Byte 10 High Byte of the CAN object number (Index)

Byte 11 Subindex according to CANopen Specification for the drive

Byte 12 Data with a write access (Low Byte)

Byte 13 Data with a write access

Byte 14 Data with a write access

Byte 15 Data with a write access (High Byte)

CAN specific data

(standard CAN SDO)

2 = Reserved: Ethernet over EtherCAT

3 = Can over EtherCAT…)

1: Emergency message

2: SDO request

3: SDO answer

4: TXPDO

5: RxPDO

6: Remote transmission request of a TxPDO

7: Remote transmission request of a RxPDO

8…15: reserved

The drive answers every telegram with an answer in the Mailbox Input buffer.

34 Kollmorgen | December 2009

Page 35

AKD EtherCAT | 4 EtherCAT Profile

4.12.2 Mailbox Input

The drive answers every CoE telegram with a 16 byte answer telegram in the Mailbox Input buffer. The bytes

are defined as follows:

Address 0x1C00 Address 0x1C0F

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

CAN over EtherCAT specific data

(CoE Header)

CAN specific data

(standard CAN SDO)

Byte 0 Length of the data (Low Byte)

Byte 1 Length of the data (High Byte)

Byte 2 Address (Low Byte)

Byte 3 Address (High Byte)

Byte 4 Bit 0 to 5: Channel

Bit 6 to 7: Priority

Byte 5 Bit 0 to 3: Type 1 = Reserved: ADS over EtherCAT

2 = Reserved: Ethernet over EtherCAT

3 = Can over EtherCAT…)

Bit 4 to 7: Reserved

Byte 6 PDO Number (with PDO transmissions only, Bit 0 = LSB of the PDO number, see Byte 7 for MSB)

Byte 7 Bit 0: MSB of the PDO number, see Byte 6

Bit 1 to 3: Reserved

Bit 4 to 7: CoE specific type 0: Reserved

1: Emergency message

2: SDO request

3: SDO answer

4: TXPDO

5: RxPDO

6: Remote transmission request of a TxPDO

7: Remote transmission request of a RxPDO

8…15: reserved

Byte 8 Control-Byte in the CAN telegram:

write access OK: 0x60

read access OK + length of answer: 0x43 (4 Byte), 0x47 (3 Byte), 0x4B (2Byte), 0x4F (1Byte)

error with read- or write access: 0x80

Byte 9 Low Byte of the CAN object number (Index)

Byte 10 High Byte of the CAN object number (Index)

Byte 11 Subindex according to CANopen Specification for Kollmorgen drive

Byte 12 Data (Low Byte)

Byte 13 Data error code Fehlercode according to CANopen Specification in

case of an error

Byte 14 Data data value of the object in case of successfull read access

Byte 15 Data (High Byte)

Kollmorgen | December 2009 35

Page 36

AKD EtherCAT | 4 EtherCAT Profile

4.12.3 Example: Mailbox Access

In the example below, PDOs 0x1704 are mapped (see Chapter # “Fixed PDO Mappings”):

The master sends this mailbox output message:

Byte 0 0x0A The next 10 Bytes contain data (Byte 2 to Byte 11)

Byte 1 0x00 The next 10 Bytes contain data (Byte 2 to Byte 11)

Byte 2 0x00 Address 0

Byte 3 0x00 Address 0

Byte 4 0x00 Channel 0 and Priority 0

Byte 5 0x03 CoE Object

Byte 6 0x00 PDO Number 0

Byte 7 0x20 PDO Number 0 and SDO-Request

Byte 8 0x2B 2 Byte write access

Byte 9 0x12 SDO-Object 0x1C12

Byte 10 0x1C SDO-Object 0x1C12

Byte 11 0x01 Subindex 1

Byte 12 0x04 Data value 0x00001704

Byte 13 0x17 Data value 0x00001704

Byte 14 0x00 Data value 0x00001704

Byte 15 0x00 Data value 0x00001704

The drive returns the following message:

Byte 0 0x0E The next 14 Bytes contain data (Byte 2 to Byte 15)

Byte 1 0x00 The next 14 Bytes contain data (Byte 2 to Byte 15)

Byte 2 0x00 Address 0

Byte 3 0x00 Address 0

Byte 4 0x00 Channel 0 and Priority 0

Byte 5 0x03 CoE Object

Byte 6 0x00 PDO Number 0

Byte 7 0x20 PDO Number 0 and SDO-Answer

Byte 8 0x60 Successful write access

Byte 9 0x12 SDO-Object 0x1C12

Byte 10 0x1C SDO-Object 0x1C12

Byte 11 0x01 Subindex 1

Byte 12 0x00 Data value 0x00000000

Byte 13 0x00 Data value 0x00000000

Byte 14 0x00 Data value 0x00000000

Byte 15 0x00 Data value 0x00000000

36 Kollmorgen | December 2009

Page 37

AKD EtherCAT | 4 EtherCAT Profile

4.13 Fieldbus Parameters

The AKD Drive holds several fieldbus specific general purpose parameter. Some of them contain the following

EtherCAT relevant data:

FBUS.PARAM02: This parameter activates the synchronization feature of the AKD. The DC feature must be

activated in order to allow the AKD to get synchronized with the master. A value of 1 enables the Drive internal PLL functionality, a value of 0 deactivates this feature.

FBUS.PARAM03: This parameter contains the Configured Station Alias address of the AKD. An EEPROM

emulation write access to the Configured Station Alias address forces the AKD to store the Drive parameters

automatically via a DRV.NVSAVE command.

Kollmorgen | December 2009 37

Page 38

This page intentionally left blank.

38 Kollmorgen | December 2009

Page 39

5 Index

A

Abbreviations 8

AL Event 23

C

CANopen over EtherCAT 27

E

EtherCAT Proflie 21

I

Interrupt Event 23

AKD EtherCAT | 5 Index

P

Phase run-up 25

Prohibited Use 11

S

Safety Instructions

Electrical Installation 13

General 10

Slave Register 22

Symbols used 7

T

Target group 6

TwinCAT 15

U

Use as directed 11

Kollmorgen | December 2009 39

Page 40

This page intentionally left blank.

40 Kollmorgen | December 2009

Page 41

AKD EtherCAT |

This page intentionally left blank

Kollmorgen | December 2009 41

Page 42

AKD EtherCAT |

Sales and Service

We are committed to quality customer service. Inorder to serve in the most effective way, please contact

yourlocal sales representative for assistance.

If you are unaware of your local sales representative, pleasecontact us.

Europe

Kollmorgen Customer Support Europe

Internet www.kollmorgen.com

E-Mail technik@kollmorgen.com

Tel.: +49(0)203 - 99 79 - 0

Fax: +49(0)203 - 99 79 - 155

North America

Kollmorgen Customer Support North America

Internet www.kollmorgen.com

E-Mail support@kollmorgen.com

Tel.: +1 - 540 - 633 - 3545

Fax: +1 - 540 - 639 - 4162

Kollmorgen | December 2009 42

Loading...

Loading...