Kollmorgen AKD2G-S, AKD2G, AKD2G-S-7V03, AKD2G-S-7V12, AKD2G-S-6V03 Installation Manual

...Page 1

AKD®2G-Sxx with Functional Safety Option 1

STO - SIL2

Installation Manual

Manual Edition: -, Beta, December 2018

Safety Edition: S101, December2018

Valid for AKD®2G-S HardwareRevision A

Part Number907-200003-00

Original Document

Forsafe and proper use, follow

these instructions.

Keepthem for future reference.

Beta Drives: Approvals (CE, Functional Safety, UL) arepending.

Page 2

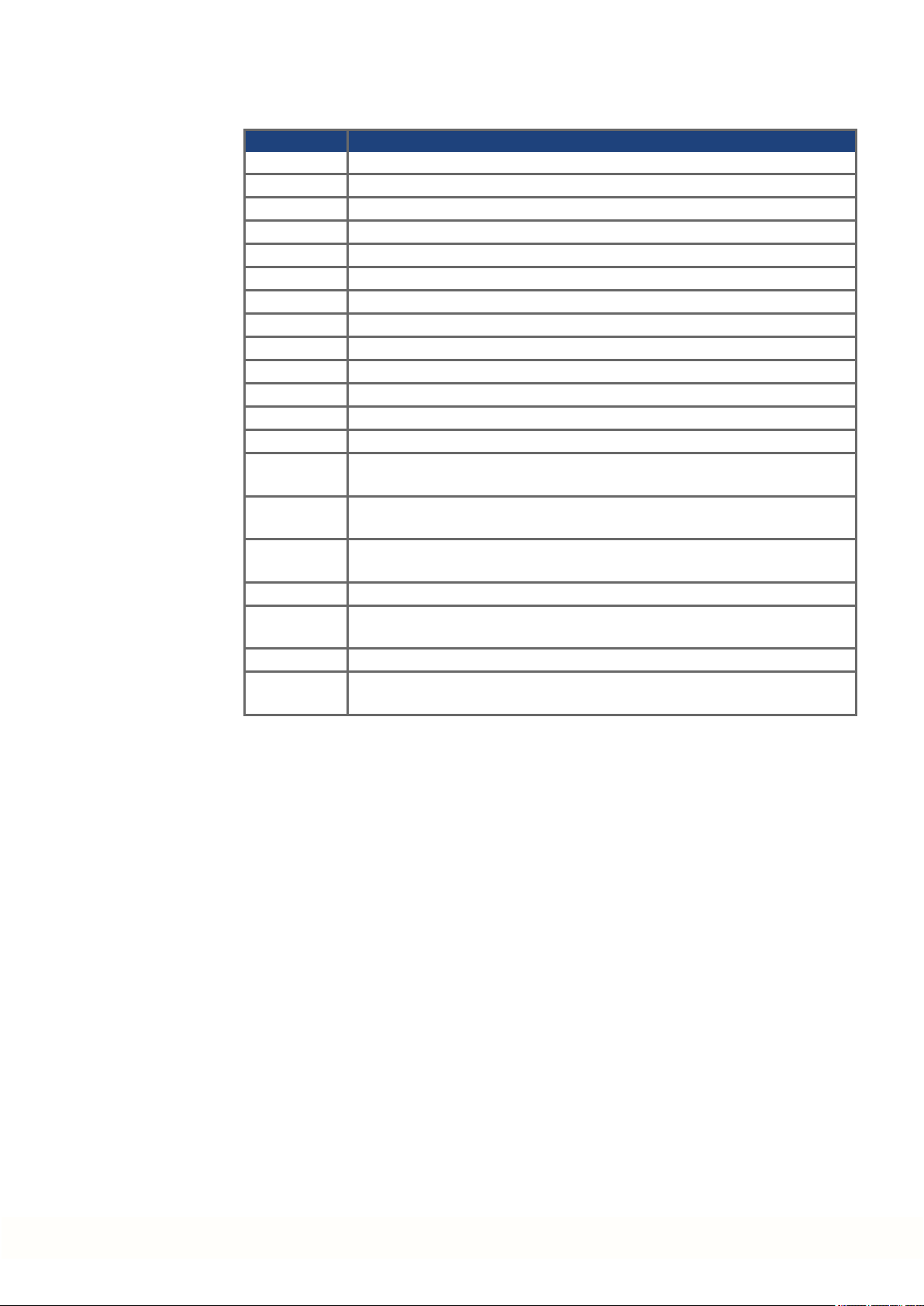

Record of Document Revisions

Revision Remarks

...

Table with lifecycle informationof this document (➜ # 145)

Beta, 12/2018 Beta edition

Hardware Revision (HR)

AKD2G Firmware Workbench KAS IDE Remarks

A from 02-00-00-000 from 2.00.0.0000 from 3.01 Beta revision

Trademarks

AKD is a registered trademark of Kollmorgen Corporation

EnDat is a registeredtrademark of Dr. Johannes Heidenhain GmbH

EtherCAT is a registered trademark and patented technology, licensedby Beckhoff Automation GmbH

Ethernet/IP is a registered trademark of ODVA, Inc.

Ethernet/IP Communication Stack: copyright (c) 2009, Rockwell Automation

HIPERFACE is a registeredtrademark of Max StegmannGmbH

Windows is a registeredtrademark of Microsoft Corporation

Technical changes which improve the performance of the device may be made without prior notice!

This document is the intellectual property of Kollmorgen. All rights reserved. No part of this work may be reproduced

in any form (by photocopying, microfilm or any other method) or stored, processed, copied or distributed by electronic

means without the written permission of Kollmorgen.

2 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 3

AKD2G-S Installation, Safety 1 | Tableof Contents

1 Table of Contents

1 Table of Contents 3

2 General 9

2.1 About thisInstallationManual 10

2.2 Using the PDF Format 10

2.3 SymbolsUsed 11

2.4 AbbreviationsUsed 12

2.5 Referred Standards 13

3 Product Safety 14

3.1 You shouldpay attention to this 15

3.2 Shock-hazard Protection 17

3.2.1 Leakage current 17

3.2.2 Residualcurrent protective device (RCD) 17

3.2.3 Isolatingtransformers 17

3.3 Stop / Emergency Stop / EmergencyOff 18

3.3.1 Stop 18

3.3.2 Emergency Stop 19

3.3.3 Emergency Off 19

3.4 Warning note labels 20

3.4.1 Notes placedon the product 20

3.4.2 Adhesive labelin the package 20

3.5 Use asDirected 21

3.6 Prohibited Use 22

4 Product life cycle handling 23

4.1 Transport 24

4.2 Packaging 24

4.3 Storage 24

4.4 Installation, setup and normal operation 25

4.5 Decommissioning 25

4.6 Maintenance and cleaning 25

4.7 Disassembly 25

4.8 SystemRepair 26

4.9 Disposal 26

5 Package 27

5.1 PackageSupplied 28

5.2 Nameplate 28

5.3 Part Number Scheme 29

6 Technical description and data 30

6.1 The AKD2G Familyof Digital Drives 31

6.2 Ambient Conditions,Ventilation, and Mounting Position 33

6.3 MechanicalData 33

6.4 Performance Data 34

6.5 Electrical data 35

6.5.1 Singleaxisvariants (S) 35

6.5.1.1 Mains supply data, 1 phaseAC, type AKD2G-Sxx- (S) 35

6.5.1.2 Mains supply data, 3 phaseAC, type AKD2G-Sxx- (S) 35

6.5.1.3 Auxiliary voltage input data, 24V DC, type AKD2G-Sxx- (S) 35

6.5.1.4 Output data, type AKD2G-Sxx- (S) 36

6.5.2 Dual axisvariants(D: I1=I2) 37

6.5.2.1 Mains supply data, 1 phaseAC, type AKD2G-Sxx- (D) 37

6.5.2.2 Mains supply data, 3 phaseAC, type AKD2G-Sxx- (D) 37

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 3

Page 4

AKD2G-S Installation, Safety 1 | Tableof Contents

6.5.2.3 Auxiliary voltage input data, 24V DC, type AKD2G-Sxx- (D) 37

6.5.2.4 Output data, type AKD2G-Sxx- (D) 38

6.6 LCD Displayand Push-buttons (B1, B2) 39

6.7 SD Card Slot 41

6.8 Electrical Motor Braking 42

6.8.1 DynamicBraking 42

6.8.2 Rheostatic energy dissipation 42

6.8.2.1 Functional description 42

6.8.2.2 Technicaldata for AKD2G-Sxx-6V 43

6.8.2.3 Technicaldata for AKD2G-Sxx-7V 44

7 Mechanical Installation 45

7.1 Important Notes 46

7.2 Guideto MechanicalInstallation 46

7.3 Dimensions 47

8 Electrical Installation 48

8.1 Important Notes 49

8.2 Guideto electricalinstallation 50

8.3 Wiring 51

8.3.1 General 51

8.3.2 Mating connectors 51

8.3.3 Cable and Wire Requirements 52

8.3.3.1 Cable material 52

8.3.3.2 Cable crosssectionsand requirements 53

8.3.4 ProtectiveEarth connection 54

8.4 EMI NoiseReduction 55

8.4.1 Recommendations for EMI noisereduction 55

8.4.2 Shielding with external shieldingbusbar 56

8.4.2.1 ShieldingConcept 56

8.4.2.2 ShieldingBusbar 57

8.4.3 Shielding connectionto the drive 58

8.4.3.1 ShieldingConcept 58

8.4.3.2 Grounding plates and shield connection clamps 59

8.4.3.3 Motor connector X1/X2 with shielding connection 59

8.5 Connection Overview 60

8.5.1 Connector PositionAKD2G-Sxx-6V 60

8.5.2 Connector PositionAKD2G-Sxx-7V 61

8.5.3 Wiring overview, single axisdrive 62

8.5.4 Wiring overview, dualaxisdrive 63

8.5.5 Connector pin assignments 64

8.5.5.1 X1 and X2: Motor, Brake, Feedback1 64

8.5.5.2 X3: Mains,regen resistor, DC-Bus 64

8.5.5.3 X10: 24 VDC 65

8.5.5.4 X11, X12: Motion Bus 65

8.5.5.5 X13, X14: CAN bus (optional) 65

8.5.5.6 X20: Service 65

8.5.5.7 X21: I/O, Feedback 4 66

8.5.5.8 X22: I/O extended, EEO2,Feedback5 67

8.5.5.9 X23: Feedback 3, EEO1,I/O 68

8.5.5.10 X41: SFA Feedback converter, EEO3/EEO4(accessory) 69

8.6 Power and Logic Voltage Supply (X3/X10) 70

8.6.1 Mainspower supply(X3) 70

8.6.1.1 Fusing 71

8.6.1.2 Wiring examplesmainspower supply 73

8.6.2 Auxiliary voltage power supply 24 VDC (X10) 75

4 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 5

AKD2G-S Installation, Safety 1 | Tableof Contents

8.6.2.1 Fusing 75

8.6.2.2 Wiring example24 VDC supply 75

8.7 DC Bus link (X3) 75

8.8 External Regen resistor (X3) 76

8.8.1 Fusing and Wiring 76

8.9 Motor Power, Brake and Feedback connection 77

8.9.1 Motor connectivity, some examples 77

8.9.2 Motor singlecable connection 78

8.9.2.1 Motor Power, Brake and Feedback connectors X1, X2 78

8.9.2.2 Feedbackconnectors X21, X22, X23 79

8.9.3 Motor dual cableconnection 80

8.9.3.1 Motor power and motor brake connectorsX1, X2 81

8.9.3.2 Feedbackconnectors X1, X2, X41, X21, X22, X23 81

8.9.4 Motor Holding Brake Connection 82

8.9.5 Feedback Connection 84

8.9.5.1 FeedbackConnector X1, X2 85

8.9.5.2 FeedbackConnector X21 86

8.9.5.3 FeedbackConnector X22 87

8.9.5.4 FeedbackConnector X23 88

8.9.5.5 FeedbackConnector X41 (SFA, accessory) 89

8.10 ElectronicGearing, EEO,Master-Slave 90

8.10.1 ElectronicGearing 90

8.10.2 Emulated Encoder Output (EEO) 91

8.10.3 Master-Slavecontrol 93

8.10.3.1 Master-Slaveusing X22 93

8.10.3.2 Master-Slaveusing optionalX23 or X41 93

8.11 Motion BusInterface (X11/X12) 94

8.12 CAN-BusInterface (X13/X14) 95

8.12.1 CAN-Bus Topology 95

8.12.2 CAN-Bus Wiring 96

8.12.3 Baud rate for CAN-Bus 97

8.12.4 Node Address for CAN-Bus 97

8.12.5 CAN-Bus Termination 97

8.13 ServiceInterface (X20) 98

8.13.1 Possible NetworkConfigurations 98

8.14 I/O Connection (X21/X22/X23) 99

8.14.1 Pinout 99

8.14.2 Technicaldata 100

8.14.3 Analog Input 101

8.14.4 Analog Output 102

8.14.5 DigitalInputs 103

8.14.5.1 Digital-In 1 and 2 103

8.14.5.2 Digital-In 3 to 12 104

8.14.5.3 Digital-In/Out 1 and 2 105

8.14.5.4 Digital-In/Out 3 to 6 106

8.14.6 DigitalOutputs 107

8.14.6.1 Digital-Out 1 to 6 107

8.14.6.2 Digital-Out 7 and 8 108

8.14.6.3 Digital-In/Out 1 and 2 109

8.14.6.4 Digital-In/Out 3 to 6 109

8.14.6.5 Digital-Out 9, Relaycontacts 110

9 Setup 111

9.1 Important Notes 112

9.2 Guideto drive setup 113

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 5

Page 6

AKD2G-S Installation, Safety 1 | Tableof Contents

9.2.1 InitialDrive Test Procedure 113

9.2.1.1 Unpacking, mounting, and wiring the AKD2G 113

9.2.1.2 Minimum wiring for drive testwithout load, example 113

9.2.1.3 Confirm connections (example: directlyto PC) 114

9.2.1.4 System integration 114

9.2.1.5 Installand start WorkBench 115

9.2.1.6 Setup the axisin WorkBench 115

9.2.1.7 Enable the axis(Hardware) 115

9.2.1.8 Move the motor axis 115

9.2.1.9 Tune the axis 115

9.2.2 Setup software WorkBench 116

9.2.2.1 Use as directed 116

9.2.2.2 Software description 117

9.2.2.3 Hardware requirements 117

9.2.2.4 Operating systems 117

9.2.2.5 Installation under Windows 7/8/10 118

9.3 Switch-On and Switch-OffBehavior 119

9.3.1 Switch-on behavior instandard operation 120

9.3.2 Switch-off behavior 120

9.4 Fault and Warning Messages 121

9.4.1 Fault and warning messages AKD2G 121

9.5 Troubleshootingthe AKD2G 122

10 Functional Safety 123

10.1 General notes 124

10.2 Use asdirected 124

10.3 Prohibited use 125

10.4 Abbreviationsused for functionalsafety 125

10.5 Enclosure, wiring 126

10.6 Functional SafetyOption 1 (I/O, SIL2 PLd) 127

10.6.1 TechnicalData 127

10.6.2 Safety Properties Overview 128

10.6.3 STO (Safe Torque Off) 129

10.6.3.1 Description 129

10.6.3.1.1 Important Notes 129

10.6.3.1.2 Precondition before activation 129

10.6.3.1.3 Activation 129

10.6.3.1.4 Restart 130

10.6.3.1.5 Timing 131

10.6.3.2 Safety Diagnosticviewin WorkBench 131

10.6.3.3 Fault Reaction / Failure Messages 132

10.6.4 Verification,Commissioning 132

10.6.4.1 Verification 132

10.6.4.2 Proof test 132

10.7 Safety Faults,Safety Warnings 133

10.7.1 Drive LCD Display 133

10.7.2 Drive Safety Faults 134

10.7.3 Drive Safety Warnings 134

10.7.4 Troubleshootingsafety functionality 134

10.8 Functional SafetyKeyword Reference Guide 135

10.8.1 AXISx.SAFE.STO Parameters 136

10.8.1.1 AXIS#.SAFE.STO.ACTIVE 136

10.8.1.1.1 Description 136

10.8.1.1.2 Context 136

6 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 7

AKD2G-S Installation, Safety 1 | Tableof Contents

10.8.1.1.3 Versions 136

10.8.1.1.4 General Information 136

10.8.1.1.5 Variants Supported 136

10.8.1.2 AXIS#.SAFE.STO.A 137

10.8.1.2.1 Description 137

10.8.1.2.2 Context 137

10.8.1.2.3 Versions 137

10.8.1.2.4 General Information 137

10.8.1.2.5 Variants Supported 137

10.8.1.3 AXIS#.SAFE.STO.B 138

10.8.1.3.1 Description 138

10.8.1.3.2 Context 138

10.8.1.3.3 Versions 138

10.8.1.3.4 General Information 138

10.8.1.3.5 Variants Supported 138

10.8.1.4 AXIS#.SAFE.STO.REPORTFAULT 139

10.8.1.4.1 Description 139

10.8.1.4.2 Context 139

10.8.1.4.3 Versions 139

10.8.1.4.4 General Information 139

10.8.1.4.5 Variants Supported 139

11 Approvals 140

11.1 Conformance with UL/cUL 141

11.2 Conformance with CE 141

11.3 Conformance with RoHS 141

11.4 Conformance with REACH 141

11.5 Functional Safetyapproval 141

11.6 Conformance with EAC 141

12 Index 143

13 Record of document revisions 145

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 7

Page 8

AKD2G-S Installation, Safety 1 |

---/ ---

8 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 9

AKD2G-S Installation, Safety 1 | 2 General

2 General

2.1 About this Installation Manual 10

2.2 Using the PDF Format 10

2.3 Symbols Used 11

2.4 Abbreviations Used 12

2.5 Referred Standards 13

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 9

Page 10

AKD2G-S Installation, Safety 1 | 2 General

2.1 About this Installation Manual

This document, the AKD®2G Installation Manual ("Instructions Manual" accordingto EC

Machinery Directive 2006/42/EC), describes the AKD®2G series of digital drives and

includes informationneeded to safely install an AKD2G.

This document is valid for AKD2G single axis drive or dual axis drive with 110V to 240V or

240V to 480V mains voltage.

Ouput stages: 3 A or 6 A or 12 A rated current

Programmability options: Base drive or Position Indexer drive

Connectivity options: analog, CANopen, EtherCAT, Ethernet/IP

I/O options: ExtendedI/O (X22), Feedback&EEO (X23)

Functional Safety options: option 1 with STO (SIL2 PLd)

A digital versionof this manual (pdf format)is available on the DVD includedwith yourdrive.

Additional documents:

WorkBench Online Help: describes how to use your drive in common applications. It also

provides tips for maximizing your system performance with the AKD2G. The Online Help

includes the Parameter and Command Reference Guide which provides information for

the parameters and commands used to program the AKD2G.

CAN-BUS Communication: describes how to use your drive in CANopen applications.

EtherCAT Communication: describes how to use your drive in EtherCAT applications.

Ethernet/IP Communication: describes how to use your drive in Ethernet/IP applications.

Accessories Manual: provides information for accessories like cables and regen resistors

used with AKD2G. Regional variants of this manual exist.

All documents can be downloadedfrom the Kollmorgen website www.kollmorgen.com.

2.2 Using the PDF Format

This document includes several features for ease of navigation

Cross References Table of contents andindex include active cross references.

Table of contents and

index

Page/chapter numbers

in the text

Lines are active cross references. Click on the line andthe appropriate pageis accessed.

Page/chapternumbers with cross references areactive links.

10 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 11

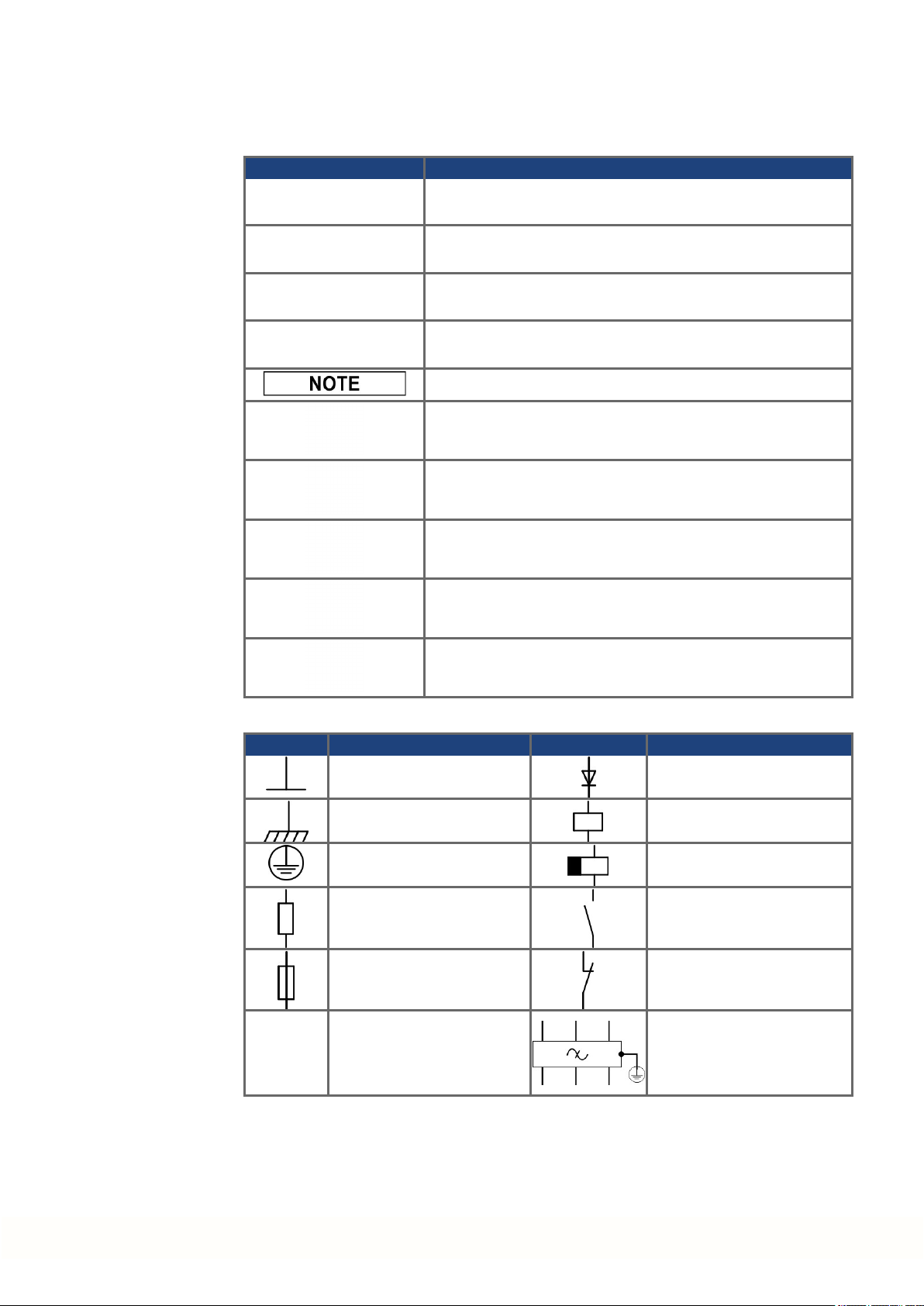

2.3 Symbols Used

Warning Symbols

AKD2G-S Installation, Safety 1 | 2 General

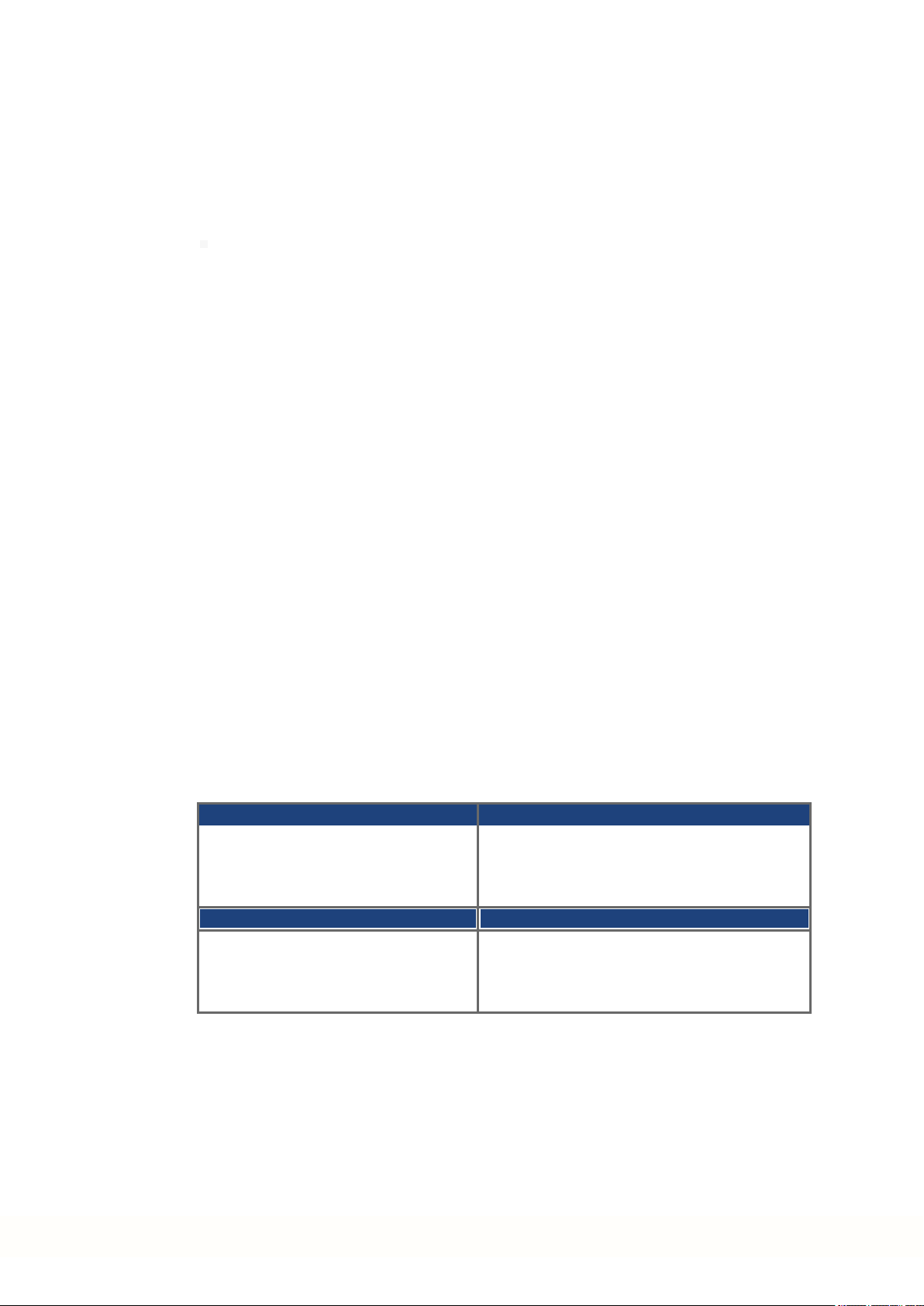

Symbol Indication

Indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minoror moderate injury.

Indicates situations which, if not avoided, could result in property damage.

This symbol indicates important notes.

Warning of a danger (general). Thetype of danger is specified

by the text next to the symbol.

Warning of danger from electricity andits effects.

Warning of danger from hot surface.

Warning of danger from suspendedloads.

Warning of danger from automatic start.

Drawing symbols

Symbol Description Symbol Description

Signal ground Diode

Chassis ground Relay

Protective earth Relay switch off delayed

Resistor Normally open contact

Fuse Normally closed contact

State-of-the-art firewall EMC filter

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 11

Page 12

AKD2G-S Installation, Safety 1 | 2 General

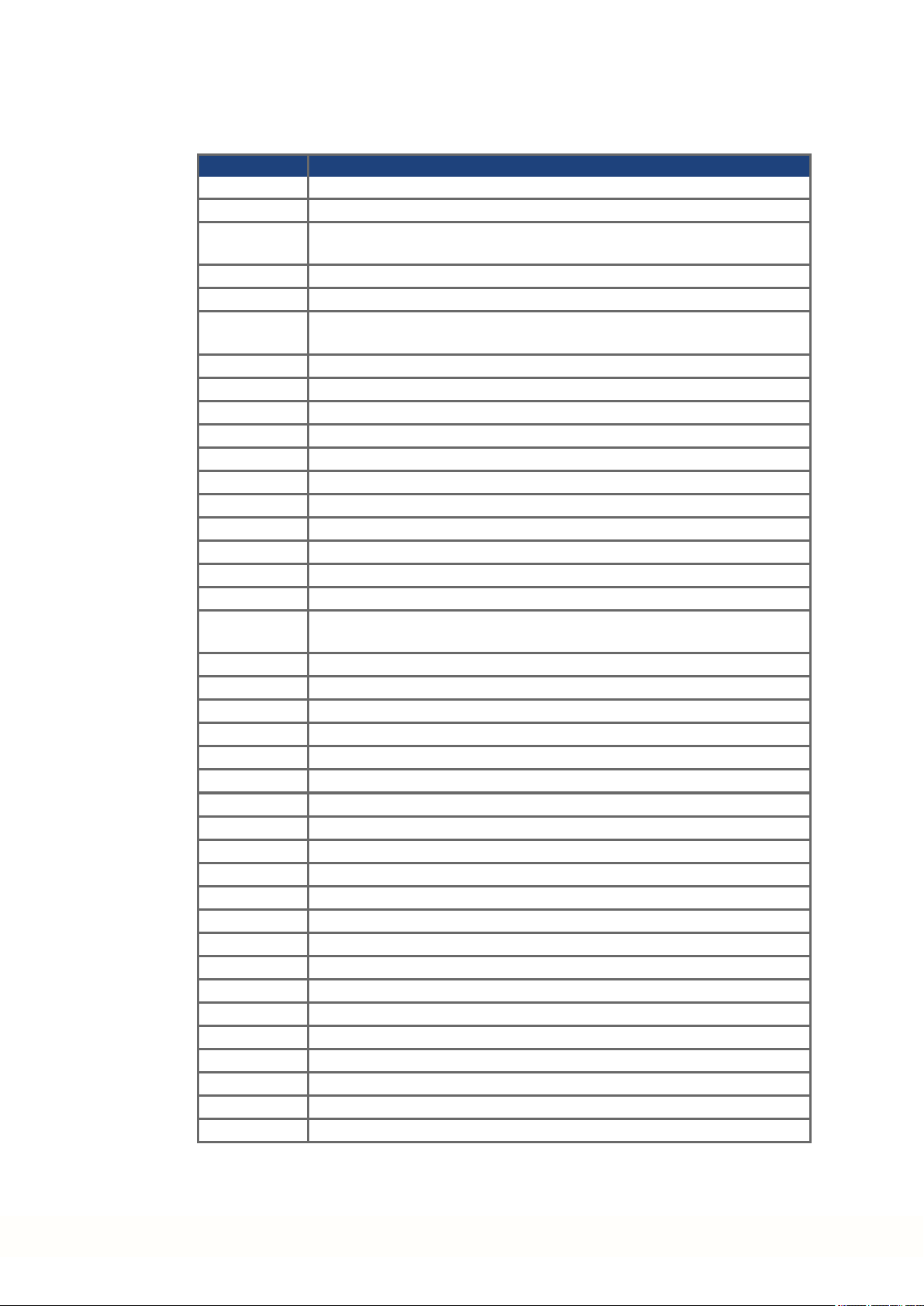

2.4 Abbreviations Used

Abbreviations related to functional safety (➜ # 125).

Abbreviation Meaning

(➜ # 53) "see page53" in this document

Ω Ohms

A#, AXIS# A# or AXIS# are placeholders for the axis number. Used with keywords or

signal names

AGND Analog ground

AMSL Above mean sea level

Axis Depends on context, either one AKD2G output stageor one load axis of

the full motionsystem.

CAT Category

CE Communité Européenne

COM Serial interface for a personal computer

DGND Digital ground

EEPROM Electrically erasableprogrammable memory

EEO EmulatedEncoder Output

EMC Electromagnetic compatibility

EMF Electromagnetic force

F-SMA Fiber optic cable connector accordingto IEC 60874-2

FSoE Fail safe over EtherCAT

KAS Kollmorgen AutomationSuite

KAS IDE Setup software (Kollmorgen AutomationSuite Integrated Development

Environment)

KDN Kollmorgen Developer Network

LED Light-emitting diode

LSB Low significant byte (orbit)

MSB Main significant byte (or bit)

NI Zero pulse

OSSD Output Signal Switching Device

PC Personal computer

PE Protective earth

PELV Protective Extra Low Voltage

PLC Programmable logic control

PWM Pulse-width modulation

RAM Random access memory (volatile memory)

RBrake/RB Regenresistor (also calleda brake resistor)

RBext External regenresistor

RBint Internal regenresistor

RCD Residual current device

RES Resolver

S1 Continuous operation

tbd To be discussed (in process)

VAC Volts, alternatingcurrent

VDC Volts, direct current

12 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 13

2.5 Referred Standards

Standard Content

ISO 4762 Hexagon socket head cap screws

ISO 11898 Road vehicles — Controller area network (CAN)

ISO 12100 Safety of machinery: Basic concepts, general principles for design

ISO 13849 Safety of machinery: Safety-related parts of control systems

IEC 60085 Electrical insulation - Thermal evaluation and designation Maintenance

IEC 60204 Safety of Machinery: Electrical equipment of machinery

IEC 60364 Low-voltageelectrical installations

IEC 60439 Low-Voltage Switchgear andControlgear Assemblies

IEC 60529 International protection rating(IP code)

IEC 60664 Insulationcoordination for equipment within low-voltagesystems

IEC 60721 Classification of environmental conditions

IEC 61000 Electromagnetic compatibility (EMC)

IEC 61131 Programmable controllers

IEC 61784 Industrial communicationnetworks - Profiles,

IEC 61491 Electrical equipment of industrial machines – Serial data link for real-time

IEC 61508 Functional safety of electrical/electronic/programmableelectronic safety-

IEC 61800 Adjustable speedelectrical power drive systems

IEC 62061 Functional safety of electrical/electronic/programmableelectronic safety-

IEC 82079 Preparationof instructions for use - Structuring, content andpresentation

UL 61800-5-1 Adjustablespeed electrical powerdrive systems,

AKD2G-S Installation, Safety 1 | 2 General

Part 3-12 Functional safety fieldbuses

communications between controls and drives.

related systems

related systems

Safety Requirements – Electrical, Thermal, andEnergy

IEC - International Electrotechnical Commission

ISO - International Organizationfor Standardization

UL - Underwriters Laboratories

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 13

Page 14

AKD2G-S Installation, Safety 1 | 3 Product Safety

3 Product Safety

3.1 You should pay attention to this 15

3.2 Shock-hazard Protection 17

3.3 Stop / Emergency Stop / Emergency Off 18

3.4 Warning note labels 20

3.5 Use as Directed 21

3.6 Prohibited Use 22

14 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 15

3.1 You should pay attention to this

This section helps to recognize risks and avoid dangers to people andobjects.

Specialist staff required!

Only properly qualified personnel arepermitted to perform such tasks as transport, installation and setup. Qualified specialist staff are persons with expertise in transport, installation,

assembly, commissioning and operation of electrotechnical equipment.

Transport, storage, unpacking: only by personnel with knowledge of handling electrostatically sensitive components.

Mechanical installation: only by personnel with mechanical expertise.

Electrical installation: only by personnel with electrotechnical expertise.

Basic tests / setup: only by personnel with expertise in electrical engineeringand drive

technology.

The qualified personnel must know and observe ISO 12100/ IEC 60364 / IEC 60664 and

national accident preventionregulations.

Read the documentation!

Read the available documentationbeforeinstallationand commissioning. Improperhandling

of the devices can cause harm to people or damage to property. The operatorof systems

using the drive system must ensure that all personnel who work with the drive read and understand the manual before using the drive.

AKD2G-S Installation, Safety 1 | 3 Product Safety

Check Hardware Revision!

Check the Hardware Revision Number of the product (see product label). This numberis the

link between your product andthe manual. The product Hardware Revision Number must

match the HardwareRevision Number onthe cover page of the manual.

Pay attention to the technical data!

Adhere to the technical data and the specifications on connection conditions. If permissible

voltage values or current values are exceeded, the devices can be damaged. Unsuitable

motororwrong wiring will damage the system components. Check the combination of drive

andmotor. Comparethe ratedvoltageand current of the units.

Perform a risk assessment!

The manufacturer of the machine must generate a risk assessment for the machine, andtake

appropriate measures to ensure that unforeseenmovements cannot cause injury or damage

to any person orproperty. Additional requirements on specialist staff may also result from the

risk assessment.

Automatic restart

The drive might restart automatically after power on, voltage dip or interruption of the supply

voltage, dependingon the parameter setting. Risk of death or serious injury for humans working in the machine.

If the parameterAXIS#.ENDEFAULT is set to 1, then place a warning sign to the machine

(Warning: Automatic Restart at Power On) and ensure, that power on is not possible, while

humans are in a dangerous zone of the machine. In case of using an undervoltageprotection

device, you must observe EN 60204-1:2006chapter 7.5 .

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 15

Page 16

AKD2G-S Installation, Safety 1 | 3 Product Safety

Observe electrostatically sensitive components!

The devices contain electrostatically sensitive components which may be damaged by incorrect handling. Electrostatically discharge your body before touching the device. Avoid contact with highly insulatingmaterials (artificial fabrics, plastic film etc.). Place the device on a

conductive surface.

Hot surface!

Drives may have hot surfaces duringoperation. The housing can reach temperatures above

80°C. Risk of minor burns! Measurethe temperature, andwait until the housing has cooled

down below 40 °C before touchingit.

Earthing!

It is vital that you ensure that the drive is safely earthed to the PE (protective earth)busbarin

the switch cabinet. Risk of electric shock. Without low-resistance earthing no personal protection can be guaranteed.

Leakage Current!

Since the leakagecurrent to PE is more than3.5 mA, in compliance with IEC61800-5-1the

PE connection must eitherbe doubled or a connecting cable with a cross-section >10 mm²

must be used. Deviating measures according to regional standards might be possible.

High voltages!

The equipment produces highelectric voltages up to 900 V. Lethal danger exists at live parts

of the device. Do not open or touch the equipment duringoperation. Keep all covers and cabinet doors closed. Built-in protection measures such as insulation or shielding may not be

removed. Work on the electrical installation may only be performedby trainedand qualified

personnel, in compliance with the regulations for safety at work, and only with switchedoff

mains supply, and securedagainst restart.

Never undo any electrical connections to the drive while it is live. There is a danger of electrical arcing with damageto contacts and personal injury. Wait at least 5 minutes after disconnecting the drive from the main supply power before touching potentially live sections of

the equipment (such as contacts) or removing any connections.

Always measure the voltage in the DC bus link and wait until the voltage is below 50 V

before handling components.

Functional Safety!

Beta drives: Safety functionality is not approvednor certified. Do not use this functionality in

applications with functional safety request.

The assessment of the safety functions according to EN13849or EN 62061must finally be

done by the user.

Reinforced Insulation

Thermal sensors, motor holdingbrakes and feedback systems built into the connected motor

must have reinforced insulation(according to IEC61800-5-1) against system components

with powervoltage, accordingto the required application test voltage. All Kollmorgen components meet these requirements.

Never modify the drive!

It is not allowed to modify the drive hardwarewithout permission by the manufacturer. Opening the housing causes loss of warranty.

16 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 17

3.2 Shock-hazard Protection

3.2.1 Leakage current

Leakagecurrent via the PE conductor results from the combination of equipment and cable

leakage currents. Theleakagecurrent frequency patternincludes a number of frequencies,

whereby the residual-current circuit breakers definitively evaluate the 50 Hz current. For this

reason, the leakagecurrent cannot be measured using a conventional multimeter. Contact

ourapplication department for help to calculate the leakage current in your application.

Since the leakagecurrent to PE is more than3.5 mA, in compliance with IEC61800-5-1the

PE connection must eitherbe doubled or a connecting cable with a cross-section >10 mm²

must be used. Use the PE terminal and the PE connection screws in orderto fulfill this

requirement.

The followingmeasures can be used to minimize leakagecurrents:

Reduce the length of the engine cable.

Use low capacitance motor cables (➜ # 52).

3.2.2 Residual current protective device (RCD)

In conformity with IEC 60364-4-41 – Regulations for installationand IEC 60204– Electrical

equipment of machinery, residual current protective devices (RCDs) can be usedprovided

the requisite regulations arecomplied with. The AKD2G is a 3-phase system with a B6

bridge. Therefore, RCDs which aresensitive to all currents must be used in order to detect

any DC fault current.

Rated residual currents in the RCDs:

AKD2G-S Installation, Safety 1 | 3 Product Safety

10 to 30 mA Protection against "indirect contact" (personal fire protection)for stationary

50 to 300 mA Protection against "indirect contact" (personal fire protection) for stationary

Recommendation: In order to protect against direct contact (with motor cables shorter than

5 m) Kollmorgen recommends that each drive be protectedindividually using a 30 mA RCD

which is sensitive to all currents.

If you use a selective RCD, the more intelligent evaluation process will prevent spurious trippingof the RCD.

3.2.3 Isolating transformers

When protection against indirect contact is absolutely essential despite a higher leakage current, or when analternative form of shock-hazard protection is sought, the AKD2G can also

be operated via an isolating transformer. A ground-leakage monitorcan be usedto monitorfor

short circuits.

Keepthe length of wiring between the transformer andthe drive as short as possible.

andmobile equipment, as well as for "direct contact".

equipment

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 17

Page 18

AKD2G-S Installation, Safety 1 | 3 Product Safety

3.3 Stop / Emergency Stop / Emergency Off

The control functions Stop, Emergency Stop andEmergency Off are defined by IEC 60204.

Notes for safety aspects of these functions can be found in ISO 13849and IEC 62061.

The parameterAXIS#.DISMODE must be set to implement the different stop categories.

Consult the WorkBench Online Help for configuring the parameter.

No functional safety!

Serious injury could result when the load is not properly blocked. With vertical load the load

could fall.

Functional safety, e.g. with hangingload (vertical axes), requires an additional mechanical brake which must be safely operated, for exampleby a safety control.

Set parameterAXIS#.MOTOR.BRAKEIMM to 1 with vertical axes, to apply the motor

holdingbrake (➜ # 82) immediately after faults or Hardware Disable.

3.3.1 Stop

The stop function shuts down the machinein normal operation. The stop function is defined

by IEC 60204.

The Stop Category must be determinedby a risk evaluation of the machine.

Stop function must have priority over assigned start functions. The following stop categories

aredefined:

Stop Category 0

Shut-down by immediate switching-off the energy supply to the drive machinery (this is an

uncontrolled shut-down). With the safety function STO (➜ # 127) the drive can be stopped

using its internal electronics (IEC 62061 SIL2).

Stop Category 1

A controlled shut-down, whereby the energy supply to the drive machinery is maintainedto

perform the shut-down, and the energy supply is only interrupted whenthe shut-down has

been completed.

Stop Category 2

A controlled shut-down, whereby the energy supply to the drive machinery is maintained.

Stop Category 0 and Stop Category 1 stops must be operableindependently of the operating

mode, whereby a Category 0 stop must have priority.

If necessary, provision must be made for the connection of protective devices and lock-outs.

If applicable, the stop function must signal its status to the control logic. A reset of the stop

function must not create a hazardous situation.

18 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 19

3.3.2 Emergency Stop

The Emergency Stop function is used for the fastest possible shutdown of the machine in a

dangerous situation. The Emergency Stop function is defined by IEC 60204. Principles of

emergency stop devices and functional aspects are defined in ISO 13850.

The Emergency Stop function will be triggeredby the manual actions of a single person. It

must be fully functional and available at all times. The user must understandinstantly how to

operate this mechanism (without consulting references or instructions).

The Stop Category for the Emergency Stop must be determinedby a risk evaluation of the

machine.

In additionto the requirements for stop, the Emergency Stop must fulfil the following requirements:

Emergency Stop must have priority over all otherfunctions andcontrols in all operating

modes.

The energy supply to any drive machinery that could cause dangerous situations must be

switched off as fast as possible, without causing any further hazards (Stop Category 0)

or must be controlledin such a way, that any movement that causes danger, is stopped

as fast as possible (Stop Category 1).

The reset must not initiate a restart.

AKD2G-S Installation, Safety 1 | 3 Product Safety

3.3.3 Emergency Off

The Emergency Off function is used to switch-off the electrical power supply of the machine.

This is done to prevent users from any risk from electrical energy (for example electrical

impact). Functional aspects for Emergency Off aredefinedin IEC 60364-5-53.

The Emergency Off function will be triggeredby the manual actions of a single person.

The result of a risk evaluation of the machine determines the necessity for an Emergency

Off function.

Emergency Off is doneby switching off the supply energy by electro-mechanical switching

devices. This results in a category 0 stop. If this stop category is not possible in the application, then the Emergency Off function must be replaced by other measures (for example by

protection against direct touching).

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 19

Page 20

AKD2G-S Installation, Safety 1 | 3 Product Safety

3.4 Warning note labels

If a warningnote label is damaged, it must be replaced immediately.

3.4.1 Notes placed on the product

AKD2G

Wait 5 minutes

after removing power

before servicing.

3.4.2 Adhesive label in the package

To meet UL, place the multi-languagelabel on the drive or on the panel near the drive.

20 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 21

3.5 Use as Directed

The AKD2G drives are exclusively intended for drivingsuitablesynchronous servomotors

with closed-loopcontrol of torque, speed, and/or position.

AKD2G are components that are built into electrical plants or machines and can only be operated as integral components of these plants or machines. The manufacturer of the machine

used with a drive must generate a risk assessment for the machine. When the drives arebuilt

into machines or plant, the drive must not be used until it has beenestablished that the

machine or plant fulfills the requirements of the regional directives.

Cabinet and wiring

Drives must only be operated in a closed control cabinet suitable for the ambient conditions

(➜ # 33). Ventilationor cooling may be necessary to keep the temperature within the cabinet

below 40°C.

Use only copper conductors for wiring. The conductor cross-sections can be derived from the

standard IEC 60204 (alternatively for AWG cross-sections: NEC Table 310-16, 75°C

column).

Power supply

The drives can be supplied by 1, 2 or 3 phase industrial supply networks.

Drives in the AKD2G series can be suppliedas follows:

AKD2G-S Installation, Safety 1 | 3 Product Safety

AKD2G-Sxx-6Vxx:

1, 2 or 3 phase industrial supply networks (not morethan200 kA symmetrical rated current at 120 V and 240V).

AKD2G-Sxx-7Vxx:

3 phase industrial supply networks (not more than200 kA symmetrical ratedcurrent at

240V, 400 V and480 V).

Connection to other voltage types of supply networks is possible with an additional isolating

transformer.

Repeated overvoltages betweenphases (L1, L2, L3) and the housingof the drive must not

exceed1000 V peak. In accordance with IEC 61800, voltagespikes (< 50 µs) between

phases must not exceed1000 V. Voltagespikes (<50µs) between a phase and the housing

must not exceed 2000 V.

EMC filter measures for AKD2G-Sxx-6Vxx must be implemented by the user.

Motor voltage rating

The rated voltage of the motors must be at least as high as the DC bus link voltage divided

by √2 produced by the drive (U

nMotor

>=UDC/√2).

Functional Safety

Beta Drives: Safety functionality is neither approved norcertified yet. Do not use this functionality in applications with functional safety request until further notice.

The network, to which the drive is connected, must be secured according to state-of-theart information technology security requirements.

The userIT specialists shall analyze whetherfurther security requirements are applicableto ensure functional safety.

Review the chapter"Use as Directed" in the Functional Safety section (➜ # 123)before

using safety functionality.

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 21

Page 22

AKD2G-S Installation, Safety 1 | 3 Product Safety

3.6 Prohibited Use

Otheruse thanthat described in chapter “Use as directed” is not intended and can lead to personnel injuries andequipment damage. The drive may not be used with a machine that does

not comply with appropriate national directives or standards. The use of the drive in the following environments is also prohibited:

potentially explosive areas

environments with corrosive and/or electrically conductive acids, alkaline solutions, oils,

vapors, dusts

ships or offshore applications

The drive must not be connected directly to the Internet. If the network, to which the drive is

connected, is not secured according to state-of-the-art information technology, this could be

a functional safety risk.

22 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 23

AKD2G-S Installation, Safety 1 | 4 Product life cycle handling

4 Product life cycle handling

4.1 Transport 24

4.2 Packaging 24

4.3 Storage 24

4.4 Installation, setup and normal operation 25

4.5 Decommissioning 25

4.6 Maintenance and cleaning 25

4.7 Disassembly 25

4.8 System Repair 26

4.9 Disposal 26

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 23

Page 24

AKD2G-S Installation, Safety 1 | 4 Product life cycle handling

4.1 Transport

Transport the AKD2G in accordance with IEC 61800-2 as follows:

Transport only by qualifiedpersonnel in the manufacturer’s original recyclablepackaging.

Avoid shocks while transporting.

Vibration/Shock: AKD2G is tested for environmental class 2M1 of IEC 60721-3-2.

Store at or below maximum stacking height 8 cartons (see "Storage" (➜ # 24))

Transport only within specified temperatureranges:

-25to +70 °C, max. rate of change 20K/hour, class 2K3.

Transport only within specified humidity:

max. 95% relative humidity at +40°C, no condensation, class 2K3.

The drives containelectrostatically sensitive components that can be damaged by incorrect

handling. Electrostatically dischargeyourself beforetouching the drive. Avoid contact with

highly insulating materials, such as artificial fabrics and plastic films. Place the drive on a

conductive surface.

If the packagingis damaged, check the unit for visible damage. Inform the shipperand the

manufacturer of any damageto the package orproduct.

4.2 Packaging

4.3 Storage

The AKD2G packaging consists of recyclable cardboard with inserts and a label on the outside of the box.

Model Package

(mm) HxWxL

AKD2G-Sxx-6V03 to 6V12 tbd 4.2

AKD2G-Sxx-7V03 to 7V12 tbd 4.3

Matingconnectors arenot included in the packageof a standarddrive.

Matingconnectors areincluded whenthe drive is orderedwith accessories (append “-A”to

the model number).

Store the AKD2G in accordance with IEC 61800-2 as follows:

Store only in the manufacturer’s original recyclable packaging.

Store at or below maximum stacking height 8 cartons.

Store only within specified temperature ranges: -25to +55 °C, max.rate of change

20K/hour, class 1K4.

Storage only within specified humidity: 5 to 95% relative humidity, no condensation, class

1K3.

Store in accordance with the following durationrequirements:

Less than 1 year: without restriction.

More than 1 year: capacitors must be re-formed before setting up and operating the

drive. Re-forming procedures aredescribedin the KollmorgenDeveloper Network

(Forming).

Total Weight

(kg)

24 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 25

AKD2G-S Installation, Safety 1 | 4 Product life cycle handling

4.4 Installation, setup and normal operation

Installation andsetup informationare given in this manual:

Mechanical installation (➜ # 45)

Electrical installation(➜ # 48)

Setup (➜ # 111)

Normal operation tested for environmental class 3K3 according to IEC 61800-2(➜ # 33).

The manufacturer of the machine defines the necessary enduser expertise basedonthe risk

assessment for the machine and describes the requirements for normal operation based on

the application.

4.5 Decommissioning

Only professional staff who arequalified in electrical engineering are allowed to decommission parts of the system.

DANGER: Lethal Voltages!

There is a dangerof serious personal injury or death by electrical shock or electrical arcing.

Switch off the main switch of the switchgear cabinet.

Securethe system against restarting.

Block the main switch.

Wait at least 5 minutes after disconnecting.

4.6 Maintenance and cleaning

The device does not require maintenance. Opening the device voids the warranty. The inside

of the unit can only be cleanedby the manufacturer.

Do not immerse or spray the device. Avoid that liquid enters the device.

To clean the device exterior:

1. Decommission the device (see chapter 4.5 "Decommissioning").

2. Casing: Clean with isopropanol or similar cleaning solution.

Caution : Highly Flammable! Risk of injury by explosionand fire.

Observe the safety notes given on the cleaning liquidpackage.

Wait at least 30 minutes after cleaningbeforeputting the device back into operation.

3. Protective grill on fan: Clean with a dry brush.

4.7 Disassembly

Only professional staff who arequalified in electrical engineering are allowed to disassemble

parts of the system.

1. Decommission the device (see chapter 4.5 "Decommissioning").

2. Check temperature.

CAUTION: High Temperature! Risk of minor burns. During operation, the heat sink of

the drive may reach temperatures above 80°C (176°F). Before touching the device,

check the temperature andwait until it has cooled below 40°C (104°F).

3. Remove the connectors. Disconnect the potential earth connection last.

4. Demount: loosen the fastening screws. Remove the device.

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 25

Page 26

AKD2G-S Installation, Safety 1 | 4 Product life cycle handling

4.8 System Repair

Only professional staff who arequalified in electrical engineering are allowed to exchange

parts of the drive system.

CAUTION: Automatic Start! During replacement work a combination of hazards andmul-

tiple episodes may occur.

Work on the electrical installationmay only be performed by trained andqualified personnel, in compliance with the regulations for safety at work, andonly with use of prescribed personal safety equipment.

Exchange of the device

Only the manufacturercan repairthe device. Opening the device voids the warranty.

1. Decommission the device (see chapter 4.5 "Decommissioning").

2. Demount the device (see chapter4.7 "Disassembly").

3. Send the device to the manufacturer.

4. Install a new device as described in this manual.

5. Setup the system as described in this manual.

Exchange of other drive system parts

If parts of the drive system (forexample cables) must be replaced, proceed as follows:

4.9 Disposal

1. Decommission the device (see chapter 4.5 "Decommissioning").

2. Exchange the parts.

3. Check all connections for correct fastening.

4. Setup the system as described in this manual.

To dispose the unit properly, contact a certified electronic scrap disposal merchant.

In accordance with the WEEE-2012/19/EC guidelineand similar, the manufacturer accepts

returns of old devices and accessories for professional disposal. Transport costs are the

responsibility of the sender.

Contact Kollmorgen andclarify the logistics.

Sendthe devices in the original packaging to the manufacturer address:

North America South America

KOLLMORGEN

201West Rock Road

Radford, VA 24141, USA

Europe Asia

KOLLMORGEN Europe GmbH

Pempelfurtstr. 1

40880Ratingen, Germany

KOLLMORGEN

AvenidaJoãoPaulo Ablas, 2970

Jardim da Glória, Cotia – SP

CEP 06711-250, Brazil

KOLLMORGEN

Floor 4, Building 9, No. 518,

North FuquanRoad, Changning District,

Shanghai 200335, China

26 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 27

AKD2G-S Installation, Safety 1 | 5 Package

5 Package

5.1 Package Supplied 28

5.2 Nameplate 28

5.3 Part Number Scheme 29

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 27

Page 28

AKD2G-S Installation, Safety 1 | 5 Package

5.1 Package Supplied

When a standard drive from the AKD2G series is delivered, the following items areincluded

in the drive package:

AKD2G

Printedcopy of AKD®2G Product Safety Guide .

DVD with WorkBench setup software .

Panel safety label

Matingconnectors arenot included in the packageof a standarddrive.

Matingconnectors areincluded whenthe drive is orderedwith accessories (append “-A”to

the model number). With the accessories option all connectors to match the drive variant are

included, excepting SubD (Feedback 3), RJ25 (CAN bus) andRJ45 (service and fieldbus

networks).

Accessories Sold Separately

Accessories must be ordered separately if required.

EMC filters for mains supply voltage, categories C2 or C3.

External regenresistor.

Connector kits

Hybrid cable. Assembled hybridmotor cables are available for all regions.

Motorcable. Assembledmotor cables are available for all regions.

Feedback cable. Assembled feedback cables areavailable for all regions.

SFA (Smart Feedback Adapter) .

SDB Module (Safe Dynamic Brake Module).

Ethernet service cable.

5.2 Nameplate

A nameplate is attached to the side of the drive. The picturebelow is similar to the nameplate

on the device.

28 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 29

5.3 Part Number Scheme

Use the part numberscheme for product identification only, not for the order process,

because not all combinations of features are possible.

Matingconnectors arenot included in the packageof a standarddrive.

Matingconnectors areincluded whenthe drive is orderedwith accessories (append “-A”to

the model number).

AKD2G-S Installation, Safety 1 | 5 Package

Example AKD2G-SPE-7V06S-A1IO-0000

AKD2G IP20 housing, position indexer, EtherCAT, 240 V to 480 V mains supply, 6 A rated

current, single axis, HardwareRevision A, dual channel STO SIL2 PLd, with additional I/O

connector X22, uncoated, no mating connectors.

Example AKD2G-SPE-6V03D-A1DX-A000-A

AKD2G IP20 housing, position indexer, EtherCAT, 120 V to 240 V mains supply, 2 x 3 A

rated current, dual axis, HardwareRevision A, dual channel STO SIL2 PLd, with all possible

connector (basis + X23), PCBs coated, with mating connectors.

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 29

Page 30

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6 Technical description and data

6.1 The AKD2G Family of Digital Drives 31

6.2 Ambient Conditions, Ventilation, and Mounting Position 33

6.3 Mechanical Data 33

6.4 Performance Data 34

6.5 Electrical data 35

6.6 LCD Display and Push-buttons (B1, B2) 39

6.7 SD Card Slot 41

6.8 Electrical Motor Braking 42

30 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 31

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.1 The AKD2G Family of Digital Drives

Available AKD2G-SP (Position Indexer) versions

Connectivity Voltage Current Axis Rev Safety

N-: Analog

C-: CANopen

E-: EtherCAT

Connector Options for Drives with

Functional Safety 1

Single Axis Dual Axis

00: Basis (X21)

IO: Basis + X22

F3: Basis + X23

DX: Basis + X22+X23

Standard features

Singleaxis or dual axis in one housing

Supply voltages: single phase AC, dual phase AC, three phase AC

Singleorgroupsupply, single or groupmains fusing

Motionbus on board, TCP/IP service channel on board

SFD3, HIPERFACE DSL motor feedback support on board

Support for second feedback

Step / Direction input on board

Encoder emulation on board

Use with synchronous servomotors, linear motors, and induction machines

SIL2 / PLd dual channel STO

6V:

120/240VAC 1~

240VAC 3~

7V:

240/400/480VAC 3~

03: 3 A

06: 6 A

12: 12 A

S-: Single

D-: Dual I1=I2

00: Basis (X21, X22)

F3: Basis + X23

DX: Basis + X23

A 1: SIL2 STO

Power section

One, two or three phase AC supply, voltage range85 to 528 V, 47 to 63 Hz.

Connection to higherAC voltage mains only via isolating transformer.

Fusingto be provided by the user.

B6 bridge rectifier, integral soft-start circuit.

DC bus link voltage range 120 to 750VDC

Output stage IGBT modulewith floatingcurrent measurement.

Internal regen resistor for all models, external regenresistor if required.

Functional Safety

Safety option 1: SIL2 / PLd dual channel STO, command by I/O, (➜ # 127).

Electrical safety

Appropriate insulation / creepagedistances andelectrical isolationfor safe electrical separation, perIEC 61800-5-1, between the powerinput / motor connections andthe signal

electronics.

Soft-start, overvoltage detection, short-circuit protection, phase-loss detection.

Temperature monitoring of the drive and motor.

Motoroverload protection: foldback mechanism.

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 31

Page 32

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

Auxiliary supply voltage 24V DC

From an external, safety approved24 V ±10% powersupply (PELV).

Parameter setting

Setup software WorkBench for setup via TCP/IP.

Downloadcontrol parameterpackages via CoE

Full digital control

Digital current loop(update period 1.2 µs / 62.5 µs)

Digital velocity loop(update period 62.5 µs)

Digital position loop (update period 250µs)

Inputs/Outputs (X21/X22/X23)

Usability depends on connector availability and usage.

2 programmable analog input (➜ # 101)

2 programmable analog output (➜ # 102)

12 programmabledigital inputs (➜ # 103)

8 programmable digital outputs (➜ # 107)

6 programmable digital input/outputs (➜ # 107)

4 safe STO inputs (dual channel STO per axis) (➜ # 123)

Connector Options

IO: X22 connector with additional digital inputs andoutputs.

F3: X23 connectorfor conventional motor feedbacks (Resolver, SFD, Tamagawa Smart

Abs, Comcoder, 1Vp-p Sin-Cos encoders, incremental encoders, EnDAT 2.1/2.2).

DX: all possible connectors for extended I/O and feedback connections.

Customization

0000: uncoated PCBs, standard

0xxx: uncoatedPCBs, customized coding

A000: coatedPCBs, standard

Axxx: coated PCBs, customized coding

Connectivity

Feedback inputs (➜ # 88)

Encoder emulation output (➜ # 91)

Digital Inputs/Outputs (➜ # 99)

Service Interface (➜ # 98)

CANopen (➜ # 95)

MotionBus interface (➜ # 94)

Accessories

SFA (Smart Feedback Adapter) (➜ # 89).

Hybrid motor cables, motor powercables, motor feedback cables.

External regenresistors.

Foraccessories referto your regional Accessories Manual.

32 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 33

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.2 Ambient Conditions, Ventilation, and Mounting Position

Storage, Transport (➜ # 24)

Normal operation Environmental class 3K3 according to IEC 61800-2

Surrounding temperature in operation

Humidity in operation Relative humidity 5 to 85%, no condensation, IEC 61800-2class

Site altitude Up to 1000 m above mean sea level (AMSL): no restriction

Pollution level Pollutionlevel 2 as per IEC 60664-1

Vibration Class 3M1 according to IEC 61800-2

Shock Class L accordingto IEC 61800-2

Drive protection IP 20 according to IEC 60529

Drive EMC immunity Increased immunity accordingto EN 61800-5-2

Mounting Vertical position, in a cabinet with protection of at least IP 54

Ventilation Built-in fan in all drive variants

Internal regen resistor used:

0 to +40 °C underrated conditions

+40 to +60 °C with current derating3 % perKelvin

Internal regen resistor not used:

0 to +50 °C underrated conditions

+50 to +60 °C with current derating2 % perKelvin

3K3

1,000 to 2,000 m AMSL: power derating 1.5%/100 m

Maximum altitude: 2000 m AMSL

The drive shuts down in case of excessively high temperature in

the control cabinet. Make sure sufficient forced ventilationis suppliedwithin the control cabinet.

6.3 Mechanical Data

Weight (with X22 and X23) kg 2.6 2.9 2.6 2.9

Width mm 76 75 76 75

Height, without connectors

front/back

Height, with connectors mm 303 340 303 340

Depth, without connectors mm 221 221 221 221

Depth, with connectors mm <235 <235 <235 <235

Dimension Drawingsee section Mechanical Installation (➜ # 45).

AKD2G-Sxx-

Units 6V03S,

6V06S,

6V12S

mm 220/235 255/272 220/235 255/272

7V03S,

7V06S,

7V12S

6V03D,

6V06D

7V03D,

7V06D

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 33

Page 34

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.4 Performance Data

Performance Data Units 6V03, 6V06, 6V12,

Normal Switchingfrequency (dynamic) kHz 15 12

Loaded Switching Frequency (dynamic) kHz 10.4 8.2

Current Loop Update Period µs 1.28*

Velocity Loop Update Period µs 62.5

Position Loop Update Period µs 250

Current Loop Bandwidth Hz 3000

Velocity Loop Bandwidth Hz 750

Position Loop Bandwidth Hz 350

Max. motor electrical frequency Hz 599

* Control updates every 1.28 µs. Current commandis updated every 62.5 µs.

AKD2G-Sxx-

7V06, 7V12

7V03

34 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 35

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.5 Electrical data

6.5.1 Single axis variants (S)

6.5.1.1 Mains supply data, 1 phase AC, type AKD2G-Sxx- (S)

Input data Units 6V03S 6V06S 6V12S

Rated supply voltage (L1/N) VAC 1 x 100 V to 240 V

Rated supply input frequency Hz 50 Hz to 60 Hz ±5%

Permittedswitch on/off frequency 1/h 30

Rated input power@240V kVA 1.2 2.38 2.64

Rated input current at 1 x 110 Vac A 5 9.9 11

Rated input current at 1 x 240 Vac A 5 9.9 11

Max. inrush current A 10

Rated DC bus link voltage VDC 310

6.5.1.2 Mains supply data, 3 phase AC, type AKD2G-Sxx- (S)

Input data Units 6V03S 6V06S 6V12S 7V03S 7V06S 7V12S

Rated supply voltage (L1/L2/L3) VAC 3 x 100 V to 240 V 3 x 200 V to 480 V

Rated supply input frequency Hz 50 Hz to 60 Hz ±5%

Permittedswitch on/off frequency 1/h 30 30

Rated input power@240V (*480V) kVA 1.2 2.38 2.64 2.24* 4.49* 7.65*

Rated input current at 3 x 110 Vac A 2.9 5.7 9.2 - - Rated input current at 3 x 240 Vac A 5 5.7 9.2 2.7 5.4 9.2

Rated input current at 3 x 400 Vac A - - - 2.7 5.4 9.2

Rated input current at 3 x 480 Vac A - - - 2.7 5.4 9.2

Max. inrush current A 10

Rated DC bus link voltage VDC 310 620

6.5.1.3 Auxiliary voltage input data, 24V DC, type AKD2G-Sxx- (S)

Input data Units 6V03S 6V06S 6V12S 7V03S 7V06S 7V12S

Aux. voltage supply (PELV) VDC 24 V (±10%, check voltage drop)

- control current without motor brake A 1

- control current with one motorbrake A 3.5

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 35

Page 36

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.5.1.4 Output data, type AKD2G-Sxx- (S)

Units 6V03S 6V06S 6V12S 7V03S 7V06S 7V12S

Rheostatic energy dissipation

max. continuous power kW 1.5 3 6 12 12 12

internal regenresistor Ω 15 15 15 33 33 33

external regen resistor Ω 33 33 33 33 33 33

Continuous output current ( ± 3%)

at 1 x 110Vac Arms 3 6 12 - - at 1 x 240Vac Arms 3 6 12 - - at 3 x 110Vac Arms 3 6 12 - - at 3 x 240Vac Arms 3 6 12 3 6 12

at 3 x 400Vac Arms - - - 3 6 12

at 3 x 480Vac Arms - - - 3 6 12

Peak output current (for 5s, ± 3%) Arms 9 18 30 9 18 30

Continuous output power @ rated input current

at 1 x 110Vac kVA tbd tbd tbd - - -

at 1 x 240Vac kVA tbd tbd tbd - - -

at 3 x 110Vac kVA tbd tbd tbd - - -

at 3 x 240Vac kVA tbd tbd tbd tbd tbd tbd

at 3 x 400Vac kVA - - - tbd tbd tbd

at 3 x 480Vac kVA - - - tbd tbd tbd

Peak output power (for 1 s)

at 1 x 110Vac kVA tbd tbd tbd - - at 1 x 240Vac kVA tbd tbd tbd - - at 3 x 110Vac kVA tbd tbd tbd - - at 3 x 240Vac kVA tbd tbd tbd tbd tbd tbd

at 3 x 400Vac kVA - - - tbd tbd tbd

at 3 x 480Vac kVA - - - tbd tbd tbd

Emissions (low/high speed fan)

Noise emission dB(A) tbd tbd tbd tbd tbd tbd

Brake output

Voltage VDC 24 V (±10%)

Output current, minimum mA required100 (fault detection)

Output current, maximum A 2.5

36 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 37

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.5.2 Dual axis variants (D: I1=I2)

6.5.2.1 Mains supply data, 1 phase AC, type AKD2G-Sxx- (D)

Input data Units 6V03D 6V06D

Rated supply voltage (L1/N) VAC 1 x 100 V to 240 V

Rated supply input frequency Hz 50 Hz to 60 Hz ±5%

Permittedswitch on/off frequency 1/h 30

Rated input power@ 240V kVA 2.38 2.64

Rated input current at 1 x 110 Vac A 9.9 11

Rated input current at 1 x 240 Vac A 9.9 11

Max. inrush current A 10

Rated DC bus link voltage VDC 310

6.5.2.2 Mains supply data, 3 phase AC, type AKD2G-Sxx- (D)

Input data Units 6V03D 6V06D 7V03D 7V06D

Rated supply voltage (L1/L2/L3) VAC 3 x 100 V to 240V 3 x 200 V to 480V

Rated supply input frequency Hz 50 Hz to 60 Hz ±5%

Permittedswitch on/off frequency 1/h 30

Rated input power@ 240V (*480V) kVA 2.38 3.82 4.49* 7.65*

Rated input current at 3 x 110 Vac A 2.9 5.7 - Rated input current at 3 x 240 Vac A 5 5.7 5.4 9.2

Rated input current at 3 x 400 Vac A - - 5.4 9.2

Rated input current at 3 x 480 Vac A - - 5.4 9.2

Max. inrush current (at 240 V/480 V, 20°C) A 10

Rated DC bus link voltage VDC 310 620

6.5.2.3 Auxiliary voltage input data, 24V DC, type AKD2G-Sxx- (D)

Input data Units 6V03D 6V06D 7V03D 7V06D

Aux. voltage supply (PELV) VDC 24 V (±10%, check voltage drop)

- current without motorbrake A 1.25

- control current with one motorbrake A 3.75

- control current with two motor brakes A 6.25

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 37

Page 38

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.5.2.4 Output data, type AKD2G-Sxx- (D)

Units 6V03D 6V06D 7V03D 7V06D

Rheostatic energy dissipation

max. continuous power kW 1.5 3 3 6

internal regenresistor Ω 15 15 33 33

external regen resistor Ω 33 33 33 33

Continuous output current ( ± 3%)

at 1 x 110Vac Arms 2x3 2x6 - at 1 x 240Vac Arms 2x3 2x6 - at 3 x 110Vac Arms 2x3 2x6 - at 3 x 240Vac Arms 2x3 2x6 2x3 2x6

at 3 x 400Vac Arms - - 2x3 2x6

at 3 x 480Vac Arms - - 2x3 2x6

Peak output current (for 5s, ± 3%) Arms 2x9 2x18 2x9 2x18

Continuous output power @ rated input current

at 1 x 110Vac kVA tbd tbd - at 1 x 240Vac kVA tbd tbd - at 3 x 110Vac kVA tbd tbd - at 3 x 240Vac kVA tbd tbd tbd tbd

at 3 x 400Vac kVA - - tbd tbd

at 3 x 480Vac kVA - - tbd tbd

Peak output power (for 1 s)

at 1 x 110Vac kVA tbd tbd - at 1 x 240Vac kVA tbd tbd - at 3 x 110Vac kVA tbd tbd - at 3 x 240Vac kVA tbd tbd tbd tbd

at 3 x 400Vac kVA - - tbd tbd

at 3 x 480Vac kVA - - tbd tbd

Emissions (low/high speed fan)

Noise emission dB(A) tbd tbd tbd tbd

Brake output

Voltage VDC 24 V (±10%)

Output current, minimum mA required 100 per brake (fault detection)

Output current, maximum A 2.5 per brake

38 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 39

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.6 LCD Display and Push-buttons (B1, B2)

The drive offers an LCD display andtwo push-buttons B1 / B2 for navigation.

Push-button actions

A short buttonpress invokes the action corresponding to the symbol directly above the button. On the dashboard for example,

a short press on B1 causes the menu system to appear, and

a short press on B2 causes a help screen to appear.

A long press (greaterthan2 seconds) on B2 returns the display to the previous screen.

More B1 / B2 Functions Description

Boot from SD card Push both buttons duringpower up to boot with data from SD

card. Press the buttons first, then hold it down while turning on

the 24 V power supply.

Boot from flash fallback

image

Remove the SD card, then press both buttons and hold them

down while turning on the 24 V powersupply to boot from an onboardrecovery image. Thefallback imageincludes a set of bootloader, operational, andcontrol FPGA that implements sufficient programming support to update missing or corrupt files.

LCD display

Left Coloredsection

Color: axis status (enabled, disabled, or faulted).

First icon: axis commandsource (analog, service, electronic gearing, or fieldbus).

Secondicon: axis operationmode (torque, velocity, or position).

Axis ID: A1 or A2.

Right Non-coloredsection:

No Fault/Warning: three virtual LEDs correspondingto axis disable sources

(Safe Torque Off, HardwareEnable, andControlledStop).

Faults or warnings: fault or warningcode.

Centerblue bar:

Drive and axis names

IP address

Drive model number

Firmware version

Bottom blue bar:

indicates whetherthe service port is connected to WorkBench, and

shows the actions that will be invoked by pushing the B1 / B2 buttons.

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 39

Page 40

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

Dual axes LCD display

Fordual-axis drives, the top section shows axis 1 information, the bottom section those for

axis 2.

Single axis LCD display

Forsingleaxis drives, the top section shows axis 1 information while the section betweenthe

centerand bottom bars is a data area wheresome important actual values of the axis arevisible: position, velocity, current.

40 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 41

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

Faults and Warnings

The display shows the code of the fault or warning that occurred. If a fault occurs, the color of

the left section switches to red. Navigate with B1 / B2 to the Fault screen to see a short

description of the fault or warning.

See WorkBench Onlinehelp for more details.

6.7 SD Card Slot

Supported SD card types

SD cards are formatted by the manufacturer. The following table outlines the SD card types

andAKD2G support.

SD Type File System Capacity Supported

SD (SDSC) FAT16 1MB to 2GB YES

SDHC FAT32 4GB to 32GB YES

SDXC exFAT (Microsoft) >32GB to 2TB NO

AKD2G offer a SD card slot for

to boot the drive with data from the SD Memory

card

These features can be started from the drive display

using push-buttons B1/B2.

Features

Boot AKD2G with data from SD card:

Remove 24V. Apply 24V with both buttons pressed. Release buttons after the display is

updated.

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 41

Page 42

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.8 Electrical Motor Braking

6.8.1 Dynamic Braking

Dynamic braking is a methodto slow down a servo system by dissipating the mechanical

energy driven by the motor back EMF.

Dynamic braking is not functional safe..

The AKD2G has a built in advanceddynamic braking mode which operates fully in hardware.

When activated, the drive shorts the motor terminals. This forces all of the dynamic braking

current to be stopping current and insures the fastest stoppingper ampere of motor terminal

current.

When current is not beinglimited, the mechanical energy is being dissipatedin the motor

resistance.

When current is being limited, energy is returned to the drive bus capacitors.

The drive also limits the maximum dynamic brakingmotor terminal current via the

AXIS#.DBILIMIT parameter to insure that the drive, motor, andcustomerload do not see

excessive currents/forces.

Whether and how the AKD2G uses dynamic brakingdepends on (AXIS#.DISMODE).

6.8.2 Rheostatic energy dissipation

When the amount of motorback EMF builds the bus capacitor voltageup enough the drive

activates the rheostatic regenerative circuit to start dumping the returned energy in the regen

resistor (also called regenerative resistor or brake resistor). All AKD2G offer internal resistor

plus the ability to connect an external resistor dependingon the application requirements.

External regenresistors aredescribed in the regional Accessories Manual.

6.8.2.1 Functional description

1. Individual drives, not coupled through the DC bus link circuit (+DC, -DC)

When the energy fed back from the motor has an averageor peak power that exceeds the preset level for the brake powerrating, the drive generates the warning "W2010 Regen Energy

Critical”. If the power exceeds the set fault level, the regenerative circuit will switch off.

2. Several drives coupled through the DC bus link (+DC, -DC)

Using the built-in regenerative circuit, several drives of the same series can be operatedfrom

a common DC-bus link (➜ # 75), without any additional measures. 90% of the combined

powerof all the coupled drives is always available for peak and continuous power. If the

powerof the drive with the lowest switch-off threshold (resulting from tolerances) exceeds

the set fault level, the regenerative circuit will switch off.

Switch-off on over voltage: With the regenerative circuit switched off, the DC bus link

voltage is not dissipated and thereforethe level increases. The drive reports an over-voltage

fault if the DC bus thresholdis exceeded. The drive power stage is disabledand the load

coasts to a stop with the fault message “F2006Bus Over voltage". The ready to operate contact (terminals X21/B5-B6) is opened(➜ # 110).

Observe the regeneration time (someminutes) after full loadwith peak brake power.

42 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 43

6.8.2.2 Technical data for AKD2G-Sxx-6V

Technical data for the regenerative circuit depends on the drive type and the mains voltage.

Supply voltages, capacitance, and switch-on voltages are all nominal values.

Brake circuit AC Supply

AKD2G-Sxx- Rated data Units 120V / 240V

6Vxxy

all types

Switch-on threshold of regenerative circuit V 380

Overvoltage limit V 420

Maximum regenerative duty cycle % 15*

AKD2G-Sxx- Rated data Units 120V / 240V

6V03S Internal regen resistor Ω 15

Continuous power, internal resistor W tbd

Peak brake power, internal resistor (0.5s) kW tbd

External regenresistor Ω 33

Continuous brake power, external resistor kW tbd

Peak brake power, external (1s) kW tbd

Absorption energy in capacitors (+/- 20%) Ws tbd / tbd

DC Bus Capacitance µF tbd

6V06S,

6V03D

Internal regen resistor Ω 15

Continuous power, internal resistor W tbd

Peak brake power, internal resistor (0.5s) kW tbd

External regenresistor Ω 33

Continuous brake power, external resistor kW tbd

Peak brake power, external resistor (1s) kW tbd

Absorption energy in capacitors (+/- 20%) Ws tbd / tbd

DC Bus Capacitance µF tbd

6V12S,

6V06D

Internal regen resistor Ω 15

Continuous power, internal resistor W tbd

Peak brake power, internal resistor (0.5s) kW tbd

External regenresistor Ω 33

Continuous brake power, external resistor kW tbd

Peak brake power, external resistor (1s) kW tbd

Absorption energy in capacitors (+/- 20%) Ws tbd / tbd

DC Bus Capacitance µF tbd

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

* depends on connected regen resistor power.

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 43

Page 44

AKD2G-S Installation, Safety 1 | 6 Technical description anddata

6.8.2.3 Technical data for AKD2G-Sxx-7V

Technical data for the regenerative circuit depends on the drive type and the mains voltage.

Supply voltages, capacitance, and switch-on voltages are all nominal values.

Brake circuit AC Supply

AKD2G-Sxx- Rated data Units 240V 400V/480V

7Vxxy

all types

Switch-on threshold of regenerative circuit V 380 760

Overvoltage limit V 420 840

Maximum regenerative duty cycle % 15*

AKD2G-Sxx- Rated data Units 240V 400V/480V

7V03S Internal regen resistor Ω 33

Continuous power, internal resistor W tbd

Peak brake power, internal resistor (0.5s) kW tbd tbd

External regenresistor Ω 33

Continuous brake power, external resistor kW tbd tbd

Peak brake power, external (1s) kW tbd tbd

Absorption energy in capacitors (+/- 20%) Ws tbd tbd / tbd

DC Bus Capacitance µF tbd

7V06S,

7V03D

Internal regen resistor Ω 33

Continuous power, internal resistor W tbd

Peak brake power, internal resistor (0.5s) kW tbd tbd

External regenresistor Ω 33

Continuous brake power, external resistor kW tbd tbd

Peak brake power, external resistor (1s) kW tbd tbd

Absorption energy in capacitors (+/- 20%) Ws tbd tbd / tbd

DC Bus Capacitance µF tbd

7V12S,

7V06D

Internal regen resistor Ω 33

Continuous power, internal resistor W tbd

Peak brake power, internal resistor (0.5s) kW tbd tbd

External regenresistor Ω 33

Continuous brake power, external resistor kW tbd tbd

Peak brake power, external resistor (1s) kW tbd tbd

Absorption energy in capacitors (+/- 20%) Ws tbd tbd / tbd

DC Bus Capacitance µF tbd

* depends on connected regen resistor power.

44 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 45

AKD2G-S Installation, Safety 1 | 7 Mechanical Installation

7 Mechanical Installation

7.1 Important Notes 46

7.2 Guide to Mechanical Installation 46

7.3 Dimensions 47

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 45

Page 46

AKD2G-S Installation, Safety 1 | 7 Mechanical Installation

7.1 Important Notes

High EMC Voltage Level!

Risk of electrical shock, if the servo amplifier(or the motor)is not properly EMC-grounded.

Do not use painted (i.e. non-conductive) mountingplates.

In unfavourable circumstances, use copper mesh tape betweenthe earthingbolts and

earth potential to deflect currents.

Protect the drive from impermissible stresses. In particular, do not let any components

become bent or any insulationdistances altered duringtransport and handling. Avoid contact with electronic components andcontacts.

The drive will switch itself off in case of overheating. Ensure that there is an adequate flow

of cool, filtered air into the bottom of the control cabinet, or use a heat exchanger(➜ # 33).

Do not mount devices that produce magnetic fields directly besidethe drive. Strongmagnetic fields can directly affect internal components. Install devices which produce magnetic

field with distance to the drives and/or shield the magnetic fields.

7.2 Guide to Mechanical Installation

The followingtools arerequired(at a minimum)to install the AKD2G; your specific installation may requireadditional tools:

M5 hexagon socket-cap screws (ISO 4762)

4 mm T-handle Allen key

No. 2 Phillips head screwdriver

Small slotted screwdriver

Install the drive unit as follows:

1. Prepare the site.

Mount the drive in a closed control cabinet (ambient conditions (➜ # 33)). The site must

be freefrom conductive or corrosive materials. For the mounting position in the cabinet

(➜ # 47).

2. Check ventilation.

Check that the ventilation of the drive is unimpeded, and keepwithin the permitted ambient temperature (ambient conditions (➜ # 33)). Keep the required space clearance above

andbelow the drive (➜ # 47).

3. Check the cooling system.

If cooling systems are used for the control cabinet, position the coolingsystem so that

condensationwater cannot drip onto the drive orperipheral devices.

4. Mount the drive.

Assemble the drive andpower supply near each otheron the conductive, groundedmounting plate in the cabinet.

5. Ground the drive.

ForEMC-compliant shieldingand grounding, (➜ # 55). Ground the mounting plate, motor

housing andCNC-GND of the control system.

46 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 47

7.3 Dimensions

AKD2G-S Installation, Safety 1 | 7 Mechanical Installation

Mounting material: three M5 hexagonsocket screws to ISO 4762, 4 mm T-handle Allen key

Outlinewidth and height dimensions are measuredon footprint level (mounting plate).

Dimensions on the front plate areslightly smaller. All dimensions in mm.

Dimensions in mm A A1 B B1 C D E F G H M P

AKD2G-Sxx-6V (3 to 12 A) 221 232 235 303 76 221,5 36 5,8 11,5 7 78 40

AKD2G-Sxx-7V (3 to 12 A) 221 232 272 340 75 259 36 5,8 11,5 6 77 39

Kollmorgen | kdn.kollmorgen.com | Beta, December 2018 47

Page 48

AKD2G-S Installation, Safety 1 | 8 Electrical Installation

8 Electrical Installation

8.1 Important Notes 49

8.2 Guide to electrical installation 50

8.3 Wiring 51

8.4 EMI Noise Reduction 55

8.5 Connection Overview 60

8.6 Power and Logic Voltage Supply (X3/X10) 70

8.7 DC Bus link (X3) 75

8.8 External Regen resistor (X3) 76

8.9 Motor Power, Brake and Feedback connection 77

8.10 Electronic Gearing, EEO, Master-Slave 90

8.11 Motion Bus Interface (X11/X12) 94

8.12 CAN-Bus Interface (X13/X14) 95

8.13 Service Interface (X20) 98

8.14 I/O Connection (X21/X22/X23) 99

48 Kollmorgen | kdn.kollmorgen.com | Beta, December 2018

Page 49

8.1 Important Notes

Only professional staff who arequalified in electrical engineering are allowed to install the

drive. Wires with colorgreen with one ormore yellow stripes must not be used other than for

protective earth (PE) wiring.

There is a dangerof serious personal injury or death by electrical shock or electrical arcing.

Capacitors can still have dangerous voltages present up to 5 minutes after switchingoff the

supply power. Control and powerconnections can still be live, even if the motoris not rotating.

Only install andwire the equipment whenit is not live.

Make sure that the cabinet is safely disconnected (for instance, with a lock-out andwarning signs).

Never remove electrical connections to the drive while it is live.

Wait at least 5 minutes after disconnecting the drive from the main supply power before

touching potentially live sections of the equipment (e.g. contacts) or undoing any connections.

To be sure, measure the voltage in the DC bus link andwait until it has fallen below 50 V.

AKD2G-S Installation, Safety 1 | 8 Electrical Installation

High Voltage up to 900 V!

Wrongmains voltage, unsuitable motororwrong wiring will damage the drive. Check the

combination of drive and motor. Comparethe rated voltage and current of the units. Implement the wiring according to the matchingconnection diagram, see (➜ # 62)and following.

Make sure that the maximum permissible rated voltage at the terminals L1, L2, L3 or +DC, –

DC is not exceededby morethan10% even in the most unfavorable circumstances (see

IEC 60204-1).

Excessively highexternal fusing will endanger cables anddevices. The fusing of the mains

powerand logic power must be installedby the user. Hints for use of Residual-current circuit

breakers (RCD) (➜ # 17).

Since the leakagecurrent to PE is more than3.5 mA, in compliance with IEC61800-5-1the

PE connection must eitherbe doubled or a connecting cable with a cross-section >10 mm²

must be used. Deviating measures according to regional standards might be possible.

The drive status shall be monitored by the PLC to acknowledgecritical situations. We

recommend wiring the ready to operate relay contact in series into the emergency off circuit

of the installation. The emergency off circuit must operate the supply contactor.