AIRMASTER

PORT ABLE

AIR-COOLED

AIR CONDITIONER

INSTALLATION &

OPERATION

2AKSM-3

42-9134 Rev. 4

MANUAL

GENERAL DESCRIPTION ..................................... 1

PRODUCT DATA AND SPECIFICATIONS......... 2, 3

UNIT DESCRIPTION

Standard Features ............................................... 4-7

General Air Flow Patterns ....................................... 7

ACCESSORIES ................................................. 8-13

APPLICATIONS ............................................... 14-15

SERVICE

Installation ............................................................. 15

Checkout of Unit.................................................... 16

Troubleshooting Guide..................................... 16-18

Inspection and Repair ...................................... 19-21

Parts Replacement Procedure ......................... 21-23

Preventative Maintenance..................................... 24

DIAGRAMS

Piping Schematic .................................................. 25

Wiring Diagram (Logic and Interconnecting).... 26-27

Unit Drawing.......................................................... 28

PARTS LIST..................................................... 29-30

WARRANTY......................................................... 31

GENERAL DESCRIPTION

The Koldwave Airmaster is a portable air-cooled zone

cooler which directs cool air to specific areas or

objects through four, adjustable, four-way grilles. Many

small computer and telephone rooms, tanning bed

rooms, laboratories, factories, and numerous areas

can be cooled by its indicated cooling capacity. The

Koldwave Airmaster can also be used for back-up

cooling or as an emergency stand-by unit.

The cord-connected Koldwave Airmaster is provided

with heavy-duty casters. The swivel casters provide

handling ease for convenient relocation. This unit is

completely self-contained with the entire refrigeration

system, electrical components, condenser and

evaporator housed in an attractively-designed, painted

metal cabinet.

NOMENCLATURE

2 A K 10 1 1

260 NORTH ELM STREET • WESTFIELD , MA 01085 • Tel No . (413) 564-5520 • F ax No . (413) 564-5815

5211 CREEKBANK ROAD • MISSISSAUGA, ONTARIO L4W 1R3 CANADA • Tel No. (905) 625-2991 • F ax No . (905) 625-6610

Series 1 = 115 Volt

Air Cooled Single Phase

Koldwave Capacity Indicator

KOLDWAVE 2AK (AIRMASTER)

2AK1011 AIRMASTER PRODUCT DATA AND SPECIFICATIONS

COOLING CAPACITY (BTU/HR) & EER

Evaporator Fan Speed

Conditions

67°F DB/57°F WB (54% RH) 9148 6653 9.71 8261 5568 9.31

72°F DB/60°F WB (50% RH) 9627 7113 9.83 8586 5906 9.32

75°F DB/62°F WB (48% RH) 9903 7287 9.86 8867 6103 9.38

80°F DB/67°F WB (52% RH) 10,613 7223 10.13 9749 6051 9.82

95°F DB/75°F WB (40% RH) 11,970 8783 10.00 11,161 7314 9.81

95°F DB/83°F WB (61% RH) 12,985 6021 10.79 11,973 5186 10.42

104°F DB/80°F WB (36% RH)** 12,603 9399 9.67 11,600 7917 9.35

Total Sensible EER* Total Sensible EER*

High Low

ELECTRICAL DATA***

Voltage/Phase/Hertz 115/1/60

Amperage 10.5

Fuse Size (Amps) 15

Watts 1196

Inrush Current (Amps) 69.7

COMPRESSOR (ROTARY)

Horsepower 0.75

Watts 845

RLA 7.4

LRA 44

RPM 3400

Refrigerant R-22

BLOWER (CONDENSER)

Speed

Amps 1.3 0.8

Watts 139 87

RPM 1570 1115

CFM @ 0.0" H2O E.S.P. 440 300

BLOWER (CONDENSER)

Speed

Amps 2.3 1.6

Watts 250 164

RPM 1090 780

CFM @ 0.0 E.S.P. 730 515

CFM @ 0.25 E.S.P. 610 450

Time delay fuses and circuit breakers are recommended.

*EER determined with condenser discharge air ducted into another area on high fan speed.

**Maximum operating condition.

***Electrical ratings per U.L Standard 484 at 95°F DB/75° WB on high speed.

High Low

High Low

CONDENSATE PUMP (OPTIONAL)

Motor HP .0125

Lift (Ft. of H2O) 11.0

Amps .48

Watts 50

EVAPORATOR

Number of Rows 2

Coil Face Area (Ft.2) 1.5

CONDENSER

Number of Rows 3

Coil Face Area (Ft.2) 2.44

EVAPORATOR AIR FILTER SIZE (INCHES)

Width 15.125

Height 18

Thickness 0.5

CONDENSER AIR FILTER SIZE (INCHES)

Width 19.25

Height 16.5

Thickness 0.5

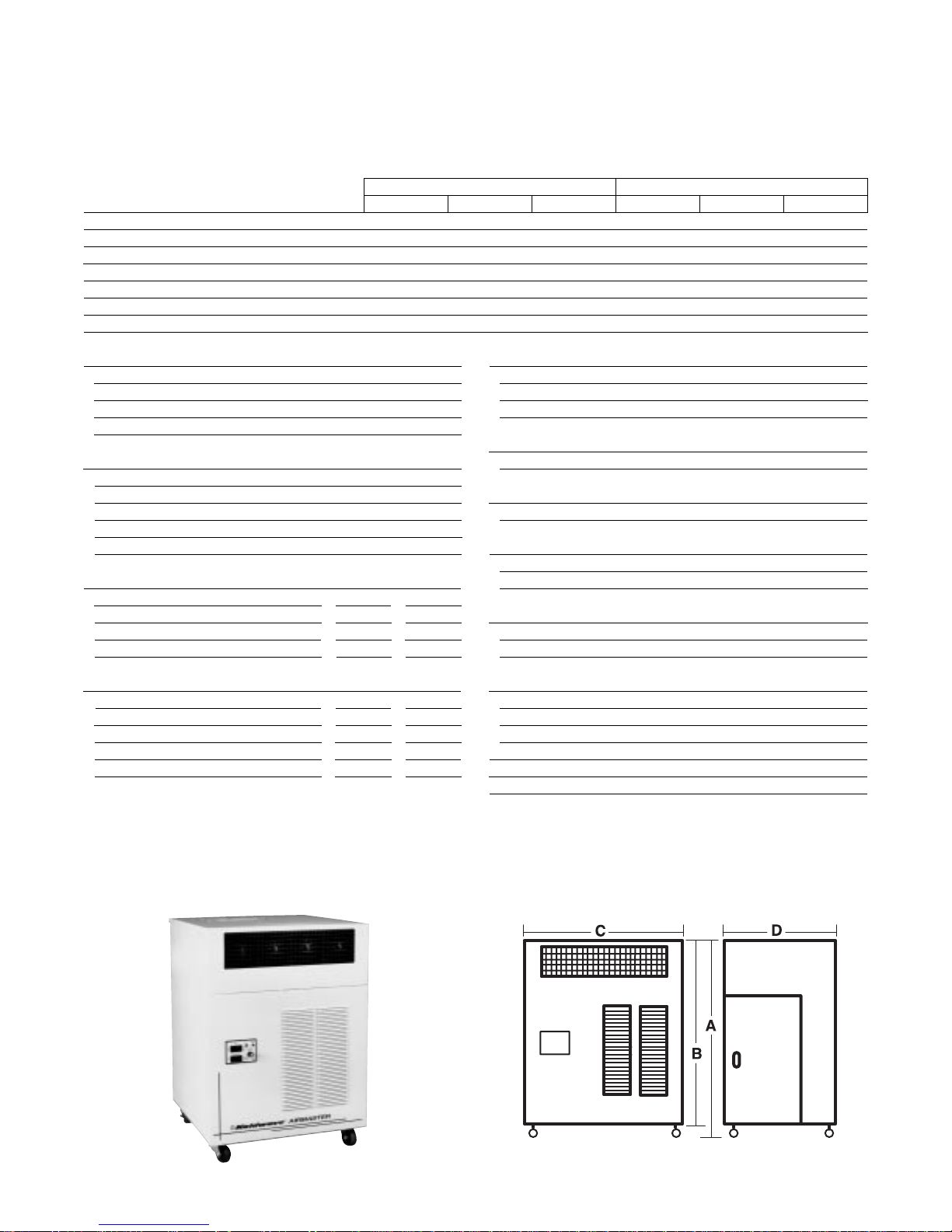

UNIT DIMENSIONS (INCHES)

(A) Height with Casters 34.25

(B) Height without Casters 31.125

(C) Length 25

(D) Depth 24

NET UNIT WEIGHT (LBS.) 182

SHIPPING WEIGHT (LBS.) 207

2

KOLDWAVE 2AK (AIRMASTER)

2AK1411M AIRMASTER PRODUCT DATA AND SPECIFICATIONS

COOLING CAPACITY (BTU/HR) & EER

Evaporator Fan Speed

Conditions

67°F DB/57°F WB (54% RH) 10,714 7736 9.44 9409 6216 8.86

72°F DB/60°F WB (50% RH) 11,200 8328 9.47 9933 6586 8.92

75°F DB/62°F WB (48% RH) 11,534 8538 9.49 10,238 6795 8.93

80°F DB/67°F WB (52% RH) 12,606 8375 9.92 11,262 6757 9.32

95°F DB/75°F WB (40% RH) 14,054 10,248 9.63 12,783 8069 9.20

95°F DB/83°F WB (61% RH) 14,917 6986 10.07 14,054 5902 9.88

104°F DB/80°F WB (36% RH)** 14,668 11,203 9.21 13,626 8725 8.95

Total Sensible EER* Total Sensible EER*

High Low

ELECTRICAL DATA***

Voltage/Phase/Hertz 115/1/60

Amperage 13.8

Fuse Size (Amps) 20

Watts 1563

Inrush Current (Amps) 79.7

COMPRESSOR (ROTARY)

Horsepower 1.0

Watts 1080

RLA 9.7

LRA 54

RPM 3400

Refrigerant R-22

BLOWER (CONDENSER)

Speed

Amps 1.4 0.8

Watts 134 89

RPM 1595 1053

CFM @ 0.0" H2O E.S.P. 400 265

BLOWER (CONDENSER)

Speed

Amps 2.3 1.6

Watts 250 164

RPM 1090 780

CFM @ 0.0 E.S.P. 730 515

CFM @ 0.25 E.S.P. 610 450

Time delay fuses and circuit breakers are recommended.

*EER determined with condenser discharge air ducted into another area on high fan speed.

**Maximum operating condition.

***Electrical ratings per U.L Standard 484 at 95°F DB/75° WB on high speed.

High Low

High Low

CONDENSATE PUMP (OPTIONAL)

Motor HP .0125

Lift (Ft. of H2O) 11.0

Amps .48

Watts 50

EVAPORATOR

Number of Rows 3

Coil Face Area (Ft.2) 1.5

CONDENSER

Number of Rows 3

Coil Face Area (Ft.2) 2.44

EVAPORATOR AIR FILTER SIZE (INCHES)

Width 15.875

Height 18

Thickness 0.5

CONDENSER AIR FILTER SIZE (INCHES)

Width 19.25

Height 16.5

Thickness 0.5

UNIT DIMENSIONS (INCHES)

(A) Height with Casters 34.25

(B) Height without Casters 31.125

(C) Length 25

(D) Depth 24

NET UNIT WEIGHT (LBS.) 185

SHIPPING WEIGHT (LBS.) 210

3

KOLDWAVE 2AK (AIRMASTER)

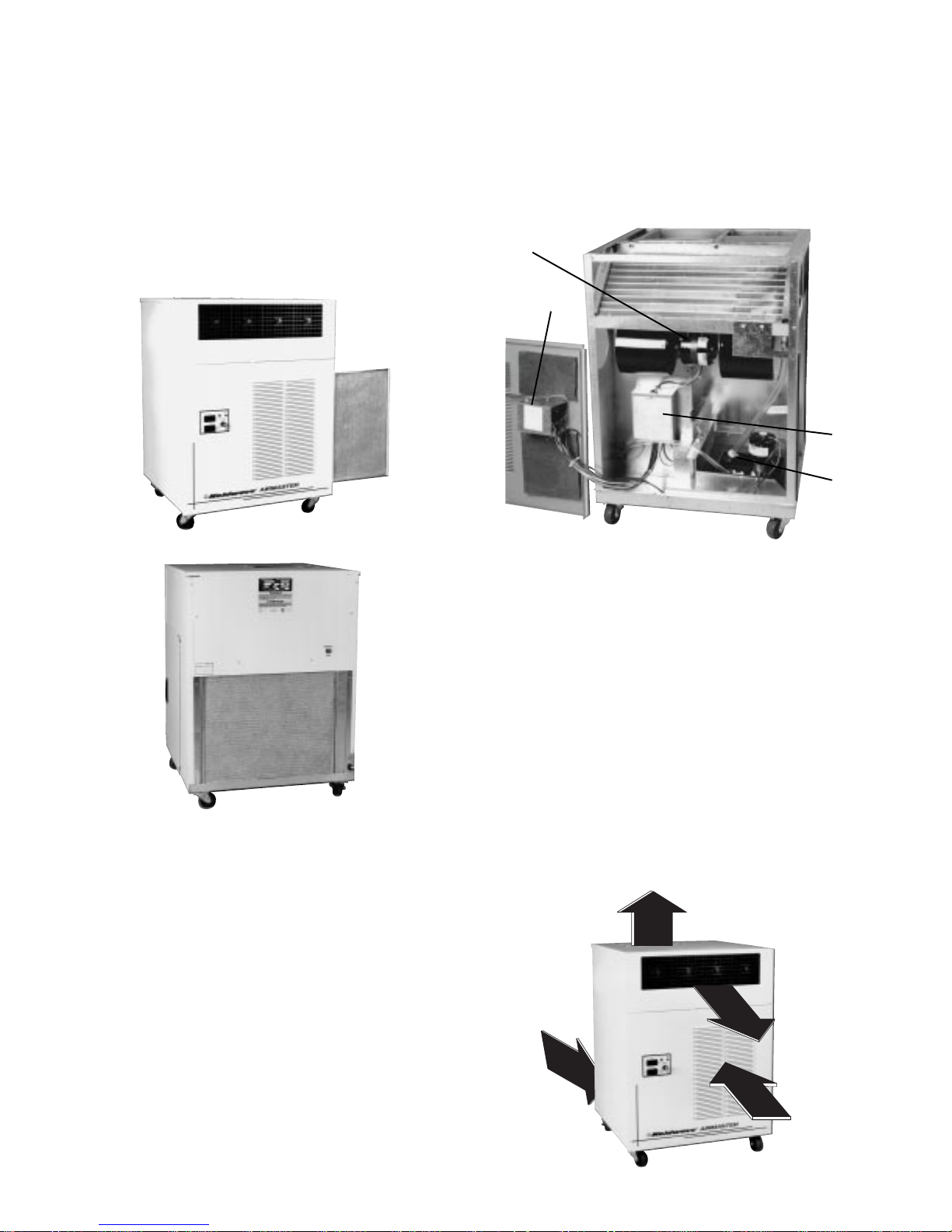

STANDARD FEATURES/UNIT CONSTRUCTION

FEATURES

• Optional 10' flexible duct extends

up to 10 feet to vent condenser

air.

• Convenient control panel houses

on-off switch, thermostat and

indicator lights.

• Large, heavy-duty casters allow

you to move the Koldwave

®

Airmaster to virtually any location.

• Four way adjustable grilles

control air discharge for even,

comfortable cooling.

• Hinged panel allows easy access

to 5-gallon condensate holding

tank.

SERVICEABILITY

The Koldwave Airmaster has removable panels to

provide full service accessibility. The interior is divided

into three sections. The upper front face encloses the

evaporator coil and blower assembly. The lower front

section contains the electrical controls, which are

secured to the removable front panel, and the

condensate holding tank an its level detection system.

The rear section encases the compressor, condenser

coil and blower assembly.

Front Left

Side

1

4

3

Back

Right

Side

1. Evaporator Coil

5

2. Terminal Block Enclosure

3. Condensate

Holding Tank

4. Condenser Fan Motor

5. Fan Motor Capacitor

6. Condenser Coil

7. Compressor (Rotary)

9

8. Compressor Capacitor

9. Evaporator Blower

10. Casters

2

6

7

8

10

4

KOLDWAVE 2AK (AIRMASTER)

CABINET

The Koldwave Airmaster cabinet is constructed of 20

gauge, cold rolled steel with painted steel finish for

corrosion protection. It is lined with thermal and sound

absorbent insulation material in the discharge area

and vibration dampening on all panels.

SAFETY ENGINEERED

In addition to the rotary compressor’s overload

protection, Koldwave Airmaster incorporated, within

the refrigeration system a manual reset high pressure

switch for maximum safety of the compressor. The cutout pressure setting is 375 ± 10 psig. In the event that

the high pressure switch setting is exceeded, the

compressor and condenser fan operation will cease.

The compressor and condenser fan can be restarted

by depressing the “reset” button located on the back

panel of the unit. The high pressure switch capillary

line screws onto an access valve on the refrigeration

discharge line to make it possible to remove or replace

a defective control without disturbing the refrigeration

system. The unit also employs an automatic reset

freeze control, located on top of condenser coil, to turn

the entire unit off at low ambients and defrost the

evaporator coil for approximately five minutes.

NOTE: Wait two minutes before restarting unit after

tripping by one of the safety features.

Back

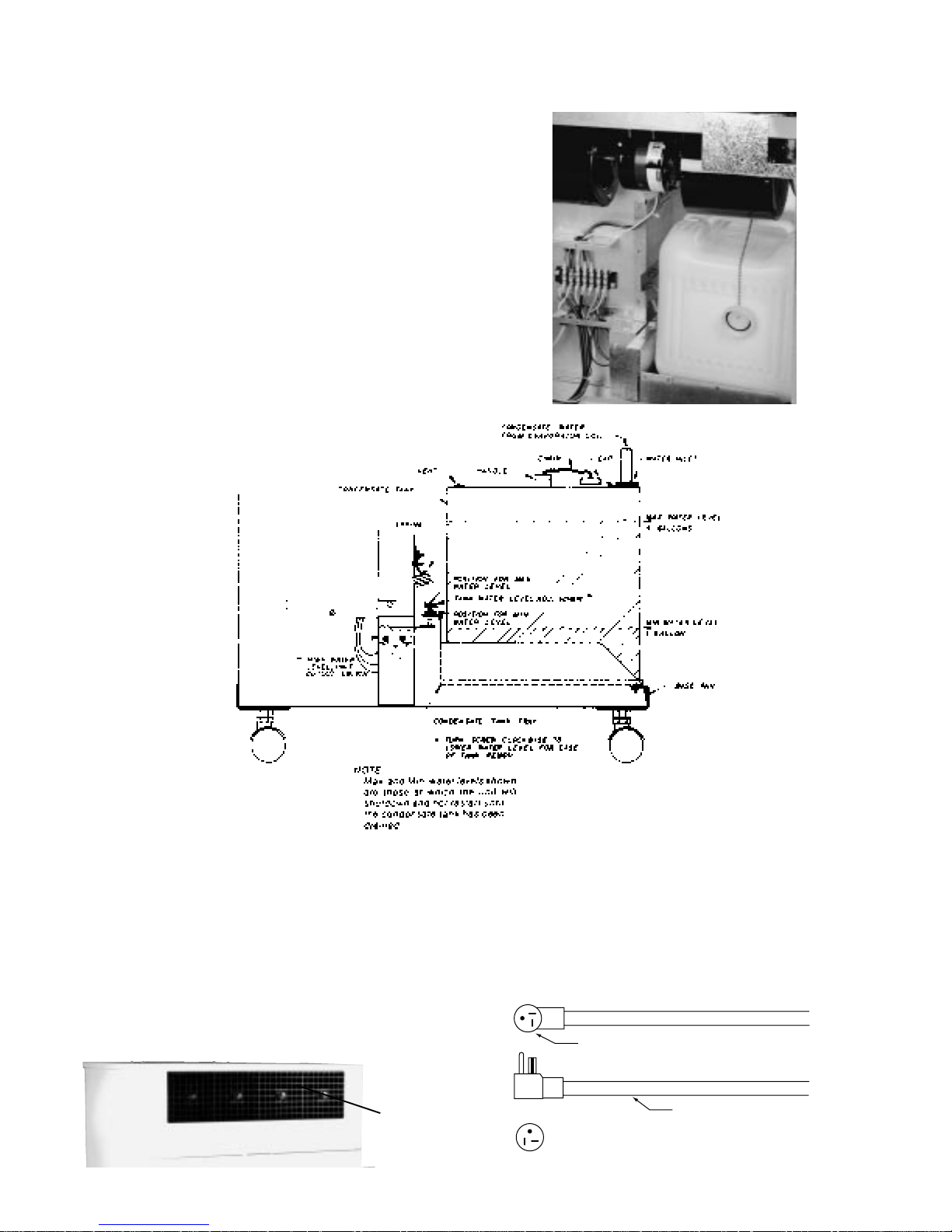

RELIABLE CONTROLS

The self-contained unit maintains the desired amount

of cooling, which can be selected by adjusting the

thermostat to warmer or cooler. The thermostat

sensing bulb is in the return air stream behind the

louvered return air grille and return air filter. The range

of the thermostat is from 65-100° with a differential of

± 3°F.

Rear of

Front Panel

Thermostat

Bulb

The three-position, mode selector rocker switch,

located in the front panel, has three functions:

1. To provide fan only operation when depressed to

the right.

2. To turn the unit off when set in the center position.

3. To activate the cooling mode when depressed to

the left.

1. Nameplate

2. H.P.C. Reset Button

3. Condenser Filter

4. Service Cord

1

2

3

The blue colored light above the thermostat indicates

the thermostat is calling for cooling mode operation.

Compressor may or may not be on, depending on the

thermostat setting. The red, “tank full” warning light

indicates condensate tank is full and needs to be

emptied. The two-position, fan-speed rocker switch,

located below the mode selector switch, provides high

fan speed when depressed to the right and low speed

when depressed to the left.

Mode

Selector

Switch

Cooling Mode

Indicator (Blue)

Tank Full

Indicator (Red)

4

Thermostat

Fan

Speed

Switch

Convenient Control Panel

5

KOLDWAVE 2AK (AIRMASTER)

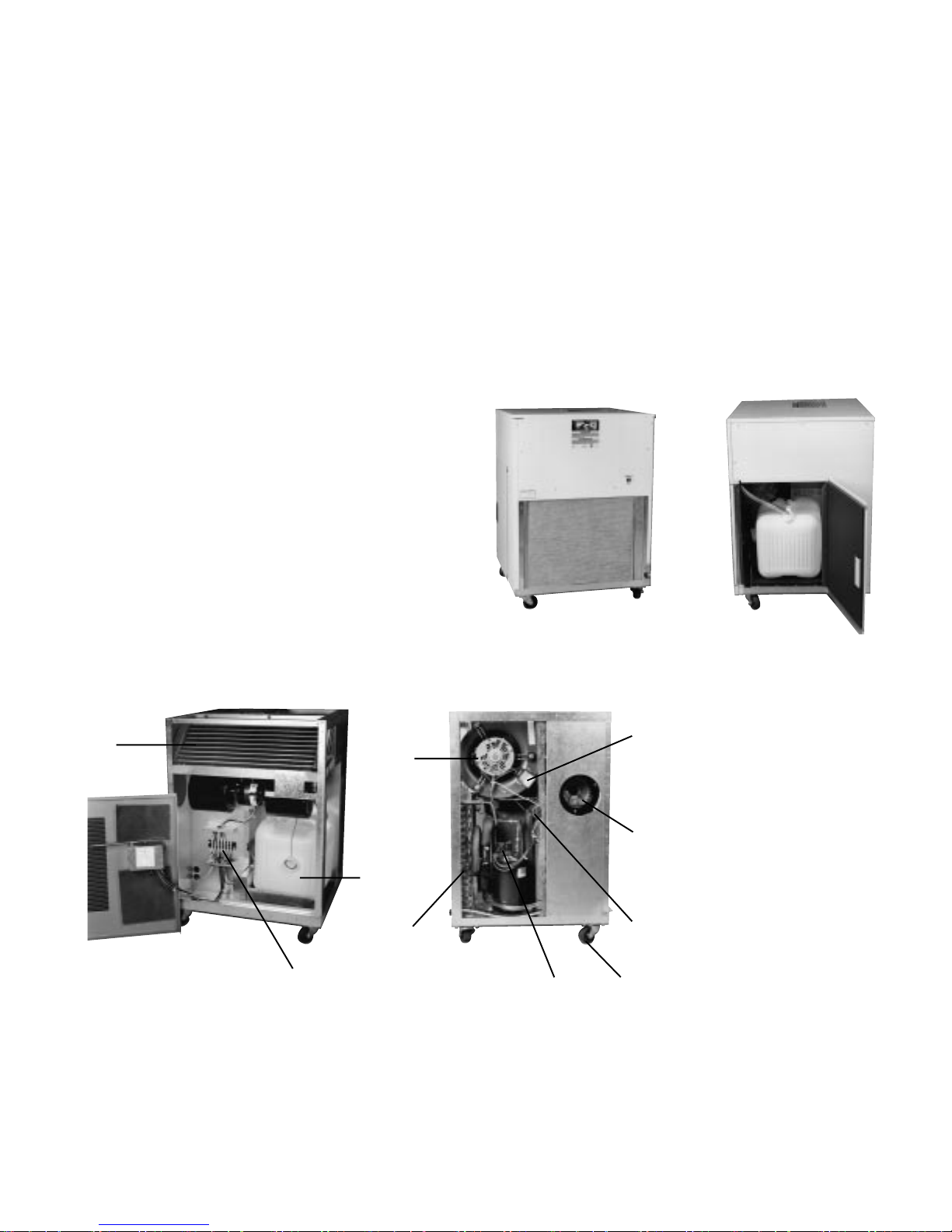

CONDENSATE RESERVOIR TANK

The Koldwave Airmaster incorporates a 5.0 gallon

capacity, polyethylene, condensate drain tank, located

in the lower, front section of the unit. A high water cutout switch is used to stop the entire unit’s operation

automatically when the tank is full of water. An

adjustment screw is provided to set the desired

condensate level where the unit cuts out. Turn screw

clockwise to lower water level and thus decrease the

tank’s weight for emptying. To prevent spillage, the

tank is equipped with a cap, which is chained to the

top of the tank, and a vent for easy drainage.

CAUTION: Turn unit off before emptying tank when

tank light is illuminated.

DISCHARGE AIR GRILLES

The Koldwave Airmaster is equipped with (4) 5" x 5",

four-way adjustable, plastic grilles, located in the upper

front panel, enabling a variety of air flow possibilities.

Pull out each black grille (approximately 3/4") and

rotate to the desired position. Release the grille and

allow it to return to the set position within the cabinet.

By this means, air flow can be positioned in any four

directions.

Adjustable

Air Grilles

SERVICE CORD

The six foot service cord employed in Model

2AK1411M will not fit in the standard household

receptacle. Required is a 20A-125 volt NEMA 5-20

receptacle. Model 2AK1011 uses a standard 15 amp

plug.

PLUG END TERMINATION

JACKET

RECEPTACLE

20A - 125V

NEMA 5-20R

6

KOLDWAVE 2AK (AIRMASTER)

AIR FILTERS

The Koldwave Air master employs two, 1/2" thick,

washable aluminum mesh air filters, located behind

the louvered front (evaporator) panel and beneath the

back (condenser) panel. The evaporator filter can be

easily removed and cleaned; just pull the filter end cap

at the bottom of filter and slide out. The condenser

filter is removed by lifting the tab at bottom of filter,

then pulling toward you and down.

ELECTRICAL

Electrical control is concentrated in an enclosed area

behind the control panel. Electrical interconnection is

achieved via a multi-position terminal strip located in a

junction box fastened to the bulkhead wall.

1

2

3

4

GENERAL AIRFLOW PATTERNS

Condenser air is drawn in through the lower rear

section of the unit and passes through the condenser

coil and extracts heat. The hot air is blown out the

upper exhaust air opening. Evaporator air is taken

through the lower, front, louvered panel and is cooled

by the evaporator coil. It’s then blown in through four,

adjustable, four-way grilles, enabling a variety of

airflow possibilities. Both condenser and evaporative

air inlets are provided with filters.

1. Evaporator Fan Motor

2. Control Enclosure

3. Terminal Block Enclosure

4. Condensate Pump Assembly (Optional)

7

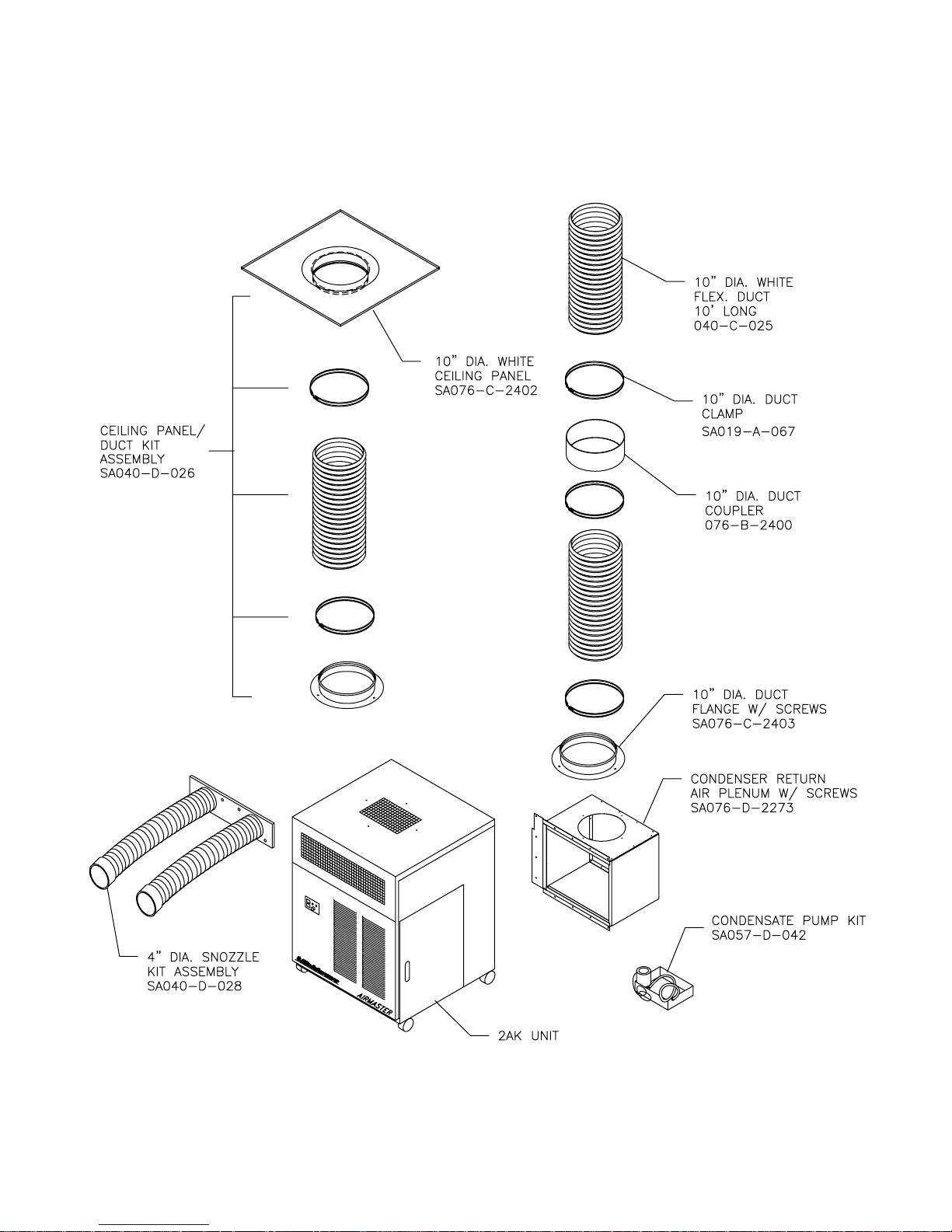

KOLDWAVE 2AK (AIRMASTER)

ACCESSORIES

8

KOLDWAVE 2AK (AIRMASTER)

CEILING PANEL/DUCT KIT ASSEMBLY

(OPTIONAL)

A 10" diameter, flexible duct kit assembly extends up

to 10 feet, to vent condenser air or to draw condenser

return air from the ceiling when condenser return air

plenum is used. It comes with 2' x 2' lay-in ceiling

panel/collar assembly, for venting into the plenum area

above the false ceiling, plus a duct collar to attach duct

to unit. Installation of the flexible duct can be achieved

in the following manner:

1. Slip one end of the duct over the lay-in ceiling

panel/collar assembly and other end over the unit

duct collar.

2. Clamp duct to lay-in ceiling panel/collar assembly

and unit duct collar (see “Duct Design” for details.

3. Place the 2' x 2' lay-in ceiling panel in the false

ceiling directly above the unit.

4. Screw duct collar to unit with four screws provided.

9

KOLDWAVE 2AK (AIRMASTER)

DUCT DESIGN

Condenser Duct

Should a longer 10" diameter duct be needed on the

condenser discharge, 10 foot flexible ducts may be

coupled together up to a maximum equivalent length

of 60 feet (allow 6 feet for every 90° bend).

10" Diameter Duct Clamp SA019-A-067

Duct Clamps

Two 10" diameter wire duct clamps are used to secure

the condenser air exhaust duct to the lay-in ceiling

panel/collar assembly and the Koldwave Airmaster

exhaust duct collar.

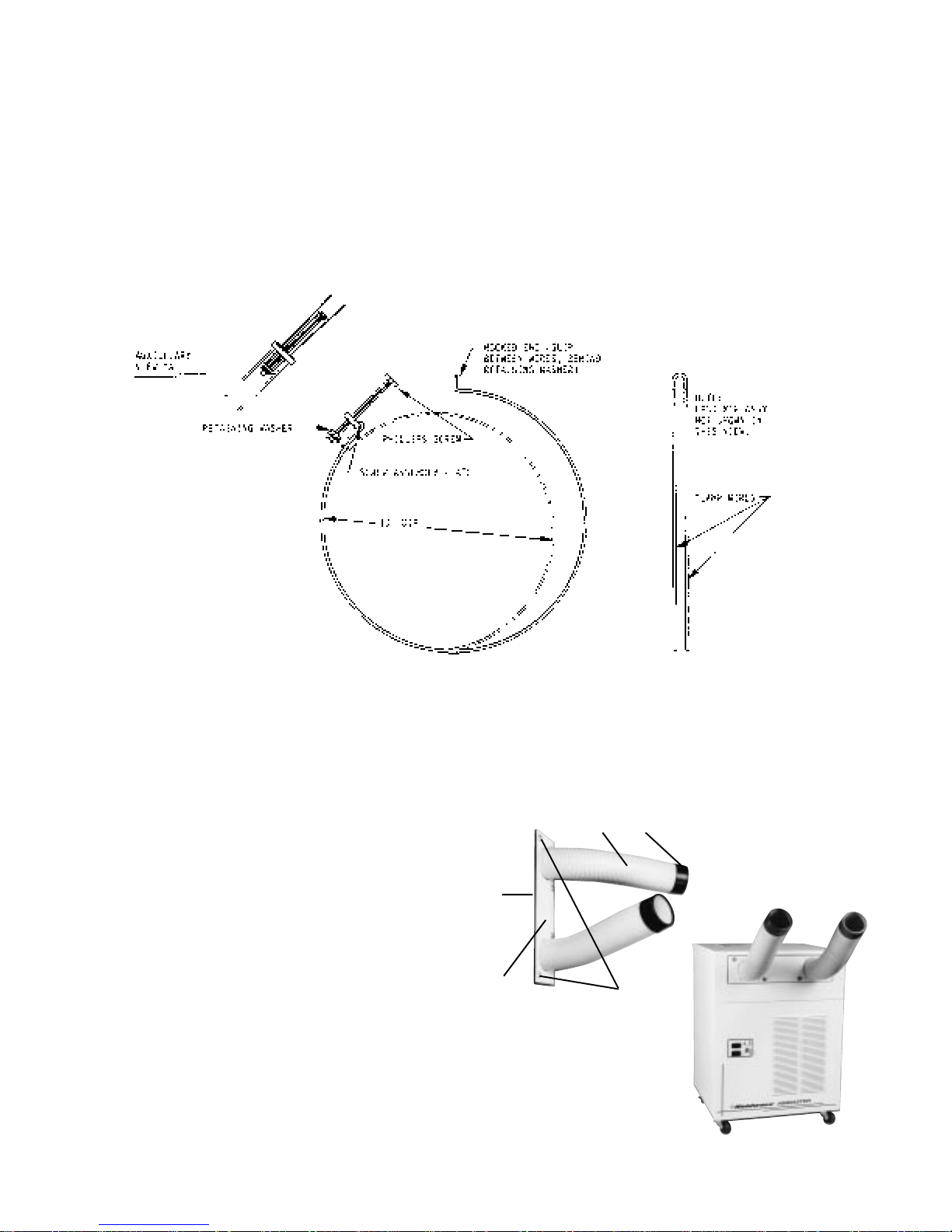

DISCHARGE AIR SNOZZLE® KIT ASSEMBLY

(OPTIONAL) SA040-D-028

A 20 gauge painted steel air discharge snozzle

mounting plate assembly can be furnished as an

optional item. Its purpose is to accommodate various

spot cooling applications, where air can be aimed and

concentrated on the object to be cooled. The plate is

designed with two 4" diameter, 16" compressed and

22" long extended flexible air duct snozzles®. The use

of the snozzles® will derate the capacity by

approximately 13%. The snozzle® plate is mounted

over the evaporator air discharge opening by 1/4 turn

Pawl Latch fasteners for each removal. It is secured in

place by tightening the four fasteners provided with the

plate assembly. It can be removed easily by tur ning

the fastener on quarter turn counter-clockwise.

3

5

®

4

2

1. 1/4 Turn Pawl

Latch Fasteners

2. Mounting Plate

3. Snozzle Caps

4. Insulation

5. Snozzle Duct

1

10

KOLDWAVE 2AK (AIRMASTER)

11

CONDENSATE RETURN AIR

PLENUM (OPTIONAL)

A 20 gauge, painted steel,

condenser return air plenum can

be furnished for applications of the

Koldwave Airmaster as a room air

conditioner. This plenum is

designed for use with a flexible

duct kit assembly. The duct collar

of the duct kit assembly can be

secured with four screws over a

10" diameter hole in the top of the

plenum. The duct can then be

connected to the lay-in ceiling

panel, so condenser return air is

drawn from the false ceiling above

the unit.

The plenum is mounted to the

condenser air intake by sheet

metal screws. A filter frame is

incorporated in its design to allow

easy removal of the filter for

cleaning from the right side of the

unit. The filter frame is made to

accept the unit’s standard

condenser air filter with the filter

handle relocated from the bottom

to side of filter at installation.

SA076-D-2273

KOLDWAVE 2AK (AIRMASTER)

NOTE: See “Application” section

for typical installation.

12

KOLDWAVE 2AK (AIRMASTER)

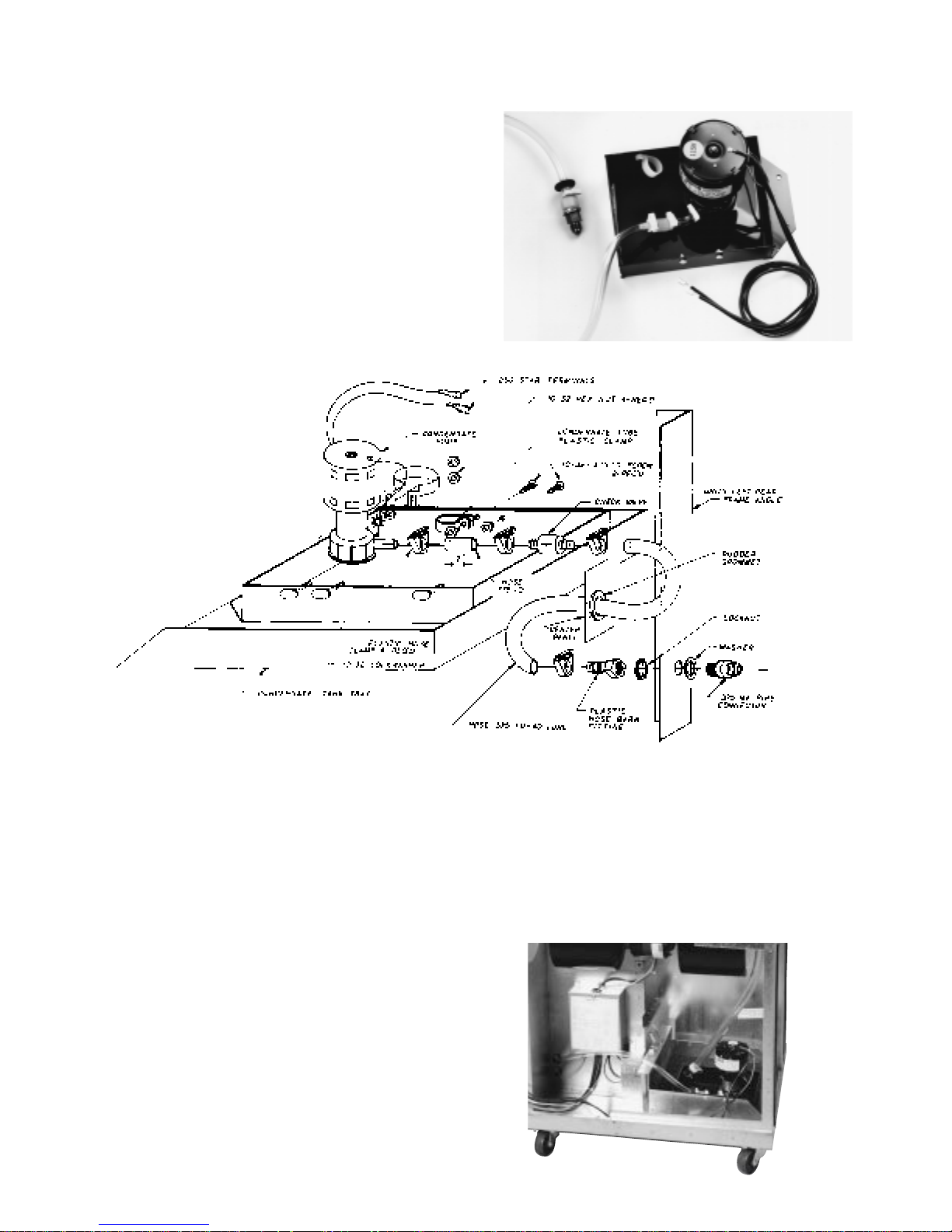

CONDENSATE PUMP KIT (OPTIONAL) SA057-D-042

A condensate pump, capable of pumping against an

11 foot head, can be installed for positive removal of

evaporator condensate. This kit is a convenience for

those who do not wish to empty the five gallon

condensate tank periodically, especially for units with

permanent installation. At the condensate pump, a

check valve is inserted in the hose and secured by

plastic clamps. The installation can be accomplished

by following the simple steps outlined in “procedures to

install condensate pump kit assembly”.

PROCEDURE TO INSTALL

CONDENSATE PUMP KIT ASSEMBLY

1. Disconnect unit from power source.

2. Pull out clear plastic drain hose from inside of tank

and remove tank from hinged tray.

3. Mount pump kit assembly in hinged tray using the

two holes provided in the tray flange facing front

panel by using the two machine screws and hex

nuts.

4. Route clear plastic hose from pump through a hole

in the bulkhead below the terminal strip enclosure

and up to another hole located in the left rear frame

angle. Both holes are plugged by knockout buttons

which should be removed. Fit a 1-1/8" O.D. rubber

grommet into the hole in bulkhead prior to inserting

plastic hose through it.

5. Insert a 3/8" MF pipe connector into 1" O.D. steel

washer and into the left rear frame angle. Lock

connector in the frame angle with a locknut.

6. Screw tightly the 3/8" FPT x 3/8" plastic hose barb

into the 3/8" MF pipe connector.

7. Insert plastic hose from pump into hose barb and

clamp with a #30 nylon hose clamp.

8. Connect pump wire leads to terminal strip positions,

number 1 and 2.

9. Insert plastic drain hose from evaporator pan into

the drain tube clamp provided in the pump kit

assembly (see the drawing).

13

KOLDWAVE 2AK (AIRMASTER)

APPLICATIONS

ZONE COOLER

Koldwave Airmaster can be employed in an open

environment as a zone cooler to cool a specific object

which the evaporator grilles or the optional snozzles®

direct the air toward. In this application, ducts for

condenser air intake and hot air exhaust are not

required. Zone cooling provides convenient,

economical and energy efficient air conditioning in

areas where cooling the entire environment is

impractical. It directs cool air only where aimed and

needed without wasting it elsewhere. Note that even

though the object is cooled with a concentrated air

supply, the surrounding area will slightly be heated up

by the condenser’s hot exhaust air. Cooling tanningbed rooms, beauty parlors and vehicle maintenance

department are just a few areas that can benefit from

this application. The figure below shows a typical

example of how the unit can be applied.

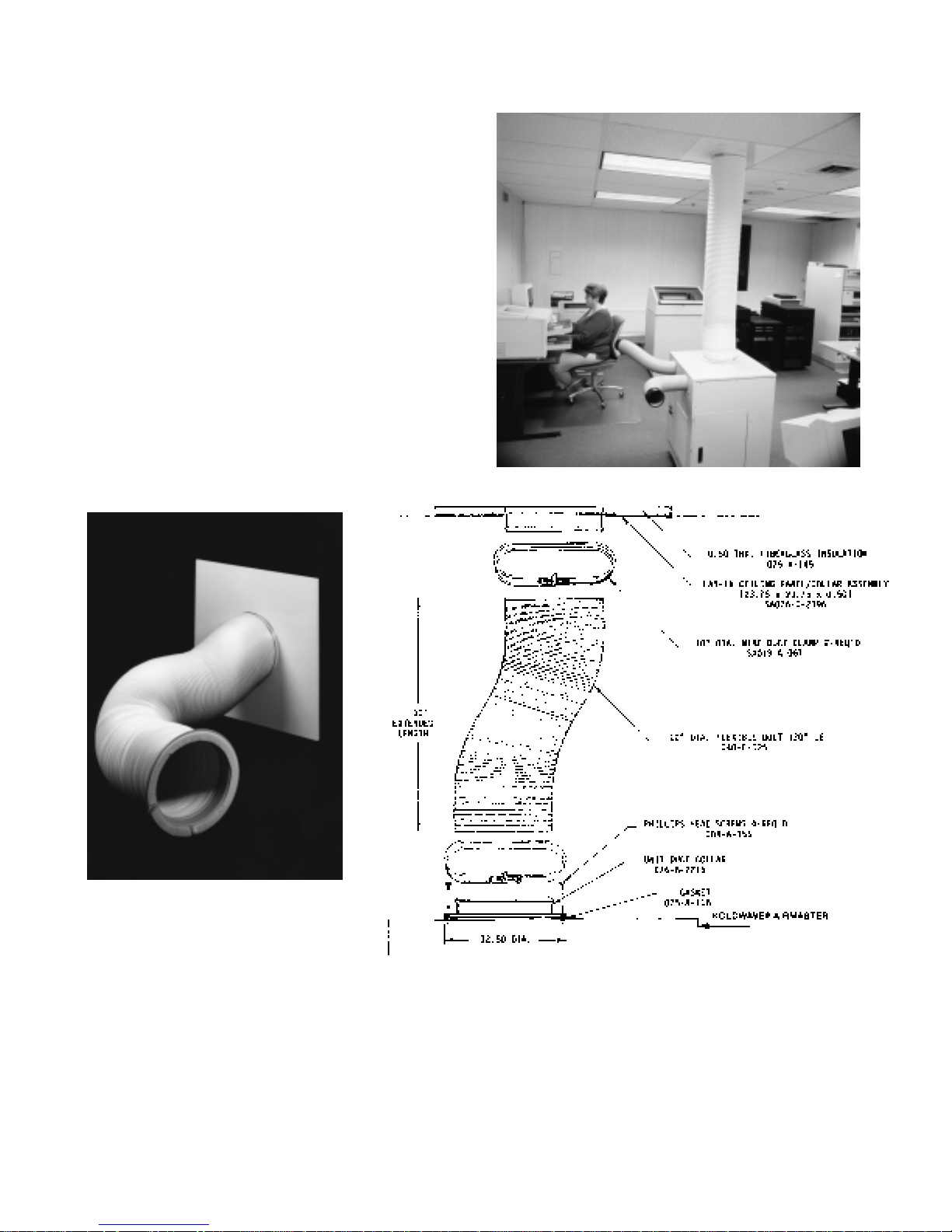

AREA COOLER

In a similar application where a specified area needs

to be cooled a condenser hot air exhaust duct may be

employed as shown in the figure below. Refer to

(optional) “Flexible Duct Kit Assembly” for more

details. Evaporator discharge grilles (as standard) or

optional snozzles may be used.

While evaporator discharge air cools the air directly in

front of the unit, warm room air will be drawn into the

rear of the unit to cool the condenser and then

discharged into the false ceiling. The net effect will be

a cooler area all around the unit.

When installed in an enclosed area used as a room air

conditioner, the Koldwave Airmaster will require makeup air for condensing. A return air plenum and return

air ducting are available to supply condensing air from

outside the conditioned space.

14

KOLDWAVE 2AK (AIRMASTER)

ROOM AIR CONDITIONER

Koldwave Airmaster may also be used as a room air

conditioner to cool the entire enclosed space it is

placed in. In this application, hot exhaust air venting

and condenser air intake ducting are definitely needed.

This can be accomplished by employing the “Flexible

Duct Kit Assembly” (optional) and the “Condenser

Return Air Plenum” (optional) as specified in the

“Optional Features” section. See figure below for

orientation of flexible ducts.

The condenser coil is cooled by the air drawn from the

false ceiling. The air passes through the hot condenser

coil, gets heated up, then discharges to an area

outside the room being cooled (outdoors).

INSTALLATION INSTRUCTIONS

Before installing: Check the air conditioner/spot cooler

for any shipping damage. Air conditioners are

thoroughly inspected at the factory and carefully

packed. If any damage is evident, file a claim with the

delivering carrier immediately.

Electrical requirements: Check the data plate on the

unit to make certain that the proper power is available.

Refer to “Specifications” section for voltage, fuse

requirements and proper NEMA receptacles. Check for

proper wall outlet as described in “Standard Features”

section. Operating the unit on improper voltages will

void the warranty.

CAUTION: An extension cord can be used provided

it is rated at least 20 amps @ 115 volts with

grounding-type attachment plug and grounding type

connector (load fitting).

Koldwave Airmaster portable air conditioner/spot

cooler requires minimal installation. It merely plugs

into a NEMA 5-20R receptacle for 2AK1411M or 5-15R

for 2AK1011 and immediately begins to cool. The

entire system is built into one compact unit which can

be moved and installed easily.

15

KOLDWAVE 2AK (AIRMASTER)

CHECK OUT OF UNIT OPERATION

Koldwave Airmaster portable spot cooler provides fan

only air circulation and cooling modes. This is

accomplished by setting the controls to operate in any

of the following:

Fan Only

Plug unit in. Depress the upper mode selector switch

to the right for fan operation. Depress the lower fan

speed selector switch to the left for low fan speed and

to the right for high speed.

Cooling Cycle

Depress the upper mode selector switch to the left for

cooling. Set the thermostat knob below actual room

dry bulb temperature level. Blue colored light located

next to the upper rocker switch on the panel should

illuminate, indicating the cooling mode of operation.

Allow unit to run fan speed set on high for twenty

minutes. Record temperature of air entering filter and

temperature of air leaving the discharge grille. In a

room of approximately 80°F dry bulb, air temperature

coming from the grille should be approximately 15°F

cooler than air returning to filter. This cycle reduces the

dry bulb temperature and it lowers the wet bulb

temperature by condensing water on the cooling coil

surface. The red colored light located next to the blue

colored light on the panel should illuminate when

condensate tank is full. Refer to “Condensate

Reservoir Tank” section.

TROUBLESHOOTING GUIDE

SERVICE PROCEDURES

Always disconnect power and discharge capacitors

before servicing. Before troubleshooting this system,

read this manual to determine electrical power and

installation requirements to allow the spot cooler to

perform at its maximum efficiency. Refer to general

description, wiring diagrams and photographs to get

an understanding of how the unit functions.

Service other than routine maintenance should be

performed only by a qualified refrigeration service

person. In service/troubleshooting, there is no

substitute for a good understanding of the Koldwave

Airmaster modes of operation, control systems,

components and safety systems (see service

performance chart).

SYSTEM PERFORMANCE CHART

The chart below shows suction and discharge

pressures (PSIG), plus total amp draw with evaporator

fan on high speed, with condenser motor on high

speed and with condenser blower baffle. The

condenser discharge air is ducted into another area

with a 10" diameter, 10' long flexible duct.

Ambient Temperatures V ersus

Suction and Discharge Pressures

Room

Model

2AK1011

2AK1411M

Use the above chart for reference when suction and discharge

pressure and total amps are a determining factor in analyzing the

problem. Refer to troubleshooting guide when above data can be

useful in determining overcharge or undercharge of unit.

Conditions

104°F DB/80°F WB

95°F DB/83°F WB

95°F DB/75°F WB

80°F DB/67°F WB

75°F DB/62°F WB

72°F DB/60°F WB

67°F DB/57°F WB

104°F DB/80°F WB

95°F DB/83°F WB

95°F DB/75°F WB

80°F DB/67°F WB

75°F DB/62°F WB

72°F DB/60°F WB

67°F DB/57°F WB

Suction

Pressure

104

100

93

78

71

69

65

93

79

93

79

71

68

63

Discharge

Pressure

317

271

277

216

198

187

171

321

290

282

224

207

193

178

Total

Amps

11.5

10.6

10.5

9.2

8.8

8.6

8.3

13.9

12.9

12.7

11.1

10.6

10.3

9.8

16

KOLDWAVE 2AK (AIRMASTER)

TROUBLE SHOOTING GUIDE continued

PROBLEM SYMPTOM POSSIBLE CAUSE REMEDY

Unit does not

operate.

Insufficient cooling.

Entire unit does not

operate.

Unit starts, but stops

immediately.

Unit operates, but

stops after a few

minutes.

Insufficient air flow

through evaporator.

Evaporator discharge

air not cool.

Compressor motor not

running.

1. Power Interruption.

2. Defective tank full unit cutout switch.

3. Condensate tank could be

full, but red light might be

defective.

1. Defective compressor

overload relay.

2. Defective compressor motor.

3. Defective run capacitor.

1. Defective compressor motor.

2. Defective over load relay.

3. Defective high pressure

switch.

4. Loose connection in

electrical circuit.

5. Manual reset button out on

HPC.

6. Unit overcharged.

7. Dirty condenser coil and

filter.

8. Condensate tank right at trip

point.

9. Condenser fan running at

high ESP.

1. Improper size of unit.

1. Dirty air filter in unit.

2. Dirty evaporator or

condenser.

3. Ice on evaporator coil.

4. Obstructed intake.

5. Defective condenser fan

motor or its capacitor.

1. Refrigerant leak.

1. Defective compressor motor.

2. Defective compressor

capcitor.

3. Defective over load relay.

4. Defective thermostat.

5. Defective wiring connection.

6. Defective wiring.

1. Check external power supply.

2. Check and replace.

3. Check tank and replace red

light if defective.

1. Replace after checking current.

2. Remove and replace.

3. Check and repalce.

1. Check and replace.

2. Replace after checking current.

3. Check cut-out setting and

replace if defective.

4. Trace loose wire(s) and firm up

connection.

5. After diagnosing and correcting

cause for unit trip out, begin

unit operation by depressing

the red button located in the

back panel.

6. Purge some refrigerant.

7. Clean filter and condenser coil.

8. Empty tank.

9. Check fan speed and correct.

1. Check if the unit is undersized

for the load, Add supplemental

unit(s).

1. Clean air filter.

2. Unusual condition requires

cleaning.

3. Defrost. Use fan only by

depressing the upper rocker

switch to right.

4. Remove obstuction.

5. Check and replace.

1. Locate leak and repair.

Evacuate and recharge.

1. Check and replace.

2. Check and replace.

3. Check and replace.

4. Check and replace.

5. Check and repair.

6. Check and replace.

No cooled air discharge.

Evaporator blower

motor not running.

1. Defective fan motor.

2. Defective fan motor

capacitor

3. Defective wiring connection.

4. Defective fan speed switch.

5. Defective thermostat.

17

1. Check and replace.

2. Check and replace.

3. Check and repair.

4. Check and replace.

5. Check and replace.

KOLDWAVE 2AK (AIRMASTER)

PROBLEM SYMPTOM POSSIBLE CAUSE REMEDY

Evaporator blower not

running up to full speed.

Evaporator fan runs,

but compressor does

not start.

Abnormal noise.

Room air temperature

discharged through

grilles.

1. Low voltage to unit.

2. Defective motor capacitor.

3. Blower wheel rubbing

against housing.

1. Low voltage to unit.

2. Thermostat.

3. Loose or defective wires.

4. Stuck compressor.

5. Compressor shorted, open

or burned.

6. Shorted or open run

capacitor.

7. HPC holding unit off.

1. Loose compressor mounting

nuts.

2. Defective, improper or worn

rubber grommets on the

compressor mounting bolts.

3. Copper Tube vibrating.

4. Loose cabinet or internal

component

5. Loose blower wheel.

6. Blower wheel hitting shroud.

7. Blower bearing defective.

1. Determine reason and correct.

2. Replace capacitor.

3. Inspect wheel alignment and

correct.

1. Check power supply for proper

voltage at unit; ± 10% of rated

nameplate voltage.

2. Check the temperature control

for loose wires. Firm any loose

connections. Replace if

defective.

3. Tug on wires to see if they will

separate from connections.

Replace terminals if necessary.

4. Try a start capacitor across the

run capacitor momentarily

(three seconds).

5. Check for shorts, opens and

grounds. Remove and replace

compressor.

6. Remove and replace.

7. Check condenser fan.

1. Tighten.

2. Replace.

3. Adjust by bending slightly to

firm position. Separate tubes

touching cabinet or each other.

4. Check and tighten loose

screws.

5. Tighten scres on blower wheel

to shaft.

6. Adjust wheel position on motor

shaft.

7. Replace blower motor.

Water leaking from unit

1. Leaking evaporator or

condensate pan.

2. Dirty evaporator coil.

3. Defective drain hose

(clogged or loose

connection).

4. Defective microswitch

causing condensate tank to

overflow.

5. Hole or crack in condensate

tank.

18

1. Locate leak and repair pan.

2. Check to see if the elevation is

over 11 ft. (if it is over 11 ft., a

larger condensate pump is

required). Otherwise, replace

pump if defective. Pump will

operate properly against 11 ft.

of water total head pressure on

pump. If combination of vertical

height and horizontal drain line

exceeds 11 ft. of water

pressure drop, problems may

arise.

3. Repair or replace.

4. Remove and replace.

5. Remove and replace.

KOLDWAVE 2AK (AIRMASTER)

INSPECTION AND REPAIR OF ELECTRICAL SYSTEM

Always disconnect power and discharge capacitors

before servicing.

Thermostat

Check for continuity across terminals 1 and 2 of the

thermostat. At normal temperature (65°F or higher)

there is continuity across those two terminals. If

continuity is broken across the terminals, replace the

thermostat.

Fan/Off/Cool/Switch

At each position of the fan/off/cool switch, there should

be continuity across the following terminals.

Switch Conducting

Position Terminals

Off None

Fan Center and Left

Cool Center and Right

If there is no switch continuity in the fan and cool

position, replace the switch.

Fan Speed Switch

Switch Conducting

Position Terminals

High Speed Center and Left

Low Speed Center and Right

There should be continuity across the above terminals.

If none, replace switch.

Tank Full Unit Cut-Out Switch

Depress the microswitch to check for continuity. If

there is no continuity between common and normally

open terminals, replace the switch.

High Pressure Switch

Check for continuity across terminals 1 and 2 of the

high pressure switch. At normal pressure when the unit

is not operating, there is continuity across the two

terminals. If continuity is interrupted across the

terminals, replace the high pressure switch.

Compressor Motor

Measure resistance across the terminals of the

compressor motor.

Resistance between C-R at 70°F

approximately 0.65 OHMS ± 10%

Resistance between C-S at 70°F

approximately 4.50 OHMS ± 10%

Replace compressor when resistance is not at the

stated values.

Compressor Overload Relay

Check for continuity across overload relay’s tow

terminals. At normal room temperatures, there is

continuity across the two terminals. If no continuity

exists, replace the over load relay.

Compressor and Fan Motor Capacitors

Before and after the test, always short across two

terminals to discharge electrostatic charges. Set the

ohmmeter to 100 OHMS range and place its two

probes against the two terminals of the capacitor. At

first, the ohmmeter should indicate zero OHMS, then

the meter reading should gradually approach infinity. If

the ohmmeter shows infinity from the outset or the

meter reading does not move from zero OHMS,

replace the capacitor.

Condenser Fan Motor

Measure resistance across the terminals of the fan

motor.

Resistance across white and black

7.42 OHMS ± 10% at 25°C

Resistance across red and black

11.94 OHMS ± 10% at 25°C

Resistance across white and red

19.36 OHMS ± 10% at 25°C

Cut-out pressure – 375 psig

Cut-in (restart) pressure – 275 psig

When resistance is not within these stated values,

replace the fan motor.

19

KOLDWAVE 2AK (AIRMASTER)

Evaporator Fan Motor

Resistance across white and black

22.5 OHMS ±10% at 25°C

Resistance across red and black

26.2 OHMS ± 10% at 25°C

Resistance across white and red

48.7 OHMS ± 10% at 25°C

When the resistance is not within these stated values,

replace the fan motor.

Condensate Pump Motor (optional)

Measure resistance across the terminals of the pump

motor. 31.0 OHMS ± 8% at 25°C. when the resistance

is not within these stated values, replace the pump

motor.

Tank Full and Cooling Mode Pilot Lights

Make a test circuit as shown in figure below. If the light

fails to illuminate, replace it.

CONTROL

ENCLOSURE

TERMINAL BLOCK

ENCLOSURE

20

KOLDWAVE 2AK (AIRMASTER)

INSPECTION AND REPAIR OF REFRIGERATION LEAK

WARNING: All repair work on the refrigeration

system must be done by a qualified service

technician who is certified to handle refrigerants.

Carefully check all connection and every part for leaks

whenever the refrigerant system is repaired. Use a

leak detector or the halide torch to inspect the system.

PARTS REPLACEMENT PROCEDURE

When repairing a leak, use dry nitrogen gas. During

brazing, the inside of the pipe undergoes oxidative

reaction due to the brazing flame. It is desirable to use

a slightly reduced flame. Conduct dry nitrogen gas

through the refrigerant piping to prevent oxidation.

Always evacuate refrigeration system thoroughly with

a vacuum pump before charging the system with

refrigerant.

Always disconnect power and discharge capacitors

before servicing.

Thermostat and Rocker Switches

1. Remove evaporator filter by pulling filter end cap at

bottom and slide out.

2. Open hinged right side bottom panel.

3. Remove four Phillips head screw from front right

and left corner posts of the chassis holding front

panel. Remove front panel and pull away towards

left. Unscrew two sheet metal screws securing

cover to control box.

4. Remove thermostat sensor bulb from clip secured

on control box cover. Disconnect wires from

controls. Pull thermostat knob out and unscrew hex

nut retaining thermostat.

5. Remove wires from rocker switches, press down

four positive-locking legs of rocker switches used

for snap-in mounting and pull out. Replace controls

and reverse above procedures.

Pilot Lights

To remove pilot lights, remove evaporator filter and

front panel, disconnect wires from controls, bend

Tinnerman clip retaining light and pull out. Install new

light(s) reversing above procedure.

Condenser Fan Motor

To gain access to condenser fan motor, remove left

hand side, top, back and front cabinet panels. Remove

fan motor wires from capacitor, high pressure switch

and terminal strips. Loosen set screw in blower wheel.

Loosen clamp around motor housing and remove

motor. Unfasten clamp around motor and replace

motor, reversing above procedures.

Condenser Blower Housing

To replace the condenser blower housing, first remove

condenser fan motor as described in “Condenser Fan

Motor”. Unscrew four 1/4-20 bolts and four sheet metal

screws holding blower to chassis and top panel.

Remove six self-tapping screws off the bracket

mounted on the housing. The blower wheel can be

replaced by pulling it out through the blower housing’s

discharge opening after removing the blower cut-off

plate. Replace housing, reversing the above

procedure.

Evaporator Fan Motor Assembly

Remove the left hand side and front cabinet panels.

Open hinged right side bottom panel by pushing on the

identified area. Remove fan motor wires from terminal

strip and fan speed rocker switch. Loosen set screw in

blower wheels. Remove locknuts retaining motor to

motor base. Remove motor and blower housings.

Blower wheels can be removed after taking off the

outside blower rings. No you can replace fan motor,

housings or wheels without removing the fan board by

reversing the above procedure.

Tank, Terminal Strip and Microswitch

The lower front section of Koldwave Airmaster

encloses the electrical terminal strips and the

condensate holding tank and its water level detection

system. Access can be gained to those parts by simply

removing the front panel.

Compressor and Running Capacitor

To service the compressor and its running capacitor,

remove the left hand side panel.

21

KOLDWAVE 2AK (AIRMASTER)

High Pressure Control

To gain access to the high pressure

control, remove the condenser air filter by

holding tab at bottom of filter, lifting filter

and pulling toward you and down. Remove

back and left hand side cabinet panels by

removing 13 Phillips head screws.

Remove screw from high pressure control

plastic cover and pull cover off and three

wires behind it. Unscrew two machine

screws holding control to condenser coil

flange. Loosen 3/8" flare nut securing

control capillary tube to Shrader fitting in

compressor discharge line. Replace high

pressure control, reversing above

procedure.

Condenser Fan Motor Speeds

Koldwave Airmaster is shipped from

factory with condenser fan motor wired on

low speed. A noise baffle is mounted

partially over the condenser blower

opening. The external static pressure

(E.S.P.) at the condenser discharge

cannot exceed 0.25" of water. When

employing more than 10 ft. of duct, the

condenser fan should be wired on high

speed and the noise baffle removed. This

will prevent the unit from tripping on its

high pressure control at high ambients.

To change condenser fan speed from low

to high, replace black wire from fan at high

pressure control with taped red wire from

fan motor (see paragraph on high

pressure control above to gain access to

high pressure control).

Removal of Noise Baffle

To gain access to noise baffle, remove the

four discharge grilles by pulling out each

grille (approximately 3/4") and pushing

down to snap out the tip spring and lift out.

Unscrew (12) Phillips head screws to

remove top, and loosen left and right side

cabinet panels. Remove condenser blower

wire mesh guard. The noise baffle is

located between the condenser blower

housing and the insulation (see figure

below). Remove baffle and assemble

remaining parts by reversing above

procedure.

22

KOLDWAVE 2AK (AIRMASTER)

CONDENSER BLOWER MOTOR ASSEMBLY

EVAPORATOR BLOWER MOTOR ASSEMBLY

23

KOLDWAVE 2AK (AIRMASTER)

PREVENTATIVE MAINTENANCE

Always disconnect power and discharge capacitors

before servicing. Koldwave Airmaster portable zone

cooler has been designed to give maximum

performance and reliability with minimum

maintenance. Maintenance of the system is

concentrated in three areas covered as follows.

Blower Motors

The only required maintenance to the condenser and

evaporator blower motors is to oil them annually. This

can be accomplished by following these simple steps:

1. Remove left hand side panel to gain access to

condenser blower motor. Access can be attained to

the evaporator blower motor by removing the front

panel.

2. Remove yellow oil plugs form oil ports.

3. Add 30 drops (1/5 teaspoon) SAE 20 non-detergent

oil into the ports.

4. Replace yellow oil plugs.

Filters

The life of a filter depends entirely on its environment

and use. It is recommended that air filters be inspected

on a regular basis every five to six weeks. A clogged

filter will cause the unit to operate at greatly reduced

efficiency. This unit employs two 1/2" thick, washable,

aluminum mesh air filters located beneath the louvered

front (evaporator) panel and beneath the back

(condenser) panel. The evaporator filter can easily be

removed and cleaned; just pull filter end cap at bottom

of filter and slide out. The condenser filter is removed

by holding tab at bottom of filter, lifting and pulling

toward you and down. The filters must be washed

periodically when needed. This may be done as follow:

1. Soak filter in solution of warm water and detergent

for 15 minutes.

2. Rinse in clean, hot water and shake excess

moisture from filter.

3. Spray one side of filter with light film of oil.

4. Reinstall with oiled surface facing out from unit.

Condensate Pump (optional)

The condensate pump is located in the lower front

section of the unit. To gain access to condensate

pump, open access door on right hand side of unit.

The pump motor requires oiling every six months with

SAE 20 non-detergent oil. The pan beneath the

condensate pump should be cleaned when mineral

deposits are visible. A clean pan will prolong the life of

the pump and its operation.

24

KOLDWAVE 2AK (AIRMASTER)

General

Always disconnect power and discharge capabilities

before servicing.

If the necessary maintenance steps outlined above are

carried out regularly, the unit will provide long and

reliable service which should only be serviced by a

fully qualified service technician.

If you experience any problems or have comments

about your Koldwave product, we are always pleased

to hear from you. This the essential way in which we

can improve our equipment and assist you in meeting

you requirements.

25

KOLDWAVE 2AK (AIRMASTER)

26

KOLDWAVE 2AK (AIRMASTER)

27

KOLDWAVE 2AK (AIRMASTER)

28

KOLDWAVE 2AK (AIRMASTER)

KOLDWAVE AIRMASTER 2AK

SERVICE AND REPLACEMENT PARTS LIST

PART # DESCRIPTION 2AK10 2AK14

STRAINERS

010-A-050 STRAINER #750011-6 X X

ASSEMBLIES, STRAINER AND CAP TUBE

SA010-A-099 STRAINER CAP TUBE ASSEMBLY X

SA010-A-098 STRAINER CAP TUBE ASSEMBLY X

BLOWERS AND BLOWER ACCESSORIES

013-A-151 BLOWER WHEEL S52-34/18-1/2 CW X X

013-A-152 BLOWER WHEEL S52-33/18-1/2 CCW X X

013-C-154 BLOWER HOUSING #450C EVAPORATOR X X

013-C-155 BLOWER ASSEMBLY 90-7T CONDENSER X X

013-B-153 INLET RING #517 X X

COMPRESSORS

020-A-233 COMPRESSOR RK124AT X

020-A-261 COMPRESSOR 2P17S3R1268 X

ELECTRICAL COMPONENTS

025-A-645 SERVICE CORD 16/3 15 AMP 115V. X

025-A-624 SERVICE CORD 14/3 20 AMP 115V. X

025-A-616 RED INDICATOR LIGHT 3LF4LRN1-20L 115V. X X

025-A-617 BLUE INDICATOR LIGH 3LF4LRN1-30L 115V. X X

025-A-608 ROCKER SWITCH TIGM721 COOL/OFF/FAN X X

025-A-609 ROCKER SWITCH TIGB51 LO/HI X X

SA025-A-618A MICROSWITCH BA-2RV-A2 X X

FILTER/AIR

030-A-041 EVAPORATOR FILTER 15-7/8 X 18 X X

030-A-055 CONDENSER FILTER 16-1/2 X 19-3/8 X X

EVAPORATORS

031-A-215 EVAPORATOR COIL #61488 X

031-A-208 EVAPORATOR COIL #61259 X

CONDENSERS

031-A-216 CONDENSER COIL #61489 X X

MOTORS/BLOWERS

050-D-146 EVAPORATOR 7189-6316 X X

050-D-145 CONDENSER 7121-2186 X X

CAPACITORS/MOTORS

017-A-010 RUN CAPACITOR 25 MFD @ 370V. X X

017-A-099 RUN CAPACITOR 5 MFD @ 370V. X X

CASTERS

021-A-044 CASTERS 121-2.5 (4 BOLT MOUNT) X X

CONTROLS

066-A-090 HIGH PRESSURE SWITCH G23-5304-37 X X

066-A-104 DEFROST CONTROL A30-2316-00 X X

066-A-098 THERMOSTAT C12-2027 X X

CAPILLARY TUBES

067-A-285 CAPILLARY TUBE .049 X 56" 2 3

DISCHARGE GRILLES

SA038-D-013 GRILLE ASSEMBLY W/SPRING CLIP X X

076-A-921 SPRING CLIP XX

KNOBS AND HANDLES

041-A-015 CONTROL KNOB G-11-ML X X

042-A-016 DOOR PULL 14208-3740 X X

ASSEMBLIES/CABINET

076-C-2214 LEFT SIDE PANEL X X

076-C-2216 RIGHT SIDE PANEL X X

076-D-2210 FRONT PANEL W/SILK-SCREEN X X

076-D-2209 TOP PANEL XX

076-C-2224 REAR PANEL XX

076-C-2217 ACCESS DOOR X X

29

KOLDWAVE 2AK (AIRMASTER)

KOLDWAVE AIRMASTER 2AK

SERVICE AND REPLACEMENT PARTS LIST

PART # DESCRIPTION USAGE

OPTIONAL ACCESSORIES FOR 2AK10/14

SA019-A-067 10" DIAMETER DUCT CLAMP

SA040-D-026 10" DIAMETER CEILING PANEL/DUCT ASSEMBLY KIT

SA019-D-028 4" DIAMETER SNOZZLE KIT ASSEMBLY DIRECTIONAL COOLING

SA076-C-2403 10" DIAMETER DUCT FLANGE

SA057-D-042 CONDENSATE PUMP KIT 115V. REMOVAL OF CONDENSATE

SA076-C-2402 10" DIAMETER CEILING PANEL

040-C-025 10" DIAMETER WHITE FLEX DUCT

076-B-2400 10" DIAMETER DUCT COUPLER

SA076-D-2273 CONDENSER RETURN AIR PLENUM

SECURE CEILING PANEL TO

FLEXIBLE DUCT AND EXHUAST FLANGE

EXHAUSTING CONDENSER DISCHARGE AIR

INTO DROP-IN CEILING

FLANGE TO ATTACH EXHAUST DUCT

TO TOP PANEL OF UNIT

2' X 2' LAY-IN PANEL FOR DUCTING

CONDENSER DISCHARGE AIR

WHEN ADDITIONAL LENGTH IS NEEDED FOR

CONDENSER DISCHARGE AIR

TO JOIN ADDITONAL LENGTHS OF

CONDENSER DISCHARGE FLEXIBLE AIR DUCT

ELIMINATES USING CONDITIONED AIR/

RE-CIRCULATEDAIR FOR RETURN

30

KOLDWAVE 2AK (AIRMASTER)

LIMITED W ARRANTY

The Manufacturer warrants to the original owner that the Product will be free from defects in material or workmanship

for a period not to exceed one (1) year from start-up or eighteen months from date of shipment from the factory,

whichever occurs first. If upon examination by the Manufacturer, the Product is shown to have a defect in material

or workmanship during the warranty period, the Manufacturer will repair or replace, at its option, that part of the

Product which is shown to be defective.

The Manufacturer further warrants that the sealed refrigeration system (the product’s compressor, condenser, and

evaporator) will be free from defects in materials and workmanship for five (5) years from date of start-up or sixtysix (66) months from date of shipment from the factory, whichever occurs first. If upon examination by the

Manufacturer the Product is shown to have a defect in material or workmanship during the warranty period, the

Manufacturer will repair or replace, at its option, that part of Product which is shown to be defective. Electrical

parts (such as relays, overloads, capacitors, etc. …) are included in the one year limited warranty but not with the

five year limited warranty of the sealed refrigeration system.

This limited warranty does not apply:

(a) if the Product has been subjected to misuse or neglect, has been accidentally or intentionally damaged,

has not been installed, maintained or operated in accordance with the furnished written instructions, or

has been altered or modified in any way.

(b) to any expenses, including labor or material, incurred during removal or reinstallation of the Product.

(c) to any workmanship of the installer of the Product.

This limited warranty is conditional upon:

(a) shipment, to the Manufacturer, of that par t of the Product thought to be defective. Goods can only be

returned with prior written approval from the Manufacturer. All returns must be freight prepaid.

(b) determination, in the reasonable opinion of the Manufacturer that there exists a defect in material or

workmanship.

Repair or replacement of any part under this Limited Warranty shall not extend the duration of the warranty with

respect to such repaired or replaced part beyond the stated warranty period.

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EITHER EXPRESS OR IMPLIED, AND

ALL SUCH OTHER WARRANTIES, INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED AND

EXCLUDED FROM THIS LIMITED WARRANTY. IN NO EVENT SHALL THE MANUFACTURER BE LIABLE IN

ANY WAY FOR ANY CONSEQUENTIAL, SPECIAL, OR INCIDENTAL DAMAGES OF ANY NATURE

WHATSOEVER, OR FOR ANY AMOUNTS IN EXCESS OF THE SELLING PRICE OF THE PRODUCT OR ANY

PARTS THEREOF FOUND TO BE DEFECTIVE. THIS LIMITED WARRANTY GIVES THE ORIGINAL OWNER

OF THE PRODUCT SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER RIGHTS WHICH MAY VARY

BY EACH JURISDICTION.

31

260 NORTH ELM STREET • WESTFIELD , MA 01085 • Tel No. (413) 564-5520 • F ax No. (413) 564-5815

5211 CREEKBANK ROAD • MISSISSAUGA, ONTARIO L4W 1R3 CANADA • Tel No. (905) 625-2991 • F ax No . (905) 625-6610

Loading...

Loading...