Koldwave 5WK Series, 5WK07, 5WK14, 5WK18, 5WK23 Operation Manual

...

IOM5WK-1

Koldwave 5WK Installation, Operation, & Maintenance Manual

ATTENTION: READ THIS MANUAL AND ALL LABELS ATTACHED TO THE UNIT

CAREFULY BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE

THESE UNITS. CHECK DATA PLATES FOR ELECTRICAL SPECIFICATIONS

AND MAKE CERTAIN THAT THESE AGREE WITH THOSE AT THE POINT OF

INSTALLATION. RECORD THE UNIT MODEL AND SERIAL NUMBER IN THE

SPACE PROVIDED. RETAIN THIS DOCUMENT FOR FUTURE REFERENCE.

Model No._______________________ Serial No._______________________________

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. THIS

APPLIANCE MUST BE INSTALLED BY A LICENSED CONTRACTOR OR

QUALIFIED SERVICE PERSONNEL. READ THESE INSTALLATION, OPERATING

AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THE UNIT.

WARNING: INSTALL, OPERATE AND MAINTAIN UNIT IN ACCORDANCE WITH

MANUFACTURER’S INSTRUCTIONS TO AVOID ANY DETERING FACTORS

THAT MAY CAUSE PERSONAL INJURY OR PROPERTY DAMAGE.

INSTALLER’S RESPONSIBILITY: THIS EQUIPMENT HAS BEEN RUN TESTED

AND INSPECTED THOROUGHLY. IT HAS BEEN SHIPPED FREE FROM

DEFECTS FROM OUR FACTORY. HOWEVER, DURING SHIPMENT AND

INSTALLATION, PROBLEMS SUCH AS LOOSE WIRES, LEAKS, OR LOOSE

FASTENERS MAY OCCUR. IT IS THE INSTALLER’S RESPONSIBILITY TO

INSPECT AND CORRECT ANY PROBLEMS THAT MAY BE FOUND.

1

IOM5WK-1

Table of Contents:

GENERAL INFORMATION ...................................................................................................... 4

MODEL CONFIGURATION...................................................................................................... 5

INSTALLATION INSTRUCTIONS .......................................................................................... 6

ELECTRICAL REQUIREMENTS ....................................................................................................... 6

WATER FITTING LOCATION ......................................................................................................... 6

SPECIFICATION AND ELECTRIC DATA ............................................................................. 8

SERVICEABILITY ...................................................................................................................... 9

5WK07 UNIT CONSTRUCTION BACK VIEW ................................................................................. 9

5WK07 UNIT CONSTRUCTION SIDE VIEW ................................................................................. 10

5WK14 UNIT CONSTRUCTION FRONT VIEW .............................................................................. 11

5WK14

5WK14

5WK18 UNIT CONSTRUCTION BACK VIEW ............................................................................... 14

5WK18 UNIT CONSTRUCTION SIDE VIEW ................................................................................. 15

5WK23/26 UNIT CONSTRUCTION BACK VIEW .......................................................................... 16

5WK23/26 UNIT CONSTRUCTION LEFT VIEW ........................................................................... 17

5WK36 UNIT CONSTRUCTION BACK VIEW ............................................................................... 18

5WK36 UNIT CONSTRUCTION LEFT VIEW ................................................................................. 19

HEAT PUMP UNIT CONSTRUCTION FRONT VIEW .......................................................... 12

HEAT PUMP UNIT CONSTRUCTION BACK VIEW ............................................................ 13

UNIT OPERATION ................................................................................................................... 20

UNIT POWER ON: ....................................................................................................................... 20

FAN HI: ...................................................................................................................................... 20

FAN LO: ..................................................................................................................................... 20

COOLING HI: .............................................................................................................................. 20

COOLING LO: ............................................................................................................................. 20

HEATING HI (HEAT PUMP UNIT): ............................................................................................... 20

HEATING LO (HEAT PUMP UNIT): .............................................................................................. 20

EMPERATURE SETTING: ........................................................................................................... 20

T

UNIT OFF: .................................................................................................................................. 20

O

THER SETTINGS: ...................................................................................................................... 20

OMPRESSOR OFF TIME: ............................................................................................................ 21

C

SELF RECOVERY MODE (*): ....................................................................................................... 21

CHECK ALARMS: ........................................................................................................................ 21

OPTIONAL REMOTE CONTROL: .................................................................................................. 21

INSPECTION AND REPAIR OF ELECTRICAL SYSTEM ................................................ 23

C

OMPRESSOR AND FAN MOTOR CAPACITORS ............................................................................ 23

INSPECTION AND REPAIR OF REFRIGERANT SYSTEM ............................................. 23

PREVENTATIVE MAINTENANCE ....................................................................................... 23

NIT STORAGE .......................................................................................................................... 24

U

ELECTRICAL DIAGRAM ....................................................................................................... 25

2

IOM5WK-1

5WK07, 5WK14 115V/1 PH ..................................................................................................... 25

5WK18, 5WK23, 5WK26 208-230V 1 PH ............................................................................... 26

5WK36 208-230V/1PH ............................................................................................................. 27

TROUBLE SHOOTING GUIDE .............................................................................................. 28

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 29

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 30

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 31

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 32

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 33

3

General Information

Koldwave 5WK Series Air Conditioners and

Heat Pumps are portable, water-cooled units

designed for applications where outside air

is not available and spot cooling is required.

The Koldwave air-conditioner cools an

entire area by discharging air through its

supply grille. Only power and condenser

water supply, water discharge, and

condensate drain piping are required for

installation.

The water-cooled condenser requires only

that amount of water needed to achieve the

desired high and low refrigeration system

pressures. The minimum condenser water

pressure for 85°F entering water temperature

can be found in the Specification and

Electrical Data section in this manual. A

refrigeration system head pressure actuated

water regulating valve regulates condenser

water.

Each unit is completely self-contained with

the entire refrigeration system, electrical

components, condenser and water valve

housed in one cabinet. All Koldwave units,

except the 5WK07, are provided with

heavy-duty casters. Two swivel-locking

casters prevent sliding; two stationary

casters provide handling ease for relocation.

The Koldwave 5WK07 is supplied with pads

on the bottom of the unit.

To attain the proper control of the water

flow rate entering the automatic water valve,

refer to the Specification and Electrical Data

Section to find the minimum water pressure

required for the condenser water supply.

The condenser water temperature leaving

the unit should not exceed 100°F. Ignoring

this compliance will void the warranty on

the refrigeration system. On heat pump

models it is not recommended to operate the

unit in the heating cycle when the water

temperature is below 50°F. Doing so could

reduce the specified heating capacity and

may cause the freeze control to cycle the

compressor off, resulting in a loss of

heating.

Model 5WK26

With the heat pump option the user can

manually select between the HEAT and

COOL functions using the touch pad control

panel or using the optional remote control.

4

Model Configuration

NOMENCLATURE

Example 5WK 14 B G A 1 A A A0

Code MD US R V C SS EC CC O

Field 1,2,3 4,5 6 7 8 9 10 11 12,13

1,2,3 – MODEL (MD)

5AK – Air Cooled Portable

5WK - Water Cooled Portable

4,5 – UNIT SIZE (US)

AK – Air Cooled Models

14 – 11,000 Btuh

18 – 18,300 Btuh

30 – 28,100 Btuh

39 – 36,800 Btuh

65 – 61,200 Btuh

WK - Water Cooled Portable

07 – 6,300 Btuh

14 – 10,800 Btuh

18 – 16,100 Btuh

23 – 23,000 Btuh

26 – 23,000 Btuh

36 – 34,700 Btuh

6 - REFRIGERANT (R)

A – R22

B – R410A

7 – VOLTAGE (V)

A – 208/3/60 (used only on 5WK65)

B – 230/3/60 (used only on 5WK65)

C – 460/3/60 (used only on 5WK65)

D – 575/3/60 (not used at this time)

E – 120/1/60

F – 208/1/60

G – 230/1/60

H – 100/1/50 (not used at this time)

J – 220/1/50 (not used at this time)

8 – CONFIGURATION (C)

A – Front Discharge with Adjustable Grilles

9 CONFIGURATION (SS)

1 – Stainless Steel

2 – Painted (5WK65 only)

10 – EVAPORATOR COIL (EC)

A – Standard Copper/Aluminum

E – Electrofin Coated

11 – CONDENSER COIL (CC)

A – Standard Copper/Aluminum

E – Electrofin Coated (Air Cooled Only)

N – Cupro-Nickel

12,13 – OPTIONS (O) WK Only

A0 – Standard Cooling

AP – Standard Cooling with High Lift Condensate Pump

AT – Standard Cooling for Cooling Tower Application (no water

valve)

AV – Standard Cooling for Cooling Tower Application with High

Lift Condensate Pump (no water valve)

H0 – Heat Pump

HP – Heat Pump with High Lift Condensate Pump

HT – Heat Pump for Cooling Tower Application (no water valve)

5

Installation Instructions

IMPORTANT: Following the installation

and preventative maintenance instructions

can extend the length of service you

receive from your Koldwave unit.

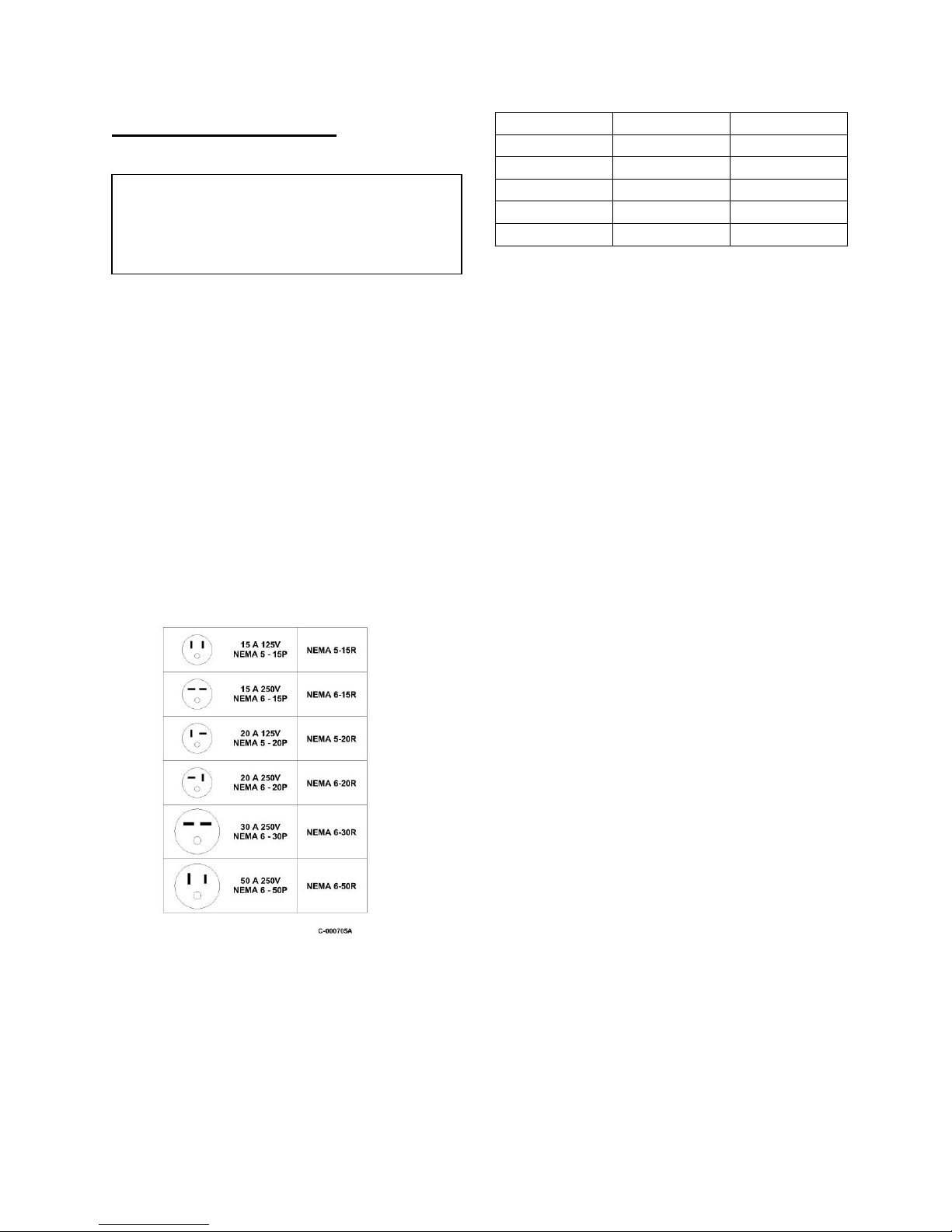

Electrical Requirements

Check the power supply to make certain it is

within 10% of the voltage listed on the data

plate located on the back of the unit.

Operating the unit on improper voltage

will void the product warranty.

Refer to the Rating Plate for voltage and

current information.

Each unit should have a dedicated circuit

breaker.

MODEL VOLTAGE PLUG TYPE

5WK07 120/1/60 5 – 15P

5WK14 120/1/60 5 – 15P

5WK18 208-230/1/60 6 – 20P

5WK23/26 208-230/1/60 6 – 20P

5WK36 208-230/1/60 6 – 20P

Some Koldwave units are equipped with

LCDI device service cords. The service

cords employed have plug configurations

and receptacle requirements as shown in the

chart above. Modifications to the cord will

void the product warranty.

Extension cords used with the Koldwave

units should match the plug configuration of

the service cord provided on the unit. The

extension cord must be equipped with an

equipment grounding conductor, grounding

type attachment plug, and a grounding type

attachment connector. The cord must also

have a rating suitable for the voltage and

ampacity.

Water Fitting Location

Prior to placing the air conditioner in the

desired position, note the exact location of

the water fittings on the valve plate on the

unit side panel.

Plug Types

6

Figure A

Water lines should be securely attached to

the water valve plate fittings. This is easily

accomplished through the quick connect

hose kit provided with the unit.

Note: The water connections must be made

as shown in Figure A. The unit will not

operate properly if the connections are not in

the correct orientation.

7

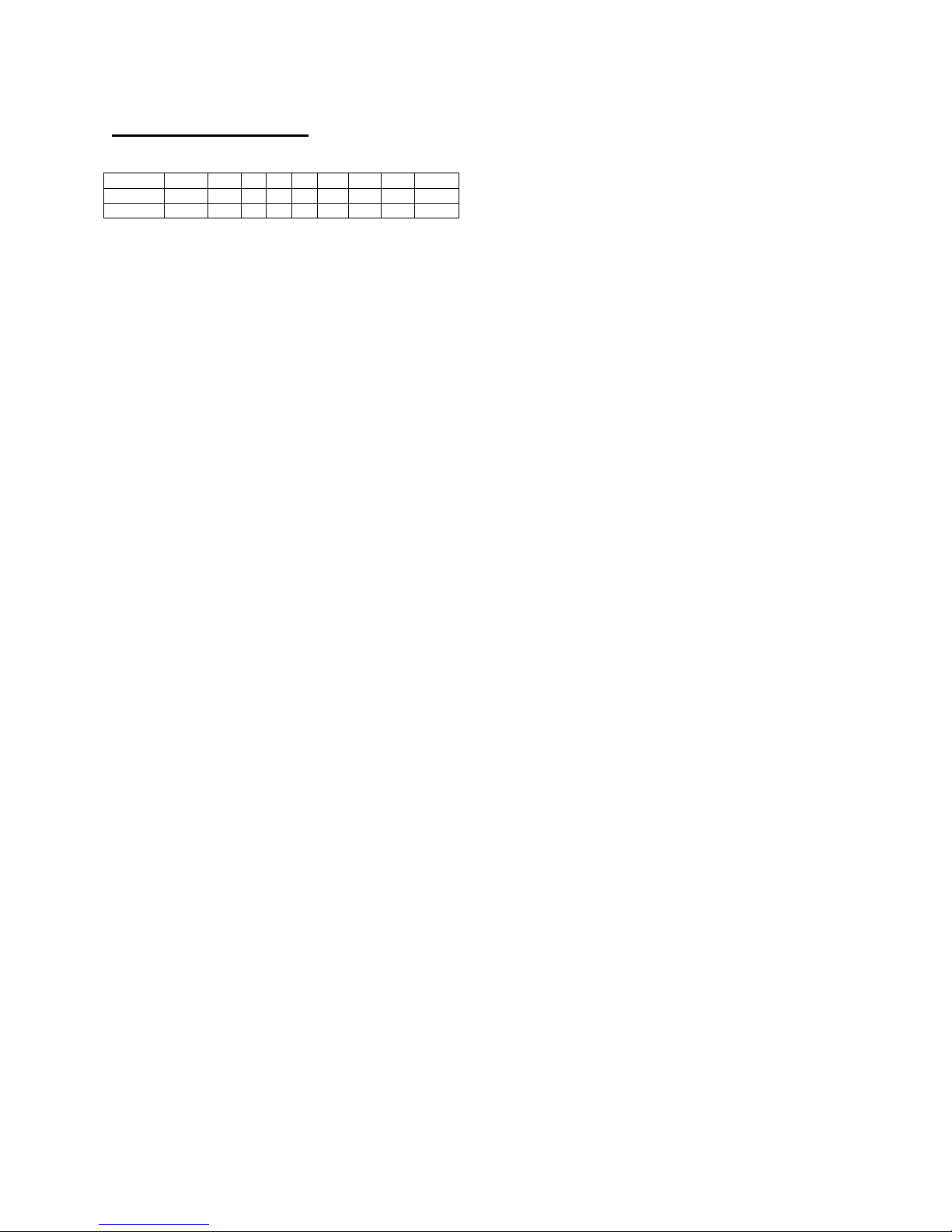

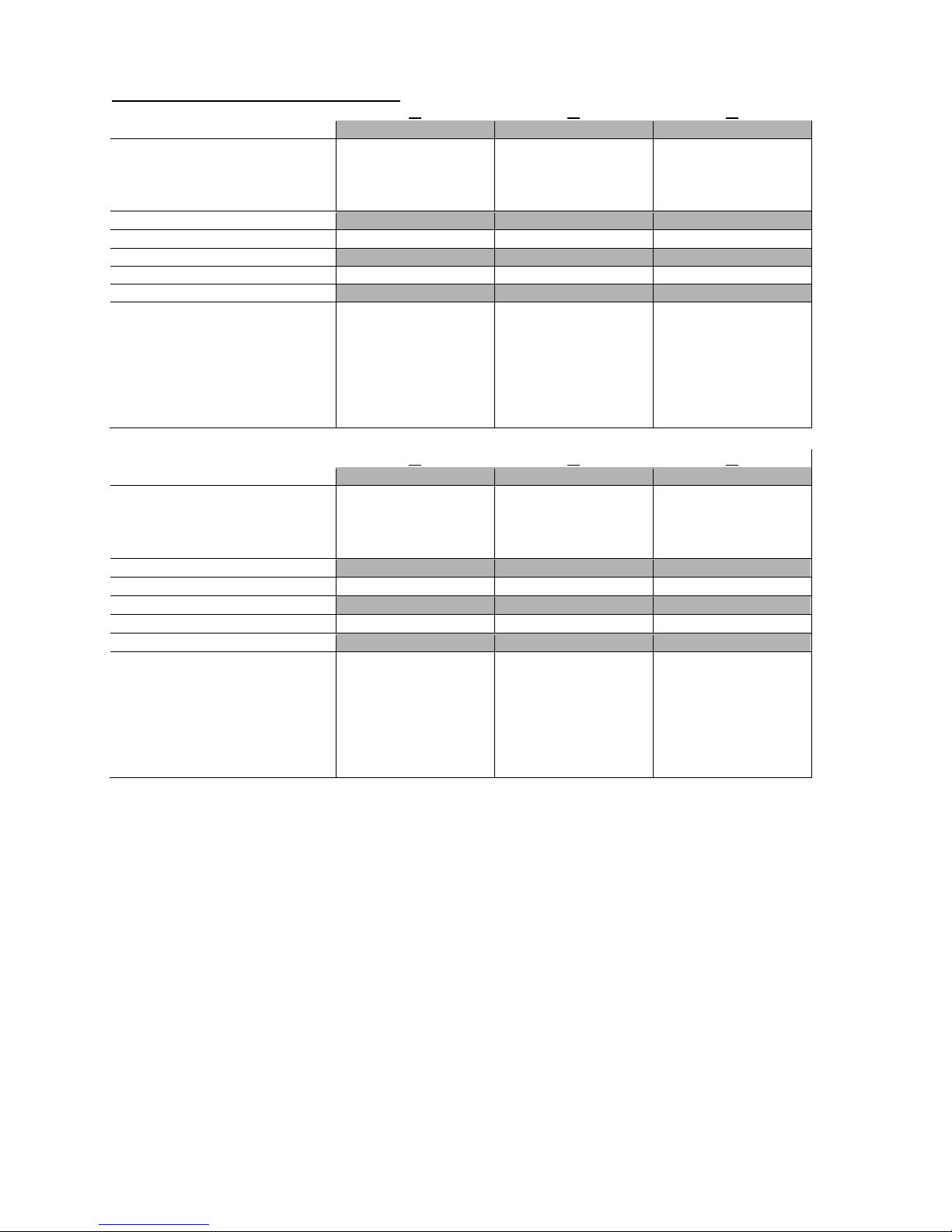

Specification and Electric Data

ELECTRIC DATA

Voltage/Phase/Hertz 115/1/60 115/1/60 230/1/60

Amperage 9.2 11.6 6.6

Fuse Size (Amps) 15 15 15

Watts 855 1107 1471

REFRIGERANT CHARGE

R410A (Ounces) 16 20 22

WATER SUPPLY

Minimum Water Pressure (PSI) 15 21 40.5

UNIT DIMENSIONS (INCHES)

Height with Casters 17.63 31.5 31.5

Height without Casters n/a 29.13 29.13

Width 22.38 25.00 25.00

Depth 12.00 10.19 10.19

Evaporator Filter (qty) (1) 15.75 x 9.13 x 0.5 (1) 15.88 x 18 x 0.5 (1) 24 x 11.75 x 0.5

NET UNIT WEIGHT (LBS.)

SHIPPING WEIGHT (LBS.)

ELECTRIC DATA

Voltage/Phase/Hertz 230/1/60 230/1/60 230/1/60

Amperage 10 10 14.2

Fuse Size (Amps) 15 15 20

Watts 2189 2189 2994

REFRIGERANT CHARGE

R410A (Ounces) 39 39 42

WATER SUPPLY

Minimum Water Pressure (PSI) 55.8 55.8 47.8

UNIT DIMENSIONS (INCHES)

Height with Casters 28.75 28.75 33.25

Height without Casters 26.38 26.38 28.5

Width 36 36 43.5

Depth 12.25 12.25 15.38

Evaporator Filter (qty) (1) 24 x 11.75 x 0.5 (1) 24 x 11.75 x 0.5 (1) 13.25 x 31.5 x 0.5

NET UNIT WEIGHT (LBS.)

SHIPPING WEIGHT (LBS.)

Time delay fuses and circuit breakers are recommended.

*** Electrical ratings based on 80/67 indoor air and 85e/95l water side conditions on high speed.

14 18

07

*** *** ***

83 122 125

89 131 134

26 36

23

*** *** ***

183 183 245

201 201 253

8

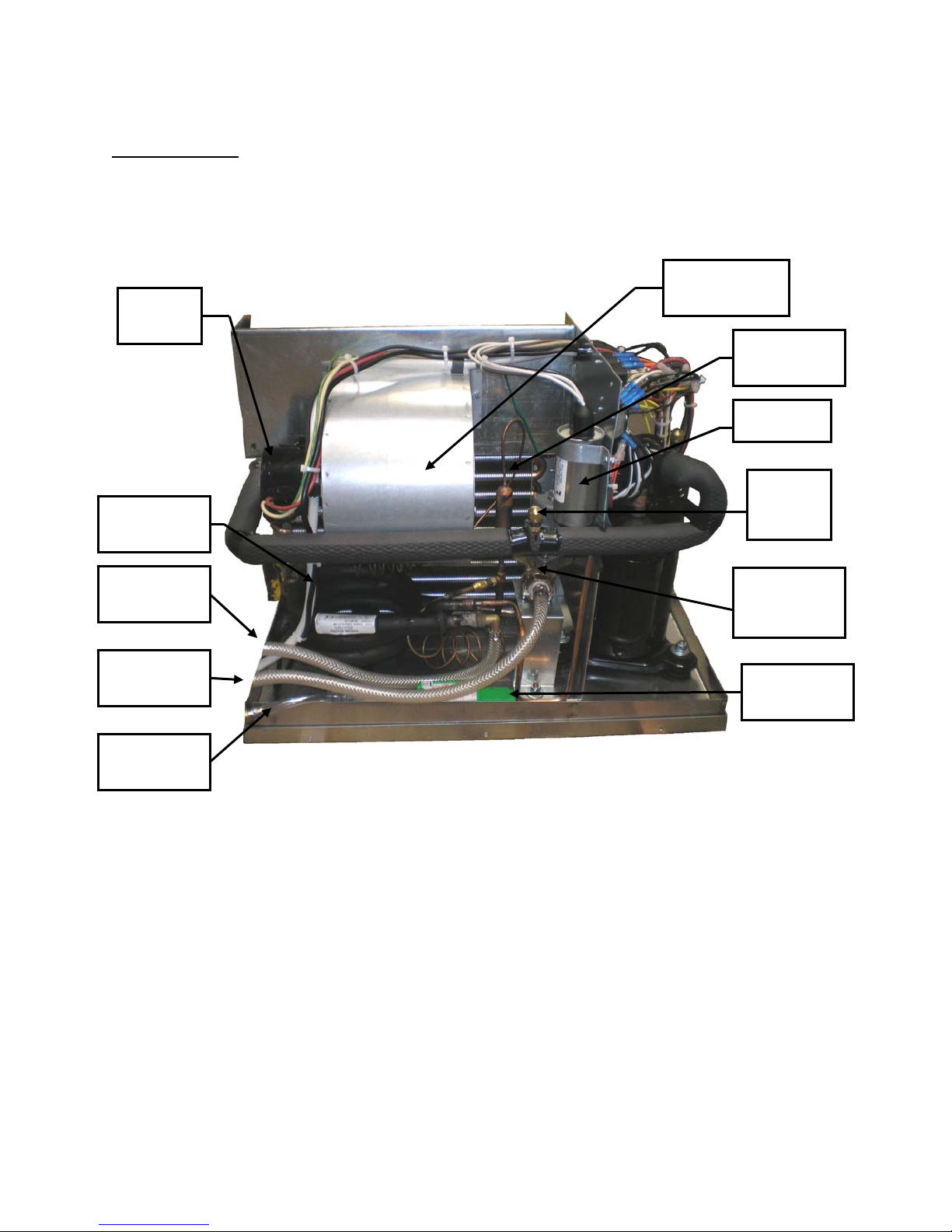

Serviceability

The Koldwave unit has removable panels to provide full service accessibility.

5WK07 Unit Construction Back View

Blower

Motor

Condenser

Coil

Blower Wheel

Housing

Evaporator

Coil

Capacitor

Suction

Service

Access

Condenser

Water Outlet

Condenser

Water Inlet

Condenser

Drain Outlet

Water

Regulating

Valve

Condensate

Pump

9

ccumulator

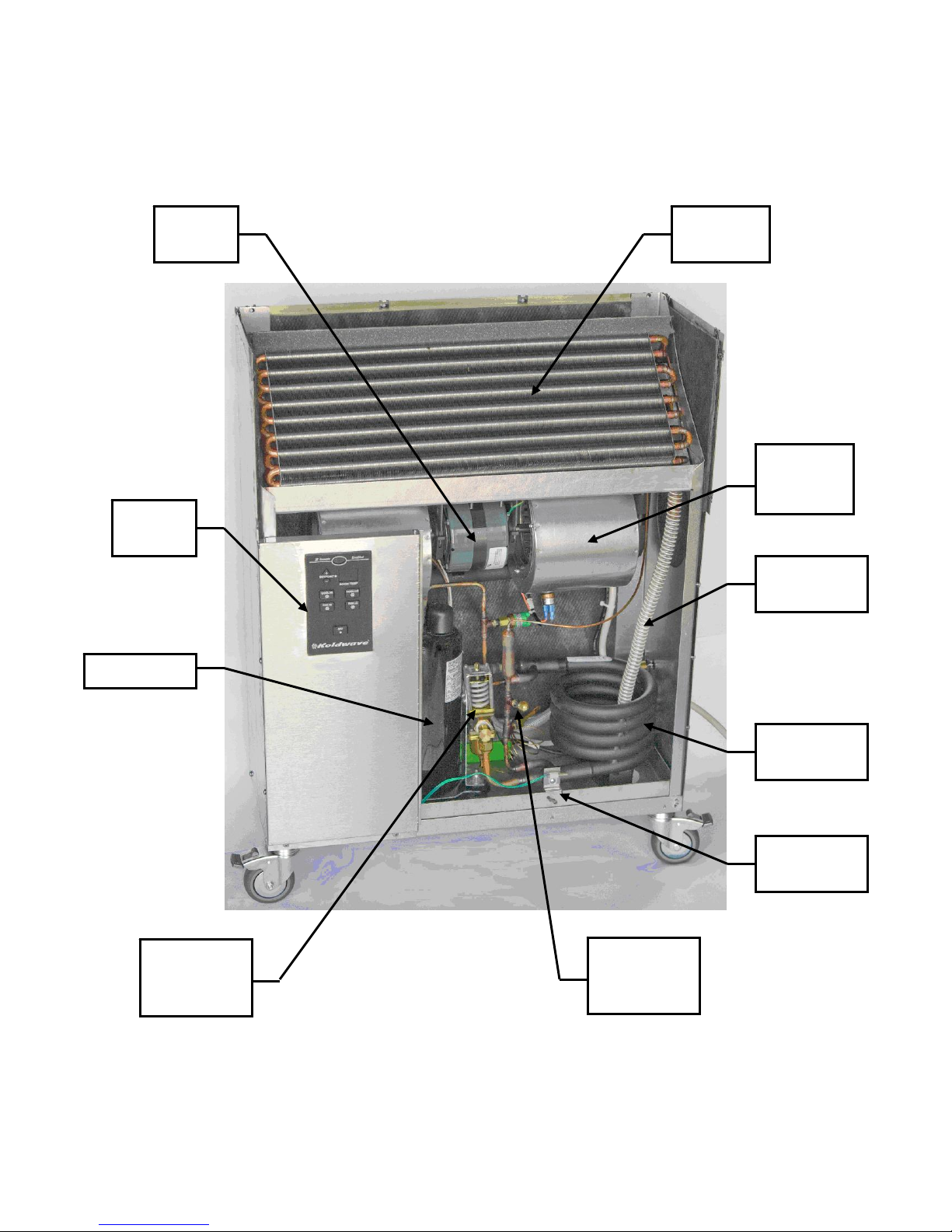

5WK07 Unit Construction Side View

Discharge

Service

Access

Compressor

Contactor

Transformer

Hard Start

Assembly

A

Compressor

10

5WK14 Unit Construction Front View

Blower

Motor

Control

Panel

Evaporator

Coil

Blower

Wheel

Housing

Compressor

Water

Regulating

Valve

Condensate

Drain Tube

Condenser

Coil

Temperature

Sensor

Discharge

Service

Access

11

Loading...

Loading...