IOM5WK-1

Koldwave 5WK Installation, Operation, & Maintenance Manual

ATTENTION: READ THIS MANUAL AND ALL LABELS ATTACHED TO THE UNIT

CAREFULY BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE

THESE UNITS. CHECK DATA PLATES FOR ELECTRICAL SPECIFICATIONS

AND MAKE CERTAIN THAT THESE AGREE WITH THOSE AT THE POINT OF

INSTALLATION. RECORD THE UNIT MODEL AND SERIAL NUMBER IN THE

SPACE PROVIDED. RETAIN THIS DOCUMENT FOR FUTURE REFERENCE.

Model No._______________________ Serial No._______________________________

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. THIS

APPLIANCE MUST BE INSTALLED BY A LICENSED CONTRACTOR OR

QUALIFIED SERVICE PERSONNEL. READ THESE INSTALLATION, OPERATING

AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THE UNIT.

WARNING: INSTALL, OPERATE AND MAINTAIN UNIT IN ACCORDANCE WITH

MANUFACTURER’S INSTRUCTIONS TO AVOID ANY DETERING FACTORS

THAT MAY CAUSE PERSONAL INJURY OR PROPERTY DAMAGE.

INSTALLER’S RESPONSIBILITY: THIS EQUIPMENT HAS BEEN RUN TESTED

AND INSPECTED THOROUGHLY. IT HAS BEEN SHIPPED FREE FROM

DEFECTS FROM OUR FACTORY. HOWEVER, DURING SHIPMENT AND

INSTALLATION, PROBLEMS SUCH AS LOOSE WIRES, LEAKS, OR LOOSE

FASTENERS MAY OCCUR. IT IS THE INSTALLER’S RESPONSIBILITY TO

INSPECT AND CORRECT ANY PROBLEMS THAT MAY BE FOUND.

1

IOM5WK-1

Table of Contents:

GENERAL INFORMATION ...................................................................................................... 4

MODEL CONFIGURATION...................................................................................................... 5

INSTALLATION INSTRUCTIONS .......................................................................................... 6

ELECTRICAL REQUIREMENTS ....................................................................................................... 6

WATER FITTING LOCATION ......................................................................................................... 6

SPECIFICATION AND ELECTRIC DATA ............................................................................. 8

SERVICEABILITY ...................................................................................................................... 9

5WK07 UNIT CONSTRUCTION BACK VIEW ................................................................................. 9

5WK07 UNIT CONSTRUCTION SIDE VIEW ................................................................................. 10

5WK14 UNIT CONSTRUCTION FRONT VIEW .............................................................................. 11

5WK14

5WK14

5WK18 UNIT CONSTRUCTION BACK VIEW ............................................................................... 14

5WK18 UNIT CONSTRUCTION SIDE VIEW ................................................................................. 15

5WK23/26 UNIT CONSTRUCTION BACK VIEW .......................................................................... 16

5WK23/26 UNIT CONSTRUCTION LEFT VIEW ........................................................................... 17

5WK36 UNIT CONSTRUCTION BACK VIEW ............................................................................... 18

5WK36 UNIT CONSTRUCTION LEFT VIEW ................................................................................. 19

HEAT PUMP UNIT CONSTRUCTION FRONT VIEW .......................................................... 12

HEAT PUMP UNIT CONSTRUCTION BACK VIEW ............................................................ 13

UNIT OPERATION ................................................................................................................... 20

UNIT POWER ON: ....................................................................................................................... 20

FAN HI: ...................................................................................................................................... 20

FAN LO: ..................................................................................................................................... 20

COOLING HI: .............................................................................................................................. 20

COOLING LO: ............................................................................................................................. 20

HEATING HI (HEAT PUMP UNIT): ............................................................................................... 20

HEATING LO (HEAT PUMP UNIT): .............................................................................................. 20

EMPERATURE SETTING: ........................................................................................................... 20

T

UNIT OFF: .................................................................................................................................. 20

O

THER SETTINGS: ...................................................................................................................... 20

OMPRESSOR OFF TIME: ............................................................................................................ 21

C

SELF RECOVERY MODE (*): ....................................................................................................... 21

CHECK ALARMS: ........................................................................................................................ 21

OPTIONAL REMOTE CONTROL: .................................................................................................. 21

INSPECTION AND REPAIR OF ELECTRICAL SYSTEM ................................................ 23

C

OMPRESSOR AND FAN MOTOR CAPACITORS ............................................................................ 23

INSPECTION AND REPAIR OF REFRIGERANT SYSTEM ............................................. 23

PREVENTATIVE MAINTENANCE ....................................................................................... 23

NIT STORAGE .......................................................................................................................... 24

U

ELECTRICAL DIAGRAM ....................................................................................................... 25

2

IOM5WK-1

5WK07, 5WK14 115V/1 PH ..................................................................................................... 25

5WK18, 5WK23, 5WK26 208-230V 1 PH ............................................................................... 26

5WK36 208-230V/1PH ............................................................................................................. 27

TROUBLE SHOOTING GUIDE .............................................................................................. 28

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 29

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 30

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 31

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 32

TROUBLE SHOOTING GUIDE CONTINUED ..................................................................... 33

3

General Information

Koldwave 5WK Series Air Conditioners and

Heat Pumps are portable, water-cooled units

designed for applications where outside air

is not available and spot cooling is required.

The Koldwave air-conditioner cools an

entire area by discharging air through its

supply grille. Only power and condenser

water supply, water discharge, and

condensate drain piping are required for

installation.

The water-cooled condenser requires only

that amount of water needed to achieve the

desired high and low refrigeration system

pressures. The minimum condenser water

pressure for 85°F entering water temperature

can be found in the Specification and

Electrical Data section in this manual. A

refrigeration system head pressure actuated

water regulating valve regulates condenser

water.

Each unit is completely self-contained with

the entire refrigeration system, electrical

components, condenser and water valve

housed in one cabinet. All Koldwave units,

except the 5WK07, are provided with

heavy-duty casters. Two swivel-locking

casters prevent sliding; two stationary

casters provide handling ease for relocation.

The Koldwave 5WK07 is supplied with pads

on the bottom of the unit.

To attain the proper control of the water

flow rate entering the automatic water valve,

refer to the Specification and Electrical Data

Section to find the minimum water pressure

required for the condenser water supply.

The condenser water temperature leaving

the unit should not exceed 100°F. Ignoring

this compliance will void the warranty on

the refrigeration system. On heat pump

models it is not recommended to operate the

unit in the heating cycle when the water

temperature is below 50°F. Doing so could

reduce the specified heating capacity and

may cause the freeze control to cycle the

compressor off, resulting in a loss of

heating.

Model 5WK26

With the heat pump option the user can

manually select between the HEAT and

COOL functions using the touch pad control

panel or using the optional remote control.

4

Model Configuration

NOMENCLATURE

Example 5WK 14 B G A 1 A A A0

Code MD US R V C SS EC CC O

Field 1,2,3 4,5 6 7 8 9 10 11 12,13

1,2,3 – MODEL (MD)

5AK – Air Cooled Portable

5WK - Water Cooled Portable

4,5 – UNIT SIZE (US)

AK – Air Cooled Models

14 – 11,000 Btuh

18 – 18,300 Btuh

30 – 28,100 Btuh

39 – 36,800 Btuh

65 – 61,200 Btuh

WK - Water Cooled Portable

07 – 6,300 Btuh

14 – 10,800 Btuh

18 – 16,100 Btuh

23 – 23,000 Btuh

26 – 23,000 Btuh

36 – 34,700 Btuh

6 - REFRIGERANT (R)

A – R22

B – R410A

7 – VOLTAGE (V)

A – 208/3/60 (used only on 5WK65)

B – 230/3/60 (used only on 5WK65)

C – 460/3/60 (used only on 5WK65)

D – 575/3/60 (not used at this time)

E – 120/1/60

F – 208/1/60

G – 230/1/60

H – 100/1/50 (not used at this time)

J – 220/1/50 (not used at this time)

8 – CONFIGURATION (C)

A – Front Discharge with Adjustable Grilles

9 CONFIGURATION (SS)

1 – Stainless Steel

2 – Painted (5WK65 only)

10 – EVAPORATOR COIL (EC)

A – Standard Copper/Aluminum

E – Electrofin Coated

11 – CONDENSER COIL (CC)

A – Standard Copper/Aluminum

E – Electrofin Coated (Air Cooled Only)

N – Cupro-Nickel

12,13 – OPTIONS (O) WK Only

A0 – Standard Cooling

AP – Standard Cooling with High Lift Condensate Pump

AT – Standard Cooling for Cooling Tower Application (no water

valve)

AV – Standard Cooling for Cooling Tower Application with High

Lift Condensate Pump (no water valve)

H0 – Heat Pump

HP – Heat Pump with High Lift Condensate Pump

HT – Heat Pump for Cooling Tower Application (no water valve)

5

Installation Instructions

IMPORTANT: Following the installation

and preventative maintenance instructions

can extend the length of service you

receive from your Koldwave unit.

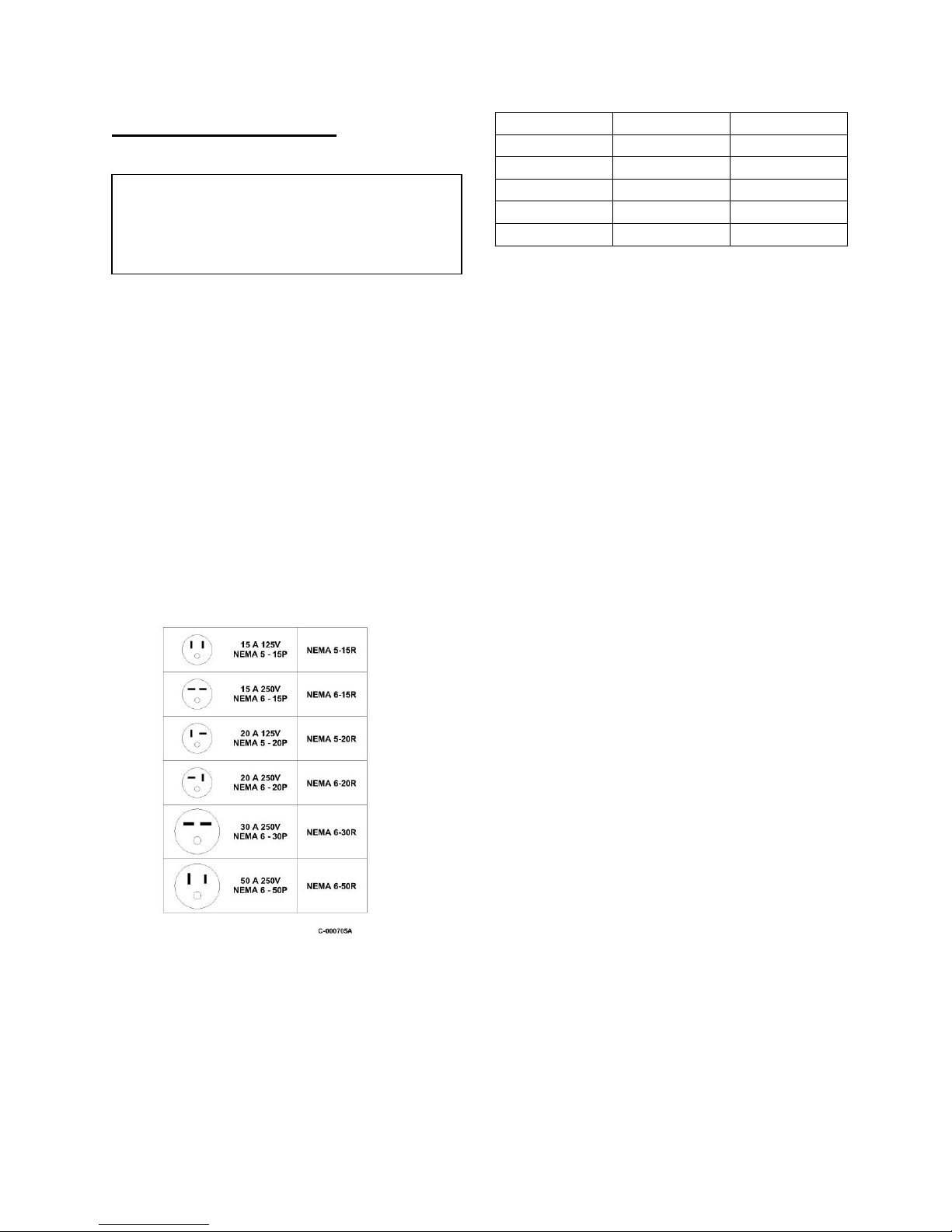

Electrical Requirements

Check the power supply to make certain it is

within 10% of the voltage listed on the data

plate located on the back of the unit.

Operating the unit on improper voltage

will void the product warranty.

Refer to the Rating Plate for voltage and

current information.

Each unit should have a dedicated circuit

breaker.

MODEL VOLTAGE PLUG TYPE

5WK07 120/1/60 5 – 15P

5WK14 120/1/60 5 – 15P

5WK18 208-230/1/60 6 – 20P

5WK23/26 208-230/1/60 6 – 20P

5WK36 208-230/1/60 6 – 20P

Some Koldwave units are equipped with

LCDI device service cords. The service

cords employed have plug configurations

and receptacle requirements as shown in the

chart above. Modifications to the cord will

void the product warranty.

Extension cords used with the Koldwave

units should match the plug configuration of

the service cord provided on the unit. The

extension cord must be equipped with an

equipment grounding conductor, grounding

type attachment plug, and a grounding type

attachment connector. The cord must also

have a rating suitable for the voltage and

ampacity.

Water Fitting Location

Prior to placing the air conditioner in the

desired position, note the exact location of

the water fittings on the valve plate on the

unit side panel.

Plug Types

6

Figure A

Water lines should be securely attached to

the water valve plate fittings. This is easily

accomplished through the quick connect

hose kit provided with the unit.

Note: The water connections must be made

as shown in Figure A. The unit will not

operate properly if the connections are not in

the correct orientation.

7

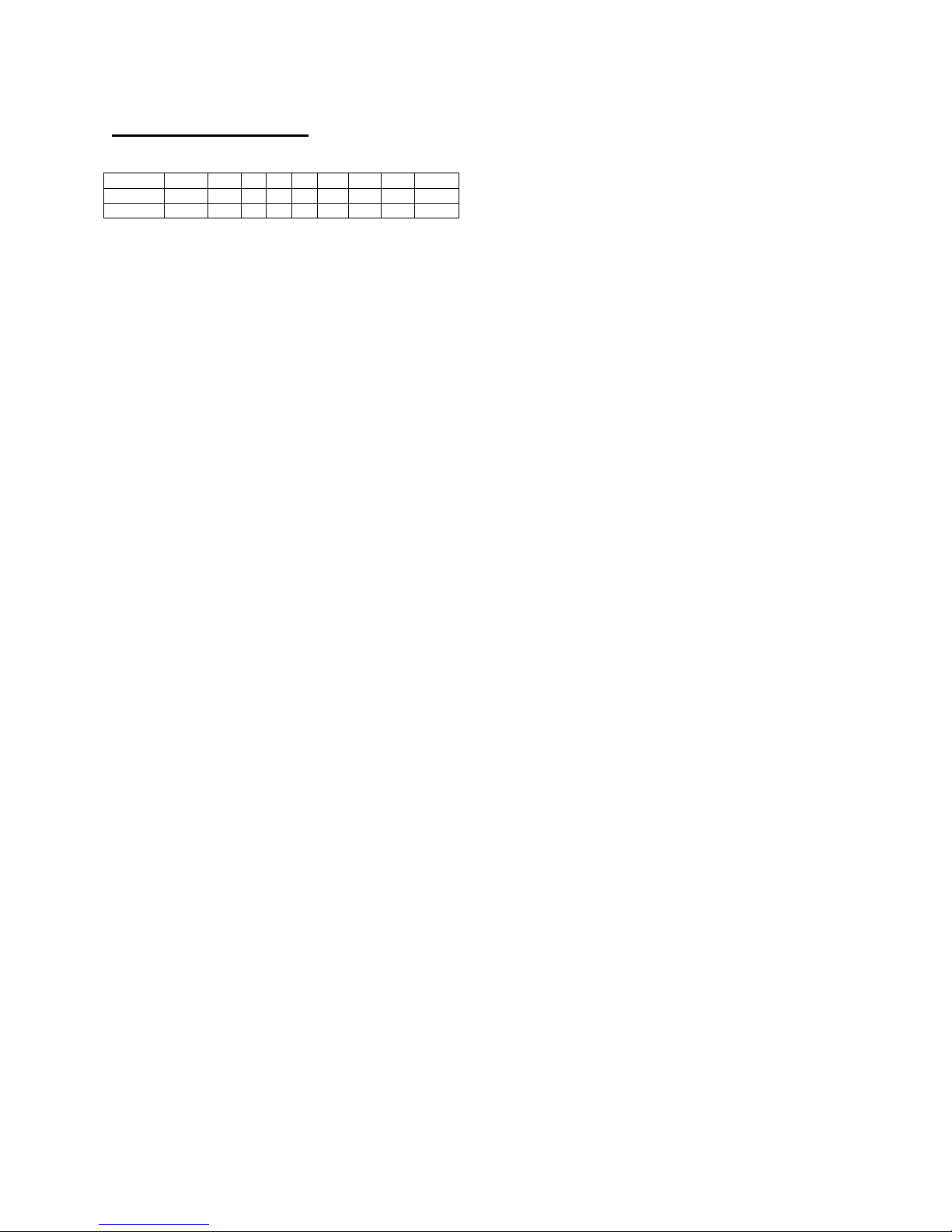

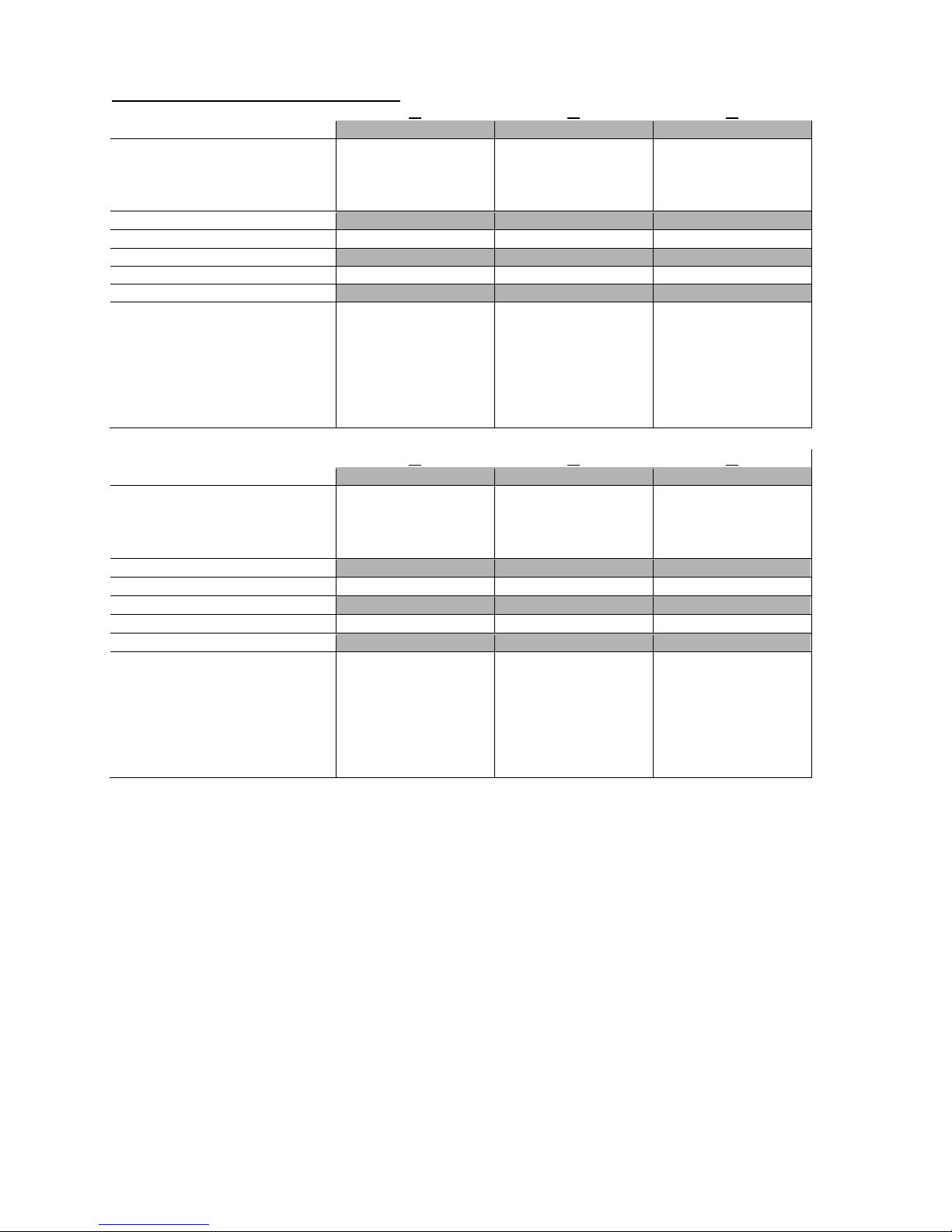

Specification and Electric Data

ELECTRIC DATA

Voltage/Phase/Hertz 115/1/60 115/1/60 230/1/60

Amperage 9.2 11.6 6.6

Fuse Size (Amps) 15 15 15

Watts 855 1107 1471

REFRIGERANT CHARGE

R410A (Ounces) 16 20 22

WATER SUPPLY

Minimum Water Pressure (PSI) 15 21 40.5

UNIT DIMENSIONS (INCHES)

Height with Casters 17.63 31.5 31.5

Height without Casters n/a 29.13 29.13

Width 22.38 25.00 25.00

Depth 12.00 10.19 10.19

Evaporator Filter (qty) (1) 15.75 x 9.13 x 0.5 (1) 15.88 x 18 x 0.5 (1) 24 x 11.75 x 0.5

NET UNIT WEIGHT (LBS.)

SHIPPING WEIGHT (LBS.)

ELECTRIC DATA

Voltage/Phase/Hertz 230/1/60 230/1/60 230/1/60

Amperage 10 10 14.2

Fuse Size (Amps) 15 15 20

Watts 2189 2189 2994

REFRIGERANT CHARGE

R410A (Ounces) 39 39 42

WATER SUPPLY

Minimum Water Pressure (PSI) 55.8 55.8 47.8

UNIT DIMENSIONS (INCHES)

Height with Casters 28.75 28.75 33.25

Height without Casters 26.38 26.38 28.5

Width 36 36 43.5

Depth 12.25 12.25 15.38

Evaporator Filter (qty) (1) 24 x 11.75 x 0.5 (1) 24 x 11.75 x 0.5 (1) 13.25 x 31.5 x 0.5

NET UNIT WEIGHT (LBS.)

SHIPPING WEIGHT (LBS.)

Time delay fuses and circuit breakers are recommended.

*** Electrical ratings based on 80/67 indoor air and 85e/95l water side conditions on high speed.

14 18

07

*** *** ***

83 122 125

89 131 134

26 36

23

*** *** ***

183 183 245

201 201 253

8

Serviceability

The Koldwave unit has removable panels to provide full service accessibility.

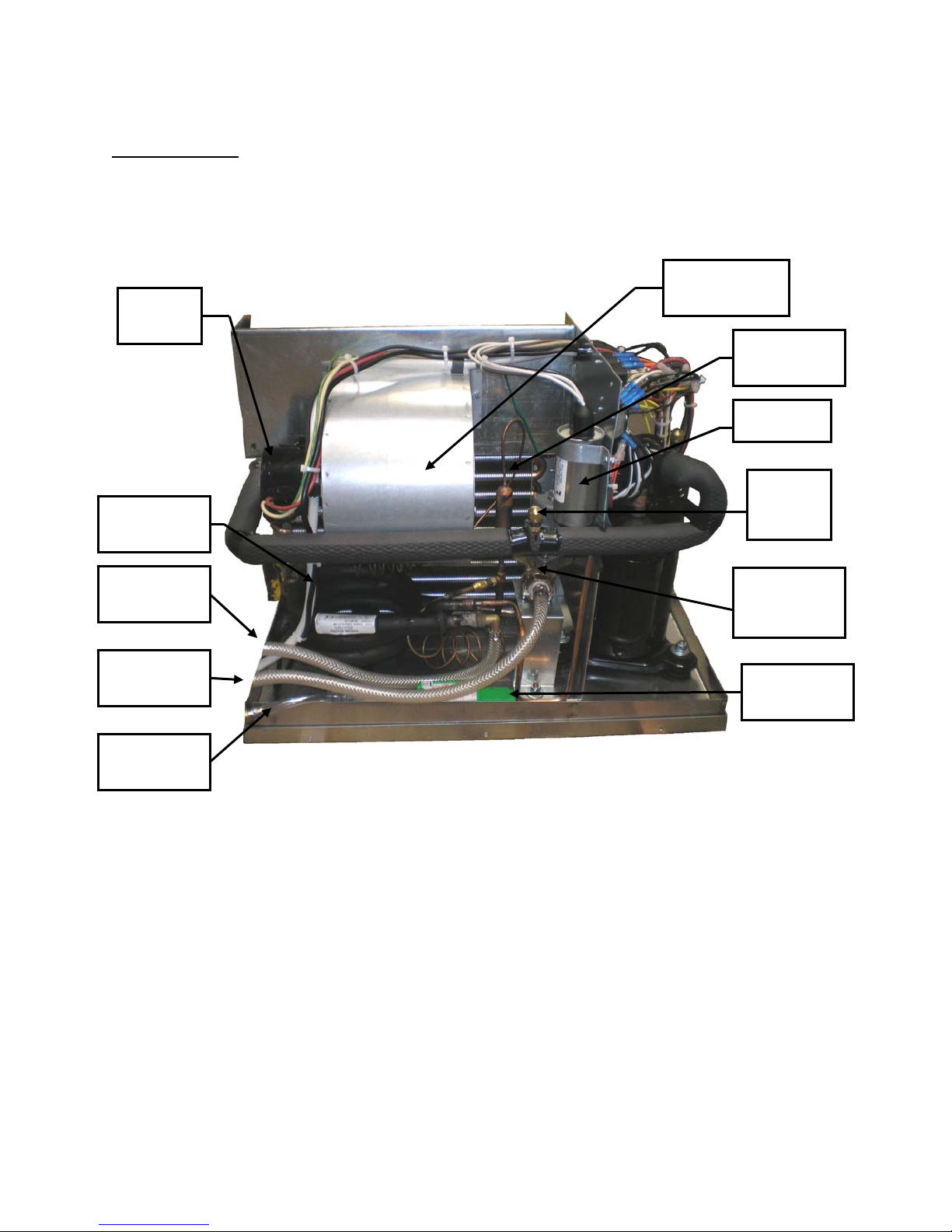

5WK07 Unit Construction Back View

Blower

Motor

Condenser

Coil

Blower Wheel

Housing

Evaporator

Coil

Capacitor

Suction

Service

Access

Condenser

Water Outlet

Condenser

Water Inlet

Condenser

Drain Outlet

Water

Regulating

Valve

Condensate

Pump

9

ccumulator

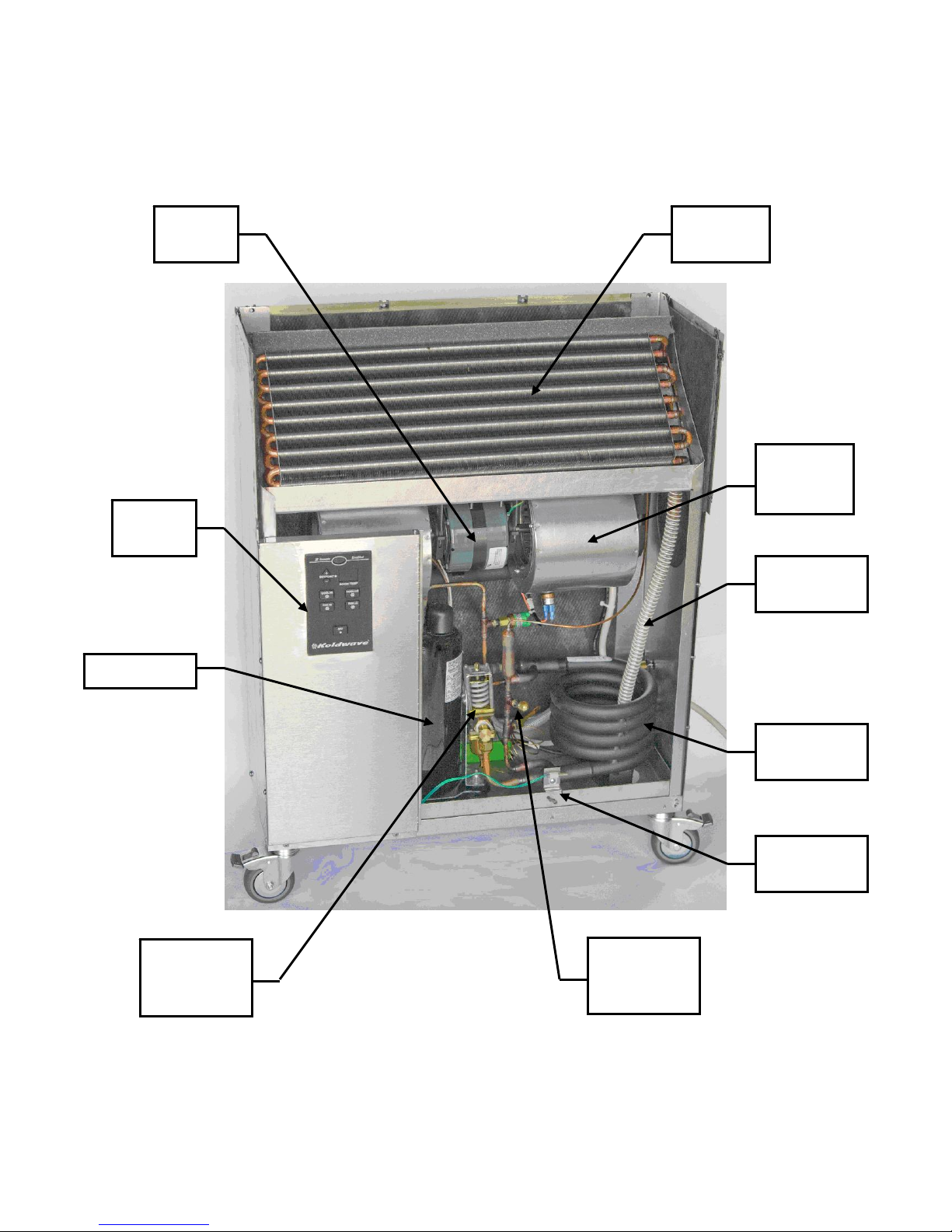

5WK07 Unit Construction Side View

Discharge

Service

Access

Compressor

Contactor

Transformer

Hard Start

Assembly

A

Compressor

10

5WK14 Unit Construction Front View

Blower

Motor

Control

Panel

Evaporator

Coil

Blower

Wheel

Housing

Compressor

Water

Regulating

Valve

Condensate

Drain Tube

Condenser

Coil

Temperature

Sensor

Discharge

Service

Access

11

ccumulator

Strainer

5WK14 Heat Pump Unit Construction Front View

Discharge

Service

Access

Water Bypass

Valve

Reversing

Valve

A

Condenser

Coil

Regulating

Valve

Water

12

5WK14 Heat Pump Unit Construction Back View

Reversing

Valve

Water Bypass

Valve

Discharge

Service

Access

Condensate

Pump

Compressor

13

5WK18 Unit Construction Back View

Blower

Motor

Blower

Wheel

Housing

Discharge

Service

Access

Suction

Service

Access

Condenser

Coil

Evaporator

Coil

Compressor &

Accumulator

Water

Regulating

Valve

14

ccumu

5WK18 Unit Construction Side View

Capacitor

Suction

Service

Access

Hard Start

Assembly

Compressor

Relay

Discharge

Service

Access

A

Compressor

lator

15

5WK23/26 Unit Construction Back View

Blower

Motor

Blower

Wheel

Housing

Condenser

Coil

Evaporator

Coil

Compressor &

Accumulator

Water

Regulating

Valve

16

ccumulat

or

5WK23/26 Unit Construction Left View

Transformer

Hard Start

Assembly

Discharge

Service

Access

Reversing

Valve

Suction

Service

Access

Condensate

Pump

Compressor

A

17

5WK36 Unit Construction Back View

Blower

Motor

Capacitor

Blower

Motor

Blower

Wheel

Housing

Compressor

Condenser

Coil

Evaporator

Coil

Water

Regulating

Valve

18

Contactor

5WK36 Unit Construction Left View

Transformer

Potential

Relay

Run

Capacitor

Discharge

Service

Access

Suction

Service

Access

Start

Capacitor

Compressor

Reversing

Valve

19

Unit Operation

Unit Power On:

Plug in the unit to the power source. The

LED display will show the current controller

version number for 0.5 seconds. Then, the

LED temperature indicator will illuminate

the set point for 5 seconds and then switch

to the room temperature reading. The Power

RED LED will illuminate. By depressing

any mode button, the Power LED will turn

off.

Fan Hi:

Depress the FAN HIGH button, the unit will

be in fan mode and the evaporator fan

blower will operate at High Speed. The

GREEN LED will illuminate accordingly.

Fan Lo:

Depress the FAN LOW button, the unit will

be in fan mode and the evaporator fan

blower will operate at Low Speed. The

GREEN LED will illuminate accordingly.

Cooling Hi:

Depress the COOL HIGH button, the unit

will be in cooling mode depending on

thermostat reading. The compressor will

turn on based on the thermostat reading and

the Compressor Off Time setting. The

evaporator fan blower will operate at High

Speed. The BLUE LED will illuminate

accordingly.

Cooling Lo:

Depress the COOL HIGH button, the unit

will be in cooling mode depending on

thermostat reading. The compressor will

turn on based on the thermostat reading and

the Compressor Off Time setting. The

evaporator fan blower will operate at Low

Speed. The BLUE LED will illuminate

accordingly.

Heating Hi (Heat Pump Unit):

Depress the HEAT HIGH button; the unit

will be in the heating mode depending on

the thermostat reading. The reversing valve

will operate to prompt the heat pump mode.

The compressor will turn on based on the

thermostat reading and the Compressor Off

Time setting. The evaporator fan blower

will operate at High Speed. The AMBER

LED will illuminate accordingly.

Heating Lo (Heat Pump Unit):

Depress the HEAT LOW button; the unit

will be in the heating mode depending on

the thermostat reading. The reversing valve

will operate to prompt the heat pump mode.

The compressor will turn on based on the

thermostat reading and the Compressor Off

Time setting. The evaporator fan blower

will operate at Low Speed. The AMBER

LED will illuminate accordingly.

Temperature Setting:

During any mode of operation, the user is

able to change the set point by depressing

the arrow buttons. The temperature

indicator will switch to display “set point

temperature”. Depressing the ARROW UP

or ARROW DOWN button will change the

set point. The SETPOINT LED will

illuminate. The temperature indicator will

switch back to display “room temperature”

after 5 seconds.

Unit Off:

Depress the OFF button at any time to turn

the SYSTEM MODE off. The unit will

remain idle until further instruction. The

Power RED LED will illuminate.

Other Settings:

During the cooling mode, the compressor

will only be energized if the temperature is

at least 2 degrees above the set point, and

de-energized once the temperature falls to 2

degrees below the set point. During the

20

heating mode, the compressor will only be

energized if the temperature is at least 2

degrees below the set point, and deenergized once the temperature rises 2

degrees above the set point. User is able to

manually change the temperature differential

(default set at 2) by depressing both UP and

DOWN arrow key and then adjust UP and

DOWN arrow to set the differential from 14 degrees. After 3 seconds, it will return to

the room temperature reading.

Compressor Off Time:

The compressor routine guarantees a 5minute minimum off time on the

compressor, and it will not energize until the

5-minute off time has been satisfy.

Self Recovery Mode (*):

The unit controller is shipped with selfrecovery mode activated so that with any

sudden power interruption, the set point and

operating mode are stored in memory and

the unit will retain these settings and resume

operation once power is restored. When the

self-recovery mode is enabled the decimal

point on the second character on the LED

display is always On. If self-recovery mode

is not enabled then the second decimal point

is always Off. However, the user is able to

enable the “Self Recovery Mode” by

depressing the OFF button for 5 seconds and

then adjust the setting from the arrow key.

A0 – Self Recovery Mode “off”

A1 – Self Recovery Mode “on” (Factory

Default Setting)

Check Alarms:

The controller will monitor and check the

status of two alarm signals:

1. Alarm_Tank_Full (E.F),

2. Alarm_Temperature_Sensor (E.S).

When E.F, or E.S alarm is present, the

Power LED will blink, signaling that the

alarm condition is present, and the unit will

lock out. Once the failure is cleared, press

the OFF button, the Power LED will stop

blinking, and the room temperature will

display.

Optional Remote Control:

The optional remote control has identical

functions as the main unit excluding the

following:

1. Ability to change the “temperature

differential” setting. User can only

adjust such setting through the main

unit panel.

2. Ability to enable or disable the “self

recovery mode” setting. User can

only adjust such setting through the

main unit panel.

* User is only allowed to change setting

when unit is OFF*

21

AC Unit Control Panel

Heat Pump Unit Control Panel

Optional Remote Control

22

Inspection and Repair of Electrical

System

* Koldwave Technical Services

Department must be contacted prior

to or during any repair/service on a

unit which is under warranty.

Service other than routine

maintenance should be performed

only by a qualified refrigeration

service person.

Always disconnect power and discharge

capacitors before servicing.

Compressor and Fan Motor Capacitors

Visually check the capacitors for bulges or

signs of leakage. Using a capacitor tester,

check each capacitor shorts, grounds, or

leakage. Also verify the capacitance in mfd

matches the capacitor rating.

Inspection and Repair of

Refrigerant System

* Koldwave Technical Services

Department must be contacted prior

to or during any repair/service on a

unit which is under warranty.

Service other than routine

maintenance should be performed

only by a qualified refrigeration

service person.

Check all connections and every part for

leaks whenever the refrigerant system is

repaired. Use a leak detector, soap solution,

or a halide torch to inspect the system.

When repairing a refrigerant leak, the

brazing flame will cause oxidation to occur

inside the copper tubing being repaired. It is

therefore desirable to use a slightly reduced

flame and to flow dry nitrogen gas through

the refrigerant piping while brazing to

prevent this oxidation from taking place.

Once the repair is completed, thoroughly

evacuate the refrigerant system with a

vacuum pump before recharging the system.

Koldwave strongly recommends a

filter/dryer be installed when any repairs are

made to the refrigeration system.

Preventative Maintenance

Your Koldwave portable spot cooler has

been designed to give maximum

performance and reliability with minimum

maintenance. Maintenance of the system is

concentrated in three areas covered in the

following paragraphs.

Blower Motors

Caution: Always disconnect the power

source before working on or near a motor

or its connected load.

The motor may require periodic cleaning to

prevent the possibility of overheating due to

an accumulation of dust and dirt on the

windings or on the motor exterior.

Filter

The life of a filter depends entirely on its

environment and use. It is recommended

that air filters be inspected on a regular basis

every four to six weeks. A clogged filter

will cause the unit to operate at greatly

reduced efficiency. This unit employs one

1/2" thick, washable aluminum mesh air

filter located behind the louvered front

(evaporator) panel. The evaporator filter can

easily be removed and cleaned; pull down

the evaporator intake hinged door and pull

the filter out. The filters must be washed

periodically when needed. This may be done

23

as follows:

1. Soak filter in solution of warm water and

detergent for 15 minutes.

2. Rinse in clean, hot water and shake excess

moisture from filter.

3. Spray one side of filter with light film of

oil.

4. Reinstall with oiled surface facing out

from unit.

Coils and Related Items

Coil Maintenance

The evaporator coil surfaces must be kept

clean of dirt and lint in order to operate at

rated efficiency. The coil should be

inspected on a regular basis and cleaned as

required.

CAUTION: Solutions used to clean coils

must not be corrosive to metals or

materials used in the manufacture of this

equipment. Take care to not damage the

coil or fins if using a high pressure spray

to apply the cleaning solutions.

Condensate Pump

Caution: Always disconnect the power

source before working on or near the

pump.

Pump Maintenance:

Do not touch or clean the sensor device with

sharp objects or tools. The sensor element is

fragile so handle with care. Replace the

pump if damaged in any way. If servicing,

clean carefully with a soft brush, cloth, or

under a slow running tap. Rinse out the tray

thoroughly.

Do not use solvent based cleaning agents.

Only mild detergents may be used, but rinse

thoroughly before refitting.

Do not use if the pump or its cable is

damaged in any way. Protect the cable and

tubing from sharp edges.

The condensate drain pan should be

periodically flushed.

Unit Storage

CAUTION:

If the unit is to be stored in an

unconditioned space where it will be

exposed to freezing temperatures, all

water must be removed from the

condenser coil prior to storage. Use 15 –

20 PSI of compressed air or nitrogen

applied to the Water In (middle)

connection. To do this turn the unit off.

Shut off the water supply. Disconnect the

3 hose manifold (Water Out, Water In,

Drain) from the unit. Place the unit in the

Cooling mode. Once the compressor

starts and runs for 15 seconds,

blow any remaining water out of the

condenser coil.

24

Electrical Diagram

5WK07, 5WK14 115V/1 PH

25

5WK18, 5WK23, 5WK26 208-230V 1 PH

26

5WK36 208-230V/1PH

27

Trouble Shooting Guide

Before troubleshooting this system, read this manual to determine electrical power and

installation requirements to allow the spot cooler to perform at its maximum efficiency. Refer to

general description, wiring diagrams and photographs to get an understanding of how the unit

functions.

Service other than routine maintenance should be performed only by a qualified

refrigeration service person.

GENERAL TROUBLESHOOTING

Problem Possible Cause Remedy

Entire unit does not operate. 1 Power interruption. 1 Check external power supply for tripped breaker or blown fuse.

2 Defective tank full unit cutout switch 2 Check and replace.

3 Condensate tank could be full. 3 Check tank and empty if necessary.

4 Unit keypad control setting may be too

high.

5 Retur n air sensor out of calibration or

defective.

6 No contr ol voltage 24VAC on tr ansformer

secondary.

Insufficient cooling. 1 Improper sizing of unit. 1 Check if the unit is undersized for the load. Add supplemental

2 Dirty air filter in unit. 2 Clean filter

3 Dir t y evaporator coil. 3 Clean evaporator coil.

4 I ce on evaporator coil. 4 Defrost; use fan only operation.

5 Obstr ucted intake. 5 Remove obstruction.

6 Other possible causes. 6 Refer to condenser, evaporator and compressor sections.

7 Low voltage. 7 Check supply power. Must be within 10% of nameplate rating.

8 Condenser coil dirty or restricted. 8 Replace condenser coil.

9 Thermostat set too high. 9 Lower setting.

10 Water bypass valve closed or not operating

or restricted.

11 Reversing valve stuck open in heating

mode. Solenoid coil not switching valve to

cooling.

12 Unit not set for heating or cooling. 12 Refer to Unit Operation section.

13 Defective wiring or connection. 13 Tug on wires to see if they will separate from connections.

14 Restriction in refrigerant system. 14 Restriction can be located by inspecting refrigerant line for

15 Water temperature too high or too low. 15 Water Out temperature must not exceed 110°F or fall below

16 Water to unit not turned on, not adjusted

correctly or low inlet water pressure.

Check reset button on power cord.

4 Lower setting.

5 Replace if error message ES is displayed on keypad.

6 Check and replace.

unit(s).

10 Adjust, clear restriction or replace.

11 Verify that no power is applied to the reversing valve solenoid

coil. If the valve is not powered and the leaving air temperature

from the evaporator coil is hot when the compressor is running,

recover refrigerant, replace reversing valve, install filter/dryer,

evacuate system and weigh in proper charge.

temperature changes. Recover refrigerant, remove restriction,

install filter/dryer, evacuate system and weigh in proper charge.

50°F. Check inlet water temperature for extremes. Adjust valve.

16 Turn water on before starting unit. Adjust flow rate as necessary.

Minimum inlet water pressure can be found in the Specification

and Electrical Data section..

28

Trouble Shooting Guide Continued

GENERAL TROUBLESHOOTING

Abnormal noise. 1 Loose compressor mounting nuts. 1 Tighten.

2 Defective, improper or worn rubber

3 Copper tube vibrating. 3 Adjust by bending slightly to firm position. Separate tubes

4 Loose cabinet or internal component. 4 Check and tighten loose screws.

5 Loose blower wheel. 5 Tighten screws on blower wheel to shaft.

6 Blower wheel hitting shroud. 6 Adjust wheel position on motor shaft.

7 Blower motor bearing defective. 7 Replace blower motor.

8 Unit overcharged 8 Recover entire refrigerant charge and weigh in proper charge.

9 Compressor motor defective. 9 Replace compressor.

Evaporator fan runs but

compressor doesn’t start

2 Keypad control. 2 Check the temperature control for loose wires. Tighten any loose

3 Loose or defective wires. 3 Tug on wires to see if they will separate from connections.

4 Compressor shorted, open or burned. 4 Check for shorts, opens and grounds. Remove and replace

5 Shorted or open run capacitor. 5 Check capacitance and replace if necessary.

6 Unit in fan only mode. 6 Change mode.

7 Defective compressor relay. 7 Check and replace.

8 Freeze control open on heat pump model. 8 Inlet water temperature cannot be less than 50°F. Replace control

Evaporator blower motor not

running.

2 Defective fan capacitor. 2 Check capacitance and replace if necessary.

3 Defective wiring or connection. 3 Tug on wires to see if they will separate from connections.

4 Defective fan speed contactor. 4 Check and replace.

5 Keypad control. 5 Check the temperature control for loose wires. Tighten any loose

Evaporator blower not running

up to full speed.

2 Defective motor capacitor. 2 Check capacitance and replace if necessary.

3 Blower wheel rubbing against housing. 3 Inspect wheel alignment and correct.

Water leaking from unit. 1 Leaking evaporator condensate pan. 1 Locate leak and repair pan.

2 Condensate pump related. 2 Check to see if the elevation is over 11 ft. Pump will operate

3 Defective drain hose (clogged or loose

Unit tripping when plugged in

(cord connected units only)

2 Building does not have a dedicated

grommets on the compressor mounting

bolts.

1 Low voltage to unit. 1 Check power supply for proper voltage at unit plus or minus 10%

1 Defective fan motor. 1 Check and replace.

1 Low voltage to unit. 1 Check power supply for proper voltage at unit plus or minus 10%

connection).

1 Undesirable "Arc" from power receptacle. 1 Disconnect power completely from receptacle and reset the plug

grounding system.

2 Replace grommets.

touching cabinet or each other.

of rated nameplate voltage.

connections. Replace if defective.

compressor.

if defective.

connections. Replace if defective.

of rated nameplate voltage.

properly against 11 ft. of water total head pressure on pump.

Otherwise, replace pump if defective. Make sure pump is sitting

level and is clean.

3 Inspect hose for loose connections, clogs or kinks. Repair or

replace.

by pressing the "reset" button. Reconnect the plug to the

receptacle. If tripping again, it means there is an "Arc" detected.

Check for shorts in unit wiring. Check for correct polarity at

receptacle. Replace the electrical receptacle outlet if defective.

2 The units must be connected to a grounding system.

29

Trouble Shooting Guide Continued

GENERAL TROUBLESHOOTING

Circuit breaker or fuses blowing 1 Low voltage to unit. 1 Check power supply for proper voltage at unit plus or minus 10%

2 Compressor short cycles 2 See section on compressor troubleshooting.

3 Defective wiring or connection. 3 Tug on wires to see if they will separate from connections.

4 Refrigerant system not equalized (wait 5

5 Improper fuses or dedicated circuit. 5 Connect unit to a dedicated circuit. Check unit rating plate for

6 Grounded component. 6 Check unit components for short to ground and correct wiring or

Electric shock from unit. 1 Grounded electric circuit. 1 An ungrounded wire or component is touching the unit casing.

2 Ungrounded unit. 2 The units must be connected to a grounding system.

Cycle too long or unit operates

continuously.

3 Air or non-condensable gases in system. 3 Recover refrigerant, install filter/dryer, evacuate system and

4 Capillary tube or strainer restricted. 4 Replace restricted capillary tube.

5 Compressor contactor stuck closed. 5 Replace contactor.

6 Low refrigerant charge. 6 Locate refrigerant leak, recover refrigerant, repair leak, install

7 Improper unit installation. 7 Check for airflow restrictions and objects blocking front of unit

8 Unit too small for its application. 8 Replace with larger unit.

9 Leak in system 9 Locate refrigerant leak, recover refrigerant, repair leak, install

10 Dirty air filter (air flow restricted) 10 Clean air filter.

min. before restart).

1 Condenser dirty, clogged or restricted. 1 Replace condenser coil.

2 Compressor motor defective. 2 Replace compressor

of rated nameplate voltage.

4 Compressor is starting under a load. If this condition persists, see

section on compressor troubleshooting.

circuit amperage.

replace component as necessary.

Use an ohmmeter or hipot tester to find trouble. Replace or

rewire.

weigh in proper charge of virgin refrigerant.

filter/dryer, evacuate system and weigh in proper charge.

filter/dryer, evacuate system and weigh in proper charge.

COMPRESSOR TROUBLESHOOTING

Compressor starts and runs but

cycles on overload

2 Capacitor incorrect or defective 2 Check capacitance and replace if necessary.

3 Condenser dirty, clogged or restricted 3 Replace condenser coil.

4 Compressor grounded 4 Check compressor windings to ground. Replace compressor if

5 Air or non-condensable gases in system 5 Recover refrigerant, install filter/dryer, evacuate system and

6 Wiring incorrect or defective 5 Tug on wires to see if they will separate from connections.

7 High head-pressure 7 Clean coils and filter, check system pressures

8 Capillary tube or strainer restricted 8 Replace restricted capillary tube.

9 Overload protector incorrect or defective 9 Replace as necessary.

10 Refrigerant overcharged 10 Recover entire refrigerant charge and weigh in proper charge.

1 Low voltage 1 Check power supply for proper voltage at unit plus or minus 10%

of rated nameplate voltage.

shorted.

weigh in proper charge of virgin refrigerant.

30

Trouble Shooting Guide Continued

COMPRESSOR TROUBLESHOOTING

Compressor tries to start when tstat closes, but cuts out on

overload; finally starts after

several attempts

2 Compressor capacitor incorrect or defective 2 Check capacitance and replace if necessary.

3 Compressor motor requires start assist 3 Unit is equipped with hard start capacitor. Check capacitance

4 Air or non-condensable gases in system 4 Recover refrigerant, install filter/dryer, evacuate system and

5 Capillary tube or strainer restricted 5 Replace restricted capillary tube.

6 Refrigerant system not equalized. 6 The unit was programmed at the factory with a 5 minute time

7 Discharge line restricted 7 Repair as necessary.

Compressor will not start; hums,

and cycles on overload protector

2 Start capacitor incorrect or defective 2

3 Compressor grounded 3 Check compressor windings to ground. Replace compressor if

4 Compressor motor or mechanism defective 4 Replace compressor.

5 Compressor motor requires start assist 5 Unit is equipped with hard start capacitor. Check capacitance

6 Wiring incorrect or defective 6 Tug on wires to see if they will separate from connections.

7 Refrigerant system not equalized. 7 The unit was programmed at the factory with a 5 minute time

8 Defective compressor relay. 8 Check and replace.

9 High head-pressure. 9 Check for mineral deposits in condenser coil. Clean filter, and

10 Compressor locked. 10 Replace compressor.

Will not start; no hum 1 Compressor motor defective. 1 Replace compressor.

2 Wiring incorrect or defective. 2 Tug on wires to see if they will separate from connections.

3 No power to cord connected unit. 3 Check reset button on LCDI cord at wall outlet.

4 Fuse or circuit breaker blown 4 Check unit for shorts or defective electrical parts. Correct shorts

5 Overload protector tripped 5 Verify compressor is not shorted. Replace overload.

6 Thermostat contacts open 6 Lower control setting and wait 5 minutes. If still no call for

7 Thermostat set too high 7 Lower control setting.

1 Low voltage 1 Check voltage at wall outlet. Must be within

10% of nameplate rating voltage.

and replace if necessary.

weigh in proper charge of virgin refrigerant.

delay between compressor starts. If the compressor cycles more

frequently, contact factory.

1 Low voltage 1 Check voltage at wall outlet. Must be within 10% of nameplate

rating voltage.

shorted.

and replace if necessary.

delay between compressor starts. If the compressor cycles more

frequently, contact factory.

check system pressures.

and replace parts as necessary then replace fuse or reset circuit

breaker as necessary.

cooling, replace control board.

31

Trouble Shooting Guide Continued

COMPRESSOR TROUBLESHOOTING

Compressor short cycles 1 Low voltage 1 Check voltage at wall outlet. Must be within 10% of nameplate

2 Capacitor incorrect or defective 2 Check capacitance and replace if necessary.

3 Compressor motor defective 3 Replace compressor

4 Wiring incorrect or defective 4 Tug on wires to see if they will separate from connections.

5 Capillary tube or strainer restricted 5 Replace restricted capillary tube.

6 Refrigerant system not equalized. 6 The unit was programmed at the factory with a 5 minute time

7 Fan motor too slow. 7 Select HI speed on control panel

8 Fan motor defective. 8 Check and replace.

9 Fan blade or blower wheel stuck. 9 Check for obstruction and clear. Realign blower within housing

10 Low refrigerant charge. 10 Locate refrigerant leak, recover refrigerant, repair leak, install

11 Refrigerant overcharged. 11 Recover entire refrigerant charge and weigh in proper charge.

12 Evaporator air flow re-circulation. 12 Clean coil and filters if necessary. Unit should have 4’ of free

13 Unit missing front panel or front seals. 13 All panels must be in place and secured for proper unit operation.

14 Unit oversized for application. 14 Replace with unit of appropriate size.

Compressor starts, but stops

after a few minutes.

2 Defective compressor run capacitor. 2 Check capacitance and replace if necessary.

3 Check the keypad error message ES. 3 Check return air sensor and replace if necessary.

4 Loose connection in electrical circuit. 4 Trace loose wire(s) and tighten connection.

5 Refrigerant overcharged. 5 Recover entire refrigerant charge and weigh in proper charge.

6 Low refrigerant charge. 6 Locate refrigerant leak, recover refrigerant, repair leak, install

7 Condenser dirty, clogged or restricted. 7 Replace condenser coil.

8 Condensate tank right at trip point. 8 Empty tank.

9 Condenser fan running at high ESP. 9 Reduce duct length.

10 High head-pressure 10 Check for obstructions within condenser coil and replace as

Compressor starts and runs but

fan does not run.

2 Shorted or open fan motor. 2 Replace motor.

3 Fan motor capacitor incorrect or defective 3 Check capacitance and replace if necessary.

1 Defective compressor motor. 1 Replace compressor.

1 Open fan motor contactor circuit. 1 Check and replace fan motor contactor as necessary.

rating voltage.

delay between compressor starts. If the compressor cycles more

frequently, contact factory.

and tighten set screw onto fan motor shaft.

filter/dryer, evacuate system and weigh in proper charge.

space in front of it.

filter/dryer, evacuate system and weigh in proper charge it.

necessary.

32

Trouble Shooting Guide Continued

HEAD PRESSURE TROUBLESHOOTING

Too high 1 Condenser dirty, clogged or restricted. 1 Replace condenser coil.

2 Air or non-condensable gases in system 2 Recover refrigerant, install filter/dryer, evacuate system and

3 Fan blade or motor defective 3 Check and replace.

4 Refrigerant overcharged 4 Recover entire refrigerant charge and weigh in proper charge.

Too low 1 Compressor motor or mechanism defective 1 Replace compressor

2 Capillary tube or strainer restricted 2 Replace restricted capillary tube.

3 Low refrigerant charge 3 Locate refrigerant leak, recover refrigerant, repair leak, install

4 Evaporator dirty, clogged or restricted 4 Clean evaporator coil.

5 Leak in system 5 Locate refrigerant leak, recover refrigerant, repair leak, install

6 Dirty air filter (air flow restricted) 6 Clean filter .

7 Inlet water temperature below 50°F. 7 Adjust regulator valve. Change water supply.

EVAPORATOR TROUBLESHOOTING

Coil freezes 1 Capillary tube or strainer restricted. 1 Replace restricted capillary tube.

2 Fan blade or blower wheel stuck. 2 Check for obstruction and clear. Realign blower within housing

3 Compressor contactor stuck closed. 3 Replace contactor.

4 Return air sensor defective. 4 Replace sensor.

5 Low refrigerant charge. 5 Locate refrigerant leak, recover refrigerant, repair leak, install

6 Evaporator dirty, clogged or restricted. 6 Clean evaporator coil.

7 Dirty air filter (air flow restricted). 7 Clean filter.

8 Defective fan motor. 8 Replace fan motor.

CONDENSER TROUBLESHOOTING

Water outlet temperature

exceeds 110°F.

2 Air or non-condensable gases in system. 2 Recover refrigerant, install filter/dryer, evacuate system and

3 Refrigerant overcharged 3 Recover entire refrigerant charge and weigh in proper charge.

4 High head-pressure 4 Adjust water regulating valve.

1 Condenser dirty, clogged or restricted. 1 Replace condenser coil.

weigh in proper charge of virgin refrigerant.

filter/dryer, evacuate system and weigh in proper charge.

filter/dryer, evacuate system and weigh in proper charge.

and tighten set screw onto fan motor shaft.

filter/dryer, evacuate system and weigh in proper charge.

weigh in proper charge of virgin refrigerant.

33

4830 Transport Drive

Dallas, TX 75247

214-638-6010 T

214-905-0806 F

www.koldwave.com

www.mestekparts.com

Rev Date: 080510

34

Loading...

Loading...