Koldwave 5KK14BEA2AA00, 5KK21BGA2AA00, 5KK30BGA2AA00 Service Manual

page 1

KOLDWAVE

Portable Air Condi oners

5KK14BEA2AA00

5KK21BGA2AA00

5KK30BGA2AA00

SERVICE MANUAL

2 page

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

Table of Contents

GENERAL DESCRIPTION..............................................................................4

General air condi oning system

Portable air condi oning system

SPECIFICATIONS.........................................................................................5

Exterior Dimension Diagram

Technical Specifi ca ons

Characteris cs

CONSTRUCTION.........................................................................................9

Internal Structure

REFRIGERANT SYSTEM CONSTRUCTION...................................................12

Compressor

Compressor lubrica on

Condenser

Capillary Tube

Evaporator

Accumulator

ELECTRICAL SYSTEM.................................................................................18

Circuit Diagram

Control panel

Program Se ng

Controller Board

Control Specifi ca ons

Self-Diagnos c Codes

Compressor

Evaporator Fan Motor

Condenser Fan Motor

Capacitor

Molded Case Circuit Breaker

Magne c Contact

Thermal Relay

Temperature Thermistor

Drain Tank Switch

page 3

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

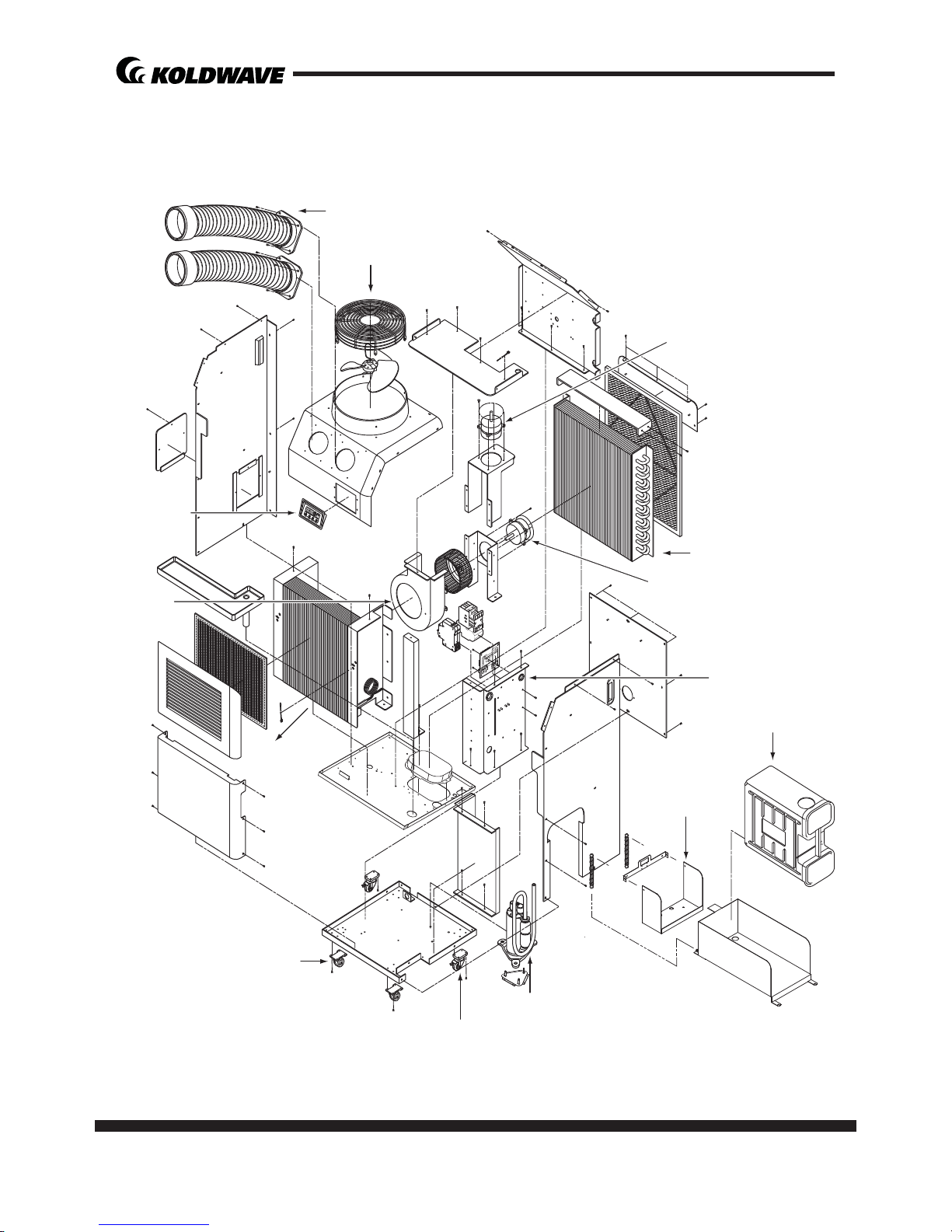

ASSEMBLY (For 5KK14BEA2AA00).................................................................32

Component parts

General Safety Informa on

Troubleshoo ng chart

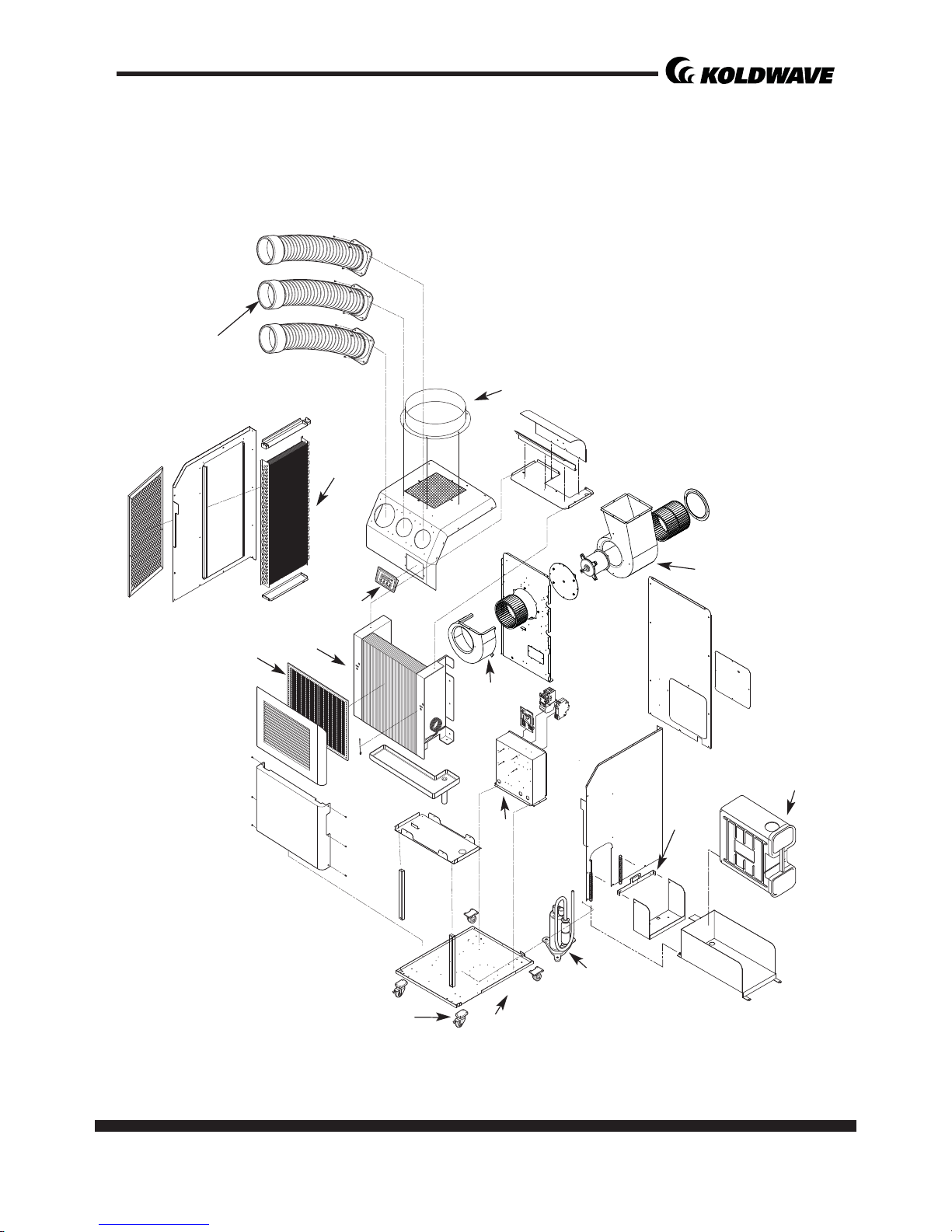

ASSEMBLY (For 5KK21BGA2AA00)................................................................33

Component parts

General Safety Informa on

Troubleshoo ng chart

ASSEMBLY (For 5KK30BGA2AA00)................................................................34

Component parts

General Safety Informa on

Troubleshoo ng chart

DISASSEMBLY (For 5KK14BEA2AA00)............................................................38

Disassembly

Control panel removal

Electrical parts and relay board removal

Fan motor removal

DISASSEMBLY (For 5KK21BGA2AA00)...........................................................45

Disassembly

Control panel removal

Electrical parts and relay board removal

Fan motor removal

DISASSEMBLY (For 5KK30BGA2AA00)...........................................................52

Disassembly

Control panel removal

Electrical parts and relay board removal

Fan motor removal

REFRGERANT SYSTEM REPAIR.......................................................................59

Brazing

Removal of Refrigerant System Components

Charging the System with R-410A Refrigerant

Refrigerant Charging Work

4 page

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

GENERAL DESCRIPTION

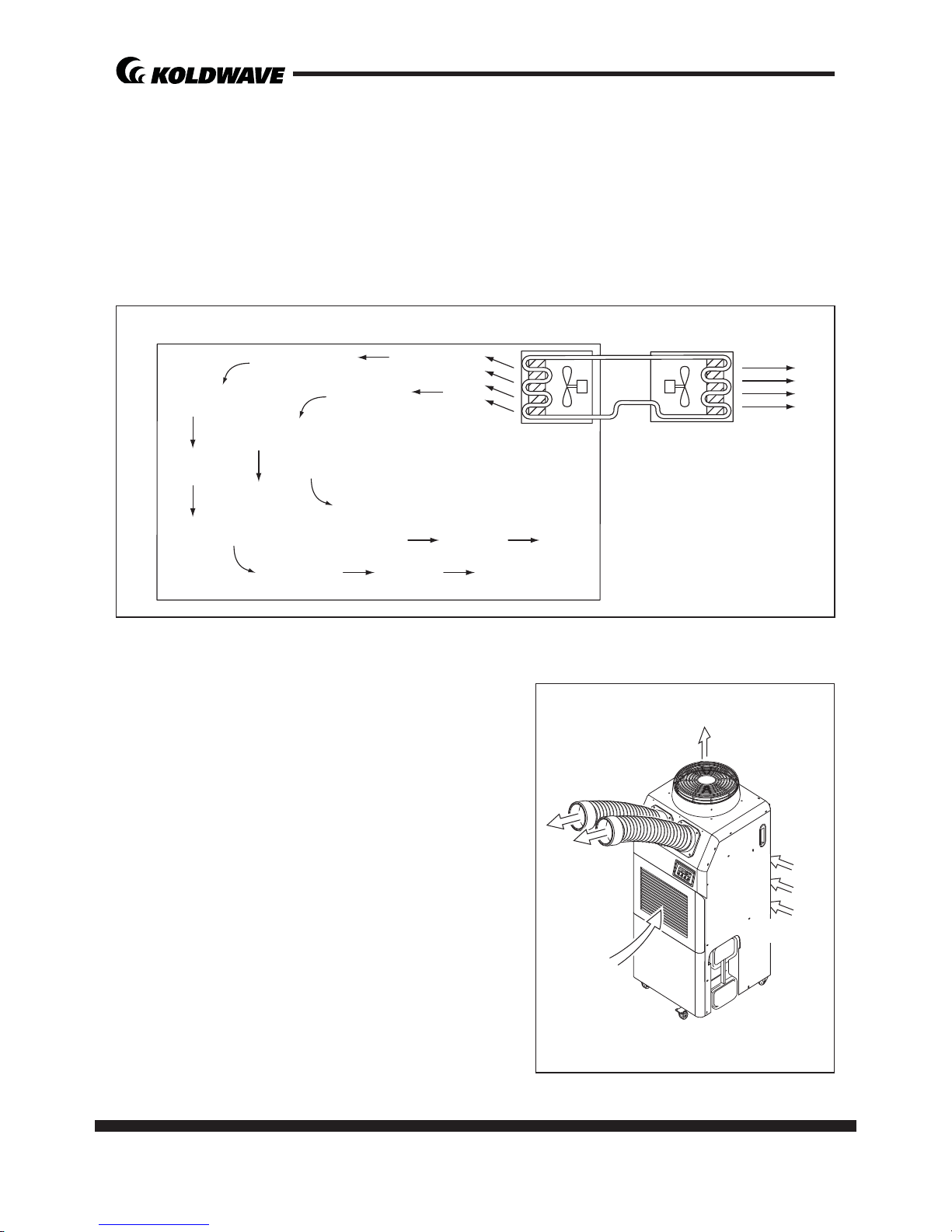

General air condi oning system

1) conven onal air condi oners cool the en re enclosed environment.

2) They act as “heat exchangers”, equiring an interior unit (evaporator) to blow cool

air into the interior and an exterior unit (condenser) to exhaust exchanged heat

to the outdoors.

Portable air condi oning system

1) The 5KK14BEA2AA00/5KK21BGA2AA00/5KK

30BGA2AA00 is a spot cooler which directs

cool air to par cular areas or objects.

2) The 5KK14BEA2AA00/5KK21BGA2AA00/5KK

30BGA2AA00 has the following features.

3) The innova ve design of the KK14BEA2AA

00/5KK21BGA2AA00/5KK30BGA2AA00 has

resulted in one compact unit, replacing the

need for two separate units.

4) With the whole cooling system built into one

compact unit, the 5KK14BEA2AA00/5KK21BG

A2AA00/5KK30BGA2AA00 requires no piping

and can be easily transported and installed.

5) The 5KK14BEA2AA00/5KK21BGA2AA00/5KK

30BGA2AA00 is economical because it cools

only the area or objects which need to be

cooled.

Condenser

Outdoor Unit

Evaporator

Indoor Unit

Intake air

(to Evaporator)

Intake air

(to Condenser)

Filter

Filter

Exhaust Hot Air

Cooling Air

page 5

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

SPECIFICATIONS

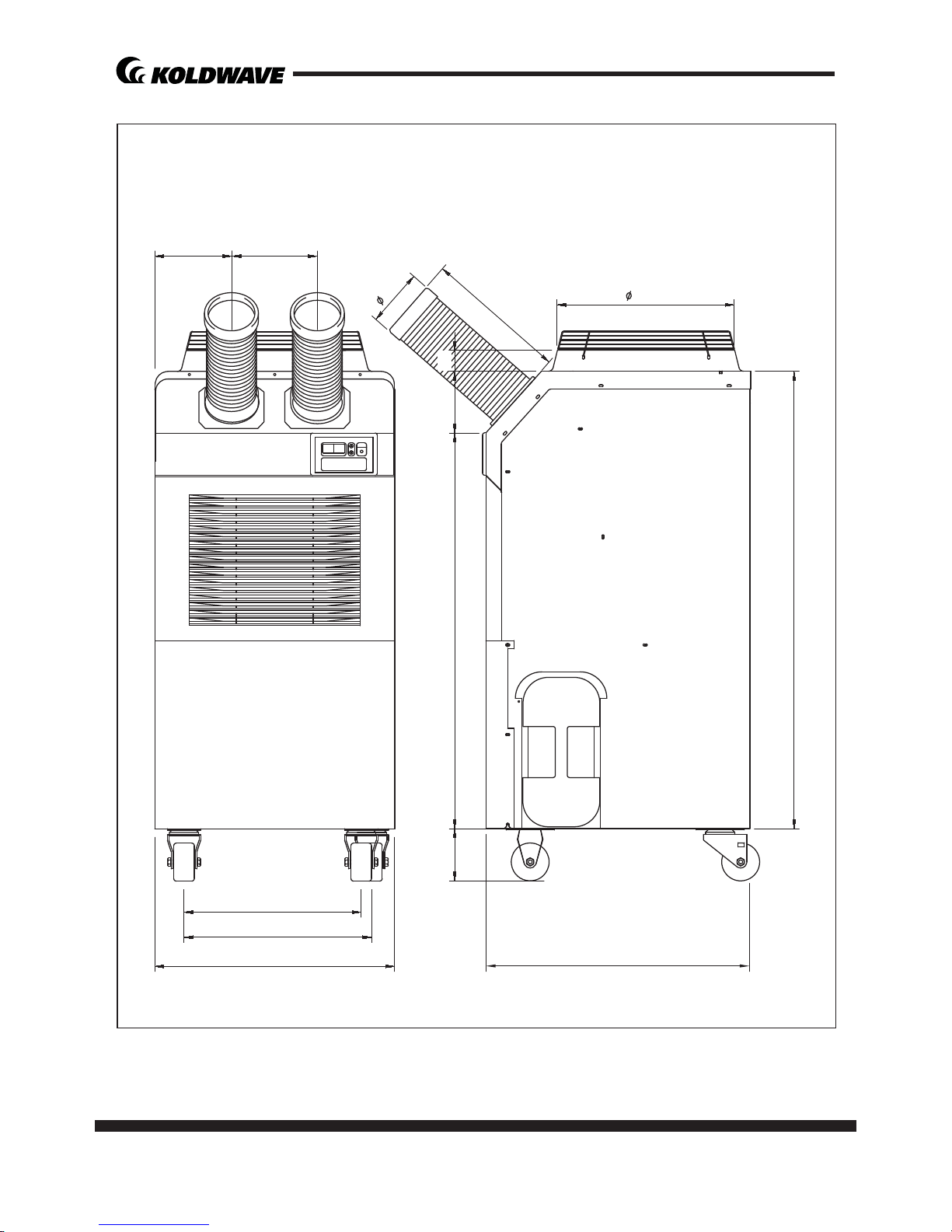

Exterior Dimension Diagram

<5KK14BEA2AA00>

4

36.2 2.9

12.5

5.9

36.2

17.5 19.8

13.1

12

5.6

20

6 page

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

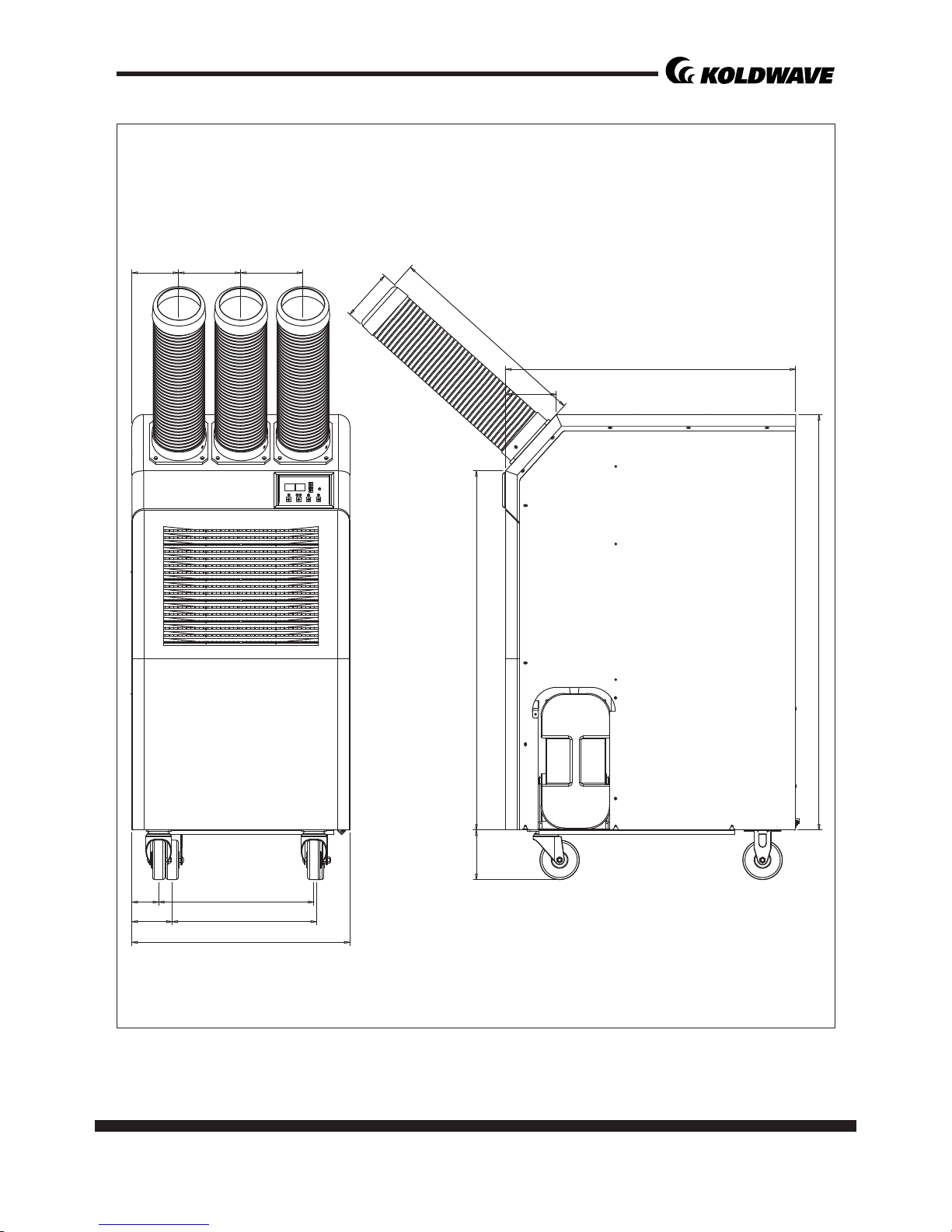

<5KK21BGA2AA00>

22.1

17.3

16.3

7.87.1

4.8 36.4 5.6 1.9

16.3

5.9

42.1

20

24.4

page 7

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

<5KK30BGA2AA00>

4.7 6.2 6.2

2.6 15.7

4.0 15.2

22.1

5 36.4

21

OD. Ø5.2

29.4

5.1

42.2

8 page

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

Specifi ca ons Unit 5KK14BEA2AA00 5KK21BGA2AA00 5KK30BGA2AA00

Cooling Capacity Btu/h 13,200 19,500 / 21,000 28,000 / 29,000

Power Supply

Phase Single Single Single

Volts 115 208 / 230 208 / 230

Hertz 60 60 60

Power Consump on Wa s 1,300 2,300 3,300

Rated Current Amps

To s h i b a

11.5

LG

10.9

11.0 / 10.0 15.1 / 14.8

EER Btu/Wh 8.6 8.9 9.3

Circuit Breaker Size Amps 15 15 20

Nema Plug Type 5-15P 6-15P 6-20P

Power Cord Gauge Awg 14 14 12

Power Cord Length 10 6 10

Dimensions (W x H x D) In .( mm )

17.5 x 19.9 x 43.3

(445 x 508 x 1092)

22.0 x 24.4x 50.4

(558 x 620 x 1280)

22.1 x 29.4x 47.3

(561 x 746 x 1200)

We ight (Net / Gross) Lbs(kg) 132 / 145.5 (60 / 66) 198 / 216 (90 / 98) 216 / 234 (98 / 106)

Condensate tank Gallons(Liters) 3.17 (12) 3.17 (12) 3.17 (12)

No. of Cool Air Outlets Pcs 1 2 3

Ambient temperature

range

˚F(˚C) 64~113 (18~45) 64~113 (18~45) 64~113 (18~45)

Se ng temperature

(Room cool mode)

˚F(˚C) 64~86 (18~30) 64~86 (18~30) 64~86 (18~30)

Se ng temperature

(Spot cool mode)

˚F(˚C) 32~86 (0~30) 32~86 (0~30) 32~86 (0~30)

Applica on Area (Room

cool mode)

²(m²) 377 (35) 527 (50) 743 (70)

Refrigerant

Type R-410A R-410A R-410A

oz(g)

To s h i b a

15.9 (451)LG15.5 (440)

42.3 (1200) 44.4(1250)

Design Pressure - Hi/Low Psig

To s h i b a

450 / 250LG450 / 270

450 / 250 450 / 280

Indoor Air Flow (High/

Low)

CFM(CMH)

283 / 247

(480 / 420)

512 / 477

(870 / 810)

741 / 635

(1560/ 1447)

Wheels

pcs 4 4 4

diameter 76mm 102mm 102mm

Hot Air Duct Diameter In.(mm) 12 (300) 16 (400) 16 (400)

Maximum Duct Length (m) 16 (5) 30 (9) 60 (18)

Safety Devices

Compressor overload protector, An -freezing thermister, Full drain tank switch,

Autome c restart (Power interrup on), Compressor me delay program, High

pressure switch

Features

Temperature control, Self-diagnos c func on, Two sppeds fan, Op onal drain

pump kit, Washable fi lters, ˚F(˚C) display

Technical Specifi ca ons

page 9

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

Condenser

Condenser Motor

Evaporator

Cooling Air Duct

Condenser Air Outlet

Control Box

• Relay Board

• Capacitor

Drain Tank

Drain Tank Switch

Compressor

Locking Swivel Caster

Caster (Rear)

Eva Scroll

Control Panel

Evaporator Motor

CONSTRUCTION

Internal Structure

<5KK14BEA2AA00>

10 page

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

Control Panel

Eva Scroll

Drain Tank

Drain Tank Switch

Condenser

Condenser Motor

Control Box

• Relay Board

• Capacitor

Caster (Rear)

Locking Swivel Caster

Compressor

Evaporator

Evaporator Motor

Cooling Air Duct

Condenser Air Outlet

<5KK21BGA2AA00>

page 11

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

Control Panel

Eva Scroll

Condenser

Control Box

• Relay Board

• Capacitor

Caster (Rear)

Locking Swivel Caster

Compressor

Drain Tank Switch

Drain Tank

Evaporator

Eva Filter

Evaporator Motor

Cooling Air Duct

Cowl

<5KK30BGA2AA00>

12 page

Service Manual

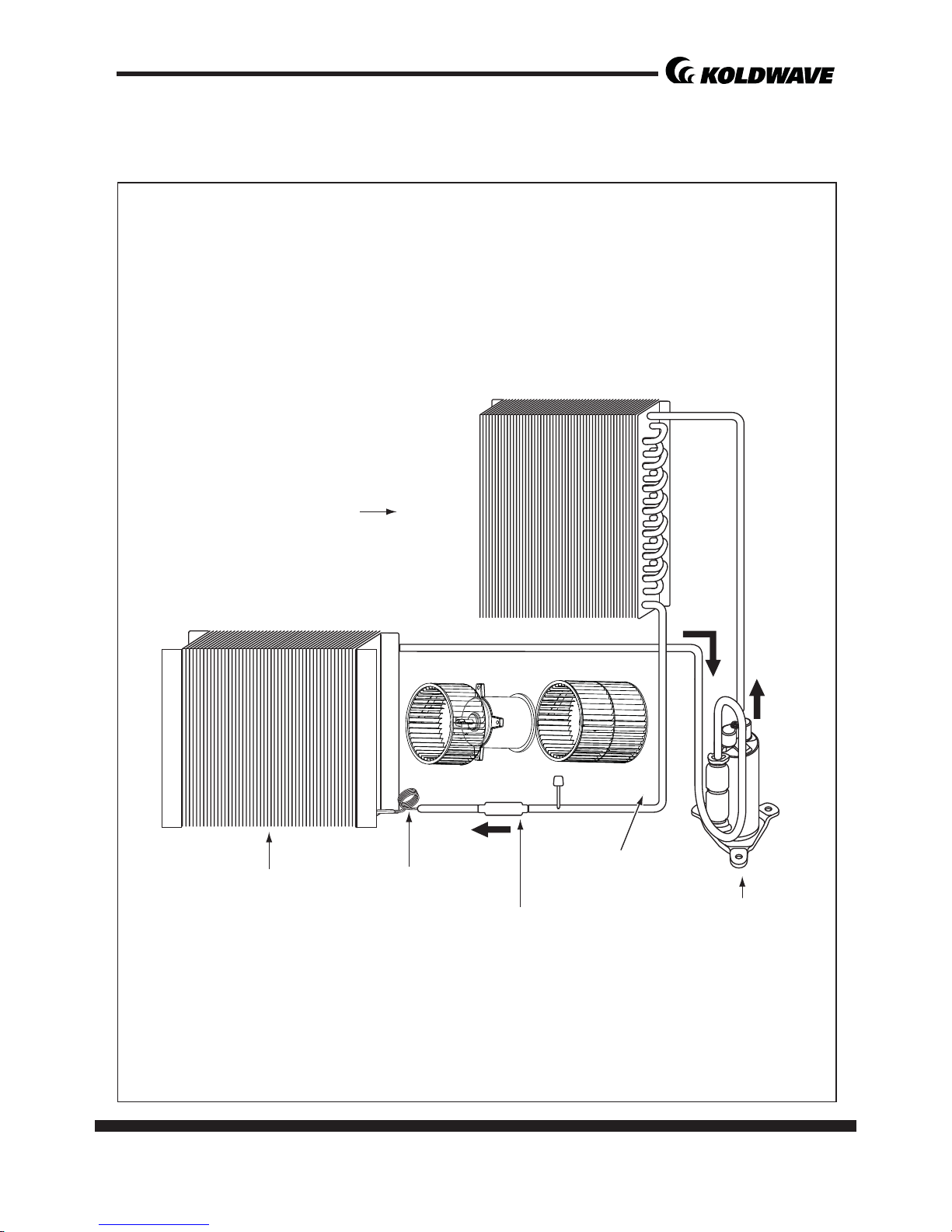

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

Flow of

Refrigerant

Condenser Air Outlet

Condenser Motor

Compressor

Accumulator

Evaporator Capillary tube

Drier

Condenser

REFRIGERANT SYSTEM CONSTRUCTION

<5KK14BEA2AA00,5KK21BGA2AA00>

page 13

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

Compressor

Accumulator

Evaporator Capillary tube

Drier

Condenser

<5KK30BGA2AA00>

14 page

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

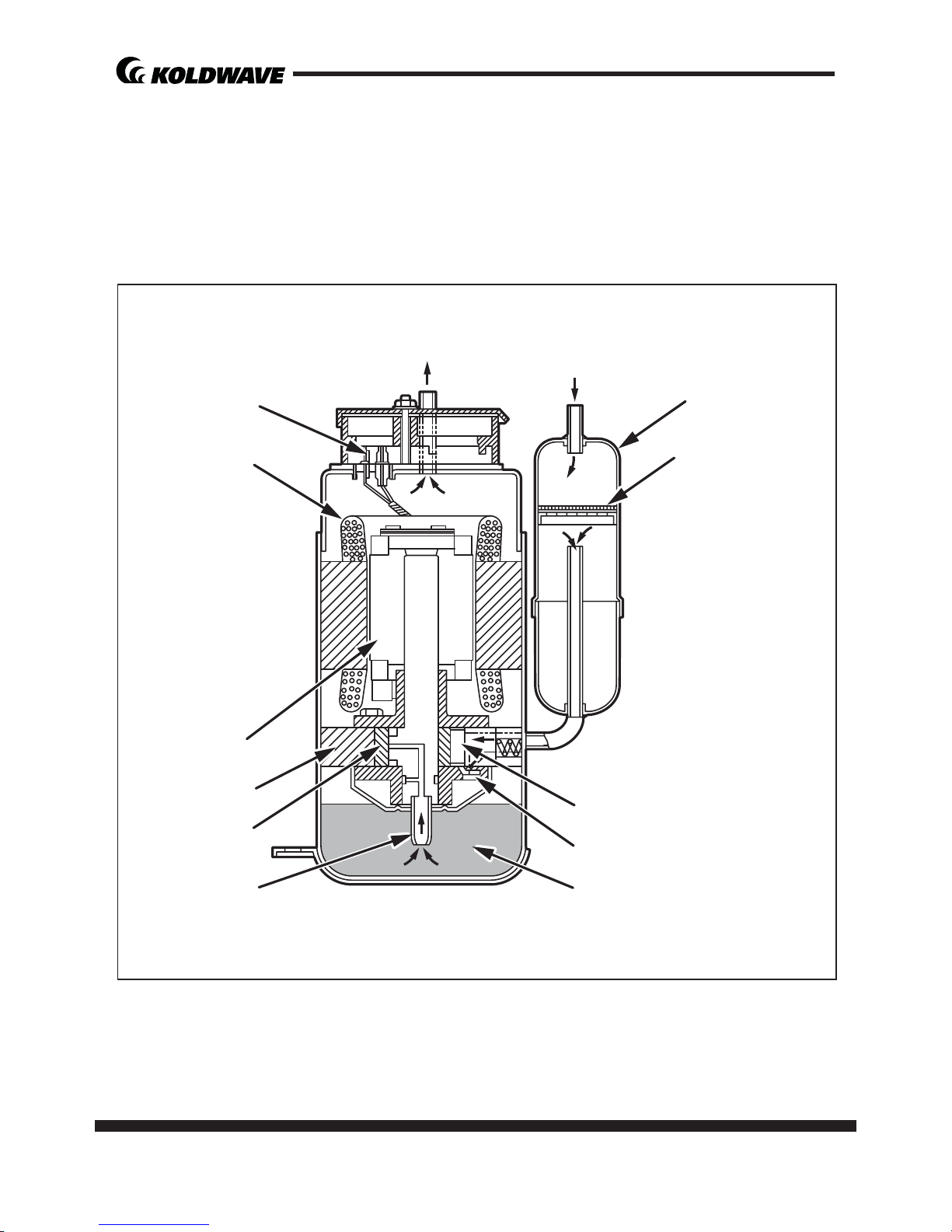

Compressor

The construc on of a rotary type compressor is divided into two mechanisms; the

drive mechanism (compressor motor), and the compression mechanism (compressor). When the rotor sha of the motor (drive mechanism) turns, the roller (compression mechanism) rotates to compress the refrigerant.

To Condenser

Accumulator

Strainer

From Evaporator

Blade

Discharge Valve

Oil

Lubricator

Roller

Cylinder

Rotor

Stator

Terminal

page 15

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

Compressor opera on

1) Start of compression

1) The cylinder is fi lled with low pressure gas.

2) Since pressure in the discharge chamber

is higher than in the cylinder, the discharge valve is kept closed.

2) Suc on and compression

1) The pressure in the cylinder increases

gradually.

2) Refrigerant suc on begins on the suc on side of the cylinder.

3) The discharge valve remains closed.

3) Discharge

1) The pressure in the cylinder exceeds that

in the discharge chamber, and the discharge valve opens.

2) On the suc on side, refrigerant suc on

con nues.

4) Comple on of compression

1) When compression is completed, all of

the refrigerant has been drawn from the

suc on chamber.

2) Opera on then returns to step 1)(Start

of compression) and the above process

of suc on and compression con nues

repeatedly in succession.

Blade

Discharge

Valve

Roller

Blade

Discharge

Valve

Roller

Blade

Discharge

Valve

Roller

Blade

Discharge

Valve

Roller

16 page

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

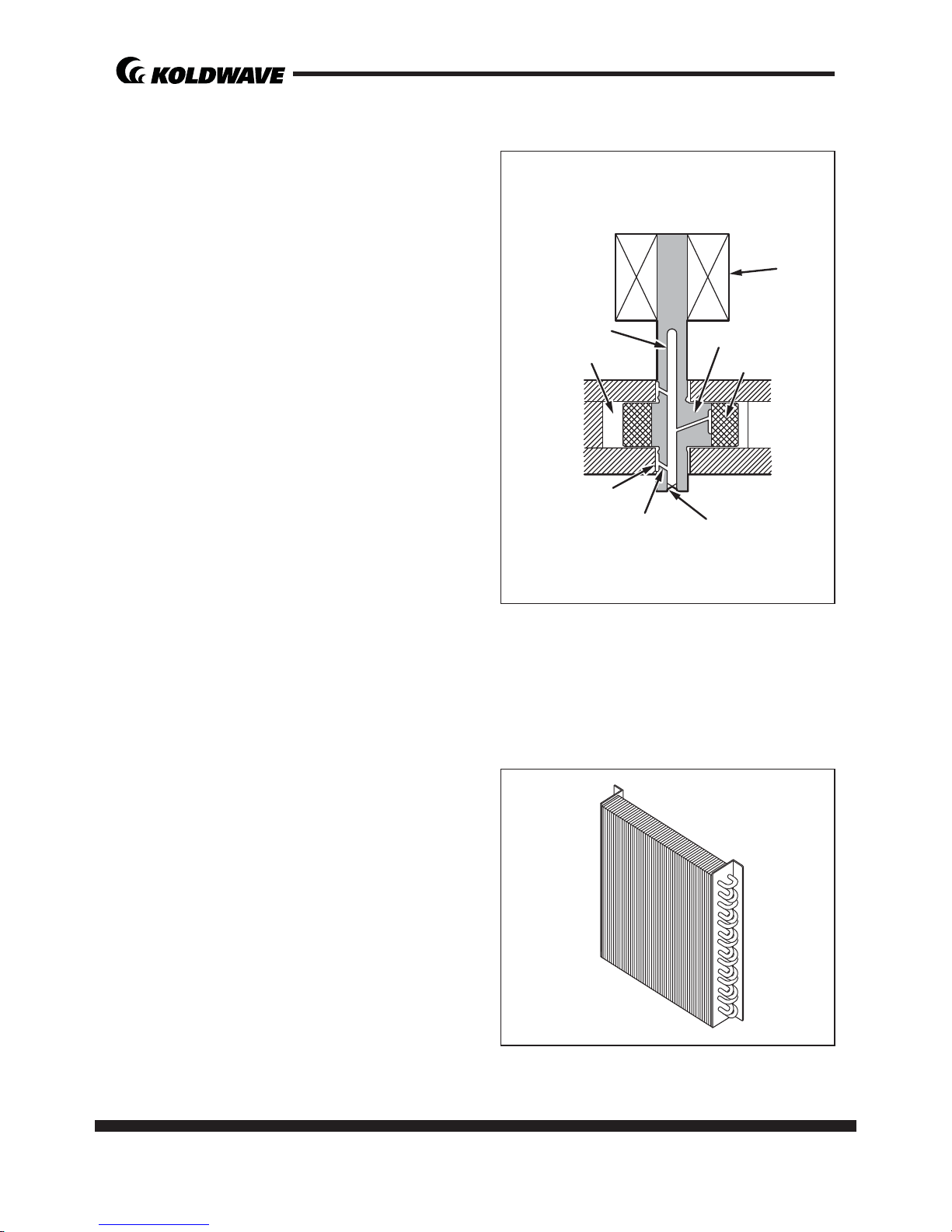

Compressor lubrica on

The lubrica on system is comprised of a

hollow sha , an oil scraper mounted at the

end face, hollow sha , a sha journal (sha

bearing), and the lubrica on groove for the

sha journal.

The lubrica on groove is wider than the oil

hole. When the sha turns, oil is scraped

upward by the oil scraper along the inside

diameter of the hollow sha . The oil is fed

through the oil hole by centrifugal force,

then supplied to the lubrica on groove for

each sha journal, lubrica ng the bearing.

In this lubrica on system, oil enters into

each bearing separately and returns to the

oil reservoir. This system eff ec vely prevents bearing temperature increases, and

off ers high reliability.

In addi on, the specially treated sha journal keeps the bearing from being

damaged during high temperature opera on.

Condenser

1) The condenser is a heat exchanger with

Louver fi ns.

2) Heat is given off and absorbed by air be-

ing pulled across the condenser fi ns by

the axial fan. The air is then expelled

through the condenser air outlet.

Oil Feed Groove

Oil Hole

Oil Scrapper

Roller

Rotor

Cylinder

Hollow Sha

Eccentric Sha

page 17

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

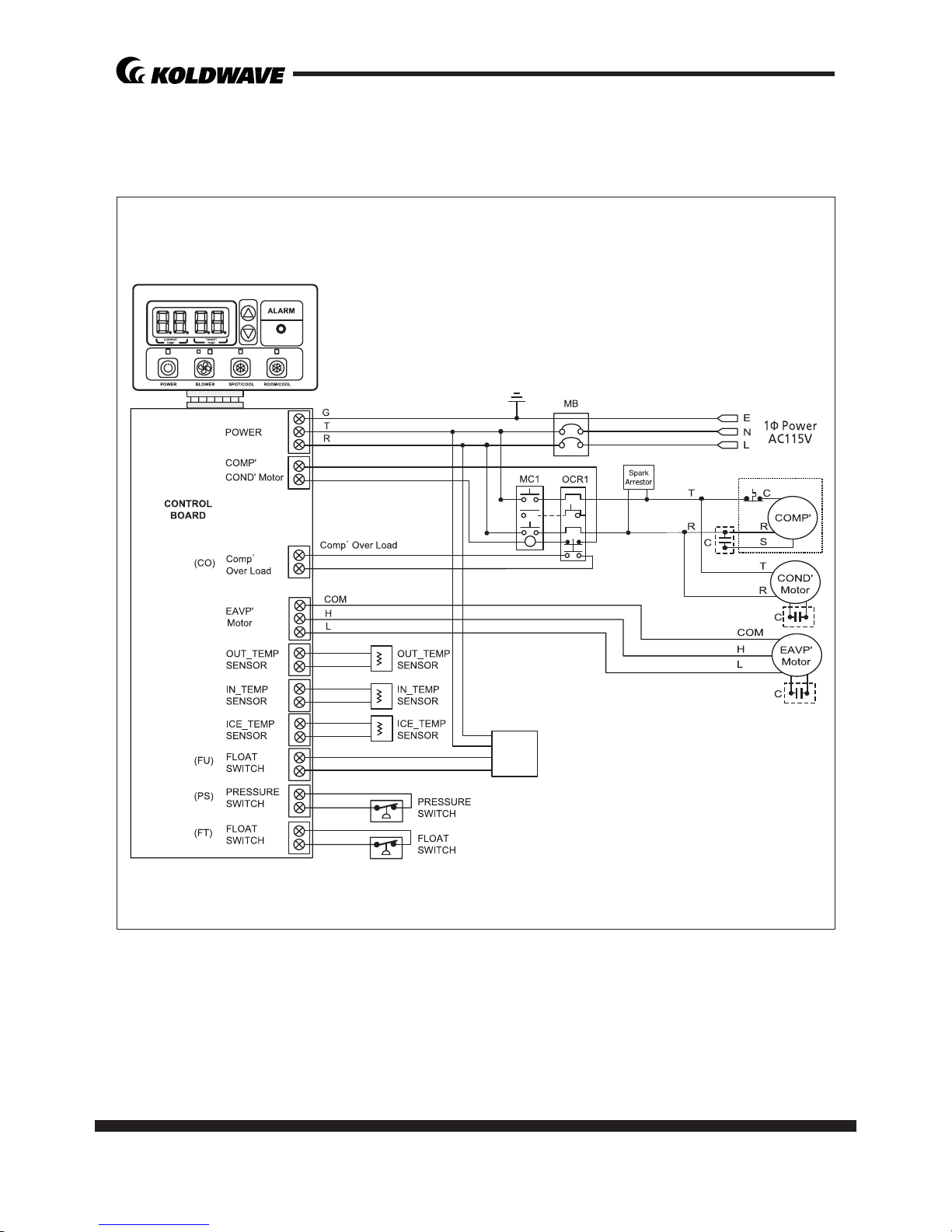

Capillary Tube

The capillary tube is a long thin tube

that u lizes line fl ow resistance as an

expansion valve. The length and the

inner diameter of the capillary tube

are determined according to the capacity of the refrigera on system,

opera ng condi ons, and the amount

of refrigerant. The high pressure, high

temperature liquid refrigerant sent

from the condenser expands rapidly as

the refrigerant is sprayed out through the fi xed orifi ce in the capillary tube. As a

result, the temperature and state of the refrigerant becomes low and mist-like, and

therefore evaporates easily.

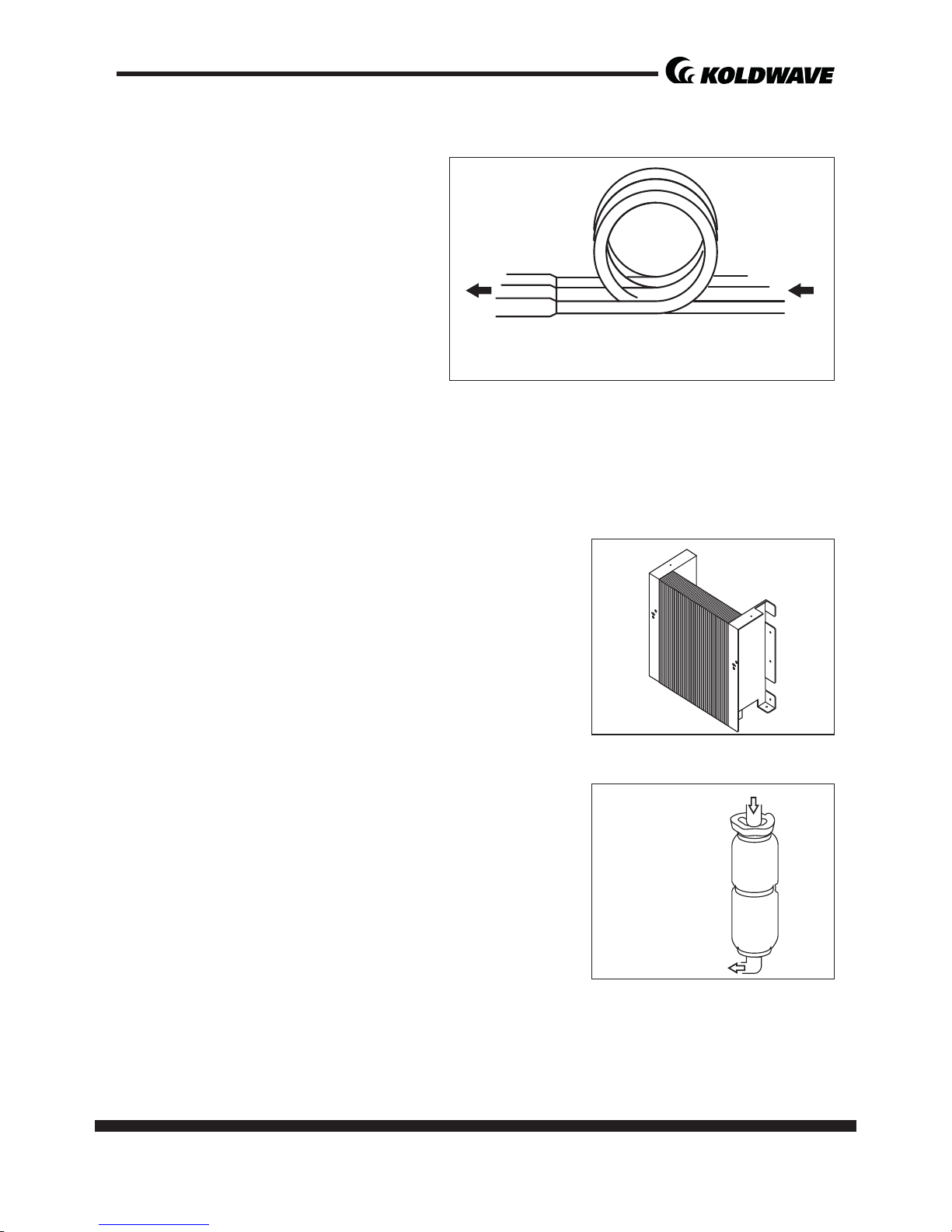

Evaporator

The evaporator is a heat exchanger covered with slit

fi ns. Heat is removed from the air being pulled across

the evaporator by the centrifugal fan.

The resul ng cool air is expelled through the cooling air

ducts.

Accumulator

The accumulator is mounted on the suc on gas piping between the evaporator and the compressor.

The accumulator separates the liquid refrigerant from

the gas refrigerant, allowing only the gas refrigerant to

enter the compressor. In the accumulator, suc on gas

isled into a cylindrical vessel where the speed of the

gas is decreased.

This process separates the refrigerant contained in

the gas by the force of gravity, causing the refrigerant to accumulate at the bo om

of the vessel. As a result, the compressor is protected from possible damage caused

by liquid refrigerant intake.

High Temp./High Pressure

Liquid Refrigerant

Low Temp./Low Pressure

Gas and Liquid Mixture

From Evaporator

To Compressor

18 page

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

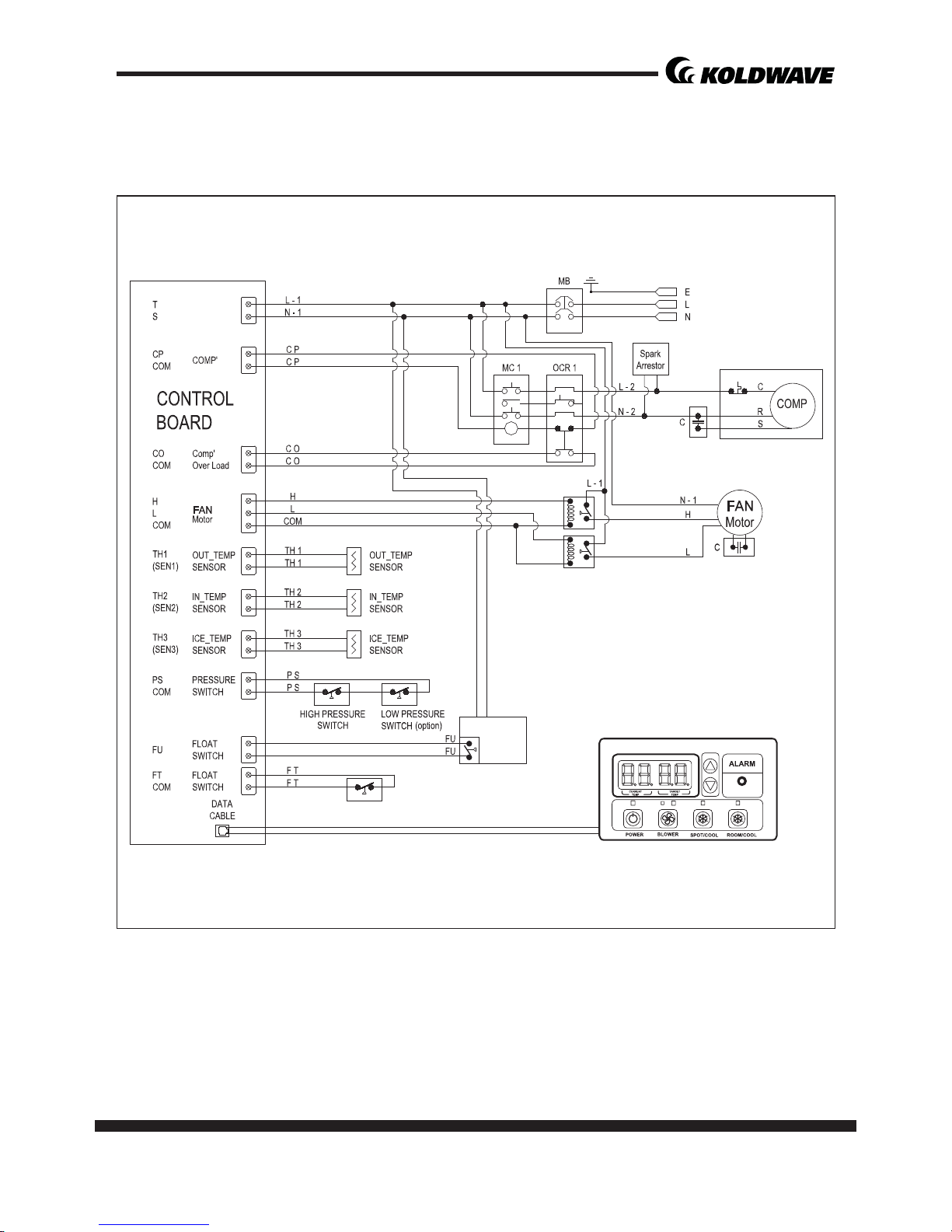

ELECTRICAL SYSTEM

Circuit Diagram

<5KK14BEA2AA00, 5KK21BGA2AA00>

(TH1)

(TH2)

(TH3)

DRAIN

PUMP

page 19

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

<5KK30BGA2AA00>

DRAIN

PUMP

(option)

RELAY

RELAY

POWER

1P AC 208/230V

(AC115)

POWER

1P AC 208/230V

(AC115)

20 page

Service Manual

5KK14BEA2AA00 / 5KK21BGA2AA00 / 5KK30BGA2AA00

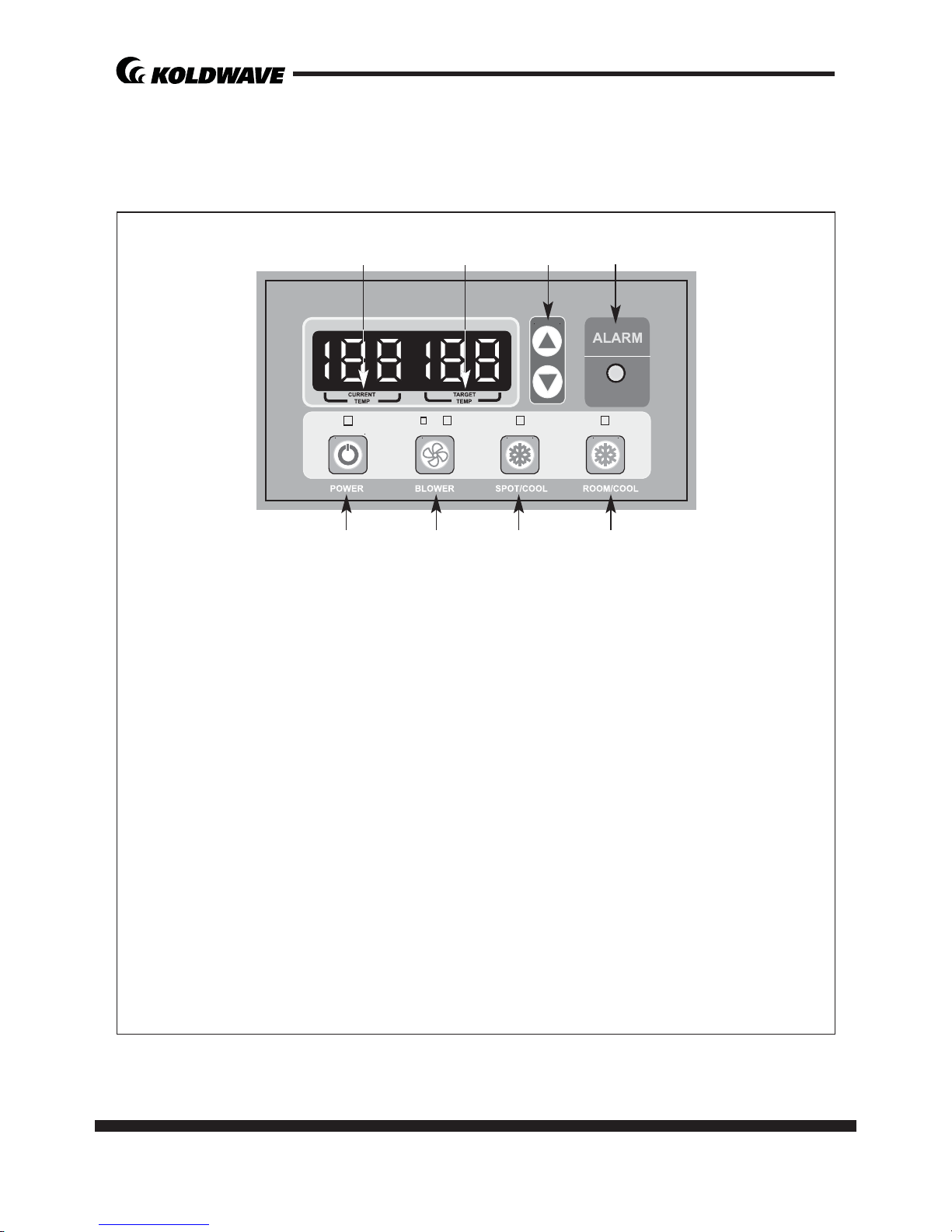

Control panel

Before opera ng the unit, it is important to be familiar with the basic opera on of

the control panel.

1. POWER BUTTON

• Ac vates unit when POWER BUTTON is pressed.

• Fan starts on low speed.

• If POWER BUTTON is pressed during opera on, unit stops.

2. BLOWER BUTTON

• Changes fan speed from LOW to HIGH when pressed.

3. SPOT / COOL BUTTON

• Ac vates compressor and begins producing cool air 5 seconds a er

bu on is pressed.

• Regulates temperature based on outlet cool air temperature.

4. ROOM / COOL BUTTON

• Ac vates compressor and produces cool air 5 seconds a er bu o n

is pressed.

• Regulates temperature based on inlet ambient air temperature.

1 2

5

3 4

6

87

Loading...

Loading...