Koldware 2K07DBH, 2K14DB, 2K10DB, 2K10DHB, 2K14DHB Installation & Operation Manual

...

KOMPAC

SERIES

AIR CONDITIONER

KKSM-3

AND HEAT PUMP

INSTALLATION &

OPERATION

MANUAL

Koolette 7,000 Btu/Hr Cooling

Kompac 9,400-16,000 Btu/Hr Cooling

King Kompac 20,500-26,000 Btu/Hr Cooling

GENERAL INFORMATION AND

CAPACITY SELECTION..................................... 1, 2

SPECIFICATIONS .................................................. 3

STANDARD AND OPTIONAL FEATURES ........ 4, 5

INSTALLATION INSTRUCTIONS ...................... 6, 7

CHECKOUT OF UNIT OPERATION ...................... 7

WATER FLOW GRAPH AND

MODES OF OPERATION ................................... 8, 9

UNIT CONSTRUCTION................................... 10-12

PARTS REPLACEMENT PROCEDURE ........ 13, 14

PREVENTIVE MAINTENANCE...................... 14, 15

TROUBLESHOOTING GUIDE ....................... 16, 17

PIPING SCHEMATICS ......................................... 18

WIRING DIAGRAMS ...................................... 19, 20

CERTIFIED DRAWINGS ...................................... 21

LIMITED WARRANTY .......................................... 22

PARTS LIST..................................................... 23,24

7,800 Btu/Hr Heating

10,900-17,900 Btu/Hr Heating

24,000-31,000 Btu/Hr Heating

KOOLETTE

KOMPAC

KING KOMPAC

GENERAL INFORMATION

DESCRIPTION

Kompac Series Air Conditioners and Heat Pumps are

designed for applications where outside air is not

available and spot cooling is required. The cord

connected Kompac Models range from a 7,000 Btu/Hr

countertop to a 26,000 Btu/Hr floor mount configuration

to meet any space requirements. Kompac and King

Kompac models are provided with casters f or portability.

All Models are completely self-contained with the entire

refrigeration system, fan motor , w ater valve, and

electrical components housed in a metal cabinet with a

baked enamel finish. Only power and condenser water

supply, water discharge, and condensate drain piping

are required for installation. With the heat pump option,

automatic changeover from cooling to heating to cooling

provides the desired comfort, depending upon

thermostat command.

The water-cooled condenser requires only that amount

of water needed to achiev e the desired high and lo w

refrigeration system pressures. The condenser water

flow rate for an y entering water temperature can be

obtained using the graph on page 8. Condenser w ater is

regulated by a refrigeration system head pressure

actuated water regulating valve.

260 NORTH ELM STREET • WESTFIELD , MA 01085 • Tel: (413) 564-5520 • F ax: (413) 564-5815

KOLDWAVE KOMPAC SERIES (KOOLETTE, KOMPAC, AND KING KOMPAC)

GENERAL REQUIREMENTS

For proper control of the water flow rate entering the

automatic water valve, the minimum water pressure

required for condenser water supply is 30 PSIG.

The condenser water temperature leaving the unit

should not exceed 110°F. Ignoring this compliance will

void the warranty on the refrigeration system. On heat

pump models, it is not recommended to operate the

unit in the heating cycle when the water inlet

temperature is below 50°F. Doing so could reduce the

specified heating capacity and may cause the freeze

control to cycle the compressor off, resulting in a loss

of heating.

IMPORTANT: Koldwave Air Conditioners have been

designed and engineered with your comfort in mind.

The length of service you can receive can be

extended by following the installation and

preventive maintenance instructions. It is important

that the warranty card be filled out completely and

returned to the factory within ten (10) days of

installation of the unit in order to receive the

benefits of the warranties.

CAPACITY SELECTION

Koldwave Kompac Series Air Conditioners and Heat

Pumps are designed for any type of application with

cooling requirements ranging from 7,000 Btu/Hr with

the Koolette, 9,400 -16,000 Btu/Hr with the Kompac

and 20,500-26,000 Btu/Hr with the King Kompac. Also

heating requirements ranging from 7,800 Btu/Hr with

the Koolette, 10,900-17,900 Btu/Hr with the Kompac

and 24,000-31,000 Btu/Hr with the King Kompac. The

Kompac Series cooling capacity designations are

shown below.

Capacity Code:07 .................................. 7,000 Btu/Hr

10 .................................. 9,400 Btu/Hr

14 ................................ 12,500 Btu/Hr

16 ................................ 16,000 Btu/Hr

20 ................................ 20,500 Btu/Hr

26 ................................ 26,000 Btu/Hr

Kompac Model designations are:

Prefix K denotes....................Koldwave Kompac Model

Suffix D denotes....................... Air Conditioning Model

Suffix H denotes..........................................Heat Pump

Suffix T denotes ........Unit for Cooling Tower Operation

Suffix S denotes ......................... Stainless Steel Finish

KOLDWAVE NOMENCLATURE

The Koldwave Kompac Series nomeclature is listed

below which explains the type of unit, the capacity, the

phase, and the voltage.

2 K 14 D H S T 1 1

Series 115 V olt

Koldwave Single Phase

Capacity Selection

Air Conditioning Model

Heat Pump Option Type of Finish

Number Code: Phase: 1 - Single Ø

Model

Voltage: 1 - 115V

2 - 208/230V

Cooling T o wer

2

KOLDWAVE KOMPAC SERIES (KOOLETTE, KOMPAC, AND KING KOMPAC)

PRODUCT SPECIFICATIONS FOR KOMPAC SERIES

2K07DB

2K07DBH

2K10DB

2K10DHB

2K14DB

2K14DHB

CAPACITY DATA

Cooling Capacity (A)

Heating Capacity (B) & (D)

Evaporator-CFM @ 0.0 ESP

7,000

7,800

250

9,400

10,900

345

12,500

14,200

410

ELECTRICAL DATA

Volts (Single Phase)

Amperes (Cooling)

Amperes (Heating)

Watts (Cooling)

Watts (Heating)

E.E.R.

C.O.P.

Fuse/Breaker amps

Compressor H.P.

Blower Motor H.P.

In Rush Current (amps)

115

8.00

7.50

897

840

7.80

2.70

15

1/2

1/25

45.20

115*

9.8

9.50

1,000

1,065

9.40

3.00

15

3/4

1/15

71.50

115*

11.60

10.80

1,276

1,301

9.80

3.20

15

1

1/15

71.50

CONDENSATE PUMP

Motor H.P.

RPM

Voltage

Amperage Draw

Lift (Feet of H2O)

1/80

3,000

115

0.48

11.00

1/80

3,000

115*

0.48

11.00

1/80

3,000

115*

0.48

11.00

CONDENSER WATER FLOW & PRESSURE DROP DATA (G)

GPM @ 85° F L.W .T.

Cond. Coil ∆P (P.S.I)

Water V alve ∆P (P.S.I)

GPM @ 60° F E.W .T. 100° F L.W.T.

Cond. Coil ∆P (P.S.I.)

Water V alve ∆P (P.S.I.)

1.75

1.40

2.00

0.44

0.60

2.00

2.25

1.70

2.00

0.56

0.70

2.00

3.00

3.00

3.00

0.75

0.80

2.00

Max. Water Side Working Pressure/With Water Valve-150 P.S.I./Without Valve-400 P.S.I.

MISC. DATA

Evap. Coil-# of Rows

Coil Face Area (FT2)

Refrigerant Charge R-22 in oz.

Water Connections

0.83

3

/8″ MF

3

14

1.05

3

/8″ MF

18

3

3

1.20

20

3

/8″ MF

DIMENSIONAL DATA (inches)

(A) Height-With Casters

(B) Height-Without Casters

(C) Length

(D) Depth

165/8

161/8

223/8

12

311/2

291/8

25

103/16

311/2

291/8

25

103/16

AIR FILTER DATA (inches)

Width

Height

Thickness

NET WEIGHT

SHIPPING WEIGHT

153/4

91/4

1/2

83

89

18

16

1/2

123

132

18

16

1/2

124

133

2K16DB

2K16DHB

16,000

17,900

480

115*

13.00

13.00

1,684

1,692

9.50

3.10

20

11/4

1/15

96.50

1/80

3,000

115*

0.48

11.00

4.00

5.30

5.00

1.00

1.00

2.00

1.20

22

3

/8″ MF

311/2

291/8

25

103/16

18

16

1/2

125

134

10.40/10.10

10.50/10.10

3

2K20DB

2K20DHB

20,500

24,000

650

208/230

2,092

2,269

9.80

3.10

15

11/2

1/7

61.90

1/77

3,000

208/230

0.26

11.00

4.50

4.20

8.00

1.10

0.50

2.00

1.90

26

3

/8″ MF

283/4

263/8

36

121/4

24

113/4

1/2

175

191

12.70/11.80

12.50/11.50

3

2K26DB

2K26DHB

26,000

31,000

800

208/230

2,708

2,839

9.60

3.20

20

1/7

72.90

1/77

3,000

208/230

0.26

11.00

6.00

6.80

14.00

1.50

0.80

2.00

1.90

30

3

/8″ MF

283/4

263/8

36

121/4

24

113/4

1/2

183

201

2K26DHBL

12.70/11.80

12.50/11.50

2

4

2K26DBL

23,200

31,000

800

208/230

2,416

2,839

9.60

3.20

20

1/7

72.90

1/77

3,000

208/230

0.26

11.00

6.00

6.80

14.00

1.50

0.80

2.00

1.90

30

3

/8″ MF

283/4

263/8

36

121/4

24

113/4

1/2

183

201

2

4

(A) Cooling Capacity Rating Test Conditions: Evaporator Air - 80°F D.B./67°F W.B .

(B) Heating Capacity Rating Test Conditions: Condenser Air - 70°F D.B./60°F W.B

(C) Time Delay Fuses and Circuit Breakers are recommended.

(D) Reverse cycle units require 50°F minimum water inlet temperature during the heating cycle.

(E) Total pressure drop for unit with Water Regulating Valve is sum of Condenser Coil and Water Valve Pressure Drop.

*Also available in 208/230 volt.

Condenser Water - 85°F E.W.T./95°F L.W.T.

Evaporator Water - 70°F E.W.T.

3

KOLDWAVE KOMPAC SERIES (KOOLETTE, KOMPAC, AND KING KOMPAC)

STANDARD AND OPTIONAL FEATURES

STANDARD FEATURES

All Kompac Series units have removable panels to

provide full service accessibility. See Part Replacement Procedure on page 10 for removal of the correct

panel when replacing a part.

Air Flow Flexibility

Air is discharged through four-way adjustable grilles,

enabling a variety of air flow possibilities. Koolette,

Kompac and King Kompac models each have three,

four and five grilles respectively. Washable, aluminum

air filters are installed in each unit. Periodic cleaning

will ensure optimal unit performance. Kompac models

have a reversible top for front or top air discharge.

Quiet, Rugged Cabinet

The Kompac Series cabinet, constructed of 20-guage,

cold rolled steel with a baked enamel finish, is completely insulated with a sound absorbent material for

cool, quiet comfort.

Automatic Water V alve

All air conditioners and heat pumps are equipped with

a direct-acting, refrigeration system head pressure

actuated water regulating valve. This valve, set at the

factory for 95-100°F outlet water temperature, permits

only that amount of water to flow that is needed to

achieve the desired refrigeration system pressures. In

addition, heat pump models are equipped with a water

bypass solenoid valve to provide immediate and

continuous water flow on heating. All models used for

cooling tower operation, “T” models, are manufactured

without water valves.

The cooling only thermostat ranges from 60-95°F with

a differential of ± 3°F. The range of the heat pump

thermostat is 63-93°F in the cooling mode and

59.5-93.5°F in the heating mode with a differential of

3.5°F.

The three position rocker switch located in the control

panel has three functions:

1. It provides fan only operation when depressed to

right.

2. It turns the unit off when set in the center position.

3. It activates the cooling or heating mode when

depressed to left, depending on unit model and

thermostat setting.

The two position switch located under the three

position switch provides high fan speed when

depressed to the right, and low fan speed when

depressed to the left.

When illuminated, the blue light above the thermostat

indicates cooling and the amber light (on heat pumps

only) indicates heating.

Built-In Condensate Pump

Each unit contains a condensate pump for the positive

removal of evaporator condensate. The condensate

pump is capable of pumping against an 11 ft. head.

Condenser Coil

The water-cooled, tube-in tube type condenser coil is

designed for a maximum water side working pressure

of 400 PSI.

Safety Engineered

All units incorporate within the refrigeration system, a

high pressure switch for maximum safety of the

compressor. The cut-out pressure setting is 375 PSIG

± 3 PSIG. During the heating cycle of the heat pump

models, a freeze control sensor set at 37 ± 2°F

monitors the water temperature leaving the condenser

to cut-out the unit and protect the condenser from

freezing.

Reliable Controls

All models have self-contained thermostats to provide

the desired amount of cooling, which can be selected

by adjusting the thermostat to warmer or cooler. On

heat pump units, when the thermostat is set at the

desired position, the unit will automatically provide

heating or cooling, whichever is desired.

Filter

All units are equipped with 1/2" thick, washable,

aluminum mesh air filter located behind the front panel

that can easily be removed and cleaned. Just pull the

filter end cap tab at bottom of filter and slide out.

Discharge Air Grilles

The Koolette is equipped with three, the Kompac with

four, and the King Kompac with five 5" x 5", four-way

adjustable, plastic grilles located in the upper front

panel, enabling a variety of air flow possibilities. Lift

each black grille (approximately 3/4") and rotate to the

desired position. Release the grille and allow it to

return to the set position within the cabinet. By this

means, air flow can be positioned in any of four

directions.

4

KOLDWAVE KOMPAC SERIES (KOOLETTE, KOMPAC, AND KING KOMPAC)

Service Cord

The six ft. long service cords employed in the Kompac

Series units have plug configurations and receptacle

requirements as shown in the chart below.

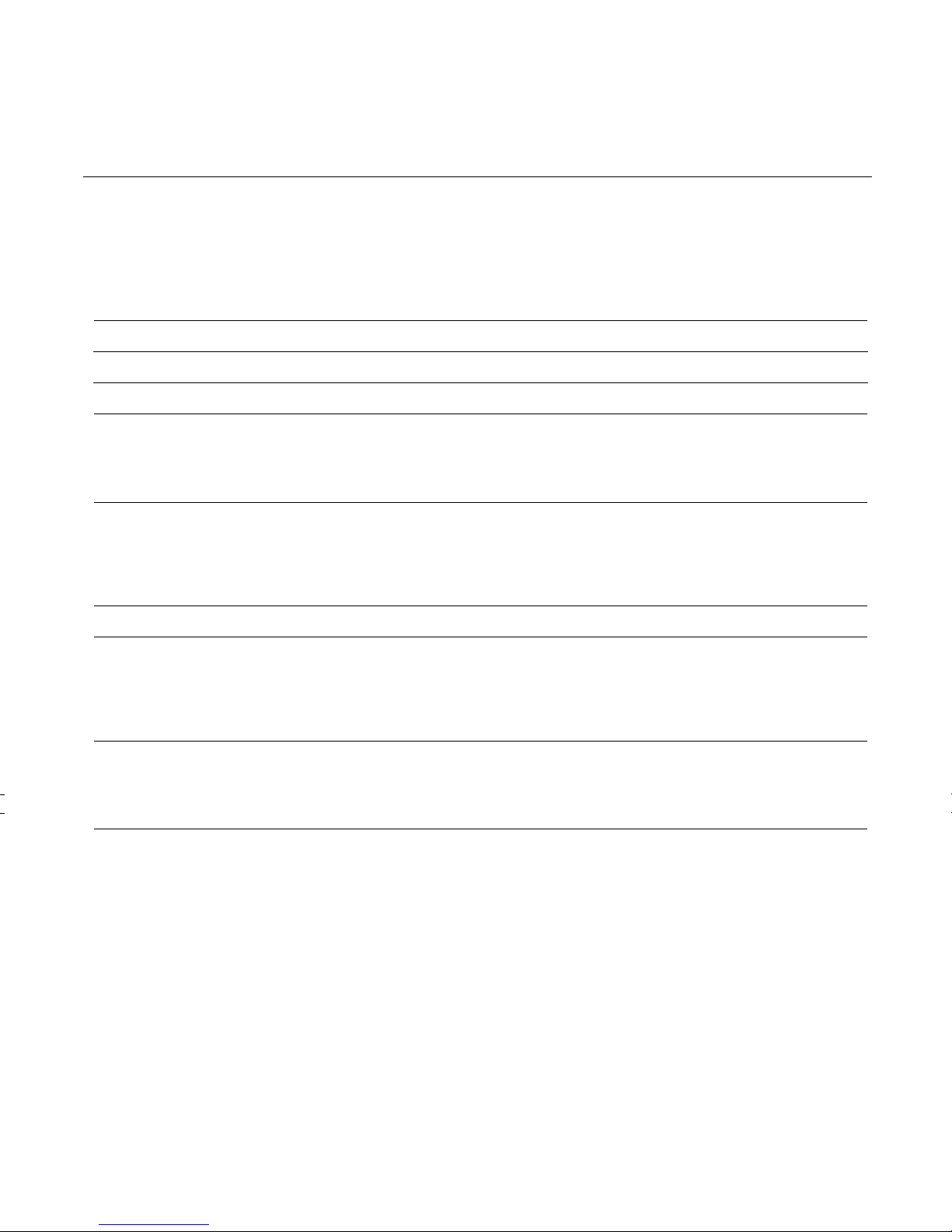

ELECTRICAL SERVICE PLUG CONFIGURATION

Conditioner

Model Plug Configuration Receptacle

2K07-14DB 15A - 125V

115V Nema 5 - 15P

2K16DB 20A - 125V

115V Nema 5 - 20P

2K10-26DB 20A - 250V

208/230V Nema 6-20P

Nema 5 - 15R

Nema 5 - 20 R

Nema 6 - 20R

OPTIONAL FEATURES

Hose Kit

When employing one of The 7′, 20′ or 40′ reinforced

plastic HK22 hose kits in applications with water

pressures exceeding 50 PSIG, a water pressure

reducing valve must be installed in the water supply

line prior to the hose kit; otherwise warranty of the

hose kit will be void. The water-out and condensate

lines of the three-section flexible plastic hose can be

fed to a sink or permanent drain. Additional hose kit

fittings and washers are provided to fit most water

faucets. When using a hose kit, avoid sharp corners

hot water pipes, and kinking or close bends to ensure

proper water flow of the supply and return lines.

Cupro-Nickel Condenser

When using chemicals to treat water in cooling tower

applications or when water contains process

contaminants, it is recommended that the air

conditioner be equipped with a 90/10 Naval Spec.

Cupro/nickel condenser.

High Pressure Water Valve

High pressure water regulating valves, designed for

use with up to 350 PSI water inlet pressure, are

available.

Treated Evaporator Coils

For air conditioning applications where airborne

contaminants are a problem, acrylic coated evaporator

coils are recommended to guard against pitting or

corrosion.

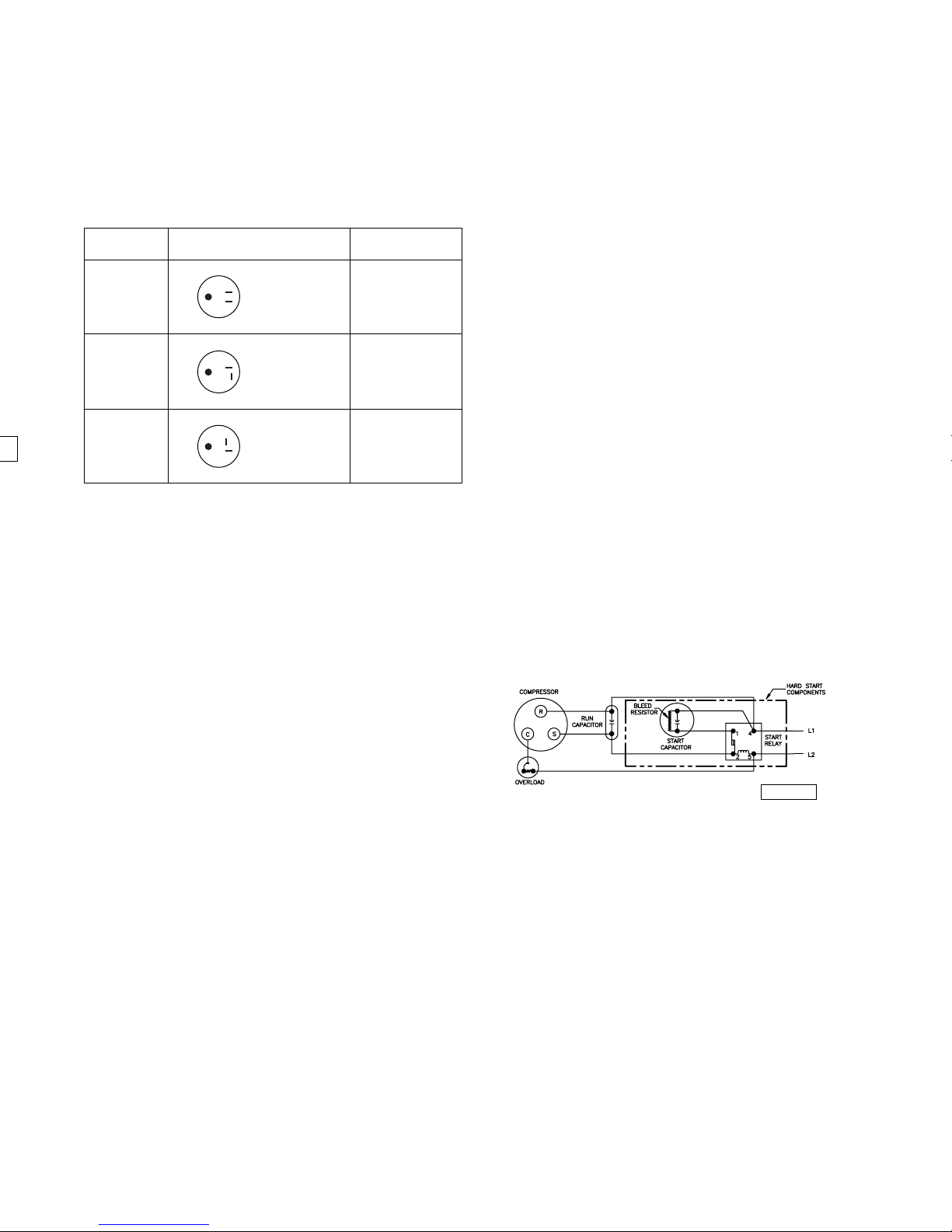

Hard Start Kit

A hard start kit consists of a start capacitor and

potential relay. The kit is available for all models when

they are expected to operate at low voltages and/or

ambient temperatures which drive up the equalization

pressure in the compressor. Compressors used by

Koldwave are designed to operate on 115 and 208/230

volts ± 10%.

Starting Component Wiring Diagram

0240019A

5

KOLDWAVE KOMPAC SERIES (KOOLETTE, KOMPAC, AND KING KOMPAC)

INSTALLATION INSTRUCTIONS

Before installing: Check the air conditioner for any

shipping damage. Air conditioners are thoroughly

inspected at the factory and carefully packed. If any

damage is evident, file a claim with the delivering

carrier immediately.

Electrical Requirements

Check the data plate on the back of the unit to make

certain that the proper power is available. Refer to the

“Specifications” section for voltage and fuse

requirements. Check for proper wall outlet as

described in “Standard Features”. Operating the unit

on improper voltages will void the warranty.

CAUTION: The use of an extension cord rated at

least 15 amps at 115 volts for (2K07-14D); 20 amps

at 115 volts for (2K16D); 20 amps for (2K10-26D) at

250 volts and with grounding-type attac hment plug,

and grounding-type connector (load fitting) may be

used.

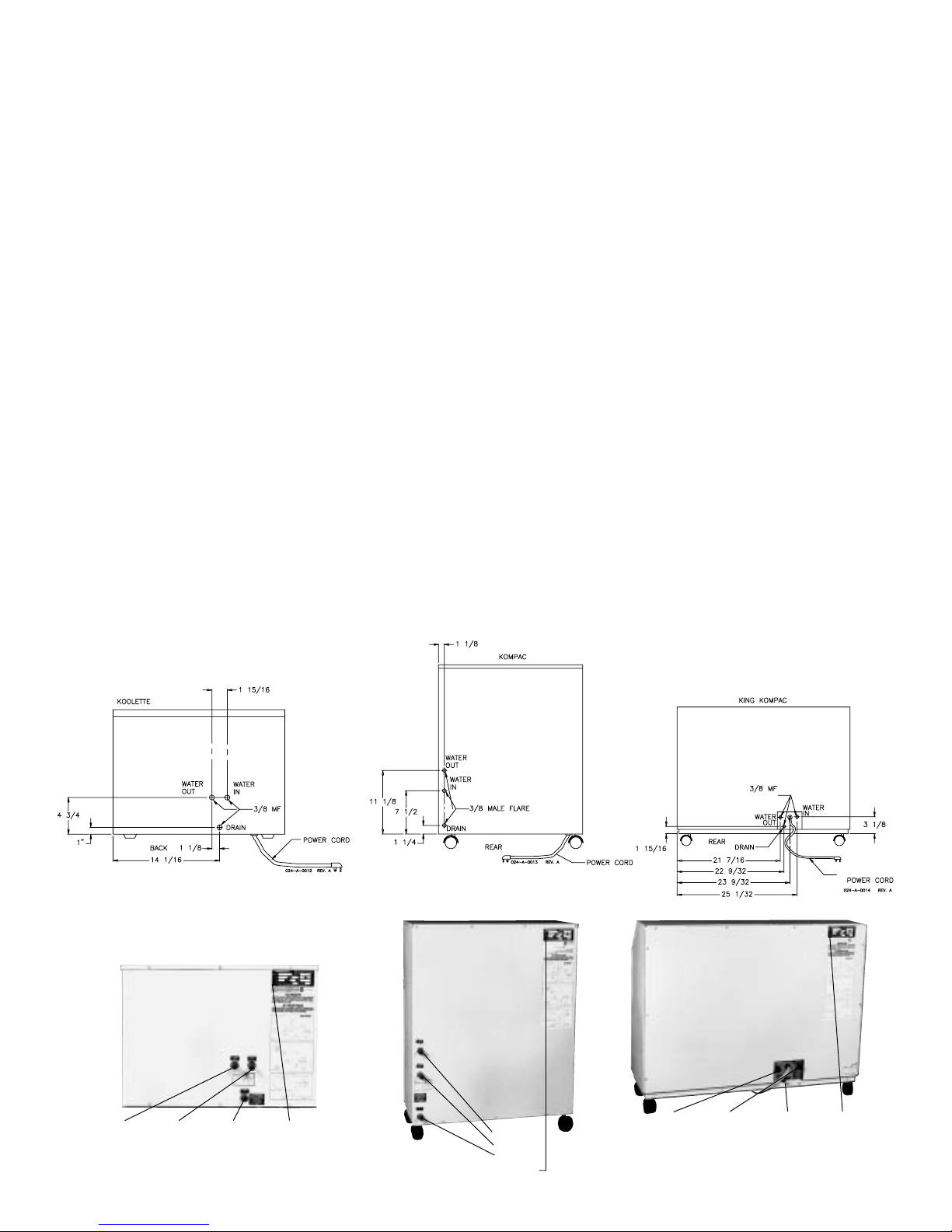

Water Fitting Location

Prior to placing the air conditioner in the desired

position, note the exact location of the water fittings on

the valve plate on the unit rear panel. Water lines

should be securely attached to water valve plate

fittings. Be sure the line attached to the water source is

also attached to the “WATER IN” connection of the

unit.

Refer to diagrams and photographs below when

installing unit.

Water Out Water In Drain Data Plate

Koolette Kompac King Kompac

6

Water Out

Water In

Drain

Data Plate

Water Out Water In Drain Data Plate

KOLDWAVE KOMPAC SERIES (KOOLETTE, KOMPAC, AND KING KOMPAC)

Conventional Installation

For proper installation, follow these simple steps:

A. Shut off cold water supply.

B. Install “T” between supply valve and faucet of cold

water line.

C. Connect water shut-off valve to branch of “T”.

D. Insert 3/8" pipe nipple in discharge end of water

shut-off valve.

E. Apply coupling over 3/8" pipe nipple and secure.

CHECKOUT OF UNIT OPERATION

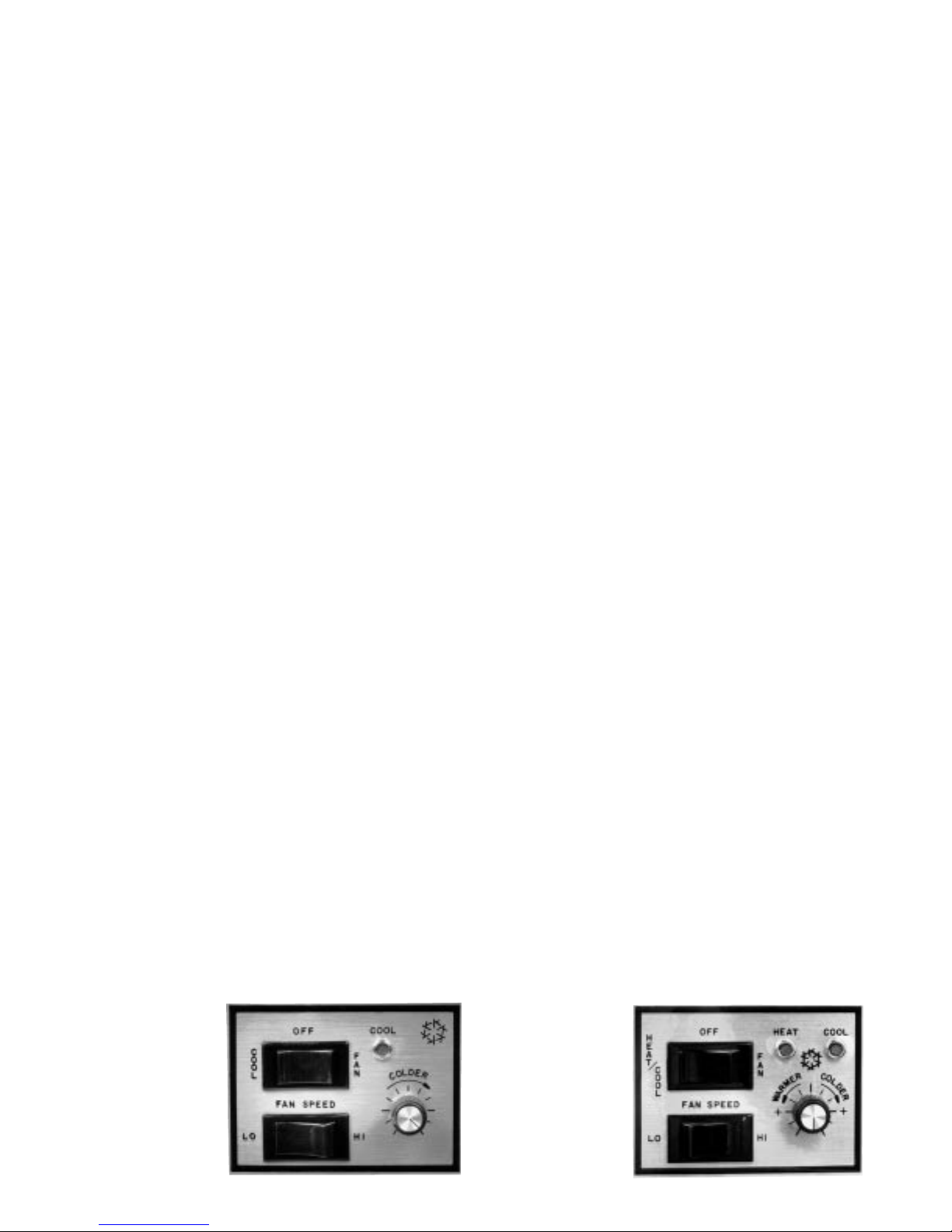

Kompac Series air conditioners and heat pumps

provide cooling and heating,respectively. This is

accomplished by setting the operating controls on

either of the following panels:

Fan Only

Plug unit in. Depress the upper mode selector switch

to the right for fan only operation. Press down on the

two position switch located below the three position

switch to the right for high fan speed; to the left for low

fan speed.

Cooling Cycle

Depress the upper mode selector switch to the left

(cool) for cooling. Set the thermostat knob by turning it

clockwise, below the actual room dry bulb temperature

level. The blue-colored light located next to the upper

rocker switch on the panel will illuminate, indicating

cooling mode operation. Allow unit ot run with fan

speed set on high for twenty minutes, record

temperature of air entering the filter and temperature

of air leaving the air discharge grille. In a room

temperature of approximately 80°F dry bulb, air

coming from the grille should be approximately 15°F

cooler than the air going to the filter. This cycle

reduces the dry bulb temperature and lowers the wet

bulb temperature by condensing water on the cooling

coil surface. The condenser leaving water temperature

should be between 95-100°F if water flow adjusted

propertly.

Note: An alternate installation method can be

achieved by drilling a 5/16" diameter hole in the cold

water line and assembling a saddle valve to the line.

Complete installation by following steps “D” and

“E”.

Heating Cycle

Depress the upper mode selector switch to the left

(heat) for heating. Set the thermostat knob, by turning

it counterclockwise, above actual room dry bulb

temperature level. The amber-colored light located next

to the upper rocker switch on the panel will illuminate,

indicating heating mode operation. Allow unit to run

with fan speed set on high for twenty minutes, record

temperature of air entering the filter and temperature

of air leaving the air discharge grille. In a room

temperature of approximately 70°F dry bulb, air

coming from the grille should be approximately 30°F

warmer than the air going to the filter. The condenser

entering water temperature must not be lower than

50°F. The temperature of the water coming from the

“water out” fitting should be 7-8 degrees colder than

the water going into the unit.

Water temperatures described for cooling and heating

modes are based on units with pressure actuated

water regulating valves installed as standard

equipment at the factory.

Cooling Only

Control Panel

Cooling/Heating

Control Panel

7

KOLDWAVE KOMPAC SERIES (KOOLETTE, KOMPAC, AND KING KOMPAC)

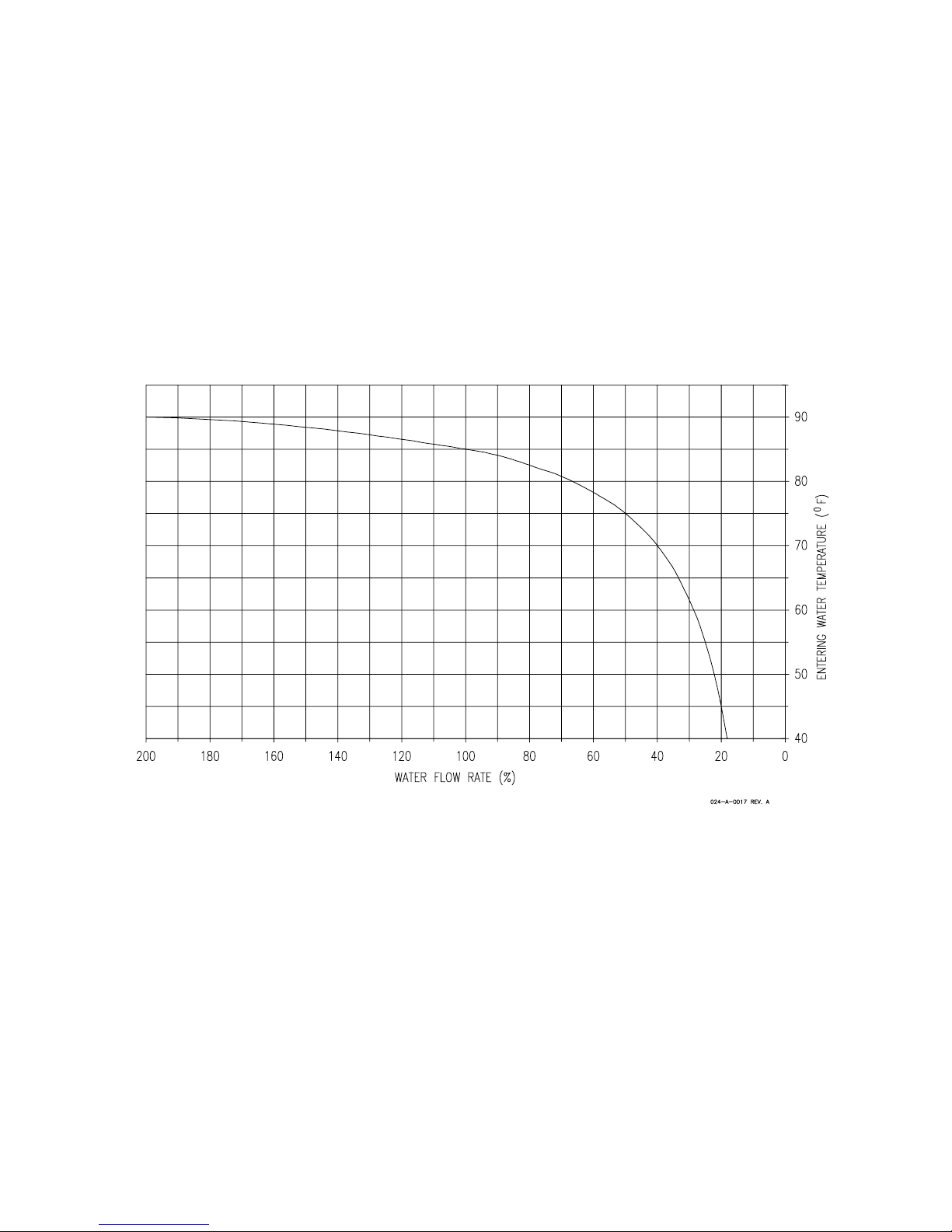

WATER FLOWS AT VARIOUS

ENTERING WATER TEMPERA TURES

The rated water flow rate at 85°F entering water

temperature (E.W.T.) is given in the specification chart

earlier in this manual. Water flow rates in that chart

will be significanly different from rated water flow at

other entering water temperatures. The variance from

rated water flow rate is found using the graph below.

Using your actual E.W.T., multiply the percentage by

the condenser flow rate at 85°F E.W.T. to obtain the

actual water flow rate required.

Water Flow Chart

For Example:

What is the actual condenser water flow rate at 50°F

E.W.T. (2K14D)?

1. The condenser water flow rate at 85°F E.W.T. is 3.0

G.P.M. from the Water Flow chart.

2. At 50°F E.W.T., the water flow rate percentage

would be 25% as seen on the graph.

3. Multiply .25 by 3.0 G.P.M. to get an actual water

flow rate of 0.75 G.P.M.

8

Loading...

Loading...