KOLDTECH

REFRIGERATOR AND

FREEZER

THIS MANUAL SHALL BE PERMANENTLY KEPT AT END USER

PREPARED FOR JOB NR.…………OR PRODUCT SR.NR………….

General Operation and Service Manual of Refrigeration

(Covering Models as shown: DT-R21F21-2D)

OASMs-616-C-05/19/07/05

CONTENTS

KOLDTECH

The Technology of Excellence

Topics Description Page

1 INTRODUCTION

2 INSTALLATION & STARTS UP

2.1 Uncrating

2.2 Handling Issue

2.3 Installation

2.4 Draining

2.5 Ventilation

2.6 Electrical Preparation

2.7 Starting

3

3

3

3

3

4

4

4

4

Topics Description Page

5 TEMPERATURE SETTING

5.1 Temperature Settings,

5.2 Controller and Parameter

6 ASSEMBLY DRAWING

7 RECOMMENDED PARTS

8 TROUBLE SHOOTING

TABLES AND TREES

9 WARRANTY & SERVICE

10 REFRIGERATION

DIAGRAM

11 TIMING DIAGRAM

12 I/O UTILITY

6

7

LAST

8

9

10-13

14

15

17

LAST

2.8 Product Loading

2.9 Machine Performance

2.10 Defrosting

3 PRODUCT CLAEANING/Tips

4 MAINTENANCE SCHDULE

4

4

4

4 /

last

5

LOCATION

13 ELECTRICAL DIAGRAM

14 TEST CERTIFICATE

15 CLAIM FORM

16 SERVICE RECORD FORM

Technical depth as italicized

page may be limited to dealer

use only.

(IF APPLICABLE)

LAST

LAST

LAST

LAST

Noted

OASMs-616-C-19-07-05/13/1/07 2 OF 18

KOLDTECH

The Technology of Excellence

1. INTRODUCTION:

Thank you for choosing our KOLDTECH product. With over 30 years of experience in

refrigeration manufacturing we are confident that our product will provide you with years of

trouble-free operation. Our products are fully engineered to be amongst the best in the industry.

We also continually improve our product designs to ensure they continue to take advantage of the

latest in refrigeration design. Every unit is fully tested in our calibrated testing laboratory prior to

leaving our factory.

As with other precision equipment, proper care and operation will ensure years of trouble-free

service. It is essential that you spend time reading this manual before operating the machine, to

familiarize yourself with our product and safety procedures. Keep the manual where end-user

could see and locate.

We thank you again for choosing KOLDTECH . If you have any further questions please feel

free to call the dealer from whom you purchased the unit. Our address and telephone number can

be found under the “Service and Repair” information section.

2. INSTALLATION AND START UP

The following procedure should be followed for trouble free installation:

2.1

Uncrating: While unpacking, take note of any damage to the unit. If damage is found do not

discard the packing materials and notify your dealer, or the freight company a.s.a.p. Do not proceed

to install the unit.

2.2

Handling Issue:

2.2.1 Precaution has been taken to ship the unit in an upright position. If the unit is tilted during

transit lubricating oil may shift from the reservoir, and operating the unit may cause excessive wear

or damage to the compressor’s moving parts. It is recommended that the unit be left standing for

48 hours before operation.

2.2.2 Inspect and clear away any packing material that may be used to secure the unit during

transit.

2.3

Installation:

2.3.1 Install the unit in a dry, well-ventilated place away from heat sources or any vibration.

Ideally for optimum performance we recommend installation in air-conditioned premises. In the

event of high relative humidity, condensation may form on the cabinet. This will not impact on the

OASMs-616-C-19-07-05/13/1/07 3 OF 18

KOLDTECH

The Technology of Excellence

ability of the cabinet to maintain internal temperature. Should ambient temperature exceed 36oC

we cannot guarantee the maintenance of internal temperature to required standards.

2.4

2.3.2 The unit should be set on a level and firm surface.

Draining: Special models may require drain pipe for condensate water, End-user should well

explore from specification sheet before plugging in and self prepare of drain pipe as appropriate.

2.5

2.6

Ventilation: ventilating grills or louvers must not be obstructed for proper operation.

Electrical Work Preparation:

2.6.1 For safety reasons, the unit must be properly earthed. Check and make sure that the outlet is

properly grounded. If a grounded plug is not available, a separate earth ground must be installed to

prevent any electrical hazard. A properly rated circuit breaker should be installed to the supply

outlet. Check for proper supply voltage before plugging in the unit. Please refer to voltage

requirements on the nameplate of the unit.

2.6.2 Plug the unit into the wall outlet. Turn the unit on using the on/off switch.

2.7

Starting: After turning on the unit for the first time, if there is any unusual odour, heat, smoke or

vibration immediately turn off and unplug the unit and call for a service technician. The unit

should be closely monitored during the first hour of operation.

2.8

Product Loading: The thermostat is set at the factory for optimum operating temperature. Time

taken to attain the operating temperature depends on the temperature of the food being loaded, the

frequency of the door opening, ambient temperature etc. The unit should reach operating

temperature during the first 4-6 hours for chiller and 8-12 hours for freezer of operation.

2.9

Machine Performance: To prevent compressor damage, the unit is equipped with a Time Delay

Circuit, which shall activate the compressor within 2 minutes after turning on the power or after

restarting.

2.10

Defrosting: Defrosting the circuit is set from the factory for optimum operation. Do not attempt to

alter the setting.

PLS NOTE do not disassemble the unit. Any service performed by parties other than our

authorized may void the warranty.

3. PRODUCT CLEANING

3.1 CLEANING Stainless Steel surface, P.V.C. and Display Glass: Users can wash by lukewarm

soapy water (or recommended cleaner) and, later, thoroughly rinses or wiping all surfaces with

water or moistened clothes respectively. Finally, polish with dry soft cloth.

OASMs-616-C-19-07-05/13/1/07 4 OF 18

KOLDTECH

The Technology of Excellence

3.2 Note: Do not use solvents or other aggressive liquids for cleaning e.g. with mixture of

chlorine or detergent etc. Do not use wire brush, steel wool or grainy –wiping pad such as

Scotbrite-pad-grain.

4. MAINTENANCE

4.1 Observe safety practice by disconnecting all electrical supply before performing any kind of

maintenance.

4.2 Do not use sharp instruments or cleaning agents on the unit. Clean (interior and exterior

surfaces) using a damp cloth and warm water. Food particles and spillage should be

removed as soon as possible to avoid build-up and odour.

4.3 To ensure efficiency and reliability it is important that the condenser coil be kept clear of

accumulated dirt and duct. It is recommended to use a non-metallic brush, vacuum cleaner

or air blower to dislodge dust from the condenser fins. The frequency of cleaning depends

on the amount of dust in the surrounding area of the installation. The condenser should be

inspected and cleaned at least every month.

4.4 Do not expose any electrical components to moisture or water. If the unit gets wet, turn it

off and unplug it from the wall outlet immediately. Do not turn it on again until the unit is

completely dry or after inspection by a qualified service technician.

4.5 Should the unit be left unused for an extended period, all food items should be removed.

The interior surface and shelves should be cleaned thoroughly. Unplug the unit from the

power source and leave the doors slightly opened.

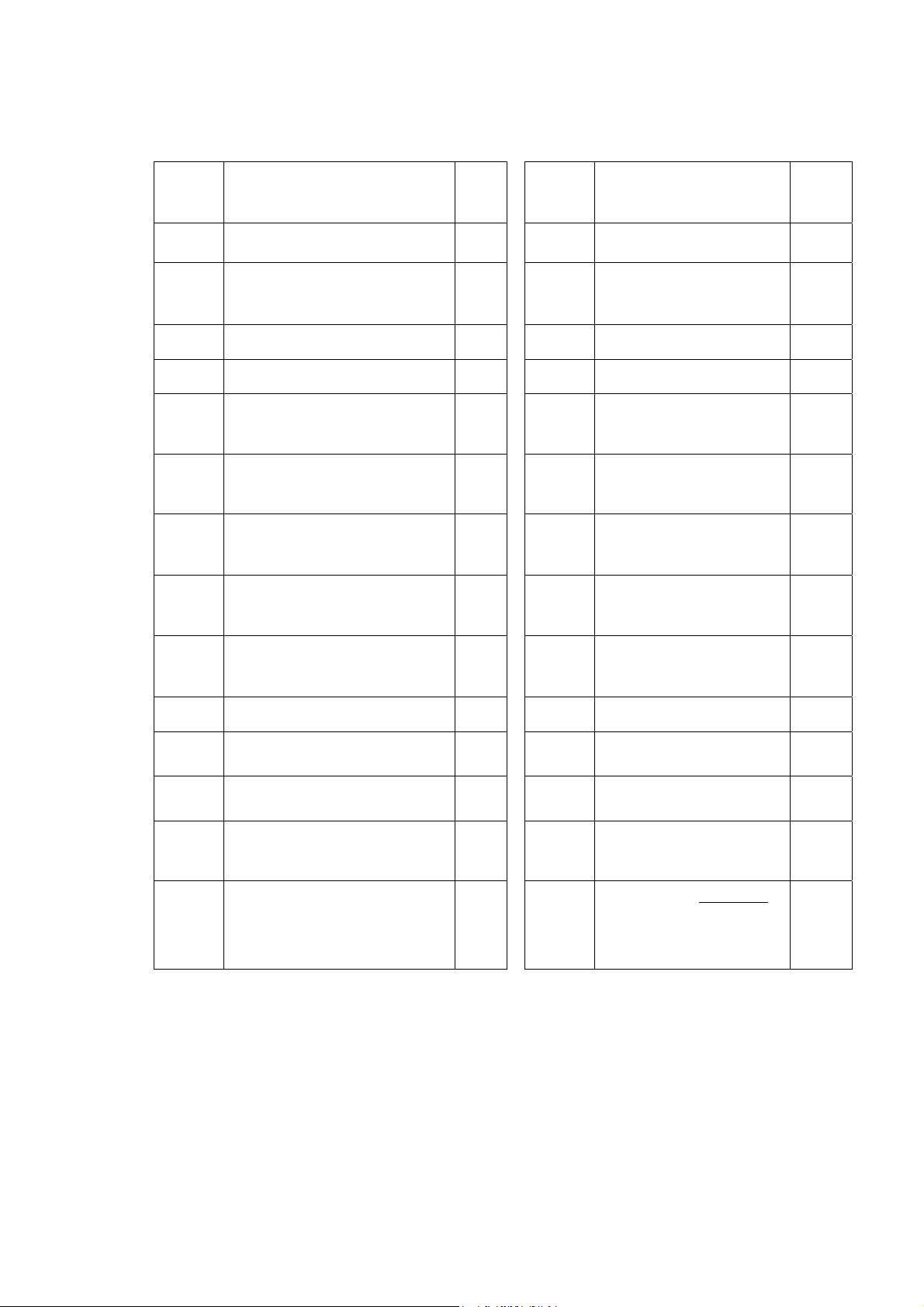

Recommended Maintenance Schedule

Frequency

Maintenance List

Daily Weekly Monthly

Clean interior and exterior surfaces X

Check operating temperature X

Check control panel alarm X

Check compressor for vibration X

Check compressor temperature X

Check condenser fan X

Clean condenser coil X

OASMs-616-C-19-07-05/13/1/07 5 OF 18

KOLDTECH

The Technology of Excellence

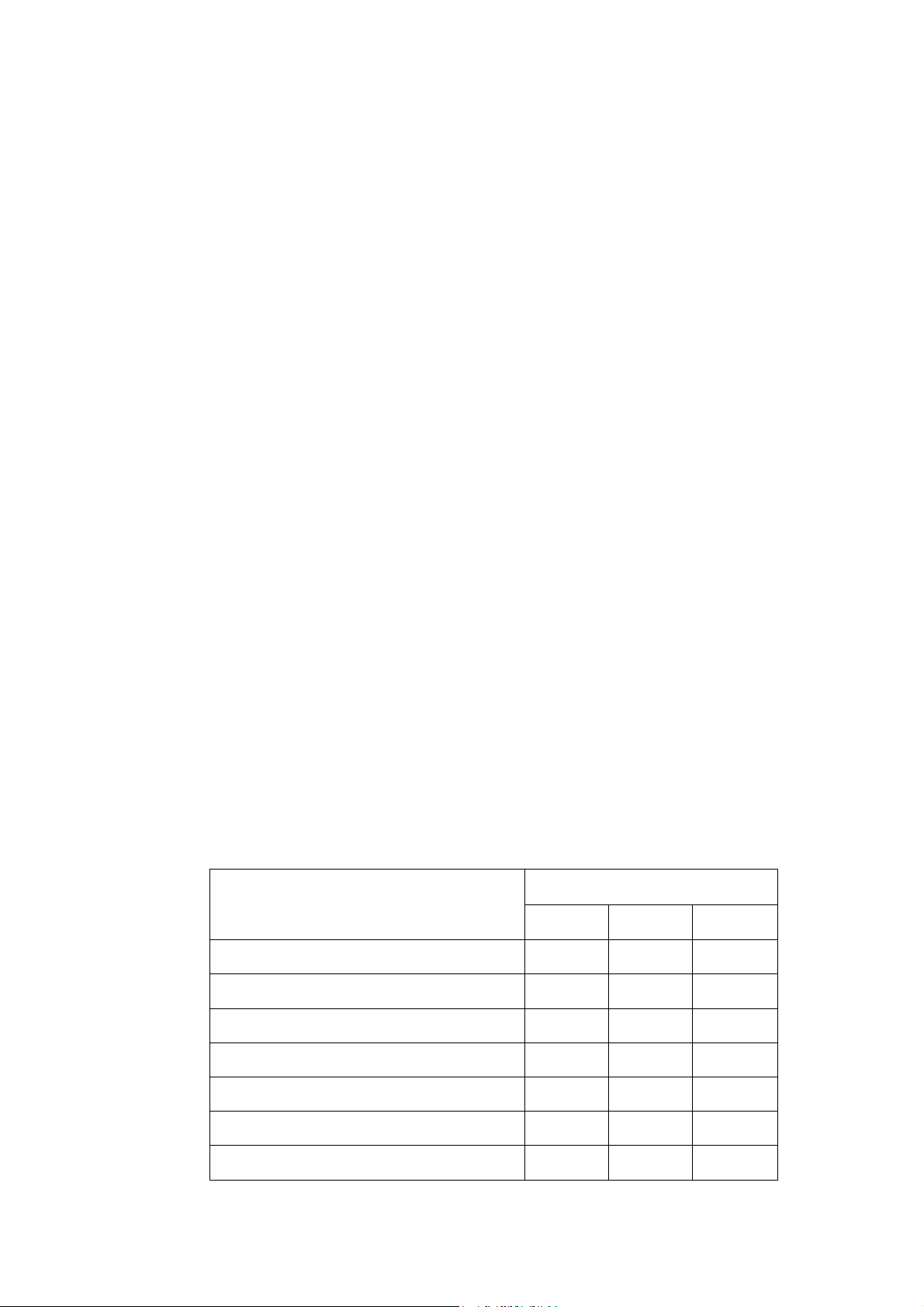

5. TEMPERATURE SETTING:

5.1 Your KOLDTECH product is equipped with an electronic thermostat with off cycle

designed for refrigeration applications at normal temperature. It provides a relay output to drive

the compressor and a probe input. An internal timer manages the off cycle defrost.

Tips: Recommended preset temperatures for specialized use.

Flowers: +4°C to +8° C

Confectionery (Candy): +14°C to +18°C

Seafood: -1°C to +1°C

Meat: -2°C to +1°C

Cakes: +7°C to +10°C

(Consult factory when needed, self-adjustment may void the given warranty)

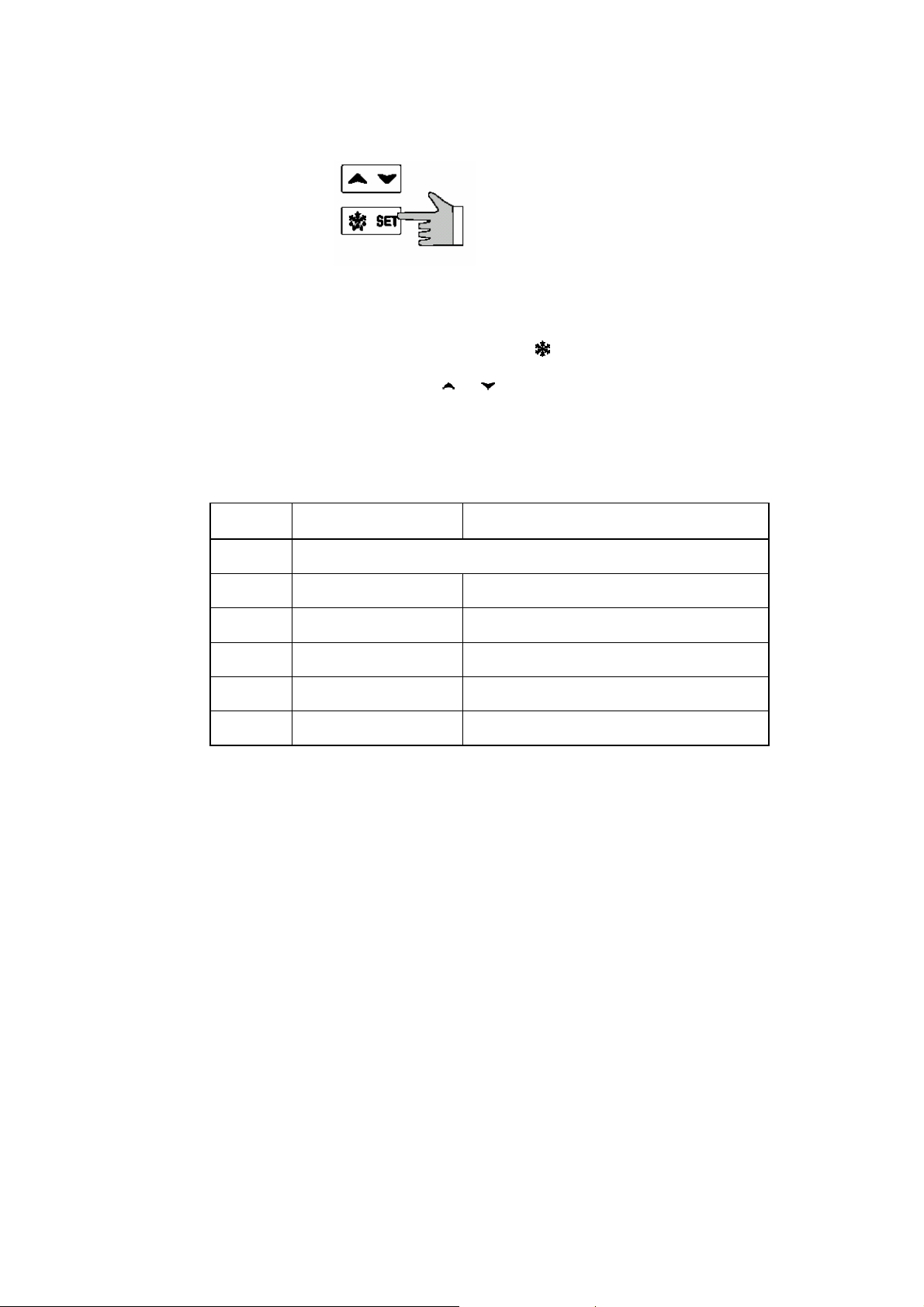

5.2 Front Panel Commands

SET: refers to display target set point, in programming mode it selects a parameter or

confirms an operation.

Presses for more 2 seconds to start a manual defrost.

(UP) Press to see the maximum stored temperature.

(DOWN) Press to see the minimum stored temperature.

Key Combinations:

+ Lock and unlock the keyboard.

SET +

SET +

To enter in programming mode.

To return to the room temperature display.

Use of LEDS

Each LED function is described in the following table

OASMs-616-C-19-07-05/13/1/07 6 OF 18

KOLDTECH

The Technology of Excellence

5.3 Changing the Set Point

1. Press the SET key for more than 2 seconds to change the Set point value.

2. The value of the set point will be displayed and the

3. To change the Set value, pushing the

or arrows within 10 sec.

LED starts blinking.

4. To memorize the new set point value, pressing the SET keys again or waits 15 sec.

5.4 Alarm Signals

Display Cause Output

"EE" Data or memory failure

"P1" Room probe failure Output according to par. "Con" and "COF"

"HA" Maximum temp. alarm Output unchanged.

"LA" Minimum temp. alarm Output unchanged.

"EA" External alarm Output unchanged.

"CA" Serious external alarm Output OFF.

Note:

The setting of operating temperature (and defrost for freezer) is already factory set.

End-user self- adjustment may void the given warranty unless consult the authorized.

(The parameter setting table, herewith given, is for the purpose of the reference of the DEALER’S service or

authorized competent service technician only.)

OASMs-616-C-19-07-05/13/1/07 7 OF 18

6. ASSEMBLY DRAWING

KOLDTECH

The Technology of Excellence

7

15

3

5

4

8

9

10

1

13

2

6

CONDENSING UNIT FOR R21 1 UNIT

CONDENSING UNIT FOR F21 1 UNIT

14

11

12

11

12

R1

L1

R2

16

L2

OASMs-616-C-19-07-05/13/1/07 8 OF 18

KOLDTECH

The Technology of Excellence

7. RECOMMENDED SPARE PARTS OF KOLDTECH PRODUCT

DESCRIPTION refers : standard equipped spec.

ITEM 60 Cycle CHILLER FREEZER

VOLTAGE 220 Volt

(others.) Volt

FREQUENCY 50 Cycle

1 COMPRESSOR 1175006 1112428

2 CONDENSER 2531112 2531112

3 CONDENSER FAN MOTOR 1012916 1012916

4 CONDENSER FAN BLADE 100105 100105

5 CONDENSER FAN GRILL 179294 179294

6 LIQUID FILTER DRIER 134034 13402

7 EVAPORATOR 2668510 2668510

8 EVAPORATOR FAN MOTOR 1012910 1012910

9 EVAPORATOR FAN BLADE 10095 10095

10 ACCUMULATOR 13510 13510

11 DIGITAL CONTROL 0874020 0874012

12 SQUARE LIGHT SWITCH 099102 099102

13 ACCESS VALVE 146014 146014

14 LAMP 098151 098151

15 HEATER DEFROST - I126346

16 HEATER DOOR 128150 128150

L1 TOP HINGES 181120 -

L2 BOTTOM HINGES 181140 -

R1 TOP HINGES - 181121

R2 BOTTOM HINGES - 181141

OASMs-616-C-19-07-05/13/1/07 9 OF 18

KOLDTECH

The Technology of Excellence

8. TROUBLE SHOOTING TABLE AND TROUBLE SHOOTING TREES

Symptoms Possible Cause Actions

Compressor is

not run

1. Main switch is disconnected

2. Fuses are blown.

3. Thermal overload is tripped.

4. Magnetic contactor /coil is out of order

5. System shut down by safety devices.

6. Liquid line (or solenoid valve) is not

open.

7. Compressor Motor drive.

1. Close switch properly.

2. Check electrical circuit and motor

winding for shorted or grounded.

Investigate for possible overloading.

Replace fuse after fault is re-corrected.

3. Overload is automatically reset. Check

unit closely when unit resumes normal.

4. Repair or replace.

5. Determine type and cause of shutdown

and correct it before resetting safety

switch.

6. Check TXV, (Repair or replace coil.)

7. Check motor if opens windings, short

Compressor is

unusually

sounded or

vibrated

High

discharge

pressure

8. Loosened wiring.

9. (of 3 Phase system), Phase may be

lost.

1. Liquid refrigerant returns into

crankcase.

2. Refrigerant Pipe is not well erected

3. Compressor mechanism loosened.

4. Internal balance springs or Neoprene

choke are broken

1. Condensation fail

2. System is overcharged refrigerant.

3. Fan is off

turn or burnt and disconnected.

8. Check all wires termination. Tighten all

the loosened screws.

9. Test all conductors continuity.

1. Check setting of expansion valves.

2. Provide proper fastener

3. Repair.

4. Replace.

1. Rectify cause of fails

2. Remove the excessive

3. Check electrical circuit.

4. Condenser fins are dusty

Low

discharge

OASMs-616-C-19-07-05/13/1/07 10 OF 18

1. Compressor valve is damage

2. Insufficient refrigerant in system.

4. Clean.

1. Check compression ratio or open it.

2. Check leaking and recharge refrigerant

KOLDTECH

The Technology of Excellence

pressure 3. Stop valve is yet closed. 3. Open stop valve properly.

High suction

pressure

Low suction

pressure

Compressor

loses oil

Compressor

thermal

protector switch

is open.

1. Excessive chilled product.

2. Expansion valve overfeeding.

1. Lack of refrigerant.

2. Evaporator is full of ice

3. Clogged liquid line.

4. Expansion valve malfunctioning.

5. Improper TXV.

1. Leaking of refrigerant.

2. Loosened cylinder ring

3. Refrigerant flood back.

4. Pipe sizing or trapping is not correct

1. Operating beyond design conditions.

2. Condenser fins are overly dirty

3. Overcharged refrigerant

1. Chilled volume to specification

2. Check remote bulb. Regulate superheat.

1. Check leaking and fix.

2. Defrost system does not work.

3. Replace Stainer-Drier

4. Check and reset for proper superheat.

5. Check for proper sizing.

1. Check leaking and recharge refrigerant.

2. Replace compressor.

3. Maintain proper superheat at

compressor.

4. Re-correct piping.

1. Tuning facilities to the allowable limits.

2. Clean Fin coil.

3. Release the excessive

Evaporator Trouble shooting

Symptoms Possible Causes Actions

Fan(s) is not turned. 1. Main switch is open.

2. Fuses are blown.

3. Motor is out of order.

4. Defective Timer or defrost

thermostat.

5. Unit is in defrosts cycle.

6. Coil is not cooled down

enough to reset thermostat.

Room temperature is too

high.

1. Room temp. is overly set.

2. Superheat is too high.

3. Refrigerant is shortage.

1. Close switch.

2. Replace fuses. Check cause of short

circuits or overload conditions.

3. Replace motor.

4. Replace defective component.

5. Wait until resuming

6. Adjust fan delay setting or wait until

resuming.

1. Properly tune thermostat.

2. Adjust thermal expansion valve.

3. Check, fix leaking, and Recharge ref.

4. Evap. Coil is highly ice

accumulation.

4. Do Manually defrost and check

defrost control setting

OASMs-616-C-19-07-05/13/1/07 11 OF 18

KOLDTECH

The Technology of Excellence

Ice is accumulating on

ceiling around

evaporator and/or on fan

guards venturi or blades.

Evap.Coil is not cleared

of frost during defrost

cycle.

1. Defrost duration is too long.

2. Fan delay does not activate

fans after defrost period.

3. Defrost thermostat or timer

is out of order

4. Frequently Defrosting action

1. During defrosting, Temp of

Evap. coil is lower than

freezing temp.

2. Cycle of defrost is not

enough

3. Defrost cycle too short.

4. Defective Timer or defrost

thermostat.

1. Adjust defrost termination value

2. Thermostat is not defrost, or adjusted

properly.

3. Replace defective component.

4. Reduce number of defrost cycle set.

1. Check heater if operation is normal.

2. Adjust Timer for more defrost cycles.

3. Adjust defrost thermostat or Timer

for longer cycle.

4. Replace defect component.

Ice accumulating in

drain pan

1. Condensate (pan) heater is

out of order.

2. Drainpipe is clogged of ice.

3. Drain heater is out of order.

4. Timer/thermostat is out of

order

1. Replace heater.

2. Clear drain line.

3. Replace heater, remove clogging

4. Replace defective component.

OASMs-616-C-19-07-05/13/1/07 12 OF 18

The Technology of Excellence

Troubleshooting Trees

KOLDTECH

Machine Does Not

Run

is the main

switch off?

Yes

check the

correct power

supply to the

machine

Yes

check

continuity of

supply cords &

protection fuse

Yes

check cap.start,

(and cap.run)

and magnetic

contactors

Yes

check control

board wiring

continuity and

termination

Yes

action as per root

cause finding

No

Turn on the

switch

Overly High or

Overly Low Pressure

Does machine

meet sufficient

refrigerant?

Yes

check suction

pipes that no

sqeezed, or

blazing clogged

no

check TXV for

moisture-based

restriction

No

check refrigerant

leakage and

amperage

consumption

No

Hi side pressure, Lo side pressure

and Current consumption shall be

related to each others, record data

during commissioning shall be

available

System Operates but

no Chilling or Freezing

check type of

refrigerant

Yes

check leakage of

refrigerant

No

yes

Yes

recharge the

refrigerant

repair the

squeezed point

or bottle

necked point

replace drier,

evacuate and

recharge

system

Isolator

Trips Oftenly

check overload is

set sufficiently

Yes

check overly

charging

refrigerant

no

check

compressor

wdg.if

shorted-turn

no

check earth

leaking

no

action as per root

cause finding

Abnormal Sound

during Operation

check securing

and all movable

mechanism

Yes

check bearings,

bush and fan

blades

Yes

no

check temp.

controller setting

& functioning

Yes

Hi side pressure, Lo side pressure and

Current consumption shall be related

to each others, record data during

commissioning shall be available

action as per root

cause finding

OASMs-616-C-19-07-05/13/1/07 13 OF 18

KOLDTECH

The Technology of Excellence

9. WARRANTY

9.1 KOLDTECH warrants equipment sold against defects in material and workmanship for a period of

twelve (12) months from the date of installation or fifteen (15) months from date of shipment (whichever

comes first). Access to warranty is conditional on the equipment being correctly installed, cared for and

operated under normal conditions

9.2 The warranty does not cover:

9.2.1 Any consequential loss, damages or expenses directly or indirectly arising from use or attempted use or

from any other cause.

9.2.2 Any part of the product which has been subject to misuse, neglect, alteration, incorrect installation,

accident, use of inappropriate chemicals, flooding, fire or acts of God.

9.2.3 Damage caused during transportation.

9.2.4 Breakage of glass, bulbs, lamps or plastic components or the replacement of gaskets or fluorescent tubes.

9.2.5 Penalty or additional labour costs for installation, removal or repair of the product outside normal

working hours

All warranty parts requested will be charged to the customer’s account unless a warranty claim is

approved. Standard credit policies will be applied.

9.3 Warranty Procedures

If your KOLDTECH product is not working while still under warranty and has not been subject

to improper use or treatment, follow the procedure listed below to obtain repairs:

Locate the rating plate sticker on your KOLDTECH product to enable you to complete the

details on the Warranty Request Form.

Complete the form with all requested details and faxes a copy to the number shown, along

with proof of purchase of the product.

Manufacturer and the authorized reserve the right to reject warranty calls where circumstances fail to meet their

warranty conditions.

9.4 Parts Ordering and Service Procedures

9.4.1 Replacement Parts

Replacement parts are available as shown:

In Australia: In Asia, South East Asia and others:

Tom Stoddart Pty Ltd

215 Jackson Road

Sunnybank Hills Q 4109

Australia

Ph: 61 7 3345 5011

Fax: 61 7 3344 6166

OASMs-616-C-19-07-05/13/1/07 14 OF 18

To contact the nearest dealers or

by e-mail to the service department.

Att: adms@welbilt-thailand.com

factory@welbilt-thailand.com

Ph: 66 02 316 0770

Fax: 66 037 294 181

KOLDTECH

The Technology of Excellence

9.4.2 Damages and Shortages

If the KOLDTECH product is damaged during transport please contact your dealer a.s.a.p.

9.4.3 Service

To arrange service on your KOLDTECH product please contact the dealers’ service

department

In Australia In Asia, South East Asia and others:

Tom Stoddart Pty Ltd

215 Jackson Road

Sunnybank Hills Q 4109

Australia

Ph: 61 7 3345 5011

Fax: 61 7 3344 6166

To contact the nearest dealers or

by e-mail to the service department.

Att: adms@welbilt-thailand.com

factory@welbilt-thailand.com

Ph: 66 02 316 0770

Fax: 66 037 294 181

10. FUNDAMENTAL REFRIGERATION DIAGRAM

4 CAPILARY TUBE

OR TXV

ab

Refrigerant Diagram

Keys :

1. Motor - Compressor

2. Condensor

3. Filter - Drier

4. Refrigerant Control device

5. Evaporator

6. Accumulator

5 EVAPORATOR COIL

6 ACCUMULATOR

SUCTION LINE

3 FILTER - DRIER

LIQUID LINE

DISCHARGE LINE

For TXV

7 ACCUMULATOR

6 EVAPORATOR COIL

5

a

b

1 COMPRESSOR

2 CONDENSER COIL

Topic Descriptions Locations

ELECTRICAL SCHEMATIC DIAGRAM

11

UTILITY INLETS/OUTLETS LAYOUT OF THIS UNIT IS N/A

12

COMBINATIVE TIMING DIAGRAM

13

COPY OF TEST CERTIFICATE

14

BLANK-CLAIM FORM

15

BLANK-SERVICE RECORD FORM

16

Last attaching, respectively.

OASMs-616-C-19-07-05/13/1/07 15 OF 18

KOLDTECH

The Technology of Excellence

CAUTION CAUTION

1 : NOT TO Overloading the outlet by multisockets

(one outlet one appliance)

3. : NOT TO Spraying the unit with water

5 : NOT TO Holding the cord when unplugging

(Hold plug head is suggested )

7 : NOT TO Having back of the unit press

against cord

9 : NOT TO Having stuff place on top of the unit

11 : NOT TO Using wet hands whilst pluging and

unplugging

2 : NOT TO Repairing or remove without know - how

4 : NOT TO Cleaning plug - pins by soaked cloth

6 : NOT TO Tempering the electric cord

8 : NOT TO Having electrical cord trapped under

the unit or other machine

10 : NOT TO Neglecting securing earthing

12 : NOT TO Playing ( Hanging ) on door leave

13 : NOT TO Storing flammable or explosive

material, liquid, or gas inside the unit

15 : NOT TO Using flammable spray near the u n it

17 : NOT TO Using the damaged electrical cord

19 : NOT TO Placing glass bottle items in freezer

21 : NOT TO A ttempting to remo ve the unit w it h

unproper method

23 : NOT TO Placing movers hands under the unit

when handling, to use dolly as necessary

when handling

14 : NOT TO Storing extremely temperature sensitive

stuffs eg medica l, r e le va nt researchin g materia ls

16 : NOT TO start up the unit when having

gas leakging near by, open windows (door )

to firstly dilute ga s density is a must

18 : NOT TO In s ta lling th e u n it e x posedly to water

or high moisture

20 : NOT TO Subjectively playing ( Setting )

temperature( R : 3 C - 13 C, F : -20 C - 0 C )

22 : NOT TO Touching frozen foods or frozen metal

container with bare hands, it can cause

cold burn

24 : NOT TO Unplugging the unit whenever

intermediate service needed

25 : NOT TO Replugging so soon, but wait for

3 - 6 minutes allowing the system pressure

balance then restart achievement

C:\Program Fires\My doc~\Sur ad eje\(C R ) \Safe ty No tices\S afe ty N o tice s

26 : NOT TO Forgetting all of the mentioned advice

REV.A : 27/10/03/SE.

OASMs-616-C-19-07-05/13/1/07 16 OF 18

KOLDTECH

f

The Technology of Excellence

time

at 5 C(chiller) Compressor Resume Runing after 1 to 2 minute breake

at 2 C(chiller)

varied off time setting

: Operating BLANK' : Of

Unit combination timing diagram

Within 1 hours

Manually reset MCB

What if Over load is tripped

Energize

Compressor Work

1

2

Condenser Fan Motor

Cut- Off Cycle

Defrost (assume air defrost type)

3

4

5

Cut- in Cycle

Evaporator Fan Motor

Resume Next Cycle

6

7

8

What if MCB is tripped

9

10

Over load automatic resume

11

12

OASMs-616-C-19-07-05/13/1/07 17 OF 18

KOLDTECH

f

The Technology of Excellence

time

Compressor Resume Runing after 1 to 2 minute breake

Of

at -18 C(Freezer

Unit combination timing diagram

at -20 C(Freezer)

Within 1 hours

Switch/Pwr Energize

1

varied time setting

Compressor Work

Condenser Fan Motor

2

3

Cut- Off Cycle

Defrost (assume ele defrost type)

4

5

Cut- in Cycle

Evaporator Fan Motor

6

7

Resume Next Cycle

What if MCB is tripped

Manually reset MCB

8

9

10

'BLANK' :

: Operating

What if Over load is tripped

Over load automatic resume

11

12

OASMs-616-C-19-07-05/13/1/07 18 OF 18

t

t

l

t

t

n

t

n

y

n

t

t

n

t

d

d

s

t

y

t

t

t

g

t

e

t

m

t

d

p

y

g

t

d

g

y

d

n

;

y

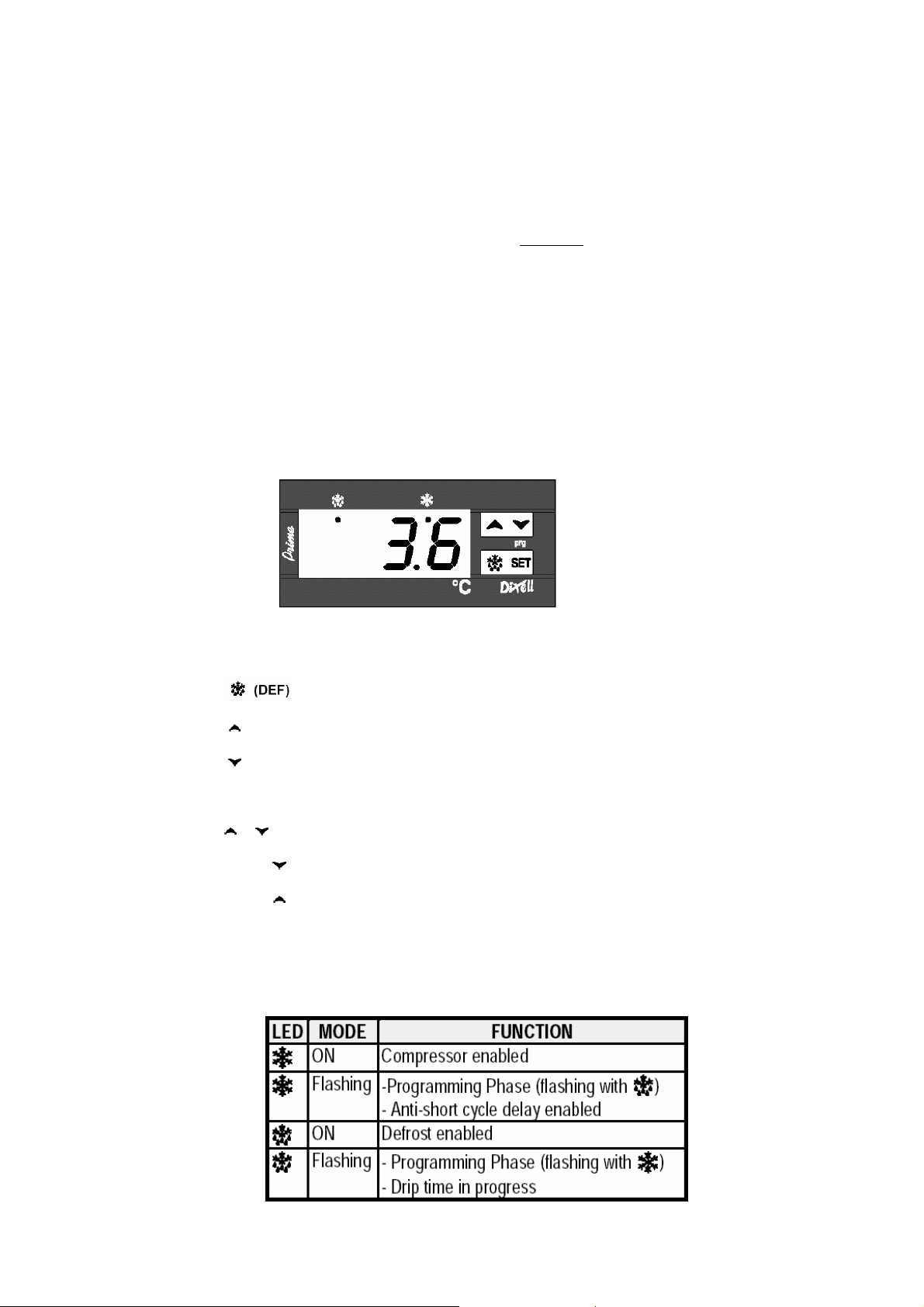

Controller application setting parameters Dixell XR20C for Up right chille

r

Name

REGULATION

Set poin

Differentia

Minimum set poin

Maximum set poin

Thermostat probe calibratio

Evaporator probe presence

Evaporator probe calibratio

Outputs deray at start up

Anti short cycle dela

Continuos cycle duratio

Compressor ON time with faulty

Compressor ON time with faulty probe

Temperature measurement uni

Label Range Original settingFactory setting

Se

Hy

LS

US

O

P2P

OE

Ods

AC

CC

Con

COF

CF

oC/ o

LS-US

0.1-25.5oC/1-255

-50oC-SET/-58oF-SET

SET-110oC/SET-230oF

o

F

-50/-58

110/230

-12-12oC/-120-120oF

n=not present; Y=pres. y

-12-12oC/-120-120oF

0-255 min 0

0-50 min 1

0.0-24.0 h 0.0

0-255 min 15

0-255 min 30

o

C -

o

F

o

F

-5/0

2/4

0

0

C / oF

o

C

2

3

-2

5

0

n

0

1

2

0

10

5

C

DISPLAY

Resolutio

Probe displaye

Res

Lo

in=integer; dE=dec.poin

P1:P2 P1

dE/-

de

P1

DEFROST

Defrost type

Defrost termination temperatur

Interval between defrost cycles

(Maximum)length for defros

Start defrost dela

Displaying during defros

MAX display delay after defrost

Draining time

First defrost after startup

Defrost delay after fast freezin

tdF

dtE

IdF

MdF

dSd

dFd

dAd

Fd

dPo

dAF

EL=el.heater; in=hot ga

-50-50oC

1-120 ore 6

0-255 min 30

0-99 min 0

rt,it,SEt,DEF i

0-255 min 30

0-120 min 0

n=after IdF;y=immed. n

0-23 h e 50' 0.0

EL

8/46

-

-

5

30

0

DEF

15

0

n

0

FANS

Fan operating mode

Fan delay after defros

Fan stop temperature

Fnc

Fnd

FSt

C-n,o-n,C-y,o-Y -

0-255 min -

-50-50oC/-58-122oF

-

-

-

-

ALARMS

Temperature alarms configuration

MAXIMUM temperature alarm

Minimum temperature alar

Temperature alarm delay

Delay of temperature alarm at start u

ALc

ALU

ALL

AL

dAO

rE=related to set;Ab=absolut

Se

-110.0oC;Set-230oF

o

C-Set/-58oF-Se

-50.0

0-255 min 15

0-23 h e 50' 1.3

Ab

110/230

-50/-58

AB

15

-5

30

6

DIGITAL INPUT

Digital input polarit

Digital input configuration i1F EAL EAL

i1P

oP=opening;Cl=closin

EAL=extern.alarm,bAL=lock regula

PAL=press.sw,dor=door sw

dEF=defrost,LHt=disable

CL

CL

Htr=Cooling-heatin

Digital input alarm dela

di

0-255 min 5

5

0=door switch,1=lock

Kind of action when I1f=Bal Nps

regulatio

,2-15=pressure switch

15 15

no,Fan=normal;CPr;F

Compressor status with open door odc

no no

C=Compr.OFF

Kind of probe

Room probe display

Evaporator probe displa

Software release

Map code

Pbc

dP1

dP2

rEL

Ptb

Ptc;ntc ntc/Ptc

--

--

- 4.0

--

ntc

-

-

-

-

t

t

l

t

t

n

t

n

y

n

t

t

n

t

d

d

s

t

y

t

t

t

g

t

e

t

m

t

d

p

y

g

t

d

g

y

d

;

y

Controller application setting parameters Dixell XR40C for Up right freeze

r

Name

REGULATION

Set poin

Differentia

Minimum set poin

Maximum set poin

Thermostat probe calibratio

Evaporator probe presence

Evaporator probe calibratio

Outputs deray at start up

Anti short cycle dela

Continuos cycle duratio

Compressor ON time with faulty

Compressor ON time with faulty probe

Temperature measurement uni

Label Range Factory seting Parameter user

Se

Hy

LS

US

O

P2P

OE

Ods

AC

CC

Con

COF

CF

oC/ o

LS-US

0.1-25.5oC/1-255

-50oC-SET/-58oF-SET

SET-110oC/SET-230oF

o

F

-50/-58

110/230

-12-12oC/-120-120oF

n=not present; Y=pres. y

-12-12oC/-120-120oF

0-255 min 0

0-50 min 1

0.0-24.0 h 0.0

0-255 min 15

0-255 min 30

o

C -

o

F

o

F

-5/0

2/4

0

0

C / oF

o

-20

-23

-15

20

C

3

0

y

0

1

2

0

5

C

DISPLAY

Resolutio

Probe displaye

Res

Lo

in=integer; dE=dec.poin

P1:P2 P1

dE/-

de

P1

DEFROST

Defrost type

Defrost termination temperatur

Interval between defrost cycles

(Maximum)length for defros

Start defrost dela

Displaying during defros

MAX display delay after defrost

Draining time

First defrost after startup

Defrost delay after fast freezin

tdF

dtE

IdF

MdF

dSd

dFd

dAd

Fd

dPo

dAF

EL=el.heater; in=hot ga

o

-50-50

C

1-120 ore 6

0-255 min 30

0-99 min 0

rt,it,SEt,DEF i

0-255 min 30

0-120 min 0

n=after IdF;y=immed. n

0-23 h e 50' 0.0

EL

8/46

EL

30

4

30

0

DEF

20

2

n

0

FANS

Fan operating mode

Fan delay after defros

Fan stop temperature

Fnc

Fnd

FSt

C-n,o-n,C-y,o-Y -

0-255 min -

o

C/-58-122oF

-50-50

-

-

-

-

ALARMS

Temperature alarms configuration

MAXIMUM temperature alarm

Minimum temperature alar

Temperature alarm delay

Delay of temperature alarm at start u

ALc

ALU

ALL

AL

dAO

rE=related to set;Ab=absolut

Se

-110.0oC;Set-230oF

o

C-Set/-58oF-Se

-50.0

0-255 min 15

0-23 h e 50' 1.3

Ab

110/230

-50/-58

AB

-10

-25

30

8

DIGITAL INPUT

Digital input polarit

Digital input configuration i1F EAL EAL

i1P

oP=opening;Cl=closin

EAL=extern.alarm,bAL=lock regula

PAL=press.sw,dor=door sw

dEF=defrost,LHt=disable

CL

CL

Htr=Cooling-heatin

Digital input alarm dela

di

0-255 min 5

5

0=door switch,1=lock

Kind of action when I1f=Bal Nps

15 15

regulation,2-15=pressure switch

no,Fan=normal;CPr;F

Compressor status with open door odc

no no

C=Compr.OFF

Kind of probe

Room probe display

Evaporator probe displa

Software release

Map code

Pbc

dP1

dP2

rEL

Ptb

Ptc;ntc ntc/Ptc

--

--

- 4.0

--

ntc

-

-

-

-

Loading...

Loading...