KOLDTECH DT-R21F21-2D, 21-1D, 72-3D, 72-6d, 21-2d General Operation And Service Manual

...

KOLDTECH

REFRIGERATOR AND

FREEZER

THIS MANUAL SHALL BE PERMANENTLY KEPT AT END USER

PREPARED FOR JOB NR.…………OR PRODUCT SR.NR………….

General Operation and Service Manual of Refrigeration

(Covering Models as shown: DT-R21F21-2D)

OASMs-616-C-05/19/07/05

CONTENTS

KOLDTECH

The Technology of Excellence

Topics Description Page

1 INTRODUCTION

2 INSTALLATION & STARTS UP

2.1 Uncrating

2.2 Handling Issue

2.3 Installation

2.4 Draining

2.5 Ventilation

2.6 Electrical Preparation

2.7 Starting

3

3

3

3

3

4

4

4

4

Topics Description Page

5 TEMPERATURE SETTING

5.1 Temperature Settings,

5.2 Controller and Parameter

6 ASSEMBLY DRAWING

7 RECOMMENDED PARTS

8 TROUBLE SHOOTING

TABLES AND TREES

9 WARRANTY & SERVICE

10 REFRIGERATION

DIAGRAM

11 TIMING DIAGRAM

12 I/O UTILITY

6

7

LAST

8

9

10-13

14

15

17

LAST

2.8 Product Loading

2.9 Machine Performance

2.10 Defrosting

3 PRODUCT CLAEANING/Tips

4 MAINTENANCE SCHDULE

4

4

4

4 /

last

5

LOCATION

13 ELECTRICAL DIAGRAM

14 TEST CERTIFICATE

15 CLAIM FORM

16 SERVICE RECORD FORM

Technical depth as italicized

page may be limited to dealer

use only.

(IF APPLICABLE)

LAST

LAST

LAST

LAST

Noted

OASMs-616-C-19-07-05/13/1/07 2 OF 18

KOLDTECH

The Technology of Excellence

1. INTRODUCTION:

Thank you for choosing our KOLDTECH product. With over 30 years of experience in

refrigeration manufacturing we are confident that our product will provide you with years of

trouble-free operation. Our products are fully engineered to be amongst the best in the industry.

We also continually improve our product designs to ensure they continue to take advantage of the

latest in refrigeration design. Every unit is fully tested in our calibrated testing laboratory prior to

leaving our factory.

As with other precision equipment, proper care and operation will ensure years of trouble-free

service. It is essential that you spend time reading this manual before operating the machine, to

familiarize yourself with our product and safety procedures. Keep the manual where end-user

could see and locate.

We thank you again for choosing KOLDTECH . If you have any further questions please feel

free to call the dealer from whom you purchased the unit. Our address and telephone number can

be found under the “Service and Repair” information section.

2. INSTALLATION AND START UP

The following procedure should be followed for trouble free installation:

2.1

Uncrating: While unpacking, take note of any damage to the unit. If damage is found do not

discard the packing materials and notify your dealer, or the freight company a.s.a.p. Do not proceed

to install the unit.

2.2

Handling Issue:

2.2.1 Precaution has been taken to ship the unit in an upright position. If the unit is tilted during

transit lubricating oil may shift from the reservoir, and operating the unit may cause excessive wear

or damage to the compressor’s moving parts. It is recommended that the unit be left standing for

48 hours before operation.

2.2.2 Inspect and clear away any packing material that may be used to secure the unit during

transit.

2.3

Installation:

2.3.1 Install the unit in a dry, well-ventilated place away from heat sources or any vibration.

Ideally for optimum performance we recommend installation in air-conditioned premises. In the

event of high relative humidity, condensation may form on the cabinet. This will not impact on the

OASMs-616-C-19-07-05/13/1/07 3 OF 18

KOLDTECH

The Technology of Excellence

ability of the cabinet to maintain internal temperature. Should ambient temperature exceed 36oC

we cannot guarantee the maintenance of internal temperature to required standards.

2.4

2.3.2 The unit should be set on a level and firm surface.

Draining: Special models may require drain pipe for condensate water, End-user should well

explore from specification sheet before plugging in and self prepare of drain pipe as appropriate.

2.5

2.6

Ventilation: ventilating grills or louvers must not be obstructed for proper operation.

Electrical Work Preparation:

2.6.1 For safety reasons, the unit must be properly earthed. Check and make sure that the outlet is

properly grounded. If a grounded plug is not available, a separate earth ground must be installed to

prevent any electrical hazard. A properly rated circuit breaker should be installed to the supply

outlet. Check for proper supply voltage before plugging in the unit. Please refer to voltage

requirements on the nameplate of the unit.

2.6.2 Plug the unit into the wall outlet. Turn the unit on using the on/off switch.

2.7

Starting: After turning on the unit for the first time, if there is any unusual odour, heat, smoke or

vibration immediately turn off and unplug the unit and call for a service technician. The unit

should be closely monitored during the first hour of operation.

2.8

Product Loading: The thermostat is set at the factory for optimum operating temperature. Time

taken to attain the operating temperature depends on the temperature of the food being loaded, the

frequency of the door opening, ambient temperature etc. The unit should reach operating

temperature during the first 4-6 hours for chiller and 8-12 hours for freezer of operation.

2.9

Machine Performance: To prevent compressor damage, the unit is equipped with a Time Delay

Circuit, which shall activate the compressor within 2 minutes after turning on the power or after

restarting.

2.10

Defrosting: Defrosting the circuit is set from the factory for optimum operation. Do not attempt to

alter the setting.

PLS NOTE do not disassemble the unit. Any service performed by parties other than our

authorized may void the warranty.

3. PRODUCT CLEANING

3.1 CLEANING Stainless Steel surface, P.V.C. and Display Glass: Users can wash by lukewarm

soapy water (or recommended cleaner) and, later, thoroughly rinses or wiping all surfaces with

water or moistened clothes respectively. Finally, polish with dry soft cloth.

OASMs-616-C-19-07-05/13/1/07 4 OF 18

KOLDTECH

The Technology of Excellence

3.2 Note: Do not use solvents or other aggressive liquids for cleaning e.g. with mixture of

chlorine or detergent etc. Do not use wire brush, steel wool or grainy –wiping pad such as

Scotbrite-pad-grain.

4. MAINTENANCE

4.1 Observe safety practice by disconnecting all electrical supply before performing any kind of

maintenance.

4.2 Do not use sharp instruments or cleaning agents on the unit. Clean (interior and exterior

surfaces) using a damp cloth and warm water. Food particles and spillage should be

removed as soon as possible to avoid build-up and odour.

4.3 To ensure efficiency and reliability it is important that the condenser coil be kept clear of

accumulated dirt and duct. It is recommended to use a non-metallic brush, vacuum cleaner

or air blower to dislodge dust from the condenser fins. The frequency of cleaning depends

on the amount of dust in the surrounding area of the installation. The condenser should be

inspected and cleaned at least every month.

4.4 Do not expose any electrical components to moisture or water. If the unit gets wet, turn it

off and unplug it from the wall outlet immediately. Do not turn it on again until the unit is

completely dry or after inspection by a qualified service technician.

4.5 Should the unit be left unused for an extended period, all food items should be removed.

The interior surface and shelves should be cleaned thoroughly. Unplug the unit from the

power source and leave the doors slightly opened.

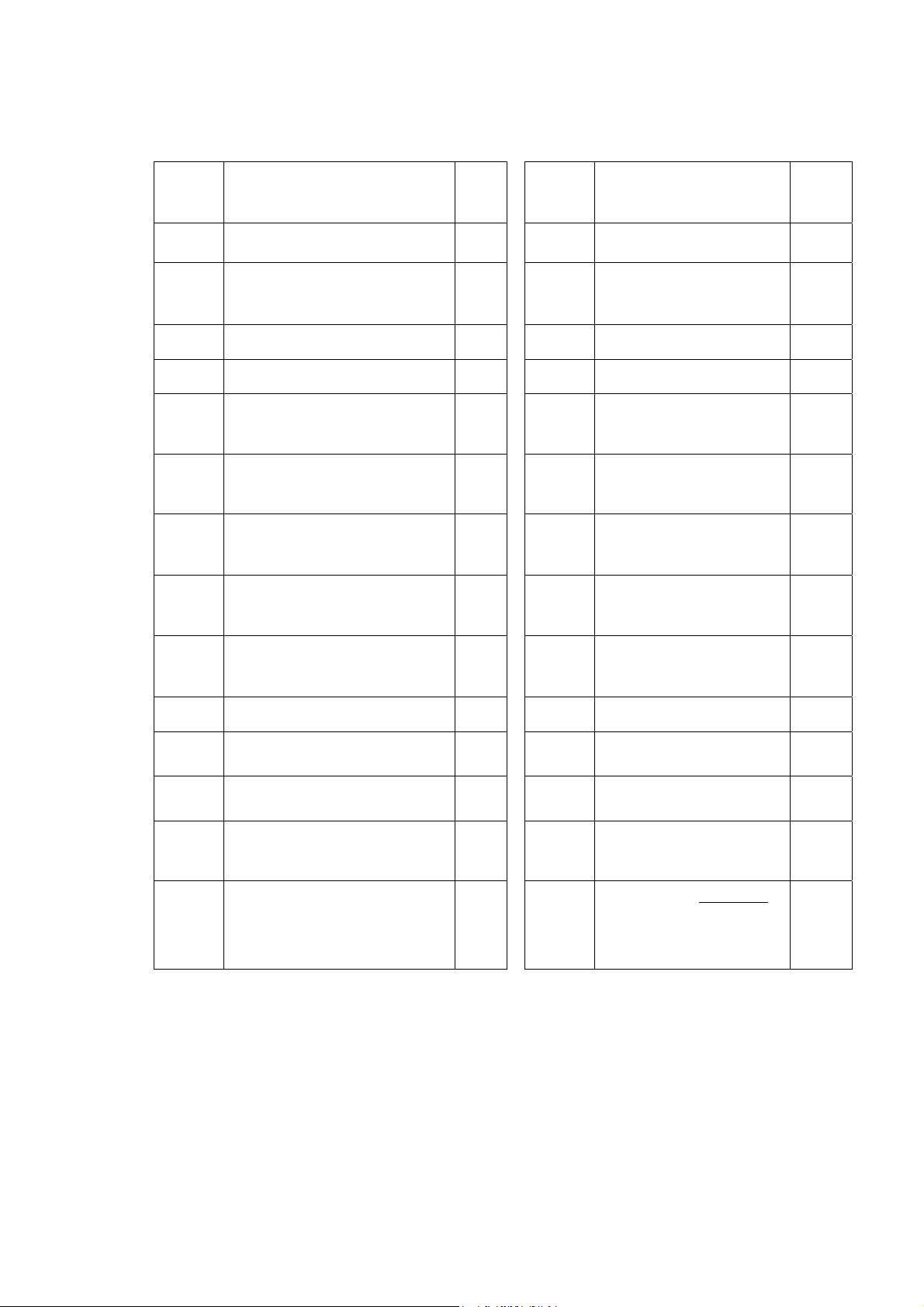

Recommended Maintenance Schedule

Frequency

Maintenance List

Daily Weekly Monthly

Clean interior and exterior surfaces X

Check operating temperature X

Check control panel alarm X

Check compressor for vibration X

Check compressor temperature X

Check condenser fan X

Clean condenser coil X

OASMs-616-C-19-07-05/13/1/07 5 OF 18

KOLDTECH

The Technology of Excellence

5. TEMPERATURE SETTING:

5.1 Your KOLDTECH product is equipped with an electronic thermostat with off cycle

designed for refrigeration applications at normal temperature. It provides a relay output to drive

the compressor and a probe input. An internal timer manages the off cycle defrost.

Tips: Recommended preset temperatures for specialized use.

Flowers: +4°C to +8° C

Confectionery (Candy): +14°C to +18°C

Seafood: -1°C to +1°C

Meat: -2°C to +1°C

Cakes: +7°C to +10°C

(Consult factory when needed, self-adjustment may void the given warranty)

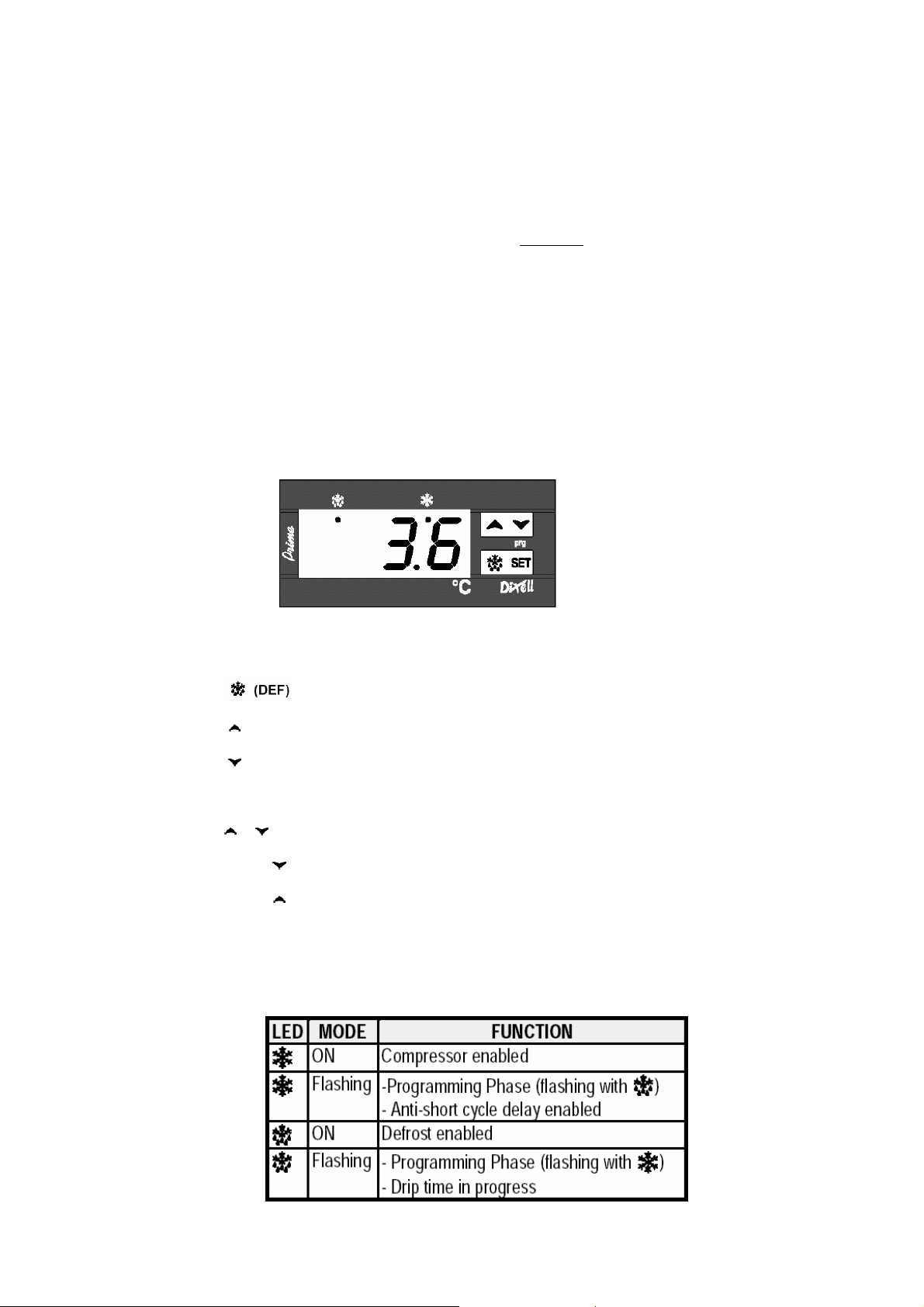

5.2 Front Panel Commands

SET: refers to display target set point, in programming mode it selects a parameter or

confirms an operation.

Presses for more 2 seconds to start a manual defrost.

(UP) Press to see the maximum stored temperature.

(DOWN) Press to see the minimum stored temperature.

Key Combinations:

+ Lock and unlock the keyboard.

SET +

SET +

To enter in programming mode.

To return to the room temperature display.

Use of LEDS

Each LED function is described in the following table

OASMs-616-C-19-07-05/13/1/07 6 OF 18

KOLDTECH

The Technology of Excellence

5.3 Changing the Set Point

1. Press the SET key for more than 2 seconds to change the Set point value.

2. The value of the set point will be displayed and the

3. To change the Set value, pushing the

or arrows within 10 sec.

LED starts blinking.

4. To memorize the new set point value, pressing the SET keys again or waits 15 sec.

5.4 Alarm Signals

Display Cause Output

"EE" Data or memory failure

"P1" Room probe failure Output according to par. "Con" and "COF"

"HA" Maximum temp. alarm Output unchanged.

"LA" Minimum temp. alarm Output unchanged.

"EA" External alarm Output unchanged.

"CA" Serious external alarm Output OFF.

Note:

The setting of operating temperature (and defrost for freezer) is already factory set.

End-user self- adjustment may void the given warranty unless consult the authorized.

(The parameter setting table, herewith given, is for the purpose of the reference of the DEALER’S service or

authorized competent service technician only.)

OASMs-616-C-19-07-05/13/1/07 7 OF 18

Loading...

Loading...