Page 1

SC200 Series Ice Machine

Installation & Operation Manual

Kold-Draft International, LLC

1525 East Lake Road

Erie, PA 16511-1088 U.S.A.

Phone: (800) 840-9577

Fax: (800) 548-9392

www.kold-draft.com

This manual is updated periodically. Visit http://www.kold-draft.com/resources/literature.php for the latest version.

Page 2

KOLD-DRAFT INTERNATIONAL, LLC

A DIVISION OF THE LEGACY COMPANIES, LLC

Installation & Operation Manual

SC200 Series Ice Machine

Copyright 2016 KOLD-DRAFT INTERNATIONAL, LLC

Unauthorized reproduction of this manual is freely permitted for all purposes except for monetary

gain.

It is not guaranteed that this service manual is up to date, technically correct, complete, or free

from writing problems or that the product is free from minor flaws or that it meets the needs of the

customer.

April 2016

Page 3

Table of Contents

Section 1 General Information

Model Number Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Date Code Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Serial Number Plate Location . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 2 Installation

Carton Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ice Cube Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 3 Operation

Initial Start Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ice Machine Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Description of Each Process . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Section 4 Service Information

Cleaning Mode Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Storage and Winterization . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Removal from Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Controls and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

Page 4

Safety Warnings and Information

W

ARNING

:

C

AUTION

:

.

Special attention should be given to potential hazard labeling on the equipment and the signal words

and symbols that are used throughout this manual. They may also be used to alert against unsafe

practices.

Indicates a potentially hazardous situation that may result in serious injury

or death.

Indicates a potentially hazardous situation that may result in personal injury

The situation may also result in equipment or property damage.

NOTE: Indicates installation, operation, or maintenance information which is important, but not

related to personal injury or property damage.

NOTE:

• Check for freight damage before proceeding with the equipment installation. Be sure to inspect the

equipment carefully for any damage that may not have been evident on the outside of the carton.

Contact the freight carrier immediately to report any damage and file a claim. Have carrier note the

damage on the bill of lading. Call Kold-Draft with your claim number to arrange replacement or repair.

• Read the entire manual before installing, operating or servicing the machine.

• To ensure optimal efficiency and productivity follow these installation instructions exactly.

• All machines have been tested and adjusted for correct performance at the factory.

• Knowledge of proper installation and service procedures is essential for the safe operation and

maintenance of KOLD-DRAFT equipment. Refer all installation and service work to qualified

technicians.

• This equipment must be installed in compliance with the applicable federal, state/province, and/or local

plumbing, electrical, and health/sanitation codes and requirements.

• Always disconnect the power supply before servicing the equipment or when the equipment will not be

used for a period of time. Some circuits remain energized when the machine is switched off.

• Never operate equipment that has been damaged or does not have all the protective covers in place.

• Never operate equipment that has been altered from the original KOLD-DRAFT specifications.

WARNING: Use only genuine KOLD-DRAFT replacement parts, Use of non-approved

parts when servicing KOLD-DRAFT equipment may create a safety hazard, cause

equipment damage, property damage and will void the warranty.

SC200 Installation & Operation Manual

3-16

1

Page 5

Ice Maker Identification

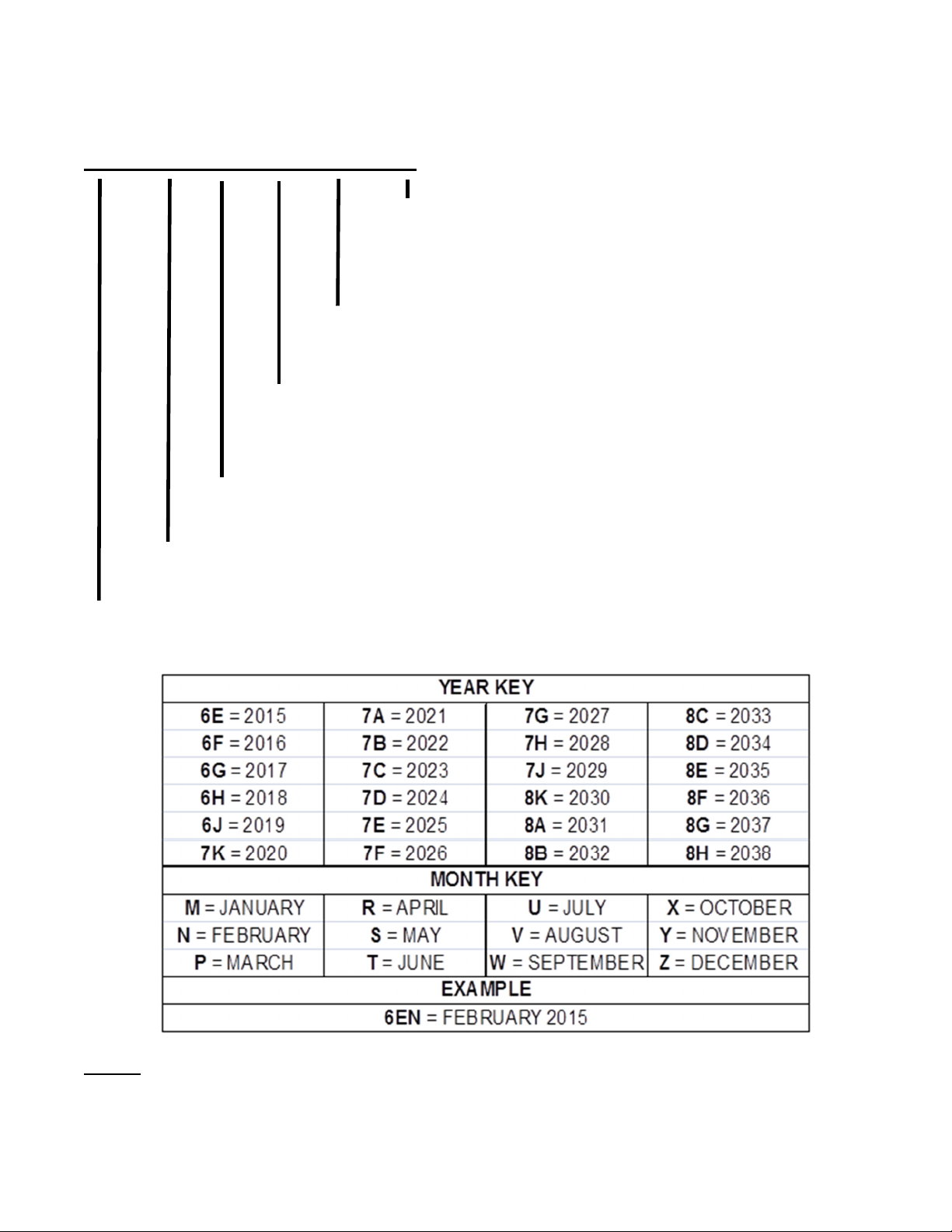

Model Number Key

SC 2 0 1 A C

Cube Size

C = Full Cube

HK = Half Cube

K = Cube-Let

Condenser Type

A = Air cooled condenser-self contained

L = Liquid cooled condenser-self contained

Electrical Characteristics

1 = 115 volt-60 hz.-1ph. (2-wire plus ground)

4 = 208/230 volt-60 hz.-1ph. (2-wire plus ground)

7 = 220/240 volt-50 hz.-1ph. (2-wire plus ground)

Modification Code

0 = No Modifications

Series

2 = 200 Series

Model Family

SC = Self Contained

Date Code Key

NOTE: The serial number plate is located in the condensing unit compartment, on the left side wall.

A complete model number and date code are essential for the accurate identification of the ice

machine and proper selection of replacement parts.

SC200 Installation & Operation Manual

2

3-16

Page 6

Installation Information

WARNING:

• Instruct all personnel in the proper use of the equipment.

• Clean up any liquid spills immediately.

• Always install equipment on a stable and level surface.

• All models are intended for indoor use only. Do not install the equipment in unprotected

outdoor areas.

• Do not install the equipment in wet areas.

• Do not locate the equipment near any heat source, in direct sunlight, in high ambient areas,

or without proper clearance for ventilation. Placing equipment in these locations will result in

reduced capacities, high system pressures and may cause equipment failure.

NOTE: Each Kold-Draft ice machine has successfully completed a quality assurance test and has

been factory inspected before shipping.

Unpacking

Unpacking a KOLD-DRAFT machine can be done by prying off the boards that are holding the

cardboard box to the shipping pallet. The box can then be lifted vertically to expose the machine.

Remove all packaging materials from the ice machine and protective film from the stainless steel

surfaces.

Carton Contents

• Kold-Draft SC200 Series Ice Machine

• Warranty card attached to the front of the machine (must be fully completed and returned to the

factory within 15 days of installation to register this product and to initiate warranty coverage.)

NOTE: Failure to return this registration form will void your warranty.

• Installation & Operation Manual. Leave these with the owner/user.

SC200 Installation & Operation Manual

3

3-16

Page 7

Installation Requirements

• The ice machine must be installed indoors and the location should be free of airborne

contaminates including any corrosive elements.

• Ambient air temperatures at the install location must be between 45°F (7°C) and 90°F (32°C).

Ambient temperatures higher than the maximum specification will result in reduced capacities

and high system pressures in air-cooled models. Temperatures lower than the minimum may

cause the machine to be unable to eject the ice from the evaporator. Ambient temperatures

less than 60°F (15°C) may cause the bin probe to malfunction.

• The machine may be built into a cabinet. Clearance is not required around the top and sides,

but must be provided in back for plumbing and electrical connections and in front for free flow

of air in and out of the condensing unit compartment.

• Do not install air cooled units in closets or small rooms where the free flow of air to the unit is

restricted.

• The location must not be near heat generating equipment.

• The location must not be near anything that can contaminate it or the ice inside.

• The ice machine should be mounted on the legs provided and leveled by screwing the leg

adjusters in or out as required. If the legs are not used, shim the bottom of the machine as

required to make it level. Seal any gaps at the floor with approved sealant or use cove molding

for larger gaps. Make sure the lower front cover remains removable for service.

• The location must be capable of supporting the weight of the ice machine, with a full bin of ice.

SC200 Installation & Operation Manual

4

3-16

Page 8

Plumbing

• The drain hose or pipe must not be reduced in size from the machine to the drain. The building

drain must be able to accommodate all the drain water from the ice machine operation.

• Individual drains will not be directly connected to a common manifold, drain or standpipe. If

individual drains are to be discharged into a common manifold, drain or standpipe, a minimum

1.5” (38mm) air gap must be provided at each connection. This is to prevent any backflow of

drain water into the ice maker or ice bin.

NOTE: Installation must provide adequate backflow prevention to comply with applicable

federal, state and local codes.

• Drain lines will be installed with a minimum drop of 1/4” per ft. (2.1cm per meter) run. Ice

machine drains and bin drains may be insulated to prevent condensation.

• Water supply temperature must be between 45°F (7°C) and 90°F (32°C). Do not connect the

ice machine to a hot water supply line. Insulate the water line from sources of heat for greater

operating efficiency. Supply water temperatures higher than the recommended maximum will

cause reduced capacities.

• The water supply must be potable, not laden with sediment, and have free chlorine levels no

greater than 0.2ppm. Supplies with higher chlorine levels should be filtered. There are no

specific requirements for water treatment, but the use of water conditioning may increase the

intervals between cleaning operations and overall machine life. Please consult a local water

conditioning supplier for specific recommendations for your area.

• A minimum 20 psig (dynamic) water supply pressure is required for proper operation of the ice

maker water valve. Please note that on liquid cooled ice machines, where the same water

supply is used for both condenser cooling and the potable water supply, the demand for

condenser coolant may cause the supply pressure to drop. This is most notable at the time of

peak load, at the beginning of the freeze cycle. The maximum water supply pressure is 100

psig (0.6 MPa). If a water pressure regulator is used, the recommended setting is 30 to 50 psig

(0.2 MPa to 0.3 MPa) dynamic.

• All water lines must be purged before connection to the ice machine.

SC200 Installation & Operation Manual

5

3-16

Page 9

Electrical

WARNING

: Failure to comply with these regulations may cause serious injury or death

CAUTION:

and cause damage to the machine and its surroundings.

Switching the machine “off” does not de-energize all circuits. Always disconnect

power before servicing.

• All KOLD-DRAFT models are intended to be installed with a permanent connection to the field

electrical supply. See rating plate on the back of the machine for power supply requirements.

• Each ice maker must be connected to a separate protected circuit with no other loads.

• Fused disconnects, installed adjacent to each ice maker, are recommended and may be

required by local codes. These components must be supplied by the installer.

• Electrical service must fall within the voltage tolerances listed below:

Maximum Overload Protection must be no greater than specified. The minimum circuit

ampacity specified does not indicate a typical running current value. Use the minimum ampacity

value for sizing branch circuit conductors up to 26 feet (8 meters) in length. For a conductor

length over this length, increase the wire gauge as required by code.

Model Nominal (V) No-Load Maximum Full-Load Minimum

SC201 115 126 104

SC204 208-230 250 198

SC207 230 250 210

Ice Cube Information

Cube Type Cube Dimensions Cube Weight Cubes per Cycle

C (Full Cube) 1-1/4 x 1-1/4 x 1-1/4 in (32 x 32 x 32 mm) 1.15 oz (32.6 g)

HK (Half Cube) 1-1/4 x 1-1/4 x 5/8 in (32 x 32 x 16 mm) .53 oz (15.0 g) 90

K (Cubelet) 1-1/4 x 5/8 x 5/8 in (32 x 16 x 16 mm) .28 oz (7.9 g) 90

SC200 Installation & Operation Manual

6

3-16

45

Page 10

Operation

Initial Start Procedure

1. Be sure that the on-off switch is in the “off” position and the ice-clean switch is in the “ice”

position.

2. Make sure all water lines and hoses are securely connected, turn on water supply and check

for leaks.

3. Move the on-off switch to the “on” position and observe the water plate opening. Any water in

the tank will then be drained. The compressor will turn on, the water plate will close and the

sump tank will start to fill.

4. Also, observe that the water pump is circulating water through the system. A momentary sucking

cavitation sound is normal at the beginning of the process when the water level is low. Check

that there are no water leaks from the hoses or water tank into the bin.

5. The machine will begin to make ice.

6. When ice is available, test the bin probe adjustment by holding ice against it. Adjust the

controller, if required. Code 90 indicates ice bin full, a cold bin probe will shut down the ice

machine right after the next harvest is complete.

7. Replace and secure all the cabinet panels.

8. Discard all the ice from the start-up cycles, then clean and sanitize the ice storage bin according

to the instructions provided.

Ice Machine Re-Start

At power up, in the ice making mode, the electronic control will monitor the conditions and

operate in the following manner:

If the evaporator temperature is colder than the harvest termination temperature at start up, the

water plate will open (lower).

If there is an obstruction preventing the water plate from closing, it will re-open (lower)

If the evaporator temperature is warmer than the harvest termination temperature and the water

plate is open, it will close (raise).

SC200 Installation & Operation Manual

7

3-16

Page 11

Controls and Adjustments

CAUTION:

On-Off Switch: Used to turn the ice machine on or off.

Switching the machine “off” does not de-energize all circuits. Always disconnect

power before servicing.

Ice-Clean Switch: The “Ice” position signals the controller to provide full operation of the ice

machine. The “Clean” position will exclude operation of the compressor and condenser fan motor

(air cooled models) and provide operation required for the cleaning procedure.

Defrost Button: Push this button anytime lowering the water plate and/or forcing the ice machine

into the defrost mode is desired. The water plate will remain down for four minutes and then return

to normal operation. Pushing the button again, while the plate is down, will immediately return the

machine to normal operation.

Float Switch: Closes water inlet valve when water sump is full

Evaporator Probe: Provides evaporator temperature information to the control board to begin and

end the defrost cycle. Adjust the left potentiometer on the control board to determine ice cube

fullness. Turn CW to extend the freeze time and CCW to shorten it.

NOTE: Ice cubes should never be frozen completely full. A small dimple in each cube

indicates a proper adjustment. Making cubes without a dimple will reduce ice machine

capacity and may cause damage to the water plate and operating mechanism.

Bin Probe: This probe will sense contact with the ice, when the bin is full and turn off the ice

machine. When ice is used and is no longer in contact the probe, it will signal the control to turn

on the ice machine. When the ice machine is off due to a full bin, the code 90 indicator will be lit

on the control board. Contact with ice should turn off the ice machine within one minute.

If adjustment is required, hold ice against the probe. Turn the right side potentiometer on the

control board CCW to shut off the machine within one minute. CW adjustment is required if the ice

machine shuts down, as if the bin is full, when ice has not contacted the probe.

Plate-Up Switch: This switch limits the upward travel of the water plate. It opens to de-energize

the actuator motor, by way of an operator, when its shaft is in the full up (closed) position.

This switch also provides a way for the controller to determine that the plate is blocked. When the

plate is closing, the controller provides a time limit for this switch to open. If the time limit is

exceeded, the controller will reopen the water plate to clear it. This will repeat until the surface is

clear.

Plate-Down Switch: This switch limits the downward travel of the water plate. It opens to deenergize the actuator motor, by way of an operator, when its shaft is in the full down (open) position.

SC200 Installation & Operation Manual

8

3-16

Page 12

Sequence of Operation

Step 1

Step 2

Step 3

Step 4

Step 5

The following tables describe the general states and sequence of operation for the ice machine

models in ice-making mode with an additional table depicting the status when the ice bin is full and

the cleaning mode. The charts provide information about the inputs to the controller and the

corresponding AC outputs associated with each part of the ice making cycle.

Note:

• Abnormal operation of the ice machine is covered in the Fault Condition section of the

manual.

Ice Making Sequence

Control Status Status Status Status Status

Bin Level Probe Warm/Not Full Warm/Not Full Warm/Not Full Warm/Not Full Warm/Not Full

Ice-Clean Switch Ice Ice Ice Ice Ice

Harvest Switch “Run” “Run” “Run” “Run” “Run”

Evaporator

Temperature Probe

Plate-Up/Down

Switches

Ice None Forming Fully Formed Fully Formed None

Compressor

(Condenser Fan)

Water Plate Closed Closed Opening Open Closing

Water Pump On On/Pause/On Off Off On

Defrost Valve

Water Valve

Actuator Motor Off Off

Dump Valve Off Off

N/A Cold Cold Warming Warm

Plate Up Plate Up Plate Lowering Plate Down Plate Rising

On On On On On

Closed/

De-energized

Open/

Energized

Fill

Freeze

Closed/

De-energized

Closed/

De-energized

Lower

Open/

Energized

Closed/

De-energized

On/CCW

Rotation

Open/

Energized

Harvest

Open/

Energized

Closed/

De-energized

Off

Open/

Energized

Raise

Closed/

De-energized

Open/

Energized

On/CW

Rotation

Closed/

De-energized

SC200 Installation & Operation Manual

9

3-16

Page 13

Sequence of Operation

Description of Each Process

The following sequence begins with the cuber as shipped from the factory with the water plate(s)

closed and ready to begin a normal ice making cycle.

Fill: The water solenoid valve will be energized until the water level switch indicates that the sump

is full. The water pump will run as the water is filling the sump. If the water plate is open, it will

close before the pump starts. The water solenoid valve will remain de-energized until the

following cycle starts. No additional water will be introduced during the freeze cycle.

Freeze: The freeze cycle begins as the sump is filling with water. The water level in the sump will

drop as the ice cubes are formed.

Lower: When the evaporator outlet reaches the set temperature point the machine will go into

harvest. The water plate begins to open and the defrost valve is energized to allow hot gas to

circulate through the evaporator. The evaporator warms to begin the ice harvest. The dump valve

is also open at this time, to drain the remaining mineral laden water from the sump. When fully

open, the water plate will stop.

Harvest: The evaporator continues to warm until the ice falls out onto the water plate and into the

ice bin. When the evaporator reaches a pre-set temperature, indicating that all the ice has

dropped out, the defrost valve is de-energized and the water plate begins to close.

Raise: The water solenoid valve will be energized, as the water plate closes, to begin filling the

sump for the next ice-making cycle. When fully closed, the water plate will stop and the water

pump will be energized. The evaporator cools and begins to remove heat from the water to make

the next batch of ice.

Ice Bin Full: When the level of ice reaches the bin probe, the ice maker stops automatically, and

it remains off until the bin probe warms up when the ice level is lowered.

Cleaning Mode: All of the operational components except refrigeration are able to function with

the make ice/clean switch in the clean position. Simply placing this switch in the cleaning position

does not complete the cleaning and sanitizing of the cuber. Instructions pertaining to the cleaning

of a machine can be found on page 12 of this manual.

Note: The frequency of the need for cleaning is determined by the supply water characteristics.

The cuber should be cleaned no less frequently than once each 6 months, and it may require

more frequent cleaning. The requirement for sanitizing frequency may be contained in local health

code regulations.

SC200 Installation & Operation Manual

3-16

10

Page 14

Water Plate Closure Problems: If the water plate is not able to close due to ice remaining on the

water plate surface, the plate will reopen until it is clear.

Shutdown-High Pressure: All models are provided with a high pressure cutoff, which interrupts

power to the compressor and to the condenser fan motor, if so equipped, when the high-side

pressure rises to the cutoff setting. The high pressure cutoff will automatically reset, restoring

power when the pressure drops. When this happens it is important to determine the cause of the

high pressure and correct it.

SC200 Installation & Operation Manual

11

3-16

Page 15

Maintenance and Service Information

Ice Machine Cleaning Procedure

It is recommended to perform this cleaning procedure a minimum of twice per year.

1. While the ice machine is operating, wait until the ice falls out of the evaporator and the

water plate fully returns to the up position. Turn the machine off and empty the storage bin.

Move the Ice-Clean Switch to the “Clean” position and turn the ice machine on.

2. While the water plate is filling pour 3 fl. oz. (90 mL) of Kold-Draft nickel-safe ice machine

cleaner (Kold-Draft part no. 500023) into the water sump though the opening along its front

edge.

3. The cleaning solution will circulate for 20 minutes and then drain. The sump will fill again,

with the water circulating and then drain. This will repeat 3 more times, to be sure all the

cleaning solution is rinsed out of the machine and then stop. When this process is

complete, turn the machine off.

4. Mix a sanitizing solution containing 0.5 ounce (15 mL) 5-1/4% sodium hypochlorite

(household bleach or equivalent) and 1 gallon (3.8 liter) warm clean water.

5. Pour the sanitizing solution into the sump. Leaving the Ice-Clean Switch in the “Clean”

position turn the machine on.

6. The sanitizing solution will circulate for 20 minutes and then drain. The sump will fill again,

with the water circulating and then drain. This will repeat 2 more times, to be sure all the

sanitizing solution is rinsed out of the machine and then stop.

7. While these solutions are circulating in the ice machine, clean and sanitize all accessible

surfaces of the ice machine and bin. Mix a cleaning solution as follows: 8 tablespoons (1/2

cup) (96g) baking soda and 1 gallon (3.8 liter) of warm clean water. Mix a sanitizing

solution as follows: 2 teaspoon (10 mL) 5-1/4% sodium hypochlorite and 1 gallon (3.8 liter)

of warm clean water. Use clean towels to apply these solutions and rinse well when done.

8. After all cleaning, sanitizing and rinsing has been completed turn the machine off. Move

the Ice-Clean Switch to the “Ice” position. Check for proper operation of the machine and

dispose of the first batch of ice

SC200 Installation & Operation Manual

12

3-16

Page 16

Cleaning Mode Start Up

At power up in the wash mode the electronic control will monitor the following criteria:

If the water plate is not in the full up (closed) position at start up, the controller will close the plate.

If there is ice on the surface of the water plate, preventing it from closing, the controller will reopen

the plate to clear it.

Storage and Winterization

Clean and sanitize the ice machine.

Disconnect the electric power supply.

Disconnect water and drain lines.

Remove and empty the water sump.

Open water valve and dump valve and blow compressed air through all lines.

Remove and drain the water plate assembly.

Reassemble water plate assembly and water sump.

Replace all cabinet panels.

Removal from Service

When the ice maker is determined to be no longer useable please be sure that it is rendered safe

for storage or disposal. All applicable recycling measures should be exercised to avoid injury and

harm to the environment.

The manufacturer and/or seller is not responsible for any harm to people, animals, property, and

the environment caused by incorrect installation and/or disposal.

SC200 Installation & Operation Manual

13

3-16

Page 17

Wiring Diagram

SC200 Installation & Operation Manual

14

3-16

Page 18

Problems and Solutions

Ice machine off as if bin is full. Ambient temp

PROBLEM POSSIBLE CAUSE SOLUTION

On-Off switch in "Off" position Move switch to "On" position.

No power at ice machine. Circuit protector

open.

Reset breaker. Check circuit for overload

condition.

Ice machine is not operating.

Condenser fan motor is not

operating on air-cooled

models. Compressor is

operating

Ice machine off because bin is full of ice. Use ice or move ice away from bin probe.

Ice machine off because bin probe is

defective.

below 50°F (10°C).

Ice-Clean switch in "Clean" position. Move switch to "Ice" position.

High pressure cut-out open on air cooled

models. Condenser dirty.

High pressure cut-out open on air cooled

models. Air circulation through condenser is

insufficient or hot air is recirculating through

the condenser.

High pressure cut-out open. Refrigeration

system is overcharged.

Compressor thermal protector is open

because of low voltage condition.

Replace bin probe.

Ambient temperature must be 60°F (15°C)

minimum.

Clean condenser. Confirm proper

operating pressures.

Provide adequate spacing between the

ice machine and walls, ceilings or other

equipment. See installation instructions

for spacing requirements. Confirm proper

pressures.

Remove refrigerant and recharge the

system to specifications.

Allow thermal protector to reset. Measure

voltage at relay while compressor is

running. Correct power supply problem if

voltage is lower than specified on the ice

machine electrical plate.

Condenser fan motor is not

operating on air-cooled

models. Compressor is

operating

Water plate re-opens

immediately after closing

Compressor thermal protector is open

because of defective run capacitor.

Relay is defective.

Compressor start capacitor or relay defective Test and replace these parts if defective.

Compressor is defective. Replace compressor.

Fan motor protector open.

Fan motor defective Replace motor.

"Plate up" switch lever is not being pushed

up completely.

Water plate is prevented from closing by

some obstruction such as ice remaining on

the water plate surface.

Replace run capacitor.

Check for voltage at terminals. Replace

relay if it does not close when the coil is

energized.

Replace motor if it does not run when cool

or at normal operating conditions.

Adjust "Plate up" switch actuator near

water plate until it releases the switch

lever completely.

Eliminate obstruction. Adjust the

evaporator temperature probe so all ice is

out of the evaporator before the water

plate begins to close.

SC200 Installation & Operation Manual

3-16

15

Page 19

PROBLEM POSSIBLE CAUSE SOLUTION

water are supplied by the same water line.

water valve strainer and clean it if needed.

valve diaphragm are open. Replace water

Check controller for output to water valve.

Defrost cycle ends before all

Water plate will not close

after defrost.

Problems and Solutions

Actuator motor output shaft is turning but

front cam is not turning.

Actuator motor will not run. No voltage

measured at actuator motor.

Connection between actuator motor shaft

and right side operator broken. Check set

screw, tighten or replace.

Inspect operation of plate up and plate

down switches. Adjust or replace if

defective.

ice is out of the evaporator

Ice remains attached to the

water plate surface at the

end of defrost.

Water valve will not close.

Potable water level

continues to rise after the

float is fully up.

Evaporator grids are distorted, slowing the

fall of the ice from the evaporator.

Excessive scale build-up in evaporator cells Clean and de-scale ice machine

Ice frozen into the water plate surface.

Thick web between ice cubes.

Over-freezing

Cold potable water supply.

No voltage measured at water valve coil.

Water valve remains open because of water

supply problem.

No voltage measured at water valve coil.

Water valve remains open because of dirty

or defective water valve.

Carefully straighten grids or replace

evaporator if the damage is severe.

Adjust web thickness to specifications.

Increase the temperature set point that

initiates harvest.

Make sure water supply temperature is

within the acceptable range.

The water supply pressure must be a

minimum of 5 PSI (34 kPa) dynamic at the

water valve. Be sure that the supply line

is of adequate size. This is especially

important for liquid cooled models where

the potable water and condenser coolant

Check for restrictions in the water supply

line including clogged filters. Check the

Disassemble and clean water valve if

needed. Make sure the bleed holes in the

valve if defective.

Line voltage measured at water valve coil.

Water level float switch OK, but line voltage

measured at water valve coil.

SC200 Installation & Operation Manual

Test for proper water float switch

operation. Reed switch could be

defective.

Controller could be defective

3-16

16

Page 20

PROBLEM POSSIBLE CAUSE SOLUTION

Water valve will not open.

Potable water level never

reaches the high water level

during the fill cycle.

Problems and Solutions

No voltage measured at water valve coil at

fill cycle.

Float switch OK but no voltage measured at

water valve coil at fill cycle.

Float switch defective.

Check for line voltage at controller output

to water valve. Controller could be

defective.

Actuator motor turns wrong

way at start or end of

defrost. When viewed from

left side, CW to open and

CCW to close.

Relationship between water plate up or

down swiitch and its operator is incorrect.

Water plate up or down switch defective. Replace switch

Adjust operators as required for proper

operation

SC200 Installation & Operation Manual

17

3-16

Loading...

Loading...