Page 1

Marine Cuber Installation

KOLD-DRA FT

CLASSIC

KOLD-DRAFT

Ice Machine Products

®

and Operation Instructions

MGT550

1525 East Lake Road, Erie, PA 16511-1031

814/453-6761

FAX 814/455-6336

©2004 KDIndustries, Inc., Erie, PA U.S.A.

Printed in U.S.A. 3/04

508 1064 01, Rev. 10/02

A Tradition of E xcellence In Ice Equipment.

Page 2

INSTALLATION AND OPERATION INSTRUCTIONS

FOR

KOLD-DRAFT

MAR

INE

CLASSIC

MGT550

SERIES ICE

CUBERS

®

®

CHECK FOR FREIGHT DAMAGE BEFORE PROCEEDING: Even though damage to

the carton may not have been evident, check for hidden damage and contact freight

carrier immediately if necessary to file a claim.

THIS EQUIPMENT MUST BE INSTALLED IN COMPLIANCE WITH THE

APPLICABLE FEDERAL, STATE/PROVINCE, AND/OR LOCAL PLUMBING,

ELECTRICAL, AND HEALTH/SANITATION CODES AND REQUIREMENTS.

CAUTION:

{

RISK OF PERSONAL INJURY, PROPERTY DAMAGE, EQUIPMENT

FAILURE, OR FIRE.

{

Refer all maintenance to qualified personnel .

{

Never operate this equipment with covers, panels, or other parts removed

or not properly secured.

{

Warn all users to clean up spillage immediately, keep storage bin doors closed,

and report any apparent leakage or unusual sounds to responsible

maintenance personnel.

INSTALLATION

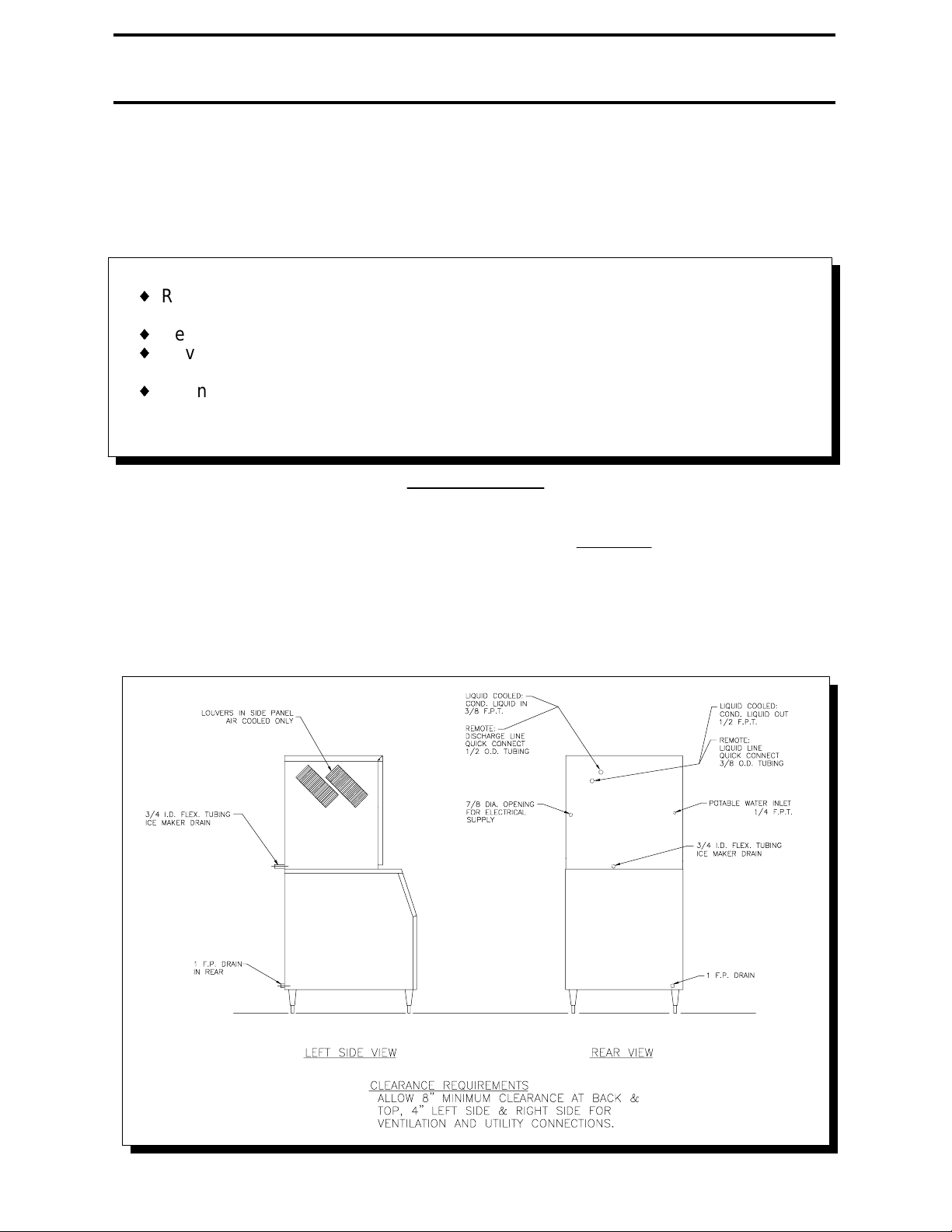

1. Position the ice storage bin so that the following minimum clearances will be

available around the i ce maker for ventilati on and utility connections:

REAR and TOP: 8 inches

RIGHT SIDE: 4 inches

LEFT SIDE : 4 inches

508106401 Rev: 10-02

- 2 -

Page 3

2. Level the bin with adjusters on legs, or by shimming i f the bin is to be sealed to

F

ollow the bin installation instructions for securing the

cuber

to the bin

.

the floor. If gaps due to shi ms are greater than 1/8 inch, instal l a cove molding

around the bin bottom. Seal the bin or molding to the floor with NSF Certified

RTV sealant (Dow-Corning RTV 732 or equal).

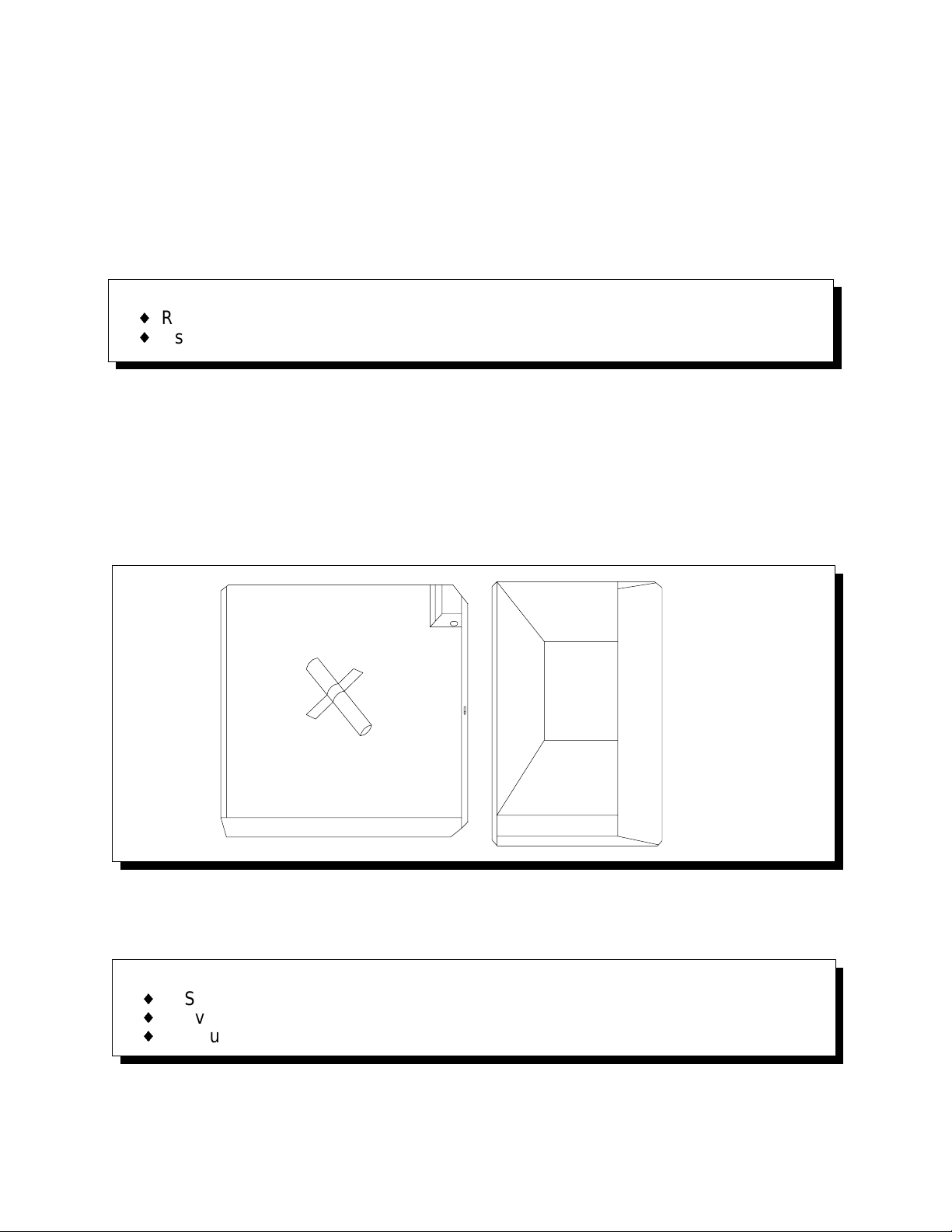

3. Remove the cuber cabinet TOP panel as follows:

Lift the front and push backward until the rear clip is disengaged from the

chassis. (Approx. 1")

CAUTION:

{

RISK OF PERSONAL INJURY OR EQUIPMENT DAMAGE.

{

Use a suitable lifting means and be careful of sharp edges.

4. Remove the remaini ng cuber cabinet panels as follows:

FRONT: Remove the (4) screws at the bottom and front-sides, pull forward.

SIDES : Pull forward and lift to disengage the clips from the chassis.

NOTE: When re-installing the panels, be sure that the screws engage the TOP

panel.

5. Remove the ice chute & drain pan. Drain tube shown below is packed with the

drain pan.

6. Install gasketing on top of bin if required. Gasket material must be posi tioned

so that it extends to the outside edge of the perimeter of the cuber chassis when

the cuber is in place.

WARNING:

{

RISK OF CONTAMINATION OF ICE IN THE BIN.

{

Provide separate, unconnected, drains for the ice maker and the bin.

{

Consult local codes for sui table connections to the building drains.

7. CAREFULLY place the cuber onto the gasketed bin, noti ng the ali gnment of the

mounting holes in the chassis if mounting means are provided on the bin.

508106401 Rev: 10-02

- 3 -

Page 4

8. Install the drain pan. Route the drain tube assembly through the rear of the

cuber, and clamp the tubing to the drain pan nipple.

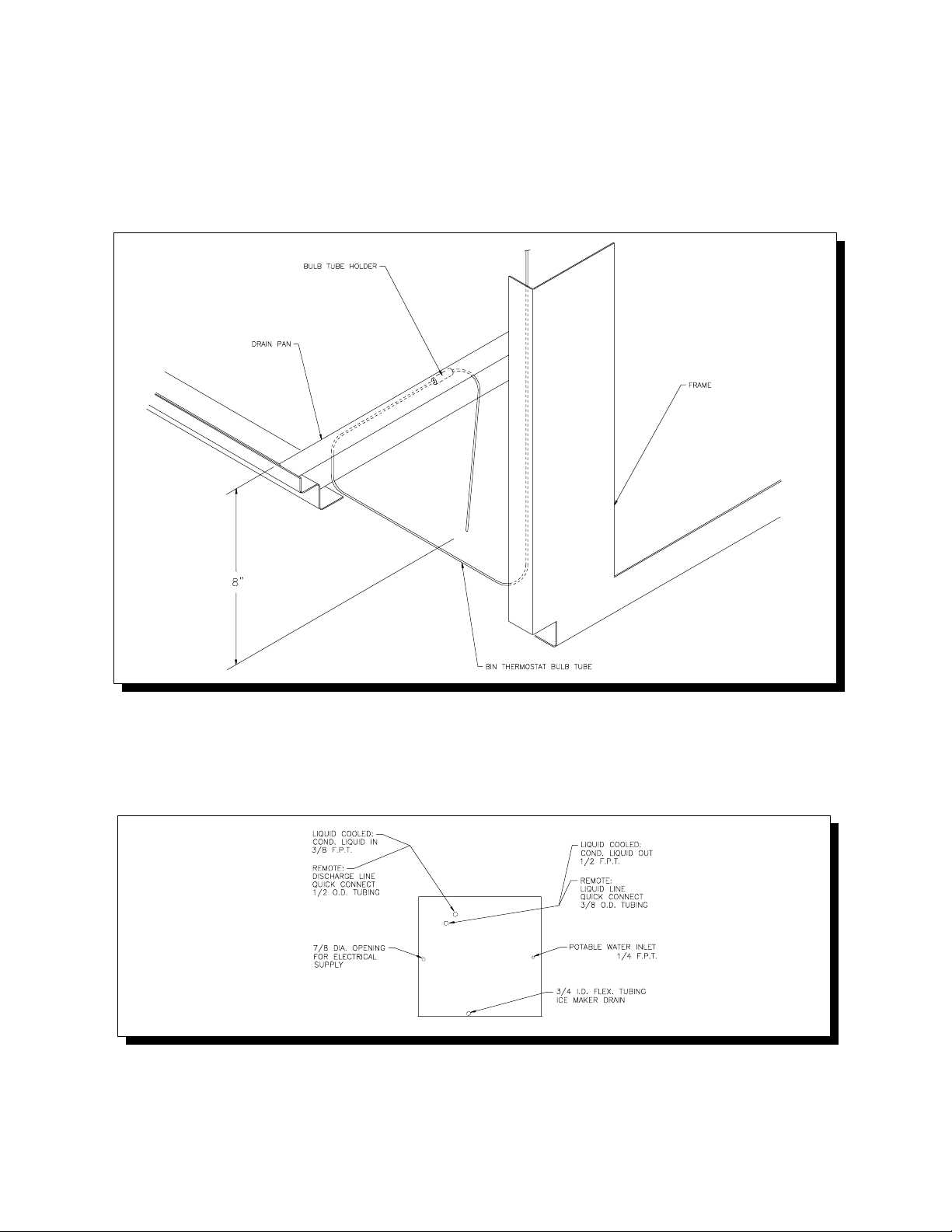

9. Route the bin thermostat capillary tube down the right front corner of the frame,

along the front rail, under the right side drain pan flange, through the bulb tube

holder and down into the bin. See the diagram below.

10. Install the Ice Chute carefully to avoid damage to the bin thermostat cap tube.

11. Electrical, water and drain locations are shown on the following drawing: All

dimensions are in inches.

12. Remove the water plate shipping strap and purge the potable water supply line.

13. If start-up will not occur immediately, secure all cuber cabinet panel s now.

508106401 Rev: 10-02

- 4 -

Page 5

INSTALLATION SPECIFICATIONS

ICE MAKER

FUSE / HACR

MODEL

ELECTRICAL

SUPPLY

MINIMUM

CIRCUIT

AMPACITY

BREAKER SIZE

(AMPS)

NORMAL MAXIMUM

WATER

INLET SIZE

(FPT)

DRAIN SIZE

(ID)

CONDENSER

COOLANT (FPT)

SUPPLY DISCHARGE

3/8 1/23/41/4 20 3017.9115/60/1MGT551W

3/8 1/23/41/4 15 20 14.3208-230/60/1MGT554W

READ THE FOLLOWING NOTES CAREFULLY PRIOR TO MAKING CONNECTIONS

CAUTION:

{

RISK OF PROPERTY DAMAGE, EQUIPMENT FAILURE, OR FIRE.

{

Failure to comply with all install ation specificati ons and instructions may cause

erratic operation and the risk of damage or fire.

Voltage tolerances: Nominal No-load MAXIMUM Full-load MINIMUM

115 126 104

208-230 198 252

Ampacity: Minimum ampacity does not indicate typical running current value. Refer to

equipment NAME PLATE data. Use minimum ampacity value for sizi ng branch circuit

conductors up to 25 feet length. For conductor length over 25 feet up to 100 feet,

increase 1 AWG size. Over 100 feet requires 2 or more AWG size increase.

Branch circuit protection: Proper protection must be provided by either fuse(s) or

HACR type circuit breaker(s). Each ice maker must be provided with a separately

protected circuit with no other load(s). A fused disconnect installed adjacent to each

ice maker is recommended (must be supplied by the installer), and may be required by

local codes. NORMAL protector size is based on rated vol tage and operati on at lower

than extreme temperature li mits. When branch circui t conductors are sized to permit,

increasing the protector size (up to the specified maximum) may avoid nuisance

protector opening under harsh operating conditi ons.

Water supply: Minimum 30 psig supply pressure while the ice maker is filling is

required. Maximum supply pressure is 100 psig. The water fill flow rate is 1.0 GPM for

each GT550 machine. Backflow/backsiphonage protection is provided by an internal

air gap (accepted by NSF). If additional protection is required by local codes or

authorities, any device(s) and install ation of the same, including specifi cation and cost,

are the responsibility of the installation specifier.

Ice maker drain: The size of the gravity drain for the ice maker purge and rinse water

must not be reduced. Individual drains from stacked ice makers may be discharged

into a standpipe or manifold with a minimum 1-1/2 inch air gap at each ice maker

connection.

508106401 Rev: 10-02

- 5 -

Page 6

Liquid condenser cool ant pressure drop: Condenser cool ant pressure drop may reach

20 psig during peak load with 85°F. cool ant temperature at recommended refrigerant

high-side pressure. The condenser coolant (water) regulating valve may require

adjustment due to variations in the coolant supply characteristics to provide opti mum

efficiency.

CAUTION:

{ RISK OF PROPERTY DAMAGE, EQUIPMENT FAILURE, OR FIRE.

{ Failure to comply with all installation speci fi cations and instructi ons may cause

erratic operation and the risk of damage or fire.

All models are intended FOR INDOOR USE ONLY with PERMANENT CONNECTION

TO THE F IELD ELECTRICAL SUPPLY.

Other operating condition requirements:

Ice maker ambient air temperature: MINIMUM 45°F.; MAXIMUM 90°F.

Potable water and condenser liquid supply:

Temperature: MINIMUM 45°F.; MAXIMUM 90°F.

Pressure: MINIMUM 30 psig; MAXIMUM 100 psig*

*If regulator is used, recommended setti ng is 30 to 50 psig.

508106401 Rev: 10-02

- 6 -

Page 7

MODEL NUMBER

PARAMETER

GT55X

C/HKK

2 3/4"3 5/8"Water fill level (Top of tank to level in control tube)

Approximate cycle time, min.

Approxi mate harvest weight, lb.

31/2415.5

7.7/7.14

20Refri gerant Charge, Oz . (R-404a) Liq.

START-UP INSTRUCTIONS

WATER LEVELS, CYCLE TIMES, AND REFRIGERANT CHARGES

* Values are for Air-cooled model at 90°F. air/70°F. water temperatures with cuber

adjusted to produce fully-formed ice. Greater capacity can be obtained by reducing the

water fill level (lowering the high-level probe) to produce ice with larger dimples. A

slight adjustment of the probe will result in a noticeable effect on dimple size. The

control stream will not rise over the dam with lower water fill levels than indicated

above.

CAUTION: REFRIGERANT CHARGES MUST BE ACCURATELY WEIGHED.

Consult the specification and troubleshooting guide if variations from the following

description of operation are noti ced:

1. Remove the top and front cabinet panels.

2. Be sure that the "ICE-OFF-WASH" switch is in the center (OFF) position.

3. Install and connect refrigerant lines and condenser on "R" models.

4. Turn on supply water and power. Be sure that condenser liquid ("W " models)

and condenser ("R" models) are ready for use before turning power on. Check

for leaks in water/liquid supply connections. NOTE, "R" MODELS ONLY: The

compressor will start immediately when power is applied, regardless of the

"ICE-OFF-WASH" switch position, if the low-side pressure is at or above the

pump-down controller cut-in setting. Be sure that the compressor stops when

the low-side pressure is between 5 and 10 psig.

508106401 Rev: 10-02

- 7 -

Page 8

5. Be sure that pump hoses are connected, then put about one pi nt of clean tap

water into the circulation system to lubricate the pump seal.

6. Move the "ICE-OFF-WASH" switch to the right "WASH" position and observe

the water fill cycle and the pump running. If all water distributor holes do not

produce full streams and the appearance of air i s evident i n the tube, pi nch the

plastic tube connected to the water solenoid valve outlet while water is running

until the streams are full all the way across the distributor tube. Water fill is

complete when the water in the liquid level control tube reaches the high-level

probe. At this time observe that the water shuts off and that there are no water

leaks (dripping i nto the drain pan).

7. Pull the right end of the water plate down, stretching the springs until the pump

stops, and hold until the pump does not re-start when released. The water plate

will open fully to dump the batch of water previously taken in, then close

immedi ately. The water pl ate should stop when it is fully closed, and the water

fill cycle will repeat.

8. After the water fill is complete move the "ICE-OFF-WASH" switch to the left

"ICE" position and observe that the compressor (and fan in "A" models) starts,

and the water pump continues to run. The refrigeration system operation

should be checked during the fi rst few cycles, and any adjustments should be

made at this time. Consult the "adjustments" section in the service manual.

Initial ice making cycles may exhibit super-cooling of the circulating water so

that ice crystals form in the circul ating water ("slush"), possibly stopping the flow

momentarily. If water goes over the control stream dam when circulation

resumes after two (2) cycles AND with all skin panels installed, consult the

Factory.

9. Test the bin thermostat by holding some ice against the capillary tube. If

necessary, adjust the thermostat so that the ice maker shuts off within 30

seconds after ice contacts the capillary tube.

10. Be sure that the drain pan/ice chute i s in place, and that the electri cal control

box cover is secured, then replace the cabinet panels (skins). Start with the

SIDE panels, then the FRONT panel, secure the FRONT panel with (2) screws

along the bottom edge, replace the TOP panel and fi nall y secure all the panels

with (2) screws in the TOP-SIDES of the machine.

11. Discard ice from start-up cycles, then clean and sanitize the bin following the

instructions provided with the bin.

12. Complete and mail the Registration Certificate and leave this manual with the

owner/user. Emphasize the "CAUTION: RISK OF PERSONAL INJURY..."

NOTICE ON THE FRONT PAGE, and the importance of the PREVENTATIVE

MAINTENANCE recommendations below.

508106401 Rev: 10-02

- 8 -

Page 9

PREVENTATIVE MAINTENANCE

CLEANING: Usually at 3 to 6 month intervals, depending on water conditions.

INSPECTIONS: During cleaning - at least twice a year.

SERVICE: All such equi pment will require service at some time. Service requirements

will be minimized with faithful preventative maintenance incl uding good housekeeping

at the installation site. A CALL FOR SERVICE AS SOON AS A POSSIBLE

PROBLEM IS NOTICED MAY AVOID EXTENSIVE REPAIRS.

CAUTION:

{

RISK OF PERSONAL INJURY OR PROPERTY DAMAGE.

{

Do not use ammonia solutions in cleaning any part of the ice maker.

{

Do not mix ice machine cleaner and sanitizer together.

{

Use rubber gloves, eye protection, and an apron.

{

Clean up splashes or spillage immediately.

{

Follow these instructions exactly.

Ice Cuber Cleaning Instructions

1. Mix 1 bag of KOLD-DRAFT ice machine cleaner (55R-01000) in two (2) quarts

of clean, warm water (180°F. MAX.) for each evaporator/water plate assembl y

to be cleaned.

2. If the cuber is operating, wait until a harvest cycle occurs then trip the

"ICE-OFF-WASH" switch to "WASH" as soon as the water plate begins to close.

3. Empty all ice from the storage bin and shut off other i ce makers on the same

bin.

4. After the water fill is completed, switch the "ICE-OFF-WASH" to "OFF". While

pinching water level control hose, carefully remove the water level control tube

from the cap. HOLD T HE TUBE HIGH ENOUGH SO THAT THE TUBE DOES

NOT OVERFLOW. Release the hose and pour about hal f of the mixed cleaner

into the tube. Replace the tube on the cap, while pinching water level control

hose, then pour the remaining cleaner into the control stream box.

5. Switch the "ICE-OFF-WASH" to "WASH" and allow the cleaner to circulate for

approximately 15 minutes, then pull the right side of the water plate down until

the pump stops and hold it until the pump will not re-start when released.

6. The water plate will open and dump the cleaner then close immediately, and the

water system will refill. Repeat this dumping and refilling three (3) times to rinse

out all of the cleaning solution.

7. Mix a sanitizing soluti on of two (2) oz. 5-1/4% sodium hypochlorite (household

bleach, or equivalent) and one (1) quart of cl ean water.

8. As in step #4, pour about half of the sanitizing solution into the water level

control tube and the remaining sanitizer into the control stream box.

9. Allow the sanitizing solution to circulate AT LEAST 15 MINUTES, then dump

and rinse two (2) times as described above. If necessary, reset the water level

probes to the proper levels.

508106401 Rev: 10-02

- 9 -

Page 10

10.While the cleaning and sanitizing solutions are circulating, clean, rinse, and

sanitize all accessible parts of the ice-making compartment of the cuber with

clean cloths. Use a cleaning solution of 8 tablespoons (1/2 cup) baking soda

per gallon of warm water, and a sanitizing soluti on of no less than 1 teaspoonful

(5 ml) 5-1/4% sodium hypochl orite per quart of clean water.

11. After cleaning has been completed, trip the "ICE-OFF-WASH" switch to "ICE"

and check to be sure that the cuber is operati ng properly, parti cularly the water

level probes. Then re-assemble and secure all cabinet enclosure panels.

ICE BIN CLEANING INSTRUCTIONS

The bin should be cleaned periodicall y. If bin drain has any horizontal run, remove ice

from left side of bin and fl ush with two quarts of hot water monthl y. (Long drain li nes

should be flushed weekly.)

1. Clean exterior of bin frequently.

2. To clean the interior, follow instructions provided with bin.

3. Empty the storage area and disconnect the electrical power supply to the ice

maker(s).

4. Remove the ice maker inspection panel, top, left and right end panels, and

drain pan. Sliding bin doors may be removed by lifting them up, then pulling out

from the bottom.

5. When cleaning the ice maker, follow the ice maker cleaning instructions and

clean the bin last.

6. Replace all enclosure panels before re-connecting the electri cal supply.

WINTER CONDITIONING

Ice cubers that are idle in the winter months require preparation to prevent damage

from freezing. The following procedure shoul d i nsure the safety of the machi ne so that

it can be started easily the following year.

1. Shut off and detach the water supply to the Ice Cuber.

2. If the cuber contains a water-cooled condenser, the cuber must be running

while air is introduced through the condenser water inlet connection to blow

water out of the condenser coils.

3. The machine should then be run into defrost to drai n the water tank and the air

blown into the water inlet to blow out the water solenoid.

508106401 Rev: 10-02

- 10 -

Page 11

508106401 Rev: 10-02

- 11 -

Loading...

Loading...