Page 1

R

Technical Service and

Replacement Parts Manual

Ice Equipment for 50 Hz. Applications

Models GB457, GB657, GB1257,

GB1258, GT357, and GT557

KDIndustries, Inc.

Erie. PA 16511-1088 U.S.A.

814-453-6761

FAX: 814-455-6336

www.kold-draft.com

LIT 09506 ENG 1-07

1525 East Lake Road

Page 2

THIS PAGE IS INTENTIONALLY BLANK

KOLD-DRAFT®

-

1-07

Page 3

SAFETY WARNINGS AND INFORMATION

KNOWLEDGE OF PROPER INSTALLATION AND SERVICE PROCEDURES IS

ESSENTIAL TO THE SAFE OPERATION AND MAINTENANCE OF KOLD-DRAFT

EQUIPMENT. REFER ALL INSTALLATION AND SERVICE WORK TO QUALIFIED

TECHNICIANS.

ALWAYS DISCONNECT THE POWER SUPPLY BEFORE SERVICING THE EQUIPMENT

OR WHEN THE EQUIPMENT WILL NOT BE USED FOR A PERIOD OF TIME. SOME

CIRCUITS REMAIN ENERGIZED WHEN THE ICE MACHINE IS SWITCHED OFF.

NEVER OPERATE EQUIPMENT THAT HAS BEEN DAMAGED OR DOES NOT HAVE ALL

THE PROTECTIVE COVERS IN PLACE.

NEVER OPERATE EQUIPMENT THAT HAS BEEN ALTERED FROM THE ORIGINAL

KOLD-DRAFT SPECIFICATIONS.

SPECIAL ATTENTION SHOULD BE GIVEN TO POTENTIAL HAZARD LABELING ON

THE EQUIPMENT AND THE SIGNAL WORDS AND SYMBOLS THAT ARE USED

THROUGHOUT THIS MANUAL.

WARNING- Warning is used to indicate the presence of a hazard which can

cause personal injury, death or substantial property or equipment damage, if the

statement is ignored.

CAUTION- Caution is used to indicate the presence of a hazard which can

cause minor personal injury or property damage, if the statement is ignored.

ELECTRICAL CAUTION- Used to indicate the presence of an electrical hazard

which can cause personal injury or property damage, if the statement is

ignored.

NOTE-

which is important, but not a cause of personal injury or property damage.

Note is used to notify personnel of installation, operation or maintenance information

KOLD-DRAFT®

-

1-07

Page 4

Table of Contents

Section 1 General Information

Equipment Identification

Serial Number Plate Location . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Model Number Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Date Code Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Section 2 Installation Information

Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Assembly and Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Section 3 Operational Information

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Controls and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Wiring Diagrams

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

GB457A/W and GB657A/W . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

GB1257A/W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

GB1258A/W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

GT357A/W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

GT557A/W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Operational Parameters

Water Fill Levels, Cycle Times and Harvest Weights . . . . . . . . . . . . 3-29

Cube Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Typical Refrigerant Operating Pressures . . . . . . . . . . . . . . . . . . . 3-29

Refrigerant Charge Information . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

KOLD-DRAFT®

-

1-07

Page 5

Table of Contents

Section 4 Service Information

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Test Procedures

Actuator Motor Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Liquid Level Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Compressor Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Illustrations

Actuator Motor, Switch and Water Plate Spring Relationship . . . . . . . . . 4-15

Water Plate Alignment . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Web Thickness Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Section 5 Parts

Ice Making Section All GB and GT550 . . . . . . . . . . . . . . . . . . . . 5-2

Water Level Control All GB and GT550 . . . . . . . . . . . . . . . . . . . . 5-3

Water Level Control GT350 . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Ice Making Section GT350 . . . . . . . . . . . . . . . . . . . . . . . . 5-5

GB4(2,3,4,5)7

Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Control and Electrical Components . . . . . . . . . . . . . . . . . . . . 5-7

Refrigeration Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

GB6(2,3,4,5)7

Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Control and Electrical Components . . . . . . . . . . . . . . . . . . . . 5-10

Refrigeration Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

GB12(2,4,5)8

Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Control and Electrical Components . . . . . . . . . . . . . . . . . . . . 5-13

Refrigeration Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

KOLD-DRAFT®

-

1-07

Page 6

Table of Contents

GT3(3,4,5)7

Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Control and Electrical Components . . . . . . . . . . . . . . . . . . . . 5-16

Refrigeration Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

GT557

Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Control and Electrical Components . . . . . . . . . . . . . . . . . . . . 5-19

Refrigeration Components . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

KOLD-DRAFT®

-

1-07

Page 7

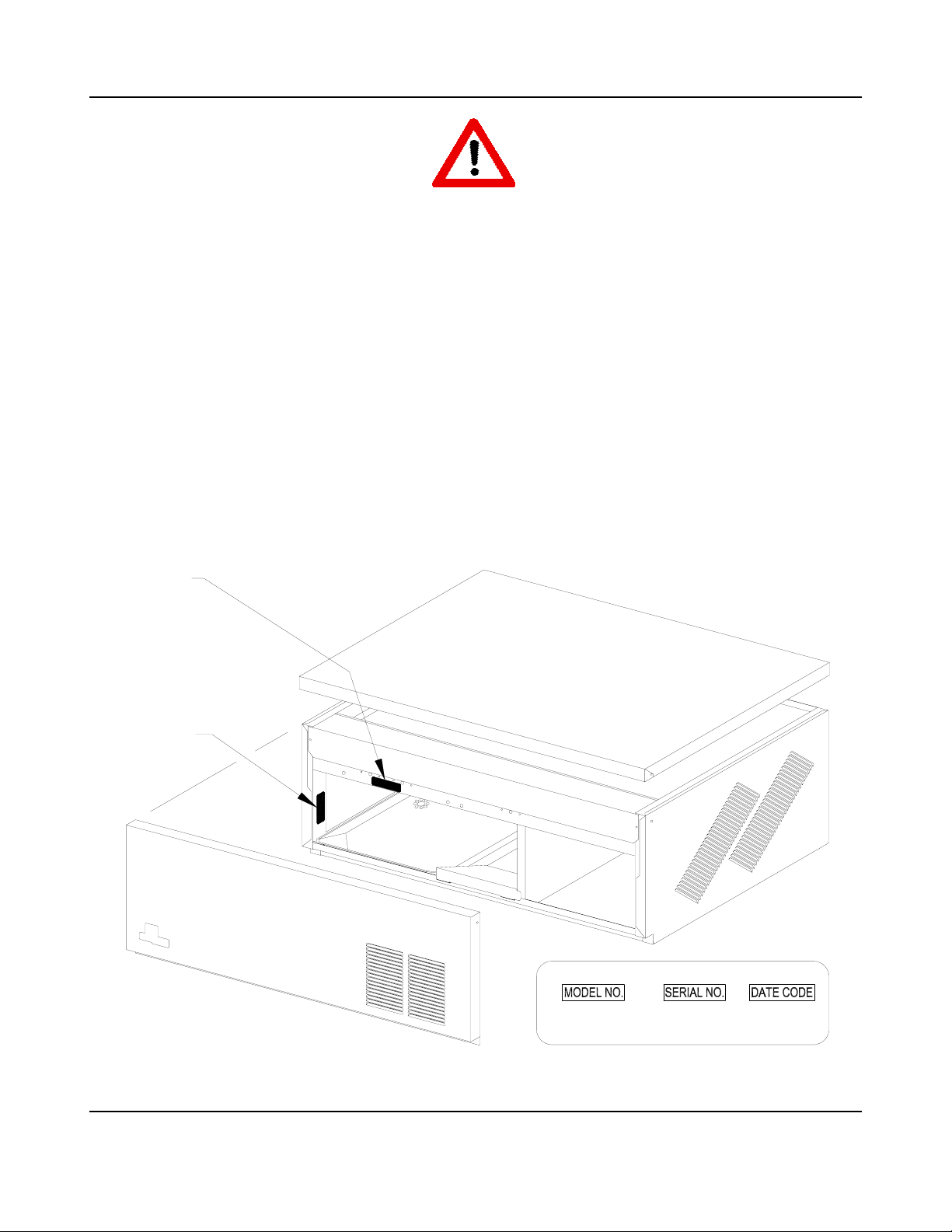

GENERAL INFORMATION EQUIPMENT IDENTIFICATION

WARNING- USE ONLY GENUINE KOLD-DRAFT REPLACEMENT PARTS

USE OF NON-APPROVED PARTS WHEN SERVICING KOLD-DRAFT EQUIPMENT MAY

CREATE A SAFETY HAZARD OR CAUSE EQUIPMENT AND PROPERTY DAMAGE.

USE OF NON-APPROVED PARTS WHEN SERVICING KOLD-DRAFT EQUIPMENT WILL

VOID THE EQUIPMENT WARRANTY.

SERIAL NUMBER PLATE LOCATION

NOTE-

A COMPLETE MODEL NUMBER AND DATE CODE ARE ESSENTIAL FOR THE

ACCURATE SELECTION OF REPLACEMENT PARTS.

SEE THE FOLLOWING FOR THE LOCATION OF THE SERIAL NUMBER PLATE.

>1/05

<1/05

KDINDUSTRIES, INC. ERIE, PA. U.S.A.

GB654WK 000000 5EU

208-230V/60HZ/1PH 22oz. R-404a

KOLD-DRAFT®

1-1

1-07

Page 8

GENERAL INFORMATION EQUIPMENT IDENTIFICATION

Classic Model Number Key

GB 4 5 1 W HK

Cube Size

C = Full Cube

HK = Half Cube

K = Cube-Let

Condenser Type

A = Air cooled condenser-self contained

W = Water cooled condenser-self contained

R = Remote air cooled condenser

Electrical Characteristics

1 = 115 volt-60 hz.-1ph. (2-wire plus ground)

4 = 208/230 volt-60 hz.-1ph. (2-wire plus ground)

5 = 208/230 volt-60 hz.-3ph. (3-wire plus ground)

7 = 220/240 volt-50 hz.-1ph. (2-wire plus ground)

8 = 220V/380V-50 hz.-3ph. (4-wire plus ground)

Modification Code

2 = R-502, Copeland compressor except GB1224/25 Bristol

3 = R-502, Bristol compressor

4 = R-404-a, Bristol inertia compressor/POE lubricant except

GT341/GT344 Bristol reed valve compressor/POE lubricant

5 = R-404a, Tecumseh compressor/POE lubricant

Series

3 = 300 Series

4 = 400 Series

5 = 500 Series

6 = 600 Series

12 = 1200 Series

Cabinet Width

GB = 42” Wide

GT = 28-1/2” Wide GT3XX models, 30” Wide GT55X models

KOLD-DRAFT®

1-2

1-07

Page 9

GENERAL INFORMATION EQUIPMENT IDENTIFICATION

DATE CODE KEY

YEAR KEY

4K = 1990 5K = 2000 6K = 2010 7K = 2020

4A = 1991 5A = 2001 6A = 2011 7A = 2021

4B = 1992 5B = 2002 6B = 2012 7B = 2022

4C = 1993 5C = 2003 6C = 2013 7C = 2023

4D = 1994 5D = 2004 6D = 2014 7D = 2024

4E = 1995 5E = 2005 6E = 2015 7E = 2025

4F = 1996 5F = 2006 6F = 2016 7F = 2026

4G = 1997 5G = 2007 6G = 2017 7G = 2027

4H = 1998 5H = 2008 6H = 2018 7H = 2028

4J = 1999 5J = 2009 6J = 2019 7J = 2029

MONTH KEY

M = JANUARY R = APRIL U = JULY X = OCTOBER

N = FEBRUARY S = MAY V = AUGUST Y = NOVEMBER

P = MARCH T = JUNE W = SEPTEMBER Z = DECEMBER

EXAMPLE

4CN = FEBRUARY, 1993 5ET = JUNE, 2005

KOLD-DRAFT®

1-3

1-07

Page 10

THIS PAGE INTENTIONALLY BLANK

KOLD-DRAFT®

1-4

1-07

Page 11

INSTALLATION INFORMATION GENERAL

NOTE!

CHECK FOR FREIGHT DAMAGE BEFORE PROCEEDING WITH THE

EQUIPMENT INSTALLATION. BE SURE TO INSPECT THE EQUIPMENT

CARFULLY FOR ANY DAMAGE THAT MAY NOT HAVE BEEN EVIDENT ON

THE OUTSIDE OF THE CARTON. CONTACT THE FREIGHT CARRIER

IMMEDIATELY TO REPORT ANY DAMAGE AND FILE A CLAIM.

WARNING

DO NOT OPERATE EQUIPMENT THAT HAS BEEN DAMAGED.

REFER ALL MAINTENANCE TO QUALIFIED PERSONNEL.

NEVER OPERATE THE ICE MAKER WITH ANY COVERS, PANELS OR

OTHER PARTS REMOVED OR NOT PROPERLY SECURED.

INSTRUCT ALL PERSONNEL IN THE PROPER USE OF THE EQUIPMENT.

CLEAN UP ANY SPILLAGE IMMEDIATELY.

CAUTION

FAILURE TO COMPLY WITH ALL KOLD-DRAFT INSTALLATION

GUIDELINES MAY CAUSE PERSONAL INJURY, EQUIPMENT OR

PROPERTY DAMAGE AND MAY VOID THE PRODUCT WARRANTY.

KOLD-DRAFT®

2-1

1-07

Page 12

INSTALLATION INFORMATION PLACEMENT

WARNING

ALWAYS INSTALL THE ICE MAKER ON A STABLE AND LEVEL SURFACE.

ALWAYS ATTACH THE ICE MAKER TO THE ICE STORAGE BIN.

ALL MODELS ARE INTENDED FOR INDOOR USE ONLY. DO NOT

INSTALL THE EQUIPMENT IN UNPROTECTED OUTDOOR AREAS.

DO NOT INSTALL THE EQUIPMENT IN WET AREAS.

DO NOT LOCATE THE EQUIPMENT NEAR ANY HEAT SOURCE, IN DIRECT

SUNLIGHT, IN HIGH AMBIENT AREAS, OR WITHOUT PROPER

CLEARANCE FOR VENTILATION. PLACING EQUIPMENT IN THESE

LOCATIONS WILL RESULT IN REDUCED CAPACITIES, HIGH SYSTEM

PRESSURES AND MAY CAUSE EQUIPMENT FAILURE.

AMBIENT OPERATING TEMPERATURES

Minimum 7°C (45°F) Maximum 32°C (90°F)

Ambient temperatures less than 15°C (60°F) may cause erratic bin thermostat operation.

Ambient temperatures higher than the maximum specification will result in reduced capacities

and high system pressures, in air cooled models.

EQUIPMENT CLEARANCE REQUIREMENTS

Clearance must be provided for ventilation and access for service. Ventilation is especially

important for models with air cooled condensers. Failure to provide adequate clearance may

result in reduced capacities and high system pressures. See the installation instructions,

provided with the ice machine, for proper minimum clearance dimensions for a particular

model.

KOLD-DRAFT®

2-2

1-07

Page 13

INSTALLATION INFORMATION PLUMBING

DRAINS

Separate drains must be provided for each ice maker and ice bin. An additional condenser

drain is required for any liquid cooled ice maker, when the condenser coolant will not be recirculated.

The size of the drain tubing must never be reduced along its length.

Make sure that the building drain system can accommodate all the drain water from the ice

machine operation.

Individual drains must never be directly connected to a common manifold, drain or standpipe.

If individual drains are to be discharged into a common manifold, drain or standpipe, a

minimum 38mm (1.5”) air gap must be provided at each connection. This is to prevent any

backflow of drain water into the ice maker or ice bin.

Drain lines must be installed with a minimum drop of 2.5 cm per meter run (.3 inch drop per

foot run).

Ice machine and bin drains may be insulated to prevent condensation.

COOLING TOWER APPLICATION

The ice machine does not need to be modified for use with a cooling tower provided the

cooling tower is properly designed for the application. Information regarding the amount of

heat rejection, as well as the pressure drop through the condenser and liquid valves is

required to properly design a cooling tower application for an ice machine.

Coolant entering the condenser must not exceed 32.2°C (90°F).

Coolant exiting the condenser must not exceed 43.3°C (110°F).

Allow for a pressure drop of 48 kPa (7 psi) between the liquid coolant inlet and outlet of the

condenser.

The condenser liquid control valve will regulate the flow of coolant through the condenser,

thereby controlling the high side pressure in the ice machine.

KOLD-DRAFT®

2-3

1-07

Page 14

INSTALLATION INFORMATION PLUMBING

POTABLE WATER SUPPLY

There are no specific requirements for water treatment provided that the water is potable, not

laden with sediment and does not exhibit a residual chlorine level greater than 0.2 ppm. The

use of water treatment, however, may increase the intervals between cleaning operations.

Do not connect the ice machine to a hot water supply line. Insulate the water line from

sources of heat or to prevent condensation.

NOTE- Purge all water supply lines before connecting them to the ice machine.

CAUTION

HIGH RESIDUAL CHLORINE (MORE THAN 0.2 PPM) CAN CAUSE CORROSION OF ICE

MAKER COMPONENTS AND EVEN THE 300 SERIES STAINLESS STEEL FRAME AND

SKIN PANELS. HIGH CHLORINE LEVELS MUST BE REDUCED, IN THE ICE MAKER

WATER SUPPLY, TO PROTECT THE EQUIPMENT AND PRESERVE THE PRODUCT

WARRANTY.

Please contact your local water conditioning expert for recommendations, about your specific

water supply, or consult the factory.

A minimum 0.2 Mpa (30 psig) dynamic water supply pressure is required for proper operation

of the ice maker water valve. Please note that on liquid cooled ice machines, where the

same water supply is used for both condenser cooling and the potable water supply, the

demand for condenser coolant may cause the supply pressure to drop. This is most notable

at the time of peak load, at the beginning of the freeze cycle.

Minimum water temperature 7°C (45°F) Maximum water temperature 32°C (90°F)

Water temperatures higher than the recommended maximum will cause reduced capacities.

Minimum water pressure 0.2 MPa (30 psig) Maximum water pressure 0.6 MPa (100 psig)

If a water pressure regulator is used, the recommended setting is 0.2 MPa to 0.3 MPa (30 to

50 psig) dynamic.

KOLD-DRAFT®

2-4

1-07

Page 15

INSTALLATION INFORMATION ELECTRICAL

WARNING

ALL KOLD-DRAFT MODELS ARE INTENDED TO BE INSTALLED WITH A

PERMANENT CONNECTION TO THE FIELD ELECTRICAL SUPPLY. DROP

CORD CONNECTIONS SHOULD NEVER BE USED WITH THIS EQUIPMENT.

ALWAYS BE SURE THE POWER SUPPLY IS THE SAME AS THE ICE

MACHINE SPECIFICATION. SEE THE ICE MACHINE ELECRICAL PLATE.

BRANCH CIRCUIT PROTECTION

PROPER PROTECTION MUST BE PROVIDED BY THE USE OF FUSES OR HACR TYPE

CIRCUIT BREAKERS. EACH ICE MAKER MUST BE CONNECTED TO A SEPARATE

PROTECTED CIRCUIT WITH NO OTHER LOADS. A FUSED DISCONNECT, INSTALLED

ADJACENT TO EACH ICE MAKER, IS RECOMMENDED AND MAY BE REQUIRED BY

LOCAL CODES.

Minimum ampacity does not indicate typical running current value. Refer to the equipment

electrical plate. Use the minimum ampacity value for sizing branch circuit conductors up to 8

meters (26 feet) in length. For conductor length over 8 meters, increase the wire gauge as

required.

Normal protector size is based on rated voltage and operation at lower than extreme

temperature limits. Branch circuit conductors may be sized to allow increasing the protector

value up to the specified maximum. This may avoid nuisance protector opening under harsh

operating conditions.

NOMINAL NO-LOAD MAXIMUM FULL-LOAD MINIMUM

220/240 250 210

380 420 360

VOLTAGE TOLERANCE

KOLD-DRAFT®

2-5

1-07

Page 16

INSTALLATION INFORMATION ASSEMBLY AND START-UP

ASSEMBLY

Remove the ice machine top-cover panel, front-cover panel and side-cover panels from the

ice machine frame.

The ice storage bin surface must be level. Use the ice storage bin leg adjusters, if they are

provided. If the bin will be mounted directly to the floor, use shims as required. Seal the bin

to the floor using a sealant with a National Sanitation Foundation certification. If there are

gaps larger than 3 mm install a cove molding around the bottom of the bin.

If not provided, a hole must be installed in the bin top corresponding to the ice drop zone.

Holes are provided in the ice machine frame for the purpose of attaching the ice machine to

the ice storage bin. Use the fasteners provided or other suitable non-corroding fasteners for

this purpose.

Apply gasket material to the ice storage bin top. The gasket material must be positioned at

the outside edge of the ice machine frame.

Carefully lift the ice machine and position it on the ice storage bin. Attach the ice machine to

the ice storage bin.

Make all plumbing and electrical connections to the ice machine and ice storage bin.

Remove all shipping materials from the ice machine including the water plate shipping strap.

Install the bin thermostat capillary tube, into the ice storage bin, according to the instructions

provided with the ice machine.

NOTE- Place the bin thermostat cap tube below any ice deflectors in the storage bin. If

ice piles up, above these deflectors, it may bridge over and not feed down to the lower

section of the bin.

START-UP

Be sure that the ice-off-wash switch is in the “off” (center) position.

Turn on the water supply and the electrical power and check all supply lines for leaks.

Make sure all pump and water tank hoses are connected, then pour .5 liter of clean potable

water into the circulation system to lubricate the pump seal.

KOLD-DRAFT®

2-6

1-07

Page 17

INSTALLATION INFORMATION ASSEMBLY AND START-UP

Move the ice-off-wash switch to the “wash” (right) position and observe the water filling the

water tank and the pump running. Pinch the flexible hose, which connects the water valve to

the water distributor tube, if the distributor tube holes do not produce full streams and it

appears and sounds like air is flowing through the tube. The water fill is complete when the

water level in the probe tube reaches the high-level probe. Observe that the water valve is

de-energized, at this time and there are no water leaks from the hoses or water tank into the

drain pan.

NOTE- For GB1220, 1240, and 1250 models observe that the water fill difference,

between the upper and lower water tanks, is less than 6 mm for “K” models and 3 mm

for “C” and “HK” models.

Pull down on the right side of the water plate, stretching the springs until the water pump

stops and the actuator motor rotates the cam arms counter-clockwise. Allow the cam arms to

rotate far enough so that the pump does not restart when the water plate is released.

Observe that the cam arms continue to turn, opening the water plate fully, dumping the water

in the tank. At this point, the cam arm rotation will reverse and close the water plate. The

cam arm rotation will stop when the water plate is fully closed and the water fill process will

repeat.

Move the ice-off-wash switch to the “ice” (left) position and observe that the compressor and

the fan motor (air cooled only) begin to run. The refrigeration system operation should be

checked and adjusted during the first few cycles. Consult the “OPERATION” section of this

manual for the proper adjustments to the refrigeration system.

Test the bin thermostat operation by holding ice against it. Adjust the thermostat, if required,

to shut off the ice machine within 30 seconds of contact between the ice and the thermostat

capillary tube.

Make sure that the drain pan, ice chute and/or ice deflectors are properly installed. Replace

and secure all the cabinet panels.

Discard all the ice from the start-up cycles, then clean and sanitize the ice storage bin

according to the instructions provided with the bin.

Complete and mail the registration certificate to the factory. Leave all instructions with the

owner/user.

NOTE- Emphasize all cautionary information to prevent personal injury, property

and/or equipment damage.

KOLD-DRAFT®

2-7

1-07

Page 18

THIS PAGE IS INTENTIONALLY BLANK

KOLD-DRAFT®

2-8

1-07

Page 19

OPERATIONAL INFORMATION COMPONENTS

Note: See the Remote Air-Cooled Condenser section of the manual for additional

components related to these ice machines.

REFRIGERANT COMPRESSOR: Provided to pump refrigerant through the refrigeration

system. See the serial number plate for refrigerant specification and electrical

characteristics.

CONDENSER: All air-cooled and liquid-cooled models are provided with a self-contained

refrigerant condenser to remove heat from the refrigeration system. These condensers are

designated in the model number as (“A”) air-cooled and (“W”) liquid-cooled. Remote aircooled condensers are also available for some models. These are designated as (“R”) in the

model number. (See the remote air-cooled section of the manual for information on these

models.)

CONDENSER FAN AND MOTOR: Provided with all air-cooled (“A”) models to draw air

through the condenser.

CONDENSER COOLANT REGULATOR VALVE: Provided with all water-cooled (“W”)

models to regulate the flow of coolant through the condenser and maintain a specified

refrigerant discharge pressure.

RECEIVER: Provided on liquid-cooled and remote air-cooled condenser models for storage

of liquid refrigerant, as required during the operation of the ice machine.

HEAT EXCHANGER: Provided to sub-cool the refrigerant, ensuring that this refrigerant is

liquid at the inlet of the expansion valve.

FILTER DRIER: Provided as insurance that all moisture and impurities are removed from the

refrigeration system.

THERMOSTATIC EXPANSION VALVE: Maintains the proper flow of refrigerant, through the

system, as the load changes during the ice making cycle.

KOLD-DRAFT®

3-1

1-07

Page 20

OPERATIONAL INFORMATION COMPONENTS

EVAPORATOR: A plated copper evaporator is found in all models. The evaporator provides

the five freezing surfaces for ice cube formation.

There are three different evaporators available for Kold-Draft models, depending on the ice

size desired. These evaporators are designated in the model number as (“C”) full cube,

(“HK”) half cube and (“K”) cube-let.

DEFROST VALVE: Directs compressor discharge gas to the evaporator, causing it to warm

and release the ice cubes during the harvest cycle.

STRAINER-WATER INLET: Protects the water valve from particles in the water supply. This

strainer can be cleaned without disconnecting any tubing. If the need for cleaning is frequent,

an external water filter should be provided.

WATER TANK: Provided as a sump to hold the amount of water required to make one batch

of ice cubes.

WATER SOLENOID VALVE: Opens to allow potable water to enter the ice machine and

closes when the water tank is filled to the correct level.

WATER PLATE: Functions as a water manifold with a flat surface. This surface is positioned

close to the evaporator and acts to form the sixth side of the ice cubes. The water plate

surface has one spray hole for each cell in the evaporator, to provide water to the freezing

surfaces. The water plate surface also has two drain holes under each cell, to allow

unfrozen water to return to the water tank to be re-circulated. The water plate swings down

during the harvest cycle to allow the ice cubes to fall out of the evaporator.

There are two different water plate configurations available for Kold-Draft models, depending

on the ice size desired. One is used for (‘C”) full cube models and the other is used for (“HK”)

half cube and (“K”) cube-let models.

WATER PUMP: Continuously circulates the water from the water tank, through the water

plate during the ice making cycle. The water pump also operates during the wash cycle to

circulate cleaning solution.

ACTUATOR MOTOR: Rotates counter-clockwise, at the beginning of the ice harvest cycle,

to lower the water plate, so the ice can fall out of the evaporator. It then rotates clockwise, at

the end of the harvest cycle, to close the water plate for the next ice making cycle.

KOLD-DRAFT®

3-2

1-07

Page 21

OPERATIONAL INFORMATION COMPONENTS

CAPACITOR-ACTUATOR MOTOR: Installed between the two actuator motor windings, the

function of this capacitor is to determine the direction of the rotation of the actuator motor.

CAM ARMS: These are attached to the actuator motor output shaft and function initially to

separate the water plate from the evaporator and then to support the water plate as it opens

fully.

SPRINGS-WATER PLATE: Function as the connection between the cam arms and the

water plate. They also act as a safety mechanism, stretching if any ice remains on the water

plate surface as it is closing against the evaporator.

Additional Component for GB1250 Series Ice Machines

CHECK VALVE-DEFROST: Installed in the defrost tubing to the master (upper) evaporator

to prevent a flow of refrigerant from the master (upper) expansion valve to the slave (lower)

evaporator. This could occur during the ice making portion of the cycle.

KOLD-DRAFT®

3-3

1-07

Page 22

OPERATIONAL INFORMATION CONTROLS AND ADJUSTMENTS

NOTE- See the Remote Air-Cooled Condenser section of the manual for additional

controls, adjustments and considerations related to these ice machines.

BIN THERMOSTAT: Provides power to the ice-off-wash switch. This thermostat functions to

shut off the ice machine, when the ice bin is full. Contact between the ice and the thermostat

capillary tube will cause the thermostat switch to open.

ADJUSTMENT: While holding ice against the thermostat capillary tube, adjust the

thermostat to shut off the ice machine within one minute. A warmer (CCW) adjustment

will shut off the ice machine sooner. A colder (CW) adjustment will delay shut off.

ICE-OFF-WASH SWITCH: Controls the mode of operation of the ice machine.

The “Ice” position provides power to all control circuits including the contactor. (The

contactor provides power to the compressor and also the condenser fan motor in selfcontained air-cooled ice machines.)

The “Wash” position provides power to all control circuits except the contactor. This position

is useful for cleaning the ice machine and for test procedures where operation of the

compressor is not required or desired.

The “Off” position interrupts power to the control circuits.

Note: See the remote air-cooled condenser section of the manual for additional

considerations for these ice machines.

WARNING

ALL ICE MACHINE CIRCUITS ARE NOT DE-ENERGIZED WHEN THIS SWITCH IS IN THE

“OFF” POSITION. ALWAYS DISCONNECT THE POWER TO THE ICE MACHINE

BEFORE SERVICING.

CONTROL STREAM: This is a small clear box, divided into two sections and located on the

front face of the water plate. Water flowing into the left section of the box is returned to the

water tank and recirculated through the system. Water flowing into the right section of the

box is drained out of the system. The velocity of the stream flowing in the box, during the ice

making cycle, is an indicator of the water pressure inside the water plate. This pressure will

increase as the ice cubes fill out in the evaporator, covering the drain holes provided for each

cell. This pressure increase will cause the stream, normally flowing into the left section of the

box, to flow over the partition and into the right section, draining the system of excess water.

KOLD-DRAFT®

3-4

1-07

Page 23

OPERATIONAL INFORMATION CONTROLS AND ADJUSTMENTS

ADJUSTMENT: The stream of water should be adjusted to fall to the left of the control

stream box partition, during the early portion of the ice making cycle, before the cubes

are full.

LIQUID LEVEL CONTROL: This control mechanism is composed of a clear water level tube,

three stainless steel water level probes and a control board.

The water level tube is mounted in front of the water tank and is connected to it by a hose.

As water fills the tank, the water level is visible in the tube.

The water level probes are positioned in the water level tube. Continuity through the water,

between the common probe and the high level probe, will de-energize the water fill circuit. A

break in continuity between the common probe and the low level probe will initiate the harvest

cycle when the evaporator is cold, or energize the water fill circuit when the evaporator is

warm.

ADJUSTMENT: The common probe should be adjusted all the way down.

The low level probe should be adjusted so the tip is approximately 15 mm from the

bottom of the probe tube.

The high level probe determines how much water is taken into the system at the

beginning of a cycle. It is adjusted as required by the size of the cube (“C”, “HK” or

“K”) and the desired fullness (dimple size) of each cube. Typically all cubes should

have a small dimple at the end of the freeze cycle. Lack of a dimple in the cubes is an

indicator that the water tank level is too high at the start of the cycle.

Note: Making cubes without a dimple will reduce ice machine capacity and may

damage the water plate surface in extreme cases. If the control stream is draining

water for more than 15 seconds, at the end of the ice making cycle, the water level in

the tank is too high. Lower the high level probe slightly until proper operation is

evident.

PUMP AND DEFROST SWITCH: This switch is actuated by the water plate and controls the

operation of the water pump. The pump operates when the water plate is closed and the

switch lever is pushed up. If this switch is not actuated when the water plate closes, because

ice is remaining on the water plate surface, the actuator motor will reverse and reopen the

water plate. This will continue until the surface is clear.

ADJUSTMENT: The switch should be actuated when front cam arm is between the 10

o’clock and 11 o’clock positions. Adjust the actuation point on GT350 series machines

by adjusting the height of the actuation screw on the water plate. All other models

have a tab on the water plate that can be easily adjusted by bending it up or down as

required.

Note: Do not bend the switch lever to make this adjustment.

KOLD-DRAFT®

3-5

1-07

Page 24

OPERATIONAL INFORMATION CONTROLS AND ADJUSTMENTS

ACTUATOR THERMOSTAT: This thermostatic switch senses the temperature of the

evaporator, during the ice making cycle and switches from its warm position to its cold

position at approximately 3.3°C (coldest setting—maximum CW adjustment). No change in

the ice machine operation will be noticed at this time. With this thermostat in its cold position,

the circuitry is set up to start the defrost cycle when the cubes are formed and the system

water level drops below the low level probe. After the ice cubes have fallen out of the

evaporator and the evaporator warms to approximately 10°C, the thermostat returns to its

warm position. This ends the defrost cycle and allows the water plate to close and begin a

new ice making cycle.

ADJUSTMENT: The normal adjustment for this thermostat is fully CW (maximum

cold) position. Adjust the thermostat warmer (CCW) only if the defrost time is

insufficient to drop all the ice from the evaporator, before the water plate begins to

close. The defrost time should be increased no more than is required to insure all the

ice has fallen from the evaporator.

Note: Adjusting the thermostat fully CCW (warm) will lock it in its cold switch contact

position. This will keep the water plate open until the thermostat is adjusted CW.

COLD WATER THERMOSTAT: This thermostatic switch is provided on all models, except

the GT350 series and it senses the temperature of the evaporator. When the evaporator is

cold, it connects the defrost valve to the water fill (blue) circuit. When the evaporator is

warm, it connects the defrost valve to the defrost (red) circuit. The water fill (blue) circuit is

energized from the harvest initiation until the water fill is complete. The defrost (red) circuit is

energized whenever the water plate is not fully closed.

The cold water thermostat also acts to prevent false harvest cycles during the water fill

portion of the cycle. If the incoming water is very cold or filling the system at an abnormally

slow rate, the evaporator could become cold enough to switch the actuator thermostat to its

cold position. If this occurs before the water fill is complete, the ice machine will start a

defrost cycle. The water plate will open, dumping the water in the water tank and closing

again to start a new cycle. The cold water thermostat prevents this by energizing the defrost

valve, providing heat to the evaporator before the actuator thermostat can switch to its cold

position.

ADJUSTMENT: The normal adjustment for this thermostat is fully CW (maximum

cold) position. Adjust the thermostat warmer (CCW) only if ice is remaining on the

surface of the water plate between cycles and not being rinsed off. This condition may

be noticed when the supply water is cold and the water level is adjusted to fully form

the cubes (small or no dimples evident in the ice). Adjusting the water level may

improve this problem.

Note: A degraded water plate surface may also contribute to this problem.

KOLD-DRAFT®

3-6

1-07

Page 25

OPERATIONAL INFORMATION CONTROLS AND ADJUSTMENTS

ACTUATOR TOGGLE SWITCH: This switch acts to limit the travel of the actuator motor in

both directions and sets up the circuitry to run the motor in the proper direction when

energized. This is a two position switch that is operated by the output shaft of the actuator

motor. When the motor shaft rotates clockwise, to raise the water plate, it pushes the switch

lever up to stop the rotation when the front cam arm is in the 12 o’clock position (water plate

fully closed). When the motor rotates counter-clockwise, to lower the water plate, it pushes

the switch lever down to stop the rotation when the cam arm is in the 7 o’clock position (water

plate fully open).

ADJUSTMENT: The switch operator, which is attached to the output shaft of the

actuator motor, can be bent slightly to allow the front cam arm to stop in the proper

positions. Bend this operator only if needed to allow the front cam arm to stop at the

12 o’clock position (water plate closed) and the 7 o’clock position (water plate open).

Note: The front water plate spring must be on the left side of the cam hub when the

water plate is fully closed (cam arm in the 12 o’clock position).

CONTACTOR: Provided with all models to carry the compressor load. On air-cooled

models, the condenser fan motor is also connected to the contactor. The contactor coil is

rated for line voltage and the contacts are rated for definite purpose applications (FLA and

LRA).

HIGH PRESSURE CUTOFF: A manual reset pressure switch is provided, which will open

the circuit to the contactor coil if the discharge pressure should reach 3 mPa (gauge) (435

psig).

ADDITIONAL CONTROLS FOR GB1250 SERIES ICE MACHINES

DELAY TIMER-MASTER ACTUATOR MOTOR: This device is used to delay the master

(upper) actuator motor for two seconds to ensure that the slave (lower) actuator motor will

always run ahead of the master motor. The lower actuator toggle switch must always be

actuated before the upper switch. This is required for reliable water plate synchronization.

RELAY-WATER PLATE SYNCRONIZATION: The purpose of this relay, designated as Relay

#1, is to connect the operation of the slave (lower) actuator motor to the position of the

master (upper) actuator toggle switch. This is required for reliable water plate

synchronization.

KOLD-DRAFT®

3-7

1-07

Page 26

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

THE ELECTRICAL SCHEMATICS ON THE FOLLOWING PAGES DESCRIBE THE

SEQUENCE OF OPERATION OF GB450, GB650 AND GT550 MODELS.

NOTE- The sequence of operation for GT350 models is similar except that these models do

not employ a cold water thermostat. The illustrations below describe this variation.

The sequence of operation for GB1250 models is identical to the GB450, GB650 and GT550

models except additional circuitry is employed to assist in the synchronization of the dual

water plates. This circuitry includes a relay and a delay timer. Also, two additional relays are

used to remove the actuator motor loads from the contacts of the actuator toggle switches.

NOTE- GB1250 models employ two each of the following electrical controls and components:

Condenser Fan Motor (air cooled models only) Water Valve

Water Pump Actuator Motor

Pump and Defrost Switch Actuator Toggle Switch

NOTE- See the Remote Air-Cooled Condenser section of the manual for additional

BK Black BU Blue PK Pink Y Yellow

BK/G Black/Green GY Gray R Red

BK/W Black/White O Orange R/W Red/White

GB450, GB650 AND GT550 GT350 VARIATION

considerations related to the operation of these ice machines.

Wire Color Code for Sequence of Operation Schematics

Energized

De-energized

KOLD-DRAFT®

3-8

1-07

Page 27

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#1 WATER FILL—EVAPORATOR TEMPERATURE ABOVE 10°C.

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Closed

Pump and Defrost Switch Up Water Pump On

Cold Water Thermostat Warm Defrost Valve Closed

Actuator Thermostat Warm

Water Level Control Low/Level Rising Water Valve Open

Actuator Toggle Switch Up Actuator Motor Off

Ice None Control Stream Low

KOLD-DRAFT®

3-9

1-07

Page 28

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#2 WATER FILL WITH COLD WATER THERMOSTAT CYCLE

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Closed

Pump and Defrost Switch Up Water Pump On

Cold Water Thermostat Cold Defrost Valve Open

Actuator Thermostat Warm

Water Level Control Low/Level Rising Water Valve Open

Actuator Toggle Switch Up Actuator Motor Off

Ice None Control Stream Low

KOLD-DRAFT®

3-10

1-07

Page 29

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#3

WATER FILL COMPLETE—ICE FORMING—EVAPORATOR TEMPERATURE > 3.3°C.

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Closed

Pump and Defrost Switch Up Water Pump On

Cold Water Thermostat Cold Defrost Valve Closed

Actuator Thermostat Warm

Water Level Control High/Level Falling Water Valve Closed

Actuator Toggle Switch Up Actuator Motor Off

Ice Forming Control Stream Low

KOLD-DRAFT®

3-11

1-07

Page 30

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#4 ICE FORMING—EVAPORATOR TEMPERATURE < 3.3°C.

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Closed

Pump and Defrost Switch Up Water Pump On

Cold Water Thermostat Cold Defrost Valve Closed

Actuator Thermostat Cold

Water Level Control High/Level Falling Water Valve Closed

Actuator Toggle Switch Up Actuator Motor Off

Ice Forming Control Stream Low

KOLD-DRAFT®

3-12

1-07

Page 31

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#5 DEFROST—START OF DEFROST

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Starting to Open

Pump and Defrost Switch Up Water Pump On

Cold Water Thermostat Cold Defrost Valve Open

Actuator Thermostat Cold

Water Level Control Low Water Valve Open

Actuator Toggle Switch Up Actuator Motor On/CCW Rotation

Ice Fully Formed Control Stream High If Excess Water

KOLD-DRAFT®

3-13

1-07

Page 32

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#6 DEFROST—WATER PLATE DROPPING

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Opening

Pump and Defrost Switch Down Water Pump Off

Cold Water Thermostat Cold Defrost Valve Open

Actuator Thermostat Cold

Water Level Control Low Water Valve Open

Actuator Toggle Switch Up Actuator Motor On/CCW Rotation

Ice Fully Formed Control Stream Off

KOLD-DRAFT®

3-14

1-07

Page 33

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#7 DEFROST—WATER PLATE OPEN FULLY

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Open

Pump and Defrost Switch Down Water Pump Off

Cold Water Thermostat Cold Defrost Valve Open

Actuator Thermostat Cold

Water Level Control Low Water Valve Closed

Actuator Toggle Switch Down Actuator Motor Off

Ice Fully Formed Control Stream Off

KOLD-DRAFT®

3-15

1-07

Page 34

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#8 END OF DEFROST—WATER PLATE STARTS TO CLOSE

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Starting to Close

Pump and Defrost Switch Down Water Pump Off

Cold Water Thermostat Warm Defrost Valve Open

Actuator Thermostat Warm

Water Level Control Low Water Valve Open

Actuator Toggle Switch Down Actuator Motor On/CW Rotation

Ice None Control Stream Off

KOLD-DRAFT®

3-16

1-07

Page 35

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#9 END OF DEFROST—WATER PLATE ALMOST CLOSED

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Almost Closed

Pump and Defrost Switch Up Water Pump On

Cold Water Thermostat Warm Defrost Valve Open

Actuator Thermostat Warm

Water Level Control Low Water Valve Open

Actuator Toggle Switch Down Actuator Motor On/CW Rotation

Ice None Control Stream Off

KOLD-DRAFT®

3-17

1-07

Page 36

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#10 END OF DEFROST—WATER PLATE CLOSED—START OF NEW CYCLE

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Closed

Pump and Defrost Switch Up Water Pump On

Cold Water Thermostat Warm Defrost Valve Closed

Actuator Thermostat Warm

Water Level Control Low/Level Rising Water Valve Open

Actuator Toggle Switch Up Actuator Motor Off

Ice None Control Stream Low

KOLD-DRAFT®

3-18

1-07

Page 37

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#11 ICE BIN FULL—BIN THERMOSTAT OPEN

Control Status Component Status

Bin Thermostat Cold/Open

IOF Switch Ice or Wash

Contactor Open Compressor (Condenser Fan) Off

Water Plate Any Position

Pump and Defrost Switch Up or Down Water Pump Off

Cold Water Thermostat Warm or Cold Defrost Valve Closed

Actuator Thermostat Warm or Cold

Water Level Control High or Low Water Valve Closed

Actuator Toggle Switch Up or Down Actuator Motor Off

Ice None to Fully Formed Control Stream Off

KOLD-DRAFT®

3-19

1-07

Page 38

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#12 WATER PLATE CLOSING BLOCKED—ICE REMAINS ON SURFACE

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Closed Compressor (Condenser Fan) On

Water Plate Closed

Pump and Defrost Switch Down Water Pump Off

Cold Water Thermostat Warm Defrost Valve Open

Actuator Thermostat Warm

Water Level Control Low Water Valve Open

Actuator Toggle Switch Up Actuator Motor On/CCW Rotation

Ice None Control Stream None

KOLD-DRAFT®

3-20

1-07

Page 39

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#13 HIGH PRESSURE CUT-OUT OPEN

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Ice

Contactor Open Compressor (Condenser Fan) Off

Water Plate Closed

Pump and Defrost Switch Up Water Pump On

Cold Water Thermostat Warm Defrost Valve Closed

Actuator Thermostat Warm

Water Level Control* High Water Valve Closed

Actuator Toggle Switch Up Actuator Motor Off

Ice None Control Stream Low

KOLD-DRAFT®

3-21

1-07

Page 40

OPERATIONAL INFORMATION SEQUENCE OF OPERATION

#14 WASH MODE

*NOTE- The low liquid level control position will open the water valve and fill the water tank.

Control Status Component Status

Bin Thermostat Warm/Closed

IOF Switch Wash

Contactor Open Compressor (Condenser Fan) Off

Water Plate Closed

Pump and Defrost Switch Up Water Pump On

Cold Water Thermostat Warm Defrost Valve Closed

Actuator Thermostat Warm

Water Level Control* High Water Valve Closed

Actuator Toggle Switch Up Actuator Motor Off

Ice None Control Stream Low

KOLD-DRAFT®

3-22

1-07

Page 41

OPERATIONAL INFORMATION WIRING DIAGRAMS

WIRING DIAGRAMS-GENERAL INFORMATION

Wiring Diagram Color Code

BK Black PK Pink

B/G Black/Green R Red

B/W Black/White R/BK Red/Black

BR Brown R/W Red/White

BU Blue W White

GY Gray Y Yellow

O Orange Y/BU Yellow/Blue

O/BK Orange/Black Y/OR Yellow/Orange

FULL RINSE WIRING MODIFICATION

All models may be set up to rinse the water

plate continuously during the defrost cycle.

This is done by moving the Y/BU wire from

terminal 3, on the actuator thermostat, to

terminal 2.

NOTE- This modification will increase

water usage. Make this modification only

if ice remains on the water plate, after

defrost, in sufficient quantities to interfere

with ice cube formation during the following

cycle. Significant Ice remaining on the

water plate is an indication of an im

adjusted ice machine. All possible

adjustments should be tried before ma

this modification. See chapter 4 for oth

adjustments.

NOTE- See the Remote Air-Cooled Condenser section of the manual for wiring

diagrams for these models.

properly

king

er

KOLD-DRAFT®

3-23

1-07

Page 42

OPERATIONAL INFORMATION WIRING DIAGRAMS

GB457A/W AND GB657A/W

KOLD-DRAFT®

3-24A

1-07

Page 43

OPERATIONAL INFORMATION WIRING DIAGRAMS

GB457A/W AND GB657A/W 220-240V/50HZ/1PH

Item Description Item Description

C1 Contactor S1 Ice-Off-Wash Switch

S2 Pump and Defrost Switch

D1 High Pressure Cutout S3 Actuator Switch

D2 Liquid Level Control

T1 Bin Thermostat

T2 Actuator Thermostat

M1 Compressor T3 Cold Water Thermostat

M2 Condenser Fan Motor

M3 Water Pump V1 Hot Gas Valve

M4 Actuator Motor V2 Water Valve

COMPRESSOR WIRING

Item Description Item Description

C1 Contactor SC Start Capacitor

M1 Compressor

RC Run Capacitor SR Start Relay

KOLD-DRAFT®

3-24B

1-07

Page 44

OPERATIONAL INFORMATION WIRING DIAGRAMS

GB1257A/W

KOLD-DRAFT®

3-25A

1-07

Page 45

OPERATIONAL INFORMATION WIRING DIAGRAMS

GB1257A/W 220-240V/50HZ/1PH

Item Description Item Description

C1 Contactor M5 Actuator Motor-Master

M6 Actuator Motor-Slave

D1 High Pressure Cutout

D2 Liquid Level Control S1 Ice-Off-Wash Switch

D3 Delay Timer S2 Pump and Defrost Switch-Upper

S3 Pump and Defrost Switch-Lower

H1 Crankcase Heater S4 Actuator Switch-Master

S5 Actuator Switch-Slave

K1 Relay #1

K3 Relay #3

K4 Relay #4 T1 Bin Thermostat

T2 Actuator Thermostat

M1 Compressor T3 Cold Water Thermostat

M2 Condenser Fan Motor (2)

M3 Water Pump-Upper V1 Hot Gas Valve

M4 Water Pump-Lower V2 Water Valve (2)

COMPRESSOR WIRING

Item Description Item Description

C1 Contactor SC Start Capacitor

M1 Compressor

RC Run Capacitor SR Start Relay

KOLD-DRAFT®

3-25B

1-07

Page 46

OPERATIONAL INFORMATION WIRING DIAGRAMS

GB1258A/W

KOLD-DRAFT®

3-26A

1-07

Page 47

OPERATIONAL INFORMATION WIRING DIAGRAMS

GB1258A/W 380V/50HZ/3PH

Item Description Item Description

C1 Contactor M5 Actuator Motor-Master

M6 Actuator Motor-Slave

D1 High Pressure Cutout

D2 Liquid Level Control S1 Ice-Off-Wash Switch

D3 Delay Timer S2 Pump and Defrost Switch-Upper

S3 Pump and Defrost Switch-Lower

H1 Crankcase Heater S4 Actuator Switch-Master

S5 Actuator Switch-Slave

K1 Relay #1

K3 Relay #3

K4 Relay #4 T1 Bin Thermostat

T2 Actuator Thermostat

M1 Compressor T3 Cold Water Thermostat

M2 Condenser Fan Motor (2)

M3 Water Pump-Upper V1 Hot Gas Valve

M4 Water Pump-Lower V2 Water Valve (2)

KOLD-DRAFT®

3-26B

1-07

Page 48

OPERATIONAL INFORMATION WIRING DIAGRAMS

GT357A/W

KOLD-DRAFT®

3-27A

1-07

Page 49

OPERATIONAL INFORMATION WIRING DIAGRAMS

GT357A/W 220-240V/50HZ/1PH

Item Description Item Description

C1 Contactor S1 Ice-Off-Wash Switch

S2 Pump and Defrost Switch

D1 High Pressure Cutout S3 Actuator Switch

D2 Liquid Level Control

T1 Bin Thermostat

M1 Compressor T2 Actuator Thermostat

M2 Condenser F an Motor

M3 Water Pump V1 Hot Gas Valve

M4 Actuator Motor V2 Water Valve

COMPRESSOR WIRING

Item Description Item Description

C1 Contactor SC Start Capacitor

M1 Compressor

RC Run Capacitor SR Start Relay

KOLD-DRAFT®

3-27B

1-07

Page 50

OPERATIONAL INFORMATION WIRING DIAGRAMS

GT557A/W

KOLD-DRAFT®

3-28A

1-07

Page 51

OPERATIONAL INFORMATION WIRING DIAGRAMS

GT557A/W 220-240V/50HZ/1PH

Item Description Item Description

C1 Contactor S1 Ice-Off-Wash Switch

S2 Pump and Defrost Switch

D1 High Pressure Cutout S3 Actuator Switch

D2 Liquid Level Control

T1 Bin Thermostat

T2 Actuator Thermostat

M1 Compressor T3 Cold Water Thermostat

M2 Condenser Fan Motor

M3 Water Pump V1 Hot Gas Valve

M4 Actuator Motor V2 Water Valve

COMPRESSOR WIRING

Item Description Item Description

C1 Contactor SC Start Capacitor

M1 Compressor

RC Run Capacitor SR Start Relay

KOLD-DRAFT®

3-28B

1-07

Page 52

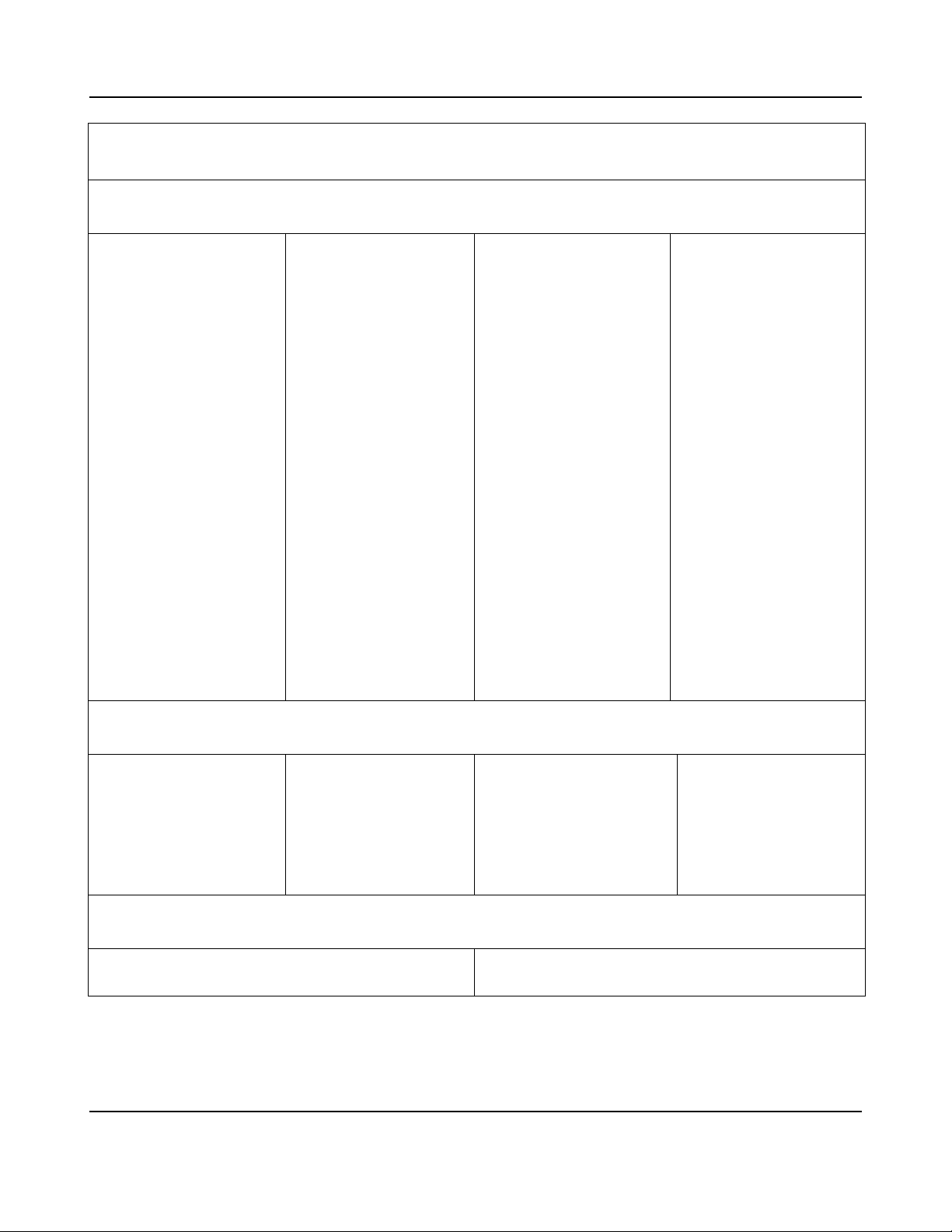

SERVICE INFORMATION OPERATIONAL PARAMETERS

WATER FILL LEVELS, CYCLE TIMES AND HARVEST WEIGHTS

Model Group and Cube Type

Parameter

Water Fill Level (mm)

(see note)

Approximate Cycle

Time (Minutes)

Approximate Ha rvest

Weight (kg)

Note- Rough measurement from top edge of water tank to water level in control tube after water fill is complete. Additional

fine adjustments may be required.

GB450 GB1250 GT350 GT550

CHKK CHKK CHKK CHKK CHKK

6.99 6.99 9.21 6.99 6.99 9.21 6.99 6.99 9.21 6.67 6.67 7.62 6.99 6.99 9.21

33 26 15 26 21 13 23 18 12 31 21 14 31 24 16

3.49 3.22 1.81 3.49 3.22 1.81 6.99 6.44 3.63 1.77 1.59 0.91 3.49 3.22 1.81

Cube Dimensions (mm) Cube Weight (g)Cube Type

C (Full Cube)

HK (Half Cube) 31 x 31 x 15 15.0 216 216 432 108 216

K (Cube-let) 31 x 15 x 15 8.5 216 216 432 108 216

31 x 31 x 31 32.6

TYPICAL REFRIGERANT OPERATING PRESSURES

Measurement Point

Beginning of Freeze Cycle

Just Before Defrost Cycle Begins

During Defrost Cycle

Note 1- High side pressure in air cooled models, at the beginning of the freeze cycle, is likely to be higher than 1720 kPa.

Note 2- High side pressure in air cooled models, at the end of the freeze cycle, is likely to be lower than 1720 kPa.

Note 3- 1720 kPa is equivalent to 40°C condensing temperature

Low Side (Suction Pressure)

REFRIGERANT CHARGE INFORMATION

Parameter

Refrigerant Charge

GB450 GB650 GB1250 GT350

CHKK CHKK CHKK CHKK CHKK

Refer to Serial Number Plate f or Refrigerant Type and Weight of Charge

GB650

CUBE INFORMATION

345 kPa

80 to 140 kPa

480 to 1030 kPa

Model Group and Ice Size

Cubes per Cycle

GB450 GB650 GB1250 GT350 GT550

108 108 216 54 108

High Side(Discharge Pressure) (R-404a)

Air Cooled

See note 1

See note 2

Approx. 1030 kPa

Liquid Cooled

1720 kPa (See note 3)

1720 kPa (See note 3)

Approx. 1030 kPa

GT550

KOLD-DRAFT®

3-29

1-07

Page 53

SERVICE INFORMATION GENERAL

WARNING

REFER ALL SERVICE WORK TO QUALIFIED TECHNICIANS.

KNOWLEDGE OF PROPER INSTALLATION AND SERVICE PROCEDURES IS

ESSENTIAL TO THE SAFE MAINTENANCE OF KOLD-DRAFT EQUIPMENT.

ALWAYS DISCONNECT THE POWER SUPPLY BEFORE SERVICING THE

EQUIPMENT. SOME CIRCUITS REMAIN ENERGIZED WHEN THE ICE

MACHINE IS SWITCHED OFF.

DO NOT OPERATE EQUIPMENT THAT HAS BEEN DAMAGED.

NEVER OPERATE THE ICE MAKER WITH ANY COVERS, PANELS OR

OTHER PARTS REMOVED OR NOT PROPERLY SECURED.

NEVER MODIFY THE CIRCUITRY OF KOLD-DRAFT EQUIPMENT FROM

THE ORIGINAL SPECIFICATIONS.

USE ONLY GENUINE KOLD-DRAFT REPLACEMENT PARTS.

USE OF NON-APPROVED PARTS WHEN SERVICING KOLD-DRAFT EQUIPMENT MAY

CREATE A SAFETY HAZARD OR CAUSE EQUIPMENT AND PROPERTY DAMAGE.

USE OF NON-APPROVED PARTS, WHEN SERVICING KOLD-DRAFT EQUIPMENT, WILL

VOID THE EQUIPMENT WARRANTY.

KOLD-DRAFT®

4-1

1-07

Page 54

SERVICE INFORMATION GENERAL

NOTE

WHEN SERVICING KOLD-DRAFT ICE MACHINE REFRIGERATION

SYSTEMS, ALL WORK PERFORMED MUST BE CONSISTANT WITH THE

BEST REFRIGERATION SERVICE PRACTICES. THESE SYSTEMS MUST

REMAIN CLEAN, DRY AND PROPERLY CHARGED WITH REFRIGERANT,

IN ORDER FOR THE ICE MACHINE TO OPERATE AS DESIGNED.

CAUTION

FAILURE TO COMPLY WITH ALL KOLD-DRAFT SERVICE GUIDELINES

MAY CAUSE PERSONAL INJURY, EQUIPMENT OR PROPERTY DAMAGE

AND VOIDING OF THE PRODUCT WARRANTY.

NOTE- See the Remote Air-Cooled Condenser section of the manual for additional

service information related to these ice machines.

KOLD-DRAFT®

4-2

1-07

Page 55

SERVICE INFORMATION PROBLEMS AND SOLUTIONS

g

g

y

p

Problem Possible Cause Solution

Ice machine is not operating.

Compressor is not operating.

Water pum p and other

components are operating

normally.

test procedure for more

information.

See compressor

Ice-Off-Wash switch in "off" position

No power at ice machine. Circuit

protector open.

Ice machine off on bin thermostat.

Bin full of ice.

Ice machine off on bin thermostat.

Bin thermostat defective.

Ice machine off on bin thermostat.

Ambient temperature below 10°C.

Ice-Off-Wash switch in "wash"

position.

High pressure cut-out open on air

cooled models. Condenser dirty.

High pressure cut-out open on air

cooled models. Air circulation

through condenser is Insufficient or

hot air is recirculating through the

condenser.

High pressure cut-out open on liquid

cooled models. Coolant liquid

interrupted or insufficient

High pressure cut-out open on liquid

cooled models. Interior of condenser

has a mineral build-up.

High pressure cut-out open.

Refrigeration system is overcharged.

Compressor thermal protector open

because of low voltage condition.

Move swit ch to "Ice" position.

Replace fuse or reset breaker. Check

circuit for overload condition.

Use ice or move ice away from bin

thermostat capillary tube.

Replace bin thermostat.

Ambient temperature must be 15°C

minimum.

Move swit ch to "Ice" position.

Clean condenser and reset high pressure

cut-out. Confirm proper operating

pressures.

Provide adequate spacing between the ice

machine and walls, ceilings or other

equipment. See installation instructions for

spacing requirements. Confirm proper

operatin

Restore adequate coolant liquid supply and

reset high pressure cut out. Confirm proper

operatin

Clean or replace condenser.

System is overcharged with refigerant.

Remove refrigerant and recharge the

s

stem to specifications.

Allow thermal protector to reset. Measure

voltage at contactor while compressor is

running. Correct power supply problem if

voltage is lower than specified on the ice

machine electrical plate.

test procedure for more information.

pressures.

pressures

See compressor

1

Compressor thermal protector open

because of defective run capacitor.

Contactor is defective.

Compressor start capacitor or relay

defective.

Compressor is defective.

Replace run capacitor.

test procedure for more information.

Check for voltage at coil terminals.

Replace contactor if it does not close when

the coil is energized.

Test and replace these parts if defective.

See compressor test procedure for more

information.

Replace compressor. See co mpressor

test

rocedure for more information.

See compressor

KOLD-DRAFT®

4-3

1-07

Page 56

SERVICE INFORMATION PROBLEMS AND SOLUTIONS

Problem Possible Cause Solution

Condenser fan motor is not

operating on air-cooled

models. Compressor is

Fan motor protector open.

Fan motor defective Replace motor.

Condenser sub-cooling >11°C at the

middle point of the freeze cycle on

liquid-cooled models.

Condenser liquid regulating valve not

closing fully during defrost on liquidcooled models.

Replace motor if it does not run when cool

or at normal operating conditions.

System is overcharged with refigerant.

Remove refrigerant and recharge the

system to specifications.

Adjust, repair or replace liquid regulating

valve.

2

Defrost performance slow.

Water plate re-opens

immediately after closing.

Water plate closes but reopens before water fill is

completed.

Air cooled ice machine installed in a

low ambient temperature location.

Ice frozen into the water plate

surface. Thick web between ice

cubes.

Ice frozen into the water plate

surface. Cubes are fully formed

without small dimples.

Ice cubes have large dimples or are

hollow at the end of the freeze cycle.

Batch weight is too light.

Evaporator grids are distorted.

Pump and defrost switch lever is not

being pushed up completely.

Water plate is prevented from closing

by some obstruction such as ice

remaining on the water plate surface.

Water plate springs are stretched or

weak and allow the water plate to

drop slightly as the water fills the

tank. The pump and defrost switch

lever is allowed to drop and re-open

the water plate.

A water plate spring is broken or

disconnected from the cam arm or

the water plate.

Ambient temperature must be 15°C

minimum.

Adjust web thickness to specifications.

Reduce the water fill level until ice cubes

are produced with small dimples.

Increase the water level until ice cubes are

produced with small dimples.

Carefully straighten grids or replace

evaporator if the damage is severe.

Adjust pump and defrost switch ac tuator on

water plate until it pushes up the switch

lever completely.

Eliminate obstruction. Adjust the actuator

thermostat so all ice is out of the evaporator

before the water plate begins to close.

Replace defective springs.

Replace broken spring or reattach

disconnected spring.

KOLD-DRAFT®

4-4

1-07

Page 57

SERVICE INFORMATION PROBLEMS AND SOLUTIONS

Problem Possible Cause Solution

Actuator thermostat will not reset

"warm". Actuator thermostat may be

adjusted fully counter-clockwise

(switch contacts locked in cold

position)

Actuator thermostat will not reset

"warm". Actuator thermostat is

defective or capillary tube is broken.

Adjust actuator thermostat clockwise to

unlock switch c o ntacts.

Replace actuator thermostat.

Water plate will not close after

defrost.

Defrost does not initiate when

water level drops below low

water level probe.

Actuator motor output shaft is tuning

but front cam is not turning.

Actuator motor will not run. No

voltage measured at actuator motor.

Defective actuator switch.

Actuator moto r will not run. Voltage

measured at actuator motor.

Actuator motor or capacitor defective.

Actuator moto r will not run. Voltage

measured at actuator motor.

Actuator motor overheated. Open

thermal overload.

Actuator thermostat will not switch

"cold". Poor contact between the

actuator thermostat capillary tube and

the evaporator.

Actuator thermostat will not switch

"cold". Actuator thermostat is

defective.

Water level control does not switch

when water level is below the low

water level probe.

Cam pin is broken or missing.

Replace actuator switch.

Replace defective actuator motor or

capacitor. See actuator motor t est

procedure for additional informati on.

Let motor cool and determine why motor is

running continuously.

3

Be sure the actuator thermostat capillary

tube is fully inserted into the evaporator

capillary tube holder.

Replace actuator thermostat.

Be sure there is no continuity path between

the probes through water or mineral

deposits on the probe cap. Make sure the

cap is clean and dry especially after

cleaning the ice machine. See water level

control test procedure for additional

information.

Defrost cycle ends and water

plate closes before all ice is out

of the evaporator.

KOLD-DRAFT®

4-5

Actuator thermostat resets "warm"

and terminates defrost too early.

Poor contact between the actuator

thermostat capillary tube and the

evaporator.

Actuator thermostat resets "warm"

and terminates defrost too early.

Improper actuator thermostat

adjustment.

Evaporator grids are distorted.

Be sure the actuator thermostat capillary

tube is fully inserted into the evaporator

capillary tube holder.

Adjust actuator thermostat counterclockwise to a warmer position to extend

defrost time.

Carefully straighten grids or replace

evaporator if the damage is severe.

1-07

Page 58

SERVICE INFORMATION PROBLEMS AND SOLUTIONS

Problem Possible Cause Solution

The water supply pressure must be a

mininmum of 138 kPa dynamic at the water

valve. Be sure that the supply line is of

adequate size. This is especially important

for liquid cooled models where the potable

water and condenser coolant water are

supplied by the same water line. Check for

restrictions in the water supply line including

clogged filters. Check the water line

strainer and clean it if needed.

This is normal operation of the cold water

thermostat. Adjus t the cold water

thermostat fully clockwise to reduce

occurances.

Adjust the cold water thermostat fully

clockwise to reduce occurances.

Adjust web thickness to specifications.

Reduce the water level until ice cubes are

produced with small dimples.

Remove the front cam pin, rotate the cam

180° and replace the pin. Be sure that the

relationship between the front cam, the

actuator motor paddle, the actuator switch

and the water plate spring is correct.

actuator motor paddle, switch and water

plate spring relationship illustration for

more information.

See

4

Defrost valve opens during

water fill.

Ice remains attached to the

water plate surface at the end

of defrost.

Cold water thermostat switches "cold"

because of slow water fill.

Cold water thermostat switches "cold"

because of very cold potable water

supply.

Cold water thermostat switches "cold"

because of improper adjustment.

Ice frozen into the water plate

surface. Thick web between ice

cubes.

Ice frozen into the water plate

surface. Cubes are fully formed

without small dimples.

A full sheet of ice cubes is on the

surface of the water plate as it opens

and the opening of the water plate is

delayed at the start of the defrost

cycle. The front cam is not properly

positioned on the motor shaft.

Water valve will not close.

Potable water level continues

to rise after contacting the tip of

the high water level probe,

during the fill cycle.

water level control test

procedure for additional

information.

KOLD-DRAFT®

4-6

See

No voltage measured at water valve

coil. Water valve remains open

because of water supply problem.

No voltage measured at water valve

coil. Water valve remains open

because of dirty or defective water

valve.

Line voltage measured at water valve

coil. Water valve remains open.

The water supply pressure must be a

mininmum of 138 kPa dynamic at the water

valve. Be sure that the supply line is of

adequate size. This is especially important

for liquid cooled models where the potable

water and condenser coolant water are

supplied by the same water line. Check for

restrictions in the water supply line including

clogged filters. Check the water line

strainer and clean it if needed.

Disassemble and clean water valve if

needed. Make sure the bleed holes in the

valve diaphram are open. Replace or

rebuild water valve if defective.

Test for continuity through the high level

probe. Replace the probe if the continuity is

broken.

1-07

Page 59

SERVICE INFORMATION PROBLEMS AND SOLUTIONS

Problem Possible Cause Solution

Be sure there is no continuity path between

Water valve will not open.

Potable water level never

reaches the high water level

probe, during the fill cycle. See

water level control test

procedure for additional

information.

Poorly formed or cloudy ice

cubes.

Actuator motor turns clockwise

at start of defrost.

No voltage measured at water valve

coil because of an abnormal probe

continuity path.

No voltage measured at water valve

coil because of a defective water

level control.

Water valve closes when water

contacts the tip of the low water level

probe, because the low and high

water level probes are reversed on

the water level control.

Water plate pressure is low. Pump

operating improperly because of low

supply voltage.

Water plate pressure is low.

Improper pump installed in ice

machine.

Water plate pressure is low. Water

plate is cracked or leaking

Ice cubes have large dimples or are

hollow at the end of the freeze cycle.

Water plate is out of alignment with

evaporator.

Ice cubes do not break apart after

defrost because of thick web

between cubes.

Ice cubes have uneven dimples.

Dimples are larger on right side of

evaporator because of low refrigerant

charge.

Ice cubes have uneven dimples.

Dimples are larger on right side of

evaporator because of high

evaporator superheat.

Ice cubes have uneven dimples.

Dimples are larger on left side of

evaporator and ice may freeze into

the right side surface of the water

plate because of low evaporator

superheat.

Actuator motor paddle is not in proper

relationship with actuator toggle

switch.

the probes through water or mineral

deposits on the probe cap. Make sure the

cap is clean and dry especially after

cleaning the ice machine.

Check the water level control output for line

voltage between the COM (common)

terminal and the blue neutral wire. Replace

the control if line voltage is not measured.

Reinstall low and high water level probe

wires on the proper terminals of the water

level control.

Measure the supply voltage with the ice

machine running. Be sure voltage is within

the specified tolerances.

Be sure the pump voltage specification

matches the ice machine voltage

specification.

Repair or replace water plate.

Increase the water level until ice cubes are

produced with small dimples.

Re-align water plate. See water plate

alinment illustration for additional

information

Adjust spacing between evaporator and

water plate.

adjustment illustration for additional

information.

Remove refrigerant and recharge the

system to specifications.

Adjust the expansion valve to decrease the

evaporator superheat.

Adjust the expansion valve to increase the

evaporator superheat.

Re-establish proper relationship between

the actuator motor paddle and the actuator

toggle switch. See actuator motor paddle,

switch and water plate spring

relationship illustration for more

information.

See web thickness

5

KOLD-DRAFT®

4-7

1-07

Page 60

SERVICE INFORMATION TEST PROCEDURES

r

ACTUATOR MOTOR TEST PROCEDURE

The following procedure is used to solve problems with the actuator motor and its related

circuitry. Use a voltmeter set for AC voltage and the proper range. Voltages listed on the

chart are to be measured across the actuator motor capacitor (red and yellow motor lead

wires).

If there is no ice in the evaporator and the water plate is not fully closed—with the water

pump running and the actuator switch tripped up—the actuator motor should be running. If it

is not, be sure there is power to the motor and also that the motor is not overheated and off

due to an open high temperature cut-off. Allow the motor to cool down before starting the

test procedure.

When servicing actuator motor problems in GB1250 models, be sure you understand the

synchronization circuit.

NOTESWhen diagnosing electrical problems, always refer to the proper wiring diagram for the

model you are servicing.

Information in the chart only applies to “new style” actuator motors. These motors

can be identified by the rectangular shaped gearbox and visible motor windings.

Contact the factory for test parameters for “old style” actuator motors.

Actuator Motor Test Parameters

Voltage Reading Capacitor Motor Remedy

290 - 370 Good Good

Line voltage Open Good Replace capacito

Line voltage in one actuator

switch position and 0 volts in

the other position.

290 - 370 volts in one actuator

switch position and 0 volts in

the other position.

0 volts in both actuator switch

positions. Be sure there is

power to the motor (line

voltage) by leaving one probe

on either capacitor lead and

placing the other probe on the

white motor lead.

Open and >

Good

Shorted or >

One motor

winding open

One motor

winding open

Both motor

windings open

Tap gear case to align

bearings

Replace capacitor and motor

Replace motor

Disconnect the actuator motor

from the circuit and test the

winding resistance. If

approximately 400 ohms from

white to red or yellow, replace

the capacitor. If the resistance

is erratic, replace the motor.

KOLD-DRAFT®

4-8

1-07

Page 61

SERVICE INFORMATION TEST PROCEDURES

LIQUID LEVEL CONTROLLER TEST PROCEDURE

The following procedure is used to solve problems with the liquid level control and its related

circuitry. This control senses electrical conductivity, through the water, between its probes.

Even very pure water is somewhat conductive and adjusting the control sensitivity from the

middle range, should not be required.

It is important to note, that this control does not directly energize the water fill valve, while the

actuator thermostat is in the “cold” position. The water plate rinse is powered through the

actuator switch, while the water plate is opening. The rinse water flow stops, when the water

plate is fully open and the actuator switch is pushed down. The water fill for next cycle starts

when the actuator thermostat switches to its “warm” position and the water plate begins to

close.

NOTE- Although the three probe terminals at the top of the control board operate at

low voltage (12 volts AC), all other control board terminals carry line voltage with the

obvious potential for electrical shock. Do not allow the control board to get wet and

use caution when checking voltages.

Before testing the water level control, be sure that there is line voltage at the input terminals.

Also, the Ice-Off-Wash switch should be in the “Wash” position—the water supply must be

turned on—the water plate must be fully closed with the pump and defrost switch lever up—

there must be no ice in the evaporator so the actuator thermostat is in the “warm” position.

The water valve should be energized if none of the water level probes is touching water. If

the valve will not open, measure the voltage at the valve coil. If zero volts, check for possible

conductive path through water or mineral deposits on the probe tube cap. Clean and dry the

cap and measure the valve coil voltage again. If zero volts, check the control output between

the N.O. (normally open) terminal and the brown input wire. Replace the water level control if

line voltage is not measured between these two points.