Page 1

ELECTROMECHANICAL AND

®

ELECTRONIC ICE CUBER

SERVICE MANUAL

1525 East Lake Road, Erie, PA 16511-1088

814/453-6761

FAX 814/455-6336

©2004 KDIndustries, Inc., Erie, PA U.S.A.

Printed in U.S.A. 3/04

A Tradition of Excellence In Ice Equipment.

Page 2

Page No.

Table of Contents

Table of Contents 1B

Key to Electronic Model Numbers 2B

Key to Electro-Mechanical Model Numbers 3B

Installation Specifications- Electronic 4B

Operational Components- Electronic 6B

Sequence of Operation- Electronic 11B

Electrical Circuits 13B

Functional Tests 25B

Trouble, Cause and Remedy 26B

Service and Troubleshooting 33B

Installation and Adjustments 43B

Preventative Maintenance 47B

Operational Components- Electro-Mechanical 49B

Installation Specifications- Electro-Mechanical 53B

Kold-Draft® Service & Parts Manual

-1B-

Page 3

Key to Model Numbers-Electronic Cubers

GB 4 01 W HK

Cube Size

C = Full Cube (1-1/4” x 1-1/4” x 1-1/4”)

HK = Half Cube (5/8” x 1-1/4” x 1-1/4”)

K = Cubelet (5/8” x 5/8” x 1-1/4”)

Condenser Type

A = Air Cooled Condenser-Self Contained

W = Liquid Cooled Condenser-Self Contained

R = Remote Air Cooled Condenser

Electrical Characteristics/Refrigerant

01 = 115 Volt-60 Hz.-1 Ph. (R-12)

02 = 115-208/230 Volt-60 Hz.-1 Ph. (3-Wire) (R-12)

03 = 208/230 Volt-60 Hz.-1 Ph. (R-12)

04 = 208/230 Volt-60 Hz.-1 Ph. (R-502)

05 = 208/230 Volt-60 Hz.-3 Ph. (3-Wire) (R-502)

06 = 200 Volt-60 Hz.-1 Ph. (R-12)

07 = 230 Volt-50 Hz.-1 Ph. (R-12)

08 = 380/230 Volt-50 Hz.-3 Ph. (5-Wire) (R-502)

Electronic Cuber Series

3 = 300 Series (3/4 HP)

4 = 400 Series (3/4 HP)

5 = 500 Series (1 HP)

6 = 600 Series (1-1/2 HP)

10 = 1000 Series (2 HP Nominal)

12 = 1200 Series (2 HP Nominal)

Cabinet Width

GB = Horizontal Unit (42” Wide)

GT = Slimline Unit (28-1/2” Wide)

Kold-Draft Service & Parts Manual

2-B

Page 4

Key to Model Numbers-Electro-Mechanical Cubers

GB 1 A N 4 HK E

Electronic

Cube Size

C = Full Cube (1-1/4” x 1-1/4” x 1-1/4”)

HK = Half Cube (5/8” x 1-1/4” x 1-1/4”)

KK = Half Cube (5/8” x 1-1/4” x 1-1/4”)

K = Cubelet (5/8” x 5/8” x 1-1/4”)

Ice Production Per 24 Hours (Nominal)

64 = 75 lbs. w/40 lb. Storage Bin Included

1 = 110 lbs. w/65 lb. Storage Bin Included

2 = 200 lbs. 6 = 600 lbs. 10 = 1000 lbs.

3 = 300 lbs. 7 = 700 lbs. 11 = 1000 lbs.

4 = 400 lbs. 8 = 800 lbs. 12 = 1200 lbs.

5 = 500 lbs. 9 = 900 lbs. 16 = 1600 lbs.

20 = 2000 lbs.

Code Letter

NSF = National Sanitation Foundation Listed

D = 115/230 Volt-60 Hz.,-3-wire, NSF Listed

5 = 500 Series (1 HP)

Condenser Type

A = Air Cooled Condenser-Self Contained

W = Liquid Cooled Condenser-Self Contained

R = Remote Air Cooled Condenser-Precharged

X = Remote Air Cooled Condenser

Compressor Horsepower Rating

0 = No Condensing Unit 3 = 1/3 HP 6 = 1/5 HP

1 = 1 HP 4 = 14,000 BTU 7 = 3/4 HP

2 = 11,000 BTU 5 = 1/2 HP 8 = 3/4 HP

Machine Type

GB = Horizontal Unit, Mounts on a Bin (42” Wide)

GT = Slimline Unit, Mounts on a Bin (28-1/2” Wide)

GY = Self Contained Compact Unit (30” Wide)

GS = Self Contained Compact Unit (24” Wide)

IS = Self Contained Dispenser (31-1/4” Wide)

Kold-Draft Service & Parts Manual

3-B

Page 5

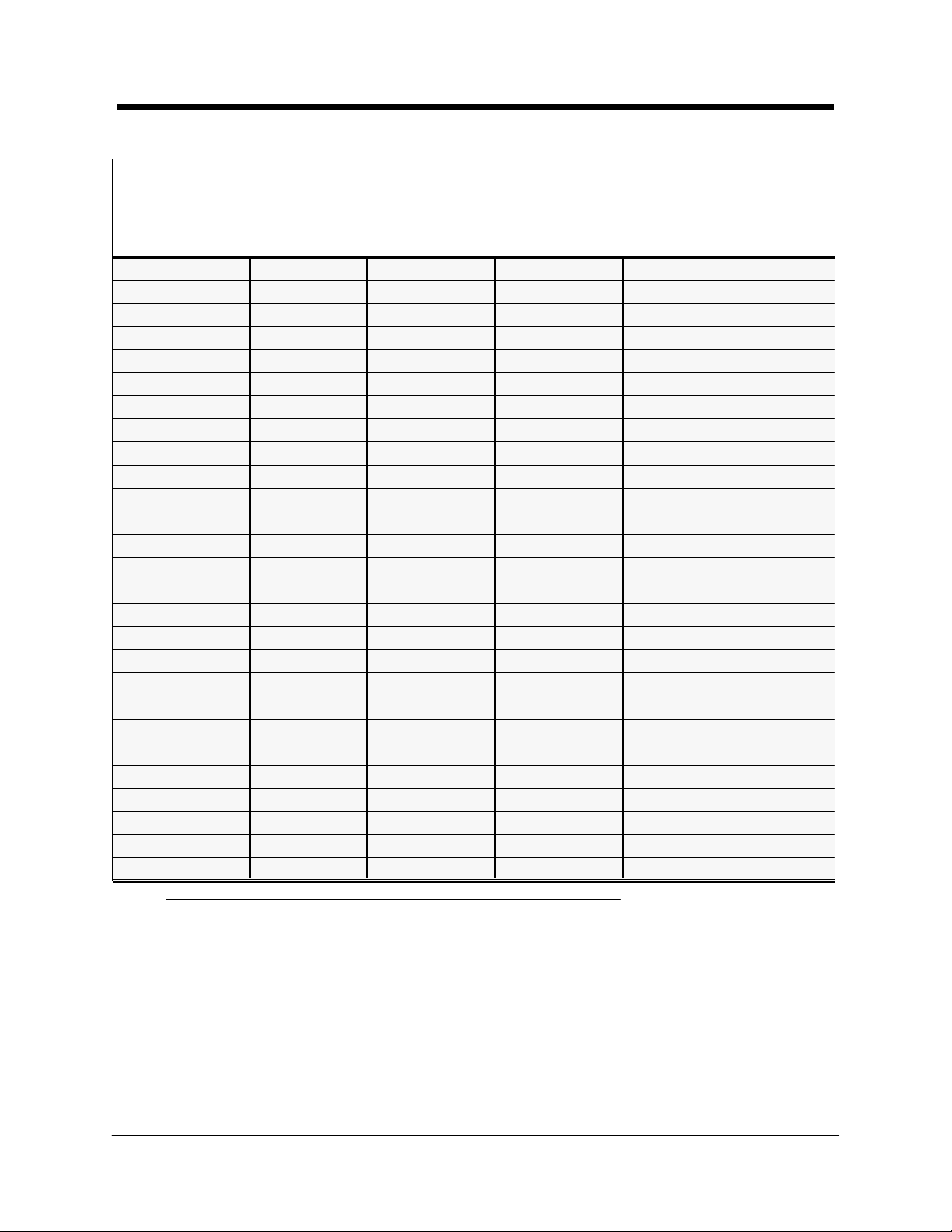

60 Hertz Electronic Cubers

Installation S

pecification

s

FUSE/HACR

BREAKER SIZEMINIMUMMINIMUM

(AMPS)INCOMINGCIRCUIT

NORMAL MAXIMUM

WIRE SIZEAMPACITYHPMODEL

NOTE: Max i m um Branch Circui t Fuse or

HACR type Circuit Breaker si ze is dependent on the size of the

conductors supplyi ng the Ice Maker. They must be no less than t he minimum ampacit y rating and no

more than "Maximum" rating on the nameplate.

25 351022.73/4GT301A

20 2512173/4GT301W

25 40/3510253/4GT401A/GB401A

20 2512183/4GT401W/GB401W

25 351020.93/4GT401R/GB401R

20 2012163/4GT402A/GB402A

15 2014153/4GT402W/GB402W

20 251216.93/4GT402R/GB402R

15 201414.41GB503A

15 201413.31GT503W/GB503W

15 201412.21GT503R/GB503R

20 30122011,000 BTUGB603A

15 20141511,000 BTUGT603W/GB603W

20 301218.911,000 BTUGT603R/GB603W

20 25121714,000 BTUGB903/1003W

20 301219.314,000 BTUGB903/1003R

30 451028.227,600 BTUGB1204W

30 451028.227,600 BTUGB1204R

20 301217.822,500 BTUGB1205W

20 301217.922,500 BTUGB1205R

30 4010303/4IS401A

25 3010233/4IS401W

15 2014151IS503W

15 1514151/3GY3A

15 1514151/3GY3W

25 351022.73/4GT7A

20 2512173/4GT7W

Supplement fuses (install ed on the Ice Maker)

required f or continuous operation without nuisance blowing, up to the indi cated nameplate "Max imum"

rating to compensate for ambient conditions.

SPECIAL NOTE: Wire sizes on this chart are good up to 80 feet.

Kold-Draft

do NOT prov ide prim ary protect ion and may be sized as

Anything 80 feet to 150 feet increase wire 1 size.

Any runs 150 feet to 250 feet increase the wire 2 sizes.

-4B-

®

Service & Parts Manual

Page 6

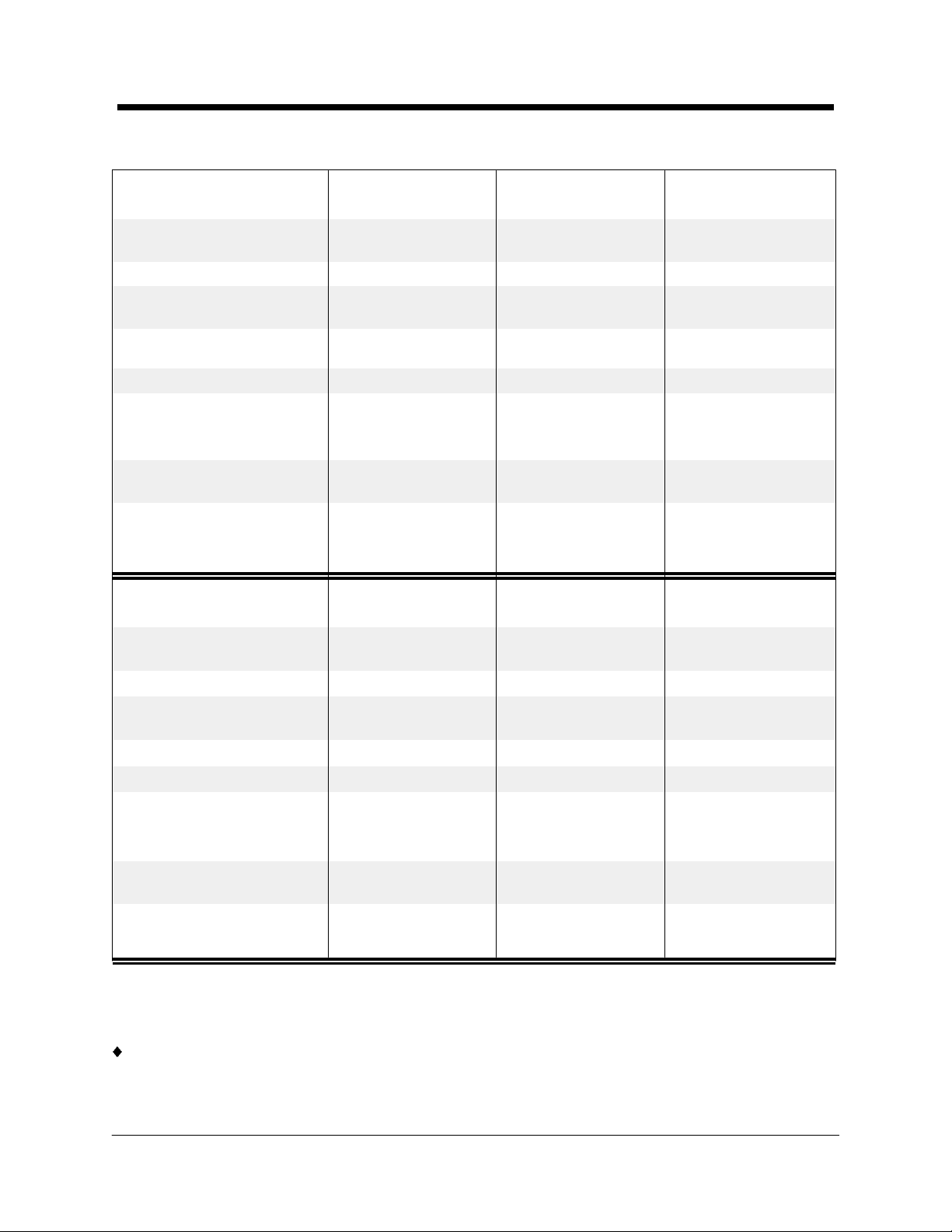

Water Levels, Pressures, Cycles and Charges

Installation Specifications

(higher than average temperatures increase pressures and cycle times)

Model

Cube Size

Full Water Level Distance

below top of tank

Suction Pressure after Defrost

Suction Pressure before

Defrost

Defrost Pressure

Cycle Times (approximate)

Refrigerant Charge

Remotes (R) see note below

Refrigerant Type

Approximate lbs. of ice per

batch

Compressor Size

Model

Cube Size

Full Water Level Distance

below top of tank

Suction Pressure after Defrost

Suction Pressure before

Defrost

Defrost Pressure

Cycle Times (approximate)

Refrigerant Charge

Remotes (R) see note below

Refrigerant Type

Approximate lbs. of ice per

batch

Compressor Size

70 psig max. 100-110

with CPR valve psig

GB1205: 22,500 BTU

TXV controlled

GB1204: 27,600 BTU

TXV controlled

7-1/2 7 lbs. 4 lbs.

lbs.

9,800 BTU

TXV controlled

with CPR valve psig

15 lbs. 14 lbs. 8 lbs. 15 lbs. 14 lbs. 8 lbs.

14,000 BTU

TXV controlled

3 lbs.3 lbs.

7-1/2 7 lbs. 4 lbs.

lbs.

6,800 BTU

TXV controlled

GB600/GT600GB903/GB1000GB1200

C HK K C HK K C HK K

2-5/8" 2-3/4" 3-1/2" 2-5/8" 2-3/4" 3-1/2" 2-5/8" 2-3/4" 3-1/2"

20 psig20 psig55-60 psig

0-2 psig0-2 psig 10-15 psig

40-60 psig 55 psig max. 40-60

21 min. 17 min. 12 min.27 min. 22 min. 15 min.19 min. 17 min. 11 min.

3 lbs.3 lbs.3 lbs.

R-12 R-12R-502

7-1/2 7 lbs. 4 lbs.

lbs.

11,000 BTU

TXV controlled

GT300GB400/GT400/IS400GB500/GT500/IS500

C HK K C HK K C HK K

2" 3" 2-5/8" 2-3/4" 3-1/2" 2-5/8" 2-3/4" 3-1/2"

11-13 psig20-25 psig15-20 psig

03 psig0

40 psig40-60 psig40-60 psig

28 min. 21 min. 15 min.28 min. 25 min. 14 min.26 min. 20 min. 13 min.

13 oz. GT301A

10 oz. GT301W

R-12 R-12R-12

3-3/4 3-1/2 lbs. 2 lbs.

lbs.

6,800 BTU

cap. tube controlled

NOTE: Remote condenser application cubers require a total minimum charge of 10-1/2

lbs. GB1200 series cubers use R-502, all others use R-12.

{

For maximum fuse size check electrical rating plate on left rear of cuber.

Kold-Draft® Service & Parts Manual

-5B-

Page 7

Kold-Draft® Electronic Cuber Construction

Operational Components

Skins

The skins consist of the top, left end, back, right end panels and front inspection panel.

Condensing Units

Varies with each model. For compressor size and charge, refer to the Water Levels,

Pressures, Cycles and Charges Chart on the previous page.

Evaporator

The GB series Full Cube (C) evaporator is made up of 108 cells, 1-1/4" each way.The

Cubelet (K) evaporator is made up of 216 cells, 1-1/4" x 1-5/8" x 5/8" deep. The Half

Cube (HK) evaporator is made up of 216 cells, 5/8" x 1-1/4" x 1-1/4" deep. The material

is copper and the entire assembly is tinned, preventing corrosion and making its use

acceptable to any sanitary board. A seal is not required between the evaporator and

water plate, normally there is an approximately 1/32" clearance between them. Refer to

Water Plate-Evaporator Alignment for adjustments.

Note: GT300 evaporators contain 1/2 the number of cells of a GB evaporator.

Refrigerant Control

1. Thermostatic expansion valves are used on all GB and IS models and GT400,

GT500 and GT600 models. For replacement of the valve, consult the Parts

Price List for type of expansion valve. It has been regulated properly on test

before being shipped, to give minimum superheat and maximum flooding of the

evaporator and should not require adjustment.

Sometimes after shipping or storage, the expansion valve sticks and allows

more refrigerant to pass than necessary, increasing the low side pressure

and temperature, thus excessive frostback and a long cycle. If this condition

does not correct itself during the second cycle, it will be necessary to adjust the

superheat on the expansion valve, closing the valve clockwise 1/8 to 1/4 turn to

increase superheat, reducing the suction pressure and preventing frostback. If

valve hunts (varies suction pressure up and down) more than 2 to 3 lbs. when

suction pressure is below 13 lbs., it indicates that the valve should be opened

more.

2. The GT300 series are capillary systems and do not have an expansion valve.

Water Plate

The water plate is made of approved plastics and is used to distribute the water

through jet holes into the freezing cells of the evaporator, and also to return water

through two drain holes in each cell in the water plate. On the front of the water plate is

a control stream, that should be set at the base of the dam once the water fill is

complete. Backing the screw out increase the flow. At the end of a cycle when cubes

are virtually frozen there is an increasing water pressure in the system causing the

stream to rise and go over the dam dumping dreg water.

Circulation Tank

The circulation tank is secured to the bottom of the water plate. It serves as a reservoir

to hold enough water to make one batch of ice.

Kold-Draft® Service & Parts Manual

-6B-

Page 8

Circulation Strainer

Operational Components

The circulation strai ner has a large screen inserted i n the tank outlet to prevent dirt or

particles of precipitated mineral from clogging the jet holes or the control stream. It also

protects the pump impeller. If the screen becomes clogged with precipitated minerals, it

is advisable to clean the whole circulation system with ice machine cleaner.

Water Pump

The water pump is a centrifugal type, direct with sealed bearings that require no

lubrication. The inlet tube is at the bottom of the water circulation tank, and the outlet at

the top of the pump is connected to the header of the water plate.

Water Level Probe Assembly (GBR-03170)

This probe is connected to the main water circulation tank by means of flexible tubing.

The height of water in the probe assembly indicates the height of water in the

circulation tank. Thermistor probes determine water valve on/off levels. Refer to the

Water Levels, Pressures, Cycles and Charges chart for the correct setting per model

for the upper probe. The bottom probe is positioned so that 15-30 seconds after the

water flows over the dam on the control stream box on the water plate, the water level

is below the glass tip and harvest is initiated.

Pump and Defrost Switch

A spring loaded switch is mounted in the control box. It controls the defrost circuit and

water pump, and is operated by an adjustable screw in the lift plate attached to the

water plate. As the water plate closes after defrost, the adjustable screw lifts up and

makes contact with the pump switch to cut one connection to the defrost circuit and

start the circulation water pump.

Water Inlet Valve

The water inlet valve is mounted int front left of the freezing compartment and controls

the rate of flow of water into the water tank when the cuber is filling. It is a constant flow

type requiring a minimum 15 psi. An external "Y" type strainer is used with the valve.

For pressures over 100 psi or if there i s water hammering, a pressure regulator should

be used.

Actuator Motor and Cam Assembly

The assembly is located just to the right and front of the evaporator. The actuator motor

drives the cam shaft directly and i s reversible. A cam on each end of the shaft forces

the water plate down, separating the water plate from the ice in the evaporator. The two

springs on the cams pull the water plate up at the end of the defrost cycle, and hold the

water plate against the bottom of the cams during the freeze cycle. To prevent the

water plate from opening after current has stopped flowing to the actuator motor, a drift

stop spring with a plastic end (GBR-00965) presses against the actuator motor shaft,

on the front of the motor. If the drift stop is not aligned with the motor shaft it can be

removed easily and bent into shape.

Evaporator Probe (GBR-03176)

Resistance values of the probe change due to temperature changes on the evaporator.

These changes are transmitted to the printed circuit card and allows one probe to

perform three functions; 'cold water control', 'actuator control' and 'overheated

evaporator cut out'.

1. COLD WATER CONTROL opens the hot gas valve during the fill cycle when the

evaporator cools to 45} F. (red L.E.D. shines bright on P.C. card). The hot gas

Kold-Draft® Service & Parts Manual

-7B-

Page 9

will shut-off when the water fill is complete or when the evaporator warms to 50

Operational Components

F. (red L.E.D. off or dimly lit).

2. ACTUATOR CONTROL resets cold when the evaporator reaches 26} F.

(orange L.E.D. shines bright) and will send power through the actuator toggle

switch to the actuator motor at harvest. It also sends power to the actuator

motor when the evaporator warms to 40} F. after harvest, to return the water

plate (orange L.E.D. off).

3. OVERHEAT TEMPERATURE FUNCTION shuts the cuber down when the

evaporator temperature reaches 140} F., should the hot gas valve stick open. It

will re-energize the cuber when the evaporator cools to 120} F.

Bin Probe (GBR-03177)

The bin probe is mounted to a flexible probe holder on the ice chute or through a

bracket in the bin. Its resistance values change with temperature fluctuations at the

probe tip due to the proximity of ice. These changes are transmitted to the Bin Control

on the P.C. card and turn the ice maker on or off.

To Set Bin Control

}

1. Do not attempt to set the Bin Control while the unit is filling with water. The P.C.

card has a circuit to fill the water tank befor eshutting off on "Full Bin Condition".

2. Once the water fill is complete, hold ice to the tip of the probe. The ice maker

should shut off in 15-30 seconds. if longer, adjust the bin potentiometer on the

P.C. card slowly counter-clockwise until the unit shuts off.

3. After the ice maker stops, remove the cubes from the probe tip. the ice maker

should start within one minute, if the ambient air is above 50} F.

The bin probe is a standard length, but when stacking units check the chart below to

determine whether a stacked cuber will require a bin probe extension (GBR-03240) in

addition to the bin probe (GBR-03177) to reach into the bin.

GBR-03177 Probe

& GBR-03240 Extension

GBR-03177 Probe

& GBR-03240 Extension

GBR-03177 Probe

& GBR-03240 Extension

GBR-03177 Probe

& GBR-03240 Extension

GBR-03177 Probe

& GBR-03240 Extension

GBR-03177 Probe

& GBR-03240 Extension

GBR-03177 ProbeGBR-03177 Probe

Kold-Draft® Service & Parts Manual

T-100 CrusherGBR-03177 Probe

Any Kold-Draft® BinAny Kold-Draft® Bin

-8B-

Page 10

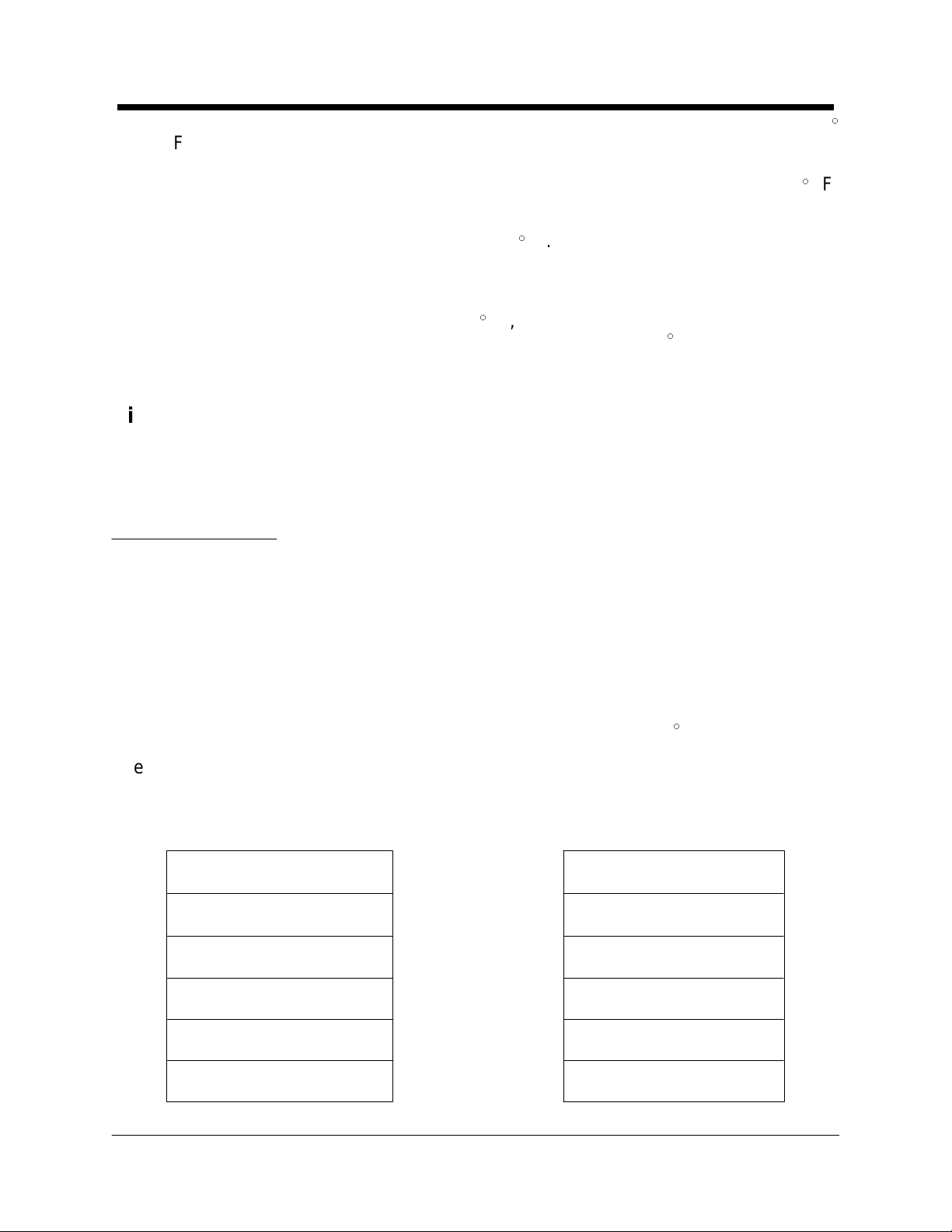

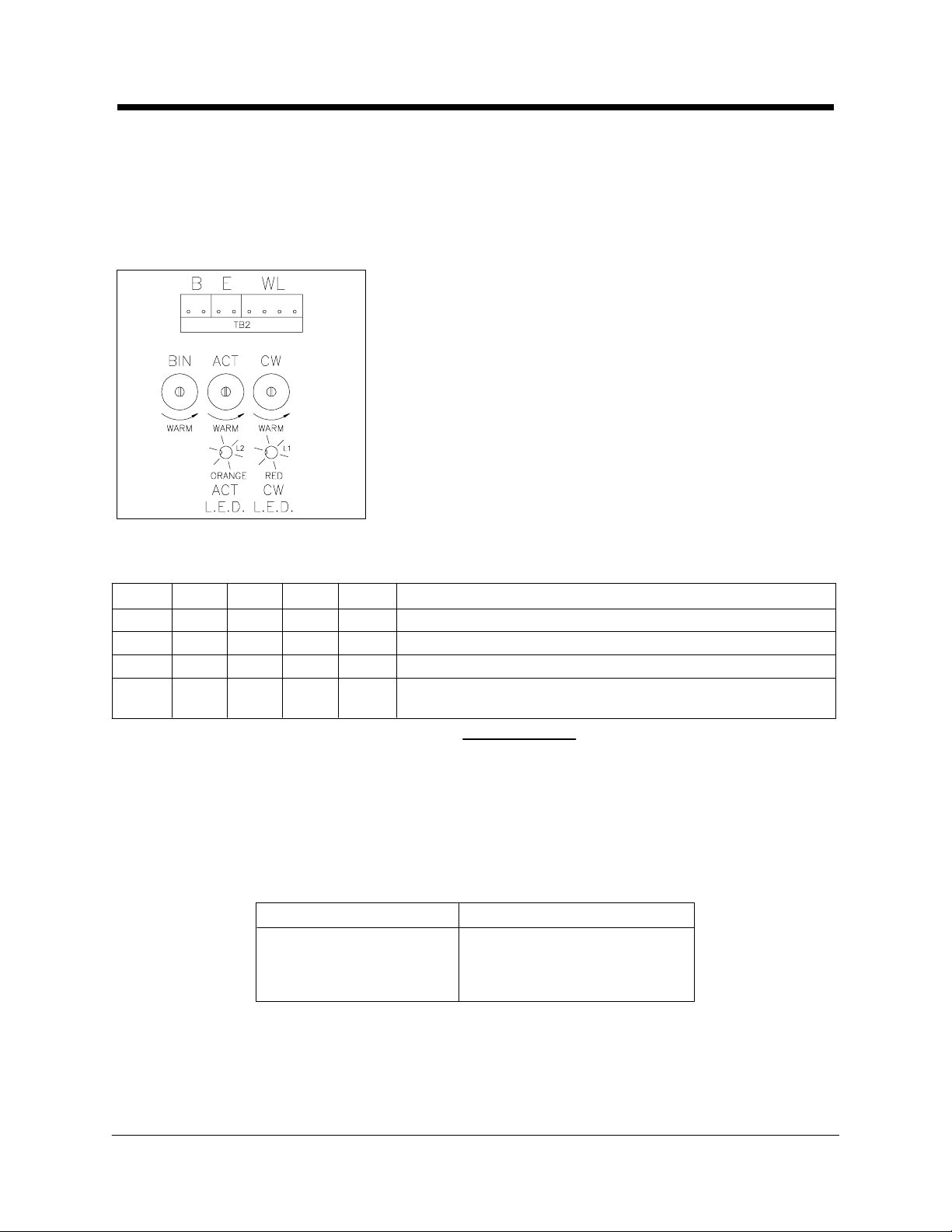

Printed Circuit Card

Operation

al Components

GBR-03135-02 type P.C. cards have been used since August, 1980. Refer to

Engineering Bulletin #10-80 for pre-August, 1980 detail s, but note that all of the older

P.C. cards should have been updated with retrofit kits offered by the factory after

August, 1980.

GBR-03135-02-E P.C. cards replaced the GBR-03135-02 from October, 1982 through

December, 1990.

Since January, 1991, we have been providing 102 1165 01 as a replacement for both

GBR-03135-02 and GBR-03135-02-E P.C. cards. To replace a GBR-03135-02 card, a

GBR-03122 wiring adapter kit is required.

TB2 (upper left of P.C. Card)

1. B: Pins 1 and 2, location of

bin probe which turns the

cuber on and off according to

ice demand.

2. E: Pins 3 and 4, location to

connect evaporator probe

which relays evaporator

temperature to P.C. card,

allowing card to set to the

cold or warm side, the cold

water control, actuator control

and thermal over temperature

protector.

3. WL: Pins 5, 6, 7 and 8,

location to connect water level probes, which turn the water inlet valve on and

off (W). It initiates harvest when water falls below the lower probe (L) when

actuator control is set cold.

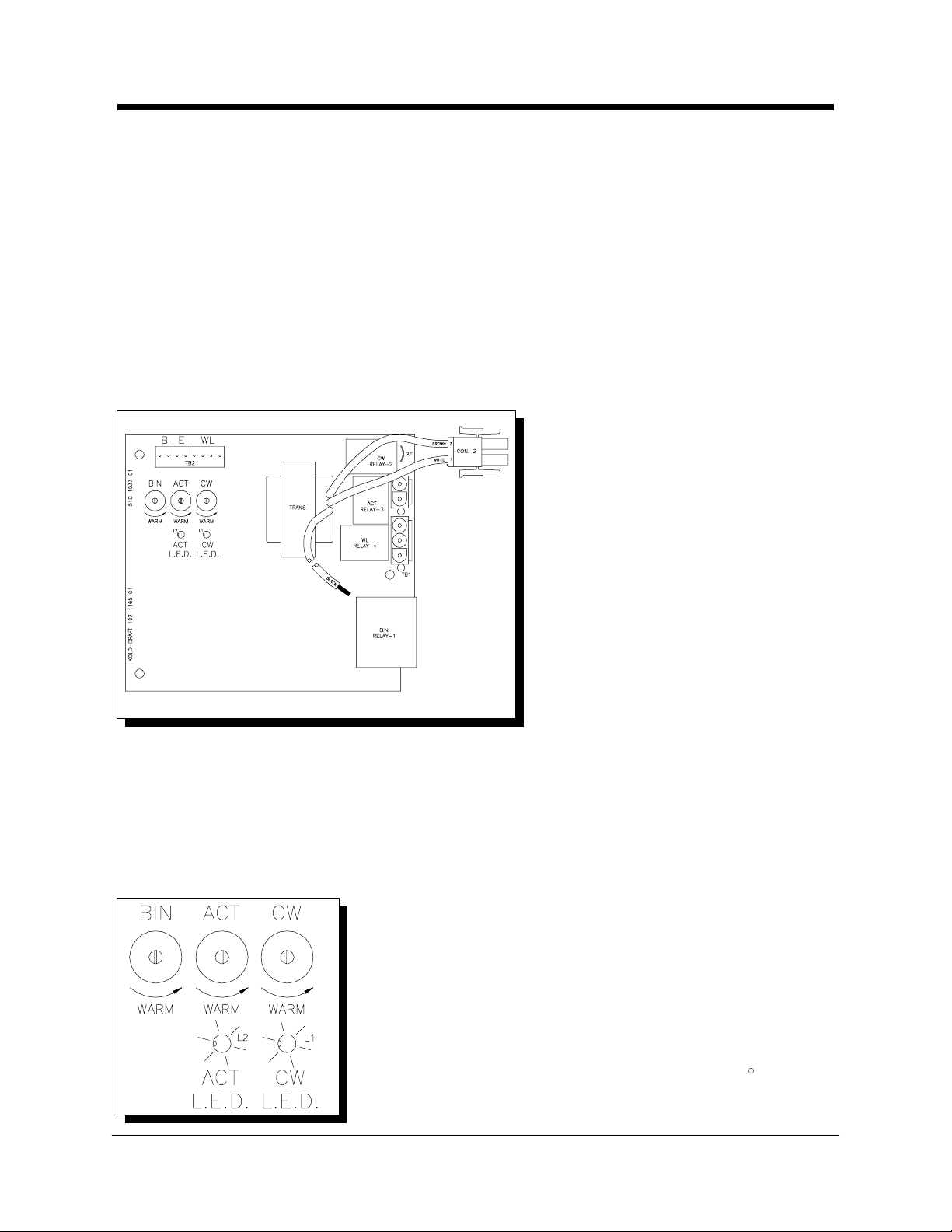

Adjustable Potentiometers and L.E.D.'s (located beneath TB2)

1. Bin Potentiometer: Adjustment to turn unit off on

contact of bin probe with ice in 15-30 seconds,

provided the water fill is satisfied.

2. Actuator Potentiometer: Adjust to raise water plate

15-30 seconds after ice harvest.

3. Cold Water Potenti ometer: Adjustment to open hot

gas valve should evaporator cool to 45} F. during

water fill cycle.

Kold-Draft® Service & Parts Manual

-9B-

Page 11

4. Cold Water L.E.D. (red): Il luminates when the evaporator is colder than 45} F.

Operation

al Components

Off when CW control is set at 50} F. or above.

5. Actuator L.E.D. (orange): Illuminates when the evaporator temperature is colder

than 26} F. Off when actuator control is set warm at 40} F. or above.

Bin Relay (lower right corner of P.C. Card)

On P.C. cards made since January, 1984, this relay is replaceable, should it ever fail.

Output Sockets and Relays 2, 3 & 4 (upper right corner of P.C. Card)

The connections for output supply from the P.C. card to the small motors and valves

when sequenced by the relays.

Transformer (upper center of P.C. Card)

The same P.C. card is used on all Electronic cubers. The transformer has 2 leads

(brown and white) attached to a plug which mates to a plug from the front wire channel.

On 115 volt ice makers, the plugs mate white-to-white (brown open on transformer

plug). On 208/230 and 115/230 (3 wire) volt ice makers, the plug mate brown-to-brown

(white open on transformer plug).

Kold-Draft® Service & Parts Manual

-10B-

Page 12

With the Electronic cuber mounted to a bin, the water turned on, the electricity

Sequence of Operation

connected and the wash switch in the 'ON' position, we can follow through one

complete cycle.

The bin, actuator and cold water controls are set to the warm side (L.E.D.'s 'OFF'-dimly

lit). The water plate is in the 'UP' position. The pump and defrost switch is held up by

the lift bolt on the water plate energizing the pump. The water inlet valve is open and

the evaporator is cooling. The water level in the main water tank is rising and the

corresponding water level is indicated in the water level probe assembly. Water is

being pumped from the bottom of the circulation tank into the header at the left end of

the water plate, through the lateral tubes under each row of cells, through the squirt

holes in the center of each cell. The water stream hits the top of each cell then

cascades down the 4 sides of each cell and returns to the main water tank through

drain holes on each side of the squirt hole. When enough water to make one batch is in

the main water tank and the water level probe assembly, water will touch the upper

thermistor probe and the water inlet valve shuts off. The control stream at the front l eft

corner of the water plate should be fl owing at the base of the dam. The screw at the

inlet of the control stream may be adjusted to obtain a proper setting.

When the evaporator temperature reaches 45} F. the evaporator thermistor probe

signals the P.C. card to set the cold water control 'cold' (red L.E.D. 'ON'-comes on

bright).

The evaporator continues to co ol, at 32} F. minute layers of ice form on the top and the

4 sides of each cell. As this proce ss continues, the water level will decrease in the main

water tank and the water level probe assembly.

NOTE: When the circulating water reaches a temperature of 32} F., it MAY be

supercooled and it MAY partially crystallize in the water tank. If this occurs, the flow of

water in the control stream nozzle will stop or fluctuate considerably and most of the

circulation will stop for about 30 seconds. This is STRICTLY A NORMAL OPERATION

AND THE CONTROL STREAM SHOULD NOT BE ADJUSTED AT THIS TIME.

When the evaporator temperature reaches 26} F., the evaporator thermistor probe

signals the P.C. card to set the actuator control 'cold' (orange L.E.D. 'ON'-comes on

bright).

The water continues to freeze until each cell is al most completely full of ice. As the ice

comes closer to the jet stream in the center of each cell, the head pressure in the water

plate increases, causing the contr ol stream to rise and flow over the dam in the control

stream box. This water will be dissipated to the drain pan, lowering the level in the

water level probe assembly. Within 15-30 seconds the water will leave the bottom

thermistor probe and expose it to air.

The harvest cycle is initiated, every circuit in the system is simultaneously engaged.

The hot gas valve opens sending hot gas to warm the evaporator. The water inlet valve

opens and the water rinses the water plate. The actuator circuit is energized through

the actuator control, through the actuator toggle switch to the actuator motor, causing

the actuator motor to turn counter-clockwise and separate the water plate from the

evaporator. When the water plate opens approximately one inch the pump and defrost

switch drops, turning the water pump off. The pump switch now completes a second

Kold-Draft® Service & Parts Manual

-11B-

Page 13

circuit to the defrost val ve to keep it open duri ng the harvest cycle. The actuator motor

Sequence of Operation

shaft continues to turn a 1/2 turn revolution until the trip lever on the actuator motor

snaps the actuator toggle to the right and breaks the actuator circuit stopping the

actuator motor in the down position.

As the evaporator warms, the cubes on the left edge of the evaporator slide out of the

evaporator and rest on the water plate. There is a small fin connecti ng the bottom of

the cubes together so that they will come down in unison and clearing the water plate,

slide into the bin where they will break apart.

After the ice is out of the evaporator, the evaporator and the evaporator thermistor

probe warm up rapidly. When the evaporator probe senses a temperature between

40}-45} F., its resistance change signals the P.C. card and the actuator control sets

'warm' (orange L.E.D. 'OFF'-dimly lit)and completes the circuit from the defrost circuit to

the reversing side of the actuator toggle switch and actuator motor.

NOTE: The actuator control does not start the defrost cycle; it only ends it after the ice

falls out. The motor revolves clockwise raising the water plate. When the water plate is

almost closed, the lift bolt on the water plate pushes up the pump and defrost switch

lever starting the pump and breaking one circuit to the hot gas valve. The water plate

continues to the full 'UP' position when the actuator toggle arm will snap the actuator

toggle to the left causing the actuator motor to stop. When the evaporator temperature

reaches 50} F., the cold water control will switch to the warm side shutting off the hot

gas valve (red L.E.D. 'OFF'-dimly lit). When the water level is high enough to touch the

upper thermistor probe, it breaks the circuit to the water plate.

NOTE: Should some ice cubes be left on the water plate, keeping it partially open

when the water plate comes up, the actuator motor will continue to operate and the

springs will stretch to allow the cams to take their vertical position and snap the

actuator toggle switch. Since the lift plate cannot push up the defrost switch, the circuit

is complete through this switch to the stop 'up' side of the actuator toggle switch. When

the actuator toggle arm snaps the actuator toggle switch to the stop 'up', the actuator

motor will immediately reverse itself and open the plate allowing the captive ice to fall

off. When the plate i s in the open position, the actuator toggle arm will again reverse

the actuator toggle switch and the actuator motor and cause the plate to close. This will

continue until the water plate is clear and the l ift plate can push up the defrost switch,

breaking the circuit through this switch to the stop 'up' side of the actuator toggle

switch, so that the motor will stop with the cams up when the actuator toggle arm

pushes the actuator toggle to the stop 'up' position.

The ice maker has now completed its full cycle and started another freezing cycle. This

will be regularly repeated until the bin i s full and the bin control shuts off the ice maker

automatically. When some ice i s removed from the bin, the ice maker will start up and

refill the bin.

Kold-Draft® Service & Parts Manual

-12B-

Page 14

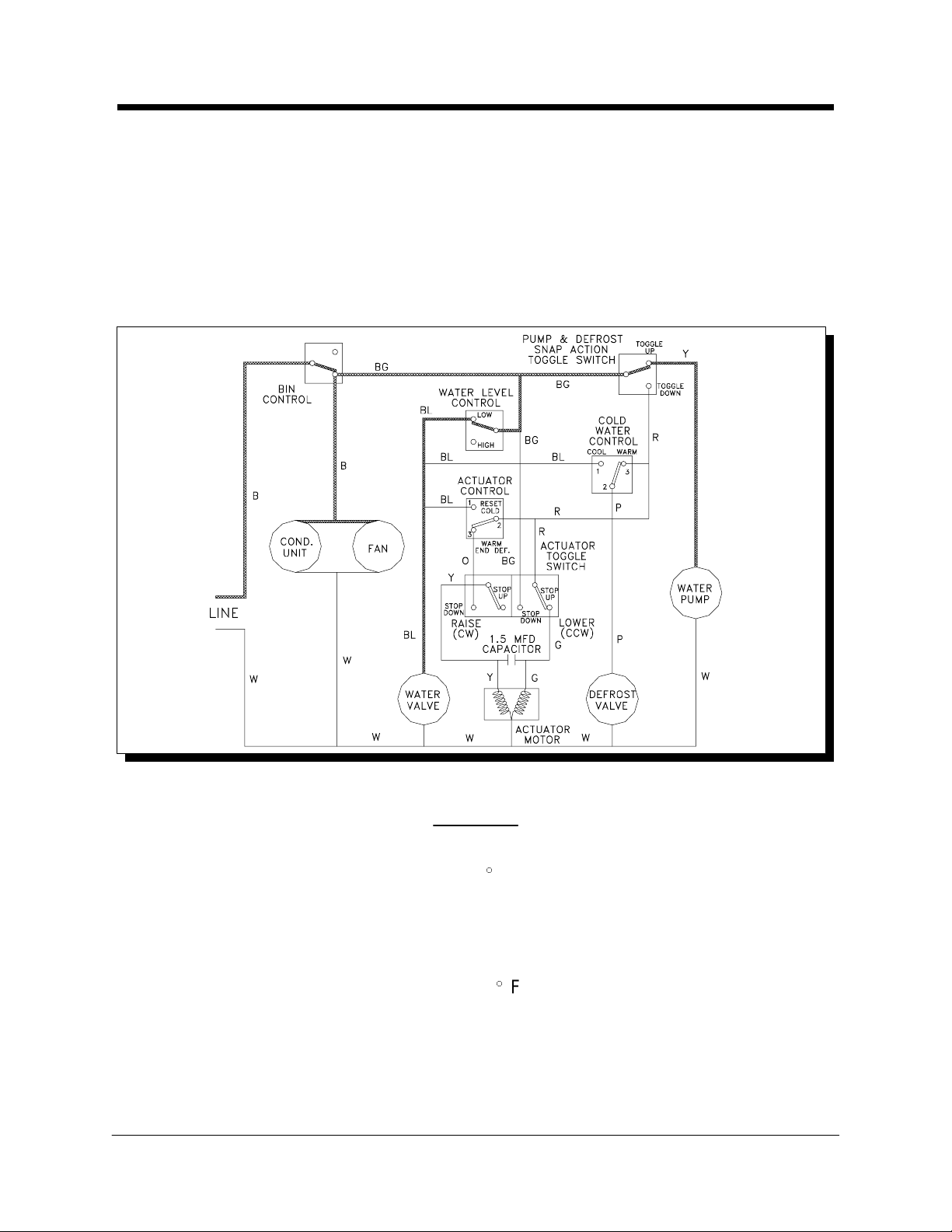

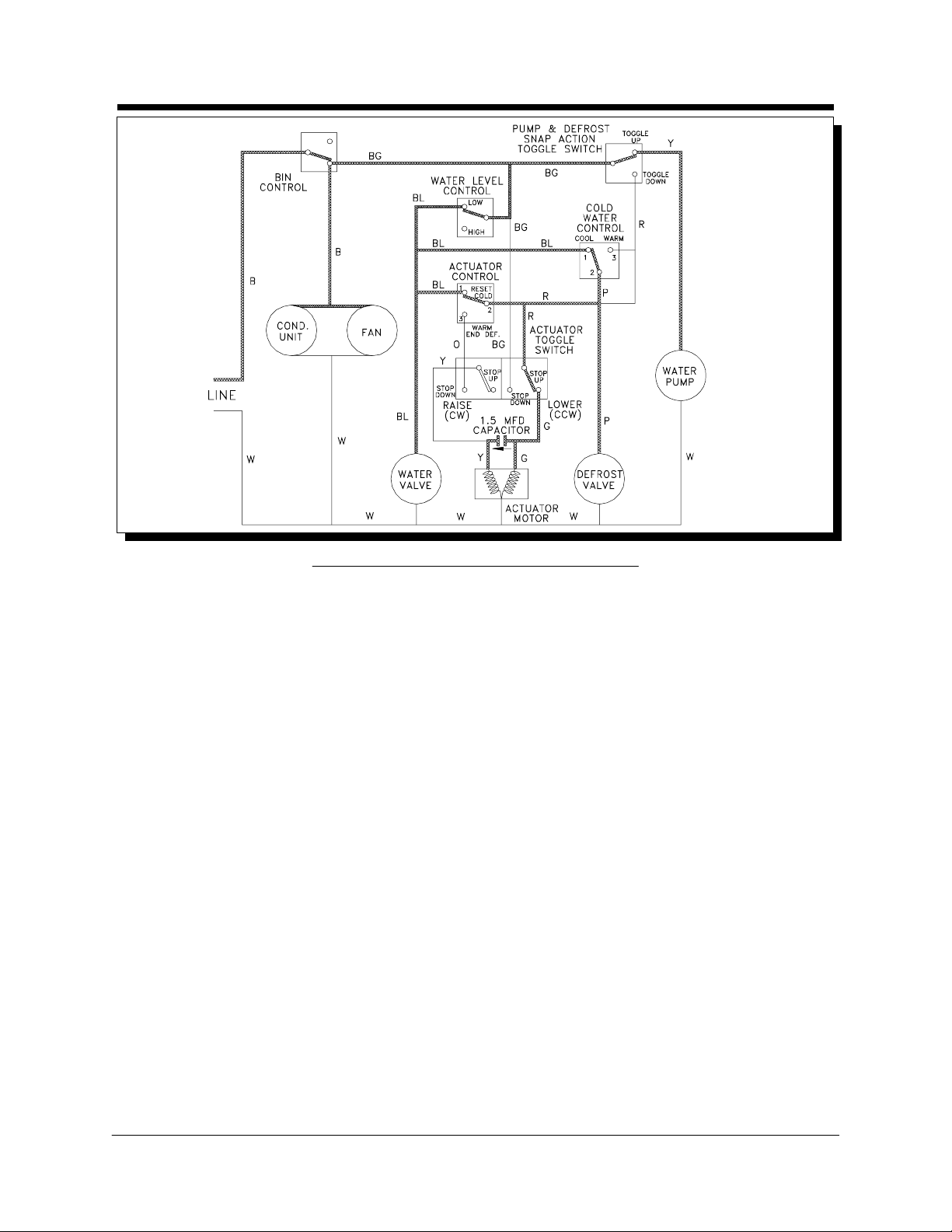

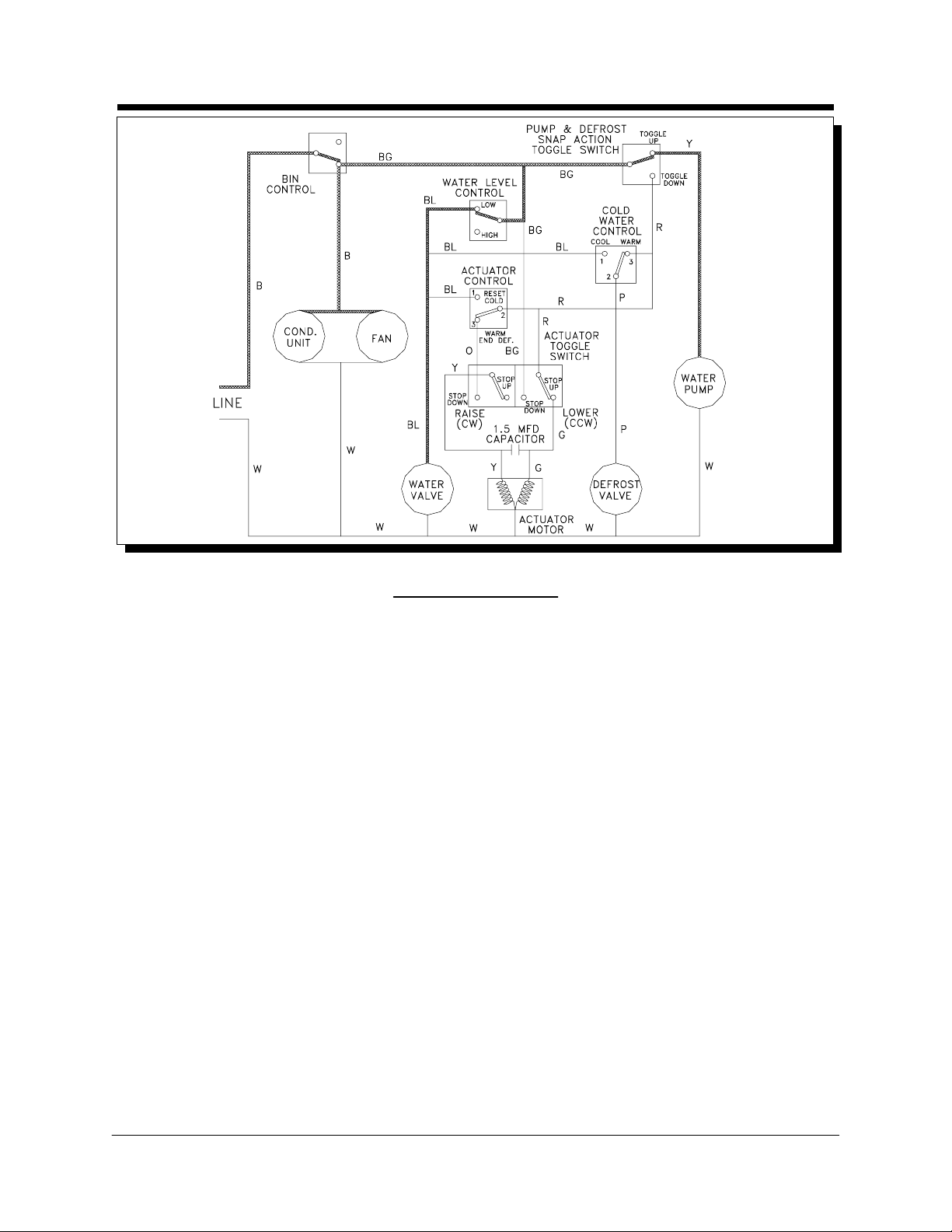

The schematic wiring diagrams, provided on these pages, show the flow of electric

Electrical Cir

cuits

current at several steps in the operation of the ice maker. The dark lines show current

flow on all wiring diagrams. Following the diagrams is a description of the operation

specificall y related to the circui ts that are used at each step. These circuits appl y to all

electronic and electromechanical ice makers built since 1964 and to those ice makers

in the field which have been revised to the 1964 wiring.

'EC' refer to Thermostatically controlled ice makers

'EEC' refer to Electronically controlled ice makers

EC1: Water fill (circulating water above 45} F.) - Current to condensing unit, water

pump and water valve. Water filling circulation tank and control tank. Water pump

circulating water through water header, distri bution laterals and jet holes to indi vidual

evaporator cells. Evaporator is cooling water (approximately 2 minutes).

EEC1: Water fill (circulating water above 45} F.) - Current to condensing uni t, water

pump and water valve. Water filling circulation tank and water level probe assembly.

Water pump circulati ng water through water header, distribution laterals and jet holes

to individual evaporator cells. Evaporator is cooling water (approximately 2 minutes).

Kold-Draft® Service & Parts Manual

Water Fill

-13B-

Page 15

Water Fill

E

lectrical Circuit

s

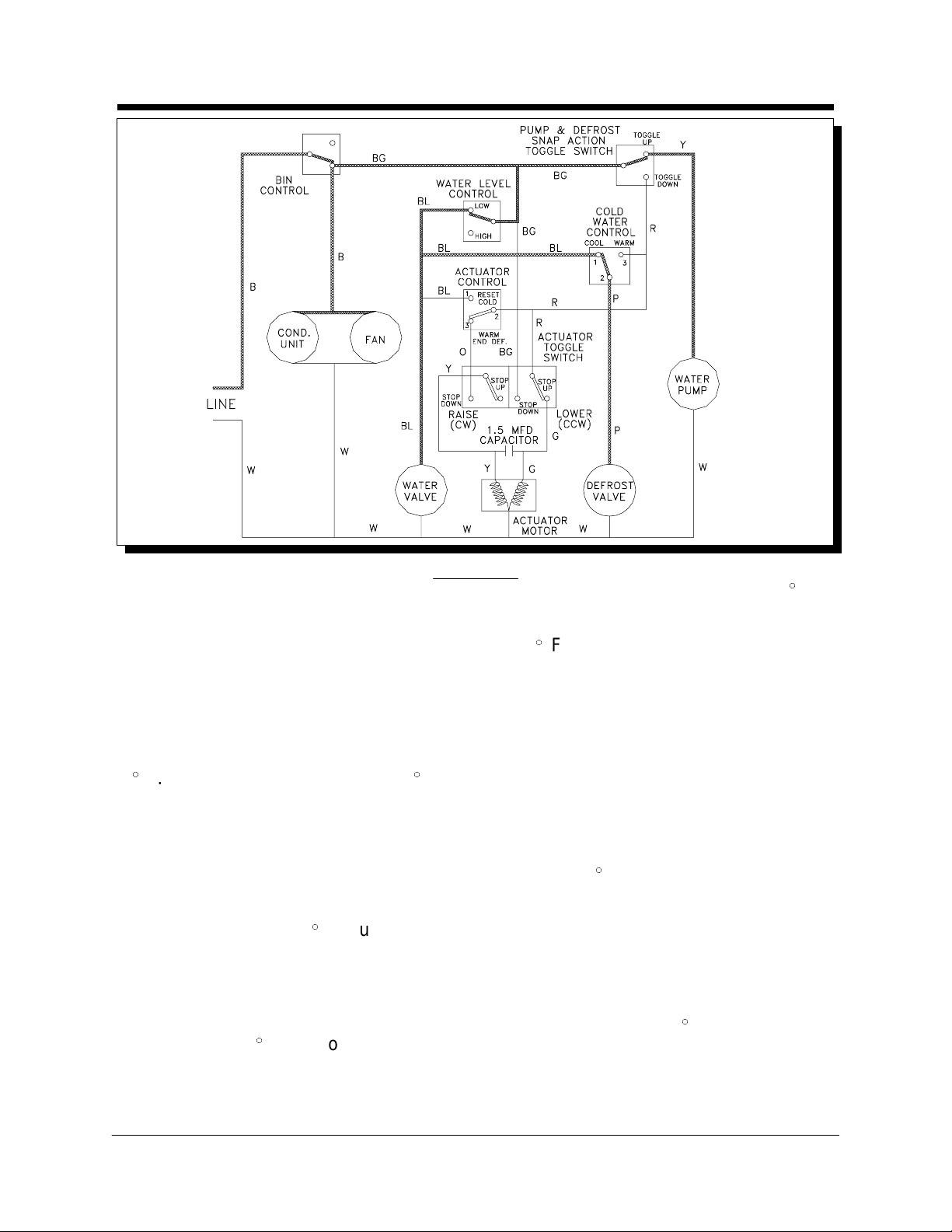

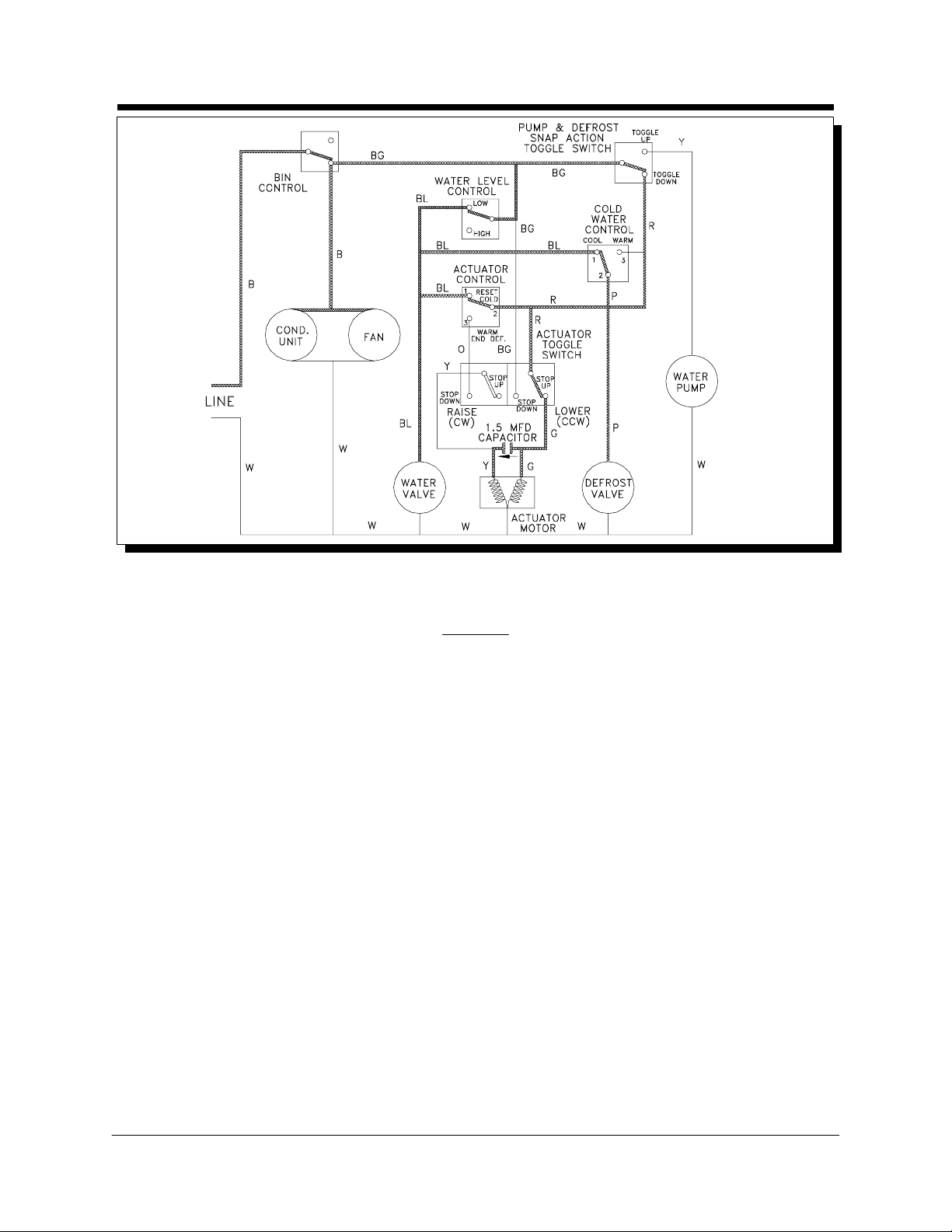

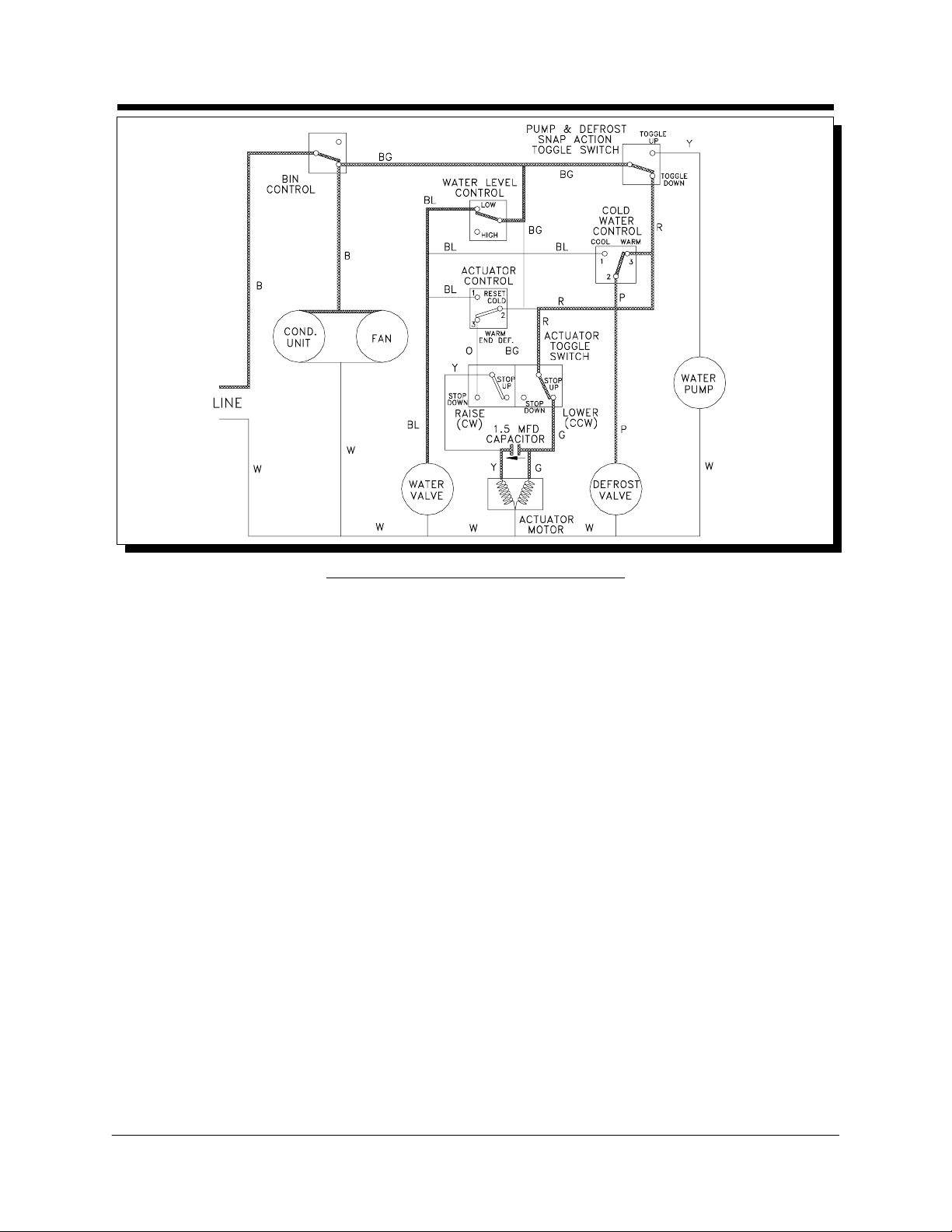

EC2: W ater fill (ice maker with cold water thermostat-circulating water below 40} F.) -

Current to condensing unit, water pump, water valve and through blue circuit through

cold water thermostat, pink circuit to defrost valve. When the incoming water is cold

and the compressor can cool the water below 40} F. during the 'Fill Cycle', the cold

water thermostat will switch to the cool side connecting the pink and blue circuits giving

power to the defrost valve allowing hot gas from the compressor to go through the

evaporator warming up the circulating water. GS models have no cold water

thermostat.

EC2a: Water fill (ice maker with cold water thermostat-circulating water warms up to

50} F.) - If the water warms up to 50} F. before the water fill is complete and the weight

control switch drops, the cold water thermostat will switch to the warm side shutting the

defrost valve and the compressor will start to cool the water again.

EEC2: W ater fill control (circulating water below 40 to 45} F.) - Current to condensing

unit, water pump, water valve and through blue circui t through cold water thermostat,

pink circuit to defrost valve. W hen the incoming water is col d and the compressor can

cool the water below 40} F. during the 'Fill Cycle', the cold water thermostat will switch

to the cool side connecting the pi nk and blue circuits giving power to the defrost valve

allowing hot gas from the compressor to go through the evaporator warming up the

circulating water.

EEC2a: W ater fill control (circulating water warms up to 50 to 55} F.) - If the water

warms up to 50} F. before the water fill is complete and water touches the top

thermistor water level probe, the cold water control will switch to the warm side shutting

the defrost valve, and the compressor will start to cool the water again. A red L.E.D. is

mounted on the printed circuit card below the cold water control potentiometer as a

service aid. It is on (bright) when the cold water control is in the cold position.

Kold-Draft® Service & Parts Manual

-14B-

Page 16

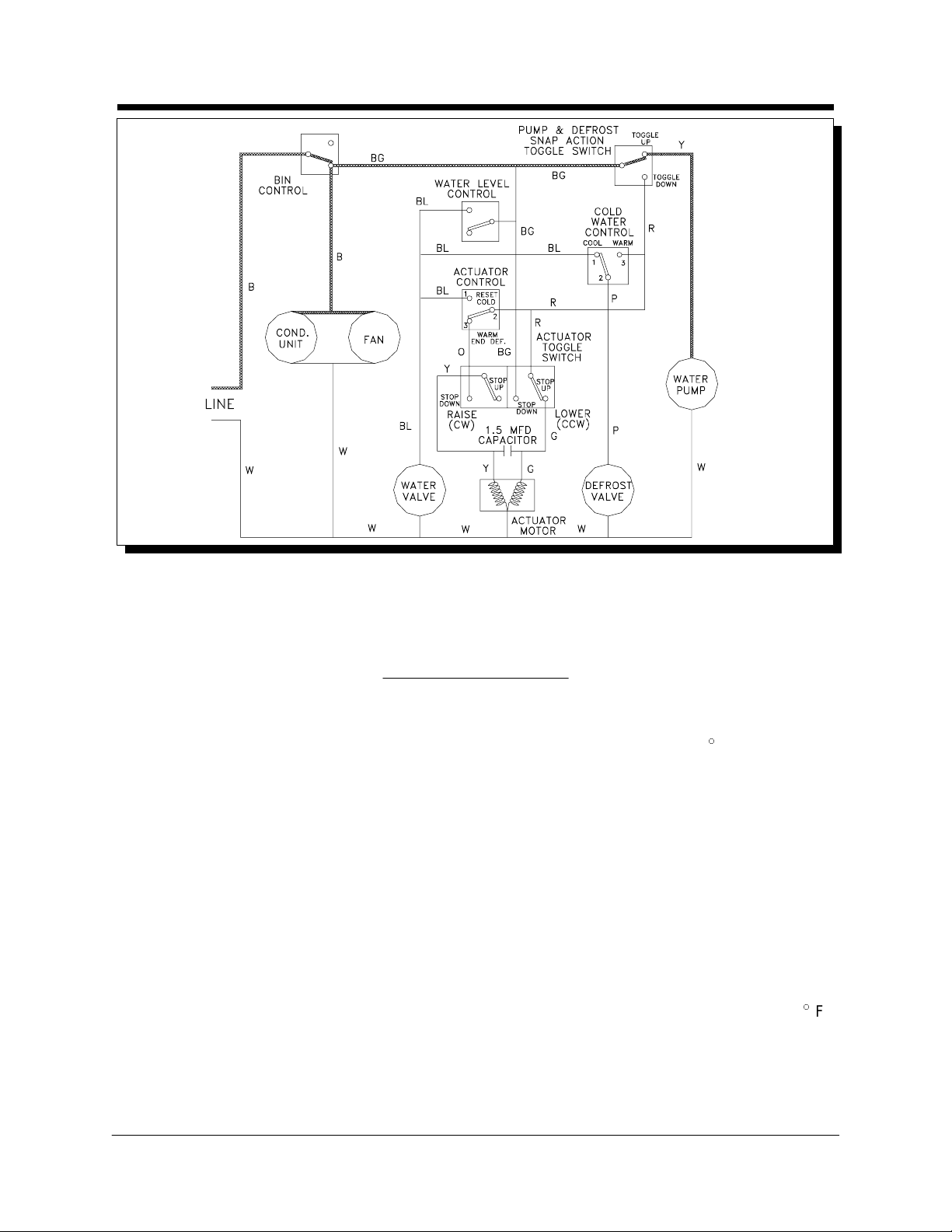

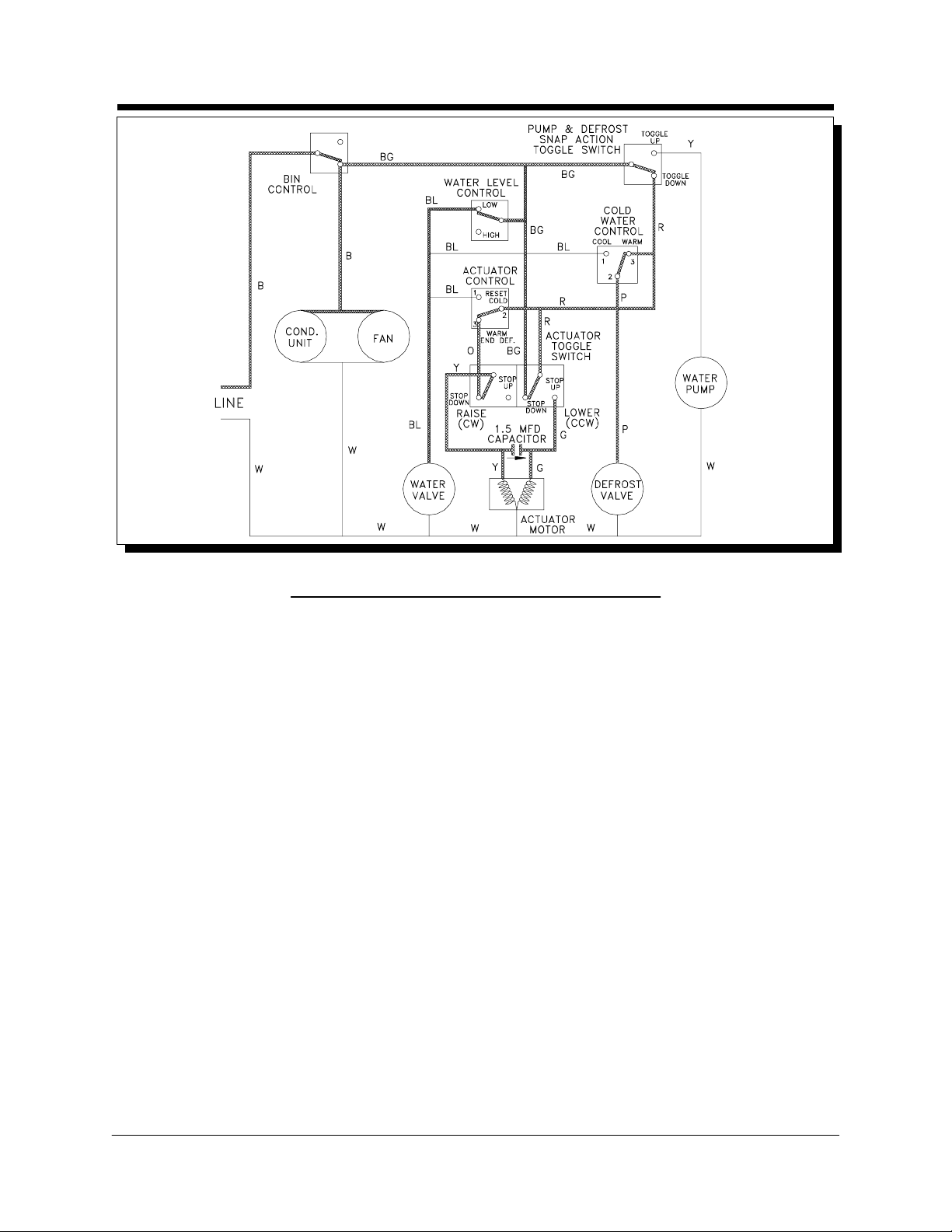

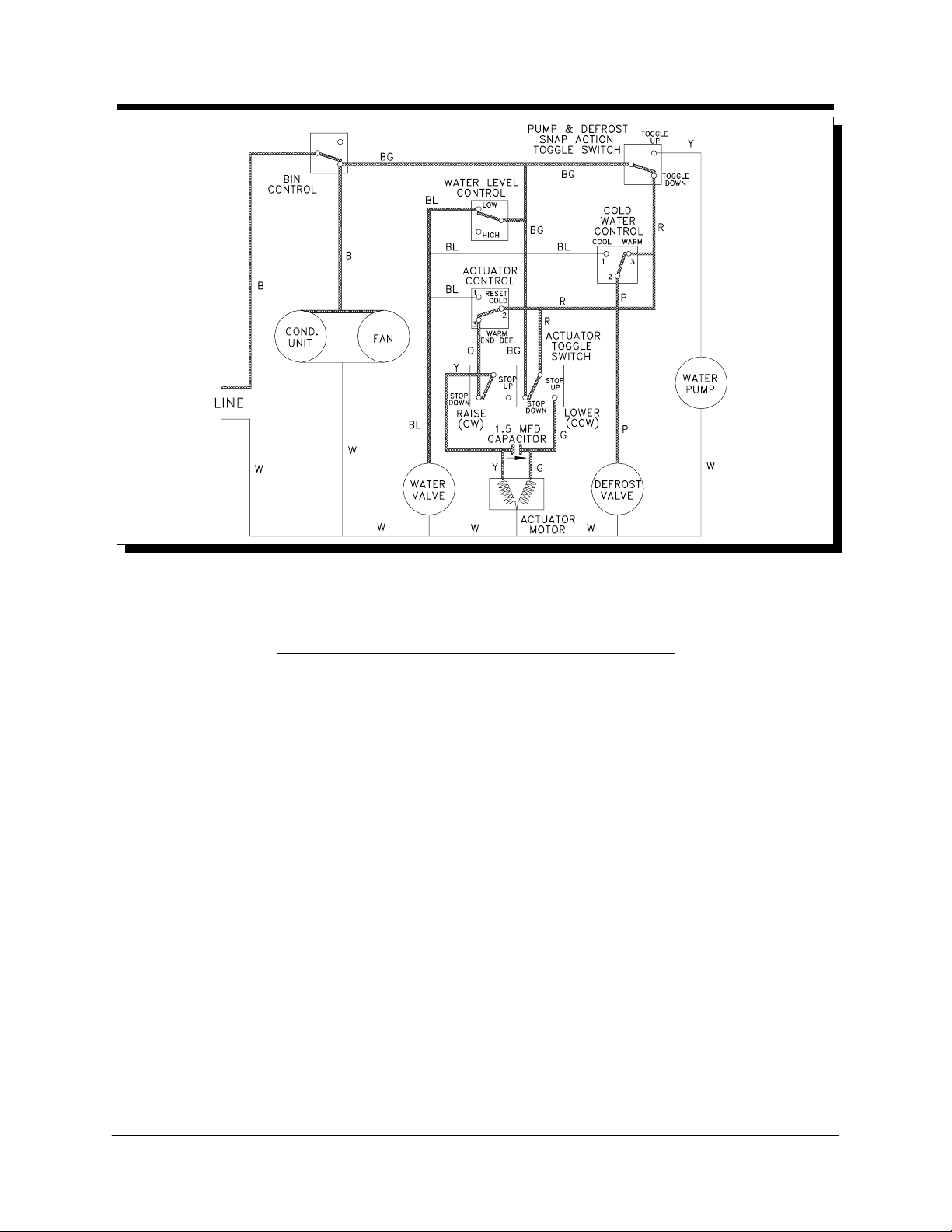

Start of Freeze Cycle

Electrical Circuits

EC3: Tanks full, weight switch drops (freeze cycle evaporator above 20} F.) - Sufficient

water is in the ci rculation tank and control tank so that the weight of the water in the

control tank pulls the weight control switch down shutting the water valve. If the cold

water thermostat is still on the cool side and the circulating water is still being warmed

as the weight control switch drops, this switch cuts off power to the blue circuit and

through the cold water thermostat to the defrost valve shutting the defrost valve. Water

level should settle in the control tank at a preset distance below the top of the main

circulation tank. (Refer to the Water Levels, Pressures, Cycles and Charges chart.)

Current to condensing unit and water pump. Water freezing in cells. Springs hold water

plate edges against bottom of cams. Cams and hinge leaves hold water plate

approximately 1/32" from evaporator to adequate fin between the cubes.

EEC3: Tank and water level probe assembly full-freeze cycle evaporator above 26

Sufficient water is in the circulati on tank and water level probe assembly so that water

touches the top thermistor probe and the water valve shuts off.

Kold-Draft® Service & Parts Manual

-15B-

}

F. -

Page 17

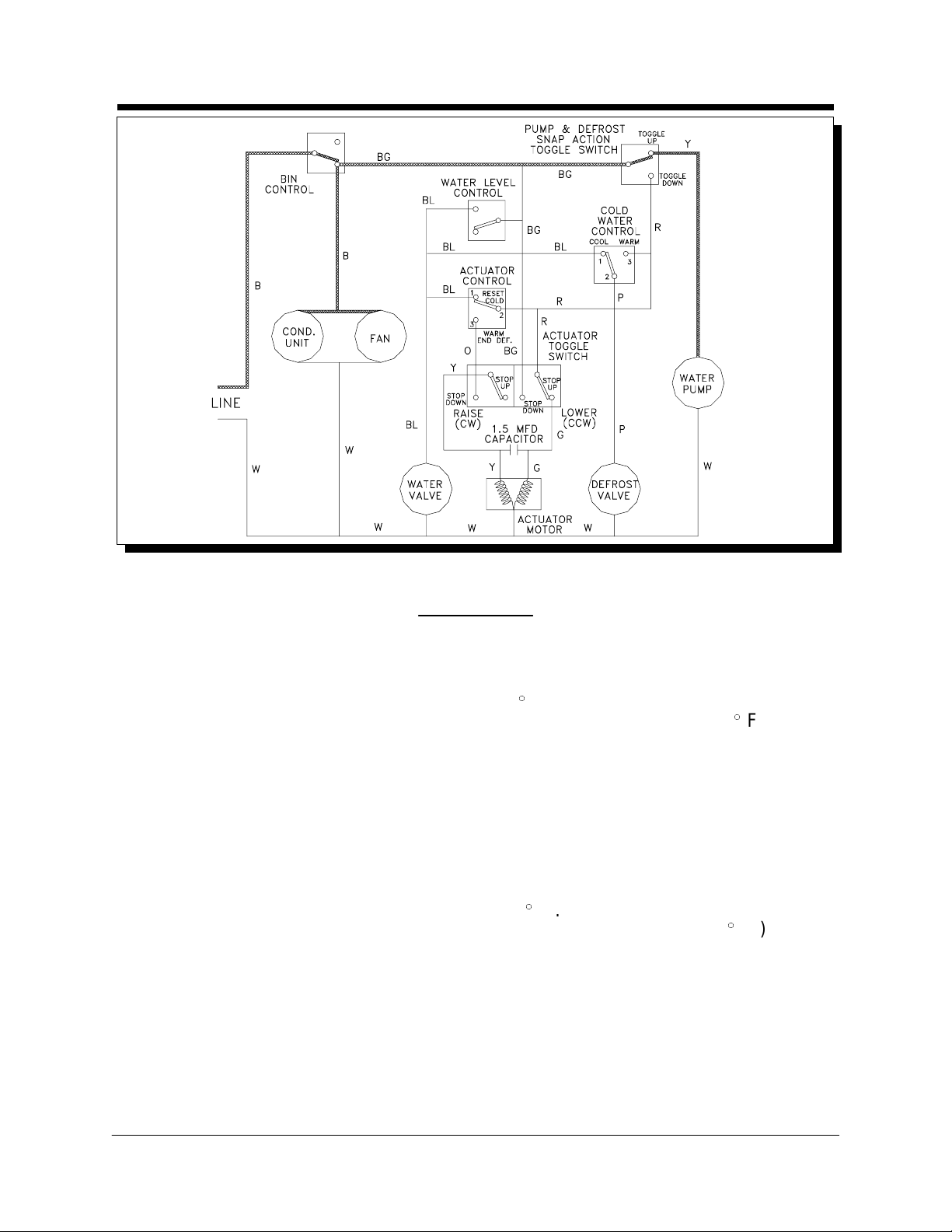

Freeze Cycle

Electrical C

ircuits

EC4: Freeze cycle with evaporator below 20} F. - During the freeze cycle, the

evaporator and the actuator thermostat get cold enough (approximately 20} F.) to reset

the actuator control ready for the next defrost cycle. The particular time when this

happens is unimportant since the water control stays off and prevents defrost until the

cubes are full and the water is used up, and there is no change in the current flow at

this step. During this peri od the water is being used up in the formation of ice and the

water level drops slowly in the circulation tank and the water level probe tube.

EEC4: Freeze cycle with evaporator below 26} F. - During the freeze cycle, the

evaporator and the thermistor probe get cold enough (approximately 26} F.) to reset

the actuator control ready for the next defrost cycle. The particular time when this

happens is unimportant since the water control stays off and prevents defrost until the

cubes are full and the water is used up, and there is no change in the current flow at

this step. During this peri od the water is being used up in the formation of ice and the

water level drops slowly in the circul ation tank and the water level probe tube.

L.E.D. i s

a service aid. It is on (bright) when the actuator control is in the cold position.

mounted on the printed circuit card bel ow the actuator control potentiometer as

An orange

Kold-Draft® Service & Parts Manual

-16B-

Page 18

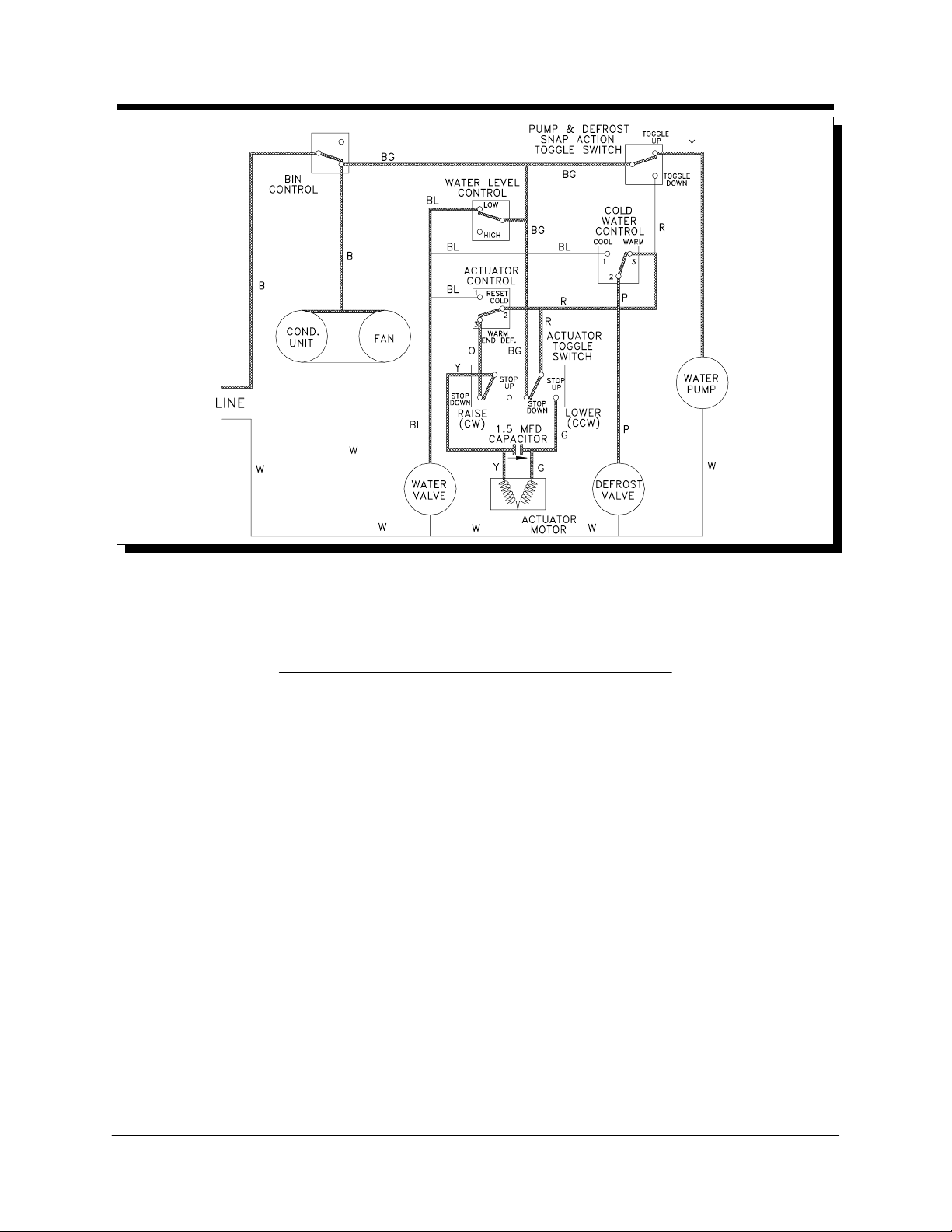

End of Freeze Cycle- Start of Defrost

Electrical Circuits

EC5: Start of defrost - Cubes are full and some have almost frozen over jet holes

forcing some of the remaining water faster through the control stream over the control

stream dam, lowering the water level rapi dly in the control tank until it i s light enough

for the weight control switch to snap up. Current flows to condensing unit, water pump,

through the weight control switch and the blue circuit to the water valve, also from blue

through the actuator thermostat, first connection is complete to the red defrost circuit.

From red, current flows through the actuator toggle switch givi ng 115 vol ts on the gray

actuator motor circuit; current through the capacitor which changes phase and boosts

the voltage to 200 vol ts on the yellow actuator motor circuit giving counter-clockwise

rotation. Current from the blue circuit flows through the cold water thermostat to the

pink circuit and defrost valve. Cams start rotating counter-clockwise pressing on the

cam brackets on the water plate to release it from the ice (approximately 15 seconds).

The open defrost valve allows hot refrigerant gas from the compressor to go through

the evaporator coil to start releasing the cubes.

EEC5: Start of defrost - Cubes are full and some have almost frozen over jet holes

forcing some of the remaining water faster through the control stream over the control

stream dam, lowering the water level rapidly in the water level probe assembly until the

bottom thermistor probe is exposed to air and trips the water level control on in 5-20

seconds. Current flows to condensing unit, water pump, through the weight level

control and the blue circuit to the water valve, also from blue through the actuator

control, first connection is complete to the red defrost circuit. From red, current flows

through the actuator toggle switch giving 115 vol ts on the gray actuator motor circuit;

current through the capacitor which changes phase and boosts the voltage to 200 volts

on the yellow actuator motor circuit giving counter-cl ockwise rotation. Current from the

blue circuit flows through the cold water control to the pink circuit and defrost valve.

Cams start rotating counter-clockwise pressing on the cam brackets on the water plate

to release it from the (approximately 15 seconds).The open defrost valve allows hot

refrigerant gas from the compressor to go through the evaporator coil to start releasing

the cubes.

Kold-Draft® Service & Parts Manual

-17B-

Page 19

Defrost

Elec

trical Cir

c

uits

EC6: Water plate lowering - The pump and defrost switch lever drops, stopping the

pump and completing the second connection to the red defrost circuit. The actuator

motor and cams continue to rotate counter-clockwise lowering the water plate. The

open water valve allows water to begin rinsing off the water plate. Current to the

condensing unit, actuator motor, water valve and defrost solenoid (approximately 20

seconds).

EEC6: Same as EC6

Kold-Draft® Service & Parts Manual

-18B-

Page 20

Defrost

Electrical Circuits

EC7: Defrost - W ater pl ate is wide open and actuator toggle rod on the actuator motor

coupling pushes the actuator toggle switch to the left, stopping the motor with the water

plate in the 'down' position and completing the third connection to the red defrost

circuit. Current to the condensi ng unit, water valve and defrost solenoid. Excess water

concentrated with minerals, drains from the water tank. Freshes water washes water

plate and tank. Hot refrigerant gas continues flowing through the evaporator releasing

the ice slowly. Edge of the evaporator and actuator thermostat bulb remain cool (32 to

}

35

F.) as long as ice remains in the evaporator (approximately 2 to 4 minutes

depending on ambient and hot gas temperature). Ice releases on the left side first and

rests on the water plate, then the ice falls out substantially all at one time as the fin

between cubes tends to hold them together until they drop into the bin. After ice falls

out, the side of the evaporator warms up rapidly to 45} F. (approximately 30 seconds).

The actuator toggle pushed left al so completes yellow/orange circuit but with no power

in the orange circuit, the actuator motor gets no power during the defrost period.

EEC7: Defrost - Water plate is wide open and actuator toggle lever on the actuator

motor rear shaft pushes the actuator toggle switch to the right, stopping the motor with

the water plate in the 'down' position and completing the third connection to the red

defrost circuit. Current to the condensing unit, water valve and defrost solenoid. Excess

water concentrated with minerals, drains from the water tank. Freshes water washes

water plate and tank. Hot refrigerant gas continues flowing through the evaporator

releasing the ice slowly. Edge of the evaporator and evaporator probe remain cool (32

to 35

}

F.) as long as ice remains in the evaporator (approximately 2 to 4 minutes

depending on ambient and hot gas temperature). Ice releases on the left side first and

rests on the water plate, then the ice falls out substantially all at one time as the fin

between cubes tends to hold them together until they drop into the bin. After ice falls

out, the side of the evaporator warms up rapidly to 45} F. (15-30 seconds). The

actuator toggle pushed right also completes yellow/orange circui t but with no power in

the orange circuit, the actuator motor gets no power during the defrost period.

Kold-Draft® Service & Parts Manual

-19B-

Page 21

End of Defrost-Water Plate Starts Closing

E

lectrical Circuits

EC8: Water plate starts closing - Warm actuator thermostat bulb on the side of the

evaporator switches actuator thermostat from cold position disconnecting the first

circuit to red; the current from black/green to the red circuit continues through the

actuator toggle and pump toggle switches. The actuator thermostat switching to the

warm position completes the red/orange circuit and through the actuator toggle gives

115 volts to the yellow winding on the actuator motor. The capacitor changes the phase

and boosts the voltage to 200 volts to the gray winding of the motor to give clockwise

rotation. Cams rotating clockwise pull up the springs and water plate. Current to

condensing unit, defrost water valve and actuator motor (approximately 20 seconds).

The cold water thermostat bulb on the edge of the evaporator will warm up at about this

time or dur ing closing and switch the cold water thermostat to the warm side connecting

the red to the pink circuit; since red is energized, the defrost valve stays open.

EEC8: Water plate starts closing - Warm evaporator probe on the side of the

evaporator switches actuator control from cold positi on disconnecti ng the first circuit to

red; the current from black/green to the red circuit continues through the actuator

toggle and pump toggle switches. The actuator control switching to the warm position

completes the red/orange circuit and through the actuator toggl e gi ves 115 volts to the

yellow winding on the actuator motor. The capacitor changes the phase and boosts the

voltage to 200 volts to the gray winding of the motor to give clockwise rotation. Cams

rotating clockwise pull up the springs and water plate. Current to condensing unit,

defrost water valve and actuator motor (approximately 20 seconds). The cold water

control will warm up at about this time or during closing and switch to the 'warm' side

turning off the red L.E.D. Models with GBB-03135-02-E P.C. cards will turn off the hot

gas valve at this time, regardless of the water plate position. Refer to model wiring

diagrams for circuit details.

Kold-Draft® Service & Parts Manual

-20B-

Page 22

End of Defrost-Water Plate Finishes Closing

Electrical C

ircuits

EC9: Water plate almost closed - Lift plate pushes up the pump and defrost toggle

switch, starting pump and disconnecting the second circuit to red, but current from

black/green to red continues through actuator toggle switch. Current to all operating

parts of the cuber. W ater starting to fill the tank. Hot gas from the defrost valve keeps

the evaporator warm to melt any small piece of ice that may be left on the water plate

as it closes. Cams continue rotating to upright position (approximately 5 seconds).

EEC9: Same as EC9

Kold-Draft® Service & Parts Manual

-21B-

Page 23

Start of New Cycle

Electrical Circuits

EC10: Water plate closed - End Defrost - Front cam in upright position pushes actuator

toggle switch to the right disconnecti ng the third and final circuit to red, stopping the

actuator motor with the water plate up and closing the defrost valve (cycle

completed-same circuit as EC1 - Water fill). Current to condensing unit, water pump

and water valve, cycle starts.

EC11: (Circuit not shown) - Bin full - Ice against bin thermostat tube opens bin

thermostat shutting off all parts of the ice maker. W hen ice is removed, bin thermostat

closes; ice maker will start up and operate regardless of what part of the cycle it was in

when it was shut off.

EEC10: Water plate closed - End Defrost - Front cam in upright position pushes

actuator toggle switch to the left disconnecting the third and final circuit to red, stopping

the actuator motor with the water plate up and closing the defrost valve (cycle

completed-same circuit as EC1 - Water fill). Current to condensing unit, water pump

and water valve, cycle starts.

EEC11: (Circuit not shown) - Bin full - Ice against bin probe after water fill cycle is

completed, opens bin control rel ay shutting off all parts of the ice maker. When ice is

removed, bin control relay closes; ice maker will start up and operate regardless of

what part of the cycle it was in when it was shut off.

Kold-Draft® Service & Parts Manual

-22B-

Page 24

Abnormal Opening of Water Plate

E

lectrical circuit

s

EC12: Abnormal opening of water plate - Sometimes a cube may stick to the water

plate while it is closing (EC8) and by stretching the springs, prevents the water plate

from closing enough to push the pump and defrost toggle switch up as it normally does

(EC9). The ci rcuit through the pump and defrost toggle switch will remain complete to

the defrost 'red' circuit to the lowering (counter-clockwise) side of the actuator toggle

switch so that, when the front cam pushes the actuator toggle switch to the ri ght, the

actuator motor will immediately reverse and, with cams rotating counter-clockwise, the

water plate will re-open. Current to condensing unit, water valve and through the pump

and defrost toggle switch to the actuator motor. Any other obstruction between the

water plate and the evaporator can cause the same effect as a cube on the water plate.

If the collar on the pump and defrost switch lift rod is set incorrectly so the switch will

not go all the way up, abnormal opening will occur. Further, if the water level is set

much too high and/or spring is unhooked, allowing the water plate to sag during the

water fill so that the defrost switch goes down, the circuit will be completed to the

actuator motor and the plate will open. Likewise, abnormal opening can be created

during the water fill or the beginning of the freeze cycle if the water plate is pulled down

by hand, stretching the springs until the pump and defrost switch goes down,

completing the circuit to the actuator motor. This is done to rinse the ice machine after

using ice machine cleaner. Opening by hand is also used to observe the jet streams by

allowing the cams to go down to horizontal, then pushing up on the pump toggle rod.

Further opening by hand allows a quick partial check of the weight control switch as the

water drains from the control tank and the switch snaps up with a small amount of water

left in the tank (during this check the the control tank tube, it must be a full 11" long to

prevent binding between the control tank and the control stream box on the water

plate).

EEC12: Same as EC12

Kold-Draft® Service & Parts Manual

-23B-

Page 25

Water Plate Closing After Abnormal Opening

Electrical C

ir

cuits

EC13: W ater plate cl osing after abnormal opening - Since the evaporator and actuator

control are warm during abnormal opening, a circuit is complete through the actuator

control to the orange circuit of the actuator toggle switch. As soon as the water plate is

wide open and the actuator toggle rod on the motor coupling pushes the actuator

toggle switch to the left, the motor will immediately reverse and with cams turning

clockwise, close the water plate.

EEC13: Same as EC13

If the obstruction remains, EC12 and EC13 will repeat. If the obstruction is removed,

such as the cube falling out, EC13 will be followed by EC9 and EC10 and normal

operation will resume.

Kold-Draft® Service & Parts Manual

-24B-

Page 26

Without the use of special tools or testers, these tests can quickly determine any major

S

peedy F

unction

al Tests

faults with the control module P.C. card, probes, or functional components. A small

screwdriver is required to fit the slots on the potentiometers.

Before starting the test, be sure that there is power to the ice maker and check

the fuses in the control module box and the supplemental line fuses (if installed).

A "Open" terminals simulate a 'Cold' signal to the

P.C. card.

B "Short" terminals simulate a 'Hot' signal to the

P.C.card.

C Turn the wash switch to "Wash" to prevent

compressor short cycling during tests. To

perform a speedy test, induce the following

conditions on TB2.

D A screwdriver may be used to short the pins.

LWEB

OpenOpenOpenShortOpen

H**

Cuber stops, Orange and Red L.E.D.'s ON brightOpenOpenOpenOpenOpen

Cuber runs, Orange and Red L.E.D.'s ON brightOpenOpenOpenOpenShort

Cuber stops, Orange and Red L.E.D.'s OFF (may glow dimly)OpenOpenOpenShortShort

Harvest begins (allow plate to open fully), both L.E.D.'s ON brightOpenShortOpenOpenShort

Press relay #1 plunger*, water plate closes, both L.E.D.'s OFF or

dim

* If Relay #1 plunger is not accessible, CAREFULLY jumper the CONTACTS (B to

B/G)

** Used only with optional Status Indicator. See text for details if necessary.

To Test Probes

A The nominal resistance of all probes at +32o F is 5650 ohms. The only practical

accurate method is to test resistance of the probe in ice water (as near to +32

F as possible). The ranges of acceptable resistances are :

Acceptable RangeProbe

5400-5900 OHMSBin (GBR-03177)

5530-5770 OHMSEvaporator (GBR-03176)

4650-6650 OHMSWater Level (GBR-03170)

B To ROUGHLY test probes using the P.C. card, connect each probe in turn to the

'E' pins with all other pins left open. Turn the cold water potentiometer to

mid-range (12 O'clock). A warm probe will turn BOTH L.E.D.'s 'OFF'.

Submerging the probe in ice water will turn the RED L.E.D. 'ON'. Reaction time

is 5-20 seconds. Be sure to return the cold water potentiometer to its original

position after the probe tests.

o

Kold-Draft® Service & Parts Manual

-25B-

Page 27

Note: Common to Electronic and thermostatically controlled cubers (regular type)

Trouble, Cause & Remedy

Electronic only (bold type)

Thermostatically controlled cuber only (italicized type)

REMEDYCAUSE/SYMPTOMTROUBLE

not the compressor.

the condenser fan.

Condenser fan operating, but

the condensing unit is operating

intermittently during the freeze

cycle. Determine if the unit

returns to normal operation at

the end of the defrost cycle.

Line fuse blownCuber will not start

Bin full of ice

wires.

No money i n meter if m eter is

used.

Room too cold (below 45 deg.

F.)

loose.

counter-clockwise position.

Bin relay coil

Compressor stuck or defective.Condensing fan operating but

Defective overload switch.

Open wash switch.

cut-out.

Dirty condenser coil.

Low Voltage

electronic system.

Check circuit for short or

ground. Replace fuse.

Repair or replace.Open circuit in cord or feed

Warm room. Consult factory

for cold room application.

Check defrost circuit.Overheated evaporator.

Replace fuse.Blown fuse on PC card.

Install bin probe properly.Bin probe disconnected or

Adjust clockwise (colder)Bin potentiometer in full

Check probe resistance.Defective bin probe

Check probe resistance.Shorted evaporator probe.

A good coil has 100 ohms

resistance. Replace if

defective. Check wiring.

Test PC card.Defective PC card.

Jar with mallet. Replace if

defective.

Replace capacitor or relay.Defective capacitors or relay.

Repace overload switch or if

internal, replace compressor.

Switch to “Ice” position or

replace if defective.

Check charge and condenser.Open high or low pressure

Check wiring.Circuit not complete.Compressor operating but not

Replace motor.Fan motor defective.

Clean coil.

Correct to proper voltage, not

less than 5% below t hat stated

on nameplate.

Reduce the chargeRefrigerant overcharge

Replace fuse.Fuse blown one leg of 3-wire

Kold-Draft® Service & Parts Manual

-26B-

Page 28

REMEDYCAUSE/SYMPTOMTROUBLE

Trouble, Cause & Remedy

Compressor cuts out.

Water plate opens and closes

constantly. Wat er plate closes

all the way when cams are up,

but defrost valve stays open

and pump does not run.

Water plate opens before water

probe assembly tube or weight

control tank is full.

Water plate will not completely

close.

Defective run capacitor.

Open high or low pressure

cutout.

Maladjusted pump & defrost

switch.

Water plate does not close all

the way.

Spring missing or springs

weak, allowing water plate to

lower slightly, as water fills

tank, until the pump switch

drops and the plate opens

under power.

Drift stop not adjusted. Cams

drif t counter-cloc kwise until the

water plate lowers enough to

drop the pump switch.

Slow water fill.

Orange and Red L.E.D.s

bright on PC card.

Actuator thermostat out of

adjustment or defective.

Obstruction between the

evaporator and water plate.

Lift bolt, for pump toggle on

water plate, is too high,

holding the water plate away

from the cams.

Collar on lift rod too low,

holding the water plate away

from the cams.

Run capacit or should draw 1 t o

3 amps. GB2 & GB4, 4 amps.

Check refrigeration system

pressure.

Adjust lift bolt on water plate

to push switch lever up,

closing the hot gas valve

and starting the pump when

the water plate is up.

Adjust t he lift rod collar to push

the pump switch up, closing the

hot gas valve and starting the

pump when the waterplate is

up

Remove any obstruction.

Adjust hinge for proper water

plate gap. Confirm that water

plate bracket s are tight agai nst

cams. Ckeck springs.

Replace springs.

Remove drift stop from the

front of the actuator motor.

Bend the spring for more

tension on the motor shaft.

Improve water supply. Clean

strainer.

Adjust cold water control on

PC card. Test evaporator

probe and PC card.

Adjust or replace actuator

thermostat.

Remove obstruction. Check

clearance between the water

plate and evaporator.

Adjust lift bolt so the water

plate comes up against the

cams while the lift bolt holds

the pump switch up.

Adjust collar so the wat er plate

comes up against the cams

while the lift rod holds the

pump switch up.

Kold-Draft® Service & Parts Manual

-27B-

Page 29

Water plate closes before

Trouble, Cause & Remedy

cubes drop.

Water plate stays wide open

after defrost and all ic e i s out of

the evaporator

evaporator will not defrost.

Water pump does not operate.

Actuator pot on PC card

adjusted too cold.

Actuator thermostat adjusted

too cold.

Orange L. E. D. stays l it o n P C

card.

Orange L.E.D. is off, but no

voltage to the yellow

actuator motor lead.

No voltage to #3 (orange lead)

of actuator thermostat.

Voltage to #3 (orange lead) of

actuator thermostat, but no

voltage to yellow actuator

motor lead.

Inadequate hot gas volume.

Red L.E.D. is on.

Red L.E.D. is off.

Cold water thermostat not

making contact.

or in control module box.

Pump windings burned out or

off on thermal overload.

water pump and pump-defrost

switch.

REMEDYCAUSE/SYMPTOMTROUBLE

Adjust to warmer position

(ccw). Waterplate should

remain down 10 to 30

seconds after ice drops.

Test probe resistance.Faulty evaporator probe.

Test PC cardFaulty PC card.

Adjust to a warmer position

(ccw). Water plate should

remain down 10 to 30 seconds

after ice drops.

Straighten fins.Bent evaporator fins.

Adjust the actuator control

slightly clockwise. Test the

evap. probe and PC card.

Check wiring. Replace

actuator toggle switch.

Actuator thermostat adjusted

too warm or bulb has lost

charge.

Wiring loose or defective

actuator toggle switch.

Check for leaks and recharge.Refrigerant charge low.Water plate open, but

Check for tube obstruction or

cold condenser.

Replace valve or coil.Defective hot gas valve.

Check voltage at defrost

valve coil. If not 115 V. test

PC card.

Check evaporator probe and

PC card.

Tap cold water thermostat or

short across pink and red

leads. If defrost valve opens,

change thermostat.

Replace fuseFuse blown in transformer box

Replace pump motor.Pump bearings defective.

Allow to cool , or repl ace m otor.

Check for 115 V., plus or minus

10%

Check circuit and switch.Circuit incomplete between

Kold-Draft® Service & Parts Manual

-28B-

Page 30

not pumping water.

Trouble, Cause & Remedy

A few cloudy cubes, others OK

Holes in all cubes sometimes

but solid cubes most of the

time.

Control stream does not go

over t he dam at the end of the

freeze cycle.

Kold-Draft® Service & Parts Manual

Water pump pressure too lowMost cubes not fully formed.

system

evaporator.

Some holes in waterplate

clogged.

Superheat too low.Holes in left side cubes.

Superheat too high.Holes in right side cubes.

filling tank or temporary power

loss near the end of t he freeze

cycle.

Bin control turns cuber off

during water fill.

Bin thermostat turns cuber off

during water fill.

Water level too low.Holes in cubes all of the time.

Lower water level probe too

high.

-29B-

REMEDYCAUSE/SYMPTOMTROUBLE

Replace impeller.Impeller loose.Water pump motor running but

Clean or replace strainer.Clogged strainer in tank outlet.

Replace impeller.Impeller broken.

Check bearings. Check

voltage. Replace pump.

Clean or replace strainer.Clogged strainer in tank outlet.

Fix leak or replace water plate.Leak in water circulation

Correct alignment.Waterplate not aligned with

Open holes with 1/16” drill.

Flush laterals.

Close TXV in 1/8 turn

increments until corrected.

Open TXV in 1/8 turn

increments until corrected.

Correct power source.Power shut off while water is

Interlock between water fill

control and bin control not

operating. Check PC card.

This condition can happen

occasionally on any cuber, but

the frequency can be reduced

by adjusting the bin

thermostat warmer

(counter-clockwise). The

machine will then turn of f more

quickly when ice contacts the

bulb. Test by applying ice

cubes to the bulb tube. The

machine should restart within

five minutes.

Measure from the top edge of

the water tank down to the

water level in the water level

control tube. Sight carefully

across the water in the control

tube. See “Chart of Water

Levels, etc.” Increase water

level if required.

Adjust water level probe to

remain immersed in water in

control tube at least 10

seconds after the control

stream starts going over the

dam.

Page 31

Control stream does not go

Troub

le, Cause and Remedy

over the dam at the end of the

freeze cycle. (Continued from

previous page.)

Holes in all cubes. Control

stream does go over the dam.

plate will not come down.

Some cubes hang up in the

evaporator and become

distorted.

individual cubes.

Leak in water systemHoles in cubes all of the time.

Control stream too high

allowing water to splash over

the dam during the freeze

cycle.

Control stream obstructed.Cuber will not harvest. Water

Warm air infiltration from

compressor compartment or

room.

Orange L.E.D. does not

come on.

come on, but probe is good.

Inoperative lower probe.

Actuator thermostat out of

adjustment.

switch.

Fin too thin.Cubes do not harvest i n a slab.

Deformed evaporator cells.

Fin too thick.Slab does not break up into

REMEDYCAUSE/SYMPTOMTROUBLE

Water dripping steadily off the

circul ati on tank indi cat es a l eak

which should be located and

repaired. Make sure all lateral

plugs are in place.

Lower control stream. Turn

adjusting screw clockwise.

Loosen adjusting screw to fl ush

out foreign matter.

Check motor and circuit.Actuator motor problem.

A. Secure all skin panel s.

B. Skin gaskets must seal.

C. All panels must seal to

prevent air from the

compressor compartment

getting into the ice making

compartment. Check top cover

over the partition especially.

Check evaporator probe

resistance.

Test PC card.Orange L.E.D. does not

Check water level probe

connections. Test probe

resistance. Test PC card.

Adjust switch differential.Control tank will not snap up

Adjust slightly counter

clockwise.

Replace switch.Defective actuator toggle

Restore power.Power supply has failed.

Adjust waterplate hinges to

1/32” fin thickness.

Straighten cells with smooth

jaw pliers.

Adjust hi nges up or evaporat or

down. Leave 1/32” space

between the waterplate and

evaporator.

Kold-Draft® Service & Parts Manual

-30B-

Page 32

Unusually long cycles.

Trouble, Cause and Remedy

Some cubes do not for m in the

right side corners of the

evaporator.

causing shear pins to break.

synchronization on GB4,

GB903, GB1003 or GB1205

cubers.

Voltage below required

potential at the cuber.

Hot air leaks between

condensing unit compartment

and freezing compartment.

Expansion valve too far open.

Expansion v alv e too far closed

with large holes in right side

cubes.

Water level too high.

Refrigerant low.

Fan not operating.

Spray holes at the ends of the

lateral s are f rozen shut and wil l

not thaw because of very low

incoming water temperature.

Water fill level too high.Ice freezes to water plate

Incorrect clearance between

the water plate and evaporator.

Control stream will not go over

dam at the end of the freeze

cycle.

REMEDYCAUSE/SYMPTOMTROUBLE

Check power source for full

vol tage. Run m ini mum 12 G A.

wire directly to the cuber to

prevent line loss.

Clean condenser.Dirty condenser.

All skin panels must be tightly

sealed.

Close TXV in 1/8 turn

increments so that there is no

frost back to the compressor

and pressures are according to

the “Chart of Water Levels,

etc.”

Open TXV in 1/8 turn

increments. Recheck to see

that there i s no frostbac k to t he

compressor at the end of the

freeze cycle.

Adjust water level according to

“Chart of Water Levels, etc.”

Check for and repai r leak. Add

refrigerant as required.

Replace compressor.Compressor defective.

Adjust control stream.Control stream too low.

Check fan wires, repl ace motor

if nec essary.

Thaw out by shutting off unit

and adjust the cold water

control warmer (CCW). Adj ust

expansion valve 1/8 turn

closed.

Adjust fill level per “Chart of

Water Levels, etc.”

Adjust water plate and/or

evaporator as required.

Adjust control stream.Misadjusted control stream.

Cracked water plate causing

pressure loss. Repair or

replace water plate.

See GB900/GB1000 section.Water plates out of

Kold-Draft® Service & Parts Manual

-31B-

Page 33

Water valve stays closed.

Troub

le, Cause and Remedy

Water valve stays open after

water covers the upper probe

tip. Will not shut off.

Water valve stays open more

than 5 seconds after water

covers the upper probe tip.

Water level probe connector

loose or dirty.

assembly.

Circuits okay, 115 volts to

water valve. Coil open. Flow

control jammed or cockeyed.

Water level probe connector

loose or dirty.

assembly.

Water pressure below 15

P.S.I.

Upper probe covered with

scale.

REMEDYCAUSE/SYMPTOMTROUBLE

Clean connector and install

properly. Low probe lead to

right. Use NC123 or any

electrical contact cleaner.

Check probe resistance.Defective water probe

Replace coil, clear valve

passages or replace valve.

Test PC card.Defective PC card.

Clean connector and install

properly. Low probe lead to

right. Use NC123 or any

electrical contact cleaner.

Check probe resistance.Defective water probe

Test PC card.Defective PC card.

Increase water pressure to

ice machine.

Replace water valve.Defective water valve.

Clean cuber w ith ice machi ne

cleaner. If necessary,

remove and clean probe

carefully.

Kold-Draft® Service & Parts Manual

-32B-

Page 34

GB900/GB1000/GB1200/GB4

Service and Troubleshooting

These ice makers differ from other Kold-Draft® ice makers in that two ice making

sections are refrigerated by one condensing unit. GB900/GB1000/GB1200 series are

electronic versions of the GB4.

The upper ice making section, also known as the "master," contains the controls

necessary to operate both sections si multaneously, while the lower or "slave" section

contains only those switches required to operate the actuator motor and water pump,

and to provide synchronization between the two water plates.

The GB4 uses an electrical synchronization system to ensure that both water plates are

fully closed before the freeze cycle begins, and to prevent repeated false harvesting

caused by "out of time" actuator motors.

There are two key parts in the synchronization system. A modified rotor in the top

actuator motor to slow the motor by 5 seconds, and a resistor between the upper and

lower actuator toggle switches to stall the lower motor in the closed position at the end

of harvest.

Synchronization is achieved by the lower actuator motor running slightly faster than the

upper motor, stalling upon direction reversal in the full upright (12 O'clock) position,

thus allowing the upper motor to catch up and synchronize. Upon upper motor direction

reversal, both motors continue to the end of the travel limit in the other direction and

repeat the same synchronization procedure. With ice in the evaporators, both plates go

down and stop together in the full down position automatically synchronized. When dry

cycling the cuber without ice, the lower actuator motor trips the lower actuator toggle

switch and raises ahead of the upper actuator motor. Synchronization occurs when the

lower actuator motor stalls after raising to the 12 O'clock position and waits for the

upper actuator motor to catch up.

This diagram shows the synchronization

circuit. The dotted lines indicate an

interim sub-circuit which was used from

9-81 until 1-83. To update any GB4, cut

the yellow/white in the upper channel,

tape the ends and install a modified rotor

kit (GBR-03110-01) in the upper actuator

motor. Cubers made before 9-81 do not

have the yellow/white wire in the upper

channel (unless they have been field

modified) and only the modified rotor is

required for updating.

Kold-Draft® Service & Parts Manual

-33B-

Page 35

The ice maker use two water pumps and they are connected to the transformer

Service and Troubleshooting

independently to decrease the load on the 115 v. tap.

As can be seen from the above diagram, the 4-amp fuse protects the transformer as it

does in all GB series ice makers, but the pumps will continue to operate if the fuse

opens as the pumps are actually connnected in Series across the line taps of the

transformer.

To allow the water pumps to operate independently, a D.P.D.T. pump & defrost toggle

switch is used in the l ower channel. The left contacts power the pump when the water

plate is closed, and the right contacts permit caught-cube false harvesting through the

red circuit.

The transformer box contains high and low pressure cut-outs, as do all 1 H.P. and

larger Kold-Draft® cubers, and also a high and low cut-out relay.

The above diagram illustrates the cut-out circuitry, and shows that compressor current

is controlled by a heavy-duty relay rather than the cut-out contacts which are not heavy

enough to reliably handle the amperage required of the GB4 compressor. The high and

low pressure cut-outs supply voltage only to the coil of the control relay, which will

open if either of the cut-outs open due to excessively high or low refrigerant pressure.

Kold-Draft® Service & Parts Manual

-34B-

Page 36

The ice maker contains two evaporators and therefore two expansion valves, but only

Service and Troubleshooting

only one hot gas defrost valve.

As can be seen by the simplified refrigeration diagram above, the hot gas defrost

tubing from each evaporator is joined at the hot gas valve, and provides a refrigeration

circuit (during the freeze cycle) between the evaporators. As the evaporator inlet

pressures are never exactly equal, refrigerant can flow from one evaporator inlet to the

other through the hot gas tubing, causing frost on the tubi ng. To the service man not

familiar with the GB4, this can be a startling phenomenon (hot gas lines are not

supposed to be cold). but is perfectly normal and has little or no effect on the operation

of the cuber. To minimize frost on the hot gas tubing (which turns to water during the

defrost cycle) a ball check valve was added 8-82 to the hot gas line feeding the upper

evaporator. During harvest, the check valve opens fully and allows unrestricted hot gas

to both evaporators. During the freeze cycle the upper evaporator expansion valve,

which is set at a slightly lower superheat than the lower expansion valve, will cause the

check valve to close and block refrigerant flow through the hot gas tubing.

Theoretically, both expansion valves can be set at the same superheat, as the

gravity-operated ball check valve requires approximately 1/4 p.s.i. to unseat. Hot gas

line frost will not occur as long as the inlet pressure in the upper evaporator is equal to

or greater than the inlet pressure in the lower evaporator.

Kold-Draft® Service & Parts Manual

-35B-

Page 37

GB1204/GB1205

Service and Troubleshooting

The GB1200 series cubers are derived from the GB903/GB1003 series ice makers, and

therefore share the same synchronization circuits, water pump control wiring and

refrigeration circuit.

The compressor used in the GB1205 series is 208/230 volt-60 hz.-3 phase. The

GB1204 series uses a 208/230 volt-60 hz.-1 phase, and therefore uses a line contactor

for compressor operation. The following diagram illustrates the contactor circuit, and

also shows the transformer connection to provide singl e phase 115 volt power for the

water pumps and solenoid valves.

Although the refrigeration circuit is identical to the GB4/GB903/GB1003, the

compressors in the GB1200 series use R-502 refrigerant along with R-502 expansion

valves.

Kold-Draft® Service & Parts Manual

-36B-

Page 38

Actuator Motor Electrical Tests

Service and Troubleshooting

on the white

motor

lead. If power is OK:

Winding open

position, 0 v. in the other position

Winding open

AND>

position, 0 v. in the other position

Change capacitor.

Good

Open

"B" from table

tightness. Change motor if all OK.

The following tests are for troubleshooting the actuator motor and related circuits:

Use an AC voltmeter set for proper range. Vo ltages in the tables are measured across

the motor reversing capacitor (between the colored motor lead wires).

> If there is no i ce in the evaporator(s) and the water plate(s) i s (are) not fully cl osed

with the pump(s) running AND the actuator switch(es) tripped UP, the actuator motor(s)

should be running. If not, be sure that there is power to the motor(s) and that it (they)

is (are) not off due to high temperature (NEW STYLE). Always refer to the proper

wiring diagram when troubleshooting.

> In dual evaporator models if only one motor appears to be running as it should, be

sure that you understand the synchronization circuit (see text).

> For OLD STYLE motors in 208-230/60 or 220-240/50 CLASSIC cubers, the voltage

between the white motor lead (connected to the voltage reducti on capacitor) and the

colored lead (gray or yellow) being powered by the actuator switch must be 90 to 130

volts. This varies with li ne voltage, and if not within these li mits the motor(s) may not

provide adequate performance. Be sure that the proper capacitor is installed (see

text).

> Motor winding resistance's at 75o F out of the circuit are as follows:

All OLD STYLE motors, white to gray or yellow, approximately 450 ohms.

NEW STYLE 115 volt motors, white to black or yellow, approximately 95 ohms.

NEW STYLE 230 volt motors, white to red or yellow, approximately 400 ohms.

Voltages for test table below

Actuator Motor Style "A" "B"

OLD STYLE, ALL 180-240 90-130

NEW STYLE, 115 VOLT 180-240 LINE

NEW STYLE, 230 VOLT 290-370 LINE

RemedyMotorCapacitorVoltage Reading

Tap gearcase to align bearings; check

cam shaft for binding; check drift stop

Change both motor and capacitor.One Motor

Change motor.One Motor

Disconnect motor from circuit and

test winding resistance's (see text). If

normal, change the capacitor, and if

erratic change the motor.

"B" from table in one actuator switch

0 v. in both positions EXCEPT DUAL

EVAP. SLAVE DURING NORMAL STALL.

Be sure there is power to the motor ("B"

from table) by leaving one probe on either

capacitor lead and placing the other probe

Open

Good"A" from table in one actuator switch

Shorted

OR>

GoodGood"A" from table

Both Motor

Windings open

Testing C/R-C Network GB-3244 (electronic cubers only)

CAUTION: To protect your meter, short all terminals together before testing.

1- Set ohm meter on R x 1000 (1k) scale.

2- W to G- Connect test leads. Reverse test leads and the meter should deflect. A good component will

cause the meter to drop to about 200k ohms and then climb back to infinity.

3- G to Y- Connect test leads and then reverse. The meter should drop to about 150k ohms and then

climb back to infinity.

4- If the meter goes to the approx. ohm readings listed above and stays there, the capacitor is shorted

and should be replaced.

5- If the meter doesn’t deflect at all, the capacitor is open and should be replaced.

®

Kold-Draft

Service & Parts Manual

-37B-

Page 39

Pump Intake Hose - Collapsing

Service and Troubleshooting

1. If hose is too long or has been twisted, the tubing will collapse. These two

conditions can be corrected very easily by checking the length so that the

tubing is approximately 3-3/8" long, or by twisting the tubing to make certain it is

straight.

2. Dirty water tank outlet screen - In this instance, the tubing will collapse and

remain collapsed until the screen is cleaned. This could cause cloudy cubes,

because not enough water is being circulated.

3. Occasionally at the beginning of a cycle, if the water is super-cooled and

crystalization occurs in the water, the crystals would plug up the screen and

cause a collapse of the hose. Thi s condition would last for less than a minute

until the crystals thaw and the ice maker would begin functioning properly. Thi s

condition is not serious and would not damage any of the ice maker

components. The condition cures itself and is of short duration.

4. The hose may also collapse due to aging. The hose should be replace and a

spring (GBR-00212-01) installed.

Water Plate Problems

1. Improper setting of the fin thickness- Under tolerance fin thickness may cause

icing of injection and return holes, on the water plate surface. Refer to the

alignment page.

2. If the injection holes on the water plate become blocked, some of the freezing

cells will be devoid of ice at time of harvest. The blockage can be removed by

using a 1/16” drill bit to clean the injection holes. Note- Freezing cells void of

ice may collapse due to expansion of ice in surrounding cells.

3. If the injection holes are cleaned and water is still not flowing, then the laterals

have become clogged. To clean the laterals, remove the rubber plugs at the

end of the water plate. Run a small brush through the laterals and flush out all

debris. Place new plugs in the holes using an allen wrench or similar blunt end