Page 1

KOLD-DRAFT

CLASSIC

GB/GT/T-250

K

OLD-DRAFT

Ice Machine Products

®

T-260/AKD

Service and Parts Manual

1525 East Lake Road, Erie, PA 16511-1088

814/453-6761

FAX 814/455-6336

©2004 KDIndustries, Inc., Erie, PA U.S.A.

Printed in U.S.A. 5/07

LIT-09502 Rev.4/07

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

A Tradition of Excellence In Ice Equipment.

Page 2

Page No.

Table of Contents, 3/02

Table of Contents, CLASSIC Models, 5/03 printing ....................1

Key to CLASSIC Cuber Model Numbers .............................2

CLASSIC Cuber Installation Specifications ..........................3

CLASSIC Cuber Installation Guidelines ..............................5

General Information .............................................. 11

Preventive Maintenance ..........................................12

GB & GT CLASSIC Cuber Installation Instructions ....................14

CLASSIC Cuber Start-up Instructions ...............................19

Chart of Refrigerant Operating Pressures, Ice Cube Sizes and Weights 20

GB Multiplexing (Stacking) Instructions .............................21

GT3XX Multiplexing (Stacking) Instructions ..........................25

Operational Components, CLASSIC Cubers ..........................32

Controls and Adjustments, CLASSIC Cubers ......................... 37

Sequence of Operation, CLASSIC Cubers ...........................42

Service and Troubleshooting, CLASSIC Cubers:

Actuator Motor ...............................................46

Water Plate ..................................................57

Liquid Level Controller .........................................59

Cube Quality .................................................60

Compressor Charts, CLASSIC Cubers ..............................62

Wiring Diagrams, CLASSIC Cuber (Jan. '92 through Feb. '96) ........... 68

Wiring Diagrams, CLASSIC Cuber (March '96 through Sept. '97) .........77

Wiring Diagrams, CLASSIC Cuber (Oct. '97 and later) .................. 81

T-25X/T-26X Crusher Installation Instructions .........................95

T-25X/T-26X Crusher Installation Specifications .......................99

T-25X/T-26X Crusher Preventative Maintenance ......................100

AKD-125 Dispenser Installation Instructions ........................101

AKD-125 Dispenser Installation Specifications ......................104

AKD-125 Dispenser Preventative Maintenance ...................... 105

Wiring Diagrams, T-250/T-251 .....................................106

Wiring Diagrams, AKD-125 ........................................107

Parts List-Pictorial, CLASSIC Cubers ...............................108

Parts List-Pictorial, T-25X/T-26X/AKD-125 ........................... 139

Parts List-Numerical, CLASSIC Models ..............................140

Date Code ......................................................150

Rev:3/02 Kold-Draft® Service & Parts Manual

- 1 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 3

Key to Model Numbers

GB 4 5 1 W HK

C = Full Cube (1-1/4" 1-1/4" x 1-1/4")

HK = Half Cube (1-1/4" x 1/1/4" x 5/8")

K = Cubelet (5/8" x 5/8" x 1-1/4")

A = Air Cooled Condenser-Self Contained

W = Liquid Cooled Condenser-Self Contained

R = For Remote Air Cooled Condenser

1 = 115 Volt-60 Hz.-1 Ph. (2-wire plus Ground)

4 = 208/230 Volt-60 Hz.-1 Ph. (2-wire plus Ground)

5 = 208/230 Volt-60 Hz.-3 Ph. (3-wire plus Ground)

7 = 220/240 Volt-50 Hz.-1 Ph. (2-wire plus Ground)

Electrical Characteristics

Condenser Type

Cube Size

2 = R-502, Copeland Compressor except GB1224/GB1225 (Bristol)

3 = R-502, Bristol Compressor

4 = R-404a, Bristol Inertia Compressor/Polyolester Lubricant except

3 = 300 Series

4 = 400 Series

5 = 500 Series

6 = 600 Series

12 = 1200 Series

Cabinet Width

GB = Horizontal Unit (42" wide)

GT3XX = Slimline Unit (28-1/2" wide)

GT5XX = Slimline Unit (30" wide)

Kold-Draft® Service & Parts Manual Rev:3/

Classic Cuber Series

Modification Code

GT341/GT344 (Bristol Reed Valve Compressor w/POE Lubricant)

5 = R-404a, Tecumseh Compressor w/POE Lubricant

- 2 -

02

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 4

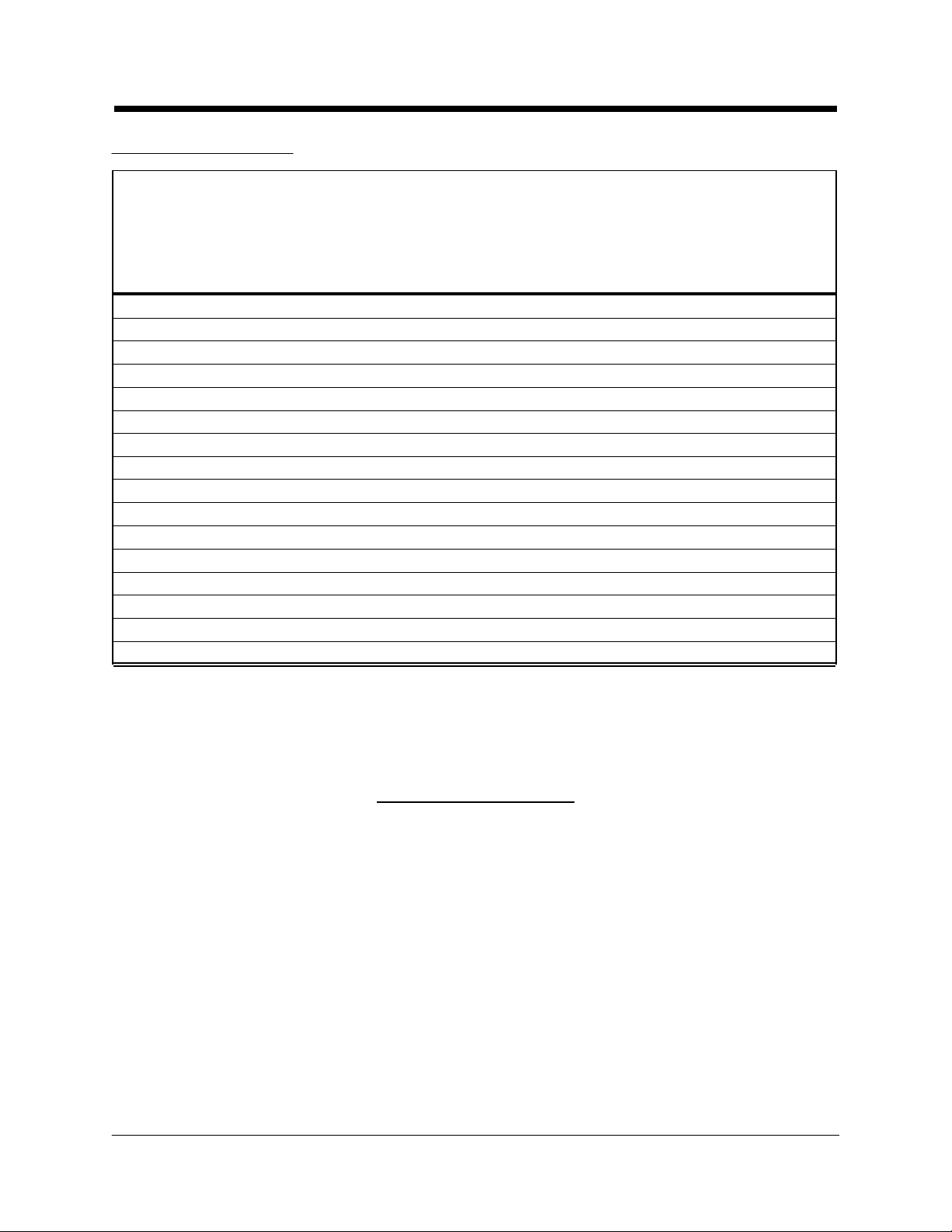

GB Series Cubers

Installation Specifications

FUSE/HACR

BREAKER SIZEMINIMUM

(AMPS)CIRCUITELECTRICAL

NORMAL MAXIMUM

AMPACITYSUPPLYMODEL

25 3021115/60/1GB441A

20 3017.8115/60/1GB441W

20 3017.8115/60/1GB441R

20 2515.3208-230/60/1GB644R

30 5029.1208-230/60/1GB1244W

30 5029.1208-230/60/1GB1244R

20 2515.5208-230/60/3GB1245W

20 2515.5208-230/60/3GB1245R

35 55 32208-230/60/1GB1254W

35 5532208-230/60/1GB1254R

20 2516.9208-230/60/3GB1255W

20 2517.6208-230/60/3GB1255R

25 3523.3115/60/1GB431A

25 3020.1115/60/1GB431W

25 4025115/60/1GB431R

15 2012.7208-230/60/1GB434A

15 159.6208-230/60/1GB434W

15 1511.1208-230/60/1GB444A

15 1510.2208-230/60/1GB444W

20 3019.9115/60/1GB451A

20 2516.4115/60/1GB451W

15 2011.9208-230/60/1GB454A

15 1511.3208-230/60/1GB454W

15 1510.1208-230/60/1GB454R

20 2516.6208-230/60/1GB634A

20 2515.7208-230/60/1GB634W

15 2514.8208-230/60/1GB634R

20 2516.2208-230/60/1GB644A

20 2515.3208-230/60/1GB644W

20 3018208-230/60/1GB654A

20 3017.3208-230/60/1GB654W

20 3017.4208-230/60/1GB654R

30 4528.2208-230/60/1GB1224W

30 4528.2208-230/60/1GB1224R

20 3018.8208-230/60/3GB1225W

35 5534208-230/60/1GB1254A

Rev:3/02 Kold-Draft® Service & Parts Manual

- 3 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 5

GT Series Cubers

Installation Specifications

FUSE/HACR

BREAKER SIZEMINIMUM

(AMPS)CIRCUITELECTRICAL

AMPACITYSUPPLYMODEL

NORMAL MAXIMUM

20 2517.8115/60/1GT331A

20 2516.6115/60/1GT331W

15 158.6208-230/60/1GT334W

20 2517.8115/60/1GT341A

20 2516.6115/60/1GT341W

15 158.6208-230/60/1GT344A

15 158.6208-230/60/1GT344W

20 2515.6115/60/1GT351A

15 2014.4115/60/1GT351W

15 159.3208-230/60/1GT354A

15 158.6208-230/60/1GT354W

25 35 23.4115/60/1GT551A

20 3017.9115/60/1GT551W

20 3520115/60/1GT551R

15 2514.9208-230/60/1GT554A

15 2014.3208-230/60/1GT554W

Voltage Tolerances

Full-load MINIMUMNo-load MAXIMUMNominal

104126115

198252208/230

210250220/240

Kold-Draft® Service & Parts Manual Rev:3/02

- 4 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 6

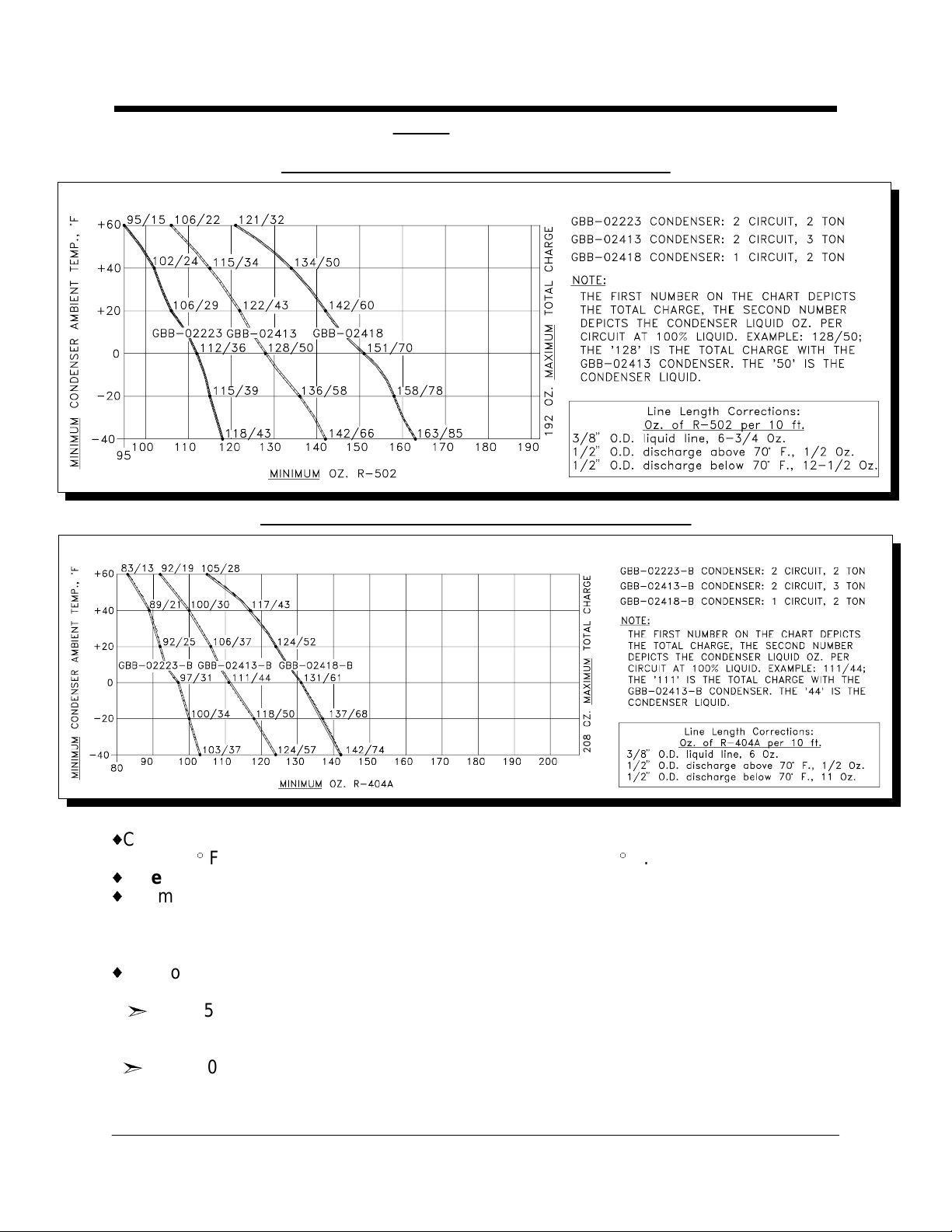

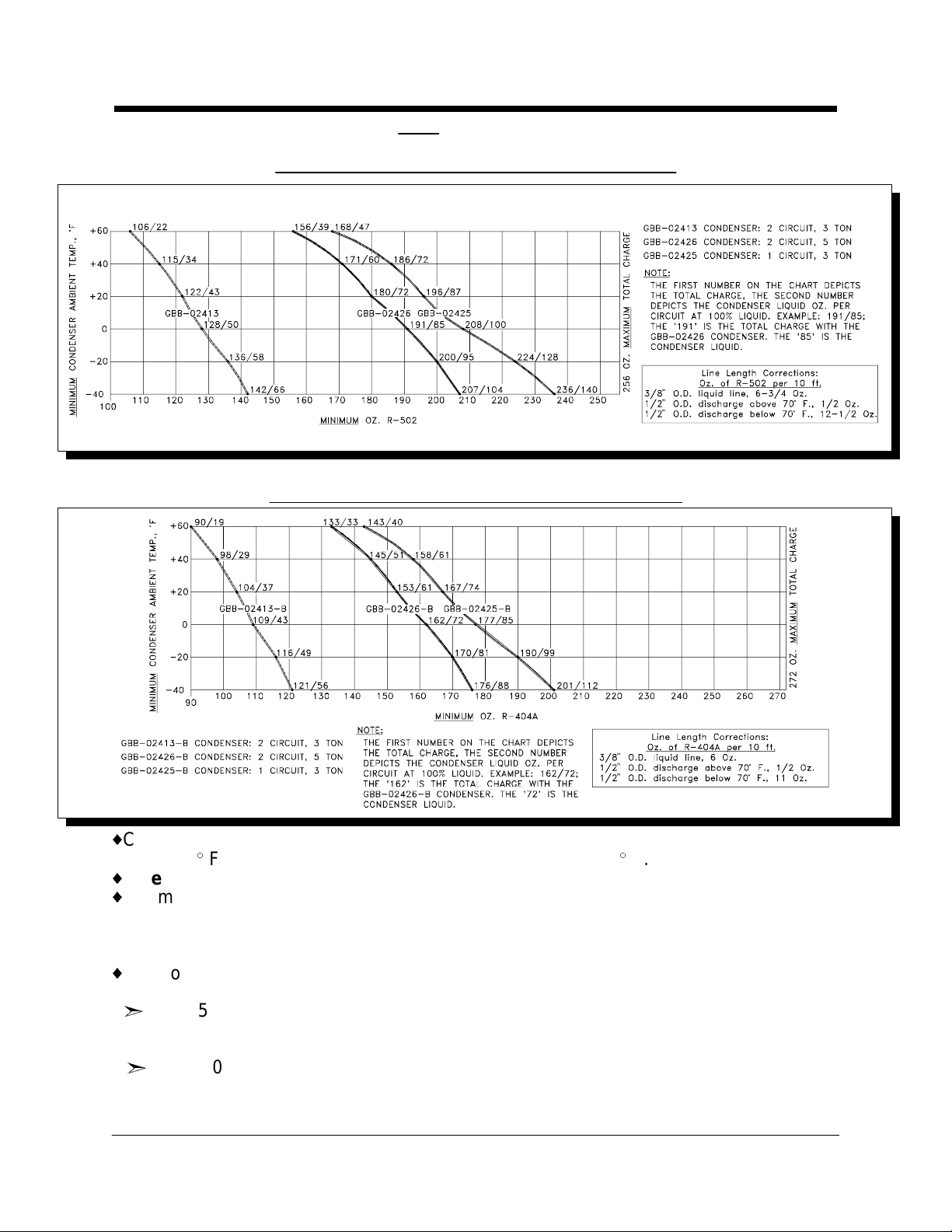

Kold-Draft® Remote Condenser Single Evaporator Cuber Charging Requirements

Installation Guidelines

R-502, Factory charge is 96 oz. (6 lbs.)

R-404a, Factory charge is 84 oz. (5.25 lbs.)

{

Charts based on 30 ft. of 1/2" O.D. discharge (15 ft. exposed to ambient temperature

under 70} F.) and 30 ft. of 3/8" O.D. liquid return lines, at 20} F., T.D.

{

Lines over 50 ft. are not recommended.

{

Minimum Condenser Height: Condenser must be install ed above refrigerant line quick

connects at rear of ice machine. No part of the refrigerant lines, between the cuber

and the condenser, should fall below this point.

SEE SEPARATE INSTRUCTIONS FOR THE CONDENSER.

{

For Condensers other than Kold-Draft®, the install er must determine the condenser

liquid volume at minimum operating temperature.

ˆFor R-502 Cubers, the basic charge is 2 lbs. To this, add the condenser liquid

volume calculation and the line charge calculation from the Line Length Correction

Chart to obtain the minimum total charge.

ˆFor R-404a Cubers, the basic charge is 1-3/4 lbs. To this add the condenser liqui d

volume calculation and the line charge calculation from the Line Length Correction

Chart to obtain the minimum total charge.

Rev:3/02 Kold-Draft® Service & Parts Manual

- 5 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 7

Kold-Draft® Remote Condenser Dual Evaporator Cuber Charging Requirements

Installation Guidelines

R-502, Factory charge is 128 oz. (8 lbs.)

R-404a, Factory charge is 112 oz. (7 lbs.)

{

Charts based on 30 ft. of 1/2" O.D. discharge (15 ft. exposed to ambient temperature

under 70} F.) and 30 ft. of 3/8" O.D. liquid return lines, at 20} F., T.D.

{

Lines over 50 ft. are not recommended.

{

Minimum Condenser Height: Condenser must be installed above refrigerant line quick

connects at rear of ice machine. No part of the refrigerant lines, between the cuber

and the condenser, should fall below this point.

SEE SEPARATE INSTRUCTIONS FOR THE CONDENSER.

{

For Condensers other than Kold-Draft®, the install er must determine the condenser

liquid volume at minimum operating temperature.

ˆFor R-502 Cubers, the basic charge is 3-1/2 l bs. To this, add the condenser l iquid

volume calculation and the line charge calculation from the Line Length Correction

Chart for the total charge.

ˆFor R-404a Cubers, the basic charge is 3 lbs. To this, add the condenser liquid

volume calculation and the line charge calculation from the Line Length Correction

Chart to obtain the minimum total charge.

Kold-Draft® Service & Parts Manual Rev:3/02

- 6 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 8

GB Cubers

energy efficiency can be obtained by reducing water fill level (lowering the high-level

Installation Guidelines

GB4XX GB6XX GB12XX

PARAMETER

Water fill level

*Approximate cycle time, min. 15 33/26 13 25.5/21 12 22.5/18

Approximate harvest weight, lb. 4.0 7.7/7.1 4.0 7.7/7.1 8.0 15.4/14.2

---------------------------------------------------------------------------------------------------------------------------------------

REFRIGERANT CHARGE,

-------------------------------------------------------------------------------------------------------------------------------------- GB44X GB 4 5X GB64X GB124X

REFRIGERANT CHARGE,

Oz. (R-404a) Air cooled: 22 19 28 62

(Top of tank to level in control tube)

GB43X GB63X GB122X

Oz. (R-502) Air cooled: 25 Air cooled: 35 ------

Liq. cooled: 22 Liq. cooled: 22

Liq. cooled: 20 20 22 52

Remote(MAX): 208 208 208 272

Remote(MAX):192 Remote(MAX):192 Remote(MAX):256

K C/HK K C/HK K C/HK

3-5/8" 2-3/4" 3-5/8" 2-3/4" 3-5/8" 2-3/4"

MODEL SERIES/CUBE SIZE

MODEL SERIES

MODEL SERIES

GB65X GB125X

Liq. cooled: 60

GT Cubers

MODEL SERIES/CUBE SIZE

GT3XX GT55X

K C/HK K C/HK

PARAMETER

Water fill level

*Approximate cycle time, min. 14 31/21 15.5 31/24

Approximate harvest weight, lb. 2.0 3.9/3.5 4.0 7.7/7.1

--------------------------------------------------------------------------------------------------------------------------------------

REFRIGERANT CHARGE, Oz. (R-502

--------------------------------------------------------------------------------------------------------------------------------------

GT34X GT35X GT55X

REFRIGERANT CHARGE,

Oz. (R-404a) Air cooled: 24 Air cooled: 19 Air cooled: 30

(Top of tank to level in control tube)

3" 2-5/8" 3-5/8" 2-3/4"

MODEL/SERIES

GT33X

)

Liq. cooled: 22

MODEL SERIES

Liq. cooled: 20 Liq. cooled: 20

------ ------

Air cooled: 27

Liq. cooled: 20

Remote(MAX):208

* Values are for Air-cooled (or GB12XXW) models at 90} F. air/70} F. water

temperatures with cuber adjusted to produce fully-formed ice. Greater capacity and

Rev:3/02 Kold-Draft® Service & Parts Manual

- 7 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 9

probe) to produce ice with larger dimples. A slight adjustment of the probe will result in

Installation Guidelines

a noticeable effect on dimple size. The control stream will not rise over the dam with

lower water fill levels than indicated above.

All Liquid Cooled Models

The recommended condensing temperature is 104} F.(40} C.). If necessary to adjust

the coolant regulator valve, the high si de pressure at mid-freeze cycle should be 230

psig for R-502 or 250 psig for R-404a.

All Remote Air Cooled Models

Fan cycling controls are not provided and are not beneficial except to automatically

stop the fan during off-cycles. If such controls are used the settings should not allow

fan cycling during freeze cycles. The suggested settings for fan cycli ng controls are:

ON at approx. 250 psig; OFF at approx. 220 psig

CAUTION: Fan cycling controls do not reduce the minimum charge requirements. If

there is not an adequate amount of liquid refrigerant in the receiver at start-up, the

system will pump down repeatedly or run at a very high superheat (l ow back-pressure)

with little -or- no refrigeration at the evaporator(s). Refer to the Remote Condenser

Model Charging Requirements section.

CAUTION:

{ RISK OF PROPERTY DAMAGE, EQUIPMENT FAILURE, OR FIRE.

{ Failu re to comply with all installation specifications and instructions may cause

erratic operation and the risk of damage or fire.

Ambient Operating Temperatures

Minimum: 45

Maximum: 90} F. (32

}

F. (7} C.) NOTE: Under 60} F may cause erratic bin thermostat operation

}

C.)

Potable Water and Condensing Liquid Supply

Minimum Water Temperature: 45} F. (7} C.)

Maximum Water Temperature: 90} F. (32} C.)

Minimum Water Pressure: 30 psig

Maximum Water Pressure: 100 psig*

* If regulator is used, recommended setting is 30 to 50 psig

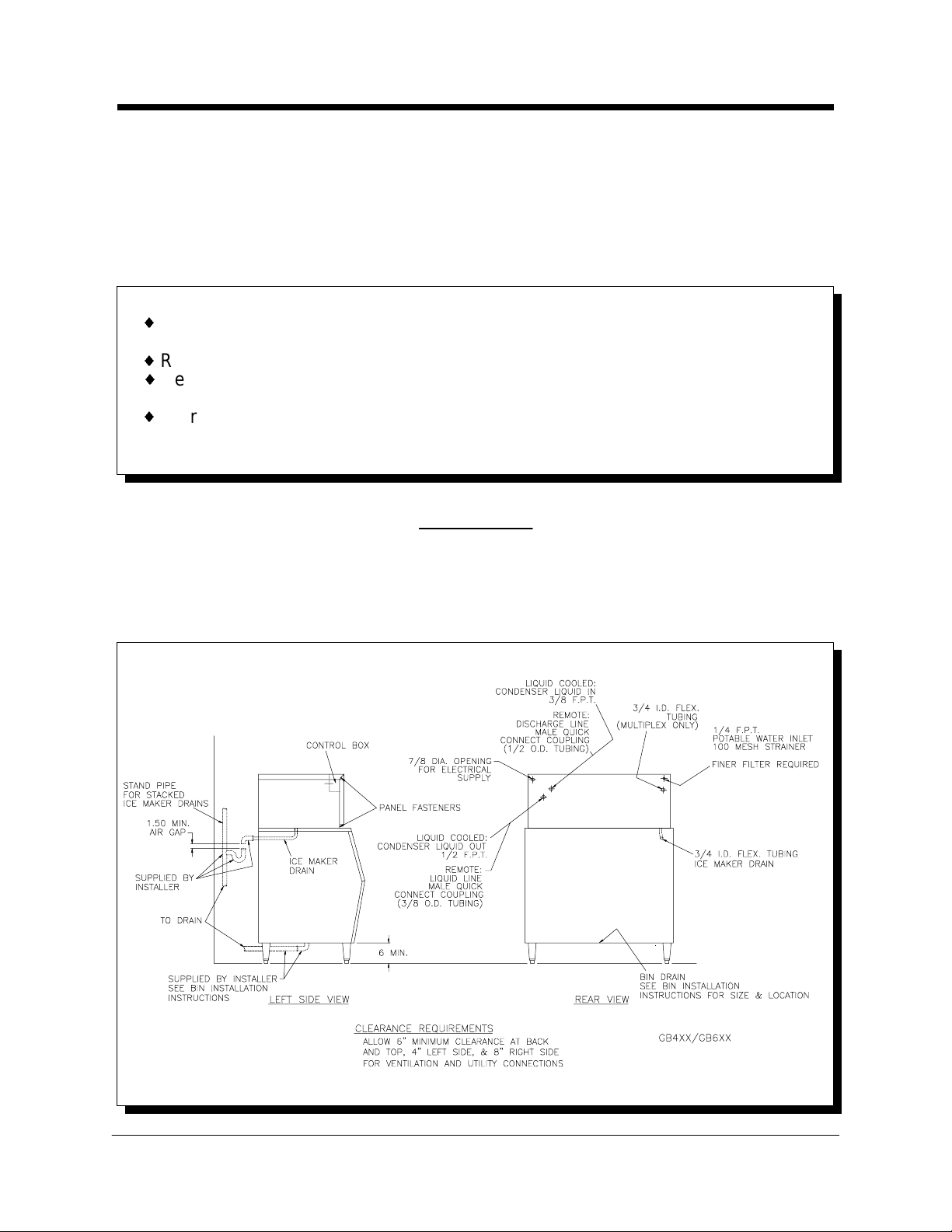

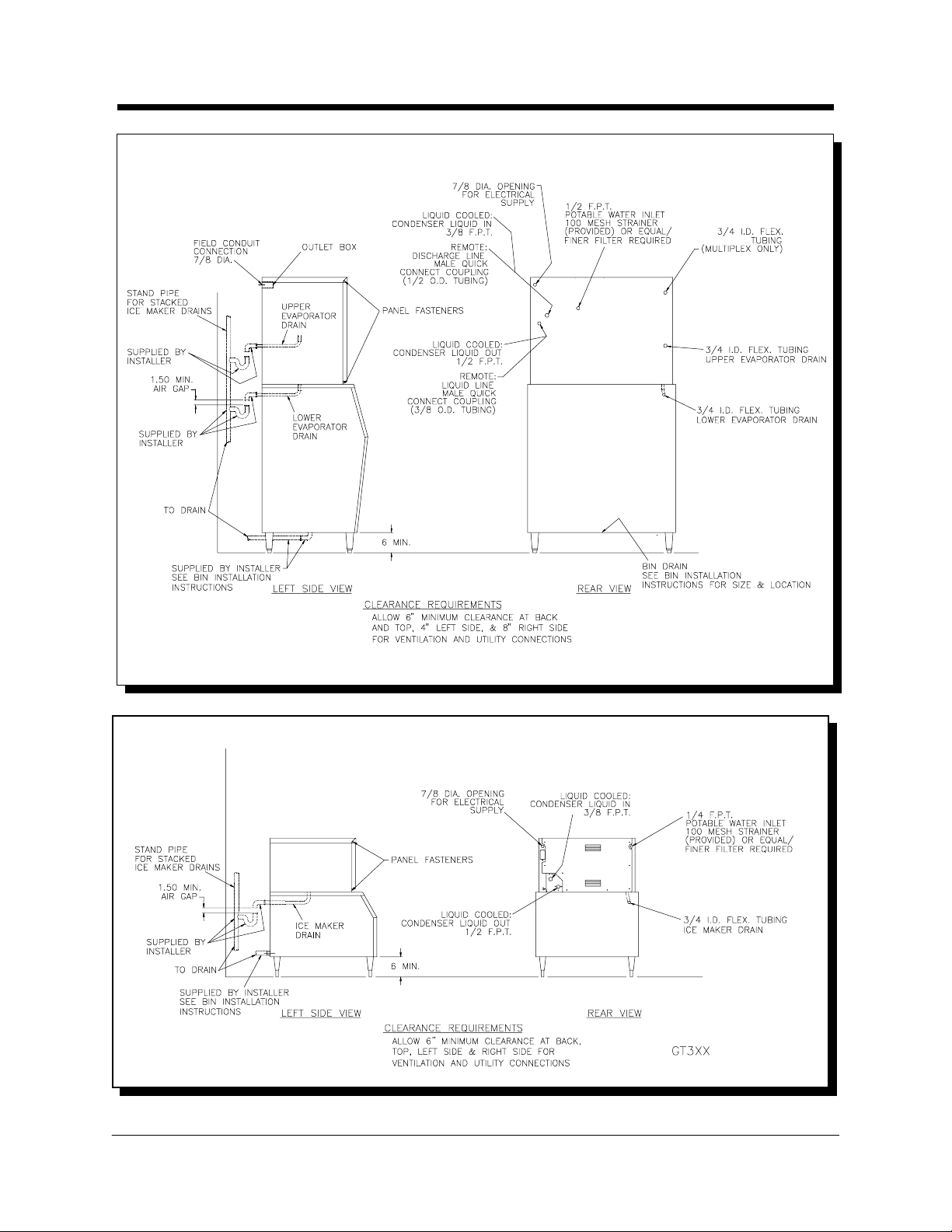

Clearance Requirements

GB Cubers (except GB1250A---see the following drawings)

REAR (beyond condenser if protruding from cabinet) and TOP: 6 inches

RIGHT SIDE: 8 inches

LEFT SIDE: 4 inches

GT 3XX Cubers GT55X Cubers

REAR and TOP: 6 inches 8 inches

RIGHT SIDE: 6 inches 4 inches

LEFT SIDE: 6 inches 4 inches

Kold-Draft® Service & Parts Manual Rev:3/02

- 8 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 10

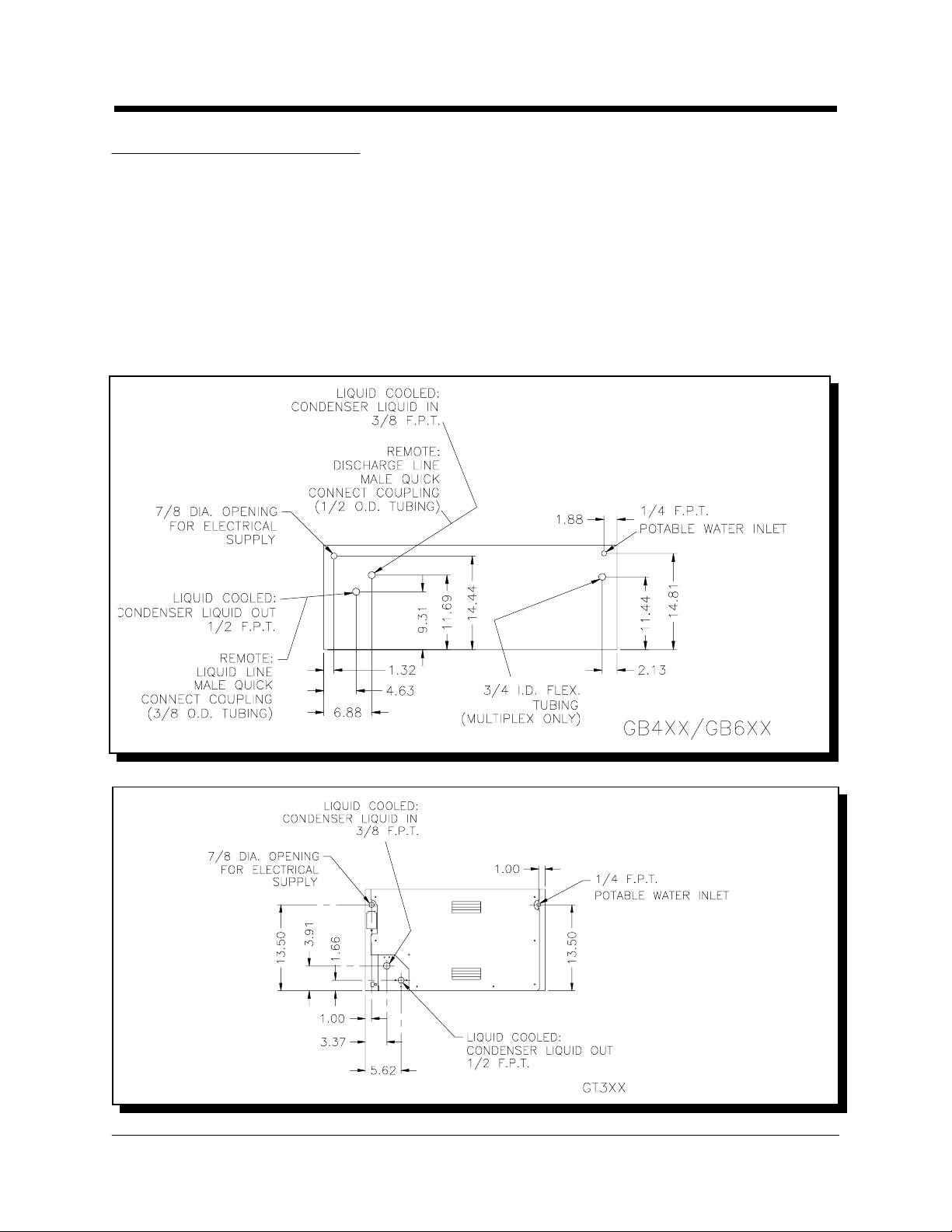

Plumbing Requirements

Installation Guidelines

Potable Water Inlet Fitting: 1/4" F.P.T. (GB430/GB440/GB450/GB630/GB640/GB650)

1/2" F.P.T. (GB1220/GB1240/GB1250)

1/4" F.P.T. (GT330/GT340/GT350/GT550)

Drain: 3/4" I.D. flexible tubing

Liquid Cooled Condenser Inlet Fitting: 3/8" F.P.T.

Liquid Cooled Condenser Outlet Fitting: 1/2" F.P.T.

Remote Air Cooled Liquid Line Fitting: 3/8" Tubing Quick Connect

Remote Air Cooled Discharge Line Fitting: 1/2" Tubing Quick Connect

Electrical, water and drain locations are shown on the following (5) drawings:

Rev:3/02 Kold-Draft® Service & Parts Manual

- 9 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 11

Water Treatment

Please consult your local water conditioning supplier for specific recommendations.

Installation Guidelines

There are no specific requirements for water treatment provided that the ice making

supply water is potable and not laden with sediment. The use of additional water

treatment may facilitate or reduce the frequency of the need for cleaning as well

as reduce the corrosive effects of chlorinated (greater than 0.2 ppm residual

chlorine) water supplies.

Kold-Draft® Service & Parts Manual Rev:3/02

- 10 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 12

General Information

CAUTION:

{ RISK OF PROPERTY DAMAGE, EQUIPMENT FAILURE OR FIRE.

{ Failure to comply with all installation specifications and instructions may cause

erratic operation and the risk of damage or fire.

Ampacity: Minimum ampacity does not indicate typical running current value. Refer to

equipment NAME PLATE data. Use minimum ampacity value for sizing branch circuit

conductors up to 25 feet in length. For conductor length over 25 feet up to 100 feet,

increase 1 AWG size. Over 100 feet requires a 2 or more AWG size increase.

Branch circuit protection: Proper protection must be provided by either fuse(s) or

HACR type circuit breaker(s). Each ice maker must be provided with a separately

protected circuit with no other load(s). A fused disconnect installed adjacent to each ice

maker is recommended (must be supplied by installer), and may be required by local

codes. NORMAL protector size is based on rated voltage and operati on at lower than

extreme temperature limits. When branch circuit conductors are sized to permit,

increasing the protector size (up to the specified maximum) may avoid nuisance

protector opening under harsh operating conditions.

Water supply: Minimum 30 psig supply pressure while the ice maker is filling is

required. The water fill rate is 0.6 GPM for each GT330, GT340, or GT350, 1 GPM for

each GB430, GB440, GB450, GB630, GB640, GB650, or GT550, and 2 GPM for each

GB1220, GB1240, or GB1250. Backflow/Backsiphonage protection is provided by an

internal ai r gap (accepted by NSF). If additional protection is required by local codes or

authorities, any device(s) and installati on of the same, including specification and cost,

are the responsibility of the installation specifier.

Ice maker drain: The size of the gravity drain for the ice maker purge and rinse water

must not be reduced. Individual drains from stacked ice makers may be discharged into

a standpipe or manifold with a minimum 1-1/2 inch air gap at each ice maker

connection.

Liquid condenser coolant pressure drop: Condenser coolant pressure drop may

reach 20 psig during peak load with 85} F. coolant temperature at recommended

refrigerant high-side pressure. The condenser coolant (water) regulating valve may

require adjustment due to variations in the coolant supply characteristics to provide

optimum efficiency.

Remote condenser models: Remote condenser models from the factory carry a

minimal charge and will likely require an additional refrigerant charge to accommodate

all condenser ambient temperatures and/or the volume potentially contained in

refrigerant lines and condensers. There is a label on the receiver that i ndicates factory

charge and the maximum charge, along with a space to write in the total system

charge. Ice makers are provided with re-sealable refrigerant l ine connection coupl ings.

For all remote condenser installations refer to the Installation Guidelines located in

the front of this manual.

All models are intended FOR INDOOR USE ONLY with PERMANENT CONNECTION

TO THE FIELD ELECTRICAL SUPPLY. The remotely-installed condensers supplied by

Kold-Draft® may be installed outdoors, and they require a separate electrical supply.

Rev:3/02 Kold-Draft® Service & Parts Manual

- 11 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 13

Cleaning: Usually at 3 to 6 months intervals, depending on water conditions.

Preventative Maintenance

Inspections: During cleaning - at least twice a year.

Service: All such equipment will require service at some time. Service requirements

will be minimized with faithful preventative maintenance including good housekeepi ng

at the i nstal lati on si te. A CALL F OR SERVICE AS SOON AS A POSSIBL E PROBLEM

IS NOTICED MAY AVOID EXTENSIVE REPAIRS.

CAUTION:

{ RISK OF PERSONAL INJURY OR PROPERTY DAMAGE.

{ Do not use ammonia solutions in cleaning any part of the ice maker.

{ Do not mix ice machine cleaner and sanitizer together.

{ Use rubber gloves, eye protection and an apron.

{ Clean up splashes or spillage immediately.

{ Follow these instructions exactly.

Ice Cuber Cleaning Instructions

1. GB & GT55X: Mix one bag of Kold-Draft® ice machine cleaner (55R-01000) in

(2) quarts, or GT3XX: Mix 1/2 bag of Kold-Draft® ice machine cleaner

(55R-01000) in (1) quart of clean, warm water (180

evaporator/water plate assembly to be cleaned.

2. If the cuber is operating, wait until a harvest cycle occurs then trip the

'ICE-OFF-WASH' switch to 'WASH' as soon as the water plate begins to close.

3. Empty all ice from the storage bin and shut off other ice makers on the same

bin.

4. After the water fill is completed, switch the 'ICE-OFF-WASH' to 'OFF'. While

pinching the water level control hose, carefully remove the water level control

tube from the cap. HOLD THE TUBE HIGH ENOUGH SO THAT THE TUBE

DOES NOT OVERFLOW. Release the hose and pour about half of the mixed

cleaner into the tube. Replace the tube on the cap, while pinching the water

level control hose, then pour the remaining cleaner into the control stream box.

5. Switch the 'ICE-OFF-WASH' to 'WASH' and allow the cleaner to circulate for

approximately 15 minutes, then pull the right side of the water plate down until

the pump stops and hold it until the pump will not re-start when released.

6. The water plate will open and dump the cleaner then close immediately, and the

water system will refill. Repeat this dumping and refilling three (3) times to rinse

out all of the cleaning solution.

7. Mix a sanitizing solution of two (2) oz. 5-1/4% sodium hypochlorite (household

bleach or equivalent) and one (1) quart clean water.

8. As in step #4, pour about half of the sanitizing solution into the water level

control tube and the remaining sanitizer into the control stream box.

9. Allow the sanitizing solution to circulate AT LEAST 15 MINUTES, then dump

and rinse two (2) times as described above. If necessary, reset the water level

probes to the proper levels.

}

F. MAX.) for each

Kold-Draft® Service & Parts Manual Rev:3/02

- 12 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 14

10. While the cleaning and sanitizing solutions are circulating, clean, rinse and

Preventative Maintenance

sanitize all accessible parts of the ice-making compartment of the cuber with

clean cloths. Use a cleaning solution of 8 tablespoons (1/2 cup) baking soda

per gallon of warm water, and a sanitizing solution of no less than 1 teaspoonful

(5 ml.) 5-1/4% sodium hypochlorite per quart of clean water.

11. After cleaning has been completed, trip the 'ICE-OFF-WASH' switch to 'ICE'

and check to be sure that the cuber is operating properly, particularly the water

level probes. Then re-assemble and secure all cabinet enclosure panels.

Ice Bin Cleaning Instructions

The bin should be cleaned periodical ly. If bin drain has any horizontal run, remove ice

from left side of bin and flush with two (2) quarts of hot water monthly. (Long drain lines

should be flushed weekly.)

1. Clean exterior of bin frequently.

2. To clean the interior, follow the instructions provided with bin.

3. Empty the storage area and disconnect the electrical power supply to the ice

maker(s).

4. Remove the ice maker inspection panel, top, left and right end panels, and

drain pan. Sliding bin doors may be removed by lifting them up, then pulling out

from the bottom.

5. When cleaning the ice maker, follow the ice maker cleaning instructions and

clean the bin last.

6. Replace all enclosure panel s and drain pan before re-connecting the electrical

supply.

CAUTION:

{ RISK OF PERSONAL I NJ URY, EQ UI PMENT DAMAGE O R CONTAMINATION

OF THE ICE BIN.

{ Do not use ammonia solutions or strong detergents in cleaning any part of the

ice maker or bin.

{ Never use appliance polishes, finish preservatives or cleaners in ice storage

areas.

Winter Conditioning

Ice cubers that are idle in the winter months require preparation to prevent damage

from freezing. The following procedure should insure the safety of the cuber so that it

can be started easily the following year.

1. Shut off and detach the water supply to the ice cuber.

2. If the cuber contains a water-cooled condenser, the cuber must be running

while air is introduced through the condenser water inlet connection to blow the

water out of the condenser coils.

3. The cuber shoul d then be run into defrost to drain the water tank and air should

be introduced into the water inlet to blow out the water solenoid.

Rev:3/02 Kold-Draft® Service & Parts Manual

- 13 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 15

CHECK FOR FREIGHT DAMAGE BEFORE PROCEEDING. Even though damage to

GB &

GT

Cuber

Installation Instructions

the carton may not have been evident, check for hidden damage and contact freight

carrier immediately, if necessary, to file a claim.

THIS EQUIPMENT MUST BE INSTALLED IN COMPLIANCE WITH THE

APPLICABLE FEDERAL, STATE/PROVINCE AND/OR LOCAL PLUMBING,

ELECTRICAL AND HEALTH/SANITATION CODES AND REQUIREMENTS.

CAUTION:

{ RISK OF PERSONAL INJURY, PROPERTY DAMAGE, EQUIPMENT FAILURE

OR FIRE.

{ Refer all maintenance to qualified personnel.

{ Never operate this equipment with covers, panels or other parts removed or not

properly secured.

{ Warn all users to clean up spillage immediately, keep storage bin doors closed,

and report any apparent leakage or unusual sounds to responsible maintenance

personnel.

Installation

NOTE: For Multiplex Installations, please refer to Multiplex specific instructions before

proceeding.

Clearance and Utility provisions are shown on the following (4) drawings:

Kold-Draft® Service & Parts Manual Rev:3/02

- 14 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 16

GB &

GT

Cuber

Installation Instructions

GB1220

GB1240

GB1250

Kold-Draft® Service & Parts Manual Rev:3/02

- 15 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 17

GB &

GT

Cuber

Installation Instructions

GT55X

1. Position the ice storage bin so that minimum clearances will be available

around the ice maker for ventilation and utility connections.

2. Level the bin with adjusters on legs, or by shimming if the bin is to be sealed to

the floor. If gaps due to shi ms are greater than 1/8 inch, instal l a cove molding

around the bin bottom. Seal the bin or molding to the floor with NSF Certified

RTV sealant (Dow Corning RTV 732 or equal).

3. Remove the cuber cabinet TOP Panel as follows: Lift from the front and pull

forward (GT55X push backward) until the rear clip is disengaged from the

chassis..

4. Remove the remaining cuber cabinet panels as follows:

FRONT: Remove the (4) screws at the bottom and front-sides, pull forward.

SIDES: Pull forward and lift to disengage the clips from the chassis.

NOTE: When re-installing the panels, make sure that the screws engage the

TOP panel.

5. GB: Remove the ice deflector(s), ice chute(s) and drain pan(s). The Drain tube

assembly(s) is(are) packed with the drain pan(s).

GT3XX: Remove the ice chute/drain pan. The drain tube is packed with the

drain pan.

GT55X: Remove the ice chute and drain pan. The drain tube is packed with the

drain pan.

Kold-Draft® Service & Parts Manual Rev:3/02

- 16 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 18

6. Install gasketing on top of bin if required. Gasket material must be positioned so

GB &

GT

Cuber

Installation Instructions

that it extends to the outside edge of the perimeter of the cuber chassis when

the cuber is in place.

7. CAREFULLY place the cuber onto the gasketed bin, noting the alignment of the

mounting holes in the chassis if mounting means are provided on the bin.

Follow the bin installation instructions for securing the cuber to the bin.

8. GB: Install the drain pan(s), ice chute(s) and ice deflector(s). Route the drain

tube assembly(s) through the rear of the bin, and clamp the tubing to the

drain pan nipple(s).

GT3XX: Install the drain pan/chute. Route the drain tube through the rear of the

bin, and clamp the tubing to the drain pan nipple.

GT55X: Install the drain pan. Route the drain tube through the rear of the

cuber, and clamp the tubing to the drain pan nipple.

WARNING:

{ RISK OF CONTAMINATION OF ICE IN THE BIN.

{ Provide separate, unconnected drains for the ice maker and the bin.

{ Consult local codes for sui table connections to the building drains.

9. Purge the potable water supply line.

10. Remove the water plate shipping strap(s).

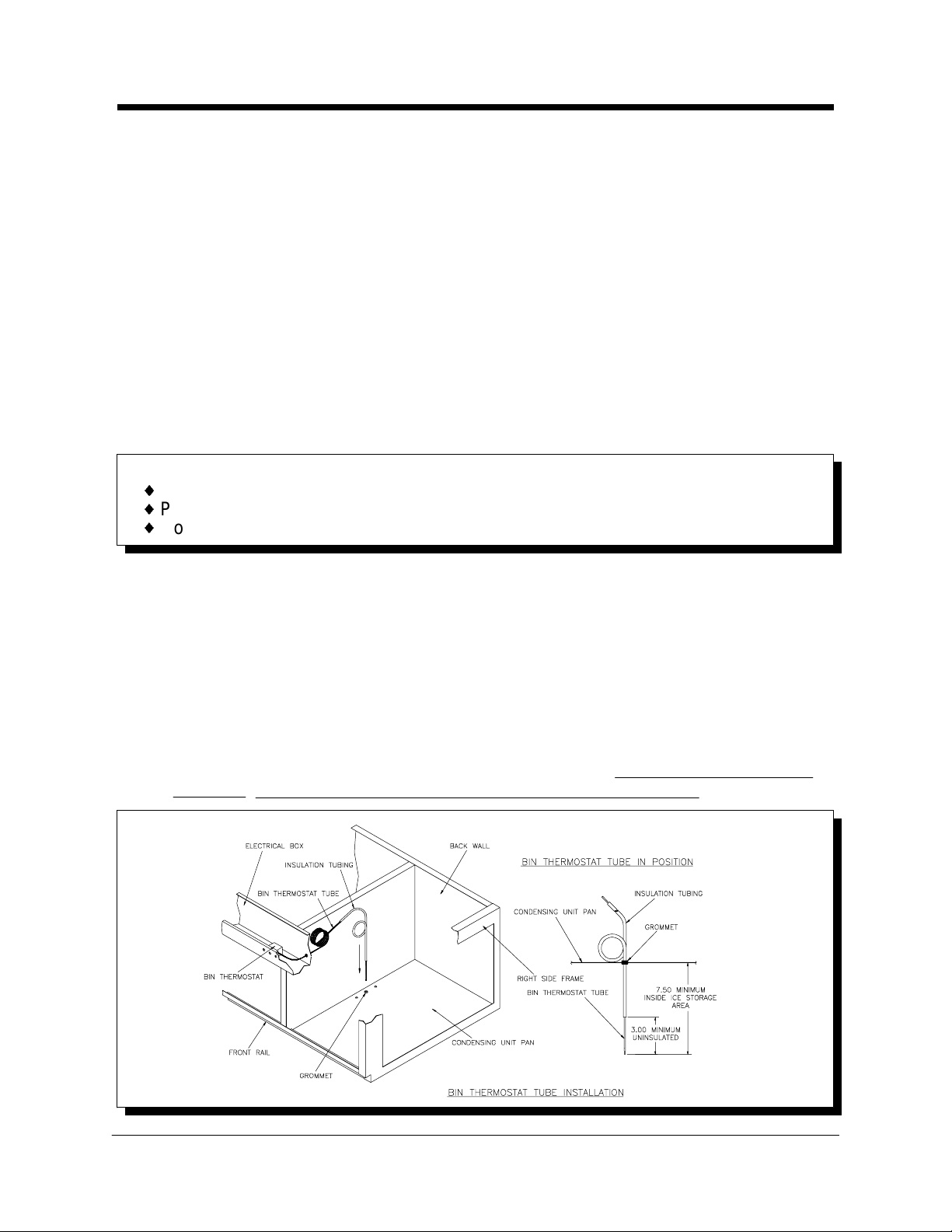

11. GB: Route the bin thermostat capillary tube through the grommet, in the

condensing unit pan and push all the way down. (See the following diagrams)

Note- It may be necessary to increase the distance that the cap tube enters the

ice storage area. Bin geometry, deflectors, baffles, etc., may cause an ice jamb

above the bin door opening. Carefully uncoil the insulated loop of cap tube,

while recoiling it further up, to lower the bin fill level. Cautio

cap tube. THIS SECTION IS AS REVISED SEPTEMBER, 2004.

n: do not kink the

Kold-Draft® Serv ice & Parts Manual Rev:3/02

- 17 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 19

GT3XX: Route the bin thermostat capillary tube through the grommet in the

GB &

GT

Cuber

Installation Instructions

right end frame wall and under the ice chute. See the diagram and notes

following for location and securing of the capillary tube.

GT3XX CUBER S

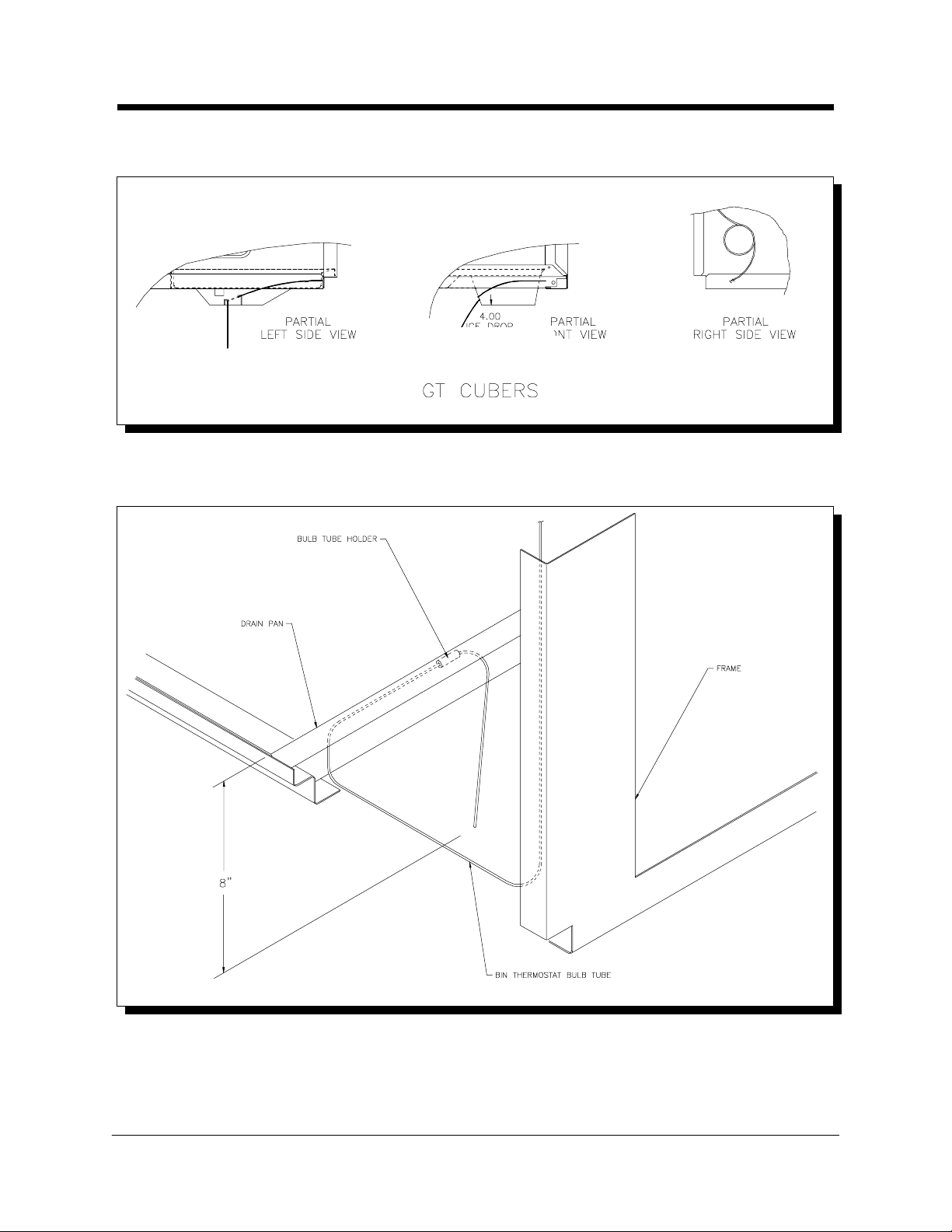

GT55X: Route the bin thermostat capillary tube along the right end frame

wall and front rail, out through the bulb hol der and down into the bi n. See the

diagram following for location and securing of the capillary tube.

GT55X CUBERS

12. If start-up will not occur immediately, secure all cuber cabinet panels now.

INSTALLER NOTE: There is no electrical interconnection provisi on in "R" models for

the condenser fan.

Kold-Draft® Serv ice & Parts Manual Rev:3/02

- 18 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 20

Consult the Installation Specifications, Sequence of Operation and Service and

Cuber

Start-up

Instructions

Troubleshooting sections if variations from the following description of operation are

noticed.

1. Remove the top and front cabinet panels.

2. Be sure that the 'ICE-OFF-WASH' switch is in the center 'OFF' position.

3. Install and connect refrigerant lines and condenser on "R" models.

4. Turn on supply water and power. Be sure that condenser liquid ("W" models) or

refrigerant lines and condenser ("R" models) are ready for use before turning

power on. Check for leaks in water/liquid supply connections. NOTE, "R"

MODELS ONLY: The compressor will start immediately when power is applied,

regardless of the 'ICE-OFF-WASH' switch position, if the low-side pressure

is at or above the pump-down controller cut-in setting. Be sure that the

compressor stops when the low-side pressure is between 5 and 10 psig.

5. Be sure that pump hoses are connected, then pour approximately one pint of

clean tap water into the circulation system to lubricate the pump seal.

6. Move the 'ICE-OFF-WASH' switch to the right 'WASH' position and observe the

water fill cycle and the pump running. If all water distributor holes do not

produce full streams and the appearance of air i s evident i n the tube, pi nch the

plastic tube connected to the water solenoid valve outlet while water is running

until the streams are full all the way across the distributor tube. Water fill is

complete when the water in the liquid level control tube reaches the high-level

probe. At this time, observe that the water shuts off and that there are no water

leaks (dripping into the drain pan). NOTE: In dual-evaporator models, be

sure that the Master and Slave water fill level difference is less than 1/4"

for "K" or 1/8" for "C" or HK" cube sizes. See LIQUID LEVEL

CONTROLLER text.

7. Pull the right end of the water plate down, stretching the springs until the pump

stops, and hold until the pump does not re-start when released. The water plate

will open fully to dump the batch of water previously taken in, then close

immediately. The water plate should stop when it is fully closed, and the water

fill cycle will repeat.

8. After the water fill is complete, move the 'ICE-OFF-WASH' switch to the left

'ICE' position and observe that the compressor (and fan in "A" models) starts,

and the water pump continues to run. The refrigeration system operation should

be checked during the first few cycles, and any adjustments should be made at

this time. Consult the "Controls and Adjustments" section in this manual.

Initial ice making cycles may exhibit super-cooling of the circulating water so

that ice crystals form in the circulating water (slush), possibly stopping the flow

momentarily. If water goes over the control stream dam when circulation

resumes after two (2) cycles AND with all skin panels installed, consult the

Factory.

Kold-Draft® Service & Parts Manual Rev:3/02

- 19 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 21

9. Test the bin thermostat(s) by holding some ice against the capillary tube(s). If

Cuber

Start-up

Instructions

necessary, adjust the thermostat(s) so that the ice maker(s) shut off within 30

seconds after ice contacts the capillary tube(s).

10. Be sure that the (GB: drain pan(s), ice chute(s) and deflector(s) are in place,)

(GT: drain pan and ice chute is in place,)

and that the electrical control box cover(s) is(are) secured, then replace the

cabinet panels(skins). Start with the SIDE panels, then the FRONT panel.

Secure the FRONT panel with (2) screws along the bottom edge, replace the

TOP panel and finally secure all the panels with (2) screws in the TOP-SIDES

of the machine.

11. Discard ice from start-up cycles, then clean and sanitize the bin following the

instructions provided with the bin.

12. Complete and mail the Registration Certificate and leave all instructions with the

owner/user. Emphasize the "CAUTION: RISK OF PERSONAL INJURY..."

notice on the first page of the GB & GT Cuber Installation Instructions, and

the importance of Preventative Maintenance.

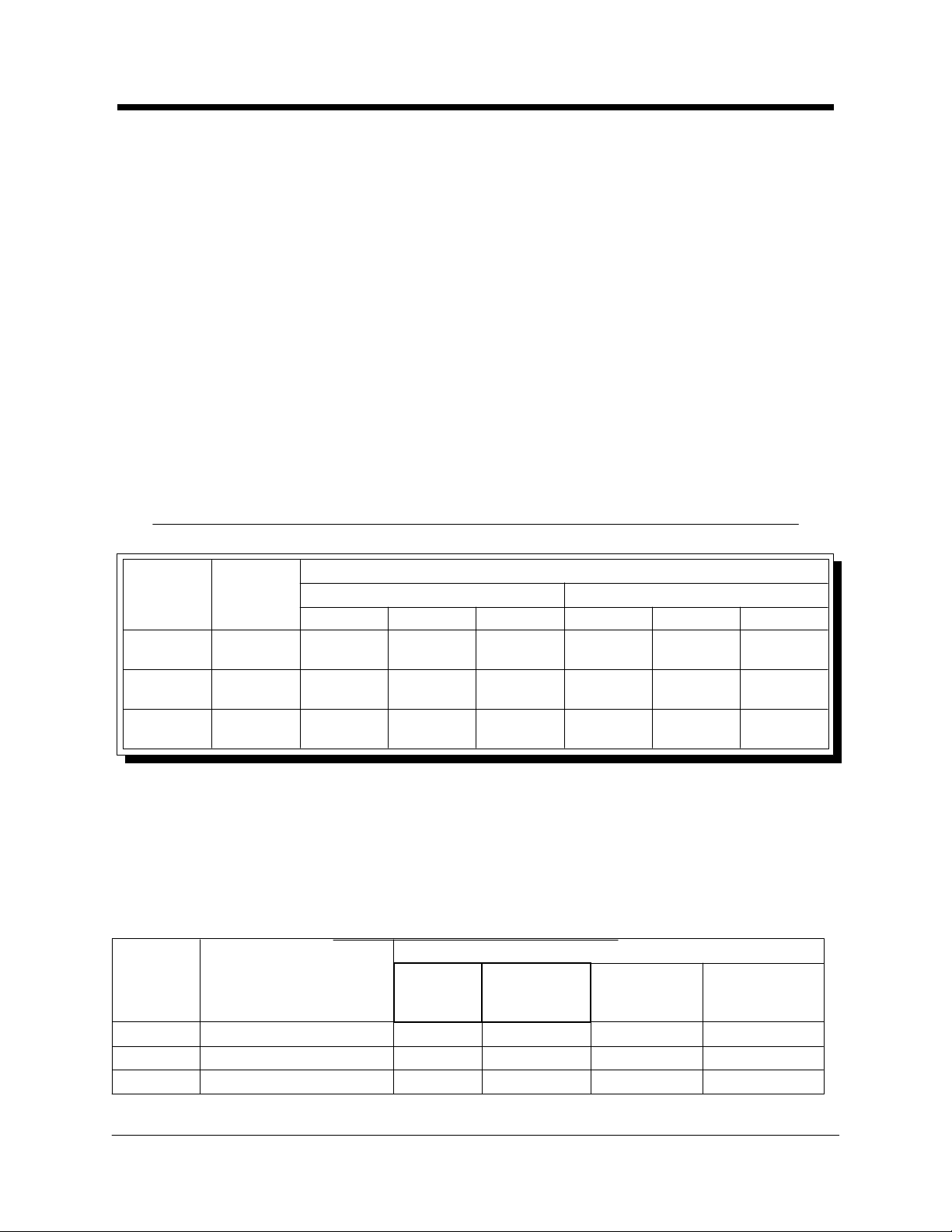

CHART OF TYPICAL REFRIGERANT OPERATING PRESSURES

All pressures are in psig

TIME

R-502 or

R-404a

freeze cycle

harvest

Approx. 150Approx. 15070 to 150Harvest

cycle

HIGH-SIDELOW-SIDE,

Minimum

R-404aR-502

RAWRAW

200 Min. ******250*180 Min. ******230*Approx. 50Beginning of

200 Min. *******250*180 Min. *******230*12 to 20Just before

Approx. 150Approx. 150150

150

Minimum

All pressures may vary with operating conditions and adjusrments.

* 104o F condensing temperature--adjustable with coolant regulator valve.

** High-side pressure at beginning of freeze cycle in "A" models is likely to be

higher than pressures shown for "W" models.

*** High-side pressure just before harvest in "A" models in cool ambients is likely to

be lower than pressures shown for "W" models.

**** See remote condenser charging requirements if lower than minimum shown.

ICE CUBE SIZES AND WEIGHTS

Weights and Cubes per Batch

CUBE SIZE

LETTER

DIMENSIONS

(Inches/cm)

Weight,

each cube

(oz./g)

GT3XX

GB4XX,

GB6XX

GT5XX

GB12XX

216108541.15/32.61.2 x 1.2 x 1.2/3.1 x 3.1 x 3.1C

4322161080.53/151.2 x 1.2 x 0.6/3.1 x 3.1 x 1.5HK

4322161080.3/8.50.6 x 0.6 x 1.2/1.5 x 1.5 x 3.1K

Kold-Draft® Service & Parts Manual Rev:3/02

- 20 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 22

Section I

GB Multiplexing Instructions

Stacking new GB Classic units above new GB Classic units

and old GB Classic units above new GB Classic units

CAUTION:

{ RISK OF PERSONAL INJURY, PROPERTY DAMAGE, EQUIPMENT FAILURE

OR FIRE.

{ Refer all maintenance to qualified personnel.

{ Never operate this equipment with covers, panels or other parts removed or not

properly secured.

{ Use a suitable lifting means and be careful of sharp edges.

NOTE: Please refer to Section II of these instructions for installing a new GB Classic

unit above an old GB Classic unit.

1. Remove cabinet panels from upper and lower ice makers.

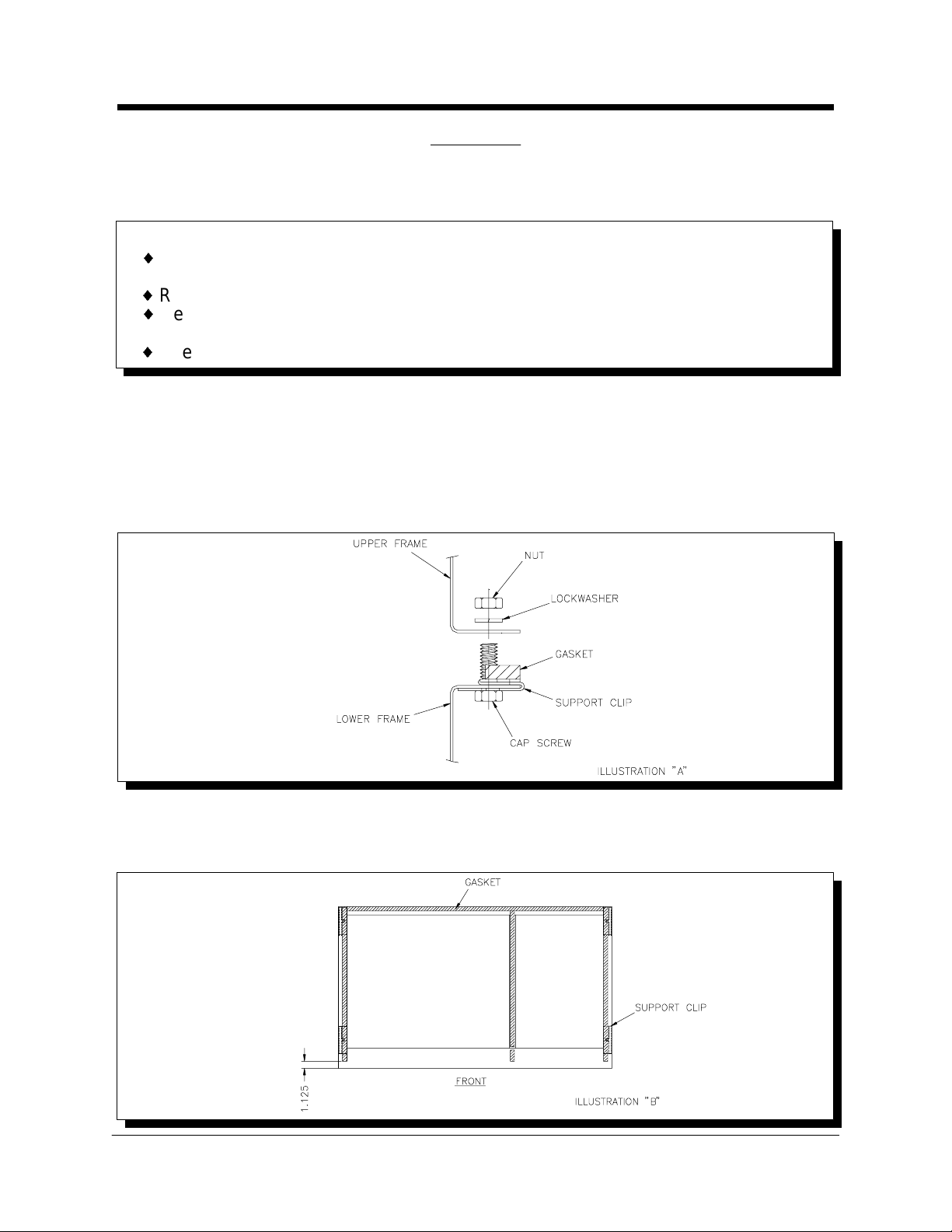

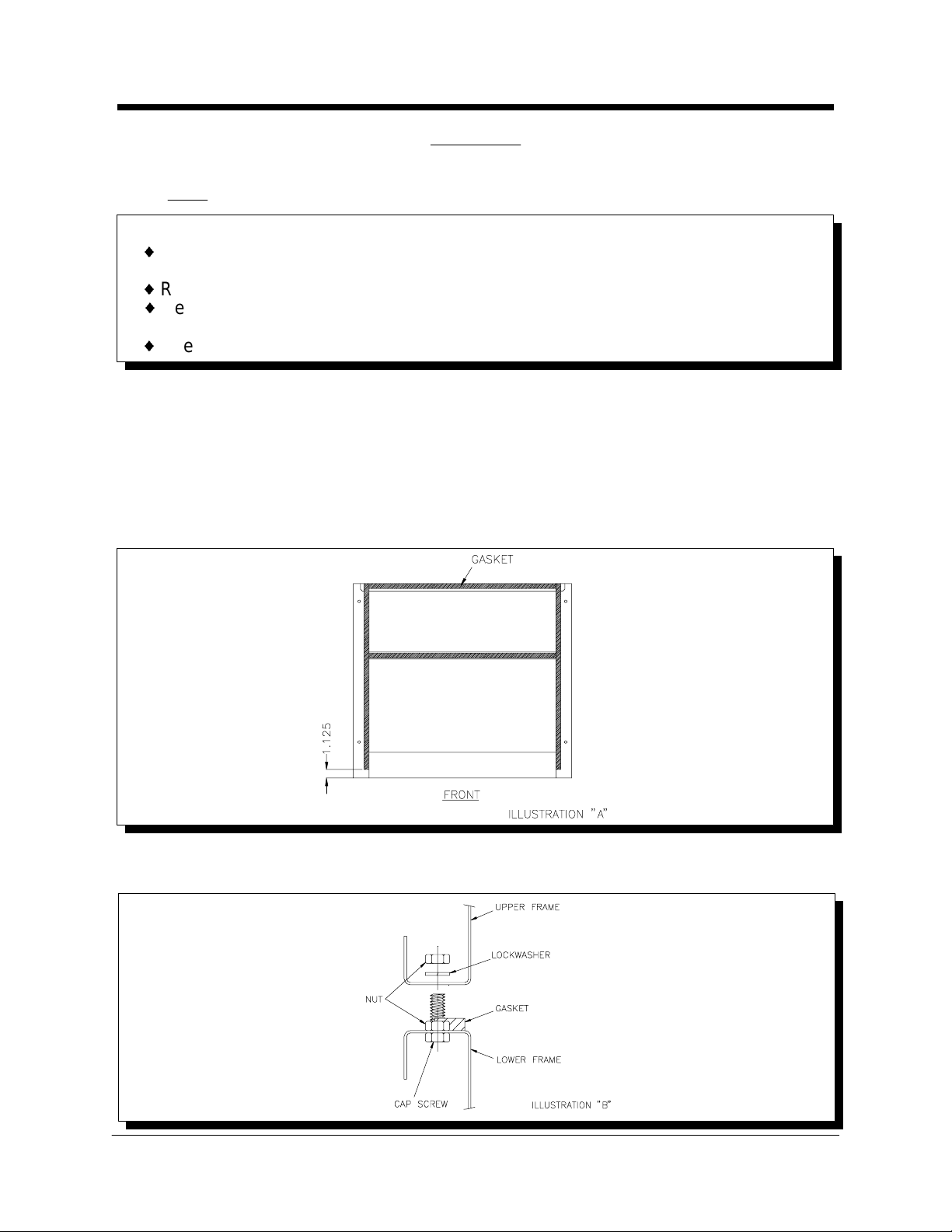

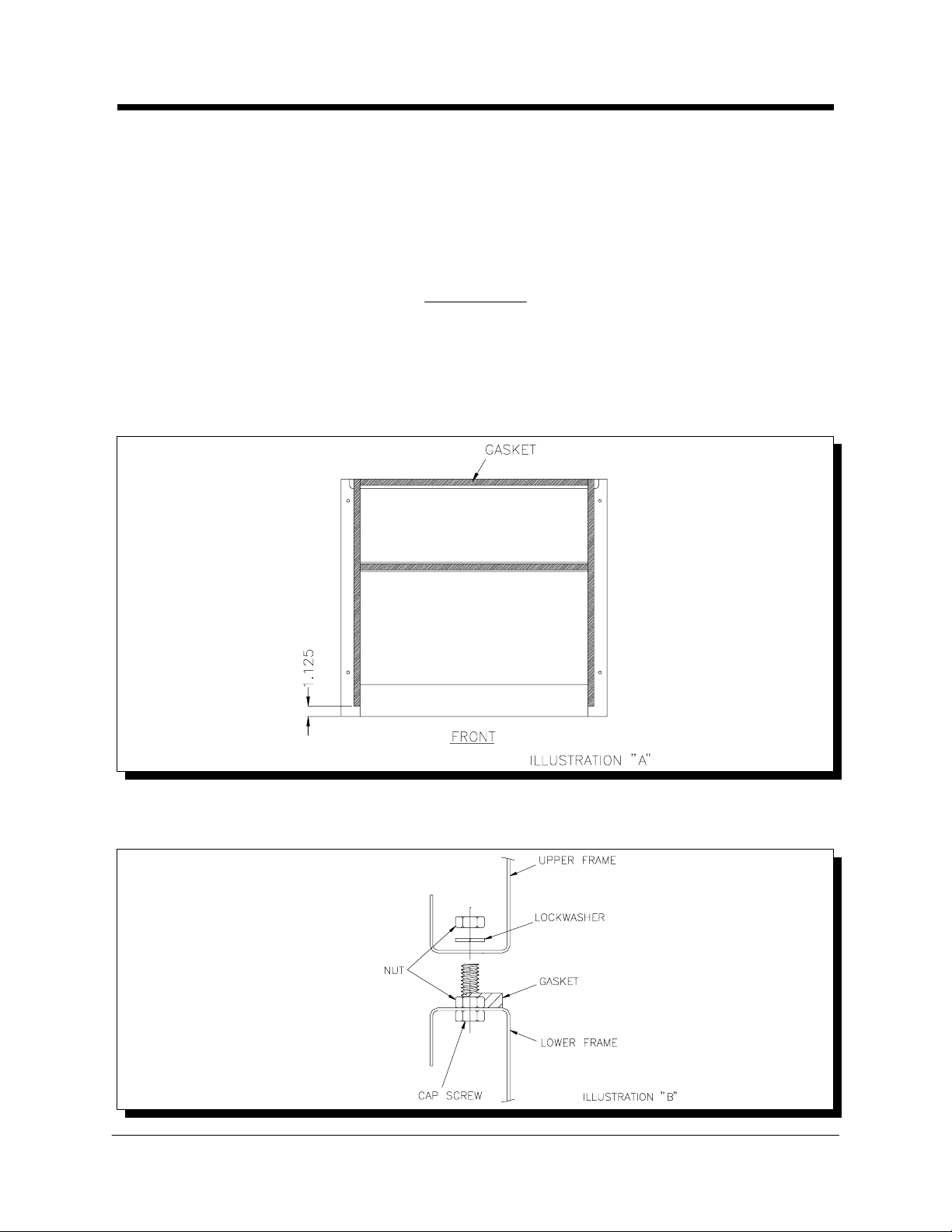

2. Mount support clips on top side flanges of lower ice maker frame and position

so the clip hol es are aligned with the holes in the frame. (See Illustration "A")

The lower flange of the front support clips must slide into the space between the

top side flange of the ice maker and the top flange of the electrical box.

3. Apply gasket (supplied with kit) to the lower ice maker frame and cut to fit. (See

Illustration "B") Place gasket over the supports clips already in position and

pierce the gasket where it covers the mounting holes.

Kold-Draft® Service & Parts Manual Rev:3/02

- 21 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 23

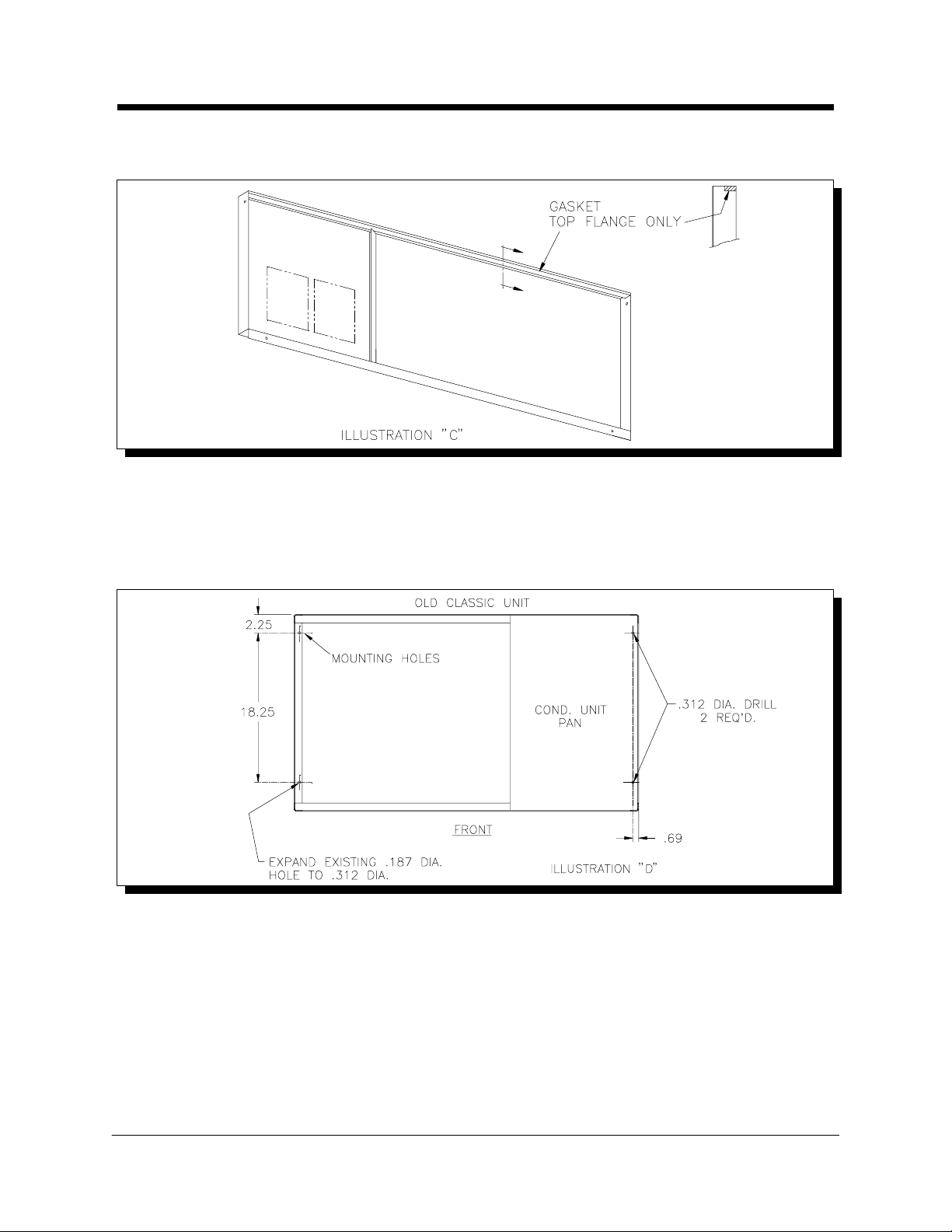

4. Apply gasket to the top inside flange of the lower ice maker front cabinet panel.

GB Multiplexing Instructions

(See Illustration "C")

5. On installations with old GB Classic units it is necessary to drill (2) 5/16" dia.

holes and enlarge (1) 3/16" dia. hole to 5/16" dia. in the bottom of the old

Classic frame. (See Illustration "D") The transformer box will have to be moved

temporarily in order to do this. The two right side holes can be drilled through

the cond. unit pan from the underside, using the existing frame holes as a

guide.

6. Position upper ice maker on lower unit and align mounting holes. Install cap

screws, lock washers and nuts. (See Illustration "A") CAUTION: Support upper

unit until all fasteners are secured.

7. Install the upper ice maker drain pan and ice chute. Connect the drain hose

elbow assembly to the drain pan and route the drain hose through the rear of

the lower ice maker. If the old GB Classic drain pan does not have a hose

flange, exchange it with the pan from the new GB Classic unit.

8. Route the upper ice maker bin thermostat capillary tube or probe wire down to

the lower ice maker chute opening for positi oning. Keep capillary tube or wire

toward the front of the partition wall out of the path of falling ice. Stacking a third

ice maker will require a bin thermostat with a longer capillary tube (new GB

Kold-Draft® Service & Parts Manual Rev:3/02

- 22 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 24

Classic unit) or an extension cord (old GB Classic unit). Consult the factory for

GB Multiplexing Instructions

more information.

9. Install the Ice Chute (see instructions on Page 31), and side cabinet panels. On

some early new GB Classic units it may be necessary to crimp the back catches

of the side panels on the lower ice maker so the panel is held tight to the frame.

10. Follow start-up instructions to complete the installation.

Section II

Stacking new GB Classic units above old GB Classic units

1. Remove cabinet panels from upper and lower ice makers.

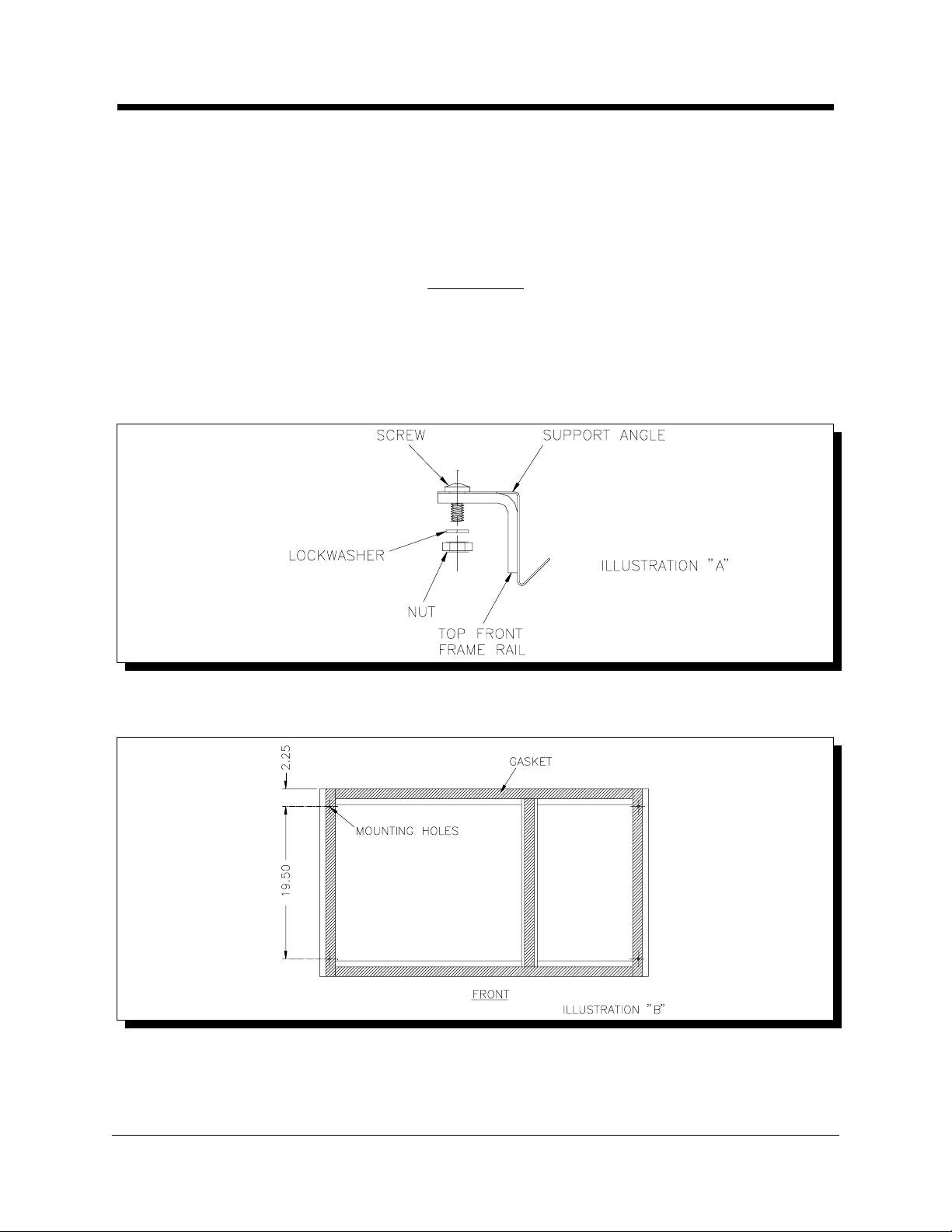

2. Mount inspection panel support angle to top front frame rail of lower (old GB

Classic) unit with #8-32 screw, nuts and lock washers provided. (See Illustration

"A")

3. Apply gasket (supplied with kit) to the lower ice maker frame and cut to fit.

Pierce gasket where it covers the mounting holes. (See Illustration "B")

4. Install (4) 1/4-20 cap screws up through mounting holes of the lower ice maker

and secure with (4) nuts.

Kold-Draft® Service & Parts Manual Rev:3/02

- 23 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 25

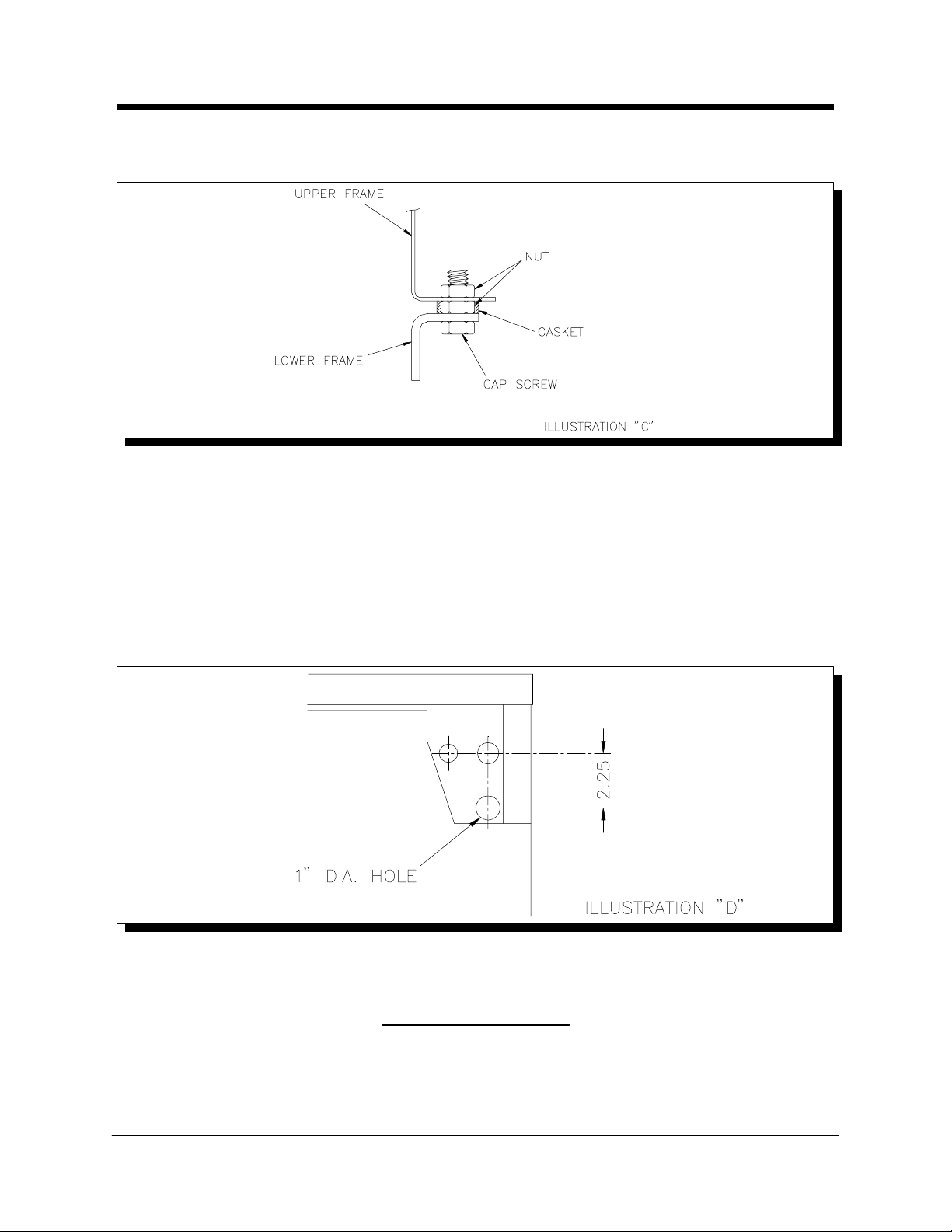

5. Position upper ice maker over lower unit and lower in place. Secure with (4)

GB Multiplexing Instructions

nuts. (See Illustration "C") CAUTION: Support upper unit unti l all fasteners are

secured.

6. Route upper ice maker bin thermostat capillary tube through grommeted hole in

the partition wall, down to the lower ice maker chute opening for positioning.

Keep capillary tube toward the front of the partition wall out of the path of falling

ice. Stacking a third ice maker will require a bin thermostat with a longer

capillary tube. Consult the factory for more information.

7. Install the upper ice maker drain pan and ice chute. Connect the drain hose

elbow assembly to the drain pan and route the drain hose through the rear of

the lower ice maker. If a 1" dia. hole has not been provided in the rear gusset of

the lower ice maker, it will have to be provided by the installer. (See Illustration

"D")

8. Install the Ice Chute (see instructions on Page 31), and side cabinet panels.

9. Follow start-up instructions to complete the installation.

Ice Chute Installation

The stainless steel i ce chute provided with 102 1207 01 GB Model Stacking Kits is to

be installed in all except the TOP cuber in the stack. See the Ice Chute instal lation

instructions on Page 31 for details.

Kold-Draft® Service & Parts Manual Rev:3/02

- 24 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 26

Section I

GT3XX

Multiplexing Instructions

{ Use a suitable lifting means and be careful of sharp edges.

NOTE: The next Two Sections only apply to GT3XX Cubers, the GT55X Cuber is

NOT stackable

CAUTION:

{ RISK OF PERSONAL INJURY, PROPERTY DAMAGE, EQUIPMENT FAILURE

OR FIRE.

{ Refer all maintenance to qualified personnel.

{ Never operate this equipment with covers, panels or other parts removed or not

properly secured.

Stacking new GT3XX Classic units above new GT3XX Classic units

NOTE: Please refer to Section II of these instructions for installing a new GT Classic

unit above an old GT Classic unit and Section III for install ing an old Classic (pre-1992

GT400, 500, 600) above a new GT Classic unit.

1. Remove cabinet panels from upper and lower ice makers.

2. Apply gasket (suppli ed with kit) to the lower ice maker frame and cut to fit.

(See Illustration "A")

3. Install (4) 1/4-20 cap screws up through mounting holes of the lower ice maker

and secure with (4) nuts. (See Illustration "B")

Kold-Draft® Service & Parts Manual Rev:3/02

- 25 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 27

4. Position upper ice maker over lower unit and lower in place. Inst all lock washers

GT3XX

Multiplexing Instructions

and secure with (4) nuts. (See Illustration "B") CAUTION: Support upper unit

until all fasteners are secured.

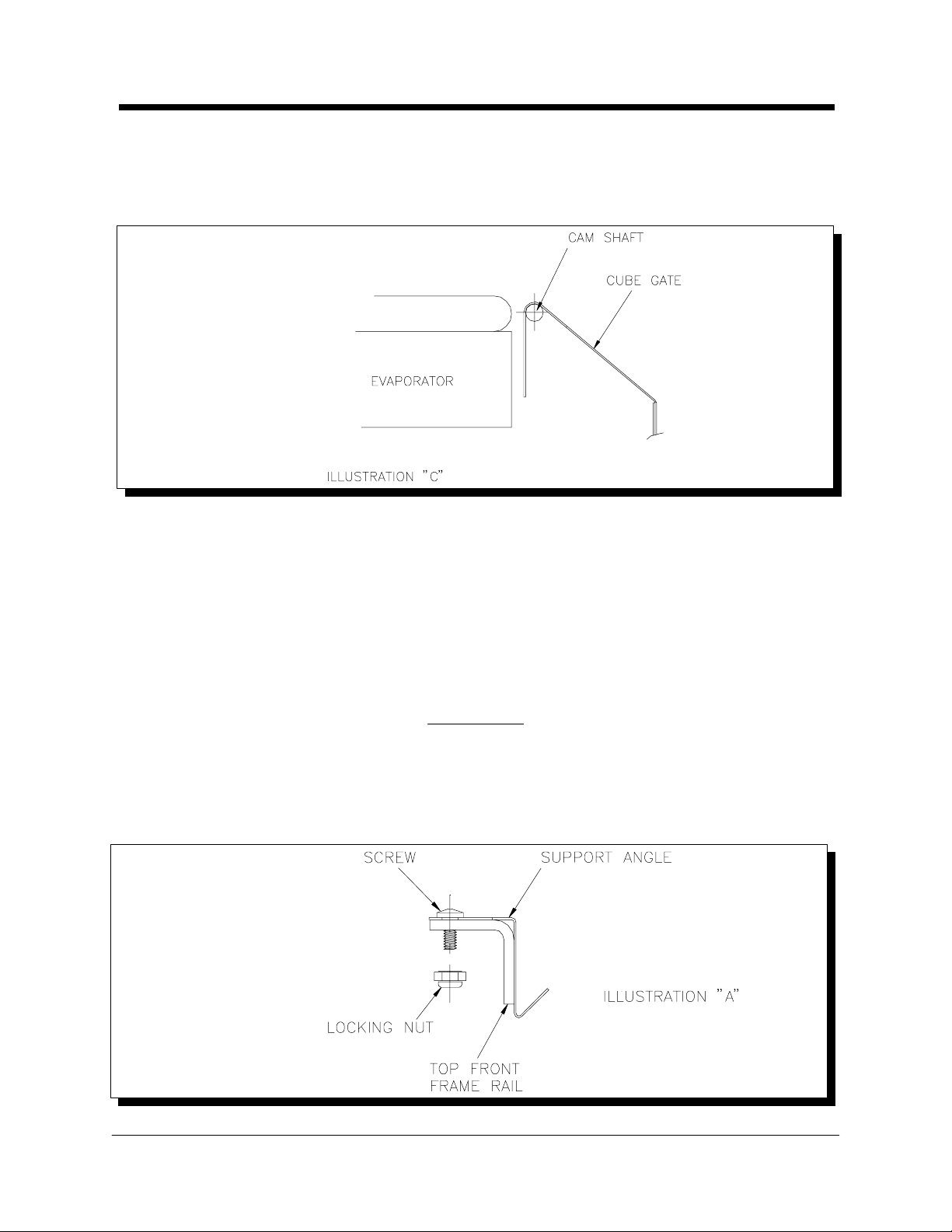

5. Hang cube gate on lower ice maker cam shaft. (See Illustration "C")

6. Remove the standard drain pan/chute from the upper ice maker and replace

with the Multiplex model (supplied with kit). Connect the drain hose to the drai n

pan nipple, and route it down so that it spills on the lower ice maker drain pan.

Secure the hose with a clamp.

7. Route the upper ice maker bin thermostat capillary tube through the

grommetted hole in the right side wall, down to the lower ice maker chute

opening for positioning. Keep capillary tube toward the front of the side wall out

of the path of falling ice. Stacking a third ice maker will require a bin thermostat

with a longer capillary tube. Consult the factory for more information.

Section II

Stacking new GT3XX Classic units above old GT30X Classic units

1. Remove cabinet panels from upper and lower ice makers.

2. Mount inspection panel support angle to top front frame rail of lower (pre-1992

GT Classic) unit with #8-32 screws and nuts provided. (See Illustration "A")

Kold-Draft® Service & Parts Manual Rev:3/02

- 26 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 28

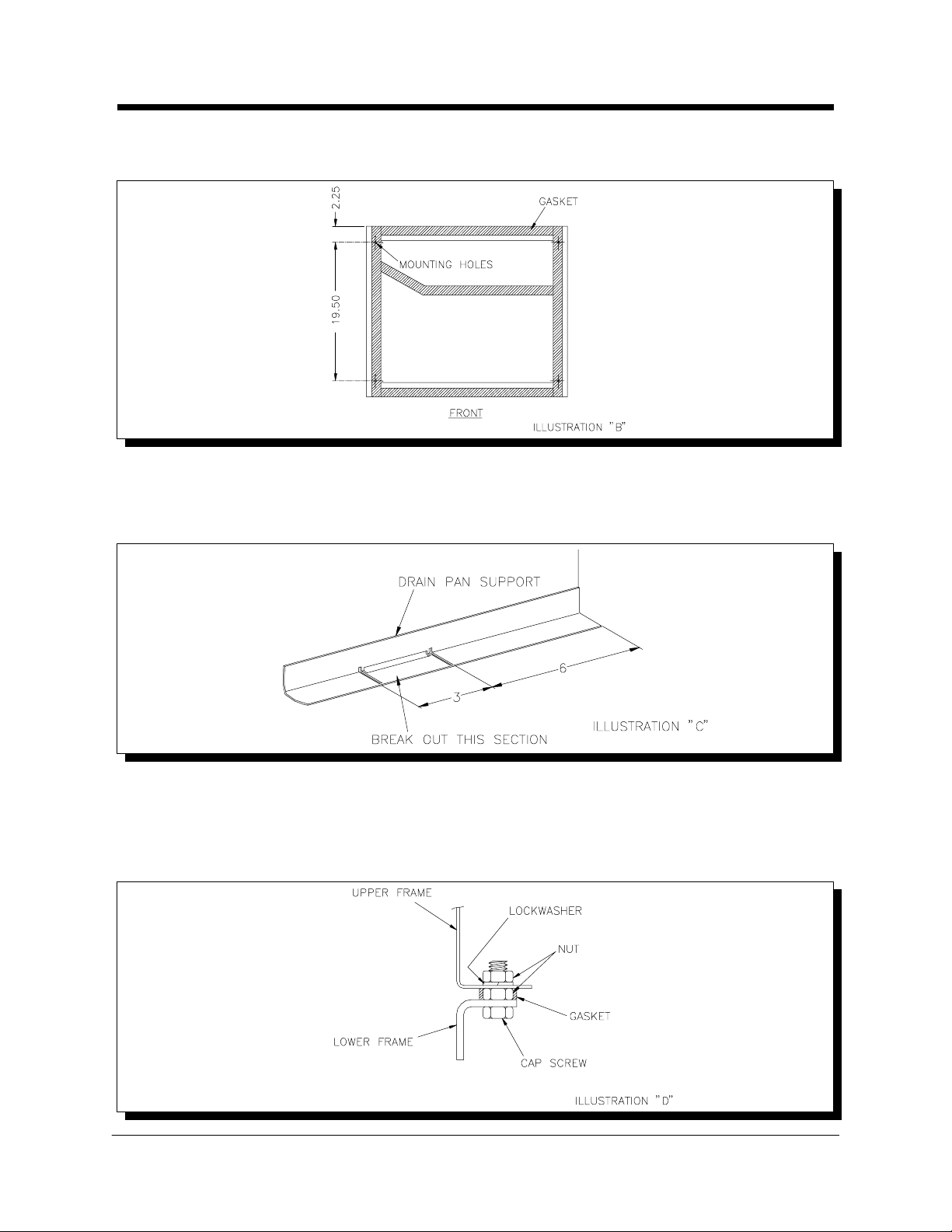

3. Apply gasket (supplied with kit) to the lower ice maker frame and cut to fit.

GT3XX

Multiplexing Instructions

Pierce gasket where it covers the mounting holes. (See Illustration "B")

4. The new Classic unit drain pan support angle must be modified for use with

pre-1992 Classic units. Remove the standard drain pan/chute from the new

Classic unit. Locate the notched section of the support angle, clip the tabs and

break out of unit. (See Illustration "C")

5. Install (4) 1/4-20 cap screws up through mounting holes of the lower ice maker

and secure with (4) nuts.

6. Position upper ice maker over lower unit and lower in place. Inst all lock washers

and secure with (4) nuts. (See Illustration "D") CAUTION: Support upper unit

until all fasteners are secured.

Kold-Draft® Service & Parts Manual Rev:3/02

- 27 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 29

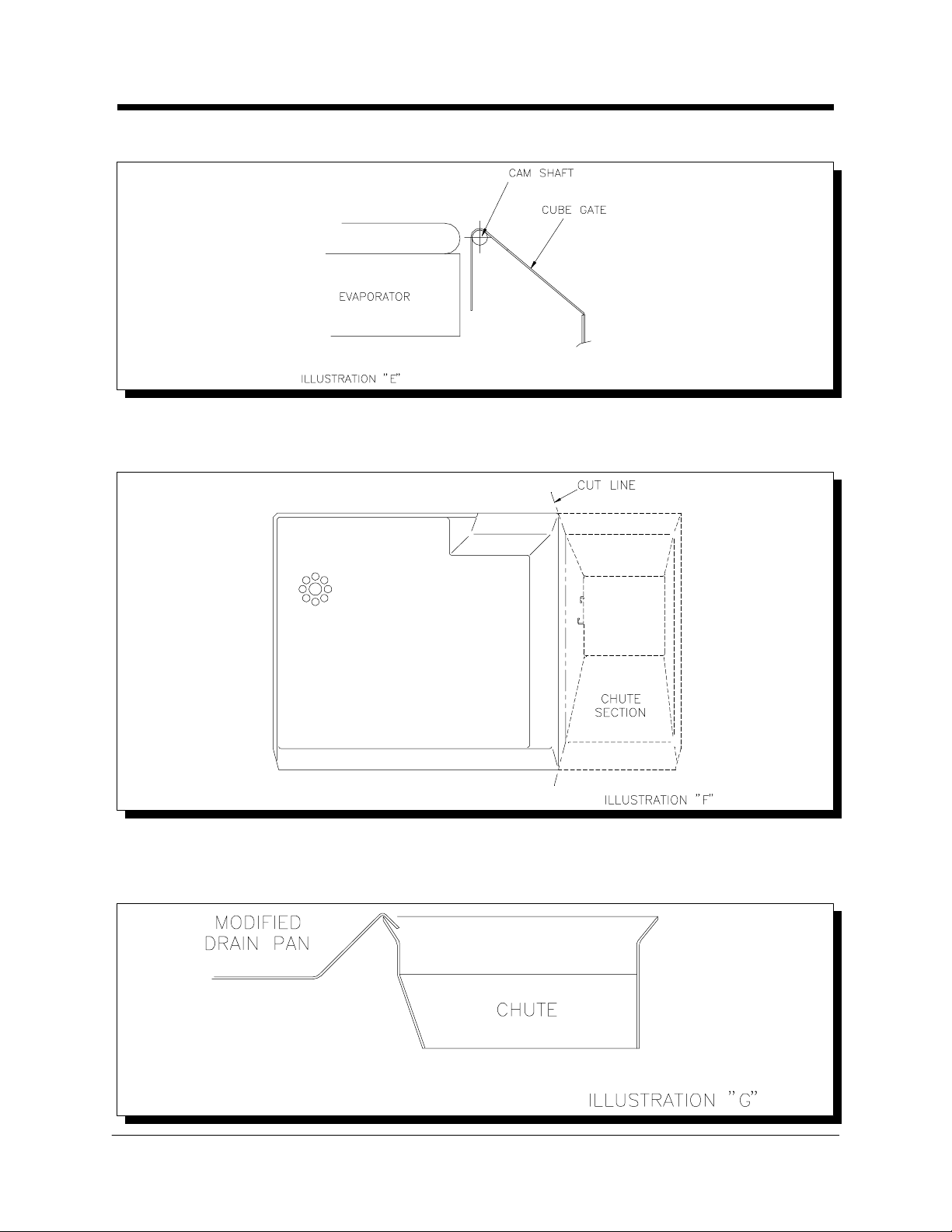

7. Hang cube gate on lower ice maker cam shaft. (See Illustration "E")

GT3XX

Multiplexing Instructions

8. Modify the multiplex chute (suppli ed with kit). Carefully separate the chute from

the drain pan with an utility knife and discard the chute section. (See Illustration

"F")

9. Install drain section in upper ice maker and move to the left side. Install chute

(supplied with kit) and position to the right side of the drain pan, under the drain

pan lip. (See Illustration "G") Route upper ice maker bin thermostat capillary

Kold-Draft® Service & Parts Manual Rev:3/02

- 28 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 30

tube through grommetted hole in the partition wall, down to the lower ice maker

GT3XX

Multiplexing Instructions

chute opening for positioning. Keep capillary tube toward the front of the

partition wall out of the path of falling ice. Stacking a third ice maker will require

a bin thermostat with a longer capillary tube. Consult the factory for more

information.

10. Install the side cabinet panel s and follow start-up instructions i ncluded with the

ice maker to complete installation.

Section III

Stacking old (pre-1992) GT Classic (GT400, 500, 600) units above

new GT3XX Classic units

1. Remove cabinet panels from upper and lower ice makers.

2. Apply gasket (supplied with kit) to the lower ice maker frame and cut to fit.

(See Illustration "A")

3. Install (4) 1/4-20 cap screws up through mounting holes of the lower ice maker

and secure with (4) nuts. (See Illustration "B")

Kold-Draft® Service & Parts Manual Rev:3/02

- 29 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 31

4. To allow for proper mounting, it is necessary to enlarge a 3/16" dia. hole in the

GT3XX

Multiplexing Instructions

bottom of the old GT Classic frame to 5/16" dia. (See Illustration "C")

5. Position upper ice maker over lower unit and lower in place. Install lock washers

and secure with (4) nuts. (See Illustration "B") CAUTION: Support upper unit

until all fasteners are secured.

6. Hang cube gate on lower ice maker cam shaft. (See Illustration "D")

7. Remove the standard drain pan and chute from the upper ice maker and

replace with the plastic drain pan and the multiplex chute. (supplied with kit)

Connect the drain hose to the drain pan nipple, and route it down so that it spills

on the lower ice maker drain pan. Secure the hose with a clamp.

8. Route the upper ice maker bin prove wire down to the lower ice maker chute

opening for positioning. Keep capillary tube toward the front of the side wall, out

of the path of falling ice.

Kold-Draft® Service & Parts Manual Rev:3/02

- 30 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 32

Kold-Draft® Service & Parts Manual Rev:3/02

GB Multiplex Ice Chute Installation Instructions

- 31 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 33

{

Operational Components

1992 and later models

{

Refer to the specific model wiring diagrams in addition to this text.

{

The following list of components and their functions is common to all models except

as noted in the text.

1. Compressor: All models are provided with a refrigerant compressor which is

rated for the electrical and refrigerant characteristics indicated on the

Nameplate located on the rear of the cuber.

2. Condenser: All models, except those which use a remote condenser (R), are

provided with a self-contained refrigerant condenser, either forced air (A) or

liquid (W) cooled, rated for the refrigerant type and pressure indicated on the

Nameplate. Remote condenser (R) models are intended for use with

remotely-installed forced air-cooled condensers meeting the requirements

indicated on the Nameplate.

3. Condenser Fan: Air cooled models (A) are provided with a condenser fan

motor and blade combination which have the proper air volume capacity for the

refrigeration system and minimum ventilation noise level. Note the installation

clearance requirements for each model.

4. Condenser Coolant Regulator Valve: Liquid cooled models (W) are provided

with a mechanical valve to regulate the flow of liquid coolant through the

condenser. This compensates for variations in the refrigeration load and

variations in coolant temperature to provide maximum efficiency. High-side

refrigerant pressure determines the valve modulation. Refer to the Controls

and Adjustments section for further information.

5. Heat Exchanger, Liquid-to-Suction: All models are provided with a

tube-in-tube heat exchanger which should sub-cool the liquid refrigerant

approximately 12} F. during the freeze cycle.

Rev:3/02 Kold-Draft® Service & Parts Manual

- 32 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 34

6. Filter-Drier: All models are provided with a liquid-line filter-drier which is rated

Operational Components

for the refrigerant type and high-side design pressures indicated on the

Nameplate.

7. Thermostatic Expansion Valve (TEV): All models are provided with

mechanical TEV's which are suitable for the refrigeration load and the

refrigerant type indicated on the Nameplate. GB1220/1240/1250 Dual

evaporator models employ two TEV's. See the Controls and Adjustments

section for further information.

8. Evaporator: All models are provided with a plated copper evaporator, two

evaporators in GB1220/1240/1250 models, which determines the ice cube size

which will be produced. Each cube is formed in an individual cell with five

freezing surfaces. In order to change the size of ice produced, the evaporator,

and possibly the water plate, must be changed. The evaporator(s) is(are)

mounted horizontally with the open side down, and ice is harvested by gravity

without mechanical assistance. The small holes in part of the top surface allow

air in as the ice falls out. Refrigerant is carried by the serpentine coil of plated

copper tubing on the top surface of the evaporator.

9. Water Solenoid Valve: Each evaporator/water plate/tank section is provided

with a line-voltage solenoid valve which supplies all ice making and rinsing

water to the cuber. See the Controls and Adjustments section for details

regarding how and when the valve is energized.

10. Hot Gas (Defrost) Valve: All models are provided with a line-voltage hot gas

solenoid valve which routes the compressor discharge gas to the evaporator as

required, for harvesting ice or for cold-water effect compensation. See the

Controls and Adjustments section for details regarding how and when this

valve is energized.

11. Liquid Line Solenoid Valve: Remote condenser models (R) are provided with

a line-voltage liquid line solenoid valve which is energized only while the

'ICE-OFF-WASH' switch is in the 'ICE' position. The purpose of this valve is to

allow the low side to pump down during off periods. See the wiring diagrams

and the Control and Adjustments section for details regarding how this valve

is controlled.

12. Head Pressure Control Valve (Low Ambient): Remote condenser models (R)

are provided with a non-adjustable mechanical pressure regulating valve which

closes off the condenser liquid return and bypasses compressor discharge gas

to the receiver during cool ambient temperature operation (below 75} F.).

During this function, liquid refrigerant floods the condenser coil while the

receiver liquid pressure is maintained high enough for effective refrigeration.

REMOTE CONDENSER MODELS ARE NOT FACTORY CHARGED TO

THE MAXIMUM AND WILL LIKELY REQUIRE ADDITIONAL REFRIGERANT

CHARGE AT INSTALLATION. See the Installation Guidelines section for

determining the proper charge and for calculating the additional charge required

for the expected lowest ambient temperature operating conditions.

Kold-Draft® Service & Parts Manual Rev:3/02

- 33 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 35

{

Operational Components

WARNING: RISK OF SERIOUS DAMAGE TO THE COMPRESSOR!

Insufficient refrigerant charge will result in repeated pump-down cycles until the

compressor overloads or fails.

13. Harvest Regulator Valve: Remote condenser models (R) are provided with a

non-adjustable mechanical pressure regulating valve. The purpose of this valve

is to maintain high-side refrigerant mass for adequate heat transfer when the

hot gas valve is open, if the discharge pressure falls below 150 psig. This valve

only functions as required, and it is not likely to open when the condenser

ambient temperature is above 75} F.

14. Quick-Connect Refrigerant Fittings: Remote condenser models (R),

Kold-Draft® remote condensers and Kold-Draft® remote line sets are provided

with re-sealable fittings for refrigerant line connections. Kold-Draft® condensers

and line sets are VAPOR-CHARGED only.

15. Strainer-Water Inlet: All models are provided with an in-line potable supply

water strainer. This strainer is not intended to remove supply water turbidity,

which is inherent to the water supply, but rather to protect the water solenoid

valve(s) from damage due to an unusual event, such as follows a water shut-off

for plumbing work. If the need for cleaning the strainer is frequent, an external

water filter should be provided. The strainer may be cleaned without

disassembly of tubing.

16. Receiver-Refrigerant: Liquid cooled (W) and Remote condenser (R) models

are provided with receiver tanks, which are rated for the refrigerant charge type,

amount and pressures indicated on the Nameplate. Air cooled models (A) do

not employ a receiver.

17. Check Valve-Receiver Inlet: Remote condenser models (R) are provided with

a check valve at the receiver inlet. The purpose of this valve is to minimize

refrigerant backflow to the condenser during harvest and off cycles and to

maintain receiver pressure during harvest for proper operation of the harvest

regulator valve with low condenser ambient temperatures.

18. Check Valve-Harvest Regulator Valve Inlet: Remote condenser models (R)

are provided with a check valve in the supply tubing to the harvest regulator

valve. The purpose of this valve is to avoid migration of high-side refrigerant to

the liquid line during off cycles, when the high-side pressure is lower than the

setting of the harvest regulator valve. Without this check valve, the pumpdown

controller (see the Controls and Adjustments section) would not function

properly.

19. Check Valve-Hot Gas Line: GB1220/1240/1250 Dual evaporator models are

provided with a check valve in the hot gas tubing to the Master (upper)

evaporator. The purpose of this valve is to prevent refrigerant migration from

the upper to the lower evaporator during freeze cycles, which can occur due to

gravity. Frost on the hot gas tubing indicates refrigerant migration from the

lower to the upper evaporator, which is due to refrigeration imbalance. See the

Service and Troubleshooting section for more details.

Rev:3/02 Kold-Draft® Service & Parts Manual

- 34 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 36

20. Water Plate: All models are provided with a plastic water plate beneath each

Operational Components

evaporator. The flat top surface of the water plate is provided with holes for

injection of water into each evaporator cell and for return of unfrozen water to

the water circulation system. This surface forms the sixth surface of the cubes

and is spaced from the evaporator so that a thin, uniform web of ice is formed.

The cubes are connected together to promote harvest in one or more large

sections, rather than individually which would cause excessive melting and

require a much longer harvest time.

21. Water Tank: A plastic water tank, or sump, is attached to the bottom of each

water plate. The volume of this tank contains enough water for a single batch of

ice, along with some excess water to carry away the impurities from the water

supply. The impurities are excluded from the ice by the constant circulation

during the freezing cycle. Unfrozen water is returned to the tank, from the water

plate, during the freeze cycle. The excess water, with concentrated impurities, is

drained from the system each cycle along with the fresh water which rinses the

water plate while it is opening for harvest.

22. Water Pump: Each evaporator/water plate/tank section is provided with a water

pump. The purpose of this pump is to recirculate the ice-making water

constantly, through the water plate, during the freeze cycle. The pump does not

run during the harvest cycle. All water pumps are designed exclusively for the

application electrical requirements and ice maker type (GB/GT) to provide the

proper water circulation rate. See the Controls and Adjustments section for

details regarding how and when the pump is energized.

Kold-Draft® Service & Parts Manual Rev:3/02

- 35 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 37

23. Actuator Motor and Cams: The opening and closing of the water plate for

Operational Components

freezing and harvesting cycles is accomplished by the actuator motor. The

connection between the actuator motor and water plate is through plastic cams

and springs. When the water plate is closed for freezing, the cam lever with the

spring attached is in the noon position with the spring slightly stretched, keeping

the water plate tight against the cam surface at the motor coupling. See the

Service and Troubleshooting section for alignment and adjustments. At the

beginning of a harvest cycle, the actuator motor runs counter-clockwise (CCW,

facing the cuber) and the cam surface forces the water plate away from the ice.

As the motor continues to run, the cam lever travels to the 7 O'Clock position

when the motor stops with the water plate open for harvesting the ice. After the

ice has been harvested, the actuator motor runs clockwise (CW) to turn the cam

levers back to the noon position for the next freeze cycle.

CAUTION: Overfreezing, so that more cam force is required to separate the

water plate from the ice causes undue component wear. See the Controls and

Adjustments and Service and Troubleshooting sections for proper

adjustments to avoid this condition.

Rev:3/02 Kold-Draft® Service & Parts Manual

- 36 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 38

1. Bin Thermostat: The bin thermostat provides power to the 'ICE-OFF-WASH'

Controls and Adjustments

switch. See the GB & GT Cuber Installation Instructions for the proper

placement and securing of the bin thermostat capillary tube.

Adjustment of this control can be made with the 'ICE-OFF-WASH' switch (see

below) in the 'WASH' position to avoid unnecessary compressor cycling. While

holding some ice against the end of the capillary tube the cuber should shut

down within one minute. Turn the adjustment warmer (CCW) to shut down

sooner, or colder (CW) to delay shut down (may be necessary in cool ambients

to avoid premature shut down). Ideally, the shut down will occur after the ice

has harvested and before the water plate closes. This adjustment should be

checked with the ice storage area full and with the unit at typical ambient

temperature.

Note: The compressor control circuit in remote condenser models (R) is

supplied upstream from the bin thermostat in order to allow the low-side

pumpdown cycle during off periods.

2. High Temperature Shutoff Thermostat: Before October, 1996 some models

were provided with a high temperature shutoff thermostat on the suction line

near the compressor inlet. This control provides power to the bin thermostat and

to the compressor circuit pressure switches in remote condenser (R) models. If

the suction line temperature rises to 130} F. due to a refrigeration problem,

such as the hot gas valve mechanically stuck open, power will be shut off to all

operating components of the cuber including the compressor in remote

condenser models (R). This control will automatically reset when the suction

line cools to 110} F., restoring power to the operating components.

3. ICE-OFF-WASH Switch: The 'ICE' position connects power from the bin

thermostat to all control circuits, except the compressor circuit in remote

condenser (R) models, and to the respective electrical operating components

except the compressor motor (and condenser fan motor in self-contained air

cooled models) which is (are) powered by the contactor.

The 'WASH' position allows all electrical operating components to be powered

without the compressor running for in-place cleaning or test procedures (see

Kold-Draft® Service & Parts Manual Rev:3/02

- 37 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 39

additional details under Pump-Down Controller, Relay-Hot Gas Control and

Controls and Adjustments

Relay-Rinse and Hot Gas Control).

The 'OFF' position (center) interrupts power to all control circuits, except the

compressor circuit in remote condenser (R) models, and to the respective

electrical operating components.

{

Warning: All cuber circuits are not de-energized when this switch is in the

'OFF' position. Disconnect power to the cuber before servicing.

4. Liquid Level Controller (LLC) and Water Level Probes: A clear plastic tube,

which contains three stainless steel probes and indicates the water level in the

circulation system, is located at the front of all models. The high and low level

probes sense the water shut-off level and harvest initiation level, respectively.

The common probe serves as a reference for the high and low level probes

since conductivity of low-voltage alternating current (AC) through the water

provides the signals. The high level probe de-energizes the water fill circuit

when contacted by water. The low level probe initiates harvest (during normal

operation) or energizes the water fill circuit (start-up or cleaning cycles when

the evaporator is warm) when the level of water is below this probe. Once the

water fill has been completed and the water fill circuit has been de-energized,

no further changes in the water fill or harvesting operation will be noted until the

level is below the low level probe. The LLC input and outputs are line voltage.

Note that both normally open (N.O.) and normally closed (N.C.) LLC

connections are used. The blue circuit, which powers the harvest initiate and

water fill circuits, is connected to common (COM). The black/green main power

circuit is connected to the N.O. terminal to power the blue circuit whenever the

LLC relay is energized, as during water fill and harvest initiation. The red

"defrost" circuit is connected to the N.C. terminal as a fail-safe circuit to avoid

water plate lockup in a partially-closed position.

5. Pump and Defrost Switch: The operation of each water pump is controlled by

a pump and defrost switch which is actuated by a tab or bolt on the side of the

water plate. The pump runs when the water plate is closed, and it stops as the

water plate opens. With the water plate open enough so that the pump is not

energized, the red circuit, which powers the water plate opening actuator motor

winding, is energized. If this switch is not actuated to start the pump before the

water plate is completely closed, the actuator motor will repeatedly re-open the

water plate. If the water plate closing is obstructed by ice which did not fall off,

the springs will stretch so that the cam may continue to rotate, but the water

plate tab or bolt cannot actuate the pump and defrost switch and the water plate

will re-open to clear the obstruction. This switch must be actuated to start the

pump when the spring-end of the front cam is between the 10 and 11 O'clock

position while rotating clockwise to close the water plate. If the water plate

springs have weakened over time, the water plate will not pull up tightly against

the front cam and the pump switch adjustment will be affected. Be sure that the

springs are not stretched, then if adjustment is necessary it is made by bending

the tab or adjusting the bolt on the water plate. Do not bend the switch lever, but

be sure that the tab or bolt engages the switch lever as the water plate closes.

The pump and defrost switch in all single evaporator models, and the Master

(upper) pump and defrost switch in dual evaporator models manufactured

between January, 1992 and March, 1996 is a two-pole switch. The second pole

provides power to the water solenoid valve through the black-to-yellow actuator

toggle switch circuit to rinse the water plate as it opens for harvest. Rinse will

not begin until approximately the same time as the pump stops, and the water

Rev:3/02 Kold-Draft® Service & Parts Manual

- 38 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 40

solenoid valve will be de-energized as soon as the water plate is fully open only

Controls and Adjustments

during harvest cycles when the actuator thermostat, described later, is

switched cold.

Since March, 1996 all single- and dual-evaporator models employ ONLY

single-pole pump and defrost switches, and water plate rinse begins

immediately upon harvest initiation. See EB#96001 for details.

6. Actuator Thermostat: All models are provided with an actuator thermostat

which senses the evaporator temperature. During the freeze cycle the actuator

thermostat switches cold (at approx. +26} F. in its coldest adjustment) to set up

the electrical circuit for harvest, connecting the blue LLC output (COM), which is

not energized until the water level is below the low water level probe, to the red

circuit. No change in cuber operation will be evident at this time. After ice has

harvested this thermostat switches warm, above 50

}

F., connecting the water

plate closing and water fill circuits to the blue LLC output which is energized at

that time. Setting the actuator thermostat warmer will keep the water plate open

longer after the ice has dropped.

Note: At the full warm (CCW) adjustment the actuator thermostat is locked in

the cold switch contact position and will not reset warm, to raise the water plate,

regardless of evaporator temperature. This control should never be set warmer

than necessary to insure that all ice is out of the evaporator(s) before the water

plate(s) begin closing.

7. Cold Water Thermostat: All models except GT330/GT340/GT350 series are

provided with a cold water thermostat which senses the evaporator temperature

along with the actuator thermostat. In self-contained models, (A) or (W) except

dual evaporator models (before 9/96), this control connects the hot gas valve to

the blue LLC output when it is switched cold or to the red circuit when it is

switched warm. The red circuit is energized whenever the water plate is not fully

closed, and the blue circuit is energized from harvest initiation until completion

of the water fill. The hot gas valve will be energized throughout the harvest

cycle and until the water plate is completely closed and thereafter only if the

cold water thermostat trips cold during the water fill.

Remote condenser models (R), and all dual evaporator models before

September, 1996, do not have a red circuit connection to the cold water

thermostat, so that the hot gas valve may be de-energized when the water plate

is not fully closed but only if the cold water thermostat has reset warm. This

allows cycling of the water plate, for example to dump cleaning solutions,

without energizing the hot gas valve which would cycle the compressor in

remote condenser models (R) due to the low-side pump-down controller,

described later.

Note: The calibrations of the cold water and actuator thermostats may overlap.

When there is no red circuit connection to the cold water thermostat it is

necessary to provide a hot gas valve latching circuit until the actuator

thermostat switches warm to avoid the possibility of the hot gas valve being

de-energized before the water plate begins closing. This circuit is provided by

the hot gas control relay, or by the rinse and hot gas control relay in dual

evaporator models (before 9/96), described later.

The cold water thermostat additionally, acts as a foolproof

control in the event that the evaporator temperature decreases very rapidly

during the water fill due to very cold supply water, or if the water fill rate is

abnormally slow due to inadequate water supply or a restricted filter/strainer,

etc. Refer to the Cold Water Thermostat Cycle in the Sequence of Operation

Kold-Draft® Service & Parts Manual Rev:3/02

- 39 -

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Page 41

section for the description of the cold water thermostat function in this case.

Controls and Adjustments

The proper adjustment is usually fully cold (CW). When supply

water is very cold, less than 50} F., and ice is being fully-formed (control stream

goes over the dam) or when the ice is not cleared from the water plate surface

by the rinse water due to water plate surface breakdown (also see Water Plate

Service section), the cold water thermostat may be adjusted warmer (CCW).

This will provide additional heat to the water, only during the fill cycle, to avoid

progressive freezing-up of the water plate which will result in early failure. A

warmer setting is recommended for remote condenser models (R) and all dual

evaporator models with cold supply water.

8. Actuator Toggle Switch: The travel of the actuator motor in all models is

controlled by the actuator toggle switch, which is tripped by a paddle on the

motor gearbox output shaft. When the water plate is fully closed, as during the

freeze cycle, the switch lever is in the 'up' position. This connects the water

plate opening winding of the motor to the red circuit, and also connects the

water solenoid valve coil to the water plate rinse circuit. When the water plate

is fully open, as during the harvest cycle, the switch lever is in the 'down'

position. This connects the water plate closing winding of the actuator motor

and the water solenoid valve coil to the warm actuator thermostat circuit, and

also connects the red circuit to the black/green main power circuit which powers

the fail-safe circuit, described under Liquid Level Controller.

The paddle which trips this switch may be bent slightly to insure that the

water plate stops in its widest open position. This is necessary for proper

harvest of half-cubes (HK). In dual evaporator models only, the paddle may be

bent to provide slight overtravel, toward the 1 O'clock position (not

recommended with NEW STYLE Actuator Motors), when the Master (Upper)

water plate closes, for a slight additional synchronization time. See additional

details under Timer-Master Actuator Motor Delay.

9. Capacitor(s)-Actuator Motor: All actuator motors employ a capacitor between

the two windings to determine the direction of rotation when the motor is

energized.

Models manufactured between approximately 1964 and 5-1-95 employ the

OLD STYLE actuator motor which requires a 1.5 mfd. capacitor for this purpose.

These motors were all rated 115 Volts, and in 208-240 Volt applications, where

an internal transformer was not employed to provide 115 Volts to the actuator

motor, a second capacitor in series with the motor winding, white wire, was

employed for voltage reduction. The value of the second capacitor was 1.5 mfd.

for 220-240 Volt/50 Hz. models, or 2.0 mfd. for 208-230 Volt/60 Hz. models.

Models manufactured after 5-1-95 employ a NEW STYLE actuator motor

which is rated either 115 Volts or 230 Volts and requires only one capacitor

installed between the windings of each motor for direction of rotation. The 115

Volt motor capacitor is rated 4 mfd., and the 230 Volt motor capacitor is rated 1

mfd. Replacement Actuator Motor kits after June, 1995 are provided

with only the NEW STYLE actuator motors. Refer to the Service and

Troubleshooting section to determine which style is installed and the

respective troubleshooting information.

10. Contactor: All models are provided with a contactor which carries the

compressor load, and the fan motor load in air cooled models (A). The contactor

coil is rated for line-voltage, and the contacts are rated for definite purpose

applications (FLA and LRA).

Rev:3/02 Kold-Draft® Service & Parts Manual