Page 1

KOLD-DRAFT

CLASSIC

GB450R GT550R

®

KOLD-DRA FT

Ice Machine Products

®

GB650R

GB1250R

Precharged Remote Air-Cooled

Condenser Installation Instructions

1525 East Lake Road, Erie, PA 16511-1088

814/453-6761

FAX 814/455-6336

©2004 KDIndustries, Inc., Erie, PA U.S.A.

Printed in U.S.A. 3/04

508 1044 01

A Tradition of E xcellence I n I ce Equipment.

Page 2

wrench to prevent tubing twist when tightening these fittings.

INSTALLATION AND OPERATION INSTRUCTIONS

FOR KOLD-DRAFT® CLASSIC® GB SERIES REMOTE

AIR-COOLED CONDENSERS

CHECK FOR FREIGHT DAMAGE BEFORE PROCEEDING: Even though damage to

the carton may not have been evident, check for hidden damage and contact freight

carrier immediately if necessary to file a claim.

THIS EQUIPMENT MUST BE INSTALLED IN COMPLIANCE WITH THE

APPLICABLE FEDERAL, STATE/PROVINCE, AND/OR LOCAL PLUMBING,

ELECTRICAL, AND HEALTH/SANITATION CODES AND REQUIREMENTS.

CAUTION:

{

RISK OF PERSONAL INJURY, PROPERTY DAMAGE, EQUIPMENT

FAILURE, OR FIRE.

{

Refer all maintenance to qualified personnel .

{

Never operate this equipment with covers, panels, or other parts removed

or not properly secured.

{

Warn all users to clean up spillage immediately, keep storage bin doors

closed, and report any apparent leakage or unusual sounds to responsible

maintenance personnel.

{

If system components are modified or substituted for components not specified

by Kold-Draft®, proper operation can be compromised to the point of system

failure.

{

Kold-Draft® reserves the right to disallow any warranty claims which result

from the use of non Kold-Draft® condensers and/or line sets.

INSTALLATION

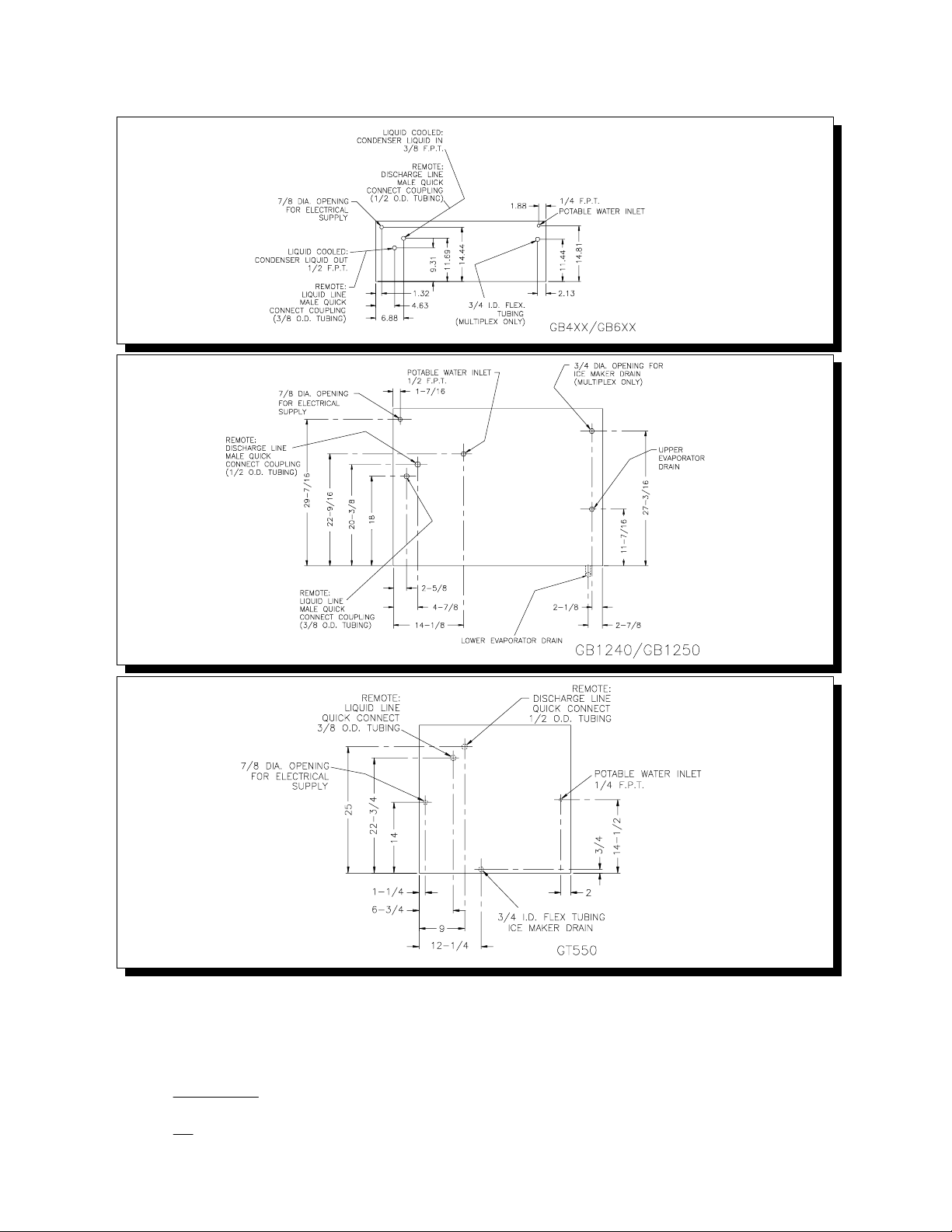

1. Uncrate the condenser and install the mounti ng legs. Be sure to install the l eg

stabilizer between the legs.

CAUTION:

{

RISK OF PERSONAL INJURY OR EQUIPMENT DAMAGE.

{

Use a suitable lifting means and be careful of sharp edges.

2. Fasten the condenser to the roof or wall using whatever method will satisfy the

building codes in your area. The condenser must not be lower than the

receiver.

3. The line sets are packed separately, with the quantity and length marked on the

carton. Make sure that the lines are correct for your installation.

4. A single circuit condenser installation, which uses one line set, will require a

1-3/4" dia. hole to pass the lines through a ceiling or wall. The lines for a 2

circuit condenser require a 2" dia. hole.

5. Each line set consists of a 3/8" l iquid line, and a 1/2" insulated discharge li ne.

Connect the 3/8" line to the lower (liquid) fitting on the condenser, and to the

"Refrigerant In" on the ice maker. The 1/2" line connects to the upper (inlet)

fitting on the condenser, and the "Refrigerant Out" on the ice maker.

6. Each fitting on the line sets, condenser and ice maker is self-sealing, and

should be tightened 1/4 turn more than hand tight. Always use a backup

508 1044 01 Rev. 3-02

-1-

Page 3

7. The condenser fan motor requires a separate 208-230 volt, 60 Hz, single phase

power supply whi ch complies with all appli cable code requi rements. The system

is designed for continuous fan motor operation. If desired, a condenser fan

cycling control may be installed to stop the fan during cuber off-cycles.

Suggested pressure calibrations are approx. 250 psig ON/220 psig OFF.

CAUTION: For multiple-circuit installations, a separate pressure control must

be installed on each circuit, and all of the controls must be parallel-wired so that

all controls must be open to stop the fan.

508 1044 01 Rev. 3-02

-2-

Page 4

8. The refrigerant lines should be routed inside the building or otherwise

mechanically protected wherever possible.

In cold weather operation, the liquid return line (3/8") may sweat or frost. If this

is objectionable, insulation may be installed on the liquid line inside the bui lding.

INSTALLER NOTE: There is no electrical interconnection provision i n "R" Models for

the condenser fan.

Ampacity: Minimum ampacity does not indicate typical running current value. Refer to

equipment NAME PLATE data. Use minimum ampacity value for sizi ng branch circuit

conductors up to 25 feet length. For conductor length over 25 feet up to 100 feet,

increase 1 AWG size. Over 100 feet requires 2 or more AWG size increase.

Branch circuit protection: Proper protection must be provided by either fuse(s) or

HACR type circuit breaker(s). Each ice maker must be provided with a separately

protected circuit with no other load(s). A fused disconnect installed adjacent to each

ice maker is recommended (must be supplied by the installer), and may be required by

local codes. NORMAL protector size is based on rated vol tage and operati on at lower

than extreme temperature li mits. When branch circui t conductors are sized to permit,

increasing the protector size (up to the specified maximum) may avoid nuisance

protector opening under harsh operating conditi ons.

Remote condenser models from the factory carry a minimal charge and will likely

require an additional refrigerant charge to accommodate all condenser ambient

temperatures and/or the volume potentially contained in refrigerant lines and

condensers. There is a label on the receiver that indicates factory charge and the

maxi mum c har ge, along with a space to write in the total system charge. Ice makers

are provided with re-sealable refrigerant line connection coupli ngs.

All models are intended FOR INDOOR USE ONLY with PERMANENT CONNECTION

TO THE FIELD ELECTRICAL SUPPLY. The remotely-installed condensers supplied

by Kold-Draft® may be installed outdoors, and they require a separate electrical

supply.

Other operating condition requirements:

Ice maker ambient air temperature: MINIMUM 45°F.; MAXIMUM 90°F.

Remote condenser ambient air temperature: SEE CHART BELOW

HIGH AMBIENT

APPLICATION

(OVER 110

GB454

GT550

GB650

GB12501075, 1/4, 2SINGLE CIRCUIT

}

F.)

PART

NUMBER

GBB-02223-B

GBB-02413-B

GBB-02425-B

GBB-02426-B

CONFIGURATION

2 TON

3 TON

3 TON

5 TON

FAN MOTOR

RPM, HP, F LA

1075, 1/4, 2TWO CIRCUIT

NORMAL AMBIENT

APPLICATION

(UNDER 110

GB454

GT550

GB6501075, 1/4, 2TWO CIRCUIT

GB12501075, 1/3, 3.5TWO CIRCUIT

}

F.)

508 1044 01 Rev. 3-02

-3-

Page 5

Kold-Draft® Remote Condenser Single Evaporator Cuber Charging Requirements

®

Kold-Draft

Remote Condenser Dual Evaporator Cuber Charging Requirements

{

Charts based on 30 ft. of 1/2" O.D. discharge (15 ft. exposed to ambient temperature

under 70} F.) and 30 ft. of 3/8" O.D. liquid return lines, at 20} F., T.D.

{

Lines over 50 ft. are not recommended.

{

Minimum Condenser Height: Condenser must be installed above refrigerant line quick

connects at rear of ice machine. No part of the refrigerant lines, between the cuber

and the condenser, should fall below this point except for a trap directly behind

cuber.

{

For Condensers other than Kold-Draft®, the installer must determine the condenser

liquid vol ume at minimum operating temperature.

ˆFor Single Evaporator Cubers, the basic charge is 1-3/4 lbs. To this add the

condenser liquid volume calculation and the line charge calculation from Line Length

Correction Chart for the minimum total charge.

ˆFor Dual Evaporator Cubers, the basic charge is 3 lbs. To this add the condenser

liquid volume calculation and the line charge calculation from the Line Length

Correction Chart for the minimum total charge.

CAUTION:

{

RISK OF PROPERTY DAMAGE, EQUIPMENT FAILURE, OR FIRE.

{

Failure to comply with all install ation specificati ons and instructions may cause

erratic operation and the risk of damage or fire.

-4-

508 1044 01 Rev. 3-02

Page 6

REFRIGERANT CHARGE, MODEL NUMBER

Oz. (R-404A) GB454R GB650R GB1250R GT550R

--------------------------------------------------------------------------------------------------------------------------------------

Factory: 84 84 112 84

Maximum: 208 208 272 208

CAUTION: REFRIGERANT CHARGES MUST BE ACCURATELY WEIGHED.

NOTE: The compressor will start immediately when power is applied, regardless of

the "ICE-OFF-WASH" switch position, if the low-side pressure is at or above the

pump-down controll er cut-in setti ng. Disconnect the BLUE contactor coil wire for initial

warm-up period. Be sure that the compressor stops when the low-side pressure is

between 5 and 15 psig.

CAUTIONS

1. Try to keep the compressor warmer than the condenser. In most installations,

the ice maker runs enough so that residual motor heat minimizes liquid

migration to the crankcase. If the ice maker is in a cool location, or will be OFF

for extended periods, a crankcase heater must be used (All Models include a

Factory-installed crankcase heater).

2. Avoid placing the condenser in the exhaust air stream of other roof-top

equipment. Stay away from kitchen exhaust fans to prevent grease

accumulation on the fins. Use a curb, which extends above the deepest

508 1044 01 Rev. 3-02

-5-

Page 7

expected pond in the condenser area of the roof. A 3" pond can cut air flow in

half if a curb is not used.

508 1044 01 Rev. 3-02

-6-

Loading...

Loading...