Kojair Golden Line Series, Biowizard Series, Ergosilence Series User Manual

Microbiological Safety Cabinet class II EN 12469 certified by TÜV

USER MANUAL

Serial number:

Date of delivery:

Customer:

Kojair Tech Oy Tel. +358 3 471 7000 info@kojair.com

Teollisuustie 3 Fax +358 3 471 7077 www.kojair.com

35700 Vilppula

FINLAND

The definition of the Microbiological Safety Cabinet is as follows:

A ventilated enclosure intended to offer protection to the user and environment from the aerosols

arising from the handling of potentially hazardous and hazardous micro-organisms, with discharge to

the atmosphere being filtered.

You are owner of one of the most modern and silent Class II Microbiological Safety Cabinets

available. The Golden Line –series is microprocessor-controlled and therewith widely customizable.

All the standard-configurations of Golden Line series are type-tested and approved by TÜV

Rheinland according to current EN –standard 12469:2000 (the standard for Biosafety cabinets)

NOTICE! Only use this product for its intended purpose.

rev.3.01

1. FEATURES AND SAFETY ........................................................................................ 4

1.1. Introduction to the cabinet .................................................................................. 4

1.2. Construction materials ....................................................................................... 5

1.3. Positioning the cabinet and safety instructions .................................................. 5

2. USING THE CABINET ............................................................................................... 7

2.1. Control panel ...................................................................................................... 7

2.2. What t o do at first start-up .................................................................................. 9

2.3. Control panel functions .................................................................................... 12

2.3.1 User settings ..................................................................................................... 13

2.4. Daily maintenance and cleaning ...................................................................... 14

2.5. UV-light ............................................................................................................ 16

2.5.1. instruction for UV-light ...................................................................................... 17

2.5.1.1. introduction ...................................................................................................... 17

2.5.1.2 UV-light button .................................................................................................. 17

2.5.1.3 timer in the menu .............................................................................................. 18

3

rev.3.01

NOTE! Only Class III Microbiological Safety Cabinets can be used for working

1. FEATURES AND SAFETY

1.1. INTRODUCTION TO THE CABINET

Microbiological safety cabinets are intended to reduce the risk to the operator when handling hazardous

or potentially hazardous micro-organisms. They do not necessarily protect the operator from all the

hazards involved. Some types of cabinet can also protect the materials being handled in them from the

environmental contamination.

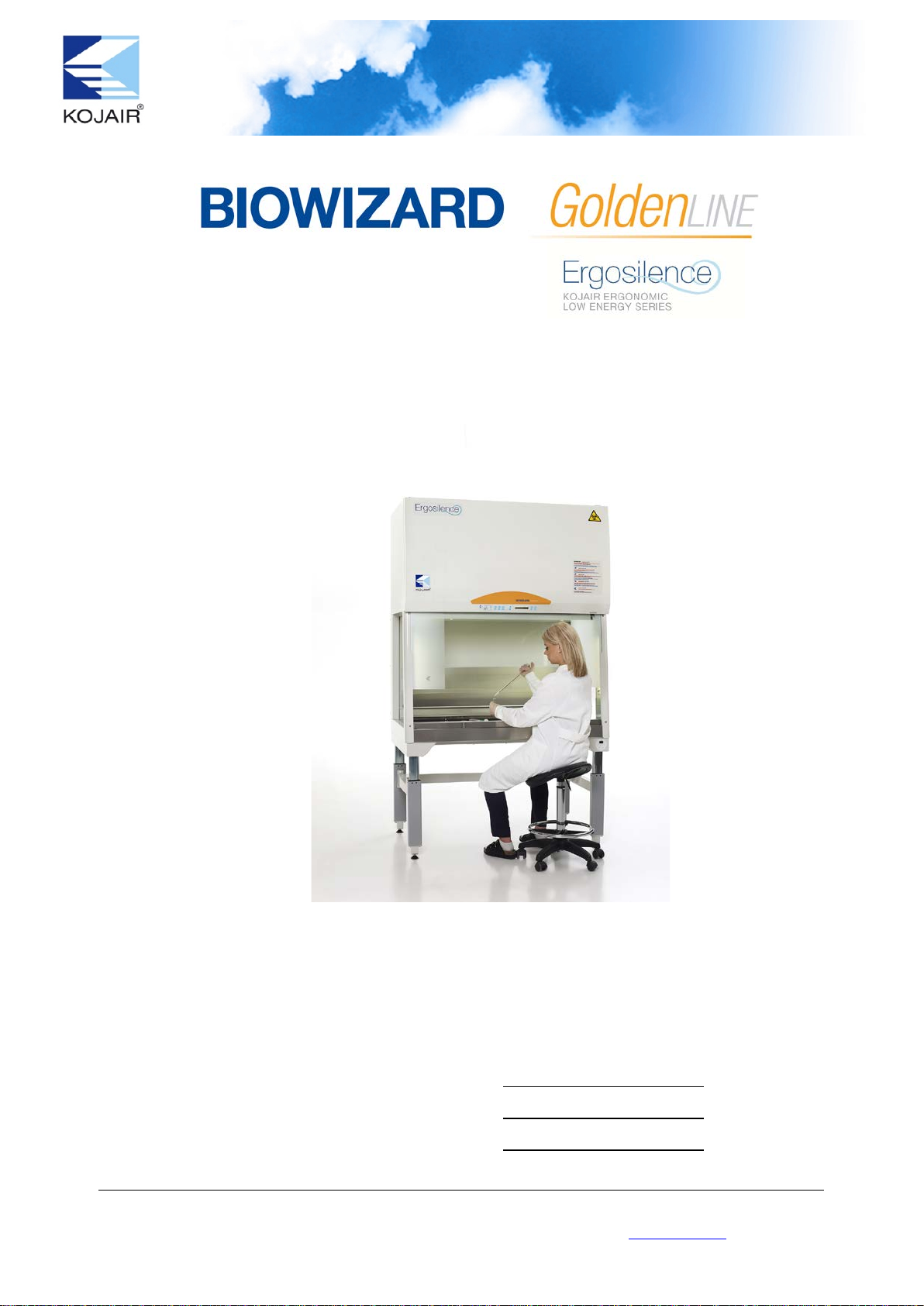

Kojair Golden Line is a Class II Microbiological Safety Cabinet operating on the recirculation principle. It

protects the products handled on the work surface from contamination and safeguards the operator

against substances hazardous to health.

Picture 1. Kojair Golden Line Class II Safety Cabinet

Examples of the uses of the cabinet are cellular culture, handling pathogenic micro-organisms, isotopes,

sterile work for operations, handling medical substances in hospitals and pharmacies as well as the

production and maintenance of electronic items in which particle-free air is a necessity.

4

with Group 4 pathogens. The Kojair BW3 is a class III safety cabinet which

protects the user and the environment from Group 4 pathogens.

Please contact your local Kojair representative for more information.

rev.3.01

NOTE! The Cabinet may crash. Use special attention when moving and

transportation equipment.

The basic principle of the cabinet is that the replacement air moves through the grid at the front edge of

the work surface to the bottom basin and then again to the recirculation system. Simultaneously it forms

an air curtain in the work opening, which prevents air from flowing outwards.

The recirculated air inside the cabinet is purified as it flows through the HEPA-filter and it flows laminarly

through the workspace. (See picture 2).

Picture 2. Principle of the airflow

1.2. CONSTRUCTION MATERIALS

The main construction material of the cabinet is painted mild steel. The work surface and the collecting

pan located below it are made of stainless steel (AISI 304).

The front and side walls are made of 6 mm thick laminated safety glass.

1.3. POSITIONING THE CABINET AND SAFETY INSTRUCTIONS

installing the cabinet. Take into account the center of gravity when placing

For more information about the cabinets safe handling and moving see the service manual part

2.2

The cabinet should be positioned so that there are no external or conflicting airflow disturbances when it

is operating such as open windows or personnel passing in front of it.

The cabinet should be switched on at least 15 minutes before starting the work so there is time to clean

the workspace. Before starting the actual work it is recommended that the work is carefully prepared so

that equipment and material are moved in and out of the cabinet as little as possible.

A continuous in-and-out movement disturbs the airflow and weakens the protection given by the cabinet.

For the cabinet to give the best possible protection, you should try to minimize rapid hand and arm

movements as much as possible.

5

rev.3.01

However, it is better if the cabinet can always be in the normal operating

NOTE! Before starting work, check that HEPA-filter on the roof of the

workspace is intact.

NOTE! Beware that you do not obstruct the airflow by obstructing the grid on

the worktable. The safe working area is between the grids (see picture 3.).

Picture 3. Safe working area.

While you are working, the front glass of the cabinet should be in the working position. If the front glass

is not in the correct position, the user will hear immediate warning from the alarm. If you intend to switch

off the cabinet when you have finished working, it is better to close the front window before shutting

down the cabinet.

mode. When you are not working in the cabinet, close the front glass and

device automatically switches to half speed mode. See chapter, 2.1 Control

panel.

It is strongly recommended that gas flames are used on the left side of the work space as short time as

possible. That is because the flame can disturb the airflow and it will warm up the recirculated air, which

can cause an alarm.

6

Loading...

Loading...