Compact Vibrometer 107В

Operating Instructions Manual

Vibrometer 107В

Vibrometer 107В

Page

INTRODUCTION................................................................................1

1. SPECIFICATION.......................................................................1

1.1. Standard Conditions for Operation

1.2. System Specication

1.3. ISO-10816

2. 107B INSTRUMENT DESCRIPTION AND FUNCTION...........4

2.1. Getting know the instrument and its Accessories

2.1.1. Operation key

3. TAKING MEASUREMENT WITH THE INSTRUMENT.............5

3.1. Instrument Display and Measurement Mode

3.1.1. Set up of accelerometer sensitivity factor

3.1.2. Setting system real time and date

3.1.3. Setting up LCD back light

3.2. Selection of Measurement Mode

3.3. Measurement Procedure

3.3.1. Accelerometer mounting

3.3.2. Taking vibration measurements

3.3.3. Make new directory / save / read / delete le

3.3.4. Vibration result and spectrum overview

4. DELIVERY SET..................................................................................10

CONTENT

Vibrometer 107В

Vibrometer 107В

Introduction

This manual is intended for the study of the Compact FFT Vibrometer -107В (hereinafter

“Instrument”). The manual contains the description of the instrument, delivery set,

operating principles and specication.

FFT Vibrometer - 107В is a compact, handheld, microprocessor based vibration-measuring

instrument designed to measure vibration parameters of the rotating machine according to

ISO 10816, as well as other international standards which have been set on the same level

- vibration acceleration, RMS vibration velocity, vibration displacement and Vibration

spectrum analysis in FFT. It allows to measure the dynamic signals followed up by the

record it into the non-volatile memory, as well overview and analyze the spectrum.

1.0 Specication

1.1 Standard Conditions for Operation:

s Ambient temperature, -10 to 55°С, (±5)°С;

s Relative humidity 80% at temperature 30°С;

s Atmospheric pressure, 84 to 106.7 KPa (630 - 800 mm Hg);

s Vibration frequency, not more than 30 Hz;

s Max acceleration, 10 m/s2;

s Pulses per minute, 10 - 50;

s Maximum acceleration in respect to shock, 50 m/s2;

s Pulse duration 10 - 12.5 msec;

s Total shock number 1000.

1.2 System Specication

1.2.1 Setting range of accelerometer conversion ratio (sensitivity), pC*s2/m - 0.1 to

1

Vibrometer 107В

500.

1.2.2 Maximum input charge value, pC - 2000.

1.2.3 Noise oor, not more than, pC, not more than - 0.03

1.2.4 The dynamic range measurement of the RMS (root-mean-square) values of

vibration acceleration, vibration velocity and vibration displacement is limited by

the maximum input charge value on the top and the level of noise floor of charge

amplifier at the bottom and depends upon conversion ratio of the accelerometer

(vibration transducer).

Table-1

Measurable Frequency Range Dynamic Range

Parameter Hz RMS

Vibration Acceleration 2 - 10000 0.01 - 200 m/s2

Vibration Velocity 2 - 16 0.8 - 1000 mm/s

10 - 1000 0.1 - 79 mm/s

Vibration Displacement 2 - 16 0.05 - 50 mm

10 - 100 0.003 - 1.2 mm

10 - 1000 0.003 - 0.02 mm

1.2.5 The limits of relative error at the charge measurement, the error of accelerometer

is not taken into account, in the frequency band, Hz:10 to 0.707 cut-off frequencies of

low-pass lter ±5 %.

1.2.6 Damping at cut-off frequencies of low-pass lter, dB, not more than -3dB at cut-off

frequency of low-pass lter, no more than -7.5%.

1.2.7 Frequency ranges of spectrum analysis: cut-off frequencies of low-pass lter, Hz

- 100, 200, 300, 400, 500, 600, 700, 800, 900, 1000, 2000, 3000, 4000, 5000, 6000,

7000, 8000, 9000, 10000: cut-off frequency of low-pass lter, Hz -10.

1.2.8 Spectrum resolution, lines - 800.

1.2.9 Weight function - Hanning function.

1.2.10 Calculating time of FFT spectrum, not more than: 20 sec.

2

Vibrometer 107В

1.2.11 Absolute error of sinusoidal signal frequency, not more than, ± 0.75•(Fв / 800),

where Fв – upper frequency of band analysis.

1.2.12 The error of magnitude wave constituent, more than -1.5dB.

1.2.13 Operating mode setting, not more than -1min.

1.2.14 When measuring the signals with amplitude factor up to 5, the limits of

complementary error of the instrument (without vibratory converter) do not exceed

0.5 of the basic error limits.

1.2.15 Display: graphical LCD, 64 х 98 points.

1.2.16 Power supply, 3.6V NiMH battery. Battery power control.

1.2.17 Continuous operation on batteries, not less than 8hours.

1.2.18 Current consumption 220V, 50 Hz AC, not more than 5VA.

1.2.19 Electric strength and insulation resistance of the instrument corrsponds to the

requirements of GOST 22261-94.

1.2.20 The limits of complementary error of the instrument at voltage changing from

3.6Volts to 2.8Volts.

1.2.21 The limits of complementary error of the instrument (without vibratory

converter), caused by the change of climate and mechanical factors, within the

range from standard values to the limit operating values, do not exceed 0.5 of

the of basic error limits.

1.2.22 The instrument operates normally when affected by acoustic noise with acoustic

pressure 100 dB in the frequency band from 125 to 8000 Hz. Acoustic noise factor is

not more than 0.03 %/dB.

1.2.23 The instrument stands the impact of external magnetic eld 80 А/m , 50 Hz,

inuence coefcient of the magnetic eld, however, is not more than 0.05 %/А•m-1.

1.2.24 Probability of no-failure operation, not less than 0.92 per 2000 hrs.

1.2.25 The average instrument life, not less than 10 years.

1.2.26 Failure time, 1000 hours. The average failure time is set for standard conditions

for operation.

1.2.27 Dimensions, not more than 55 х 118 х 28 (mm).

1.2.28 Weight, not more than 210 gram.

3

Vibrometer 107В

1.3. Reference ISO 10816-3

Measuring points for horizontal machine set

4

Guide for Vibration Severity Zone - ISO 10816-3

11 0.44

7.1 0.28

4,5 0.18

3,5 0.11

2,8 0.07

2,3 0.04

1.4 0.03

0,71 0.02

mm/s rms inch/s rms

Group 4 Group 3 Group 2 Group 1

<<< Classification

140 5.51

113 4.45

90 3.54

71 2.80

56 2.20

45 1.77

36 1.42

28 1.10

22 0.87

18 0.71

11 0.43

µm rms mil rms

rigid flexible rigid flexible rigid flexible rigid flexible

<<< Foundation

Pumps > 15 kW Medium sized machines Large machines

radial, axial, mixed flow

15 kW < P ≤ 300 kW

300 kW < P < 50 MW

<<< Machine Type

integrated driver external driver motors motors

160 mm ≤ H < 315 mm 315 mm ≤ H

Group 4 Group 3 Group 2 Group 1

<<< Classification

A

Newly commissioned

C

Restricted for long-term operation

B No restriction for long-term operation

D

Vibration and others causes damage

Vibrometer 107В

2.0 107B Instrument Description and Function

General view of the instrument and piezoelectric accelerometer with cable is shows in Fig-1.

4

1. 107B Vibrometer

2. Accelerometer, 1.5m

2 3. Detachable measuring tip

Fig-1a: Sensor w/cable 4. Socket for measuring probe

5. USB socket for PC com

3 6. Socket for AC charger

Fig-1b: Measuring tip 7. LED, AC charge indicator

Fig-1c: 107B Vibrometer

2.1 Getting to know the Instrument and its Accessories

The instrument is built from a light and strong alloy casing protected by silicon sleeve

with the rechargeable internal battery power supply, socket for the measuring probe

and USB port for le upload to PC for data management, see Fig-2a. The socket to

connect the instrument to the accelerometer, external power source and USB port are

located in the upper side panel of the instrument. The only six push button keypad and

LCD are located on the front panel. One LED indicators placed in standing end indicate

device connected to the external AC power source, Fig-2b.

Fig-2a. Top view of 107B Fig-2b: LED at standing side

Processor unit is the main component of the instrument; it provides control over the

measurement circuit, data measurement, signal analysis and data display. Using the

5

1

6 5 4

7

Vibrometer 107В

keypad, the user can operate the instrument.

The initial state of the instrument displayed on the screen shows the last measurement

mode with setting, see Fig-2.1a, Fig-2.1b or Fig-2.1c depend last end mode.

Fig-2.1a Fig-2.1b Fig-2.1c

2.1.1 Operation key

Six buttons of the keypad perform several functions.

Turn ON key Setup menu / Hold down + forward /back key

OK / Start Return / back to earlier step key / OFF (press and hold)

Adjust up Adjust down

3.0 Taking Measurement with the Instrument

Before using the instrument, it is a good practices to check proper mechanical

functioning of the controls, connectors and power state when switch on.

Note the device automatically switches off after 150 seconds when no further operation.

3.1 Instrument Display and Measurement Mode

Press button to turn on your instrument.

The instrument will display prompt self-test prompt as Fig-3a, when completed screen

display to last measurement mode, Fig-3a, 3b, 3c or 3d.

6

V e l o c i t y MM / S

1 0 - 1 0 0 0

H z

*

6 .6 2 pc 3. 2 7 v

2 5m a r 0 7 1 5 :5 0 : 21

A c c e l er . M / S

2

1 0 - 8 0 0

H z

*

6 . 6 2 pc 3 . 2 7 v

2 5 m a r 0 7 1 5 : 5 0 : 3 8

D is p l ac e m e n t u M

1 0 - 1 0 0 0 H z

*

6 .6 2 pc 3. 2 7 v

2 5m a r 0 7 1 5 :5 1 : 15

Vibrometer 107В

Fig-3a Fig-3b Fig-3c Fig-3d

The upper screen line shows the measurement modes. The next line displays the

frequency band in which the RMS value is measured. The other two lines indicate

respectively the conversion ratio value of piezoelectric accelerometer with respect to

charge pC X S2/m and battery voltage, date and real time information.

3.1.1 Initial setup of accelerometer sensitivity factor and frequency band

To start measuring, set the conversion ratio of piezoelectric accelerometer with respect

to charge by pressing follow by key to display Fig-3.1, the using as either

or key to input accelerometer sensitivity value provide by the OEM and

follow by key.

Fig-3.1

To set the value of upper limit of frequency band in which the measurement will be

conducted. Press and using or key to change the cut-off frequency

of LF (low lters) follow press again for change of cut-off of HPF (high pass

lter) and same using or key to change the new input value.

To conrm the input values, press to accept. The device will automatically switch

display to last mode selected to ready for taking new vibration measurement.

7

A c c e l e r o m e t e r :

S =

6 . 6 2

•

•

•

Vi brome te r

Ko HTe c t 7 9 5 m 1 0 7

(c ) 0 7 0108v3.01c

No .0 7 0 1081059

ww w.k ohtect. co m

V e l o c i t y MM / S

1 0 - 1 0 0 0

H z

*

6 .6 2 pc 3. 2 7 v

2 5m a r 0 7 1 5 :5 0 : 21

A cc e l er . M / S

2

1 0 - 8 0 0

H z

*

6 .6 2 pc 3. 2 7 v

2 5m a r 0 7 1 5 :5 0 : 38

D is p l ac e m e n t u M

1 0 - 1 0 0 0

H z

*

6 .6 2 pc 3. 2 7 v

2 5m a r 0 7 1 5 :5 1 : 15

Vibrometer 107В

Note: The instrument memorizes the cut-off frequency of low-pass lter per each

measurement mode A, V and S even after auto-off.

3.1.2 Setting the system real time and date

At any operation mode display, press three times to enter date / time menu

follow by to see set items.

Press and to set desire date and time and follow to conrm correct

input setting.

When all date and time settings are correctly input, press twice to return

operation mode display to begin new task.

3.1.3 Setting up LCD back light

At any operation mode display, press four times to turn back light ON/OFF.

To exit, press .

3.2 Selection of Measurement Mode

After turn on the device and input all initial setting, 107B display the default velocity

measurement mode shows in Fig-3b. To select other mode, just press or

button to get to desire display measurement mode or other operation.

3.3 Measurement Procedure

3.3.1 Accelerometer mounting

The following mounting methods are recommended for the accelerometer: stud bolt

М5, magnetic base (magnet retention force: pulling 50…70 Н; shift 15…20 Н) and

handheld probe. Mounting method defines the upper limit of operating frequency

performance: stud bolt with metallic silicone adhesive – up to 20 kHz, magnet – up

to 3 kHz, handheld probe up to 900 Hz.

8

•

•

•

•

Vibrometer 107В

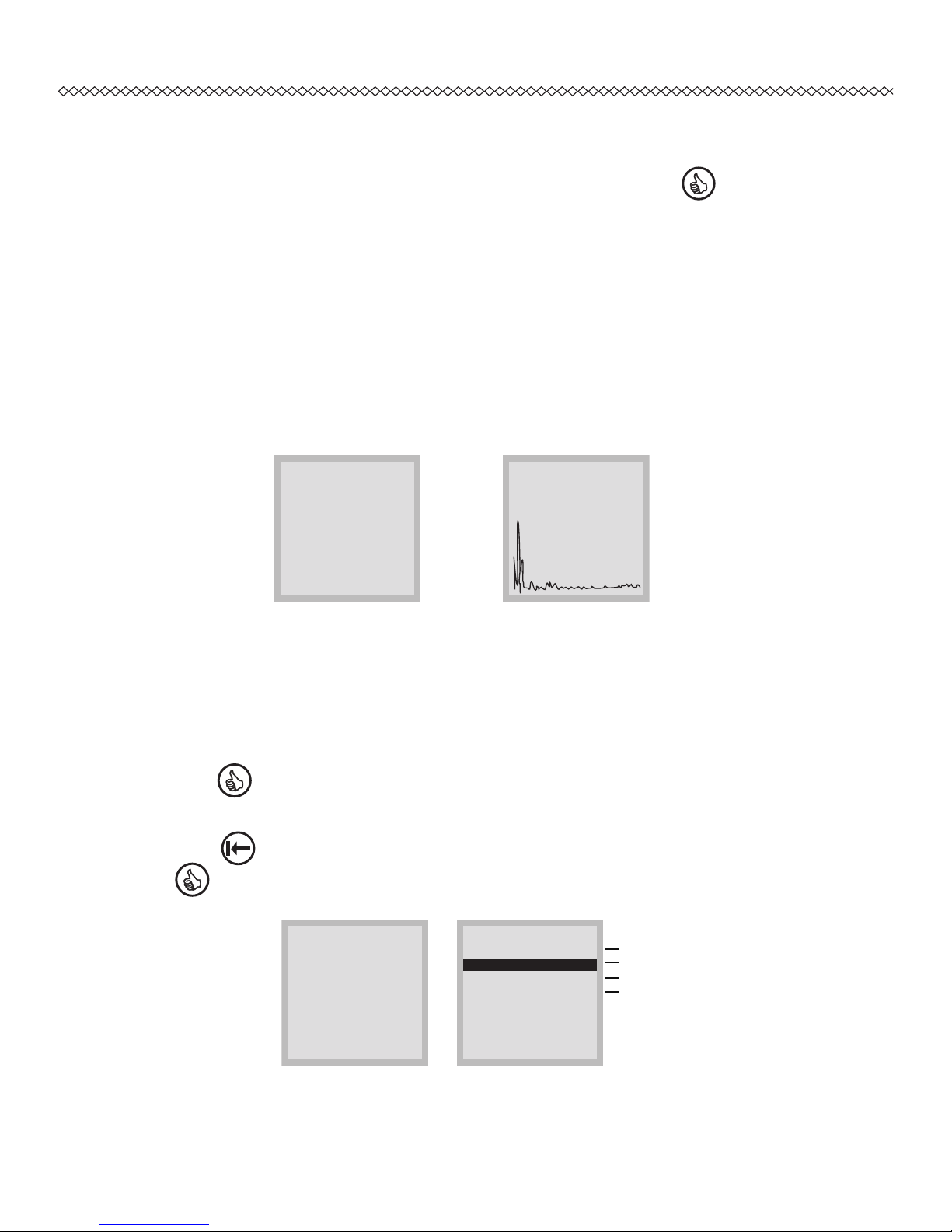

3.3.2 Taking vibration measurements

After selected the desire measurement display, (e.g. Fig 3.2, press to start

vibration measurement (107B automatic adjustment of the internal amplier and

measuring - the number of averaging is set automatically depending upon the upper

frequency).

Measurement process terminates automatically after measurement and result

calculation to display the measured overall vibration reading and waveform, see

Fig-3.3.

Measurement process can be interrupted by pressing the turn “ON” key.

Fig-3.2 Fig-3.3

Velocity measuring mode Result is RMS value & waveform

3.3.3 Make new directory / save / read / delete les

To save vibration reading with spectrum in the instrument as Fig-3.3:

Press key follow by choosing the desired directory to save

OR.

Press to return main display to go to “My documents” mode, Fig-3.4 and press

to enter main directory as Fig-3.5 to save.

Fig-3.4 Fig-3.5

9

V e r o c i t y MM / S

1 0 - 1 0 0 0

H z

*

6 .6 2 pc 3. 2 7 v

2 5m a r 0 7 1 5 :5 0 : 21

V

0 . 0 9 6 0 2

M y d o cu m e n t s

*

6 .6 2 pc 3. 2 7 v

2 5m a r 0 7 1 5 :5 0 : 52

/ 0 3 2 5 _ 0 1 0 7 0 2

. .

0 3 2 5 _ 1 5 3 7 1 7

S y s t e m _ 1 0 5 9

1 0 7 B _ 0 7 0 2 2 7 . b i n

0 3 2 5 _ 0 1 3 4 1 5 . f f t

< d i r >

2 5 . 0 3 . 0 7 1 5 : 3 7

Current sub-directory

Back to earlier directory

Directory name

System directory folder

System update file “xxx.bin”

Vibration data date file “xx..x.fft”

•

•

•

•

•

Vibrometer 107В

Note: 107B will self generated directory or le names in term of date and time (“0325”

mean 25 March and “103415” mean 10hrs, 34 mins, 15 sec). File name that follow by

“fft” extension format representing data le, see Fig-3.5

By pressing each time, the display right lower section will change from

selection to make new directory, save, read or delete folder/le.

Press or to move to desired directory (directory line are shows with

series of numeric without “xxx.fft” extension) to be saved.

Press to conrm data saved.

Note: sub-directory created are only allow max. 10 data les to be saved.

3.3.4 Vibration result and spectrum overview

When the FFT spectrum measurements has recorded and displayed the result, you

may view the spectrum of the waveform, using the following keys obtain required

information:

To view desired spectrum detail info, go to “Documents” display mode and press

then using or key to look for deired data le and press to

read measurement data.

Press and hold to display, Fig- 3.6a. The display will show the peak value for

specic frequency in the velocity measured mode, while peak - to - peak value in

the displacement mode.

To switch horizontal compression scale, press while still hold down on

key.

Note: (Horizontal compression scale: х8 - all 800 lines at the display (98 points across),

х1 – spectrum fragment out of 98 lines at the display).

10

•

•

•

•

•

Vibrometer 107В

11

Fig-3.6a Fig-3.6b Fig-3.6c

To switch spectrum between “LIN”/ “LOG” reading or view the vibration shock

energy in dB, press to toggle while still holding down on key, see Fig-3.6c.

To exit and review last spectrum measured, press to toggle.

To move the cursor (over the frequency peaks), press key and review the

spectrum by press again. Fig-3.7a (10.02Hz) Fig-3.7b (57.59Hz)

Fig-3.7a Fig-3.7b

4.0 Delivery Set

S/No: Description Qty Note

1 107B, Vibrometer w/chargeable battery builtin 1

2 Vibration accelerometer w/1.5m cable attached 1

3 Magnetic adaptor for accelerometer 1

4 External measuring tip for accelerometer 1

5 AC batter charger,220-230 Volts 1

6 Carrying case with form-inserted 1

7 Operating instruction manual in CD-ROM 1

8 CD-ROM PC software 1

9 USB PC Communication cable 1

10 Maker Calibration Certicate 1

Table-4.0

•

•

•

V

0 . 0 6 8 0 2

1 0. 0 2 Hz x 8 L’ I N

L =0 . 0 16 7 5

V

0 . 0 6 8 0 2

5 7. 9 7 2H z x8 L’ I N

L =0 . 0 19 0 4

V

0 . 0 6 8 0 2

3 2. 5 5 Hz x 8 L’ I N

L =0 . 0 18 5 5

S

2 . 0 3 9

4 6 . 3 4

2 66 . 7 Hz X8 L IN

L =0 . 6 65 7

1 . 88 3

S

8 6 . 5 3

d B

4 0. 0 6 Hz x 1 L OG

L =8 6 d B

Loading...

Loading...