Page 1

35 590 01 Rev. C

KohlerPower.com

TP 3.0, WP 2.0, WP 3.0

Trash Pump & Water Pump Owner's Manual

IMPORTANT: Read all safety precautions and instructions carefully before

operating equipment.

Ensure unit is stopped and level before performing any

maintenance or service.

Record product information to reference when ordering parts or obtaining warranty coverage.

Specifi cation

Serial Number

Purchase Date

EN

ESS

FRC

Page 2

2 35 590 01 Rev. CKohlerPower.com

California Proposition 65 Warning

Engine exhaust from this product contains chemicals known

to State of California to cause cancer, birth defects, or other

reproductive harm.

California Proposition 65 Warning

This product contains chemicals known to State of California

to cause cancer, birth defects, or other reproductive harm.

WARNING

Explosive Fuel

can cause fi res

and severe

burns.

Do not fi ll fuel

tank while

engine is hot or

running.

Gasoline is extremely

fl ammable and its vapors

can explode if ignited.

Never refuel while smoking

or in vicinity of an open

fl ame. Store gasoline only

in approved containers, in

well ventilated, unoccupied

buildings, away from sparks

or fl ames. Spilled fuel

could ignite if it comes in

contact with hot parts or

sparks from ignition. Never

use gasoline as a cleaning

agent.

WARNING

Hot Parts can

cause severe

burns.

Do not touch

engine while

operating or just

after stopping.

Never operate pump with

heat shields or guards

removed. Do not modify

pump.

Place pump in a place

where pedestrians or

children are not likely to

touch pump.

Be sure to carry pump only

by its carrying handles.

WARNING

Rotating Parts

can cause

severe injury.

Stay away

while pump is in

operation.

Keep hands, feet, hair,

and clothing away from all

moving parts to prevent

injury. Never operate pump

with covers, shrouds, or

guards removed.

CAUTION

Electrical Shock

can cause injury.

Do not touch

wires while

engine is

running.

Never operate pump in rain

or snow.

Never touch pump with wet

hands or electrical shock

will occur.

Safety Precautions

WARNING: A hazard that could result in death, serious injury, or substantial property damage.

CAUTION: A hazard that could result in minor personal injury or property damage.

NOTE: is used to notify people of important installation, operation, or maintenance information.

Read this manual carefully before operating this machine. This manual should stay with this

machine if it is sold.

Important Label on Pump

WARNING

Carbon Monoxide. Can cause

severe nausea, fainting or death.

Avoid inhaling exhaust fumes.

Only use product outdoors.

Engine exhaust gases contain poisonous carbon

monoxide.

Carbon monoxide is odorless, colorless, and can

cause death if inhaled.

Page 3

3

35 590 01 Rev. C

KohlerPower.com

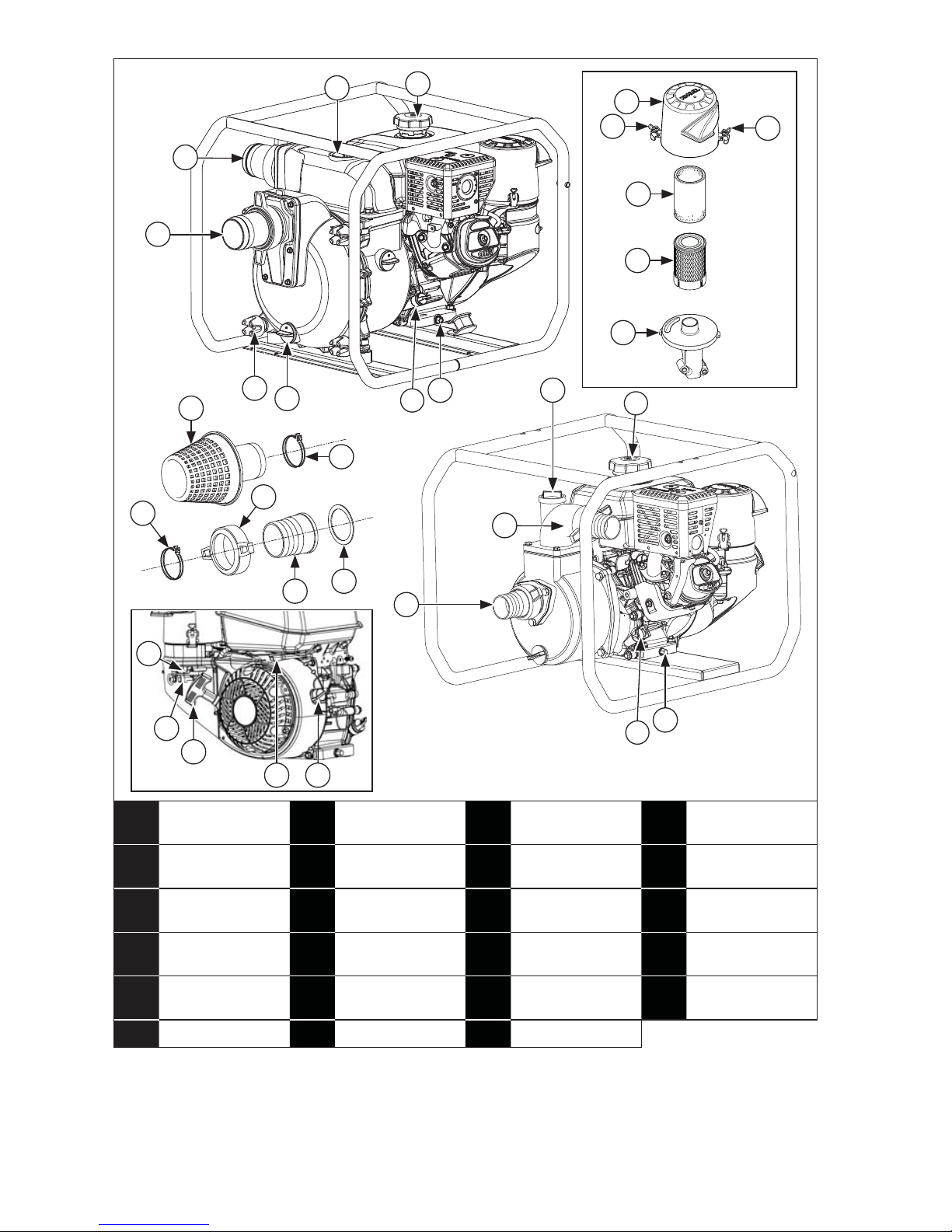

EN

S

V

W

T

T

U

O

N

O

P

Q

R

H

B

D

E

C

A

H

B

A

E

D

G

F

C

J

K L

I

M

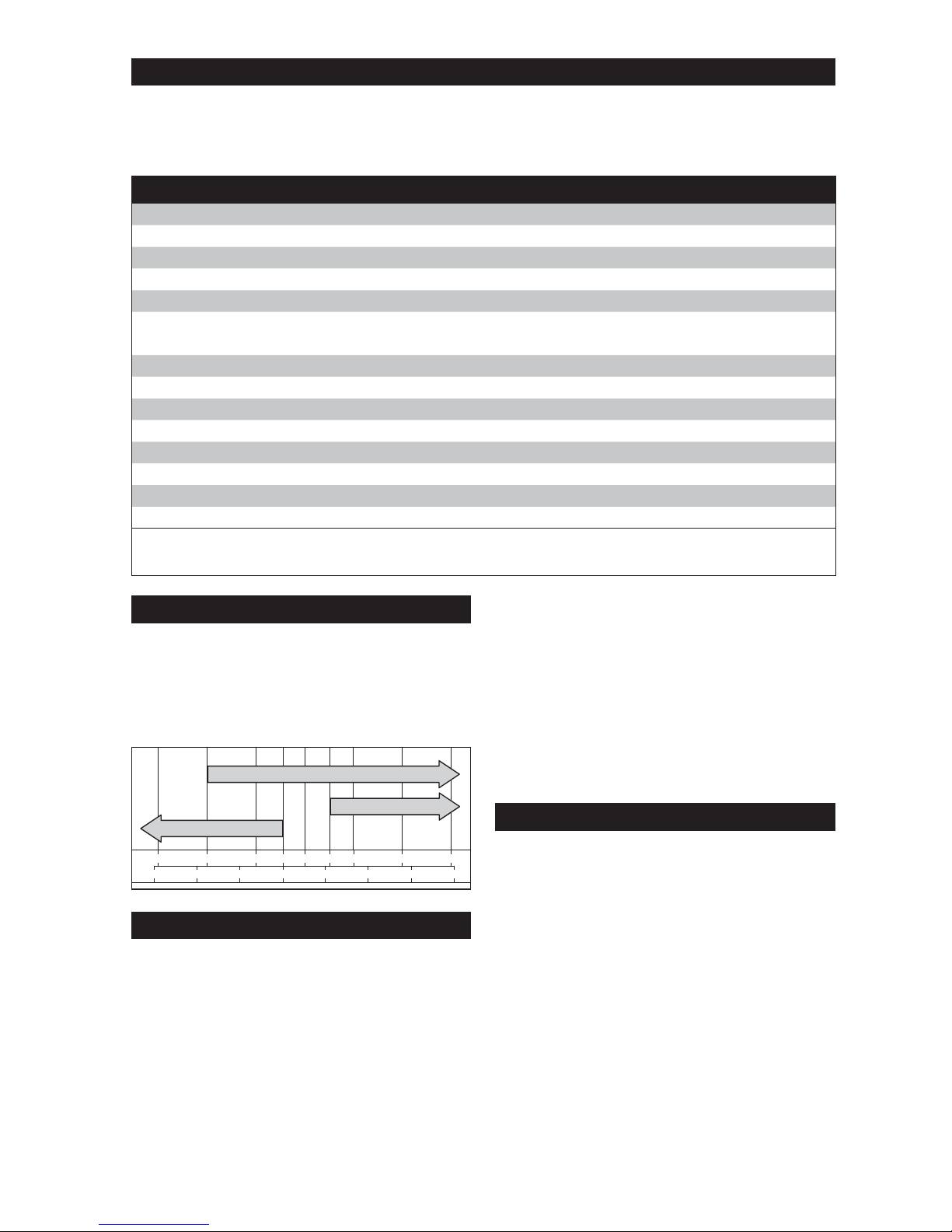

A

Pump Suction

Port

B

Pump

Discharge Port

C

Oil Fill Plug/

Dipstick

D Fuel Cap

E Pump Filler Cap F Knob Nut G

Pump Drain

Plug

H Oil Drain Plug

I Fuel Shut-Off J Choke Lever K Throttle Lever L

On/Off Switch

(if equipped)

M

Recoil Starter

Handle

N

Air Cleaner

Cover

O Bail P Precleaner

Q Paper Element R

Air Cleaner

Base

S Suction Strainer T Clamp

U Coupling V Rubber Seal W Hose Joint

Page 4

4 35 590 01 Rev. CKohlerPower.com

Pre-Start Checklist

1. Ensure pump is at least 3.3 ft. (1 m) from

building or other equipment.

2. Place pump on a fl at sturdy surface. Select a

clean location, ventilated and protected from

inclement weather. Select a location which

will not impede movement of people or

vehicles.

3. Make sure pump remains stable and

immobile while in operation. Do not forget

that suction hose tends to pull pump towards

water source during pumping.

4. Place pump as close as possible to liquid

being drawn in. A shorter vertical distance

between pump and liquid surface will yield

more rapid priming and greater volume of

liquid pumped. If pump is operated beside a

pit or body of water, be sure it is well

anchored so it does not fall in.

5. Submerge suction strainer (S) completely

within liquid, taking care that it is not blocked.

6. Refer to all warning labels prior to starting.

7. Check oil level. Add oil if low. Do not overfi ll.

8. Check fuel level. Add fuel if low. Check fuel

system components and lines for leaks.

Never refuel while unit is running.

9. Check that air cleaner components and all air

inlets are unobstructed, equipment covers,

and guards are in place and securely

fastened.

Starting

WARNING

Carbon Monoxide. Can cause

severe nausea, fainting or

death.

Avoid inhaling exhaust fumes.

Only use product outdoors.

Engine exhaust gases contain poisonous

carbon monoxide.

Carbon monoxide is odorless, colorless, and

can cause death if inhaled.

WARNING

Rotating Parts can cause severe

injury.

Stay away while pump is in

operation.

Keep hands, feet, hair, and clothing away

from all moving parts to prevent injury. Never

operate pump with covers, shrouds, or

guards removed.

NOTE: Never attempt to operate pump without

priming water or pump will overheat.

Extended dry operation will destroy

mechanical seal.

If unit has been operated dry, stop

engine immediately and allow pump to

cool before adding priming water.

NOTE: Always use a suction strainer (S) with

suction hose. Gravel or debris sucked

into pump will cause serious damage

to impeller and pump casting.

NOTE: Pump is not designed for on-board

use. Do not use it while installed on a

vehicle.

Do not leave pump inside vehicle or in

trunk.

When operating or transporting pump,

be sure it is kept upright. If it tilts, fuel

may leak from fuel tank.

1. Immerse suction strainer (S) completely in

liquid that is to be sucked up. If there is a risk

that it could become blocked up, then place

suction strainer (S) on a stone base.

2. Fill body of pump with water via pump

discharge port (B) or through pump fi ller cap

(E).

3. Connect two discharge and suction couplings

(U).

4. Turn fuel shut-off (I) valve to ON position (if

equipped).

5. Turn engine on/off switch (L) to ON position

(if equipped).

6. Start engine as follows:

Cold engine: Place throttle lever (K) midway

between SLOW and FAST positions. Place

choke lever (J) into ON position.

Warm engine: Place throttle lever (K) midway

between SLOW and FAST positions. Return

choke lever (J) to OFF position as soon as

engine starts. A warm engine usually does

not require choke on.

7. Slowly pull recoil starter handle (M) until just

past compression-STOP! Return recoil

starter handle (M); fi rmly pull straight out to

avoid excessive rope wear from starter rope

guide.

8. Gradually return choke lever (J) to OFF

position after engine starts and warms up.

Engine/equipment may be operated during

warm up period, but it may be necessary to

leave choke lever (J) partially on until engine

warms up.

Page 5

5

35 590 01 Rev. C

KohlerPower.com

EN

Cold Weather Starting

NOTE: Ensure water in pump body is not

frozen before starting.

When starting pump in low ambient

temperatures, allow engine to idle before

increasing fl ow of liquid. Follow chart for

temperature and time.

< -4° F (< -20° C) 5 minutes

-4° to 14° F (-20° to -10° C) 2 minutes

14° to 23° F (-10° to -5° C) 1 minutes

> 41° F (> 5° C) 20 seconds

1. Use proper oil for temperature expected.

2. Use fresh winter grade fuel. Winter grade

fuel has higher volatility to improve starting.

Operation

WARNING

Rotating Parts can cause severe

injury.

Stay away while pump is in

operation.

Keep hands, feet, hair, and clothing away

from all moving parts to prevent injury. Never

operate pump with covers, shrouds, or

guards removed.

NOTE: If there is no fl ow of liquid through

pump, stop it and check suction circuit

(suction strainer (S) and pipes).

NOTE: Avoid placing any fl ammable materials

near exhaust outlet during operation.

Do not place any material on pump

during operation.

Pump controls fl ow of liquid in accordance with

its running speed. Pump engine is equipped

with a speed control lever that enables fl ow

from pump to be controlled.

Flow from pump also depends on suction and

discharge elevation heads and on quality of

liquid that is being pumped (clean / muddy

water).

1. Move position of speed control lever (MAX to

increase fl ow, MIN to reduce it).

Angle of Operation

Do not operate this engine exceeding maximum

angle of operation; see specifi cation table.

Engine damage could result from insuffi cient

lubrication.

Stopping

1. If equipped, move throttle lever (K) to slow or

idle position; stop engine.

2. Pump stops.

3. If equipped, close fuel shut-off (I) valve.

4. Disconnect suction and discharge pipes and

allow liquid to fl ow out.

5. If pump is not used again on same day, rinse

it out.

Rinsing

After pump has stopped and cooled down.

1. Fill pump body with clean water via pump

discharge port (B) or through pump fi ller cap

(E).

2. Slowly pull on recoil starter handle (M)

several times until resistance is encountered

and then allow it to return gently.

3. Unscrew and remove pump drain plug (G)

from pump and allow water to fl ow out.

4. Screw pump drain plug (G) back into

position.

5. Repeat operation if necessary.

6. Clean suction strainer (S), remove any dirt if

necessary and rinse with clean water.

Engine Speed

NOTE: Do not tamper with governor setting to

increase maximum engine speed.

Overspeed is hazardous and will void

warranty.

High Altitude Operation

This engine may require a high altitude

carburetor kit to ensure correct engine

operation at altitudes above 4000 ft. (1219

meters). To obtain high altitude kit information

or to fi nd a Kohler authorized dealer

KohlerPower.com or call 1-800-544-2444 (U.S.

and Canada).

This engine should be operated in its original

confi guration below 4000 ft. (1219 meters) as

damage may occur if high altitude carburetor kit

is installed and operated below 4000 ft. (1219

meters).

Carburetor Icing

NOTE: Running engine with cover (N)

positioned for cold weather operation

in normal conditions can damage

engine.

Carburetor icing can take place when certain

combinations of temperature and humidity

exist. Result of carburetor icing is rough running

at idle or low speed as well as black or white

smoke.

To reduce likelihood of carburetor icing, air

cleaner cover (N) can be rotated to draw

warmer air from muffl er side. For cold weather

operation, position air cleaner cover (N) with

snowfl ake decal out.

For normal operation, position air cleaner cover

(N) with sun decal out.

Page 6

6 35 590 01 Rev. CKohlerPower.com

Oil Recommendations

We recommend use of Kohler oils for best

performance. Other high-quality detergent

oils (including synthetic) of API (American

Petroleum Institute) service class SJ or higher

are acceptable. Select viscosity based on air

temperature at time of operation as shown in

table below.

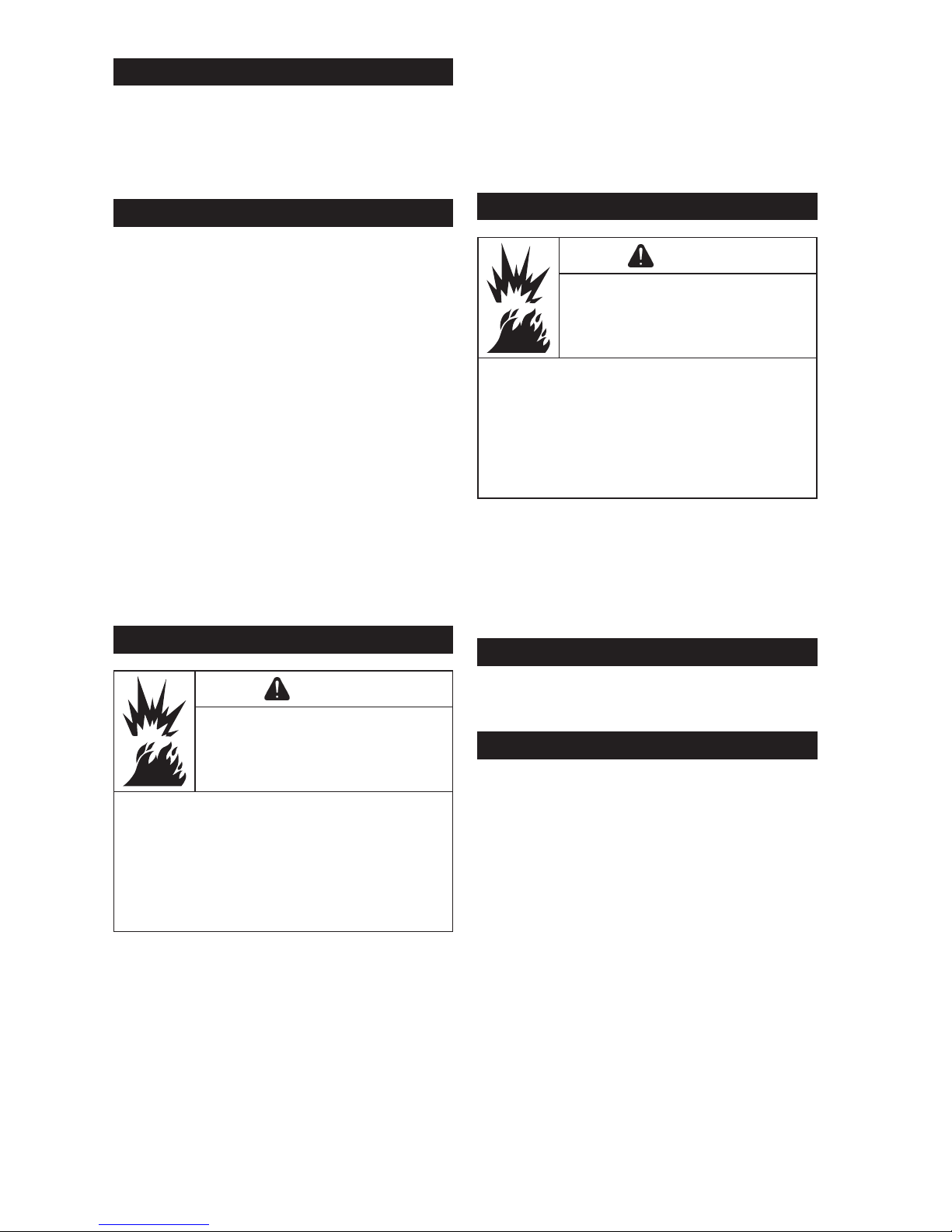

°F

-20

020324060

50 80 100

°C

-30 -20

-10 0

10 20 30

40

5W-30

10W-30

SAE 30

Check Oil Level

NOTE: To prevent extensive engine wear or

damage, never run engine with oil level

below or above operating range

indicator on dipstick (C).

Ensure engine is cool. Clean oil fi ll plug/dipstick

(C) areas of any debris.

1. Remove dipstick (C); wipe oil off.

2. Reinsert dipstick (C) into tube; rest on oil fi ll

neck; turn counterclockwise until cap drops

down to lowest point of thread leads; do not

thread cap onto tube.

a. Remove dipstick (C); check oil level.

Level should be at top of indicator on

dipstick (C).

or

b. Remove oil fi ll plug (C). Level should be

up to point of overfl owing fi ller neck.

3. If oil is low, add oil up to point of overfl owing

fi ller neck.

4. Reinstall dipstick (C) or oil fi ll plug (C) and

tighten securely.

Change Oil

Change oil while engine is warm.

1. Clean area around oil fi ll cap/dipstick (C) and

oil drain plug (H).

2. Remove oil drain plug (H) and oil fi ll cap/

dipstick (C). Drain oil completely.

3. Reinstall oil drain plug (H). Torque to 13 ft. lb.

(17.6 N·m).

4. Fill crankcase with new oil, up to point of

overfl owing fi ller neck.

5. Reinstall oil fi ll cap/dipstick (C) and tighten

securely.

6. Dispose of used oil in accordance with local

ordinances.

Maintenance Instructions

All maintenance operations are to be carried out as described in maintenance table. Their

frequency is given for your information, for pumps operating with fuel or oil in accordance with

specifi cations given in this manual.

If pump is used under extreme conditions, reduce interval between maintenance operations.

Maintenance Schedule

After fi rst 5 Hours

● Change oil.

Every 50 Hours or Annually

● Service/replace precleaner (P).

Every 100 Hours or Annually

1

● Change oil.

● Clean cooling areas.

Every 200 Hours

2

● Check and adjust valve clearance when engine is cold.

Every 200 Hours

● Replace air cleaner element (Q).

Every 300 Hours

● Check fuel fi lters (tank outlet fi lter and in-line fi lter) and clean or replace if needed (if equipped).

Every 500 Hours or Annually

1

● Replace spark plug and set gap.

1

Perform these procedures more frequently under severe, dusty, dirty conditions.

2

Have a Kohler portable dealer perform this service.

Page 7

7

35 590 01 Rev. C

KohlerPower.com

EN

● Methyl Tertiary Butyl Ether (MTBE) and

unleaded gasoline blend (max 15% MTBE by

volume) are approved.

● Do not add oil to gasoline.

● Do not overfi ll fuel tank.

● Do not use gasoline older than 30 days.

Add Fuel

WARNING

Explosive Fuel can cause fi res

and severe burns.

Do not fi ll fuel tank while engine is

hot or running.

Gasoline is extremely fl ammable and

its vapors can explode if ignited. Store

gasoline only in approved containers, in

well ventilated, unoccupied buildings, away

from sparks or fl ames. Spilled fuel could

ignite if it comes in contact with hot parts or

sparks from ignition. Never use gasoline as a

cleaning agent.

Ensure engine is cool.

1. Clean area around fuel cap (D).

2. Remove fuel cap (D). Fill to base of fi ller

neck. Do not overfi ll fuel tank. Leave room

for fuel to expand.

3. Reinstall fuel cap (D) and tighten securely.

Fuel Line

Low permeation fuel line must be installed on

carbureted Kohler Co. engines to maintain EPA

and CARB regulatory compliance.

Fuel Valve

Engines are equipped with a fuel valve

and integral screen fi lter located at inlet of

carburetor. It controls and fi lters fuel fl ow from

tank to carburetor. Clean fuel valve cup of

debris.

1. Remove two nuts, two screws, and

carburetor cover panel.

2. Turn fuel valve lever to OFF position.

3. Remove fuel valve cup. Remove O-ring and

fi lter screen.

4. Clean screen and fuel valve cup with solvent

and wipe it off.

5. Check screen and O-ring, replace if

damaged.

6. Reinstall O-ring followed by fuel valve cup.

Rotate fuel valve cup until it is fi nger tight.

Turn with a wrench 1/2 to 3/4 full turn.

7. Turn fuel valve to ON position and check for

leaks. If fuel valve leaks repeat steps 5 & 6.

8. Tighten fuel cap (D) securely.

Oil Sentry™ (if equipped)

This switch is designed to prevent engine

from starting in a low oil or no oil condition. Oil

Sentry™ may not shut down a running engine

before damage occurs. In some applications

this switch may activate a warning signal. Read

your equipment manuals for more information.

Assembly of Hoses

Suction:

1. Connect suction strainer (S) to 1 end of

reinforced hose and secure with clamp (T).

2. Insert smaller end of hose joint (W) through

larger end of coupling (U). Connect other end

of hose to hose joint (W) and coupling (U)

and secure with clamp (T).

3. Place rubber seal (V) at end of hose joint

(W), and attach hose joint (W) to pump

suction port (A). Tighten coupling (U).

Discharge:

1. Connect suction strainer (S) to 1 end of hose

and secure with clamp (T).

2. Insert smaller end of hose joint (W) through

larger end of coupling (U). Connect other end

of hose to hose joint (W) and coupling (U)

and secure with clamp (T).

3. Place rubber seal (V) at end of hose joint

(W), and attach hose joint (W) to pump

discharge port (B). Tighten coupling (U).

Fuel Recommendations

WARNING

Explosive Fuel can cause fi res

and severe burns.

Do not fi ll fuel tank while engine is

hot or running.

Gasoline is extremely fl ammable and

its vapors can explode if ignited. Store

gasoline only in approved containers, in

well ventilated, unoccupied buildings, away

from sparks or fl ames. Spilled fuel could

ignite if it comes in contact with hot parts or

sparks from ignition. Never use gasoline as a

cleaning agent.

NOTE: E15, E20 and E85 are NOT approved

and should NOT be used; effects of

old, stale or contaminated fuel are not

warrantable.

Fuel must meet these requirements:

● Clean, fresh, unleaded gasoline.

● Octane rating of 87 (R+M)/2 or higher.

● Research Octane Number (RON) 90 octane

minimum.

● Gasoline up to 10% ethyl alcohol, 90%

unleaded is acceptable.

Page 8

8 35 590 01 Rev. CKohlerPower.com

9. Reinstall carburetor cover panel securing

with hardware removed in step 1.

Spark Plugs

CAUTION

Electrical Shock can cause injury.

Do not touch wires while engine

is running.

Never operate pump in rain or snow.

Never touch pump with wet hands or

electrical shock will occur.

Clean out spark plug recess. Remove plug and

replace.

1. Check gap using wire feeler gauge. Adjust

gap, see specifi cation table for adjustment.

2. Install plug into cylinder head.

3. Torque plug to 20 ft. lb. (27 N·m).

Cleaning Pump

1. Clean pump, especially air inlets and outlets

of engine with a cloth and a brush.

2. Check general condition of pump and

replace defective parts.

Air Cleaner

NOTE: Running engine with cover (N)

positioned for cold weather operation

in normal conditions can damage

engine.

NOTE: Operating engine with loose or

damaged air cleaner components

could cause premature wear and

failure. Replace all bent or damaged

components.

NOTE: Paper element (Q) cannot be blown

out with compressed air.

Move bails (O) on air cleaner cover (N) down;

remove latches from under tabs on base (R);

remove cover (N).

Precleaner:

1. Remove precleaner (P) from paper element

(Q).

2. Replace or wash precleaner (P) in warm

water with detergent. Rinse and allow to air

dry.

3. Lightly oil precleaner (P) with new engine oil;

squeeze out excess oil.

4. Reinstall precleaner (P) over paper element

(Q).

Paper Element:

1. Separate precleaner (P) from element (Q);

service precleaner (P) and replace paper

element (Q).

2. Install new paper element (Q) on base (R);

install precleaner (P) over paper element (Q).

Position air cleaner cover (N) for normal

operation (sun decal out) or cold weather

operation (snowfl ake decal out); place latches

under tabs on base (R); lift up bails (O) to

secure cover (N).

Breather Tube

Ensure both ends of breather tube are properly

connected.

Air Cooling

WARNING

Hot Parts can cause severe

burns.

Do not touch engine while

operating or just after stopping.

Never operate pump with heat shields or

guards removed. Do not modify pump.

Place pump in a place where pedestrians or

children are not likely to touch pump.

Be sure to carry pump only by its carrying

handles.

Proper cooling is essential. To prevent over

heating, clean screens, cooling fi ns, and other

external surfaces of engine. Avoid spraying

water at wiring harness or any electrical

components. See Maintenance Schedule.

Repairs/Service Parts

We recommend that you use a Kohler portable

dealer for all maintenance, service, and

replacement parts for engine. To fi nd a Kohler

portable dealer visit KohlerPower.com or call

1-800-544-2444 (U.S. and Canada).

Transporting Pump

Before transporting pump, check that bolts

are correctly tightened, close fuel valve. Pump

should be transported in its normal operating

position; never lay it on its side. Ensure where

pump is to be stored or used is carefully

prepared beforehand.

Storage

If pump is not used for a long period of time,

storage operations should be carried out as per

instructions below.

NOTE: Never operate pump without fi lling

pump body with water and immersing

suction strainer (S) in water

beforehand.

1. Add Kohler PRO Series fuel treatment or

equivalent to fuel tank. Run engine 2-3

minutes to get stabilized fuel into fuel system

(failures due to untreated fuel are not

warrantable).

Page 9

9

35 590 01 Rev. C

KohlerPower.com

EN

2. Change oil while engine is still warm from

operation. Remove spark plug and pour

about 1 oz. of engine oil into cylinder.

Replace spark plug and crank engine slowly

to distribute oil.

3. Using clean water rinse pump and pipes

thoroughly.

4. Clean outside of pump and apply a rustprevention product to any worn or damaged

areas.

5. Cover pump with a protective cover to

protect it against dust and store it in a clean

and dry place.

Troubleshooting

Do not attempt to service or replace major engine components, or any items that require special

timing or adjustment procedures. This work should be performed by a Kohler portable dealer.

Problem

Possible Cause

Engine Not

Starting

Engine

Stopped

Automatic

Priming Fault

Low Flow

Air cleaner blocked ●●

Fuel level too low ●●

Blocked fuel fi lter ●●

Fuel supply blocked or leaking ●●

Level of liquid being pumped is too

low

●

Water level too low in pump body ●

Intake is blocked ●

Half-couplings not making an airtight

connection

●

Inadequate tightening of pump drain

plug

●

Air in suction circuit ●

Engine speed control lever set to

MIN position

●

Pipe too long or bent ●

Suction side is too high up ●

Pipes leaking ●

Clogging-up of impeller ●

Wearing of impeller ●

Damage to mechanical seal ●

Loss of engine power ●

Page 10

10 35 590 01 Rev. CKohlerPower.com

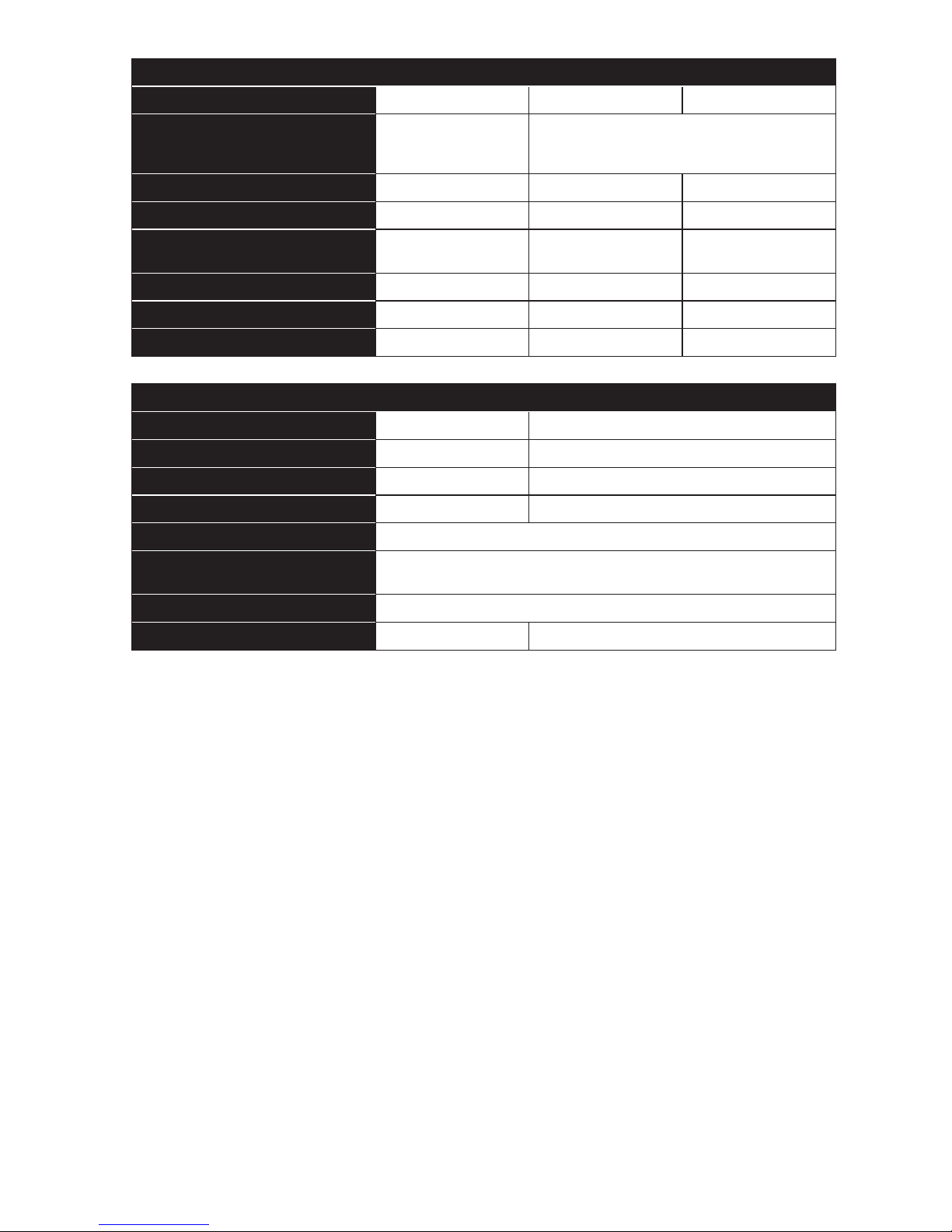

Specifi cations

Model

TP 3.0 WP 2.0 WP 3.0

Overall Dimensions (L x W x H)

27.0 in. (685 mm)

20.9 in. (530 mm)

21.3 in. (540 mm)

24.3 in. (615 mm)

18.8 in. (476 mm)

19.2 in. (487 mm)

Suction and Discharge Size 3 in. (76 mm) 2 in. (51 mm) 3 in. (76 mm)

Dry Weight 137.0 lbs. (68.5 kg) 66.0 lbs. (29.9 kg) 77.0 lbs. (34.9 kg)

Maximum Flow Rate 317 gal./min.

(1,200 l/min.)

159 gal./min.

(602 l/min.)

265 gal./min.

(1,003 l/min.)

Maximum Suction Head 26 ft. (8 m) 26 ft. (8 m) 26 ft. (8 m)

Maximum Lift Head 85 ft. (26 m) 85 ft. (26 m) 98 ft. (30 m)

Maximum Debris Size 1.1 in. (28 mm) N/A N/A

Engine Specifi cations

Bore

3.1 in. (78 mm) 2.8 in. (70 mm)

Stroke 2.3 in. (58 mm) 2.1 in. (54 mm)

Displacement 16.9 in. (277 cc) 12.7 in. (208 cc)

Oil Capacity (Refi ll) 1.16 U.S. qt. (1.1 L) 0.63 U.S. qt. (0.60 L)

Spark Plug Gap 0.03 in. (0.76 mm)

Maximum Angle of Operation

(@ full oil level)*

25°

Fuel See fuel section

Fuel Tank Capacity 2 gal. (7.4 L) 1 gal. (4.3 L)

*Exceeding maximum angle of operation may cause engine damage from insuffi cient lubrication.

Additional specifi cation information can be found at KohlerPower.com.

Exhaust Emission Control System for models TP 3.0, WP 2.0, WP 3.0 is EM for U.S. EPA,

California, and Europe.

Page 11

11

35 590 01 Rev. C

KohlerPower.com

EN

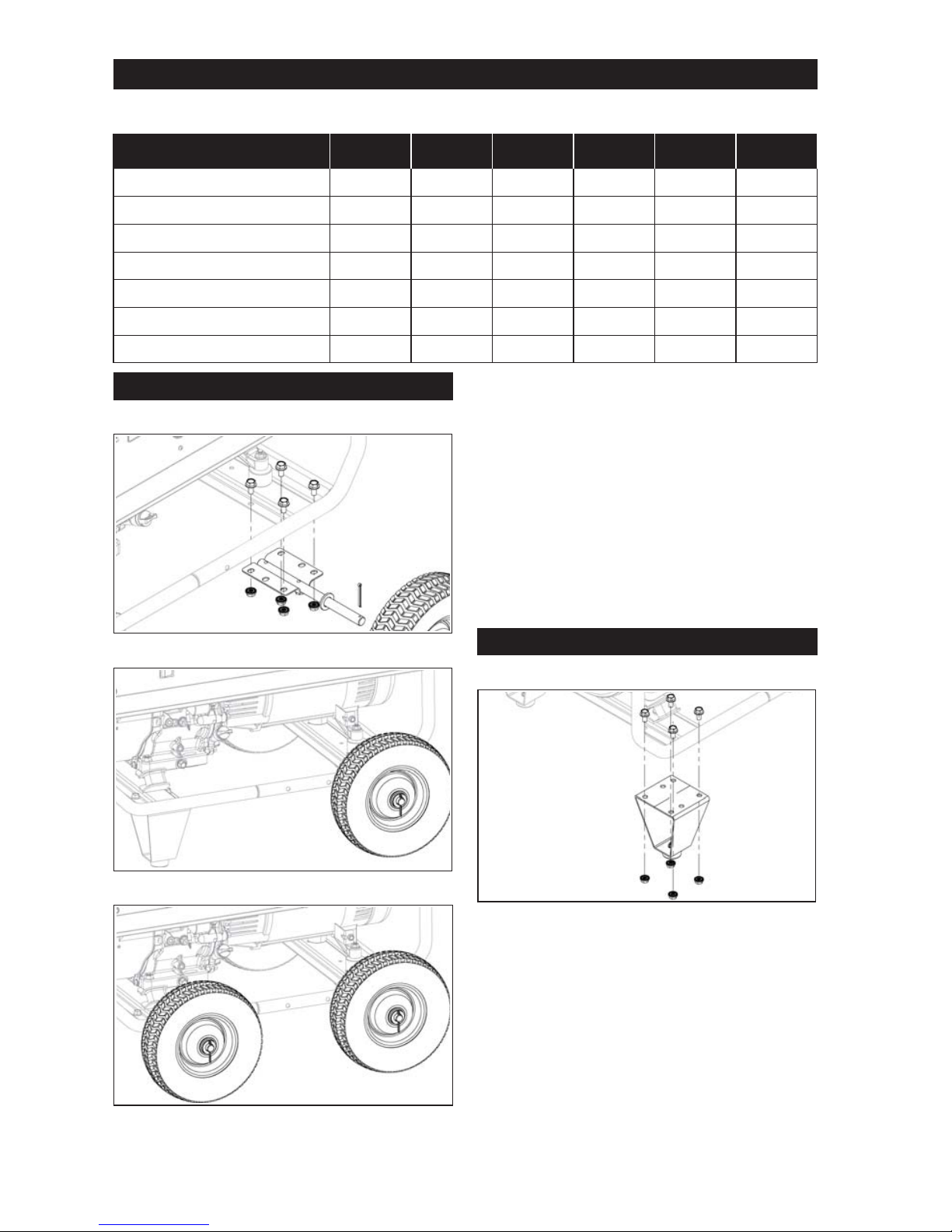

Install Wheel Kit

Wheel Kit

Wheel Kit (Wheels and Legs)

Wheel Kit (4 Wheels)

NOTE: Tilt unit so fuel tank cap is upward to

ensure no fuel leakage.

NOTE: A clamping device or an assistant to

hold assembly while installing kit will

make process easier.

Wheel kit includes 2 wheels and mounting

hardware to be installed opposite of engine

side. Wheel kit and leg kit are designed to

be installed together. 2 wheel kits can be

combined for a 4 wheel confi guration.

1. Place 4 screws into holes of frame.

2. Bring bracket of wheel under frame and align

screws with bracket holes.

3. Thread nuts to screws. Torque to 221 in. lb.

(25 N·m).

Install Leg Kit

Leg Kit

NOTE: Tilt unit so fuel tank cap is upward to

ensure no fuel leakage.

NOTE: A clamping device or an assistant to

hold assembly while installing kit will

make process easier.

Leg kit includes 2 legs and mounting hardware.

Leg kit and wheel kit are designed to be

installed together. 2 leg kits can be combined

for a 4 legged confi guration.

1. Place 4 screws into holes of frame.

2. Bring leg under frame and align screws with

leg holes.

3. Thread nuts to screws. Torque to 221 in. lb.

(25 N·m).

Accessory System

Accessory kits available for models in table below which includes custom kits consisting of legs,

handles, wheels, lifting kits — whatever you want, any way you want it.

Accessory System

PRO 5.2 /

5.2 E

PRO 7.5 /

7.5 E GEN 5.0 WP 2.0 WP 3.0 TP 3.0

Wheel Kit ●●●●●●

Leg Kit ●●●●●●

Lifting Kit ●●●

Wheelbarrow Handle Kit ●●●●●●

Cord Management Kit ●●●●●●

Hand Truck Handle Kit ●●●

Isolator Kit ●●●●●●

Page 12

12 35 590 01 Rev. CKohlerPower.com

Install Wheelbarrow Handle Kit

Wheelbarrow Handle Kit

Wheelbarrow handle kit includes two

wheelbarrow handles and mounting hardware.

1. Align handle with holes on frame.

2. Place washers between handle and frame

while installing screw.

3. Thread nut to screw. Torque to 4 in. lb.

(0.5 N·m).

Install Cord Management Kit

Cord Kit

Cord management kit includes 2 posts and

mounting hardware. Cord management kit can

be installed anywhere on unit on same side, not

across unit.

1. Place post sides together onto frame.

2. Place 3 nuts into holes in 1 side.

3. While holding together, insert screws into

other side and thread into nuts. Torque to

221 in. lb. (25 N·m).

Install Lift Kit

Lifting Kit

NOTE: A clamping device or an assistant to

hold assembly while installing kit will

make process easier.

Lift kit includes lift bar and mounting hardware.

1. Align lift bar holes under holes of frame.

2. While holding in this position, install screws.

3. Thread nuts to screws. Torque to 221 in. lb.

(25 N·m).

Install Hand Truck Handle Kit

Hand Truck Handle Kit

NOTE: A clamping device or an assistant to

hold assembly while installing kit will

make process easier.

Hand truck handle kit includes hand truck

handle and mounting hardware.

1. Position hand truck handle on unit aligning

frame holes and handle holes.

2. Place washer between handle and frame.

3. While holding in this position, install screws.

4. Thread nuts to screws. Torque to 4 in. lb.

(0.5 N·m).

5. Install release knob through frame. Place

washer and hitch pin on inside of assembly.

Install Isolator Kit

Isolator Kit

Isolator Kit includes 4 isolators and mounting

hardware.

1. Align isolator holes under holes of frame.

2. While holding in this position, install screws.

3. Thread nuts to screws. Torque to 221 in. lb.

(25 N·m).

Page 13

13

35 590 01 Rev. C

KohlerPower.com

ESS

TP 3.0, WP 2.0, WP 3.0

Manual del propietario de la bomba

de residuos y de la bomba de agua

IMPORTANTE: Lea atentamente todas las instrucciones y precauciones de seguridad

antes de poner el equipo en funcionamiento.

Asegúrese de que la unidad está parada y nivelada antes de realizar

tareas de mantenimiento o reparación.

Registre la información del producto con el fi n de consultarla para realizar pedidos de piezas o para obtener la

cobertura de la garantía.

Especifi cación

Número de serie

Fecha de compra

Page 14

14 35 590 01 Rev. CKohlerPower.com

Advertencia: la Propuesta 65 de California

El escape de motor de este producto contiene sustancias químicas

identifi cadas por el Estado de California como causantes de cáncer,

defectos de nacimiento u otros daños genéticos.

Advertencia: la Propuesta 65 de California

Este producto contiene sustancias químicas identifi cadas por el Estado

de California como causantes de cáncer, defectos de nacimiento u

otros daños genéticos.

ADVERTENCIA

La explosión del

carburante puede

provocar incendios

y quemaduras

graves.

No llene el tanque

de combustible

con el motor en

funcionamiento o

caliente.

La gasolina es muy infl amable

y sus vapores pueden hacer

explosión si se infl aman.

No reposte nunca mientras

fuma ni cerca de una llama

al descubierto. Almacene

la gasolina siempre en

contenedores homologados,

en locales desocupados, bien

ventilados y lejos de chispas

o llamas. El combustible

derramado podría infl amarse

si entra en contacto con las

piezas calientes del motor o las

chispas de encendido. No utilice

nunca gasolina como agente de

limpieza.

ADVERTENCIA

Las piezas

calientes

pueden causar

quemaduras

graves.

No toque el

motor durante el

funcionamiento o

inmediatamente

después de

pararse.

No ponga nunca la bomba

en funcionamiento con

las protecciones térmicas

desmontadas. No modifi que la

bomba.

Coloque la bomba en un lugar

donde no la vayan a tocar los

peatones ni los niños.

Asegúrese de transportar

la bomba por sus asas de

transporte únicamente.

ADVERTENCIA

Las piezas

rotatorias pueden

causar lesiones

graves.

Manténgase

alejado de

la bomba

cuando esté en

funcionamiento.

Para evitar lesiones, mantenga

las manos, los pies, el pelo y la

ropa alejados de las piezas en

movimiento. No ponga nunca la

bomba en funcionamiento con

las cubiertas, revestimientos

térmicos o protecciones

desmontados.

PRECAUCIÓN

Las descargas

eléctricas pueden

provocar lesiones.

No toque los

cables con

el motor en

funcionamiento.

No utilice nunca la bomba bajo

la lluvia o la nieve.

No toque nunca la bomba con

las manos mojadas, ya que

se produciría una descarga

eléctrica.

Precauciones de seguridad

ADVERTENCIA: Un peligro que podría provocar la muerte, lesiones graves o daños materiales considerables.

PRECAUCIÓN: Un peligro que podría provocar lesiones personales o daños materiales de poca gravedad.

NOTA: Se utiliza para notifi car al personal sobre información importante para la instalación, el funcionamiento

o el mantenimiento.

Lea este manual con atención antes de utilizar esta máquina. Este manual deberá acompañar a la máquina en

caso de que esta se venda.

Etiqueta importante en la bomba

WARNING

Carbon Monoxide. Can cause

severe nausea, fainting or death.

Avoid inhaling exhaust fumes.

Only use product outdoors.

Engine exhaust gases contain poisonous carbon

monoxide.

Carbon monoxide is odorless, colorless, and can

cause death if inhaled.

Page 15

15

35 590 01 Rev. C

KohlerPower.com

ESS

S

V

W

T

T

U

O

N

O

P

Q

R

H

B

D

E

C

A

H

B

A

E

D

G

F

C

J

K L

I

M

A

Puerto de succión

de la bomba

B

Puerto de

descarga de

la bomba

C

Tapón de llenado

de aceite con

varilla

D

Tapón de

combustible

E

Tapón del

depósito de

la bomba

F Tuerca de botón G

Tapón de drenaje

de la bomba

H

Tapón de drenaje

del aceite

I

Corte de

combustible

J

Palanca del

estrangulador

K

Palanca del

acelerador

L

Interruptor

de encendido/

apagado

(si está incluido)

M

Manivela

del motor de

arranque de

retroceso

N

Tapa del fi ltro

de aire

O Fiador P Prefi ltro

Q Filtro de papel R

Soporte del fi ltro

de aire

S Filtro de succión T Abrazadera

U Acople V Sello de goma W Junta del tubo

Page 16

16 35 590 01 Rev. CKohlerPower.com

Lista de control previa al arranque

1. Asegúrese de que la bomba se encuentre por lo

menos a 1 m (3.3 pies) de distancia de otro equipo.

2. Coloque la bomba en una superfi cie lisa y fuerte.

Seleccione un lugar limpio, ventilado y protegido de

las inclemencias del tiempo. Seleccione un lugar

que no impida el movimiento de las personas ni los

vehículos.

3. Asegúrese de que la bomba permanezca estable y

no se mueva durante la operación. No olvide que la

manguera de succión tiende a jalar la bomba hacia

la fuente del agua durante el bombeo.

4. Coloque la bomba lo más cerca posible al líquido

que va a absorber. Una distancia vertical más corta

entre la bomba y la superfi cie del líquido producirá

un cebado más rápido y un volumen más grande

de líquido bombeado. Si opera la bomba a un lado

de un foso o caudal de agua, asegúrese de que

esté bien anclada de manera que no caiga adentro.

5. Sumerja el fi ltro de succión (S) completamente

dentro del líquido, teniendo cuidado de que no esté

bloqueado.

6. Consulte todas las etiquetas de advertencia antes

de poner en marcha.

7. Comprobar el nivel de aceite. Añada aceite si está

bajo. No rellene por encima del límite.

8. Compruebe el nivel de combustible. Añada

combustible si está bajo. Compruebe si los

componentes y las tuberías del sistema de

combustible presentan alguna fuga. No reposte

nunca con la unidad en funcionamiento.

9. Verifi que que los componentes del fi ltro de aire y

todas las entradas de aire están libres de

obstrucciones, y que las cubiertas y protecciones

del equipo están en su sitio y bien sujetas.

Arranque

ADVERTENCIA

El monóxido de carbono puede

causar náuseas graves, desmayo

o la muerte. Evite inhalar el humo

de escape. Utilice el producto

únicamente al aire libre.

ADVERTENCIA

Las piezas rotatorias pueden causar

lesiones graves.

Manténgase alejado de la bomba

cuando esté en funcionamiento.

Para evitar lesiones, mantenga las manos, los

pies, el pelo y la ropa alejados de las piezas

en movimiento. No ponga nunca la bomba en

funcionamiento con las cubiertas, revestimientos

térmicos o protecciones desmontados.

NOTA: Nunca intente operar la bomba sin el agua

de cebado o la bomba se calentará. La

operación de secado por periodos largos

destruirá el sello mecánico.

Si la unidad operó en seco, pare el motor

inmediatamente y permita que la bomba se

enfríe antes de añadir el agua de cebado.

NOTA: Siempre use un fi ltro de succión (S) con

manguera de succión. La grava o los

desechos que absorba la bomba causarán

un daño grave al rotor y al armazón de la

bomba.

NOTA: La bomba no está diseñada para uso a

bordo. No la use mientras se encuentre

instalada en un vehículo.

No deje la bomba adentro de un vehículo ni

en la cajuela.

Cuando opere o transporte la bomba,

asegúrese de mantenerla recta. Si se

inclina, se puede fugar combustible del

tanque.

1. Sumerja completamente el fi ltro de succión (S) en

el líquido que se va a aspirar. Si existe el riesgo de

que se vaya a bloquear, entonces ponga el fi ltro de

succión (S) en una base de piedra.

2. Llene el cuerpo de la bomba con agua mediante el

puerto de descarga (B) o a través de la tapa del

tanque (E).

3. Conecte dos acoples de descarga y de succión (U).

4. Gire la válvula de corte de combustible (I) a la

posición ON (si está incluida).

5. Gire el interruptor de encendido/apagado del

motor (L) a la posición ON (si está incluido).

6. Arranque el motor como se indica a continuación:

Motor frío: Ajuste la palanca del acelerador (K) en

la posición intermedia entre SLOW (lento) y FAST

(rápido). Ponga la palanca del estrangulador (J) en

la posición ON.

Motor caliente: Ajuste la palanca del acelerador (K)

en la posición intermedia entre SLOW (lento) y

FAST (rápido). Vuelva a poner la palanca del

estrangulador (J) en la posición OFF tan pronto

como arranque el motor. Normalmente, un motor

caliente no requiere que el estrangulador esté

encendido.

7. Lentamente tire hacia fuera de la manivela del

motor de arranque de retroceso (M) justo hasta

después de la compresión; ¡PARE! Vuelva a la

manivela del motor de arranque de retroceso (M),

tire de ella hacia fuera con fuerza para evitar el

excesivo desgaste del cable de la guía de cable

de arranque.

8. Cuando el motor haya arrancado y se haya

calentado, vuelva a colocar progresivamente la

palanca del estrangulador (J) en la posición OFF.

Durante el periodo de calentamiento se podrá

trabajar con el motor o equipo, pero será necesario

dejar la palanca del estrangulador (J) parcialmente

activada.

Page 17

17

35 590 01 Rev. C

KohlerPower.com

ESS

Arranque en tiempo frío

NOTA: Asegúrese de que el agua que está en el

cuerpo de la bomba no esté congelada

antes de arrancar.

Cuando arranque la bomba en temperaturas bajas,

permita que el motor funcione al ralentí antes de

incrementar el fl ujo del líquido. Siga la tabla para

temperatura y tiempo.

< -20° C (< -4° F) 5 minutos

-20° a -10° C (-4° a 14° F) 2 minutos

-10° a -5° C (14° a 23° F) 1 minutos

> 5° C (> 41° F) 20 segundos

1. Utilice el aceite apropiado para la temperatura

prevista.

2. Use combustible de grado invierno reciente. El

combustible de grado invierno tiene una mayor

volatilidad que mejora el arranque.

Funcionamiento

ADVERTENCIA

Las piezas rotatorias pueden causar

lesiones graves.

Manténgase alejado de la bomba

cuando esté en funcionamiento.

Para evitar lesiones, mantenga las manos, los

pies, el pelo y la ropa alejados de las piezas

en movimiento. No ponga nunca la bomba en

funcionamiento con las cubiertas, revestimientos

térmicos o protecciones desmontados.

NOTA: Si no hay fl ujo o líquido a través de la

bomba, párela y revise el circuito de succión

(fi ltro de succión (S) y tubería).

NOTA: Evite colocar cualquier material infl amable

junta a la salida del escape durante la

operación.

No coloque ningún material sobre la bomba

durante la operación.

La bomba controla el fl ujo de líquido de acuerdo con

su velocidad de ejecución. El motor de la bomba está

equipado con una palanca de control de velocidad

que permite controlar el fl ujo de la bomba.

El fl ujo de la bomba depende también de la succión

y los cabezales de elevación de descarga y de la

calidad del líquido que se va a bombear (agua limpia/

fangosa).

1. Mueva la posición de la palanca de control de

velocidad (MAX para incrementar el fl ujo, MIN

para reducirlo).

Ángulo de funcionamiento

No haga funcionar el motor si supera el ángulo

máximo de funcionamiento, consulte la tabla de

especifi caciones. El motor puede dañarse como

resultado de una lubricación insufi ciente.

Parada

1. Mueva la palanca del acelerador (K), si está

incluida, a la posición “slow” (lento) o “idle” (ralentí);

pare el motor.

2. La bomba se para.

3. Cierre la válvula de corte de combustible (I), si está

incluida.

4. Desconecte los tubos de succión y descarga y

permita que el líquido fl uya hacia afuera.

5. Si no va a usar la bomba de nuevo ese día,

enjuáguela.

Enjuague

Después que la bomba se haya parado y enfriado.

1. Llene el cuerpo de la bomba con agua limpia

mediante el puerto de descarga (B) o a través de la

tapa del tanque (E).

2. Jale lentamente la manivela del motor de arranque

de retroceso (M) varias veces hasta encontrar

resistencia, después permítale regresar

suavemente.

3. Desatornille y quite el tapón de drenaje (G) de la

bomba y permita que el agua fl uya hacia afuera.

4. Atornille el tapón de drenaje de la bomba (G) en su

posición.

5. Repita la operación de ser necesario.

6. Limpie el fi ltro de succión (S), quite cualquier

basura que haya de ser necesario y enjuague

completamente con agua limpia.

Velocidad del motor

NOTA: No altere los ajustes del regulador para

aumentar la velocidad máxima del motor.

El exceso de velocidad es peligroso y

anulará la garantía.

Funcionamiento a gran altitud

Este motor puede requerir un kit de carburador

de gran altitud para garantizar un funcionamiento

correcto del motor a altitudes superiores a

1.219 metros (4.000 pies). Para obtener información

sobre el kit de gran altitud o encontrar a un distribuidor

autorizado de Kohler, consulte KohlerPower.com o

llame a 1-800-544-2444 (EE.UU. y Canadá).

Este motor debe ponerse en funcionamiento en su

confi guración original por debajo de los 1.219 metros

(4.000 pies), pues pueden producirse daños si se

instala y pone en funcionamiento el kit de carburador

de gran altitud por debajo de los 1.219 metros

(4.000 pies).

Formación de hielo en el carburador

NOTA: Si en condiciones normales pone el motor en

funcionamiento con la tapa (N) posicionada

en funcionamiento en clima frío, puede

dañar el motor.

La formación de hielo en el carburador se produce

ante determinadas combinaciones de temperatura y

humedad. El resultado de la formación de hielo en el

carburador es un funcionamiento irregular a velocidad

de ralentí o lenta, así como humo negro.

Para reducir la probabilidad de que se forme hielo

en el carburador, se puede girar la tapa del fi ltro de

aire (N) para obtener aire más caliente del lado del

silenciador. Para el funcionamiento en clima frío,

coloque la tapa del fi ltro de aire (N) con la etiqueta de

copo de nieve por fuera.

Para el funcionamiento normal, coloque la tapa del

fi ltro de aire (N) con la etiqueta de sol por fuera.

Page 18

18 35 590 01 Rev. CKohlerPower.com

Recomendaciones de lubricante

Recomendamos el uso de un aceite de Kohler para

obtener un mejor rendimiento. También se puede

utilizar otro aceite detergente de alta calidad API

(American Petroleum Institute) SJ o superior, incluidos

los aceites sintéticos. Seleccione la viscosidad

en función de la temperatura del aire durante el

funcionamiento como se muestra en la tabla que

aparece a continuación.

°F

-20

020324060

50 80 100

°C

-30 -20

-10 0

10 20 30

40

5W-30

10W-30

SAE 30

Comprobación del nivel de aceite

NOTA: Para evitar las averías y el desgaste

excesivo del motor, nunca ponga el motor

en funcionamiento con un nivel de aceite

inferior o superior al indicador de nivel de

funcionamiento de la varilla (C).

Asegúrese de que el motor esté frío. Limpie los

residuos de las áreas de la varilla de nivel/tapón

de llenado de aceite (C).

1. Extraiga la varilla de nivel (C); limpie el exceso

de aceite.

2. Vuelva a introducir la varilla de nivel (C) en el tubo,

asiéntela en el cuello de llenado de aceite, gírela

en sentido contrario a las agujas del reloj hasta

introducir toda la rosca del tapón de llenado. No

enrosque el tapón en el tubo.

Instrucciones de mantenimiento

Todas las operaciones de mantenimiento se realizarán según lo descrito en la tabla de mantenimiento. Su

frecuencia se da para su información, para las bombas que operan con combustible o aceite de acuerdo con las

especifi caciones que se dan en este manual.

Si la bomba se usa bajo condiciones extremas, disminuya el intervalo entre operaciones de mantenimiento.

Programa de mantenimiento

Después de las 5 primeras horas

● Cambie el aceite.

Una vez al año o cada 50 horas

● Limpie/cambie el prefiltro (P).

Una vez al año o cada 100 horas

1

● Cambie el aceite.

● Limpie las zonas de refrigeración.

Cada 200 horas

2

● Compruebe y ajuste el juego de las válvulas con el motor frío.

Cada 200 horas

● Cambie el elemento del fi ltro de aire (Q).

Cada 300 horas

● Verifi que los fi ltros de combustible (fi ltro de salida del tanque y fi ltro en línea) y límpielos o cámbielos si es

necesario (si están incluidos).

Una vez al año o cada 500 horas

1

● Cambie la bujía y ajuste la separación entre electrodos.

1

Estas operaciones de mantenimiento deberán ejecutarse con mayor frecuencia en ambientes muy

polvorientos o sucios.

2

Pida a un distribuidor móvil de Kohler que realice esta operación.

a. Saque la varilla (C) y compruebe el nivel de

aceite. El nivel debe situarse en la parte

superior de la varilla de nivel (C).

o

b. Extraiga el tapón de llenado (C). El nivel debe

alcanzar el punto de desbordamiento del

cuello de llenado.

3. Si el nivel de aceite es más bajo, añada aceite

hasta el punto de desbordamiento del cuello de

llenado.

4. Vuelva a colocar la varilla de nivel (C) o el tapón de

llenado (C) y apriete fi rmemente.

Cambio del aceite

Cambie el aceite con el motor caliente.

1. Limpie el área que rodea el tapón de llenado de

aceite/varilla (C) y el tapón de drenaje (H).

2. Quite el tapón de drenaje (H) y el tapón de llenado

con varilla (C). Drene el aceite por completo.

3. Vuelva a instalar el tapón de drenaje del aceite (H).

Apriételo a 17,6 Nm (13 ft lb).

4. Llene de aceite nuevo el cárter hasta el punto de

desbordamiento del cuello de llenado.

5. Vuelva a colocar el tapón de llenado con varilla (C)

y apriete fi rmemente.

6. Deseche el aceite usado en conformidad con las

normativas locales.

Page 19

19

35 590 01 Rev. C

KohlerPower.com

ESS

● No añada aceite a la gasolina.

● No llene el tanque de combustible por encima del

límite.

● No utilice gasolina con más de 30 días de

antigüedad.

Añadir Combustible

ADVERTENCIA

La explosión del carburante puede

provocar incendios y quemaduras

graves.

No llene el tanque de combustible con

el motor en funcionamiento o caliente.

La gasolina es muy infl amable y sus vapores

pueden hacer explosión si se infl aman. Almacene

la gasolina siempre en contenedores homologados,

en locales desocupados, bien ventilados y lejos de

chispas o llamas. El combustible derramado podría

infl amarse si entra en contacto con las piezas

calientes del motor o las chispas de encendido. No

utilice nunca gasolina como agente de limpieza.

Asegúrese de que el motor esté frío.

1. Limpie el área que rodea el tapón de combustible (D).

2. Quite el tapón de combustible (D). Llene hasta la

base del cuello de llenado. No llene el tanque de

combustible por encima del límite. Deje espacio

para que se expanda el combustible.

3. Vuelva a instalar el tapón del combustible (D) y

apriete bien.

Tubería de combustible

Debe instalar una tubería de combustible de baja

permeabilidad de motores carburados de Kohler Co.

para respetar las normas EPA y CARB.

Válvula de combustible

Los motores están equipados con una válvula de

combustible y un fi ltro de rejilla integrado situado en

la entrada del carburador. Ésta controla y fi ltra el fl ujo

de combustible del tanque al carburador. Limpie los

residuos de la copa de la válvula de combustible.

1. Extraiga dos tuercas, dos tornillos y la cubierta del

carburador.

2. Gire la palanca de la válvula de combustible a la

posición OFF.

3. Extraiga la copa de la válvula de combustible.

Extraiga la junta tórica y el fi ltro de rejilla.

4. Limpie la rejilla y la copa de la válvula de

combustible con disolvente y limpie el exceso.

5. Compruebe la rejilla y la junta tórica y cámbielas si

están dañadas.

6. Vuelva a instalar la junta tórica seguida de la copa

de la válvula de combustible. Gire con la mano la

copa de la válvula de combustible hasta que quede

bien apretada. Gire de 1/2 a 3/4 de vuelta con una

llave.

7. Gire la válvula de combustible a la posición ON y

compruebe si hay fugas. Si la válvula de

combustible tiene fugas, repita los pasos 5 y 6.

8. Apriete fi rmemente la copa de combustible (D).

9. Vuelva a colocar la cubierta del carburador

fi jándola con los tornillos quitados en el paso 1.

Oil Sentry™ (si está incluido)

Este interruptor está diseñado para evitar que el motor

arranque con poco aceite o ninguno. El Oil Sentry™

no puede apagar un motor en marcha antes de que

se produzca un daño. En algunas aplicaciones este

interruptor puede activar una señal de aviso. Lea los

manuales de su equipo para más información.

Ensamble de los tubos

Succión:

1. Conecte el fi ltro de succión (S) a un extremo del

tubo reforzado y sujete con la abrazadera (T).

2. Introduzca el extremo menor de la junta del tubo

(W) por el extremo mayor del acople (U). Conecte

el otro extremo del tubo a la junta del tubo (W) y al

acople (U) y sujete con la abrazadera (T).

3. Coloque el sello de goma (V) en el extremo de la

junta del tubo (W) y conecte la junta del tubo (W) al

puerto de succión de la bomba (A). Apriete el

acople (U).

Descarga:

1. Conecte el fi ltro de succión (S) a un extremo del

tubo y sujete con la abrazadera (T).

2. Introduzca el extremo menor de la junta del tubo

(W) por el extremo mayor del acople (U). Conecte

el otro extremo del tubo a la junta del tubo (W) y al

acople (U) y sujete con la abrazadera (T).

3. Coloque el sello de goma (V) en el extremo de la

junta del tubo (W) y conecte la junta del tubo (W) al

puerto de descarga de la bomba (B). Apriete el

acople (U).

Recomendaciones de combustible

ADVERTENCIA

La explosión del carburante puede

provocar incendios y quemaduras

graves.

No llene el tanque de combustible con

el motor en funcionamiento o caliente.

La gasolina es muy infl amable y sus vapores

pueden hacer explosión si se infl aman. Almacene

la gasolina siempre en contenedores homologados,

en locales desocupados, bien ventilados y lejos de

chispas o llamas. El combustible derramado podría

infl amarse si entra en contacto con las piezas

calientes del motor o las chispas de encendido.

No utilice nunca gasolina como agente de limpieza.

NOTA: E15, E20 y E85 are NO están autorizados y

NO deben utilizarse; la garantía no cubre los

efectos producidos por el uso de

combustible antiguo, pasado o contaminado.

El combustible debe cumplir con los siguientes

requisitos:

● Gasolina limpia, fresca y sin plomo.

● Octanaje de 87 (R+M)/2 o superior.

● El “Research Octane Number” (RON), deberá ser

de 90 octanos como mínimo.

● Se autoriza el empleo de gasolina de hasta un

volumen máximo del 10% de alcohol etílico y el

90% sin plomo.

● Se autorizan las mezclas de metil-ter-butil-éter

(MTBE) y gasolina sin plomo (hasta un máximo

del 15% de MTBE en volumen).

Page 20

20 35 590 01 Rev. CKohlerPower.com

Bujías

PRECAUCIÓN

Las descargas eléctricas pueden

provocar lesiones.

No toque los cables con el motor en

funcionamiento.

No utilice nunca la bomba bajo la lluvia o la nieve.

No toque nunca la bomba con las manos mojadas,

ya que se produciría una descarga eléctrica.

Limpie el rebaje de la bujía. Extraiga la bujía y

sustitúyala.

1. Compruebe la separación de electrodos con una

galga de espesores. Para ajustar la separación,

consulte la tabla de especifi caciones de ajuste.

2. Coloque la bujía en el cabezal del cilindro.

3. Apriete la bujía a 27 Nm (20 ft lb).

Para limpiar la bomba

1. Limpie la bomba, especialmente las entradas y las

salidas de aire del motor con un trapo y un cepillo.

2. Revise las condiciones generales de la bomba y

reemplace las piezas defectuosas.

Filtro de aire

NOTA: Si en condiciones normales pone el motor

en funcionamiento con la tapa (N)

posicionada en funcionamiento en clima frío,

puede dañar el motor.

NOTA: El funcionamiento del motor con

componentes del fi ltro de aire sueltos o

dañados puede causar daños y desgaste

prematuro. Sustituya todos los componentes

doblados o dañados.

NOTA: El papel fi ltrante (Q) no puede expulsarse

con aire comprimido.

Mueva los fi adores (O) de la tapa del fi ltro de aire (N)

hacia abajo, extraiga las pestañas de la parte inferior

del soporte (R) y extraiga la tapa (N).

Prefi ltro:

1. Extraiga el prefi ltro (P) del papel fi ltrante (Q).

2. Sustituya o lave el prefi ltro (P) con agua templada y

detergente. Aclárelo y déjelo secar al aire.

3. Lubrique ligeramente el prefi ltro (P) con aceite

nuevo y escurra el exceso de aceite.

4. Vuelva a instalar el prefi ltro (P) sobre el papel

fi ltrante (Q).

Elemento de papel:

1. Separe el prefi ltro (P) del elemento fi ltrante (Q),

limpie el prefi ltro (P) y sustituya el elemento

fi ltrante (Q).

2. Instale un nuevo elemento fi ltrante (Q) en la

base (R) e instale el prefi ltro (P) sobre el papel

fi ltrante (Q).

Coloque la tapa del fi ltro de aire (N) para el

funcionamiento normal (etiqueta de sol por fuera) o

el funcionamiento en clima frío (etiqueta de copo de

nieve por fuera), coloque las pestañas en la parte

inferior de la base (R), levante los fi adores (O) para

sujetar la tapa (N).

Tubo del respirador

Asegúrese de que ambos extremos del respirador

están conectados adecuadamente.

Refrigeración por aire

ADVERTENCIA

Las piezas calientes pueden causar

quemaduras graves.

No toque el motor durante el

funcionamiento o inmediatamente

después de pararse.

No ponga nunca la bomba en funcionamiento

con las protecciones térmicas desmontadas.

No modifi que la bomba.

Coloque la bomba en un lugar donde no la vayan a

tocar los peatones ni los niños.

Asegúrese de transportar la bomba por sus asas

de transporte únicamente.

Es esencial una refrigeración adecuada. Para evitar

el sobrecalentamiento, limpie los fi ltros, los álabes

de refrigeración y demás superfi cies externas del

motor. Evite rociar agua al haz de cables o a cualquier

componente eléctrico. Consulte el Programa de

mantenimiento.

Reparaciones/Piezas de recambio

Recomendamos que utilice un distribuidor móvil de

Kohler para el mantenimiento, la reparación o la

sustitución de piezas del motor. Para encontrar un

distribuidor móvil de Kohler, visite KohlerPower.com

o llame al 1-800-544-2444 (EE. UU. y Canadá).

Para transportar la bomba

Antes de transportar la bomba, compruebe que los

tornillos estén bien apretados y cierre la válvula de

combustible. Se debe transportar la bomba en su

posición de funcionamiento normal, nunca la coloque

sobre su costado. Asegúrese de que el lugar donde

guardará y usará la bomba se haya preparado

cuidadosamente con anticipación.

Almacenamiento

Si no usa la bomba por un periodo prolongado, las

operaciones de almacenamiento se deberán realizar

según las siguientes instrucciones.

NOTA: Nunca opere la bomba sin llenar su cuerpo

con agua e sumergir el fi ltro de succión (S)

en agua antes.

1. Añada el tratamiento de combustible Kohler PRO

Series o equivalente al depósito de combustible.

Arranque el motor durante 2-3 minutos para que el

combustible se estabilice en el sistema de

combustible (la garantía no cubre los fallos

provocados por combustible sin tratar).

2. Cambie el aceite con el motor aún caliente. Extraiga

la bujía y vierta aproximadamente 28 g (1 oz) de

aceite de motor en el cilindro. Sustituya la bujía

y arranque el motor lentamente para distribuir

el aceite.

3. Enjuague completamente la bomba y los tubos con

agua limpia.

4. Limpie la parte externa de la bomba y aplique un

producto antioxidante a cualquier área desgastada

o dañada.

Page 21

21

35 590 01 Rev. C

KohlerPower.com

ESS

5. Cubra la bomba con una cubierta protectora para

preservarla del polvo y guárdela en un lugar limpio

y seco.

Localización de averías

No intente reparar o cambiar componentes principales del motor o cualquier elemento que requiera unos

procedimientos de ajuste o sincronización especiales. Este trabajo debe ser realizado por un distribuidor móvil

de Kohler.

Problema

Causa posible

El motor no

arrancará

El motor

se paró

Falla del cebado

automático

Flujo bajo

Filtro de aire bloqueado ●●

Nivel de combustible muy bajo ●●

Filtro de combustible bloqueado ●●

Suministro de combustible bloqueado

o con fuga

●●

El nivel de líquido que se está

bombeando es muy bajo

●

El nivel del agua es muy bajo en el

cuerpo de la bomba

●

La entrada está bloqueada ●

Los semicoples no hacen una conexión

hermética

●

Apretamiento inadecuado del tapón

de drenaje de la bomba

●

Aire en el circuito de succión ●

Palanca de control de velocidad en

la posición MIN

●

Tubo muy largo o doblado ●

Lado de succión muy alto ●

Fuga en la tubería ●

Obstrucción del rotor ●

Desgaste del rotor ●

Daño en el sello mecánico ●

Pérdida de la energía del motor ●

Page 22

22 35 590 01 Rev. CKohlerPower.com

Especifi caciones

Modelo

TP 3.0 WP 2.0 WP 3.0

Dimensiones totales (Largo x

Ancho x Alto)

685 mm (27,0 in)

530 mm (20,9 in)

540 mm (21,3 in)

615 mm (24,3 in)

476 mm (18,8 in)

487 mm (19,2 in)

Succión y tamaño de la descarga 76 mm (3 in) 51 mm (2 in) 76 mm (3 in)

Peso en seco 137.0 lbs. (68,5 kg) 66.0 lbs. (29,9 kg) 77.0 lbs. (34,9 kg)

Caudal máximo 317 gal./min.

(1,200 l/min.)

159 gal./min.

(602 l/min.)

265 gal./min.

(1,003 l/min.)

Succión máxima del cabezal 8 m (26 ft) 8 m (26 ft) 8 m (26 ft)

Elevación máxima del cabezal 26 m (85 ft.) 26 m (85 ft) 30 m (98 ft)

Tamaño máximo de desechos 28 mm (1.1 pul.) N/D N/D

Especifi caciones del motor

Orifi cio

78 mm (3,1 in) 70 mm (2,8 in)

Carrera 58 mm (2,3 in) 54 mm (2,1 in)

Desplazamiento 277 cc (16,9 in) 208 cc (12,7 in)

Capacidad de aceite (rellenado) 1,1 L (1,16 U.S. qt) 0,60 L (0,63 U.S. qt)

Abertura de bujía 0,76 mm (0,03 in)

Ángulo de funcionamiento máximo

(con nivel máximo de aceite)*

25°

Combustible Véase la sección de combustible

Capacidad del tanque de

combustible

7.4 L (2 gal.) 4.3 L (1 gal.)

*Si se excede el ángulo máximo de funcionamiento puede dañarse el motor debido a lubricación insufi ciente.

Puede encontrar información adicional sobre las especifi caciones en KohlerPower.com.

El sistema de control de emisiones de escape para los modelos TP 3.0, WP 2.0, WP 3.0 es EM para la EPA

estadounidense, California y Europa.

Page 23

23

35 590 01 Rev. C

KohlerPower.com

ESS

Instalación del kit de ruedas

Kit de ruedas

Kit de ruedas (ruedas y patas)

Kit de ruedas (4 ruedas)

NOTA: Incline la unidad de manera que el tapón del

tanque de combustible quede hacia arriba

para que no se produzcan fugas de

combustible.

NOTA: Un dispositivo de sujeción o un ayudante

que sujete el conjunto durante la instalación

del kit facilitarán el proceso.

El kit de ruedas incluye 2 ruedas y los elementos

de montaje para su instalación en el lado contrario

al motor. El kit de ruedas y el kit de patas están

diseñados para su instalación juntos. Es posible

combinar 2 kits de ruedas para una confi guración

de 4 ruedas.

1. Introduzca 4 tornillos en los orifi cios del bastidor.

2. Sitúe el soporte de la rueda bajo el bastidor y

alinee los tornillos con los orifi cios del soporte.

3. Enrosque las tuercas en los tornillos. Aplique un

par de apriete de 25 Nm (221 in lb).

Instalación del kit de patas

Kit de patas

NOTA: Incline la unidad de manera que el tapón del

tanque de combustible quede hacia arriba

para que no se produzcan fugas de

combustible.

NOTA: Un dispositivo de sujeción o un ayudante

que sujete el conjunto durante la instalación

del kit facilitarán el proceso.

El kit de patas incluye 2 patas y los elementos de

montaje. El kit de patas y el kit de ruedas están

diseñados para su instalación juntos. Es posible

combinar 2 kits de patas para una confi guración

de 4 patas.

1. Introduzca 4 tornillos en los orifi cios del bastidor.

2. Sitúe la pata bajo el bastidor y alinee los tornillos

con los orifi cios de la pata.

3. Enrosque las tuercas en los tornillos. Aplique un

par de apriete de 25 Nm (221 in lb).

Sistema de accesorios

Kits de accesorios disponibles para los modelos indicados en la tabla siguiente, que incluye kits personalizados

compuestos por patas, brazos, ruedas, kits de elevación... Todo lo que desee, del modo que desee.

Sistema de accesorios

PRO 5.2 /

5.2 E

PRO 7.5 /

7.5 E GEN 5.0 WP 2.0 WP 3.0 TP 3.0

Kit de ruedas ●●●●●●

Kit de patas ●●●●●●

Kit de elevación ●●●

Kit de brazos de carretilla ●●●●●●

Kit de tendido de cables ●●●●●●

Kit de brazos de carro manual ●●●

Kit de aislantes ●●●●●●

Page 24

24 35 590 01 Rev. CKohlerPower.com

Instalación del kit de brazos de carretilla

Kit de brazos de carretilla

El kit de brazos de carretilla incluye dos brazos de

carretilla y los elementos de montaje.

1. Alinee el brazo con los orifi cios del bastidor.

2. Coloque arandelas entre el brazo y el bastidor

cuando instale el tornillo.

3. Enrosque la tuerca en el tornillo. Apriételo a 0,5 Nm

(4 in lb).

Instalación del kit de tendido de cables

Kit de cables

El kit de tendido de cables incluye 2 postes y los

elementos de montaje. El kit de tendido de cables se

puede instalar en cualquier lugar de la unidad en un

mismo lado, no de un lado a otro de la unidad.

1. Coloque los lados de los postes juntos sobre el

bastidor.

2. Coloque 3 tuercas en los orifi cios en 1 lado.

3. Mientras los sujeta juntos, introduzca los tornillos

por el otro lado y enrósquelos en las tuercas.

Aplique un par de apriete de 25 Nm (221 in lb).

Instalación del kit de elevación

Kit de elevación

NOTA: Un dispositivo de sujeción o un ayudante

que sujete el conjunto durante la instalación

del kit facilitarán el proceso.

El kit de elevación incluye una barra de elevación y

los elementos de montaje.

1. Alinee los orifi cios de la barra de elevación bajo los

orifi cios del bastidor.

2. Mientras sujeta en esta posición, instale los tornillos.

3. Enrosque las tuercas en los tornillos. Aplique un

par de apriete de 25 Nm (221 in lb).

Instalación del kit de brazos de carro manual

Kit de brazos de carro manual

NOTA: Un dispositivo de sujeción o un ayudante

que sujete el conjunto durante la instalación

del kit facilitarán el proceso.

El kit de brazos de carro manual incluye el brazo del

carro manual y los elementos de montaje.

1. Sitúe el brazo del carro manual sobre la unidad

alineando los orifi cios del bastidor con los orifi cios

del brazo.

2. Coloque una arandela entre el brazo y el bastidor.

3. Mientras sujeta en esta posición, instale los tornillos.

4. Enrosque las tuercas en los tornillos. Apriételo a

0,5 Nm (4 in lb).

5. Instale la rueda de liberación a través del bastidor.

Coloque la arandela y el pasador en el interior del

conjunto.

Instalación del kit de aislantes

Kit de aislantes

El kit de aislantes incluye 4 aislantes y los elementos

de montaje.

1. Alinee los orifi cios del aislante bajo los orifi cios del

bastidor.

2. Mientras sujeta en esta posición, instale los tornillos.

3. Enrosque las tuercas en los tornillos. Aplique un

par de apriete de 25 Nm (221 in lb).

Page 25

25

35 590 01 Rév. C

KohlerPower.com

FRC

TP 3.0, WP 2.0, WP 3.0

Manuel du propriétaire - Pompe à résidus et

pompe à eau

IMPORTANT : Lisez toutes les consignes et précautions de sécurité avant

d'utiliser le matériel.

Le moteur doit être arrêté et de niveau avant d'exécuter tout

travail de maintenance ou d'entretien.

Enregistrez les informations concernant le produit pour référence lors de la commande de pièces ou de

demande de couverture de garantie.

Spécifi cations

Numéro de série

Date d'achat :

Page 26

26 35 590 01 Rév. CKohlerPower.com

AVERTISSEMENT

Les pièces

tournantes

peuvent causer

de graves

blessures.

Tenez-vous

éloigné de

la pompe

pendant qu'elle

fonctionne.

Tenez vos mains, pieds,

cheveux et vêtements à l’écart

de toutes les pièces mobiles

pour prévenir les blessures.

Ne faites jamais fonctionner la

pompe si des couvercles, des

enveloppes ou des protections

ont été enlevés.

AVERTISSEMENT

Carburant

explosif pouvant

causer des

incendies et des

brûlures graves.

N'ajoutez pas de

carburant si le

moteur est chaud

ou s'il tourne.

L’essence est extrêmement

infl ammable et le contact de

ses vapeurs avec une source

d’allumage peut provoquer une

explosion. Ne faites jamais

le plein en fumant ou à côté

d'une fl amme. Entreposez

l'essence dans des récipients

approuvés et dans des

bâtiments non occupés, à

l'abri des étincelles ou des

fl ammes. Des éclaboussures de

carburant peuvent s'enfl ammer

au contact de pièces chaudes

ou d'étincelles provenant de

l'allumage. N’utilisez jamais

d’essence comme agent

nettoyant.

AVERTISSEMENT

Les pièces

chaudes peuvent

causer de graves

brûlures.

Ne touchez

pas au moteur

pendant qu’il

tourne ou si vous

venez tout juste

de l'arrêter.

Ne faites jamais fonctionner

la pompe si des écrans

thermiques ou des

protections ont été enlevés.

Ne modifi ez pas la pompe.

La pompe doit être installée

dans un endroit inaccessible

par les piétons ou les enfants.

La pompe ne doit être portée

que par les poignées.

ATTENTION

Les chocs

électriques

peuvent causer

des blessures.

Ne touchez pas

aux fi ls pendant

que le moteur

tourne.

Ne laissez jamais tourner la

pompe sous la pluie ou la

neige.

Ne touchez jamais la pompe

avec les mains mouillées. Il y

a risque de choc électrique.

Consignes de sécurité

AVERTISSEMENT : Un danger pouvant entraîner la mort, de graves blessures ou des dommages

matériels.

ATTENTION : Un danger pouvant entraîner des blessures légères ou des dommages matériels.

REMARQUE : Cette mention est utilisée pour attirer l'attention sur des détails importants concernant

l'installation, l'utilisation ou l'entretien.

Lisez ce manuel avec précaution avant d'utiliser cette machine. Ce manuel doit rester avec la machine si

celle si est vendue.

Étiquette importante sur la pompe

WARNING

Carbon Monoxide. Can cause

severe nausea, fainting or death.

Avoid inhaling exhaust fumes.

Only use product outdoors.

Engine exhaust gases contain poisonous carbon

monoxide.

Carbon monoxide is odorless, colorless, and can

cause death if inhaled.

Californie Proposition 65 Avertissement

L'échappement de moteur émanant de ce produit comprend

des agents chimiques qui, selon l'État de Californie, sont la

cause de cancers, d'anomalies congénitales, ou d'autres lésions

génésiques.

Californie Proposition 65 Avertissement

Ce produit comprend des agents chimiques qui, selon l'État de

Californie, sont la cause de cancers, d'anomalies congénitales ou

d'autres lésions génésiques.

Page 27

27

35 590 01 Rév. C

KohlerPower.com

FRC

S

V

W

T

T

U

O

N

O

P

Q

R

H

B

D

E

C

A

H

B

A

E

D

G

F

C

J

K L

I

M

A

Port d'aspiration

de pompe

B

Port de décharge

de pompe

C

Bouchon du

goulot d'huile/

Jauge

D

Bouchon de

carburant

E

Bouchon du

goulot de pompe

F

Écrou

G

Bouchon de

vidange de

pompe

H

Bouchon de

vidange d'huile

I

Soupape de

coupure de

carburant

J

Levier

d'étrangleur

K

Levier

d'accélérateur

L

Bouton marche/

arrêt (le cas

échéant)

M

Poignée de

lanceur à rappel

N

Couvercle du

fi ltre à air

O

Crochet

P

Préfi ltre

Q

Élément papier

R

Base du fi ltre

à air

S

Crépine

d'aspiration

T

Collier

U

Raccord

V

Joint en

caoutchouc

W

Raccord de

fl exible

Page 28

28 35 590 01 Rév. CKohlerPower.com

Liste de vérifi cation à utiliser avant le

démarrage

1. Assurez-vous que la pompe se trouve à au moins

1 m (3,3 pi) du bâtiment ou autre matériel.

2. Placez la pompe sur une surface stable et solide.

Sélectionnez un endroit propre, aéré et protégé du

mauvais temps. Sélectionnez un endroit qui

n'empêche pas les déplacements de personnes ou

de véhicules.

3. Assurez-vous que la pompe reste stable et

immobile pendant le fonctionnement. N'oubliez pas

que le fl exible d'aspiration a tendance à entraîner la

pompe vers la source d'eau pendant le pompage.

4. Placez la pompe le plus proche possible du liquide

de remplissage. Une distance verticale courte entre

la pompe et la surface du liquide permet un

amorçage plus rapide ainsi que le pompage d'un

plus gros volume de liquide. Si la pompe fonctionne

à côté d'une fosse ou d'un réservoir d'eau, vérifi ez

son installation pour qu'elle ne tombe pas à

l'intérieur.

5. Immergez entièrement la crépine d'aspiration (S)

dans le liquide, en prenant soin de ne pas la

bloquer.

6. Vérifi ez toutes les étiquettes avant de commencer.

7. Vérifi ez le niveau d'huile. Ajoutez de l'huile si le

niveau est bas. Ne remplissez pas trop le réservoir.

8. Vérifi ez le niveau de carburant. Ajoutez du

carburant si le niveau est bas. Recherchez la

présence de fuites sur les conduites et les

composants du système d'alimentation en

carburant. Ne faites jamais le plein pendant le

fonctionnement de l'appareil.

9. Assurez-vous que le fi ltre à air et toutes les

admissions d'air ne sont pas bouchés, et que tous

les couvercles d'équipement et toutes les

protections sont en place et bien fi xés.

Démarrage

AVERTISSEMENT

Monoxyde de carbone. Peut

être cause de nausées,

évanouissements ou décès.

Évitez l’inhalation des gaz

d’échappement. Ce produit ne

doit être utilisé qu’à l’extérieur.

Les gaz d’échappement du moteur contiennent du

monoxyde de carbone, gaz extrêmement toxique.

Le monoxyde de carbone est un gaz inodore et