VEIL WALL FACED

INSTALLATION INSTRUCTIONS

INTELLIGENT TOILET

K-8423A-0

• We appreciate your commitment to Kohler quality. Please take a few minutes before you begin installation to review

this manual to become familiar with tools, materials and installation methods. If you encounter any installation or

performance problems, please don't hesitate to contact us. Thanks again for choosing Kohler Co.

• Please follow instructions closely to avoid costly mistakes caused by improper installation. Cover and protect the

components and fittings at all times during installation. Flush the plumbing lines before initial use.

• All information in this manual is based upon the latest product information available at the time of publication. Kohler

Co. reserves the rights to make changes in product characteristics, packaging or availability at any time without notice.

• Before continuing, please ensure there is no existing damage to the toilet and that there is suitable space for installation

with no interference with other bathroom fixtures such as shower door openings. Before proceeding with installation,

ensure there is ample room (approx 600mm) down each side of the pan to allow for servicing.

• To prevent serious damage, do not use corrosive solutions (see back page for care and cleaning information).

Any use of non-recommended products could void the Kohler warranty.

• This manual includes important care and cleaning information - please save these instructions.

COMPLIANCE: Ensure installation adheres to local building code & applicable plumbing/electrical standards.

• The Kohler Veil Intelligent Toilet - Wall Faced (

Technical Specification for Plumbing and Drainage Products - Bidet Douche Seats.

• Installation must comply with AS/NZS 3500.1 Plumbing and Drainage - Water Services and AS/NZS 6400 Water

Efficient Products - Rating and Labelling.

K-8423A-0) is WaterMark certified according to ATS 5200.051

Backflow Prevention

• The supplied Dual Check Valve is WaterMark certified according to AS 2845.1 Water Supply - Backflow Prevention

Devices - Materials, Design and Performance Requirements.

• Each site must have High Hazard Backflow Prevention installed upstream of the installation.

• For domestic installations, consult with a Licensed Practitioner (Plumber) before installation.

• For commercial applications, refer to a Hydraulic Consultant before specification or installation.

WARNING: Risk of electric shock. Disconnect power before servicing.

WARNING: Risk of electric shock. Connect only to a properly-grounded, grounding-type receptacle which is

protected by a Ground-Fault Circuit-Interrupter (GFCI) or Residual Current Device (RCD)

WARNING: Risk of electric shock. This product must be grounded. Connect only to a dedicated 220~240V AC,

50/60Hz circuit protected with grounded circuit-breaker or grounded electric leak circuit breaker

WARNING: 10A power supply is required.

Product Functions

• Hands-free flushing

• Manual dual-flush option

• Backflow prevention

• Pre-set water inlet level & flush volume

• Suitable for either S-trap or P-trap installations

Advantages for the In-wall Water Tank

• Anti-impact, rust-proof, macromolecule water tank reduces the possibility of leakages.

• Advanced water tank system is able to adjust 4.5/3 litre water discharge. To maintain the 4-star WELS rating, switch

off the Auto-flush option.

• No influence on wall structure, superb sound-proof effectiveness.

• Easy and quick installation saves time and labour.

• Easy servicing, wall reconstruction is not required.

• Sanitary system with no residual waste.

• Super thin tank body saves installation space and is applicable for all thin mounting walls.

Kohler Co. Jan 2018 1 1345889-A02-A

The concept of in-wall tank design & installation

• Compared to traditional setups, the in-wall tank provides an easier and faster installation method, which gives a

more artistic and complete finish.

• The greatest advantage of the in-wall tank is that the toilet installation is not limited to certain locations. It can be

hung almost anywhere which affords a far greater use of bathroom space.

Component information

• Pan with faceplate .......... 20313A-0

• Remote assembly ........... 1235953

• Hydro-Tower 500 in-wall tank .. 18647A-NA

• Faceplate .................................. 1268687

Required tools and materials

• 19mm spanner or adjustable wrench

• Blade

• File

• Hacksaw

• Hex key

• Impact drill

• Level

• Electrical tape + thread sealing tape

• Electrical insulation conduits

• Grease

• Plug for bidet water supply

• Screws/bolts to affix in-wall tank to wall

frame and bottom plate (not supplied). Recommended

to use M6x40 coach screws with appropriate washers.

• Screwdriver

• Rulers/measuring tape

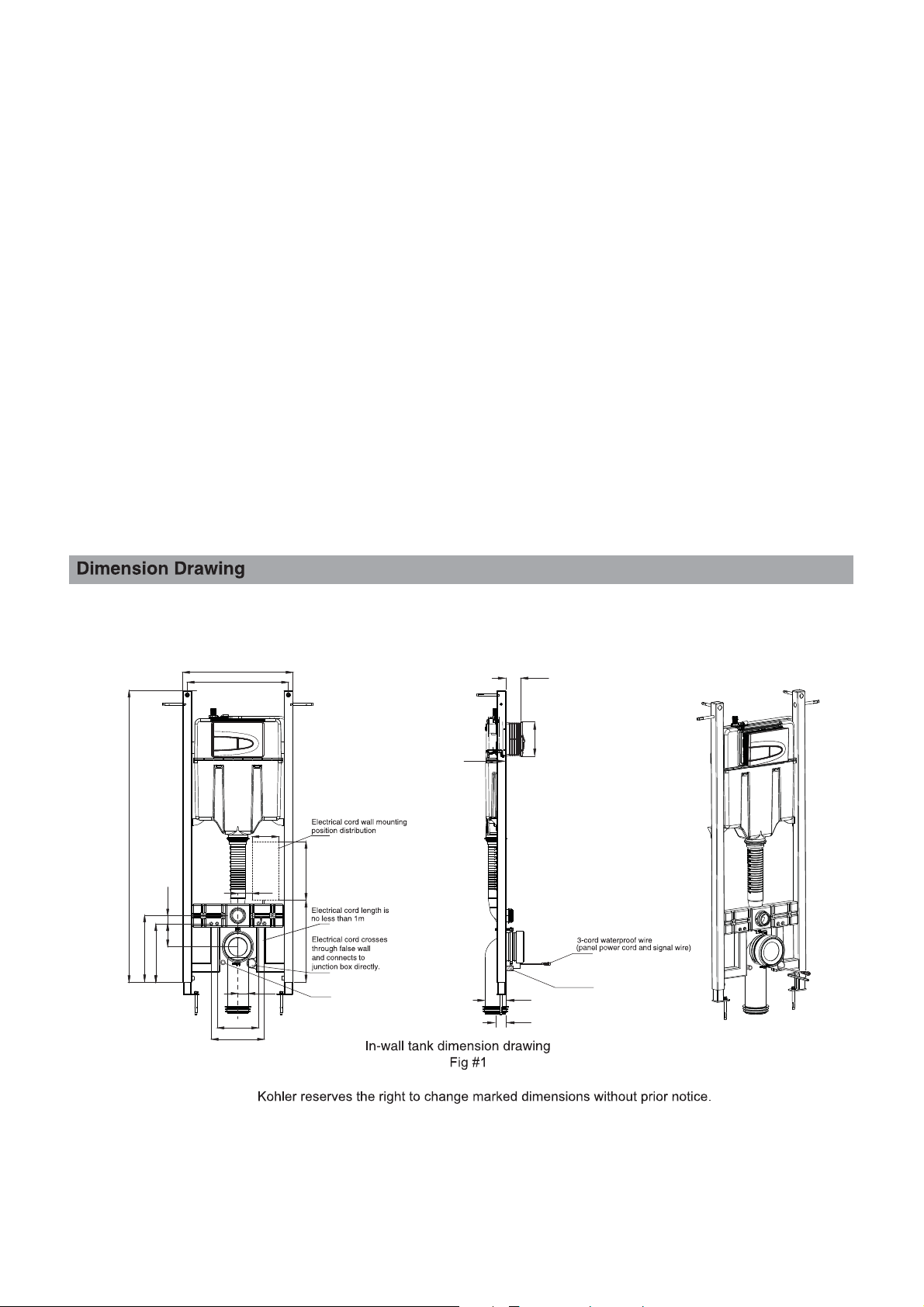

1mm - 2.5mm hard cord should be reserved as power input during the wall construction. In the circuit, a 220V, 50Hz,

10A minimum Ground-Fault Circuit Interrupter (GFCI) or Earth Leakage Circuit-Breaker (ELCB) is required. For

detailed positioning of the hard cord, see diagram below.

478±3

438±3

13~62

88±2

110

150±1

Unit:mm

1265±4

345 ±2

35±2

60

100±3

254±3

45±3

230±3

255

355

Bidet water supply pipe

Bidet water supply connector

90

45

NOTE: S-trap installation shown as default. P-trap configuration is achievable by using a DN80 waste pipe connector.

Kohler Co. Jan 2018 2 1345889-A02-A

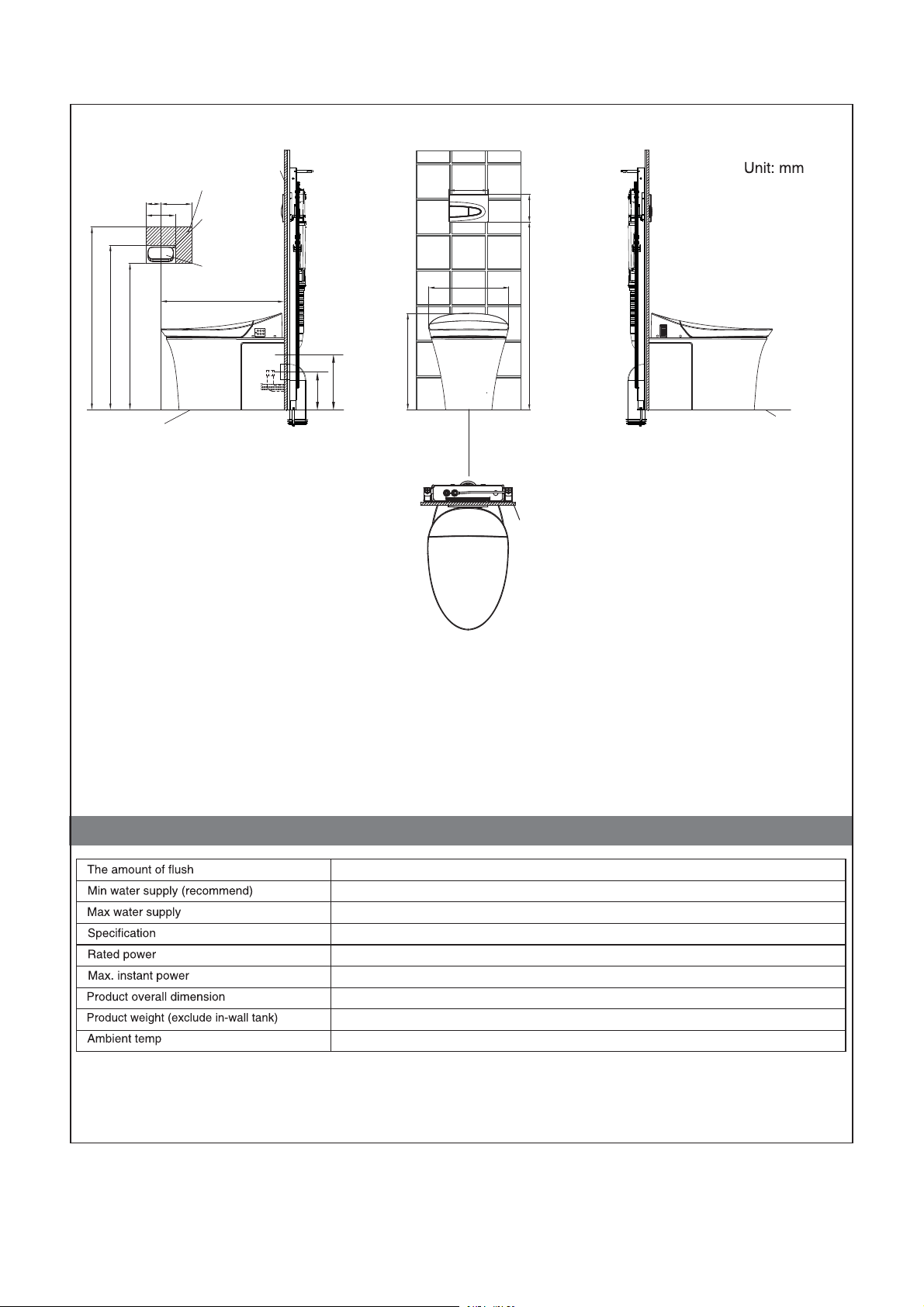

1000

900

Finished floor

800

160

Finished wall

Reference area

170

for installation

Reference area

80

215

150

for application

Remote control

675

(208)

(308)

From floor to

fixing hole centre

533

438

1027

Finished floor

Finished wall

Toilet dimension drawing

Kohler reserves the right to change marked dimensions without prior notice.

SPECIFICATION(8423A-0)

4.5L/3L

70kPa (Dynamic pressure)

740kPa (Static pressure)

220V~ , 50Hz

1000W

1600W

675mm x 438mm x 533mm (Height shall be calculated from floor to the top of the product)

About 48.5Kg.

1- 40 °C

Note: Refer to the User Guide for intelligent bidet specification.

Fig.#2

Kohler Co. Jan 2018 3 1345889-A02-A

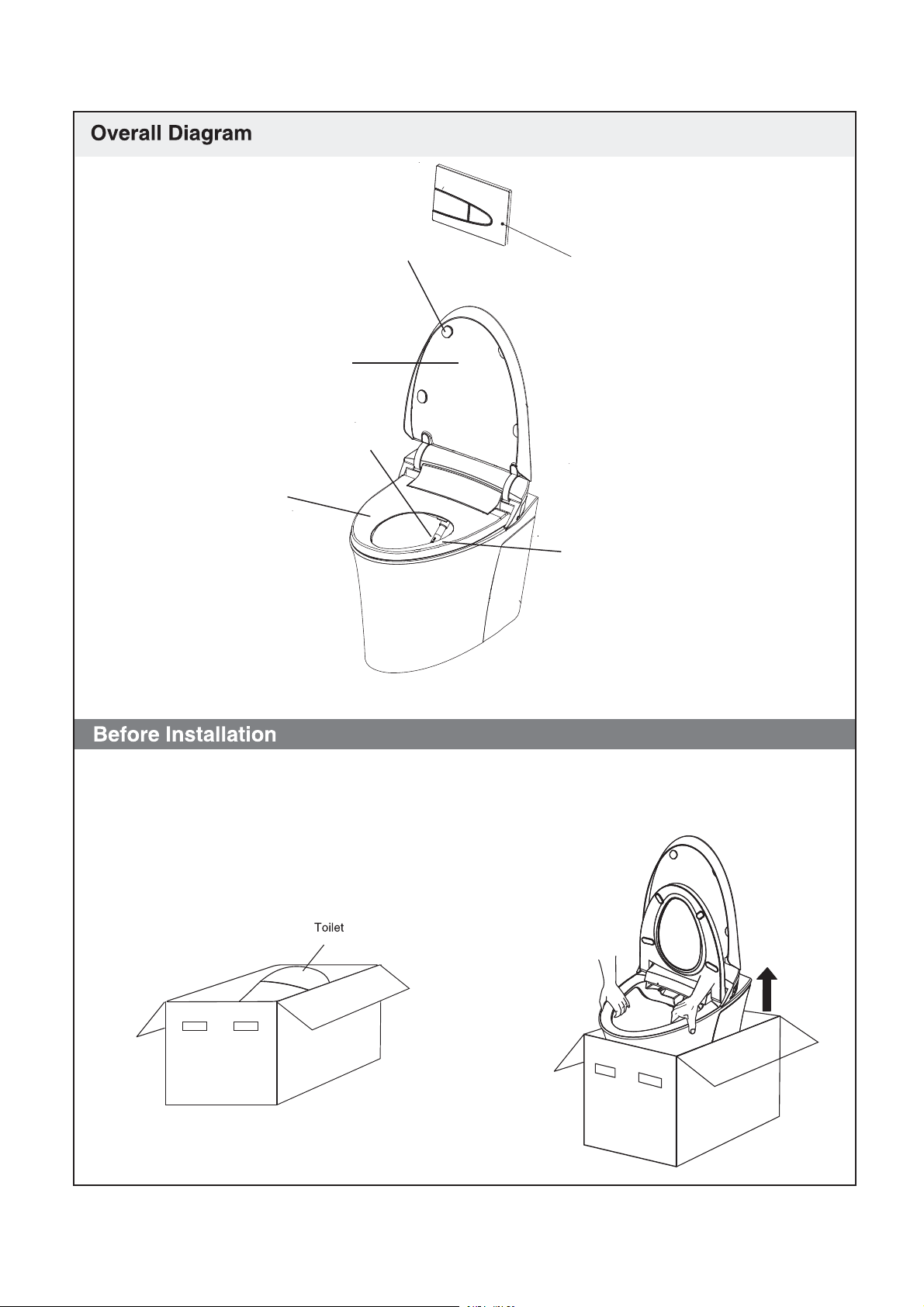

Antibacterial cover

Antibacterial seat

Seat bumpers x4 Flush control panel

(touchless flush detection zone)

Bidet nozzle

Bidet function detection zone

Fig.#3

A. Hold the edge of toilet bowl and slide out from packaging box.

WARNING: Risk of product damage or personal injury. When lifting up the toilet, please hold it by the rim.

Product is heavy, please employ a two-person lift.

Fig.#4

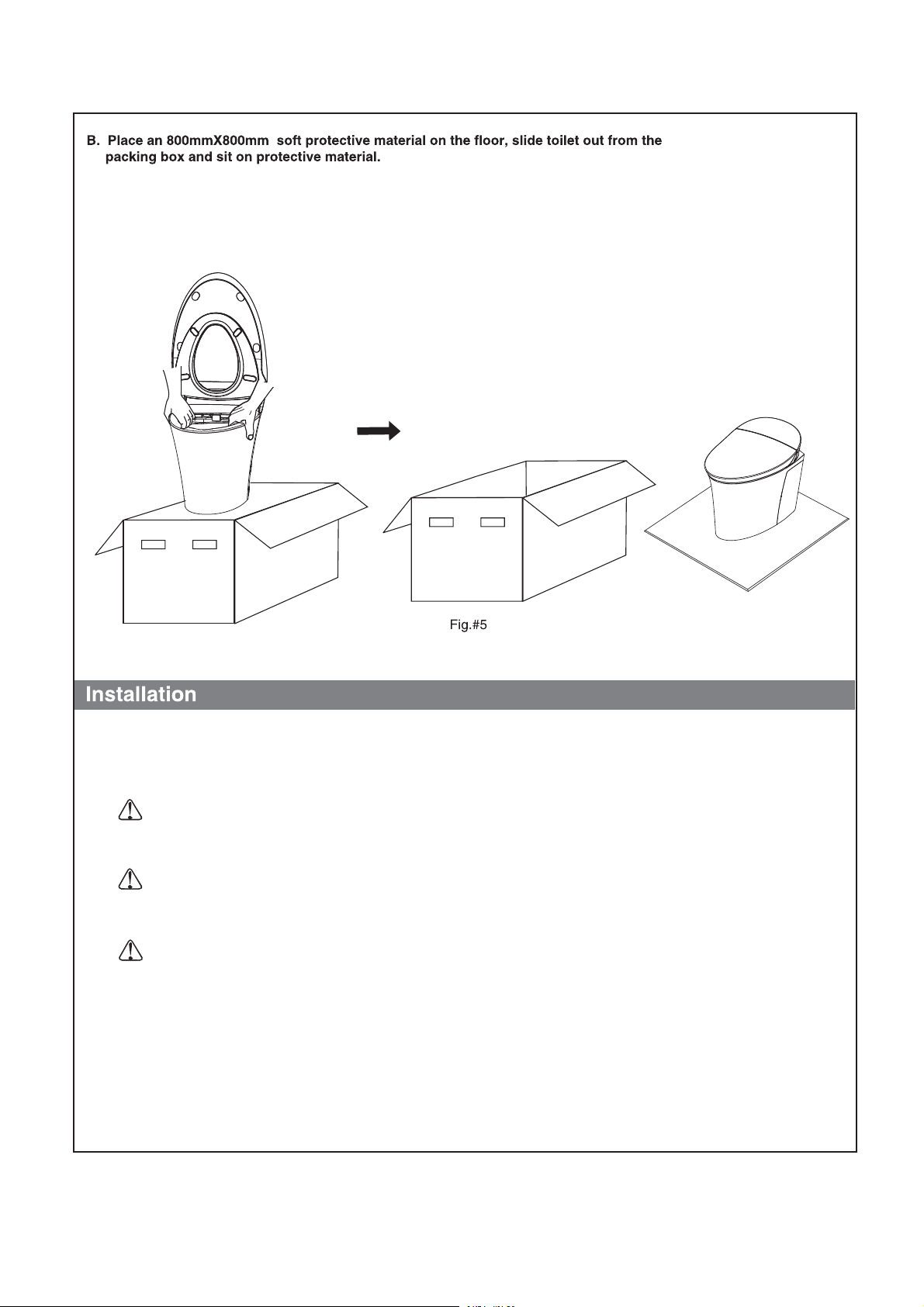

Kohler Co. Jan 2018 4 1345889-A02-A

A. Where applicable, remove the old toilet

B. Warning for installation

WARNING: Risk of electric shock. Disconnect power before servicing.

Note: The power supply and water pipe of this product is designed for wall face style . Installation

method is marked in dimension drawing.

WARNING: Risk of electric shock. For plug-in installation/wall-mounted electrical supply: Connect only

to a properly-grounded, grounding-type circuit which is protected by a Ground-Fault Circuit-Interrupter

(GFCI) or Earth Leakage Circuit Breaker (ELCB).

WARNING: Bathtub and sprinkler head shall be far away from electrical parts (e.g. remote controller,

power receptacle etc.) if it is wall-hung style, water proof or splash proof receptacle is required. If

wall-mounting power supply is adopted, require anti-water and anti-splash power receptacle.

Kohler Co. Jan 2018 5 1345889-A02-A

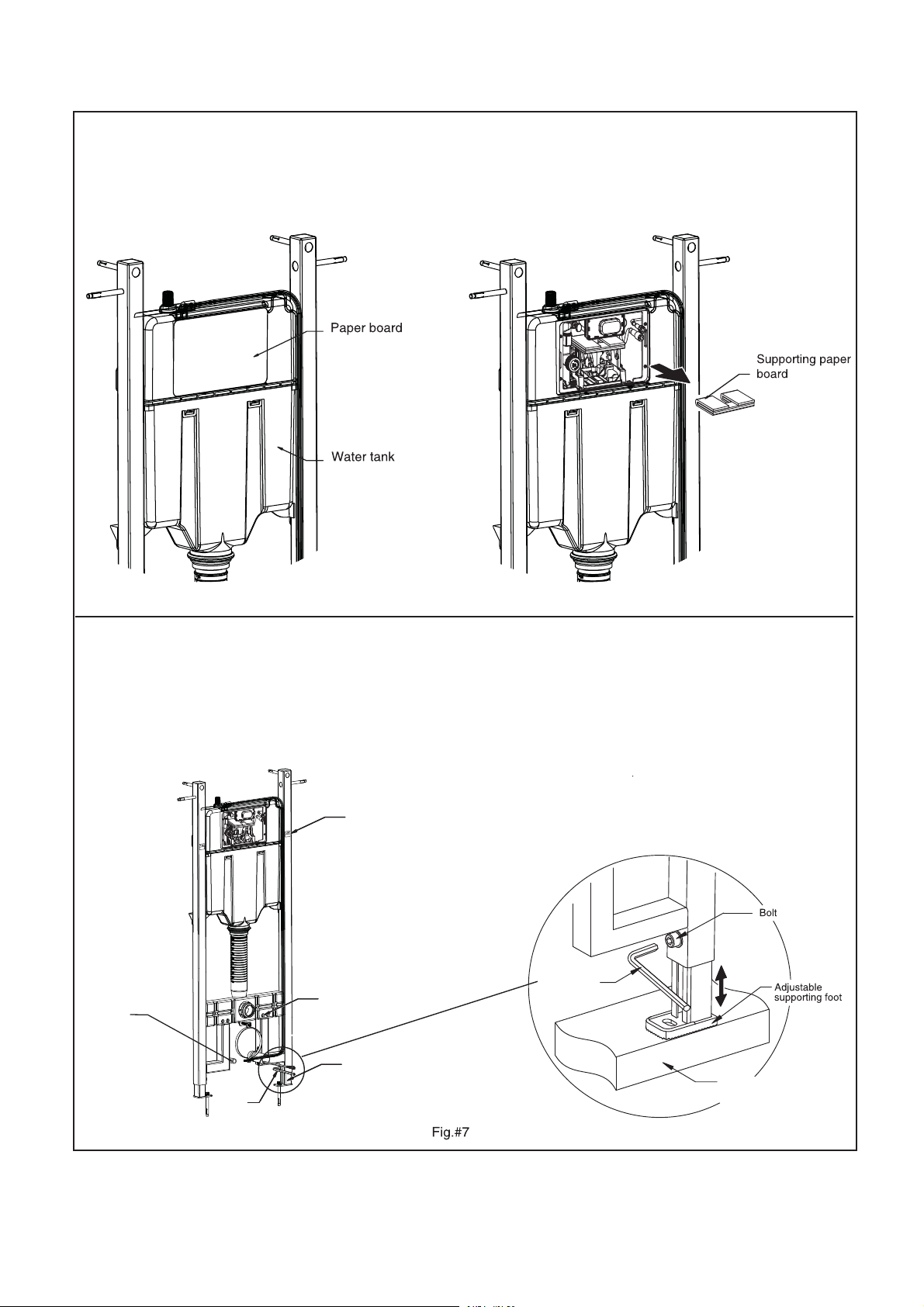

C. In-Wall tank installation

1. Remove the in-wall tank from packing box. Remove paper board from cistern access opening.

Then remove the support paper board under the motor assembly.

Fig.#6

2. Adjust the supporting feet height by loosening the bolts with hex key.

Slide the feet up or down to attain the ideal measurement of 308mm from the floor to the centre of the

bowl fixing holes. The frame should be installed on top of the bottom plate (usually 45mm high). Please allow

for this height when adjusting the feet.

Ensure the adjustment is even by using a level, and tighten the bolts to set the height.

IMPORTANT: Protect electronic connection point and wires from accidental damage.

1 metre height label

(treat 1m as minimum).

Recommended to install frame with

1m mark at 1020mm from floor.

Hex key

Bidet water supply

Bowl fixing holes

Adjustable

Hex

key

support feet

Bottom

plate (nog)

Kohler Co. Jan 2018 6 1345889-A02-A

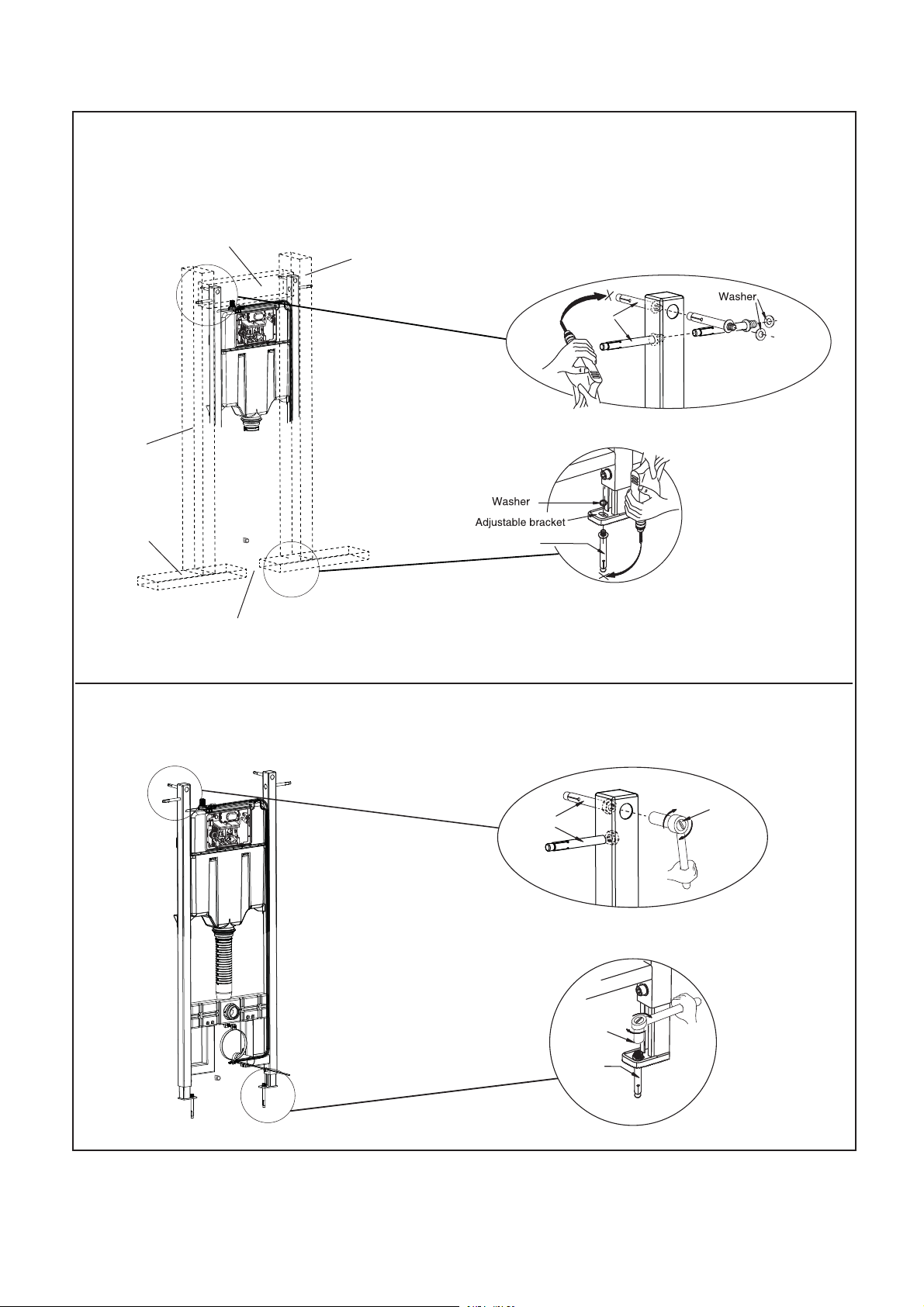

3. Construct a mounting frame to surround the in-wall tank. This should consist of vertical studs and a horizontal

nog,adjacent to the steel supports. If installation is an S-trap configuration, ensure the bottom plate has at least a

100mm cut-out in the centre for the discharge elbow.

If required, drill pilot holes with a drill as shown in Fig A and B.

Insert coach screws with washers into the installation holes in the framework, then tighten.

Repeat for all screws.

Nog

Stud

Coach

screw

Stud

Bottom plate

Gap for

discharge elbow

(S-trap install)

4. Tighten screw by wrench as shown in Fig A.

Tighten screw by wrench as shown in Fig B.

Recommend M6x40 coach

screw with 3mm washer.

Coach screw

Fig.#8

Coach

Screw

A

B

Socket

Wrench

A

Recommend M6x40 coach

screw with 3mm washer.

Socket

Wrench

Coach

Screw

Fig.#9

B

Kohler Co. Jan 2018 7 1345889-A02-A

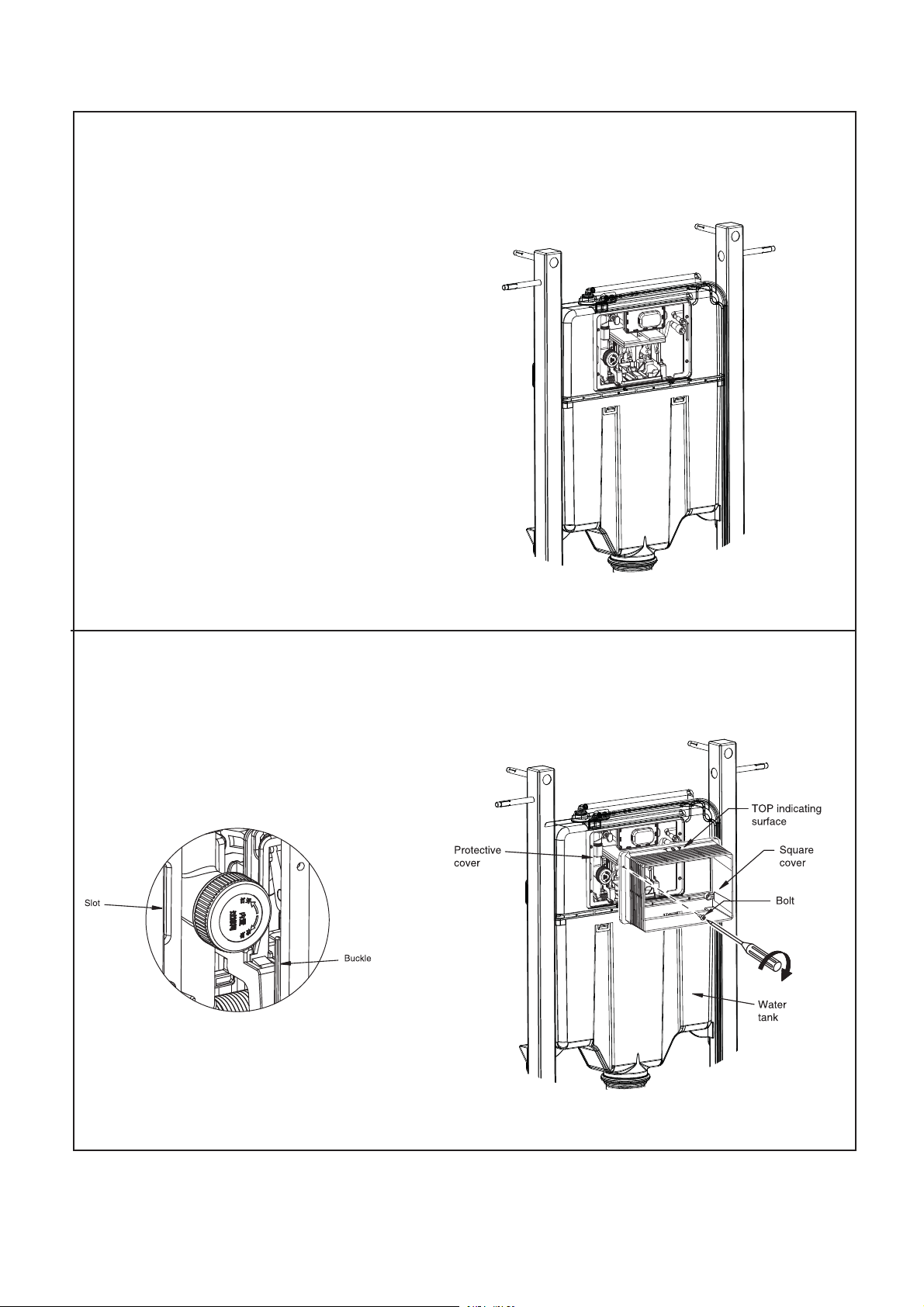

5. Ensure water tank internal valve is OFF.

6. Connect a temporary rubber or plastic hose onto

valve and flush the water supply line. Ensure

water is clean with no residual debris fouling the

inside of the pipeline.

Fig.#10

7. Place square cover within protection cover of water tank.

Snap the buckle into the slot and tighten square cover

bolts on tank.

NOTE: Square cover has the word TOP on it indicating

which surface should face upwards when installed.

Fig.#11

Kohler Co. Jan 2018 8 1345889-A02-A

Loading...

Loading...