Page 1

PowerWAVE 1000

(1–3 kVA)

User Manual

Page 2

TS_600_00 PW1000 1-3kVA User Manual 6/4/17

Page 3

TS_600_00 PW1000 1-3kVA User Manual 6/4/17

Document Control

PDF ISSUE DATE REVISION SUMMARY

TS_600_00 06/04/2017 First Issue

Page 4

TS_600_00 PW1000 1-3kVA User Manual 6/4/17

Uninterruptible Power Supplies Ltd has taken every precaution to

produce an accurate, complete and easy to understand manual and will

therefore assume no responsibility nor liability for direct, indirect or

accidental personal or material damage due to any misinterpretation of or

accidental mistakes in this manual.

© 2017 Uninterruptible Power Supplies Ltd

This manual may not be copied or reproduced without written permission

of Uninterruptible Power Supplies Ltd.

USEFUL CONTACTS

www.upspower.co.uk UPS Limited web site

service@upspower.co.uk Service department – booking service, fault reporting etc.

technical@upspower.co.uk Technical queries

sales@upspower.co.uk Hardware sales

servicesales@upspower.co.uk Extended warranty agreements etc

Page 5

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 I

Table of Contents

Safety 1

1.1 Description of symbols used in this manual 1

1.2 User precautions 1

1.3 Important safety notes 2

1.4 Storage instructions 2

General Description 3

2.1 Introduction 3

2.1.1 Advanced design features 3

2.1.2 PW1000 1-3kVA Model range 4

2.2 UPS Operating principles 4

2.2.1 Basic block diagram 4

2.2.2 System operating modes 5

2.3 Operator control panel 7

2.3.1 LED Indicators 7

2.3.2 Operator keypad 8

2.3.3 LCD Display 8

2.4 UPS Rear view 10

2.4.1 Communication Ports 10

2.5 External battery cabinet 12

2.6 Warranty 13

2.6.1 Extended warranty 13

2.6.2 Additional service/maintenance support 13

Installation 14

3.1 Unpacking the UPS equipment 14

3.2 Selecting a suitable installation location 14

3.2.1 Clearances 15

3.3 Assembling the UPS mounting hardware 17

3.3.1 Hardware accessories pack 17

3.3.2 Stand-alone Tower assembly 17

3.3.3 Rack installation 17

3.4 Assembling the external battery cabinet mounting hardware 20

3.4.1 Stand-alone tower installation 20

3.4.2 Combined tower installation 21

3.4.3 Rack installation 21

3.5 Electrical installation 22

3.6 Initial UPS power-up and commissioning 22

Operation 23

4.1 Introduction 23

4.2 UPS start-up procedures 24

4.2.1 How to start the UPS (from utility mains) 24

4.2.2 How to start the UPS (from battery) 25

Page 6

:

II TS_600_00 PW1000 1-3kVA User Manual 6/4/17

4.2.3 How the monitor the UPS input/output operating conditions 26

4.3 UPS shut down procedures 27

4.3.1 How to turn off the UPS (from ON INVERTER or ECO Mode) 27

4.3.2 How to turn off the UPS (from ON BATTERY Mode) 27

4.4 Manual load transfer between inverter and bypass 27

4.5 Functions menu 28

4.5.1 How to disable the alarm buzzer operation 28

4.5.2 How to perform a battery test 28

4.5.3 Functions menu 29

4.5.4 Operating parameters setting menu 30

Maintenance 31

5.1 Introduction 31

5.2 Scheduled maintenance 31

5.2.1 Preventative maintenance inspection 31

5.2.2 Battery maintenance and testing 31

Troubleshooting 33

6.1 Introduction 33

6.2 Fault identification 33

6.2.1 Error codes 33

6.2.2 Audible warning alarm 33

6.2.3 Warning symbols 34

6.3 Troubleshooting a fault condition 34

6.4 Troubleshooting an operational problem 35

6.5 UPS Fault handling 35

6.5.1 Output load short circuit when the output supply is via inverter 36

6.5.2 Output short-circuit when the output supply via the bypass line 36

6.5.3 Inverter/internal over-temperature 36

6.5.4 Inverter over-current and output voltage out of tolerance 36

6.6 UPS System reset 36

Options 37

7.1 Communications options 37

7.2 RS-232 Computer serial interface 37

7.3 Emergency Power Off (EPO) / Remote ON/OFF (ROO) 38

7.4 CS141 /SMNP adapters 38

7.5 AS400 (dry contact) card 39

Specification 40

Page 7

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 1

1

Safety

1.1 Description of symbols used in this manual

1.2 User precautions

WARNING: The warning symbol is used where there is danger of an electrical shock, equipment damage or

personal injury.

CAUTION: The caution symbol is used to highlight important information to avoid possible equipment

malfunction or damage.

WARNING: Do not attempt to install this UPS system until you are satisfied that you have read and understood

ALL the safety instructions and hazard warnings contained in this manual.

WARNING: Keep this manual with the UPS for future reference.

WARNING: DO NOT OPEN THE CASE. If you open the case of the UPS you will be exposed to dangerous

voltages. The UPS does not contain any user-serviceable parts, so do not attempt to repair this unit yourself as

doing so will void your warranty. If the UPS malfunctions it must be serviced or repaired by a trained engineer.

Always contact your local service agent if repair is necessary.

WARNING: Do not disconnect the power cord from the UPS AC Input socket while the UPS is turned on. The

UPS is equipped with an EMI filter, and to prevent a potential leakage current hazard the AC mains supply must

be securely grounded at all times. You should double check that the UPS supply earth connection is properly

grounded before you connect AC mains to the UPS.

WARNING: Uninterruptible Power Supplies Ltd will assume no responsibility or liability for accidents or injuries

due to incorrect operation or manipulation of the UPS or peripheral equipment.

CAUTION: The PW1000 1-3kVA is a Class A UPS product (according to EN 62040-3).

In a domestic environment the UPS may cause radio interference and the user may be required to undertake

additional measures.

Page 8

1: Safety

2 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

1.3 Important safety notes

1. The UPS warranty will become null and void if liquids are spilt on the UPS case, or foreign objects are dropped into

the unit. Such mishaps could severely damage the UPS and present a shock hazard to anyone who touches the unit.

2. The ventilation grills on the UPS front panel must be kept free of obstruction at all times.

3. The UPS is must be installed in a sheltered and controlled environment away from direct sunlight. The operating

temperature should be between 0~40°C (ideally 20°C) with relative humidity of 0~90%, non-condensing. Further

details concerning the installation environment are included in the installation chapter of this manual.

4. Before installing the equipment you must check to ensure that the input voltage stated on the UPS data-plate on the

back of the unit matches your local utility supply voltage.

5. The UPS warranty will be rendered void, and the manufacturer reserves the right to refuse replacement or

compensation, if the UPS malfunctions due to:

• Accidental damage to the UPS.

• Damage or malfunction due to installing the UPS in an environment that does not meet the conditions specified in

this manual.

• Damage or malfunction due to improper installation, configuration or maintenance carried out by an unauthorised

person.

1.4 Storage instructions

If you intend to store the UPS for an extended period, in a moderate climate, the batteries should be charged for 12 hours

every 3 months by connecting the UPS to the utility supply. If the ambient temperature at the storage location is above

25°C, this should be carried out every 2 months.

CAUTION: Please read the following notes carefully prior to installation and use.

CAUTION: Always switch off the UPS before moving it.

Page 9

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 3

2

General Description

2.1 Introduction

Congratulations on your purchase of the PW1000 1-3kVA UPS.

High reliability, low operating cost and excellent electrical performance are just some of the highlights of this innovative

UPS solution.

Uninterruptible Power Supplies Ltd. specialises in the installation and maintenance of Uninterruptible Power Systems; and

this UPS is just one example of our wide range of state-of-the-art power protection devices that will provide your critical

equipment with a steady and reliable power supply for many years.

2.1.1 Advanced design features

By using the latest technological developments in power engineering, the PW1000 1-3kVA represents a new generation of

transformerless UPS-System. Its advanced double conversion Voltage and Frequency Independent (VFI) topology

responds fully to both the highest availability and environmentally friendly requirements, compliant with IEC 62040-3 (VFISS-111) standards. A full UPS specification is provided in Chapter 8 of this manual.

Following, are some of this unit’s advanced design features:

• True online technology continuously supplies your critical applications with stable, regulated, transient-free pure

sine-wave AC power.

• High-Frequency Transformerless technology and tower-convertible enclosure enables the UPS to be integrated

into even the most difficult environments with space constraints.

• User-friendly design that permits simple and trouble-free installation. All units are supplied with input and output

power cables as standard.

• Smart battery management system which extends the battery life span.

• Highly efficient PWM sine-wave technology yields excellent UPS efficiency. The high crest factor of the inverter

handles peak inrush current loads and so avoids a need to upgrade to a UPS with a higher power rating.

• Compliant with various stringent international EMC standards for electromagnetic interference & protection.

• Selection of output voltages (200/208/220/230/240) available to match the UPS to local supply specifications or

specific load voltage requirements.

• A selectable bypass voltage tolerance (low/high sensitivity) restricts the range of voltages that can be applied to the

load when the UPS operates on bypass. The ranges are ±15% (low sensitivity) and ±10%V (high sensitivity). For

example, if the output voltage setting is 230V the bypass sensitivity Low range is 230V ±15%.

• Selectable 50Hz or 60 Hz operation.

• Fully digitized control logic for better functionality and enhanced power protection. Digital signal processing (DSP)

also provides efficient communication capabilities for enhanced remote control and monitoring flexibility.

• Active power factor correction (PFC) control function constantly maintains the UPS input power factor to >0.99 at

100% load, with resulting outstanding energy efficiency.

• Wide input voltage tolerance, from 110V~300V, allows the UPS to operate normally without draining the battery

unnecessarily during significant mains voltage dips, which helps extend the battery service life.

• DC-start function permits the UPS to be started during a utility power failure if required.

• Overload protection system automatically switches the UPS to bypass mode if an overload occurs and

automatically switch back to inverter mode once the overload condition ceases. Should the output become shortcircuited, the UPS puts the system in stand-by mode, provides visible and audible alarms, and turns off the output

supply automatically until the short circuit situation is resolved manually.

Page 10

2: General Description

4 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

2.1.2 PW1000 1-3kVA Model range

The PW1000 1-3kVA UPS range comprises 1 kVA, 2 kVA and 3 kVA models, each of which is designed as a selfcontained UPS comprising a rectifier, battery charger, inverter, static switch and battery pack. All the models in this range

are easy to install, and supplied with suitably terminated power cables.

The PW1000 1-3kVA operates as a stand-alone UPS module and can be mechanically configured as a floor-standing

tower unit or installed in a standard 19 inch rack. An accessory pack which contains all the parts necessary to configure

the unit for either type of installation is supplied with the UPS.

Optional external battery cabinets are available to increase the UPS autonomy time. The battery cabinet design

compliments the UPS cabinet and the two cabinets can be mechanically connected together to form a single unit when

installed as a tower system – see chapter 3 (Installation) for mechanical configuration details.

2.2 UPS Operating principles

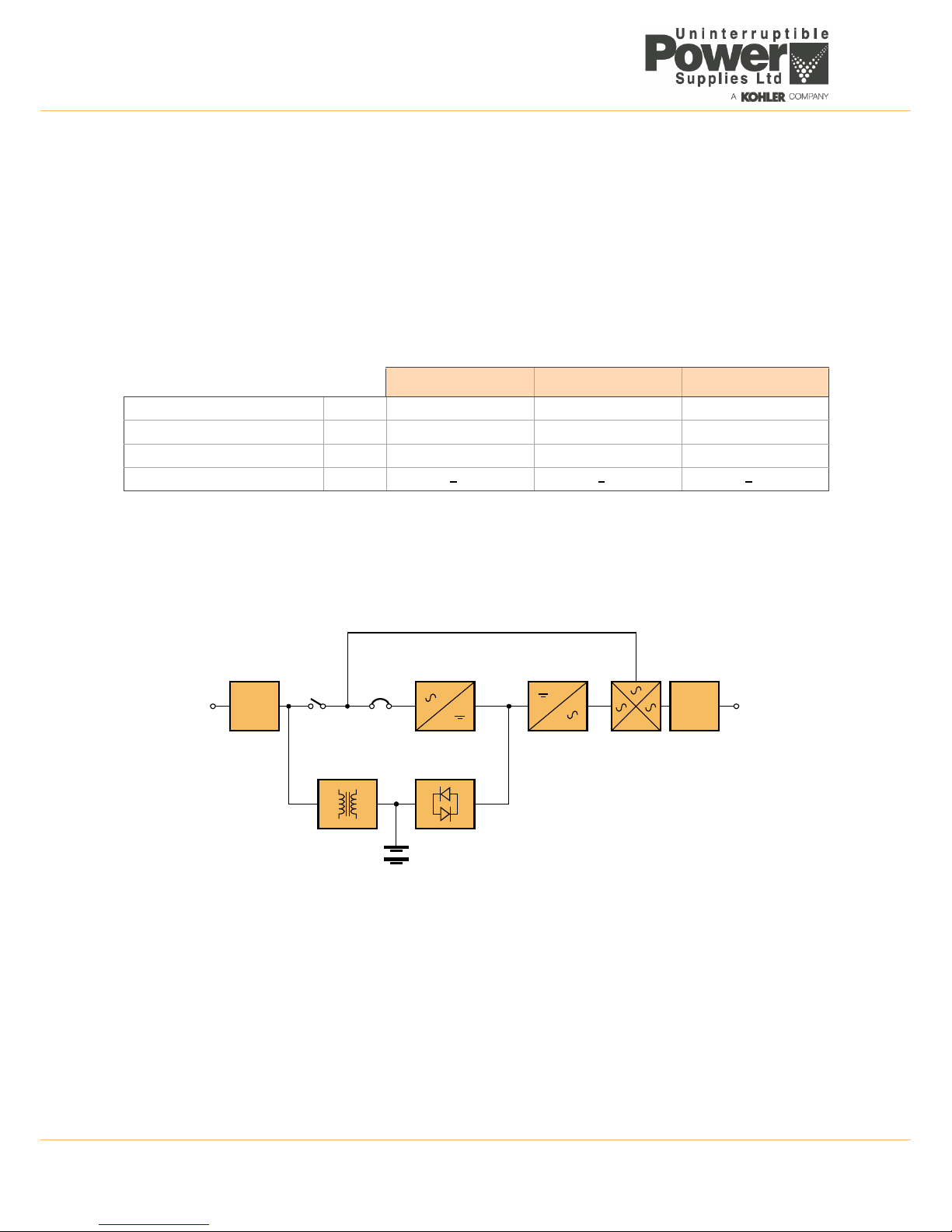

2.2.1 Basic block diagram

Figure 2.1 UPS Functional block diagram

EMI Filters

The UPS has an input and output EMI filter to reduce the effects of electromagnetic noise generated by the UPS on other

adjacent equipment – e.g. reduces external radio interference.

Battery charger

A regulated battery charger, power from the AC Input supply, charges the battery whenever the input supply is available.

DC/DC Boost converter

In times of AC Input supply failure, the DC/DC Boost Converter turns on and boosts the battery voltage to a level suitable

for use by the inverter. It provides a regulated DC output for the inverter while the battery voltage decays during discharge

and includes voltage and current monitoring and overload protection.

1 kVA 2 kVA 3 kVA

Maximum output power (0.9 pf) kVA (kW) 1.0 (0.9) 2.0 (1.68) 3.0 (2.7)

Dimensions (WxHxD) mm 440 x 88 x 400 440 x 88 x 600 440 x 88 x 600

Weight (with internal batteries) kg 12 22 26.5

Sound level dBA <

50 <50 <50

EMI

FILTER

EMI

FILTER

AC/DC (PFC)

CONVER TER

DC/AC

INVERTER

STATIC

SWITCH

BATTERY

CHARGER

DC/DC BOOST

CONVER TER

BATTERY

AC

Input

AC

Output

Bypass Line

Safety

Relay

Input

CB

Page 11

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 5

2: General Description

AC/DC Converter

As its name suggests, the AC/DC Converter converts the AC Input supply into a controlled DC supply that is suitable for

use by the inverter. The converter uses a leading-edge switched-mode technique which produces an input power factor of

almost unity over its full operating range (0.99 at full rated linear load) and thereby maximises the UPS efficiency.

The converter can satisfy the inverter DC power demands over an AC Input voltage range of between 110V~300V which

means that the battery is not called upon during power dips (brownouts), thereby maximising battery life and availability.

DC/AC Inverter

The inverter converts the DC voltage connected to its input, from the AC Input supply via the AC/DC converter or from the

battery via the DC/DC converter, and produces a regulated AC Output voltage that is suitable to power the connected load

equipment. The control logic associated with the Inverter power block is substantial, and in addition to the controlling the

output sine wave voltage it also provides various levels of overload protection, frequency regulation and synchronisation,

and output voltage error detection.

Static switch

The static switch provides a means of connecting the UPS AC Output (load) to the inverter output or the bypass line,

which is connected directly to the UPS AC Input. The control logic within this power block will transfer the load to the

bypass supply in the event of overload or UPS (inverter) malfunction. The load can also be transferred between the

inverter and bypass line manually if required. Note that a controlled transfer can take place only if the inverter and bypass

line are synchronised in frequency and phase.

2.2.2 System operating modes

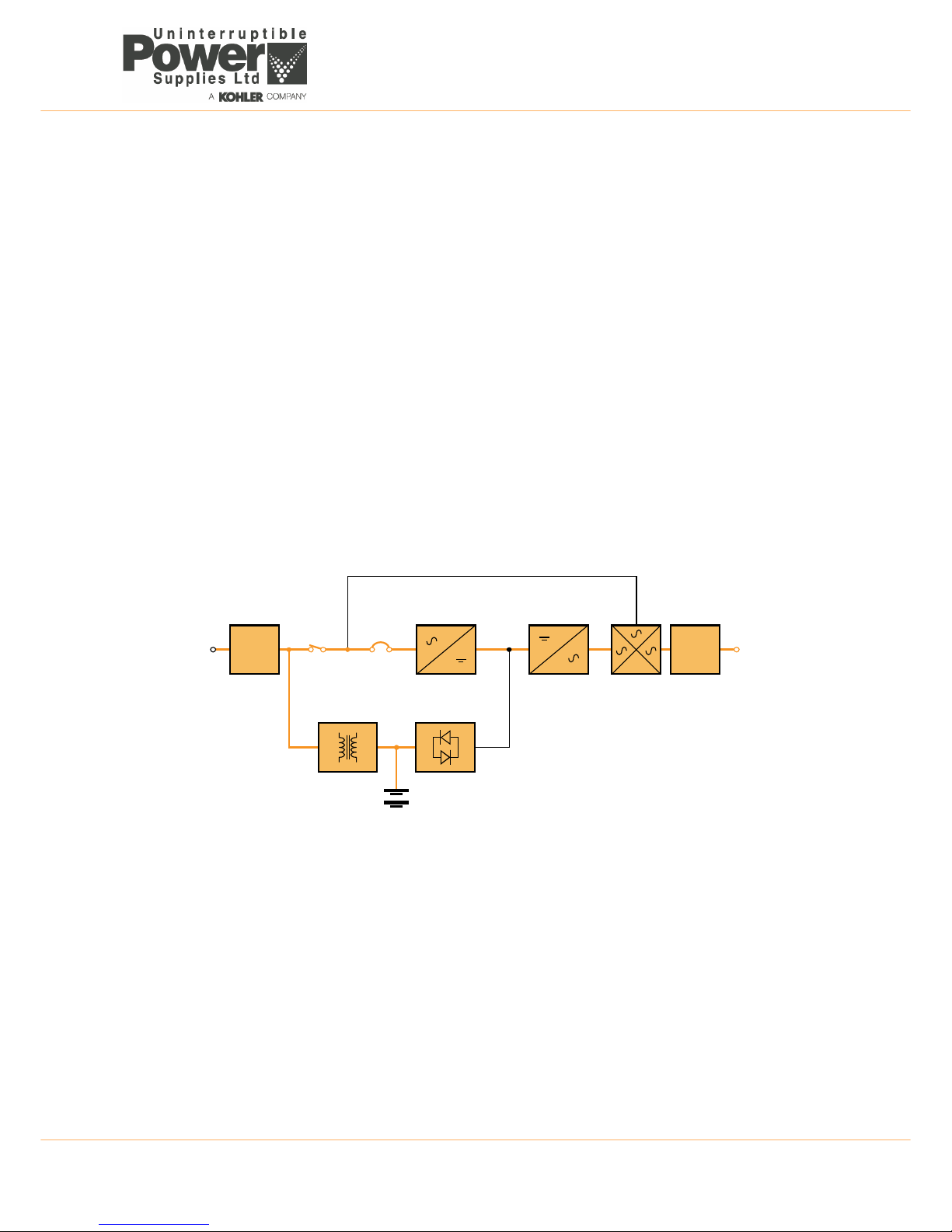

ON-INVERTER operation

Figure 2.2 ON-INVERTER operation

• The battery is being permanently charged by the battery charger.

• The AC/DC converter is processing the AC Input supply and turning it into controlled DC.

• The inverter is converting the AC/DC converter output back into AC suitable for the load.

• The static switch is connecting the inverter output to the UPS AC Output terminals.

EMI

FILTER

EMI

FILTER

AC/DC (PFC)

CONVER TER

DC/AC

INVERTER

STATIC

SWITCH

BATTERY

CHARGER

DC/DC BOOST

CONVER TER

BATTERY

AC

Input

AC

Output

Bypass Line

Safety

Relay

Input

CB

Page 12

2: General Description

6 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

ON BATTERY operation

Figure 2.3 ON-BATTERY operation

• The battery is discharging through the DC/DC boost converter which presents the inverter with a controlled input

voltage as the battery discharges.

• The Inverter is converting the DC/DC boost converter output back into AC suitable for the load.

• The static switch is connecting the inverter output to the UPS output terminals.

• The load will continue to receive its regulated power until the battery discharges to its low voltage cut-out level.

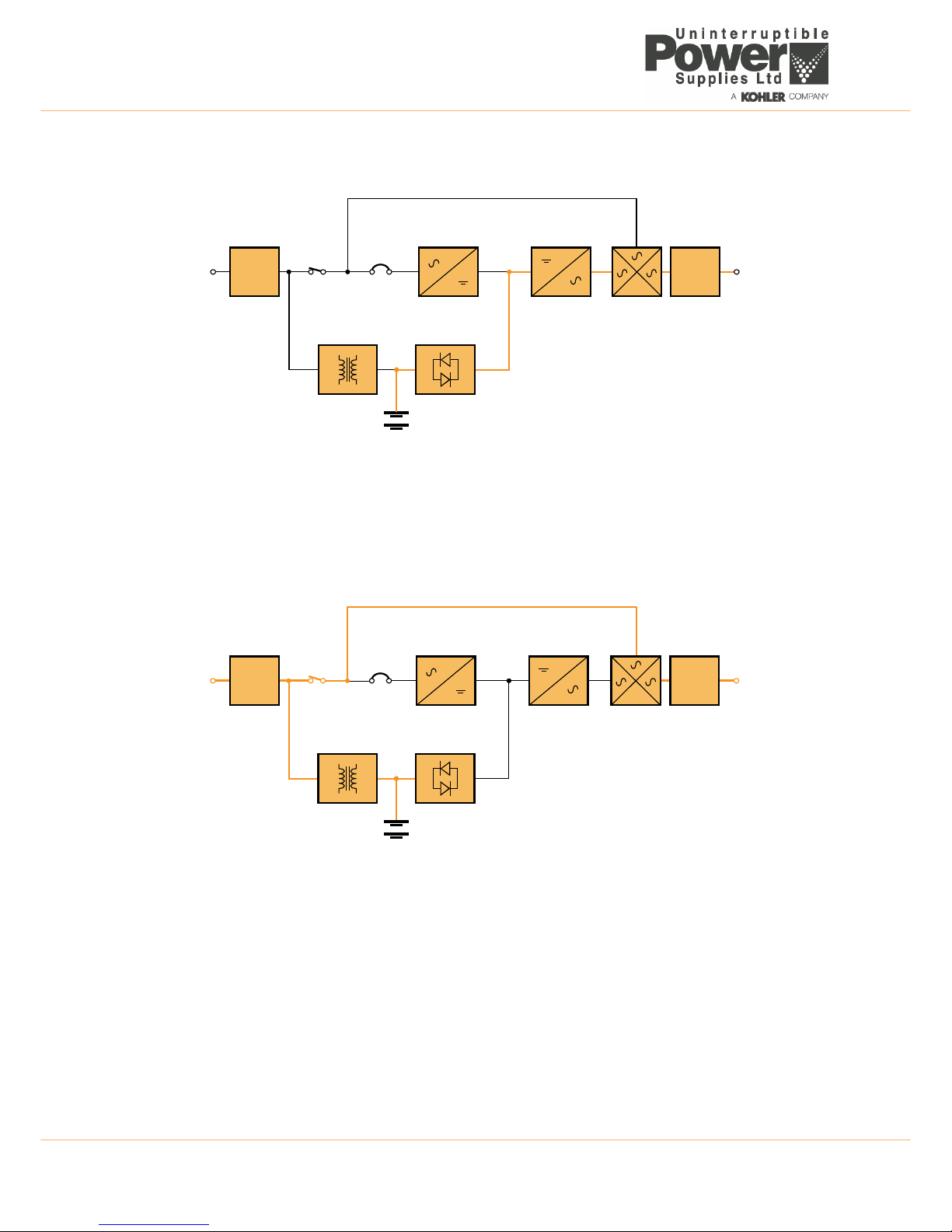

ON BYPASS operation

Figure 2.4 ON-BYPASS operation

• The battery is being permanently charged by the battery charger as long as the battery charger is still serviceable

and able to operate. If the load has transferred to bypass due to an internal malfunction the battery charger may

have shut down.

• The AC/DC converter, DC/DC boost converter and inverter are all inoperative.

• The static switch is connecting the bypass line to the UPS output terminals.

Note: When operating in this mode the load is unprotected from utility power disturbances.

EMI

FILTER

EMI

FILTER

AC/DC (PFC)

CONVER TER

DC/AC

INVERTER

STATIC

SWITCH

BATTERY

CHARGER

DC/DC BOOST

CONVER TER

BATTERY

AC

Input

AC

Output

Bypass Line

Safety

Relay

Input

CB

EMI

FILTER

EMI

FILTER

AC/DC (PFC)

CONVER TER

DC/AC

INVERTER

STATIC

SWITCH

BATTERY

CHARGER

DC/DC BOOST

CONVER TER

BATTERY

AC

Input

AC

Output

Bypass Line

Safety

Relay

Input

CB

Page 13

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 7

2: General Description

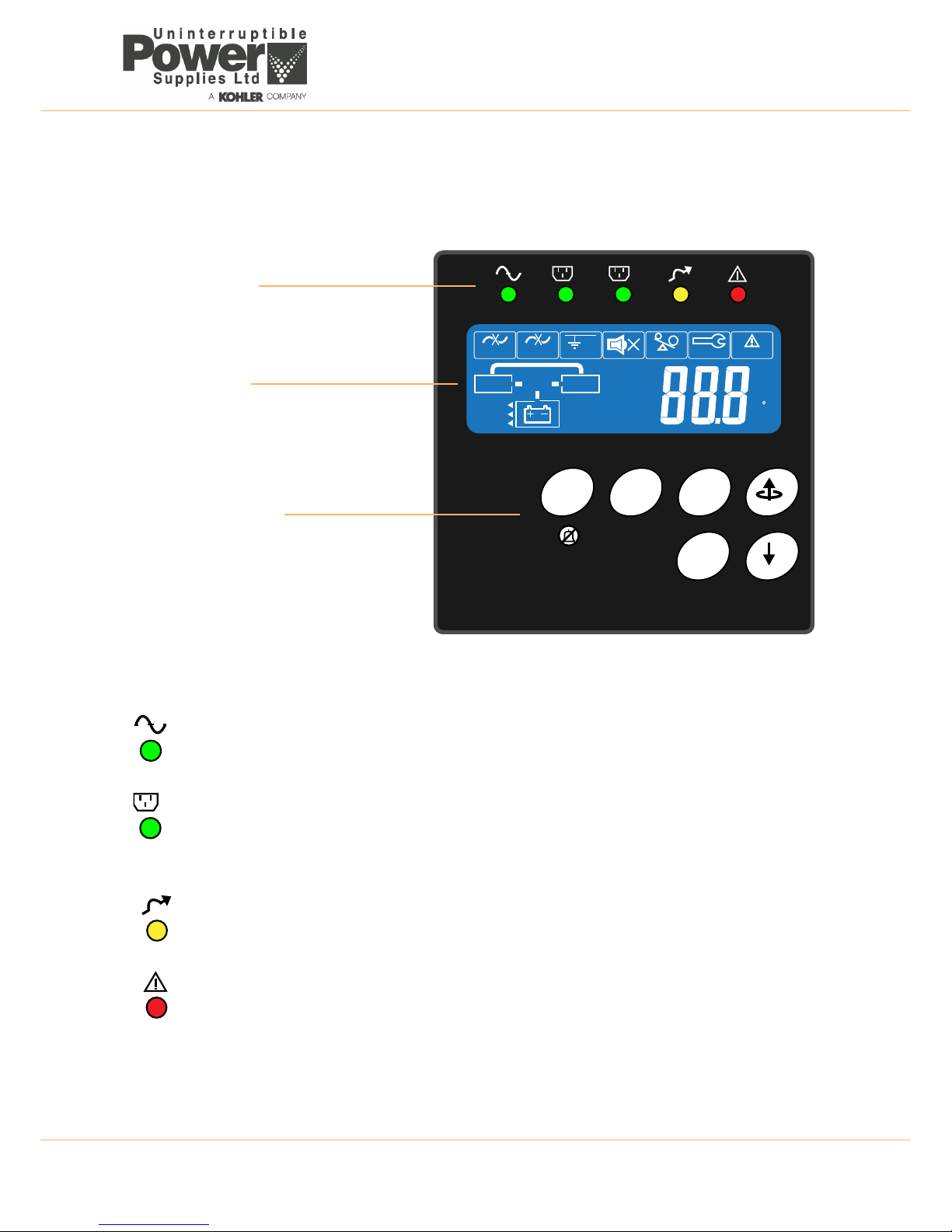

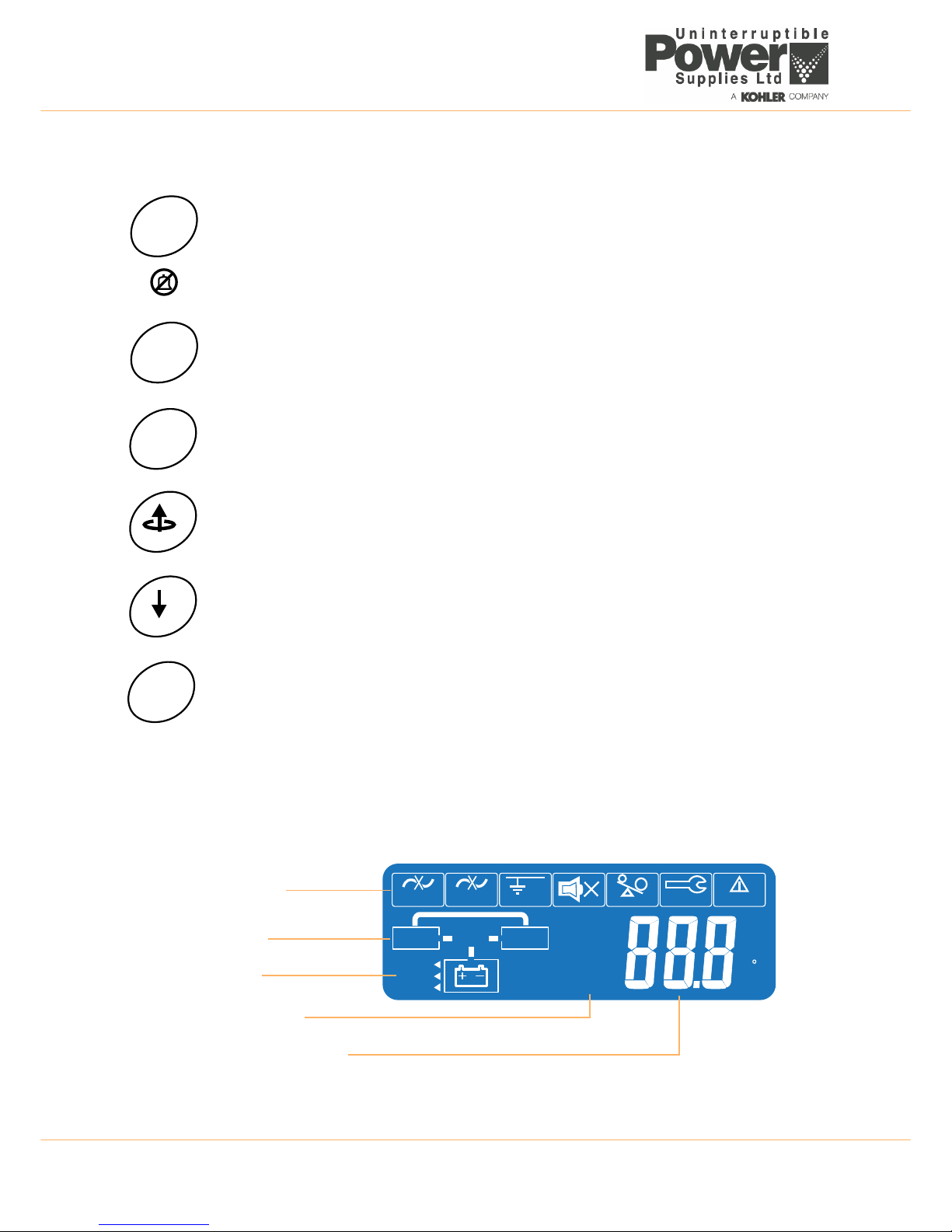

2.3 Operator control panel

The UPS is controlled from the operator control panel located on the front of the unit.

The user-friendly UPS control panel comprises three areas:

Figure 2.5 Operator control panel

2.3.1 LED Indicators

Input mains supply status

This led is permanently ON if the mains supply is within in the normal operating range of 160~300 VAC, and

flashes if the supply falls to 120~159 VAC. If the led is OFF it indicates a mains supply failure.

Programmable outlet status

The programmable outlets are normally connected to less critical loads which can be shed when the utility

power fails. This reduces the load on the battery as it discharges and thereby increases the back-up time for

the more critical loads which are connected to the unswitched UPS outlet(s). The indicators are permanently

ON when the outlets are live.

Bypass supply status

This led is permanently ON when the UPS is operating in the ECO mode and flashes when the load is

transferred to bypass – either manually or due to a detected fault.

UPS fault indication

This LED illuminates to indicate the presence of a fault condition within the UPS that needs attention. It is

usually accompanied by an audible alarm.

ON OFF Enter

Function

INPUT

UPS

LOAD

Service

Overload

Utility

?

Wiring Fault

Alarm

Bypass

Fault

Parallel IDMode

KVA

WHz

Mins

%

C

BypassStep

Utility Invert er

VoltageAdjust

Buzzer Code

BatteryAutonomy

FrequencyWindow

Low

Testi ng

1

2

Led indicators

A row of LEDs indicate the UPS input and

output power status, together with a

general fault warning.

LCD Display

Provides indication of the UPS operating

mode together with the input, output, and

battery supply parameters. It also displays

error messages and UPS set-up data via a

system of configuration menus.

Operator Keypad

The keypad contains 6 keys that are used

to navigate through the UPS control menu

system and turn the UPS OFF/ON.

1

Page 14

2: General Description

8 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

2.3.2 Operator keypad

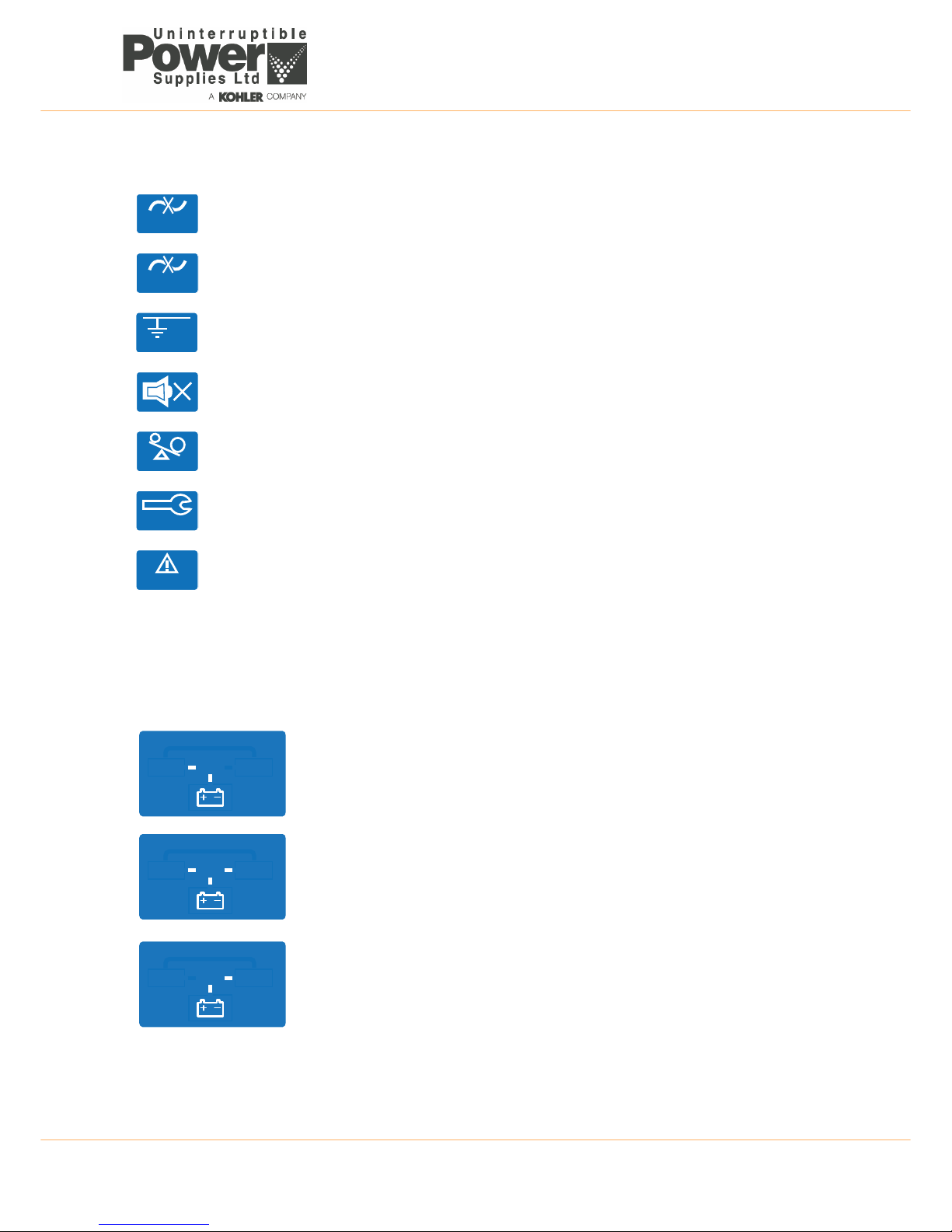

2.3.3 LCD Display

The LCD display contains a row of warning symbols, a mimic diagram which indicates the power path through the UPS, a

battery status indicator and a multi-function 3-digit numerical display which can be selected to indicate a range of

operating parameters. Each of these areas are described below.

Figure 2.6 LCD Display

ON Button

This button is used to turn ON the UPS and activate certain functions when operated in combination

with other buttons (as described later in this chapter). The button must be pressed for approximately

one second to turn ON the UPS – accompanied by double ‘beep’.

This symbol shows that the ON button is also used to cancel the audible alarm. When the alarm is

cancelled, the audible warning will turn OFF but the alarm LED will remain ON if the fault is still present.

OFF Button

This button must be pressed for approximately one second to turn OFF the UPS – accompanied by

double ‘beep’.

ENTER Button

The ENTER button is used to select a parameter from the UPS monitoring and configuration menus.

UP (BACK) Button

This button is used to navigate UP through the UPS menus, or change a menu parameter. It is also

used with the ON button to manually transfer the load between the UPS and bypass supply.

DOWN (NEXT) Button

During normal operation, this button is used to scroll through the metered parameters shown on the

LCD display. It is also used in conjunction with the ON button to access the UPS configuration menus.

FUNCTION Button

This button is used to access the UPS configurations display menu.

ON

OFF

Enter

Function

INPUT

UPS

LOAD

Service

Overload

Utility

?

Wiring Fault

Alarm

Bypass

Fault

Parallel ID Mode

KVA

WHz

Mins

%

C

Bypass Step

Utility Inverter

VoltageAdjust

Buzzer Code

BatteryAutonomy

Frequency Window

Low

Testing

Warning symbols

Mimic diagram

Battery status

Metering parameters

3-Digit alpha-numeric display

Page 15

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 9

2: General Description

Warning symbols

Mimic diagram

The LCD Mimic diagram indicates the existing power flow through the UPS. The INPUT, UPS, LOAD and BATTERY

symbols are permanently shown on screen and their interconnecting lines appear, or disappear, depending on the UPS

mode of operation – see the table below.

Bypass input abnormal:

UPS fails to transfer to bypass, bypass abnormal in ECO mode

Utility input abnormal:

The utility mains supply is outside the UPS pre-set operating window

Wiring fault:

Site wiring problem such as reversed Line-Neutral connection

Alarm buzzer silent

The alarm buzzer has been silenced or disabled

Overload:

The UPS output is overloaded

Service:

The UPS is operating in its service mode

Alarm:

An alarm condition is present. This remains active after the audible alarm is reset if the alarm still exists.

UPS OFF

This mimic is displayed when the utility power is first applied to the UPS, or if the UPS is

turned OFF. It shows that the battery is being charged from the utility supply (INPUT) but

the LOAD is not connected to the UPS, and is therefore unpowered.

ON INVERTER

This mimic is displayed during normal UPS operation. It shows the battery being

charged from the utility supply (INPUT) and the LOAD connected to the UPS output

(Inverter), and is therefore being supplied with processed, backed-up power.

ON BATTERY

This mimic is displayed if the utility supply fails. It shows the battery now providing the

UPS (Inverter) and LOAD power. The battery will sustain the UPS output until it is fully

discharged, whereupon the UPS will shut down.

Bypass

Utility

?

Wiring Fault

Overload

Service

Alarm

INPUT

UPS

LOAD

INPUT

UPS

LOAD

INPUT

UPS

LOAD

Page 16

2: General Description

10 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

Battery status indicators

There are three ‘flags’ to the left of the battery icon which indicate the battery status.

Fault

Indicates a battery fault and is normally accompanied by an illuminated Alarm warning symbol

and an audible warning from the buzzer. An error code will be shown on the LCD 3-digit

alphanumeric display which helps with fault identification.

Low

When the UPS is operating ON BATTERY the Low flag will turn on when the battery is nearing its end of discharge. This is

accompanied by an increase in the number of short successive beeps produced by the alarm buzzer.

Testing

The Testing flag flashes when a battery test is operation – see paragraph 4.5.2.

Meter Display

When the UPS is turned ON, you can use the DOWN and UP buttons to scroll through the measurement display screens.

The display sequence is as numbered in the table below and loops around in either direction.

2.4 UPS Rear view

2.4.1 Communication Ports

Several communication options can connected to the PW1000 1-3kVA. These are described briefly below with further

details provided in Chapter 7 (Options).

USB port (Figure 2.7 item 3)

A USB type B socket is provided to allow the UPS to be connected to a PC using a standard USB peripheral interface

cable. The USB communication protocol complies with USB version 1.0 (1.5 Mbps) and USB HID version 1.0. This facility

can be used in conjunction with UPS monitoring and shut down software (not supplied).

RS-232 Interface port (Figure 2.7 item 2)

The RS-232 port allows the UPS to be connected to a PC and provides the same functions as the USB port.

Emergency power off (EPO) (Figure 2.7 item 1)

If an external emergency power off (EPO) facility is required, the external circuit must be connected to the two pin plug

located on the rear panel. A plug-in connector with screwed terminal connections is supplied ready fitted to the EPO

socket to simplify the connection of the external cable if the UPS is located in a confined space, such as when it is rack

mounted. The EPO input requires a normally-open contact which closes to active the EPO function. If the UPS is shut

down by the EPO input (closed), it has to be restarted manually after the EPO input is removed (opened).

Optional interface cards (Figure 2.7 item 4)

An optional SNMP/ CS141 interface card can be fitted in the card slot to enable the UPS to be integrated into a network

monitoring and control system.

ON BYPASS

This mimic is displayed if the UPS develops a fault, or is overloaded, whereupon the

LOAD is transferred to the bypass line and connected directly to the utility supply

(INPUT). The battery will remain on charge if the UPS battery charger is healthy.

1 Utility Voltage (V) 4 Inverter Frequency (Hz) 7 Battery Voltage (V)

2 Utility Frequency (Hz) 5 Inverter Load % 8 Battery Autonomy (mins)

3 Inverter voltage (V) 6 Inverter Load (A) 9 UPS Temperature (°C)

INPUT

UPS

LOAD

INPUT

UPS

LOAD

Fault

Low

Testi ng

Page 17

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 11

2: General Description

Figure 2.7 Rear panel detail

AC INP UT

AC OUTPUT

INPUT BREAKER

EXT>BAT.

INTERFACE

12

EPO

RS232USB

AC OUTPUT

INPUT BREAKER

INTERFACE

AC INPUT

1

2

EPO

RS232USB

AC OUTPUT

INPUT BREAKER

BREAKER

OUTPUT

BREAKER

OUTPUT

INTERFACE

AC INPUT

AC OUTPUT

1

2

EPO

RS232USB

1

2

3

810 9

10

4 6 7

5

8

8

1 kVA

2 kVA

3 kVA

Model

Model

Model

1 Emergency Power Off (by dry contact) 7 Unswitched AC Outlets

2 RS232 Port 8 Two switched (programmable) AC outlets

3 USB Port 9 Mains input supply circuit breaker

4 Communications card options slot 10 Cooling fans

5 External battery connector 11/12 Output circuit breaker (CB) for AC Outlets 7/8

6 AC Input (utility mains) power socket 13 16A Unswitched AC Outlet

7

9

56 4 7

1

2

3

114 896 7

510 7813 12

1

2

3

Page 18

2: General Description

12 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

2.5 External battery cabinet

An external battery pack can be connected to the UPS to extend the UPS autonomy time, where required. The batteries

are contained in a purpose-designed, matching cabinet which can be installed as a stand-alone unit or attached to the

UPS cabinet to form a single tower assembly.

When the external battery cabinet is rack-mounted it should be installed immediately below the UPS cabinet.

Note: If required, up to three external battery cabinets can be connected to the UPS – see Figure 2.8.

The following external battery cabinets are available:

Figure 2.8 External battery cabinet

Up to three external battery cabinets can be added to the UPS system by connecting the output cable of the first cabinet

(5) to the input connector of the second cabinet (4).

230V–1kVA 230V–2kVA 230V–3kVA

Battery voltage 36V 72V 72V

Battery number and capacity 6x 7Ah 12x 7Ah 12x 9Ah

Battery strings 2x Strings of 3 batts. 2x Strings of 6 batts. 2x Strings of 6 batts.

Dimensions (WxHxD) in/mm 17.3 x 3.5 x 15.8 in (2U)

440 x 88 x 400 mm

17.3 x 3.5 x 23.6 in (2U)

440 x 88 x 600 mm

17.3 x 3.5 x 23.6 in (2U)

440 x 88 x 600 mm

Weight kg/lb 11kg / 24.25lb 17.5kg / 38.6lb 17.5kg / 38.6lb

DC BREAKER

To Ext. Battery

UPS. BAT.

1 2 543

1 DC Breaker (option) – Battery over-current protection

2 DC Fuses – Battery over-current protection

3 Earth – Safety earth bonding

4 Input connector – For additional extended battery cabinets

5 DC Power cord – Battery cable to UPS cabinet

Page 19

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 13

2: General Description

2.6 Warranty

The PW1000 1-3kVA UPS is supplied with a limited warranty that the UPS and its component parts are free from defects

in materials and workmanship for a period of one year from the date of commissioning or fifteen months from the date of

original delivery, whichever is the sooner. This warranty is the only warranty given and no other warranty, expressed or

implied, is provided.

This warranty does not apply to any losses or damages caused by misuse, abuse, negligence, neglect, unauthorised

repair or modification, incorrect installation, inappropriate installation environment, accident, act of God, or inappropriate

application. If the UPS fails to conform to the above within the warranty period then Uninterruptible Power Supplies Ltd.

will, at its sole option, repair or replace the UPS. All repaired or replaced parts will remain the property of Uninterruptible

Power Supplies Ltd.

As a general policy, Uninterruptible Power Supplies Ltd. does not recommend the use of its products in:

• life support applications where failure or malfunction of the product can be reasonably expected to cause failure of

the life support device, or to significantly affect it’s safety or effectiveness.

• applications concerned with direct patient care.

Uninterruptible Power Supplies Ltd. will not knowingly sell its products for use in such applications unless it receives in

writing assurances satisfactory to Uninterruptible Power Supplies Ltd. that:

• the risks of injury or damage have been minimized.

• the customer assumes all such risks.

• the liability of Uninterruptible Power Supplies Ltd. is adequately protected under the circumstances.

2.6.1 Extended warranty

The standard warranty may be enhanced by protecting the UPS with an extended warranty agreement (maintenance

contract).

An extended warranty agreement enhances the standard warranty by providing the following:

• regular preventative maintenance inspections.

• guaranteed speed of response to operational problems.

• 24 hour telephone support.

• fully comprehensive cover (excluding batteries and capacitors).

Contact the Service Support Hotline on 0800 731 3269 for further details.

2.6.2 Additional service/maintenance support

In addition to providing support for the PW1000 1-3kVA UPS, Uninterruptible Power Supplies Ltd. can provide

maintenance and support on a wide range of different UPS products. If you are interested in an extended warranty for your

PW1000 1-3kVA UPS, or for any other UPS products you may have, please contact us at the following address:

CAUTION: The UPS contains batteries that must be re-charged for a minimum of 12 hours every three months

to prevent deep-discharging. Batteries that have been deep-discharged, for whatev er reason, are not covered

by this warranty.

Uninterruptible Power Supplies Ltd.

Woodgate

Bartley Wood Business Park

Hook

Hampshire

RG27 9XA

Tel: 01256 386700

0800 731 3269 (24 Hr.)

Fax: 01256 386701

Email: service@upspower.co.uk

Page 20

14 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

3

Installation

3.1 Unpacking the UPS equipment

The manufacturer has designed robust packaging for your product to help ensure it reaches you in good order; however,

accidents and damage may sometimes occur during shipment. You should inspect the UPS carefully upon receipt and if

there are signs of damage you must inform the carrier and dealer immediately.

Save any recyclable packaging for re-use or dispose of it appropriately and correctly.

1. Remove the UPS from the packing carton.

2. Check the package contents. The standard unit includes:

a) User Manual.

b) IEC output cables (for UPS with IEC sockets only).

c) IEC input power cable (for UPS with IEC sockets only).

d) A UPS accessories kit which allows the UPS to be configured for Tower or Rack installation.

3. Before proceeding, check the data plate on the rear of the UPS and verify that the unit’s voltage and power ratings

comply with the equipment order details. Contact the dealer immediately if this is incorrect.

3.2 Selecting a suitable installation location

As the UPS weighs several kilograms, the location where it is to be installed must be able to safely support its weight.

To ensure correct operation and a long service life, always install the UPS in accordance with the following environmental

standards:

• The ambient temperature and humidity must be within the limits specified in Chapter 8 of this manual. The battery

temperature must be maintained at 20°C to ensure its lifespan is not reduced

• The UPS is not designed for outdoor use

• The installed location must be clean, dry and free of excessive dust

• The UPS must not be installed in a corrosive environment or in the vicinity of flammable items

• The ventilation grills at the front of the UPS and extractor fans at the rear of the UPS must not be obstructed

• The UPS equipment must be installed with the clearances illustrated in Figure 3.2 as a minimum

CAUTION: Read the safety information contained in chapter 1 before installing the UP S.

WARNING: Under no circumstances should you connect electrical power to a damaged unit or attempt to

start it using its internal batteries.

Page 21

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 15

3: Installation

3.2.1 Clearances

Figure 3.1 Tower installation clearances

Figure 3.1 shows the required clearances when planning a PW1000 tower installation. The total width of the system

hardware can range from 88mm, for a stand-alone UPS cabinet, up to 352mm where the maximum of three (optional)

battery cabinets are attached to the UPS cabinet – only one battery cabinet shown in the diagram above.

The left hand diagrams show the ‘operating’ clearances necessary to provide adequate cooling. For maintenance, at least

800mm side access is required, and where necessary the cables connected to the UPS should be made sufficiently long

to allow the UPS to manoeuvred to a position where the clearances shown in the right hand diagrams are obtainable.

Y Z

A

Front

A1 B11400mm

1000mm

Min. Clearance

For Maintenance

A

B

C

TOP

200mm

200mm

800mm

400mm

Min. Clearance

Normal Operation

A

B

C

TOP

200mm

200mm

800mm

400mm

Min. Clearance

Normal Operation

Y

B B

B1

A1

Y

C

Y

Z Z

Up to 3 battery cabinets can

be connected to the UPS

making maximum total

system width of 352mm

Y

Z

UPS Cabinet

88 x 405mm

Battery Cabinet

88 x 405mm

Notes

Up to 3 battery cabinets can

be connected to the UPS

making maximum total

system width of 352mm

Y

Z

UPS Cabinet

88 x 405mm

Battery Cabinet

88 x 405mm

Notes

A

Front

A

B

C

TOP

200mm

200mm

800mm

400mm

Min. Clearance

Normal Operation

A

B

C

TOP

200mm

200mm

800mm

400mm

Min. Clearance

Normal Operation

B B

B1

A1

C

Up to 3 battery cabinets can

be connected to the UPS

making maximum total

system width of 352mm

Y

Z

UPS Cabinet

88 x 600mm

Battery Cabinet

88 x 600mm

Notes

Up to 3 battery cabinets can

be connected to the UPS

making maximum total

system width of 352mm

Y

Z

UPS Cabinet

88 x 600mm

Battery Cabinet

88 x 600mm

Notes

A1 B11600mm

1000mm

Min. Clearance

For Maintenance

A1 B11600mm

1000mm

Min. Clearance

For Maintenance

Z

PW1000 1kVA

(Tower Clearances)

PW1000 2kVA / 3kVA

(Tower Clearances)

Y Z

A

Front

A1 B11400mm

1000mm

Min. Clearance

For Maintenance

A

B

C

TOP

200mm

200mm

800mm

400mm

Min. Clearance

Normal Operation

Y

B B

B1

A1

Y

C

Y

Z Z

Up to 3 battery cabinets can

be connected to the UPS

making maximum total

system width of 352mm

Y

Z

UPS Cabinet

88 x 405mm

Battery Cabinet

88 x 405mm

Notes

A

Front

A

B

C

TOP

200mm

200mm

800mm

400mm

Min. Clearance

Normal Operation

B B

B1

A1

C

Up to 3 battery cabinets can

be connected to the UPS

making maximum total

system width of 352mm

Y

Z

UPS Cabinet

88 x 600mm

Battery Cabinet

88 x 600mm

Notes

A1 B11600mm

1000mm

Min. Clearance

For Maintenance

Z

PW1000 1kVA

(Tower Clearances)

PW1000 2kVA / 3kVA

(Tower Clearances)

Page 22

3: Installation

16 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

Figure 3.2 Rack mounted installation clearances

When the UPS is rack-mounted a minimum of 200mm should be available between the rear of the UPS and the back of

the rack cabinet to enable adequate ventilation and provide space for cabling. It is permissible to install the PW1000 1kVA

model in a cabinet with a depth of 600mm, although this will only provide 195mm rear clearance rather than the desired

200mm shown in the above diagram.

The rack cabinet must have a ventilated door and a minimum clearance of 800mm must be provided at the front and rear

of the cabinet to allow full UPS access for installation and maintenance.

B

PW1000

1.0 kVA

(440x405mm )

600 mm

Rack

Front

A

B

PW1000

2.0 / 3.0 kVA

(440x600mm)

800 mm

Rack

Front

A

C1

C1

C1

C2

800mm

800mm

0mm

115°

A

B

C1

D

Min. Clearance

250mmC2

D D

It is necessary to open the door fully to fit/

remove the assembly. If the cabinet is

placed against a wall ensure sufficient

space is provided (C2).

The rack doors must be ventilated.

E

E

200mm E

Page 23

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 17

3: Installation

3.3 Assembling the UPS mounting hardware

3.3.1 Hardware accessories pack

The accessories pack which is shipped inside the UPS packing carton contains all the hardware required to safely install

your UPS as a tower or rack-mounted system.

Figure 3.3 Accessories pack

3.3.2 Stand-alone Tower assembly

1. Turn the UPS on its side and,

using screws (D) provided,

attach the four tower feet (A) to

the base of the enclosure as

shown in Figure 3.4.

Note: You will have to remove

the M3 screws already fitted to

the UPS side panels in order to

make way for the new feet

attachments.

2. Carefully lift the assembly and

stand it on its feet.

3. If necessary, rotate the UPS

LCD control panel so that it is

correctly orientated. To achieve

this, carefully pull the control

panel forward to unclip it from its

mounting, rotate it to the correct angle, then relocate it and press it back into place.

4. This completes the tower hardware configuration.

3.3.3 Rack installation

The PW1000 1-3kVA UPS and battery enclosure(s) can be installed on adjustable mounting rails fitted in a standard 19

inch rack. If the UPS is to be connected to an external batteries, you should install the battery cabinet(s) immediately

below the UPS following the same procedure as for mounting the UPS. The UPS/Battery enclosures are then connected

together using the supplied cable.

Due to their relative weights, it is preferable to mount UPS and battery enclosures near the bottom of the rack.

Key Point: Always mount the batteries below the UPS and as far away from other heat-generating sources as

possible.

A

B

C

D E F

G

A x4 Tower feet E x8 M3 x 6mm Countersunk

B x2 Rack mounting handles F x6 M4 x 8mm Countersunk

C x2 Rack mounting side-plates G x1 EPO connecting socket

D x8 M3 x 6mm Domed

A

D

Figure 3.4 Tower assembly

Page 24

3: Installation

18 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

Rack mounting handles

When rack-mounting the UPS, mounting handles are attached to the front of both side of the UPS. These are used to help

you when inserting/removing the UPS and also provide a means of securing the UPS once it is in position.

Figure 3.5 Rack mounting handles

1. Attach the rack-mounting handles (B) to the side-plates (C) using three M4x8mm countersunk screws (F).

2. Secure the side-plates to the front of both sides of the UPS, as shown, using four M3x6mm countersunk screws (E).

Note: You will have to remove the M3 screws already fitted to the UPS side panels in order to make way for the new

handle attachments.

Adjustable mounting rails

Figure 3.6 UPS Rack mounting kit

E

B

C

F

B1 1 x Adjustable mounting rail (Left)

B2 1 x Adjustable mounting rail (Right)

B3 2 x Adapter plate

B4 2 x Rack mounting handle

B5 12 x Captive nuts

B6 8 x Dome head bolts

B1

B4B3 B5

B6

B7

B2

B1

B2

Page 25

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 19

3: Installation

The adjustable mounting rail kit contains a pair of mounting rails (left and right handed) that are fitted to each side of the

cabinet and secured by two screws – front and back. The length of the rails is adjustable between 543 mm and 925 mm,

making them compatible with most standard 19 inch rack assemblies of 600 mm to 900 mm depth.

1. Extend the adjustable mounting rail and hold in place (see Figure 3.6).

2. Align the two holes in the back of the adjustable mounting rail with the holes in the cabinet’s

vertical fixing rail (see Figure 3.7).

3. Identify and mark the two vertical fixing rail holes to which the adjustable mounting rail is to

be fixed.

4. Clip captive nuts (B5) to the two vertical fixing rails holes identified above.

5. Secure the rear of the adjustable mounting rail to the vertical fixing rail using two dome

headed bolts (B6).

6. With the rear of the adjustable mounting rail secured in place, and the adjustable mounting

rail extended, identify the four fixing points that will align with the equipment mounting

handles and clip four captive nuts to the required fixing points.

7. Secure the adjustable mounting rail to the rack’s front vertical fixing rail using two

countersunk bolts (B7) and adapter plate (B3) (see Figure 3.8).

8. Repeat the above steps to fit the second adjustable mounting rail.

Figure 3.8 2U Adjustable rail front mounting

9. When both mounting rails are fitted, carefully insert the UPS / Battery enclosure into the rack so that it rests correctly

on the rails. Then secure it in place using the four dome head bolts (B6) as shown in Figure 3.8.

WARNING: The UPS / Battery enclosure is heavy. When lifting the equipment ensure that adequate manpower

is available and any mechanical lifting aids are suitable for the weights involved.

WARNING: When inserting the enclosure into the rack ensure that it is held level. If it is inserted at an angle it

could pivot about the back of the mounting rail runners if the front of the enclosure is tilted upwards.

B6

B2

Figure 3.7

B5

B3

B7

B6

Adjustable rail

Rack fixing rail

Adapter plate

B3

Page 26

3: Installation

20 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

3.4 Assembling the external battery cabinet mounting hardware

If an optional external battery cabinet is included as part of the UPS system it can be installed in one of three ways:

• as a stand-alone tower unit located adjacent to, but independent of, the UPS cabinet

• as a ‘combined tower,’ where the battery cabinet is attached to the UPS cabinet to form a single tower assembly

• rack-mounted immediately below the UPS cabinet

The hardware accessories pack which is shipped inside the packing carton contains all the hardware required to safely

install the battery cabinet using either of these methods.

Figure 3.9 External battery cabinet hardware kit

3.4.1 Stand-alone tower installation

1. Attach the four tower feet to the base of the cabinet in the same manner described in paragraph 3.3.2 for the main

UPS cabinet.

2. Stand the battery cabinet on its feet and place it adjacent to the UPS cabinet, as shown below.

Figure 3.10 Battery cabinet tower assembly

A B C

E F

G

A x4 Tower feet F x6 M4 x 8mm Countersunk

B x2 Rack mounting handles G x2 Cabinet attachment link

C x2 Rack mounting side-plates H x1 6-pin Anderson securing plate

D x8 M3 x 6mm Domed I x1 4-pin Anderson securing plate

E x8 M3 x 6mm Countersunk

H I

D

A

D

Page 27

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 21

3: Installation

Connect the battery cabinet to the UPS

1. On the UPS back panel, remove the screw securing the

hinged battery connector cover plate and let the cover plate

fall open.

2. Connect the DC cable from the battery cabinet to the

external battery connector on the back of the UPS cabinet.

3. With the battery cable inserted, fit the Anderson securing

plate over the battery connector plug.

4. Attach the Anderson securing plate (H) or (I) to the UPS

back panel using the screw you previously removed from

the hinged cover plate.

5. Remove the screw from the protective earth terminal on the

UPS rear panel.

6. Connect the earth tail from the DC cable to the UPS cabinet

chassis earth.

7. This completes the mechanical installation.

3.4.2 Combined tower installation

Figure 3.12 shows the method used to join the

battery cabinet to the UPS cabinet. This entails fitting

a small cabinet attachment link (G) between the

cabinets at the top and bottom and only fitting the

feet to the cabinets’ outer-edge. Proceed as follows:

1. Determine which side the battery cabinet is to be

installed relative to the UPS cabinet (either side

is permissible).

2. Remove the centre screws from mid-way along

the cabinet inner-sides where the attachment

links (G) are to be fitted. Note that a link is fitted

to the top and bottom of the cabinets, as shown

in Figure 3.12.

3. Lay the battery cabinet on its side and attach the

feet to its outer edge only (see Figure 3.10).

4. With the battery cabinet still on its side (with the

feet pointing downwards), carefully place the

UPS cabinet on top of the battery cabinet and fit

the two attachment links using the supplied

dome-headed screws (D). Ensure that the front

of the cabinets are correctly aligned before you

fully tighten the screws.

5. With the two cabinets now firmly held together, fit the two outer feet to the UPS cabinet.

6. Carefully stand the assembled tower upright and move to its intended installation location.

7. Connect the battery cables to the UPS as described above and illustrated in Figure 3.11.

8. This completes the mechanical installation.

3.4.3 Rack installation

When the battery cabinet is rack-mounted, install in the same manner used to install the UPS (see paragraph 3.3.3).

Figure 3.11 Battery cable connection

I

G

G

G

G

Figure 3.12 Combined tower installation

Page 28

3: Installation

22 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

3.5 Electrical installation

Carry out the following electrical installation procedure once the UPS, and external battery cabinet where applicable, have

been mechanically installed at their intended location.

1. Connect the UPS AC INPUT power socket to the utility mains supply using the supplied power cable.

2. If an external battery cabinet is used, connect the battery power cable and protective earth cable to the UPS as shown

in Figure 3.11.

3. If the UPS is installed in an equipment rack, connect a protective earth bonding cable between the rack and the UPS

earth screw located adjacent to the battery connector (see Figure 2.7).

4. The optional UPS communications card and other optional facilities, such as the emergency power off cables, can be

connected at this stage or installed later (see chapter 7 for details)

3.6 Initial UPS power-up and commissioning

The UPS operating parameters are set to default values by the manufacturer. These basic settings can be changed to suit

a particular site or application requirements using the following commissioning procedure.

1. If the load equipment is connected to the UPS, either disconnect it or ensure that the load power switches are OFF.

2. Connect utility mains power to the UPS and turn on the UPS following the instructions in paragraph 4.2.1, but do not

connect power to the load at this stage.

3. Scroll through the Functions menu, as described in paragraph 4.5.3, and make a note of any operating parameters

that require changing.

4. Make any required operating parameter changes as described in paragraph 4.5.4.

5. Turn off the UPS (paragraph 4.3.1) but leave the utility mains connected for at least four hours to charge the battery.

6. Once the battery is charged, turn on the UPS and carry out a battery test as described in paragraph 4.5.2.

7. If the battery test is successful, the UPS can be brought into operation.

8. Check all metered parameters to ascertain that the input/battery/output indications are correct.

9. Congratulations. Your UPS is now fully operational and providing protected power for your load.

WARNING: Do not disconnect the power cable while the UPS is operating as the cable provides the UPS

protective earth connection.

WARNING: Ensure you use the correct external battery cabinet. The 1kVA UPS uses a 36V external battery

pack whereas the 2kVA/3kVA UPS uses a 72V battery pack.

CAUTION: The commissioning procedure must be carried out by an electrically-trained engineer.

CAUTION: We recommend that the battery is charged for further 4 hours before you connect any mission-

critical load to the UPS. This is to ensure that the battery is charged to a level that enables the UPS to perform

to its full specification.

Page 29

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 23

4

Operation

4.1 Introduction

This chapter describes the UPS operating and set-up procedures.

The UPS is essentially a ‘plug-and-play’ unit and does not require a trained operator to turn it off and on.

Set-up procedures are included in this chapter to enable you to re-configure the UPS operating parameters to suit

particular local requirements. The factory default settings are satisfactory for the majority of installations, but if you find it

necessary to makes any adjustments this should be done before the UPS is put into service.

UPS Operating procedures

• How to start the UPS (from utility mains) - see paragraph 4.2.1

• How to start the UPS (from battery) - see paragraph 4.2.2

• How the monitor the UPS input/output operating conditions - see paragraph 4.2.3

• How to turn off the UPS (from ON INVERTER or ECO Mode) - see paragraph 4.3.1

• How to turn off the UPS (from ON BATTERY Mode) - see paragraph 4.3.2

• How to disable the alarm buzzer operation - see paragraph 4.5.1

• How to perform a battery test - see paragraph 4.5.2

UPS Set-up procedures

• Functions menu - see paragraph 4.5.3

• Operating parameters setting menu - see paragraph 4.5.4

CAUTION: If adjustment is necessary it should be carried out by an electrically-trained engineer who is aware

of the effects on the system of any changes made.

Page 30

4: Operation

24 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

4.2 UPS start-up procedures

4.2.1 How to start the UPS (from utility mains)

1. Connect the UPS AC INPUT to the utility mains supply using the power cable provided.

2. Ensure that the UPS output circuit breakers and battery breaker in the external battery cabinet (if used) are closed.

3. Connect the load equipment to the UPS AC OUTPUT power outlets – we recommend that the individual load power

switches are turned OFF at this stage.

4. Turn ON the UPS utility mains supply.

a) The UPS control system will boot-up and initially

turn on all the LEDs and LCD symbols.

(If the UPS fails to power-up, check that the input

breaker is closed on the back of the unit.)

b) After a few seconds the UPS fans will start, and the

LEDs and LCD symbols will extinguish.

c) This will be followed by the default UPS OFF

screen. The LCD mimic should indicate the UPS OFF

mode and the only active LED should be the green

input mains LED (as shown here).

5. Verify that the indicated utility supply voltage is correct.

6. Press and hold the ON button until the buzzer beeps

twice (1-2 seconds).

a) UPS should turn ON.

7. IF THE UPS IS SET TO OPERATE IN ON INVERTER

MODE (standard):

a) The LCD mimic diagram should change to indicate

the ON INVERTER mode.

b) The two programmable power outlet LED

indicators should change to Green.

8. IF THE UPS IS SET TO OPERATE IN ECO MODE:

a) The UPS should turn ON, as above, then after

approximately 5 seconds the LCD mimic diagram

should change to indicate the ON BYPASS mode.

b) The yellow BYPASS LED should turn on.

9. Check the UPS output voltage and frequency on the

LCD meter.

10. Although not essential, we advise that you perform a

battery test before you turn on the load to ensure that

the UPS batteries perform correctly. The battery test

procedure is detailed in paragraph 4.5.2.

11. If the battery test is satisfactory, and UPS output

voltage is correct, turn ON the load power switches.

12. Check the UPS output current and percentage load on the LCD meter.

13. The UPS is now fully operational and providing uninterruptible* power to your load equipment.

*If the UPS is operating in

ECO

mode there will be a slight break in the supply if the utility mains fails while the UPS

switches to the ON

BATTERY

mode.

INPUT

UPS

LOAD

V

Utility

1

2

Figure 4.1

INPUT

UPS

LOAD

V

Utility

1

2

Figure 4.2

INPUT

UPS

LOAD

V

Utility

1

2

Figure 4.3

Page 31

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 25

4: Operation

4.2.2 How to start the UPS (from battery)

If there is no utility mains power available, the UPS can be started directly from battery power. This requires the battery to

be fully charged and should only be attempted if the battery has previously been on charge for at least four hours.

Note: Depending on the load demand the UPS will only function on battery for a short time unless the utility mains supply

is connected.

1. Connect the load equipment to the UPS AC OUTPUT power outlets – we recommend that the individual load power

switches are turned OFF at this stage.

2. Ensure that the UPS output circuit breakers and battery breaker in the external battery cabinet (if used) are closed.

3. Press and hold the ON button for approximately three seconds, until the buzzer beeps twice, then release it.

4. Within a further ten seconds, press and hold the ON button once again (for 3 seconds), until the buzzer sounds

another two beeps.

Note: If you fail to press the ON button for the second time within the allowed ten seconds the UPS will shut down and

you will have to start the procedure again.

a) The UPS control system will boot-up and initially turn on all the LEDs and LCD symbols for approximately one

second.

b) After approximately five seconds the UPS fans will start, and the LEDs and LCD symbols will extinguish.

5. This will be followed by the default UPS ON BATTERY

screen.

a) The LCD mimic diagram should change to indicate

the ON BATTERY mode.

b) The two green programmable power outlet LEDs

should turn on.

c) The utility mains status LED should remain OFF.

d) The Utility Abnormal icon should be displayed on

the LCD screen.

e) The alarm buzzer will beep once per second to

inform you that the battery is discharging.

6. Check the UPS output voltage and frequency on the

LCD meter.

7. Turn ON the individual load power switches.

8. Check the UPS output current and percentage load on the LCD meter.

9. The UPS is now fully operational in its ON BATTERY mode.

CAUTION: Restore the UPS utility mains supply as soon as possible.

INPUT

UPS

LOAD

V

Utility

1

2

Utility

Figure 4.4

Page 32

4: Operation

26 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

4.2.3 How the monitor the UPS input/output operating conditions

When the UPS is turned ON, you can use the DOWN and UP buttons to scroll through the measurement display screens.

The display sequence is as numbered in the table below and loops around in either direction.

A rectangular box appears around the INPUT, LOAD and BATTERY icons to indicate which is associated with the meter

display, as Illustrated in the examples below.

Figure 4.5 LCD Meter display (sample screens)

1 Utility Voltage (V) 4 Inverter Frequency (Hz) 7 Battery Voltage (V)

2 Utility Frequency (Hz) 5 Inverter Load % 8 Battery Autonomy (mins)

3 Inverter voltage (V) 6 Inverter Load (A) 9 UPS Temperature (°C)

INPUT

UPS

LOAD

V

Utility

INPUT

UPS

LOAD

V

Inverter

INPUT

UPS

LOAD

V

Battery

Utility (input) voltage

Inverter (output) voltage

Battery (charge) voltage

Page 33

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 27

4: Operation

4.3 UPS shut down procedures

4.3.1 How to turn off the UPS (from ON INVERTER or ECO Mode)

Use this procedure to shut down the UPS when it is operating in the ON INVERTER or ECO mode.

1. Press and hold the OFF button for approximately 5

seconds.

a) The UPS will disconnect the load power and the two

programmable power outlet LED indicators should

turn OFF.

b) The utility input mains LED should remain ON.

c) The LCD mimic should indicate the UPS OFF mode,

which shows that the battery is still being charged

from the utility mains.

d) The cooling fans will remain running.

2. Disconnect (or turn OFF) the Utility input supply.

a) All LED indicators and the LCD panel will turn off.

b) The cooling fans will stop.

3. The UPS is now totally shut down.

4.3.2 How to turn off the UPS (from ON BATTERY Mode)

Use this procedure to shut down the UPS when it is operating in the ON BATTERY mode.

1. Press and hold the OFF button for approximately 5 seconds.

a) The UPS will disconnect the load power. and the two programmable power outlet LED indicators should turn

OFF.

b) All LED indicators and the LCD panel will turn off.

c) The cooling fans will remain running for approximately 10 seconds and then shut down.

2. The UPS is now totally shut down.

4.4 Manual load transfer between inverter and bypass

Use this procedure to manually transfer the load between the inverter and bypass.

1. With the UPS operating ON INVERTER, transfer the

load to bypass by pressing the ON and UP buttons

simultaneously for three seconds.

a) The load will transfer to bypass.

b) The BYPASS LED will flash off/on.

c) The buzzer will beep at approximately 3 second

intervals.

2. To transfer the load from bypass to inverter repeat the

process by pressing the ON and UP buttons

simultaneously for three seconds.

a) The load will transfer to inverter

b) The BYPASS LED will turn off

c) The buzzer alarm will silence.

INPUT

UPS

LOAD

V

Utility

1

2

Figure 4.6

INPUT

UPS

LOAD

V

Utility

1

2

Figure 4.7

Page 34

4: Operation

28 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

4.5 Functions menu

4.5.1 How to disable the alarm buzzer operation

If an alarm condition arises, the buzzer can be silenced by briefly pressing the ON button. However there may be

circumstances where you would like to disable the buzzer permanently.

1. With the UPS running, press the FUNCTION button. This will take you immediately to the Buzzer ON/OFF screen.

2. Press the UP button to change the Buzzer operational status between OFF-ON, as required. A cross (X) appears next

to the buzzer icon when it is disabled.

Figure 4.8 Buzzer ON/OFF

3. When the required status is displayed, press the FUNCTION button to return to the default LCD screen.

4.5.2 How to perform a battery test

When a battery test is performed, the UPS operates in ON BATTERY mode for 10 seconds to monitor the battery

performance. If the battery doesn’t satisfy the test criteria a fault is displayed on the LCD panel.

1. With the UPS turned ON, press the FUNCTION button

twice. This will take you to the Battery Test screen, which

will indicate that the battery test is OFF.

2. Press the UP button to start the battery test.

3. During the test, the following indications should appear.

a) The warning buzzer will beep once per second (if the

buzzer is enabled).

b) The LCD mimic will change to ON BATTERY mode.

c) The Testing flag to the left of the battery icon will

flash off/on to indicate that the test is in progress.

d) The LCD returns to the Monitor menu during the

battery test.

4. When the test is completed, the UPS will switch back to its

normal operating mode and the following indications

should appear.

a) The warning buzzer will stop.

b) The LCD mimic will change to ON INVERTER mode.

[or ECO mode if selected]

c) The Testing flag to the left of the battery will turn off.

d) The LCD remains indicating the battery autonomy.

5. The UPS is now operating in its normal operating mode

and the LCD metering can be selected as normal, using the UP and DOWN buttons.

CAUTION: The battery must be fully charge d before you select a battery test. Do not initiate the test unti l the

UPS has been switched on with the battery being charged for at least four hours.

Buzzer

Buzzer

Testi ng

INPUT

UPS

LOAD

Mins

BatteryAutonomy

Testi ng

INPUT

UPS

LOAD

Mins

BatteryAutonomy

Figure 4.9 Battery Test

Page 35

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 29

4: Operation

4.5.3 Functions menu

The Functions menu, shown in Figure 4.10, can be

accessed when the UPS is operating by pressing the

FUNCTION button. The menu allows the operator to enable/

disable the buzzer, initiate a battery test and observe (but

not change) several UPS configuration set-up values.

Once the menu is open you can scroll down through the

screens by pressing the DOWN button, as shown.

Buzzer:

Allows the UPS buzzer to be enabled or disabled. This is

described in detail in paragraph 4.5.1.

Testing:

Initiates a battery test by switching the UPS to ON BATTERY

mode for 10 minutes and monitoring the battery

performance. This is described in detail in paragraph 4.5.2.

Bypass Voltage Window:

Displays the bypass voltage window setting. This shows the

acceptable bypass voltage range that can be connected to

the load when the UPS is operating ON BYPASS and can be

either Lo (±15%)or Hi (±10%). This percentage relates to

the set inverter operating voltage – for example, if the

inverter voltage setting is 230V the bypass sensitivity Lo

range is 230V ±15%, i.e., 195.5-264.5V.

Bypass Frequency Window:

Displays the bypass frequency window to which the inverter

will synchronise, which is either1 [±1Hz] or 3 [±3Hz].

Inverter Voltage:

Displays the selected inverter output voltage setting, which

is either [200V], [208V], [220V], [230V] or [240V].

Mode:

Displays the selected UPS operating mode, which be either

Std (standard) or Eco.

Inverter Voltage Adjustment:

Displays any applied output voltage offset adjustment,

which can be either [-3%], [-2%], [-1%], [0%], [+1%], [+2%]

or [+3%].

Buzzer

Testing

V

Inverter

Voltage

Hz

Bypass

Frequency Window

%

Inverter

VoltageAdjust

Mode

Bypass

Voltage

Window

Function

Figure 4.10 Functions menu

Page 36

4: Operation

30 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

4.5.4 Operating parameters

setting menu

Figure 4.11 shows the operating

parameters than can be accessed

and adjusted by the user.

1. Ensure that the UPS output is

turned OFF.

2. To access the settings menu,

press the ON and DOWN

buttons simultaneously for

three seconds, until the buzzer

beeps twice.

3. Press the DOWN button

repeatedly to scroll down to

the parameter the you wish to

change.

4. To change a parameter, press

the UP button to scroll through

the option range until the

required value is shown.

5. To select the chosen value

press the DOWN button.

a) This will temporarily store

the value and scroll down

to the next parameter

menu screen.

6. When you reach the final

screen (Inverter Voltage

Adjust), press the ENTER

button.

a) Any changes are now

saved.

b) The LCD return to its

default screen

7. Turn OFF the UPS utility mains

supply and allow 1 minute for

the UPS electronics to fully

power down.

8. When the utility mains power

is next turned on, the UPS will

operate with the new

parameter settings applied.

CAUTION: These

parameters should be

adjusted by an

electrically-trained

engineer who is aware of

the effects on the system

of any changes made.

Buzzer

Testing

V

Inverter

Voltage

Hz

Bypass

Frequency Window

Mode

Bypass

Voltage

Window

Mode

Frequency

%

Inverter

VoltageAdjust

Enter

ON

Figure 4.11 Operating parameter setting menu

Hi

Lo

1

3

200

208

220

230

240

Std

Eco

3

2

1

0

50

60

3

2

1

0

(See paragraph 4.5.1)

(See paragraph 4.5.2)

Page 37

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 31

5

Maintenance

5.1 Introduction

The UPS does not contain any user-serviceable parts, so the day-to-day maintenance requirements are minimal other

than to ensure that the environment in which the UPS is installed is kept cool and dust free. A clean, controlled operating

environment will help maximise the useful working life and reliability of both the UPS and its batteries.

5.2 Scheduled maintenance

The UPS system and batteries should receive regular preventative maintenance from a trained engineer to maximise both

the useful working life and system reliability. If the UPS is commissioned by a Uninterruptible Power Supplies Ltd. service

engineer, the engineer will leave a service record book with the UPS which will be used to log its full service history.

We recommend that the UPS system is maintained every six months by an Uninterruptible Power Supplies Ltd. trained

engineer or approved service agent, who will complete the following. Preventative maintenance inspections form an

integral part of all Extended Warranty Agreements (maintenance contracts) offered by Uninterruptible Power Supplies Ltd.

5.2.1 Preventative maintenance inspection

During a preventative maintenance inspection a trained Uninterruptible Power Supplies engineer will check and validate:

• Site environmental conditions

• Integrity of the electrical installation

• Cooling airflow

• Load characteristics

• Integrity of alarm and monitoring systems

• Operation of all installed options

• All stored event logs

5.2.2 Battery maintenance and testing

The batteries should be inspected and tested every six months, depending on the ambient temperature.

The battery test takes approximately two minutes to complete and can be performed only if:

• There are no alarm conditions present.

• The battery is fully charged.

• The UPS input mains supply is present.

The battery test procedure can be carried out from the UPS front panel and performed irrespective of the UPS operating

mode (ON-INVERTER or ON-BYPASS/ECO) and whether or not the load is connected.

WARNING: Do not remove the covers from the UPS case. If you remove a cover from the UPS case you will

be exposed to potentially lethal voltages.

Page 38

5: Maintenance

32 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

Battery disposal and recycling

Batteries contain dangerous substances that can harm the environment if disposed of carelessly. If you have a faulty

battery it should be checked and replaced by a trained Uninterruptible Power Supplies engineer who will dispose of any

faulty batteries in accordance with any regulations set by local environmental waste disposal organisations.

WARNING: Do not attempt to remove or replace the UPS battery yourself. If a battery is faulty ALWAYS seek

assistance form Uninterruptible Power Supplies Ltd. or one of its local service agents.

Page 39

TS_600_00 PW1000 1-3kVA User Manual 6/4/17 33

6

Troubleshooting

6.1 Introduction

If the UPS shuts down due to a fault condition, caused by an internal malfunction or severe overload, it might need to be

reset to bring it back into operation – see paragraph 6.6. Depending on the nature of the fault, the UPS may either shut

down entirely and disconnect the load supply or transfer the load to the internal bypass.

6.2 Fault identification

Unless there is a total UPS failure, the UPS will generally:

• illuminate the red FAULT LED

• display a Buzzer Code (error code) number on the LCD screen – the code indication may be steady or flashing

depending on other factors

• sound the audible warning alarm – the audible warning may be cancelled by pressing the ON button briefly

• illuminate the warning symbols at the top of the LCD screen if applicable

6.2.1 Error codes

6.2.2 Audible warning alarm

Figure 6.2 Audible warning alarm interpretation

Buzzer Codes

05

Weak or faulty battery

06

Output short-circuited

07

EPO Operated

11

UPS Over temperature

12

Inverter overload

14

Fan failure

28

Bypass overload

39

Low input voltage (<160V) or disconnected battery

Audible Alarm (beeps)

Continuous beep UPS Faulty, Inverter shut down, keypad error, all functions inhibited

Single beep every two seconds UPS Faulty, load continued to be supplied via inverter or bypass.

Single beep every second UPS On-Battery mode, battery discharging

Quick and short successive beeps Battery low, nearing end of discharge

Two quick and short beeps Confirm / RS232 port receiving.

One quick and short beep Service Mode OK

INPUT

UPS

LOAD

Alarm

Buzzer Code

1

2

Figure 6.1 LCD Fault Display (Fan failure example)

Page 40

6: Troubleshooting

34 TS_600_00 PW1000 1-3kVA User Manual 6/4/17

6.2.3 Warning symbols

6.3 Troubleshooting a fault condition

If the UPS develops a fault during operation (red FAULT illuminated), you should check the error codes listed below for

appropriate solutions. Should the problem persist, please contact your local service agent for assistance.

Bypass input abnormal:

UPS fails to transfer to bypass, bypass abnormal in ECO mode

Utility input abnormal:

The utility mains supply is outside the UPS pre-set operating window

Wiring fault:

Site wiring problem such as reversed Line-Neutral connection

Alarm buzzer silent

The alarm buzzer has been silenced or disabled

Overload:

The UPS output is overloaded

Service:

The UPS is operating in its service mode

Alarm: