Kohler PRO 5.4 DES Owner's Manual

38 590 01 Rev. B

KohlerPower.com

PRO 5.4 DES

Generator Owner's Manual

IMPORTANT: Read all safety precautions and instructions carefully before

operating equipment.

Ensure engine is stopped and level before performing any

maintenance or service.

Record product information to reference when ordering parts or obtaining warranty coverage.

Specifi cation

Serial Number

Purchase Date

EN

ESS

FRC

2 38 590 01 Rev. BKohlerPower.com

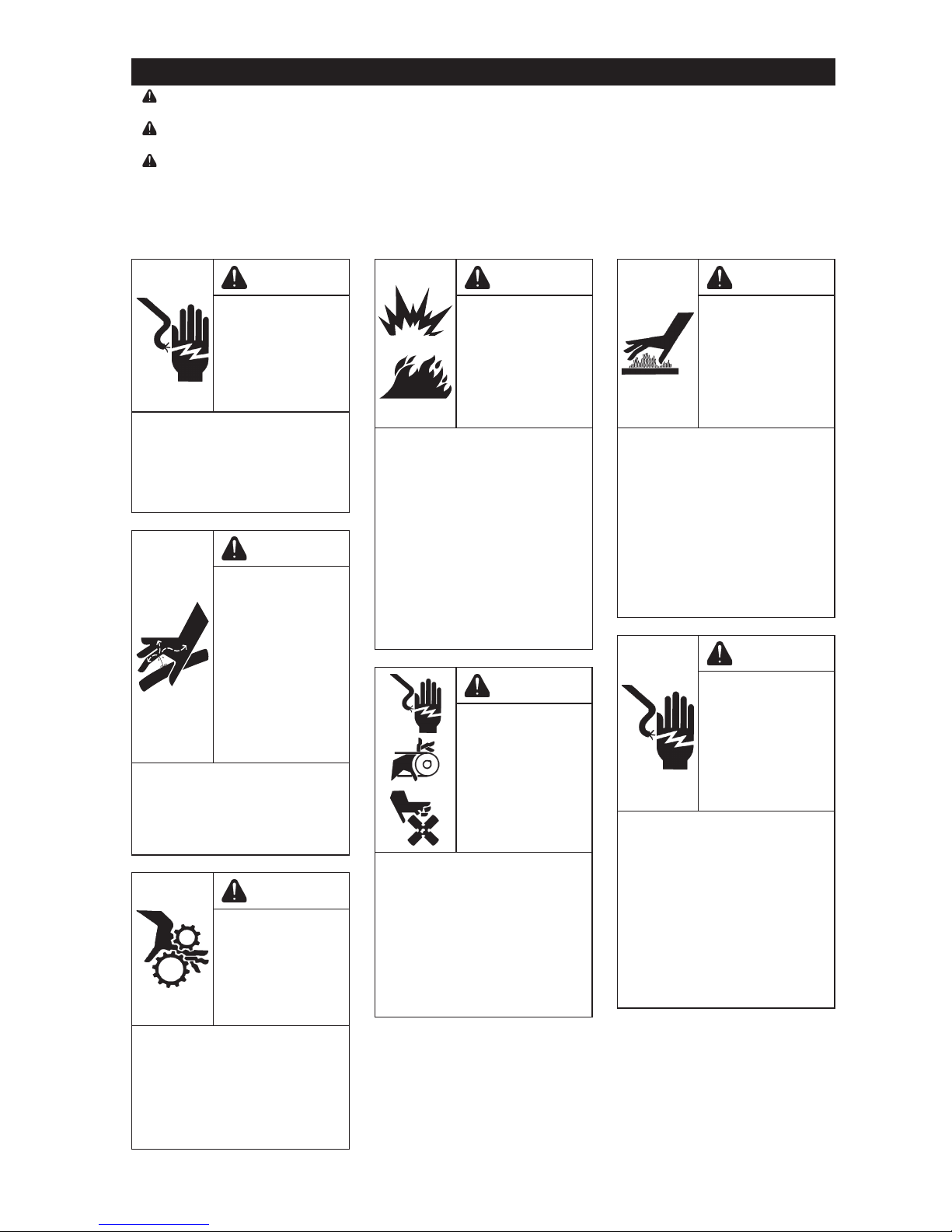

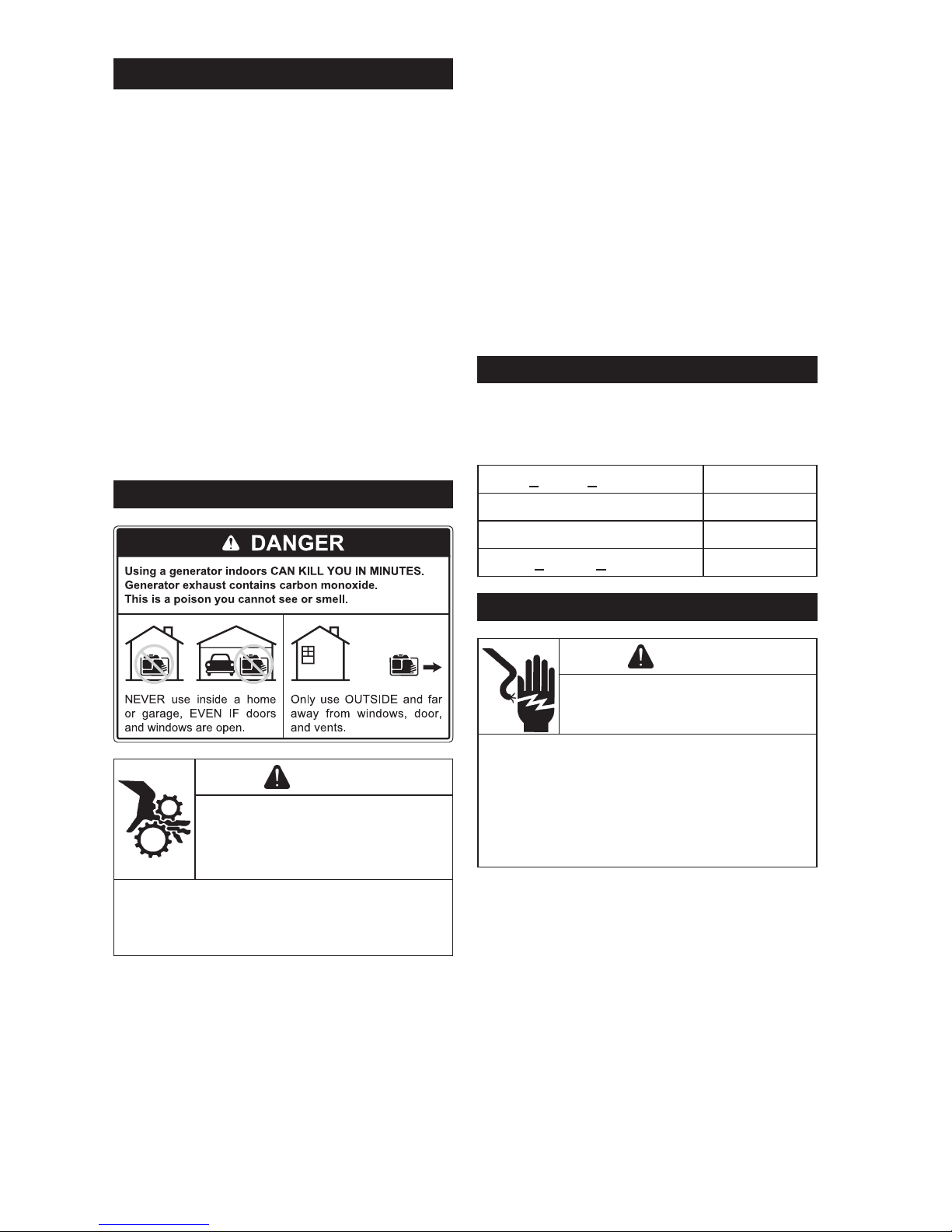

CAUTION

Electrical Shock

can cause injury.

Do not touch

wires while

generator is

running.

Never operate generator in

rain or snow.

Never touch generator

with wet hands or electrical

shock may occur.

WARNING

High Pressure

Fluids can

puncture skin

and cause

severe injury or

death.

Do not work

on fuel system

without proper

training or safety

equipment.

Fluid puncture injuries are

highly toxic and hazardous.

If an injury occurs, seek

immediate medical

attention.

WARNING

Rotating Parts

can cause

severe injury.

Stay away while

generator is in

operation.

Keep hands, feet, hair,

and clothing away from all

moving parts to prevent

injury. Never operate

generator with covers,

shrouds, or guards

removed.

WARNING

Fuel can cause

fi res and severe

burns.

Do not fi ll fuel

tank while

engine is hot or

running.

Fuel is fl ammable and its

vapors can ignite. Store fuel

only in approved containers,

in well ventilated,

unoccupied buildings. Do

not fi ll fuel tank while engine

is hot or running, since

spilled fuel could ignite if

it comes in contact with

hot parts or sparks from

ignition. Do not start engine

near spilled fuel. Never use

fuel as a cleaning agent.

WARNING

Accidental

Starts can cause

severe injury or

death.

Disconnect and

ground spark

plug lead(s)

before servicing.

Before working on

generator or equipment,

disable engine as follows:

1) Disconnect spark plug

lead(s). 2) Disconnect

negative (–) battery cable

from battery.

Do not allow children to

operate generator.

WARNING

Hot Parts can

cause severe

burns.

Do not touch

engine while

operating or just

after stopping.

Never operate generator

with heat shields or guards

removed. Do not modify

generator.

Place generator in a place

where pedestrians or

children are not likely to

touch generator.

Be sure to carry generator

only by its carrying handles.

WARNING

Hazardous

Voltage.

Backfeed to

utility system

can cause

property

damage, severe

injury, or death.

Never plug a portable

generator directly into a

building outlet.

If generator is used for

standby power, have a

certifi ed, licensed electrician

install an automatic

transfer switch to prevent

inadvertent interconnection

of standby and normal

sources of supply.

Safety Precautions

DANGER: A hazard that will result in death, serious injury, or substantial property damage.

WARNING: A hazard that could result in death, serious injury, or substantial property damage.

CAUTION: A hazard that could result in minor personal injury or property damage.

NOTE: is used to notify people of important installation, operation, or maintenance information.

Read this manual carefully before operating this machine. This manual should stay with this

machine if it is sold.

3

38 590 01 Rev. B

KohlerPower.com

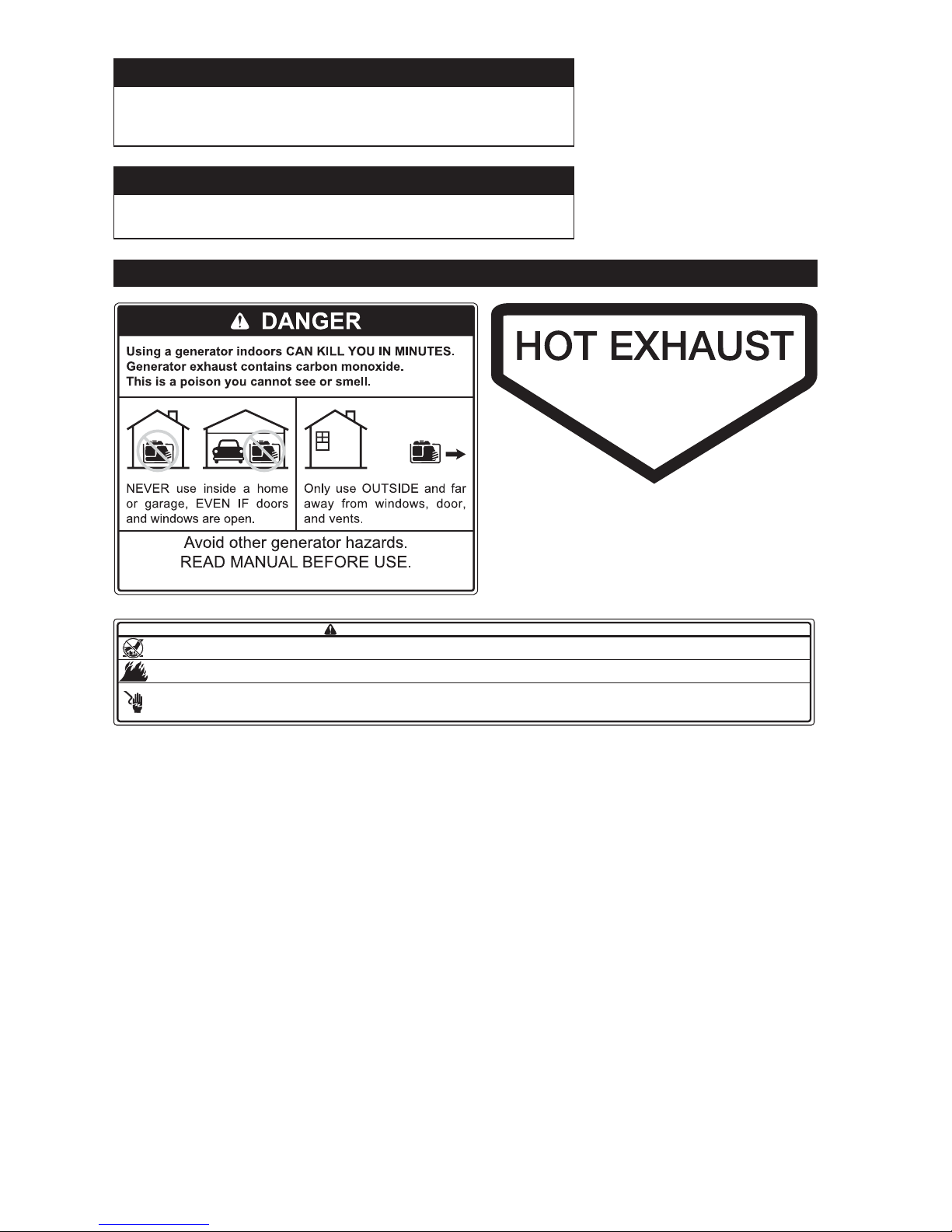

California Proposition 65 Warning

Engine exhaust from this product contains chemicals known

to State of California to cause cancer, birth defects, or other

reproductive harm.

California Proposition 65 Warning

This product contains chemicals known to State of California

to cause cancer, birth defects, or other reproductive harm.

Important Labels on Generator

WARNING / ADVERTENCIA / AVERTISSEMENT

Ɣ Hot parts can cause severe burns. / Las piezas calientes pueden causar quemaduras graves. / Les pièces chaudes peuvent causer de graves brûlures.

Ɣ Do not touch generator while operating or just after stopping. / No toque el generador durante el funcionamiento o inmediatamente después de pararse. / Ne touchez pas le générateur pendant qu'il tourne ou si

vous venez tout juste de l'arrêter.

Ɣ Explosive Fuel can cause fires and severe burns. / La explosión del carburante puede provocar incendios y quemaduras graves. / Carburant explosif pouvant causer des incendies et des brûlures graves.

Ɣ Do not fill fuel tank while generator is hot or running. / No llene el tanque de combustible mientras el generador esté caliente o funcionando. / N'ajoutez pas de carburant si le moteur est chaud ou s'il tourne.

Ɣ Electrical shock can cause injury. / Las descargas eléctricas pueden provocar lesiones. / Les chocs électriques peuvent causer des blessures.

Ɣ Do not touch wires while generator is running. / No toque los cables con el generador en funcionamient. / Ne touchez pas aux le générateur pendant que le moteur tourne.

Ɣ Do not connect generator to a building's electrical system unless using an isolation (transfer) switch installed by a certified, licensed electrician. / No conecte el generador al sistema eléctrico de un edificio a menos

que use un aislamiento (transferencia) interruptor instalado por un electricista certificado y certificado. / Ne branchez pas le générateur dans le système électrique d’un bâtiment sauf si un commutateur-converteur

a été installé par un électricien agréé et compétent.

EN

4 38 590 01 Rev. BKohlerPower.com

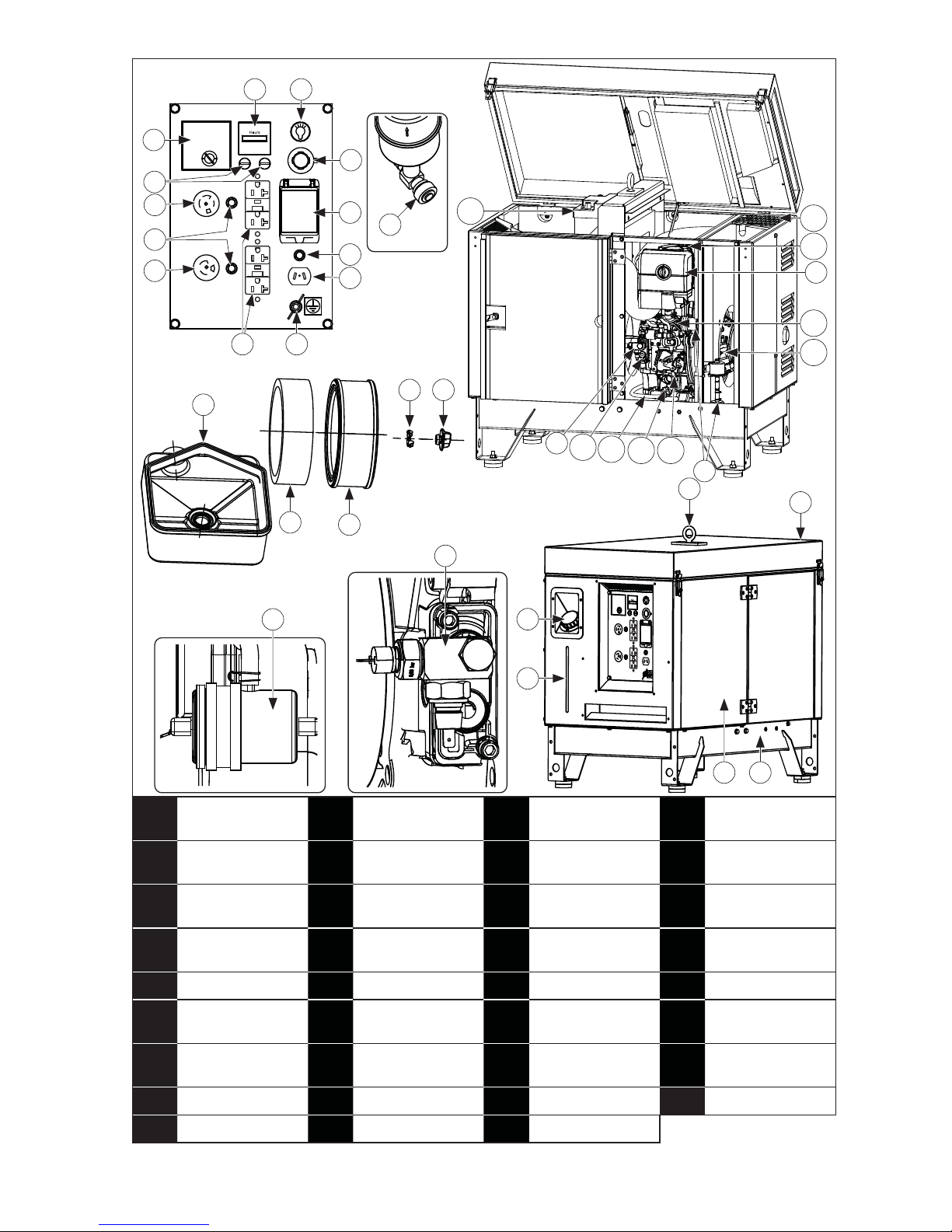

I

W

Q

X

Y

U

S

T

N

M

J

K

L

G

H

C

D

E F

A

B

J

G

H

AE

AD

AC AB

AA

Z

P

O

R

V

X

AI

AG

AF

AH

A

Generator Top

Cover

B Lifting Ring C Fuel Tank Cap D

Fuel Level

Indicator

E

Engine Access

Door

F

Retention

Container

G Fuel Filter H Solenoid Valve

I Fuel Valve J

Air Cleaner

Cover

K Precleaner L Paper Element

M Wing Nut N

Air Cleaner

Cover Nut

O

240/120V/30A

Electrical Socket

P

120V/30A

Electrical Socket

Q Circuit Breaker R Fuse S MODYS T Pilot Light

U Hour Meter V

Remote Start

Socket

W Ground Terminal X Circuit Protector

Y

12V DC

Receptacle

Z

GFCI

Receptacle

AA

Recoil Starter

Handle

AB Stop Lever

AC Oil Drain Valve AD Oil Drain Hose AE Oil Filter AF Dipstick

AG Oil Fill Cap AH Exhaust Silencer AI Starter Battery

5

38 590 01 Rev. B

KohlerPower.com

Pre-Start Checklist

1. Ensure generator is at least 3.3 ft. (1 m) from

building or other equipment and not covered

with any material.

2. Refer to all warning labels prior to starting.

3. Check oil level. Add oil if low. Do not overfi ll.

4. Check fuel level. Add fuel if low. Stop

refueling when indicator reaches F (full)

level. Check fuel system components and

lines for leaks. Never refuel while unit is

running.

5. Test GFCI receptacles (Z).

6. Check starter battery.

7. Ground generator.

8. Check that air cleaner components and all air

inlets are unobstructed, equipment covers,

and guards are in place and securely

fastened.

9. Ensure electrical devices (load) are not

connected to generator.

Starting

WARNING

Rotating Parts can cause severe

injury.

Stay away while generator is in

operation.

Keep hands, feet, hair, and clothing away

from all moving parts to prevent injury. Never

operate generator with covers, shrouds, or

guards removed.

Electric Start:

1. Turn main AC circuit breaker (Q) OFF.

2. Turn fuel (I) ON.

3. Ensure generator top cover (A) and engine

access door (E) is closed.

4. Turn MODYS (S) key to ON position.

5. Press START button on MODYS (S).

Recoil Start:

1. Turn main AC circuit breaker (Q) OFF.

2. Turn fuel (I) ON.

3. Ensure generator top cover (A) is closed.

4. Turn solenoid valve (H) on.

5. Turn MODYS (S) key to ON position.

6. Slowly pull recoil starter handle (AA), until

there is some resistance then let it return to

its initial position slowly.

7. Pull recoil starter handle hard (AA), quickly

then let it return to its initial position slowly.

Repeat operation until engine starts as

necessary.

8. Turn solenoid valve (H) off.

9. Close engine access door (E) to engine of

generator.

Cold Weather Starting

When starting generator in low ambient

temperatures, allow engine to idle before

connecting a load. Follow chart for temperature

and time.

< -4° F (< -20° C) 5 minutes

-4° to 14° F (-20° to -10° C) 2 minutes

14° to 23° F (-10° to -5° C) 1 minutes

> 41° F (> 5° C) 20 seconds

Operation

WARNING

Hazardous Voltage. Backfeed to

utility system can cause property

damage, severe injury, or death.

Never plug a portable generator directly into

a building outlet.

If generator is used for standby power,

have a certifi ed, licensed electrician install

an automatic transfer switch to prevent

inadvertent interconnection of standby and

normal sources of supply.

Once pilot light (T) illuminates and generator

has reached a steady running speed

(approximately 3 minutes):

1. Check that circuit protectors (X) are pushed

in. Press if necessary.

2. Connect appliances to electrical sockets of

generator.

3. Hour meter (U) shows number of hours that

generator has worked.

Angle of Operation

Do not operate this engine exceeding maximum

angle of operation; see specifi cation table.

Engine damage could result from insuffi cient

lubrication.

EN

6 38 590 01 Rev. BKohlerPower.com

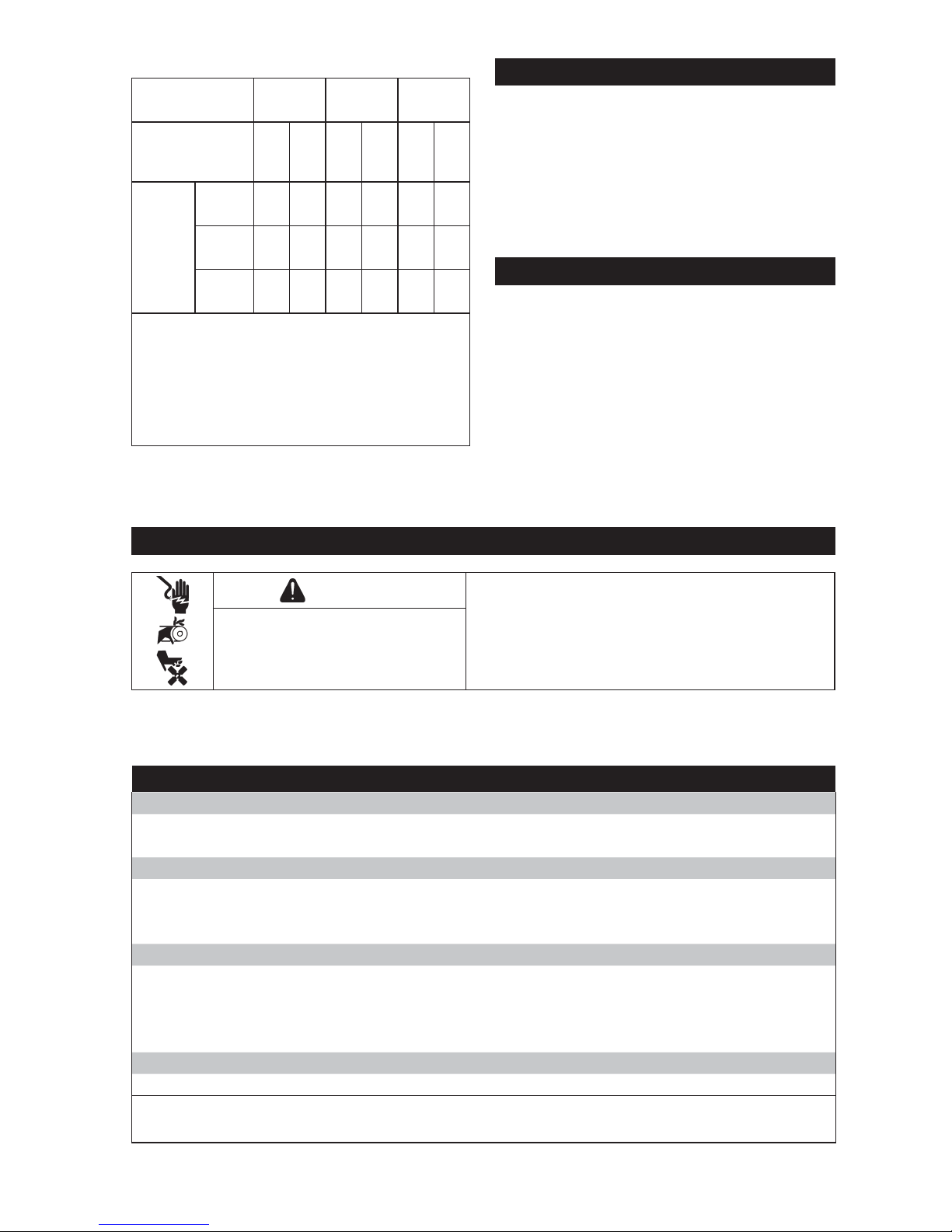

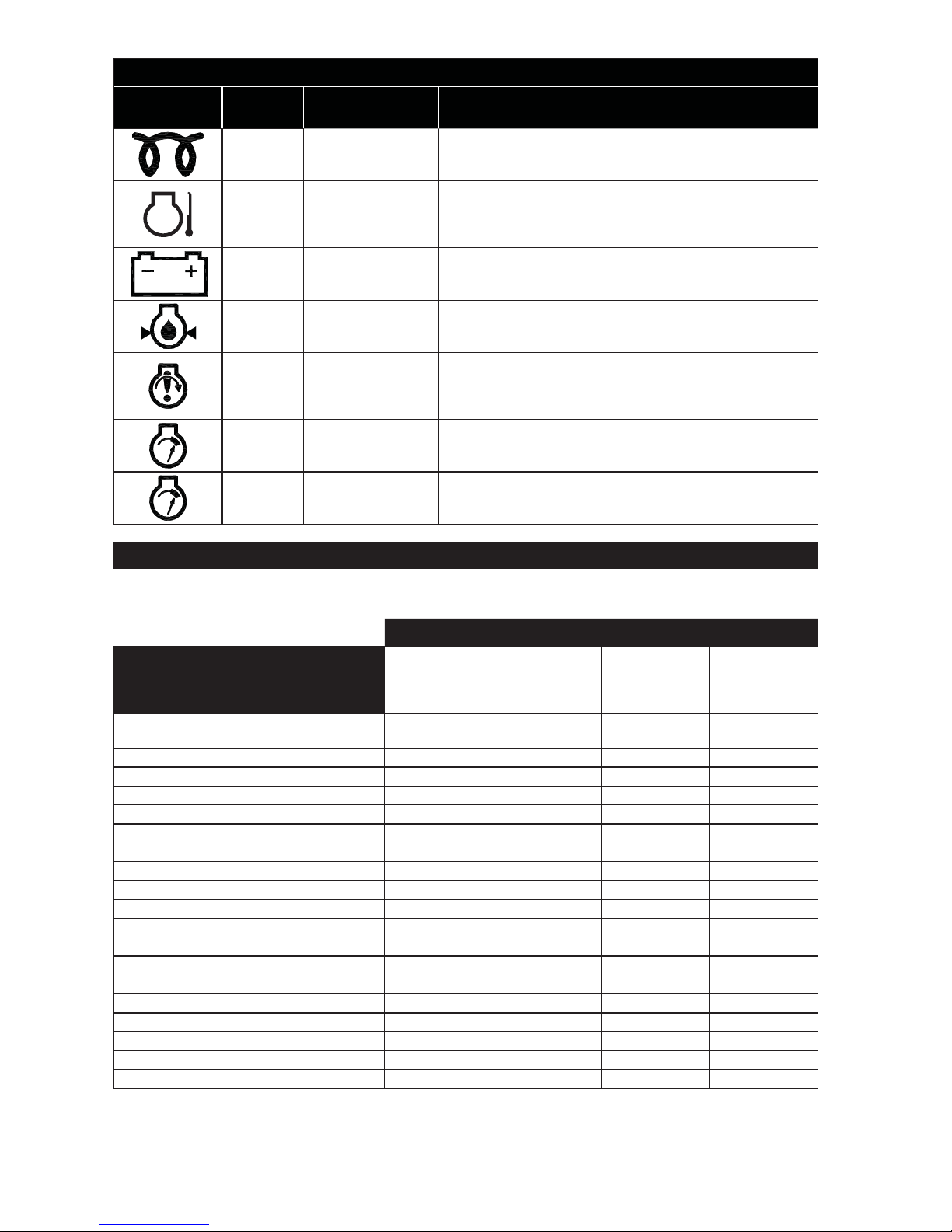

Cable Selection

Generator

Socket Type

10 A 16 A 32 A

Recommended

Cable Cross

Section

mm

2

AWG

mm

2

AWG

mm

2

AWG

Length

of

Cable

Used

0 to

50 m

4106 9107

51 to

100 m

10 7 10 7 25 3

101 to

150 m

1

10 7 16 5 35 2

1

This cable length is maximum permitted

length, and must not be exceeded.

Installation method=cables on raceway

or non-drilled tablet/Permitted drop in

voltage=5%/Multi-core conductors/Cable

type PVC 70°C (e.g. H07RNF)/Ambient

temperature=86° F (30° C).

Maintenance Instructions

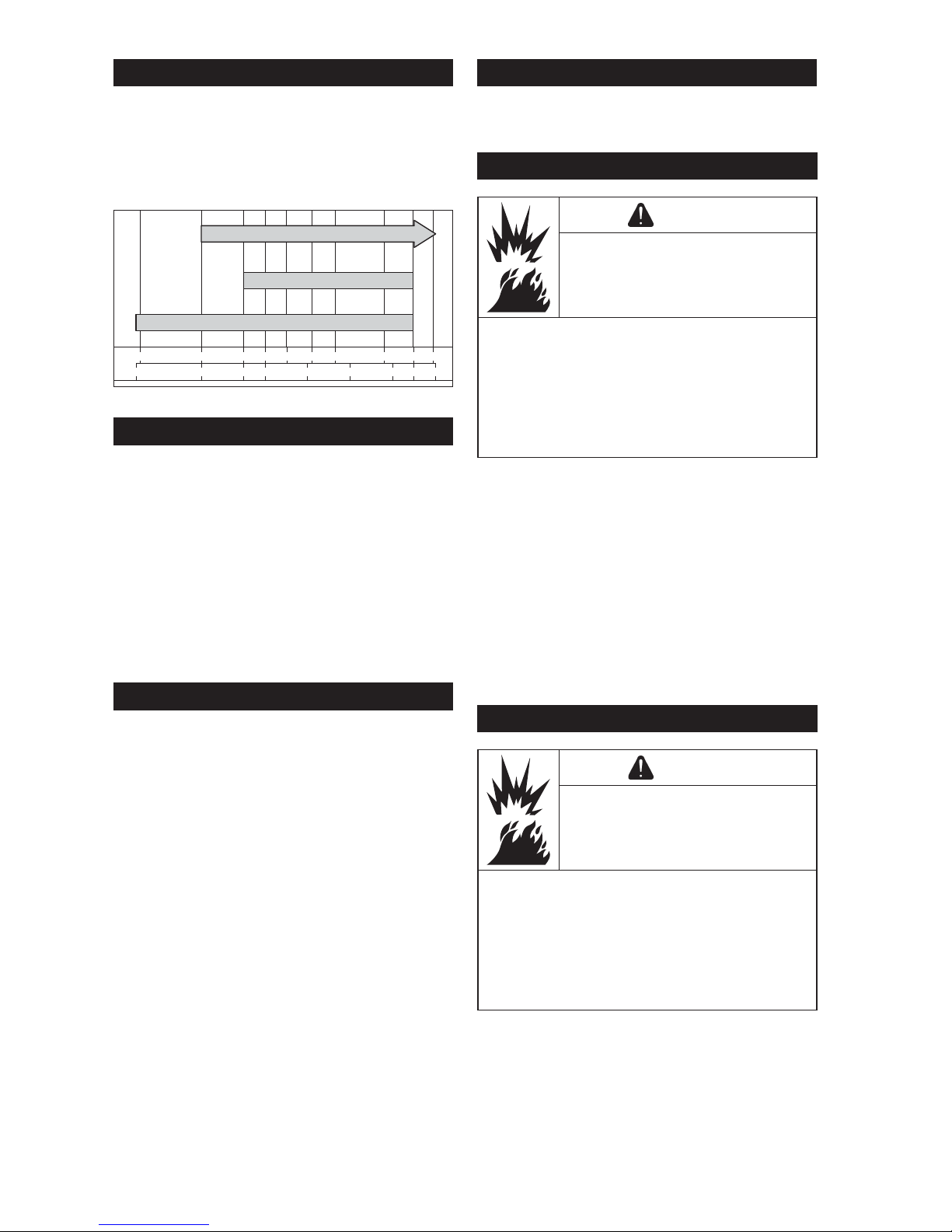

WARNING

Before working on generator or equipment,

disable engine as follows: 1) Disconnect spark

plug lead(s). 2) Disconnect negative (–) battery

cable from battery.

Do not allow children to operate generator.

Accidental Starts can cause

severe injury or death.

Disconnect and ground spark

plug lead(s) before servicing.

Safety is an obligation of owner. Periodic inspection, adjustment and lubrication will keep your

generator in safest and most effi cient condition possible. Most important points of generator

inspection, adjustment, and lubrication are explained on following pages.

Maintenance Schedule

After fi rst 50 Hours of operation

● Service/replace precleaner (K).

● Change oil and fi lter (AE).

Every 250 Hours

1

● Change oil.

● Replace air cleaner element (L).

● Replace fuel fi lters (G).

Every 500 Hours

1

● Replace internal oil fi lter (AE).

● Replace fuel fi lters (G).

● Clean fuel tank.

● Clean spark arrester.

Every 500 Hours

2

● Set and clean injectors.

1

Perform these procedures more frequently under severe, dusty, dirty conditions.

2

Have a Kohler portable dealer perform this service.

Stopping

1. Disconnect electrical devices and allow

engine to run without any load for 1-2

minutes.

2. Turn MODYS (S) key to OFF position

(generator stops).

3. Open engine access door (E), close fuel

valve (I).

4. Close engine access door (E).

Engine Speed

NOTE: Do not tamper with governor setting to

increase maximum engine speed.

Overspeed is hazardous and will void

warranty.

7

38 590 01 Rev. B

KohlerPower.com

Oil Recommendations

We recommend use of Kohler oils for best

performance. Other high-quality detergent

oils (including synthetic) of API (American

Petroleum Institute) service class CH-4 or

higher are acceptable. Select viscosity based

on air temperature at time of operation as

shown in table below.

°F

-20 5

-15 -5

23 32 40 60

50 80 95 100

°C

-30

0

10 20 30 35

40

5W-30*

15W-40

SAE 30

*Synthetic base oil.

Check Oil Level

Ensure engine oil level is between upper

and lower limit of dipstick (AF). Add oil as

necessary.

1. Remove dipstick (AF); wipe oil off.

2. Reinsert dipstick (AF) into tube; press

completely down.

3. Remove dipstick (AF); check oil level. Level

should be at top of indicator on dipstick (AF).

4. If oil is low on indicator, add oil up to top of

indicator mark.

5. Reinstall and secure dipstick (AF).

Change Oil and Filter

Change oil while engine is warm (not hot), not

immediately after stopping engine.

1. Clean area around oil fi ll cap (AG) and

remove. Obtain oil drain hose (AD) and

orient it outside of engine access door (E)

into a container. Open oil drain valve (AC)

and allow oil to drain completely.

2. Close oil drain valve (AC).

3. Using a hex wrench, remove oil fi lter screw

and remove oil fi lter (AE).

4. Coat new oil fi lter seal with clean engine oil

and clean oil fi lter holder.

5. Install new oil fi lter (AE), reinstall screw and

tighten it correctly.

6. Fill crankcase with new oil. Level should be

at top of indicator on dipstick (AF).

7. Reinstall oil fi ll cap (AG) and tighten securely.

8. Start engine; check for oil leaks. Stop engine;

correct leaks. Recheck oil level. Place oil

drain hose (AD) to original position.

9. Dispose of used oil and fi lter in accordance

with local ordinances.

Oil Sentry™ (if equipped)

This feature is designed to prevent engine

from starting in a low oil or no oil condition. Oil

Sentry™ will shut down a running engine.

Fuel Recommendations

WARNING

Fuel can cause fi res and severe

burns.

Do not fi ll fuel tank while engine is

hot or running.

Fuel is fl ammable and its vapors can ignite.

Store fuel only in approved containers, in well

ventilated, unoccupied buildings. Do not fi ll

fuel tank while engine is hot or running since

spilled fuel could ignite if it comes in contact

with hot parts or sparks from ignition. Do not

start engine near spilled fuel. Never use fuel

as a cleaning agent.

Fuel must meet these requirements:

● Clean, fresh, commercial-grade diesel fuel.

● ASTM D-975 - 1D or 2D, EN590, or

equivalent.

● Biodiesel fuels less than 20% methyl ester or

B20 are acceptable. Fuels meeting

specifi cation of BQ-9000, EN 14214 or

equivalent are recommended.

● Aviation fuels include JP5, JP4, JP8 and,

JET-A (if 5% oil is added).

● Do not overfi ll fuel tank.

Check Fuel Level

WARNING

Fuel can cause fi res and severe

burns.

Do not fi ll fuel tank while engine is

hot or running.

Fuel is fl ammable and its vapors can ignite.

Store fuel only in approved containers, in well

ventilated, unoccupied buildings. Do not fi ll

fuel tank while engine is hot or running since

spilled fuel could ignite if it comes in contact

with hot parts or sparks from ignition. Do not

start engine near spilled fuel. Never use fuel

as a cleaning agent.

Visually check fuel level indicator (D). If

necessary, add fresh clean fuel free from water.

1. Unscrew fuel tank cap (C).

2. Fill fuel tank using a funnel, taking care not to

spill any fuel. Do not overfi ll tank (there

should not be any fuel in fi ller neck).

3. Screw fuel tank cap (C) back on.

EN

8 38 590 01 Rev. BKohlerPower.com

2. Separate precleaner (K) from paper element

(L); service precleaner (K) and replace paper

element (L).

3. Check condition of rubber seal and replace if

necessary.

4. Install new paper element (L) on base; install

precleaner (K) over paper element (L);

reinstall element cover and secure with wing

nut (M).

Reinstall air cleaner cover (J) and secure with

air cleaner cover nut (N).

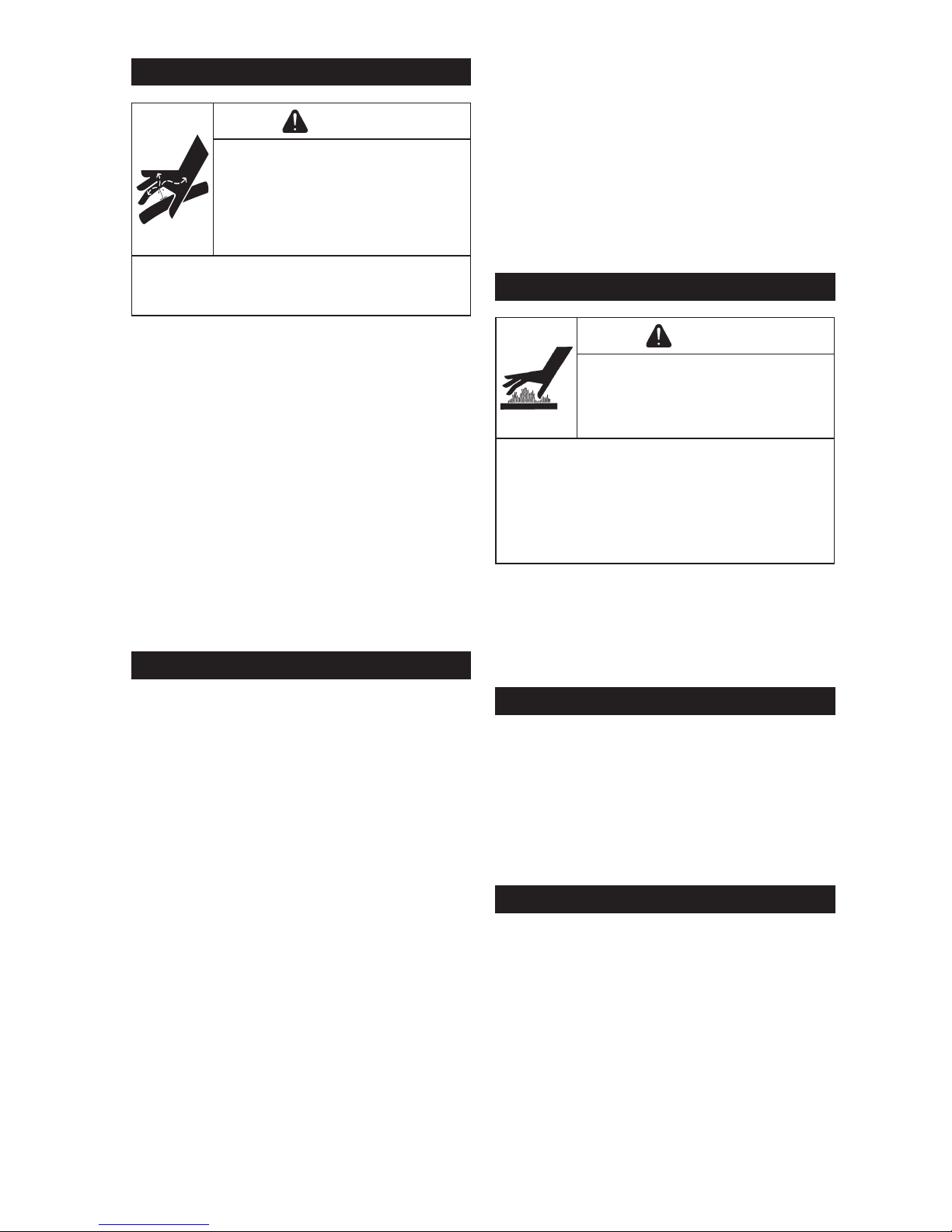

Air Cooling

WARNING

Hot Parts can cause severe

burns.

Do not touch engine while

operating or just after stopping.

Never operate generator with heat shields or

guards removed. Do not modify generator.

Place generator in a place where pedestrians

or children are not likely to touch generator.

Be sure to carry generator only by its

carrying handles.

Proper cooling is essential. To prevent over

heating, ensure air cooling inlet and outlet

areas are clean and unobstructed. Avoid

spraying water at wiring harness or any

electrical components. Refer to Maintenance

Schedule.

Ground Terminal

Ground terminal (W) connects earth line for

prevention of electric shock. When electric

device is grounded, be sure to ground

generator also.

Connect generator to ground: Attach a 6 AWG

(10 mm2) copper wire to generator’s ground

connection and to a galvanized steel grounding

rod (not provided) driven 3.3 ft. (1 m) into

ground.

Connecting Alternating Current (AC)

NOTE: Ensure all electric devices including

lines and plug connection are in good

condition before connection to

generator.

NOTE: Ensure total load is within generator

rated output.

NOTE: Ensure receptacle load current is within

receptacle rated current.

1. Start engine.

2. Ensure AC pilot light (T) is on.

3. Plug into AC receptacle (O, P or Z).

4. Turn on any electric devices.

Fuel Filters

WARNING

High Pressure Fluids can

puncture skin and cause severe

injury or death.

Do not work on fuel system

without proper training or safety

equipment.

Fluid puncture injuries are highly toxic

and hazardous. If an injury occurs, seek

immediate medical attention.

NOTE: This generator is equipped with 2 fuel

fi lters; these 2 fi lters must be replaced

at same time. Fuel will run out during

this operation; provide an appropriate

container.

1. Close fuel valve (I).

2. Remove 1 fuel fi lter (G) by removing hose

clips and loosening screw on retaining clip, if

equipped.

3. Install new fuel fi lter (G) by tightening screw

on retaining clip, if equipped.

4. Reconnect hoses, securing them with clips.

5. Follow previous steps for second fuel fi lter

(G).

6. Wipe away any traces of fuel with a clean

cloth and check that there are no leaks.

Air Cleaner

NOTE: Operating engine with loose or

damaged air cleaner components

could cause premature wear and

failure. Replace all bent or damaged

components.

NOTE: Paper element (L) cannot be blown out

with compressed air.

Loosen air cleaner cover nut (N) and remove

air cleaner cover (J).

Precleaner:

1. Remove precleaner (K) from paper element

(L).

2. Replace or wash precleaner (K) in warm

water with detergent. Rinse and allow to air

dry.

3. Saturate precleaner (K) with new engine oil;

squeeze out excess oil.

4. Reinstall precleaner (K) over paper element

(L).

Paper Element:

1. Clean area around paper element (L).

Remove wing nut (M), element cover, and

paper element (L) with precleaner (K).

9

38 590 01 Rev. B

KohlerPower.com

AC Rated Power

AC rated power is maximum amount of power

generator can support.

AC Surge Power

AC surge power is additional power generator

momentarily produces to aid in starting of

electrical devices requiring power above

generator's rated power requirements.

GFCI Receptacle

CAUTION

Electrical Shock can cause injury.

Do not touch wires while

generator is running.

Never operate generator in rain or snow.

Never touch generator with wet hands or

electrical shock may occur.

To reduce chance of electrical shock:

1. Do not attempt to operate equipment if

ground fault circuit interrupter (GFCI) RESET

button pops out repeatedly during use.

2. Remember that only receptacles labeled

GFCI have ground fault circuit interrupter

protection.

Ground Fault Circuit Interrupter (GFCI) stops

power to protected receptacles (Z) if a ground

fault (electrical leak) is detected. If RESET

button pops out, equipment plugged into

receptacle (Z) may be faulty. If this happens,

check equipment carefully. If equipment

appears to be in good condition, press RESET

button fi rmly until a click is heard. This will

restore power. If RESET button pops out again,

unplug equipment immediately. Contact a

Kohler portable dealer before attempting to use

it again.

GFCI Receptacle Test

1. Start generator.

2. Press TEST button, if functioning properly

RESET button should pop out, stopping

power to outlet.

3. If GFCI operation is correct, push RESET

button in. If GFCI operates incorrectly,

contact a Kohler portable dealer.

Overload (Capacity of Generator)

Never exceed rated load of generator (in Amps

and/or Watts) when it is running continuously.

See specifi cations table for rated outputs.

Before connecting and operating generator,

calculate electrical power required by electric

appliances (in Watts). This electrical power

rating is usually found on manufacturer's

plate on bulbs, electrical appliances, motors,

etc. Sum total of power required by these

appliances should not exceed nominal power

rating of generator.

Circuit protectors (X) and circuit breaker (Q) will

stop power to protected receptacles (O, P or

Z) when an overload of a connected electrical

device is detected or AC output voltage rises to

protect generator and any connected electric

devices.

When overload occurs and power generation

stops, proceed as follows:

1. Turn off any connected electric devices and

stop generator.

2. Reduce total wattage of connected electric

devices within application range.

3. Check for blockages in cooling air inlet and

outlet areas and around control unit. If any

blockages are found, remove them.

4. After checking, restart generator.

Battery Charging Using DC Receptacle

CAUTION

Electrical Shock can cause injury.

Do not touch wires while

generator is running.

Never operate generator in rain or snow.

Never touch generator with wet hands or

electrical shock may occur.

NOTE: This section refers to charging 12V

batteries in other equipment like motor

vehicles or off-road vehicles. No

jump-starting is possible.

NOTE: Follow safety procedures when

handling batteries to avoid damage to

electrical components and battery

explosions. Refer to battery

manufacturers safety data sheet on

safety risks of working with batteries.

Refer to battery manufacturer's

instruction on battery charging/

maintaining procedures.

NOTE: Generator DC rated voltage is 12V DC

circuit protector (X) will turn off

automatically if current above rated

fl ows during battery charging. Start

generator fi rst, then connect generator

to battery for charging. Before starting

to charge battery, ensure DC circuit

protector (X) is in RESET position. If

DC circuit protector (X) turns off again,

stop charging battery immediately and

contact a Kohler portable dealer.

EN

10 38 590 01 Rev. BKohlerPower.com

NOTE: Do not connect a VRLA (valve

regulated lead acid) battery. To charge

a VRLA battery, a special (constantvoltage) battery charger is required.

NOTE: Do not connect any load to battery or

use engine starter motor while

charging. This causes high current to

fl ow through generator which will burn

out coil.

NOTE: Prior to charging battery, remove

positive and negative cables to battery.

1. Start generator.

2. Press DC circuit protector (X) in.

3. Connect red battery charger lead to positive

battery terminal. Connect black battery

charger lead to negative battery terminal. Do

not reverse these positions. Connect cord to

DC receptacle (Y).

Operating Range of DC Power Supply

(Charging 12V battery only):

This power source is designed to charge

batteries up to 40Ah that are half-discharged.

Do not charge batteries of a higher capacity

than 40Ah.

12V Battery:

Time required for recharging a battery varies

depending on discharge level of battery. When

specifi c gravity of battery reaches 1.26 to 1.28,

charging is complete. When charging, check

battery’s specifi c gravity once an hour. Average

time for charging a half-discharged 40Ah

battery is approximately 5 hours. Be sure to

check battery fl uid level before charging.

DC Circuit Protector

NOTE: Reduce load of connected electric

device below specifi ed rated output of

generator if DC circuit protector (X)

turns off. If DC circuit protector (X)

turns off again, stop using device

immediately and contact a Kohler

portable dealer.

DC circuit protector (X) button will pop out,

stopping power to DC receptacle (Y) when

electric device being connected to generator is

operating at current above rated fl ows. To use

this equipment again, press DC circuit protector

(X) button.

Starter Battery

As starter battery (AI) is maintenance-free, just

check condition and tightness of connections

and its general cleanliness.

Generator and Retention Container

NOTE: Clean inside and outside of generator

regularly. Clean generator more

frequently if it is installed in a densely

wooded area or in a corrosive

atmosphere, or if it has been made

dirty by dust or organic material (rotting

leaves, moss, fecal matter, etc.).

NOTE: When cleaning exterior, a cleaning

foam may be used and wiped off using

a soft, absorbent cloth. Stubborn stains

may be removed using a suitable

solvent (white spirit or equivalent) and

wiped off using a soft, absorbent cloth.

1. Wash outside of generator using water with a

mild detergent added (e.g. car shampoo).

2. Rinse with clear fresh water to remove any

trace of cleaning product.

3. Open generator top cover (A) and engine

access door (E).

4. Check that there is no fl uid or debris in

retention container (F). If necessary, pump

fl uid into a suitable container.

5. Any fl uids present in retention container (F)

(rainwater, engine oil or fuel) must be

recycled or eliminated according to local

regulations in force.

6. Close generator top cover (A) and engine

access door (E).

Transporting Generator

Before transporting generator, check that

bolts are correctly tightened, close fuel valve

and disconnect battery. Generator should be

transported in its normal operating position;

never lay it on its side. Ensure where generator

is to be stored or used is carefully prepared

beforehand.

Repairs/Service Parts

We recommend that you use a Kohler portable

dealer for all maintenance, service, and

replacement parts for engine. To fi nd a Kohler

portable dealer visit KohlerPower.com or call

1-800-544-2444 (U.S. and Canada).

Storage

Long-term storage of your generator will require

some preventative procedures to guard against

deterioration.

NOTE: Do not connect with any electrical

devices (unloaded operation).

If generator will be out of service for 2 months

or more follow procedure below.

1. Replace fuel fi lter (G).

2. Add STP® Diesel Fuel Injector Treatment to

fuel following directions on bottle.

3. Start engine, ensure there are no fuel leaks

and then stop engine.

4. While engine is still warm, change oil and

replace oil fi lter (AE).

5. Clean precleaner (K).

6. Clean generator.

7. Cover generator with a protective cover to

protect it against dust and store it in a clean

and dry place.

11

38 590 01 Rev. B

KohlerPower.com

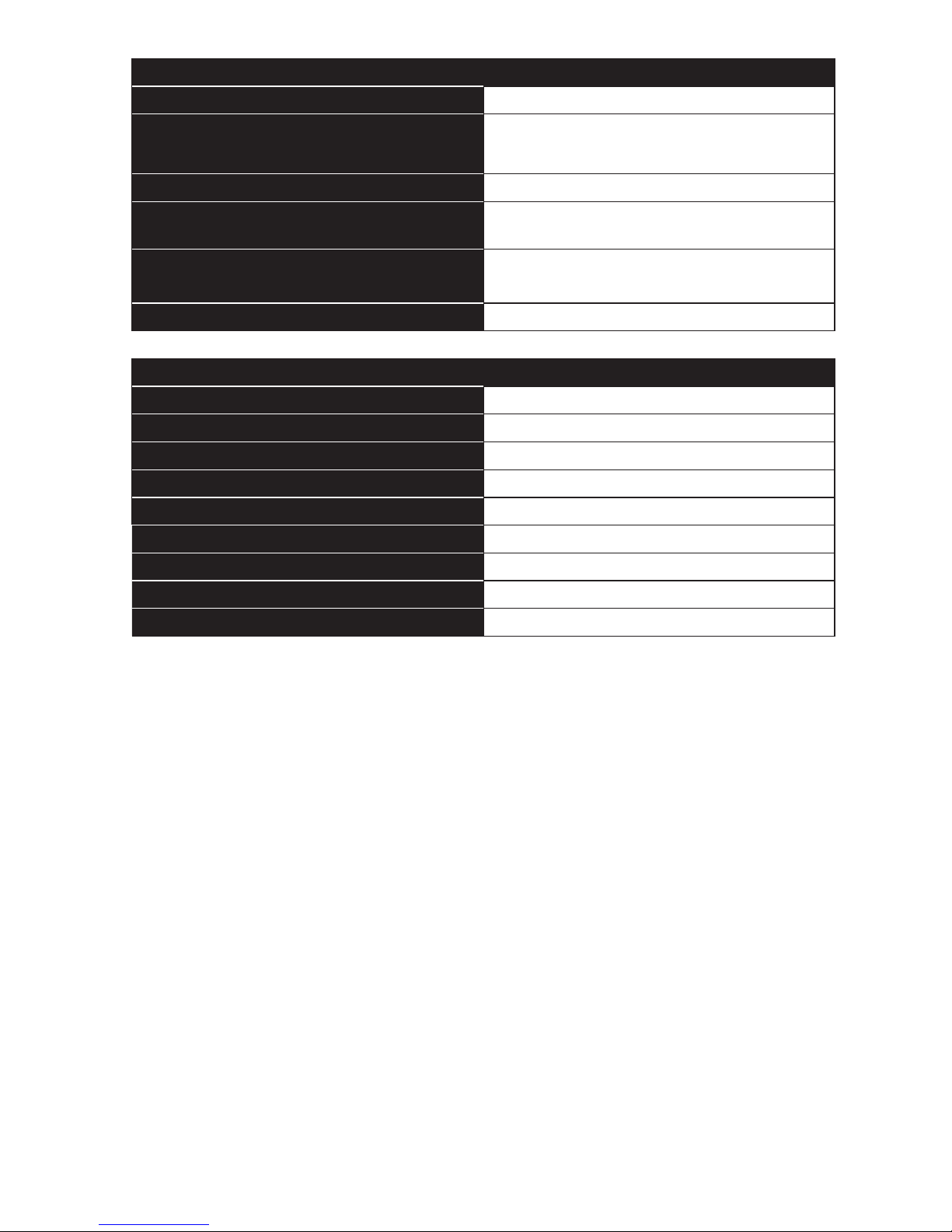

Repairing Minor Faults - MODYS Alarms and Faults

Pictograms

Color of

LED

Type of Fault Issue Possible Solution

Green Plug preheating

No issue: plug

preheating sequence

–

Red

Engine

temperature

Shutdown: abnormal

engine temperature

Allow generator to cool

down and check air

cleaner and vents on

enclosure.

Red

Battery or

charging

alternator

Problem with alternator

charge output or weak

battery

Contact a Kohler

portable dealer.

Red

Oil pressure or

low oil level

Shutdown: incorrect oil

pressure or low oil level

Allow generator to cool

down, top up and check

oil level.

Red Non-starting fault

3 consecutive

unsuccessful starting

attempts

Check that generator has

been started according to

recommendations in this

manual.

Red Overspeed

Shutdown: generator

rotation speed

excessive

Contact a Kohler portable

dealer.

Flashing

Red

Speed too low

Shutdown: insuffi cient

generator rotation

speed

Contact a Kohler portable

dealer.

Troubleshooting

Do not attempt to service or replace major engine components, or any items that require special

timing or adjustment procedures. This work should be performed by a Kohler portable dealer.

Problem

Possible Cause

Engine Not

Starting/

Running

Abnormally

Engine

Stopped

No Electric

Current

Tripping

of Circuit

Breaker

Load connected to generating set

during start-up

●

Start and Stop control ON or OFF ●

Oil level too low ●●

Unsuitable fuel ●

Fuel level too low ●●

Fuel valve closed ●

Clogged fuel fi lter ●

Clogged air fi lter ●

Fuel supply blocked or leaking ●

Faulty starter battery ●

Blocked ventilation inlets ●

Circuit protectors not actuated ●

Faulty appliance supply cord ●

Faulty electrical sockets ●

Faulty alternator ●

Device connected or faulty cord ●

Overload ●

Battery Incorrectly Connected ●●

Faulty MODYS Fuses (R) ●

EN

12 38 590 01 Rev. BKohlerPower.com

Specifi cations

Model

PRO 5.4 DES

Overall Dimensions

19.2 in. (990 mm) Length

15.6 in. (610 mm) Width

16.7 in. (940 mm) Height

Dry Weight 437 lbs. (198 kg)

AC Rated Power 4700 Watt

(120 Volts x 39.2 Amps)

(240 Volts x 19.6 Amps)

AC Surge Power 5400 Watt

(120 Volts x 45.0 Amps)

(240 Volts x 22.5 Amps)

DC Rated Power 100 Watt (12 Volts x 8.3 Amps)

Engine Specifi cations

Bore

3.4 in. (86 mm)

Stroke 3.0 in. (76 mm)

Displacement 27 cu. in. (442 cc)

Oil Capacity (Refi ll) 1.6 U.S. qt. (1.5 L)

Maximum Angle of Operation (@ full oil level)* 25°

Run Time 18.3 hours (1/2 load)

Fuel See fuel section

Fuel Tank Capacity 6 Gal. (22.7 L)

Noise Level 65-68 dB(A) @ 7 m

*Exceeding maximum angle of operation may cause engine damage from insuffi cient lubrication.

Additional specifi cation information can be found in service manual at KohlerPower.com.

Exhaust Emission Control System for model PRO 5.4 DES is EM, DDI and EGR for U.S. EPA,

California, and Europe.

Loading...

Loading...