Page 1

PRO 5.2, PRO 5.2 E, PRO 7.5, PRO 7.5 E

Generator Service Manual

IMPORTANT: Read all safety precautions and instructions carefully before operating equipment. Refer to operating

instruction of equipment that this engine powers.

Ensure engine is stopped and level before performing any maintenance or service.

For all engine related maintenance, disassembly and reassembly, refer to service manual of engine

powering this equipment.

2 Safety

3 Specifi cations

6 Troubleshooting

9 Electrical System

14 Disassembly/Inspection and Service

16 Reassembly

KohlerPower.com37 690 01 Rev. --

1

Page 2

Safety

SAFETY PRECAUTIONS

WARNING: A hazard that could result in death, serious injury, or substantial property damage.

CAUTION: A hazard that could result in minor personal injury or property damage.

NOTE: is used to notify people of important installation, operation, or maintenance information.

WARNING

WARNING

Explosive Fuel can

cause fi res and severe

burns.

Do not fi ll fuel tank while

engine is hot or running.

Gasoline is extremely fl ammable

and its vapors can explode

if ignited. Never refuel while

smoking or in vicinity of an open

fl ame. Store gasoline only in

approved containers, in well

ventilated, unoccupied buildings,

away from sparks or fl ames.

Spilled fuel could ignite if it comes

in contact with hot parts or sparks

from ignition. Never use gasoline

as a cleaning agent.

WARNING

Rotating Parts can cause

severe injury.

Stay away while

generator is in operation.

Keep hands, feet, hair, and

clothing away from all moving

parts to prevent injury. Never

operate generator with covers,

shrouds, or guards removed.

WARNING

Carbon Monoxide can

cause severe nausea,

fainting or death.

Avoid inhaling exhaust

fumes.

Engine exhaust gases contain

poisonous carbon monoxide.

Carbon monoxide is odorless,

colorless, and can cause death if

inhaled.

Accidental Starts can

cause severe injury or

death.

Disconnect and ground

spark plug lead(s) before

servicing.

Before working on engine or

equipment, disable engine as

follows: 1) Disconnect spark plug

lead(s). 2) Disconnect negative (–)

battery cable from battery.

Do not allow children to operate

generator.

Hot Parts can cause

severe burns.

Do not touch generator

while operating or just

after stopping.

Never operate generator with heat

shields or guards removed. Do not

modify generator.

Place generator in a place where

pedestrians or children are not

likely to touch generator.

Be sure to carry generator only by

its carrying handles.

Cleaning Solvents can

cause severe injury or

death.

Use only in well

ventilated areas away

from ignition sources.

Carburetor cleaners and solvents

are extremely fl ammable. Follow

cleaner manufacturer’s warnings

and instructions on its proper and

safe use. Never use gasoline as a

cleaning agent.

WARNING

WARNING

Electrical Shock can

cause injury.

Do not touch wires while

engine is running.

Never operate generator in rain or

snow.

Never touch generator with wet

hands or electrical shock may

occur.

Hazardous Voltage.

Backfeed to utility system

can cause property

damage, severe injury, or

death.

Never plug a portable generator

directly into a building outlet.

If generator is used for standby

power, have a certifi ed, licensed

electrician install an automatic

transfer switch to prevent

inadvertent interconnection of

standby and normal sources of

supply.

CAUTION

CAUTION

2 37 690 01 Rev. --KohlerPower.com

Page 3

Specifi cations

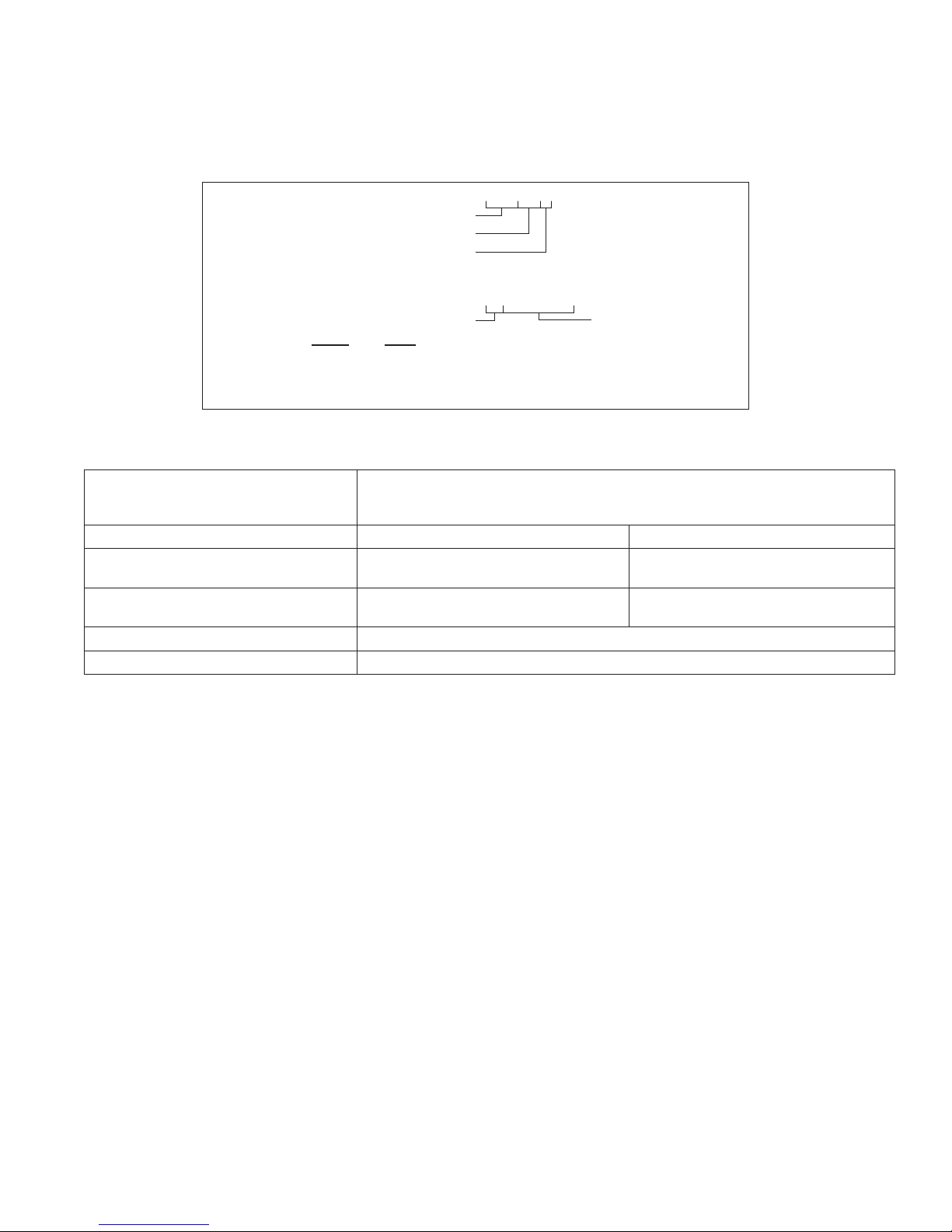

ENGINE IDENTIFICATION NUMBERS

Kohler engine identifi cation numbers (model, specifi cation and serial) should be referenced for effi cient repair,

ordering correct parts, and engine replacement.

Model . . . . . . . . . . . . . . . . . . . . . PRO5.2E

PRO

Numerical Designation

Optional

Specifi cation . . . . . . . . . . . . . . . PA-PRO52E-3001

Serial . . . . . . . . . . . . . . . . . . . . . 4323500328

Year Manufactured Code Factory Code

Code Year

43 2013

44 2014

45 2015

SPECIFICATIONS PRO 5.2/PRO 5.2 E PRO 7.5/PRO 7.5 E

Overall Dimensions (L x W x H) 670 mm (26.4 in.)

545 mm (21.5 in.)

535 mm (21.1 in.)

Dry Weight 76 kg (168 lbs.)/86 kg (189 lbs.) 90 kg (199 lbs.)/100 kg (220 lbs.)

AC Rated Power

AC Surge Power

DC Rated Power 100 Watt (12 Volts x 8.3 Amps)

Fuel Tank 30.2 L (8 gal.)

4500 Watt

5200 Watt

(120 Volts x 37.5 Amps)

(240 Volts x 18.8 Amps)

(120 Volts x 43.3 Amps)

(240 Volts x21.7 Amps)

6300 Watt

7500 Watt

(120 Volts x 52.5 Amps)

(240 Volts x 26.3 Amps)

(120 Volts x 62.5 Amps)

(240 Volts x 31.3 Amps)

337 690 01 Rev. -- KohlerPower.com

Page 4

Specifi cations

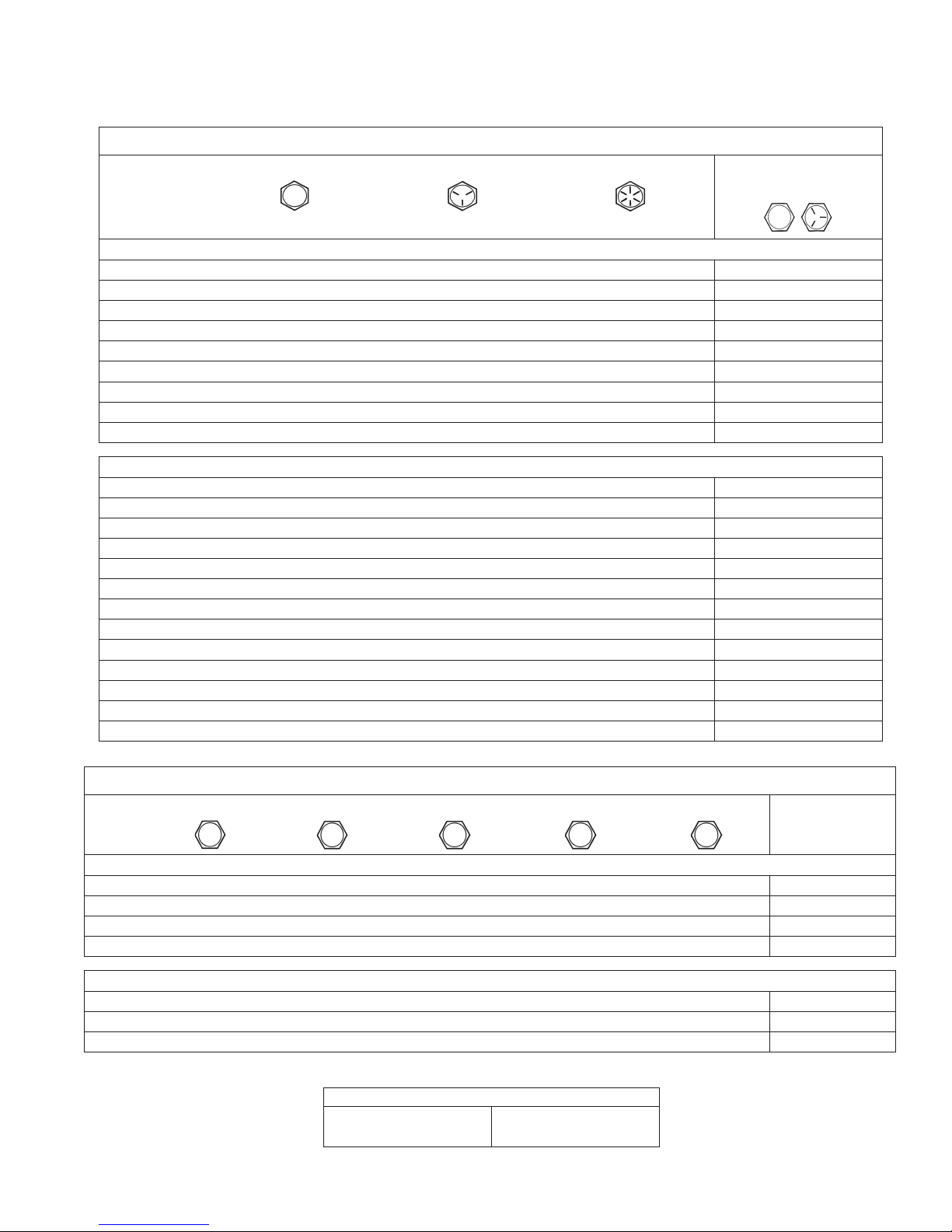

TORQUE SPECIFICATIONS

3

Alternator Front Cover 53.5 N·m (474 in. lb.)

Alternator Rear Cover 4.5 N·m (40 in. lb.)

AVR and Brush Assembly 4.0 N·m (35 in. lb.)

Battery Mounting Bracket

M6 Screws

M8 Screws

9.9 N·m (87 in. lb.)

25.0 N·m (221 in. lb.)

Carbon Canister Mounting Bracket 9.9 N·m (87 in. lb.)

Control Panel Back Cover 5.8 N·m (51 in. lb.)

Control Panel Electrical Components

M3 Screws

M4 Screws

1.3 N·m (11 in. lb.)

2.9 N·m (26 in. lb.)

Control Panel 9.9 N·m (87 in. lb.)

Engine/Alternator Isolators 18.3 N·m (162 in. lb.)

Frame Assembly

M6 Screws

M10 Screws

11.5 N·m (102 in. lb.)

30.0 N·m (266 in. lb.)

Fuel Tank Mounting 9.9 N·m (87 in. lb.)

Muffl er Assembly

M8 Screws

M10 Screws

Muffl er Cover Assembly

Rotor Assembly

Stator Assembly

Wire Connector

25.0 N·m (221 in. lb.)

32.5 N·m (288 in. lb.)

9.9 N·m (87 in. lb.)

22.0 N·m (195 in. lb.)

10.4 N·m (92 in. lb.)

2.5 N·m (22 in. lb.)

3

Values are in Metric units. Values in parentheses are English equivalents.

4 37 690 01 Rev. --KohlerPower.com

Page 5

GENERAL TORQUE VALUES

English Fastener Torque Recommendations for Standard Applications

Bolts, Screws, Nuts and Fasteners Assembled Into Cast Iron or Steel

Grade 2 or 5 Fasteners

Size Grade 2 Grade 5 Grade 8

Tightening Torque: N·m (in. lb.) ± 20%

8-32 2.3 (20) 2.8 (25) — 2.3 (20)

10-24 3.6 (32) 4.5 (40) — 3.6 (32)

10-32 3.6 (32) 4.5 (40) — —

1/4-20 7.9 (70) 13.0 (115) 18.7 (165) 7.9 (70)

1/4-28 9.6 (85) 15.8 (140) 22.6 (200) —

5/16-18 17.0 (150) 28.3 (250) 39.6 (350) 17.0 (150)

5/16-24 18.7 (165) 30.5 (270) — —

3/8-16 29.4 (260) — — —

3/8-24 33.9 (300) — — —

Tightening Torque: N·m (ft. lb.) ± 20%

5/16-24 — — 40.7 (30) —

3/8-16 — 47.5 (35) 67.8 (50) —

3/8-24 — 54.2 (40) 81.4 (60) —

7/16-14 47.5 (35) 74.6 (55) 108.5 (80) —

7/16-20 61.0 (45) 101.7 (75) 142.5 (105) —

1/2-13 67.8 (50) 108.5 (80) 155.9 (115) —

1/2-20 94.9 (70) 142.4 (105) 223.7 (165) —

9/16-12 101.7 (75) 169.5 (125) 237.3 (175) —

9/16-18 135.6 (100) 223.7 (165) 311.9 (230) —

5/8-11 149.5 (110) 244.1 (180) 352.6 (260) —

5/8-18 189.8 (140) 311.9 (230) 447.5 (330) —

3/4-10 199.3 (147) 332.2 (245) 474.6 (350) —

3/4-16 271.2 (200) 440.7 (325) 637.3 (470) —

Specifi cations

Into Aluminum

Metric Fastener Torque Recommendations for Standard Applications

Size

4.8

Tightening Torque: N·m (in. lb.) ± 10%

M4 1.2 (11) 1.7 (15) 2.9 (26) 4.1 (36) 5.0 (44) 2.0 (18)

M5 2.5 (22) 3.2 (28) 5.8 (51) 8.1 (72) 9.7 (86) 4.0 (35)

M6 4.3 (38) 5.7 (50) 9.9 (88) 14.0 (124) 16.5 (146) 6.8 (60)

M8 10.5 (93) 13.6 (120) 24.4 (216) 33.9 (300) 40.7 (360) 17.0 (150)

Tightening Torque: N·m (ft. lb.) ± 10%

M10 21.7 (16) 27.1 (20) 47.5 (35) 66.4 (49) 81.4 (60) 33.9 (25)

M12 36.6 (27) 47.5 (35) 82.7 (61) 116.6 (86) 139.7 (103) 61.0 (45)

M14 58.3 (43) 76.4 (56) 131.5 (97) 184.4 (136) 219.7 (162) 94.9 (70)

Property Class

5.8

8.8

10.9 12.9

Torque Conversions

N·m = in. lb. x 0.113 in. lb. = N·m x 8.85

N·m = ft. lb. x 1.356 ft. lb. = N·m x 0.737

Noncritical

Fasteners

Into Aluminum

537 690 01 Rev. -- KohlerPower.com

Page 6

Troubleshooting

TROUBLESHOOTING GUIDE

When troubles occur, be sure to check simple causes which, at fi rst, may seem too obvious to be considered. For

example, a starting problem could be caused by an empty fuel tank.

Some general common causes of engine troubles are listed below and vary by engine specifi cation. Use these to

locate causing factors.

Condition Possible Cause Solution

No AC output Circuit breaker in OFF position. Switch circuit breaker to ON.

Circuit protector popped out. Press circuit protectors.

Engine not operating at rated RPM. Adjust engine running at normal operating

temperature to 3750 ± 100 RPM.

Circuit breaker or receptacles faulty. Test for voltage at circuit breaker and

receptacles.

Stator is faulty. Test for voltage and resistance.

Brushes are faulty. Test for resistance between brushes and

slip ring.

AVR is faulty. Test for voltage.

Low voltage at stator Field polarity was lost. Flash rotor fi eld.

Alternator can't output

rated power

Tests

Stator voltage

Engine not operating at rated RPM. Adjust engine running at normal operating

temperature to 3750 ± 100 RPM.

Overload condition. Calculate electrical power required by

electric appliances (in Watts). Reduce

total wattage of connected electric devices

within application range.

Appliance is faulty. Repair faulty appliance.

6 37 690 01 Rev. --KohlerPower.com

Remove rear cover and start engine with

no load. Check if stator terminals have

correct voltage.

Page 7

Stator resistance

Troubleshooting

With engine stopped, check main coil

stator winding resistance between wires

with ohmmeter or circuit tester. Replace if

out of specifi cation.

With engine stopped, check exciting coil

stator winding resistance between wires

with ohmmeter or circuit tester. Replace if

out of specifi cation.

Brush resistance

Flashing Field

With engine stopped, remove brush.

Check brush and slip ring of rotor for

resistance. Replace if out of specifi cation.

With engine stopped, momentarily touch

the brush terminals with leads from a good

12 volt battery.

737 690 01 Rev. -- KohlerPower.com

Page 8

Troubleshooting

Replace AVR

With engine stopped, replace AVR with a

new AVR. Start engine and adjust trimmer

on back of AVR. Test terminal voltage.

Voltage should be between 95-135V. If

voltage is met, original AVR is not adjusted

properly or faulty. Replace as necessary. If

voltage not met, check circuit breakers and

receptacles.

Unit Item

Main Winding

Field Winding Between slip ring 47.9Ω±10% 46.6Ω±10% 56.4Ω±10%

Exciter Winding Blue-Blue 1.30Ω±10% 1.60Ω±10% 1.02Ω±10%

DC Winding Orange-Orange - 0.10Ω±10% 0.08Ω±10%

Brush Length 9mm

NOTE: Alternator should not be in contact with panel, AVR, etc during above resistance tests. Alternator should be

tested at room temperature.

Red-Blue 0.37Ω±10% 0.27Ω±10% 0.13Ω±10%

White-Black 0.37Ω±10% 0.27Ω±10% 0.13Ω±10%

GEN 5.0 PRO5.2/5.2E PRO7.5/7.5E

Generator Spec.

REMARK

Red-White

(PRO 7.5 E)

Service limit:

5mm

8 37 690 01 Rev. --KohlerPower.com

Page 9

PRO 5.2 Wiring Diagram

Electrical System

F

F

BA

E

C

D

O

N

G

K

K

H

J

I

J

I

L

M

P Q

A Main Winding 1 B Main Winding 2 C Exciter Field Coil D Sub Coil

E Voltage Selector F Circuit Breaker G

I GFCI Receptacle J Circuit Protector 20A K Circuit Protector 30A L Ground Terminal

M Engine Switch N Maintenance Minder O AVR P Oil Sentry

Q Spark Plug R Ignition Module

240/120V/30A

Electrical Socket

R

H

120V/30A

Electrical Socket

™

937 690 01 Rev. -- KohlerPower.com

Page 10

Electrical System

PRO 5.2 E Wiring Diagram

H

BA

C

D

E

U

F

T

AD

G

S

AB

AC

H

I

M

Z

M

J

R

V

W

Y

L

K

L

L

K

N

O

P

Q

X

AA

A Main Winding 1 B Main Winding 2 C Exciter Field Coil D Sub Coil

E DC Winding F Auto Idle Coil G Voltage Selector H Circuit Breaker

I

M Circuit Protector 30A N Ground Terminal O Auto Throttle Switch P 12V DC Receptacle

Q On/Off/Start Switch R Auto Idle Module S Maintenance Minder T AVR

U Rectifi er V Diode W Battery Fuse X Starter Motor

Y 12 Volt Battery Z Stator AA

AC Spark Plug AD Oil Sentry

240/120V/30A

Electrical Socket

J

120V/30A

Electrical Socket

™

K GFCI Receptacle L Circuit Protector 20A

Electronic Throttle

Control

AB Ignition Coil

10

37 690 01 Rev. --KohlerPower.com

Page 11

PRO 7.5 Wiring Diagram

Electrical System

E

BA

C

D

M

L

E

F

G

I

H

I

H

J

K

N O

A Main Winding 1 B Main Winding 2 C Exciter Field Coil D Sub Coil

E Circuit Breaker F

I Circuit Protector 20A J Ground Terminal K Engine Switch L Maintenance Minder

M AVR N Oil Sentry

240/120V/30A

Electrical Socket

™

G

O Spark Plug P Ignition Coil

Electrical Socket

P

120V/30A

H GFCI Receptacle

1137 690 01 Rev. -- KohlerPower.com

Page 12

Electrical System

PRO 7.5 E Wiring Diagram

G

F

BA

Q

C

D

E

S

R

AB

AA

G

Z

H

I

P

V

U

X

W

K

J

K

L

J

L

M

N

O

T

Y

A Main Winding 1 B Main Winding 2 C Exciter Field Coil D Sub Coil

E DC Winding F Auto Idle Coil G Circuit Breaker H

I

M Auto Throttle Switch N 12V DC Receptacle O On/Off/Start Switch P Auto Idle Module

Q Maintenance Minder R AVR S Rectifi er T Starter Motor

U Battery Fuse V Diode W 12 Volt Battery X Stator

Y

120V/30A

Electrical Socket

Electronic Throttle

Control

J GFCI Receptacle K Circuit Protector 20A L Ground Terminal

Z Ignition Coil AA Spark Plug AB Oil Sentry

240/120V/30A

Electrical Socket

™

12

37 690 01 Rev. --KohlerPower.com

Page 13

WARNING

Accidental Starts can cause severe injury or

death.

Disconnect and ground spark plug lead(s)

before servicing.

CAUTION

Electrical Shock can cause injury.

Do not touch wires while engine is running.

Check Control Panel

Remove control panel from frame. Remove control box

from control panel and check each components and

wiring.

Disassembly

1. Remove the end cover and disconnect wire

terminals from wiring board.

2. Remove control panel.

3. After disconnecting individual wires, remove control

panel components.

Electrical System

Before working on engine or equipment, disable engine as

follows: 1) Disconnect spark plug lead(s). 2) Disconnect

negative (–) battery cable from battery.

Do not allow children to operate generator.

Reassembly

NOTE: Circuit diagrams provide colored wires used for

easy identifi cation. To replace wires, use heat-

resistant type wires (permissible temperature

range 75°C (167°F) or over) and same gauge of

wire that is removed.

1. Install receptacles, circuit breakers, sockets,

switches, etc. on control panel.

2. Connect wires to control panel components.

3. Assemble wire terminals to wiring board.

4. Assemble end cover to rear cover. Torque screws to

4 N·m (35 in. lb.).

5. Attach control panel and control box to frame.

1337 690 01 Rev. -- KohlerPower.com

Page 14

Disassembly/Inspection and Service

PRO 5.2, PRO 5.2 E, PRO 7.5, & PRO 7.5 E Components

R

Q

S

T

N

P

O

M

B

L

C

D

A

E

F

K

J

I

G

A Control Panel B Control Box C Rotor D Through Bolt

E Stator F Stator Cover G Rear Cover H AVR

I End Cover J Wiring Board K Brush Holder L Front Cover

M Muffl er Bracket N Muffl er Cover O Muffl er P Exhaust Pipe

Q Fuel Valve R Fuel Hose S Fuel Tank Cap T Fuel Filter

H

14 37 690 01 Rev. --KohlerPower.com

Page 15

WARNING

Accidental Starts can cause severe injury or

death.

Disconnect and ground spark plug lead(s)

before servicing.

Disassembly/Inspection and Service

Before working on engine or equipment, disable engine as

follows: 1) Disconnect spark plug lead(s). 2) Disconnect

negative (–) battery cable from battery.

Do not allow children to operate generator.

Be sure to memorize location of individual parts when

disassembling generator so that generator can be

reassembled correctly. Tag disassembled part with

necessary information to facilitate easier and smoother

reassembly.

For more convenience, divide parts into several groups

and store them in boxes.

To prevent screws from being misplaced or installed

incorrectly, replace them temporarily to their original

position.

Handle disassembled parts with care; clean them before

reassembly using a neutral cleaning fl uid.

Remove battery before disassembling generator.

(Electric start models).

Be sure to attach foam rubber linings inside covers on

their original position when reassembling generator.

When deformation or damage of foam rubber lining is

found, replace it with new part. Failure to do so will result

in poor performance and durability of generator.

Tie wires and fuel hoses using cable ties as they were in

original confi guration.

Remove Fuel Tank

1. Close fuel valve and remove fuel hose from

carburetor. Drain fuel into an approved container.

2. Disconnect fuel hose from fuel valve.

3. Remove screws from fuel tank, and remove fuel

tank.

Remove Muffl er

1. Remove screws securing muffl er cover, and muffl er

cover.

2. Remove screws for muffl er bracket.

3. Remove screws securing exhaust pipe to engine,

and remove muffl er.

Remove Control Panel

CAUTION

Electrical Shock can cause injury.

Do not touch wires while engine is running.

NOTE: When removing wiring terminals from wiring

board, it may be helpful to document the order.

1. Remove end cover.

2. Disconnect wire connections from alternator.

3. Remove wire terminals from wiring board.

4. Disconnect wiring from control panel to engine.

5. Remove screws securing control panel to frame.

6. To access inside control panel, remove screws

securing control box to control panel.

Remove AVR

1. Remove screws attaching AVR to rear cover and

remove AVR unit.

Remove Brush Holder

1. Remove screw attaching brush holder to rear cover

and remove brush holder.

Inspection

1. Inspect brushes for freedom of movement in brush

holder.

2. Check continuity between each brush tip and its wire

terminal.

3. Inspect brush-to-rotor contact surface for unusual

wear or contamination.

4. Check brush free length. Replace the brush

assembly if the length is less than 3/16 in.(5 mm).

Remove Stator

NOTE: Take care not to damage stator coil and rotor

coil when removing/installing them.

NOTE: Place stator core side down. Do not set stator on

coil end. Coils may be damaged.

NOTE: It may be easier in some instances to tip

generator set on a side. Ensure oil is drained

from engine prior to doing this.

NOTE: Rear cover and stator are screwed together. Do

not loosen or remove screws. Remove rear

cover from stator after separated from alternator.

NOTE: Stator is heavy; be prepared to handle the

weight to maneuver for inspection and service.

1. Remove nuts fi xing rear cover onto rubber mounts.

2. Remove stator.

a. Remove stater and rear cover as an assembly.

b. Remove screws connecting rear cover and stator.

3. Remove rear cover.

Remove Rotor

1. Remove through bolt of rotor.

2. Place a wooden block or similar material under rotor

to support weight as rotor is removed.

3. With a rubber mallet, tap rotor a few times. Rotor

should slide off engine shaft.

Remove Front Cover

1. Remove screws and washers securing front cover,

and remove front cover.

1537 690 01 Rev. -- KohlerPower.com

Page 16

Reassembly

PRO 5.2, PRO 5.2 E, PRO 7.5, & PRO 7.5 E Components

R

Q

S

T

N

P

O

M

B

L

C

D

A

E

F

K

J

I

G

A Control Panel B Control Box C Rotor D Through Bolt

E Stator F Stator Cover G Rear Cover H AVR

I End Cover J Wiring Board K Brush Holder L Front Cover

M Muffl er Bracket N Muffl er Cover O Muffl er P Exhaust Pipe

Q Fuel Valve R Fuel Hose S Fuel Tank Cap T Fuel Filter

H

16

37 690 01 Rev. --KohlerPower.com

Page 17

Reassembly

Install Front Cover

1. Attach front cover to engine main bearing cover.

Torque to 53.5 N·m (474 in. lb.).

Install Rotor

NOTE: Before installing rotor make sure crankshaft

taper and rotor are clean, dry, and completely

free of any lubricants. Presence of lubricants

can cause rotor to be over stressed and

damaged when screw is torqued to

specifi cations.

1. Mount rotor to engine shaft. Tighten through bolt.

Install Stator

1. Assemble rear cover to stator and pull out stator wire

harness through opening of rear cover.

2. Torque stator and rear cover screws to 10.4 N·m

(92 in. lb.).

3. Press stator with rear cover evenly onto rotor. Tap

with a rubber mallet to ensure rotor bearing is

pressed into rear cover.

4. Tighten rear cover screws to front cover. Torque to

4.5 N·m (40 in. lb.).

5. Set rubber mount screws into rear cover. Do not

tighten nuts at this moment.

Install Brush Holder

NOTE: Install brush holder evenly onto rear cover using

locating pin. If set incorrectly, damage may occur

when tightened with screw or when generator is

started.

1. Install brush holder. Torque screw to 4 N·m

(35 in. lb.).

Install Muffl er

1. Assemble muffl er pipe and gasket to engine exhaust

and snug screws.

2. Assemble muffl er bracket to rear cover and snug

screws.

3. Torque screws to:

M8 25 N·m (221 in. lb.).

M10 32.5 N·m (288 in. lb.).

4. Attach muffl er cover to muffl er. Torque to

9.9 N·m (87 in. lb.).

Install Control Panel

1. Place control panel onto frame. Torque to

9.9 N·m (87 in. lb.).

Install Fuel Tank

1. Mount fuel tank on frame. Torque nuts to

9.9 N·m (87 in. lb.).

2. Replace fuel hose to fuel valve.

Generator is now completely reassembled. Before

starting or operating engine, be sure to follow steps

below.

1. Make sure all hardware is tightened securely.

2. Turn on fuel supply.

3. Replace battery (if equipped).

4. Start generator following starting instructions.

5. Check for proper voltage at receptacles.

Install AVR

1. Attach connectors to brush holder, AVR unit. Torque

screws to 4 N·m (35 in. lb.).

Install End Cover

1. Tighten earth (ground) wire (green) to rear cover

with screw and washer.

2. Assemble earth (ground) wire between frame and

rear cover rubber mount. Torque nuts to

18.3 N·m (162 in. lb.).

3. Assemble wire terminal to wiring board.

4. Assemble end cover to rear cover. Torque screws to

4 N·m (35 in. lb.).

37 690 01 Rev. -- KohlerPower.com

17

Page 18

18

KohlerPower.com 37 690 01 Rev. --

Page 19

1937 690 01 Rev. -- KohlerPower.com

Page 20

© 2013 by Kohler Co. All rights reserved.

20

KohlerPower.com 37 690 01 Rev. --

Loading...

Loading...