Page 1

34 590 01 Rev. A

KohlerPower.com

EN

PRO 12.3 EFI

Generator Owner's Manual

IMPORTANT: Read all safety precautions and instructions carefully before

operating equipment.

Ensure generator is stopped and level before performing any

maintenance or service.

Record product information to reference when ordering parts or obtaining warranty coverage.

Specication

Serial Number

Purchase Date

ESS

FRC

Page 2

2 34 590 01 Rev. AKohlerPower.com

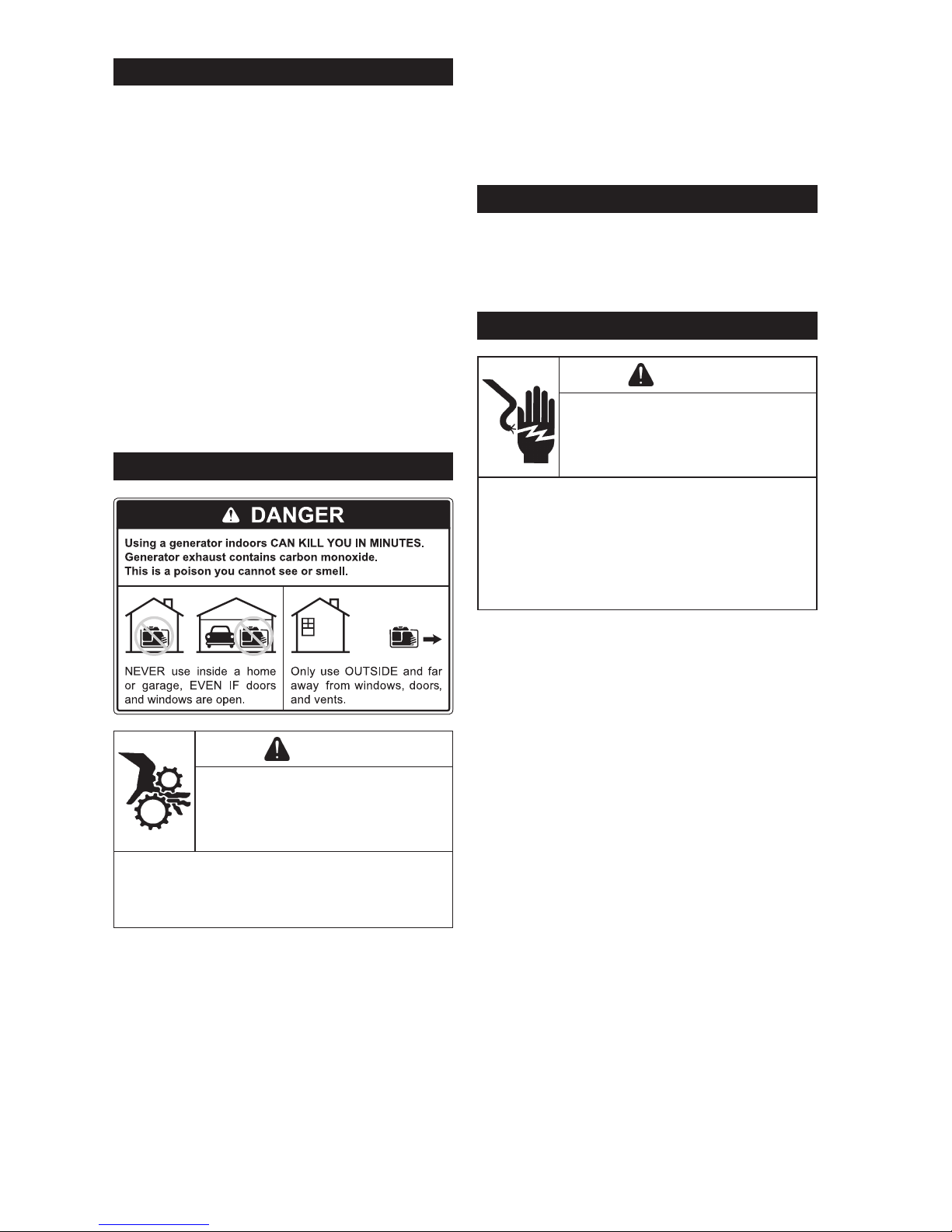

CAUTION

Electrical Shock

can cause injury.

Do not touch

wires while

generator is

running.

Never operate generator in

rain or snow.

Never touch generator

with wet hands or electrical

shock may occur.

WARNING

Rotating Parts

can cause

severe injury.

Stay away while

generator is in

operation.

Keep hands, feet, hair,

and clothing away from all

moving parts to prevent

injury. Never operate

generator with covers,

shrouds, or guards

removed.

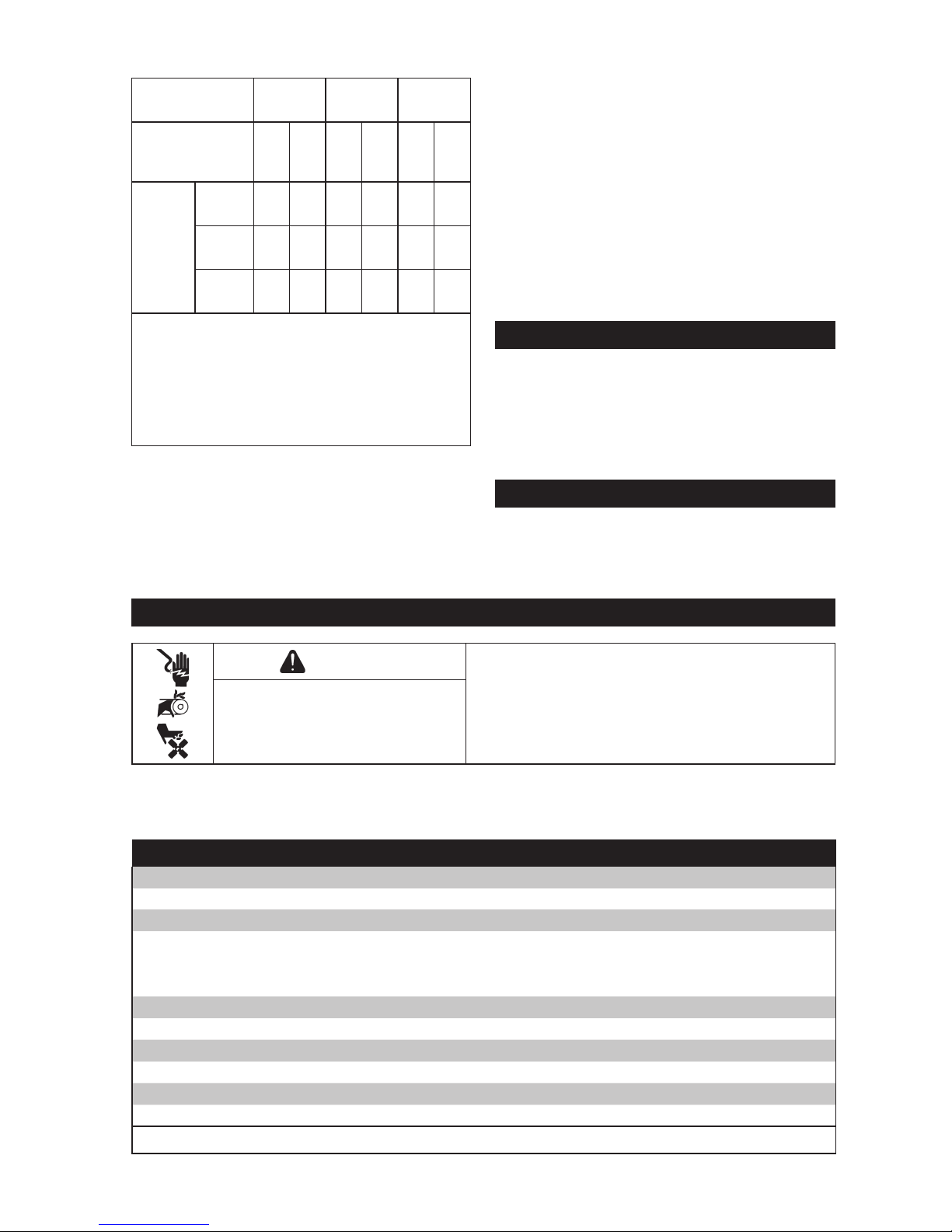

WARNING

Accidental

Starts can cause

severe injury or

death.

Disconnect and

ground spark

plug lead(s)

before servicing.

Before working on

generator or equipment,

disable engine as follows:

1) Disconnect spark plug

lead(s). 2) Disconnect

negative (–) battery cable

from battery.

Do not allow children to

operate generator.

WARNING

High Pressure

Fluids can

puncture skin

and cause

severe injury or

death.

Do not work

on fuel system

without proper

training or safety

equipment.

Fluid puncture injuries are

highly toxic and hazardous.

If an injury occurs, seek

immediate medical

attention.

WARNING

Hazardous

Voltage.

Backfeed to

utility system

can cause

property

damage, severe

injury, or death.

Never plug a portable

generator directly into a

building outlet.

If generator is used for

standby power, have a

certied, licensed electrician

install an automatic

transfer switch to prevent

inadvertent interconnection

of standby and normal

sources of supply.

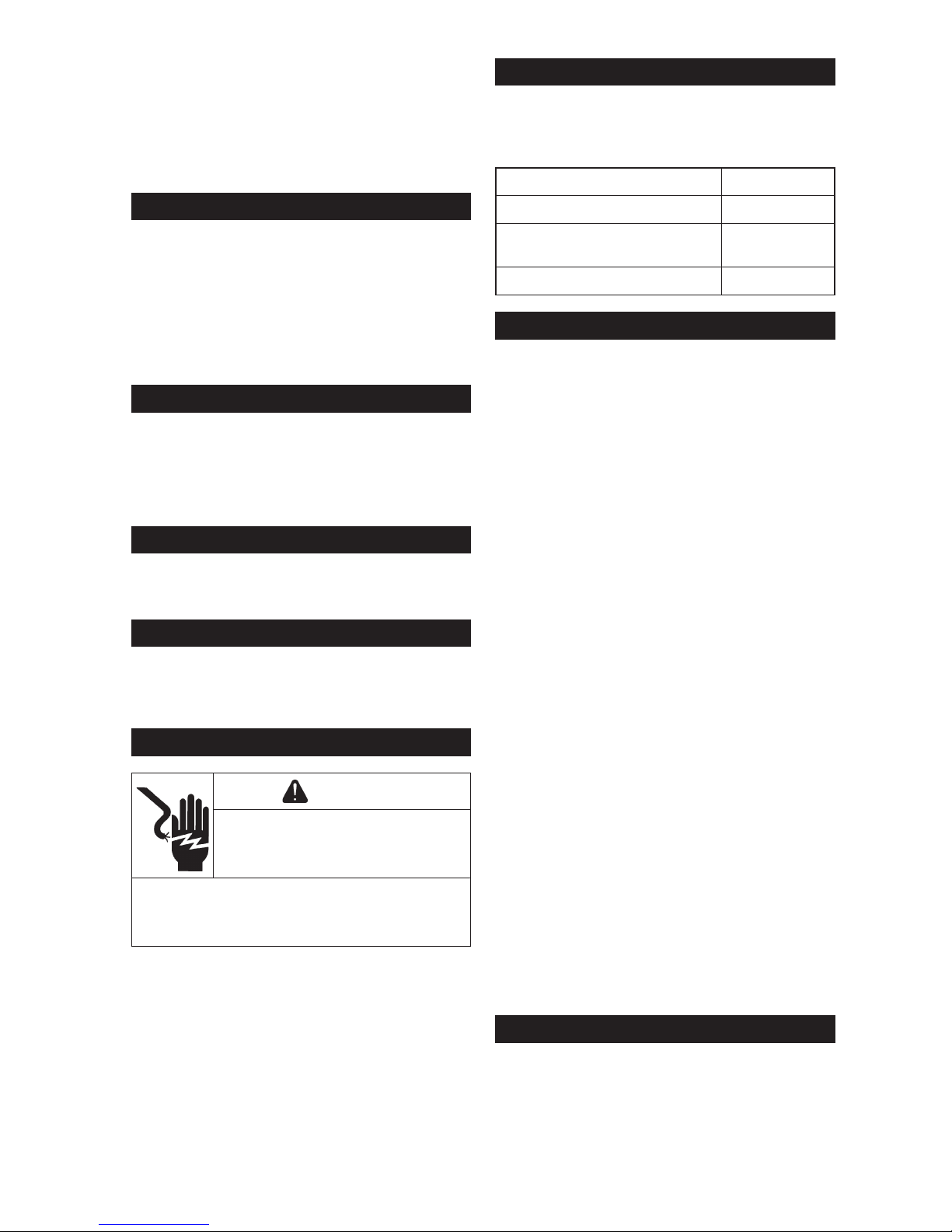

WARNING

Explosive Fuel

can cause res

and severe

burns.

Do not ll fuel

tank while

generator is hot

or running.

Gasoline is extremely

ammable and its vapors

can explode if ignited.

Never refuel while smoking

or in vicinity of an open

ame. Store gasoline only

in approved containers, in

well ventilated, unoccupied

buildings, away from sparks

or ames. Spilled fuel

could ignite if it comes in

contact with hot parts or

sparks from ignition. Never

use gasoline as a cleaning

agent.

WARNING

Hot Parts can

cause severe

burns.

Do not touch

generator while

operating or just

after stopping.

Never operate generator

with heat shields or guards

removed. Do not modify

generator.

Place generator in a place

where pedestrians or

children are not likely to

touch generator.

Be sure to carry generator

only by its carrying handles.

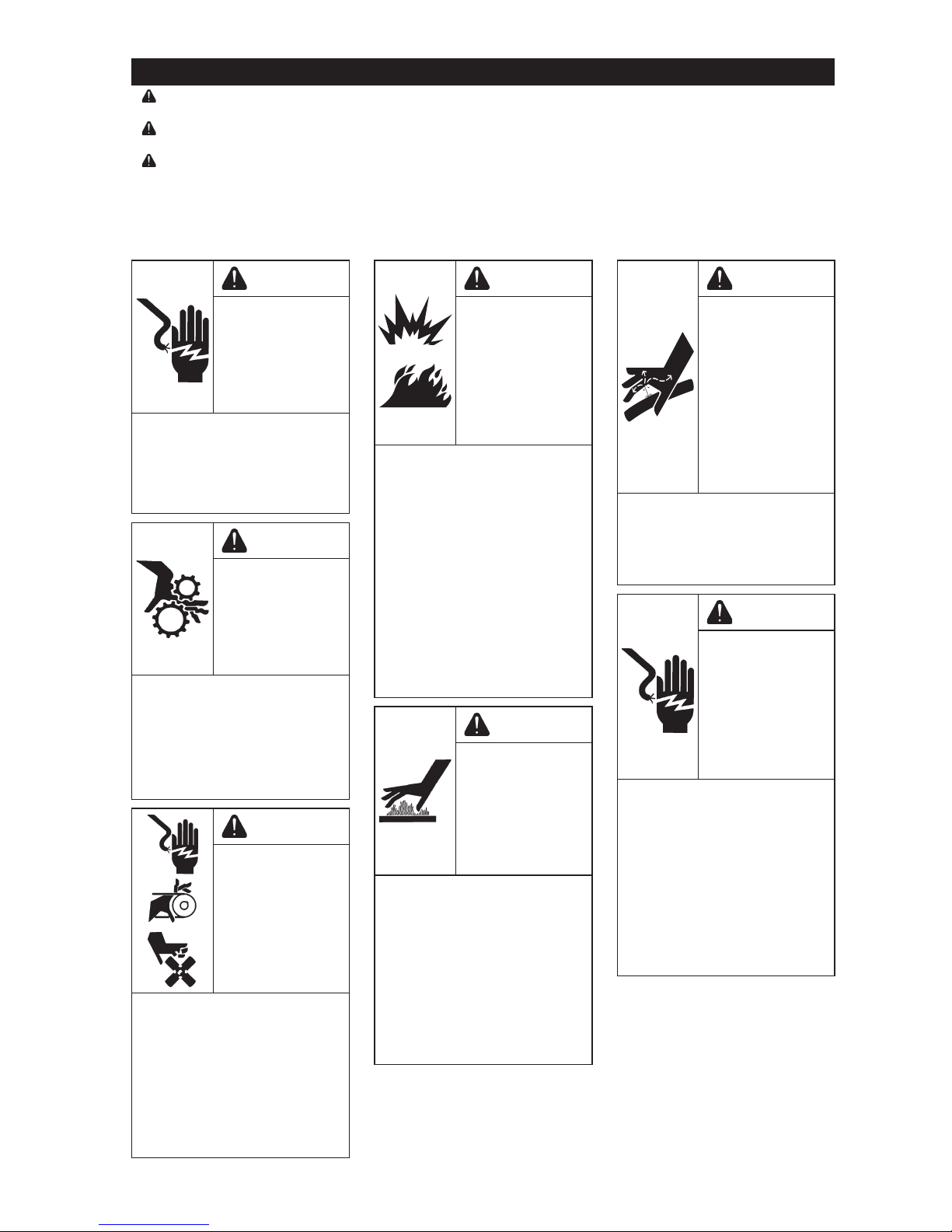

Safety Precautions

DANGER: A hazard that will result in death, serious injury, or substantial property damage.

WARNING: A hazard that could result in death, serious injury, or substantial property damage.

CAUTION: A hazard that could result in minor personal injury or property damage.

NOTE: is used to notify people of important installation, operation, or maintenance information.

Read this manual carefully before operating this machine. This manual should stay with this

machine if it is sold.

Page 3

3

34 590 01 Rev. A

KohlerPower.com

EN

California Proposition 65 Warning

Engine exhaust from this product contains chemicals known

to State of California to cause cancer, birth defects, or other

reproductive harm.

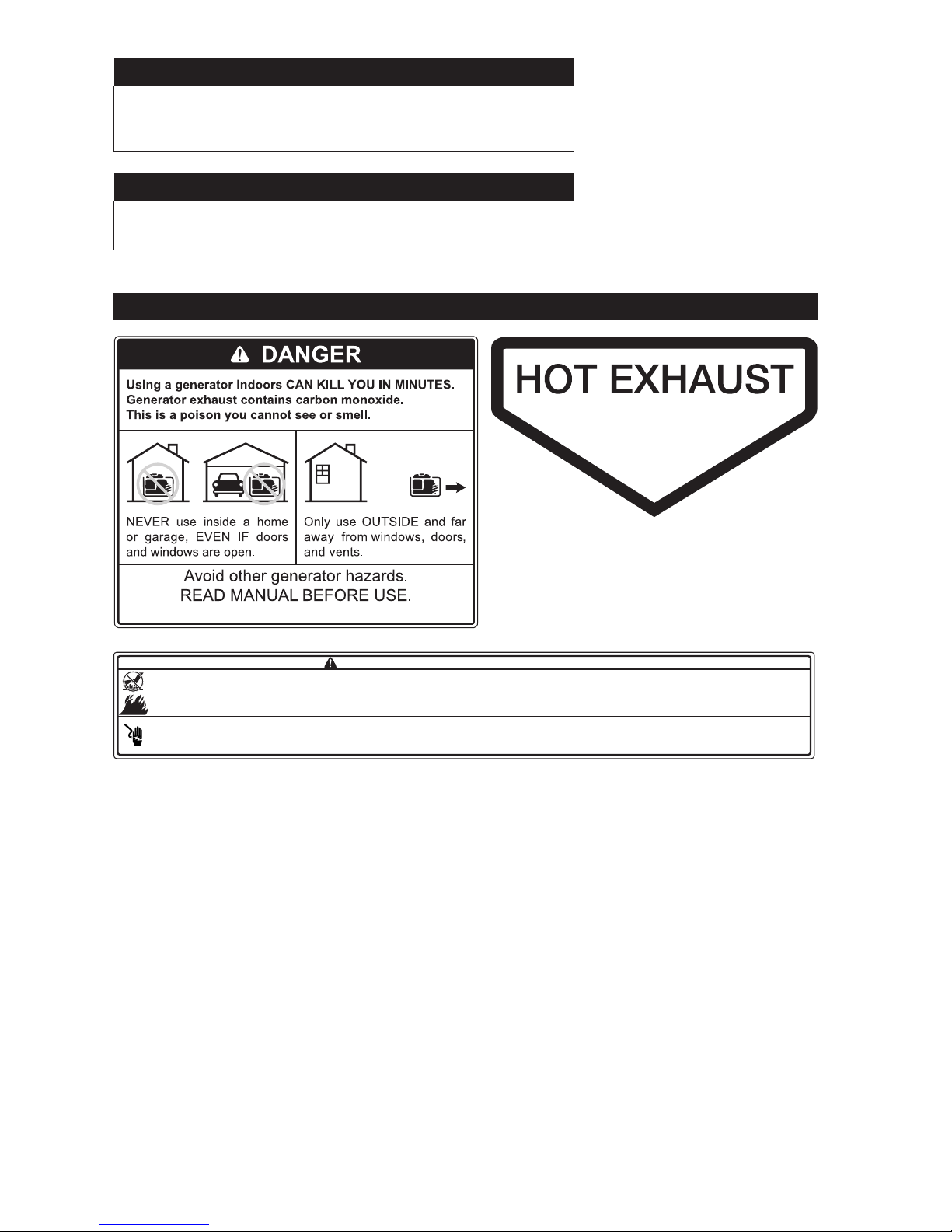

Important Labels on Generator

WARNING / ADVERTENCIA / AVERTISSEMENT

● Hot parts can cause severe burns. / Las piezas calientes pueden causar quemaduras graves. / Les pièces chaudes peuvent causer de graves brûlures.

● Do not touch generator while operating or just after stopping. / No toque el generador durante el funcionamiento o inmediatamente después de pararse. / Ne touchez pas le générateur pendant qu'il tourne ou si

vous venez tout juste de l'arrêter.

● Explosive Fuel can cause fires and severe burns. / La explosión del carburante puede provocar incendios y quemaduras graves. / Carburant explosif pouvant causer des incendies et des brûlures graves.

● Do not fill fuel tank while generator is hot or running. / No llene el tanque de combustible mientras el generador esté caliente o funcionando. / N'ajoutez pas de carburant si le moteur est chaud ou s'il tourne.

● Electrical shock can cause injury. / Las descargas eléctricas pueden provocar lesiones. / Les chocs électriques peuvent causer des blessures.

● Do not touch wires while generator is running. / No toque los cables con el generador en funcionamient. / Ne touchez pas aux le générateur pendant que le moteur tourne.

● Do not connect generator to a building's electrical system unless using an isolation (transfer) switch installed by a certified, licensed electrician. / No conecte el generador al sistema eléctrico de un edificio a menos

que use un aislamiento (transferencia) interruptor instalado por un electricista certificado y certificado. / Ne branchez pas le générateur dans le système électrique d’un bâtiment sauf si un commutateur-converteur

a été installé par un électricien agréé et compétent.

California Proposition 65 Warning

This product contains chemicals known to State of California

to cause cancer, birth defects, or other reproductive harm.

Page 4

4 34 590 01 Rev. AKohlerPower.com

W

Z

AG

AF

AE

AD

AB

AC

AA

V

U

C

B

F

T

Y

S

L

M N

R

Q

P

AH

AH

X

A

K

D

H

I

F

O

J

E

G

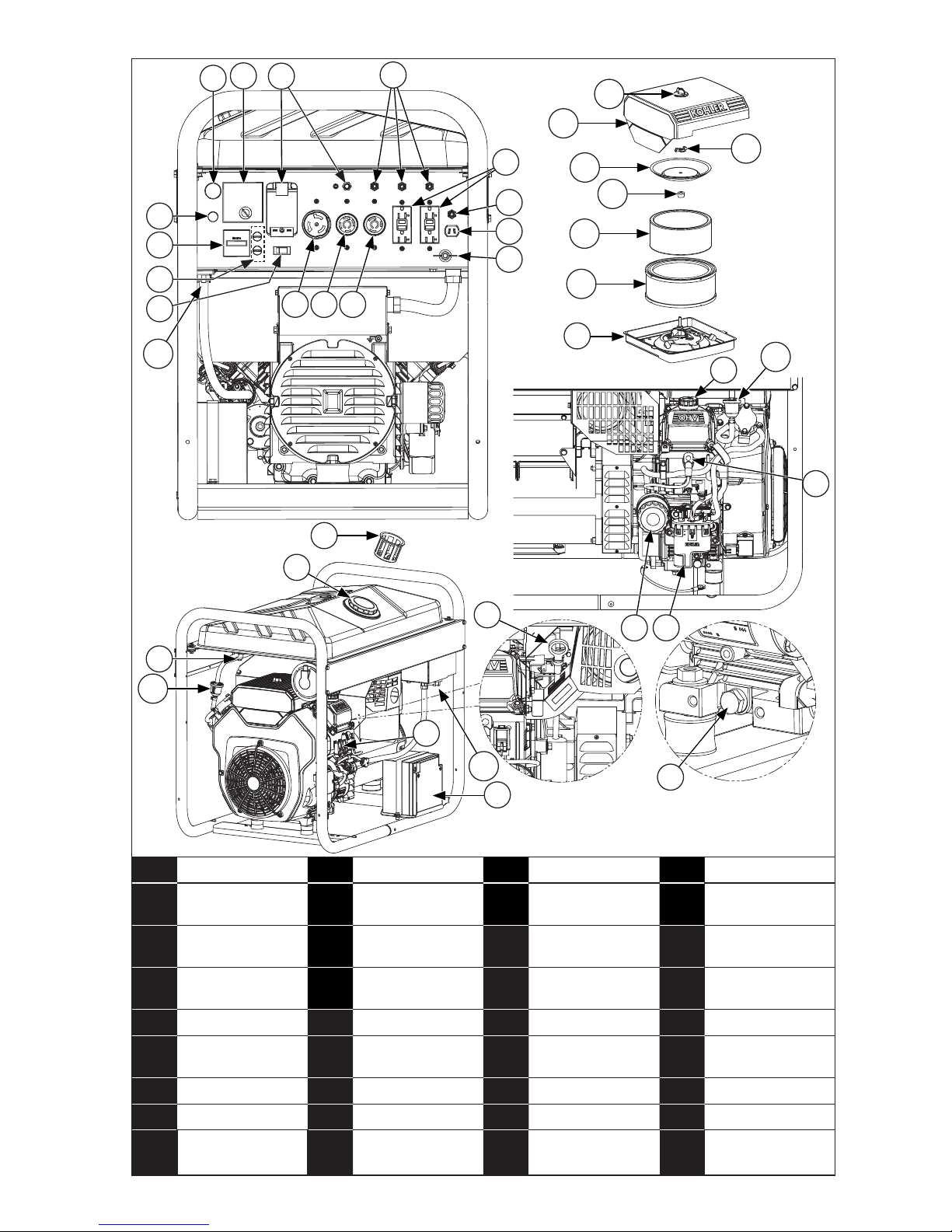

A Hour Meter B MODYS C Pilot Light D MIL Light

E Circuit Breaker F Circuit Protector G

GFCI

Receptacle

H

12V DC

Receptacle

I Ground Terminal J Fuse K Auto Idle L

240/120V/50A

Electrical Socket

M

240/120V/30A

Electrical Socket

N

120V/30A

Electrical Socket

O Fuel Tank Cap P Fuel Valve

Q Fuel Filter R Engine Fuses S Starter Battery T Dipstick

U Oil Drain Plug V Oil Filter W

Fuel Pump

Module

X Spark Plug

Y Oil Fill Cap Z Air Cleaner Base AA Paper Element AB Precleaner

AC Rubber Seal AD Element Cover AE Wing Nut AF Air Cleaner Knob

AG

Air Cleaner

Cover

AH

Unique EFI

Fuel Filter

AI

Wireless

Connect

AJ

Diagnostic

Button

AJ

AI

Page 5

5

34 590 01 Rev. A

KohlerPower.com

EN

Pre-Start Checklist

1. Ensure generator is at least 3.3 ft. (1 m) from

building or other equipment and not covered

with any material.

2. Refer to all warning labels prior to starting.

3. Check oil level. Add oil if low. Do not overll.

4. Check fuel level. Add fuel if low. Stop

refueling when indicator reaches F (full)

level. Check fuel system components and

lines for leaks. Never refuel while unit is

running.

5. Check starter battery (S).

6. Ground generator.

7. Check that air cleaner components and all air

inlets are unobstructed, equipment covers,

and guards are in place and securely

fastened.

8. Ensure electrical devices (load) are not

connected to generator.

Starting

WARNING

Rotating Parts can cause severe

injury.

Stay away while generator is in

operation.

Keep hands, feet, hair, and clothing away

from all moving parts to prevent injury. Never

operate generator with covers, shrouds, or

guards removed.

NOTE: Auto Idle (K) switch must be in OFF

position when using electric devices

that require a large starting current,

such as a compressor or a submersible

pump. Auto Idle (K) controls engine

speed according to connected load.

Results are better fuel consumption

and less noise.

NOTE: MODYS (B) automatically performs 5

start-up attempts.

1. Turn main AC circuit breaker (E) OFF.

2. Turn fuel valve (P) ON.

3. Turn MODYS (B) key to ON position.

4. Press START button on MODYS (B).

5. Test GFCI receptacles (G).

Cold Weather Starting

1. Use proper oil for temperature expected.

2. Disengage all possible external loads.

3. Use fresh winter grade fuel. Winter grade

fuel has higher volatility to improve starting.

Operation

WARNING

Hazardous Voltage.

Backfeed to utility system can

cause property damage, severe

injury, or death.

Never plug a portable generator directly into

a building outlet.

If generator is used for standby power,

have a certied, licensed electrician install

an automatic transfer switch to prevent

inadvertent interconnection of standby and

normal sources of supply.

When running speed of generator has

stabilized (approximately 3 minutes):

1. Check that circuit breakers (E) are pushed in.

Press if necessary.

2. Connect appliances to be used to electrical

sockets (G, L, M and N) of generator.

3. Hour meter (A) shows number of hours that

generator has worked.

Angle of Operation

Do not operate this engine exceeding maximum

angle of operation; see specication table.

Engine damage could result from insufcient

lubrication.

Page 6

6 34 590 01 Rev. AKohlerPower.com

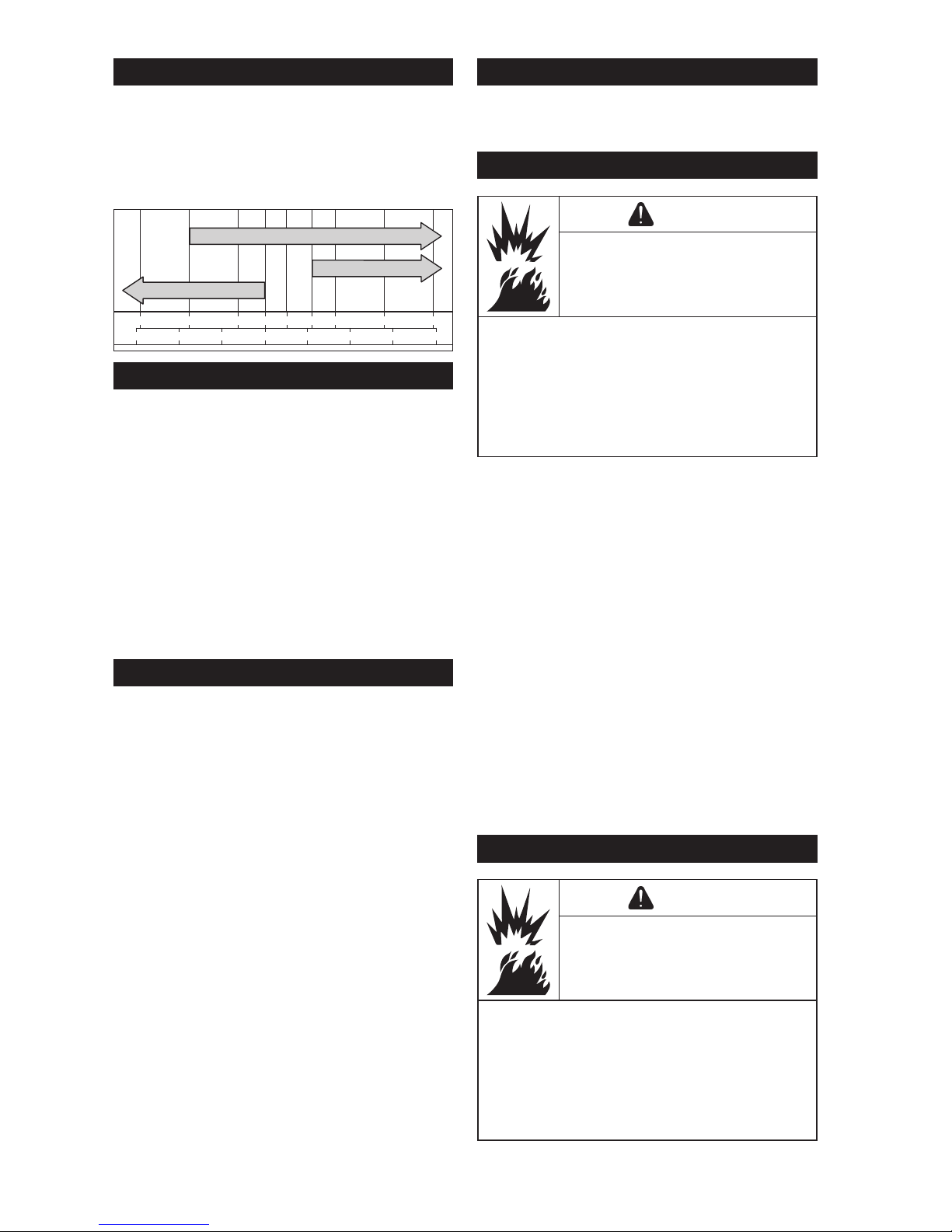

Cable Selection

Generator

Socket Type

10 A 16 A 32 A

Recommended

Cable Cross

Section

mm

2

AWG

mm

2

AWG

mm

2

AWG

Length

of

Cable

Used

0 to

50 m

4 10 6 9 10 7

51 to

100 m

10 7 10 7 25 3

101 to

150 m

1

10 7 16 5 35 2

1

This cable length is maximum permitted

length, and must not be exceeded.

Installation method=cables on raceway

or non-drilled tablet/Permitted drop in

voltage=5%/Multi-core conductors/Cable

type PVC 70°C (e.g. H07RNF)/Ambient

temperature=86° F (30° C).

Maintenance Instructions

WARNING

Before working on generator or equipment,

disable engine as follows: 1) Disconnect spark

plug lead(s). 2) Disconnect negative (–) battery

cable from battery.

Do not allow children to operate generator.

Accidental Starts can cause

severe injury or death.

Disconnect and ground spark

plug lead(s) before servicing.

Safety is an obligation of owner. Periodic inspection, adjustment and lubrication will keep your

generator in safest and most efcient condition possible. Most important points of generator

inspection, adjustment, and lubrication are explained on following pages.

Maintenance Schedule

First 25 Hours or Annually

1

● Service/replace precleaner (if equipped).

Every 100 Hours or Annually

1

● Change oil.

● Replace air cleaner element (AA).

● Remove and clean shrouds and cooling areas.

Every 200 Hours

1

● Replace unique Electronic Fuel Injection (EFI) fuel lter.

Every 200 Hours or Annually

1

● Change oil and lter (V).

Every 500 Hours or Annually

1

● Replace spark plugs (X) and set gap.

1

Perform these procedures more frequently under severe, dusty, dirty conditions.

Auto Idle

NOTE: Auto Idle will only function when unit is

on 120V function.

ON Position. When Auto Idle (K) switch is

in ON position, Auto Idle (K) controls engine

speed according to connected load. Results are

better fuel consumption and less noise.

OFF Position. When Auto Idle (K) switch is in

OFF position, engine runs at rated rpm (3,600

rpm) regardless of whether there is a load

connected or not.

NOTE: Turn Auto Idle to OFF when unit is using

240V conguration.

Stopping

1. Disconnect electrical devices and allow

engine to run without any load for 1-2

minutes.

2. Turn MODYS (B) key to OFF position

(generator stops).

3. Close fuel valve (P).

Engine Speed

NOTE: Do not tamper with governor setting to

increase maximum engine speed.

Overspeed is hazardous and will void

warranty.

Page 7

7

34 590 01 Rev. A

KohlerPower.com

EN

Oil Recommendations

We recommend use of Kohler oils for best

performance. Other high-quality detergent

oils (including synthetic) of API (American

Petroleum Institute) service class SJ or higher

are acceptable. Select viscosity based on air

temperature at time of operation as shown in

table below.

°F -20 020324060

50 80 100

°C -30 -20 -10 0 10 20 30 40

5W-30

10W-30

SAE 30

Check Oil Level

NOTE: To prevent extensive engine wear or

damage, never run engine with oil level

below or above operating range

indicator on dipstick (T).

Ensure engine is cool. Clean dipstick area of

any debris.

1. Remove dipstick (T); wipe oil off. Reinsert

dipstick (T) into tube; press completely down.

2. Remove dipstick (T); check oil level. Level

should be at top of indicator on dipstick (T).

3. If oil is low on indicator, add oil up to top of

indicator mark.

4. Reinstall and secure dipstick (T).

Change Oil and Filter

Change oil while engine is warm.

1. Clean area around dipstick (T) and oil drain

plug (U). Remove oil drain plug (U) and

dipstick (T). Allow oil to drain completely.

2. Clean area around oil lter (V). Place a

container under lter to catch any oil and

remove lter. Wipe off mounting surface.

Reinstall oil drain plug (U). Torque to 10 ft. lb.

(13.6 N·m).

3. Place new lter in shallow pan with open end

up. Fill with new oil until oil reaches bottom of

threads. Allow 2 minutes for oil to be

absorbed by lter material.

4. Apply a thin lm of clean oil to rubber gasket

on new lter.

5. Refer to instructions on oil lter (V) for proper

installation.

6. Fill crankcase with new oil. Level should be

at top of indicator on dipstick (T).

7. Reinstall dipstick (T) and tighten securely.

8. Start engine; check for oil leaks. Stop engine;

correct leaks. Recheck oil level.

9. Dispose of used oil and lter in accordance

with local ordinances.

Oil Sentry™ (if equipped)

This switch is designed to prevent engine

from starting in a low oil or no oil condition. Oil

Sentry™ will shut down a running engine.

Fuel Recommendations

WARNING

Explosive Fuel can cause res

and severe burns.

Do not ll fuel tank while

generator is hot or running.

Gasoline is extremely ammable and

its vapors can explode if ignited. Store

gasoline only in approved containers, in

well ventilated, unoccupied buildings, away

from sparks or ames. Spilled fuel could

ignite if it comes in contact with hot parts or

sparks from ignition. Never use gasoline as a

cleaning agent.

NOTE: E15, E20 and E85 are NOT approved

and should NOT be used; effects of

old, stale or contaminated fuel are not

warrantable.

Fuel must meet these requirements:

● Clean, fresh, unleaded gasoline.

● Octane rating of 87(R+M)/2 or higher.

● Research Octane Number (RON) 90 octane

minimum.

● Gasoline up to 10% ethyl alcohol, 90%

unleaded is acceptable.

● Methyl Tertiary Butyl Ether (MTBE) and

unleaded gasoline blend (max 15% MTBE by

volume) are approved.

● Do not add oil to gasoline.

● Do not overll fuel tank.

● Do not use gasoline older than 30 days.

Check Fuel Level

WARNING

Explosive Fuel can cause res

and severe burns.

Do not ll fuel tank while

generator is hot or running.

Gasoline is extremely ammable and

its vapors can explode if ignited. Store

gasoline only in approved containers, in

well ventilated, unoccupied buildings, away

from sparks or ames. Spilled fuel could

ignite if it comes in contact with hot parts or

sparks from ignition. Never use gasoline as a

cleaning agent.

Page 8

8 34 590 01 Rev. AKohlerPower.com

Engine Fuse Replacement

This engine has three (3) blade type automotive

fuses (R). Replacement fuses (R) must have

same rating as blown fuse. Use fuse chart

below to determine correct fuse (R).

Wire Color Fuse Rating

2 Solid Red Wires 10-amp Fuse

1 Red Wire with Black Stripe

1 Red Wire with White Stripe

10-amp Fuse

2 Purple Wires 30-amp Fuse

Air Cleaner

NOTE: Operating engine with loose or

damaged air cleaner components

could cause premature wear and

failure. Replace all bent or damaged

components.

NOTE: Paper element (AA) cannot be blown

out with compressed air.

Loosen knob (AF) and remove air cleaner cover

(AG).

Precleaner (AB):

1. Remove precleaner (AB) from paper element

(AA).

2. Replace or wash precleaner (AB) in warm

water with detergent. Rinse and allow to air

dry.

3. Saturate precleaner (AB) with new engine oil;

squeeze out excess oil.

4. Reinstall precleaner (AB) over paper element

(AA).

Paper Element (AA):

1. Clean area around element (AA). Remove

wing nut (AE), element cover (AD), and

paper element (AA) with precleaner (AB).

2. Separate precleaner (AB) from element (AA);

service precleaner (AB) and replace paper

element (AA).

3. Check condition of rubber seal (AC) and

replace if necessary.

4. Install new paper element (AA) on base (Z);

install precleaner (AB) over paper element

(AA); reinstall element cover (AD) and

secure with wing nut (AE).

Reinstall air cleaner cover (AG) and secure with

knob (AF).

Breather Tube

Ensure both ends of breather tube are properly

connected.

Visually check level of fuel. If necessary, ll up.

1. Unscrew fuel tank cap (O).

2. Fill fuel tank using a funnel, taking care not to

spill any fuel. Do not overll tank (there

should not be any fuel in ller neck).

3. Screw fuel tank cap (O) back on.

Fuel Filter

1. Open fuel tank cap (O).

2. Remove fuel lter (Q) from tank neck.

3. Clean fuel lter (Q) with a non-ammable

solvent or solvent with a high ash point. Dry

it fully. Replace as necessary.

4. Reinstall fuel lter (Q).

5. Reinstall fuel tank cap (O).

Electronic Fuel Injection (EFI) System

EFI is an electronically-controlled fuel

management system which is monitored by an

Electronic Control Unit (ECU). A Malfunction

Indicator Light (MIL) will illuminate if problems

or faults are detected. Servicing by a Kohler

portable dealer is necessary.

Fuel Line

High pressure fuel line meeting SAE R9

standard must be installed on Kohler Co.

engines equipped with an EFI system.

Fuel System Components

High pressure components inside fuel pump

module (W) are not serviceable. Engines are

equipped with a special EFI fuel lter (AH). See

Maintenance Schedule.`

Spark Plugs

CAUTION

Electrical Shock can cause injury.

Do not touch wires while

generator is running.

Never operate generator in rain or snow.

Never touch generator with wet hands or

electrical shock may occur.

Clean out spark plug recess. Remove plug and

replace.

1. Check gap using wire feeler gauge. Adjust

gap, see specication table for adjustment.

2. Install plug into cylinder head.

3. Torque spark plug (X) to 20 ft. lb. (27 N·m).

Page 9

9

34 590 01 Rev. A

KohlerPower.com

EN

Air Cooling

WARNING

Hot Parts can cause severe

burns.

Do not touch generator while

operating or just after stopping.

Never operate generator with heat shields or

guards removed. Do not modify generator.

Place generator in a place where pedestrians

or children are not likely to touch generator.

Be sure to carry generator only by its

carrying handles.

Proper cooling is essential. To prevent over

heating, ensure air cooling inlet and outlet

areas are clean and unobstructed. Avoid

spraying water at wiring harness or any

electrical components. Refer to Maintenance

Schedule.

Ground Terminal

Ground terminal (I) connects earth line for

prevention of electric shock. When electric

device is grounded, be sure to ground

generator also.

Connect generator to ground: Attach a 6 AWG

(10 mm2) copper wire to generator’s ground

connection and to a galvanized steel grounding

rod (not provided) driven 3.3 ft. (1 m) into

ground.

Connecting Alternating Current (AC)

NOTE: Ensure all electric devices including

lines and plug connection are in good

condition before connection to

generator.

NOTE: Ensure total load is within generator

rated output.

NOTE: Ensure receptacle load current is within

receptacle rated current.

1. Start engine.

2. Ensure AC pilot light (C) is on.

3. Plug into AC receptacle (G, L, M or N).

4. Turn on any electric devices.

AC Rated Power

AC rated power is maximum amount of power

generator can support.

AC Maximum Power

AC maximum power is additional power

generator momentarily produces to aid in

starting of electrical devices requiring power

above generator's rated power requirements.

GFCI Receptacle

CAUTION

Electrical Shock can cause injury.

Do not touch wires while

generator is running.

Never operate generator in rain or snow.

Never touch generator with wet hands or

electrical shock may occur.

To reduce chance of electrical shock:

1. Do not attempt to operate equipment if

ground fault circuit interrupter (GFCI) RESET

button pops out repeatedly during use.

2. Remember that only receptacles labeled

GFCI have ground fault circuit interrupter

protection.

Ground Fault Circuit Interrupter (GFCI) stops

power to protected receptacles (G) if a ground

fault (electrical leak) is detected. If RESET

button pops out, equipment plugged into

receptacle (G) may be faulty. If this happens,

check equipment carefully. If equipment

appears to be in good condition, press RESET

button rmly until a click is heard. This will

restore power. If RESET button pops out again,

unplug equipment immediately. Contact a

Kohler portable dealer before attempting to use

it again.

GFCI Receptacle Test

1. Start generator.

2. Press TEST button, if functioning properly

RESET button should pop out, stopping

power to outlet.

3. If GFCI operation is correct, push RESET

button in. If GFCI operates incorrectly,

contact a Kohler portable dealer.

Overload (Capacity of Generator)

Never exceed rated load of generator (in Amps

and/or Watts) when it is running continuously.

See specications table for rated outputs.

Before connecting and operating generator,

calculate electrical power required by electric

appliances (in Watts). This electrical power

rating is usually found on manufacturer's

plate on bulbs, electrical appliances, motors,

etc. Sum total of power required by these

appliances should not exceed nominal power

rating of generator.

Circuit protectors (F) and circuit breaker (E)

will stop power to protected receptacles (G, H,

L, M or N) when an overload of a connected

electrical device is detected or AC output

voltage rises to protect generator and any

connected electric devices.

Page 10

10 34 590 01 Rev. AKohlerPower.com

When overload occurs and power generation

stops, proceed as follows:

1. Turn off any connected electric devices and

stop generator.

2. Reduce total wattage of connected electric

devices within application range.

3. Check for blockages in cooling air inlet and

outlet areas and around control unit. If any

blockages are found, remove them.

4. After checking, restart generator.

Battery Charging Using DC Receptacle

CAUTION

Electrical Shock can cause injury.

Do not touch wires while

generator is running.

Never operate generator in rain or snow.

Never touch generator with wet hands or

electrical shock may occur.

NOTE: This section refers to charging 12V

batteries in other equipment like motor

vehicles or off-road vehicles. No

jump-starting is possible.

NOTE: Follow safety procedures when

handling batteries to avoid damage to

electrical components and battery

explosions. Refer to battery

manufacturers safety data sheet on

safety risks of working with batteries.

Refer to battery manufacturer's

instruction on battery charging/

maintaining procedures.

NOTE: Generator DC rated voltage is 12V DC

circuit protector (F) will turn off

automatically if current above rated

ows during battery charging. Start

generator rst, then connect generator

to battery for charging. Before starting

to charge battery, ensure DC circuit

protector (F) is in RESET position. If

DC circuit protector (F) turns off again,

stop charging battery immediately and

contact a Kohler portable dealer.

NOTE: Do not connect a VRLA (valve

regulated lead acid) battery. To charge

a VRLA battery, a special (constantvoltage) battery charger is required.

NOTE: Do not connect any load to battery or

use engine starter motor while

charging. This causes high current to

ow through generator which will burn

out coil.

NOTE: Prior to charging battery, remove

positive and negative cables to battery.

1. Start generator.

2. Press DC circuit protector (F) in.

3. Connect red battery charger lead to positive

battery terminal. Connect black battery

charger lead to negative battery terminal. Do

not reverse these positions. Connect cord to

DC receptacle (H).

Operating Range of DC Power Supply

(Charging 12V battery only):

This power source is designed to charge

batteries up to 40Ah that are half-discharged.

Do not charge batteries of a higher capacity

than 40Ah.

12V Battery:

Time required for recharging a battery varies

depending on discharge level of battery. When

specic gravity of battery reaches 1.26 to 1.28,

charging is complete. When charging, check

battery’s specic gravity once an hour. Average

time for charging a half-discharged 40Ah

battery is approximately 5 hours. Be sure to

check battery uid level before charging.

DC Circuit Protector

NOTE: Reduce load of connected electric

device below specied rated output of

generator if DC circuit protector (F)

turns off. If DC circuit protector (F)

turns off again, stop using device

immediately and contact a Kohler

portable dealer.

DC circuit protector (F) button will pop out,

stopping power to DC receptacle (H) when

electric device being connected to generator is

operating at current above rated ows. To use

this equipment again, press DC circuit protector

(F) button.

Starter Battery

As battery (S) is maintenance-free, just check

condition and tightness of connections and its

general cleanliness.

Circuit Breaker

Generating set's electrical circuit is protected

by one or more magnetothermal, differential or

thermal cut-out switches. If an overload and/or

short circuit occurs, supply of electrical energy

may be cut.

If necessary, replace circuit breaker (E) in

generating set with circuit breakers with

identical nominal ratings and specications.

Cleaning Generator Set

1. Remove all dust and debris from around

exhaust silencer.

2. Clean generator and in particular air inlets

and outlets of engine and alternator using a

cloth and a brush.

3. Check general condition of generator and, if

necessary, replace any faulty parts.

Page 11

11

34 590 01 Rev. A

KohlerPower.com

EN

Replacing Protective Fuses

NOTE: Comply with technical specications for

fuses. Using wrong fuse may cause

damage to generator.

Replace fuses (J) in event of failures due to

overcurrents. Before replacing worn fuses

(J) with new ones, always contact a Kohler

portable dealer to determine cause of failure

and overcurrent.

1. Turn MODYS (B) key to OFF position.

Generator stops.

2. Unscrew 12V fuse holder for MODYS (B)

and lighting and 240V fuse holder for

MODYS (B) and working hours counter.

3. Visually check condition of both fuses (J).

4. Replace worn fuse(s) (J) with a new one of

5x20 type, rating 2A.

5. Screw two fuse holders back in.

Transporting Generator

Before transporting generator, check that bolts

are correctly tightened, close fuel valve (P)

and disconnect battery. Generator should be

transported in its normal operating position;

never lay it on its side. Ensure where generator

is to be stored or used is carefully prepared

beforehand.

Repairs/Service Parts

We recommend that you use a Kohler portable

dealer for all maintenance, service, and

replacement parts for engine. To nd a Kohler

portable dealer visit KohlerPower.com or call

1-800-544-2444 (U.S. and Canada).

Storage

Long-term storage of your generator will require

some preventative procedures to guard against

deterioration.

NOTE: Do not connect with any electrical

devices (unloaded operation).

If engine will be out of service for 2 months or

more follow procedure below.

1. Add Kohler PRO Series fuel treatment or

equivalent to fuel tank. Run engine 2-3

minutes to get stabilized fuel into fuel system

(failures due to untreated fuel are not

warrantable).

2. Change oil while engine is still warm from

operation. Remove spark plug(s) (X) and

pour about 1 oz. of engine oil into cylinder(s).

Replace spark plug(s) (X) and crank engine

slowly to distribute oil.

3. Clean generator.

4. Store generator in a dry, well-ventilated

place, with cover placed over it. When

covering generator, be sure to do so only

after engine and mufer/shield have

completely cooled down. Generator must

remain in same position as normal operation.

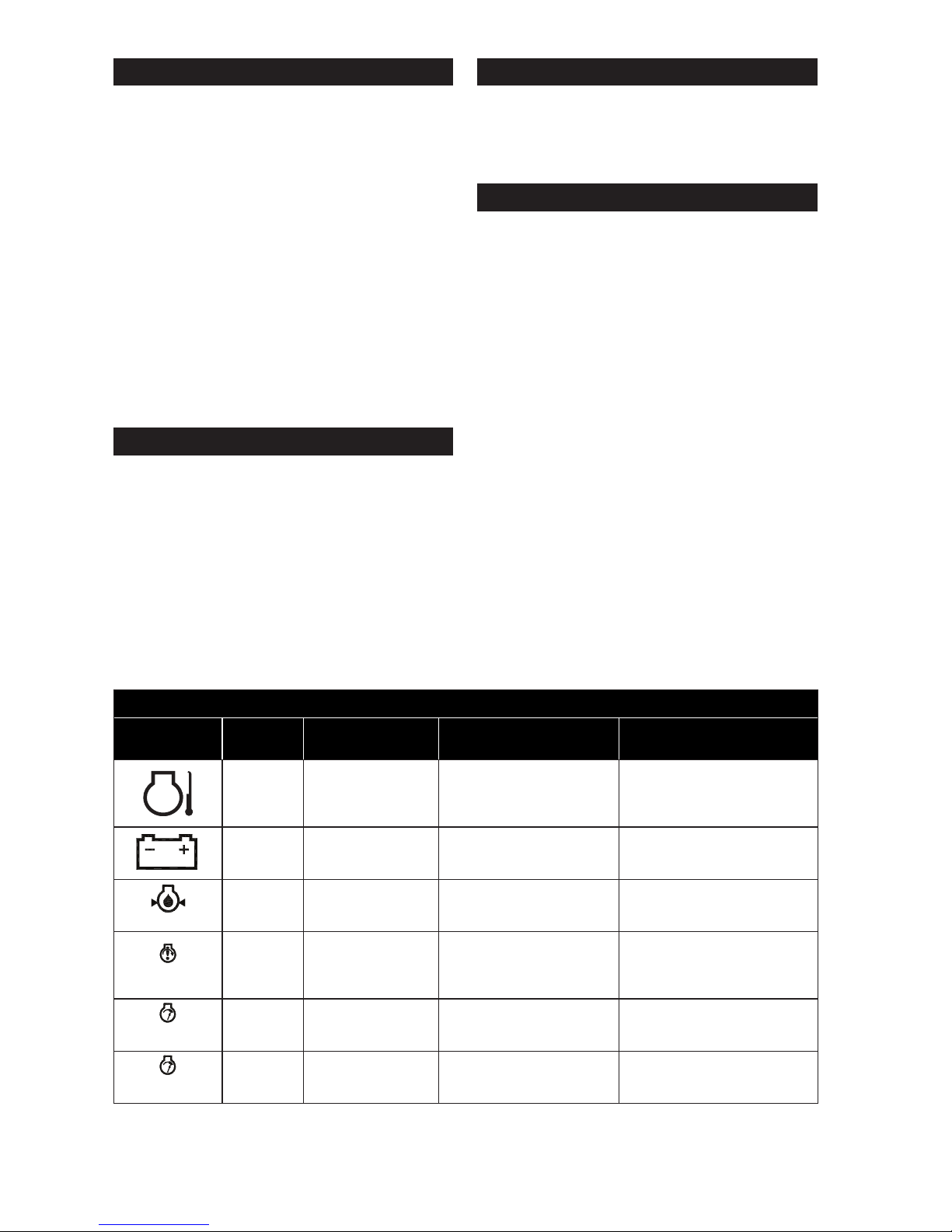

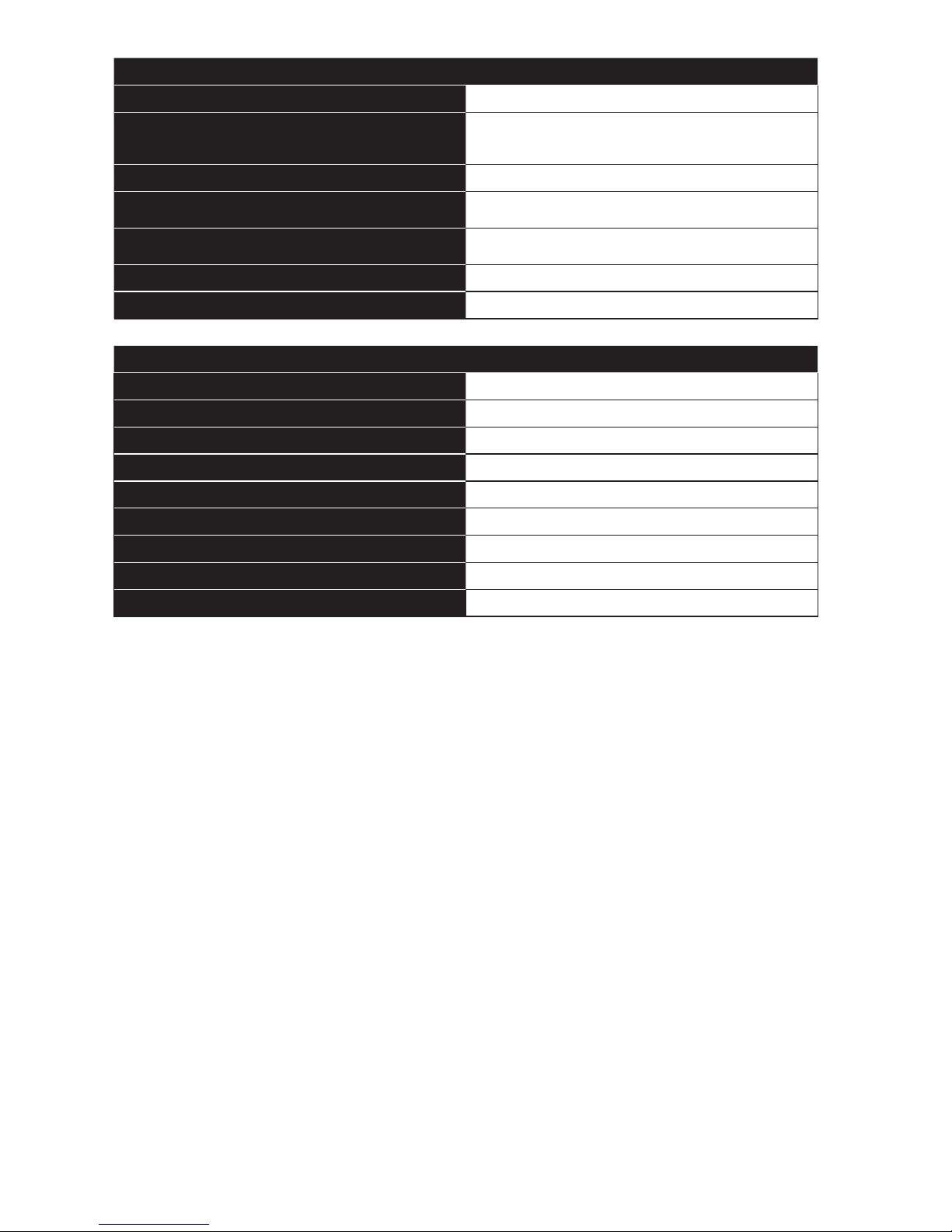

Repairing Minor Faults - MODYS Alarms and Faults

Pictograms

Color of

LED

Type of Fault Issue Possible Solution

Red

Engine

temperature

Shutdown: abnormal

engine temperature

Allow generator to cool

down and check air

cleaner and vents on

enclosure.

Red

Battery or

charging

alternator

Problem with alternator

charge output or weak

battery

Contact a Kohler

portable dealer.

Red

Oil pressure or

low oil level

Shutdown: incorrect oil

pressure or low oil level

Allow generator to cool

down, top up and check

oil level.

Red Non-starting fault

3 consecutive

unsuccessful starting

attempts

Check that generator has

been started according to

recommendations in this

manual.

Red Overspeed

Shutdown: generator

rotation speed

excessive

Contact a Kohler

portable dealer.

Flashing

Red

Speed too low

Shutdown: insufcient

generator rotation

speed

Contact a Kohler

portable dealer.

Page 12

12 34 590 01 Rev. AKohlerPower.com

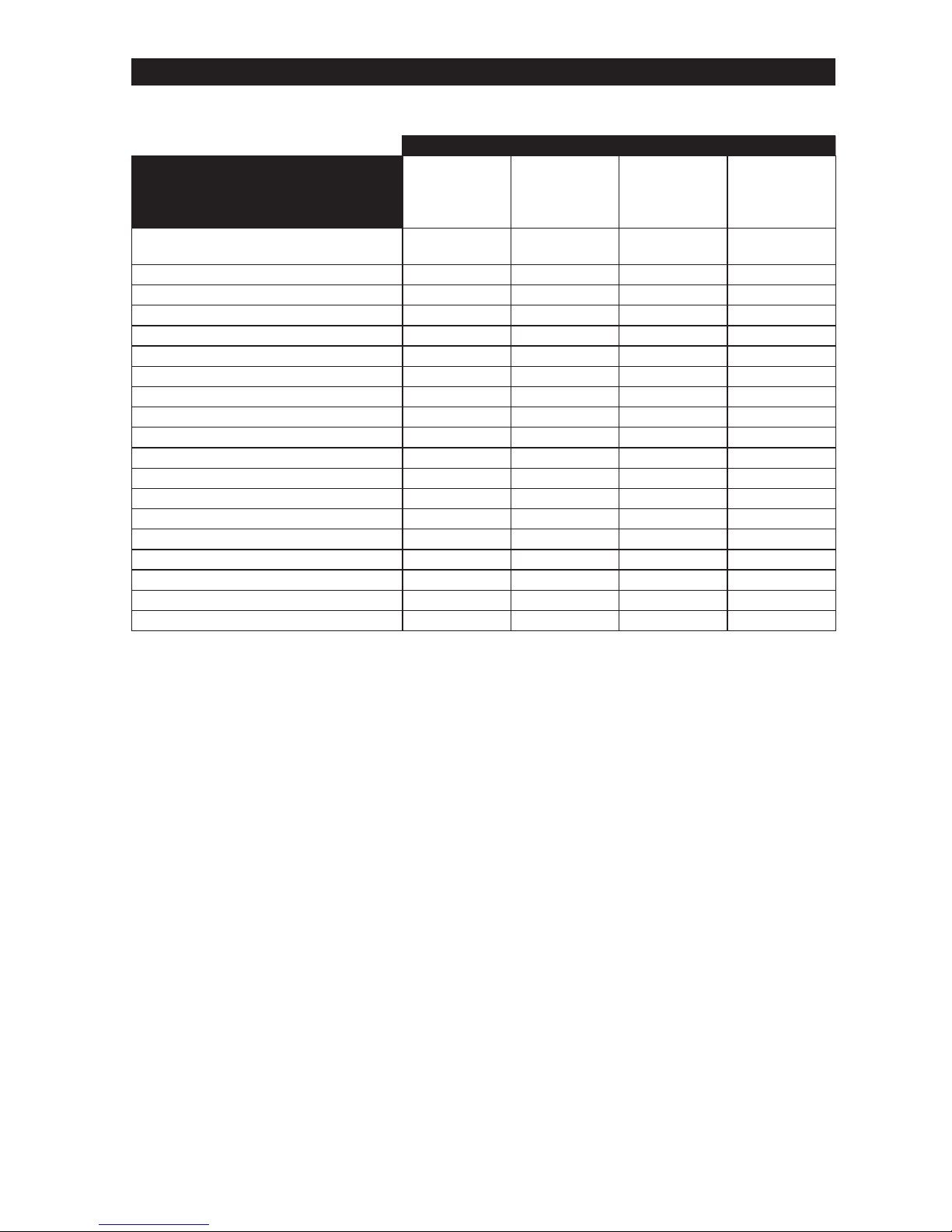

Troubleshooting

Do not attempt to service or replace major engine components, or any items that require special

timing or adjustment procedures. This work should be performed by a Kohler portable dealer.

Problem

Possible Cause

Engine Not

Starting/

Running

Abnormally

Engine

Stopped

No Electric

Current

Tripping of

Circuit

Breaker

Load connected to generating set

during start-up

●

Start and Stop control ON or OFF ●

Fuel valve closed ●

Fuel level too low ● ●

Unsuitable fuel ●

Oil level too low ● ●

Clogged air cleaner ●

Clogged fuel lter ●

Faulty starter battery. ●

Fuel supply blocked or leaking ● ●

Blocked ventilation inlets ●

Circuit protectors not actuated ●

Faulty appliance supply cord ●

Faulty electrical sockets ●

Faulty alternator ●

Device connected or faulty cord ●

Overload ●

Battery incorrectly connected ● ●

Faulty MODYS Fuses (J) ●

Page 13

13

34 590 01 Rev. A

KohlerPower.com

EN

Specications

Model PRO 12.3 EFI

Overall Dimensions (L x W x H)

35.2 in. (895 mm)

22.4 in. (570 mm)

30.3 in. (770 mm)

Dry Weight 306 lbs. (162 kg)

AC Rated Power 10,500 Watt

(120 Volts x 87.5 Amps)

(240 Volts x 43.8 Amps)

AC Maximum Power 12,300 Watt

(120 Volts x 102.5 Amps)

(240 Volts x 51.3 Amps)

Number of Phase Single Phase 240 Volts

DC Rated Power 100 Watt (12 Volts x 8.3 Amps)

Engine Specications

Bore 3.2 in. (80 mm)

Stroke 2.72 in. (69 mm)

Displacement 42.4 cu. in. (694 cc)

Oil Capacity (Rell) 1.7-2.0 U.S. qt. (1.6-1.9 L)

Maximum Angle of Operation (@ full oil level)* 25°

Run Time 10 hours (1/2 load)

Fuel See fuel section

Fuel Tank Capacity 8.7 U.S. gal. (33.0 L)

Spark Plug Gap 0.03 in. (0.76 mm)

*Exceeding maximum angle of operation may cause engine damage from insufcient lubrication.

Additional specication information can be found at KohlerPower.com.

Exhaust Emission Control System for model PRO 12.3 EFI is EM, O2S, ECM, MPI for U.S. EPA,

California, and Europe.

Page 14

14 34 590 01 Rev. AKohlerPower.com

Available Accessories

The most customizable generators the job site has ever seen.

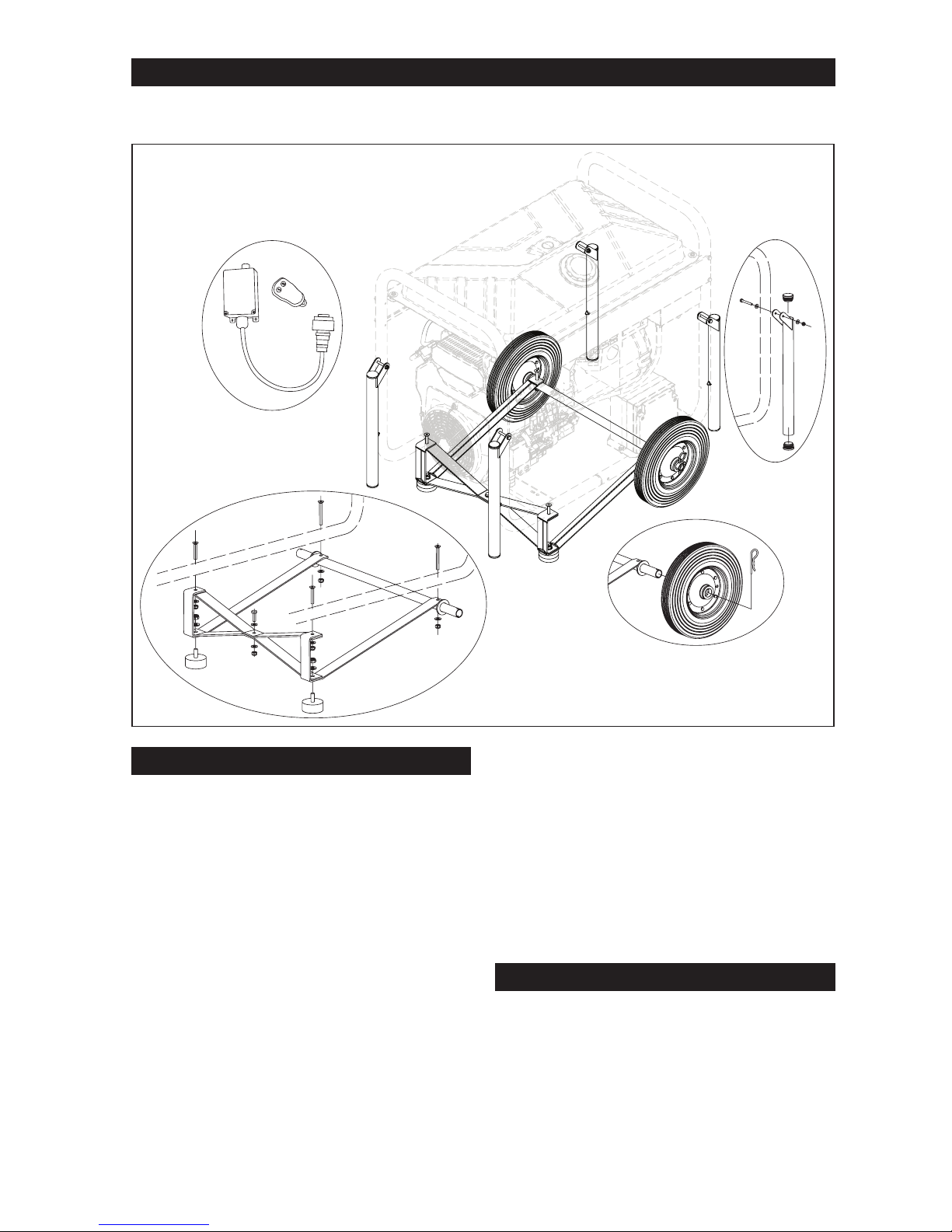

Mobility Kit

Install Mobility Kit

NOTE: Place blocks underneath to raise

generator to install wheels and legs.

NOTE: A clamping device or an assistant to

hold assembly while installing kit will

make process easier.

Mobility kit includes 2 solid rubber wheels, 2

legs, 4 handles and mounting hardware.

1. Align cross member holes at center and

place screw into hole. Insert washer and

thread nut to screw. Tighten loosely.

2. Assemble rubber bumpers to cross member

and axle brace. Insert washer and thread nut

to rubber bumper screw. Tighten loosely.

3. Position legs under frame. Install screws

through frame into cross member. Insert

washer and thread nut to screw. Tighten

loosely.

4. Align holes in axle to axle brace and frame.

Install screws through frame and axle. Insert

washer and thread nut to screw. Tighten

loosely.

5. Torque all nuts to 221 in. lb. (25 N·m).

6. Install wheels onto axle, push cotter pin into

hole in axle.

Install Handle:

1. Align handle with holes on frame.

2. Install screws with washers through leg.

Place another washer on other side and

thread nut on.

3. Tighten screws enough to allow handle to

move free.

Wireless Remote Kit

Wireless remote for starting or stopping

generator from a distance of up to 164 ft.

(50 m). No tools required for installation.

Wireless remote kit includes 1 wireless remote,

1 receiver which plugs into generator (AI) and

mounting hardware.

Page 15

15

34 590 01 Rev. A

KohlerPower.com

ESS

PRO 12.3 EFI

Manual del Usuario del Generador

IMPORTANTE: Lea atentamente todas las instrucciones y precauciones de seguridad

antes de poner el equipo en funcionamiento.

Asegúrese de que el generador está parado y nivelado antes de

realizar tareas de mantenimiento o reparación.

Registre la información del producto con el n de consultarla para realizar pedidos de piezas o para obtener la

cobertura de la garantía.

Especicación

Número de serie

Fecha de compra

Page 16

16 34 590 01 Rev. AKohlerPower.com

PRECAUCIÓN

Las descargas

eléctricas pueden

provocar lesiones.

No toque los

cables con el

generador en

funcionamiento.

No utilice nunca el generador

bajo la lluvia o la nieve.

No toque nunca el generador con

las manos mojadas, ya que podría

producirse una descarga eléctrica.

ADVERTENCIA

Las piezas rotatorias

pueden causar

lesiones graves.

Manténgase alejado

del generador

cuando esté en

funcionamiento.

Para evitar lesiones, mantenga

las manos, los pies, el pelo y la

ropa alejados de las piezas en

movimiento. No ponga nunca el

generador en funcionamiento

con las cubiertas,

revestimientos térmicos o

protecciones desmontados.

ADVERTENCIA

Los líquidos a alta

presión pueden

perforar la piel y

provocar lesiones

graves o la muerte.

No trabaje en

el sistema de

combustible sin

una formación

o el equipo

de seguridad

adecuado.

Las lesiones por perforación

de líquidos son muy tóxicas

y peligrosas. Si se produce

cualquier lesión, pida asistencia

sanitaria inmediatamente.

ADVERTENCIA

Las piezas calientes

pueden causar

quemaduras graves.

No toque el

generador durante

el funcionamiento

o inmediatamente

después de pararse.

No ponga nunca el generador

en funcionamiento con

las protecciones térmicas

desmontadas. No modique el

generador.

Coloque el generador en un lugar

donde no lo vayan a tocar los

peatones ni los niños.

Asegúrese de transportar el

generador por sus asas de

transporte únicamente.

ADVERTENCIA

Tensión peligrosa.

La retroalimenta-

ción al sistema de

suministro eléctrico

puede causar

daños materiales,

lesiones graves o

la muerte.

No conecte nunca un generador

portátil directamente a la toma

de un edicio.

Si el generador se va a utilizar

para corriente auxiliar, pida

a un electricista autorizado

y cualicado que instale un

conmutador de transferencia

automático para evitar la

interconexión accidental de las

fuentes de alimentación auxiliar

y normal.

ADVERTENCIA

Los arranques

accidentales pueden

provocar lesiones

graves o la muerte.

Antes de llevar a

cabo trabajos de

mantenimiento

o reparación,

desconecte y aísle

el cable de la bujía.

Antes de realizar cualquier

trabajo en el generador o en

el equipo, desactive el motor

como se indica a continuación:

1) Desconecte los cables de las

bujías. 2) Desconecte el cable del

polo negativo (-) de la batería.

No deje que los niños manejen

el generador.

ADVERTENCIA

La explosión del

carburante puede

provocar incendios y

quemaduras graves.

No llene el tanque

de combustible con

el generador en

funcionamiento o

caliente.

La gasolina es muy inamable

y sus vapores pueden hacer

explosión si se inaman. No

reposte nunca mientras fuma ni

cerca de una llama al descubierto.

Almacene la gasolina siempre

en contenedores homologados,

en locales desocupados, bien

ventilados y lejos de chispas o

llamas. El combustible derramado

podría inamarse si entra en

contacto con las piezas calientes

del motor o las chispas de

encendido. No utilice nunca

gasolina como agente de limpieza.

Precauciones de seguridad

PELIGRO: Un peligro que provoca la muerte, lesiones graves o daños materiales considerables.

ADVERTENCIA: Un peligro que podría provocar la muerte, lesiones graves o daños materiales considerables.

PRECAUCIÓN: Un peligro que podría provocar lesiones personales o daños materiales de poca gravedad.

NOTA: Se utiliza para noticar al personal sobre información importante para la instalación, el funcionamiento

o el mantenimiento.

Lea este manual con atención antes de utilizar esta máquina. Este manual deberá acompañar a la máquina en

caso de que esta se venda.

Page 17

17

34 590 01 Rev. A

KohlerPower.com

ESS

Advertencia: la Propuesta 65 de California

El escape de motor de este producto contiene sustancias químicas

identicadas por el Estado de California como causantes de cáncer,

defectos de nacimiento u otros daños genéticos.

Advertencia: la Propuesta 65 de California

Este producto contiene sustancias químicas identicadas por el Estado

de California como causantes de cáncer, defectos de nacimiento u

otros daños genéticos.

Etiquetas importantes en el generador

WARNING / ADVERTENCIA / AVERTISSEMENT

● Hot parts can cause severe burns. / Las piezas calientes pueden causar quemaduras graves. / Les pièces chaudes peuvent causer de graves brûlures.

● Do not touch generator while operating or just after stopping. / No toque el generador durante el funcionamiento o inmediatamente después de pararse. / Ne touchez pas le générateur pendant qu'il tourne ou si

vous venez tout juste de l'arrêter.

● Explosive Fuel can cause fires and severe burns. / La explosión del carburante puede provocar incendios y quemaduras graves. / Carburant explosif pouvant causer des incendies et des brûlures graves.

● Do not fill fuel tank while generator is hot or running. / No llene el tanque de combustible mientras el generador esté caliente o funcionando. / N'ajoutez pas de carburant si le moteur est chaud ou s'il tourne.

● Electrical shock can cause injury. / Las descargas eléctricas pueden provocar lesiones. / Les chocs électriques peuvent causer des blessures.

● Do not touch wires while generator is running. / No toque los cables con el generador en funcionamient. / Ne touchez pas aux le générateur pendant que le moteur tourne.

● Do not connect generator to a building's electrical system unless using an isolation (transfer) switch installed by a certified, licensed electrician. / No conecte el generador al sistema eléctrico de un edificio a menos

que use un aislamiento (transferencia) interruptor instalado por un electricista certificado y certificado. / Ne branchez pas le générateur dans le système électrique d’un bâtiment sauf si un commutateur-converteur

a été installé par un électricien agréé et compétent.

Page 18

18 34 590 01 Rev. AKohlerPower.com

W

Z

AG

AF

AE

AD

AB

AC

AA

V

U

C

B

F

T

Y

S

L

M N

R

Q

P

AH

AH

X

A

K

D

H

I

F

O

J

E

G

A Medidor de horas B MODYS C Luz piloto D Luz MIL

E Interruptor de carga F Protector de circuitos G Receptáculo GFCI H

Receptáculo de CC

de 12V

I Terminal de masa J Fusible K Ralentí automático L

Tomacorriente eléctrico

de 240/120V/50A

M

Tomacorriente eléctrico

de 240/120V/30A

N

Tomacorriente eléctrico

de 120V/30A

O

Tapón del tanque de

combustible

P Válvula de combustible

Q Filtro de combustible R Fusibles del motor S

Batería del motor de

arranque

T Varilla de nivel

U

Tapón de drenaje del

aceite

V Filtro de aceite W

Módulo de la bomba

de combustible

X Bujía

Y

Tapón de llenado de

aceite

Z

Soporte del ltro de

aire

AA Filtro de papel AB Preltro

AC Sello de goma AD Tapa del ltro AE Tuerca de mariposa AF

Rueda del ltro de aire

AG Tapa del ltro de aire AH

Exclusivo ltro

de combustible EFI

AI Conectar Wireless AJ

Botón de diagnóstico

AJ

AI

Page 19

19

34 590 01 Rev. A

KohlerPower.com

ESS

Lista de control previa al arranque

1. Asegúrese de que el generador esté al menos a 1

m (3,3 ft) del edicio o de cualquier otro equipo y

no esté tapado con ningún material.

2. Consulte todas las etiquetas de advertencia antes

de poner en marcha.

3. Comprobar el nivel de aceite. Añada aceite si está

bajo. No rellene por encima del límite.

4. Compruebe el nivel de combustible. Añada

combustible si está bajo. Deje de rellenar cuando el

indicador haya alcanzado el nivel F (lleno).

Compruebe si los componentes y las tuberías del

sistema de combustible presentan alguna fuga. No

reposte nunca con la unidad en funcionamiento.

5. Compruebe la batería del motor de arranque (S).

6. Conecte a masa el generador.

7. Verique que los componentes del ltro de aire y

todas las entradas de aire están libres de

obstrucciones, y que las cubiertas y protecciones

del equipo están en su sitio y bien sujetas.

8. Asegúrese de que no haya dispositivos eléctricos

(carga) conectados al generador.

Arranque

ADVERTENCIA

Las piezas rotatorias pueden causar

lesiones graves.

Manténgase alejado del generador

cuando esté en funcionamiento.

Para evitar lesiones, mantenga las manos, los

pies, el pelo y la ropa alejados de las piezas en

movimiento. No ponga nunca el generador en

funcionamiento con las cubiertas, revestimientos

térmicos o protecciones desmontados.

NOTA: El interruptor de ralentí automático (K) debe

estar en la posición OFF cuando se utilicen

dispositivos eléctricos que precisen una

elevada corriente de arranque, como un

compresor o una bomba sumergible. El

ralentí automático (K) controla la velocidad

del motor según la carga conectada. Los

resultados son un mejor consumo de

combustible y menos ruido.

NOTA: MODYS (B) efectúa automáticamente 5

intentos de arranque.

1. Gire el interruptor de carga (E) de CA a la posición

OFF.

2. Gire la válvula de combustible (P) a ON.

3. Gire la llave de MODYS (B) a la posición ON.

4. Presione el botón de ARRANQUE de MODYS (B).

5. Pruebe los receptáculos GFCI (G).

Arranque en tiempo frío

1. Utilice el aceite apropiado para la temperatura

prevista.

2. Desconecte todas las posibles cargas externas.

3. Use combustible de grado invierno reciente. El

combustible de grado invierno tiene una mayor

volatilidad que mejora el arranque.

Funcionamiento

ADVERTENCIA

Tensión peligrosa.

La retroalimentación al sistema de

suministro eléctrico puede causar

daños materiales, lesiones graves o

la muerte.

No conecte nunca un generador portátil

directamente a la toma de un edicio.

Si el generador se va a utilizar para corriente

auxiliar, pida a un electricista autorizado

y cualicado que instale un conmutador

de transferencia automático para evitar la

interconexión accidental de las fuentes de

alimentación auxiliar y normal.

Cuando la velocidad de operación del generador se

haya estabilizado (aproximadamente 3 minutos):

1. Verique que los interruptores de carga (E) estén

oprimidos. Presione si es necesario.

2. Conecte los aparatos que se vayan a utilizar a los

tomacorrientes eléctricos (G, L, M y N) del

generador.

3. El medidor de horas (A) muestra la cantidad de

horas que ha funcionado el generador.

Ángulo de funcionamiento

No haga funcionar el motor si supera el ángulo

máximo de funcionamiento, consulte la tabla de

especicaciones. El motor puede dañarse como

resultado de una lubricación insuciente.

Page 20

20 34 590 01 Rev. AKohlerPower.com

Selección del cable

Tipo de

tomacorriente del

generador

10 A 16 A 32 A

Sección transversal

del cable

recomendada

mm

2

AWG

mm

2

AWG

mm

2

AWG

Longitud

del cable

que se

utilizó

0 a

50 m

4 10 6 9 10 7

51 a

100 m

10 7 10 7 25 3

101 a

150 m

1

10 7 16 5 35 2

1

La longitud de este cable es la máxima permitida

y no se debe exceder.

Método de instalación = cables en el canal o en

la tablilla sin perforaciones/Caída permitida en

voltaje = 5%/Conductores multinúcleo/Tipo de cable

PVC 70°C (por ejemplo, H07RNF)/Temperatura

ambiente = 86° F (30° C).

Instrucciones de mantenimiento

ADVERTENCIA

Antes de realizar cualquier trabajo en el generador

o en el equipo, desactive el motor como se indica a

continuación: 1) Desconecte los cables de las bujías.

2) Desconecte el cable del polo negativo (–) de la batería.

No deje que los niños manejen el generador.

Los arranques accidentales pueden

provocar lesiones graves o la muerte.

Antes de llevar a cabo trabajos

de mantenimiento o reparación,

desconecte y aísle el cable de la bujía.

La seguridad es una obligación del propietario. La inspección, el ajuste y la lubricación de forma periódica

mantendrán su generador en el estado más seguro y eciente posible. Los puntos más importantes de

inspección, ajuste y lubricación del generador se explican en las siguientes páginas.

Programa de mantenimiento

Una vez al año o después de las primeras 25 horas

1

● Realice el mantenimiento/sustitución del preltro (si está incluido).

Una vez al año o cada 100 horas

1

● Cambie el aceite.

● Cambie el elemento ltrante (AA).

● Quite y limpie los revestimientos y las zonas de refrigeración.

Cada 200 horas

1

● Cambie el exclusivo ltro de combustible de Inyección electrónica de combustible (EFI).

Una vez al año o cada 200 horas

1

● Cambie el aceite y el ltro (V).

Una vez al año o cada 500 horas

1

● Cambie las bujías (X) y ajuste la separación entre electrodos.

1

Estas operaciones de mantenimiento deberán ejecutarse con mayor frecuencia en ambientes muy

polvorientos o sucios.

Ralentí automático

NOTA: Ralentí automático sólo funcionará cuando la

unidad está en función de 120V.

Posición ON. Cuando el interruptor de ralentí

automático (K) está en la posición ON, el ralentí

automático (K) controla la velocidad del motor de

acuerdo con la carga conectada. Los resultados son

un mejor consumo de combustible y menos ruido.

Posición OFF. Cuando el interruptor de ralentí

automático (K) está en la posición OFF, el motor

funciona al nivel nominal de rpm (3.600 rpm), haya o

no una carga conectada

NOTA: Gire ralentí automático en OFF cuando la

unidad está utilizando la conguración de 240V.

Parada

1. Desconecte los dispositivos eléctricos y deje que el

motor funcione sin ninguna carga durante 1-2

minutos.

2. Gire la llave de MODYS (B) a la posición OFF

(el generador se para).

3. Cierre la válvula de combustible (P).

Velocidad del motor

NOTA: No altere los ajustes del regulador para

aumentar la velocidad máxima del motor. El

exceso de velocidad es peligroso y anulará

la garantía.

Page 21

21

34 590 01 Rev. A

KohlerPower.com

ESS

Recomendaciones de lubricante

Recomendamos el uso de un aceite de Kohler para

obtener un mejor rendimiento. También se puede

utilizar otro aceite detergente de alta calidad API

(American Petroleum Institute) SJ o superior, incluidos

los aceites sintéticos. Seleccione la viscosidad

en función de la temperatura del aire durante el

funcionamiento como se muestra en la tabla que

aparece a continuación.

°F -20 020324060

50 80 100

°C -30 -20 -10 0 10 20 30 40

5W-30

10W-30

SAE 30

Comprobación del nivel de aceite

NOTA: Para evitar las averías y el desgaste

excesivo del motor, no ponga nunca el motor

en funcionamiento con un nivel de aceite

inferior o superior al indicador de nivel de

funcionamiento de la varilla (T).

Asegúrese de que el motor esté frío. Limpie los

residuos del área de la varilla de nivel.

1. Extraiga la varilla de nivel (T); limpie el exceso de

aceite. Introduzca de nuevo la varilla de nivel (T) en

el tubo y presione completamente hacia abajo.

2. Saque la varilla (T) y compruebe el nivel de aceite.

El nivel debe situarse en la parte superior de la

varilla de nivel (T).

3. Si el indicador muestra poco nivel de aceite, añada

aceite hasta la parte superior de la marca del

indicador.

4. Instale de nuevo y je la varilla de nivel (T).

Cambio del aceite y el ltro

Cambie el aceite con el motor caliente.

1. Limpie el área que rodea la varilla de nivel (T) y el

tapón de drenaje (U). Retire el tapón de drenaje (U)

y la varilla de nivel (T). Deje que el aceite drene

completamente.

2. Limpie el área que rodea el ltro (V). Coloque un

envase debajo del ltro para recoger el aceite y

extraiga el ltro. Limpie la supercie de montaje.

Vuelva a instalar el tapón de drenaje del aceite (U).

Aplique un par de apriete de 13,6 Nm (10 ft lb).

3. Coloque un ltro nuevo con el extremo abierto

hacia arriba en una bandeja. Vierta aceite nuevo

hasta que alcance la parte inferior de los tornillos.

Espere 2 minutos hasta que el material del ltro

absorba el aceite.

4. Aplique una película na de aceite limpio a la junta

de goma del nuevo ltro.

5. Consulte las instrucciones sobre el ltro del aceite

(V) para una instalación correcta.

6. Llene el cárter con aceite nuevo. El nivel debe

situarse en la parte superior de la varilla de nivel

(T).

7. Vuelva a instalar la varilla (T) y apriete bien.

8. Arranque el motor y compruebe si hay fugas de

aceite. Detenga el motor y repare las fugas.

Compruebe de nuevo el nivel de aceite.

9. Deseche el aceite usado y el ltro en conformidad

con las normativas locales.

Oil Sentry™ (si está incluido)

Este interruptor está diseñado para evitar que el motor

arranque con poco aceite o ninguno. El sistema Oil

Sentry™ apagará el motor en marcha.

Recomendaciones de combustible

ADVERTENCIA

La explosión del carburante puede

provocar incendios y quemaduras graves.

No llene el tanque de combustible con el

generador en funcionamiento o caliente.

La gasolina es muy inamable y sus vapores

pueden hacer explosión si se inaman. Almacene

la gasolina siempre en contenedores homologados,

en locales desocupados, bien ventilados y lejos de

chispas o llamas. El combustible derramado podría

inamarse si entra en contacto con las piezas

calientes del motor o las chispas de encendido. No

utilice nunca gasolina como agente de limpieza.

NOTA: E15, E20 y E85 are NO están autorizados y

NO deben utilizarse; la garantía no cubre los

efectos producidos por el uso de

combustible antiguo, pasado o contaminado.

El combustible debe cumplir con los siguientes requisitos:

● Gasolina limpia, fresca y sin plomo.

● Octanaje de 87 (R+M)/2 o superior.

● El “Research Octane Number” (RON) deberá ser

de 90 octanos como mínimo.

● Se autoriza el empleo de gasolina de hasta un

volumen máximo del 10% de alcohol etílico y el

90% sin plomo.

● Se autorizan las mezclas de metil-ter-butil-éter

(MTBE) y gasolina sin plomo (hasta un máximo del

15% de MTBE en volumen).

● No añada aceite a la gasolina.

● No llene el tanque de combustible por encima del

límite.

● No utilice gasolina con más de 30 días de

antigüedad.

Compruebe el nivel de combustible.

ADVERTENCIA

La explosión del carburante puede

provocar incendios y quemaduras graves.

No llene el tanque de combustible con el

generador en funcionamiento o caliente.

La gasolina es muy inamable y sus vapores

pueden hacer explosión si se inaman. Almacene

la gasolina siempre en contenedores homologados,

en locales desocupados, bien ventilados y lejos de

chispas o llamas. El combustible derramado podría

inamarse si entra en contacto con las piezas

calientes del motor o las chispas de encendido. No

utilice nunca gasolina como agente de limpieza.

Page 22

22 34 590 01 Rev. AKohlerPower.com

2. Coloque la bujía en el cabezal del cilindro.

3. Apriete la bujía (X) a 27 Nm (20 ft lb).

Sustitución de fusibles del motor

Este motor lleva tres (3) fusibles de automoción de

tipo plano (R). Los fusibles de repuesto (R) deben

tener la misma intensidad que el fusible fundido.

Utilice el siguiente cuadro de fusibles para encontrar

el fusible correcto (R).

Color del hilo

Intensidad del

fusible

2 cables rojos lisos

Fusible de 10

amperios

1 cable rojo con rayas negras

1 cable rojo con rayas blancas

Fusible de 10

amperios

2 cables morados

Fusible de 30

amperios

Filtro de aire

NOTA: El funcionamiento del motor con

componentes del ltro de aire sueltos o

dañados puede causar daños y desgaste

prematuro. Sustituya todos los componentes

doblados o dañados.

NOTA: El papel ltrante (AA) no puede expulsarse

con aire comprimido.

Aoje la rueda (AF) y extraiga la tapa del ltro de aire

(AG).

Preltro (AB):

1. Extraiga el preltro (AB) del papel ltrante (AA).

2. Sustituya o lave el preltro (AB) con agua templada

y detergente. Aclárelo y déjelo secar al aire.

3. Engrase el preltro (AB) con aceite nuevo y escurra

el exceso de aceite.

4. Vuelva a colocar el preltro (AB) sobre el papel

ltrante (AA).

Elemento de papel (AA):

1. Limpie el área que rodea al elemento (AA). Retire

la tuerca de mariposa (AE), la tapa del ltro (AD) y

el ltro de papel (AA) con el preltro (AB).

2. Separe el preltro (AB) del elemento ltrante (AA),

limpie el preltro (AB) y sustituya el elemento

ltrante (AA).

3. Compruebe el estado de la goma (AC) y cámbiela

si es necesario.

4. Instale el nuevo ltro de papel (AA) en la base (Z),

instale el preltro (AB) sobre el ltro de papel (AA),

vuelva a instalar la tapa del ltro (AD) y sujétela

con una tuerca de mariposa (AE).

Vuelva a instalar la tapa del ltro de aire (AG) y

sujétela con la rueda (AF).

Tubo del respirador

Asegúrese de que ambos extremos del respirador

están conectados adecuadamente.

Verique el nivel de combustible visualmente. Si es

necesario, rellene.

1. Desenrosque el tapón del tanque de combustible

(O).

2. Llene el tanque de combustible con un embudo,

teniendo cuidado de no derramarlo. No llene el

tanque por encima del límite (no debe haber nada

de combustible en el cuello de llenado).

3. Vuelva a enroscar el tapón del tanque de

combustible (O).

Filtro de combustible

1. Abra el tapón del tanque de combustible (O).

2. Quite el ltro de combustible (Q) del cuello del

tanque.

3. Limpie el ltro de combustible (Q) con un disolvente

incombustible o que tenga un alto punto de

inamabilidad. Séquelo totalmente. Cambie en

caso necesario.

4. Vuelva a instalar el ltro de combustible (Q).

5. Vuelva a instalar el tapón del tanque de combustible

(O).

Sistema de inyección electrónica de

combustible (EFI)

EFI es un sistema de gestión de combustible

controlado electrónicamente que es monitorizado por

una Unidad de Control Electrónica (UCE). Una luz

indicadora de fallo (MIL) se iluminará si se detectan

problemas o fallos. Se necesita el mantenimiento por

un distribuidor móvil de Kohler.

Tubería de combustible

En los motores Kohler Co. equipados con un sistema

EFI debe instalarse una tubería de combustible de alta

presión que cumpla con las normas del SAE R9.

Componentes del sistema de combustible

Los componentes de alta presión en el módulo de

la bomba de combustible (W) no se pueden reparar.

Los motores están equipados con un ltro de

combustible EFI especial (AH). Consulte el Programa

de mantenimiento.

Bujías

PRECAUCIÓN

Las descargas eléctricas pueden

provocar lesiones.

No toque los cables con el generador

en funcionamiento.

No utilice nunca el generador bajo la lluvia o la nieve.

No toque nunca el generador con las manos mojadas,

ya que podría producirse una descarga eléctrica.

Limpie el rebaje de la bujía. Extraiga la bujía y

sustitúyala.

1. Compruebe la separación de electrodos con una

galga de espesores. Para ajustar la separación,

consulte la tabla de especicaciones de ajuste.

Page 23

23

34 590 01 Rev. A

KohlerPower.com

ESS

Refrigeración por aire

ADVERTENCIA

Las piezas calientes pueden causar

quemaduras graves.

No toque el generador durante el

funcionamiento o inmediatamente

después de pararse.

No ponga nunca el generador en funcionamiento

con las protecciones térmicas desmontadas. No

modique el generador.

Coloque el generador en un lugar donde no lo

vayan a tocar los peatones ni los niños.

Asegúrese de transportar el generador por sus

asas de transporte únicamente.

Es esencial una refrigeración adecuada. Para evitar

el recalentamiento, asegúrese de que las zonas de

entrada y salida de refrigeración por aire estén limpias

y libres de obstrucciones. Evite rociar agua al haz de

cables o a cualquier componente eléctrico. Consulte

el Programa de mantenimiento.

Terminal de masa

El terminal de masa (I) conecta el cable de masa para

evitar descargas eléctricas. Cuando el dispositivo

eléctrico esté conectado a masa, asegúrese de

conectar a masa también el generador.

Conecte a masa el generador: conecte un cable de

cobre de 6 AWG (10 mm2) a la conexión a masa del

generador y a una pica de tierra de acero galvanizado

(no incluida) introducida 1 m (3,3 ft) en el suelo.

Conexión de corriente alterna (CA)

NOTA: Asegúrese de que todos los dispositivos

eléctricos, incluidos los cables y enchufe de

conexión, estén en buenas condiciones

antes de conectarlos al generador.

NOTA: Asegúrese de que la carga total esté dentro

de los límites de salida nominal del generador.

NOTA: Asegúrese de que la corriente de carga del

receptáculo esté dentro de los límites de

corriente nominal del receptáculo.

1. Arranque el motor.

2. Asegúrese de que la luz piloto de CA (C) esté

encendida.

3. Enchufe en el receptáculo de CA (G, L, M o N).

4. Encienda cualquier dispositivo eléctrico.

Potencia nominal de CA

La potencia nominal de CA es la cantidad de potencia

máxima que puede soportar el generador.

Potencia máxima de CA

La potencia máxima de CA es una potencia adicional

producida momentáneamente por el generador para

ayudar a poner en marcha dispositivos eléctricos que

requieren una potencia superior a la potencia nominal

del generador.

Receptáculo GFCI

PRECAUCIÓN

Las descargas eléctricas pueden

provocar lesiones.

No toque los cables con el generador

en funcionamiento.

No utilice nunca el generador bajo la lluvia o la nieve.

No toque nunca el generador con las manos mojadas,

ya que podría producirse una descarga eléctrica.

Con el n de reducir la posibilidad de descarga eléctrica:

1. No intente operar el equipo si el botón RESET del

interruptor del circuito de fallos de conexión a tierra

(GFCI) salta repentinamente de forma repetida

durante el uso.

2. Recuerde que sólo los receptáculos con la etiqueta

GFCI están protegidos por un interruptor del

circuito de fallos de conexión a tierra.

El interruptor del circuito de fallos de conexión a

tierra (GFCI) interrumpe el paso de corriente a los

receptáculos protegidos (G) si se detecta un fallo

de conexión a tierra (escape eléctrico). Si el botón

RESET salta hacia fuera, es posible que el equipo

enchufado al receptáculo (G) esté defectuoso. Si

esto ocurre, examine con atención el equipo. Si el

equipo parece estar en buenas condiciones, pulse

rmemente el botón RESET hasta oír un chasquido.

De esta forma se restablecerá la corriente. Si el

botón RESET vuelve a saltar, desenchufe el equipo

inmediatamente. Póngase en contacto con un

distribuidor móvil de Kohler antes de volver a utilizarlo.

Prueba del receptáculo GFCI

1. Ponga en marcha el generador.

2. Pulse el botón TEST; si funciona correctamente,

el botón RESET deberá saltar hacia fuera,

interrumpiendo la corriente enviada a la salida.

3. Si el funcionamiento del GFCI es correcto, presione

el botón RESET hacia adentro. Si el GFCI no

funciona correctamente, póngase en contacto con

un distribuidor móvil de Kohler.

Page 24

24 34 590 01 Rev. AKohlerPower.com

Sobrecarga (capacidad del generador)

No supere nunca la carga nominal del generador

(en amperios y/o vatios) cuando este se encuentre

en funcionamiento continuamente. Consulte la salida

nominal en la tabla de especicaciones.

Antes de conectar y utilizar el generador, calcule la

potencia eléctrica que requieren los aparatos eléctricos

(en vatios). Esta especicación de la potencia eléctrica

gura normalmente en la etiqueta del fabricante en

bombillas, aparatos eléctricos, motores, etc. La suma

total requerida por estos aparatos no debe superar la

potencia nominal del generador.

Los protectores de circuitos (F) y el interruptor de

carga (E) detendrán le energía de los receptáculos

protegidos (G, H, L, M o N) cuando se detecte la

sobrecarga de un dispositivo eléctrico conectado o

cuando el voltaje de salida de la CA se eleve para

proteger al generador y a cualquier dispositivo

eléctrico conectado.

Cuando ocurre una sobrecarga y se interrumpe la

generación de corriente, proceda del siguiente modo:

1. Apague todos los dispositivos eléctricos

conectados y pare el generador.

2. Reduzca el vataje total de los dispositivos

eléctricos conectados, dentro de los límites de

aplicación.

3. Compruebe si existe alguna obstrucción en las

zonas de entrada y salida de refrigeración por aire

y en torno a la unidad de control. Si encuentra

alguna obstrucción, elimínela.

4. Después de la comprobación, vuelva a arrancar el

generador.

Carga de baterías por medio del receptáculo de CC

PRECAUCIÓN

Las descargas eléctricas pueden

provocar lesiones.

No toque los cables con el generador

en funcionamiento.

No utilice nunca el generador bajo la lluvia o la nieve.

No toque nunca el generador con las manos mojadas,

ya que podría producirse una descarga eléctrica.

NOTA: Esta sección se reere a la carga de

baterías de 12 V en otros equipos, como

vehículos de motor o vehículos todoterreno.

No es posible el arranque con pinzas.

NOTA: Siga los procedimientos de seguridad

cuando manipule baterías con el n de evitar

los daños en los componentes eléctricos y la

explosión de las baterías. Consulte la cha

de datos de seguridad del fabricante de la

batería acerca de los riesgos de seguridad

del trabajo con baterías. Consulte las

instrucciones del fabricante de la batería

acerca de los procedimientos de carga/

mantenimiento de la batería.

NOTA: La tensión nominal de CC del generador es

de 12 V. El protector de circuitos de CC (F)

se apagará automáticamente si la corriente

supera el valor nominal durante la carga de

la batería. Ponga en marcha primero el

generador y luego conecte el generador a la

batería para cargarla. Antes de poner en

marcha para cargar la batería, asegúrese de

que el protector de circuitos de CC (F) se

encuentre en la posición RESET. Si el

protector de circuitos de CC (F) se vuelve a

apagar, deje de cargar la batería

inmediatamente y póngase en contacto con

un distribuidor móvil de Kohler.

NOTA: No conecte una batería regulada por válvula.

Para cargar una batería regulada por válvula

se necesita un cargador de batería especial

(tensión constante).

NOTA: No conecte ninguna carga a la batería ni

utilice el motor de arranque durante la carga.

Esto provoca el paso de una corriente alta a

través del generador que quemaría la

bobina.

NOTA: Antes de cargar la batería, retire los cables

positivo y negativo de la batería.

1. Ponga en marcha el generador.

2. Presione el protector de circuitos de CC (F).

3. Conecte el cable rojo del cargador de batería al

terminal positivo de la batería. Conecte el cable

negro del cargador de batería al terminal negativo

de la batería. No invierta estas posiciones. Conecte

el cable al receptáculo de CC (H).

Límites de alimentación de CC (sólo carga de

baterías de 12 V):

Esta fuente de alimentación está diseñada para cargar

baterías de hasta 40 Ah semidescargadas. No cargue

baterías de capacidad superior a 40 Ah.

Batería de 12 V:

El tiempo necesario para recargar una batería

depende del nivel de descarga de la batería. Cuando

la gravedad especíca de la batería alcanza de 1,26

a 1,28, la carga ha concluido. Durante la carga,

compruebe la gravedad especíca de la batería una

vez cada hora. El tiempo medio de carga de una

batería de 40 Ah semidescargada es de unas 5 horas.

Asegúrese de comprobar el nivel de líquido de la

batería antes de cargar.

Page 25

25

34 590 01 Rev. A

KohlerPower.com

ESS

Protector de circuitos de CC

NOTA: Reduzca la carga del dispositivo eléctrico

conectado, por debajo de la salida nominal

especicada del generador, si el protector de

circuitos de CC (F) se apaga. Si el protector

de circuitos de CC (F) se vuelve a apagar,

deje de usar el dispositivo inmediatamente y

póngase en contacto con un distribuidor

móvil de Kohler.

El botón del protector de circuitos de CC (F) saltará

hacia afuera, interrumpiendo el paso de corriente

del receptáculo de CC (H) cuando el dispositivo

electrónico conectado al generador funcione con una

corriente superior al valor nominal. Para usar este

equipo de nuevo, presione el botón del protector de

circuitos de CC (F).

Batería del motor de arranque

Debido a que la batería (S) no requiere

mantenimiento, verique simplemente la condición y

el ajuste de las conexiones y su limpieza general.

Interruptor de carga

El circuito eléctrico del conjunto del generador

está protegido por uno o más interruptores

magnetotérmicos, diferenciales o de corte automático.

Si ocurre una sobrecarga y/o un corto circuito, es

posible que se suspenda el suministro de energía

eléctrica.

Si es necesario, reemplace el interruptor de carga

(E) del conjunto generador con otros interruptores de

potencial nominal y especicaciones idénticas.

Limpieza del conjunto del generador

1. Quite el polvo y los residuos que hay alrededor del

silenciador del escape.

2. Limpie el generador y, en especial, las entradas y

las salidas de aire del motor y el alternador con un

trapo y un cepillo.

3. Revise las condiciones generales del generador y,

si es necesario, reemplace cualquier pieza

defectuosa.

Sustitución de los fusibles protectores

NOTA: Respete las especicaciones técnicas de los

fusibles. El uso de un fusible incorrecto

puede dañar el generador.

Sustituya los fusibles (J) en caso de fallo por

sobrecorriente. Antes de sustituir un fusible (J)

gastado por otro nuevo, contacte siempre con un

distribuidor móvil de Kohler para averiguar la causa

del fallo y la sobrecorriente.

1. Gire la llave de MODYS (B) a la posición OFF. El

generador se para.

2. Desenrosque el portafusibles de 12 V para MODYS

(B) y la iluminación y el portafusibles de 240 V para

MODYS (B) y el contador de horas de

funcionamiento.

3. Compruebe visualmente el estado de los dos

fusibles (J).

4. Sustituya los fusibles (J) gastados por otros nuevos

de tipo 5 x 20 con una intensidad de 2 A.

5. Vuelva a enroscar los dos portafusibles.

Transportación del generador

Antes de transportar el generador, verique que los

pernos estén bien apretados, cierre la válvula del

combustible (P) y desconecte la batería del motor de

arranque. Se debe transportar el generador en su

posición de funcionamiento normal, nunca la coloque

sobre su costado. Asegúrese de que el lugar donde

guardará y usará el generador se haya preparado

cuidadosamente con anticipación.

Reparaciones/Piezas de recambio

Recomendamos que utilice un distribuidor móvil de

Kohler para el mantenimiento, la reparación o la

sustitución de piezas del motor. Para encontrar un

distribuidor móvil de Kohler, visite KohlerPower.com o

llame al 1-800-544-2444 (EE. UU. y Canadá).

Almacenamiento

El almacenamiento de larga duración de su generador

requiere algunos procedimientos preventivos para

protegerlo del deterioro.

NOTA: No conecte con ningún dispositivo eléctrico

(funcionamiento sin carga).

Si el motor no se pone en funcionamiento durante 2

meses o más, siga el procedimiento siguiente.

1. Añada el tratamiento de combustible Kohler PRO

Series o equivalente al depósito de combustible.

Arranque el motor durante 2-3 minutos para que el

combustible se estabilice en el sistema de

combustible (la garantía no cubre los fallos

provocados por combustible sin tratar).

2. Cambie el aceite con el motor aún caliente.

Extraiga las bujías (X) y vierta aproximadamente

28 g (1 oz) de aceite de motor en los cilindros.

Sustituya las bujías (X) y arranque el motor

lentamente para distribuir el aceite.

3. Limpie el generador.

4. Almacene el generador en un lugar seco y bien

ventilado, con la tapa puesta. Asegúrese de no

tapar el generador hasta que el motor y el

silenciador/protector se hayan enfriado del todo. El

generador debe permanecer en la misma posición

que para el funcionamiento normal.

Page 26

26 34 590 01 Rev. AKohlerPower.com

Reparación de fallos menores - Alarmas y fallos de MODYS

Símbolos

Color

del LED