Page 1

IN-WALL TANK

K-6283K/ K-6286K/K-6286RK-6284K/

·

·

·

·

Read installation guide in illustration and word file

carefully, and install the tank according to

instructions in the guide to avoid product damage

and installation inconvenience caused by

inappropriate operation.

All data contained is based upon the last product

information available at the time of publication.

Kohler Co. Reserves the right to implement changes

of product characteristics, packaging and availability

at any time without further notice.

Do not apply erosive cleanser and solvent in the

tank, which will damage tank spares and result in

leakage in the tank. Kohler will not be responsible

for any damage related to above mentioned

cleanser or solvent.

Do not apply spares that are not provided by Kohler,

and please note that glass adhesive tape shall not

be applied to the installation of Kohler spares.

Kohler will not be responsible for any damage

related to installation with spares not provided by

Kohler.

Ordering Information

ODEON Tank Cover......................................K-6283K-**

(With Iron Rack For Wall-Hung

Toilet)

ODEON In-Wall Tank (Without Iron Rack For Wall-Hung

Toilet).....................................K-6286K-NA/K-6286R-NA

ODEON In-Wall Tank

................................................K-6284k-NA

Function Explanation

·

·

·

·

·

Anti flow-backwards

Adjustment of inlet water level

Adjustment of flushing volume

Single/double gear

Adjustable toilet height

flushing

Design And Installation Concept Of In-wall

Tank

·

·

Installation of in-wall tank is much easier and nicelooking comparative to that of traditional tank.

Meanwhile, the space layout will be more

reasonable due to the application of in-wall tank

pipes and connectors.

The most remarkable advantage of in-wall tank is

that the installation will never be limited to certain area,

and can be installed wherever as you wish, which will

make the bathroom layout more reasonable and nicelooking, and make good use of every inch of the

bathroom space.

Advantages Of In-wall Tank

·

·

·

·

·

·

·

·

Anti-strike and erosion proof tank of macromolecule

materials, and leak proof.

Advanced tank spares, adjustable to of 3/6

liters, with single/double gear technology.

Sustainable to pressure of 400 kgs.

Impact free to wall structures, and excellent sound

insulation effect.

Easy installation and time efficient.

No requirements of other installation spares.

Easy maintenance and no necessity of removing the

wall in the process of maintenance.

Clean, garbage free, and space-saving efficient.

flushing

INSTALLATION

INSTRUCTIONS

-1-

1048671-K01-B

Copyright 2006 Kohler Co.

C

ODEON

Page 2

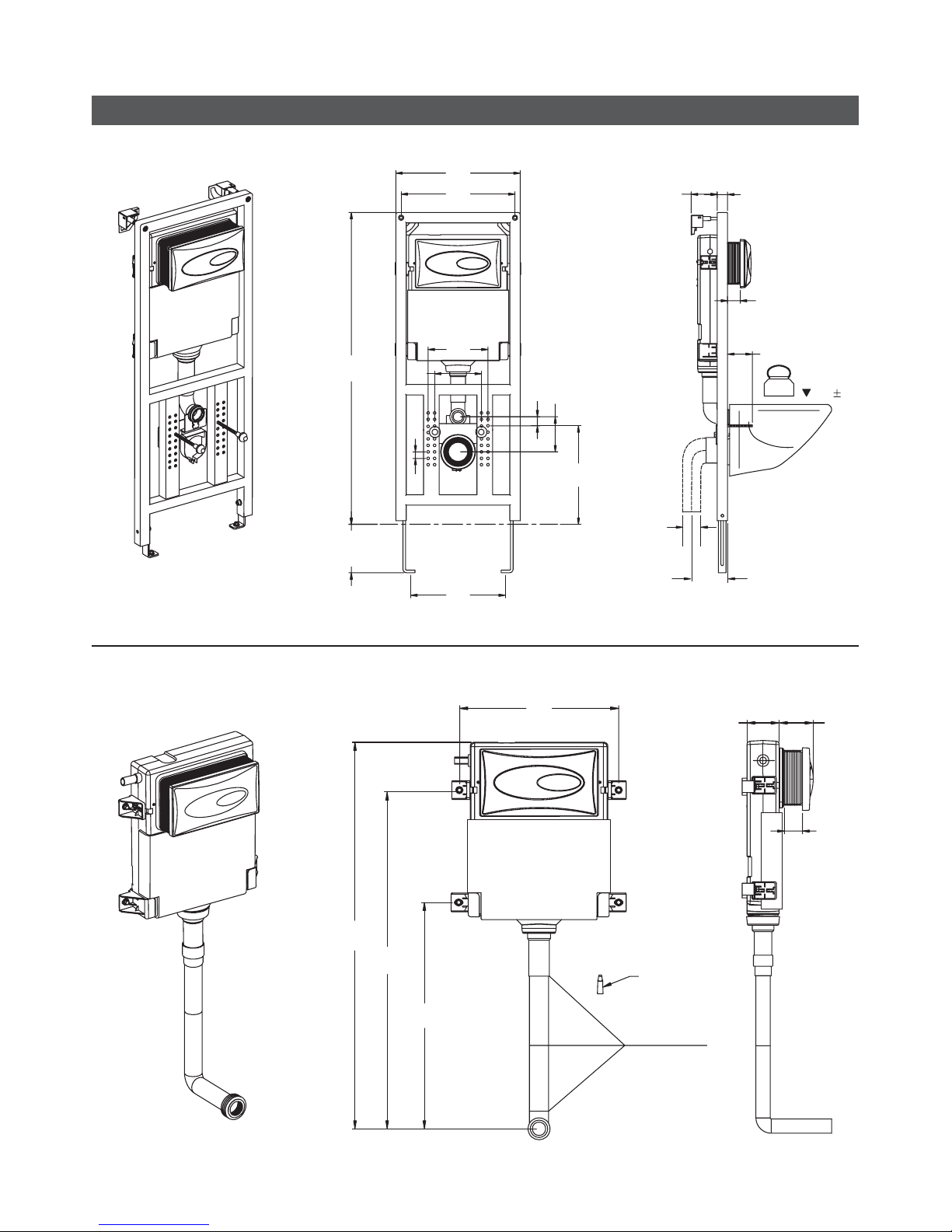

ROUGHING-IN

UNIT: mm

Installation dimensions with iron rack K-6284K

-2-

1048671-K01-B

Installation dimensions without iron rack for wall hung K-6286K/K-6286R

UNIT: mm

Adhesive

Adhesive

Agglutination

1275

1150

850

438

95

100

15-55

478

438

0-200

1190

300

25

135

35

180

230

365

OK

FFB

100-155

15-55

0-140

400kg

40

400 10

95-135

90

Page 3

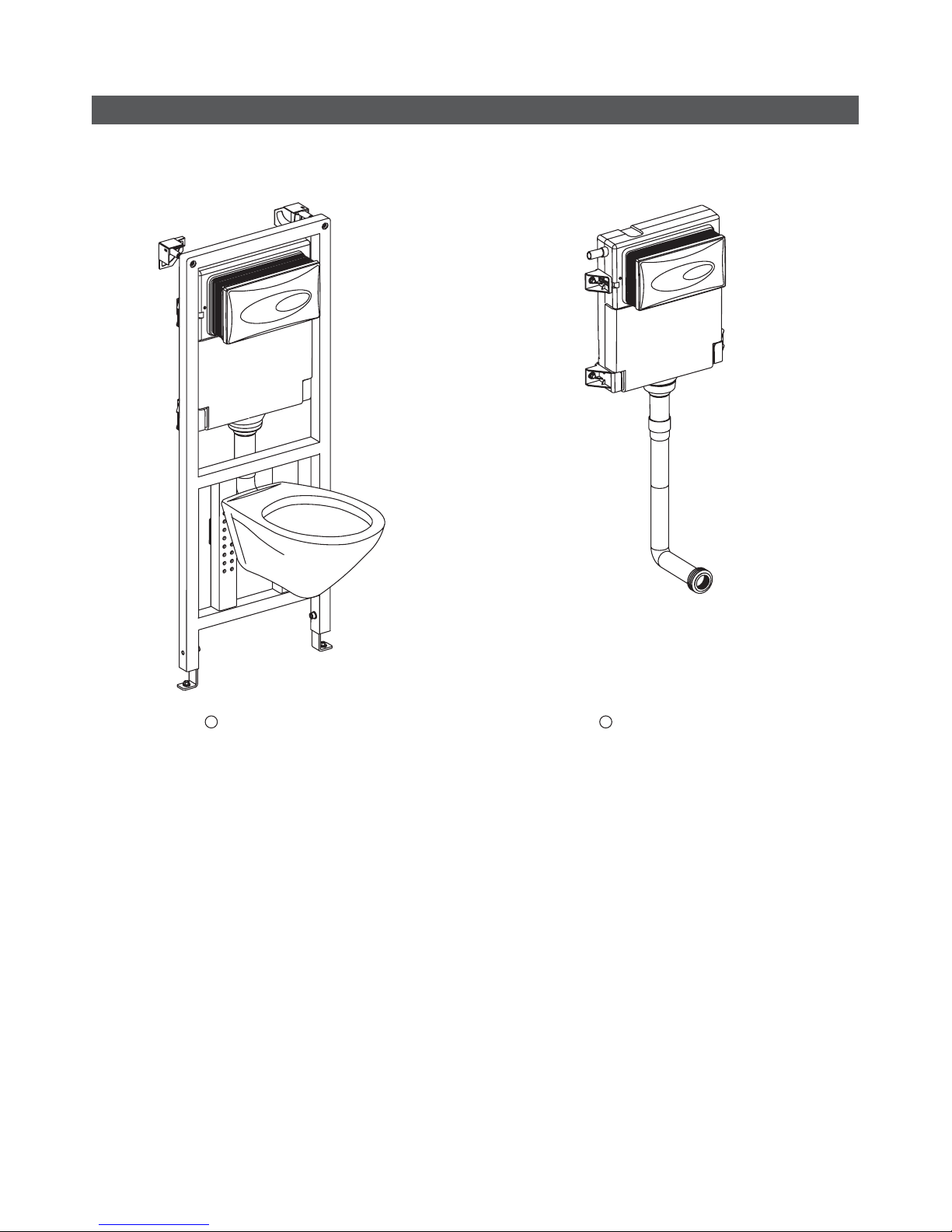

INSTALLATION

Ways of Installation

In-wall Tank With Iron Rack For

Wall-Hung Toilet

-3-

1048671-K01-B

In-wall Tank Without Iron Rack

For Wall-Hung Toilet

K-6286K-NA/K-6286R-NA

1 2

K-6284K-NA

Page 4

-4-

1048671-K01-B

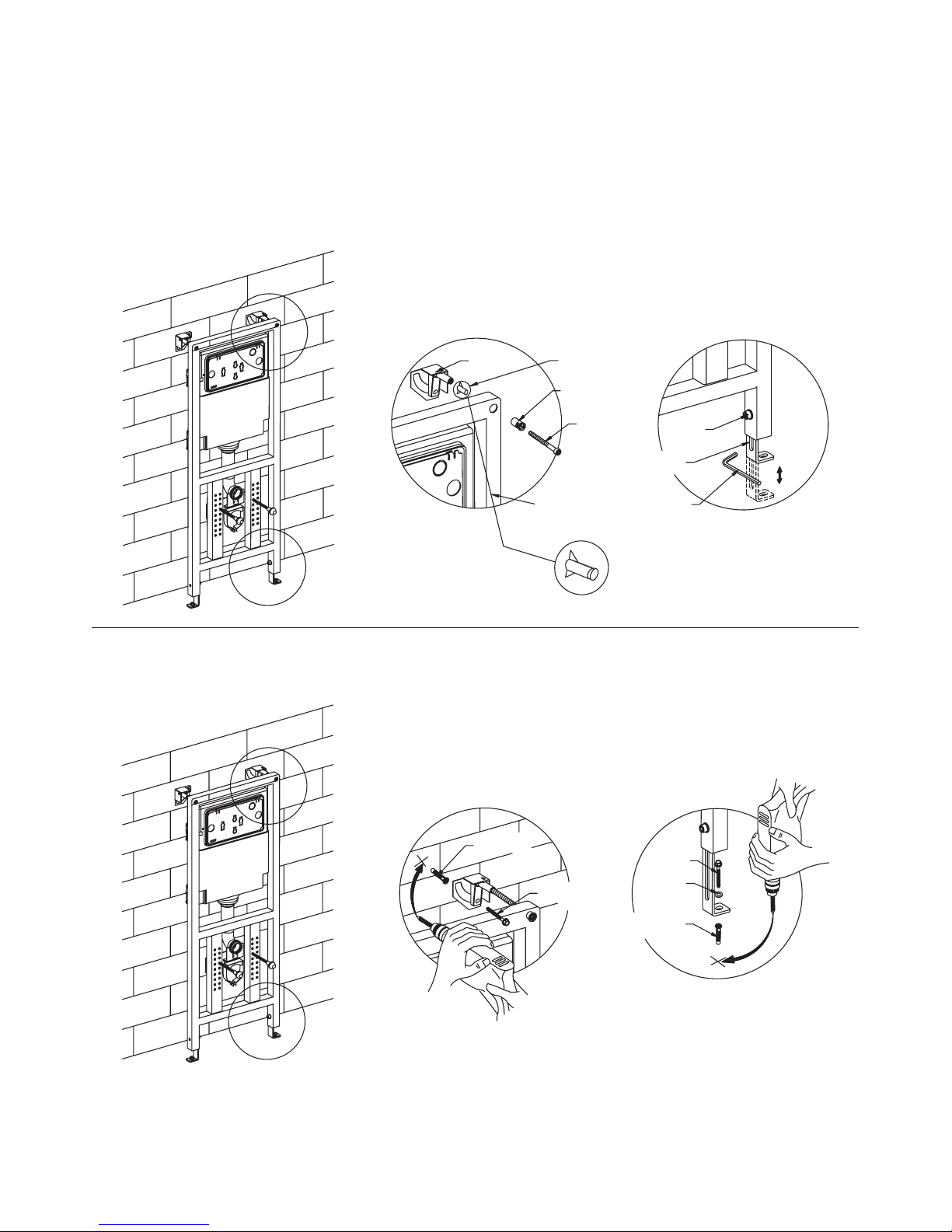

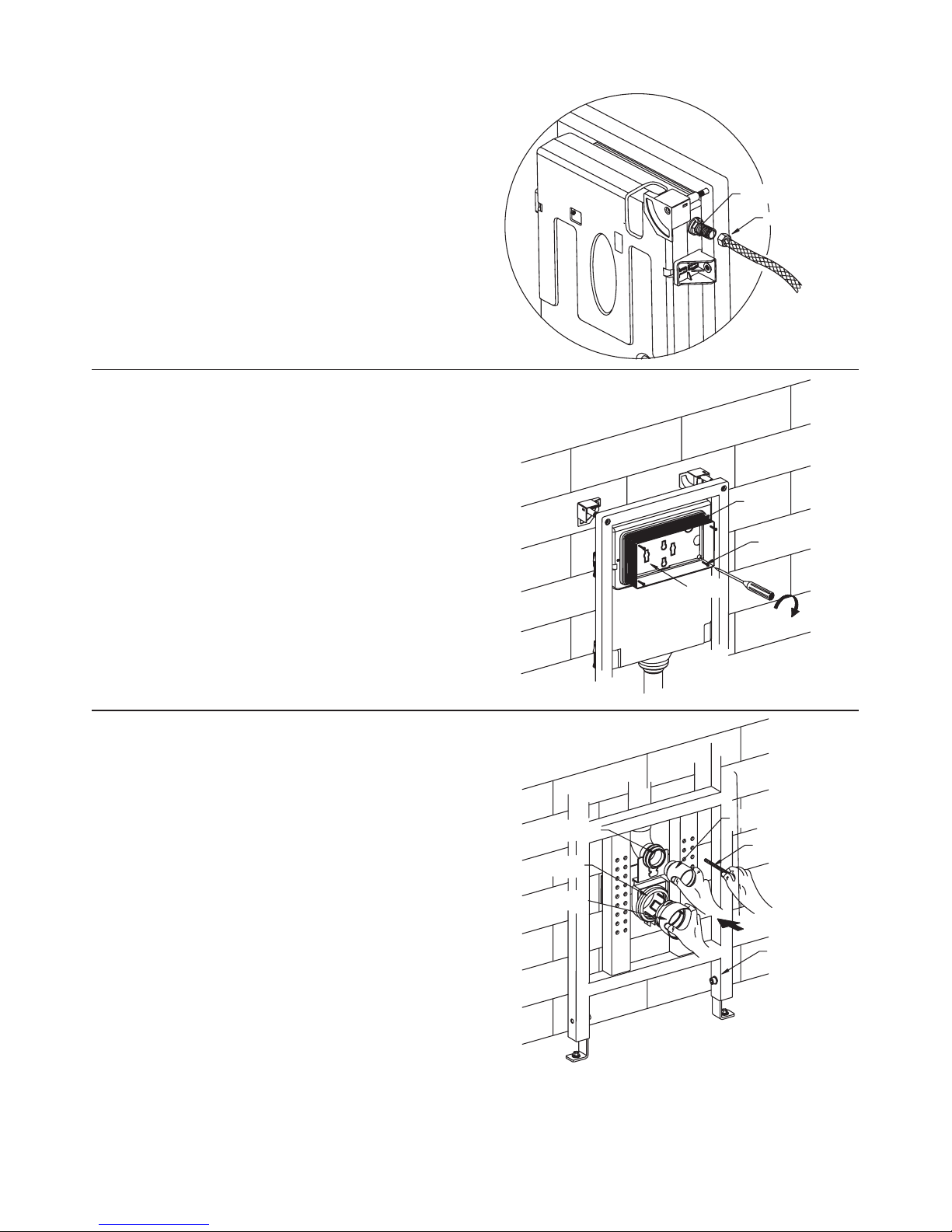

Installation

1. Install the fixing cap in the holes of fixing frame, then

tighten the hexagonal screws on the fixing frame with

medium allen key as shown in illustration A.

Tighten the bolts with medium allen key as shown in

illustration B, and adjust the height of the adjustable

bracket according to customer's requirements.

Fixing Frame

Fixing Cap

Hexagonal Screw

Tank Frame

Nut

Adjustable Bracket

Medium Allen Key

AB

2. Drill four holes with diameter of 12mm and depth of

60mm with churn drilling as shown, and fill in the

holes with bulge screw and tighten the long screw.

Bulge Screw

Long

Screw

Gasket

Bulge Screw

Long Screw

A. Installation Procedures For In-wall Tank With Iron Rack

Nut

Page 5

-5-

1048671-K01-B

3. Tighten the hexagonal long screw with medium allen

key as shown in illustration A.

Tighten the screw of adjustable brackets with

medium allen key as shown in illustration B, and

tighten the long screw with spanner.

Ensure the tank to remain level.

Level

Hexagonal screw

Screw

Medium Allen Key

Adjustable Bracket

Spanner

Long

Screw

Loosen

Tighten

AB

4. Fix the drainage cap on the fixing bracket as shown

in the illustration. Tighten the screws with medium

allen key and install the drainage cap on the

drainage hole.

Drainage

Hole

Fixing Bracket

Drainage Cap

Screw

Medium Allen Key

Page 6

-6-

1048671-K01-B

5. Install the water pipe to the connecting pipe at the

side of the tank for water supply. ()Inlet valves

should be shut down

6. Install the rectangular shield in the block screen of

the tank, and tighten the screw to fix the rectangular

shield to the tank.

Rectangular

Shield

Screw

Block

Screen

7. Tighten the long screw into the holes of tank bracket,

and cover the drainage cap with big filtration cap,

and the drainage hole with small filtration cap.

Connecting

Pipe

Water Pipe

Drainage Hole

Drainage Cap

Big Filtration Cap

Small Filtration Cap

Long Screw

Tank Bracket

Page 7

-7-

1048671-K01-B

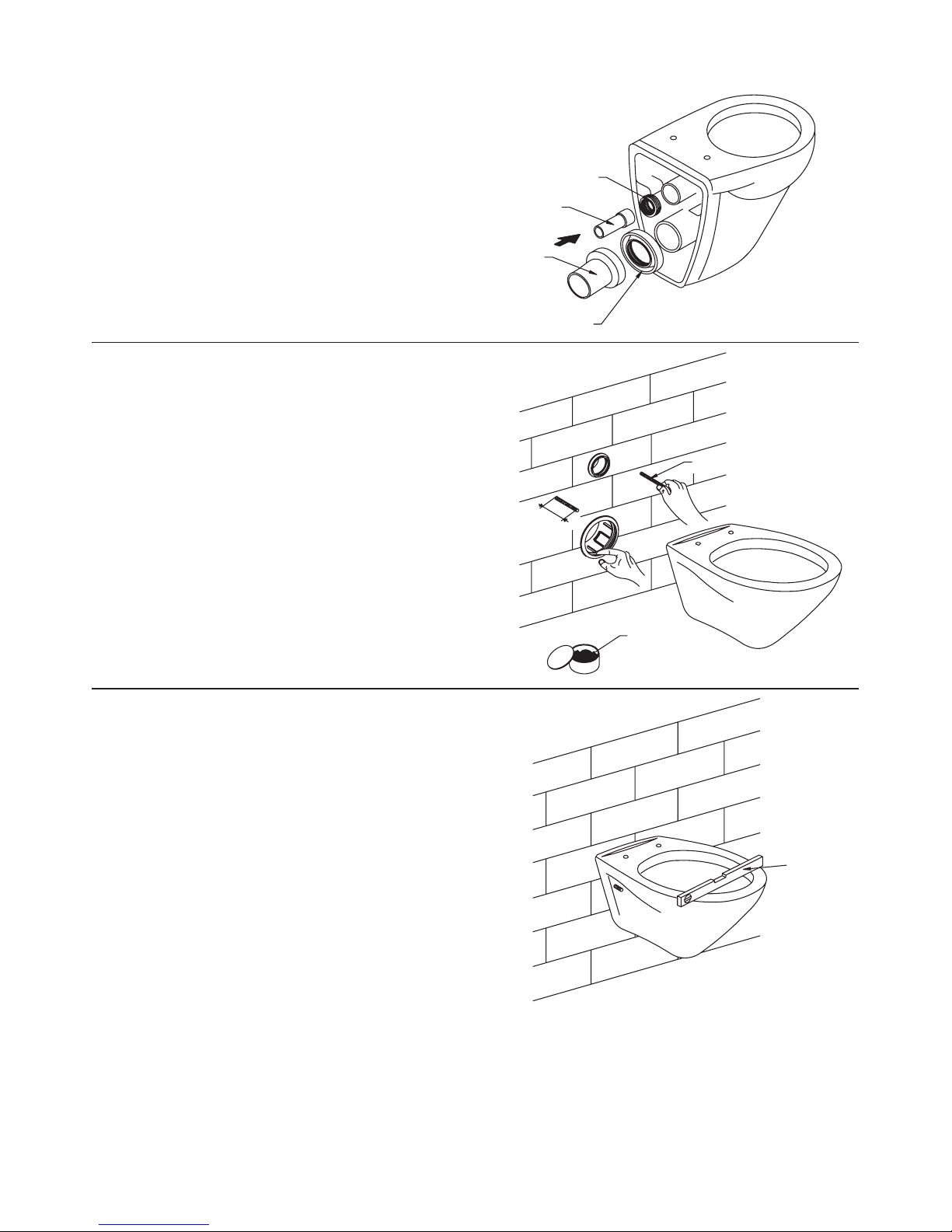

8. When finishing the brickwork of the wall, take out the

big and small filtration caps, and eliminate unwanted

rectangular shield with a sharp knife.

9. Install the inlet pipe and outlet pipe to the toilet as

shown, and mark on the pipes at the back side of the

tank with a ruler and a pencil, and reserve

appropriate space according to the distance from the

back of the tank to the outlet hole on the wall.

Rectangular Shield

Big Filtration Cap

Small Filtration Cap

Inlet Pipe

Outlet ipeP

10. Eliminate unwanted part of the pipe and outlet

pipe according to the marks of reserved space, and

rasp a smooth surface with files.

inlet

Inlet Pipe

Reserved

Space

Outlet ipeP

Page 8

-8-

1048671-K01-B

11. Install the big and small leak-proof gaskets on inlet

pipe and outlet pipe, then install it to corresponding

pipes on the toilet tank.

Small Leak-proof Gasket

Inlet Pipe

Outlet ipeP

Big Leak-proof Gasket

12. 48mm-58mm of the long screw shall be reserved

outside the wall as shown in the illustration. If the

long screw outside the wall is not long enough or

much longer than that needed, it should be adjusted

with screwdriver or by hand. Then apply lubricant to

drainage pipe and limber pipe to ensure a smooth

installation.

Long Screw

Lubricant

48mm-58mm

13. Install the toilet as shown in the illustration, and use

a spirit level to ensure the toilet to remain level.

Spirit Level

Page 9

-9-

1048671-K01-B

14. Install the rubber cover gasket, hexagonal nut and

decoration cap onto long screw according to the

order shown in the illustration.

Screw Cover

Rubber Cover

Hexagonal Nut

Decoration Cap

Gasket

Long Screw

15. When fixing the adjustable board to block screen,

the locknut should be put directly on positing of the

sign of OPEN . Remark: Stir pole shall remain

level.

Block Screen

Locknut

Adjustable Board

Stir Pole

Page 10

1048671-K01-B

16. Fix the adjustable board on the wall by tightening

the locknut as shown in the illustration. And the

locknut should be directly put on the position of the

sign of LOCK . (Indications are marked on the

adjustable board, please refer to indications in

installation)

17. Install the cover as shown in the illustration. Put the

lock on the cover directly on the reversed lock on

adjustable board, then push the cover and lock it.

The installation shall begin from bottom to top.

Lock

Adjustable Board

Reversed Lock

Cover

Adjustable Board

Locknut

-10-

Page 11

18. In-wall tank toilet is ready to be put into use.

Long Flush

Button

Short Flush

Button

-11-

Finished Installation Illustration

1048671-K01-B

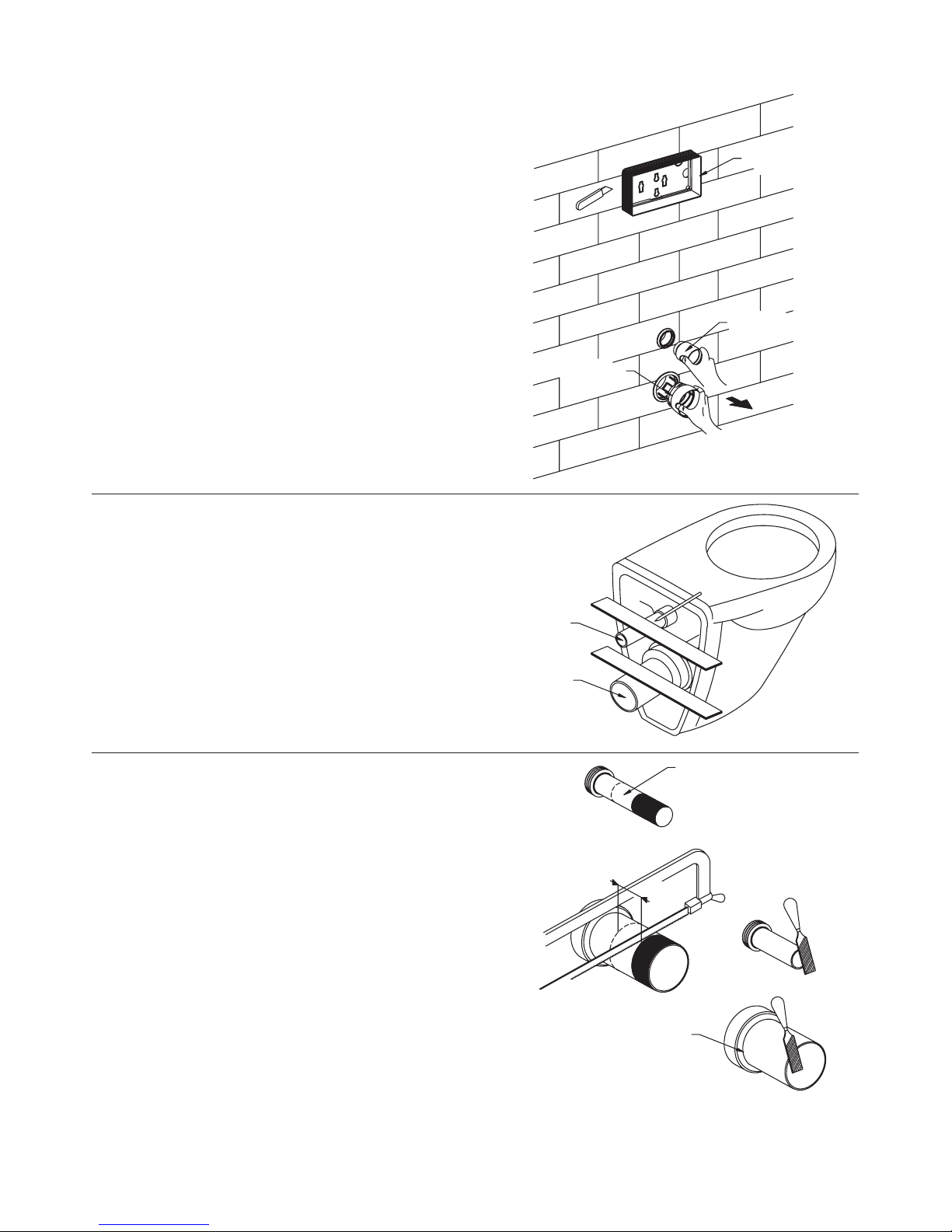

1. Mark on the wall for appropriate position for fixing

bracket, and drill four holes with diameter of 12mm

and depth of 60mm with churn drilling as shown in

illustration, and fill in the holes with bulge screw and

tighten the long screw to set the fixing bracket.

Note: Ensure the fixing bracket to remain level.

Bulge Screw

Long Screw

Fixing Bracket

B. Installation Procedures For In-wall Tank Without Iron Rack For Wall-Hung Toilet

Page 12

2. Install the fixing bracket first, then put the tank on the

fixing bracket, and fix the fixing frame in the slot of

the tank, and tighten the screws. Lock the fixing slot

to corresponding position on fixing frame.

Fixing Frame

Fixing Slot

Long Screw

Fixing Bracket

Tank

-12-

1048671-K01-B

3. Install the rectangular shield in the block screen of

the tank, and tighten the screw to fix the rectangular

shield to the tank.

4. Fix the leak-proof gasket to syphon as shown in

illustration, and adjust the syphon to appropriate

position to be fixed to the wall-hung toilet.

Rectangular Shield

Screw

Leak-proof Gasket

Syphon

Page 13

5. When finishing the brickwork, eliminate unwanted

part of the rectangular shield.

Sharp Knife

Rectangular Shield

-13-

1048671-K01-B

7. Fix the adjustable board on the wall by tightening the

locknut as shown in the illustration. And the locknut

should be directly put on the position of the sign of

LOCK . (Signs are marked on the adjustable

board, please refer to the indications in installation)

6. When fixing the adjustable board to block shield, the

locknut should be put directly on positong of the sign

of OPEN .

Remark: Stir pole shall remain level.

Adjustable Board

Locknut

Stir Pole

Block

Shield

Locknut

Adjustable Board

Page 14

Lock

Adjustable Board

Reversed Lock

Cover

8. Install the cover as shown in the illustration. Put the

lock on the cover directly on the reversed lock on

adjustable board, then push the cover and lock it.

The installation shall begin from bottom to top.

-14-

1048671-K01-B

9. In-wall tank toilet is ready to be put into use.

Long Flush

Button

Short Flush

Button

Finished Installation Illustration

Page 15

A. Hold the cover with both hands and push upward to

take down the cover.

MAINTENANCE AND CONTROL PROCEDURES

Cover

Cover

B. Tighten the locknut to the marked position of

OPEN to take out the adjustable board.

Locknut

C. Pin the indentation on block screen with screwdriver

to take out the block screen.

Block

Screen

-15-

1048671-K01-B

Page 16

D. Wash Filtration Net

Close corner valve first, then loosen and take out the

tighten nut, and wash the waste on filtration net with

clean water. Then reset the tighten nut to the original

position.

Open

Close

Corner Valve

Tighten Nut

Filtration Net

Loosen Nut

E. Adjust The Control Pole Of Drainage Valve

Pin the pole first to take out the control button as

shown in the illustration. Then take out the fixing

frame with both hands.

Pole

Control Button

Fixing Frame

Fixing Frame

-16-

1048671-K01-B

Page 17

F. Pull out reversed lock on the fixing frame as shown

in the illustration, and adjust the height of the control

poles to ensure the leak-proof of drainage valve.

Fixing Frame

Reversed

Lock

Control

Pole

G. Adjust Drainage Valve

Drainage volume and overflow level of the tank can

be adjusted by drainage valve: 1) Heavy drainage

adjustment: Open adjustment switch to open the

small hole. 2) Slight drainage adjustment: adjust the

height of floating box and the water level of slight

drainage will be at the bottom of the floating box.

Control Pole

Drainage Valve

Adjustment Switch

Floating Box

-17-

1048671-K01-B

Page 18

H. Adjust Inlet Valve

Hoist and reduce the water level in the tank by

adjusting the control pole. Turn the control pole

counterclockwise to lower down the floating box and

reduce the water level of the tank. Turn the control

pole clockwise to hoist the floating box and increase

the water level in the tank.

Control Pole

Floating Box

TROUBLE SHOOTING PROCEDURESTROUBLE SHOOTING PROCEDURES

No water fills in via inlet

valve

The inlet valve is closed Open inlet valve (refer to page 15)

Floating box of inlet valve is blocked by tank wall Adjust floating box to appropriate position

Floating box of inlet valve is block by waste Wash the floating box with clean water

Wrong installation of adjustable board Reset (refer to page 9)

Control pole is too long

Adjust the control pole to appropriate

position

Water level of the inlet valve is not appropriate

No drainage when

pressing the heavy and

slight drainage button

Too high or too low

water level

Leak of the toilet and

squat

Symptoms

Probable Causes

Recommended Action

Control pole is too short

Inappropriate adjustment of the overflow pipe

Toilet swing

Hexagonal nut is loose

Readjust water level (refer to page 16)

Adjust the control pole to appropriate

position

Adjust the overflow pipe to appropriate

position

Tighten the hexagonal nut (refer to page 9)

Kohler plumbing fixtures and fittings are warranted to

be free of manufacturing defects.

To obtain warranty service, contact Kohler either

through your Dealer or Plumbing Contractor or by

writing Kohler Co., Attn: Consumer Affairs Department,

Kohler, WI 53044 U.S.A.

Some states do not allow limitations on how long an

implied warranty lasts or the exclusion or limitation of

incidental or consequential damages, so this limitation

and exclusion may not apply to you. This warranty

gives you specific legal rights. You may also have rights

which vary from state to state.

This is our exclusive written warranty.

Kohler Co., Kohler, Wisconsin 53044

Kohler Co. will, at its election repair, replace, or make

appropriate adjustment where Kohler Co. inspection

discloses any such defects occurring in normal usage

within one year after installation.

Co.

Kohler Co. is not

responsible for installation costs.

Implied warranties, including that of

merchantability and fitness for a particular purpose,

are expressly limited in duration to the duration of

this warranty. To the extent permitted by law,

Kohler Co. disclaims all implied warranties

including merchantability and fitness for a

particular purpose. Kohler Co. disclaims any

liability for special, incidental, or consequential

damages.

LIMITED ONE-YEAR WARRANTYLIMITED ONE-YEAR WARRANTY

-18-

1048671-K01-B

Page 19

IN-WALL TANK

SERVICE PARTS PAGE

K-6283K/K-6284K

-19-

Expanding Bolt Cap

Fixation Base

Screw Base

Self-tapping Screw

Frame Screw

Screw Cap

Mechanical kit for pipe connection

Screw M5 x 20

Fixation Frame

Screw M12 x 40

Installation Frame

Mechanical kit for Fixation with Floor

Washer, 10 2

Screw M10 x 30

Bracket Nut

Bracket

Washer, 19 8 3

Assembling kit for wall-Hung bowl

Screw, M12 x 179

Screw Cover

Rubber Washer

Screw, M12 x 10

Washer

Screw Cover

Straight Outlet Pipe System

Outlet Pipe, Rear

Rubber Gasket

Outlet Pipe, Front

Outlet Pipe

Rubber Gasket

Plug, Big

Assembling Kit Tank with Wall

INSTALLATION

INSTRUCTIONS

1048671-K01-B

ODEON

Cap

Rubber Gasket

Curve Pipe

Straight Pipe

Rubber Gasket

Interior Hexagon Wrench

Optional Parts

Page 20

-20-

KI07 1045103 Takeup Mechanical

1045104 Takeup

1045105 Swith Arm, Left, Rear

1047622 Swith Arm, Left, Front

1047623 Swith Arm, Right, Rear

1047624 Swith Arm, Right, Front

1045106 Location Pin

1045107 Bracket

1047626 Hook

1045108 Hook, Left

1045109 Hook, Right

Roof Panel

1045111 Drive Mechanical

1045112 Takeup

1045113 Push Bar

1045114 Spring

1045115 Fix Bar

1045116 Clip Ring

Square Mask

Foam Piece

Screw ST 35

4

Cover Assembly Kit

Right Location Block

Spring

Right Location Shank

Left location block

Left Location Shank

Fixation Shank

Location Panel

628 -*

In-wall Tank Cover

3K

Cover

Stainless Steel

Push Button Spring

Fixation Cover

Big Push Button

Small Push Button

IN-WALL TANK

SERVICE PARTS PAGE

K-6283K/K-6284K

INSTALLATION

INSTRUCTIONS

1048671-K01-B

Screw ST 38

ODEON

Page 21

Tank Mount Kit

Wrap

-21-

Bracket

T Shape Pint

Straight Pin

Washer 10 2

Self-screw 7 x 83.6

Bracket, Left

Bracket, Right

Panel Lock Kit

Tank Outlet Pipe

747UKB Side Fill Valve

Flush Valve Assembly

P51 Flush Valve

G12 Filter/G12

G06 Valve/G06

Tank Inlet Connection

Washer

Locknut

Screw

Lock Sheath

Connection Pipe

O-Ring

Adjustment Pipe

Rubber Gasket

Outlet Pipe

Rubber Gasket

Plug, Small

Inlet hose

Bracket

Bracket A

Joint Nut

Hook

Foam Rubber

Joint Nut

Rubber Gasket

Plastic Tank

Fill Valve Assembly

IN-WALL TANK

SERVICE PARTS PAGE

K-6283K/K-6284K

INSTALLATION

INSTRUCTIONS

1048671-K01-B

ODEON

Page 22

IN-WALL TANK

SERVICE PARTS PAGE

K-6286K/K-6286R

INSTALLATION

INSTRUCTIONS

ODEON

-22-

1048671-K01-B

Cap

Rubber Gasket

Curve Pipe

Straight Pipe

Rubber Gasket

Optional Parts

Page 23

IN-WALL TANK

SERVICE PARTS PAGE

K-6286K/K-6286R

INSTALLATION

INSTRUCTIONS

ODEON

-23-

1048671-K01-B

KI07 1045103 Takeup Mechanical

Page 24

IN-WALL TANK

SERVICE PARTS PAGE

K-6286K/K-6286R

INSTALLATION

INSTRUCTIONS

ODEON

-24-

1048671-K01-B

Loading...

Loading...